Abstract

Air frying technique was used for the preparation of fish cutlet-a popular fish snack with low fat content, better protein content and color. The process conditions viz: temperature varying from 160 to 200 °C and time varying from 5 to 15 min were optimized using response surface methodology. A factorial design with 9 runs satisfying rotatability conditions under correlated errors was formulated for the experiment. The parameters of first order response surface model with interaction were estimated by generalized least square method. The optimum temperature—time combination for air-frying condition was found to be 180 °C and 12 min, respectively for low fat content, better protein content and colour, comparable texture profile and sensory acceptability when compared to deep fried fish cutlet samples. Air-fried fish cutlets can be a healthier protein rich snack product as an alternative to deep fat fried fish cutlets.

Keywords: Air-frying, Fat content, Fish cutlet, Response surface methodology, Auto-correlation, Optimization

Introduction

The consumption of fish and fishery products can be increased through the development of diversified value added products like minced, coated or surimi from fish meat. This also improves the nutritional and livelihood security of the society. Development of coated fish products is a common practice of home makers, food processors and food establishments. Fish cutlet, a coated product developed from fish mince, normally prepared by deep fat frying using oil as frying medium (Ninawe and Rathnakumar 2008). In deep frying, simultaneous exchange of heat, moisture and oil takes place between product and heating medium. Mellema (2003) reported that mass transfer phenomena in deep frying involve the outflow of moisture and intrusion of fat caused by transfer of heat energy to the product. One of the main draw backs of deep frying is the repeated frying and higher fat content. The oil consumption through repeated frying causes increasing health issues like coronary heart disease, cancer, diabetes and hypertension (Saguy and Dana 2003). The quality of fried product depends upon the quality of oil used, frying time and temperature. Now days, consumers prefer nutrient rich healthier food product.

Air-frying is a healthier alternative frying technique to fry the food product without the use of fat or oil. Air fryer cooks the food through circulation of heated air by rapid air technology. Hot gas is circulated by the blower motor assembly into the air fryer cavity where the hot air is directed in a manner wherein a conflicting, colliding turbulent gas flow is directed at a food product kept for the accelerated cooking. The heat radiated from the heating element cooks the food fast and effectively as the food item is situated quite close towards heating element without loss of much energy. The air fryer imitates the movement and flow of heat currents just like boiling oil in a pot by circulating hot air at higher temperature. This movement of hot air cooks inside of the food item while formulating crispiness outside (Anonymous 2016). The flow of air inside the air frying equipment is different from hot air drying or convective drying. There have been few studies where air-fryer has used to fry different food products. Abd Rahman et al. (2017) optimized hot air-frying conditions for frying sweet potato (Ipomoea batatas). The comparison between deep and air fried potato strip was done by Shaker (2015). They found that air-fried food products were having better sensory and texture acceptability with less fat content. Priya et al. (2017) reported that air-fried fish fingers were having good acceptability and economic viability compared to deep fried fish fingers. Mohan et al. (2017) also reported that air- fried tilapia steaks found to have better fatty acid profile compared to deep oil fried tilapia steaks.

The main objective in air-frying technique is to optimize the time–temperature combination, which may vary from product to product. Since frying time and temperature are considered as input variables, there is very likely chance that observations measured on different time interval tend to be correlated. This can be overcome by choosing the proper experimental design and parameter estimation. Response surface methodology is a good technique that can be used to formulate the experimental design, developing statistical models and optimize the process conditions (Myers and Mongomery 2002). The present study optimized the time–temperature combinations of air frying technique for the development of healthy fish cutlet using response surface methodology. The air-fried fish cutlet at optimum condition was compared with the deep fried samples.

Materials and methods

Sample preparations

Pink Perch (Nemipterus japonicas) was purchased from the local market, Ernakulum, Kerala, India for the study. The fish was brought to the laboratory in 1:1 iced condition and washed, cleaned in potable water. The fish mince was obtained after cooking in 2% brine solution for 7–8 min. The ingredients used for the preparation of cutlets were fish mince, green chili, cooked potato, chopped onion, mint leaves, ginger, garlic, pepper powder, clove powder, cinnamon powder, turmeric powder, water, salt and oil (Ciftfishpro 2018). The ingredients were mixed well and cutlets of uniform size were made with average weight of 40 g and thickness of 1.5 cm. The cutlets were dipped in batter mix prepared from wheat flour, corn flour, Bengal gram flour, salt, sodium triphosphate, turmeric powder and guar gum (Ciftfishpro 2018). The battered cutlets were then coated with bread crumbs.

Air-frying process

Fish cutlets were fried by a Philips commercial model Air-fryer (Model HD9220, United Kingdom). Fish cutlets varying 6–7 numbers were air-fried at a time under controlled time and temperature process conditions. The air-fried cutlets were cooled at room temperature and stored in air tightened container for further analysis. Deep fried control samples were also prepared in sunflower oil medium for comparing with the air-fried cutlets.

Experimental design

Modified two-level factorial design was used to optimize the time and temperature of air-frying process conditions by adding center points at before, end and in-between each runs as given by Das (2003). The resultant experimental design was having 9 runs with 3 levels for each processing conditions (Table 2.). This would allow the experimental design to be rotatable under auto-correlated errors. The experimental designs with actual and coded values are given in Table 1.

Table 2.

The results of response variables for different experimental runs

| Time (min) | Temperapture (°C) | Fat (%) | Moisture (%) | Protein (%) | Hardness (N) | Cohesiveness | Springiness (mm) | Chewiness (Nmm) | Stiffness (N/mm) | OAS |

|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 180 | 4.28 | 61.27 | 14.78 | 34.12 | 0.28 | 4.50 | 42.72 | 9.31 | 7.64 |

| 5 | 160 | 4.24 | 61.19 | 15.59 | 34.47 | 0.33 | 4.69 | 54.03 | 8.79 | 6.37 |

| 10 | 180 | 4.26 | 59.86 | 14.90 | 34.24 | 0.29 | 4.62 | 42.84 | 9.43 | 7.80 |

| 5 | 200 | 3.76 | 63.34 | 12.19 | 21.57 | 0.25 | 4.64 | 25.52 | 5.36 | 7.36 |

| 10 | 180 | 4.39 | 61.34 | 14.89 | 34.12 | 0.28 | 4.50 | 42.72 | 9.31 | 7.64 |

| 15 | 160 | 4.28 | 58.74 | 13.93 | 33.79 | 0.29 | 4.59 | 45.07 | 9.86 | 7.23 |

| 10 | 180 | 4.2 | 61.23 | 14.68 | 34.00 | 0.26 | 4.38 | 42.60 | 9.19 | 7.68 |

| 15 | 200 | 5.37 | 55.28 | 16.19 | 25.96 | 0.30 | 5.23 | 41.32 | 7.85 | 7.00 |

| 10 | 180 | 4.23 | 61.34 | 14.89 | 34.26 | 0.29 | 4.54 | 42.80 | 9.27 | 7.75 |

| Deep fried sample | 8.05 | 59.37 | 13.59 | 35.02 | 0.30 | 5.39 | 71.91 | 8.16 | 8.01 | |

Table 1.

Experimental design with actual and coded values

| Process conditions | Coded values | ||

|---|---|---|---|

| − 1 | 0 | 1 | |

| Time (X1, minutes) | 5 | 10 | 15 |

| Temperature (X2, °C) | 160 | 180 | 200 |

Statistical model development

A first order response surface model with interaction given in Eq. (1) was used to predict response variables as a function of time and temperature.

| 1 |

where is a response variable of order , is intercept, is a column vector of 1’s of order , X1 is a design matrix of order with is a vector of regression coefficients. Further, term e is an vector of errors which follows N-variate normal distribution with .

Suppose the elements of e are correlated and ‘V’ is known, then the best linear unbiased estimator of is . The generalized least square (GLS) estimate of is obtained as

| 2 |

The goodness of fit of the model used was assessed by coefficient of determination (R2) and root mean square error (RMSE). The estimated parameters were used to predict the response variable Y and same was used to construct response surface plots as a function of time and temperature. The multiple response surface optimization was done based on the desirability score derived from the predicated values of response variable. The combination with highest desirability score was selected as optimum time–temperature combination. The statistical analysis was carried out using SAS 9.3.

Analysis of response variables

Texture profile analysis

Instrumental texture profile analysis was carried out using Food texture analyzer (Llyod LF 2450) to see the effect of time and temperature on air-fried fish cutlets and control sample. The test was done at speed of 12 mm/min using 100 N load cell. The probe used for the experiment was a 75 mm diameter cylindrical probe. Uniform samples were allowed for a compression of 40% with a trigger force 0.5 kg. From the double compressions, parameters such as hardness 1, cohesiveness, springiness, stiffness and chewiness were determined to assess the texture profile of the product.

Proximate composition

Proximate analysis of air-fried and control samples were carried out as per AOAC (2012). Moisture, protein, fat and ash contents of fish cutlets at varying process conditions were measured. The carbohydrate content was measured by method of difference (FAO 1998).

Sensory evaluation

Organoleptic evaluation of air and oil fried cutlets was done by a group of 10 trained panelists, who were asked to evaluate the product by giving score for appearance, color, taste, texture and odor of the samples on a 9 point hedonic scale (Fishken 1990). A score of 4 in the scale was considered as rejection score for different samples. Overall acceptability score (OAS) was obtained by taking the average score of all attributes for each sample.

Results and discussion

The results of different response variable for different levels of time and temperature are given in Table 2.

The model given in Eq. (1) was fitted to the experimental data as a function of time and temperature using GLS method. The estimated regression coefficients along with coefficient of determination (R2) and root mean square (RMSE) are given in Table 3. Abtahi et al. (2016) used response surface methodology to optimize the deep-fat frying process of coated zucchini pieces. The fitted model was found to be significant (p < 0.01) for all the response variables to explain the total variability in the data in terms of variability due to time, temperature and their interaction. The R2 values of fitted model was found to be significant for all the response variables with lower RMSE values.

Table 3.

Estimated regression coefficients with R2 and RMSE

| Response variables | Regression coefficients | R2 | RMSE | |||

|---|---|---|---|---|---|---|

| (X1) | (X2) | (X1X2) | ||||

| Fat (%) | 4.410 | 0.410 | 0.150 | 0.390 | 0.98 | 0.07 |

| Moisture (%) | 59.640 | − 2.630 | − 0.330 | − 1.400 | 0.96 | 0.64 |

| Protein (%) | 14.480 | 0.590 | − 0.280 | 1.420 | 0.99 | 0.10 |

| Hardness (N) | 28.950 | 0.930 | − 5.190 | 1.270 | 0.99 | 0.10 |

| Cohessiveness | 0.300 | 0.002 | − 0.016 | 0.023 | 0.84 | 0.02 |

| Springiness (mm) | 4.790 | 0.120 | 0.150 | 0.170 | 0.89 | 0.09 |

| Chewiness (Nmm) | 41.48 | 1.710 | − 8.060 | 6.190 | 0.99 | 0.09 |

| Stiffness (N/mm) | 7.960 | 0.890 | − 1.360 | 0.360 | 0.99 | 0.09 |

| OAS | 6.99 | 0.130 | 0.190 | − 0.300 | 0.96 | 0.07 |

Proximate analysis

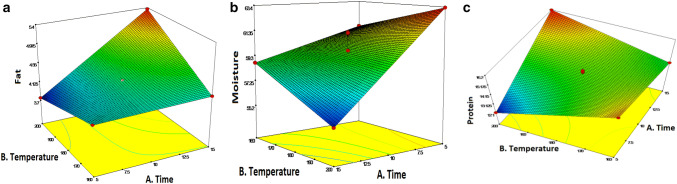

The R2 values of fitted model for fat, protein and moisture content were 0.98, 0.96 and 0.99, respectively. The response surface plots for predicting fat, moisture and protein contents are given in Fig. 1. It can be observed from Table 3 that the air-fried samples were having 50% reduction in fat content compared to the deep fried sample due to the absence of oil. The linear and interaction effect of air-frying time and temperature was significant (p < 0.05). The fat content was found to be increasing when the levels of temperature increasing at any fixed level of frying time. Since no oil was used for frying, the increase in fat might be due to drainage of fat from fish mince and other ingredients as no other liquid would replace the water removed from the pores of the product because of capillary pressure. According to Moreira and Barrufet (1998), the higher amount of fat content in deep fried samples may be due to the equilibrium reaction between the adhesion and drainage on the surface of the cutlet when the product removed from the oil.

Fig. 1.

Response surface plots of fat (a), moisture (b) and protein (c) contents

In air frying, the product was prepared in closed system where forced convection heat transfer happens inside the chamber to transfer water molecules by rapid air flowing mechanism. The moisture content of air-fried fish cutlet was found to be decreasing at increasing levels of frying time and temperature and their effect was significant (p < 0.05). It was noted that effect of temperature was less significant compared to frying time as higher level of temperature at short frying time showed higher moisture content than medium temperature at long time frying. The moisture content in air fried samples was slightly higher compared to deep fried sample where oil fills the voids in the product and suppresses the absorption of moisture. Abd rahman et al. (2017) observed that fat content was increasing with increasing frying time at fixed temperature and moisture content was decreasing with increasing levels of frying time and temperature for air-fried sweet potato.

The protein content was found to be significantly decreasing at increasing levels of frying temperature at lower levels of frying time; the same was increasing when the frying time increased at higher levels of temperature. This trend was noticed from 200 to 180 °C frying temperature and frying time up to 10 min, further remained constant irrespective of frying time. When the temperature was raised at lower frying time, the proteins might have undergone aggregation by populating unfolded or partially unfolded monomer states (Rosa et al. 2017).

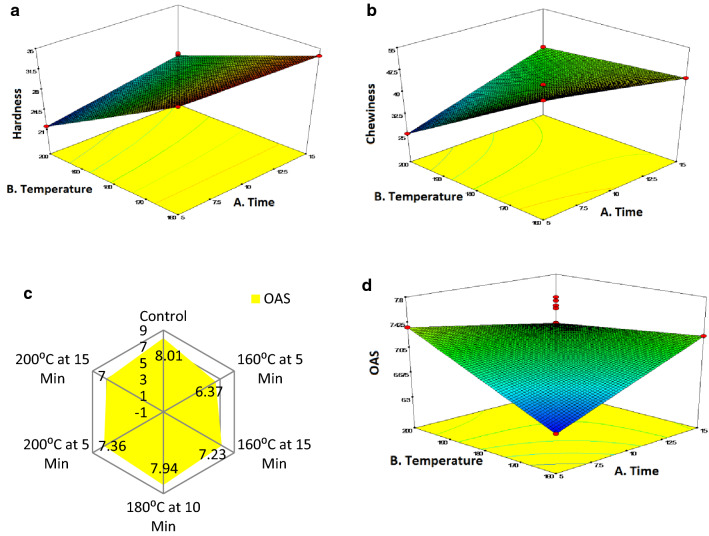

Texture profile analysis

The response surface plots drawn using the fitted model for hardness and chewiness are given in Fig. 2. A surface crust has been formulated on the surface of the fish cutlet due to changes in the outer layers during frying. The changes include the formulation of rough layer with the release of intracellular material, protein denaturalization, water evaporation, expansion and tissue browning. All these changes influence the acceptability of the product by the consumers. It was observed from Table 2. that deep and air fried samples showed similar range of values for hardness, cohesiveness, springiness and stiffness up to 180 °C of frying temperature; but at higher temperature (200 °C) all the values were significantly lower than the control sample. The value of chewiness was higher for control sample compared to air-fried samples; where the chewiness values were decreasing significantly when the levels of temperature increased. The hardness and stiffness were increased with increasing levels of frying time and significantly decreased with increasing levels of frying temperature. After initial stages of frying up to 10 min, the hardness increased significantly at constant temperature. This might be due to fast gelatinization of surface starch and partial denaturalization of protein after initial frying time (Bouchon et al. 2001). The hardness of deep fried samples was higher than all the air-fried samples. The product changed from soft material to hard product with crispier crust during longer duration exposure to heat, water and sheer stress, the starch granules and other ingredients begin to gelatinize, giving structure and more solid texture to the product (Yamsaengsung et al. 2011). The effect of frying time was not significant (p > 0.05) for cohesiveness, but decreased with increased levels of frying temperature. The springiness showed an increasing trend with increasing levels of frying time and temperature (Table 3).

Fig. 2.

Response surface plots of hardness (a), chewiness (b), OAS (d) and observed OAS (c)

Sensory evaluation

Sensory evaluation (Howgate 1992) was carried out by 10 trained panelists and based on their assessment the attributes of air fried fish cutlets were comparable to deep fried one. The cutlets fried in 160 °C at 5 min and 200 °C at 15 min were having less acceptability with score less than 7 against the score 8 of deep fried sample for all the sensory attributes. The highest overall acceptability score 7.84 was obtained for samples fried in 180 °C at 10 min followed by 200 °C at 5 min. The OAS for deep and air fried samples are given in Fig. 2. The fitted model for OAS produced an R2 of 0.96 with RMSE 0.07. From the response surface plot given in Fig. 2d, it could be inferred that OAS was increasing when the levels of frying temperature and time increased, but later at higher temperature and time (200 °C at 15 min), the OAS started to decrease. This is evident from the negative regression coefficient for the interaction term for time and temperature (Table 3). The reason for less acceptability at lower temperature and time could be under cooking with mild browning and crust formation on the surface. The cutlets exposed to higher levels of temperature and time leads to the hard crust formation on the surface due to over cooking and that could be the reason for less acceptability. The OAS for deep fried sample was 8.01, which was slightly higher compared to air-fried samples. This could be due to the oil content influence the taste buds in the tongue as it carries lot of aromatic, pigmented and volatile compounds.

Optimization, validation and comparison

The response variables mentioned in the Table 2 were taken into account for optimizing the time–temperature combinations of air-frying process as these variables are considered as most important variables affecting the quality of food during frying. Desirability function has been formulated by giving maximum importance to fat content and OAS. Based on the desirability, the optimum combination was found to be fish cutlets fried in 180 °C temperature at 12 min time for good quality product and the corresponding desirability score was 0.68. A validation study was also conducted at optimized air-fried condition in 3 replications. The values obtained for all the response variables were within the confidence limits.

The optimized air-fried and deep fried cutlet samples were compared by taking into all the response variables. The deep fried cutlet samples had 13% fat content, which reduced to 5% at optimum air-fried condition. This proves that air-fried fish cutlets was significantly having lower fat content compared to deep fried fish cutlets. The higher fat content in the deep fried cutlet samples might be due to interaction between product and frying medium; other factors like oil properties, frying time and temperature, drainage time and cooling phase also influences the fat content (Vitrac 2000). It is understood that increase in frying temperature and time decrease the moisture content of the fried product. The moisture content was slightly higher (61%) for air-fried samples at optimum condition than deep fried samples (59%). The higher moisture content in air-fried samples might be due to absence of oil as a medium and lower moisture content in deep fried samples might be due to the oil used for frying fills the voids of the sample (Moreira et al. 1999). The protein content (15%) was also slightly higher for air-fried cutlets at optimum condition compared to deep fried samples (11%). The ash content (2%) was same for both the samples. There is no any change in the mineral content in both air and deep fried samples.

The texture profile analysis of air-fried samples at optimum condition was carried out along with the deep fried sample. The hardness of air and deep fried sample was 27.85 N and 35.01 N, respectively. The lower value for air fried sample indicates that lower force was required to break the product and it had crispier crust than deep fried samples. The cohesiveness value (0.38) was same for both air and deep fried samples. This tells that both the samples are having same strength of internal bonds to hold the product together. The springiness value of air fried samples was 4.79 mm and deep fried sample was 5.38 mm. These values were not significantly different for air and deep fried samples; indicate that almost same mastication energy is required in the mouth. The chewiness of air fried and deep fried samples was 50.29 Nmm and 71.90 Nmm, respectively. The air-fried samples required less mastication energy than deep fried samples to chew the product until it is ready to swallow. The stiffness of air-fried sample was 7.02 N/mm, which was not statistically different (p > 0.05) from deep fried samples (8.15 N/mm).

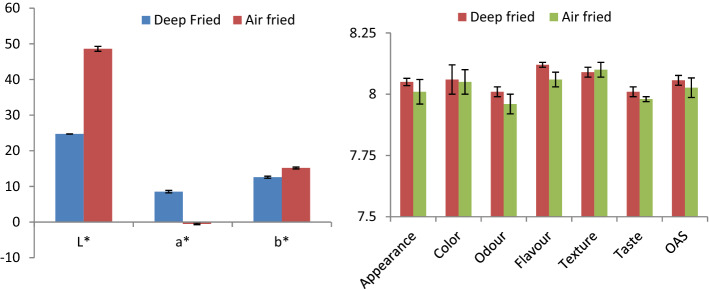

The colour parameters like L*, a* and b* were measured at optimum condition and compared with the control sample. L*, the most important colour parameter for the fried food product, represents the lightness and darkness of the air and deep fried samples. The values of L*, a* and b* were significantly different (p < 0.05) for air and deep fried samples. Higher amount of water loss and oil gain due to heat and mass transfer are responsible for significant color changes in deep frying (Heredia et al. 2014). It can be understood from the Fig. 3 that air fried samples were much lighter than deep fried samples. Deep fried samples were much brownish than air fried samples. This might be due to higher non-enzymatic browning reactions happens in deep fried samples than air fried samples (Dueik et al. 2010). The same kind of results has reported in deep fried products such as tofu, chicken nuggets, pork meat and donuts by Baik and Mittal 2003; Ngadi et al. 2007; Sosa-Morales et al. 2006. The b* values were almost same for both the samples. According to Krokida et al. (2001), the colour changes also influenced by type of oil used, frying time and temperature etc.

Fig. 3.

Comparison of colour and sensory attributes of air (180 °C at 12 min) and deep fried cutlet samples

The comparative evaluation of sensory attributes like appearance, colour, odour, flavour, texture, taste and OAS was carried out for deep and air-fried cutlet samples. Based on the score obtained for sensory attributes, it was found that air-fried fish cutlets were comparable to deep fried ones. The OAS for air and deep fried samples was 8.03 and 8.06, respectively and these values were not significantly different to each other (p > 0.05). The sensory score for appearance, colour, texture and taste were almost same for air and deep fried samples (Fig. 3). The consumers are having good acceptability to air-fried cutlets and it indicates that air-fried fish cutlets can be an alternative healthier daily snack in place of deep fried cutlets.

Conclusion

The optimum air-frying process condition was found to be 180 °C and 12 min for the development of air-fried fish cutlets. The air-fried fish cutlets were having lower fat content compared to deep fried samples. The colour parameters were having superior quality than deep fried samples. The texture profile analysis indicated that air-fried samples produced good texture characteristics. The sensory attributes of air-fried samples were equally comparable with the deep fried samples. In total, the results indicated that air-frying can be an alternative frying method for the development of healthier snack products in place of conventional deep fat frying.

Acknowledgments

The authors thank the Director, ICAR-CIFT, Cochin, for permitting to carry out this work and Mr. Nobi Varghese, Technical assistant and all other staff of Fish Processing Division, ICAR-CIFT, for the support given for the study.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- Abd Rahman NA, Abdul Razak SZ, Lokmanalhakim LA, Taip FS, Mustapa Kamal SM. Response surface optimization for hot air-frying technique and its effects on the quality of sweet potato snack. J Food Process Eng. 2017;40(4):1–8. doi: 10.1111/jfpe.12507. [DOI] [Google Scholar]

- Abtahi MS, Hosseini H, Fadavi A, Mirzaei H, Rahbari M. The optimization of the deep-fat frying process of coated zucchini pieces by response surface methodology. J Culin Sci Technol. 2016;14(2):176–189. doi: 10.1080/15428052.2015.1111181. [DOI] [Google Scholar]

- Anonymous (2016) Hot air frying. http://www.hotairfrying.com/what-is-hot-air-frying. Accessed 29 July 2019

- AOAC . Official Methods of Analysis. 19. Washington: Association of official analytical chemists; 2012. [Google Scholar]

- Baik OD, Mittal GS. Kinetics of tofu color changes during deep-fat frying. LWT Food Sci Technol. 2003;36:43–48. doi: 10.1016/S0023-6438(02)00175-5. [DOI] [Google Scholar]

- Base SAS® 9.3 Procedures Guide (2011) SAS Institute Inc., Cary, NC

- Bouchon P, Hollins P, Pearson M, Pyle DL, Tobin MJ. Oil distribution in fried potatotes monitored by infrared microspectroscopy. J Food Sci. 2001;66:918–923. doi: 10.1111/j.1365-2621.2001.tb08212.x. [DOI] [Google Scholar]

- Ciftfishpro (2018) Information system on CIFT value added fish products. http://ciftfishpro.cift.res.in/cutlet.html. Accessed 16 Nov 2019

- Das RN. Robust second order rotatable designs: part III (RSORD) J Indian Soc Agric Stat. 2003;56(2):117–130. [Google Scholar]

- Dueik V, Robert P, Bouchon P. Vacuum frying reduces oil uptake and improves the quality parameters of carrot crisps. Food Chem. 2010;119:1143–1149. doi: 10.1016/j.foodchem.2009.08.027. [DOI] [Google Scholar]

- FAO (1998) Method of food analysis. United Nations

- Fishken D. Sensory quality and the consumer: viewpoints and directions. J Sens Stud. 1990;5(2):203–209. doi: 10.1111/j.1745-459X.1990.tb00490.x. [DOI] [Google Scholar]

- Heredia A, Castello ML, Arguelles A, Andrès A. Evolution of mechanical and optical properties of French fries obtained by hot air- frying. LWT Food Sci Technol. 2014;57:755–760. doi: 10.1016/j.lwt.2014.02.038. [DOI] [Google Scholar]

- Howgate P (1992) Codex review on inspection procedures for the sensoric evaluation of fish and shellfish. CX/FFP 92/14

- Krokida MK, Oreopoulou V, Maroulis ZB, Marinos-Kouris D. Effect of osmotic dehydration pretreatment on quality of French fries. J Food Eng. 2001;49:339–345. doi: 10.1016/S0260-8774(00)00232-6. [DOI] [Google Scholar]

- Mellema M. Mechanism and reduction of fat uptake in deep-fat fried foods. Trends Food Sci Technol. 2003;14:364–373. doi: 10.1016/S0924-2244(03)00050-5. [DOI] [Google Scholar]

- Mohan CO, Ninan George, Zynudheen AA, Ravishankar CN. Air frying Vs oil frying of farmed tilapia (Oreochromis mossambicus) steaks. Fishtech Rep. 2017;3(1):14–15. [Google Scholar]

- Moreira RG, Barrufet MA. A new approach to describe oil absorption in fried foods: a simulation study. J Food Eng. 1998;35:1–22. doi: 10.1016/S0260-8774(98)00020-X. [DOI] [Google Scholar]

- Moreira RG, Castell-Perez ME, Barrufet MA. Deep fat frying: fundamentals and applications. New York: Springer; 1999. [Google Scholar]

- Myers RH, Mongomery DC. Response surface methodology—process and product optimization using designed experiments. New York: Wiley; 2002. [Google Scholar]

- Ngadi M, Li Y, Oluka S. Quality changes in chicken nuggets fried in oils with different degrees of hydrogenation. LWT Food Sci Technol. 2007;40:1784–1791. doi: 10.1016/j.lwt.2007.01.004. [DOI] [Google Scholar]

- Ninawe AS, Rathnakumar K. Fish processing technology and product development. New Delhi: Narendra Publishing House; 2008. [Google Scholar]

- Priya ER, Sarika K, Kumar Lekshmi RG, Greeshma SS. Air frying—a healthy alternative for conventional frying. Fishtech Rep. 2017;3(1):12–13. [Google Scholar]

- Rosa M, Roberts CJ, Rodrigues MA. Connecting high-temperature and low temperature protein stability and aggregation. PLoS ONE. 2017;12(5):1–12. doi: 10.1371/journal.pone.0176748. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Saguy S, Dana D. Integrated approach to deep fat frying: engineering, nutrition, health and consumer aspects. J Food Eng. 2003;56:143–152. doi: 10.1016/S0260-8774(02)00243-1. [DOI] [Google Scholar]

- Shaker MA. Comparison between traditional deep fat frying and air frying for production of healthy potato strips. Int Food Res J. 2015;22(4):1557–1563. [Google Scholar]

- Sosa-Morales ME, Orzuna-Espiritu R, Velez-Ruiz JF. Mass, thermal and quality aspects of deep-fat frying of pork meat. J Food Eng. 2006;77:731–738. doi: 10.1016/j.jfoodeng.2005.07.033. [DOI] [Google Scholar]

- Vitrac O (2000) Caracterisation experimentale et modelisation de l’operation de friture. In: Sciences biologiques fondamentales et appliquees, Ensia, French

- Yamsaengsung R, Ariyapuchai T, Prasersit K. Effects of vacuum frying on structural changes of bananas. J Food Eng. 2011;106:298–305. doi: 10.1016/j.jfoodeng.2011.05.016. [DOI] [Google Scholar]