Abstract

Proximate composition, cooking quality and sensory characteristics of traditional Turkish egg pasta, erişte, fortified with edible insect and legume flours were evaluated. Egg pasta samples were produced using different blends of wheat flour: legume (lentil and white kidney bean) flour and wheat flour: edible insect (mealworm and grasshopper) flour. Optimum cooking time significantly (p < 0.05) increased with the fortification of egg pasta. The fortification of egg pasta with edible insect flours resulted in a reduced volume expansion from 236.7% (control) to 215.6% and 196.9% for grasshopper flour (W:G) and mealworm flour (W:M) samples, respectively. On the other hand, W:M and W:G samples exhibited significantly (p < 0.05) higher nutritional profile in terms of protein, ash and crude fiber content. Results showed that the smoothness of pasta was also influenced; strengthened by addition of white kidney bean flour and weakened by the addition of grasshopper flour. The received scores from sensory evaluation showed that flours including lentil flour (W:L) and white kidney bean flour (W:B) samples had higher flavor and overall acceptability values with compared to the mealworm flour (W:M), grasshopper flour (W:G) and control sample (C).

Keywords: Edible insects, Eriste, Cooking properties, Legume flour, Fortification

Introduction

It is known that the consumption of noodles, pasta and similar products particularly in the Asian and Middle Eastern region is very high since they can be easily prepared in a short time, have low cost and are suitable for long term storage properties (Alireza Sadeghi and Bhagya 2008). Turkish egg pasta, also known as erişte, is one of the extensively consumed traditional Turkish food. In recent years, it has become very popular to fortify pasta type products with various high-protein sources to improve their nutritional properties (Chillo et al. 2008; Duda et al. 2019; Van Huis et al. 2014).

Protein is an essential part of any diet. In many countries, proteins from animal sources are expensive and therefore tend to be out of reach for much of the population. As a result, in many undeveloped and developing countries where consumption of animal proteins is scarce and expensive, plant proteins are used as a main protein source meeting the needs of almost 10% of the daily protein and 5% of the daily energy intake. Not only this but also higher levels of cholesterol and risk for cardiovascular diseases and cancer associated with consumption of animal proteins are widely revealed in growing number of studies and such studies have contributed significantly to a growing interest in producing protein rich but non-meat based food alternatives for food (Davis et al. 2010; Day 2013; Multari et al. 2015). Therefore, plant protein-based meat substitutes were seen to be an effective step in reducing stated problems. However, the level of digestibility of these protein sources for human consumption is important as much as the amount of essential amino acids found in protein source (Çabuk et al. 2018). Low digestibility and solubility of plant proteins due to the presence of anti-nutritional substances is one of the important issues limiting the use of these proteins in the food industry. (McSweeney et al. 2005; Enneking and Wink 2000). During processing of plants, due to heat exposure or alkali treatments Maillard reaction compounds, oxidized forms of sulphur amino acid and unnatural amino acid derivatives may also form and result in decreasing the nutritive value as well (Gilani et al. 2005). Therefore, researches on an alternative protein sources of high nutritive value, edible insects, has increased in recent years.

Edible insects have an important role in the nutrition of people in many regions and have significant importance in the diet (Banjo et al. 2006). Edible insects already have been consumed by people in Africa, Asia and Latin America as a vital source of protein. Although the use of edible insects varies from region to region, it is known that more than 1900 insect species can be eaten today (Nonaka 2009) and many of them contain essential amino acids necessary for human health (Yi et al. 2013). Beetles, mealworms, caterpillars of butterflies, bees, wasps, ants, grasshoppers, locusts, crickets, termites, true bugs, scale insects, dragonflies are some examples of commonly eaten edible insects and among the insect species, the most favorable species for mass production is the mealworm and grasshopper (Zielińska et al. 2015; Spranghers et al. 2017; Blásquez et al. 2012).

Edible insects are now recognized as a nutritious food choice with significant amount of macronutrients. Edible insects are potent source of energy and protein. They have high levels monounsaturated and/or polyunsaturated fatty acids, and are rich in micronutrients such as copper, iron, magnesium, manganese, phosphorous, selenium and zinc, as well as vitamin A, vitamin B12 Insect proteins also have higher digestibility levels than vegetable proteins. It has been found that the absorption of this protein in the human body is in the range of 76–96% (Rumpold and Schluter 2013; Kouřimská and Adámková 2016).

Taken together, studies highlight a great opportunity to develop and introduce a healthy, nutritious novel food products made with insect flours. Therefore, this present paper seeks to extend and enrich the information on the use of edible insects in food products. The aim of this study is to determine some chemical, cooking and sensory properties of traditional egg pasta, erişte, and compared with the ones produced with two most commonly used pulse flours; lentil and white kidney bean.

Materials and methods

Raw materials

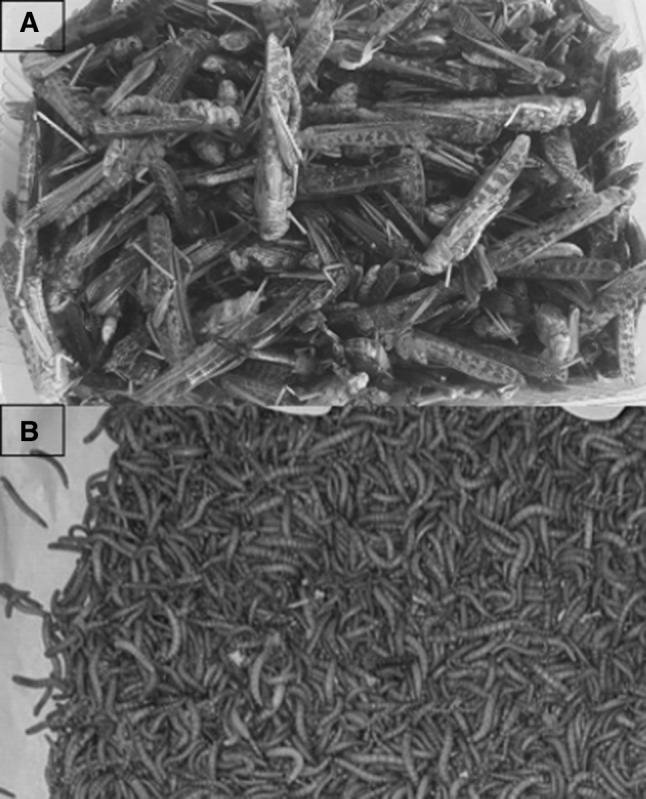

Wheat flour (0.5 ash, 10.3 protein, 73.8 starch, 1.6 crude fiber, db) bean flour, lentil flour, salt, sunflower oil and eggs were purchased from the local market. Mealworm (Tenebrio Molitor) and grasshopper (Locusta Migratoria) (Fig. 1) were provided by Mira Canlı Hayvan Böcek Turizm İnşaat Tarım Sanayi Co. (Antalya, Turkey). Samples were milled by grinding (Custom Grind, model 80365; Hamilton Beach, Glen Allen, VA, USA) and then passed through a 40-mesh sieve and stored in an airtight container for further utilization in different preparations. The flours were kept at 4 °C until used.

Fig. 1.

Insects used for egg pasta production. a grasshopper (L. Migratoria); b mealworm (T. molitor)

Egg pasta preparation

Traditional egg pasta was produced with composite flours which were prepared by substituting wheat flour (Control) with different flours including white kidney bean flour (W:B), lentil flour (W:L), grasshopper flour (W:G) and mealworm flour (W:M) as 15 g/100 g (db). Pasta samples were prepared following the methods that were previously described by Dirim and Çalışkan (2017). Briefly, 210 g of flour, 72 g of distilled water, 52 g of egg, 3 g of salt and 8 g of sunflower oil were mixed and kneaded for 10 min. The dough was thinned and brought into a regular shape at the same thickness with a pasta machine (Marcato Atlas 150, İstanbul, Turkey). Flattened pieces were dried in the oven (Memmert 150, Germany) at 60 °C for 10 min. Then, using pasta machine, the pieces were cut into long stripes with a width of 0.65 cm. The final shape was achieved by cutting the long stripes into 3 cm length short stripes. The second drying of egg pasta samples took place at in the oven for 90 min at 60 °C. The obtained egg pasta samples were stored in an airtight container at room temperature for further use.

Determination of proximate composition and color

The moisture, total ash, protein, starch and crude fiber content of egg pasta samples were determined according to AOAC (1995). Color values of egg pasta samples were measured using a Minolta CR-400 Colorimeter (Minolta Camera Co., Osaka, Japan,) calibrated with a white standard plate for six times and results as the average of six measurements were recorded in CIE L*a*b* scale in terms of lightness (L*) and color (a*-redness; b*-yellowness).

Cooking parameters

The optimal cooking time

The optimal cooking time was determined by boiling 3 g of pasta samples in 150 ml of distilled water. Samples were taken every 1 min from the boiling water after 8 min of cooking, placed between two glass slides and squeezed to observe the white core strand of pasta samples. The optimal cooking time was determined as the time when white core was disappeared as judged by squeezing between two glass slides (AACC 2000).

Cooking loss

The amount of solid substances in the cooking water of the egg pasta samples were determined as described in AACC (2000) with minor modifications in order to determine cooking loss values of samples. Briefly, 15.0 g of samples were soaked in a boiling distilled water (150 ml) and cooked for 20 min. The cooked pasta samples were drained, rinsed with distilled water in a buchner funnel. Both cooking water and rinse water were collected in a pre-weighted beaker. The cooking loss was determined by evaporating to dryness the cooking and rinse water in an oven at 105 °C. Cooking loss was reported as the percentage of the residue.

Water absorption and volume expansion

In order to determine water absorption during cooking of samples, fifteen grams of pasta samples were placed into 150 ml of boiling distilled water and cooked for 20 min. Afterwards, the cooked pasta was drained and weighted in order to determine the water absorption. The water absorption (%) was considered as difference in weight of cooked versus uncooked samples and expressed as the percentage (Yalcın and Basman 2008).

To determine the volume expansion of pasta samples, uncooked and cooked samples were immersed in 150 ml a graduated cylinder filled with 50 ml of distilled water and the volume of distilled water displaced was measured. The volume expansion (%) was considered as difference in volume of cooked versus uncooked samples and expressed as the percentage (Yalcın and Basman 2008).

Sensory analysis

Descriptive analysis was used to measure the rating of consumer acceptance was measured. In this study, 20 semi-trained panelists aged between 18 and 45 years (10 males and 10 females) without allergies and regular consumers of egg pasta among staff and students of the Department of Gastronomy and Culinary Arts (Alanya Hamdullah Emin Pasa University, Antalya, Turkey) based on their willingness to try pasta samples prepared with insects as an ingredient were invited to participate and informed that some samples contain edible insects. Panelists were asked to evaluate color, odor, flavor, taste, firmness, elasticity, smoothness, stickiness, and overall acceptability of samples which were to rate on a five-point scales from 1 to 5 with 1 being poor and 5 being excellent.

Statistical analysis

Data analysis was performed using one-way (ANOVA) procedures using Minitab Statistical Software (Minitab 17.0 for Windows, Minitab, USA). All analyses were carried out in triplicates. Data were presented as a mean ± standard deviation. Tukeys’ test was used for comparison of means with a level significance of 0.05.

Results and discussion

Determination of proximate composition

The proximate composition of the pasta samples fortified with different flours are represented in Table 1. Moisture content is a significant factor affecting the storage duration and microbial quality of the pasta like products. Results showed that moisture content of the pasta samples fortified with different flours vary between 11.4 ± 0.4 and 12.9 ± 0.4 g/100 g. It is also observed that insect flour fortified samples showed higher moisture content compared to legume flour fortified ones. Ash contents ranged from 1.8 ± 0.0 g/100 g for lentil flour enriched (W:L) samples to 2.2 ± 0.1 g/100 g for mealworm flour enriched (W:M) samples. However, there was not a significant (p > 0.05) difference in ash values among pasta samples. The highest crude fiber contents were shown by grasshopper and mealworm flour enriched samples, respectively. Among legume flour pasta samples, crude fiber content was higher for bean flour enriched pasta samples with 1.5 ± 0.1 g/100 g than for pasta with lentil flour. However, it is clearly seen that edible insect flours provided better fiber content probably due to higher crude fiber content in the chemical structure of insects (Stull et al. 2018; Van Huis et al. 2013). With the fortification of grasshopper flour, the protein content increased to 19.5 ± 0.0 from 12.9 ± 0.0 g/100 g with a corresponding decrease in starch content from 67.8 ± 1.0 to 58.40 ± 1.0 g/100 g. In contrast to our results, in a study conducted by Giménez et al. (2012) greater increase in protein content of pasta samples fortified with broad bean flour blends. It is well known that depending on the species, insect flours are mainly composed of proteins and fats, followed by fibers (Zielińska et al. 2015).

Table 1.

Proximate composition of control and fortified egg pasta samples (g/100 g, db)

| Pasta sample | Moisture content | Ash content | Protein content | Starch content | Crude fiber content |

|---|---|---|---|---|---|

| Flours | |||||

| Wheat | 14.5 ± 1.0c | 1.9 ± 0.1d | 10.3 ± 0.0e | 73.8 ± 0.2a | 1.6 ± 0.2c |

| Lentil | 8.0 ± 0.4b | 3.1 ± 0.0c | 29.3 ± 0.0c | 58.7 ± 0.1b | 1.3 ± 0.0c |

| Bean | 3.0 ± 0.1a | 3.0 ± 0.1c | 28.3 ± 0.2d | 43.6 ± 0.4c | 5.7 ± 0.7b |

| Grasshopper | 4.2 ± 0.8a | 4.2 ± 0.1a | 61.7 ± 0.2a | – | 6.8 ± 0.3a |

| Mealworm | 4.8 ± 0.2a | 4.0 ± 0.1b | 57.6 ± 0.1b | – | 6.1 ± 0.1ab |

| Egg pastas | |||||

| Control | 9.6 ± 0.5b | 1.6 ± 0.4a | 12.9 ± 0.0d | 67.8 ± 1.0a | 0.8 ± 0.0c |

| W:L | 11.4 ± 0.4ab | 1.8 ± 0.0a | 14.6 ± 0.1c | 64.1 ± 1.0b | 0.7 ± 0.0c |

| W:B | 11.5 ± 0.1ab | 1.9 ± 0.0a | 14.7 ± 0.0c | 62.9 ± 1.1c | 1.5 ± 0.1b |

| W:G | 12.8 ± 1.1a | 1.9 ± 0.2a | 19.5 ± 0.0a | 58.4 ± 1.0d | 2.2 ± 0.1a |

| W:M | 12.9 ± 0.4a | 2.2 ± 0.1a | 18.3 ± 0.0b | 58.7 ± 1.1d | 1.7 ± 0.1b |

Data represent the mean ± one standard deviation (n = 3). Different letters for each column indicate significant differences (p < 0.05). Control: %100 wheat flour, W:L: %85 wheat flour + %15 lentil flour W:B: %85 wheat flour + %15 white kidney bean flour, W:G: %85 wheat flour + %15 grasshopper flour, W:M: %85 wheat flour + %15 mealworm flour

Color measurements

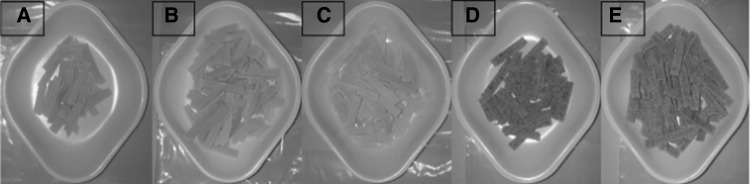

Regarding egg pasta productions, Fig. 2 shows the pasta samples produced fortified with different flours. Incorporation of different flours significantly (p < 0.05) affected the L*, a* and b* values of pasta samples (Table 2). However, this effect was dependent on the type of the flour. The results of the color analysis showed that all formulations with edible insect flours led pasta samples with reduced lightness (L*) compared to control samples. Moreover, fortification with edible insect flours decreased the yellowness (b*) in samples. On the other hand, no changes were calculated for the samples fortified with legume flours. Decrease in lightness of some flours by supplementation of edible insect flour (cricket) has also been reported by (Duda et al. 2019).

Fig. 2.

Egg pasta samples obtained with a Control: %100 wheat flour, b W:L: %85 wheat flour + %15 lentil flour, c W:B: %85 wheat flour + %15 white kidney bean flour, d W:G: %85 wheat flour + %15 grasshopper flour, e W:M: %85 wheat flour + %15 mealworm flour

Table 2.

Color profile (L*, a*, b*) analysis of control and fortified egg pasta samples

| Pasta sample | L* | A* | B* |

|---|---|---|---|

| Control | 70.8 ± 1.5a | 1.6 ± 0.3a | 23.0 ± 0.9a |

| W:L | 69.2 ± 2.5a | 2.3 ± 0.8a | 25.8 ± 1.3a |

| W:B | 71.7 ± 2.1a | 2.4 ± 0.4a | 24.9 ± 1.0a |

| W:G | 60.5 ± 0.3b | 2.1 ± 0.0a | 17.0 ± 0.2b |

| W:M | 56.1 ± 0.1b | 2.7 ± 0.0a | 13.1 ± 0.1b |

Data represent the mean ± one standard deviation (n = 3). Different letters for each column indicate significant differences (p < 0.05). Control: %100 wheat flour, W:L: %85 wheat flour + %15 lentil flour W:B: %85 wheat flour + %15 white kidney bean flour, W:G: %85 wheat flour + %15 grasshopper flour, W:M: %85 wheat flour + %15 mealworm flour

Cooking parameters

The cooking quality parameters including cooking loss, water absorption, volume increase, and optimal cooking time assessed for pasta samples fortified with different flours were as reveled in Table 3. The cooking time of egg pasta samples ranged between 15.3 ± 0.4 min to 23.0 ± 0.0 min. It was clearly seen that fortification with mealworm flours had greatest impact and increased the cooking time for 7.7 min when compared to control sample. Moreover, among legume flour enriched pasta samples, W:B sample showed significantly higher (p < 0.05) cooking time of 20.0 ± 0.0 min than W:L ones (17.5 ± 0.7 min). This was disagreement with literature where decreased cooking times for the samples containing legume flours were reported. For instance, Rosa-Sibakov et al. (2016) observed that enhancement of semolina flour with faba bean lowered the optimal cooking times about 4 min, while concluded that 35% fortification of pasta samples with split pea and faba bean reduced the optimal cooking time from 9.30 min down to 8.50 and 8.70 min for faba bean and split pea, respectively. In our study, the difference in cooking times of pasta samples compared to control sample could be caused by higher amount in fiber and lower amount in starch content resulting in a slower rate of water diffusion and consequently raised the optimal cooking times.

Table 3.

Cooking quality parameters of control and fortified egg pasta samples

| Pasta sample | Cooking loss (%) | Water absorption (%) | Volume expansion (%) | Optimal cooking time (min) |

|---|---|---|---|---|

| Control | 6.1 ± 0.1d | 206.9 ± 9.1a | 236.7 ± 4.7a | 15.3 ± 0.4d |

| W:L | 6.5 ± 0.0bc | 210.6 ± 5.6a | 250.0 ± 0.0a | 17.5 ± 0.7c |

| W:B | 6.3 ± 0.1 cd | 209.6 ± 2.4a | 246.9 ± 4.4a | 20.0 ± 0.0b |

| W:G | 6.9 ± 0.1a | 191.8 ± 5.4ab | 215.6 ± 4.4b | 20.0 ± 0.0b |

| W:M | 6.5 ± 0.1b | 179.5 ± 2.3b | 196.9 ± 4.4c | 23.0 ± 0.0a |

Data represent the mean ± one standard deviation (n = 3). Different letters for each column indicate significant differences (p < 0.05). Control: %100 wheat flour, W:L: %85 wheat flour + %15 lentil flour W:B: %85 wheat flour + %15 white kidney bean flour, W:G: %85 wheat flour + %15 grasshopper flour, W:M: %85 wheat flour + %15 mealworm flour

The cooking loss of pasta samples enriched with different pulse and edible flours were investigated. Fortification of wheat flour by 15% of both legume and edible insect flours significantly (p < 0.05) increased the cooking loss. Results revealed that fortification of wheat flour with 15% of edible insect flours had greater impact on the cooking loss causing an increase from 6.1 ± 0.1 to 6.5 ± 0.1% and 6.9 ± 0.1% for W:M and W:G fortified samples, respectively. Higher cooking loss values may be attributed to the weak gluten network formation unlike control sample due to fortification of gluten free flours resulting in reduction of gluten amount in the total composition (Padalino et al. 2016; Yano 2019; Roncolini et al. 2019). Wheat gluten proteins form strong gluten network due to formation of molecular disulphide bonds during pasta processing. On the other hand, legumes are mainly composed of soluble proteins that are responsible for the formation of weak network structure which further facilitated penetration of water to the core of the pasta easier and leaching of the solids during cooking (Petitot et al. 2010; Rayas-Duarte et al. 1996). This can also be said for the samples fortified with edible insect flours; due to inclusion of high fiber content flours, gluten network of pasta samples interrupted (Pauter et al. 2018).

Regarding the water absorption of pasta samples, presence of insect flours produced a decrease in water absorption compared with the control. The cooked pasta samples of mealworm flour showed the lowest value of 179.5 ± 2.3 g/100 g of sample and it was significantly lower than of control, W:L and W:B pasta samples (Table 3). It has been previously observed that addition of different flours with high protein content alter the water absorption capacity of food products mainly depending on the amino acid composition of the protein, dietary fiber and starch content and amylose/amylopectin ratio of flours (Mahmoud et al. 2012; Köber et al. 2007). For instance, incorporation of barley flour reduced the water absorption capacity of bread samples (Al-Attabi et al. 2017) while, another study with broad bean flour presented higher water absorption values than wheat control (Giménez et al. 2012). In addition, studies carried out replacing wheat flour with increasing amounts of mealworm, larvae of black soldier fly and cricket flours showed decreases in water absorption of muffin samples due to protein content (González et al. 2019).

Volume expansion is one of the significant factors used to predict pasta cooking quality and related to the water absorption capacity of pasta samples. A significant variation with respect to the volume expansion of edible insects supplemented pasta samples was revealed. Supplementation with edible insect flours had given a negative impact on volume expansion of samples decreasing values from 236.7 ± 4.7 to 215.6 ± 4.4% and 196.9 ± 4.4% for W:G and W:M samples, respectively. This trend could likely be due to the low water absorption of these samples having more fibrous and less starchy structure letting lower penetration of water molecules resulting in a lower hydration capacity, thus lower volume expansion.

Sensory evaluation

The sensory research was conducted for all samples at AHEP University of Gastronomy and Culinary Arts Department aimed at examining the sensory properties of the products and their consumer acceptance. The results of sensory evaluation of the pasta samples fortified with flours compared to the control are shown in Fig. 3. Colors of pasta samples were intensively affected by edible insect flour enhancement. Samples prepared with legume flours had the highest color scores as compared to control sample whereas score values of the flours declined (down to 3.0 ± 0.7) with grasshopper flour enhancement followed by mealworm flour (3.5 ± 0.8). Edible insect flours had also the greatest impact on smoothness with the lowest score of 2.4 ± 0.1 when grasshopper flour was used probably because of the presence of no- digestible fibers in flour which can be correlated with the cooking tests data, where the smoothness decreased with increase in fiber content in the samples. Results also revealed that no changes were perceived in firmness score values compared to control sample. Samples prepared from edible inset flours in combination with wheat flour were fairly rated by assessors with respect to odor. Moreover, changes in the elasticity were perceived with respect to the control sample. The overall acceptability also shows that enhancement of different flours influences the overall approval of the pasta samples. Results clearly showed that control samples had highest score (4.1 ± 0.6) and highly acceptable pasta samples that closely resembled the control was produced from bean flour (4.0 ± 0.8) and lentil flour (3.9 ± 0.9). To sum up, due to the sensory analysis test, it can be concluded that panelists prefer legume flours over edible insect flours which might be due to the odor and darker color of the samples. Even though, the smoothness and odor of the edible insect fortified ones were scored lower compared to all other samples, the score values were still over 3.0 which clearly shows that with the modifications in the end product to mask the odor and improve the smoothness, edible insect flours might be a good protein source for pasta like products in the food industry. Padalino et al. (2015) suggested that increase in the protein content when the substitution percentage increases. However, our results followed an opposite trend. This is possibly related to both starch and crude fiber content of the samples rather than protein content. Because although the highest protein contents were obtained with grasshopper and mealworm fortified samples, respectively, the lowest elasticity and smoothness was obtained again with these samples. This clearly shows that the higher amount of crude fiber in edible flours may have played a significant role and caused lower elastic and less smooth texture.

Fig. 3.

Sensory evaluation of control and fortified egg pasta samples obtained with Control: %100 wheat flour, W:L: %85 wheat flour + %15 lentil flour W:B: %85 wheat flour + %15 white kidney bean flour, W:G: %85 wheat flour + %15 grasshopper flour, W:M: %85 wheat flour + %15 mealworm flour

Conclusion

Due to increase in global population and raise in the awareness of food insecurity especially in the Middle Eastern region, improving nutritional quality of foods which have low cost and higher storage stability like pasta like products gained a huge importance in food industry. While plant based foods have shown to be a good protein source alternative, there are still disadvantages regarding their functionality. Insects have been used in animal feeding industry for many years. Therefore, in this research, a traditional product having various names in Middle Eastern region, egg pasta; erişte; fortified edible insect flours were developed and comparisons were made with control and selected legume flours. Results clearly showed that fortification with both plant and insect flours significantly improved the nutritional profile of samples. It can be clearly concluded that edible insect flours are potential protein source; samples fortified with grasshopper flour showed the highest improvement in protein content while providing a reduction in starch content. On the other hand, it was shown that replacement of wheat flour with different sources of flours were able to modify cooking characteristics of the pasta samples due to weakened gluten network structure of pasta dough with fortifications. However, the cooking loss values were still lower than the suggested value (< %12). Therefore, present research revealed that edible insect flours can be successfully incorporated in pasta to improve their nutritional value especially protein content and results of sensory analysis suggested that herbs and spices may be used to improve acceptability of edible insect flour fortified pasta samples by modifying the smell in further studies. However, it should be kept in mind that quality characteristics of the developed food products are highly dependent on the type of the insect flour.

Acknowledgements

This Research was financed by Alanya Hamdullah Emin Paşa University, Turkey. Special thanks are extended to Mira Canlı Hayvan Böcek Turizm İnşaat Tarım Sanayi Co. (Antalya, Turkey) for the supply of edible insect samples.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- AACC . International approved methods of analysis. 10. St Paul: American Association of Cereal Chemist; 2000. [Google Scholar]

- Al-Attabi ZH, Merghani TM, Ali A, Rahman MS. Effect of barley flour addition on the physico-chemical properties of dough and structure of bread. J Cereal Sci. 2017;75:61–68. doi: 10.1016/j.jcs.2017.03.021. [DOI] [Google Scholar]

- Alireza Sadeghi M, Bhagya S. Quality characterization of pasta enriched with mustard protein isolate. J Food Sci. 2008;73(5):S229–S237. doi: 10.1111/j.1750-3841.2008.00742.x. [DOI] [PubMed] [Google Scholar]

- AOAC . Official methods of analysis of aoac international. Washington, DC: Association of Official Analytical Chemists; 1995. [Google Scholar]

- Banjo A, Lawal O, Songonuga E. The nutritional value of fourteen species of edible insects in southwestern Nigeria. Afr J Biotech. 2006;5(3):298–301. [Google Scholar]

- Blásquez JR-E, Moreno JMP, Camacho VHM. Could grasshoppers be a nutritive meal? Food Nutr Sci. 2012;3(02):164. [Google Scholar]

- Çabuk B, Nosworthy MG, Stone AK, Korber DR, Tanaka T, House JD, Nickerson MT. Effect of fermentation on the protein digestibility and levels of non-nutritive compounds of pea protein concentrate. Food Technol Biotechnol. 2018;56(2):257–264. doi: 10.17113/ftb.56.02.18.5450. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Chillo S, Laverse J, Falcone P, Del Nobile MA. Quality of spaghetti in base amaranthus wholemeal flour added with quinoa, broad bean and chick pea. J Food Eng. 2008;84(1):101–107. doi: 10.1016/j.jfoodeng.2007.04.022. [DOI] [Google Scholar]

- Davis J, Sonesson U, Baumgartner DU, Nemecek T. Environmental impact of four meals with different protein sources: case studies in Spain and Sweden. Food Res Int. 2010;43(7):1874–1884. doi: 10.1016/j.foodres.2009.08.017. [DOI] [Google Scholar]

- Day L. Proteins from land plants–potential resources for human nutrition and food security. Trends Food Sci Technol. 2013;32(1):25–42. doi: 10.1016/j.tifs.2013.05.005. [DOI] [Google Scholar]

- Dirim S, Çalışkan G. Enhancement of the functional properties of home-made style turkish noodles (erişte) with the addition of fresh mints. J Food Phys. 2017;30:4–14. [Google Scholar]

- Duda A, Adamczak J, Chełmińska P, Juszkiewicz J, Kowalczewski P. Quality and nutritional/textural properties of durum wheat pasta enriched with cricket powder. Foods. 2019;8(2):46. doi: 10.3390/foods8020046. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Enneking D, Wink M (2000) Towards the elimination of anti-nutritional factors in grain legumes. In: Linking research and marketing opportunities for pulses in the 21st century. Springer, pp 671–683

- Gilani GS, Cockell KA, Sepehr E. Effects of antinutritional factors on protein digestibility and amino acid availability in foods. J AOAC Int. 2005;88(3):967–987. doi: 10.1093/jaoac/88.3.967. [DOI] [PubMed] [Google Scholar]

- Giménez MA, Drago SR, De Greef D, Gonzalez RJ, Lobo MO, Samman NC. Rheological, functional and nutritional properties of wheat/broad bean (Vicia faba) flour blends for pasta formulation. Food Chem. 2012;134(1):200–206. doi: 10.1016/j.foodchem.2012.02.093. [DOI] [Google Scholar]

- González CM, Garzón R, Rosell CM. Insects as ingredients for bakery goods. A comparison study of H. illucens, A. domestica and T. molitor flours. Innov Food Sci Emerg Technol. 2019;51:205–210. doi: 10.1016/j.ifset.2018.03.021. [DOI] [Google Scholar]

- Köber E, Gonzalez M, Gavioli N, Salmoral E. Modification of water absorption capacity of a plastic based on bean protein using gamma irradiated starches as additives. Radiat Phys Chem. 2007;76(1):55–60. doi: 10.1016/j.radphyschem.2006.05.017. [DOI] [Google Scholar]

- Kouřimská L, Adámková A. Nutritional and sensory quality of edible insects. NFS J. 2016;4:22–26. doi: 10.1016/j.nfs.2016.07.001. [DOI] [Google Scholar]

- Mahmoud EAM, Nassef SL, Basuny AMM. Production of high protein quality noodles using wheat flour fortified with different protein products from lupine. Ann Agric Sci. 2012;57(2):105–112. doi: 10.1016/j.aoas.2012.08.003. [DOI] [Google Scholar]

- McSweeney C, Gough J, Conlan L, Hegarty M, Palmer B, Krause D. Nutritive value assessment of the tropical shrub legume Acacia angustissima: anti-nutritional compounds and in vitro digestibility. Anim Feed Sci Technol. 2005;121(1–2):175–190. doi: 10.1016/j.anifeedsci.2005.02.017. [DOI] [Google Scholar]

- Multari S, Stewart D, Russell WR. Potential of fava bean as future protein supply to partially replace meat intake in the human diet. Compr Rev Food Sci Food Saf. 2015;14(5):511–522. doi: 10.1111/1541-4337.12146. [DOI] [Google Scholar]

- Nonaka K. Feasting on insects. Entomol Res. 2009;39(5):304–312. doi: 10.1111/j.1748-5967.2009.00240.x. [DOI] [Google Scholar]

- Padalino L, Mastromatteo M, Lecce L, Spinelli S, Conte A, Del Nobile M. Effect of raw material on cooking quality and nutritional composition of durum wheat spaghetti. Int J Food Sci Nutr. 2015;66(3):266–274. doi: 10.3109/09637486.2014.1000838. [DOI] [PubMed] [Google Scholar]

- Padalino L, Conte A, Del Nobile MA. Overview on the general approaches to improve gluten-free pasta and bread. Foods (Basel, Switzerland) 2016;5(4):87. doi: 10.3390/foods5040087. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Pauter P, Różańska M, Wiza P, Dworczak S, Grobelna N, Sarbak P, Kowalczewski PŁ. Effects of the replacement of wheat flour with cricket powder on the characteristics of muffins. Acta Sci Polon Technol Aliment. 2018;17(3):227–233. doi: 10.17306/J.AFS.0570. [DOI] [PubMed] [Google Scholar]

- Petitot M, Boyer L, Minier C, Micard V. Fortification of pasta with split pea and faba bean flours: pasta processing and quality evaluation. Food Res Int. 2010;43(2):634–641. doi: 10.1016/j.foodres.2009.07.020. [DOI] [Google Scholar]

- Rayas-Duarte P, Mock C, Satterlee L. Quality of spaghetti containing buckwheat, amaranth, and lupin flours. Cereal Chem. 1996;73(3):381–387. [Google Scholar]

- Roncolini A, Milanovic V, Cardinali F, Osimani A, Garofalo C, Sabbatini R, Clementi F, Pasquini M, Mozzon M, Foligni R, Raffaelli N, Zamporlini F, Minazzato G, Trombetta MF, Buitenen A, Van Campenhout L, Aquilanti L. Protein fortification with mealworm (Tenebrio molitor L.) powder: Effect on textural, microbiological, nutritional and sensory features of bread. PLoS ONE. 2019;14:e0211747. doi: 10.1371/journal.pone.0211747. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Rosa-Sibakov N, Heiniö R-L, Cassan D, Holopainen-Mantila U, Micard V, Lantto R, Sozer N. Effect of bioprocessing and fractionation on the structural, textural and sensory properties of gluten-free faba bean pasta. LWT Food Sci Technol. 2016;67:27–36. doi: 10.1016/j.lwt.2015.11.032. [DOI] [Google Scholar]

- Rumpold BA, Schluter OK. Nutritional composition and safety aspects of edible insects. Mol Nutr Food Res. 2013;57(5):802–823. doi: 10.1002/mnfr.201200735. [DOI] [PubMed] [Google Scholar]

- Spranghers T, Ottoboni M, Klootwijk C, Ovyn A, Deboosere S, De Meulenaer B, Michiels J, Eeckhout M, De Clercq P, De Smet S. Nutritional composition of black soldier fly (Hermetia illucens) prepupae reared on different organic waste substrates. J Sci Food Agric. 2017;97(8):2594–2600. doi: 10.1002/jsfa.8081. [DOI] [PubMed] [Google Scholar]

- Stull VJ, Finer E, Bergmans RS, Febvre HP, Longhurst C, Manter DK, Patz JA, Weir TL. Impact of edible cricket consumption on gut microbiota in healthy adults, a double-blind, randomized crossover trial. Sci Rep. 2018;8(1):10762. doi: 10.1038/s41598-018-29032-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Van Huis A, Van Itterbeeck J, Klunder H, Mertens E, Halloran A, Muir G, Vantomme P. Edible insects: future prospects for food and feed security. Rome: Food and Agriculture Organization of the United Nations; 2013. [Google Scholar]

- Van Huis A, Van Gurp H, Dicke M. The insect cookbook: food for a sustainable planet. New York: Columbia University Press; 2014. [Google Scholar]

- Yalcın S, Basman A. Quality characteristics of corn noodles containing gelatinized starch, transglutaminase and gum. J Food Qual. 2008;31(4):465–479. doi: 10.1111/j.1745-4557.2008.00212.x. [DOI] [Google Scholar]

- Yano H. Recent practical researches in the development of gluten-free breads. NPJ Sci Food. 2019;3(1):7. doi: 10.1038/s41538-019-0040-1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Yi L, Lakemond CM, Sagis LM, Eisner-Schadler V, van Huis A, van Boekel MA. Extraction and characterisation of protein fractions from five insect species. Food Chem. 2013;141(4):3341–3348. doi: 10.1016/j.foodchem.2013.05.115. [DOI] [PubMed] [Google Scholar]

- Zielińska E, Baraniak B, Karaś M, Rybczyńska K, Jakubczyk A. Selected species of edible insects as a source of nutrient composition. Food Res Int. 2015;77:460–466. doi: 10.1016/j.foodres.2015.09.008. [DOI] [Google Scholar]