Abstract

The worldwide coronavirus disease 2019 pandemic has greatly impacted dental practice. Issues confronting practicing dentists include possible transmission of disease by droplets/aerosol or contact with contaminated surfaces. Dentists are at increased risk because of their proximity to the oropharynx. In an effort to reduce potential exposure to aerosols generated during treatment, a device has been developed in which a polycarbonate shield is mounted to the dental operating microscope with an attached high-velocity vacuum hose. Anemometer measurements show an exhaust outflow of 3.9 ft/min at a position approximating the patient’s oropharynx. More research may be warranted using this or similar approaches to mitigate aerosol transmission.

Key Words: Aerosol, COVID-19, dental operating microscope, endodontics

Significance.

The COVID-19 pandemic has increased concerns about the transmission of the virus in aerosols generated during dental procedures. As a method to reduce unimpeded aerosol transmission, a polycarbonate shield with an attached high-speed vacuum line was mounted on the dental operating microscope.

The global coronavirus disease 2019 (COVID-19) pandemic, because of an exponential increase in severe acute respiratory syndrome coronavirus 2 infections1, has had a major impact on health care delivery2 , 3. As of April 2020, the Centers for Disease Control and Prevention (CDC)4 and the American Dental Association5 issued guidance to postpone all but emergency and urgent dental conditions. The rationale is to prevent disease transmission and to conserve personal protective equipment.

The transmission of the severe acute respiratory syndrome coronavirus 2 virus is believed to occur primarily via droplets/aerosol originating from the oropharynx or by contact with surfaces contaminated with the virus2 , 6 , 7. The CDC recommends that aerosol-generating procedures performed on known or suspected COVID-19 patients should be in negative-pressure/airborne infection isolation rooms (AIIRs)8. However, an important additional clinical concern is how to deliver aerosol-generating procedures to patients who are infected but asymptomatic. The onset for COVID-19 infection is up to 14 days, and about 80% of patients may be either asymptomatic or have symptoms reminiscent of mild flu or seasonal allergies9. Moreover, the growing recognition of nosocomial transmission via aerosol generation has prompted a reexamination of aerosol production in the dental operatory10.

Given the lack of available negative-pressure rooms/AIIRs for dental treatment and the need to deliver endodontic treatment for patients who may or not be infected, there is a need to develop an engineering solution to mitigate aerosol exposure in the dental operatory. The description of a polycarbonate shield mounted to the dental operating microscope (DOM) with an attached high-velocity vacuum hose is provided. A description of its construction and the measurement of evacuated airflow are also provided.

Materials and Methods

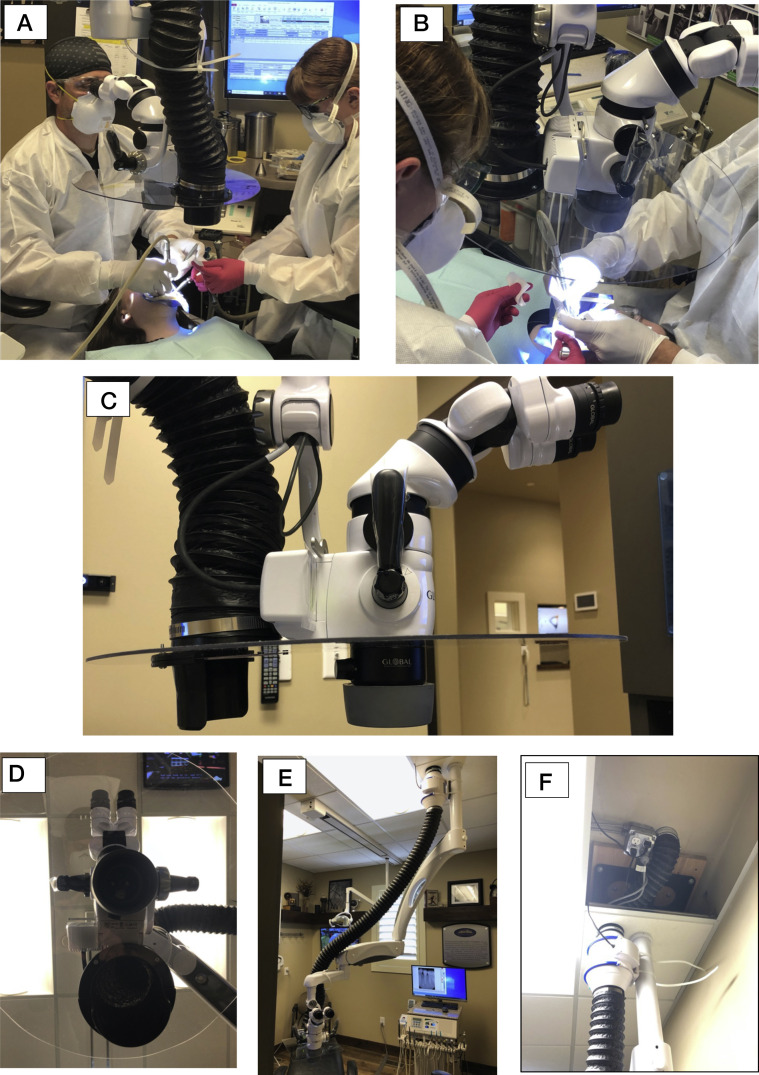

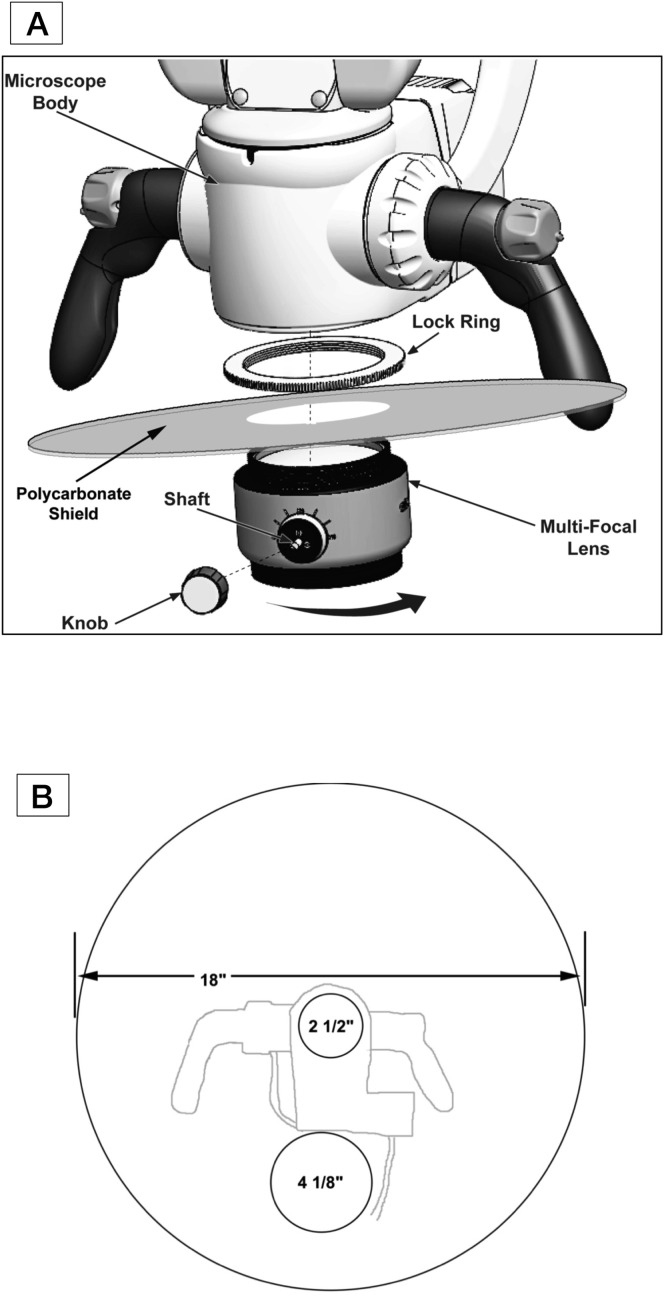

The materials used in the construction of this device are listed in Table 1 . Figures 1 and 2 illustrate the DOM shield device and its use during endodontic treatment.

Table 1.

A Description of the Parts Used in Construction

| Description of item | Company | Catalog/part no. | Purpose |

|---|---|---|---|

| 18 × 24 × .093 clear polycarbonate | Home Depot | 1PC1824A | Shield |

| 4-inch in-line duct fan | AC Infinity | AI-CLS4 | Fan |

| 4-inch flexible ducting | AC Infinity | AI-DTA4 | Ducting |

| Two 4-inch inlet flange | POWERTEC | POWERTEC 70126 | Used to attach ducting to the shield |

| Second flange cut in half to create directional edge | |||

| Air carbon filter | AC Infinity | AC-DCF4 | Air filter |

| 2 ½-inch Hole Dozer saw | Milwaukee | 59-56-9631 | To cut the hole for objective lens |

| 4 1/8-inch Hole Dozer saw | Milwaukee | 49-56-9646 | To cut the hole for the vent ducting |

| 24-inch Cable Tie | Commercial Electric | GT-630HD | Used to support ducting and fan |

| #10-32 × 1/2 inch flat-head screw | Everbilt | 803971 | To hold the inlet flange to the shield |

Figure 1.

(A) The setup of the evacuation system using a mock patient. (B) A view of the DOM shield system from the dental assistant’s perspective. (C) A close-up of the 18-inch round polycarbonate shield attached to the objective lens of the microscope. Note the exhaust hose has a flange on the bottom of the shield and on the side opposite of the DOM to facilitate collection of the exhaust flow from the microscope side of the shield. (D) A view of the polycarbonate shield from the patient’s perspective. (E) A side view illustrating the position of the exhaust hose on the DOM arms. (F) The location of the exhaust fan/blower/filter.

Figure 2.

(A) A schematic illustration of the attachment of the round polycarbonate shield to the DOM. (B) An 18-inch diameter round polycarbonate shield with holes for the DOM objective lens and attachment of the exhaust hose.

Shield

Both polycarbonate (Lexan) and acrylic (Plexiglass) have advantages and disadvantages in this application. The benefit of Plexiglass is that it is more transparent, less inclined to chemical discoloration, and tends to be more scratch resistant, but it does not have the same strength as polycarbonate. Polycarbonate has a higher impact resistance, allowing drilling without cracking.

An 18 × 24 rectangular 0.093-inch thick sheet of clear polycarbonate (Part 1PC1824A; Home Depot, Atlanta, GA) was cut into an 18-inch diameter disk using a band saw. Next, a template was created by first removing the objective housing from the Global 6A microscope body (M1028G 300; Global Surgical Co, St Louis, MO) (Fig. 2 A). Then, cardboard was affixed to the base of the microscope, and an outline was drawn. The polycarbonate disk was placed over the template. Using a Milwaukee Hole Dozer Bi-Metal Hole Saw (Milwaukee Tool, Brookfield, WI), a 2.5-inch hole was drilled through the polycarbonate to allow the DOM objective lens to hold the polycarbonate to the microscope body (Fig. 2 A and B). A 4 1/8-inch hole was drilled just posterior to the LED light housing to permit attachment of the exhaust hose (Figs. 1 C and D and 2 B). Four additional 1/8-inch holes were drilled to attach the 4-inch inlet flange to the polycarbonate shield (Part 70126; Powertec Inc, Waukegan, IL) (Fig. 1 C). A second inlet flange was cut in half and attached under the shield to help direct airflow (Fig. 1 C).

Installation

Shield

After removing the locking ring from the objective lens, the threads of the objective lens were placed into the 2 ½-inch hole in the polycarbonate shield (Fig. 2 A). The locking ring was then reattached to the objective lens. The shield and objective lens were then threaded onto the body of the microscope. It is important to note that the DOM positioning handles need to be placed in an upward direction (Fig. 1 A–C).

Ventilation and Fan Installation

Two ceiling tiles were removed. Using the same Milwaukee Hole Dozer 4 1/8” Hole Saw, a hole was placed in the ceiling tile and in the ceiling gypsum board (Sheetrock [Home Depot, Atlanta, GA]) to gain access to the attic. After testing other fans, the AC Infinity Cloudline S4 in-line duct fan (AC Infinity Inc, City of Industry, CA) was selected as producing the least amount of vibration on the microscope. The AC Infinity Cloudline S4 in-line duct fan features an 8-speed manual controller and plugs into a 110-V outlet. The fan has dual ball bearings, and very little vibration was noted when using the DOM. The AC Infinity Flexible 4-inch aluminum ducting (Part A1-DTA4, AC Infinity Inc) was cut to length and attached to the Powertec 4-inch inlet flange (Part 70126, Powertec Inc) on the polycarbonate disk with a 4-inch metal worm gear clamp (supplied with aluminum ducting) (Fig. 1 C). A second inlet flange was cut in half and placed under the shield to help direct the intake airflow (Fig. 1 C). The inlet flange (Powertec) and a cut inlet flange were attached to the shield with 4 #10 machine screws.

The other end of the flexible ducting was attached to the intake end of the duct fan (Fig. 1 E and F). The ducting was attached to the microscope-mounting pole with two 24-inch cable ties (Fig. 1 E and F). The excess flexible ducting was placed on the exhaust end of the duct fan and placed through the drop ceiling, gypsum board, attic, and out the roof. An AC Infinity carbon filter (Part AC-DCF4, AC Infinity Inc) was used at the terminus. A suitable HEPA filter was not available because of current government COVID-19 restrictions.

The acrylic shield and hosing can be disinfected with 0.5% sodium hypochlorite. Prior studies have shown that a 1-minute exposure of either 0.1% or 0.5% sodium hypochlorite is effective in reducing coronavirus levels ∼1000-fold on a stainless steel surface with serum as an additional contaminant11.

The velocity of the exhaust system was determined by placing a handheld hot-wire anemometer (TES-1340; TES Electrical Electronic Corp, Taipei, Taiwan) directly under the vacuum inlet and 10 inches beneath the DOM objective lens (to approximate the location of the patient’s oropharynx). The TES-1340 has a dynamic airflow range with a stated accuracy of ±3%. Airflow was measured over a 1-minute period with recording of the mean airflow.

Results

To date, patients have accepted the use of this exhaust device as contributing to both their safety as well as the dentist and staff. Although noticeable, the sound of the exhaust is not disturbing. The results of the anemometer indicated that the mean exhaust airflow is 498 ft/min at the vacuum hose inlet. At the DOM objective lens, the mean airflow was 163 ft/min at 2.5 inches below the lens, 59 ft/min at 5 inches below the lens, and 3.9 ft/min at 10 inches below the lens (10” is approximately at the patient’s oropharynx).

Discussion

The CDC has issued guidelines that confirmed or suspected COVID-19 patients be treated in AIIR facilities. Yet a much broader range of patients who require endodontic treatment may be either uninfected or infected and asymptomatic. To address this larger population, a device was developed with the potential to reduce oropharyngeal aerosol transmission. Measurements of airflow indicate that this device generated an exhaust airflow of about 3.9 ft/min at the approximate location of the patient’s airway. The use of this device may mitigate aerosol transmission, serves as a sneeze guard, is accepted by patients, does not interfere with the delivery of endodontic treatment, and is relatively inexpensive. Moreover, mitigation in aerosol transmission may have many benefits in reducing exposure to other airborne pathogens to the dentist and staff.

However, there are limitations to this device. First, it does not replace the AIIR recommended by the CDC for treating COVID-19 confirmed or suspected patients. Second, the demonstration of substantial exhaust airflow from the region of the oropharynx is consistent but not sufficient to establish a significant reduction in aerosol transmission. This latter point should be evaluated in future research in a proper research environment12. However, this device coupled with appropriate personal protective equipment may offer benefits in the delivery of endodontic treatment.

Acknowledgments

The author denies any conflicts of interest related to this study.

References

- 1.Center for Systems Science and Engineering, Johns Hopkins University. COVID-19 Dashboard. 2020. 2020. https://coronavirus.jhu.edu/map.html Available at: Accessed May 17, 2020.

- 2.World Health Organization Report of the WHO-China Joint Mission on Coronavirus Disease 2019 (COVID-19) 2020 4-17-20. https://www.who.int/docs/default-source/coronaviruse/who-china-joint-mission-on-covid-19-final-report.pdf Available at: Accessed May 17, 2020.

- 3.World Health Organization Rolling update on coronavirus disease (COVID-19). 2020. 2020. https://www.who.int/emergencies/diseases/novel-coronavirus-2019/events-as-they-happen Available at: Accessed May 17, 2020.

- 4.Centers for Disease Control and Prevention CDC guidance for providing dental care during COVID-19. 2020. 2020. https://www.cdc.gov/oralhealth/infectioncontrol/statement-COVID.html Available at: Accessed May 17, 2020.

- 5.American Dental Association ADA urges dentists to heed April 30 interim postponement recommendation. 2020. 2020. https://www.ada.org/en/publications/ada-news/2020-archive/april/ada-urges-dentists-to-heed-april-30-interim-postponement-recommendation Available at: Accessed May 17, 2020.

- 6.van Doremalen N., Bushmaker T., Morris D.H. Aerosol and surface stability of SARS-CoV-2 as compared with SARS-CoV-1. N Engl J Med. 2020;382:1564–1567. doi: 10.1056/NEJMc2004973. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Centers for Disease Control and Prevention How COVID-19 spreads. 2020. 2020. https://www.cdc.gov/coronavirus/2019-ncov/prevent-getting-sick/how-covid-spreads.html?CDC_AA_refVal=https%3A%2F%2Fwww.cdc.gov%2Fcoronavirus%2F2019-ncov%2Fprepare%2Ftransmission.html Available at: Accessed May 17, 2020. [PubMed]

- 8.Centers for Disease Control and Prevention Interim infection prevention and control recommendations for patients with suspected or confirmed coronavirus disease 2019 (COVID-19) in healthcare settings. 2020. 2020. https://www.cdc.gov/coronavirus/2019-ncov/hcp/infection-control-recommendations.html?CDC_AA_refVal=https%3A%2F%2Fwww.cdc.gov%2Fcoronavirus%2F2019-ncov%2Finfection-control%2Fcontrol-recommendations.html Available at: Accessed May 17, 2020.

- 9.Wu Z., McGoogan J.M. Characteristics of and important lessons from the coronavirus disease 2019 (COVID-19) outbreak in China: summary of a report of 72314 cases from the Chinese Center for Disease Control and Prevention. JAMA. 2020 doi: 10.1001/jama.2020.2648. [Epub ahead of print] [DOI] [PubMed] [Google Scholar]

- 10.Azarpazhooh A., Diogenes A.R., Fouad A.F. Insights into the May issue of the Journal of Endodontics. J Endod. 2020;46:561–562. doi: 10.1016/j.joen.2020.03.023. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Kampf G., Todt D., Pfaender S. Persistence of coronaviruses on inanimate surfaces and their inactivation with biocidal agents. J Hosp Infect. 2020;104:246–251. doi: 10.1016/j.jhin.2020.06.001. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Tellier R., Lu Y., Cowling B.J. Recognition of aerosol transmission of infectious agents: a commentary. BMC Infect Dis. 2019;19:101. doi: 10.1186/s12879-019-3707-y. [DOI] [PMC free article] [PubMed] [Google Scholar]