Abstract

The U.S. Bureau of Mines (USBM) was established on July 1, 1910 with a mission to address the previous decade’s coal mine fatality incidence rate of greater than 2,000 annually. The need for federal government involvement to assure dependable and safe mine rescue respirators was recognized by the USBM with the first respirator approval being issued in 1919. Prior to this, some occupations exposed individuals to inhalation hazards. Firefighters, in particular, had a critical need of respiratory protection. This article provides a brief summary of pre-World War I (WWI) (1914 to 1918) respiratory protection for firefighters based largely on the work of Bruce J. Held. Also discussed is the then newly established United States Bureau of Mines’ (USBM) role with the U.S. War Department during WWI for protection against chemical warfare agents.

Keywords: work of breathing, resistance, respirator, respiratory protective device

INTRODUCTION

According to Held (1974), prior to World War I, respirators were primarily produced to protect fire service personnel in the United States (U.S.) from inhalation hazards. Until WWI, respirators used in mining and industry were homemade masks, such as cloth scarves and other filtering type devices, along with respirators imported from European manufacturers such as Dräger, Westphalia, Fleuss, and Siebe-Gorman.

Before the 18th century, smoke and dust generated during mining and industrial operations were the only recognized inhalation hazards. Advances in respiratory protection came about after the discovery of the separate natures of particulate aerosols, gases, and vapors. In 1827, the Scottish botanist Robert Brown discovered the phenomenon of the Brownian movement – the theory that the random bouncing motion of extremely small particles was caused by collisions of rapidly moving gas molecules. Understanding behavior of small particles, the properties of filter media and their interactions led to the improvement of particulate respirators.

Pre-World War I Firefighting

While it now may seem unusual, during the 18th and 19th centuries firefighters were required to have full grown beards. Before a fire, firefighters would soak their beards in water and clamped it in their teeth to act as filters. These “beard filters” may have kept some of the larger ashes from the firefighter’s mouth. After fires, firefighters were known to drink ample quantities of steam beer, which they misguidedly thought would cleanse their lungs.

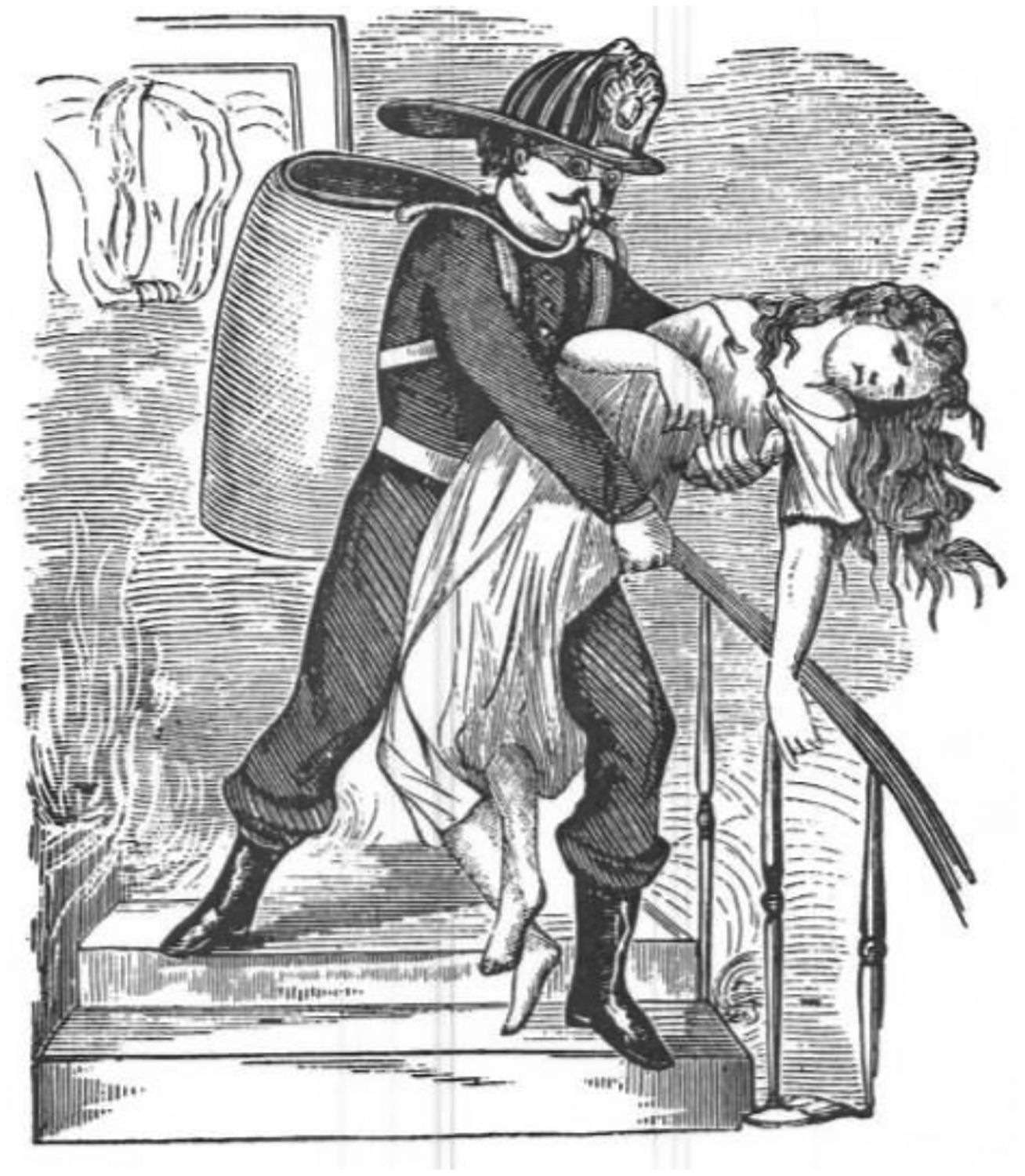

According to the National Institute for Occupational Safety and Health (NIOSH, 1979), at the beginning of the 19th century industrial revolution, respirator evolution became more sophisticated. In 1825, John Roberts developed a “smoke filter” for firefighters (Figure 1, from NIOSH, 1979), consisting of a leather hood and a hose strapped to the leg. The design was based on the correct assumption that the most breathable air during a fire was near the floor. An inverted funnel at the end of the hose contained a woolen cloth to trap particulates and a wet sponge to protect against gases and vapors.

Figure 1.

John Roberts’ Smoke Filter

LaCour’s Device (Figure 2, from NIOSH, 1979), invented in 1863, was the first known self- contained breathing apparatus and was used by New York fire departments (Held, 1974). LaCour’s Device consisted of an airtight bag made of India rubber sandwiched between canvas layers. The bag was inflated outside with bellows before the rescuer entered the fire and was designed to last 10 to 30 minutes.

Figure 2.

LaCour’s Device

The user would breathe clean air through a tube attached to the bottom of the bag, and exhale through a second tube attached to the top of the bag. It was thought that the exhaled air would somehow miraculously be revitalized by the time it reached the bottom of the bag. Since there were no check valves in the system, the user had to use his tongue to cover one tube to inhale and the other tube to exhale. This had to be done while holding the mouthpiece with their teeth or lips to prevent the loss of copious amounts of air. In 1877, LaCour’s Device was approved for use by the U.S. Navy.

The Merriman’s Smoke Mask (Figure 3, from NIOSH, 1979) was invented around 1892 and was the earliest known airline respirator in the U.S. It operated using an air pump which was an integral part of the fire fighters’ water hose (Held, 1974). Water passing through the hose created a vacuum that siphoned air into the respirator, possibly by the venturi effect.

Figure 3.

Merriman’s Smoke Mask

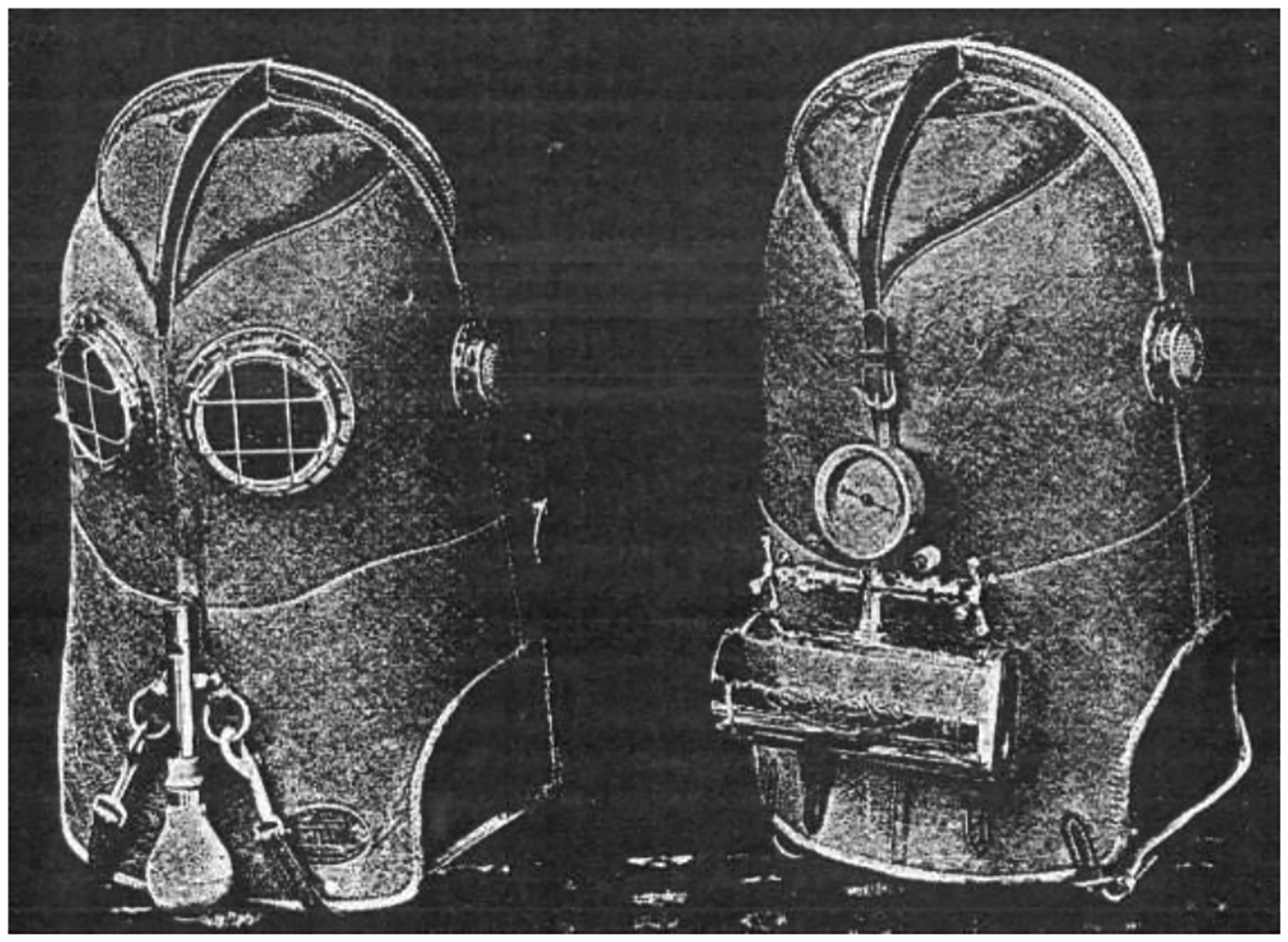

One of the first filter type firefighter protective apparatus was the Nealy Smoke Mask (Figure 4, from NIOSH, 1979), which was patented on September 18, 1877. This mask was described in the Fireman’s Journal of December 8, 1877 as a valuable invention that consisted of a cap equipped with a mask that fit tightly to the head. Vision was made possible through eyes in the mask made of mica or glass. There was a tapered mouthpiece with a hinged lid, which could be opened to speak. With the mouthpiece lid closed, the lungs and eyes were protected as filtered air was inhaled through two rubber tubes connected to either a single or a series of air filters consisting of moistened sponge material carried on the chest. The filters were connected to a rubber water bag which could be squeezed to keep the filters moistened.

Figure 4.

Nealy Smoke Mask

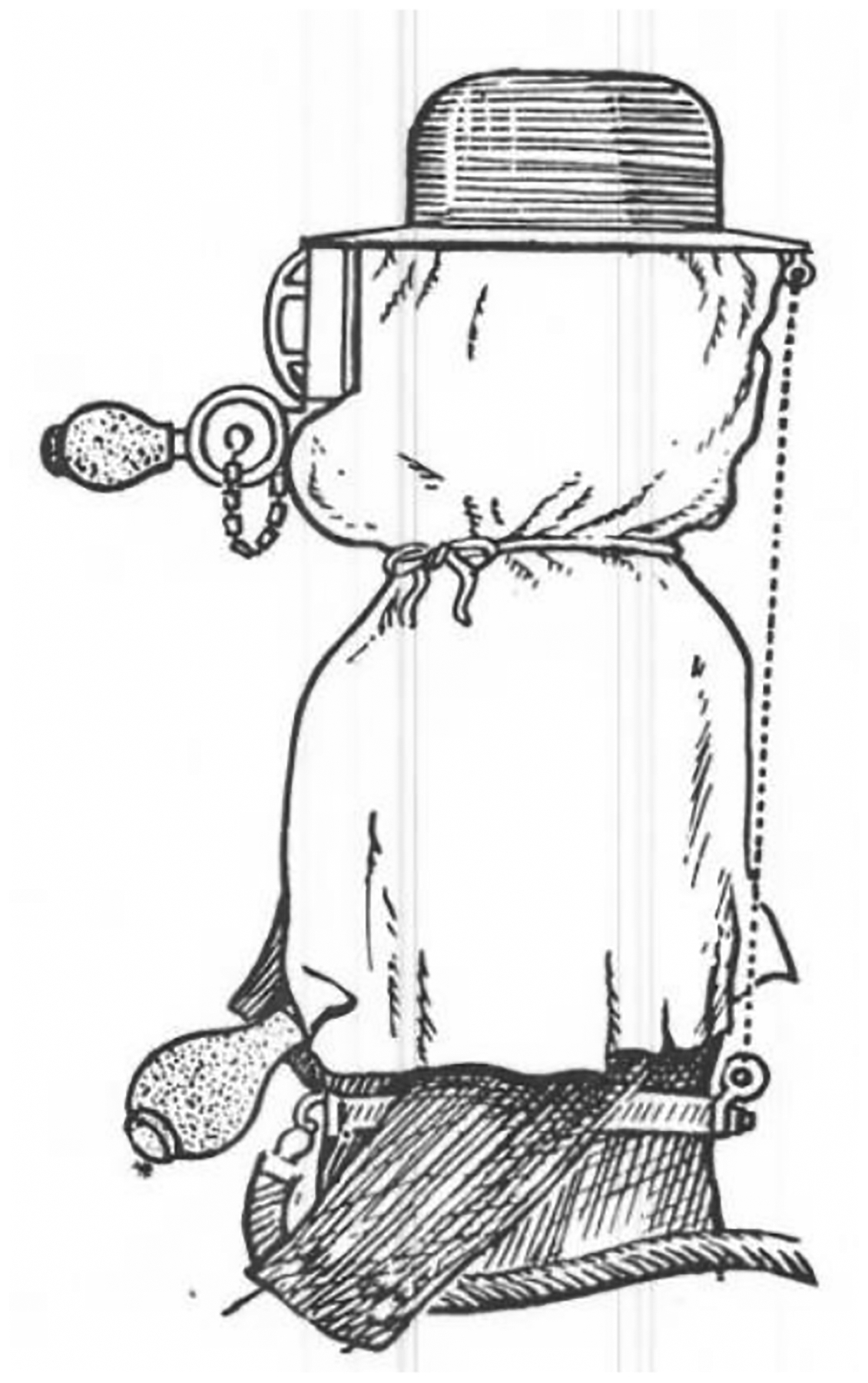

The Loeb Patented Smoke Respirator (Figure 5, from NIOSH, 1979), invented around 1875 and used by the Brooklyn New York Fire Department, was equipped with a filter element, located in the front of mask, that contained charcoal and wool soaked in glycerin (Held, 1974). The apparatus was suspended from a metal framed window fitted with protective grating and a visor wiper, which hung from the helmet. A squeeze bulb positioned at the user’s head was supposed to give “nerve-strengthening essences” when squeezed. In other words, it was said to provide courage to the wearer if he lost his nerve while fighting the fire. Another squeeze bulb at the waist was connected to a whistle so that the wearer could alert his comrades if he needed help. This device had a cord connected from the hat rim to a hook in the wearer’s belt to prevent the helmet from falling off. A trailing guide rope and an airtight hood completed the respirator ensemble. The Fireman’s Herald advertisement declared that this device “…protects the respiratory organs from the effects of deleterious admixtures to the air such as vapors, fumes, and smoke.”

Figure 5.

Loeb Patented Smoke Respirator

The Vajen-Bader firefighters’ respirator (Figure 6, from NIOSH, 1979) as pictured in the July 30, 1896 issue of the Fireman’s Herald was made of a leather helmet lined with sheepskin, which had a small compressed air cylinder on the back (Held, 1974. It was advertised as “…Proof against fire, smoke, gases, poisonous fumes, and bad airs. See plainly. Hear distinctly and breathe freely for one to two hours. No encumbrances whatsoever.” However, tests conducted by Siebe Gorman in England determined that five minutes breathing time was more accurate.

Figure 6.

Vajen-Bader fire fighters’ respirator

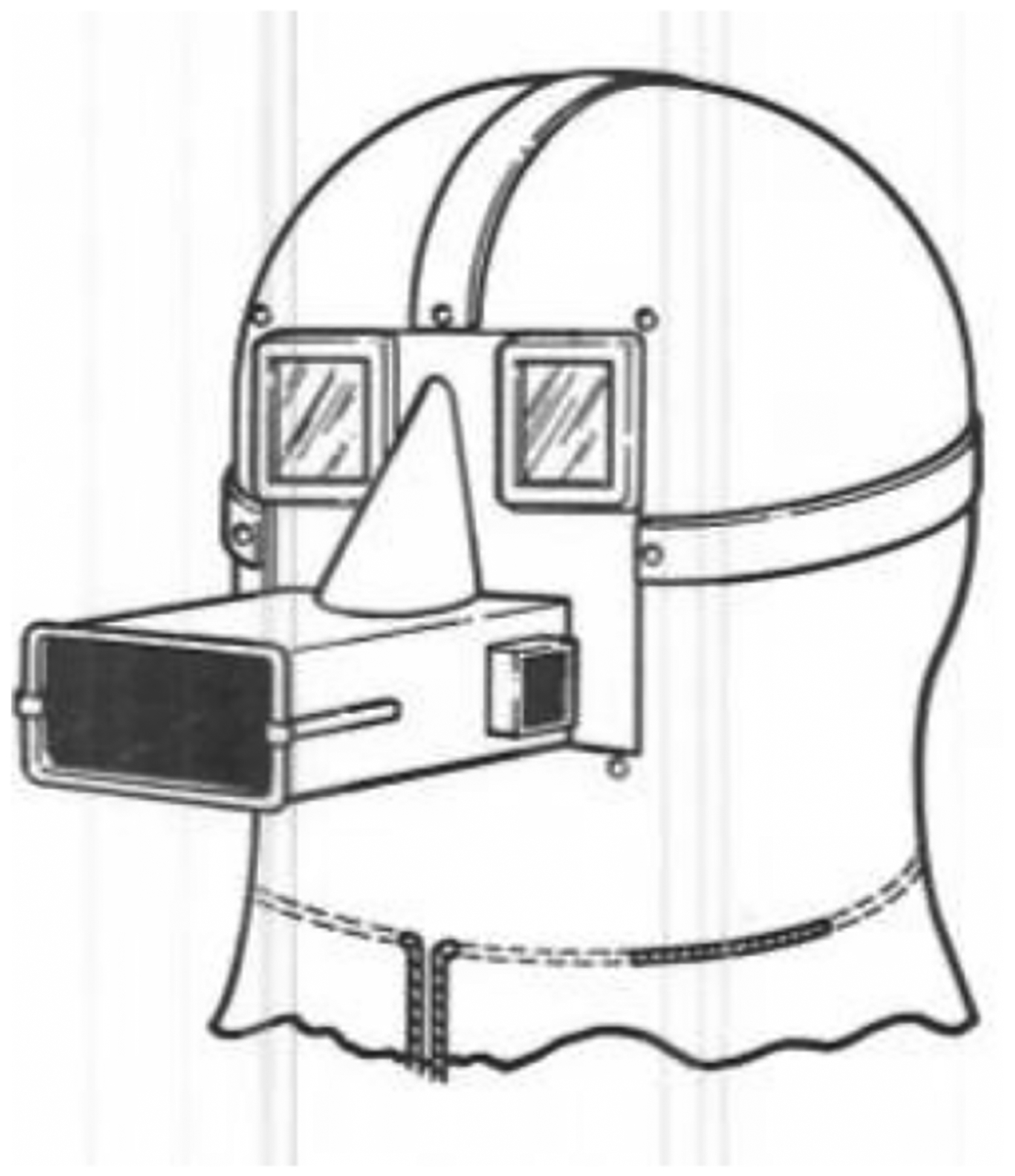

According to Held (1974), there were very few new respirator developments between 1900 and the beginning of World War I on July 28, 1914. However, Louis M. A. Muntz was granted a patent in 1902 for his respirator shown in Figure 7, from NIOSH (1979). The respirator had a box equipped with a filter consisting of a water filled sponge and charcoal. An exhalation valve was located on the side of the filter box with an inhalation valve in the front. Both valves were hinged metal flaps. The inhalation valve opened inward during inhalation and closed during exhalation, while the exhalation valve worked in reverse.

Figure 7.

Muntz Respirator

U.S. Bureau of Mines Involvement in WWI War Effort

Although short-lived, the USBM wartime research revealed the value of chemical science and engineering professionals to respiratory protection. Early in the war, the USBM established the Chemical Warfare Service as a distinct unit of the War Department. Never before was chemistry recognized as a separate branch of the military.

In March 1917, the War Gas Investigations Branch was established within the USBM to research the use of toxic gas as an instrument of war and to develop a chemical warfare defense. According to Van. H. Manning (BOM, 1919), besides investigating and developing gas masks, USBM’s scope of work included research relating to: poisonous and irritating gases and smokes, smoke screens, gas shells and bombs, flame throwers, trench projectors for firing gas bombs, signal lights, and incendiary bombs. The USBM selected personnel, procured equipment, and, paid all associated costs from its own funds until June 30, 1917. Funding for USBM research from 1917 until the end of the war June 30, 1918 was provided by the Army ($2,212,000) and Navy ($250,000).

The USBM built a research staff comprising more than 700 prominent chemists and obtained the cooperation of many universities and chemical companies. Certain Army officials believed that the work could be coordinated better by having it under military control and in June 1918 the USBM research was transferred to the War Department. At that time, the USBM chemists received commissions from the Army to continue their work under the newly developed Army’s Director of Gas Service.

Besides developing sorbent materials to protect against wartime gases, the USBM developed efficient methods for manufacturing chloropicrin, phosgene, mustard gas, brombenzylcyanide, cyanogen chloride, and other noxious substances on a large scale. The USBM also developed a smoke funnel for the Navy where chemicals mixed and reacted to provide a smoke screen to hide a fleeing ship which no doubt saved many ships from submarine attacks.

The National Research Council (NRC) was organized to act as an intermediary between the country’s university scientists and the various departments of the Government in order to determine the U.S. research agenda. On April 6, 1917, the NRC appointed the Advisory Chemical Board, to make recommendations related to warfare gases. During these investigations, the USBM collaborated closely with officials of the War Department, the Navy Department, and the Navy and Army liaison officials of the NRC on their progress. When USBM research obtained practical application, military officials were notified, and they determined whether further studies were warranted.

Initially, the USBM studied previous military research on the use of warfare gases; however, the Army had done minimal work in this field. Various areas of research were evaluated, and it was determined that developing gas masks for the Army was the most crucial. The Navy requested that W. E. Gibbs, a USBM engineer and inventor of the Gibbs breathing apparatus, develop an emergency escape breathing apparatus and a longer lasting breathing apparatus comparable to that used in mine rescue. It is interesting to note that later, the Gibbs respirator was the very first respirator approved for industrial use on January 15, 1920. Gibbs also developed an aviator rebreathing apparatus and soda lime canisters to absorb carbon dioxide in submarines, extending their submersion time from the previous record of 12 hours to 48 hours.

Around June 1917, Lieutenant Commander A. H. Marks, who was vice president of the Goodrich Rubber Company before offering his services to the Government, was the pioneer in developing a gas mask for the Navy and had the facilities of the Goodrich Company at his disposal. According to BOM (1919), “Only the best material is permissible in each and every part of a gas mask. Hence, the rubber companies, in cooperation with the research staff of the bureau, had to work out problems that were entirely new to’ the rubber industry. Every joint in a mask must be absolutely tight, and the sewing must be perfect.”

On May 1, 1917, the War Department requested the USBM manufacture 25,000 gas masks for shipment overseas. The USBM searched for manufacturers of gas mask components who could produce acceptable materials and do it quickly. By June 11, 1917, two American Can Co. factories in Brooklyn New York were at work assembling gas masks.

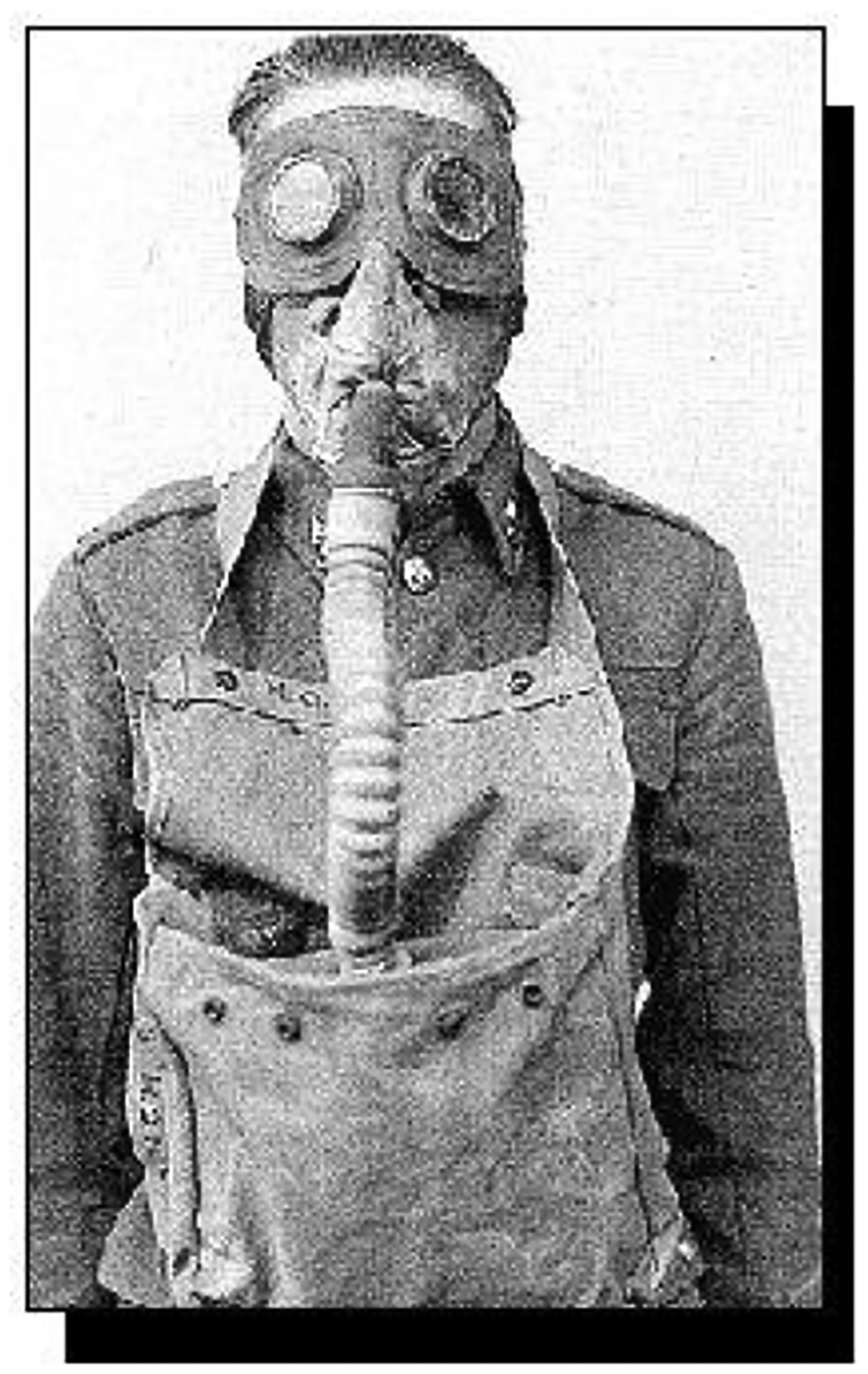

The masks were of the box-type gas mask (Figure 8), used by the English. The wearer would inhale air that passed through a box or canister containing absorbents. Credit is given to SBCCOM (2005) for figures 8 – 10. The USBM improved on the English box type gas mask by enlarging the charcoal canister. The sorbent material was tested against chlorine, phosgene, and prussic acid, and proved to be highly efficient. However, at the time it was not known that chloropicrin would be one of the most important war gases. Over 20,000 masks were shipped overseas before the end of June, and within two weeks another 7,000 were produced but were never shipped. The masks shipped overseas were tested by the English, who found that they would not provide adequate protection against chloropicrin and other new gases dispersed by the Germans. Subsequently the masks were only used for training purposes.

Figure 8.

British Large Box Respirator

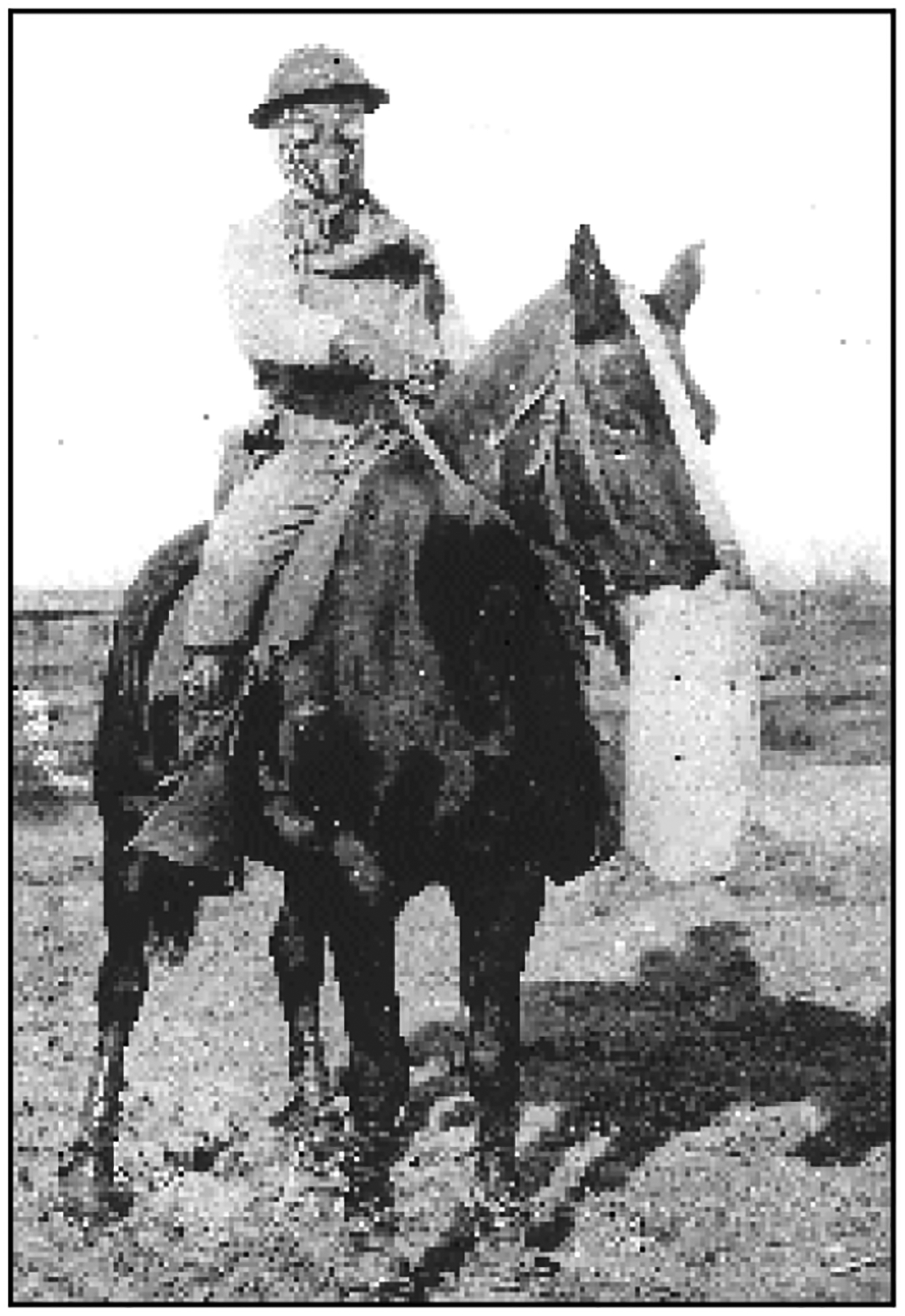

Figure 10.

Horse Gas Mask

USBM facilities in Pittsburgh, Pennsylvania developed laboratory instrumentation to mechanically test canisters. Soldiers’ lung volume and rate of breathing at rest and at various work rates were determined and machines were developed to duplicate the test under any work rate conditions. The first mechanical tests of this type were performed around April 1, 1918, using phosgene. Later machines were built for testing against chlorine, hydrocyanic acid, and chloropicrin. USBM Pittsburgh facilities were able to test about 150 canisters a day. This mechanical canister testing application was later used for testing industrial respirators. Research on absorbents also included studies on the effectiveness of charcoal under different conditions, such as the effect of moisture, aging, etc.

The rubberized cloth for facepieces had to be impermeable to gases. In the summer of 1917, the USBM dedicated a research branch to determine the permeability of various gases on fabrics used for masks and protective clothing and by the following June approximately 1,000 fabrics had been tested.

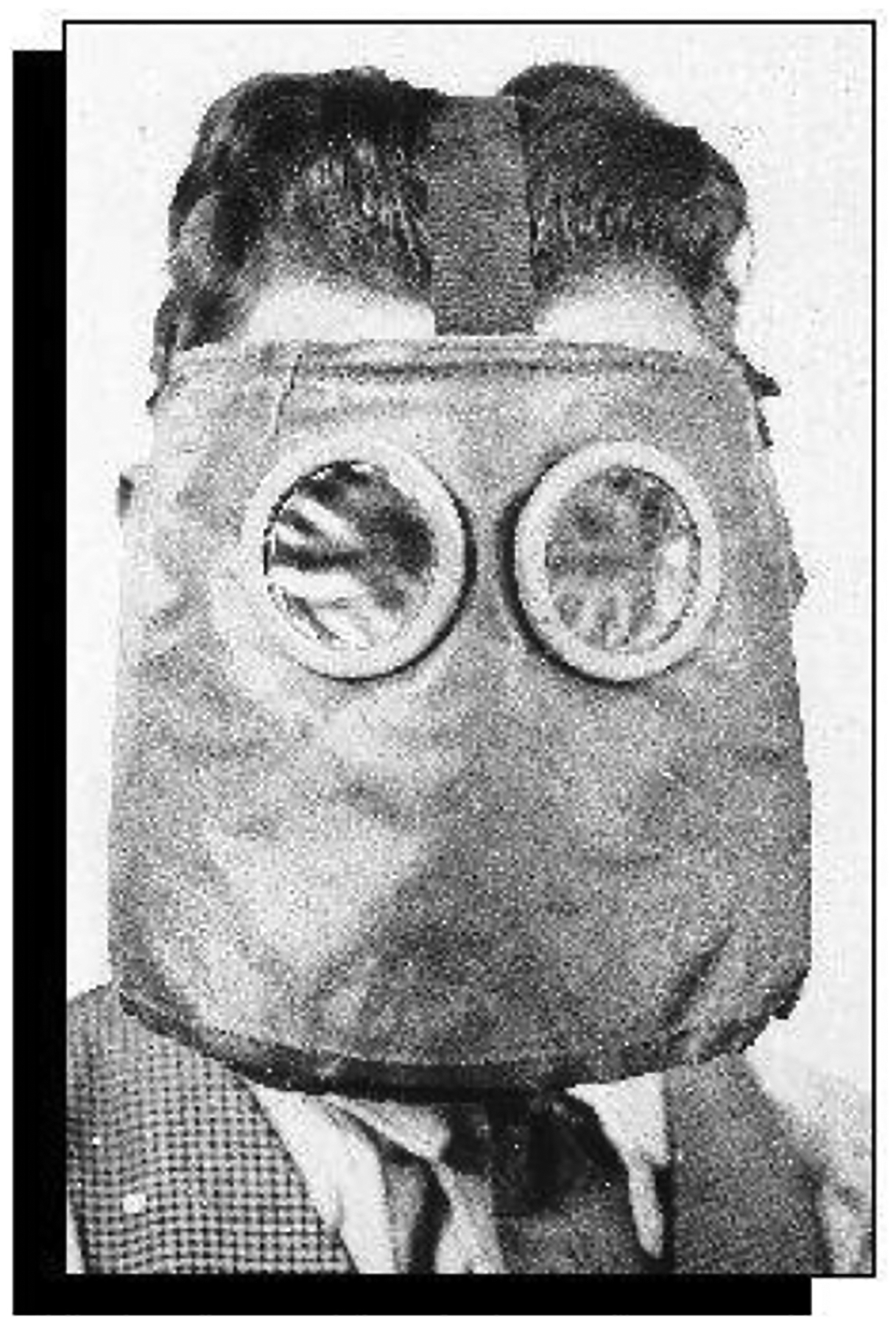

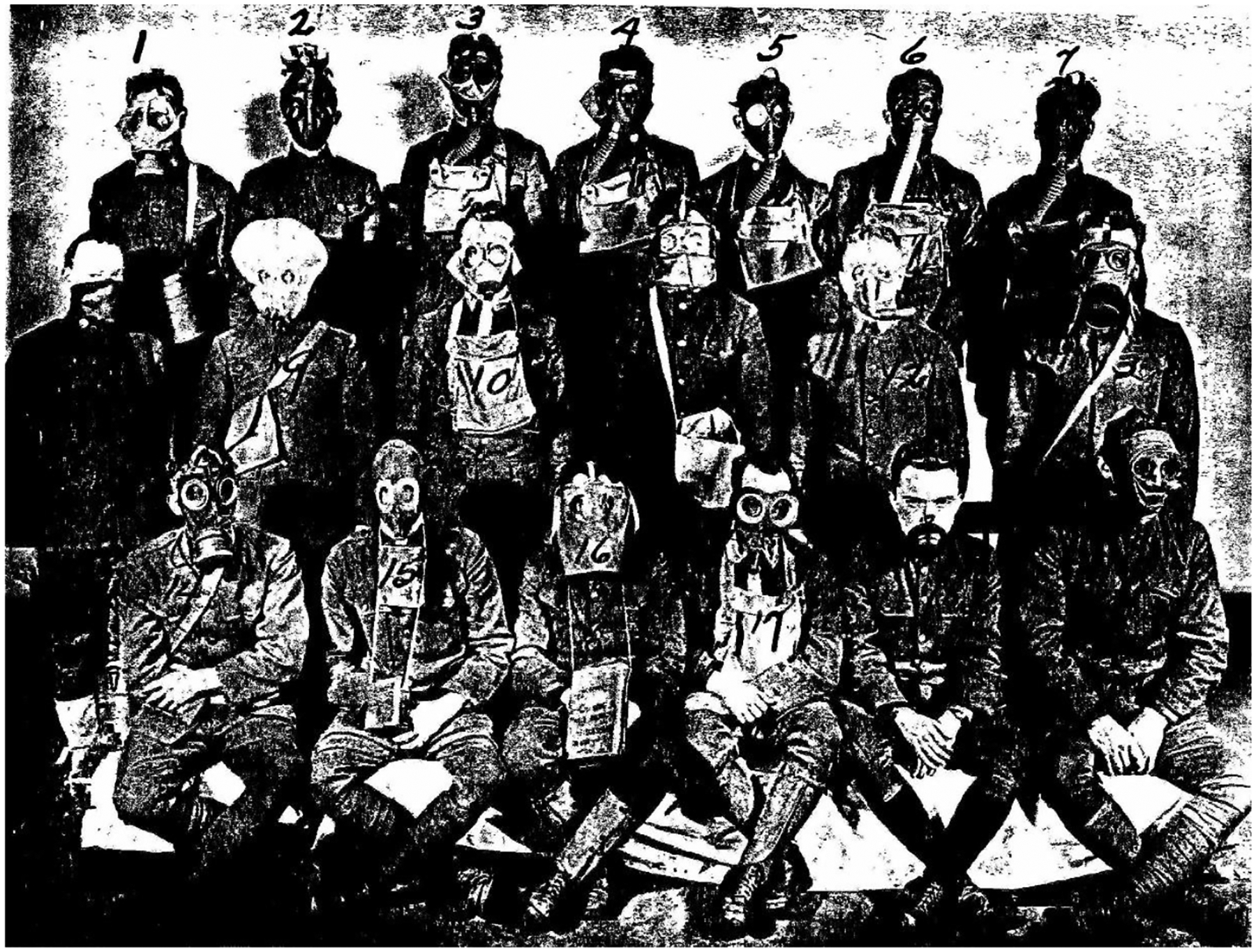

Next, the Tissot-type gas mask, initially designed by the French for artillery service, was modified and improved by the USBM. As shown in Figure 9, this mask had no mouthpiece or nose clip. The inhaled air impinged on the eye pieces and reduced fogging resulting in increased visibility. A similar type of mask was developed for the Aviation Service. A horse mask, shown in Figure 10 and a trench fan similar to those used by the British were designed. Figure 11, from NIOSH (1979) shows the range of designs of World War I military gas masks.

Figure 9.

French M2 Mask

Figure 11.

WW 1 Military Gas Masks

The USBM investigated charcoal to maximize its efficiency against gases, and the capability of large scale production. Private industry experts assisted and many substances were carbonized into charcoal and tested as sorbent material. This included testing various types of wood, nut shells, including coconut shells and palm nuts, lamp black, carbon black, blood, and seaweed. In December 1917, Dr. H. B. Lemon, of the University of Chicago developed the first coconut charcoal, which formed the basis for most of the charcoal used in gas masks. According to BOM (1919), one preparation method was to let the charcoal cool in air to maximize the amount of oxygen absorbed and then reheat it to a comparatively low temperature. Another method was to grind the charcoal to about 8 to 14 mesh (1.41 to 2.38 mm) and oxidize it with a steam treatment.

For protection against acid gases and vapors, the USBM developed a sorbent mixture of caustic soda and calcium hydroxide for use in gas mask canisters. The sorbent granules had to be hard enough so that rough shaking would not produce fine particles, which could clog the canister and cause excessive breathing resistance. The USBM had a factory capable of producing 800 pounds daily. Sodium permanganate was used to oxidize gases or vapors and facilitate their absorption. At the beginning of the war, sodium permanganate was not produced in the U.S.

Thus, in the fall of 1917 a supply of raw materials was procured and methods were devised to produce this substance. The new supply of raw materials and the new methods devised by USBM for processing sodium permanganate resulted in higher quality sorbent and increased production by over 50 percent.

The USBM solved a problem that had baffled scientists for years by developing a combination of substances, which through catalytic action removes carbon monoxide (CO) from air at ordinary temperatures.

Twenty grams placed in gas mask canisters protected against an atmosphere containing 1 percent CO for one hour. This discovery, of high importance in warfare, was also of value in private industries. Thus the USBM solved a baffling problem for the army and many industries.

Extensive research went into developing smoke filters for gas masks. Canister capacity was increased using baffles and screens, which resulted in a canister size reduction without affecting sorbent capacity. The USBM also developed a small, 30 minute canister for protection against chlorine for submarine use.

There was also evidence that the field of industrial hygiene was emerging. Dr. Yandell Henderson was the technical advisor for all of the gas mask related features. Dr. Henderson recognized the need to carefully supervise sanitation conditions and control measures to protect workers producing poison gases. Trained U.S. inspectors (early industrial hygienists?) began inspecting plants and poisoning among workers was significantly reduced. Also, special canisters were developed to protect workers that were producing warfare gases.

By May 1918, some Army officials felt that the work could be coordinated better under military control. However, the Advisory Chemical Board was satisfied with USBM work and stated, “The efficiency, success, fine spirit, and enthusiasm under the leadership of the Bureau of Mines is a matter upon which we wish to congratulate the bureau, as well as upon the splendid group of unselfish, self-sacrificing men who carried on this arduous and dangerous work.” However, Army officers prevailed, and on June 25, 1918, under the authority given by what is known as the Overman Act of May 20, 1918, President Wilson transferred this work from the USBM to the Chemical Warfare Service of the Army, which was given full responsibly for toxic chemical warfare and defense. Congress made the Chemical Warfare Service a permanent part of the Army in 1920. Shortly after transferring to the War Department in June 1918, the committee on noxious gases was dissolved. On March 5, 1919, the USBM returned to its primary mission of mine safety research and established Schedule 13 for certifying self-contained breathing apparatus for mine rescue in August 1919.

Footnotes

Publisher's Disclaimer: Disclaimer

Publisher's Disclaimer: The findings and conclusions of this article are those of the authors and do not necessarily represent the views of the National Institute for Occupational Health and Safety. Mention of a commercial product or trade name does not constitute endorsement by the National Institute for Occupational Safety and Health.

REFERENCES

- Held Bruce J. (1974) History of Respiratory Protective Devices in the U.S., University of California, Lawrence Livermore Laboratory, California (Work performed under the U. S. Energy research & Development Administration under contract No. W-7405-Eng.−48)

- National Institute for Occupational Safety and Health (NIOSH). (1979) A Guide to Industrial Respiratory Protection, NIOSH Pub No. 76–189

- Department of the Interior, Bureau of Mines (BOM). (1919) War Gas Investigations, Advance Chapter from Bulletin 178 War Work of the Bureau of Mines by VAN. H. MANNING

- U.S. Army Soldier and Biological Chemical Command (SBCCOM). (2005) History of the Army’s Protective Masks.