Abstract

The coronavirus pandemic is having a clear impact on the supply chains of virtually all manufacturers, retailers, and wholesalers. As the world attempts to navigate through this difficult time, most companies are struggling to maintain a steady flow of required goods and services. Whether it is frozen foods and grocery items (i.e., toilet papers), or ventilators and masks, or even the services (i.e., clinic visits), the supply chain has been facing multiple obstacles. Most models and frameworks built in the extant literature are not been able to capture these disruptions and as such, firms are not having proper strategies to deal with. For firms with complex supply chains (i.e., manufacturing, retailing), it is indeed critical to identify strategies to deal with such a crisis. In this paper, we intend to offer strategic insights in terms of major issues firms are facing and strategic options firms are contemplating. We rely on the twitter data from NASDAQ 100 firms to generate themes regarding the issues faced by the firms and the strategies they are adopting using text analytics tools. We find that firms are facing challenges in terms of demand-supply mismatch, technology, and development of a resilient supply chain. Moreover, moving beyond profitability, firms are experiencing difficulties to construct a sustainable supply chain. We provide futuristic strategic recommendations for the rebuilding of the supply chain.

Keywords: Covid-19, Supply chain, Strategic insights, Twitter

1. Introduction

As the world manages to contain Covid-19 outbreak, various countries and various firms are focusing on finding a vaccine, developing protocol to treat infected patients and creating a safe working environment for employees. As the situation evolves, there is a growing concern about economic as well as social impact of the pandemic which may define norms for “new normal”. For many countries and many firms, the inability to respond to the Covid-19 outbreak lies in its supply chain—transportation of goods whether it is masks or ventilators or grocery items or even services (e.g., visiting clinic) (Ranney, Valerie, & Jha, 2020). Similarly, many countries are worried about unavailability of personal protective equipments (PPE) which are essential for frontline healthcare employees to fight the disease. Lack of PPE is blamed for high rates of infection and death in Italy.1 Similarly, many observers believe that United States require many more respirators and surgical masks than what is available currently.2 This scarcity can partly be attributed to susceptibility of the supply chain. For instance, China has been producing approximately half the world’s face masks3 before Covid-19. However, with Covid-19 spreading across China, the country was unable to export necessary medical equipments. While the infection has declined in China, exports of equipments are still being challenged as most global economies are in the grasp of Covid-19, disrupting the value chain. Because of Covid-19, multiple vulnerabilities in global supply chain have been exposed across sectors4 and industries (Ivanov & Dolgui, 2020). Unavailability of hand sanitizers, non-medical masks, PPE, basic consumption items such as bread, eggs, milk, or long waiting time for visits to clinics are the examples of supply chain suseptibilities faced by companies globally. Existing strategies of strict demand supply matching followed by most companies may not be long-term strategies any longer. Firms need to evaluate their supply chain strategies, supply chain designs, and supply chain dependencies to avoid perceptual reaction to future pandemics and prepare themselves to adequately address unexpected disruptions.

Given the challenges associated with the issue, it is important to understand which direction global supply chains may evolve and possible solutions that are being looked upon by firms. This issue is challenging as today’s supply chain is incredibly complex with partners from multiple geographies connected to the global trade ecosystem5 . Most firms lack visibility beyond tier 1 (or their direct suppliers). Lack of visibility can pause a major threat to a firm. Although relatively small-sized, lower tier suppliers are responsible for multiple disruptions in the supply chain. These challenges initiated our investigation where we focus on understanding the conversation on the web related to supply chain challenges during Covid-19, potential strategies firms are enacting, and what the futuristic supply chain strategies and design be.

2. Research procedure

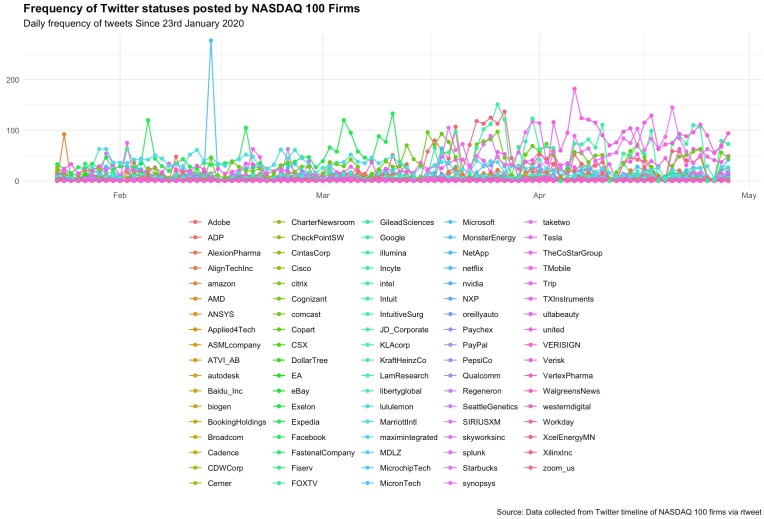

To identify the supply-chain issues experienced by various companies and the strategies they have implemented, we rely on their tweets. The official twitter handle name was accessed from each company’s website. Some twitter handles such as Amgen Inc., Analog Devices, etc., which were in non-English language were excluded. We have also excluded companies without official twitter handle (Chae & Park, 2018). After all exclusions, we collected data from 89 firms. We looked at relevant tweets from January 23rd, 2020 (when Hubei province initiated locked down) to April 30th, 2020, comprising of 41,986 tweets.

We also collected tweets from users. Multiple criteria were applied to screen the tweets. The hashtag "#supplychain" and/or mention of any of the NASDAQ firm’s twitter handle was given as a criterion. These tweets comprised of data till 7th May 2020. A total of 30,500 observations after removing duplicate and irrelevant (for example, consistent with the extant literature (Chae, 2015), we found that a large proportion of tweets was for jobs associated with supply chain; we removed them as these tweets were not relevant to our investigation) tweets were collected and were analyzed similarly. To get the scenario of the entire industry along with the firms of our interest, we have collected timeline data from some of the prominent supply chain professionals and news portals. We started with 30 such accounts but were able to collect data from 26 twitter handles due to privacy restrictions in some accounts. A total of 63,987 tweets were collected. We excluded the tweets posted before 23rd January 2020. Finally, we got 7359 tweets from prominent supply chain professionals.

In total, we had 41,986 tweets from NASDAQ 100 firms, 35,000 tweets from individual users, and 7,359 tweets from supply chain professionals. We cleaned the data by removing URLs, emojis, punctuations, and commonly used words (stopwords).

3. Preliminary analysis

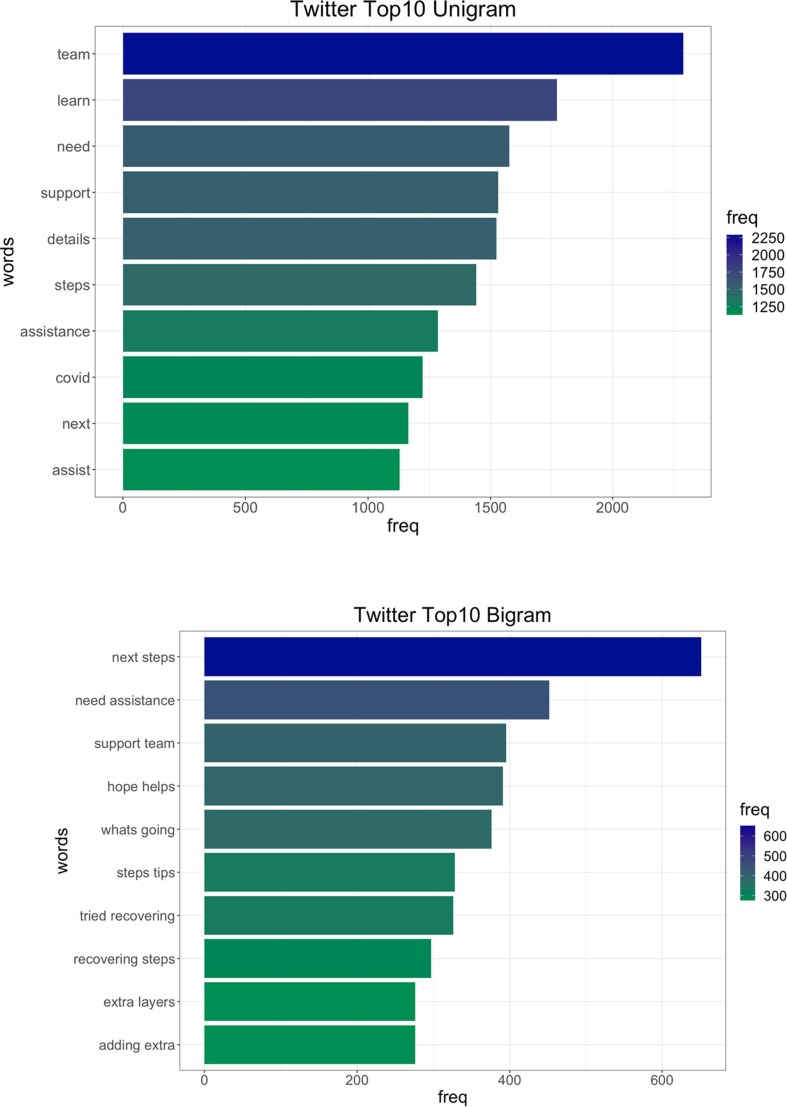

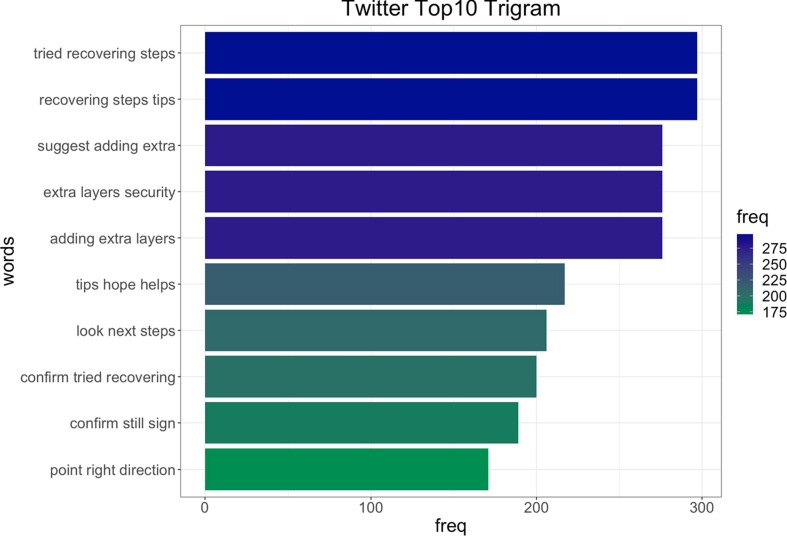

Table 1 highlights the most commonly used words by NASDAQ 100 companies, Fig. 1 represents the daily frequency of tweets and Fig. 2 represents the word cloud of 100 most frequent words.

Table 1.

Frequency of words in Tweets used by NASDAQ 100 firms.

| Words | Frequency |

|---|---|

| team | 2288 |

| learn | 1772 |

| need | 1576 |

| support | 1531 |

| details | 1524 |

| steps | 1441 |

| assistance | 1285 |

| covid | 1223 |

| next | 1165 |

| assist | 1129 |

Fig. 1.

Daily frequency of Tweets.

Fig. 2.

Word cloud of 100 most frequent words.

From the data analysis, it is clear that Covid-19 is among the top 10 most frequently used words. To develop deeper insights, we constructed unigram, bigram, and trigram. Unigram breaks the sequence of characterless into individual one that highlights how many times a particular word appears; a bigram consists of a sequence of two words; and a trigram consists of a sequence of three words (Chen, He, Xu, Gey, & Meggs, 1997). Unigrams, bigrams, and trigrams provide us required information regarding those supply-chain aspects which are getting attention in tweeter. Fig. 3 represents the top 10 unigrams, bigrams, and trigrams.

Fig. 3.

Unigram, Bigram and Trigram.

We also performed a topic analysis to get topics and relevant keywords related to each topic to get more insights from the data and generate themes. Some of the most relevant topics identified through the analysis were ‘technology’ and ‘support’. Based on such topics, we segregated tweets. Once segregated, we revisited the original tweets and finalized our themes. Based on the findings, we came across four major themes.

4. Insights (Themes) from text analysis

Our text analysis results reveal some interesting insights associated with the supply chain. From the multiple tweets we analyzed, we find the following themes.

Demand Supply Challenges during Covid-19: Demand uncertainty is one of the fundamental challenges reflected in most tweets. While some sectors have seen a decline in demand, others have seen a sudden spike in demand. As people started following “Stay at home” orders, some sectors such as automobiles, crude oil, and transportation have seen a decline in demands. Contrary to that, most technology companies have experienced an increase in demand. Companies have faced sudden challenges in mitigating these surge in demands. Multiple tweets highlighted the challenges faced by companies. PSD Global, a management consulting firm, tweeted (on 7th May 2020), “The Pandemic Lockdown & StayHome have created unparalleled logistics for #SupplyChain management. Keeping fleets organized & attuned to driver safety, stress & morale”. Similarly, Biogen tweeted (on 29th April 2020), “Food insecurity is a daily concern for many. During #COVID19, demand is rising. Here’s how our partners @Communityserv & @Gr8BosFoodBank are adjusting to keep up with demand. #InThisTogether #Boston”. Firms operating in the healthcare sector have seen a sudden surge in demand that is challenging to fulfill in a short period. Cerner tweeted (on 15th April 2020), “Across the globe, health care leaders are responding to the surge of testing and treatment demands associated with the virus. Cerner's COVID-19 Surge Capacity Guide aims to help our clients plan, supply, staff and operate amid the spread of this virus”. Similarly, a sudden change in demand may create challenges for matching supply and demand in a short time. As reflected in multiple tweets, companies are forced to match demand-supply equations even on a daily basis.

Technological challenges during Covid-19: Technology has emerged as an important factor that determines the success or failure of a firm during Covid-19. However, our analyses reveal that all firms may not be at a similar level of technology readiness. There are multiple concerns associated with the use of technology. Apart from technology readiness, security breaches are also a common concern expressed in multiple tweets. Among the technologies adopted, firms are adopting multiple technologies that can give them visibility across the value chain as well as those which help in increasing efficiency. Tweeter data shows that companies are looking for solutions to gain visibility across the value chain. A tweet from R2 logistics highlights (May 5th, 2020), “Full visibility of your #SupplyChain is just a click away. With R2's #TMS and reporting features, customers can view their entire #logistics network from any device”. Similarly, multiple companies have shown the use of technology to increase efficiencies, as the Cisco system tweeted (3rd April 2020), “Digital solutions help retailers maintain agility to navigate supply chain disruption”. Multiple companies have also highlighted innovative logistic solutions they are using. JD.com, China’s largest online retailer has retweeted (on 20th February 2020), “As #logistics operations struggle to deliver goods in #China due to #COVID19 @JD_Corporate is deploying delivery staff, autonomous shuttles and drones to deliver medical supplies, food, and commercial cargo”. Many firms are also focusing on IoT based systems, reflected in our trigram as well.

Building a Resilient Supply Chain: As Covid-19 challenges the entire value chain, there is a growing discussion among firms as well as practitioners regarding how to create a resilient supply chain. Dipanjali Ghosh, President NASSCOM tweeted (6th April 2020), “Today we have 90%+ employees working from home, with only critical staff on campus to ensure no disruption to clients' business. With the help of Gov't, the industry has shown tremendous resilience and moved to the #WFH model. India and Indian IT will emerge only stronger!”. Similarly, Worday Inc. tweeted (on 24th April 2020), “Operational and personal resiliency are more important than ever.” Multiple tweets show that there are also suggestions made to improve supply chain resilience. Common among them is the use of technology such as AI and blockchain-based technologies which may help supply chains become more resilient. Others suggest that greater collaboration among value chain members are required to create a more resilient supply chain. Collaborations have also taken place among competitors to provide greater value to all members. Tealbook- a procurement and supplier partner has tweeted (on 7th May 2020), “We're learning during the #COVID19 crisis that collaboration between industries & competitors allows everyone to provide their greatest value”. Liberty Global tweeted (on 27th March 2020), “Our network is performing a more critical role and we are committed to playing our part in keeping the country connected. @VirginMediaCorp CTIO, Jeanie York, explains how our network is staying resilient in the face of rising demand”.

Sustainable Supply Chain Challenges: While Covid-19 has been blamed for economic downturns, it has shifted organizational focus towards a sustainable supply chain. Not only organizations are focused on maintaining economic sustainability, but multiple tweets show that organizations are now facing challenges associated with social sustainability as well. The CEO of Activision Blizzard, Bobby Kotick tweeted (on April 14th, 2020) “My #1 priority is the safety and health of our employees and community”. Similarly, Adobe tweeter handle published a blog (on April 25, 2020) about the effective communication strategies in healthcare.6 Adobe has also postponed Adobe Summit EMEA which was supposed to take place in London on May 13th and 14th, highlighting the safety of their community as a top priority. Multiple other tweets highlighted employee health and wellbeing, helping employees to cope up with remote working conditions, skill improvements, etc. as top priorities. Not only social sustainability but organizations have also started focusing on environmental sustainability across the supply chain. Multiple solutions primarily based on technological advancement have been proposed by multiple companies to reduce greenhouse gas emission.

Based on the above discussion, we highlight that firms across the globe are dealing with four major challenges: demand-supply mismatch, technological challenges, sustainable supply chain challenges, and challenges associated with building a resilient supply chain.

Given the supply chain issues and some of the actions firms are implementing to tackle those issues, we provide implementable and futuristic supply chain strategies that may help the firms overcome supply chain challenges in this turbulent time and prepare a more sustainable supply chain design to absorb any future shocks.

5. Strategic recommendations

-

(1)

Focus on sustainable supply chain: While it is known for quite some time that sustainable supply chain practices consist of economic, environmental, and social aspects, till now, firms have put only limited emphasis on the social and environmental aspects (Villena & Gioia, 2020). Covid-19 has, however, forced companies to put greater emphasis on this aspect. Health and wellbeing of not only their employees but those who work for a supplier’s suppliers are also vital for firms and without a sustainable approach to supply chain, firms may not be able to effectively combat the effects of Covid-19 on the supply chain. The tweet from the CEO of Activision Blizzard which suggests the safety and health of employees and community as their top priority epitomizes the firm’s focus on the sustainable supply chain.

-

(2)

A dire need of a dynamic response: Pandemic such as Covid-19 impacts the supply chain of any firm by hurting the sourcing, production, and distribution capabilities of its suppliers. To remain strong in the event of such a pandemic, a firm needs to respond to any issue in the supply chain proactively and flexibly. As reflected in the tweet of JD.com, JD corporate is deploying delivery staff, autonomous shuttles, and drones to deliver various products on demand. A dynamic response to detect, assess, and process signals, systems, and resources will help firms identify loopholes, integrate resources to close those loopholes, and navigate through global crises such as Covid-19.

Most firms, however, follow strict rules for their supply chain. These include a specific number of days for distribution, specific production time, delivery rules, etc. These responses are proved to be inadequate during the crisis. Covid-19 made paper towel, frozen and canned food shelves of retail stores empty within hours across many countries including United States7 . Many manufacturers of these commodities have perhaps experienced this for the first time. Thus, reacting to the Covid-19 requires flexibility in the supply chain and the overall ecosystem of a firm. Adopting dynamically, a firm can respond to Covid-19 or other rare events’ vulnerabilities on the supply chain and minimize the effect of these events. By “adopt dynamically”, we mean that in the course of actions during Covid-19, firms need to focus on multiple best practices explored or invented by their suppliers, competitors, and ecosystem. Firms need to tape into those best practices dynamically such that firms can optimize cost and delivery, improve visibility across the network, and accelerate reaction times to issues in production and delivery. Such dynamic response will allow firms to adopt and reconfigure supply chains such that external shocks cannot disrupt the supply chain.

-

(3)Derive values from technology deployment: Leveraging technology is the key to success in this turbulent environment with uncertainties. Our analysis of tweeter data has revealed that the use of technology can be vital for visibility across the supply chain as well as for gaining efficiency. Harnessing the power of technology such as artificial intelligence (AI), automation, IoT, blockchain, edge computing, deep learning, advanced computing power, application programming interfaces (APIs) and high power satellites can help a firm become vigilant about supply chain challenges and a firm can undertake strategies and practices to mitigate the same. This is also evident from a tweet from Cognizant. Cognizant tweeted (on March 1st, 2020) citing retail biz article by Gaurav Sharma, “#Blockchain can simplify the ethical sourcing of materials and provide transparency into the #supplychain says Gaurav Sharma via @retail_biz”. Thus, technology ensures that a firm navigates through challenging times and continues to be in business. We provide the following recommendations to firms that may be helpful to move forward.

-

a.Firms should ensure to capture data across the value chain. While some of these data may not be available easily, by implementing technology, firms can gain access to data. This is also evident from a tweet of the supply chain management review (SCMR) (on April 27th, 2020), “High-Quality Data Is the Key to End-to-End Supply Chain Visibility in the Food & Beverage Industry.” Once a firm starts acquiring this massive data, it needs a technology infrastructure to process these data. Converting data into meaningful information will help to predict disruptions and prepare necessary actions.

-

b.One of the critical issues that raise vulnerabilities in the supply chain is the lack of visibilities. Lack of visibility is critical to combat disruption. A report by Dun & Bradstreet (2020) highlighted, “At least 51,000 (163 Fortune 1000) companies around the world have one or more direct or Tier 1 suppliers in the impacted region, and at least five million companies (938 Fortune 1000) around the world have one or more Tier 2 suppliers in the impacted region”8 (pg. 2). Lack of visibility arises for many reasons including complexity in the supply chain. Firms can deploy advanced technologies that can help firms achieve end-to-end visibility, understand complexities, and reduce the vulnerabilities and uncertain impact of any pandemics or rare events. Therefore, technology can help a firm develop early warning signals about disruptions.

-

c.Once visibility is achieved, one of the things critical to managing disruption is to monitor supply partners. Monitoring requires understanding supply partners’ actions, the ability to detect issues, and the ability to take necessary corrective actions. By deploying required technologies, a firm can properly monitor its supply partners’ actions that can be helpful in the event of a pandemic such as Covid-19.

-

a.

-

(4)

Develop a culture of collaboration: While Covid-19 has turned the supply chain upside down across industries and firms, it also indicates that a culture of collaboration is a new need. While collaboration in the supply chain has been emphasized by multiple scholars (Cao & Zhang, 2011), in reality, most supply chains are transactional in nature.9 However, the transactional supply chain will not be beneficial during and post Covid-19. By developing a culture of collaboration across its supply network and even with competitors, a firm can develop trust among supply chain partners that can help in data-sharing and joint problem-solving. Embedding partners across the supply chain will help a firm jointly combat supply chain disruptions. The use of technology can facilitate such collaboration among supply chain partners. A recent report by Bain.com10 supports this sentiment which shows that collaborative platforms across firms increase information sharing and improve decision quality and response time.

-

(5)

Diversify supply chain: While many firms keep relationships with a few key suppliers, some firms emphasize on a diversified portfolio of suppliers. Given the Covid-19’s impact on the value chain of many firms, it is critical to examine if firms’ supply chain suffered due to concentrated supply chain. A recent Deloitte11 study suggests that some firms have started diversifying businesses across multiple geographies to reduce supply chain risks and continue businesses even during a pandemic. Text analysis of the tweets also provides a preliminary hint that firms are moving in the direction of achieving a diversified supply chain; New York Supply Chain (TNYSCM) tweeted (on 30th April 2020), “#fashion #SupplyChain: Diversifying the supply chain has become more urgent and more difficult”. Building on Deloitte Study and our analysis of tweets, we argue that such a low concentration of suppliers reduces reliance on a single supplier and subsequently protects a firm from supply chain disruptions. Firms that manage to have a diversified supplier portfolio will be able to mitigate the risks posed by Covid-19 or any future pandemics/rare events. Firms that have strong relationships with suppliers but not necessarily a diversified portfolio, have visibility that signals risks, and have embraced priority-based actionable strategies, will be able to create an agile supply chain that can witness shocks from Covid-19, quickly reconfigure based on changes in the external environment and manage disruption. However, firms that rely on a few suppliers from one particular geography may face extreme supply chain disruptions during and post Covid-19. Dependence on a few suppliers creates a lack of agility that prevents reconfiguring the supply chain whenever required. Hence, the central learning from Covid-19 is to diversify production, sourcing, and logistics whenever and however required such that external shocks cannot disrupt the supply chain.

-

(6)

Synchronize strategic processes: In the event of any pandemic such as Covid-19, the responsiveness of supply chain processes is very critical. However, most firms have not experienced such turbulences in their lifetime; system and processes are not trained to absorb shocks of disruptions; as such, making supply chain responsive to the disruption is not easy. In our analysis of tweets, we find that many firms are looking at synchronizing their strategic processes such that systems and processes are ready to handle the shocks in future, as evident from a tweet by Cisco Systems (on 11th February 2020), “How can #IT make flexible fulfillment a reality? Delivery options are more in-demand than ever before-and seamless integration provides your customers a better experience.” How do firms synchronize strategic processes? A recent IBM report shows that intelligent workflows will dissolve cellular processes and mechanize processes that can improve efficiencies across the supply chain. Building on such insights, it is evident that if a firm mechanizes processes by converting into intelligent workflows—starting from demand management to delivery strategies, firms will provide a platform to processes, people and technology to interact. This will bridge the current gap in a firm’s ability to intuit the changes in the environment, respond to that with the help of intelligent workflows, and generate required businesses.

6. Next-generation supply chain: A forward-looking approach

The next-generation supply chain needs a significant change in outlook. Based on our analysis, we recommend firms adopt a forward-looking approach. These forward-looking strategies must comprise of multiple facets of the supply chain including people, processes, and technology. This would enable firms to create a supply chain that can combat future exogenous shocks. Some of the strategies that firms can include are

-

(a)

Firms need to reevaluate sourcing strategies in real-time. A firm can design its supply network in such a way that it can balance risk and operational flexibility, manage supply chain disruptions, and keep supply chain agile.

-

(b)

While technology is in place in deigning supply chain decisions, firms need to integrate advanced technologies such as AI and deep learning-based tools in the supply chain decision framework. The inclusion of these tools can help firms to determine and extract signals from markets regarding disruptions and visibility in the supply chain and equip the firms with necessary actions to be deployed. This can help in mitigating the unseen and sudden effects of any rare events such as Covid-19.

-

(c)

A firm also needs to assess vulnerabilities across the supply chain closely as the effects of Covid-19 or similar exogenous shocks may be realized in some parts of the supply chain and may remain unnoticed. One of the ways to assess such vulnerabilities is to develop scenario-based supply chain models and optimization routines. Firms can deploy existing data and use simulation to knock out every possible negative effect. This will help firms to not only assess vulnerabilities but also mitigate risk and continue the businesses.

-

(d)

Many firms had to lay off their employees during this turbulent time due to changes in business practices and profit patterns. While this may be a short-term strategy, a firm needs to consider its long-term impact. Such lay-off may impact the entire value chain of the firm. One of the ways that firms can handle is to have a forward-looking human resource supply chain strategy that includes the selection of the critical workforce that can handle the turbulence in any environment and the firm manages them under any circumstances. This will need scenario planning, resource optimization, and efficiency management.

-

(e)

Firms also need to collaborate with multiple stakeholders and be more strategic in their approach to supply chain management. Without a culture of collaboration, developing a new-age supply chain strategy may not be feasible for a firm.

-

(f)

Finally, there is a greater need for a firm to look beyond profitability. Ensuring the wellbeing of not only a firm’s employees but also those employed even with suppliers is critical if a firm wants to avoid disruptions in the supply chain.

The effects of Covid-19 on manufacturing, distribution, and retailing and current state of largely broken global supply chains of many products and services direct towards a dire need of forward-looking strategies. As firms attempt to continue businesses amid Covid-19, firms are realizing the role of the sustainable supply chain, dynamic response strategies, value of technology deployment and culture of collaboration, diversified supply base and synchronized strategic processes that are vital for success during rare events such as Covid-19.

Acknowledgement

Authors thank the Editor-in-Chief: Naveen Donthu for his valuable comments on an earlier version of the manuscript.

Biographies

Amalesh Sharma is Assistant Professor of Marketing at the Mays Business School at Texas A&M University. He earned his PhD in Marketing from the Georgia State University, Atlanta. Prior to getting a PhD, he obtained a M.S. in Business Economics, and a M.S. in Managerial Science from Georgia State University, a PGDM from ITM Business School, Navi Mumbai, India, and a B.S. in Physics from the University of Delhi. His substantive areas of interest include Supply Network, Innovation, Marketing-Mix Decisions, Customer Management, and International Business. Amalesh's research has been published in top-tier journals (e.g., Marketing Science, Journal of Marketing Research, Journal of Marketing, Journal of International Business Studies, Journal of Operations Management, Journal of the Academy of Marketing Science, Journal of Retailing, Applied Marketing Analytics, Journal of Business Research, and Harvard Business Review). Amalesh worked in CPG and Financial and Banking Industries prior to joining PhD.

Anirban Adhikary is Assistant Professor of Operations Management, Quantitative Methods and Information Systems Area at Indian Institute of Management Udaipur, Udaipur, India. His research interest includes operational issues in firms’ supply chain management and firm performance. He has published papers in multiple top-tier academic journals such as Journal of International Business Studies, Journal of Operations Management, and Journal of Business Research.

Sourav Bikash Borah is Assistant Professor of Marketing at Indian Institute of Management (IIM) Ahmedabad, Ahmedabad, India. He earned his PhD in Marketing from IIM, Bangalore. His research interest includes service management strategy, supplier-relationships, and business strategies in emerging markets. He has published papers in multiple top-tier academic journals such as Journal of Operations Management, Journal of International Business Studies, Journal of the Academy of Marketing Science, Journal of International Marketing, and Journal of Business Research. Prior to joining PhD, he worked in automobile as well as banking and financial sector.

“Business Impact of the Coronavirus: Business and Supply Chain Analysis Due to the Coronavirus Outbreak.” Dun & Bradstreet. February 2020.

References

- Cao M., Zhang Q. Supply chain collaboration: Impact on collaborative advantage and firm performance. Journal of Operations Management. 2011;29(3):163–180. [Google Scholar]

- Chae B.K. Insights from hashtag# supplychain and Twitter Analytics: Considering Twitter and Twitter data for supply chain practice and research. International Journal of Production Economics. 2015;165:247–259. [Google Scholar]

- Chae B.K., Park E.O. Corporate social responsibility (CSR): A survey of topics and trends using Twitter data and topic modeling. Sustainability. 2018;10(7):2231. [Google Scholar]

- Chen, A., He, J., Xu, L., Gey, F. C., & Meggs, J. (1997, July). Chinese text retrieval without using a dictionary. In ACM SIGIR Forum (Vol. 31, No. SI, pp. 42-49). New York, NY, USA: ACM.

- Ivanov D., Dolgui A. Viability of intertwined supply networks: Extending the supply chain resilience angles towards survivability. A position paper motivated by COVID-19 outbreak. International Journal of Production Research. 2020:1–12. [Google Scholar]

- Ranney M.L., Valerie G., Jha A.K. Critical supply shortages—the need for ventilators and personal protective equipment during the Covid-19 pandemic. New England Journal of Medicine. 2020;382 doi: 10.1056/NEJMp2006141. [DOI] [PubMed] [Google Scholar]

- Villena V.H., Gioia D.A. A more sustainable supply chain companies tend to focus on their top-tier suppliers, but the real risks come lower down. Harvard Business Review. 2020;98(2):84–93. [Google Scholar]