Abstract

A safe work environment is crucial in high-risk industries, such as construction refurbishment. Safety incidents caused by uncertainty and unexpected events in construction refurbishment systems are difficult to control using conventional safety management techniques. Resilience engineering (RE) is proposed as an alternative to traditional safety management approaches. It presents a successful safety management methodology designed to deal with uncertainty in high-risk work environments. Despite the fact that RE resides in the safety domain, there is no common set of RE indicators to measure and assess resilient in the work environment. The main aim of this research is to explore RE indicators that have been identified as important in developing and assessing the resilient work environment in high-risk industries, particularly in construction refurbishment. Indicators have been attained through a systematic literature review of research and scholarly articles published between the years 2004 and 2019. The literature review explored RE indicators in various industries. Descriptive analysis and co–occurrence-based network visualization were used for data analysis. The findings revealed 28 RE indicators in 11 different high-risk industries. The results show that the four commonly used indicators were: top-management commitment, awareness, learning, and flexibility, all of which have a strong relationship with RE. The findings of this study are useful for stakeholders when making decisions concerning the most important RE indicators in the context of their research or practice as this would avoid the ambiguity and disparity in the identification of RE indicators.

Keywords: RE indicators, resilience engineering, safety, safety management

1. Introduction

Complex and intractable work systems such as construction refurbishment highlight the need for effective safety management techniques. Generally, more than 2.3 million workers around the world suffer from work-related accidents every year [1]. This has led researchers to focus more on innovative safety management tools, which aid in managing safety risks. At the same time, resilience engineering (RE) has gained attention as a safety management concept among researchers and practitioners. This is because of the fact that it presents a new rationale regarding work safety and approaches to accidents [[2], [3], [4]]. It is a positive approach to project success in an environment of pressure and complexity [2] and presents a momentum for safety management [5].

By their nature, construction refurbishment projects are more difficult to control than the new build as the former has unique uncertainty such as unavailability of information, often experiences changes in design, and is constrained through lack of space [6]. For instance, in construction refurbishment projects, unforeseen site conditions may arise, which heightens risk, if work was to continue as planned [7]. Some preconstruction condition information, such as the strength of a wall, the material used in the structure only becomes available during the execution of work [8]. In sum, the construction project work environment is an intractable system, because unforeseen events and unplanned influencers can occur at any time during the construction phase [9].

Traditional safety management (Safety I) assumed that the work system is well defined and tractable [10]. Its objective is to focus on reducing the number of adverse outcomes such as accident rates, incident rates, and near misses [10]. An uncertain work environment demands a new perspective of safety to respond to unexpected events, more than preventing accidents [11]. Modern safety management tools, as defined in Safety II, look everyday activities as an event rather than focusing on “what goes wrong” with the assumption that the system is intractable [10]. Safety I concentrates on how accidents happen or “something went wrong” and Safety II focuses on “working safely,” which encompasses how people adjust and perform in the expected/unexpected working conditions [10]. As a modern safety management tool, RE is a basis of managing risk in an incompletely described and underspecified system [12]. The application of RE is highly suitable in the construction industry because of its dynamic, complex, and unstable nature [13]. In an environment where the outcome is unpredictable, unforeseen and uncontrollable, people need to adjust their performance to respond to match with the emerging working conditions, learn to overcome malfunctions and design errors [10]. In this regard, Saurin et al [14] have emphasized the importance of creating a resilient work environment in construction refurbishment projects as a way of managing project uncertainty.

Assessing system resilience, particularly in complex and large-scale systems, has attracted an increasing level of attention from industry as well as academia [15]. Pertinent to this study, previous researchers have used numerous RE indicators to explore and measure resilience in safety-critical industries [16]. Selecting appropriate RE indicators for a construction refurbishment work environment is critical. There is no common agreement concerning RE indicators identified in previous research. Recent publications on assessing resilience has largely used self-reported questionnaires focusing on large-scale respondents in different industries, predominantly from construction [13], petrochemical [17], and process [2] industries.

The current diversity in RE indicators creates ambiguity for researchers and safety practitioners when modeling and evaluating resilience in a work environment. This highlights the need for research on RE indicators to avoid disparity in the identification of RE indicators that cause confusion to researchers and industry practitioners when assessing resilience. The aim of the study is to identify the most important RE indicators for construction refurbishment projects. Considering this, it is worth reviewing studies that used RE indicators to present a compiled set of RE indicators in high-risk industries and understand on what basis authors select the RE indicators in the context of the study. This was achieved from a review of more than 14 years of literature/scholarly articles that explored or tested RE indicators from 2004 to 2019. Interestingly, this is not the first systematic review in the domain of RE. However, key findings of extant studies have been used to inform this study; see Righi et al [5], Patriarca et al [18], and Bergström et al [19]. Noteworthy, this research focuses on RE indicators explored and tested in the safety domain, following Bergström et al [19].

The balance of the article is structured as follows: Section 2 provides an introduction to RE; Section 3 explains the methodology followed a review of the literature; Section 4 details the results and discussion under two main headings Overview of the studies and Comparative review of RE indicators in the safety domain; and finally, the conclusions of the article are presented.

2. Resilience engineering

The concept of RE originated in the early 1980s in cognitive system theory [20] and attracted widespread attention after the first RE symposium in Sweden 2004 [5]. There are widespread studies on resilience from different perspectives, including ecology, psychology, sociology, engineering, and management science [21]. Similarly, there are a growing number of resilience studies that focus on the perspective of safety [21].

The key idea of resilience is to adjust performance before, during, or after any disruptive event [3]. Adopting this view, the major concern of RE is to create a resilient system [22]. RE provides a methodical investigation and practical application of the resilience concept [5]. Therefore, RE carries all the indicators and activities that would help to manage (increase) system resilience [23]. This resulted in the emergence of several RE indicators from different domains such as, organizational, social, economic, and engineering [15].

Contrary to conventional safety management approaches that look for system dysfunction, RE recognizes the success factors that help to avoid adverse events [24]. Therefore, RE is concerned with the normal functions of a system rather than looking for incidents [17]. Different researchers have given alternative definitions of RE. Consider the following two examples: RE refers to an “Intrinsic ability of a system to adjust its functioning before, during, or after changes and disturbances so that it can continue to perform the required operations under both expected and unexpected conditions” [25]; or RE refers to a “System's potential for adaptive action when information varies, conditions change, or new kinds of events occur to challenge the viability of previous adaptations, models, or assumptions” [26]. In summary and adopting a management-driven safety context, it is the application of RE to adjust a system's performance to avoid losing control of an ongoing function, sustain control in major disruption, and recover as soon as possible after an incident [2].

Nevertheless, resilience has been used in different disciplines, which has created confusion and diverse metaphors. Woods [27] has introduced four conceptual perspectives of resilience by considering the ability of resilience system to create, manage, and sustain, namely rebound, robustness, graceful extensibility, and sustained adaptability. The author intended to summarize the various definitions and sense of resilience into the aforementioned four groups [27]. Also, there are four predominant cornerstones of RE, namely anticipating, learning, monitoring, and responding. These cornerstones have contributed to anchor the agreement on RE structures and help to develop questionnaires to identify the indicators [18]. Adhering to these four cornerstones of RE, Woods et al [28] have developed a stress-sustain model that envisaged how resilient organizations perform in each cornerstone and how it stretches to respond to surprises. In a complex work environment, trade-off decisions on safety-production, optimality-brittleness, efficiency-thoroughness are inescapable and knowledge on safety and uncertainty are vital for an adaptive system [3,25].

RE harmonizes the performance and safety instead of treating them as mutually exclusive [17]. Therefore, higher resilience results in improved safety performance with fewer safety incidents [29]. This is because RE models encourage managers to develop proactive safety-related hazard mitigation strategies that reduce the risk related to system operation [30]. Generally, the strong and positive association between RE and safety performance means that RE is a useful concept in safety management. In particular, research surveys permit researchers to conclude that RE shapes safety risks within a system to achieve enhanced safety performance. However, the relationship between RE and safety is more complex than a simple methodology to improve safety [31]. As an example, it is a collective effort of everyone at work and a work system should allow employees maneuver to react and avoid blindly following rules in unexpected situations [31]. This suggests that complex safety systems should focus on strategic development of a resilient work environment as part of Occupational health and safety (OHS) management. In recent RE systematic reviews of the safety domain, Bergström et al [19] identified a clear relationship between safety and RE by concluding that resilience systems can adapt to the inherent risks of the environment. RE has therefore been used as a safety management tool in several domains, including aviation, healthcare, petrochemical plants, manufacturing, railways, and construction [5].

One of the key aspects of safety management is to measure performance through indicators and audits [5]. Some researchers have identified RE surveys as safety indicators that organization should use to measure safety performance [32]. RE indicators can provide a guideline for managing safety in the work environment and are a helpful analytical tool. By their nature, key features of RE indicators are closer to the leading indicators taken to prevent accidents/dangerous events [33]. One of the disadvantages that RE indicators suffer is, it is not mandated by the law and logically needs time, effort, and personnel input to implement [33]. Pillay [34] suggested a lack of consistency of indicators and difficulty in measuring resilience created a fundamental problem with RE [35]. It is unable to quantify resilience itself and only its potential can be measured [36]. Therefore, RE indicators are used to measure the “potential for resilience” in a work environment.

The selection of RE indicators varies depending on an industry's researchers focus [13]. However, some indicators of RE are not popular among researchers and practitioners [22]. The researchers accept different terminologies when selecting RE indicators [2].

RE indicators are applicable to multilevels of organizations starting from one single worker to the organization as whole [37]. Researchers have used these RE indicators to compute the effect of resilience on the work environment as whole [17]. Similarly, RE indicators are used as leading indicators or precursors. Examining RE indicators through questionnaire surveys or safety auditing may help to assess the gap between work as imagined and work as performed [38]. The significance of RE indicators is likely to be high when these indicators feed important data into trade-off decisions regarding production and safety [36]. This posits that RE indicators play an important role in shaping a resilient work environment and managing safety performance.

3. Methodology

This research uses a systematic literature review (SLR) to explore the RE indicators that support and create a safe work environment in high-risk industries in the domain of safety. An SLR involves drawing collective findings of relevant materials that address a particular research question [39]. Indeed, undertaking a systematic review is more likely to support the theoretical progress of undiscovered areas of scientific discipline [5]. The systematic process is comprehensive and uses an informed level of quality literature for identifying, evaluating, and appraising to combine the evidence [40]. This review adopts the guideline of Preferred Reporting Items for Systematic Reviews and Meta-Analysis (PRISMA) [41].

Structured searches were carried out with four databases including, that is, Web of Science, Google Scholar, Scopus, Science Direct from the start of 2004 until March 2019. The four databases include the peer-reviewed journals in the area of RE in the safety domain. However, further articles were added through forward screening and backward screening of selected articles. Developing a prior protocol is a crucial step in the process of reporting quality literature [42]. A review protocol [43] was developed to identify the relevant articles for RE studies in safety domain. A review protocol consisted of three main inclusion criteria: studies that have explored or include a factor analysis of RE indicators; studies that have been conducted in the domain of safety in high-risk industries; and peer-reviewed conference and journal articles published in English. The keywords in the search being: Resilience engineering; indicators of RE; and safety. The material collection process transitioned through three steps, including title analysis, abstract analysis, and content analysis. Title analysis was the initial filtration process where the title of the study was evaluated based on the research aim and study domain. This was followed by abstract analysis, which is an in-depth analysis based on industry, the aim of the research, methodology, and keywords. Finally, content analysis enabled the selection of the set of articles that exactly matched with the inclusion criteria in the protocol.

Regarding the data extraction and analysis, a spreadsheet was developed to facilitate the data analysis, including identification data: title, year of publication, sector, and contents of study: RE indicators and reason for selecting particular indicators. A descriptive analysis was conducted by using tables. The co-occurrence of keywords was used to determine the significance of the indicators using VoSviewer software - Leiden University's Centre for Science and Technology Studies (CWTS), Netherlands [44].

As previously mentioned, the study used “science mapping” [45] to conceptualize the methodical patterns in the sourced literature. This method was selected because it helps to create links between literature concepts and allows for literature-associated discoveries [44]. A wide variety of science mapping tools are available such as VOSviewer, CiteSpace, Sci2, BibExcel, CoPalRed, VantagePoint, and Gephi [44]. The selection of appropriate tools depends on the individual capabilities and strengths of each tool and the method of analysis. VOSviewer was chosen for the present study as it offers the basic functionality required to network visualization of literature [44]. Science mapping was performed in two stages: (i) creation of networks through co-occurrence of keywords of the selected articles and (ii) generation of maps that extract the meaningful information such as patterns, trends, evolution, and outliers.

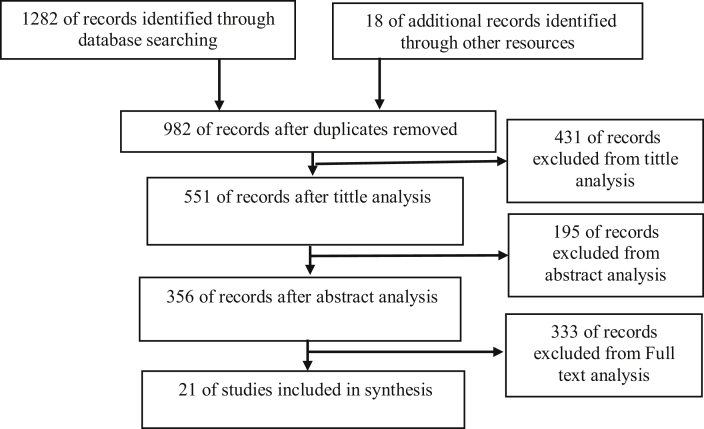

According to PRISMA guideline study follows, formal reporting of the systematic review is necessary to maintain the quality and validity of the study. Fig. 1 illustrates the process of selecting studies for SLR according to the PRISMA flowchart. The database searching resulted in 1,282 articles, which was reduced to 982 after duplicates. Furthermore, 18 articles were added through forward screening and backward screening. Four hundred thirty-one articles were removed from title screening because they were not in the domain of safety. One hundred ninety-five articles were removed from the abstract selection because they focused on other aspects of resilience rather than RE indicators. Three hundred thirty-three articles were removed at the full-text screening stage because of the unavailability of full text and no related findings to support the research questions on this review. After all screening stages, 21 articles were selected for the systematic review process.

Fig. 1.

Stages of the material selection process. (Adopted from [57]).

4. Results and discussion

Based on the literature review and the spreadsheet developed for data analysis, the results have been categorized into two main sections. Section 4.1 presents the publishing framework of selected studies and Section 4.2 presents the results obtained from the analysis of data related to the research aim.

4.1. Publishing framework

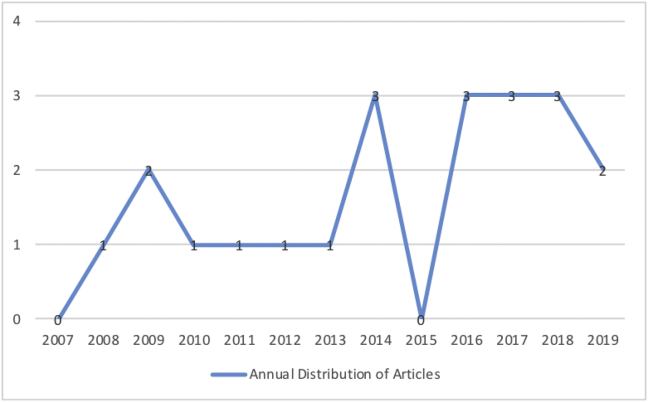

Fig. 2 shows the annual distribution of articles discussed on RE indicators in high safety-critical industries over the period 2004 to October 2019. At first glance, it is clear that RE indicators and their consideration started receiving some attention after year 2007. As can be seen in Fig. 2, there is a gradual rate of increase of interest in assessing resilience from 2008 onwards. Nevertheless, the RE indicators need to be considered for the development of concept. This appears promising and significant growth of number of publications concerning RE indicators from 2008. A summary of statistics, including research context based on industry and method, is provided in Table 1.

Fig. 2.

Annual distribution of published studies on RE indicators. RE, resilience engineering.

Table 1.

Descriptive analysis of industry and research method

| Descriptive analysis | All articles count |

|---|---|

| No. of articles | 21 |

| Research context by industry | |

| Chemical and petrochemical industry | 9 |

| Construction industry | 3 |

| Manufacturing industry | 1 |

| Oil and gas/gas refinery industry | 2 |

| Process industry | 2 |

| Pharmaceutical industry | 1 |

| Waste management industry | 1 |

| Healthcare industry | 1 |

| Automotive industry | 1 |

| Electricity industry | 1 |

| Mining industry | 1 |

| Research method | |

| Questionnaire survey | 14 |

| Interview survey | 5 |

| Literature review | 1 |

| Case study | 2 |

| Observation | 2 |

Table 1 revealed that RE indicators have been investigated across 11 different high-risk industries, which are potentially prone to accidents because of increasing complexity [19]. More than a quarter of the articles on RE indicators have been published in the context of chemical and petrochemical industries. Two articles out of nine focused on the chemical industry and the rest fell under a petrochemical industry classification. Secondly, compared to other industries, researchers have given significant attention to the construction industry in assessing a resilient work environment. The five research methods used in selected 21 studies were recorded in Table 1. Most studies (n = 14) are quantitative studies that used a questionnaire survey methodology to asses and measure resilience by using RE indicators. Only five studies used interview surveys and only two studies used case studies. The indicators of the RE concept calls for assessing and measuring resilience. Quantitative analysis methods such as principal component analysis, factor analysis, and artificial neural networks were often used to assess the level of resilience in work systems by using these indicators. Therefore, it is logical that the mainstream articles applied a questionnaire survey as the research method.

4.2. Comparative review of RE indicators in the safety domain

As previously stated, in this section, the results related to RE indicators are detailed. To achieve this, selected articles are arranged in a table composed of three sections, as shown in Table 2. To provide a detailed summary of the RE indicators used in each industry, the first section presents the industry corresponding to each source. The following section presents a list of RE indicators and their corresponding sources. The last section presents the reason for the selection of particular RE indicators in the corresponding study.

Table 2.

Summary of RE indicators and selection criteria

| No | RE indicator and selection criteria | [46] |

[33] |

[13] |

[58] |

[48] |

[59] |

[49] |

[22] |

[50] |

[60] |

[47] |

[17] |

[2] |

[31] |

[51] |

[38] |

[61] |

[37] |

[55] |

[54] |

[62] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

13 |

14 |

15 |

16 |

17 |

18 |

19 |

20 |

21 |

||

| Industry (Reference [1]) | ||||||||||||||||||||||

| CPI | WI | CI | CI | RI | RI | CPI | PrI | CPI | HI | CPI | CPI | PrI | CPI/RI PhI/AI | EI | MI | CPI | MaI | CI | CPI | |||

| RE indicator | ||||||||||||||||||||||

| 1 | Top management commitment | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | ||

| 2 | Preparedness | x | x | x | x | x | x | x | x | x | x | x | x | |||||||||

| 3 | Teamwork | x | x | x | x | |||||||||||||||||

| 4 | Redundancy | x | x | x | x | x | x | |||||||||||||||

| 5 | Reporting culture | x | x | x | x | x | x | x | x | x | x | |||||||||||

| 6 | Fault-tolerant | x | x | x | x | |||||||||||||||||

| 7 | Flexibility | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | ||

| 8 | Buffering capacity | x | ||||||||||||||||||||

| 9 | Learning culture | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x |

| 10 | Margins | x | ||||||||||||||||||||

| 11 | Self-organization | x | x | x | x | |||||||||||||||||

| 12 | Awareness | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | |

| 13 | Tolerance | x | ||||||||||||||||||||

| 14 | Anticipation | x | x | x | ||||||||||||||||||

| 15 | Attention response | x | ||||||||||||||||||||

| 16 | Cross-scale interactions | x | ||||||||||||||||||||

| 17 | Involvement of staffs | x | x | |||||||||||||||||||

| 18 | Competency | x | ||||||||||||||||||||

| 19 | Safety management system | x | x | |||||||||||||||||||

| 20 | Accident investigation | x | x | |||||||||||||||||||

| 21 | Co-worker safety perception | x | x | |||||||||||||||||||

| 22 | Risk assessment/management | x | x | |||||||||||||||||||

| 23 | Supervisor safety perception | x | x | |||||||||||||||||||

| 24 | Competency | x | ||||||||||||||||||||

| 25 | Management of change | x | x | |||||||||||||||||||

| 26 | Just culture | x | x | x | x | x | x | |||||||||||||||

| 27 | Transparency | x | ||||||||||||||||||||

| 28 | Allocation of resources | x | ||||||||||||||||||||

| Selection criteria | ||||||||||||||||||||||

| 01 | Industry focus selection | x | x | x | x | x | x | x | x | |||||||||||||

| 02 | New directions (concepts, precepts, principles, and methods) for RE framework | x | x | x | x | x | x | x | x | x | ||||||||||||

| 03 | Pervious similar studies on RE indicators | x | x | x | x | x | x | x | x | x | x | x | ||||||||||

AI, automotive industry; CI, construction industry; CPI, chemical and petrochemical industry; EI, electricity industry; HI, healthcare industry; MaI, manufacturing industry; MI, mining industry; PhI, pharmaceutical industry; PrI, process industry; RE, resilience engineering; RI, oil and gas/gas refinery industry; WI, waste management industry.

As illustrated in Table 2, researchers have used various RE indicators in assessing, analyzing, or measuring resilience in high safety risk industries. Altogether, 28 RE indicators are used in the domain of workplace safety. However, it is apparent that the usage of these indicators varies considering the particular research aim, complexity, and nature of the industry.

RE indicators need to be developed in a way that maintains a balance of control in the system without losing standard performance [46]. Despite the fact that researchers have used a wide variety of RE indicators, Table 2 reveals the following three main reasons for the justification of the selection of RE indicators in each article: (i) industry focus selection; (ii) indicators required to develop new directions (concepts, precepts, principles, and methods) for RE framework; and (iii) indicators that have been used in previous similar studies.

From the articles reviewed, it is apparent that most researchers have focused on the characteristics of a particular industry that they are working in when selecting RE indicators. Indicators used in one study have been rejected in another study as the authors have noted that those indicators are ineffective in the context of study. Each of the indicators has its special meaning in the various application fields, given that researchers are able to customize the indicators for a specific field to better evaluation of performance [47]. Despite management commitment, learning culture, anticipation, awareness, and flexibility being widely acknowledged as RE indicators [38,46,48], researchers have varied their focus depending on the industry they work with. As an example, assessment of RE indicators in high-risk environment demonstrated that preparedness, awareness, and flexibility are the most significant factors in petrochemical plants, whereas the factors of redundancy and teamwork remain insignificant [17]. Anticipation and preparedness are two indicators highlighted in rail engineering planning [13]; change management was emphasized in refinery industry [13]. Analysis of work performed in the field of RE suggests that the significance of the indicators varies depending on the industry. This is because every industry is unique and distinctive. Therefore, it is important to select the indicators contingent on the complexity and the nature of the industry.

RE concept can be easily associated with other safety concepts [35]. To enhance safety practices, researchers have merged safety concepts, which also helps to fill the gaps in one particular safety concept. Table 2 reveals the studies that carried RE into a new direction by integrating new concepts, principles, and methods. Also, it is found that the aforementioned research focus influences the selection of RE indicators. Four new research perspectives for RE framework were found based on the analysis of selected studies. Accordingly, studies focus on creating (i) resilience safety culture [46,49], (ii) safety climate resilience [13], (iii) integrated RE [17,47,50], (iv) integrated method of assessing health and safety [37,51] focus on different amalgamation of RE indicators. In this case, researchers have used integrated indicators by considering all grounding concepts such as resilience, safety climate, safety culture, and safety management system.

Indicators for “resilience safety culture” were developed by integrating two concepts safety culture and resilience [49]. RE is a new perspective to organizational safety culture. However, there was an overlap between some of the RE indicators and the concept of safety culture [37,38]. For example, although reporting culture, just culture, flexible culture, and learning culture falls under RE indicators, they can also be categorized as a sub-component of safety culture [37,52]. Despite most of the indicators appearing to be similar to the measure of safety culture, there is a difference in these measures when used in practice [46].

Traditionally, the dimensions of safety culture are based on technological, behavioral, and human factors, as well as socio-technical systems. The new lens of resilience towards safety culture has led to shift the way of addressing safety cultural dimensions. The scale that has been used to measure the safety culture may be quite different from the scale that has been developed based on RE. Traditionally, safety culture investigates why things go wrong and why system loss control, whereas in the lens of RE, safety culture investigates how to manage the things without losing control [46]. RE has enhanced the concept of safety culture by integrating resilience capabilities under indicators of safety culture. Table 3 describes how commonly used attributes of management commitment, awareness, flexibility, and learning change from the traditional perspective of safety culture to create a resilient safety culture.

Table 3.

Difference between dimensions of safety culture in the perspective of Safety I and Safety II

| Indicator | Safety culture in Safety I | Safety culture in the lens of resilience—Safety II |

|---|---|---|

| Top Management commitment | Providing adequate resources and consistently support the development and implementation of safety activities [63]. | More concern on the value of human performance and engaging and follow-up with actions related to human performance [3]. |

| Flexibility | Reconfiguring of the system after facing an emergency situation [64]. | Focuses on adjusting to new conditions by minimizing the disruptions to normal working conditions [3]. |

| Awareness | Focused on promotional strategies such as displaying safety posters, mission statements, slogans, and publish materials to aware the people on safety [65]. | Not only promotional strategies, but also knowing “what is going on” in the workplace in regards to quality of performance, status of the current condition, and the level of defense [3]. |

| Learning | Learning from reported sources such as accidents, incidents, unsafe acts, and unsafe conditions [3]. | Learning from both success and failures [3]. |

In developing the concept of “Safety climate resilience,” Chen et al [13] have added “Supervisor safety perception” and “Co-worker safety perception” as two additional indicators in recognition that safety climate and the nature of the construction site is specific. Similarly, Azadeh et al [47] introduced “integrated resilience engineering” framework with four new RE indicators (teamwork, redundancy, fault-tolerant, and self-organization) required for effective work process. Although two indicators “self-organization and fault-tolerant” can fall under “flexibility,” some authors consider them as two separate indicators because of their significant impact of organizational safety in a particular industry [47]. Costella et al [37] have used four common RE indicators for method of assessing health and safety by considering their interface with each other and appear without defined limits. Researchers have used different RE indicators based on different terminologies, given that the selection of RE indicators tends to be adjustable with the research focus and perspective of the study.

Table 2 reveals several studies that depend on the previous similar studies when selecting RE indicators. It is apparent that researchers also tend to select commonly used RE indicators, which are derived from the primary studies of resilience such as Hollnagel and Woods [53] and Woods and Wreathall [36]. Thus, these indicators appear to be matched with different circumstances, irrespective of industry or research perspective.

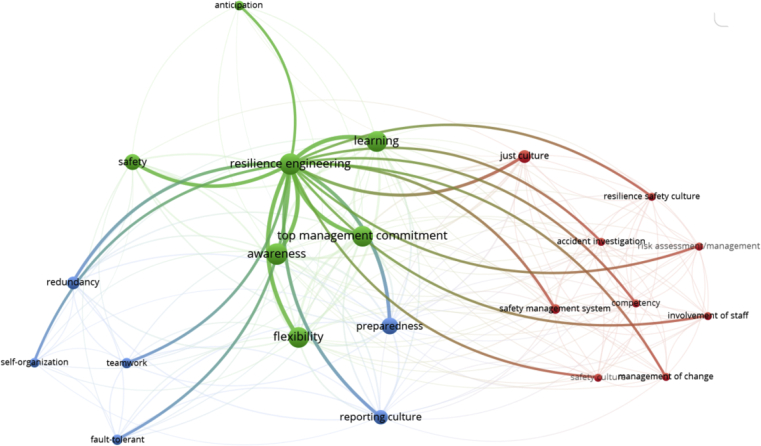

Besides, a co-occurrence network of keywords was created using VOSviewer [15] to show the nature of the relationship among co-occurring keywords. The weight of the link between two keywords is determined by the occurrence of same keywords together in a number of publications [44]. The keywords occur not less than two times in the selected articles were used to generate the co-occurrence network. This co-occurrence network is created by considering the closeness and strength of the links. Fig. 3 shows the co-occurrence network of keywords in selected articles and it highlights the links between the RE and indicators.

Fig. 3.

Co-occurrence network.

Through the network visualization, it is observed that there are 22 nodes that link with the node of “resilience engineering.” First, the network visualizes a strong link between safety and RE. In VOSviewer, the size of the node represents the number of publications that have corresponding keyword and frequently co-occurred keywords tend to be close to each other in the network visualization [45]. Furthermore, the strength of the relationship is determined by the thickness of the line. The stronger the relationship between two nodes, the thicker the line between nodes in the network.

According to the analysis of network visualization, the four RE indicators (top-management commitment, awareness, learning, and flexibility) have higher weights than other indicators as they are represented by larger circles. As well as, these four indicators have located close to the node “resilience engineering,” and the lines between each indicator and node RE are thicker than the lines between the node RE and the rest of the indicators. It is observed that RE indicators, top-management commitment, awareness, learning, and flexibility have largely used in the selected articles irrespective of the industry it applies. The aforementioned four indicators more keen to evaluate the organization's resiliency based on human interaction and internal process, whereas factors such as teamwork, redundancy, fault-tolerant, and self-organization affect system's resiliency [54]. Furthermore, analysis of network visualizes that RE indicators represented in the blue cluster has been used to assess an integrated RE work environment. Indicators in the red cluster are widely used to assess resilience safety culture.

A thorough investigation of above findings shows that most researchers have focused common sets of indicators (top-management commitment, awareness, learning, and flexibility), whereas others remain undeveloped (teamwork, redundancy, fault-tolerant, self-organization). Some indicators discussed in the resilience concept are still not popular, such as buffering capacity, margin, and cross-scale interactions [22]. Researchers disinclined the use of aforementioned indicators. This is because, either they are still undeveloped or difficult in the application or define in particular industries. For example, buffering capacity is a very important indicator in some industries such as nuclear power plant and processing plant, but difficult to define in the construction work environment.

The four indicators mentioned previously (top-management commitment, awareness, learning, and flexibility) have been successfully adopted in many industries at the introduction stage of RE. As well as, these four indicators considered as the most vital factors of the resilience concept at the introductory level [31], which have interfaces with each other and not retain with defined boundaries [17]. Each factor has a unique meaning pertaining to distinctive application field [47].

To the date, there are very few studies pertaining to RE in the construction industry. The construction industry is a loosely couple system that brings much freedom to workers [55]. The construction industry has shown its highest technical performance, but the social and human interactions are yet to be enhanced compared to well-developed technical solutions [56]. Considering the nature of construction industry, it is difficult to define some indicators such as buffering capacity” “margin” fault-tolerant. In this case, it is worth to focus on tacit or abstract dimensions such as management commitment, learning at this introductory stage. Pertaining to these results, top-management commitment, awareness, learning, and flexibility can be used to assess the resilience in construction refurbishment work environment. The construction refurbishment industry will gain positive extraction from these four indicators for the development of a resilient work environment. A more robust understanding of the initial indicators will push towards working on other RE indicators that can integrate with construction work environment in the future.

Research on assessing resilience through these indicators remains at an early stage and particular investigation is shown to be limited to 12 diverse but risk-prone industries. Therefore, it is recommended to give special effort to develop and make use of theses RE indicators in all applicable high safety risk industries. On the other hand, it is apparent that researchers are more inclined to reproduce the Safety I indicators instead of developing new indicators pertaining to Safety II from the perspective of RE. However, this can be justified because the concept of RE is still in its infant stage. Starting with already known indicators will provide a stronger foundation to the RE and cater to further development of the RE concept.

The industries, such as the petrochemical and chemical industries, have already reached to an expert level in practicing RE. Therefore, it is easy to step forward towards the development of RE indicators. Researchers and practitioners in these industries could have been given more attention towards developing a set of Safety II indicators connected to theory of RE rather than reproducing Safety I indicators. Other industries like construction, manufacturing, etc, need further understanding of RE with more commonly established factors. Once those being improved in the lens of RE towards Safety II, it will help to create a better-grounded concept of RE in those industries and cater to the development of RE as a safety management tool. This would enable to promote a resilient work environment in high safety-critical industries, which ultimately reduce the number of safety incidents reported in each year.

5. Conclusion

This systematic review of the literature explored RE indicators that have been used to assess the level of resilience in high safety risk industries. RE is an area that has garnered growing attention in the domain of safety. Nevertheless, regardless of the popularity of RE over the last few decades, researchers have paid less attention to RE indicators. Notably, these RE indicators play a significant role in streamlining the performance and actions that organization required in the context of resilience. A lack of universally agreed indicators is one of the key reasons for the paucity of research directed towards RE indicators. Addressing this shortcoming, the approach undertaken for this study was an SLR to explore the widely used RE indicators in the domain of safety.

This research documents the growth within the use of RE indicators in research over the time of interest since 2004. After the screening process, out of a total of 1,282 articles identified by the search, 21 articles were selected and analyzed in detail as each of these articles presented a set of RE indicators based on their arguments. Analysis of the publishing framework of selected articles highlighted the importance of RE indicators in high safety risk industries. Over one-third of the articles found to be based on the petrochemical industry. It is also noted that there was a significant focus on construction. Within selected articles, a variety of research methods were applied with the use of questionnaire analysis being the most popular.

The findings presented in this research revealed 28 RE indicators used over different industries subjected to different terminologies. The findings revealed that the selection of the indicators mainly based on the complexity and nature of the industry where study applies, research direction on the perspective of RE and previous similar studies on RE indicators. Therefore, it is difficult to rely on a universally agreed set of RE indicators in assessing resilience. However, the co-occurrence of network highlighted four indicators (top-management commitment, awareness, learning, and flexibility) that have widely been used in almost all the industries. Certainly, these indicators play a significant role in introducing, assessing, and maintaining resilient work environment in construction refurbishment projects at the introductory stage. However, little attention has been given to the development of RE indicators particularly focusing on improving safety performance.

Despite the contribution made in this study, there are some limitations to the SLR. Therefore, the findings are circumscribed by the selection criteria used to select the articles such as searching keywords and the omission of non-English studies. The topic is of great value for the development of RE indicators through a better focus on enhancing safety performance and revealing unexplored RE indicators. The growing attention towards RE will lead to the development of a commonly agreed industry-based set of RE indicators in future research.

Conflicts of interest

All authors have no conflicts of interest to declare.

References

- 1.International Labour Organization I. 2018. The enormous burden of poor working conditions.https://www.ilo.org/moscow/areas-of-work/occupational-safety-and-health/WCMS_249278/lang--en/index.htm Available from: [Google Scholar]

- 2.Shirali G.A., Mohammadfam I., Ebrahimipour V. A new method for quantitative assessment of resilience engineering by PCA and NT approach: a case study in a process industry. Reliab Eng Sys Safety. 2013;119:88–94. [Google Scholar]

- 3.Hollnagel E., Woods D.D., Leveson N. Ashgate Publishing, Ltd.; 2007. Resilience engineering: concepts and precepts. [Google Scholar]

- 4.Dekker S., Hollnagel E., Woods D., Cook R. Lund University School of Aviation; 2008. Resilience engineering: new directions for measuring and maintaining safety in complex systems. [Google Scholar]

- 5.Righi A.W., Saurin T.A., Wachs P. A systematic literature review of resilience engineering: research areas and a research agenda proposal. Reliab Eng Sys Safety. 2015;141:142–152. [Google Scholar]

- 6.Noori A., Saruwono M., Adnan H., Rahmat I., editors. Conflict, complexity, and uncertainty in building refurbishment projects. Springer Singapore; Singapore: 2016. [Google Scholar]

- 7.Hon C.K.H., Chan A.P.C. Safety management in repair, maintenance, minor alteration, and addition works: knowledge management perspective. J Manage Eng. 2013;30(6) [Google Scholar]

- 8.Bhuiyan S.I., Jones K., Wanigarathna N., editors. Procs 31st Annual ARCOM Conference. 2015. An approach to sustainable refurbishment of existing building. [Google Scholar]

- 9.Wood H., Gidado K., editors. Project_Complexity_in_Construction.pdf. COBRA; 2008. [Google Scholar]

- 10.Hollnagel E. Is safety a subject for science? Safety Science. 2014;67:21–24. [Google Scholar]

- 11.Patterson M., Deutsch E.S. Safety-I, Safety-II and resilience engineering. Curr Prob Pediatr Adolescent Health Care. 2015;45(12):382–389. doi: 10.1016/j.cppeds.2015.10.001. [DOI] [PubMed] [Google Scholar]

- 12.Hollnagel E. CRC Press; 2017. FRAM: the functional resonance analysis method: modelling complex socio-technical systems. [Google Scholar]

- 13.Chen Y., McCabe B., Hyatt D. A resilience safety climate model predicting construction safety performance. Safety Sci. 2018;109:434–445. [Google Scholar]

- 14.Saurin T.A., Rooke J., Koskela L., Kemmer S. Vol. 1. 2013. Guidelines for the management of complex socio-technical systems: an exploratory study of a refurbishment project; pp. 13–22. (21st Annual Summit of the International Group for Lean Construction). [Google Scholar]

- 15.Hosseini S., Barker K., Ramirez-Marquez J.E. A review of definitions and measures of system resilience. Reliab Eng Sys Safety. 2016;145:47–61. [Google Scholar]

- 16.Shin S., Lee S., Judi D., Parvania M., Goharian E., McPherson T., Burian S. A systematic review of quantitative resilience measures for water infrastructure systems. Water. 2018;10(2):164. [Google Scholar]

- 17.Azadeh A., Salehi V., Arvan M., Dolatkhah M. Assessment of resilience engineering factors in high-risk environments by fuzzy cognitive maps: a petrochemical plant. Safety Sci. 2014;68:99–107. [Google Scholar]

- 18.Patriarca R., Bergström J., Di Gravio G., Costantino F. Resilience engineering: current status of the research and future challenges. Safety Sci. 2018;102:79–100. [Google Scholar]

- 19.Bergström J., van Winsen R., Henriqson E. On the rationale of resilience in the domain of safety: a literature review. Reliab Eng Sys Safety. 2015;141:131–141. [Google Scholar]

- 20.Schafer D., Abdelhamid T.S., Mitropoulos P., Mrozowski T. Building a Sustainable Future; 2009. Resilience engineering: a new approach for safety management. [Google Scholar]

- 21.Bellamy L.J., Chambon M., Guldener V.V. Getting resilience into safety programs using simple tools - a research background and practical implementation. Reliab Eng Sys Safety. 2018;172:171–184. [Google Scholar]

- 22.Shirali G.A., Motamedzade M., Mohammadfam I., Ebrahimipour V., Moghimbeigi A. Assessment of resilience engineering factors based on system properties in a process industry. Cognition Technol Work. 2016;18(1):19–31. [Google Scholar]

- 23.Steen R., Aven T. A risk perspective suitable for resilience engineering. Safety Sci. 2011;49(2):292–297. [Google Scholar]

- 24.Hollnagel E. Resilience engineering in practice: a guidebook. 2011. Prologue: the scope of resilience engineering. [Google Scholar]

- 25.Hollnagel E. Ashgate Publishing, Ltd.; 2013. Resilience engineering in practice: a guidebook. [Google Scholar]

- 26.Woods D. Escaping failures of foresight. Safety Sci. 2009;47(4):498–501. [Google Scholar]

- 27.Woods D.D. Four concepts for resilience and the implications for the future of resilience engineering. Reliab Eng Sys Safety. 2015;141:5–9. [Google Scholar]

- 28.Woods D.D., Chan Y.J., Wreathall J., editors. 5th Resilience Engineering Symposium. 2014. The stress–strain model of resilience operationalizes the four cornerstones of resilience engineering. [Google Scholar]

- 29.Wehbe F., Hattab A.M., Hamzeh F. Exploring associations between resilience and construction safety performance in safety networks. Safety Sci. 2016;82:338–351. [Google Scholar]

- 30.Niskanen T. A resilience engineering-related approach applying a taxonomy analysis to a survey examining the prevention of risks. Safety Sci. 2018;101:108–120. [Google Scholar]

- 31.Adolph L., Lafrenz B., Grauel B. Proceedings of the Human Factors and ergonomics society europe. 2012. Safety management systems, safety culture and resilience engineering: comparison of concepts. [Google Scholar]

- 32.Penaloza G.A., Formoso C.T., Saurin T.A. 2017. Safety performance measurement systems based on resilience engineering: A. [DOI] [PubMed] [Google Scholar]

- 33.Rubio-Romero J.C., Pardo-Ferreira MdC., Varga-Salto JDl, Galindo-Reyes F. Composite leading indicator to assess the resilience engineering in occupational health & safety in municipal solid waste management companies. Safety Sci. 2018;108:161–172. [Google Scholar]

- 34.Pillay M. Resilience engineering: an integrative review of fundamental concepts and directions for future research in safety management. Open J Safety Sci Technol. 2018;7(4):129. [Google Scholar]

- 35.Pęciłło M. The resilience engineering concept in enterprises with and without occupational safety and health management systems. Safety Sci. 2016;82:190–198. [Google Scholar]

- 36.Woods D., Wreathall J. Ohio University; Columbus: 2003. Managing risk proactively: the emergence of resilience engineering. [Google Scholar]

- 37.Costella M.F., Saurin T.A., Guimaraes dMB. A method for assessing health and safety management systems from the resilience engineering perspective. Safety Sci. 2009;47(8):1056–1067. [Google Scholar]

- 38.Pillay M., Borys D., Else D., Tuck M. Safety culture and resilience engineering–exploring theory and application in improving gold mining safety. Gravity Gold. 2010:21–22. [Google Scholar]

- 39.Kitchenham B. vol. 33. Keele University; Keele, UK: 2004. pp. 1–26. (Procedures for performing systematic reviews). [Google Scholar]

- 40.Martinez-Aires M.D., Lopez-Alonso M., Martinez-Rojas M. Building information modeling and safety management: a systematic review. Safety Sci. 2018;101:11–18. [Google Scholar]

- 41.Moher D., Liberati A., Tetzlaff J., Altman D.G., Group P. 2010. Preferred reporting items for systematic reviews and meta-analyses: the PRISMA statement. [PMC free article] [PubMed] [Google Scholar]

- 42.Okoli C., Schabram K. 2010. A guide to conducting a systematic literature review of information systems research. [Google Scholar]

- 43.Tranfield D., Denyer D., Smart P. Towards a methodology for developing evidence-informed management knowledge by means of systematic review. Br J Manag. 2003;14(3):207–222. [Google Scholar]

- 44.Hosseini M.R., Martek I., Zavadskas E.K., Aibinu A.A., Arashpour M., Chileshe N. Critical evaluation of off-site construction research: a scientometric analysis. Auto Constr. 2018;87:235–247. [Google Scholar]

- 45.Van Eck N.J., Waltman L. Springer; 2014. Visualizing bibliometric networks. Measuring scholarly impact; pp. 285–320. [Google Scholar]

- 46.Shirali G., Shekari M., Angali K.A. Assessing reliability and validity of an instrument for measuring resilience safety culture in sociotechnical systems. Safety Health Work. 2018;9(3):296–307. doi: 10.1016/j.shaw.2017.07.010. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 47.Azadeh A., Salehi V., Ashjari B., Saberi M. Performance evaluation of integrated resilience engineering factors by data envelopment analysis: the case of a petrochemical plant. Process Safety Environ Protect. 2014;92(3):231–241. [Google Scholar]

- 48.Azadeh A., Salehi V., Mirzayi M., Roudi E. Combinatorial optimization of resilience engineering and organizational factors in a gas refinery by a unique mathematical programming approach. Human Fact Ergono Manufact Serv Ind. 2017;27(1):53–65. [Google Scholar]

- 49.Shirali G.A., Shekari M., Angali K.A. Quantitative assessment of resilience safety culture using principal components analysis and numerical taxonomy: a case study in a petrochemical plant. J Loss Prevent Process Ind. 2016;40:277–284. [Google Scholar]

- 50.Azadeh A., Zarrin M. An intelligent framework for productivity assessment and analysis of human resource from resilience engineering, motivational factors, HSE and ergonomics perspectives. Safety Sci. 2016;89:55–71. [Google Scholar]

- 51.Saurin T.A., Junior G.C.C. Evaluation and improvement of a method for assessing HSMS from the resilience engineering perspective: a case study of an electricity distributor. Safety Sci. 2011;49(2):355–368. [Google Scholar]

- 52.Reason J. Achieving a safe culture: theory and practice. Work Stress. 1998;12(3):293–306. [Google Scholar]

- 53.Hollnagel E., Woods D.D. CRC Press; 2005. Joint cognitive systems: foundations of cognitive systems engineering. [Google Scholar]

- 54.Rabbani M., Yazdanparast R., Mobini M. An algorithm for performance evaluation of resilience engineering culture based on graph theory and matrix approach. Int J Sys Assurance Eng Manag. 2019;10(2):228–241. [Google Scholar]

- 55.Saurin T.A., Formoso C.T., Cambraia F.B. An analysis of construction safety best practices from a cognitive systems engineering perspective. Safety Sci. 2008;46(8):1169–1183. [Google Scholar]

- 56.Lehtiranta L. Relational risk management in construction projects: modeling the complexity. Leadership Manag Eng. 2011;11(2):141–154. [Google Scholar]

- 57.Moher D., Liberati A., Tetzlaff J., Altman D.G., PRISMA G. Reprint—preferred reporting items for systematic reviews and meta-analyses: the PRISMA statement. Phys Ther. 2009;89(9):873–880. [PubMed] [Google Scholar]

- 58.Chen Y., McCabe B., Hyatt D. 2017. A belief network to predict safety performance of construction workers-from the perspectives of resilience. [Google Scholar]

- 59.Azadeh A., Asadzadeh S.M., Tanhaeean M. A consensus-based AHP for improved assessment of resilience engineering in maintenance organizations. J Loss Prevent Process Ind. 2017;47:151–160. [Google Scholar]

- 60.Azadian S., Shirali G.A. Designing a questionnaire to assess crisis management based on a resilience engineering approach. Jundishapur J Health Sci. 2014;6(1) [Google Scholar]

- 61.Huber S., Wijgerden vI., Witt dA., Dekker S.W. Learning from organizational incidents: resilience engineering for high-risk process environments. Process Safety Progress. 2009;28(1):90–95. [Google Scholar]

- 62.Zarrin M., Azadeh A. Mapping the influences of resilience engineering on health, safety, and environment and ergonomics management system by using Z-number cognitive map. Human Fact Ergon Manufact Service Ind. 2019;29(2):141–153. [Google Scholar]

- 63.Wiegmann D.A., Zhang H., Von Thaden T.L., Sharma G., Gibbons A.M. Safety culture: an integrative review. Int J Aviation Psychol. 2004;14(2):117–134. [Google Scholar]

- 64.Cooper M.D. Towards a model of safety culture. Safety Sci. 2000;36(2):111–136. [Google Scholar]

- 65.Choudhry R.M., Fang D., Mohamed S. The nature of safety culture: a survey of the state-of-the-art. Safety Sci. 2007;45(10):993–1012. [Google Scholar]