Abstract

Background

This study investigated the effect of traditional and improved solar drying methods on the sensory quality and nutritional composition of the dried fruit products; using mangoes and pineapples, as a case study. The fruits were dried under five solar drying methods namely; open sun drying (OSD), black-cloth shade (BCS), white-cloth shade (WCS), a conventional solar dryer (CSD), and a newly improved solar dryer (ISD) technology. The ISD unit was made of a modified solar concentrator plate containing multiple metallic solar collectors arranged in series. The ISD drying cabinet was also enclosed with a specialized greenhouse cover materials. The drying operations were conducted following a completely randomized design (CRD) experimental procedure.

Results

The mean drying air temperatures for the OSD, BCS, WCS, CSD and ISD methods were 26.8, 26.7, 24.5, 32.6 and 40.3 °C; respectively. Results showed that the five solar drying methods were capable of retaining the sensory quality and nutritional composition of dried mango and pineapples. The nutritional parameters retained were proximate and mineral content. The sensory quality parameters were taste, aroma, colour and acceptability of the dried fruit products. However, the sensory quality and nutritional content of the fruit products dried under the ISD method were higher than that of the products dried under the CSD method, suggesting an enhanced capacity and superior role of the ISD dryer technology in fruit processing.

Conclusion

The ISD technology was, therefore, recommended as a better fruit drying method than the traditional solar drying methods. Using the ISD method could be a feasible solution and a strategic pathway to addressing the high post-harvest losses of fruits as well as other perishable fresh produce in East Africa.

Keywords: Food science, Food technology, Agriculture, Solar dryers, Value-addition, Fruits, Post-harvest loss, Renewable energy

Food science, Food technology, Agriculture, Solar dryers, Value-addition, Fruits, Post-harvest loss, Renewable energy.

1. Introduction

Most fruits constitute an exclusive source of essential nutrients which are essential to human health. Thus, increased consumption of fruits significantly reduces both chronic and malnutrition-related diseases such as diabetes and obesity (Mozaffarian, 2016). The fruits have large quantities of phytochemicals; that serve as antioxidants and protect the humans against cytotoxicity and mutagenicity (Bennett et al., 2011). Despite the health benefits, availability of fruits is seasonal, and consumption is limited in East Africa. The region is home to one of the world's lowest intake of nutrient-rich fruits with the mean daily consumption of fruits being below half of 400g per capita, the minimum threshold recommended by the World Health Organization (Fanzo, 2012).

Consequently, East Africa is home to one of the most nutritionally insecure people globally (Ruel et al., 2005). The main hindrance to the increased consumption of fruits is seasonal scarcity caused by the enormous post-harvest losses of fruits after bumper harvest. The post-harvest loss is aggravated by the recurring failure of most farmers to adequately process their fresh fruits to prolong shelf life for future consumption and marketing, especially during the off-season (Wakholi et al., 2015). The post-harvest losses (PHL) of the fresh perishable fruits were estimated at 40 and 50% in Uganda and Tanzania; respectively (Wakholi et al., 2015).

To overcome the PHL and seasonality of perishable fruits, farmers often employ several technologies mainly; drying, canning, freezing, refrigeration and modified atmospheric storage (Sagar and Suresh Kumar, 2010). The main ecological and socio-economic factors which influence the choice of the solar drying technologies are; climatic conditions, crop type and other socio-economic factors like ease of use, energy costs and affordability (Chua and Chou, 2003; Kumar et al., 2016). Comparably, drying, which includes: oven drying, vacuum, microwave, freeze-drying and solar drying methods is the most preferred food processing technology in Africa and other developing societies (Sagar and Suresh Kumar, 2010). This is because the drying process uses reduced energy and is low-cost; making it appropriate for the resource-constrained farming communities in East Africa. Besides, the food drying process tends to dehydrate the fresh produce to safe storage moisture content levels; which further prolongs shelf life (Kumar et al., 2016; Sagar and Suresh Kumar, 2010). Drying also causes considerable losses in weight and volume of food; thereby reducing packaging, transportation and storage costs of the dried products (Chan et al., 2012; Sagar and Suresh Kumar, 2010). The food drying process impedes microbial degradation, including fungi and mould growth on the dried products (Immaculate et al., 2012).

The oven drying, microwave, vacuum and freeze-drying methods involve dehydrating the fresh produce under controlled temperatures, humidity and pressure conditions; which often guarantee high quality of the dried products (Orphanides et al., 2016). But all the drying methods are too costly and are high-energy demanding, and are not widely adopted among the resource-constrained local farming communities in East Africa, particularly in Uganda and Tanzania (Chua and Chou, 2003). As a result, most farmers and agro-processors have no option but to rely on the traditional solar drying methods namely; open sun drying, conventional solar dryers, white-cloth and black-cloth shade drying methods; since they are sustainable and perceived to be more cost-effective. This is so because all the traditional solar drying methods use renewable solar energy; which is freely available in large quantities even in remote areas (Chua and Chou, 2003; Hii et al., 2012; Orphanides et al., 2016; Kumar et al., 2016).

However, the literature suggests that solar drying is susceptible to several drawbacks such as contamination by dust, rain and animals (Prakash et al., 2016); scavenging by animals (Lamidi et al., 2019); inadequate and excessive drying of food (Chua and Chou, 2003; Hii et al., 2012). These drawbacks often compromise the sensory quality attributes and nutritional composition of the solar-dried products, especially in fruits and vegetables (Sagar and Suresh Kumar, 2010; Prakash et al., 2016). In response, a newly improved solar dryer was proposed as an alternative to the local solar drying methods. In addition to the cost-effectiveness and renewable energy factors, only the improved solar drying methods which do not compromise both the sensory attributes and nutritional content of the dried fruit products should be recommended for scaling. If so, the improved solar drying (ISD) method could serve to address the enormous PHL of fruits and other fresh horticultural produce. Consequently, the ISD technology could also be employed locally to increase the farmers' income, food and nutritional security.

In this study, therefore, the effect of using the ISD and the traditional solar drying methods on the sensory quality attributes and nutritional content of the dried fruits was evaluated. The sensory quality parameters assessed were aroma, taste, colour and acceptability of the dried fruit products. Likewise, the nutritional parameters were proximate composition, mineral elements and vitamins. It was hypothesized that using the ISD and the traditional solar drying methods could significantly reduce the sensory quality attributes and nutritional composition of the dried fruit products.

2. Materials and methods

The fruit drying experiments were conducted at the Nelson Mandela African Institution of Science and Technology, NM-AIST (-3.40059 °N; 36.79671°E) in Arusha, Tanzania.

Ethical approval: some of the procedures performed in this study, especially during the sensory evaluation of the solar-dried fruits involved human participants. And as such, ethical clearance was obtained from the Ethics Committee of the ‘National Institute for Medical Research (NIMR)’ in Tanzania (Approval ID: NIMR-1912-AR). All individual participants gave ‘written informed consent’ for their participation in the study.

2.1. Selection and preparation of the fruit samples

Mangoes (Mangifera indica L.) and pineapples (Ananas comosus) were selected among the local fruit types because they constitute one of the most important sources of macro- and micronutrients including phytochemicals (Jödicke et al., 2019). The most locally-preferred commercial cultivars of the mango and pineapple fruits were selected and included; Dodo and Smooth cayenne, respectively. Only physiologically mature and ripe mango and pineapple fruits were bought from a local market in Tengeru town, Arusha. Twenty fruits (for the mango and pineapple) were picked from the same batch at one randomly selected stall, put in a cool-box and were transported to the NM-AIST for processing. The fruit samples were processed in the NM-AIST Life Sciences and Bio-Engineering laboratory. External non-edible portions of the mango and pineapple samples were washed and peeled off using a kitchen knife. Edible portions of the mangoes and pineapples were sliced at cross-sectional portions of 3 mm thickness (Kumar et al., 2016; Tunçkal et al., 2018). The samples were cut into a uniform oval shape of diameter 2.5 cm using a metallic slicer.

Three replicate fruit drying cycles were performed simultaneously under the four main traditional solar drying methods namely; Open Sun Drying (OSD), Conventional Solar Dryer (CSD), White-Cloth Shade (WCS) and Black-Cloth Shade (BCS) methods as well as under the newly proposed ‘Improved Solar Drying (ISD)’ technology (Figure 1). And for each drying cycle, six replicate plates of the fresh mango and pineapple slices were prepared. Each plate consisted of 20 identical pieces of either the mango and pineapple slices. The initial mass of each plate (containing the 20 slices of the fresh fruit samples) was measured using an electric weighing scale (model: GX4000; range: 0.01–4100g; supplier: A&D Co., Japan). And for each fruit sample type, the 1st plate of the fresh slice samples was kept in a refrigerator and was maintained at temperatures below -4 °C; to preserve them until nutritional analyses along with the dried fruits (Tunçkal et al., 2018). These fresh slices provided the baseline parameters for moisture content, sensory quality and nutritional composition of the mangoes and pineapples; when assessing the drying performance of the solar drying methods. The five remaining plates (of fresh fruit samples) were dried under the OSD, CSD, BCS and WCS and ISD methods (Figure 1).

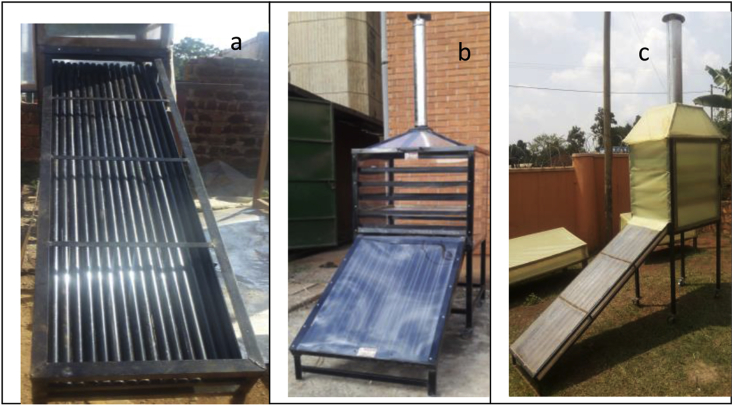

Figure 1.

The four traditional solar drying methods and the proposed improved solar dryer. a) Convention Solar Dryer (CSD) method, b) White-Cloth Shade (WCS) and Black-Cloth Shade (BCS) methods, c) Improved Solar Dryer (ISD) method, and d) the traditional Open Sun Drying (OSD) method.

2.2. The fruit drying experiments

Experiments to assess the effect of using the five solar drying methods namely the; OSD, CSD, BCS, WCS and ISD on the sensory quality attributes and nutritional composition of the dried fruit products followed completely randomized design (CRD) procedures (Mead, 2017). The solar drying methods constituted the experimental drying units, whereas the mango and pineapple fruits were the treatment variables. The fruit drying experiments were started from 8:00 am to 6:00 pm under ambient solar radiation. Drying operations were conducted in the open ground from May 3rd to 6th, 2019. The fruit slices were dried until they attained satisfactory moisture content levels of 8% or below; which is the optimum safe storage moisture level for most fruit types (Wills and Golding, 2016).

The open sun drying (OSD) method was made of a 1 m2 tarpaulin; which was enclosed in a perforated white drying mesh. The tarpaulin and mesh were raised at 1.5 m above the ground on wooden-stands to minimize dust contamination of the mango and pineapple samples during the drying process (Figure 1d). Conversely, the White-Cloth Shade (WCS) and Black-Cloth Shade (BCS) solar drying methods were mimicked in white-transparent plastic buckets of 10 L by volume; and were covered with clean white and black silk-cloths, respectively (Figure 1b).

A medium-scale Conventional Solar Drier (CSD) unit was fabricated following standard protocols described by Hii et al. (2012). The food drying cabinet of the CSD dryer was customized to a medium-size (volume: 1m3) of drying capacity (Figure 1a). The cabinet was enclosed with non-perforated greenhouse plastic polyethene material (type: PVC UV-treated; Gt4 gauge). The PVC greenhouse cover material was selected to enclose the drying cabinet because of its distinctive ability to screen ultraviolet (UV) solar thermal radiations. The PVC greenhouse plastic material was used because the UV solar thermal radiations destroy most of the light-sensitive nutrients when exposed to fresh food during drying (George et al., 2015).

An improved medium-scale solar dryer (ISD) was prototyped and fabricated following standard construction protocols described by Hii et al. (2012). The physical ISD unit was fabricated while taking into account technical performance modifications suggested by Kumar et al. (2016). But the ISD dryer was further modified to have an auxiliary improved solar concentrator plate, made of 15 pieces of cylindrical metallic concentrators (Figure 2a). Each metallic solar concentrator consisted of one focal length, along which solar thermal energy was concentrated. The 15 metallic pieces translated into 15 focal lengths from the metallic solar concentrators in the modified solar collector plate attached to the new ISD system (Figure 2b). The modified solar concentrator plates served to enhance absorption and retention of additional thermal energy into the ISD system; to improve drying.

Figure 2.

The new proposed improved solar dryer (ISD) for tropical fruits. a) the multiple metallic solar thermal energy concentrators, b) the ISD with a modified solar concentrator, c) full ISD with cabinet enclosed with greenhouse cover.

Like the CSD drying method, a 1 m3 volume of the ISD drying cabinet was made, and its drying cabinet was enclosed with a duplicate greenhouse plastic polyethene material (Figure 2c). Besides screening the UV-radiations, the greenhouse materials serve to boost the drying by maximizing retention of the absorbed solar thermal energy. Absorption of extra thermal energy increases the internal air temperatures within the cabinet through the greenhouse effect (Chauhan and Kumar, 2016). The warmed air dries the food in the cabinet, which generates cumulative thermal energy which further accelerates drying of the produce by natural convection (Hii et al., 2012). . The convective effect offset the excessive internal thermal energy and moisture in the ISD cabinet via the chimney. It prohibits over-drying and moisture re-absorption during drying.

2.3. Data collection

During the drying experiments, data for the ambient weather conditions including solar radiation (Wm−2), air temperatures (oC) and relative humidity (%) were recorded using solimeters, thermometers and humidity probes; respectively. The solar radiation energy was recorded using an integrated solarimeter (model: KIMO; accuracy: ±1 Wm-2; range: 1–1300 Wm-2). Air temperatures were recorded by a digital Lutron thermometer (model: DL-9601A; accuracy: ±0.1 °C; range: -200 to 350 °C); and relative humidity was measured by a digital humidity probe (model: EE181-L-Air; accuracy: ±0.1%; range: 0–100%). The instruments were embedded in an automated weather station instrument (model: JL-03-Q4; supplier: Shandong, China); placed on the same vicinity where drying experiments were conducted. The data were retrieved from the loggers by connecting RS232 cables.

One set of thermocouples (type: T-type; model: TT-T22S; Omega, UK) and humidity sensors (model: HC2S3-L; supplier: Campbell Scientific Inc., USA) were attached to the OSD, WCS and BCS methods; and put in the drying cabinet of the CSD and ISD dryers. The thermocouples and humidity sensors were remotely connected to the digital data loggers (model: CR-3000; supplier: Campbell Scientific Inc. Ltd, USA); and recorded data for the internal drying air temperatures and humidity, respectively. Mass of the fruit slices was measured using a digital weighing-scale (model: GX-4000; range: 0.01–4100g; accuracy: ±0.01g; supplier: A&D Co., Japan). The parameters were recorded every 30 min, and the measurements were continued until the drying samples attained a constant weight. The mass and moisture content (%) of the slice samples was estimated using the wet basis method (Wang et al., 2018; Wankhade et al., 2014).

2.4. Evaluating the organoleptic quality of the fruits

The organoleptic quality of the fresh fruit samples, as well as the samples dried under the five drying methods (OSD, WCS, BCS, CSD and ISD), was evaluated using a hedonic scale procedure (Civille and Carr, 2015). The sensory attributes of the dried fruits were assessed by a panel of 15 trained consumers and agro-processors purposively selected from a pool of traders in Tengeru market, Arusha. Ethical clearance was obtained from the local food and drug authority. The panellists include seven female and eight male evaluators aged between 20 and 55 years. The average age of the panellists was 38 years, with a standard deviation of 15 years. The number, sex and age bracket of the panellists were consistent with a standard panel of sensory food evaluators suggested recommended by Civille and Carr (2015). They suggested that a panel of 14 evaluators is enough to have reproducible results. The organoleptic quality attributes of the fruit samples evaluated were aroma, taste, colour and acceptability. Each of the panellists was randomly presented with the fresh, and dried fruit slice samples for evaluation and the scoring was based on the following nine points of the standard hedonic scale; 1 = dislike extremely; 2 = dislike very much; 3 = dislike moderately; 4 = dislike slightly; 5 = neither like nor dislike; 6 = like slightly; 7 = like moderately; 8 = like very much, and 9 = like extremely.

Figure 3, presents images of both the fresh and dried pineapples and mangoes.

Figure 3.

Images of the fresh and dried fruit (mango and pineapple) samples. Images of fresh (a), sliced (b) and dried (c) pineapples (cv. Smooth cayenne); Images of fresh (d), sliced (e) and dried (f) mangoes (cv. Dodo).

2.5. Evaluating the proximate and nutritional quality of the fruits

The proximate and nutritional composition parameters evaluated included the moisture content, dry matter, total carbohydrates, sugars, acidity and phenols; mineral content (phosphorus, calcium, iron, copper, zinc and manganese); and vitamins (vitamins A and C).

2.5.1. Evaluation of the moisture content and dry matter content

The moisture content of the dried fruit samples was estimated on a wet basis method (Wang et al., 2018; Wankhade et al., 2014). The initial (100g) and final masses of the fresh and dried fruit samples were determined, respectively using a digital weighing scale. The moisture was estimated was as the ratio equivalent of the difference in the initial and final mass of the fruit samples to 100 g of the fresh sample. The dry matter content of the samples was evaluated using the dry basis method following standard protocols described by the Association of Official Analytical Chemists (AOAC, 1995). Exactly 10 g of the samples were weighed and put in a porcelain crucible of known mass. The samples were dried to a constant mass in the oven set at 100 °C for 18 h. The mass of the dried fruits samples was taken for dry matter analysis using the AOAC procedure.

2.5.2. Determination of total carbohydrates

Carbohydrate content in the fresh and dried slice samples for both mangoes and pineapples were determined using the titrimetric method while following the standard AOAC procedures (AOAC, 1995). Exactly 5 g of both the fresh and dried slice samples were measured using the digital weighing scale. The samples were put in porcelain crucibles and mixed with 5 ml of 1M hydrochloric acid (HCl). The mixture was heated for 3–5 min to complete acid hydrolysis. About 20 ml of 2M NaOH (sodium hydroxide) was added, and the mixture was neutralized by addition of 10 ml of Fehling solution. A standard glucose (Sigma-Aldrich) solution was used to build calibration titrimetric points and curves (as the standards). The total carbohydrates content of the sample solutions were estimated and expressed as g of glucose equivalent per 100 g of the samples as guided by the standard calibration curves.

2.5.3. Determination of total sugars (or soluble carbohydrates)

The total sugar sugars (glucose, fructose and sucrose) content in the fresh and dried fruits (mangoes and pineapples) were analyzed using the high-performance liquid chromatography (HPLC) procedures while following the slight modifications outlined by Sadasivam and Manickam (1992).

Exactly 2 g of the fresh sample and that dried using the five drying methods (thus the OSD, WCS, BCS, CSD and ISD), were put in a beaker and were serially diluted with 700 μL of distilled and de-ionized water. Five 5 ml of 0.5M Sulphuric acid (H2SO4) was added to the sample solution followed by 20 ml of CH3CN (Acetonitrile of methanol). The solution was mixed to homogeneity for 1 h using a tissue homogenizer device and afterwards centrifuged for 15 min at 3 600 rpm. The supernatant was removed using a plastic syringe (of 10 ml) and the Whatman filter paper. An additional 1 ml of the supernatant was further filtered into the HPLC vial. The Vial was sealed with a septum and a plastic cup until the HPLC analyses were done.

The total sugar content was determined by injection of 20 μL of each sample solution into the HPLC using a LiChrospher 100-NH2 (5 μm; 4 × 4 mm pre-column; number: 1.50966.0001); together with the LiChrospher 100-NH2 (4 × 250 mm separation column; number: 50834.0001). The HPLC column temperature was using thermostat Jetstream-2 and maintained at 20 °C. A mobile phase consisting of 80:20 (V/v) of distilled water to acetonitrile solution was also maintained at a constant flow rate of 1 ml per minute.

2.5.4. Determination of total acidity

The total acidity was determined using a potentiometric titration method, where the acid content in the slice sample solutions was neutralized following protocols outlined by Polish (1990). Exactly 25 g of the mango and pineapple slide samples each dried using the five solar drying methods (OSD, WCS, BCS, CSD and ISD) were homogenized by crushing into powder using a blender. The homogenized mixture of the sample powder was put in a volumetric flask (of 250 cm3) and was diluted with distilled water up to the 250 cm3 mark. The mixture was boiled in a water bath for 30 min on a stove. Afterwards, the mixture was re-diluted with distilled water to the original 250 cm3 volume and was filtered using a Whatman filter paper. Exactly 25 ml of the filtrate was put in a beaker, and titrated with 0.1M NaOH solution at room temperature (of 26 °C). During titration, a glass electrode pH-meter was dipped into the solution, and the titration was stopped when a pH of 8.0 was achieved. The volume of the NaOH used corresponded to the total acidity of the sample, and the titrimetric values expressed as mmoles of acid per 100 g of the dried fruit products.

2.5.5. Determination of total phenol

The total phenolic content (TPC) from the mango and pineapple fruit samples were estimated using Folin–Ciocalteu procedure (Singleton et al., 1999); and gallic acid as the standard solution while following protocols outlined by the AOAC (1995). The mango and pineapple slice sample products dried using the OSD, WCS, BCS, CSD and ISD methods were homogenized by crushing them into powder form using the blender. The homogeneous samples were analyzed using an ultraviolet-visible spectrophotometer (model: Agilent Cary-60; Agilent Technology Co., Santa Clara, USA). The TPC in the homogeneous sample was extracted by shaking 0.5 g of the samples with 10 ml of methanol and HCl at concentrations of 50% and 1M, respectively for 30 min. The TPC extraction process was repeated twice and the resultant supernatants were combined into one beaker. The solution was filtered using the Whatman filter paper and the extracts were kept in the refrigerator which was kept at -20 °C until the samples were analyzed.

During analyses, 0.5 ml of the sample extracts were shaken with 2.5 ml of the Folin-Ciocalteu medium, and the solution was incubated at 37 °C in the oven for 1 min. The solution was mixed with 2 ml of 7.5 % Sodium carbonate solution. The resultant mixture was again incubated at 30 °C for 30 min, and absorbance readings of TPC of the samples were measured calorimetrically using the spectrophotometer machine. The spectrophotometer was set at 760 nm, and the TPC readings were measured against the standard calibration curves of the gallic acid. The TPC readings were expressed as mg of the gallic acid equivalents per 100 g of the fresh slice samples.

2.5.6. Determination of the mineral content

The phosphorus (P) content was determined using the spectrophotometer set at 420 nm, after treating the fruit samples with ammonium molybdate followed by ascorbic acid. Calcium (Ca) content was estimated using a flame photometer following the protocols outlined by Allen (1989). The micro-mineral elements namely; iron (Fe), copper (Cu), zinc (Zn) and manganese (Mn) were analyzed using device and method of an Atomic Absorption Spectrophotometer (AAS), following procedures described by Tee et al. (1996).

2.5.7. Determination of vitamin A

Vitamin A (or β-carotene) content was analyzed using a modified ultraviolet scanning method while following protocols described by Prior et al. (2005). The carotenoid content in the fresh and dried fruit samples was quantified by the KoneLab spectrophotometer; which was set at 450 nm. Sigma-Aldrich media were selected as the standard media for the β-carotene and were used to build the standard calibration curves for which the carotenoid levels in the samples were measured. The aggregate carotenoid content in the fresh and dried samples for the mango and pineapple slices was quantified as μg of β-carotene equivalent per 100 g of the fruit sample.

2.5.8. Determination of vitamin C

Vitamin C (L ascorbic acid) was determined using a colourimetric method (Ranganna, 1986). The mango and pineapple samples were mixed with 50 ml of 3% metaphosphoric acid (HPO3) and diluted with additional 50ml of HPO3. Each fruit sample mixture was homogenized using a tissue homogenizer (model: PT3100-D; Polytron, Switzerland). The slurry was centrifuged and filtered using Whatman-42 filter paper. Exactly 5 ml of the filtrate were mixed with 10 ml of 2,6-dichlorophenol-indophenol dye, and absorbance of the dye was measured by the spectrophotometer (model: SICAN-2301; Inkarp, India). The ascorbic acid (mg/100g of the sample solution) was estimated using Eq. (1).

| (1) |

2.6. Data analyses

Analyses of the sensory and nutritional parameters were performed in triplicates, and all data were analyzed using Analysis of Variance (ANOVA) in the GenStat software (Payne et al., 1995). A one-way ANOVA was used to compare means of the nutritional parameters between the drying methods. The means were separated using a Tukey's HSD test, and their statistical significance was determined at 5% (p < 0.05) level.

3. Results

3.1. Solar drying conditions for the mangoes and pineapples

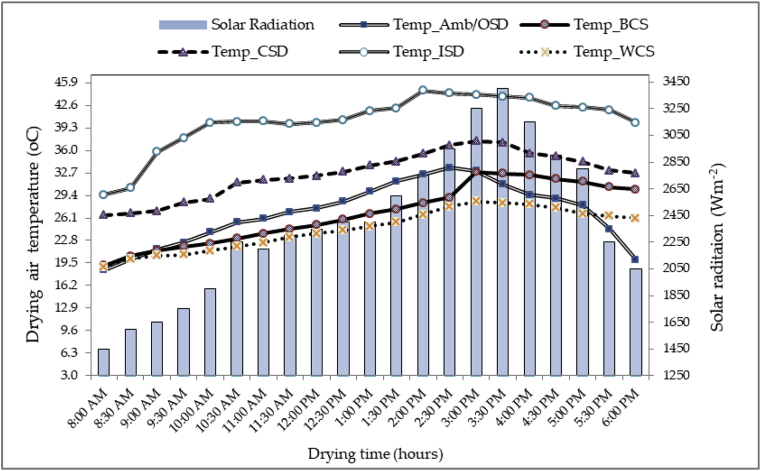

The solar drying experiments were performed out-door with mean daily temperature and relative humidity of 26.8 °C and 26.7%, respectively. Figure 4 presents the ambient solar radiation during the experiment run and drying air temperatures achieved by the five solar drying methods.

Figure 4.

Mean ambient solar thermal energy and drying air temperatures of the five local solar drying methods (OSD, BCS, WCS, CSD and ISD) at NM-AIST, Arusha, Tanzania.

The mean drying air temperatures for the OSD, BCS, WCS, CSD and ISD methods were 26.8, 26.7, 24.5, 32.6 and 40.3 °C; respectively (Figure 4). Results suggest that modifying the ISD by incorporating multiple metallic solar concentrators increases the drying air temperatures by 7.7 and 13.5 °C above that of the CSD and OSD methods, respectively.

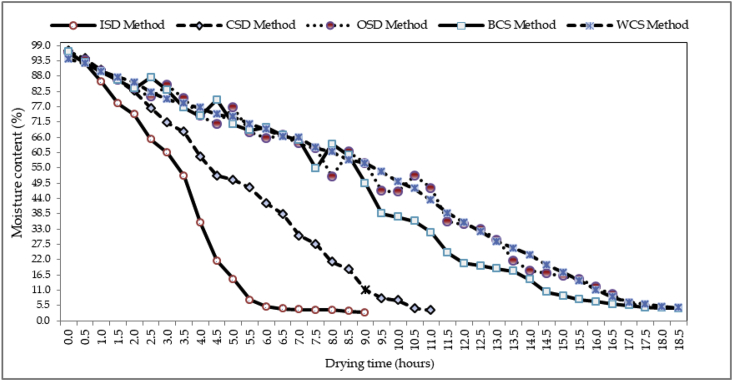

Figure 5 presents variations in the moisture content of the mango slices with drying time. It was observed that the mango slices put under the CSD and ISD methods dried faster than the slices dried under the OSD, BCS and WCS methods. On average, it took 6 and 9 h to dry the mango slices under the ISD and CSD methods respectively as compared to the 16 h taken by the OSD, BCS and WCS methods (Figure 5).

Figure 5.

Variation in the moisture content with drying time for the mango slices dried under the solar drying methods (OSD, BCS, WCS, CSD and ISD) at NM-AIST, Tanzania.

The rate of dehydration and quantity of moisture desiccated from mango samples dried under the OSD method was comparable to that of the BCS and WCS methods. Figure 6 shows the variations in the moisture content of the pineapples with drying time.

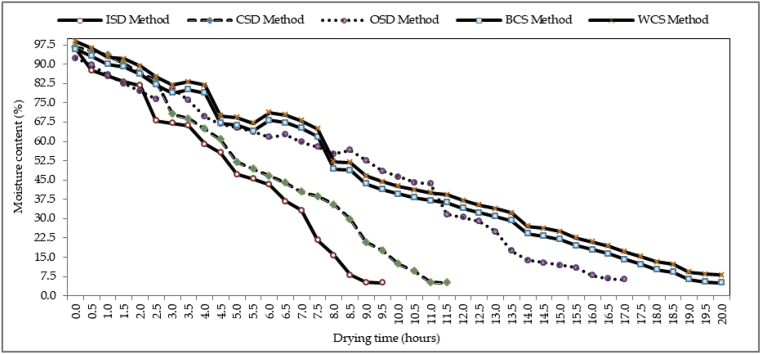

Figure 6.

Mean variations in the moisture content of the pineapples with drying time.

Like the mango fruits, it was observed that the pineapples slices put in the CSD and ISD methods dried faster than the slices dried under the OSD, BCS and WCS methods (Figure 6). But both the mango and pineapple fruits dried faster in the ISD method than the CSD methods, suggesting a better role of the proposed ISD dryer in accelerating the fruit drying process.

3.2. Organoleptic quality

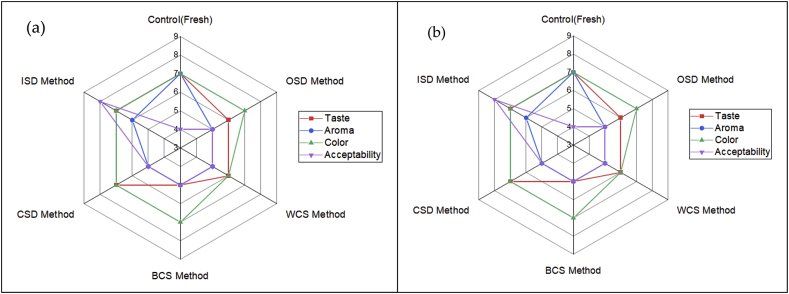

Evaluation of the organoleptic quality of the fresh and dried fruits was done based on the sensory attributes, namely taste, aroma, colour and acceptability. Figure 7 shows the average scores of organoleptic properties tested for the mango and pineapple fruits. The desirable organoleptic attributes of the dried fruit products significantly varied between the solar drying methods. Matching scores were got for both mangoes and pineapples. The mean rank of desirable organoleptic attributes for the mangoes and pineapples ranged from 4 (dislike slightly) to 9 (like extremely). The organoleptic attributes of the dried pineapple slices were scored higher than that of the fresh slices, with the highest acceptability scores for the products dried under the CSD and ISD methods (Figure 7b).

Figure 7.

A radar chart showing the average scores for the organoleptic attributes for the; (a) mangoes and (b) pineapple fruits. Values are means of ranks for the 15 panellist determinations of the desired organoleptic properties, namely taste, colour, aroma and acceptability of the dried products.

The average scores for the taste, aroma and colour of the mango products dried under the CSD and ISD methods were higher than those dried under the OSD, WCS and BCS methods (Figure 7a). The overall acceptability of the fresh mango slices was lower than that of the solar-dried slices, despite the component organoleptic attributes being scored high. However, the organoleptic attributes were highest in the mango and pineapple products dried under the ISD method, suggesting higher acceptability of the fruit products dried using the ISD dryer (Figure 7).

3.3. Nutritional quality of the fresh and dried fruits

Table 1 presents the proximate composition parameters for the fresh and dried mangoes and pineapples. There were significant (p < 0.05) variation in the concentration of the proximate parameters of the solar-dried fruit products between the five drying methods (Table 1).

Table 1.

Proximate composition of the mango and pineapples dried under the five solar drying methods at NM-AIST, Tanzania.

| Proximate parameters |

Fresh/raw (Control) |

OSD Method |

WCS Method |

BCS Method |

CSD Method |

ISD Method |

|---|---|---|---|---|---|---|

| Mangoes | ||||||

| Moisture content (g/100g) | 89.73 ± 1.12a | 84.55 ± 1.75b | 84.67 ± 1.75b | 84.77 ± 1.75b | 87.21 ± 1.78c | 89.43 ± 1.78d |

| Dry matter content (%) | 24.74 ± 0.3a | 27.6 ± 1.2b | 26.3 ± 1.2b | 26.1 ± 1.3b | 29.7 ± 1.5c | 34.5 ± 1.6d |

| Carbohydrates (g/100g) | 10.6 ± 0.5a | 11.7 ± 0.6b | 12.1 ± 0.6b | 12.2 ± 0.7b | 14.9 ± 0.4c | 16.5 ± 0.5d |

| Total sugars (g/100g) | 9.1 ± 0.3a | 9.2 ± 0.4b | 9.7 ± 0.4b | 9.8 ± 0.4b | 11.2 ± 0.6c | 14.3 ± 0.3d |

| Total acidity (%) | 0.53 ± 0.02a | 0.47 ± 0.05b | 0.43 ± 0.04b | 0.45 ± 0.03bc | 0.32 ± 0.03c | 0.24 ± 0.03d |

| Total Phenols (g/100g) | 0.85 ± 0.02a | 0.44 ± 0.06b | 0.46 ± 0.04b | 0.51 ± 0.04b | 0.72 ± 0.03c | 0.75 ± 0.03c |

|

Pineapples | ||||||

| Moisture content (g/100g) | 43.75 ± 0.72a | 45.85 ± 1.01b | 46.12 ± 1.05b | 46.45 ± 1.06b | 47.42 ± 1.11c | 48.98 ± 1.13d |

| Dry matter content (%) | 18.47 ± 0.1a | 23.6 ± 0.5b | 23.9 ± 0.6b | 24.1 ± 0.4b | 25.8 ± 0.3c | 26.9 ± 0.3d |

| Carbohydrates (g/100g) | 23.3 ± 0.2a | 24.4 ± 0.3b | 24.9 ± 0.4b | 25.3 ± 0.5b | 26.8 ± 0.5c | 27.9 ± 0.6d |

| Total sugar (g/100g) | 15.7 ± 0.1a | 16.8 ± 0.3b | 17.0 ± 0.3b | 17.4 ± 0.4b | 21.9 ± 0.3c | 24.2 ± 0.3d |

| Total acidity (%) | 3.4 ± 0.01a | 2.9 ± 0.01b | 2.8 ± 0.02b | 2.7 ± 0.01b | 2.3 ± 0.02c | 1.8 ± 0.02d |

| Total Phenols (g/100g) | 0.43 ± 0.02a | 0.30 ± 0.04b | 0.32 ± 0.03b | 0.31 ± 0.02b | 0.39 ± 0.02c | 0.41 ± 0.03b |

Values are the arithmetic means of measurements taken from three replicate fruit samples, with their corresponding standard errors (SE). The values per solar drying method (OSD, WCS, BCS, CSD and ISD) within the same row, followed by different alphabetical letters were significantly different (p < 0.05).

Irrespective of the drying method, the quantity of moisture dehydrated from both the mangoes and pineapples samples as well as the concentration of the dry matter content, carbohydrates and total sugars significantly (p < 0.05) increased in the dried products. The increase in the concentration of the dry matter content, carbohydrates and total sugars were more pronounced in the fruits dried using the improved solar drying (CSD and ISD) methods than the traditional solar drying methods (Table 1).

Conversely, the fruits dried under the OSD, WCS and BCS methods lost significantly (p < 0.05) higher quantities of total acidity and phenols than the CSD and ISD methods. And there was no significant (p > 0.05) variation in the concentration of the proximate composition of both the mango and pineapple samples dried under the OSD, WCS and BCS methods. All the proximate composition parameters for the mangoes and pineapples dried under the ISD method were significantly (p < 0.05) higher than the CSD method, suggesting an upgraded and superior capacity of the ISD in retaining the proximate content in the dried fruit (mango and pineapple) products.

Table 2 presents the mineral and vitamin composition of the fresh as well as the dried mango and pineapple samples. All the five solar drying methods caused a significant (p < 0.05) increase in the macro- and micro mineral elements of the dried mango and pineapple samples. There was no significant difference in the mineral gains between the OSD, WCS and BCS methods. The mineral content was higher in the fruit samples dried under the CSD and ISD dryers than the OSD, WCS and BCS methods. The relative increase in the concentration of the mineral content was significantly higher (p < 0.05) in the fruits dried under the ISD method than CSD method, further confirming the enhanced capacity of the proposed ISD dryer in retaining the mineral composition during the drying process (Table 2).

Table 2.

Mineral and vitamin content of the mango and pineapples dried under the five solar drying methods at NM-AIST, Tanzania.

| Nutritional parameters |

Fresh/raw (Control) |

OSD Method |

WCS Method |

BCS Method |

CSD dryer Method |

ISD dryer Method |

|---|---|---|---|---|---|---|

| Mangoes | ||||||

| Calcium (g/100g) | 8.48 ± 0.11a | 9.61 ± 0.12b | 9.78 ± 0.11b | 9.98 ± 0.12b | 11.61 ± 0.13c | 13.22 ± 0.14d |

| Phosphorus (g/100g) | 6.01 ± 0.11a | 6.52 ± 0.12b | 6.62 ± 0.13b | 6.69 ± 0.12b | 7.35 ± 0.13c | 7.99 ± 0.14d |

| Iron (g/100g) | 0.015 ± 0.005a | 0.053 ± 0.008b | 0.057 ± 0.007b | 0.059 ± 0.006b | 0.076 ± 0.010c | 0.083 ± 0.011d |

| Manganese (g/100g) | 0.008 ± 0.001 | 0.013 ± 0.005b | 0.017 ± 0.004b | 0.019 ± 0.003b | 0.026 ± 0.004b | 0.032 ± 0.005b |

| Zinc (g/100g) | 0.110 ± 0.002a | 0.133 ± 0.004b | 0.136 ± 0.003b | 0.139 ± 0.005b | 0.143 ± 0.007c | 0.162 ± 0.006d |

| Copper (g/100g) | 0.022 ± 0.005a | 0.026 ± 0.002b | 0.025 ± 0.001b | 0.028 ± 0.003b | 0.034 ± 0.004c | 0.039 ± 0.004c |

| Vitamin C (mg/100g) | 36.4 ± 0.3a | 27.5 ± 0.4b | 29.6 ± 0.5b | 30.6 ± 0.4b | 33.5 ± 0.5c | 35.6 ± 0.4a |

| Vitamin A (mg/100g) | 851±3a | 820±4b | 825±5b | 827±5b | 836±4c | 849±6a |

|

Pineapples | ||||||

| Calcium (g/100g) | 4.31 ± 0.13a | 5.21 ± 0.14b | 5.72 ± 0.15b | 5.98 ± 0.14b | 6.81 ± 0.16c | 8.02 ± 0.15d |

| Phosphorus (g/100g) | 4.03 ± 0.13a | 4.73 ± 0.11b | 4.67 ± 0.09b | 4.79 ± 0.11b | 5.25 ± 0.14c | 6.49 ± 0.14d |

| Iron (g/100g) | 0.145 ± 0.003a | 0.491 ± 0.002b | 0.498 ± 0.004b | 0.494 ± 0.003b | 0.523 ± 0.004c | 0.591 ± 0.006d |

| Manganese (g/100g) | 1.15 ± 0.03a | 1.52 ± 0.02b | 1.65 ± 0.04b | 1.66 ± 0.03b | 1.98 ± 0.05c | 2.31 ± 0.06d |

| Zinc (g/100g) | 0.051 ± 0.002a | 0.059 ± 0.004b | 0.058 ± 0.005b | 0.061 ± 0.005b | 0.763 ± 0.003c | 0.837 ± 0.005c |

| Copper (g/100g) | 0.124 ± 0.003b | 0.127 ± 0.002b | 0.129 ± 0.001b | 0.301 ± 0.002b | 0.347 ± 0.003c | 0.392 ± 0.003d |

| Vitamin C (mg/100g) | 23.4 ± 0.2a | 17.8 ± 0.2b | 17.9 ± 0.1b | 18.5 ± 0.2b | 19.9 ± 0.3c | 22.1 ± 0.2a |

| Vitamin A (mg/100g) | 11.8 ± 0.4a | 8.8 ± 0.5b | 9.2 ± 0.6b | 9.4 ± 0.5b | 10.5 ± 0.7a | 11.6 ± 0.8a |

Values are the arithmetic means of measurements taken from three replicate fruit samples, with their corresponding standard errors (SE). Values indicated were quantified on a wet basis. The values per solar drying method (OSD, WCS, BCS, CSD and ISD) within the same row, followed by different alphabetical letters were significantly different (p < 0.05).

All the solar drying methods caused significant (p < 0.05) reductions in the concentration of the vitamin content in the dried mango and pineapple products except for the ISD. The losses were less pronounced in the fruits dried under the improved solar drying (CSD and ISD) methods than the traditional solar drying methods. The decline in the vitamin content was not significantly (p > 0.05) different between the OSD, WCS and BCS methods. However, loss of vitamins was lower in the fruits dried using the ISD method than the CSD method, proposing better suitability of the ISD dryer in retaining volatile vitamins.

4. Discussion

4.1. The organoleptic quality of the fruit

Relative to the organoleptic quality attributes of the fresh mango and pineapple fruits, the solar-dried fruits were considered acceptable. The overall acceptability of the dried fruit products could have been influenced by the type of solar drying methods used. The results collaborate with the findings of Calín-Sánchez et al. (2013), who reported that, drying using improved and modern food drying technologies significantly improved the sensory properties of the pomegranate fruits. Elias et al. (2008) also reported that drying improved the taste and texture of the persimmons, and consequently influenced over 80% consumer acceptability of the dried fruit products.

However, the panellists were from diverse social settings and had limited exposure to the solar-dried fruits particularly the dried mango slices, which could have influenced their perception and assessed the overall acceptability of the dried mangoes as ‘dislike slightly’. The results are consistent with the findings of Owureku-Asare et al. (2017), who identified the knowledge, exposure and perceived quality as the leading social factors influencing consumer acceptability of the dried fruits. The higher organoleptic quality of the mangoes and pineapples dried under the CSD and ISD methods than the OSD, WCS and BCS methods was probably contributed by the better drying conditions mainly drying rate and uniformity. The transition from direct solar drying to solar dryers increases the drying air temperatures, thermal energy and drying rate of the fresh agro-produce (Hii et al., 2012; Kumar et al., 2016; Orphanides et al., 2016); which could have consequently improved the organoleptic quality of the dried mango and pineapple fruits.

4.2. The nutritional quality of the fruits

All the solar drying methods caused a significant increase in the concentration of the proximate composition of the dried mangoes and pineapples except for the hydrated moisture and phenolic content, and the increase could be associated with the fruit dehydration process. The increase in proximate composition was because all the solar drying processes, irrespective of the dryer modifications, cause considerable changes in biological, physical and chemical composition in all the fresh succulent fruit types including mangoes and pineapples (Hii et al., 2012; Kumar et al., 2016; Orphanides et al., 2016; Prakash et al., 2016). The relatively higher quantities of the proximate content in the fruits dried under the CSD and ISD methods than those dried under the OSD, WCS and BCS methods could be due to the increased temperatures and reduced drying times which have probably accelerated the fruit drying process. For instance, the increase in total acidity, carbohydrates and total sugars were probably caused by enhanced dehydration that led to the excessive moisture removal from the fruits, and this could have amplified the concentration effect of the proximate nutrients (Abrol et al., 2014). Similarly, Abrol et al. (2014) further attributed the increase in the total acidity of the dried fruits to the development of additional acids from the inter-conversion of soluble and related biochemical reactions of sugars.

Some phenols, including esters, have an aromatic ring with hydroxyl-substituents and are highly vulnerable to thermal and oxidative degradation (Bennett et al., 2011; Grajek and Anna, 2010). Therefore, substantial quantities of the phenols could have been lost from the mango and pineapple fruits during the preparation processes of peeling and slicing, since they were directly exposed to oxygen. The results are consistent with the findings of Grajek and Anna (2010) and Bennett et al. (2011), who also reported a high loss of phenols from the fruits due to increased oxidative degradation under oxygen during the peeling process. On the other hand, the higher loss of the total phenolic content from the fruit slices dried under the OSD, WCS and BCS methods than the slices dried under the CSD and ISD methods could have been caused by the prolonged solar drying process. This is so because, the prolonged fruit drying process causes additional loss of volatile nutrients from the dried fruits (Abrol et al., 2014). The results also collaborate the observations made by An et al. (2016) and Bennett et al. (2011); who observed significant reductions in the total phenolic content from the solar-dried fruits when subjected to the prolonged drying times. Additional loss of phenols could have also been caused by the direct exposure of the fruits to ultraviolet solar radiations and prolonged oxidation; as it was also the case for the same type of fruits solar-dried by Abrol et al. (2014), and Bennett et al. (2011).

Composition of mineral elements in the dried mangoes and pineapples increased in the five solar drying methods, and the increase could be linked to the excessive desiccation coupled with the ultimate substantial increase in dry matter content of the dried fruits. The high dehydration of the fruit slices to a moisture level of 10% or lower was probably the leading cause of the substantial increase in the dry matter and mineral content, as a result of enriched concentration-effect after the drying process (Abrol et al., 2014). The results further collaborated with findings of Suna et al. (2014), who reported strong positive correlation relationships between the dry matter and mineral elements, and the moisture content in different fruit types during and after the drying process.

The OSD method caused the highest loss of vitamins from the dried fruits, and this was probably because the fruits were fully exposed to uncontrolled thermal UV radiations during the open sun drying process. The vitamins (mostly vitamin A, B6 and C) in fruits are highly vulnerable to the UV radiations and oxidative damage, especially in the presence of moisture, metal ions and light (George et al., 2015; Li et al., 2017). The solar UV radiations stimulate the β-carotene oxidation process (George et al., 2015; Li et al., 2017); and was responsible for the loss of vitamins in the fruits samples.

The fruits dried under the OSD, WCS and BCS methods were slowly dehydrated and as such retained higher (above 16%) moisture content for a longer drying time during the drying process relative to the fruits dried under the CSD and ISD methods. Retention of higher moisture levels during the prolonged drying process could have also increased the loss of vitamins from the fruits dried under the OSD, WCS and BCS methods. This was so because maintaining the moisture content of fruits above 15% for an extended duration during drying catalyzes enzymatic reactions and related biochemical processes, which increase the loss of vitamins (Abrol et al., 2014; Grajek and Anna, 2010).

However, the drying cabinets of the CSD and ISD dryers were covered with UV-treated greenhouse material which screened out the thermal UV radiations, and simultaneously increased the internal temperatures of the drying air through the greenhouse effect (Chauhan and Kumar, 2016). Therefore, enclosing the drying cabinet with the specialized UV-treated greenhouse cover material also improved the fruit drying for the CSD and ISD dryers in terms of enhancing the nutrient retention and increasing the drying air temperatures.

5. Conclusion

A modified passive-mode solar dryer dubbed an ‘improved solar dryer (ISD)’ prototype was developed. In this study, the effects of using the traditional solar drying methods and the ISD on both the sensory quality attributes and nutritional content of dried fruit products were evaluated, using mangoes and pineapples.

Results show that the sensory quality attributes were better retained in the mango and pineapple products dried using the ISD dryer than that dried using the traditional solar drying methods. Correspondingly, the highest retention in the concentration of the nutritional content was attained in the mango and pineapple products dried using the ISD dryer than the fruit products dried using the traditional solar drying methods. Therefore, results confirm the superior role of the ISD dryer in retaining the sensory quality attributes and nutritional content of the dried fruit products.

The ISD technology is, therefore, recommended against the traditional solar drying methods. If successfully deployed, the ISD technology could serve to address the seasonality of fresh fruits and associated post-harvest losses of perishable horticultural produce through effective drying and value-addition. It could also increase the availability of dried food products in East Africa.

However, future efforts should be devoted to economic feasibility assessment to ascertain the cost implication vis-à-vis profitability; of replacing the traditional solar drying methods with the new ISD technology mainly within the resource-constrained farming communities in East Africa.

Declarations

Author contribution statement

Ssemwanga Mohammed: Conceived and designed the experiments; Performed the experiments; Wrote the paper.

Makule Edna: Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data.

Kayondo Siraj: Analyzed and interpreted the data.

Funding statement

This work was supported by DAAD/RUFORUM (Award No. 91635724).

Competing interest statement

The authors declare no conflict of interest.

Additional information

No additional information is available for this paper.

References

- Abrol G.S., Vaidya D., Sharma A., Sharma S. Effect of solar drying on Physico-chemical and antioxidant properties of mango, banana and papaya. Natl. Acad. Sci. Lett. 2014 [Google Scholar]

- Allen S. Chemical analysis of ecological materials. J. Geosci. Environ. Protect. 1989;3(9) Second Edition. Blackwell Scientific Publications, London. [Google Scholar]

- An K., Zhao D., Wang Z., Wu J., Xu Y., Xiao G. Comparison of different drying methods on Chinese ginger (Zingiber officinale Roscoe): changes in volatiles, chemical profile, antioxidant properties, and microstructure. Food Chem. 2016;197:1292–1300. doi: 10.1016/j.foodchem.2015.11.033. [DOI] [PubMed] [Google Scholar]

- AOAC . sixteenth ed. Vol. 2. AOAC (Association of Official Analytical Chemists) International; Arlington; USA: 1995. (Official Methods of Analysis of AOAC International). 1995. [Google Scholar]

- Bennett L.E., Jegasothy H., Konczak I., Frank D., Sudharmarajan S., Clingeleffer P.R. Total polyphenolics and anti-oxidant properties of selected dried fruits and relationships to drying conditions. J. Funct. Foods. 2011;3:115–124. [Google Scholar]

- Calín-Sánchez Á., Figiel A., Hernández F., Melgarejo P., Lech K., Carbonell-Barrachina Á.A. Chemical composition, antioxidant capacity, and sensory quality of pomegranate (Punica granatum L.) Arils and rind as affected by drying method. Food Bioprocess Technol. 2013 [Google Scholar]

- Chan C.W.E., Lye Y.P., Tan N.L., Eng Y.S., Tan P.Y., Wong C.Z. Effects of drying method and particle size on the antioxidant properties of leaves and teas of Morus alba, Lagerstroemia speciosa and Thunbergia laurifolia. Chem. Ind. Chem. Eng. Q./CICEQ. 2012;18:465–472. [Google Scholar]

- Chauhan P.S., Kumar A. Performance analysis of greenhouse dryer by using insulated north-wall under natural convection mode. Energy Rep. 2016;2:107–116. [Google Scholar]

- Chua K., Chou S. Low-cost drying methods for developing countries. Trends Food Sci. Technol. 2003;14:519–528. [Google Scholar]

- Civille G., Carr B. fifth ed. CRC Press; 2015. Sensory Evaluation Techniques. [Google Scholar]

- Elias N. de F., Berbert P.A., Molina M.A.B. de, Viana A.P., Dionello R.G., Queiroz V.A.V. Nutritional and sensory evaluation of Osmo-convective dried Fuyu persimmons. Ciência Tecnol. Aliment. 2008;28:322–328. [Google Scholar]

- Fanzo J. UNDP Africa Policy Notes; 2012. The Nutrition Challenge in Sub-saharan Africa.https://ideas.repec.org/p/rac/wpaper/2012-012.html [Google Scholar]

- George D.S., Razali Z., Santhirasegaram V., Somasundram C. Effects of ultraviolet light (UV-C) and heat treatment on the quality of fresh-cut Chokanan mango and Josephine pineapple. J. Food Sci. 2015;80:S426–S434. doi: 10.1111/1750-3841.12762. [DOI] [PubMed] [Google Scholar]

- Grajek W., Anna O. The influence of food processing and home cooking on the antioxidant stability in foods. Funct. Food Product Dev. 2010;178 [Google Scholar]

- Hii C.L., Jangam S.V., Ong S.P., Mujumdar A.S. first ed. TPR Group Publication; Singapore: 2012. Solar Drying: Fundamentals, Applications and Innovations. [Google Scholar]

- Immaculate J., Sinduja P., Jamila P. Biochemical and microbial qualities of Sardinella Fimbriata sun-dried in different methods. Int. Food Res. J. 2012;19:1699–1703. [Google Scholar]

- Jödicke K., Arendt S., Hofacker W., Speckle W. The influence of process parameters on the quality of dried agricultural products determined using the cumulated thermal load. Dry. Technol. 2019:1–12. [Google Scholar]

- Kumar M., Sansaniwal S.K., Khatak P. Progress in solar dryers for drying various commodities. Renew. Sustain. Energy Rev. 2016;55:346–360. [Google Scholar]

- Lamidi R.O., Jiang L., Pathare P.B., Wang Y.D., Roskilly A.P. Recent advances in sustainable drying of agricultural produce: a review. Appl. Energy. 2019;233–234:367–385. [Google Scholar]

- Li P., Yu X., Xu B. Effects of UV-C light exposure and refrigeration on phenolic and antioxidant Profiles of subtropical fruits (Litchi, Longan, and Rambutan) in different fruit forms. J. Food Qual. 2017;2017:1–12. [Google Scholar]

- Mead R. Chapman and Hall/CRC; 2017. Statistical Methods in Agriculture and Experimental Biology. [Google Scholar]

- Mozaffarian D. Dietary and policy priorities for cardiovascular disease, diabetes, and obesity: a comprehensive review. Am. Heart Assoc. 2016 doi: 10.1161/CIRCULATIONAHA.115.018585. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Orphanides A., Goulas V., Gekas V. Drying technologies: Vehicle to high-quality herbs. Food Eng. Rev. 2016;8:164–180. [Google Scholar]

- Owureku-Asare M., Ambrose R.P.K., Oduro I., Tortoe C., Saalia F.K. Consumer knowledge, preference, and perceived quality of dried tomato products in Ghana. Food Sci. Nutr. 2017 doi: 10.1002/fsn3.439. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Payne R.W., Lane P.W., Baird D.B., Harding S.A., Murray D.A., Morgan G.W., Todd A.D., Thompson R., Tunnicliffe Wilson G., Webster R., Welham S.J. Numerical Algorithms Group; 1995. Genstat 5 Release 3.2 Reference Summary; p. 147pp. [Google Scholar]

- Polish . 1990. Polish Norm PN-A-75101-04: 1990 the estimation of total acidity in fruits and vegetables. Polish Norm PN-A-75101-04 1, 3. [Google Scholar]

- Prakash O., Kumar A., Sharaf-Eldeen Y.I. Review on Indian solar drying status. Curr. Sustain./Renew. Energy Rep. 2016;3:113–120. [Google Scholar]

- Prior R.L., Wu X., Schaich K. Standardized methods for the determination of antioxidant capacity and phenolics in foods and dietary supplements. J. Agric. Food Chem. 2005;53:4290–4302. doi: 10.1021/jf0502698. [DOI] [PubMed] [Google Scholar]

- Ranganna S. 1986. Handbook of Analysis and Quality Control for Fruit and Vegetable Products. [Google Scholar]

- Ruel M., Minot N., Smith L. World Health Organisation (WHO); Geneva: 2005. Patterns and Determinants of Fruit and Vegetable Consumption in Sub-saharan Africa: a Multicountry Comparison. [Google Scholar]

- Sadasivam S., Manickam A. Biochemical Methods for Agricultural Sciences. 1992. Biochemical methods for agricultural sciences. [Google Scholar]

- Sagar V.R., Suresh Kumar P. Recent advances in drying and dehydration of fruits and vegetables: a review. J. Food Sci. Technol. 2010;47:15–26. doi: 10.1007/s13197-010-0010-8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Singleton V., Orthofer R., Lamuela-Raventos R. Analysis of total phenols and other oxidation substrates and oxidants by means of Folin-Ciocaulteau reagent. Methods Enzymol. 1999 [Google Scholar]

- Suna S., Tamer C., İnceday B., Sinir G., Çopur Ö. Impact of drying methods on physicochemical and sensory properties of apricot pestil. Indian J. Tradit. Knowl. 2014;13:47–55. [Google Scholar]

- Tee E.S., Kuladevan R., Young S.I., Khor S.C., Zakiyah H. Kuala Lumpur; Malaysia: 1996. Procedures for Estimating Nutrient Values for Food Composition Databases, Laboratory Procedures in the Nutrient Analysis of Foods. [Google Scholar]

- Tunçkal C., Coskun S., Doymaz I., Ergun E. Determination of sliced pineapple drying characteristics in A closed loop heat pump assisted drying system. Int. J. Renew. Energy Dev. 2018;7:35–41. [Google Scholar]

- Wang W., Li M., Hassanien R.H.E., Wang Y., Yang L. Thermal performance of indirect forced convection solar dryer and kinetics analysis of mango. Appl. Therm. Eng. 2018;134:310–321. [Google Scholar]

- Wankhade P., Sapkal D.R., Sapkal V. Design and performance evaluation of solar dryer. IOSR-J. Mech. Civil Eng. 2014 2278-1684. [Google Scholar]

- Wakholi C., Cho B.-K., Mo C., Kim M.S. Current state of Postharvest fruit and vegetable management in East Africa. J. Biosyst. Eng. 2015;40:238–249. [Google Scholar]

- Wills R., Golding J. UNSW Press; 2016. Postharvest: an Introduction to the Physiology and Handling of Fruit and Vegetables. [Google Scholar]