Abstract

This is the final article in a series of four articles on respirator history. This article continues to follow the history of respirator approval, use, and improvements in the U.S. as discussed in our article entitled, History of U.S. Respirator Approval, published in the ISRP Journal, Vol. 35, No. 1, 2018 (Spelce et al., 2018). This article is entirely about the history of respirators for protection against particulate hazards since the most extensive records available for the United States Bureau of Mines (USBM) approval schedules are for dust/fume/mist respirators.

Keywords: respirator approval, certification history, particulate respirator, air-purifying respirator, and dust/fume/mist respirator

INTRODUCTION

A formative event in the history of dust/fume/mist respirator approval regulations occurred in the early 1930’s. The Hawks Nest Tunnel disaster, a hydroelectric project near Gauley Bridge in West Virginia, drew national attention due to the injuries and deaths that occurred. This disaster was one of the worst industrial disasters in American history. According to available records, the tunneling construction site did not provide respirators to their workers. (Cherniack 1986) Because of their exposure to silica dust, many workers developed silicosis. For various reasons, definitive statistics as to the death toll from the Hawks Nest disaster were difficult to determine. Congressional hearings placed the death toll at 476 and other sources indicate a range from 700 to over 1,000 deaths amongst approximately 3,000 workers who worked underground.

This preventable tragedy hastened the promulgation of the United States Bureau of Mines (USBM) first dust/fume/mist (DFM) respirator approval standards codified in 30 CFR Part 14, Schedule 21 - Procedure for Testing Filter-Type Dust/Fume/Mist Respirators for Permissibility. (USBM 1934) “Considerable work was done by the Bureau of Mines in dispersoid (dust, fume, mist, and fog) respirators during 1925, and 1926, and further work was done in 1932, 1933, and 1934.” (Schrenk, H.H. 1940) By 1934, the Bureau had substantial expertise with respirator approval requirements having already established the core activities of the approval program for other respirator classes. The USBM had already developed standards for and approved oxygen breathing apparatus (1919), gas mask respirators (1919), and hose mask respirators (1927). By 1937, the Bureau expanded its schedule for testing hose masks to include a variety of supplied-air respirators including Type CE abrasive blasting respirator. (ibid.)

The most extensive records available from the approval schedules are for DFM respirators. The USBM published a number of Information Circulars and journal articles that described important principles and aims of the respirator approval program and performance requirements for these respirators. “To promote the development and manufacture of respiratory equipment of known good quality, the Bureau of Mines prepared what is considered to be minimum requirements for safe and durable equipment and devised methods for testing the devices for conformity to these requirements” (ibid.) They applied certain basic requirements to all types of respiratory equipment. “These requirements are as follows: (a) they must give adequate protection; (b) they must be reasonably comfortable and physically convenient to wear; (c) they must provide an acceptable period of protection; and (d) they must be constructed of durable materials.” (ibid.)

In an earlier publication, H.H. Schrenk noted “The general approval requirements are that the respirators must give adequate protection with reasonable comfort for a satisfactory period of time in any atmosphere for which they are designed. In addition to examining the respirator for design, durability, and practicability, three main tests are made to ascertain efficiency, resistance, and fit of the facepiece.” (Schrenk 1939) He pointed out that “The filtering-efficiency tests are based on the so-called safe or permissible limits. From data available, 1 milligram of silica dust per cubic meter, or approximately 8 million particles per cubic foot, is considered safe to breathe. Therefore, if the air passing through the respirator does not contain more than this amount, it is considered safe.” In other words, the permissibility of the respirator is based primarily on the amount of leakage and not on the relation between leakage and amount retained.” (ibid.)

The Bureau established laboratory tests to evaluate the effectiveness of the respirators for their intended purposes “….to reveal quality and performance under conditions that simulate those of actual use.” (Schrenk 1940) The following are two examples of such tests:

“Dispersoid (dust, fume, mist and fog) respirators are tested against relatively high concentrations of quartz dust, lead dust, chromic acid mist, siliceous mist, lead-paint mist, or lead fume, depending on the purpose for which the device is designed. The efficacy of a respirator is based not on the percentage efficiency but on the so-called permissible limits; that is, the leakage shall not exceed the amount considered safe to breathe. The device must have a reasonable service period before its resistance to a flow of 85 liters per minute exceeds 2 inches of water; that is, the filter must be able to retain considerable dust without undue increase in resistance.”

(ibid.)

Another USBM expert put the dust test concentrations and filter efficiency into its proper perspectives. “The term “efficiency,” as applied to filters for particulate matter, is meaningless unless the conditions under which efficiency is measured are strictly defined. To employ an example that has been used a number of times, “Chicken wire is 100 per cent efficient against chickens, but not against sparrows.” Hence, among other things, one should specify the size characteristics of the test aerosol. (Pearce 1958) The respirator service life was based on a test period under low and high dust concentrations to load (cake) the filter intentionally causing increased breathing resistance. “As the particulate matter is removed by the filter, plugging of the interstices of the filter occurs, and its efficiency increases. When a filter is tested against an aerosol in which the concentration of particulate matter is high enough to cause significant plugging of the filter, the efficiency changes from minute to minute. If the average efficiency is determined over a protracted period, this value would depend on the concentration of particulate matter and the rate at which it was drawn to the filter.” (ibid.) The USBM evaluated a prime factor limiting the actual use of a DFM respirator at a worksite - breathing resistance. Filter performance improves as the contaminant is collected by the filter; however it results in greater breathing resistance.

Schrenk described “The service life of a suitable mechanical-filter respirator, therefore, is not based on efficiency, but on resistance.” (Schrenk 1939) The USBM intended the respirator to give satisfactory service without cleaning or changing the filter for a period of about 8 hours. “In other words, the resistance of the respirator must not increase unduly before a reasonable amount of dust is retained.”

(ibid.)

“The dispersoid respirator is worn while coal dust is blown into the face. If no leakage occurs there is a sharp line of demarcation at the point of contact of the facepiece with the face.” (Schrenk 1940) This is shown in Figure 1.

Regarding testing with human subjects the Bureau stated, “The laboratory tests yield much valuable information, but the final decision depend on the performance of the device when worn by persons under actual conditions of use and in maximum concentrations of contaminants for which the device is approved or concentrations that are considered to give an adequate test of the efficacy of the device.” (ibid) They also reported, “The Man Tests not only check the efficiency of the apparatus but also give information on comfort, freedom of movement, field of vision, and practicability.”

(ibid.)

Figure 1.

Coal Dust Test

There are many references where the USBM considered an approved respirator safe for its intended use. One additional example to illustrate the purpose of an approval follows: “The Bureau of Mines has prepared, as circumstances have dictated, a series of schedules setting forth the minimum requirements that various types of equipment should meet to be considered safe and satisfactory for use under certain hazardous or unhealthful conditions.” (Pearce 1957)

30 CFR 14, SCHEDULE 21 OF 1934 – DUST/FUME/MIST RESPIRATORS

The USBM Schedule 21 established procedures for testing filter-type dust/fume/mist respirators. Mechanical-filter respirators operate by trapping particulate matter in the filter during inhalation (USBM, 1934). According to H.H. Schrenk, Chief Chemist, Health Division, USBM most of the first approved mechanical-filter respirators consisted of a suitable filter or fibrous material contained in a holder that connected directly to a half mask respirator. There were two types of filter elements or holders – those were the filter element attached to each side of the facepiece or a single filter attached to the front of the facepiece. Filter elements were designed to be readily removable for cleaning or replacement purposes. Inhalation and exhalation valves were not mandatory; however, most dust/fume/mist respirators at least had inhalation valves. Consensus at that time was that both inhalation and exhalation valves were desirable (Schrenk 1939).

Schedule 21 had been updated three times (i.e. 1955, 1965, and 1969) prior to inclusion into 30 CFR 11 along with the requirements for all other respirator classes. In 1917, a major landmark in the USBM’s history occurred when the Pittsburgh Mining Experiment Station was moved from Lawrenceville to the newly constructed Central Experiment Station at 4800 Forbes Avenue, Pittsburgh, PA. (CDC 2010). Certification testing for all Schedule 21 editions took place at this location (USBM 1934),

Schedule 21 described testing for the following types of dust/fume/mist respirators (USBM 1934).

Type A respirators protected against mechanically generated pneumoconiosis-producing dusts such as, free silica and asbestos, and nuisance dusts such as aluminum, iron ores and flour as produced in dust clouds from mining, quarrying and tunneling operations and various industrial grinding, crushing, and mineral processing.

Type B protected against fumes of metals, such as lead, manganese, copper, chromium, iron, antimony, and arsenic resulting from condensation of their vapor or from chemical reactions between their vapors and gases.

Type C protected against mists produced by spray painting, chromic acid mists from plating, and mists of other materials whose liquid did not produce harmful vapors.

Types AB, AC, etc. were combinations of Types A, B, and C.

Type D filters protected against dusts, fumes, and mist.

Figure 1 (courtesy of the National Institute for Occupational Safety and Health [NIOSH]) shows test subjects after participating in the Direct Leakage Man Test using coal dust as the challenge agent. This test consisted of three men with full, average, and lean facial features exercising in a room containing visible airborne powdered bituminous coal. During the 30-minute test, test subjects alternated between walking at 3.5 mph for five minutes and sitting for five minutes. At the end of the test, forced nasal discharge, sputum, nasal cavities, and the part of the face covered by the respirator must not show appreciably amounts of coal dust than similar observations made before testing.

Figure 1 illustrates the effects of face seal leakage by intentionally producing mask leaks by inserting toothpicks under the facepiece. If you look closely, you will see the streaking of coal dust on faces covered by the mask (Schrenk 1939). The men pictured on the right and left illustrate leakage at the places indicated by the white streaking lines that illustrate the streaming effects of severe leakage. The man in the middle of the photograph had a good face seal fit, since no particulate was streaming into his nostrils.

Mechanical airflow resistance testing occurred at 85 lpm (liters per minute) representing a very high breathing rate before and after each respirator performance test. Permissible levels of inhalation and exhalation breathing resistances varied depending upon the class of dust/fume/mist respirator. Laboratory tests were established to evaluate the effectiveness of the respirators for their intended purpose.

Respirators approved as Type A for dust were mechanically tested at a moderately high breathing rate of 32 lpm in an atmosphere with a geometric mean of 0.6 micron sized free silica produced from ground flint. There were two tests: High Dust and Low Dust Concentrations. The High Dust Test consisted of three respirators tested for three 30-minute periods in a 50±10 mg/m3 silica atmosphere. With the respirator facepiece sealed to a test fixture the penetration could not exceed 9 mg total for the three respirators or 4 mg for any of them. The Low Dust Concentration Test involved three respirators tested for two 156-minute periods in 5±2 mg/m3 silica atmosphere. Penetration could not exceed 30 mg total for the three respirators or 12 mg for any single respirator.

There were two types of Type B Fume Respirators; “Low Filter Plugging Fumes” and “Fast-Plugging Fumes.” Low Filter Plugging Fumes do not cause an appreciable increase in filter airflow resistance such as lead, manganese, copper, and chromium fumes. Mechanical Airflow Resistance Tests for these respirators took place in an atmosphere of 15±5 mg/m3 lead oxide fume, produced by decomposition and combustion of tetraethyl lead, at 32 lpm. Leakage in each respirator could not exceed 1.5 mg. Fast-Plugging Fumes such as magnesium, zinc, cadmium, aluminum, and antimony significantly increase filter resistance. Fast-Plugging Fume respirators had to pass the Low-Plugging Fumes Test plus an additional test. In this test, three respirators were tested at 32 lpm in 100±25 mg/m3 magnesium oxide produced from burning magnesium ribbon and continued until 200 mg magnesium oxide was pulled through their filters. Finally, they had to pass the Mechanical Airflow Resistance Test with maximum inhalation and exhalation resistances of 50 and 25 mm H2O, respectively.

Type C Mist respirators included three tests. The chromic acid mist test consisted of three respirators tested for two - 156-minute periods at 32 lpm in 15±5 mg/m3 chromic acid mist produced by electrolyzing an aqueous solution of chromic acid. Penetration could not exceed 1 mg for any respirator. Passing this test was required for a chromic acid mist approval. For approval as protection against all mists required passing the lead-paint mist, water mist carrying silica dust, and silica dust test. The lead-paint mist test required testing three respirators for two 156-minute periods at 32 lpm in 300 to 600 mg/m3 lead spray paint mist. Penetration could not exceed 1.5 mg lead for any respirator.

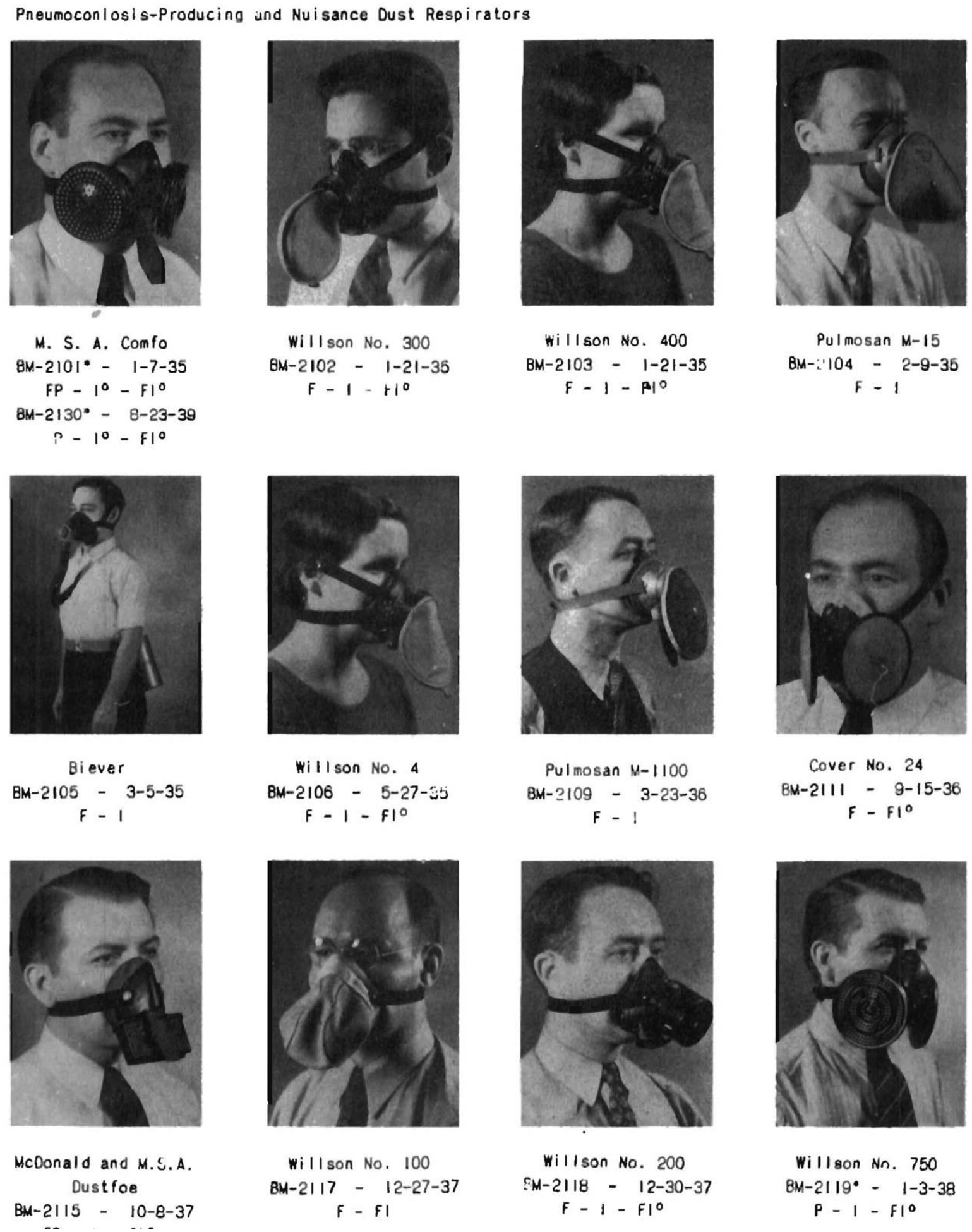

Similarly, the water-silica mist test entailed testing three respirators for two 156-minute periods at 32 lpm in 10±5 mg/m3 aqueous silica mist. Penetration could not exceed 5 mg silica for any respirator. A photo from the reference of the Wilson dust/mist respirator, BM-2146, stood out because of its beak-like appearance (Figure 2, photo from USBM 1943). Figure 3, includes photographs of some of the early-approved dust/fume/mist respirators (photographs from USBM 1943). The authors are fascinated by the extended exhalation valves on some of the respirators (such as the MSA Comfo and Pulmosan M-1100) and wondered what kind of sounds were emitted through these long valves (a kazoo or whoopee cushion comes to mind).

Figure 2.

Wilson BM-2146 Respirator

Figure 3.

USBM Schedule 21 Approved Respirators

30 CFR 14, SCHEDULE 21A OF 1955 – REVISED DUST/FUME/MIST RESPIRATORS

Revisions of Schedule 21 to Schedule 21A, under 30 CFR 14 occurred in 1955 and included approval criteria for respirators with single-use filters designed for disposal after use, and for reusable filters designed for reuse after cleaning per manufacturer’s instructions. There were two classes of respirators with single use or reusable filters (USBM 1955).

Approved for protection against pneumonoconiosis1 producing dust and nuisance dust but not for fumes.

Approved against dusts that were not more toxic than lead.

Approved respirators also provided protection against lead fumes, silica and chromic acid mists. Respirators with combination approval provided protection against various types of particulate matter.

Facepieces of all respirator categories had to pass a newly added pressure tightness test consisting of a panel of 15 to 20 men (requirement did not include women) having a variety of facial shapes and sizes. The pressure tightness test is a positive wearer seal check. The Occupational Safety and Health Administration (OSHA) currently requires performance of a user seal check (Z88.2–2015 uses the term wearer seal check) before each donning of a tight-fitting respirator.

Each respirator category also had to pass a modified Coal Dust Tightness Test, in which three men are exposed to a high concentration of coal dust blown gently into their breathing zone for a period of three minutes. To meet the requirements of this test, the forced nasal discharge at the end of the test period (as shown on a white cloth), the sputum, and the nasal cavities were examined by aid of a speculum and illumination and must not show appreciably more amounts of coal dust than similar observations made before testing. In addition, the part of the face covered by the facepiece of the respirator could not show appreciably more black particulate matter than similar observations made before the test.

Respirators approved as protection against fumes were equipped with organic vapor cartridges and 15 to 20 men had to pass an isoamyl acetate (banana oil) fit test. According to S.J. Pearce, Assistant Chief, Branch of Health Research, USBM (Pearce 1958):

The air in the test space may contain 100 p.p.m. of isoamyl acetate per million parts of air by volume. 1 per cent of ammonia, or 2 per cent of phosgene, depending on the facepiece being tested. Isoamyl acetate, in the above concentration, and 1 per cent ammonia give comparable results. That is, if the facepiece allows enough isoamyl acetate to leak into the breathing zone of the wearer to be faintly detectable by its odor, the wearer would be able to detect a faint odor of ammonia if he entered a 1 per cent ammonia-air mixture with an appropriate canister.

Thus, facepieces worn under the same conditions in 1 per cent (10,000 p.p.m.) of ammonia or 2 per cent (20,000 p.p.m.) of phosgene that would leak enough to allow ammonia or phosgene to be detected definitely by the wearer by odor would have efficiencies of 99.5 and 99.995 per cent, respectively. There is a widespread notion that eyeglasses or spectacles with metal temple pieces extending over and back of the ears can be worn with safety with gas-mask facepieces, especially if the temple pieces are flat and lie close to the wearer’s temples. Tests at the Bureau of Mines in a 1 per cent ammonia-air mixture have shown that none of the commercially available full facepieces can be worn with such spectacles without the wearer detecting a definite to strong odor of ammonia.

Following is a partial list of requirements that changed from the original version (Schedule 21 – 1934):

Exhalation valves were required, and inhalation valves were optional.

Added Pressure-Tightness Tests to assess the fitting characteristics of the respirator.

Revised the Direct Leakage and Man Test (coal dust test) by eliminating work exercises.

The high concentration silica dust defined the test period as one 90-minute test, not three 30-minute test periods.

Eliminated the low concentration Silica Dust Test.

Water Silica Mist and Chromic Acid Mist Tests defined the sampling period after 156 minutes and after 312 minutes, respectively.

Added a Lead Dust Test.

Eliminated the Lead Paint Test.

The information below provides details of further amendments to Schedules 21B in the 1965 and 1969 revisions.

30 CFR 14, SCHEDULE 21B OF 1965 – SECOND REVISION OF DUST/FUME/MIST RESPIRATORS

Publication of Schedule 21B in 1965 included classes of respirators based on the type of particulate matter they were designed to protect against. Schedule 21B proposed rulemaking notice, released October 1964, describes the purposes of changes to Schedule 21A (1955) including:

(1) Extend certification of approval to respirators designed to protect against dusts, fumes, and mists that are significantly more toxic than lead; (2) permit certification of combinations of dispersoid-filter and other types of respirators; (3) revise current tests to realize accuracy and speed of testing; and (4) revise the fees for inspection and testing (USBM, 1964).

The industrial use of extremely toxic particulates, such as beryllium, and the increasing use of radioactive materials, resulted in promulgation of Schedule 21B (Ferber 1966). In view of the increased use and reliability of ACGIH® threshold limit values (TLVs®). (ACGIH® and TLVs® are registered trademarks of the American Conference of Governmental Industrial Hygienists.), the terms million particles per cubic foot of air (mppcf) and milligrams per cubic meter (mg/m3) were introduced into a Bureau schedule for the first time in Schedule 21B (USBM, 1965). These two terms from the TLVs, used to define classes of particulate respirators, arose from the sampling methods used. If particle sampling required a midget impinger or Greenberg Smith Impinger, the analysis was done using a microscope equipped with a calibrated Porton graticule eyepiece to size and count the particles and results were reported as mppcf. In the other sampling method, results were obtained using an appropriate filter paper and an appropriately sensitive balance to weight the filter before and after sampling and measurements were reported as mg/m3. TLV descriptions were also added to various tests.

The following categories of respirators were approved as protection against dusts, fumes, or mists with threshold limit values (TLVs) greater than 0.1 mg/m3 or 2.4 mppcf. These respirators included:

dusts resulting principally from the disintegration of a solid, such as the dust clouds produced in various processes of mining, quarrying, and tunneling, and in various industrial operations, such as grinding, crushing, and general processing of minerals and other materials such as arsenic, cadmium, chromium, lead, manganese, aluminum, asbestos, coal, flour, iron ore, and free silica.

fumes resulting from sublimation or condensation of their respective vapors, or from the chemical reaction between their respective vapors and gases from various metals such as, aluminum, antimony, arsenic, cadmium, chromium, copper, iron, lead, magnesium, manganese, mercury (except mercury vapor), and zinc resulting from sublimation or condensation of their respective vapors, or from the chemical reaction between their respective vapors and gases.

mists produced in chromium plating and other mists of materials whose liquid vehicle does not produce harmful gases or vapors such as spray coating with vitreous enamels, chromic acid mist, as produced in chromium plating and other mists of materials whose liquid vehicle does not produce harmful gases or vapors.

and, respirators that are a combination of the preceding types of particulate matter.

Tests were similar to those of previous Schedule 21 versions but updated according to understandings of permissible levels of exposure, and experience gained from certification testing. For example, the Silica Dust Test broadened the relative humidity range, narrowed the suspension concentration in the Silica Dust Test to a range between 50 and 60 mg and the range of particle sizes to between 0.4 and 0.6 micron. It also reduced the amount of unretained test suspension (penetration) to a total of 4.5 mg from 9.0 mg for the three respirators and the amount of unretained test suspension to a total of 2 mg from 4 mg for a single respirator. The Lead Dust, Silica Mist, and Chromic Acid Mist Tests had similar changes.

The facepieces of all respirator classes had to pass a Pressure Tightness Test by a panel of 15 to 20 people having a variety of facial shapes and sizes. As mentioned in the last section, the Pressure Tightness Test is a positive facepiece wearer seal check. In addition, each respirator category had to pass the modified Coal Dust Tightness Test as described for Schedule 21A earlier in this article.

Schedule 21B also added a respirator class category for high efficiency particulate air (HEPA) filtering respirators. The first approved respirators with (HEPA filters provided protection against dusts, fumes, and mists for TLVs less than 0.1 mg/m3 or up to 10, 100, or 1,000 times the TLV for radionuclides, depending on the type of respiratory inlet covering (e.g., half-facepiece or full-facepiece). Filters had to be 99.97 percent efficient tested against 0.3 micron sized dioctyl phthalate (DOP). This DOP Filter Test had the same criteria as the DOP Test for HEPA filters set forth in 30 CFR Part 11, which was promulgated in 1972 (30 CFR Part 11 1972).

Certification testing included passing a 90-minute, Lead Dust, Lead Fume Test, and a Chromic Acid Mist Test. Respirators approved for protection against radionuclides2 had to pass a 0.2 micron uranine mechanical test. Uranine is a water-soluble yellow-green dye used to produce the test aerosol. Respirators approved for protection against radionuclides also had to pass facepiece tests which included isoamyl acetate fit tests and DOP quantitative fit tests. The National Toxicology Program, an interagency program within the U.S. Department of Health and Human Services, later found that DOP may be carcinogenic. Quantitative Fit Testing now routinely uses oils with similar properties such as polyethylene glycol (molecular weight 400) and corn oil.

To meet the requirements of both the Uranine Test and the DOP Test, the respirator had to perform according to the tolerances shown in Table I.

Table I.

Requirements for Uranine and DOP Chamber Tests

| Where the contaminant concentration does not exceed the TLV or concentration limits for the radionuclides involved by a factor of: | Maximum allowable penetration for a single respirator Percentage of ambient concentration |

Maximum allowable penetration for average of three test Percentage of ambient concentration |

|---|---|---|

| 10 | 1 | 0.5 |

| 100 | 1 | 0.5 |

| 1,000 | 0.1 | 0.05 |

There was an interesting requirement for HEPA filter respirators. In addition to the exhalation valve being protected against damage, they had to be provided with a dead-air space, or other means designed to prevent inward leakage of contaminated air during inhalation. Valve covers were required to provide dead-air space to trap the last portion of exhaled breath in the valve cover. During the next inhalation, any leakage around the exhalation valve could allow inhalation of this small pocket of exhaled air surrounding the exhalation valve instead of contaminated air. In contrast, if the exhalation valve cover were missing, the air immediately surrounding the valve could potentially be contaminated workplace air and inhaled if the valve did not close immediately after exhalation or allowed leakage. 30 CFR 11 changed this requirement to “Exhalation valves shall be … designed and constructed to prevent inward leakage of contaminated air.” (USBM 1972) This change has resulted in all respirators with exhalation valves having an exhalation valve cover.

While approval of HEPA filters first happened in 1965, in the early 1940’s Arthur D. Little designed the very first HEPA filter during the WW II, Manhattan Project. “Considering the condensation nuclei of radioactive iodine to be the most harmful, researchers focused on the ability to capture solid particles that were created by the condensation of gases and liquid aerosols into solid matter (Cvac 2017).” Under certain air velocity conditions, 0.3 micron is also a particle size that is the most difficult to remove by filtration (penetrates filters most easily).

30 CFR 14, AMENDED SCHEDULE 21B OF 1969 – THIRD REVISION OF DUST/FUME/AND MIST RESPIRATORS

On 19 June 1969, 30 CFR 14, Schedule 21B (USBM 1969) was updated to include approval of filters permissible for protection against radon daughters, and radon daughters attached to dusts. Added for this new respirator class were breathing resistance requirements. Respirators equipped with a canister, cartridge(s), or filter(s) not attached directly to the facepiece had the added requirement to have an inhalation valve(s) in the breathing system. The Coal Dust Tightness Test was also updated to again include Man Test exercises with specified protection factors.

This new class of respirators had to pass a 312-minute, Lead Fume Test. Radon is a radioactive gas, associated with underground mining industries, which decays into polonium, lead, and bismuth radioactive isotopes, which emit alpha particles. Radon daughter particles easily attach to airborne dust, smoke, and mist. When inhaled they are fine enough to reach the deepest sections of the lungs.

Maximum inhalation and exhalation pressures for other dust/fume/mist respirators were 50 and 20 mm H2O, respectively. However, respirators approved for radon daughters could not exceed 18 mm H2O inhalation pressure and the exhalation pressure could not exceed 15 mm H2O. The preamble to the updated Schedule 21B does not provide a rationale for the substantially reduced breathing resistances for radon daughter class of respirators. These reduced breathing resistance requirements may have considered the reduced pulmonary functions of some miners.

30 CFR PART 11 OF 1972 – INTEGRATION OF ALL RESPIRATOR APPROVAL SCHEDULES INTO A SINGLE RULE

Several significant national occupational safety and health improvements occurred in the late 1960’s and early 1970’s. This was an important period for the safety and health protection of workers. A summary follows:

1969 – Coal Mine Safety and Health Act of 1969 (Public Law 91–173, December 31, 1969).

Section 202(h), Section 204, requires mine operators (employers) to provide their employees with respirators jointly approved by the Secretary of Interior, and the Secretary of Health, Education, and Welfare (HEW).

Section 101(b), Requires that no improved mandatory health or safety standard promulgated under this Title (Title I General, Health and Safety Standards; Review) shall reduce the protection afforded miners below that provided by any mandatory health or safety standard.

1970 – Occupational Safety and Health Act [Williams-Steiger Occupational Safety and Health Act (OSH Act) of 1970, December] effective in 1971 established the Occupational Safety and Health Administration (OSHA).

This Act also established the National Institute for Occupational Safety and Health (NIOSH) as a research institute focused on the study of worker safety and health, and empowering employers and workers to create safe and healthy workplaces. NIOSH is part of the U.S. Centers for Disease Control and Prevention, in the U.S. Department of Health and Human Services.

1971 – 1973, 29 CFR 1910.134 paragraph (b) (11), OSHA required the implementation of a comprehensive respiratory protection program where respirator use is permissible and required respirators approved by either by U.S. Department of the Interior (DOI), Bureau of Mines and Department of Agriculture, (DOA) (OSHA 1971, 1973).

OSHA incorporated ANSI Z88.2 1969 Practices for Respiratory Protection.

OSHA adopted all of its startup standards, including about 425 workplace exposure limits for chemical substances with the majority based on the ACGIH’s TLVs for the year 1968.

NIOSH began planning for a Testing and Certification Laboratory (TCL) in Morgantown WV at the Appalachian Center for Occupational Safety and Health, Morgantown, WV. TCL and officially began operations in May 1972. By January 1974 there were 45 persons actively engaged in the testing and certification of respirators, detector tubes, coal mine personal dust samplers, lineman’s gloves, and safety toe shoes (NIOSH, 1975).

1970 – 1974, Transition of respirator approval program roles among DOI/USBM, DOA, Department of Health, Education, and Welfare / Bureau of Occupational Safety and Health (Federal Register, July 1970) and NIOSH (Federal Register, June 1971), DOI/Mining Enforcement and Safety Administration (MESA) associated with implementing national legislation and 30 CFR 11 (USBM, Schedule 21C, 1972).

March 1972 – 30 CFR 11 replaced 30 CFR 14 in March 1972, when NIOSH started jointly approving respirators with the USBM. Initially the USBM was responsible for respirator testing and application processing, and NIOSH was responsible for quality assurance and quality control. The previously separate respirator schedules for Self-Contained Breathing Apparatus (SCBAs), Airlines, Gas Masks, Chemical Cartridge Respirators, and dust/fume/mist respirators were included in separate subparts of 30 CFR 11 (USBM 1972). DOA pesticide respirator approvals were transferred into 30 CFR 11.

May 1972 – An Interagency memorandum of understanding between USBM and NIOSH defined their roles and transferred applications and testing to NIOSH, Morgantown, WV.

March 1973 – 30 CFR 11 officially changed the regulations, transferring testing and receipt of applications from the USBM, Pittsburgh, PA to NIOSH, Morgantown WV (NIOSH, 1975).

July 1973 – The Department of the Interior administratively established Mining Enforcement and Safety Administration (MESA) and delegated many of the functions previously assigned to the Secretary of the Interior under the Federal Coal Mine Safety and Health Act of 1969 including the respirator approval program to MESA. The respirator approvals were issued jointly by MESA/NIOSH (MSHA website). 1977 – Federal Mine Safety and Health Act [Pub. L. 91–173; Approved December 30, 1969; 83 Stat. 742]. MESA regulatory responsibilities were transferred to the Mine Safety and Health Administration (MSHA) under the U.S. Department of Labor. NIOSH and MSHA jointly issued respirator approvals.

30 CFR 11 approved several classes of dust/fume/mist respirators, radon daughters, and single-use respirators.

Approval of respirators continues in classes based on the concept of permissibility. 30 CFR 11 updated the TLV description for respirator classes again. For example: §11.130 (a) – “Respirators, either with replaceable or reusable filters designed as respiratory protection against dusts (1) having an air contamination level not less than 0.05 milligram per cubic meter of air, including but not limited to coal, arsenic, cadmium, chromium, lead, and manganese; or (2) dusts having an air contamination level not less than 2 million particles per cubic foot of air, including but not limited to aluminum, flour, iron ore, and free silica, resulting principally from the disintegration of a solid, e.g. dust clouds produced in mining, quarrying, and tunneling, and in dusts produced during industrial operations, such as grinding, crushing, and the general processing of minerals and other materials.”

Subpart E, §11.40 – 11.43 added extensive new quality control requirements.

The following requirements for inhalation and exhalation valves to be protected from distortion were added: exhalation valves would be: (1) provided where necessary; (2) protected against damage and external influence; and (3) designed and constructed to prevent inward leakage of contaminated air [§11.137].

§11.140–10 added an exhalation valve leakage test.

§11.140–5 added requirements for a single-use respirator class.

§11.140–9 updated breathing resistance limits and added breathing resistances for single-use respirators.

§11.2–1 eliminated the pressure tightness and Coal Dust Tightness Tests and replaced them with Z88.2–1969 Practices for Respiratory Protection that addressed selection, fit, use, and maintenance of approved respirators.

Also eliminated were the Lead Dust and Chromic Acid Mist Tests.

In §11.140–4, the Silica Dust Test reduced the amount of unretained test suspension from 2 to 1.5 mg for any single respirator. An efficiency was sometimes used in describing the performance differences among 30 CFR 11 approved respirator classes. Small changes in a respirator’s percentage efficiency occurred with regulatory reductions in the allowable unretained silica dust and silica mist. For illustrative purposes, the following shows the effect on respirator efficiency:

30 CFR 11 and Schedule 21B (1965) Silica Dust Tests both had an airflow of 32 lpm for 90 minutes. The total amount of air passing through the filter under this specification is 2880 liters (32 liters × 90 minutes) or 2.88 m3 of air.

30 CFR 11 and Schedule 21B had a test dust concentration of 50 to 60 mg/m3 test range. The respirator total exposure to dust at the test mid-range concentration, 55 mg/m3 is 158.4 mg (55 mg/m3 × 2.88 m3).

30 CFR 11 reduced the allowable unretained dust to 1.5 mg for a respirator. In Schedule 21B, the allowable unretained dust for the three respirators was 4.5 mg, or an average of 1.5 mg. Schedule 21B also had 2 mg allowable unretained dust for any single respirator which was changed in 30 CFR 11 to 1.5 mg. The following are sample calculations for these respirator efficiencies: 1) for both 30 CFR 11 and Schedule 21B, the 1.5 mg penetration through the respirator is 0.95% (1.5 mg/158.4 mg × 100). The respirator efficiency is 99.05% (100 – .95); and 2) for Schedule 21B with 2 mg penetration for any single respirator the penetration is 1.26% (2 mg/158.4 mg × 100); the respirator efficiency is 98.74% (100 – 1.26). The efficiency change associated with the reduction from 2 to 1.5 mg allowable unretained test suspension for a single respirator between 30 CFR 11 and Schedule 21B is 0.31% (99.05 – 98.74). Face seal leakage was not evaluated in the Silica Dust, Silica Mist, and Lead Fume Tests.

The TLV level used to describe classes of permissible dust/fume/mist respirator filters was changed. The level was reduced from not less than 0.1 mg/m3 or 2.4 mppcf to not less than 0.05 mg/m3 or 2 mppcf. Permissible Exposure Limits less than 0.05mg/m3 or 2 mppcf required HEPA filters.

High-Efficiency Particulate Air Respirators:

Approved respirators with HEPA filters provided protection against radionuclides.

HEPA filters had to be at least 99.97% efficient against 0.3 micron DOP particles and also tested against silica dust and mist.

Mechanical HEPA filters increase the surface area, usually by folding or pleating to reduce breathing resistance. Manufacturers had to ensure that this did not increase the breathing resistance. Because of increased breathing resistance, HEPA filters could not pass the low breathing resistance requirements for asbestos and radon daughter certification. These reduced breathing resistance requirements may have been established due to consideration of the pulmonary functions of miners. However, a 1980 OSHA memorandum allowed the use of respirators equipped with HEPA filters to be acceptable for protection against asbestos provided the maximum use concentration permitted in each class of respirator is not exceeded (OSHA 1980).

Radon Daughter Respirators - Respirators approved with dust/fume/mist filters for protection against radon daughters also had to pass the Silica Dust Test for lower breathing resistance requirements.

Respirators for Asbestos - Respirators approved with dust/mist filters for protection against asbestos had to meet the same lower breathing requirements as radon daughters.

Single-use Respirators – Single-use (were commonly referred to as disposable) respirators were approved for protection against pneumoconiosis- and fibrosis-producing dusts (Fibrosis is abnormal formation of fibrous (scar) tissue), or dusts and mists, including, but not limited to aluminum, asbestos, coal, flour, iron ore, and free silica. While some single-use respirators had approval for use with asbestos, the OSHA Asbestos Standards specifically prohibited using single-use dust respirators for asbestos work (OSHA 2019).

Single-use respirators had different Silica Dust Test and requirement. This respirator class had a permissible penetration of 1.8 mg compared to 1.5 mg for dust/mist respirators with replaceable filters. This respirator class had an airflow cycled through the respirator by a breathing machine at a rate of 24 respirations/minute with a minute volume of 40 liters using a breathing machine cam with a moderate workrate of 622 kg-m3/min. The Silica Dust Test aerosol particles size was 0.4 to 0.6 micron diameter. Approved single-use respirators allowed use of the filter until it became hard to breathe through, or damaged. Then the entire respirator needed to be discarded. The breathing resistances for this respirator class was also lower than that of a respirator with replaceable filters (i.e. inhalation resistance initial - 12 mmH20; inhalation resistance final – 15 mmH20; exhalation resistance – 15 mmH20).

42 CFR 84, 1995 – NIOSH RESPIRATOR CERTIFICATION PROCEDURES

30 CFR 11, dust/fume/mist respirator requirements were updated many times as described above. NIOSH funded and conducted research supporting the development of advanced instrumentation technology that had become commercially available to measure the instantaneous-penetration of most penetrating particle sizes. With this instrumentation, NIOSH proposed changes to the approval test philosophy and classification of dust/fume/mist respirators. In May 1994, NIOSH published proposed rules (59FR 26850) using this new technology (NIOSH 1994). The proposed rules would replace MSHA Mineral Resources requirements (30 CFR 11) with NIOSH Public Health requirements (42 CFR 84); incorporated a modular strategy for continuously updating approval standards; and update dust/fume/mist respirator testing and classification consistent with two decades of advances in respiratory protection technology. NIOSH stated “NIOSH had long been concerned with the health risks to workers due to the inappropriate selection and use of dust/mist and dust/mist/fume respirators.” (NIOSH 1994). NIOSH proposed tests based on new laboratory technology to “….eliminate the need to test and classify filter respirators according to composition of contaminant (e.g., “dust, fume, and mist”, “asbestos”), since the penetration rate for particulates in the atmosphere, regardless of composition, will not exceed that of the test particulate.” (ibid.). With the new test philosophy, approved respirators were also classified according to the filter’s demonstrated efficiency against most penetrating particles size (worst-case) laboratory aerosols. “To revise respirator nomenclature to be consistent with this fundamental change in certification philosophy, the words “dust, fume and mist” have been changed to particulate in the proposed rule.” (ibid.).

On 10 July 1995, the respirator certification regulation, 30 CFR 11, was replaced by 42 CFR 84 (NIOSH 1995). The primary regulatory changes introduced by 42 CFR 84 are associated with a new approval concept, performance requirements for particulate respirator filters, and instrumentation technology. 42 CFR 84 updated filter requirements and tests to provide an assessment of the effectiveness of the filter based upon its efficiency to remove particulates of the most penetrating size from the ambient air regardless of the particulate composition and toxicity (NIOSH, 1994). The approval philosophy for filters changed from minimum requirements considered safe to breathe for various types of dust/fume/mist respirators to acceptable filter efficiency levels against laboratory generated aerosols with particles of the most penetrating size. The classification of filters in this manner eliminated the need to test and classify the filter according to composition of the contaminant (e.g. dust, fume, pesticide, paint spray, etc.) since the penetration rate for particulates at a worksite, regardless of its composition, will not exceed that of the 42 CFR 84 aerosol and test conditions.

Since the new particulate filter tests were not designed to simulate loading of the filter at the worksite, 42 CFR 84 also revised airflow resistance requirements. The final rules apply airflow resistance requirements to the complete respirator at a rate of 85±2 lpm; 35 mm H2O inhalation and 25 H2O mm exhalation resistance. The final rule did not include final airflow resistances because filter loading and clogging experienced at actual worksites is not represented by the new tests (NIOSH, 1995).

Under 42 CFR 84, and a Memorandum of Understanding between NIOSH and MSHA, NIOSH exclusively approves all respirators except respirators used for mine emergencies, which continue to require joint approval by both NIOSH and MSHA. Except for the dust/fume/mist respirators described below, respirators approved before 10 July 1995 by NIOSH/MSHA that continue to be on the NIOSH Certified Equipment List still maintain their approval.

42 CFR 84 only updated the particulate, non-powered air-purifying class of respirators. Manufacturers could sell respirators with dust/fume/mist filters approved under Part 11 until 10 July 1998. Distributors and users could continue to sell and use Part 11 dust/fume/mist respirators until their supplies were exhausted. MSHA and OSHA permitted 30 CFR 11 approved respirator use until depleted (NIOSH, 1998).

Under 42 CFR 84, there are nine classifications of particulate air-purifying respirators. NIOSH currently certifies respirators under three series of filters: N, R, and P and three filter efficiency levels: 95, 99, and 100. The filter efficiencies relate to the percentage of particles removed from the air. For example, 95% efficiency means the filter removes 95% of the test particles and 5% of the test particles pass through the filter.

The P100 filters remove 99.97% of the challenge particles - not 100%. OSHA Respirator Standards consider N, R, and P 100 filters as HEPA filters. Healthcare facilities can use all nine classes as protection against TB.

Filters approved under 42 CFR 84 can be used without workplace particle size analysis because NIOSH filter testing criteria use a test aerosol with particles of the most penetrating size based on test conditions. This and the DOP aerosol degrading properties considered this as “worst-case” respirator test conditions. Criteria includes:

Using non-charged NaCl (sodium chloride) and DOP aerosols, which are very rigorous challenge agents for electrostatically charged filters;

Testing 20 filters;

Challenging the filters with very high airflow through the filters, which simulates an exceptionally high work rate of 85 liters/min for single filters and 42.5 liters/min per filter for pairs of filters;

Challenging the filters against a very high loading concentration - the challenge concentration is 200 mg/m3; and

Testing filters against 0.3 micron aerodynamic sized particles, which are in the range of the most filter penetrating sized aerosols (0.1 to 0.4 micron) under these test conditions.

P-series class of filters are largely defined by their minimal degradation in oil aerosols. Oil aerosols can degrade the efficiency of some electrostatically enhanced filters to capture particles. The definition of oils are hydrocarbon liquids with high boiling points, high molecular weights, and low vapor pressure. Oil aerosols can consist of mineral, vegetable, animal, and synthetic substances that are slippery, combustible, and soluble in organic solvents such as ether but not soluble in water. A partial list of filter degrading oils includes mist from the following oils: alboline, white mineral oil, bayol F, blandlub; drakeol, paraffin oil, liquid petrolatum, water-insoluble petroleum-based cutting oils, heat-treating oil, hydraulic oil, lubricating oil, drawing oil, crystol 325, cable oil, drawing oil, engine oil, heat-treating oils, dioctyl phthalate, corn oil, and transformer oil.

N-series filters are tested against a 0.3 micron aerodynamic sized NaCl aerosol with a 0.075 count median diameter (CMD). NaCl is mildly degrading to the filter when applied under test conditions. Experiments have shown that NaCl can have substantial temporary impact of the filter performance when intermittently loaded on a filter (Moyer 2000). 42 CFR 84 applies a continuous load of NaCl up to 200 mg during approval tests. N-series filters cannot be used in atmospheres containing oil aerosols. N-series filters have no service time limitation in most workplace settings. However, in high particulate concentrations, the user must prove that the integrity of the filters does not degrade or that the total mass loading of the filters is less than 200 mg in order to use beyond 8 hours (NIOSH Guide 1996).

R-series filters only have service time limitations when used as protection against oil degrading atmospheres. R-series filters cannot be extended beyond 8 hours of use in an oil aerosol atmosphere unless evaluated by the user to prove that the integrity of the filters does not degrade or that the total mass loading of the filters is less than 200 mg.

Testing of both R- and P-series filters occurs against a 0.3 micron sized DOP aerosol with a 0.185 MMAD.

Originally, use of approved P100 filters permitted use in oil degrading atmospheres and had no time limitations. However, NIOSH has since stated that prolonged oil exposure can result in a reduction in efficiency of P100 filters to efficiencies much less than P95 filters (NIOSH User Notice, 1997). NIOSH has requested each manufacturer of P100 filters establish service time recommendations as part of their user instructions.

The old approval number sequence under 30 CFR 11 for dust/fume/mist filters was TC-21C-XXXX and had the NIOSH/MSHA emblem. Particulate respirators approved under 42 CFR 84 have the approval number sequence of TC-84A-XXXX. All approval labels bear the NIOSH and Department of Health and Human Services emblem. Chemical cartridge and airline respirators that include particulate filter elements have labels indicating the new particulate filter classification, TC-84A.

Largely the certification testing for other respirator types is still the same as under 30 CFR 11. The 42 CFR 84 preamble states:

The new technical requirements of part 84 only address air-purifying respirators. Other classes of respirators, such as self-contained breathing apparatus, gas masks, etc., are not affected by the new filter penetration test requirements. Therefore, NIOSH intends to continue issuing new and extension of approval numbers in the same format designation (TC number) as issued under existing part 11 for those respirator types whose technical requirements for approval under part 84 have not been modified from existing part 11. A new approval number series will be initiated for the products whose technical requirements have been upgraded under part 84. By checking the approval number, respirator users will be able to quickly and easily distinguish those products that have demonstrated the improved performance requirements of the new part 84 from those that have demonstrated compliance with only the existing part 11 standards that are transferred to part 84.

SUMMARY AND FUTURE CHALLENGES

Particulate respirator testing and certification has greatly evolved improving the effectiveness of an approved respirator since it’s early inception in the USBM. Will existing respirator filter certification testing technology meet the challenges of the future, such as enhanced protection against nanoparticles? NIOSH has identified the potential hazards of occupational exposures to nanoparticles, which are very small (nearly atomic scale) with diameters less than 100 nm (<0.1 micron) in at least one dimension. Because of their small size, air sampling results indicating low mass concentrations contain greater numbers and larger surface area/unit mass of nanoparticles than for the same mass concentration of larger particles. In addition, nanoparticles may be more biologically reactive than larger particles of similar chemical composition because of their smaller, more lung penetrating size, and their increased surface area dose.

NIOSH is proactive and initiated a laboratory research program to better understand respirator performance against nanoparticles. NIOSH nanoparticle filtration research is ongoing and NIOSH has dedicated a website to post findings of this research as results become available. The authors anticipate that NIOSH may consider filter certification tests to include advancement such as:

More challenging cyclic flow rates;

Challenging filters during certification testing with the recently discovered most penetrating particle size (50 – 100 nm) instead of traditional 300 nm sized particles;

Confirming laboratory filter performance results in actual workplaces; and

Replacing forward light scattering photometry with ultrafine condensation particle counters that can detect filter particle penetration in the nano-size range.

Ultimately, the use of a NIOSH-approved respirator determines its effectiveness. A conforming respiratory protection program requires use of an approved respirator. OSHA, MSHA, DOE, other agencies and ANSI accredited standards development organizations, and approved standards (e.g. ASTM International, and F3387–2019) define respirator program requirements. Failure to select, fit, use and maintain respirators in accordance with these requirements will adversely impact the protection that the approved respirator can provide. Furthermore, failure to wear the proper approved respirator in a contaminated atmosphere for even a short duration when needed will substantially adversely affect the protection it can provide.

Acknowledgements

The authors thank NIOSH for providing many photographs of mining and respirators. Portions of this article were written by David Spelce while in an official capacity as a Department of the Navy employee.

Footnotes

Publisher's Disclaimer: Disclaimer

Publisher's Disclaimer: Mention of any company or product or photograph of product does not constitute endorsement by the authors. Instances of their use are to provide historical content and perspectives only.

Publisher's Disclaimer: The findings and conclusions in this report are those of the author(s) and do not necessarily represent the official position of the Centers for Disease Control and Prevention and National Institute for Occupational Safety and Health.

Pneumonoconiosis is a disease of the lungs caused by the habitual inhalation of mineral or metallic particles.

Radionuclides are isotopes that emit radiation resulting in formation of new nuclides. Examples include uranium and thorium.

REFERENCES

- CDC, Information Circular 9520 One Hundred Years of Federal Mining Safety and Health Research, https://www.cdc.gov/niosh/mining/UserFiles/works/pdfs/2010-128.pdf, site visited December 18 2019

- CDC, History of the Mining Program, https://www.cdc.gov/niosh/mining/content/history.html, site visited February 20, 2019.

- Cherniack M [1986]. The Hawk’s Nest Incident America’s Worst Industrial Disaster. New Haven and London: Yale University Press. [Google Scholar]

- Cvac Quality HEPA Replacements for vacuum Cleaner Filtration. http://www.c-vac.com/history.html site visited August 30, 2017.

- Federal Register Volume 35, Number 133, Friday, July 10, 1970.

- Federal Register Volume 36, Number 126, Wednesday, June 30, 1971.

- Ferber BI, Bureau of Mines Respirator Approval Schedules: new and Revised; AIHA Journal Article (J27, 110 to 114) 1966 [DOI] [PubMed]

- Moyer ES and Bergman MS Applied Occupational and Environmental Hygiene, 15:8, 600–608, Electrostatic N95 Respirator Filter Media Efficiency Degradation Resulting Intermittent Sodium Chloride Aerosol Exposure. 2000. [DOI] [PubMed] [Google Scholar]

- MSHA Legislative History of U.S. Mine Safety and Health. https://www.msha.gov/about/history site visited March 25, 2019.

- National Institute for Occupational Safety and Health (NIOSH). (1994) Respiratory Protective Devices; Proposed Rule, Federal Register, Vol. 59, No. 99, 42 C.F.R. Sect. 84, May 1994 [PubMed] [Google Scholar]

- National Institute for Occupational Safety and Health (NIOSH). NIOSH Guide to the Selection and Use of Particulate Respirators Certified Under 42 CFR 84. DHHS (NIOSH) Pub. No. 96–101. Cincinnati, Ohio: NIOSH, 8 June 1995. [Google Scholar]

- National Institute for Occupational Safety and Health (NIOSH) NIOSH Guide to the Selection and Use of particulate Respirators certified under 42 CFR 84, DHHS (NIOSH) Publication No. 96–101, January 1996

- National Institute for Occupational Safety and Health (NIOSH). NIOSH Respirator User Notices, Differences and Limitations Between Part 11 Particulate Respirators and Part 84 Particulate Respirators, June 20, 1996.

- National Institute for Occupational Safety and Health (NIOSH). Respirator User Notice, Letter to All Users of P-Series Particulate Respirators - NIOSH Service Time Recommendations for P-Series Particulate Respirators, 1997.

- OSHA - U.S. Department of Labor Occupational Safety and Health Administration. Memorandum FOR Regional Administrators. Respirator Selection. December 1980

- OSHA: 29 CFR 1910.1001 Asbestos. Federal Register 21458. Washington, D.C.: U.S. Government Printing Office, Office of the Federal Register, last amended May 14, 2019. [Google Scholar]

- NIOSH. (1998) Clarification of the phase-out of 30 CFR 11-approved respirators with particulate filters, Letter to All Manufacturers, July 30, 1998.

- Pearce SJ, United States Department of Interior - Bureau of Mines. Bureau of Mines Approval System for Respiratory Protective Devices, Information Circular 7792 (Revision of I.C. 7600). June 1957

- Pearce SJ, A Discussion of the Bureau of Mines Approval Schedules for Respiratory Protective Devices, American Industrial Hygiene Association Journal, 19:2, 126–129, 1958 [DOI] [PubMed] [Google Scholar]

- Schrenk HH United States Department of the Interior – Bureau of Mines. Information Circular 7086, Testing Respiratory Protective Equipment for Approval. August 1939.

- Schrenk HH United States Department of the Interior – Bureau of Mines. Information Circular 7130, Testing Respiratory Protective Equipment for Approval. August 1940.

- Spelce D, Rehak TR, Metzler RW, Johnson JS. (2018) History of U.S. Respirator Approval, Journal of the International Society of Respiratory Protection (ISRP), 35 No. 1. [PMC free article] [PubMed] [Google Scholar]

- United States Department of the Interior – Bureau of Mines. Procedures for Testing Filter-Type Dust, Fume, Mist Respirators for Permissibility, 30 CFR Part 14 - Procedure for Testing Filter-Type DUST, Fume, and Mist Respirators For Permissibility Schedule 21, 20 August 1934.

- United States Department of the Interior – Bureau of Mines. Information Circular 7237. List of Respiratory Protective Devices Approved by The Bureau Of Mines, March 1943.

- United States Department of the Interior – Bureau of Mines. Procedures for Testing Filter-Type Dust, Fume, Mist Respirators for Permissibility, 30 CFR PART 14 - Filter Type, Dust, Fume, and Mist Respirators, Schedule 21A, April 19, 1955.

- United States Department of the Interior – Bureau of Mines. 30 CFR Part 14 Filter-Type Dust, Fume, and Mist, Proposed Rulemaking, Federal Register Wednesday October 7, 1964, pages 13822–13827.

- United States Department of the Interior – Bureau of Mines. Procedures for Testing Filter-Type Dust, Fume, Mist Respirators for Permissibility, 30 CFR PART 14 - Filter Type, Dust, Fume, and Mist Respirators, Schedule 21B, January 19, 1965, Amended March 23, 1965.

- United States Department of the Interior – Bureau of Mines. Procedures for Testing Filter-Type Dust, Fume, Mist Respirators for Permissibility, 30 CFR PART 14 - Filter Type, Dust, Fume, and Mist Respirators, Schedule 21B, 19 June 1969

- United States Department of the Interior–Bureau of Mines. 30 CFR – PART 11 – Respiratory Protective Devices, Test for Permissibility and Fees; Part 12 – Supplied-Air Respirators; Part 13 – Gas Masks; Part 14 – Filter-Type Dust, Fume, and Mist Respirators; Part 14a – Nonemergency Gas Respirators Chemical Cartridge, including Paint spray Respirators, 25 March 1972.