Abstract

A simple reverse phase liquid chromatographic gradient method has been developed and validated for the simultaneous determination of specified & un-specified impurities of Telmisartan and Hydrochlorothiazide in combination oral solid dosage forms. The developed method is effective to separate a total of sixteen (16) peaks and quantify eleven (11) specified impurities of Telmisartan and three (3) specified impurities of Hydrochlorothiazide with a minimum chromatographic resolution of 2.5. The separation was acquired with Inertsil ODS-3V, 150 × 4.6 mm, 3.5 μm column at a flow rate of 1.0 mL min-1 with the mobile phase-A consists of 0.02 M potassium dihydrogen phosphate (pH of 3.5) and mobile phase-B consists of a mixture of Milli-Q water and acetonitrile (100: 900 v/v) respectively. The detection of impurities was carried out at 230 nm and column temperature was maintained at 40 °C. Further optimized chromatographic conditions were applied to design of experiments to find out the critical quality attributes and established the design space. The binary combination of drug product was subjected to the different stress conditions such as acid, base, oxidation, heat and photolysis as per the recommendations of international conference on harmonization (Q2). The degradation Product found in stress patterns are well separated among main analyte compounds. The method was validated to be specific, robust and rugged in terms of change of chromatographic, instrumental and technical variables.

Keywords: Analytical quality by design, Design of experiments, Telmisartan, Hydrochlorothiazide, Solid dosage form, HPLC-UV, Stability indicating

Graphical abstract

1. Introduction

The multi component dosage forms has lot of importance due to greater patients acceptability, multiple action and quick relief from the multi-disease. Telmisartan (TMS) is an angiotension receptor blocker that shows high affinity from the angiotensin II type 1-receptors, has a long duration of action, and has the longest half-life of an ARB. In addition to blocking the Renin-Angiotensin System (RAS), TMS acts as a selective modulator of Peroxisome proliferator-activated receptor gamma (PPAR-γ), a central regulator of insulin and glucose metabolism. Hydrochlorothiazide (HCZ) is a diuretic (water pill) drug that help to control blood pressure by getting rid of excess salt and water. In the present study, TMS and HCZ in a bilayer tablet formulation was used to evaluate the chromatographic separation of TMS, HCZ and its related impurities..

TMS, a non-peptide molecule, is chemically described as 4’-[(1, 4′-dimethyl-2′-propyl [2, 6′-bi-1Hbenzimidazol]-1′-yl) methyl]-[1, 1′-biphenyl]-2-carboxylic acid and empirical formula is C33H30N4O2. TMS has a pKa of 6 and practically insoluble in water and in the pH range of 3–9, sparingly soluble in strong acid (except insoluble in hydrochloric acid), soluble in strong base (e.g. Sodium hydroxide - about 12 mg mL-1), slightly soluble in methanol, sparingly soluble in methylene chloride [1].

HCZ is chemically described as 6-chloro-3, 4-dihydro-2H-1, 2, 4-benzothiadiazine-7 sulfonamide 1,1-dioxide and empirical formula is C7H8ClN3O4S2. HCZ is a white, or practically white, practically odorless, crystalline powder. It has a pKa of 7.9 and the solubility in water is about 0.7 mg mL-1 and freely soluble in sodium hydroxide solution [1]. The structures of HCZ and TMS compounds with specified impurities are shown in Fig. 1. The immediate release tablets required a hydrophilic and hydrophobic excipient to enhance the disintegration and flowability of powder. Lubricant like magnesium stearate excipients influence the extraction of test solution. All these inactive ingredients influence the actual selectivity of the HPLC method development during in-vitro determinations and stability studies.

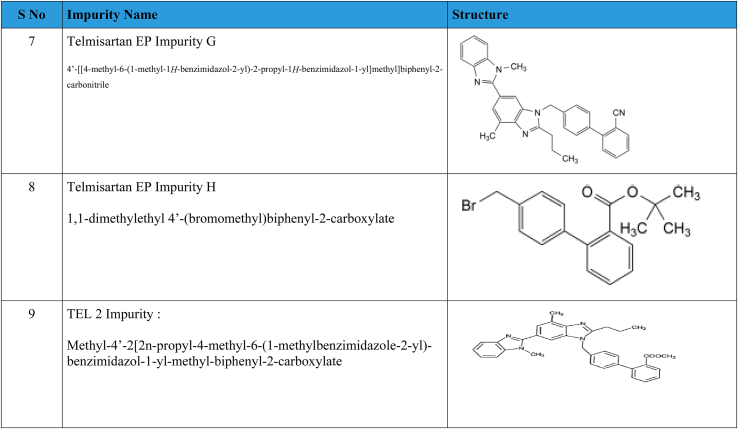

Fig. 1.

Chemical Structures of TMS, HCZ and its impurities.

Literature reveals various HPLC methods have been reported with human plasma and with the combination of other active drug compounds [[2], [3], [4], [5], [6], [7], [8], [9]]. Very limited methods have been reported for the quantification impurities of TMS alone or with combination of TMS and HCZ impurities [[10], [11], [12]]. The selectivity and sensitivity were not effective in the listed articles in terms of impurities evaluations. In the published literature, none of these methods that were found relevant to the application of estimation of all possible relevant impurities. There was only one method [13] is published with 9 impurities (7 impurities of TMS, 2 impurities of HCZ) which did not report 4 other process degradant impurities of the active drug substance. From the overall literature, there was no method which can determine the stated impurities of the both active components including the process degradant impurities of the active drug components. Hence, we developed and validated a unique harmonized stability indicating method [[14], [15], [16], [17], [18], [19], [20], [21], [22], [23], [24]] for specific determination of listed related compounds of TMS and HCTZ simultaneously in drug substance and drug product tablet dosage form.

2. Materials and methods

2.1. Chemicals and reagents

TMS (purity-99.2%) and impurities are TMS-EP-A, TMS-EP-B, TMS-EP-C, TMS-EP-D, TMS-EP-E, TMS-EP-F, TMS-EP-G and TMS-EP-H official in European Pharmacopoeia. TMS-EP-C is a process related impurity and TMS-EP-D is unspecified impurity. Chloro analogue, Diacid and TEL-2/TMS-2 are API process impurities. TMS-EP-A, TMS-EP-B, Chloro analogue, Diacid and TMS-2 are obtained from Dr. Reddy’s laboratories Ltd. Potassium dihydrogen phosphate AR Grade-Merck (India) limited. HCZ (purity-99.5%), Chlorothiazide (CTZ) and Disulphonamide (DSA), TMS-EP-E and TMS-EP-F are obtained from Synpure Laboratories.

All other chemicals and solvents used as Analytical/HPLC grade. The analysis was carried out on Waters Alliance HPLC systems 2695 separation module connected to 2996 Photo diode array detector. Data acquisition was carried out using Empower software. Different chromatographic columns used during initial method optimization viz. Kromosil C18, 125 × 4.0 mm, 5 μm, Waters Symmetry Shield RP-18, 250 × 4.6 mm, 5 μm and Inertsil ODS 3 V, 150 × 4.6 mm, 3.5 μm (make-GL Sciences).

2.2. Chromatographic conditions

The separation of TMS, HCZ and all related impurities were achieved using 20 mM Potassium dihydrogen phosphate buffer, pH adjusted to 3.5 using 1% Ortho phosphoric acid solution as mobile phase-A. Purified water and acetonitrile in the ratio of 100:900 as mobile phase–B at a flow rate of 1.0 mL/min with a gradient elution method (For Gradient proportions, refer Table 1). Detection and purity establishment of the main drug and impurities were achieved using photo diode array (PDA) detector at 230 nm with an injection volume of 10 μL and column temperature is 40 °C. The run time optimized was found to be 65 min.

Table 1.

Gradient program.

| Time (Min) | % A | % B |

|---|---|---|

| 0 | 85 | 15 |

| 2 | 85 | 15 |

| 12 | 65 | 35 |

| 30 | 50 | 50 |

| 40 | 40 | 60 |

| 50 | 20 | 80 |

| 51 | 0 | 100 |

| 60 | 0 | 100 |

| 61 | 85 | 15 |

| 65 | 85 | 15 |

2.3. Standard preparation (0.3%)

The dilute standard solution for TMS and HCZ was prepared with diluent to obtain a concentration of 1.5 μg/mL and 0.6 μg/mL, respectively. Representative chromatograms of the blank and standard preparation were shown in Fig. 2, Fig. 3A, Fig. 3B. The system suitability and chromatographic evaluation is represented in Table 2.

Fig. 2.

Blank Chromatogram.

Legend: Flow rate 1.0 mL/min, UV Wavelength 230 nm; injection volume 10 μL; Column temperature 30°C; Gradient Elution; Run time: 65 min.

Fig. 3A.

Diluted standard chromatogram.

Legend: Flow rate 1.0 mL/min, UV Wavelength 230 nm; injection volume 10 μL; Column temperature 30°C; Gradient Elution; Run time: 65 min.

Fig. 3B.

Telmisartan EP CRS solution chromatogram.

Legend: Flow rate 1.0 mL/min, UV Wavelength 230 nm; injection volume 10 μL; Column temperature 30°C; Gradient Elution; Run time: 65 min.

Table 2.

Relative response factors (RRF) for quantitative chromatography.

| S No | Compound Name | RRT | RRF | Resolution | Tailing Factor |

|---|---|---|---|---|---|

| 1 | DSAa | 0.82 | 0.75 | – | 1.2 |

| 2 | CTZa | 0.90 | 1.04 | 2.6 | 1.2 |

| 3 | HCTZ | 1.00 | 1.00 | 2.2 | 1.1 |

| 4 | TMS-EP-Ab | 0.37 | 1.27 | 9.5 | 1.1 |

| 5 | TMS-EP-Eb | 0.67 | 0.96 | 36.4 | 1.1 |

| 6 | TMS-EP-Fb | 0.76 | 0.89 | 8.5 | 1.1 |

| 7 | TMS-EP-Bb | 0.85 | 0.80 | 7.6 | 1.1 |

| 8 | TMS | 1.00 | 1.00 | 8.7 | 1.1 |

| 9 | TMS-EP-Gb | 1.10 | 0.83 | 6.9 | 1.1 |

| 10 | TEL2b | 1.17 | 0.71 | 5.0 | 1.1 |

| 11 | Dimer acidb | 1.40 | 0.85 | 16.4 | 1.2 |

| 12 | TMS-EP-Cb | 1.50 | 0.62 | 5.5 | 1.0 |

| 13 | Chloroanalogb | 1.54 | 0.94 | 3.1 | 1.1 |

| 14 | TEL1b | 1.62 | 1.32 | 6.2 | 1.1 |

| 15 | TMS-EP-Hb | 1.77 | 1.10 | 18.1 | 1.0 |

Relative Retention Time (RRT) and RRF with respect to HCTZ peak.

RRT and RRF with respect to TMS peak.

2.4. Sample preparation

The drug samples and formulation samples were prepared in 0.01 M HCl: Methanol (800:200) which is used as a diluent to achieve a concentration of 500 μg/mL of TMS and 200 μg/mL of HCZ. Impurities spiked sample chromatograms are shown in Fig. 4A, Fig. 4B.

Fig. 4A.

Spiked sample Chromatogram.

Legend: Flow rate 1.0 mL/min, UV Wavelength 230 nm; injection volume 10 μL; Column temperature 30°C; Gradient Elution; Run time: 65 min.

Fig. 4B.

Spiked sample Chromatogram with Impurity-D.

Legend: Flow rate 1.0 mL/min, UV Wavelength 230 nm; injection volume 10 μL; Column temperature 30°C; Gradient Elution; Run time: 65 min.

3. Results and discussion

3.1. Method development

Based on TMS and HCZ pKa values, acidic mobile phase was selected for initial development trial. Based on the structural polarity nature HCZ and its related impurities may elute in the order of DSA, CTZ and HCZ peak. TMS and its related impurity may elute in the following descending order with reverse phase mobile phase contained octadecyl silane (C18) column. The impurities of HCZ viz. DSA, CTZ are highly polar and tends to elute quickly and requires aqueous mobile phase delivers moderate acidic pH for symmetrical peaks. The initial isocratic mobile phase consisting of 0.02 M potassium dihydrogen phosphate buffer solution adjusted to a pH of 4.0 and acetonitrile in the ratio of 750:250. Different kind of buffers (ammonium dihydrogen phosphate, sodium per chlorate) also optimized and found symmetric peaks with the capacity factor of first eluting HCZ impurity > 3. However, due to the typical non-polar nature of TMS impurity compounds and selectivity among the components of interest, the gradient program is utilized to elute the impurity compounds with optimal required resolution of NLT 1.5. Mobile phase-B preliminarily selected as a mixture of water and acetonitrile in the ratio of 100: 900 v/v respectively. One hundred percent aqueous buffer (mobile phase-A) has been used as initial gradient to retain high polar compounds of HCZ and its impurities, the resulted chromatogram shows that DSA, CTZ and HCZ were well separated from void peak and from each other. Due to the higher aqueous ratio of mobile phase A, partial peak distortion was observed for HCZ peaks and peak symmetry was got affected and corrected by the initial gradient addition of ~ 15% of mobile phase-B to get good symmetrical peaks of polar compounds and this effect also studied with later elution of peaks in the chromatographic development.

Gradually increased the organic phase ratio into HPLC column to elute more retained peaks like TMS and its impurities. Different gradient trials were conducted to elute all the peaks with specific retention for close eluting peaks (TLA1, TMS) with higher % B. The pH of mobile phase A < 3.5 is evaluated and found that there are 2 impurities (DSA, TEL2) moderately increasing over time from the preparation time of drug product sample. Also this pH study in mobile phase A is extended to neutral (pH ~ 6–7) and slight basic (pH ~ 8–9) conditions, found that any of the stated conditions did not exhibit stability of the % impurities in drug product sample over time due to degradation. Hence, pH of the mobile phase A optimized at pH 3.5.

The resolution of the method has been found critical in separation with various parameters viz. pH of the mobile phase (3.5), column temperature (40) which are enhances the separation sensitivity between the imp-C and imp-B peaks of TMSFrom various column brands as stated above with this chromatographic condition found to be typical separation and one column among them delivers the effective separation for the components of interest. The column Inertsil ODS 3 V (150 × 4.6) mm 3.5 μm found to be sensitive and selective separation among the peaks (resolution NLT 1.5) at the retention times range from 8 to 15 min and 40–50 min which is not obtained by any further modification of gradient change, mobile phase composition or various column brands. The elution order of components of interest are presented in Table 2.

3.2. Software aided method optimization

Quality by design (QbD) is well established in the development and manufacture of pharmaceutical drug substance and drug product processes as described in ICH Q8, Q9 and Q11. The objective of AQbD is to design a rugged, robust method that consistently delivers the intended performance (Reid et al., 2013). Design of Experiments (DoE) is the simple method to optimize the experimental condition with two or more variables (Anderson and Patrick, 2004; Krull et al., 2009; Monks et al., 2011). QbD approach is more applied to method development than method validation since method validation is the process of demonstrating that a well-developed analytical method is suitable for its intended purpose. DOE for analytical methods during the development stage is needed for better improvement, a quantitative understanding of the factors that influence resolution, selectivity is an integral part of the method development. Optimized chromatographic conditions were evaluated for Critical Method attributes (CMAs), based on the developmental knowledge and screening studies. viz. buffer pH, flow rate and column temperature.

3.3. Design of experiments

The development and optimization of analytical methods with systematic and scientific manner is specified as analytical quality by design (AQbD). The application of AQbD principle during analytical method development and validation shows a significant positive impact of method life cycle. The QbD approach [[25], [26], [27], [28], [29], [30], [31]] is more applied to method development than method validation since method validation is the process of demonstrating that a well-developed analytical method is suitable for its intended purpose.

Fundamentally, analytical QbD requires identification of analytical target profile (ATP) before the analytical technology is considered. As a next step critical method attributes (CMAs) of the method are identified (for example: flow rate, column temperature and buffer pH) based on developmental knowledge and experiments. Design-of-experiments (DoE) studies were performed to identify design space. CMAs and experimental resulted ATPs been shown in Table 3. The Three-Level Factorial design was selected with the help of Design expert11 trial version software and executed all the suggested experiments in a randomized manner. The designed model and obtained results with the possible combination studies are shown in Table 3

Table 3.

Design of Experiments for the optimized chromatographic parameters.

| Std | Run | Factor1 |

Factor2 |

Factor3 |

Response1 |

Response2 |

Response3 |

|---|---|---|---|---|---|---|---|

| Flow rate | Column Temperature | Buffer pH | Resolution btw DSA & CTZ | Resolution btw CTZ & HCTZ | Resolution btw TMS C & Chloro analog | ||

| 14 | 5 | 0.8 | 50 | 3.5 | 2.5 | 2.8 | 2.9 |

| 13 | 6 | 0.8 | 50 | 3.5 | 2.5 | 2.8 | 2.9 |

| 10 | 9 | 0.8 | 30 | 3.5 | 2.8 | 3.1 | 2.9 |

| 6 | 12 | 0.8 | 50 | 2.5 | 2.4 | 2.9 | 2.9 |

| 5 | 14 | 0.8 | 50 | 2.5 | 2.4 | 2.9 | 2.9 |

| 2 | 16 | 0.8 | 30 | 2.5 | 2.8 | 3.3 | 3.1 |

| 9 | 17 | 0.8 | 30 | 3.5 | 2.9 | 3.2 | 3.1 |

| 1 | 18 | 0.8 | 30 | 2.5 | 2.8 | 3.1 | 2.8 |

| 17 | 3 | 1 | 40 | 3 | 2.6 | 2.9 | 2.9 |

| 18 | 4 | 1 | 40 | 3 | 2.6 | 2.9 | 2.8 |

| 15 | 1 | 1.2 | 50 | 3.5 | 2.3 | 2.6 | 2.9 |

| 3 | 2 | 1.2 | 30 | 2.5 | 2.4 | 2.8 | 2.8 |

| 8 | 7 | 1.2 | 50 | 2.5 | 2.3 | 2.5 | 2.9 |

| 11 | 8 | 1.2 | 30 | 3.5 | 2.4 | 2.8 | 2.9 |

| 4 | 10 | 1.2 | 30 | 2.5 | 2.5 | 2.9 | 2.7 |

| 7 | 11 | 1.2 | 50 | 2.5 | 2.4 | 2.6 | 2.8 |

| 16 | 13 | 1.2 | 50 | 3.5 | 2.4 | 2.6 | 2.8 |

| 12 | 15 | 1.2 | 30 | 3.5 | 2.5 | 2.9 | 2.9 |

3.4. Effects of CMAs on responses

A second-order quadratic polynomial design was selected to identify the significant factors that are influencing the resolutions of selected ATPs, the predefined CMAs ((Flow rate), (column temperature), and (Buffer pH)) are studies as suggested by Design Expert, the total of 18 experiments were conducted are shown in Table 3. The linear analysis of variance (ANOVA) data shown in Table 4, depicting the model selected is significant (p-value < 0.05) to recognize the effects of factors affecting the all three responses resolution.

Table 4.

ANOVA data.

| Sum of Squares | df | Mean Square | F-value | p-value | ||

|---|---|---|---|---|---|---|

| Response 1 | ||||||

| Model | 0.4512 | 2 | 0.2256 | 27.11 | <0.0001 | significant |

| A-Flow rate | 0.2256 | 1 | 0.2256 | 27.11 | 0.0001 | |

| B-column Temp | 0.2256 | 1 | 0.2256 | 27.11 | 0.0001 | |

| Response 2 | ||||||

| Model | 0.7200 | 2 | 0.3600 | 90.00 | <0.0001 | significant |

| A-Flow rate | 0.3600 | 1 | 0.3600 | 90.00 | <0.0001 | |

| B-column Temp | 0.3600 | 1 | 0.3600 | 90.00 | <0.0001 | |

| Response 3 | ||||||

| Model | 0.1250 | 2 | 0.0625 | 8.84 | 0.0029 | significant |

| A-Flow rate | 0.0625 | 1 | 0.0625 | 8.84 | 0.0095 | |

| B-column Temp | 0.0625 | 1 | 0.0625 | 8.84 | 0.0095 | |

3.5. Effect of chromatographic factors on responses

The linear quadratic ANOVA data of response 1 (Table 4) conforms that flow rate & column temperature (P-value < 0.0001) are showing highly significant effect on Resolution between DSA & CTZ, Chlorothiazide impurity and HCZ peak. The linear quadratic ANOVA data of response 2 (Table 4) conforms that flow rate & column temperature (P-value < 0.0095) are showing moderate effect on resolution between Telmisartan Impurity C & Chloro analogue impurity.

4. Method validation

4.1. Method precision and accuracy

Specified amounts of impurity compounds of HCZ, TMS spiked in the stock sample solution and evaluated the compound recoveries using the HPLC technique. Standard computing and recovery analyses were also conducted on the sample to determine the accuracy of the impurity compounds and drug substances (HCZ & TMS). The study was carried out in triplicate (3) preparation using five (5) concentration levels from LOQ – 0.04% (0.08 μg/mL) to 0.5% (1.00 μg/mL) for HCZ & it’s Impurity compounds where as LOQ – 0.04% (0.2 μg/mL) to 0.5% (2.5 μg/mL) for TMS & it’s impurity compounds. The % recovery values fall to the linear regression of more than 0.998. Representative chromatograms of the spiked sample preparation are shown in Table 4.

4.2. Specificity

4.2.1. Matrix interferences

The specificity of the analyte compounds of interest evaluated against the presence of formulation matrix components, diluent used for sample preparation, mobile phase used for chromatographic analysis.

4.2.2. Forced degradation

The stress studies carried out on a drug product to establish its inherent stability characteristics, leading to identification of degradation products and hence supporting the suitability of the proposed analytical procedures. It also requires that analytical test procedures for stability samples should be stability indicating with qualified analytical method validation characteristics. The forced degradation of placebo and formulation was carried out as per ICH guidelines [32]. The acid (1.7 N HCl, refluxed at 60 °C for 10 h), base (1.7 N HCl, refluxed at 60 °C for 10 h), Peroxide (1.7% H2O2, refluxed at 60 °C for 10 h) and Water (10 mL H2O, refluxed at 60 °C for 10 h) and thermal (105 °C for 24 h) stress conditions were studied out by refluxing the drug substance one in the presence of other in matrix formulation. The % impurity evaluation and peak purity results of the stress condition summarized in Table 5, respectively.

Table 5.

Peak purity Results in stressed condition.

| A: For TMS Impurities | |||||

|---|---|---|---|---|---|

| Compound Name | % Degradation | Mass balance | Purity Angle | Purity Threshold | Purity flag |

| As such Sample | NA | 100.0 | 0.847 | 1.001 | No |

| Acid Degradation (1.7 N HCl, refluxed at 60 °C for 10 h) | 1.5 | 98.5 | 0.613 | 1.006 | No |

| Base Degradation (1.7 N HCl, refluxed at 60 °C for 10 h) | 2.6 | 97.4 | 0.508 | 1.008 | No |

| Peroxide degradation (1.7% H2O2, refluxed at 60 °C for 10 h) | 5.2 | 94.8 | 0.089 | 1.018 | No |

| Heat degradation (105 °C for 24 h) | 1.4 | 98.6 | 0.178 | 1.009 | No |

| Water degradation (10 mL H2O, refluxed at 60 °C for 10 h) | 0.1 | 99.9 | 0.131 | 1.009 | No |

| B: For HCZ Impurities | |||||

| Degradation Condition | % Degradation | Mass balance | Purity Angle | Purity Threshold | Purity flag |

| As such Sample | NA | 100.0 | 0.376 | 0.985 | No |

| Acid Degradation (1.7 N HCl, refluxed at 60 °C for 10 h) | 20.7 | 79.3 | 0.107 | 1.054 | No |

| Base Degradation (1.7 N HCl, refluxed at 60 °C for 10 h) | 13.2 | 86.8 | 0.122 | 1.061 | No |

| Peroxide degradation (1.7% H2O2, refluxed at 60 °C for 10 h) | 23.7 | 76.3 | 0.159 | 1.83 | No |

| Heat degradation (105 °C for 24 h) | 12.2 | 87.8 | 0.277 | 1.170 | No |

| Water degradation (10 mL H2O, refluxed at 60 °C for 10 h) | 11.6 | 88.4 | 0.096 | 1.075 | No |

4.3. Limits of detection (LOD) and quantification (LOQ)

The method was observed with a sensitive level of detection of impurities is at 0.025% (~0.125 μg/mL for TMS; ~0.05 μg/mL for HCZ) with respect to respective active drug concentration in sample using signal to noise ratio evaluation. The LOQ for HCZ & TMS and its Impurity compounds was determined at a signal-to-noise ratio of 10:1, by inoculating a range of dilute solutions with specified concentrations. LOQ was obtained for the listed impurity compounds at 0.04% level (~0.2 μg/mL for TMS; ~0.08 μg/mL for HCZ) with respect to respective active drug concentration in sample. The accuracy study was performed at LOQ level by preparing the six (6) individual spiked preparations, and the % recovery results were summarized in Table 6.

Table 6.

Accuracy at LOQ evaluation.

| S No | Impurity Name | Limit of Quantitation (LOQ) |

|

|---|---|---|---|

| Concentration (%) | % Recoverya | ||

| 1 | DSA | 0.043 | 109.4 |

| 2 | CTZ | 0.038 | 104.3 |

| 3 | HCTZ | 0.042 | 107.0 |

| 4 | TMS-EP-A | 0.037 | 108.9 |

| 5 | TMS-EP-E | 0.044 | 113.6 |

| 6 | TMS-EP-F | 0.042 | 108.7 |

| 7 | TMS-EP-B | 0.040 | 104.8 |

| 8 | TMS | 0.041 | 102.6 |

| 9 | TMS-EP-G | 0.043 | 107.9 |

| 10 | TEL2 | 0.040 | 108.3 |

| 11 | Dimer acid | 0.037 | 103.9 |

| 12 | TMS-EP-C | 0.040 | 102.6 |

| 13 | Chloroanalog | 0.041 | 103.9 |

| 14 | TEL1 | 0.040 | 104.8 |

| 15 | TMS-EP-H | 0.039 | 105.9 |

Determined on 6 homogeneous sample preparations.

4.4. Linearity

Linear calibration area for the related substance were established at five (5) determinations over the calibration range tested, i.e. LOQ (0.04%) to 0.5% for the listed impurity compounds and drug substance (HCZ and TMS) as an unspecified impurity compound. Linearity analysis solutions were prepared by diluting the pure stock solutions of the drug substance and impurities to the expected concentrations. As such, the solutions were fixed at five (5) concentration levels from LOQ to 150% of the specification level (LOQ-0.04%, 0.10, 0.20, 0.30 and 0.50%) for Impurity compounds, HCZ and TMS (unspecified). The linear regression coefficient was found >0.998. Calibration graphs were plotted by analysis of each calibration solutions. The peak area against the concentration data was treated by least-squares linear regression analysis.

4.5. Stability of mobile phase & sample solutions

The stability of HCZ, TMS and Impurity compounds in the precision spiked sample solution evaluated at room temperature at every 24 h frequency intervals up to 72 h with the fresh preparation of mobile phase every time. The stability of mobile phase was also determined by analyzing freshly prepared precision spiked sample solution at every 24 h frequency intervals and found sample, standard and mobile phase solutions were stable up to 48 h at room temperature.

5. Conclusion

The method provides selective quantification of TMS and HCZ impurities without interference of blank, placebo, thereby affirming the stability-indicating nature of the method. The proposed method is highly selective, reproducible, specific and rapid and the developed method was robust for the separation and quantification of Telmisartan and Hydrochlorothiazide in Telmisartan and Hydrochlorothiazide tablets. The practical impurity results for the 6 various drug product sample batches were evaluated with this methodology and found to be ≦ 0.04% (LOQ) for the subject specified and unspecified impurities of HCZ & TMS except DSA, TEL2 and TMS-A, which were observed at ≦ 0.1%.

CRediT authorship contribution statement

Ashok K. Palakurthi: Conceptualization, Methodology, Software, Supervision, Software, Validation. Thirupathi Dongala: Data curation, Writing - original draft, Visualization, Investigation, Writing - review & editing.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

The author wish to thank the management of Aurex Laboratories LLC. for supporting this work.

Footnotes

Supplementary data to this article can be found online at https://doi.org/10.1016/j.plabm.2020.e00169.

Contributor Information

Ashok K. Palakurthi, Email: ashokchem2000@gmail.com.

Thirupathi Dongala, Email: thirupathi2009@gmail.com.

Appendix A. Supplementary data

The following is the Supplementary data to this article:

References

- 1.https://www.rxlist.com/micardis-hct-drug.htm%20access%20date:

- 2.Chen Ben-mei, Liang Yi-zeng, Wang Ya-li. Development and validation of liquid chromatography–mass spectrometry method for the determination of telmisartan in human plasma. Anal. Chim. Acta. 2005;540:367–373. [Google Scholar]

- 3.Ismail Salama Simultaneous HPLC–UV analysis of telmisartan and hydrochlorothiazide in human plasma. Bullet. Facul. Pharm. 2011;49:19–24. [Google Scholar]

- 4.Yan T. Liquid chromatographic-tandem mass spectrometric method for the simultaneous quantitation of telmisartan and hydrochlorothiazide in human plasma. J. Pharmaceut. Biomed. Anal. 2008;48:1225–1229. doi: 10.1016/j.jpba.2008.08.021. [DOI] [PubMed] [Google Scholar]

- 5.Yan Tingting, Li Hao, Gu Jingkai. Liquid chromatographic–tandem mass spectrometric method for the simultaneous quantitation of telmisartan and hydrochlorothiazide in human plasma. J. Pharmaceut. Biomed. Anal. 2008;48:1225–1229. doi: 10.1016/j.jpba.2008.08.021. [DOI] [PubMed] [Google Scholar]

- 6.Jaivik V., Jignesh M., Pranav S. Application of an LC–MS/MS method for the analysis of amlodipine, valsartan and hydrochlorothiazide in polypill for a bioequivalence study. J. Pharm. Anal. 2017;7:309–316. doi: 10.1016/j.jpha.2017.06.001. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Gupta V.K., Jain Rajeev, Lukram Ojitkumar. Simultaneous determination of ramipril, ramiprilat and telmisartan in human plasma using liquid chromatography tandem mass spectrometry. Talanta. 2011;83:709–716. doi: 10.1016/j.talanta.2010.10.011. [DOI] [PubMed] [Google Scholar]

- 8.Lories I., Samah S., Abbas A. Application of first-derivative, ratio derivative spectrophotometry, TLC-densitometry and spectrofluorimetry for the simultaneous determination of telmisartan and hydrochlorothiazide in pharmaceutical dosage forms and plasma. Il Farmaco. 2005;60:859–867. doi: 10.1016/j.farmac.2005.06.009. [DOI] [PubMed] [Google Scholar]

- 9.Brunetto María del Rosario, Contreras Yaritza, Martin Víctor Cerdà. Determination of losartan, telmisartan, and valsartan by direct injection of human urine into a column-switching liquid chromatographic system with fluorescence detection. J. Pharmaceut. Biomed. Anal. 2009;50:194–199. doi: 10.1016/j.jpba.2009.04.015. [DOI] [PubMed] [Google Scholar]

- 10.Hillaert S., Van den Bossche W. Simultaneous determination of hydrochlorothiazide and several angiotensin-II-receptor antagonists by capillary electrophoresis. J. Pharmaceut. Biomed. Anal. 2003;26:329–339. doi: 10.1016/s0731-7085(02)00643-x. [DOI] [PubMed] [Google Scholar]

- 11.Mukhopadhyay Sutirtho, Kadam Kiran, Sawant Laxman. Simultaneous determination of related substances of telmisartan and hydrochlorothiazide in tablet dosage form by using reversed phase high performance liquid chromatographic method. J. Pharm. Bioanal. Sci. 2011;3:3. doi: 10.4103/0975-7406.84441. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Balakrishna G., Kumar Rajesh, Jain Mohit. Development and validation of stability indicating HPLC method for the determination of process and degradation related impurities in telmisartan drug substance. Chem. Method. 2019;3:145–165. [Google Scholar]

- 13.Bhavani V., Siva Rao T., Raju S.V.N. Stability indicating UPLC method for the estimation of telmisartan related substances in tablets formulation. Int. J. Sci. Res. Publ. 2013;3:2. [Google Scholar]

- 14.2005. ICH Harmonised Tripartite Guideline Validation of analytical procedures: text and methodology Q2 (R1) pp. 1780–1783. (Validation of Compendial Procedures). USP 40 – NF 35, (Chapter 1225) [Google Scholar]

- 15.Rao K.L.N., Krishnaiah C., Babu K.S., Reddy K.P. Development and validation of a stability-indicating LC method for simultaneous determination of related compounds of guaifenesin, terbutaline sulfate and ambroxol HCl in cough syrup formulation. J. Saudi Chem. Soc. 2014;18:593–600. doi: 10.1016/j.jscs.2012.01.006. [DOI] [Google Scholar]

- 16.Dongala T., Palakurthi A.K., Yytla Y., Katari N.K. A novel UPLC-PDA isocratic method for the quantification fulvestrant in oil-based pre-filled syringe injection matrix formulations. J. Anal. Sci.Tech. 2019;10:12. doi: 10.1186/s40543-019-0171-7. [DOI] [Google Scholar]

- 17.Rao K.L.N., Krishnaiah C., Reddy K.P. Stability-Indicating method for simultaneous determination of polar and non-polar related compounds of Zidovudine in drug substance and drug product tablet form. Int. J. Res. Pharm. Sci. 2015;6(1):5–14. [Google Scholar]

- 18.Rao K.L.N., Rao K.P. Development and validation of a stability-indicating LC method for determination of bexarotene in softgel dosage formulation. Chromatographia. 2017;80(8):1211–1224. doi: 10.1007/s10337-017-3339-6. [DOI] [Google Scholar]

- 19.Ashok P.K., Thirupathi D., Ravindra Kumar Y., Jayashree A. Simultaneous determination of related organic impurities of ibuprofen and paracetamol in combination solid dosage form by Rp-hplc with Qbd approach. Orient. J. Chem. 2017;33:1461–1468. [Google Scholar]

- 20.Katakam L.N.R., Dongala T. A novel RP-HPLC refractive index detector method development and validation for determination of trace-level alcohols (un-sulfated) in sodium lauryl sulfate raw material. Biomed. Chromatogr. 2020 doi: 10.1002/bmc.4827. [DOI] [PubMed] [Google Scholar]

- 21.Dongala T., Lakshmi Narasimha Rao K. RP-HPLC stability indicating method development and validation of pseudoephedrine sulfate and related organic impurities in tablet dosage forms, robustness by QbD approach. Anal. Chem. Lett. 2019;9(5):697–710. [Google Scholar]

- 22.Rao K.L.N., Reddy K.P., Babu K.S., Raju K.S. Simultaneous estimation of fluticasone propionate, azelastine hydrochloride, phenylethyl alcohol and benzalkonium chloride by RP-HPLC method in nasal spray preparations. Int. J. Res. Pharm. Sci. 2010;1(4):473–480. https://pharmascope.org/ijrps/article/view/947 [Google Scholar]

- 23.Rama Mohana Reddy M., Praveen Kumar A., Krishna Reddy V. Stability-indicating hplc method for simultaneous estimation of low level impurities of telmisartan and hydrochlorothiazide in tablet dosage forms. Int. J. Pharm. Pharmaceut. Sci. 2012;4:497–504. [Google Scholar]

- 24.Reid G.L., Cheng G., Fortin D.T. Reversed phase liquid chromatographic method development in analytical quality by design framework. J. Liq. Chromatogr. Relat. Technol. 2013 doi: 10.1080/10826076.2013.765457. [DOI] [Google Scholar]

- 25.Anderson M.J., Patrick J.W. CRC Press Taylor and Francis Group; New York: 2004. RSM Simplified: Optimizing Processes Using Response Surface Methods for Design of Experiments. [Google Scholar]

- 26.Krull I., Swartz M., Turpin J. A quality-by-design methodology for rapid LC method development. LC-GC N. Am. 2009;27:48–61. part II. [Google Scholar]

- 27.Dongala T., Palakurthi A.K. HPLC-UV method development for the determination of EDTA in oxycodone HCl oral liquids with derivatization technique. Robustness by design of experiments approach. Anal.Chem. Lett. 2019;5:594–607. doi: 10.1080/22297928.2019.1674186. [DOI] [Google Scholar]

- 28.Monks K.E., Rieger H., Molnar I. Expanding the term ‘‘Design Space’’ in high performance liquid chromatography (I) J. Pharmaceut. Biomed. Anal. 2011;56(2011):874–879. doi: 10.1016/j.jpba.2011.04.015. [DOI] [PubMed] [Google Scholar]

- 29.Dongala T., Katari N.K., Palakurthi A.K. Stability-indicating HPLC method for simultaneous quantification of 14 impurities in excedrin tablet formulations and identification of new impurity by LC–MS in accelerated stability studies. Biomed. Chromatogr. 2019;33(10) doi: 10.1002/bmc.4608. Error! Hyperlink reference not valid. [DOI] [PubMed] [Google Scholar]

- 30.Kumar P.A., Raju T.V.R., Thirupathi D. Development and validation of a stability-indicating LC-method for the simultaneous estimation of levodropropizine, chloropheniramine, methylparaben, propylparaben, and levodropropizine impurities. Sci. Pharm. 2013;81(1):139–150. doi: 10.3797/scipharm.1210-18. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 31.Karthik J., King T., Sandeep S. Photostability issues in pharmaceutical dosage forms and photostabilization. AAPS. 2018;19:48–59. doi: 10.1208/s12249-017-0869-z. [DOI] [PubMed] [Google Scholar]

- 32.Janga K.Y., Tatke A., Dudhipala N., Balguri S.P. Gellan gum based sol-to-gel transforming system of natamycin transfersomes improves topical ocular delivery. J.Pharm. Exp. Ther. 2019;370:814–822. doi: 10.1124/jpet.119.256446. [DOI] [PMC free article] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.