Abstract

Aims:

The purpose of this study was to evaluate the effects of altered environmental conditions on the persistence of Francisella tularensis bacteria and Venezuelan equine encephalitis virus (VEEV), on two material types.

Methods and Results:

Francisella tularensis (F.t.) and VEEV were inoculated (c. 1 × 108 colony-forming units or PFU), dried onto porous and nonporous fomites (glass and paper), and exposed to combinations of altered environmental conditions ranging from 22 to 60°C and 30 to 75% relative humidity (RH). Viability of test organism was assessed after contact times ranging from 30 min to 10 days. Inactivation rates of F.t. and VEEV increased as both temperature and/or RH were increased. Greater efficacy was observed for paper as compared to glass for both test organisms.

Conclusions:

The use of elevated temperature and RH increased rate of inactivation for both organisms and greater than six log reduction was accomplished in as little as 6 h by elevating temperature to approximately 60°C.

Significance and Impact of the Study:

These results provide information for inactivation of nonspore-forming select agents using elevated temperature and humidity which may aid incident commanders following a biological contamination incident by providing alternative methods for remediation.

Keywords: biological agent, decontamination, environmental persistence, Francisella tularensis, Venezuelan equine encephalitis virus

Introduction

The persistence (survival over time) of biological agents outside a host are influenced by environmental conditions and the materials with which these biological agents are in contact (Sagripanti et al. 2010; Calfee et al. 2012; Wood et al. 2015; Rogers et al. 2016; Wood et al. 2018). Temperature, humidity, UV radiation and desiccation are among the environmental factors and resulting impacts that affect the viability of bacteria and viruses in the environment (Sinclair et al. 2008).

To adequately design decontamination efficacy tests as well as to plan for response or remediation following intentional releases of biological agents or naturally occurring events, scientifically defensible persistence and decontamination efficacy data are needed (Ryan et al. 2010). Several decontamination approaches have been shown to be effective for inactivation of biological select agents (Rogers et al. 2005; Rogers et al. 2007; Rogers and Choi 2008; Calfee and Wendling 2015; Wood et al. 2016; Richter et al. 2018). However, when wide outdoor areas or large buildings are affected, the logistics of scaling these technologies can become challenging and often involve fumigants or liquids that are dangerous to human health, impactful to the environment, or deleterious to the materials being decontaminated.

Francisella tularensis (F.t.) is a highly infectious Gram-negative, nonspore-forming, coccobacillus and is the causative agent of tularaemia. F.t. is categorized by the Centers for Disease Control and Prevention as a Tier 1, Category A, select agent due to its low infectious dose (as few as 10 organisms), virulence, and its ability to spread via multiple modes of transmission including aerosol exposure (Dennis, et al. 2001). Its potential use as a bioweapon has been studied as early as 1932 by Japan and the Soviet Union (Harris 1992), and later in the 1950 and 1960s by the United States (Alibek and Handelman 1999).

Venezuelan equine encephalitis virus (VEEV) can cause overt disease in both equids and humans. Human infection normally results in a self-limiting, incapacitating disease characterized by fever, headache, lymphopenia, myalgia and malaise (Kumar et al. 2018). Additionally, severe neurological disease, which includes fatal encephalitis, can occur. Because of the ease of production, high infectivity, potential for aerosolization and disease state associated with infection, there is a concern for the viruses to be used as bioweapons.

Previous studies have examined the persistence (or natural attenuation) of nonspore-forming bacteria (King et al. 2011; Aune et al. 2012; Calfee and Wendling 2012; USEPA 2015; Gut et al. 2016) and viral select agents (Berendt and Dorsey 1971; Lai et al. 2005; Graiver et al. 2009; Sagripanti et al. 2010; Yamamoto et al. 2010; Pyankov et al. 2012; Verreault et al. 2013; Brown et al. 2014) and have shown the ability of these agents to persist in various matrices or altered states (lyophilization) for months, however, many of these studies did not detail the effects when applied to common building fomites.

The purpose of this study was to evaluate the persistence of F.t. and VEEV under various environmental conditions, over time, on both glass and paper surfaces. In addition, an alternative approach to chemical inactivation was studied whereby the temperature and relative humidity (RH) were increased to determine if these altered conditions would increase the rate of attenuation. Data on F.t. and VEEV persistence under ambient laboratory conditions and under altered environmental conditions are presented as both recovery and decimal reduction time or D-value.

Materials and methods

Test organisms

Francisella tularensis was selected as a model, nonspore-forming bacterium as it showed a high level of survivability (21 days on glass when tested at 35°C and 65% RH) in previous testing (EPA, 2015). Both the virulent Schu4 strain as well as the attenuated, live vaccine strain (LVS), were procured from BEI Resources (NR-10492 and NR-646, Manassas, VA) and stored at −80°C until used to initiate each experiment. A Gram-stain was performed on the F.t. stock and the colony morphology was confirmed to be consistent with published descriptions (Holt et al. 1994).

Fresh cultures were prepared in advance of each day that coupons were inoculated by transferring one to three colonies from a streak plate (freshly grown or stored less than 2 weeks at 2–8°C) into 100 ml of Mueller Hinton broth (Molecular Toxicology, 26617.047A, Boone, NC). The culture was incubated overnight at 37°C on an orbital shaker at 200 rev min−1. The late-log-phase culture was diluted with fresh media to an optical density at 600 mm (OD600) of approximately 0·2–0·3 (SPECTRA-max Plus384 spectrophotometer; Molecular Devices, Sunnyvale, CA). The final titre was determined by analysing 1 : 10 serial dilutions of the stock suspension prepared using phosphate-buffered saline (PBS; Sigma Aldrich Cat. No. D8537, St Louis, MO) and plated onto chocolate II agar with haemoglobin and isovitaleX (Becton, Dickinson and Company, Franklin Lakes, NJ). Plates were incubated at 37°C for approximately 72 h and colony-forming units (CFU) were enumerated.

Venezuelan equine encephalitis virus was also selected for this study due to its ability to survive on glass coupons for more than 11 days at ambient temperature and RH (Sagripanti et al. 2010). The virulent VEEV strain, subtype IAB (IAB), was obtained from University of Texas Medical Branch (UTMB, Galveston, TX) and the attenuated TC83 was procured from BEI Resources (NR-9403). Both were prepared in routine cell culture media which included minimal essential media (MEM, Hyclone Cat. No. 10-009-CV, Logan, UT) and 10% foetal bovine serum (ATCC Cat. No. 30–2020, Manassas, VA). The stock viruses were propagated using Vero E6 cells (ATCC No. CRL-1586), harvested from the lysed cells with a target titre of approximately 109 plaque-forming units (PFU) per ml and stored at ≤−80°C. Titres were determined by analysing 1 : 10 serial stock dilutions in a plaque assay on Vero E6 cells, incubated for approximately 48 h, and the PFU enumerated.

Test materials

Two common indoor surface materials were used for testing: glass (nonporous surface, ASTM C1036; Brooks Brothers Glass & Mirror, Columbus, OH) and painted wallboard paper (porous surface; United States Gypsum Company, Chicago, IL). Glass was selected as a material type less difficult to decontaminate, wallboard paper was chosen as a more difficult material type to decontaminate based on previous studies (Rogers et al. 2007). Test coupons (1·9 × 7·5 cm) were cut from a larger piece of representative material. Visual inspection of the physical integrity of the test coupons was performed prior to and after testing to assess any damage or change to the coupons. Prior to testing, glass coupons were sterilized by autoclaving at 121°C for 15 min in sterilization pouches (Fisher Cat. No. NC9241087, Pittsburgh, PA) and paper by gamma-irradiation at approximately 40 kilogray (STERIS Isomedix Services, Libertyville, IL) in six mil Uline Poly Tubing (Uline Cat. No. S-3517, Chicago, IL).

Sample processing and data collection

All portions of testing were performed under Biosafety Level 3 conditions as the virulent and surrogate strains of each organism were tested side-by-side. Coupons were laid flat in a Class II Biological Safety Cabinet (BSC) and inoculated with approximately 1 × 108 CFU or PFU per coupon. A 100-microlitre (μl) aliquot of test organism (approximately 1 × 109 CFU per ml or PFU per ml) was dispensed as 10 droplets (10 μl per droplet) across the surface of the test coupons. For each type of material, five coupons were used to assess persistence of the organism at each combination of environmental condition and time point tested. Five additional coupons were used as controls (inoculated, exposed to ambient environmental conditions). All material coupons were allowed to dry for 1 h in the BSC under ambient conditions (approximately 22°C and 40% RH) before testing. Additionally, three coupons of each material were used as blanks (not inoculated) and were included for each time point tested. The blank coupons controlled for potential cross-contamination during testing as well as the sterility of the test coupons.

Coupons inoculated with F.t. or VEEV were exposed to various combinations of temperature and humidity for up to 10 days as outlined in Table 1. At each timepoint tested, agent persistence and attenuation were assessed. After inoculation and the initial drying period, the coupons were placed into airtight test chambers (Lock and Lock, HPL838P, Farmers Branch, TX) that were pre-conditioned to the prescribed environmental parameters. The test chambers were placed back into a BSC for ambient temperature exposure or into a water jacketed incubator, maintained at either 38 or 60°C (Forma Series II 3120; Thermo Fisher Scientific, Waltham, MA) for elevated temperature exposure. Elevated RH conditions (approximately 75%) were accomplished by adding a container of saturated sodium chloride (NaCl) to the bottom of the test chamber (ASTM International 2007). Ambient test conditions were only monitored, and no attempt was made to control these conditions. A data logger (Onset Hobo MX1101, Bourne, MA) was also placed at the bottom of the test chamber to monitor and record both temperature and RH every minute for the duration of testing. At time 0 (1 h following inoculation) and at the end of each assessed time point, samples were collected and extracted by placing each coupon in a conical tube that contained 10 ml PBS. All vials were agitated on their sides at room temperature on an orbital shaker (Eppendorf Innova® 40R, Hauppauge, NY) for 15 min at 200 rev min−1.

Table 1.

Overview of experimental design. Ambient test conditions (target of 22°C and 30% RH) were not controlled during testing

| Organism | Test materials | Target environmental conditions | Time points assessed (h) |

|---|---|---|---|

| Francisella tularensis Schu 4 | Glass | 60 ± 2°C, 30 ± 10% RH | 0·5, 1, 2, 6 |

| F. tularensis LVS | Paper | 38 ± 2°C, 30 ± 10% RH 38 ± 2°C, 75 ± 10% RH 22 ± 2°C, 75 ± 10% RH |

1, 6, 24, 48, 96, 168, 240 24, 48, 96 24, 48, 96 |

| VEEV IAB | Glass | 60 ± 2°C, 30 ± 10% RH | 0·5, 1, 2, 6, 12, 24, 48 |

| VEEV TC83 | Paper | 38 ± 2°C, 30 ± 10% RH 38 ± 2°C, 75 ± 10% RH 22 ± 2°C, 75 ± 10% RH |

12, 24, 48, 72, 96 24, 48, 96 24, 48, 96 |

To assess recovery from coupons inoculated with F.t., resulting liquid extracts were removed, and a series of 10-fold dilutions was prepared in PBS. An aliquot (0·1 ml) of the selected dilutions and, when necessary, the undiluted extracts were plated onto chocolate agar in triplicate. The agar plates were incubated at 37 ± 2°C for 72 ± 24 h. Colonies were enumerated to determine survivorship and reduction in the bacteria following exposure.

For samples inoculated with VEEV, resulting liquid extracts were removed and a series of 10-fold dilutions was prepared in cell culture media (MEM; Corning, Inc., Corning, NY, 10-010-CV). An aliquot (0·1 ml) of the selected dilutions and, when necessary, the undiluted extracts were plated onto monolayers of Vero E6 cells. The tissue culture plates were gently rocked every 15 min for 1 h at approximately 37°C to allow adsorption of the virus to the cells. The cultures were then overlaid with MEM that contained 2% foetal bovine serum and 0·5% methylcellulose. The cultures were incubated for 72 ± 24 h at 37 ± 2°C and 5 ± 1% CO2. Following incubation, a solution of crystal violet dye (Sigma Aldrich, HT901–8FOZ) and formalin was added to the monolayers for 20 min, removed, and the cells rinsed with sterile water to remove residual dye. Plaques were visualized as clearings in the purple monolayer of Vero E6 cells. The plaques were counted manually, and the number of PFU per ml was determined by multiplying the mean number of plaques per well by the reciprocal of the dilution.

Data treatment

Results from the decontamination tests are presented as total recovery from both control and decontaminated coupons and decimal reduction time (D-value or Di), which is the time required to achieve a 1 log (90%) reduction in viable test organisms. Recovery of viable test organisms is expressed as the base-10 logarithm of total CFU/PFU recovered from the five control or test coupons for each material type and timepoint tested. Efficacy of the decontamination process was determined by subtracting the mean of the base-10 logarithm of the number of viable test organisms extracted from the five test coupons from the mean of the base-10 logarithm of the time zero (T0) control coupons and was expressed as log reduction (LR) using Eqn (1):

| (1) |

where CFUc is the average number of viable test organisms extracted from the control samples and CFUt is the average number of viable test organism extracted from the test samples. For decontaminated test samples where no viable organism was detected, the efficacy was calculated as the log of the mean number of viable organisms recovered from the control coupons. Using the calculated LR for each test coupon, the mean (±SD) log reduction was calculated.

The effect of time and associated environmental conditions (control and test coupons) are additionally presented as D-values (Di, the time in hours required to achieve 90% (1-log) reduction in viable organisms on the test surface). Di was calculated by subtracting the number of viable test organisms extracted from the five coupons at the sooner of (i) the longest timepoint tested or (ii) the first instance of achieving a nondetect (no viable recovered test organism) from the mean of the base-10 logarithms of the control coupons, inverting this value, and then multiplying by the associated timepoint (h) using Eqn (2):

| (2) |

where ti is the sooner of the longest timepoint tested or the first timepoint achieving a nondetect for the test coupons of a particular environmental condition, CFUcj is the number of viable test organisms extracted from time zero control sample j of the same environmental condition and CFUti is the number of viable test organisms extracted from test sample i at time ti.

Results

A total of 10 decontamination tests were conducted, consisting of five tests each per organism (F.t. and VEEV) on both glass and paper surfaces. The mean recovery of F.t. from the T0 controls (N = 5) was 15 and 0·4% for F.t. Schu4; and 3·1 and 0·002% for F.t. LVS on glass and paper respectively. The mean recovery of VEEV from the T0 controls (N = 5) was 47 and 25% for IAB; and 25 and 0·01% for TC83 strains on glass and paper respectively. Recovery of viable target organisms was consistently lower on paper as compared to glass as well as for the attenuated strain of both organisms on paper as compared to the virulent strain. The average total inoculum per coupon for F.t. (Schu4 and LVS) and VEEV was 1·1 ± 0·26 × 108 CFU and 1·2 ± 0·62 × 108 PFU respectively.

The environmental test chambers were able to achieve the designated environmental parameters (Tables 2 and 3). Excursions outside the target parameters were observed only when accessing the chamber to remove coupons at designated timepoints. However, the chambers returned to target testing conditions within an average of 2 h of being opened resulting in standard deviations of 0·30–10·7°C for temperature and 2·53–10·51% for RH. These brief deviations in environmental conditions may have had a minimal impact on the results, however the time weighted averages were within the target parameters. Increased standard deviations were observed for elevated temperature tests in which RH was uncontrolled. These tests resulted in a reduction in RH as the test chamber warmed within the incubator.

Table 2.

Francisella tularensis Schu4 and LVS time to nondetect, recovery and Di

| Test organism | Actual environmental conditions | Material | Time to ND (h) | Control recovery (log10 CFU)* | Test recovery (log10 CFU)* | Control Di (h) | Test Di (h) | |

|---|---|---|---|---|---|---|---|---|

| F.t. Schu4 | 58·0 ± 7·8°C | Glass | 6 | 6·9 | 0·0 | 7·9 | 0·8 | |

| 25·8 ± 6·0% RH | Paper | 1 | 5·8 | 0·0 | 6·9 | 0·2 | ||

| F.t. LVS | Glass | 6 | 6·0 | 0·0 | 6·5 | 0·9 | ||

| Paper | 1 | 3·7 | 0·0 | 2·3 | 0·2 | |||

| F.t. Schu4 | 37·1 ± 1·8°C | Glass | 24 | 4·9 | 0·0 | 27·4 | 3·5 | |

| 72·9 ± 3·1% RH | Paper | 24 | 1·8 | 0·0 | 17·3 | 4·3 | ||

| F.t. LVS | Glass | 24 | 2·3 | 0·0 | 18·3 | 4·6 | ||

| Paper | 0† | 0·0 | 0·0 | NA | NA | |||

| F.t. Schu4 | 38·1 ± 2·1°C | Glass | 240§ | 0·2 | 3·9 | 35·0 | 75·6‡ | |

| 41·4 ± 5·6% RH | Paper | 96 | 1·7 | 0·0 | 16·7 | 16·7 | ||

| F.t. LVS | Glass | 240§ | 0·0 | 3·2 | 37·2 | 74·2‡ | ||

| Paper | 24 | 0·7 | 0·0 | 34·3 | 17·1 | |||

| F.t. Schu4 | 21·8 ± 0·3°C | Glass | 96§ | 4·3 | 0·3 | 37·1 | 14·6 | |

| 74·7 ± 3·6% RH | Paper | 48 | 2·2 | 0·0 | 20·4 | 9·3 | ||

| F.t. LVS | Glass | 48 | 2·4 | 0·0 | 23·9 | 9·1 | ||

| Paper | 0† | 0·0 | 0·0 | NA | NA | |||

Total log10 value remaining at longest timepoint or at first instance of nondetect.

No viable test organism recovered at time zero controls, theoretical limit of detection 33 CFU.

Greater reduction in controls vs decontamination samples.

Incomplete inactivation at longest timepoint tested.

Table 3.

Venezuelan equine encephalitis virus (IAB and TC83), time to nondetect, recovery and Di

| Test organism | Target environmental conditions | Material | Time (h) | Control recovery (log10 PFU)* | Test recovery (log10 PFU)* | Control Di (h) | Test Di (h) |

|---|---|---|---|---|---|---|---|

| VEEV IAB | 58·3 ± 10·7°C | Glass | 12 | 6·6 | 0·0 | 39·3 | 1·6 |

| 29·2 ± 10·5% RH | Paper | 12 | 5·8 | 0·0 | 23·9 | 1·7 | |

| VEEV TC83 | Glass | 12 | 6·1 | 0·0 | 31·2 | 1·6 | |

| Paper | 6 | 1·6 | 0·0 | 29·3 | 3·1 | ||

| VEEV IAB | 37·7 ± 0·6°C | Glass | 24 | 6·9 | 0·0 | 35·2 | 3·1 |

| 75·7 ± 2·5% RH | Paper | 24 | 6·2 | 0·0 | 28·6 | 3·2 | |

| VEEV TC83 | Glass | 24 | 6·3 | 0·0 | 39·2 | 3·2 | |

| Paper | 24 | 0·9 | 0·0 | 23·8 | 5·5 | ||

| VEEV IAB | 38·1 ± 2·1°C | Glass | 96 | 4·8 | 0·0 | 31·5 | 12·2 |

| 41·4 ± 5·6% RH | Paper | 96† | 4·4 | 1·3 | 29·5 | 15·1 | |

| VEEV TC83 | Glass | 96† | 5·3 | 1·2 | 41·0 | 14·9 | |

| Paper | 12 | 2·8 | 0·0 | 22·1 | 2·8 | ||

| VEEV IAB | 21·8 T 0·3°C | Glass | 96† | 5·9 | 3·2 | 53·3 | 21·5 |

| 74·7 T 3·6% RH | Paper | 96 | 6·2 | 0·0 | 64·4 | 12·6 | |

| VEEV TC83 | Glass | 96† | 4·9 | 3·3 | 43·1 | 24·9 | |

| Paper | 24 | 2·15 | 0·0 | 37·5 | 6·5 |

Total log10 value remaining at longest timepoint or at first instance of nondetect, theoretical limit of detection 33 PFU.

Incomplete inactivation at longest timepoint tested.

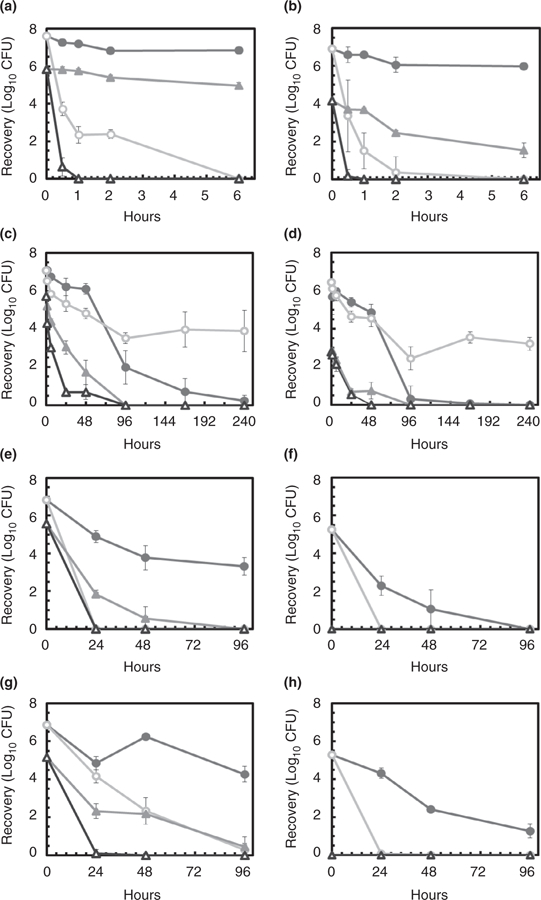

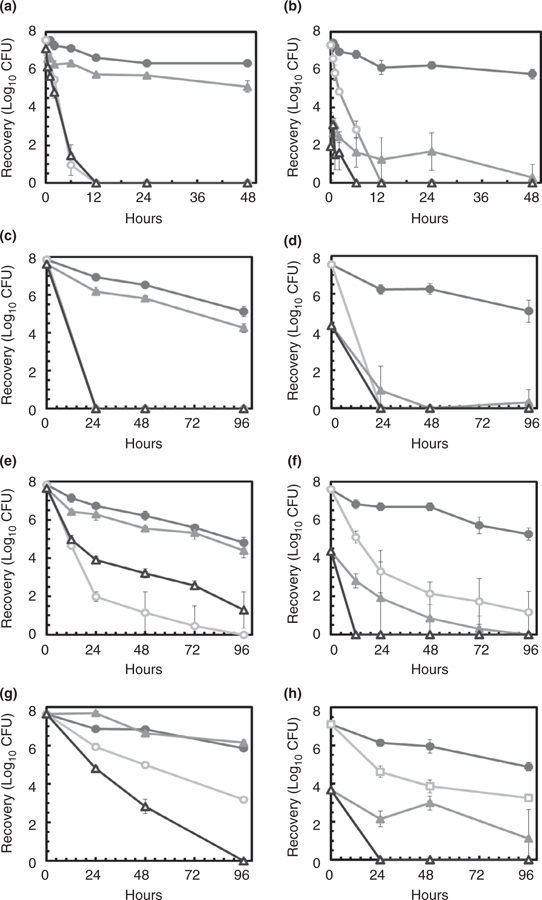

In general, as air temperature or RH increased, the ability of F.t. and VEEV to persist on glass and paper was reduced (Figs 1 and 2). The virulent strains of F.t and VEEV were recovered on all control coupons (22°C and 30% RH) at the longest duration tested (Tables 2 and 3) except for F.t. Schu4 on paper at 96 h. Mean total logs recovered (Schu4 and IAB) at the longest duration tested under control (ambient) conditions were 2·7 and 5·4 respectively. The avirulent organisms (LVS and TC83) resulted in lower viable recovered test organisms from control glass coupons and only one instance of recovery (F.t. LVS) on paper. The mean total logs recovered for these strains at the longest duration tested were 0·9 and 2·7 respectively.

Figure 1.

Recovery of Francisella tularensis (log10 CFU). (a) Schu4 and (b) LVS at 60°C, ambient RH; (c) Schu4 and (d) LVS at 38°C, ambient RH; (e) Schu4 and (f) LVS at 38°C, 75% RH; (g) Schu4 and (h) LVS at ambient temperature, 75% RH ( Glass control coupons;

Glass control coupons;  Glass test coupons;

Glass test coupons;  Paper control coupons;

Paper control coupons;  Paper test coupons).

Paper test coupons).

Figure 2.

Recovery of VEEV (log10 PFU). (a) IAB and (b) TC83 at 60°C, ambient RH; (c) IAB and (d) TC83 at 38°C, 75% RH; (e) IAB and (f) TC83 at 38°C, ambient RH; (g) IAB and (h) TC83 at ambient temperature, 75% RH ( Glass control coupons;

Glass control coupons;  Glass test coupons;

Glass test coupons;  Paper control coupons;

Paper control coupons;  Paper test coupons).

Paper test coupons).

Efficacy of the altered environmental conditions resulted in Di ranging from 0·2 to 75·6 h for F.t. and 1·6 to 24·9 h for VEEV (Tables 2 and 3). There was one instance where the Di for the controls was less than the Di for the test materials under altered environmental conditions: F.t. Schu4 and LVS on glass (38°C 30% RH). The fastest rate of inactivation for F.t. was achieved under the 60°C and 30% RH environmental condition with Di ranging from 0·2 to 0·9 h. The longest rate of inactivation was observed using the 38°C and 30% RH environmental conditions with Di ranging from 16·7 to 75·6 h. The fastest rate of inactivation for VEEV was also achieved under the 60°C and 30% RH environmental condition with Di ranging from 1·6 to 3·1 h. The longest rate of activation was observed using the 22°C and 75% RH environmental conditions with Di ranging from 12·6 to 24·9 h.

Two testing conditions were repeated to obtain an additional timepoint (F.t. at 38°C and 30% RH, and VEEV at 60°C and 30% RH) data due to low initial LR achieved. The second test for each included overlapping data points which for final data analysis were averaged and reported as a single value. Data among overlapping timepoints were generally in agreement with average standard deviations ranging from 0·0 to 2·0 (average 0·6) for F.t. and 0·0 to 4·5 (average 0·8) for VEEV.

Discussion

The results of this study show that by elevating the temperature and the RH of a contaminated building, the rate of inactivation of both F.t. and VEEV is increased on both porous and nonporous surfaces. However, it is important to note that test surface materials can rapidly equilibrate to air temperatures in the test apparatus, due to low thermal mass of the materials relative to the heat input. In a building or structure, overcoming heat loss to the exterior of the structure may be challenging (Stephens and Spackman 2017). Field-scale testing of this decontamination approach is certainly needed prior to its recommendation. Additionally, the process of test surface inoculation for this study by which an aqueous suspension of target organisms was dried onto the test surface may differ in technique from an intentional dry particle release and rates of inactivation may differ.

The amount of test organism applied to each test coupon was consistent. However, amounts recovered from time zero positive controls varied by material type and strain of test organism. Recovery from glass was higher and allowed for a full six log resolution in all but two tests and was consistent with previous attenuation work (EPA, 2015). Recoveries from paper were lowest of the two materials, and, in two instances, no viable test organism was recovered from positive controls after 1 h of drying onto the test surface. It remains unclear if the porous nature of the test surface or some other chemical or molecular mechanism is the cause of this low recovery. Additionally, for both F.t. and VEEV, the attenuated strain of the target organism resulted in lower recovery on time zero controls highlighting strain level differences that may negate the use of these attenuated strains as surrogate organism for future attenuation testing.

Persistence under ambient environmental conditions for F.t. on glass resulted in average Di of 24·2 h. Additionally, F.t. Schu4 was recovered from glass at the longest timepoint tested (10 days, 0·2 log10) under ambient conditions, which differs from previous testing (EPA, 2015) where viable F.t. Schu4 was observed after 63 days on glass under similar ambient conditions (Table 2). Ambient persistence of VEEV resulted in an average Di of 35·8 and on glass only Di 39·2 (Table 3). Using the average T0 recovery for VEEV on glass (7·54 log10), an estimated survival time of 12·3 days can be calculated assuming linear extrapolation. This calculation is consistent with previous work conducted (Sagripanti, 2010) that found a survival rate of 11 4 days.

Elevating the temperature to 60°C (ambient RH) resulted in the highest rate of inactivation of both F.t. and VEEV, resulting in no detectable viability within 1–6 h for F.t. and 6–12 h for VEEV on glass and paper. This elevated temperature is commonly used for treatment of buildings infested with bed bugs (Benoit 2011). Commercial equipment and services are readily available, and treatment could be implemented within various building configurations to achieve this elevated air temperature condition (Table S1). This approach also does not require the added complications of RH modification and material compatibility with oxidizing chemicals. However, further testing at realistic scale are needed to determine operational challenges not encountered during laboratory-scale testing.

Testing was also conducted at 38°C under both ambient and elevated RH conditions. This temperature can be achieved by most home and business recirculating heating and ventilation systems with minimal modifications. To achieve the elevated RH conditions, commercially available equipment and services are readily available (Table S2). Both F.t. and VEEV showed higher inactivation rates at 38°C with elevated RH. This elevated temperature and RH condition resulted in no detectable viability within 24 h for F.t. and between 6–24 h for VEEV depending on material. Results at the same temperature but with no RH modification indicated much higher time to nondetect of an average 150 or 54 h for F.t. and VEEV respectively. An anomaly in the test occurred for F.t. at 38°C and ambient RH conditions on glass, where the Di was higher for the decontamination surfaces (average Di 74·9 h) compared to the controls (average Di 36·1 h). A possible explanation may be the lower RH conditions observed for the elevated temperature test (19% RH) compared to the ambient control (40% RH). It may be possible that for F.t., low RH conditions may also negatively impact survivability and may warrant further investigation.

Ambient temperature (22°C), elevated RH-only tests were conducted (75%) and had varied results by organism. These test conditions for VEEV resulted in the slowest average rate of inactivation (Di 16·4 h), whereas for F.t. yielded a greater rate of inactivation (Di 11 0 h) as compared to elevated temperature of 38°C with ambient RH (Di 45·9 h), but lower than 38°C with the same elevated RH (Di 4·1 h).

In summary, both F.t. and VEEV can persist for extended periods (6–10 days) on both porous and nonporous fomites under ambient conditions. The effect of increasing both the temperature and RH increased the rate of inactivation for both organisms, and a greater than six log reduction can be accomplished in as little as 6 h by elevating temperature to approximately 60°C. These data may be useful for incident commanders and decontamination personnel to provide a less destructive, rapidly deployable means of decontamination following an accidental or intentional biological exposure incident involving nonspore-forming biological agents.

Supplementary Material

Table S1. Commercially available equipment used to elevate temperature and related system specifications.

Table S2. Commercially available equipment used to elevate RH and related system specifications.

Acknowledgements

The US Environmental Protection Agency through its Office of Research and Development funded and directed the research described herein under EP-C-15–002 with Battelle Memorial Institute. It has been subject to an administrative review but does not necessarily reflect the views of the Agency. No official endorsement should be inferred. EPA does not endorse the purchase or sale of any commercial products or services.

Footnotes

Conflict of Interest

No conflict of interest declared.

References

- Alibek K and Handelman S (1999) Biohazard. The Chilling True Story of the Largest Biological Weapons Program in the World-Told from Inside by the Man Who Ran It. Random House, New York: Delta. [Google Scholar]

- ASTM International (2007) Standard Practice for Maintaining Constant Relative Humidity by Means of Aqueous Solutions – E104. West Conshohocken, PA: ASTM International. [Google Scholar]

- Aune K, Rhyan JC, Russell R, Roffe TJ and Corso B (2012) Environmental persistence of Brucella abortus in the Greater Yellowstone Area. J Wildl Manag 76, 253–261. [Google Scholar]

- Benoit JB (2011) Stress tolerance of bed bugs: a review of factors that cause trauma to Cimex lectularius and C. Hemipterus. Insects 2, 151–172. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Berendt RF and Dorsey EL (1971) Effect of simulated solar radiation and sodium fluorescein on the recovery of Venezuelan equine encephalomyelitis virus from aerosols. J Appl Microbiol 21, 447–450. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Brown J, Stallknecht D, Lebarbenchon C and Swayne D (2014) Survivability of Eurasian H5N1 highly pathogenic avian influenza viruses in water varies between strains. Avian Dis 58, 453–457. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Calfee MW and Wendling MQ (2012) The effects of environmental conditions on persistence and inactivation of Brucella suis on building material surfaces. Lett Appl Microbiol 54, 504–510. [DOI] [PubMed] [Google Scholar]

- Calfee MW and Wendling MQ (2015) Inactivation of Burkholderia pseudomallei on environmental surfaces using spray-applied, common liquid disinfectants. Lett Appl Microbiol 61, 418–422. [DOI] [PubMed] [Google Scholar]

- Dennis DT, Inglesby TV, Henderson DA, Bartlett JG, Ascher MS, Eitzen E, Fine AD, Friedlander AM et al. (2001) Tularemia as a Biological Weapon: medical and public health management. JAMA 285, 2763–2773. [DOI] [PubMed] [Google Scholar]

- Graiver DA, Topliff CL, Kelling CL and Bartelt-Hunt SL (2009) Survival of the avian influenza virus (H6N2) after land disposal. Environ Sci Technol 43, 4063–4067. [DOI] [PubMed] [Google Scholar]

- Gut IM, Bartlett RA, Yeager JJ, Leroux B, Ratnesar-Shumate S, Dabisch P and Karaolis DKR (2016) Extraction of aerosol-deposited Yersinia pestis from indoor surfaces to determine bacterial environmental decay. Appl Environ Microbiol 82, 2809–2818. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Harris S (1992) Japanese biological warfare research on humans: a case study of microbiology and ethics. Ann New York Acad Sci 666, 21–52. [DOI] [PubMed] [Google Scholar]

- Holt JG, Sneath PH and Krieg NR (1994) Bergey’s Manual of Determinative Bacteriology, 9th edn. Baltimore, MD: William & Wilkins. [Google Scholar]

- King B, Kesavan J and Sagripanti JL (2011) Germicidal UV sensitivity of bacteria in aerosols and on contaminated surfaces. Aerosol Sci Technol 45, 645–653. [Google Scholar]

- Kumar B, Manuja A, Gulati BR, Virmani N and Tripathi BN (2018) Zoonotic viral diseases of equines and their impact on human and animal health. Open Virol 12, 80–98. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Lai MY, Cheng PK and Lim WW (2005) Survival of severe acute respiratory syndrome coronavirus. Clin Infect Dis 41, e67–e71. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Pyankov OV, Pyankova OG and Agranovski IE (2012) Inactivation of airborne influenza virus in the ambient air. J Aerosol Sci 53, 21–28. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Richter WR, Wood JP, Wendling MQS and Rogers JV (2018) Inactivation of Bacillus anthracis spores to decontaminate subway railcar and related materials via the fogging of peracetic acid and hydrogen peroxide sporicidal liquids. J Environ Manage 206, 800–806. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Rogers JV and Choi YW (2008) Inactivation of Francisella tularensis Schu S4 in a biological safety cabinet using hydrogen peroxide fumigation. Appl Biosaf 13, 15–20. [Google Scholar]

- Rogers JV, Sabourin CLK, Choi YW, Richter WR, Rudnicki DC, Riggs KB, Taylor ML and Chang JCS (2005) Decontamination assessment of Bacillus anthracis, Bacillus subtilis, and Geobacillus stearothermophilus spores on indoor surfaces using a hydrogen peroxide gas generator. J Appl Microbiol 99, 739–748. [DOI] [PubMed] [Google Scholar]

- Rogers JV, Choi YW, Richter WR, Rudnicki DC, Joseph DW, Sabourin CLK, Taylor ML and Chang JCS (2007) Formaldehyde gas inactivation of Bacillus anthracis, Bacillus subtilis, and Geobacillus stearothermophilus spores on indoor surface materials. J Appl Microbiol 103, 1104–1112. [DOI] [PubMed] [Google Scholar]

- Rogers JV, Lastivka AT and Richter WR (2016) Persistence and inactivation of Burkholderia mallei China 7 deposited on nonporous laboratory materials. Appl Biosaf 21, 66–70. [Google Scholar]

- Ryan SP, Calfee MW, Wood JP, Attwood BC and Schaefer FW III. (2010) Research to support the decontamination of surfaces and buildings contaminated with biothreat agents Chapter in Disinfection, Sterilization and Antisepsis: Principles, Practices, Current Issues, New Research and New Technologies. Washington D.C: APIC Publishing. [Google Scholar]

- Sagripanti JL, Rom AM and Holland LE (2010) Persistence in darkness of virulent alphaviruses, Ebola virus, and Lassa virus deposited on solid surfaces. Arch Virol 155, 2035–2039. [DOI] [PubMed] [Google Scholar]

- Sinclair R, Boone SA, Greenberg D, Keim P and Gerba CP (2008) Persistence of category A select agents in the environment. Appl Environ Microbiol 74, 555–563. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Stephens CB and Spackman E (2017) Thermal Inactivation of avian influenza virus in poultry litter as a method to decontaminate poultry houses. Prev Vet Med 145, 73–77. [DOI] [PubMed] [Google Scholar]

- US Environmental Protection Agency, USEPA (2015) Determination of the Persistence of Non-Spore-Forming Biological Threat Agents in the Environment. RTP, NC. EPA/600/R15/3031. Washington, DC: US Environmental Protection Agency. [Google Scholar]

- Verreault D, Killeen SZ, Redmann RK and Roy CJ (2013) Susceptibility of monkeypox virus aerosol suspensions in a rotating chamber. J Virol Methods 187, 333–337. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Wood JP, Meyer K, Kelly T, Choi YW, Rogers JV, Riggs KB and Willenberg ZJ (2015) Environmental persistence of Bacillus anthracis and Bacillus subtilis spores. PLoS ONE 10, e0138083. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Wood JP, Wendling MQS, Richter WR, Lastivka AT and Mickelsen L (2016) Evaluation of the efficacy of methyl bromide in the decontamination of building and interior materials contaminated with Bacillus anthracis spores. Appl Environ Microbiol 82, 2003–2011. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Wood JP, Richter WR, Smiley MA and Rogers JV (2018) Influence of environmental conditions on the attenuation of ricin toxin on surfaces. PLoS ONE 13, e0201857. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Yamamoto Y, Nakamura K, Yamada M and Mase M (2010) Persistence of avian influenza virus (H5N1) in feathers detached from bodies of infected domestic ducks. Appl Environ Microbiol 76, 5496–5499. [DOI] [PMC free article] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Table S1. Commercially available equipment used to elevate temperature and related system specifications.

Table S2. Commercially available equipment used to elevate RH and related system specifications.