Abstract

Purpose:

To determine the predictive power of computational fluid dynamics (CFD)-based dispersion parameters in the development of a new inline DPI that is actuated with low volumes of air.

Methods:

Four new versions of a dose aerosolization and containment (DAC)-unit DPI were created with varying inlet and outlet orifice sizes and analyzed with results from five previous designs. A concurrent in vitro and CFD analysis was conducted to predict the emitted dose (ED; as a % of loaded dose) and aerosol mass median aerodynamic diameter (MMAD) produced by each device when actuated with 10 ml air bursts. CFD simulations of device operation were used to predict flow field and particle-based dispersion parameters.

Results:

Comparisons of experimental and CFD results indicated that multiple flow field and particle-based dispersion parameters could be used to predict ED (minimum RMS Error = 4.9%) and MMAD (minimum RMS Error = 0.04 μm) to a high degree of accuracy. Based on experiments, the best overall device produced mean (standard deviation; SD) ED=82.9(4.3)% and mean MMAD (SD)=1.73(0.07)μm, which were in close agreement with the CFD predictions.

Conclusions:

A unique relationship was identified in the DAC-unit DPI in which reducing turbulence also reduced the MMAD.

Keywords: Powder dispersion, inline DPI, active DPI, CFD simulation of powder breakup, aerosolization with low air volumes, aerosol delivery to children

INTRODUCTION

There is a current need for active dry powder inhalers (DPIs) capable of high efficiency aerosolization that can be operated with low volumes (≤ 30 ml) of actuation air. As demonstrated in previous studies, these devices can be used to administer aerosolized medications simultaneously with non-invasive ventilation (NIV) without interfering with gas support (1, 2). Due to rapid device actuation (on the order of 0.2 – 0.5 s), aerosol administration can be coordinated with the initial phase of inhalation, thereby minimizing environmental losses of the aerosol during exhalation. Active DPIs operated with low air volumes can also administer ventilation gas and aerosolized powder to infants and children. For example, Laube et al. (3) evaluated the Solovent™ (BD Technologies), which was actuated with 5 ml of air, in terms of aerosol delivery through an in vitro model of a 9-month-old infant. At typical tidal volumes for this age range (50 to 100 ml), only approximately 1% of the aerosolized powder reached the tracheal filter (3). Active low-air-volume DPIs are also frequently used to administer test aerosols to animals. The PennCentury™ (Penn-Century, Inc.) device can be operated with as little as 0.2 ml of actuation air, and is designed to administer aerosol directly into the trachea of test animals. At an air volume of 0.2 ml, Hoppentocht et al. (4) reported poor device emptying and aerosolization performance, which improved with higher volumes of actuation air (4–6). Low-air-volume aerosolization devices can also function as the core dispersion unit in high flow passive DPIs that include large values of bypass air.

Our group has recently reported the development of a low-air-volume DPI operated with approximately 10 ml air volumes for the aerosolization of highly dispersible excipient enhanced growth EEG powders (1, 2, 7). The main components of these dose aerosolization and containment (DAC) unit DPIs are the inlet orifice(s), containment volume, and outlet orifice(s), which are each designed to maximize emitted dose and aerosol dispersion for different applications. Actuation of airflow through the inlet orifice forms a high momentum air jet that maintains its form through a majority of the containment volume. The study of Farkas et al. (7) reported that powder dispersion was improved if this inlet air jet did not impinge directly on the initial powder bed. As a result, the DAC-unit DPIs are designed such that the inlet air jet is directed toward the outlet orifice, and secondary velocities arising from velocity change and air compressibility are used for initial powder fluidization. Additional deaggregation then occurs once the powder is aerosolized as it traverses the outlet orifice. The DAC-unit DPI is intended to be produced as one disposable part based on either 3D printing or injection molding with the functions of containing the powder and maximizing aerosolization. Using this approach, a large number of design options are available, including the dimensions and shapes of individual components and the interconnection of these components, with the intent of maximizing aerodynamic factors leading to optimized aerosolization. To evaluate some possible design options, we have considered capsule-based devices that use sharpened capillaries to pierce the capsule and form a fixed flow pathway once the device is assembled (1, 2, 7). Refillable devices are also of interest for lab use and for aerosol exposure experiments with animals (8, 9).

An initial study of a low-air-volume DPI indicated that dispersion was maximized when the central axes of the inlet and outlet orifices were aligned, producing a mass median aerodynamic diameter (MMAD) of approximately 1.6 μm from a highly dispersible EEG aerosol formulation (7). The powder emitted dose (ED) of this device was increased to approximately 85% (of loaded dose) by retracting the distance that the inlet and outlet orifices protruded into the containment volume to approximately 2 mm (1). A custom low-volume spacer was also developed for integrating the rapidly generated aerosol plume into continuously flowing NIV gas. Farkas et al. (2) reported application of the low-air-volume DPI to deliver aerosol simultaneously with NIV therapy. Aerosol delivery efficiency of 55% (based on device loaded dose) was achieved through a low flow nasal cannula system including a low-volume spacer, 4 mm diameter connective tubing, a small diameter nasal cannula interface, and an adult nose-mouth-throat model employing cyclic breathing.

The study of Longest and Farkas (10) conducted a concurrent computational fluid dynamics (CFD) and in vitro analysis of aerosolization in five DAC-unit DPIs operated with 10 ml boluses of actuation air and a spray dried powder formulation. In vitro experiments were used to characterize aerosolization performance in terms of ED and MMAD. CFD simulations predicted both flow field-based and particle-based dispersion parameters, which were compared with the in vitro aerosolization performance. Overall, high turbulent energy was quantitatively correlated with high ED, which was advantageous, but also with increased MMAD, which was not desirable. Strong quantitative correlations were found for different non-dimensional measures of turbulent energy including the turbulent kinetic energy, specific dissipation rate, wall shear stress, and turbulent viscosity. It was theorized that aerosolization in the DAC unit was strongly influenced by the separate mechanisms of (i) initial or primary powder fluidization and (ii) secondary breakup of airborne particles. High turbulence in the vicinity of the initial powder bed improved emptying, but led to overly rapid primary breakup and increased final aerosol size. Potential reasons for this direct association between turbulence and aerosol size are described in the Discussion. In contrast, high turbulence may be desirable in regions of secondary breakup once the initial aerosol is formed.

While a number of studies have considered relationships between dispersion parameters and aerosolization performance for carrier-based and agglomerate formulations, few studies have developed quantitative correlations for spray dried formulations. Previous studies with carrier-based formulations have typically demonstrated that increased turbulence and wall impactions improve aerosol dispersion with reduced MMAD or fine particle fraction (FPF) (11–17). With agglomerate carrier-free formulations, increased wall impactions improve dispersion (18–20). Considering spray dried formulations, Coates et al. (21–23) demonstrated a qualitative relation between the integral scale strain rate and improved dispersion; however, a quantitative correlation with turbulence was not presented. For the development of a three-dimensional rod array dispersion unit, Longest et al. (24) demonstrated a strong quantitative relation between a non-dimensional form of the specific dissipation rate and dispersion. However, these previous studies with spray dried formulations did not consider ED and did not evaluate the region of primary breakup in the capsule (or inhaler), which is central to the performance of the DAC-unit DPI.

While the quantitative correlations established between dispersion parameters and aerosol performance in Longest and Farkas (10) were relatively strong, only five DAC-unit configurations were considered. Moreover, it is surprising that increased turbulence was associated with a detrimental increased MMAD, which is in contrast with most other studies evaluating turbulent dispersion (12, 14–17, 19, 22, 23, 25, 26). Based on these previous observations, a number of open questions remain unanswered. For example, can the correlations proposed by Longest and Farkas (10) be used to predict performance of future DAC-unit DPI designs? Are these correlations sufficiently predictive to capture changes in the DAC-unit inlet diameter and inhaler performance at high ED values? Aerosol dispersion was observed to correlate with multiple flow field and particle based parameters. With an expanded device set, which parameters are most predictive of performance? Are revised non-linear correlated needed to address expected diminishing returns as the MMAD approaches the original primary particle size? Finally, regarding the device, is further optimization possible based on inlet and outlet diameter modifications for a basic capsule shaped containment volume with single inlet and outlet orifices?

The objective of this study was to determine the predictive power of CFD-based dispersion parameters in the development of a new DAC-unit DPI actuated with low air volumes. Four additional DAC-unit designs were considered that modify inlet and outlet orifice configurations while maintaining a constant containment volume geometry. In vitro experiments were conducted to determine aerosol performance in terms of both ED and MMAD. CFD simulations were used to predict flow field-based and particle-based dispersion parameters for comparison with the experimental data. Ultimately, the developed correlations will help to better understand the aerosolization of spray dried formulations and optimize performance of the DAC-unit DPI as well as similar low-air-volume devices.

MATERIALS AND METHODS

Materials

Albuterol Sulfate (AS) USP was purchased from Spectrum Chemicals (Gardena, CA) and Pearlitol® PF-Mannitol was donated from Roquette Pharma (Lestrem, France). Poloxamer 188 (Leutrol F68) was donated from BASF Corporation (Florham Park, NJ). L-leucine and all other reagents were purchased from Sigma Chemical Co. (St. Louis, MO). Quali-V, Hydroxypropyl methylcellulose (HPMC) capsules (size 0) were donated from Qualicaps (Whitsett, NC).

Powder Formulation and Primary Particle Size

To test the performance of the DAC-unit devices, a single batch of spray dried excipient enhanced growth (EEG) powder formulation was produced using the optimized approach developed by Son et al. (27). Albuterol sulfate (AS) was used as a readily quantifiable model drug and mannitol was implemented as the hygroscopic excipient. Based on the study of Son et al. (27), the final AS-EEG spray dried powder formulation consisted of drug, mannitol, L-leucine and Poloxamer 188 in a ratio of 30:48:20:2% w/w. The powder formulation was produced with a laboratory scale B-90 Buchi Nano Spray Dryer (Buchi Laboratory-Techniques, Flawil, Switzerland) with a drying temperature of 70 °C and gas flow rate of 120 L/min (LPM). Primary particles produced by the spray dryer were collected in an electrostatic precipitator and then stored in amber vials in an airtight glass desiccator.

As with all DPIs, the inline DAC-unit devices are intended to disperse a powder formulation into primary particles as efficiently as possible with the input energy that is available. However, powder formulation aggregates are formed during storage and it is typically not possible to break all particle-particle bonds and fully disperse the formulation to primary particles in the form of an aerosol. The powder formulation primary particle size is therefore a theoretical lower limit on the aerosol size that can be approached by a highly efficient inhaler or with a large amount of input energy.

The primary particle size of the EEG powder formulation was tested using a Sympatec HELOS (Sympatec GmbH, Clausthal-Zellerfeld, Germany) laser diffraction system with a ASPIROS/RODOS aerosol dispersion accessory, which uses a pressure drop of 400 kPa to disperse a milligram quantity of powder. Based on a preliminary analysis, the MMAD of the primary particles was calculated (using a theoretical particle density of 1.393 g/cm3) to be 1.18 μm. Fine particle fractions less than 5 μm (FPF<5 μm) and less than 1 μm (FPF<1 μm) were also calculated to further determine primary particle characteristics. The FPF<5 μm value for this powder batch was determined to be 100% while the FPF<1 μm was 38.2%.

The extreme high pressure used by the ASPIROS/RODOS aerosol dispersion accessory (400 kPa) is not intended to simulate DPI aerosolization, however it functions to almost completely deaggregate the powder formulation and provide an estimate of powder formulation primary particle size. For comparison, the operating pressure in the hand-operated syringe of the DAC-unit is approximately 55 kPa. Correct design of the DAC-unit flow pathway is sought in order to produce an aerosol that approaches the primary particle conditions with approximately seven-fold less actuation pressure and actuation air volumes of 10 ml.

Device Designs, Construction and Operation

Four new DAC-unit devices were constructed and tested in this study. Based on previous studies, the low-air-volume DAC-unit device performs well with small (~ 2 mm) protrusion distances of the orifices into the containment volume and when the axes of the inlet and outlet orifices are aligned. With this configuration, an inlet diameter of 0.6 mm and an outlet diameter of 0.89 mm produced best case operation with an ED of 85% (of loaded dose) and an outlet MMAD of 1.8 μm (10). While smaller MMADs were possible, this configuration produced the smallest particle size with an ED that was greater than 80%. In this study, the containment volume was held constant with a characteristic cylindrical or capsule style shape. This containment geometry has an internal volume of 0.68 ml and allows for dose loadings up to approximately 60 mg in the horizontal position before the inlet jet contacts the powder bed. The DAC-unit geometry was held symmetric about the central axis; however, future asymmetrical designs will allow for increased dose loading.

Previous studies have evaluated inlet orifice diameters of 0.6 mm and larger. In this study, a smaller inlet size of 0.5 mm is compared with a 0.6 mm inlet. While this represents a small change in caliber, the associated inlet velocity increases by 44% from approximately 177 to 255 m/s. The associated inlet Mach number increases from 0.51 to 0.74, which indicates increased exposure to flow compressibility effects in the containment volume with the 0.5 mm inlet. The outlet orifice diameter was varied from the previous best case of 0.89 mm to 1.17 mm, with the larger outlet diameter expected to further decrease the jet flow velocity creating stronger secondary velocities and potentially improving ED.

One case of an angled inlet was considered in order to test the previous observation that the inlet jet should not impinge upon the powder. In Case 7, the inlet orifice was angled 10-degrees down towards the powder bed. The outlet orifice was held constant in alignment with the containment volume central axis. Table 1 presents geometric conditions for multiple DAC-unit designs, including five cases considered by Longest and Farkas (10) (Cases 1 to 5) and the four new cases considered in this study (Cases 6 to 9).

Table I.

DAC-unit designs.

| Case | Inlet diameter (mm) | Outlet diameter (mm) | Inlet/Outlet jet anglec |

|---|---|---|---|

| 1a | 0.6 | 0.89 | 0°/0° |

| 2a | 0.6 | 0.89 | −10°/10° |

| 3a | 0.6 | 0.89 | 0°/0° |

| 4a | 0.6 | 0.6 | 0°/0° |

| 5a | 0.6 | 1.17 | 0°/0° |

| 6b | 0.5 | 0.89 | 0°/0° |

| 7b | 0.6 | 0.89 | −10°/0° |

| 8b | 0.6 | 1.17 | 0°/0° |

| 9b | 0.5 | 1.17 | 0°/0° |

Cases and data from previous study of Longest and Farkas (10).

Cases and data from the current study.

Angles relative to a horizontal plane with negative values indicating a downward inlet jet.

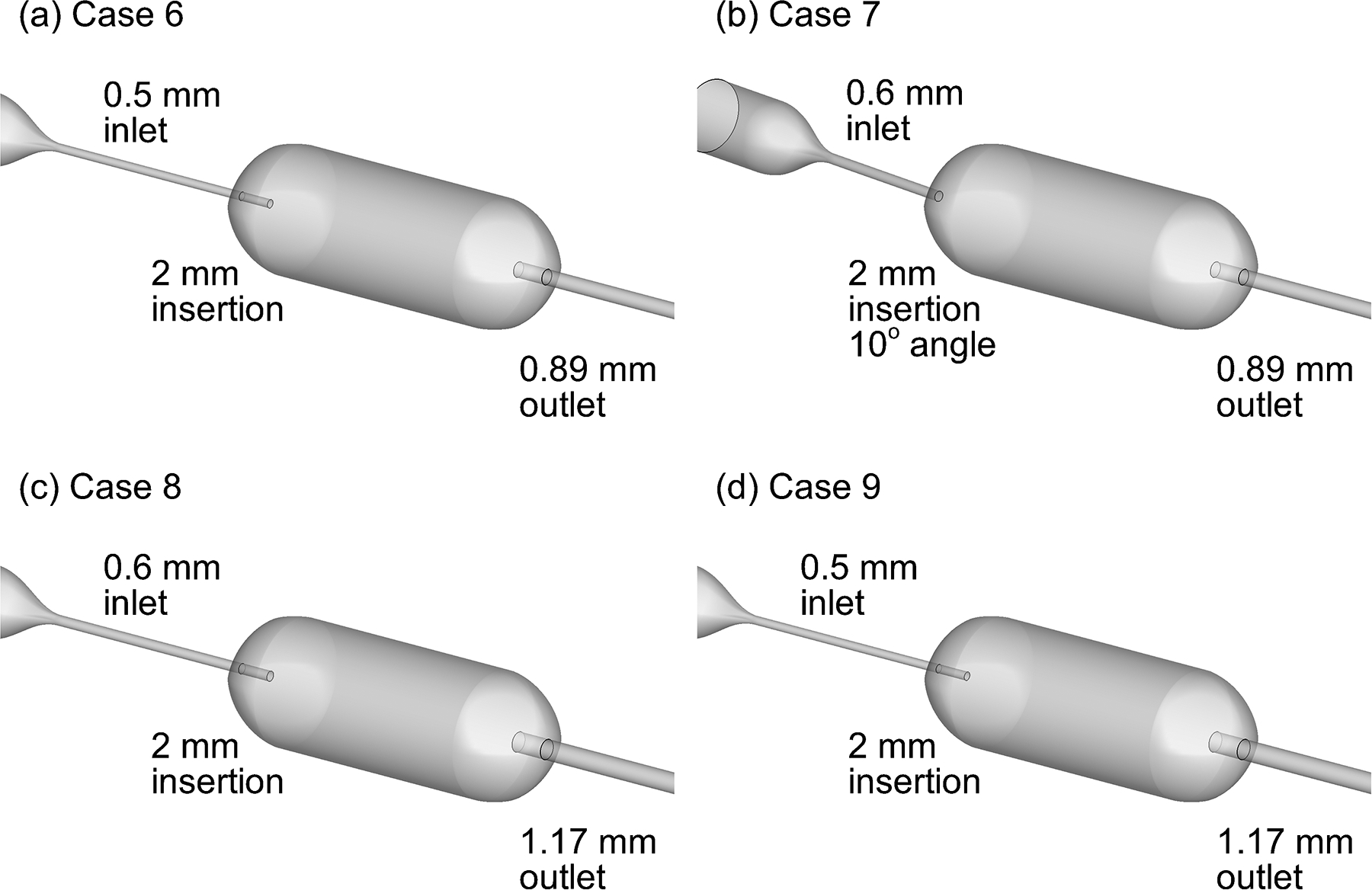

Internal flow pathways of the four new DAC-unit geometries are shown in Figure 1. Physical devices that capture these internal flow pathways were produced using 3D printing and rapid prototype assembly techniques. The DAC units were first drawn in Autodesk Inventor as separate inlet and outlet halves and saved as .STL files. Streamlined initial air inlet and aerosol outlet sections were included in the physical models allowing for inlet and outlet diameters of 4.2 and 7.0 mm, respectively. The part files were then processed using Object Studio software and were built using a Stratasys Objet24 3D Printer (Stratasys Ltd., Eden Prairie, MN) using VeroWhitePlus material at a 32 μm resolution. Support material was cleaned away from the model material using a Stratasys waterjet cleaning station and the devices were allowed to fully dry before use. Custom cut stainless steel capillary tubes were inserted into the two halves of the DAC-unit and glued into place using water-resistant epoxy. For ease of assembly and design parameter variation, the current study employed size 0 HPMC capsules to form an inner liner of the containment unit. The DAC-unit internal flow pathway was formed when the size 0 capsule was placed between the inlet and outlet halves, which were then sealed together with a twisting motion. The hollow capillaries pierced the size 0 capsule forming the protruding inlet and outlet orifices. This flexible approach is intended for optimization of the flow pathway, and with future studies the DAC unit may be built from one material without the stainless steel capillaries and separate capsule.

Figure 1.

Inner surface geometries of the four dose aerosolization and containment (DAC) unit designs considered illustrating the inlet orifice (left-hand side), containment volume, and outlet orifice (right-hand side). Designs include (a) Case 6, (b) Case 7, (c) Case 8, and (d) Case 9.

To operate the DAC-unit device, the containment volume (or capsule) is filled with a mass of powder, which in this study was 10 mg of a spray dried EEG formulation. The central axis of the device was held horizontally, such that the powder formulation creates an initial powder bed along the lower wall of the capsule. This initial powder bed is not in the path of the inlet jet for the cases with aligned inlet and outlet orifices. However, with Case 7 the inlet jet contacts the distal edge of the powder bed and divides on contact with the containment volume wall.

The DAC-unit DPI in this study is actuated with 10 ml volumes of room air provided by a hand-operated syringe. The syringe plunger is depressed quickly delivering the air in approximately 0.2 s (7), which results in a 3 L/min (LPM) flow rate through the system. In the experiments, five actuations of the syringe were performed for each trial, with a three-way valve used to fill the syringe with room air between each actuation. In future studies, a small hand operated air pump or compressed air source may be implemented for actuation.

Aerosol Characterization Experiments

Aerosol performance was assessed in each of the four cases in terms of aerodynamic size and emitted dose. A 10 mg dose of the EEG-AS formulation was weighed and manually filled into the size 0 capsules, which filled approximately 3% of the capsule volume. The capsule was placed within the two device halves, which were then closed and sealed with a 30° turn forming the DAC unit internal flow path. The air-filled syringe was sealed to the DAC-unit inlet with an airtight luer-lock connection. The outlet aerosol was fired directly into the preseparator of a Next Generation Impactor (NGI), which was turned on its side to avoid the need for an induction port. The DAC unit was positioned approximately 3 cm away from the NGI preseparator inlet using a custom adaptor. While approximately 3 LPM of airflow moved through the DAC unit in short bursts, a downstream vacuum pump was used to pull a total of 45 LPM of airflow through the NGI with environmental makeup air entering in the 3 cm gap between the device outlet and NGI inlet. The experiments were conducted under ambient conditions (T = 22 ± 3 °C and RH = 55 ± 5%) with the NGI at room temperature. The preseparator and individual stages of the NGI were coated with MOLYKOTE™ 316 silicone spray (Dow Corning, Midland, MI) to minimize particle bounce and re-entrainment. For each trial, the air syringe was refilled and actuated five times. All measurements were made with three replicates for each design configuration.

After aerosolization, drug masses retained in the DAC-unit (containment volume, outlet orifice, and outlet flow pathway), and the drug collected on the preseparator, impaction plates and the filter of the NGI were recovered by washing with appropriate volumes of deionized water and quantified by high performance liquid chromatography (HPLC) analysis. The mass of AS retained in the device, determined by HPLC, was expressed as a percentage of the loaded AS dose. AS quantification was performed with a validated HPLC method using a Waters 2695 separation module with a 2475 fluorescence detector (Waters Co., Milford, MA). Chromatography was performed using a Restek Allure PFP 150 mm × 2.1 mm column (Bellefonte, PA). The mobile phase, consisting of methanol and ammonium formate buffer (20 mM, pH 3.4) in a ratio of 70:30, respectively, was eluted at a flow rate of 0.4 mL/min and the detector was set to an excitation wavelength of 276 nm and emission at 609 nm. The column temperature was maintained at 25 °C, and the volume of each sample injected was 100 μL. The limit of quantification was 0.5 μg/ml (27, 28). The DAC unit emitted dose (ED) was calculated by subtracting the mass of AS retained in the device from the loaded AS dose.

In order to determine the nominal dose of AS in the EEG-AS formulation, known masses of the formulation were dissolved in 50 ml of water and the mean AS content per mg of formulation was determined using HPLC analysis. For each aerosolization experiment, the measured formulation AS content and the mass of formulation loaded into the capsule was used to determine the loaded dose of AS.

The cut-off diameters of each NGI stage at the operating flow rate of 45 LPM were calculated using the formula specified in USP 35 (Chapter 601, Apparatus 5) and were used to calculate MMAD and fine particle fractions of the delivered aerosol. MMAD was calculated by linear interpolation using a plot of cumulative percentage drug mass vs. cut-off diameter. One-way analysis of variance (ANOVA) and post-hoc Student’s t tests were used with JMP-Pro® 14 (SAS Institute, Cary, NC) for statistical analysis. The p-value < 0.05 was considered as significant.

CFD Simulations

Based on a flow rate of 3 LPM (50 cm3/s) and inlet diameter range of 0.5 to 0.6 mm, the inlet Reynolds number range was 6750 to 8113. The related inlet velocity range was 176.8 to 254.6 m/s, respectively, resulting in a Mach number range of 0.51 to 0.74. At these inlet velocities and Mach numbers (e.g., M > 0.3), the compressibility effects of air should be considered and will result in variable air density and enhanced secondary velocities. The inlet airflow was also fully turbulent considering that the inlet Reynolds number of the jet was >4000. Based on previously established accuracy and computational efficiency (24, 29, 30), the two-equation low Reynolds number (LRN) k-ω turbulence model was selected including shear flow and compressible corrections (31). The standard ideal gas law was used to predict the variable density of air with isothermal wall conditions. Equations governing the conservation of mass and momentum as well as the LRN k-ω model can be found in previous publications (32, 33).

Multiple time scales exist in the DAC-unit flow field. At an upper level, the actuation period was 0.2 s. Moreover, flow oscillations with a period of approximately 0.001 s were also observed to occur. To address the inherent flow oscillations, a transient solution was performed with a time step of 0.0001 s for a consistent 100 time steps. At the resulting final 0.01 s time point, startup effects were observed to be negligible and the flow was in a state of cyclic oscillation. The quality of assessing the solution at one point in time will be assessed based on the predictive power of the correlations that are developed.

Particle trajectories were considered within the DAC-unit flow field. Sample particles were initialized within a powder bed for horizontal actuation. These sample particles were only considered to be tracers recording a time history of turbulence exposure. As a result, a constant particle diameter of 1 μm was assessed. Moreover, inter-particle forces on the tracer particles were not considered. In this manner, a turbulent exposure history could be determined over the approximate trajectory course without the complexity of simulating the full scale breakup of the powder bed. The forces acting on each tracer particle were assumed to be drag and gravity, and the equations governing Lagrangian transport were provided in our previous publications (34, 35). To model random particle motion due to interactions with turbulent eddies, i.e., turbulent dispersion, a random walk method was employed (32, 36). A near-wall anisotropic correction to turbulent particle dispersion was also included (29, 37, 38). Particles were assumed to bounce with a restitution coefficient of unity upon wall contact. This boundary condition was selected because bouncing and re-entrainment were expected for primary particle aggregates through the system.

Construction of the computational grids and performance of the CFD simulations were based on previously established best practices (29, 39, 40). All grids were constructed with high quality hexahedral cells. As shown in our previous studies, hexahedral grids are more time intensive to construct, but provide higher quality solutions in shorter times with less cells (29, 41). For the cases considered, grid independent results were achieve with meshes containing 976,000 – 1,136,000 cells based on negligible changes (<3% relative difference) in the dispersion metrics. Consistent near-wall meshes and grid counts were also employed in all geometries.

The CFD package Fluent 14.5 was used to solve the flow field and particle trajectory equations in each of the cases. To remain consistent with trajectories calculated in Longest and Farkas (10), the particle tracking code was modified to apply turbulent dispersion throughout the geometry, regardless of the local value of turbulent viscosity. This was expected to be realistic considering natural time dependent variations occurring in the velocity field, which minimize the potential for particle stagnation. User-supplied Fortran and C programs were used for the calculation of initial flow and particle profiles, near-wall anisotropic turbulence approximations, near-wall particle interpolation, and dispersion metrics (35). All transport equations were discretized to be at least second order accurate in space. For the convective terms, a second order upwind scheme was used to interpolate values from cell centers to nodes. The diffusion terms were discretized using central differences. The particle trajectory solution was calculated using 4th-order Runge Kutta with an error control routine (42). Both wall impactions and discrete sampling of the turbulence field were conducted using approximately 12,000 or more representative monodisperse 1 μm particles with a density of 1.0 g/cm3. Simulating additional particles had a negligible effect on the particle-based dispersion metrics.

Dispersion Metrics

CFD-predicted dispersion metrics were based on turbulence sampled as either a flow field volume-average or time-average of particle trajectories. Quantities were non-dimensionalized to make the correlations physically relevant to a wider set of designs. Basic turbulence properties are reviewed below, followed by the approach used for flow field volume averaging, particle trajectory time averaging and non-dimensionalization.

The basic measure of turbulence in a flow field is the turbulent kinetic energy, which is defined as (31)

| (1) |

where u′, v′ and w′ represent the fluctuating velocity components in three coordinate directions. In turbulence, the instantaneous velocity at a point (turbulent velocity) is composed of a fluctuating component, e.g., u′, and a time-averaged velocity component, e.g., . Viewed from a flow field perspective, the fluctuating velocities are caused by the turbulent eddies which occur due to instability and exist over a spectrum of sizes at any instant.

A second critical turbulence parameter is the rate at which turbulent eddies are dissipated, or the specific dissipation rate (ω), which is based on the energy of the eddy, represented as k, and the turbulence length scale, l, as (31)

| (2) |

where Cμ is a constant. Multiple studies have suggested that the turbulence length scale is important for predicting the dispersion of powders (23, 24, 43), but have disagreed if eddies should be large or small to maximize powder dispersion.

Turbulence has an enhanced diffusive (or dispersive) effect on momentum, which acts similar to the physical property of molecular kinematic viscosity. To capture this analogy, a turbulent kinematic viscosity is defined

| (3) |

with units that are identical to molecular kinematic viscosity.

The product of k and ω does not have a standard physical interpretation like vT. However, this combination can be viewed as similar to ω but with an increased importance of k related to turbulent length scale l as

| (4) |

Flow field turbulence quantities were calculated as volume-averaged values over the volume of the DAC-unit through the orifice outlet length. For example, for the turbulent kinetic energy, the volume-averaged value was

| (5) |

where Vol is the volume of the DAC unit. Calculating volume-averaged values does not change the units of the underlying turbulence parameters.

Wall shear stress (WSS) is expected to correlate with ED and should be based on a total absolute viscosity (μtotal) including both molecular and turbulent viscosity components. WSS was calculated as an area-averaged value over the entire surface area (A) of the containment volume as

| (6) |

where u is the local velocity parallel to the wall and n is the local wall-normal coordinate.

An advantage of calculating properties based on particle trajectories is that the exposure history to a turbulence metric can be captured while excluding regions of the flow field that particles may not traverse. The average particle residence time based on total particle number (n) is calculated as

| (7) |

and evaluated along a particle trajectory from initialization in the powder bed until the particle exits the DAC geometry. Similarly, the average particle turbulent kinetic energy (kpart) is calculated as

| (8) |

Where k is the local turbulent kinetic energy experience by each particle along its trajectory. The units of kpart can be simplified to Joules (J); hence this quantity represents the work of turbulence on the particle over its history in the geometry. Trajectory integrals were halted if the particle residence time exceeded the 0.2 s physical actuation time of the device. In addition, based on high near-wall values of ω as previously reported (24), maximum trajectory integral values of ∫ωdt were limited to 100,000.

Non-dimensionalization of the dispersion metrics is expected to be necessary so that the results can be translated to different inlet and geometry configurations. Based on convention, non-dimensional quantities are denoted with an asterisk. In the previous correlation study of Longest and Farkas (10), non-dimensionalization of the dispersion parameters was achieved using inlet orifice average velocity (Vinlet) and inlet time scale, tinlet, defined as

| (9) |

where Vol is the DAC-unit volume available for particle motion. In this study, preliminary comparisons indicated that cases with outlet diameters of 1.17 mm, which was different from most cases in Longest and Farkas (10), differed from the previously developed correlations. To better account for the effect of outlet orifice size on an overall velocity, new velocity scale (Vscale) and time scale (tscale) parameters were developed as

| (10a) |

| (10b) |

where doutlet is the DAC-unit DPI outlet diameter in millimeters. While a more general non-dimensionalized approach may be possible, a goal of this study was to evaluate the predictive capabilities of the previously developed correlations with the addition of new cases. The newly defined Vscale and tscale parameters were then used to non-dimensionalize the turbulence quantities as needed. As an example, the non-dimensional form of the volume-averaged turbulent kinetic energy of the flow field is

| (11) |

where the 104 multiplier was included to increase values to within an approximate range of 1 to 10. For particles, the non-dimensional form of the average particle turbulent kinetic energy is

| (12) |

In the previous study of Longest and Farkas (10), field-based dispersion parameters that displayed strong correlations (defined by a correlation coefficient R2 > 0.8) with MMAD were k*field and k*field × ω*field; and field-based parameters with strong correlations with ED were k*field, k*field × ω*field, k*field / ω*field, and WSS. Particle-based dispersion parameters displaying strong correlations (R2 > 0.8) with MMAD were k*part, ω*part, (ωpart / tpart)*, k*part × ω*part, and (ωpart / tpart)* × k*part; and the particle-based parameter with strong correlation to ED was k*part. In this study, these parameters from Cases 1 to 5 are considered as a starting point and additional data points from Cases 6 to 9 are added to the previously determined correlations.

The quality of agreement between each set of data points and associated correlation is assessed based on calculation of a root-mean-square (RMS) error. For each of the nine cases, the different between the predicted (ypredicted) and experimental (yexperimental) aerosol metric (MMAD or ED) is

| (13a) |

The RMS Error value across the nine cases is then

| (13b) |

RESULTS

Aerosolization Experiments

Experimentally determined aerosolization characteristics for the four DAC-unit DPIs evaluated in this study are presented in Table II. Overall, high quality aerosolization is achieved in all cases with MMAD values less than or equal to 2.0 μm and ED values approximately greater than or equal to 80%. In the previous study of Longest and Farkas (10), Case 3 (dinlet = 0.6 mm and doutlet = 0.89 mm) was shown to provide the best overall performance with MMAD (standard deviation; SD) = 1.77 (0.08) μm and ED = 84.6 (6.3) %. Among Cases 6–9, Case 6 (dinlet = 0.5 mm and doutlet = 0.89 mm) performed very similar to Case 3 with MMAD = 1.73 (0.07) μm and ED = 82.9 (4.2) %. Compared with Case 6, Cases 7 and 8 both increased ED by approximately 10% and 5%, respectively, using either an inclined inlet (Case 7) or larger outlet (Case 8). The disadvantage of these cases is an increase in outlet aerosol size to 1.96 μm with Case 7 and 2.0 μm with Case 8. Case 9 appears inferior to Case 6 with a larger MMAD and lower ED. Selection of Case 6 vs. Case 7 likely depends on the application and expected extrathoracic or delivery system depositional losses. With adult applications, the additional 10% ED of Case 7 is likely advantageous with an expected small increase in depositional loss associated with the 1.96 μm aerosol. For pediatric applications, it is likely more important to select the smaller 1.73 μm aerosol to maximize dose delivery to the lungs.

Table II.

In vitro measured aerosolization performance.

| Description | Case 6 | Case 7 | Case 8 | Case 9 |

|---|---|---|---|---|

| MMAD (μm)# | 1.73 (0.07)*^ | 1.96 (0.07) | 2.00 (0.11) | 1.82 (0.09)* |

| GSD | 1.84 | 1.90 | 1.76 | 1.85 |

| ED (%)# | 82.9 (4.3)^ | 91.5 (1.7) | 87.6 (2.2) | 79.2 (4.1)*^ |

Mean aerosol characteristics with standard deviations (SD) shown in parenthesis (n=3).

All DAC-unit DPIs were operated in the horizontal position.

P < 0.05 One-way ANOVA.

P < 0.05 compared to Case 8 in a paired Student’s t-test.

P < 0.05 compared to Case 7 in a paired Student’s t-test.

Statistical analysis of both ED and MMAD were performed, first using one-way ANOVA, then after identifying that a statistical difference was present between the cases, a Student’s t-test was used to determine differences between individual cases (Table II). Based on this analysis, Case 8 exhibited significant differences from Case 6 (p = 0.006) and Case 9 (p = 0.043) for MMAD, as well as Case 9 (p = 0.014) for ED. Differences were also found when comparing MMAD values of Case 7 to Case 6 (p = 0.011) and ED values of Case 7 to both Case 6 (p = 0.013) and Case 9 (p = 0.002).

Flow Field Characteristics

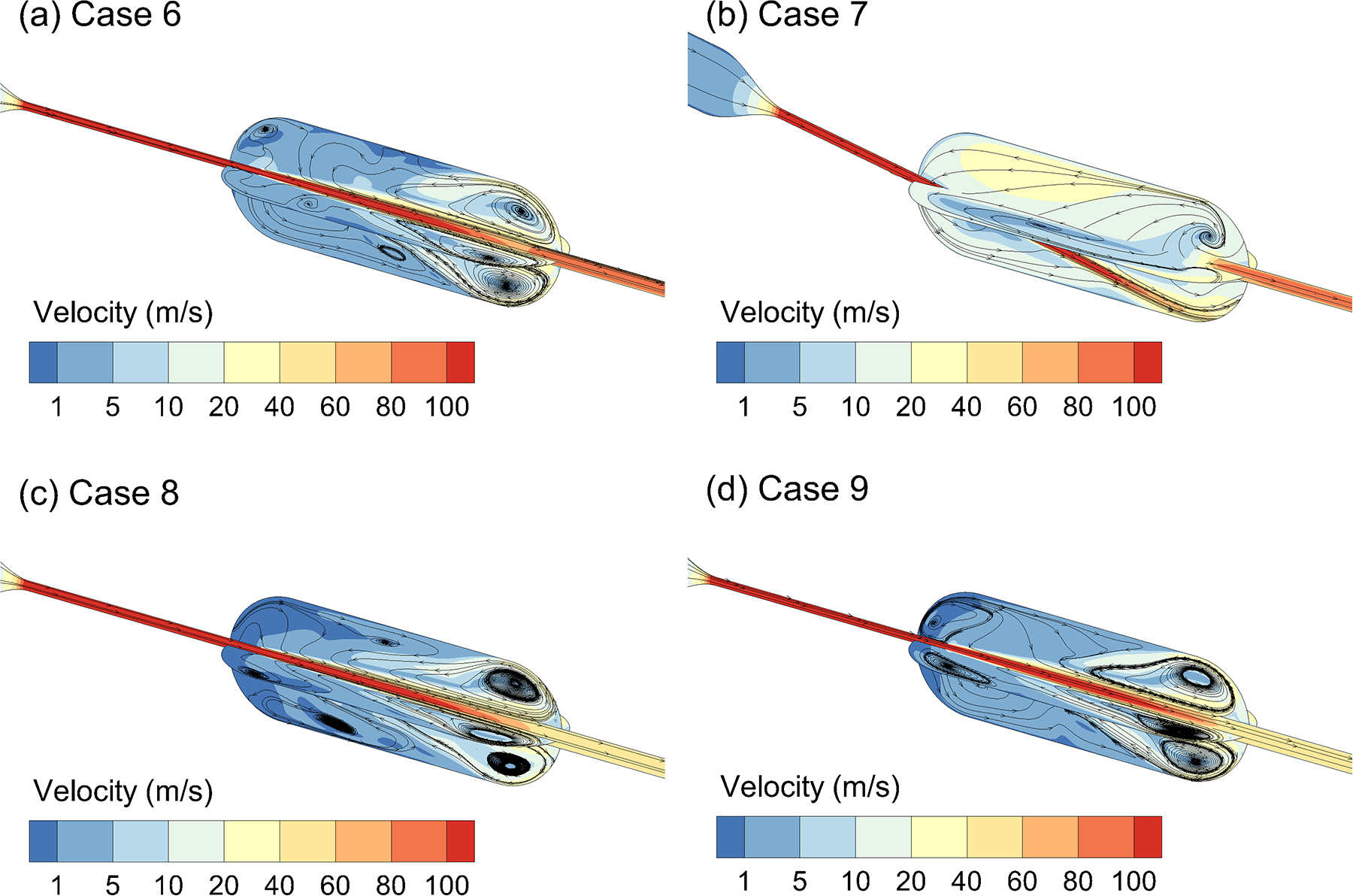

Contour plots of velocity on two cross-sectional planes with two-dimensional stream traces in each plane are presented in Figure 2 based on CFD simulations. In all cases, a strong inlet jet is observed, which continues across a majority the containment volume length until it reaches the outlet, or, with Case 7, the lower wall. Increasing the diameter ratio of the inlet vs. outlet orifice increases secondary velocities, as observed by the tighter streamline patterns in Cases 8 and 9 vs. Case 6. The recirculation pattern in Case 7 is larger and extends the length of the containment volume; however, the effect on particle residence times compared with the other cases is unknown without tracing particle trajectories. Considering velocities, near-wall velocity values of ~5 m/s and below are observed for the two cases with the lowest MMAD (Cases 6 and 9). In contrast, near-wall velocities of 10–20 m/s and higher are observed with Case 7, which also has a larger experimentally determined MMAD.

Figure 2.

Contours of velocity magnitude on two axial planes and 2D stream traces on each plane. The central core of high speed flow (inlet jet) induces significant secondary motion and complex vortical flow fields. Designs include (a) Case 6, (b) Case 7, (c) Case 8, and (d) Case 9.

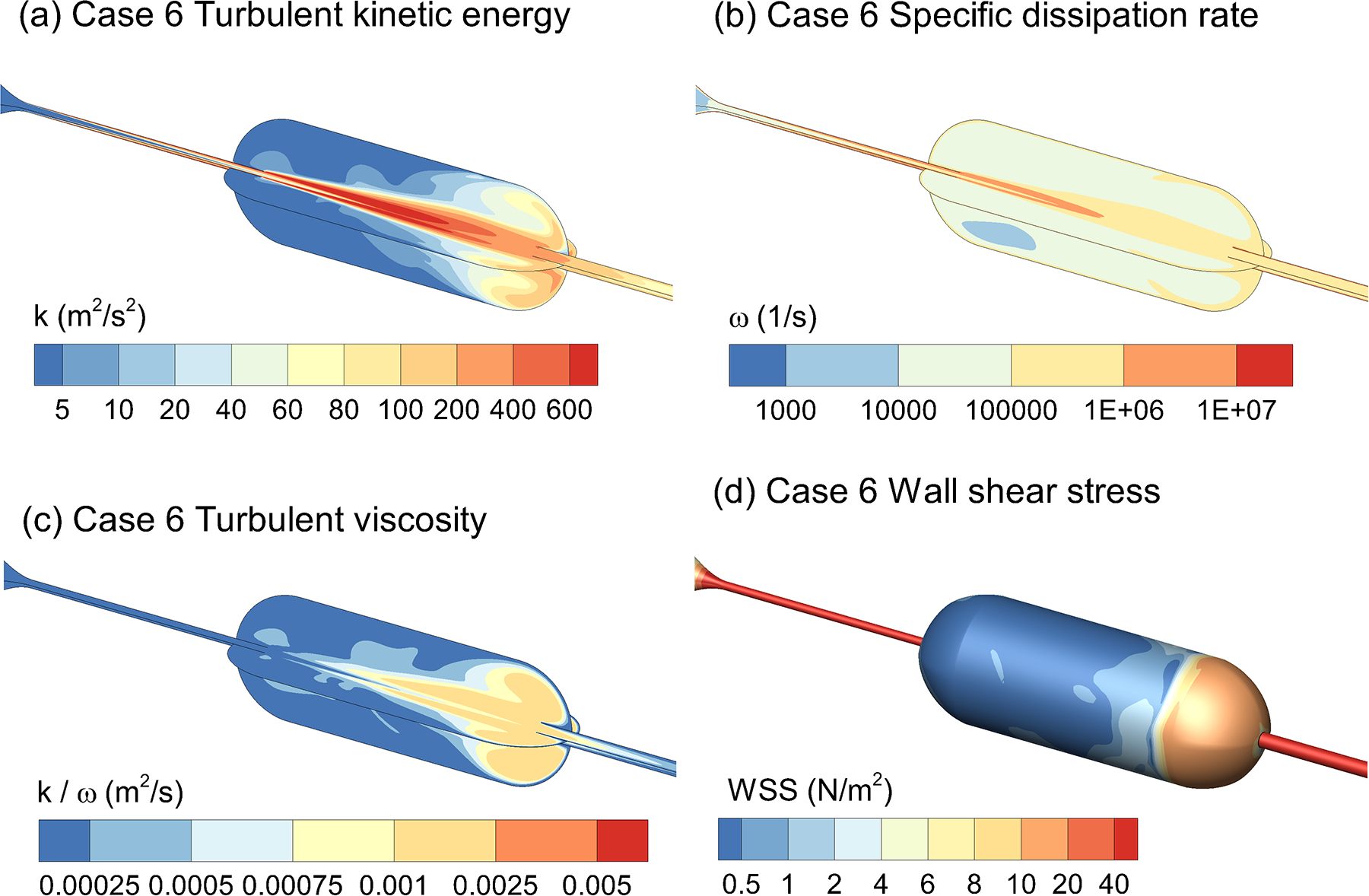

Mid-plane contours of turbulence metrics and surface contours of WSS for Case 6 are provided in Figure 3. Both turbulent kinetic energy (k) and specific dissipation rate (ω) display complex patterns with expected higher values across the region of the inlet jet (Figure 3a and b). These patterns generally minimize turbulence exposure of the powder bed and maximize turbulence exposure of the entrained aerosol. However, increased turbulence values along the containment volume walls near the outlet may not be ideal. The term k/ω provides the turbulent kinematic viscosity of the flow field, which dissipates flow momentum similar to the molecular viscosity of the fluid. Considering that the molecular kinematic viscosity of air is approximately 1.5E-5 m2/s, the turbulent viscosity is 100-fold stronger near the outlet and 10–20 fold stronger in the remainder of the flow field (Figure 3c). As a result, turbulence significantly increases shear stresses on particles through the flow field, which is typically expected to increase secondary breakup of airborne particles.

Figure 3.

Contours of flow field properties for Case 6 including the dimensional forms of (a) turbulent kinetic energy (k), (b) specific dissipation rate (ω), (c) turbulent kinematic viscosity (k/ω), and (d) Wall shear stress (WSS) on the surface of the containment volume and orifices.

The surface-based WSS pattern is illustrated in Figure 3d and shows separate regions of high (~10 N/m2) and low (~1 N/m2) values. A separation region occurs between the high and low areas of WSS where flow following the distal containment volume wall meets other secondary currents and abruptly moves away from the boundary. This separation ring with low WSS is expected to be a region with high particle deposition due to low near-wall velocity and available shear stress to remove particles.

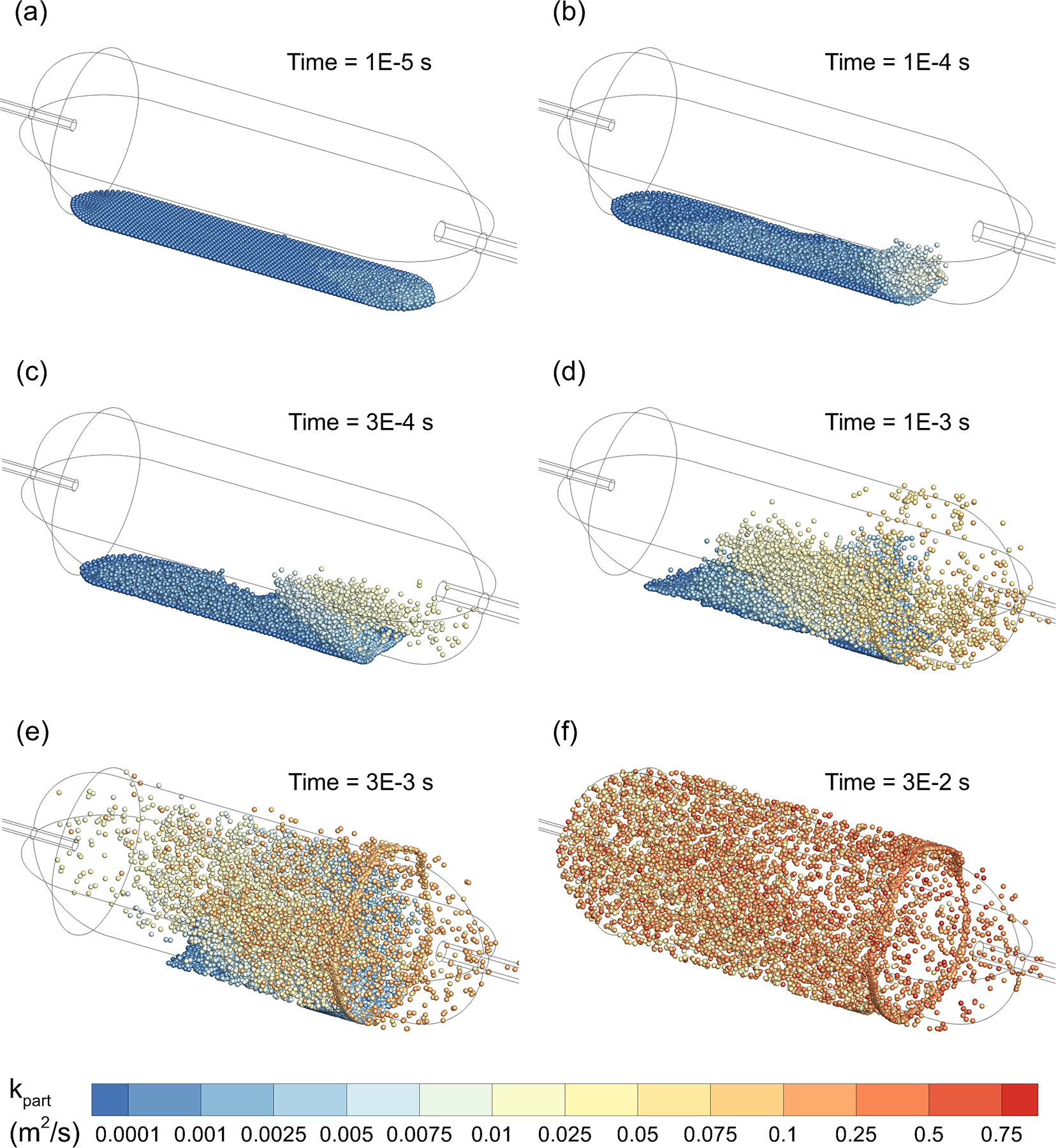

Particle Transport Characteristics

Figure 4 illustrates snapshots of particle motion starting from particles at rest in the powder bed at an initial time of 0 s. Particles are contoured based on the turbulent particle kinetic energy, kpart. Initial signs of particle motion are observed at time t = 1E-5 s near the outlet side of the containment volume (Figure 4a). At time t = 1E-4 s, observable primary fluidization of the powder has begun, which indicates the approximate time scale of primary breakup (Figure 4b). At time 3E-4 s, initially fluidized particles are entering the inlet jet flow and exiting the geometry (Figure 4c). Primary breakup of the remainder of the powder bed is observed around 1E-3 s (Figure 4d). At later times (1E-3 s and 3E-3 s), a ring of particles has collected in the low shear zone along the containment volume wall (Figures 4e and f). At the final time shown of 3E-2 s, full initial dispersion of the powder is complete with continuing particle recirculation and secondary breakup occurring. At this time point, approximately 45% of the loaded particle dose has exited the geometry based on CFD simulations.

Figure 4.

Snapshots of CFD simulated particle position over time contoured based on time-averaged particle turbulent kinetic energy at: (a) 1E-5 s, (b) 1E-4 s, (c) 3E-4 s, (d) 1E-3 s, (e) 3E-3 s, (f) 3E-2 s.

Flow Field-Based Dispersion Parameters

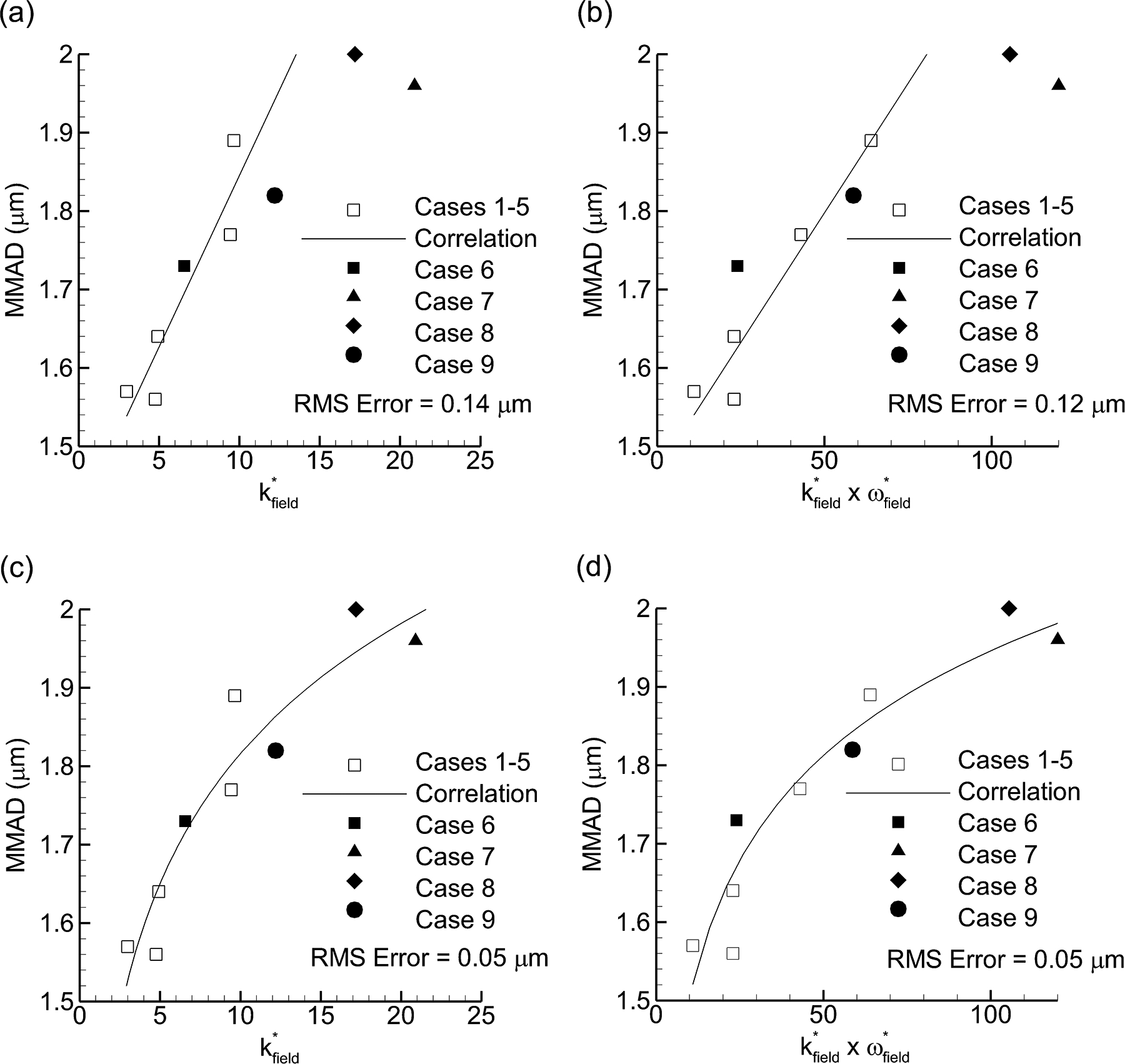

Figure 5 illustrates MMAD vs. flow field-based dispersion parameters that performed well in Longest and Farkas (10). It is important to note that the symbols represent the experimentally determined MMAD values with CFD determined dispersion parameters (k*field and k*field × ω*field). The linear correlations in Figures 5a and b are the correlations determined for Cases 1–5 in Longest and Farkas (10), which are reproduced here. Therefore, agreement between the symbols and correlations represents the ability of the CFD correlations to predict aerosol behavior. In each case, experimental and CFD agreement is quantified as the RMS Error for Cases 1–9.

Figure 5.

Mass median aerodynamic diameter (MMAD) vs. flow field-based dispersion parameters: (a) k*field with a previous linear correlation, (b) k*field × ω*field with a previous linear correlation, (c) k*field with an updated logarithmic correlation, and (d) k*field × ω*field with an updated logarithmic correlation.

Considering the k*field parameter (Figure 5a), the new data continues the trend of higher turbulence also increasing particle size, which is unique to the DAC-unit DPI. Case 7 has a relatively high value of k*field, which deviates from the otherwise linear relationship and causes an increase in the RMS Error to 0.14 μm. Much better agreement is observed between MMAD and k*field with a non-linear (logarithmic) correlation (Figure 5c), with a RMS Error value of 0.05 μm, which is within 5% of the average MMAD. Results are similar with the k*field × ω*field parameter (Figure 5d), with the RMS Error again within 5% of average diameter.

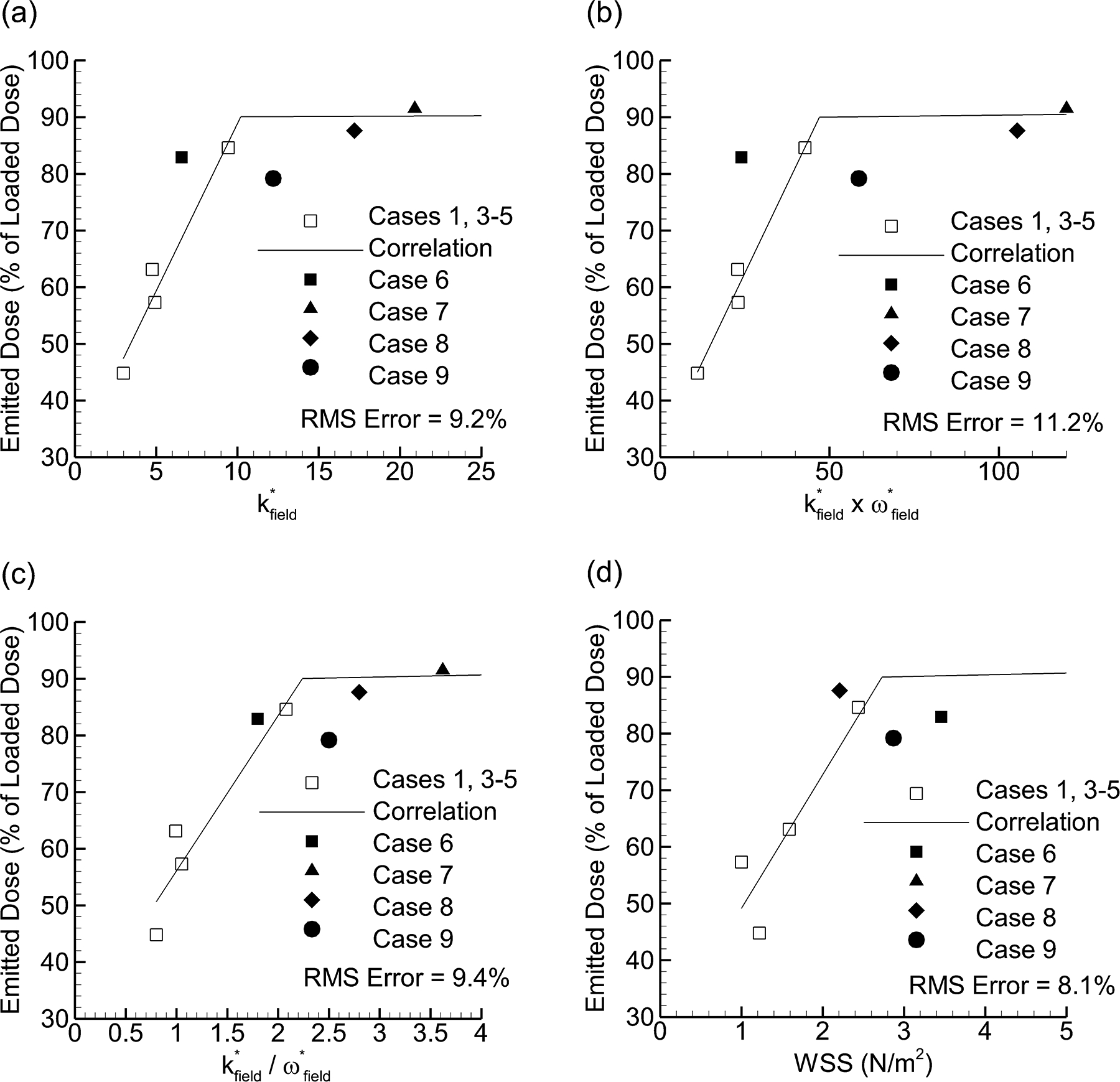

Field-based dispersion parameters vs. experimentally determined ED values are reported in Figure 6. In general, agreement with the previous CFD correlations is reasonable with all RMS Error values less than 12% ED. The surface-based WSS (Figure 6d) includes turbulent viscosity effects, but only occurs on the surface of the containment volume wall and orifices, and has the lowest observed RMS Error of the field-based parameters. The finding that WSS is best correlated with ED is consistent with the idea that higher shear stress will remove more attached particles from the capsule. For all dispersion parameters considered, DAC-unit DPI Cases 6 and 9 are the farthest from the correlation curves and contribute the most to RMS Error. It is observed that Cases 6 and 9 have the highest experimental standard deviation (Table II), which is approximately double that of the other cases, making behavior of these cases the hardest to predict. Cases 6 and 9 also have a smaller 0.5 mm inlet, which implies that some element of the physics is missing from the correlation related to ED.

Figure 6.

Emitted dose (ED) vs. flow field-based dispersion parameters: (a) k*field, (b) k*field × ω*field, (c) k*field / ω*field, (d) WSS.

Particle-Based Dispersion Parameters

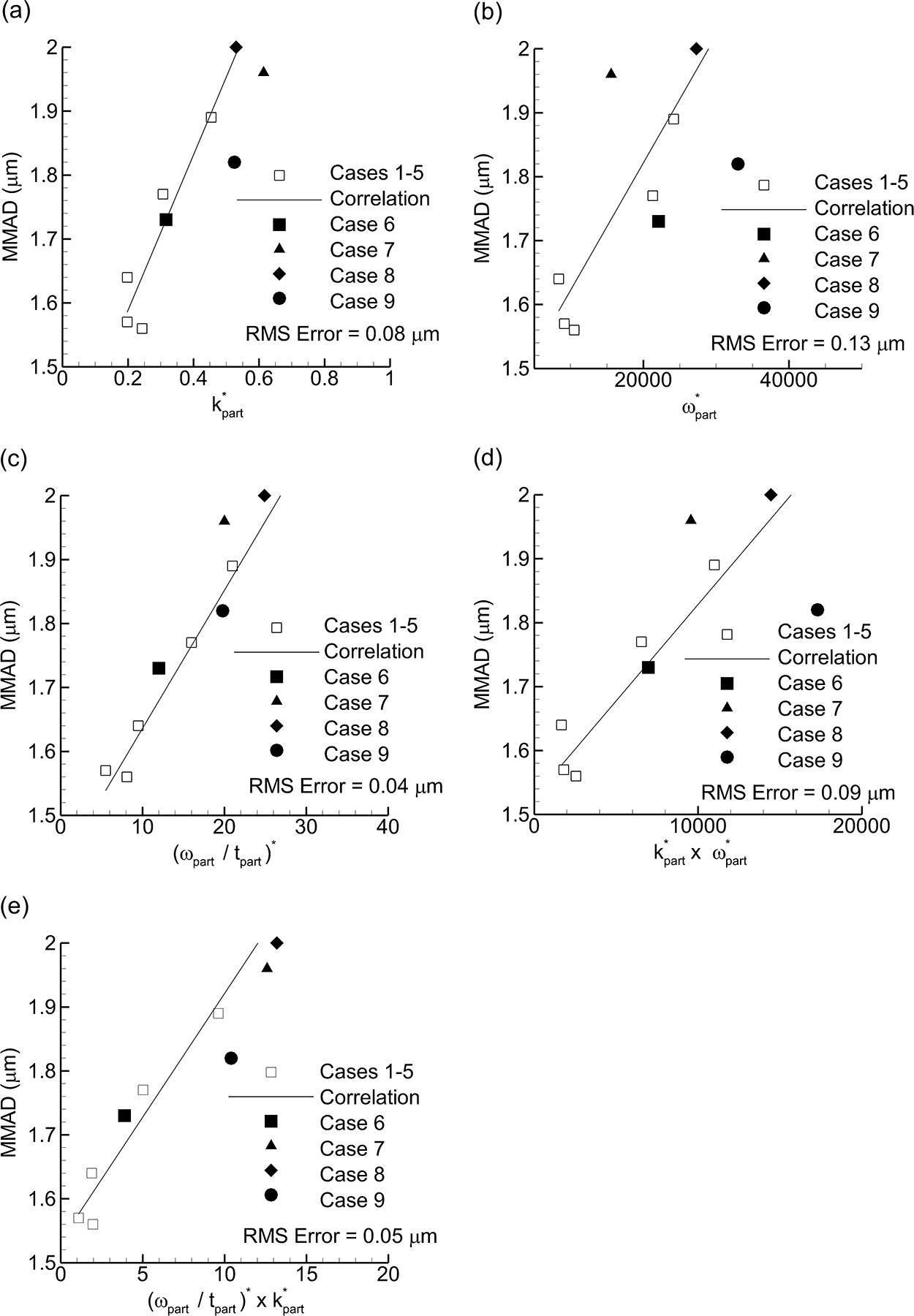

Particle-based parameters for MMAD are illustrated in Figure 7 for all 9 cases considered. Parameters with an RMS Error of 0.05 μm or smaller are (ωpart /tpart)* and (ωpart /tpart)*× k*part. Agreement between k*part and MMAD is reasonable with an RMS Error of 0.08 μm. As a result, turbulent kinetic energy as observed by the tracer particles plays a role in deaggregation; however, in the DAC-unit device, increasing k*part also increases the aerosol size. Correlation between turbulence and MMAD is best with (ωpart /tpart)* based on a RMS Error of 0.04 μm. Therefore, it appears that turbulent kinetic energy, turbulent length scale, and exposure time play a role in deaggregation. That fact that tpart appears in the denominator is interesting in that longer exposure to turbulence once aerosolization occurs and within the capsule chamber decreases particle size. As shown in Figure 7e, increasing the proportion of turbulent kinetic energy beyond that represented in ωpart (Eq. 2) does not improve agreement with the correlation curve.

Figure 7.

Mass median aerodynamic diameter (MMAD) vs. particle-based dispersion parameters: (a) k*part, (b) ω*part, (c) (ωpart / tpart)* (d) k*part × ω*part, (e) (ωpart / tpart)* × k*part.

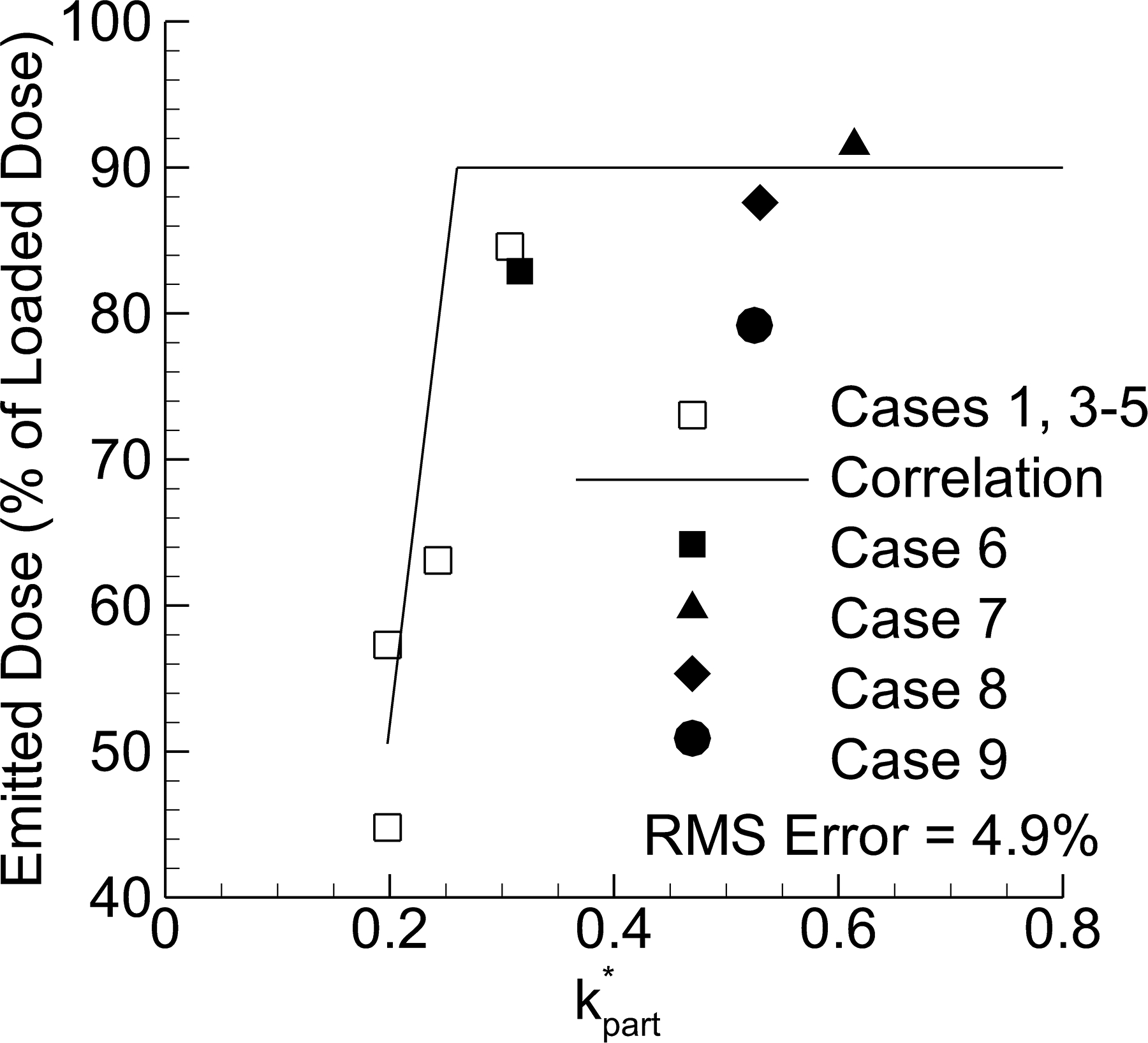

Finally, the only particle-based parameter that correlates with ED is the value of k*part. When including the additional cases of 6 to 9 to the original data, this agreement remains strong with RMS Error of only 4.9% ED. Even with significant increases in k*part values with Cases 7, 8 and 9, ED from the capsule surface cannot exceed approximately 90% of the loaded dose. As observed with the field-based parameters, the largest difference between the correlation curve and data points occurs with the instances of largest standard deviation (Table II), i.e., Cases 6 and 9.

DISCUSSION

The DAC-unit DPI provides a new design approach in which the containment unit (typically a capsule or blister) and aerosolization unit (typically a grid or tube) are combined into one element within an inhaler. Production of the DAC-unit with 3D printing will provide for an almost infinite number of design options for the individual device elements and the combination of these components. Considering this extremely large design space, quantitative analysis and design through CFD modeling was illustrated in this study to be predictive of aerosolization performance.

Through the analysis of four new devices, together with five previous cases, CFD-based dispersion parameters were demonstrated to effectively predict aerosolization performance. For both field-based and particle-based parameters, at least one metric was highly predictive of MMAD and ED, based on RMS Error values less than 0.05 μm and 5%, respectively. The new data set of this study explored performance for different inlet sizes and for devices with high ED values. Varying the inlet size significantly impacted inlet velocity, as expected, and also dimensional turbulence properties like k and ω. However, non-dimensionalizing these properties by characteristic values related to the inlet velocity and inlet time scale minimized differences in the non-dimensional dispersion parameters, which closely matched the experimental performance of the devices. Hence, dispersion parameters worked well for different air jets. Similarly, the dispersion parameters were also predictive for different sizes of the outlet orifice. With respect to emitted dose, the dispersion parameters and existing correlations were predictive for the wide range of ED values considered in this study (i.e., ~45 to 90%).

Considering that the dispersion parameters and existing correlations worked well for multiple different design changes and high ED, it is expected that the correlations will be predictive of other modifications that relate to turbulence and particle residence time. These variables may include volume of the containment unit, length of the orifice protrusions, distance between the orifices and flow rate through the system. Given that Longest and Farkas (10) evaluated powder beds in two configurations, it is expected that the correlations can also address shape of the containment volume.

For the prediction of MMAD, dispersion parameters providing the best correlation with experimental data were identified. Considering field parameters, it was observed that increasing the value of k*field by 2-fold produced a nonlinear trend with MMAD. An updated logarithmic correlation for k*field provided a good fit with MMAD, based on an RMS Error of only 0.05 μm across nine cases. More complex estimates of field properties did not improve agreement. For particle-based parameters, k*part, (ωpart /tpart)*, and (ωpart /tpart)*×k*part were similar with RMS values in the range of 0.04–0.08 μm. Physically, it appears that increasing particle exposure to turbulent kinetic energy increases aerosol size, as discussed later. Dividing ωpart by particle residence time tpart appears important as a way to include the contribution of residence time and isolate maximum exposure to the specific dissipation rate (ω). Viewed another way, once initial fluidization occurs, increasing tpart can be used to reduce (ωpart /tpart)* and thereby reduce aerosol size. This supports a theory of two stage turbulent dispersion. Compared with field-based parameters, the best particle-based correlation for MMAD was slightly more accurate in terms of RMS Error.

For the prediction of ED, WSS and k*part provided the best matches to the existing correlations. Association between WSS and ED is expected as high WSS values will increase the removal of adhered particles from the capsule walls. Correlation between k*part and ED highlights that turbulence plays a predominate role in the initial fluidization of the aerosol.

Considering that ED and MMAD are both linked to k*field, improved performance of Case 6 may not be possible. Increases in k*field to improve ED will provide a simultaneous increase in MMAD (Figure 5c). Decreasing k*field to improve MMAD will simultaneously decrease ED below ~80%. Hence, based on modifications of inlet and outlet diameters, Case 6 likely represents a nearly optimal design within the design space considered. If increasing ED is desired, an alternative choice is Case 8 in which ~90% ED was achieved with the penalty of aerosol size increasing to 2.0 μm. Future improvements in device operation to achieve a particle size near 1.5 μm with ED of approximately 90% will require consideration of different DAC variables, such as reduced volume, multiple outlets or modified shapes, or potential changes to actuation flow rate and volume.

A surprising result of this study is the strong direct correlation between turbulence magnitude and MMAD. Most previous studies on dispersion parameters (with the exception of Longest and Farkas (10)) have predicted that increasing turbulence decreases MMAD (12, 14–17, 22–24). In direct contrast, multiple quantitative correlations explored in this study predict the opposite trend in which increasing turbulence increases MMAD. To explain this observation, we present two theories. In a first explanation, aerosolization in the DAC unit is viewed in the separate phases of (i) initial or primary powder fluidization and (ii) secondary breakup of airborne particles. As shown by multiple other studies, including Longest et al. (24), elevated turbulence is desirable in phase (ii), secondary breakup. In contrast, excessive turbulence in phase (i) fluidizes the powder too quickly, which may be associated with larger initial aggregates or a cloud density that is too high producing diminished secondary breakup. For a highly dispersible spray dried formulation, phase (i) effects may be dominate producing the direct strong correlation between turbulence and MMAD. However, reduced total system turbulence will significantly reduce ED. The DAC-unit design appears beneficial in that reduced turbulence occurs in the region of primary fluidization with elevated turbulence in the region of secondary breakup. Nevertheless, if this theory is true, the DAC-unit design can be improved by decreasing turbulence in the powder bed and potentially increasing turbulence in the remainder of the flow field. This theory is also supported by the findings of Voss and Finlay (12) who suggested that decreasing inhaler turbulence and modifying the powder uptake region could be used to improve inhaler performance.

The main premise behind the second theory on the direct association between MMAD and turbulence is that the DAC-unit DPI generates very high turbulence levels for a very short amount of time. Inlet velocities are near the speed of sound creating a compressible flow environment with turbulence levels that are likely much higher than occurs with passive inhalers. The full relationship between turbulence and MMAD may be parabolic in which initial increases in turbulence decrease MMAD, as observed in previous studies. The DAC-unit device combined with a highly dispersible spray dried powder operates at much higher turbulence values in which increasing turbulence has the opposite effect and increases MMAD. This direct association may occur due to turbulence causing more frequent particle-wall and particle-particle collisions in which aggregates of the spray dried primary particles are re-formed. However, previous studies have not reported turbulence levels in the region of primary fluidization, making it difficult to confirm this theory. If this theory is true, then reducing flow rate could reduce particle size. However, the DAC-units currently operate on the steep portion of the ED curve in which reduced flow rate will also reduce ED. Future designs may seek to reduce flow rate and simultaneously maintain high ED.

Limitations of this study include considering a small number of potential designs, simplifications in the CFD model, and complexity of the in vitro experiments. A limited number of DAC-unit designs were considered to test the effect of variable inlet and outlet sizes and inlet angle. The cases selected were based on previous evidence of best performance conditions. A strength of the concurrent CFD and in vitro approach is that CFD simulations can be confirmed with a relatively small data set of in vitro experiments. Hence, it was not necessary to evaluate additional cases to confirm the CFD model and associated performance of the correlations.

A primary limitation of the CFD model was the exclusion of particle-to-particle and particle-to-wall interactions. It is somewhat surprising and an important finding that aerosolization can be accurately predicted for the spray dried formation through the use of dispersion parameters without including these phenomena. As a result, for the first time, a CFD model was used to simulate full aerosolization within an inhaler from the powder bed through outlet aerosol conditions with very good agreement in comparison with experimental results.

Several factors may complicate the experimental findings. The effects of particle cloud density on deposition in the upper stages of the impactor are unknown. It is also unknown if particle size increase is occurring before the aerosol deposits on the lower impactor stages. Both of these factors will increase the measured aerosol size. Hence, the measured sizes are a conservatively large estimate of the aerosol size exiting the DAC-unit DPI.

In conclusion, considering four additional DAC-unit DPIs confirmed previously established dispersion parameters and correlations, helped identify optimal conditions, and provided additional clarity on device performance. Overall, dispersion parameters provided excellent predictions of aerosolization performance. Aerosol size in terms of MMAD was best captured with particle-based parameters and ED was best captured with field-based parameters. If a single parameter is to be chosen for device optimization, then k*field provided high quality predictions of both MMAD and ED. Of the cases analyzed, Case 6 provided the best combined performance producing a high quality aerosol with an MMAD = 1.7 μm and an ED of 83%. The small size of this aerosol combined with a low flow delivery rate of only 3 LPM in a 10 ml bolus of air is expected to produce excellent lung penetration. As both MMAD and ED are linked to k*field, it may not be possible to simultaneously improve both metrics with additional modifications to orifice conditions. However, the DAC unit device offers numerous design alternatives including shape of the containment volume and modifications to flow rate. Previous studies have also shown significant improvement in ED through surface coatings (44). A unique feature of the DAC-unit DPI was the direct association between turbulence and MMAD. Future studies are needed to better understand this relationship and to see if device performance can be improved by reducing, instead of increasing, turbulence.

Figure 8.

Emitted dose (ED) vs. particle-based dispersion parameter k*part.

ACKNOWLEDGEMENTS

Research reported in this publication was supported by the Eunice Kennedy Shriver National Institute of Child Health & Human Development of the National Institutes of Health under Award Number R01HD087339 and by the National Heart, Lung and Blood Institute of the National Institutes of Health under Award Number R01HL139673. The content is solely the responsibility of the authors and does not necessarily represent the official views of the National Institutes of Health.

ABBREVIATIONS

- 3D

three dimensional

- AS

albuterol sulfate

- CFD

computational fluid dynamics

- DAC

dose aerosolization and containment unit

- DPI

dry powder inhaler

- ED

emitted dose

- EEG

excipient enhanced growth

- FPF

fine particle fraction

- HPLC

high performance liquid chromatography

- HPMC

hydroxypropyl methylcellulose

- LPM

Liters per minute

- M

Mach number

- MMAD

mass median aerodynamic diameters

- NGI

Next Generation Impactor

- NIV

non-invasive ventilation

- RH

relative humidity

- RMS

root-mean-square

- SD

standard deviation

- T

temperature

Footnotes

Author Disclosure Statement

Virginia Commonwealth University is currently pursuing patent protection of devices and methods described in this study, which if licensed and commercialized, may provide a future financial interest to the authors.

REFERENCES

- 1.Farkas D, Hindle M, and Longest PW. Application of an inline dry powder inhaler to deliver high dose pharmaceutical aerosols during low flow nasal cannula therapy. International Journal of Pharmaceutics. 2018;546:1–9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Farkas D, Hindle M, and Longest PW. Efficient Nose-to-Lung Aerosol Delivery with an Inline DPI Requiring Low Actuation Air Volume. Pharmaceutical Research. 2018;35:194. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Laube BL, Sharpless G, Shermer C, Sullivan V, and Powell K. Deposition of dry powder generated by solovent in Sophia Anatomical infant nose-throat (SAINT) model. Aerosol Science and Technology. 2012;46:514–520. [Google Scholar]

- 4.Hoppentocht M, Hoste C, Hagedoorn P, Frijlink HW, and De Boer AH. In vitro evaluation of the DP-4M PennCentury insufflator. Eur. J. Pharm. Biopharm 2014;88:153–159. [DOI] [PubMed] [Google Scholar]

- 5.Duret C, Wauthoz N, Merlos R, Goole J, Maris C, Roland I, Sebti T, Vanderbist F, and Amighi K. In vitro and in vivo evaluation of a dry powder endotracheal insufflator device for use in dose-dependent preclinical studies in mice. Eur. J. Pharm. Biopharm 2012;81:627–634. [DOI] [PubMed] [Google Scholar]

- 6.Morello M, Krone CL, Dickerson S, Howerth E, Germishuizen WA, Wong Y-L, Edwards D, Bloom BR, and Hondalus MK. Dry-powder pulmonary insufflation in the mouse for application to vaccine or drug studies. Tuberculosis. 2009;89:371–377. [DOI] [PubMed] [Google Scholar]

- 7.Farkas D, Hindle M, and Longest PW. Development of an inline dry powder inhaler that requires low air volume. Journal of Aerosol Medicine and Pulmonary Drug Delivery. 2018;31:255–265. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Boc ST, Farkas DR, Longest PW, and Hindle M. Spray dried pulmonary surfactant powder formulations: Development and characterization. Respiratory Drug Delivery 2018. 2018;2:635–638. [Google Scholar]

- 9.Boc ST, Farkas DR, Longest PW, and Hindle M. Aerosolization of spray dried pulmonary surfactant powder using a novel low air volume actuated dry powder inhaler. Respiratory Drug Delivery 2018. 2018;2:639–642. [Google Scholar]

- 10.Longest W, and Farkas D. Development of a New Inhaler for High-Efficiency Dispersion of Spray-Dried Powders Using Computational Fluid Dynamics (CFD) Modeling. The AAPS Journal. 2019;21:25. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Donovan MJ, Kim SH, Raman V, and Smyth HD. Dry powder inhaler device influence on carrier particle performance. Journal of Pharmaceutical Sciences. 2011;101:1097–1107. [DOI] [PubMed] [Google Scholar]

- 12.Voss AP, and Finlay WH. Deagglomeration of dry powder pharmaceutical aerosols. International Journal of Pharmaceutics. 2002;248:39–40. [DOI] [PubMed] [Google Scholar]

- 13.Shur J, Lee SL, Adams W, Lionberger R, Tibbatts J, and Price R. Effect of device design on the in vitro performance and comparability for capsule-based dry powder inhalers. The AAPS Journal. 2012;14:667–676. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.Louey MD, VanOort M, and Hickey AJ. Standarized entrainment tubes for the evaluation of phamaceutical dry powder dispersion. Journal of Aerosol Science. 2006;37:1520–1533. [Google Scholar]

- 15.Xu Z, Mansour HM, Mulder T, McLean R, Langridge J, and Hickey AJ. Dry Powder Aerosols Generated by Standardized Entrainment Tubes From Drug Blends With Lactose Monohydrate: 1. Albuterol Sulfate and Disodium Cromoglycate. Journal Of Pharmaceutical Sciences. 2010;99:3398–3414. [DOI] [PubMed] [Google Scholar]

- 16.Xu Z, Mansour HM, Mulder T, McLean R, Langridge J, and Hickey AJ. Dry Powder Aerosols Generated by Standardized Entrainment Tubes From Drug Blends With Lactose Monohydrate: 2. Ipratropium Bromide Monohydrate and Fluticasone Propionate. Journal Of Pharmaceutical Sciences. 2010;99:3415–3429. [DOI] [PubMed] [Google Scholar]

- 17.Xu Z, Mansour HM, Mulder T, McLean R, Langridge J, and Hickey AJ. Heterogeneous Particle Deaggregation and Its Implication for Therapeutic Aerosol Performance. Journal of Pharmaceutical Sciences. 2010;99:3442–3461. [DOI] [PubMed] [Google Scholar]

- 18.Wong W, Fletcher DF, Traini D, Chan HK, Crapper J, and Young PM. Particle Aerosolisation and Break-up in Dry Powder Inhalers 1: Evaluation and Modelling of Venturi Effects for Agglomerated Systems. Pharmaceutical Research. 2010;27:1367–1376. [DOI] [PubMed] [Google Scholar]

- 19.Wong W, Fletcher DF, Traini D, Chan HK, Crapper J, and Young PM. Particle Aerosolisation and Break-Up in Dry Powder Inhalers: Evaluation and Modelling of Impaction Effects for Agglomerated Systems. Journal Of Pharmaceutical Sciences. 2011;100:2744–2754. [DOI] [PubMed] [Google Scholar]

- 20.Wong W, Fletcher DF, Traini D, Chan HK, and Young PM. The use of computational approaches in inhaler development. Advanced Drug Delivery Reviews. 2012;64:312–322. [DOI] [PubMed] [Google Scholar]

- 21.Coates MS, Chan H-K, Fletcher DF, and Raper JA. Influence of air flow on the performance of a dry powder inhaler using computational and experimental analyses. Pharmaceutical Research. 2005;22:1445–1453. [DOI] [PubMed] [Google Scholar]

- 22.Coates MS, Chan H-K, Fletcher DF, and Raper JA. Effect of design on the performance of a dry powder inhaler using computational fluid dynamics. Part 2: Air inlet size. Journal of Pharmaceutical Sciences. 2006;95:1382–1392. [DOI] [PubMed] [Google Scholar]

- 23.Coates MS, Fletcher DF, Chan H-K, and Raper JA. Effect of design on the performance of a dry powder inhaler using computational fluid dynamics. Part 1: Grid structure and mouthpiece length. Journal of Pharmaceutical Sciences. 2004;93:2863–2876. [DOI] [PubMed] [Google Scholar]

- 24.Longest PW, Son Y-J, Holbrook LT, and Hindle M. Aerodynamic factors responsible for the deaggregation of carrier-free drug powders to form micrometer and submicrometer aerosols. Pharmaceutical Research. 2013;30:1608–1627. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 25.Coates MS, Fletcher DF, Chan H-K, and Raper JA. The role of capusle on the performance of a dry powder inhaler using computational and experimental analyses. Pharmaceutical Research. 2005;22:923–932. [DOI] [PubMed] [Google Scholar]

- 26.Wong W, Fletcher DF, Traini D, Chan HK, Crapper J, and Young PM. Particle Aerosolisation and Break-up in Dry Powder Inhalers: Evaluation and Modelling of the Influence of Grid Structures for Agglomerated Systems. Journal Of Pharmaceutical Sciences. 2011;100:4710–4721. [DOI] [PubMed] [Google Scholar]

- 27.Son Y-J, Longest PW, and Hindle M. Aerosolization characteristics of dry powder inhaler formulations for the excipient enhanced growth (EEG) application: Effect of spray drying process conditions on aerosol performance. International Journal of Pharmaceutics. 2013;443:137–145. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 28.Behara SRB, Longest PW, Farkas DR, and Hindle M. Development of high efficiency ventilation bag actuated dry powder inhalers. International Journal of Pharmaceutics. 2014;465:52–62. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 29.Bass K, and Longest PW. Recommendations for simulating microparticle deposition at conditions similar to the upper airways with two-equation turbulence models. Journal of Aerosol Science. 2018; 10.1016/j.jaerosci.2018.02.007 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 30.Longest PW, and Vinchurkar S. Validating CFD predictions of respiratory aerosol deposition: effects of upstream transition and turbulence. Journal of Biomechanics. 2007;40:305–316. [DOI] [PubMed] [Google Scholar]

- 31.Wilcox DC. Turbulence Modeling for CFD, 2nd Ed., DCW Industries, Inc., California, 1998. [Google Scholar]

- 32.Longest PW, Hindle M, Das Choudhuri S, and Byron PR. Numerical simulations of capillary aerosol generation: CFD model development and comparisons with experimental data. Aerosol Science and Technology. 2007;41:952–973. [Google Scholar]

- 33.Longest PW, Vinchurkar S, and Martonen TB. Transport and deposition of respiratory aerosols in models of childhood asthma. Journal of Aerosol Science. 2006;37:1234–1257. [Google Scholar]

- 34.Longest PW, Hindle M, Das Choudhuri S, and Xi J. Comparison of ambient and spray aerosol deposition in a standard induction port and more realistic mouth-throat geometry. Journal of Aerosol Science. 2008;39:572–591. [Google Scholar]

- 35.Longest PW, and Xi J. Effectiveness of direct Lagrangian tracking models for simulating nanoparticle deposition in the upper airways. Aerosol Science and Technology. 2007;41:380–397. [Google Scholar]

- 36.Gosman AD, and Ioannides E. Aspects of computer simulation of liquid-fueled combustors. Journal of Energy. 1981;7:482–490. [Google Scholar]

- 37.Longest PW, Tian G, Delvadia R, and Hindle M. Development of a stochastic individual path (SIP) model for predicting the deposition of pharmaceutical aerosols: Effects of turbulence, polydisperse aerosol size, and evaluation of multiple lung lobes. Aerosol Science and Technology. 2012;46:1271–1285. [Google Scholar]

- 38.Matida EA, Finlay WH, and Grgic LB. Improved numerical simulation of aerosol deposition in an idealized mouth-throat. Journal of Aerosol Science. 2004;35:1–19. [Google Scholar]

- 39.Vinchurkar S, and Longest PW. Evaluation of hexahedral, prismatic and hybrid mesh styles for simulating respiratory aerosol dynamics. Computers and Fluids. 2008;37:317–331. [Google Scholar]

- 40.Longest PW, and Holbrook LT. In silico models of aerosol delivery to the respiratory tract - Development and applications. Advanced Drug Delivery Reviews. 2012;64:296–311. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 41.Longest PW, and Vinchurkar S. Effects of mesh style and grid convergence on particle deposition in bifurcating airway models with comparisons to experimental data. Medical Engineering and Physics. 2007;29:350–366. [DOI] [PubMed] [Google Scholar]

- 42.Longest PW, Kleinstreuer C, and Buchanan JR. Efficient computation of micro-particle dynamics including wall effects. Computers & Fluids. 2004;33:577–601. [Google Scholar]

- 43.Finlay WH. The Mechanics of Inhaled Pharmaceutical Aerosols, Academic Press, San Diego, 2001. [Google Scholar]

- 44.Behara SRB, Farkas DR, Hindle M, and Longest PW. Development and comparison of new high efficiency dry powder inhalers for carrier-free formulations. Journal of Pharmaceutical Sciences. 2013;DOI 10.1002/jps.23775 [DOI] [PMC free article] [PubMed] [Google Scholar]