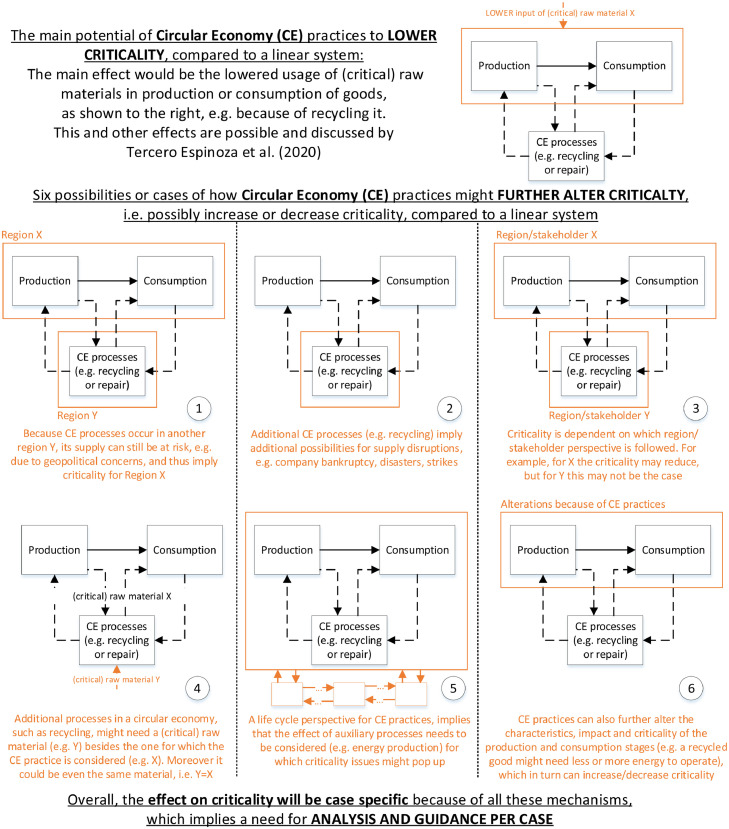

The call for circular economy, both from industry and society, is prominent. Circular economy (CE) practices entail a collection of practices to reuse, recycle etc., which is different from a linear economy where goods are disposed of after usage. One of the drivers for a CE is to reduce the dependency on primary raw materials. Such “economic and technical dependency on a certain material, as well as the probability of supply disruptions, for a defined stakeholder group within a certain time frame” is called criticality (Schrijvers et al., 2020). A circular economy could thus intuitively lead to lower criticality of these primary raw materials by for example recycling them. See Fig. 1 . In line with this, Tercero Espinoza et al. (2020) explain correctly how a circular systems and related mechanisms may indeed lower criticality, but they bring forward a too general and unsupported absolute message in their title: “Greater circularity leads to lower criticality”. (Albeit circularity is not exactly defined in their text, I deduce that circularity implies CE practices). Yet, in their main text is mentioned that “there is a potential to mitigate criticality through a move towards a more circular economy”, which is different from presenting that it will for sure be the case, and they discuss various pitfalls. This is inconsistent and confusing, and the message in the title is too general and wrong in its absoluteness. It is necessary to shed a more consistent light on the interplay between circularity and criticality. Hence, the focus of this manuscript is the additional discussion of how CE practices may further alter and thus potentially also increase criticality, besides decreasing it.

Fig. 1.

Visualization of how Circular Economy (CE) practices might influence criticality compared to a linear reference system. It pinpoints the need for analysis and guidance per case. The case numbers correspond with the numbers of the arguments in the main manuscript. (For interpretation of the references to colour in this figure legend, the reader is referred to the web version of this article.)

More precisely, despite the benefit of CE practices compared to a linear system, it can still be that the new or altered processes for these practices, have a critical nature, e.g. in the sense that they are eligible to supply disruption. Criticality after all also covers secondary raw materials, i.e. the materials derived from other products or waste flows in the society. For them also a supply risk may occur, which is also pointed out by Tercero Espinoza et al. (2020). To make matters more concrete, six further arguments are brought forward below on how CE practices can further alter criticality. They are also presented in Fig. 1. Overlap or combinations of these may also occur. The term “critical raw material” is used in this manuscript to denote materials with a high level of criticality, but keep in mind that any material is critical to a certain extent.

Criticality is commonly evaluated from a regional/country and geopolitical perspective. In other words, the country or region where a raw material is extracted is crucial in defining the extent of the criticality. As a first argument, from this geopolitical perspective, the CE processes could still occur in a country with whom the studied region has a difficult relationship or the specific supply chain is challenging. Moreover, certain reserves of anthropogenic stocks, e.g. waste or products, could still be present in such other countries.

Second, criticality should also be approached from other socioeconomic perspectives, such as a business and company perspectives. In the latter context, companies, have huge control and power, this is especially the case for international companies in the current economic systems. They influence the supply and thus its disruptions. For example, the bankruptcy or the likeliness thereof for a crucial company in a circular system may impede the whole value chain. Tercero Espinoza et al. (2020) discuss this issue of economic viability but then inconsistently mention that it is not explicitly accounted for. From another perspective, certain processes of a circular economy, just like of a linear economy, may be eligible to natural disasters or pandemics such as COVID-19. Another example is that in certain sectors, e.g. the transportation sector which is crucial in the circular economy, workers might strike. Overall, any change in a system may imply new points of potential supply disruption besides also removing other ones present in the linear reference system.

Third, whether a system is circular or materials are used are critical, will depend on the stakeholder group of interest, boundaries of the system, and related feedback effects. The necessity for a stakeholder perspective in CE is already brought forward by Schaubroeck et al. (2019). If CE practices, e.g. recycling, occurs outside Europe, it can be concluded that there is no circular economy within Europe for that recycled material, yet on a global level, it is the case. Likewise, a component may be critical for Europe, but not for another region. This aspect needs to be considered when evaluating their effect on one another. Increasing circularity in Europe may lead to lower criticality for Europe compared to a linear reference system, but not for other regions. For example, if the EU starts to recycle more instead of sending waste abroad, the other waste processing regions loose this inflow of secondary materials. Furthermore, this might affect these other regions and the supply of other goods back to Europe, even the ones not directly related due to complex socioeconomic effects.

Fourth, while criticality may be reduced or be unchanged for a certain set of materials through CE practices, it might be increased for others. For example, when refurbishing certain wooden products to extend their lifetime, tools may be used (e.g. metal or electronic equipment) for which critical raw materials are needed. This aspects of trade-off is crucial to consider, going beyond a focus on the flow of critical raw materials of interest.

Fifth, when analysing a change in an economy, e.g. into a circular economy, a life cycle perspective is needed, considering indirect affected processes, material amounts, building further on the previous argument. The latter is commonly studied through a life cycle assessment (LCA), which focuses on the environmental impact of products and services, and their life cycles, or through related methods such as life cycle sustainability assessment (LCSA), which is similar but covers the totality of sustainability impact. For example, for the LC(S)A of a product, the further impact of its end of life (EoL; e.g. recycling) should be considered, but as well the processes and materials needed for the latter such as electricity, materials and fuels to drive those EoL-processes. There can in fact be trade-offs. Similar types of trade-offs are even mentioned by Tercero Espinoza et al. (2020) in the main text. It can also be that in case of recycling a critical raw material, the net consumption of it at system level increases because of demanding processes elsewhere in the life cycle. As an example of trade-offs at life cycle level, Tran et al. (2018), albeit with a limited preliminary methodology from an EU perspective, showcase that battery recycling lowered usage of some critical raw materials but increased it for others, compared with a linear reference system. Most prominent is the decrease in input of some primary metals used for the battery, but increase in consumption of lime for the recycling processes, for which limestone is to some extent critical, as considered for the EU in 2014. Bear in mind that Tran et al. (2018) present the only application of a method and approach for criticality evaluation of primary raw materials at a complete life cycle level for a CE case study. CE case studies in literature focus commonly only on the amounts of the critical raw material itself that is factually recycled, reused etc.

Sixth, the alteration of CE practices in production and consumption can go beyond lowering input of critical raw materials, e.g. energy demand may be different for a car based on recycled materials. Additionally, keep also in mind that 100% circularity can in practice rarely be obtained because of common material losses or quality degradation, of which the latter is even specified by Tercero Espinoza et al. (2020). This may limit the extent of criticality reduction and maintain the dependency on critical supply chains and materials.

More arguments could be brought forward, but the above already illustrate that the general message “greater circularity leads to lower criticality” of Tercero Espinoza et al. (2020) does not hold. Moreover, criticality covers complex socioeconomic mechanisms (e.g. willingness to return used goods), and not one that purely relates with physical consideration, which is also the case for sustainability science. In such a situation, generalization must be approached with care and not simplistically deduced (Chiu et al., 2020). At best, various case studies are conducted and a meta-study or meta-analysis is performed of these, to possibly underscore that it might be likely the case that less criticality is obtained, but even then such a message cannot be generalized because of the complexity of our socioeconomic system. The analysis in this letter can also be extended towards the sustainability of circular economy systems, among else because it entails criticality, meaning that a circular economy is not necessarily sustainable (Schaubroeck, 2018). Tran et al. (2018) even exemplify that for some impact types, battery recycling has a higher impact (e.g. depletion of fossil fuels). We should avoid that circularity evaluation becomes a substitute for criticality or sustainability evaluation, because circular economy practices may not always lead to less criticality or more sustainability. When comparing with a linear reference system, case specific analysis of criticality and sustainability is still advised at a system level, in which, among else, (1) geopolitical aspects need to be covered for CE practices, (2) complex socioeconomic mechanisms should be considered, (3) dependency on system boundaries and stakeholder groups are specified, (4) trade-offs between materials and processes is considered, (5) a life cycle perspective is upheld and (6) alteration in production and consumption covered. Such an analysis should consider both increasing and decreasing effects on criticality and sustainability, in a scenario comparison of the linear reference system and CE system.

Declaration of Competing Interest

The author declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

Thomas Schaubroeck was supported by the Luxembourg National Research Fund (FNR) through a fellowship (https://www.list.lu/en/research/project/florec/).

References

- Chiu A.S.F., Aviso K.B., Tan R.R. On general principles at the sustainability science-policy interface. Resour. Conserv. Recycl. 2020;158 doi: 10.1016/j.resconrec.2020.104828. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Schaubroeck T. Towards a general sustainability assessment of human/industrial and nature-based solutions. Sustain. Sci. 2018:1–7. doi: 10.1007/s11625-018-0559-0. [DOI] [Google Scholar]

- Schaubroeck T., Petucco C., Benetto E. Evaluate impact also per stakeholder in sustainability assessment, especially for financial analysis of circular economy initiatives. Resour. Conserv. Recycl. 2019;150 doi: 10.1016/j.resconrec.2019.104411. [DOI] [Google Scholar]

- Schrijvers D., Hool A., Blengini G.A., Chen W.-.Q., Dewulf J., Eggert R., van Ellen L., Gauss R., Goddin J., Habib K., Hagelüken C., Hirohata A., Hofmann-Amtenbrink M., Kosmol J., Le Gleuher M., Grohol M., Ku A., Lee M.-.H., Liu G., Nansai K., Nuss P., Peck D., Reller A., Sonnemann G., Tercero L., Thorenz A., Wäger P.A. A review of methods and data to determine raw material criticality. Resour. Conserv. Recycl. 2020;155 doi: 10.1016/j.resconrec.2019.104617. [DOI] [Google Scholar]

- Tercero Espinoza L., Schrijvers D., Chen W.-.Q., Dewulf J., Eggert R., Goddin J., Habib K., Hagelüken C., Hurd A.J., Kleijn R., Ku A.Y., Lee M.-.H., Nansai K., Nuss P., Peck D., Petavratzi E., Sonnemann G., van der Voet E., Wäger P.A., Young S.B., Hool A. Greater circularity leads to lower criticality, and other links between criticality and the circular economy. Resour. Conserv. Recycl. 2020;159 doi: 10.1016/j.resconrec.2020.104718. [DOI] [Google Scholar]

- Tran H.P., Schaubroeck T., Swart P., Six L., Coonen P., Dewulf J. Recycling portable alkaline/ZnC batteries for a circular economy: an assessment of natural resource consumption from a life cycle and criticality perspective. Resour. Conserv. Recycl., Sustainable Resource Management and the Circular Economy. 2018;135:265–278. doi: 10.1016/j.resconrec.2017.08.018. [DOI] [Google Scholar]