Abstract

The objective of this study was to examine the quality enhancement of puffed products made with partial gelatinized waxy and non-waxy type rice. The partial gelatinization process increased water holding capacity of samples, regardless of the gelatinization time, with the puffed waxy rice exhibiting higher water holding capacities than the puffed non-waxy rice. The hardness of puffed rice using partial gelatinized waxy or non-waxy type rice was lower compared with non-partial gelatinized samples. Partial gelatinization also increased the final viscosity of the samples, which was decreased by the puffing treatment. The setback viscosity was higher in the partially gelatinized rice than in the non-gelatinized rice and was lower for the puffing treatment. The in vitro starch digestibility of waxy and non-waxy type rice was improved by a puffing treatment. These results suggest that puffed rice using partial gelatinization treatment enhances the quality and digestibility of soft-textured foods.

Keywords: gluten-free, in vitro digestibility, partial gelatinization, pasting properties, puffed rice

INTRODUCTION

Rice (Oryza sativa L.), a major cereal and staple food, provides energy and nutrients in the human diet (Cairano et al., 2018) and is therefore globally consumed in large quantities. Thus, rice and rice-based cereal products are the most commonly used cereal commodities for their nutritional benefits, low allergic reaction potential, and mildness (Pedron et al., 2016; Lee et al., 2019).

Celiac disease (CD) is an immune-mediated systemic disorder, in which the immune system strongly reacts to certain prolamins, gluten components responsible for the mediated responses (Cairano et al., 2018; Arslan et al., 2019). Gluten-free (GF) diets are mainly affected by the grain’s food group and thus, people adhering to a GF diet must consume foods made from GF grains (e.g. rice, corn, and millet) to replace wheat-, barley-, and rye-based foods (Thompson, 2009). Notably, rice flour is already used in the production of GF baked foods (Cairano et al., 2018); however, commercially available GF bakery products are often poor in nutritional value, flavor, and texture (Arslan et al., 2019).

The physiochemical characteristics and functional properties of cereals and staple grain flours can be physically modified through various treatments such as fine grinding and dry/wet thermal treatments (Sun et al., 2018). Pregalatinization is one of the physical methods used for modification (Nakorn et al., 2009). Moreover, the hydrothermal treatment of rice for the production of pregelatinized rice flour is a complex process with changes in the physicochemical properties of starch (Lai, 2001).

The puffing process applies heated high-pressure steam followed by an abrupt decrease in pressure causing vaporization, which instantaneously evaporates the water accumulated within the grains (Kim et al., 2018; Lee et al., 2019). This process reduces moisture and increases the specific volume of the food matrix, thereby modifying the physicochemical properties, expanding the volume, and improving the structure of the rice to produce a porous texture (An et al., 2011; Kim et al., 2018). Puffed cereals are widely used as ready-to-eat products and ingredients in snack formulations and their demand is increasing in response to changing lifestyles (Cattaneo et al., 2015). These puffed cereals, which include rice, wheat, maize, oats, and barley, are mainly appreciated for their crispness and lightness, qualities that are related to the cellular structures of the grains (Hoke et al., 2005; Hoke et al., 2007; Cattaneo et al., 2015; Mir et al., 2016). The puffing process significantly increases the volume of the rice kernels during the puffing process and the fully heat-treated rice grains become crisp and highly porous (Hoke et al., 2005; Mir et al., 2016). The objective of this study was to investigate the quality changes of puffed products based on waxy and non-waxy rice by partial gelatinization processing.

MATERIALS AND METHODS

Sample preparation

Waxy (crude ash, 0.48%; protein, 6.75%; amylose, 7.24 %) and non-waxy (crude ash, 0.38%; protein, 5.82%; amylose, 20.67%) Korean rice locally produced was purchased from markets in Gunsan region. The rice grains were washed three times under flowing tap water and then allowed to drain for 20 min. For the partial gelatinization treatment, the samples were placed into a stream container and treated with steam for 0, 5, and 10 min. Samples were dried using a convection dry oven (LDO 250F, Labtech Co., Ltd., Namyangju, Gyeonggi, Korea) until the moisture content was 14±1%. The non-waxy and waxy rice samples subjected to partial gelatinization treatment for 0, 5, and 10 min were labelled as GR0, GR5, and GR10, and GW0, GW5, and GW10, respectively; the capital letters indicating sample type and the number indicating gelatinization treatment time. The puffing treatment conditions were determined in preliminary experiments. The partially gelatinized samples [waxy (GW0) and non-waxy (GR0)] were puffed at 240°C for 6 s using a puffing machine (Basaking, HRS Co., Ltd., Seoul, Korea). The GR0, GR5, GR10, GW0, GW5, and GW10 samples that underwent subsequent puffing treatment were labelled PGR0, PGR5, PGR10, PGW0, PGW5, and PGW10, respectively. The samples were milled (HMF-995, Hanil Co., Ltd., Asan, Chungnam, Korea) or placed in plastic bags, and used further analyses.

Approximate compositions, amylose contents, water-holding capacities (WHCs), and color values

The crude ash and crude protein contents of the samples were analyzed following approved methods (protocols 08-01 and 46-12, respectively; AACC, 2000), while the amylose contents were determined following the iodine colorimetric procedure described by Williams et al. (1970) and Kang et al. (2010). The WHC of each sample was measured in accordance with the methods of Medcalf and Gilles (1965) and Lee and Kang (2016). Color value of the sample was determined using a spectrophotometer (CM-5; Konica Minolta Inc., Tokyo, Japan) calibrated with zero and white plate and expressed as lightness (L*), redness/greenness (a*), and yellowness/blueness (b*) values.

Texture analysis

To elucidate the differences in height, width, and hardness between the partial gelatinized grain and puffed partially gelatinized products, the textural properties of the samples were determined using a texture analyzer (Lloyd TA1; AMETEK, Inc., Berwyn, PA, USA) equipped with a 500 N load cell. The probe and compress conditions for use were set through preliminary experiments. The texture profiles of the partially gelatinized rice samples were analyzed with sample compression at 50% of the sample height and a test speed of 50 mm/min using a 5 mm cylindrical stainless steel probe. Texture profiling of the puffed partially gelatinized rice samples were performed with sample compression at 38.5% of the sample height using a 10-mm cylindrical stainless steel probe.

Pasting profiles and scanning electron microscopy (SEM)

The pasting properties of the samples were determined using a rapid visco-analyzer (RVA4500; Perten Instruments, Hägersten, Sweden) according to the manufacturer’s instructions for rice. The samples were analyzed based on 14% sample moisture contents. The sample-water suspension (sample in 25 mL water) was heated to 50°C, held at 50°C for 1 min, and then heated to 95°C at a heating rate of 10.04°C/min. The sample was then held at 95°C for 7.18 min and finally cooled to 50°C at a cooling rate of 11.84°C/min.

The microstructural properties were determined by SEM (S4800eds; Hitachi Ltd., Tokyo, Japan). The samples were freeze-dried prior to analysis and the microstructures of the samples coated with a thin film of gold were analyzed at 5,000× magnification.

In vitro starch digestibility

In vitro starch digestibility was measured following the methods of Zhang et al. (2011) and Jang et al. (2015). Pancreatin-derived porcine pancreas (P7545) and amyloglucosidase (A9913) were purchased from Sigma-Aldrich Inc. (St. Louis, MO, USA). Samples were milled to pass through a sieve of pore diameter 500 μm. Rice flour (500 μm, 1 g) was accurately weighted and mixed with distilled water (20 mL) at 37°C, followed by dispersion. Pancreatin-derived porcine pancreas solution (2.5 mL, 0.05 g in 35 mL 0.1 M NaHCO3) and amyloglucosidase (0.02 mL /g sample) were next added and the sample was vortexed. The pH was then adjusted to 7.5 with 0.1 N NaHCO3. Sample aliquots (0.1 mL) were collected at different times (30, 60, and 90 min) during digestion at 37°C and mixed with 1.4 mL ethanol (99.9%). These solutions were centrifuged at 600 g for 5 min and the released glucose contents of the supernatants were measured using a D-glucose kit (GOPOD-format, Megazyme, Bray, Ireland) at 510 nm.

Statistical analysis

Data were expressed as means±standard deviation (SD). The differences between the sample means were determined from the analysis of variance using SAS software (version 7.0; SAS Institute Inc., Cary, NC, USA). The P value between the mean values was identified at the 5% probability level using Duncan’s post hoc test.

RESULTS AND DISCUSSION

Moisture, WHC, hardness, and color value

Following partial gelatinization treatment, the moisture contents of the waxy and non-waxy rice samples were in the range 13.31∼14.79% and decreased following the puffing treatment (Table 1). Moisture contents for GR0, GW0, PGR0, and PGW0 samples were 14.99%, 12.81%, 9.96%, and 9.84%, respectively. Lee et al. (2019) reported that the moisture content of a puffed rice and oat snack decreased significantly with increasing explosive puffing pressure. The degree of moisture loss in puffed chitin samples was reported to increase with increasing puffing pressure (Huang et al., 2018).

Table 1.

Moisture content, water holding capacity (WHC), hardness, and color value of waxy and non-waxy rice following partial gelatinization and puffing treatment

| Samples | Moisture (%) | WHC (%) | Hardness (N) | Color values | ||

|---|---|---|---|---|---|---|

| L* | a* | b* | ||||

| Partial gelatinized rice | ||||||

| GR0 | 14.99±0.13a | 138.47±3.84b | 79.13±9.46c | 93.24±0.09b | −0.69±0.01e | 8.41±0.08ab |

| GR5 | 14.79±0.39a | 204.78±7.71a | 131.58±41.94b | 92.21±0.07e | −0.56±0.04d | 8.15±0.39b |

| GR10 | 13.59±0.01b | 218.13±8.66a | 163.80±44.50a | 92.39±0.02d | −0.60±0.05d | 8.75±0.26a |

| GW0 | 12.81±0.40c | 134.81±4.36b | 97.43±23.67c | 94.59±0.05a | −0.14±0.01a | 6.41±0.07d |

| GW5 | 13.31±0.16bc | 206.81±15.52a | 104.17±42.65bc | 93.31±0.03b | −0.32±0.01b | 7.78±0.04c |

| GW10 | 13.77±0.32b | 205.73±6.93a | 90.53±38.58c | 93.03±0.05c | −0.37±0.02c | 8.59±0.04a |

| Puffed rice | ||||||

| PGR0 | 9.96±0.11bc | 711.14±29.21b | 44.30±11.21a | 83.18±0.10d | 4.34±0.04a | 19.49±0.09a |

| PGR5 | 10.44±0.06a | 761.89±26.49b | 31.28±10.02b | 84.67±0.13a | 3.67±0.03b | 18.64±0.06b |

| PGR10 | 10.25±0.14ab | 717.90±24.91b | 32.71±7.21b | 84.45±0.08b | 3.27±0.03c | 17.84±0.06c |

| PGW0 | 9.84±0.23c | 914.47±47.00a | 27.74±9.76b | 83.76±0.09c | 3.68±0.03b | 17.55±0.03d |

| PGW5 | 10.60±0.03a | 912.65±25.47a | 17.04±7.14c | 82.51±0.08e | 4.35±0.04a | 18.77±0.13b |

| PGW10 | 10.04±0.18bc | 905.29±8.43a | 19.38±6.57c | 82.16±0.09f | 4.34±0.02a | 18.66±0.09b |

The value designated by different letters (a-f) within the same column differ significantly (P<0.05).

The values are expressed as mean±SD (n=18).

The WHCs of GR0 and GW0 samples were 138.47% and 134.81%, respectively, and increased by partial gelatinization regardless of the type of rice (waxy and non-waxy). The WHC of the PGR0 and PGW0 samples were 711.14% and 914.47%, respectively. The WHC were higher in puffed rice than in non-puffed rice and following the puffing process, the waxy rice samples presented higher WHC than the non-waxy rice. However, for the puffed samples, the WHC was not significantly affected by partial gelatinization treatment (P>0.05). This was consistent with the results reported by Tie et al. (2012) that puffed rice snacks made with waxy rice had higher water absorption indices than samples made from non- waxy rice. Mariotti et al. (2006) reported that the new organization of the outer layers and the high porosity of the matrix are responsible for the rapid hydration of the puffed cereals. The lower water absorption index and water solubility index of native rice starches imply a greater degree of associative forces in granules (Nakorn et al., 2009). Mondal and Kumar (2019) reported that with the increase in pregelatinization time, the amylose content and WHC tend to increase. Moreover, Zapotoczny et al. (2006) reported that these water absorption characteristics of puffed and extruded cereal products can be interpreted via their starch-water-protein interactions, which affect the solid phase structure of the processed materials.

The hardness values are listed in Table 1. The GR0, GR5, and GR10 samples presented hardness values of 79.13, 131.58, and 163.80 N, respectively, while those of PGR0, PGR5, and PGR10 were 44.30, 31.28, and 32.71 N, respectively. For puffing treatment, the waxy rice sample showed lower hardness than the non-waxy rice. The hardness value of the puffed samples using partially gelatinized rice were lower than those of the non-partially gelatinized samples, regardless of the rice type. In our study, hardness of the GW10 sample was lower than that of GW5. Nakorn et al. (2009) reported that in scanning electron micrographs, rice starch granules appeared to be disintegrated and holes were formed after pregelatinization, while the granular structure of high-amylose Chiang rice starch was less affected. Agama-Acevedo et al. (2018) reported that hydrothermal treatment is not commonly performed on gelatinized starches as their granule structure is usually disrupted on gelatinization; e.g., high amylose starches retain a degree of granule structure. Puffing treatment reduces the rice thousand-kernel weight and significantly increases its surface area (Hidalgo et al., 2016), while lowering the bulk density (Mir et al., 2016), as the grains expand. As a result, the extruded puffs with a less hard and crispy structure degrade into smaller particles during oral processing and require less work for bolus formation than flakes (Alam et al., 2017). In this study, rice hardness increased following partial gelatinization treatment; however, the samples treated with partial gelatinization presented lower hardness scores after the puffing treatment and was considered to be attributed to more pore formation in the grains during the puffing process.

Food color is an important quality that affects consumer preference. The L* values of the GR0 and PGR0 samples were 93.24 and 83.18, respectively, with puffed rice exhibiting lower L* values than non-puffed rice (Table 1). The a* values of the samples increased following puffing treatment. The increased a* value for puffed samples might be attributed to the browning reaction that occurs as a result of the high temperature and pressure conditions. Similar to our research results, Lee et al. (2019) reported that lightness decreased with increasing puffing pressure of puffed rice. An et al. (2011) demonstrated that the puffing process induced a browning reaction via rapid depressurization.

Pasting properties and SEM analysis

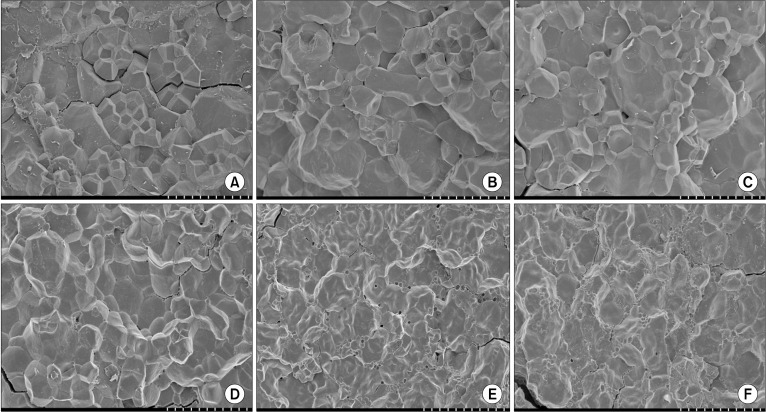

The pasting properties and scanning electron micrographs of the different rice samples are presented in Table 2 and Fig. 1, respectively. The peak viscosities of the GR0 and GW0 samples were 4,671 and 1,113 cP, respectively, and the non-waxy samples presented higher values than the waxy samples (Table 2). The peak viscosity following partial gelatinization treatment increased in the waxy samples but decreased in the non-waxy samples. The final viscosity of the partially gelatinized rice was higher in the non-waxy than in the waxy samples. Puffing treatment markedly decreased the final viscosity of all the partially gelatinized samples. The final viscosities of the PGR0, PGR5, and PGR10 samples were 640, 892, and 1,153 cP, respectively, which increased following partial gelatinization. However, the puffed rice made with partially gelatinized waxy rice exhibited the opposite trend. Similar to our research results, Lai (2001) reported that the pasting and hydration properties of hydrothermally-treated rice were markedly dependent on rice variety (or amylose content), and its opposite impact on the treated waxy and non-waxy rice may be due to the amorphous regions and semi-crystalline structure of starch granules, resulting from the different compositions of amylose and amylopectin. The set-back viscosity is a measure of the viscosity recovered during the cooling of heated starch. This parameter demonstrates the recrystallization of gelatinized starch, with higher setback values indicating greater retrogradation (Dalbhagat et al., 2019). The setback viscosity was higher in the partially gelatinized rice and lower in the puffed rice, regardless of the rice type. Thus, the setback viscosities for GR0, GW0, PGR0, and PGW0 samples were −391, −269, −1,662, and −851 cP, respectively. Similar to our results, Lai (2001) reported lower peak and higher final viscosities in hydrothermally treated rice (17.9% amylose content) and significantly higher peak viscosities in hydrothermally treated rice flour (1.2% amylose contents). Conversely, the peak viscosities of mixed-flour samples (glutinous rice flour and pre-gelatinized cassava starch) were reported to be higher than that of glutinous rice flour, a trend that became more marked when cassava starch was added (Wang et al., 2019).

Table 2.

Pasting properties of waxy and non-waxy rice following partial gelatinization and puffing treatment

| Samples | Peak viscosity (cP) | Trough viscosity (cP) | Breakdown viscosity (cP) | Final viscosity (cP) | Setback viscosity (cP) | Peak time (min) | Pasting temperature (°C) |

|---|---|---|---|---|---|---|---|

| Partial gelatinized rice | |||||||

| GR0 | 4,671±50.29a | 2,554±73.15b | 2,117±34.39a | 4,280±90.18b | −391±49.49e | 5.91±0.04a | 81.88±0.46b |

| GR5 | 3,311±190.12b | 2,673±107.82a | 638±84.87b | 5,081±132.37a | 1,770±80.06b | 5.84±0.04a | 89.87±0.41a |

| GR10 | 2,821±118.30c | 2,574±53.15ab | 247±68.13e | 5,104±57.42a | 2,283±61.15a | 5.91±0.08a | 90.45±0.43a |

| GW0 | 1,113±6.43e | 621±8.19d | 492±3.79c | 844±11.79e | −269±6.66d | 3.53±0.01c | 69.68±0.03d |

| GW5 | 2,362±14.15d | 2,041±30.62c | 322±41.06de | 2,793±27.87d | 431±39.00c | 5.62±0.15b | 77.05±0.53c |

| GW10 | 2,480±26.65d | 2,121±23.29c | 359±24.27d | 2,928±5.57c | 448±23.35c | 5.53±0.01b | 77.27±0.45c |

| Puffed rice | |||||||

| PGR0 | 2,302±334.50b | 349±7.21f | 1,953±340.59b | 640±20.52e | −1,662±354.23b | 2.07±0.01a | 91.52±5.25a |

| PGR5 | 2,942±226.01a | 516±14.43e | 2,426±211.60a | 892±22.23b | −2,050±203.79c | 2.07±0.01a | 94.95±0.09a |

| PGR10 | 3,153±260.24a | 678±21.01a | 2,475±280.08a | 1,153±18.72a | −2,001±274.75bc | 2.07±0.01a | 95.07±0.03a |

| PGW0 | 1,724±93.21c | 657±9.29b | 1,067±100.40c | 873±6.66b | −851±96.24a | 2.07±0.01a | 87.85±7.15ab |

| PGW5 | 1,673±54.37c | 595±7.37c | 1,078±58.90c | 790±10.12c | −883±64.47a | 2.07±0.01a | 80.17±3.54c |

| PGW10 | 1,605±28.94c | 567±4.36d | 1,038±33.29c | 759±7.00d | −846±35.36a | 2.07±0.01a | 83.00±2.16bc |

The value designated by different letters (a-f) within the same column differ significantly (P<0.05).

The values are expressed as mean±SD (n=18).

Fig. 1.

Scanning electron micrographs of waxy and non-waxy rice following partial gelatinization: (A) non-waxy rice (GR0), (B) non-waxy rice with 5 min of gelatinization treatment (GR5), (C) non-waxy rice with 10 min of gelatinization treatment (GR10), (D) waxy rice (GW0), (E) waxy rice with 5 min of gelatinization treatment (GW5), and (F) waxy rice with 10 min of gelatinization treatment (GW10).

The crystal shape and cracked internal structure of the non-partial gelatinized rice were confirmed by SEM, whereas the partial gelatinized rice exhibited collapsed, rounded, and amorphous crystals that changed according to the gelatinization time (Fig. 1). Tie et al. (2012) demonstrated that the pore size was very small and uniform in a puffed rice snack produced with waxy rice. In another study, SEM revealed a highly porous structure in the expanded rice kernels and that the A-type diffraction observed in raw rice was altered by the puffing process, leading to the formation of B- and V-type patterns (Mir et al., 2016). Moreover, Zhang et al. (2011) reported that compared to the granules in native starch, starch granules lost their individuality and formed agglomerates following pre-gelatinization treatment. Finally, We et al. (2010) reported that the number of pores in a puffed rice snack was greater than that present in a conventional infant snack.

In vitro starch digestion

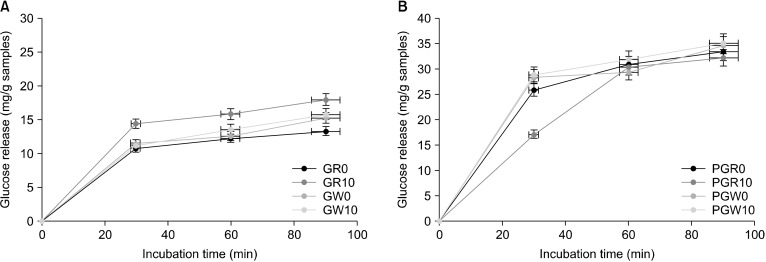

The in vitro starch digestion of samples was presented in Fig. 2. After 90 min reaction, the GR0, GR10, GW0, and GW10 samples released 13.31, 17.98, 15.26, and 15.79 mg/g glucose, respectively, while the PGR0, PGR10, PGW0, and PGW10 samples released 33.27, 32.15, 34.60, and 35.03 mg/g glucose, respectively. These results revealed that in vitro starch digestibility of samples tended to increase with partial gelatinization treatment. However, the in vitro starch digestibility was improved by puffing treatment. The waxy rice subjected to a combined treatment presented the highest in vitro digestibility, while no significant differences in digestibility were observed in the puffed rice after 60 and 90 min, regardless of rice type and gelatinization treatment (P>0.05). Alam et al., (2017) reported that a combination of high shearing and high temperature disrupted the structural integrity of the starch granules during extrusion processing, increasing their enzymatic breakdown and leading to an increased hydrolysis rate. The puffing influenced the in vitro digestibility of wheat grains, which were hydrolyzed into maltotriose, maltose, and glucose (Cattaneo et al., 2015). The results of this study demonstrated that partial gelatinization treatment of waxy and non-waxy rice showed lower hardness values and higher in vitro digestibility of the sample following puffing treatment. The WHC was higher in puffed rice than in non-puffed rice. Moreover, the puffing treatment decreased the setback viscosity in the partial gelatinized rice. Therefore, such a puffing and partial gelatinization treatment combination may improve the quality of rice-based products in terms of soft texture and digestibility.

Fig. 2.

Glucose release characteristics of waxy and non-waxy non-puffed and puffed rice following partial gelatinization during in vitro starch digestion: (A) rice with gelatinization treatment and (B) partial gelatinized rice with puffing treatment.

ACKNOWLEDGEMENTS

The authors would like to thank Park En-Ok for assistance with the sample preparation.

Footnotes

AUTHOR DISCLOSURE STATEMENT

The authors declare no conflict of interest.

References

- AACC. Approved methods of the AACC. 10th ed. American Association of Cereal Chemists; St. Paul, MN, USA: 2020. [Google Scholar]

- Agama-Acevedo E, Bello-Perez LA, Lim J, Lee BH, Hamaker BR. Pregelatinized starches enriched in slowly digestible and resistant fractions. LWT. 2018;97:187–192. doi: 10.1016/j.lwt.2018.06.007. [DOI] [Google Scholar]

- Alam SA, Pentikäinen S, Närväinen J, Holopainen-Mantila U, Poutanen K, Sozer N. Effects of structural and textural properties of brittle cereal foams on mechanisms of oral breakdown and in vitro starch digestibility. Food Res Int. 2017;96:1–11. doi: 10.1016/j.foodres.2017.03.008. [DOI] [PubMed] [Google Scholar]

- An YE, Ahn SC, Yang DC, Park SJ, Kim BY, Baik MY. Chemical conversion of ginsenosides in puffed red ginseng. LWT-Food Sci Technol. 2011;44:370–374. doi: 10.1016/j.lwt.2010.09.013. [DOI] [Google Scholar]

- Arslan M, Rakha A, Xiaobo Z, Mahmood MA. Complimenting gluten free bakery products with dietary fiber: opportunities and constraints. Trends Food Sci Technol. 2019;83:194–202. doi: 10.1016/j.tifs.2018.11.011. [DOI] [Google Scholar]

- Cairano MD, Galgano F, Tolve R, Caruso MC, Condelli N. Focus on gluten free biscuits: Ingredients and issues. Trends Food Sci Technol. 2018;81:203–212. doi: 10.1016/j.tifs.2018.09.006. [DOI] [Google Scholar]

- Cattaneo S, Hidalgo A, Masotti F, Stuknytė M, Brandolini A, De Noni I. Heat damage and in vitro starch digestibility of puffed wheat kernels. Food Chem. 2015;188:286–293. doi: 10.1016/j.foodchem.2015.05.019. [DOI] [PubMed] [Google Scholar]

- Dalbhagat CG, Mahato DK, Mishra HN. Effect of extrusion processing on physicochemical, functional and nutritional characteristics of rice and rice-based products: a review. Trends Food Sci Technol. 2019;85:226–240. doi: 10.1016/j.tifs.2019.01.001. [DOI] [Google Scholar]

- Hidalgo A, Scuppa S, Brandolini A. Technological quality and chemical composition of puffed grains from einkorn (Triticum monococcum L. subsp. monococcum) and bread wheat (Triticum aestivum L. subsp. aestivum) LWT-Food Sci Technol. 2016;68:541–548. doi: 10.1016/j.lwt.2015.12.068. [DOI] [Google Scholar]

- Hoke K, Houška M, Průchová J, Gabrovská D, Vaculová K, Paulíčková I. Optimisation of puffing naked barley. J Food Eng. 2007;80:1016–1022. doi: 10.1016/j.jfoodeng.2006.08.012. [DOI] [Google Scholar]

- Hoke K, Houšová J, Houška M. Optimum conditions of rice puffing. Czech J Food Sci. 2005;23:1–11. doi: 10.17221/3365-CJFS. [DOI] [Google Scholar]

- Huang CY, Kuo CH, Wu CH, Ku MW, Chen PW. Extraction of crude chitosans from squid (Illex argentinus) pen by a compressional puffing-pretreatment process and evaluation of their antibacterial activity. Food Chem. 2018;254:217–223. doi: 10.1016/j.foodchem.2018.02.018. [DOI] [PubMed] [Google Scholar]

- Jang HL, Bae IY, Lee HG. In vitro starch digestibility of noodles with various cereal flours and hydrocolloids. LWT-Food Sci Technol. 2015;63:122–128. doi: 10.1016/j.lwt.2015.03.029. [DOI] [Google Scholar]

- Kang CS, Park CH, Park JC, Kim HS, Cheong YK, Kim KH, et al. Flour characteristics and end-use quality of Korean wheat cultivars I. Flour characteristics. Korean J Breed Sci. 2010;42:61–74. [Google Scholar]

- Kim W, Kim SY, Kim DO, Kim BY, Baik MY. Puffing, a novel coffee bean processing technique for the enhancement of extract yield and antioxidant capacity. Food Chem. 2018;240:594–600. doi: 10.1016/j.foodchem.2017.07.161. [DOI] [PubMed] [Google Scholar]

- Lai HM. Effects of hydrothermal treatment on the physicochemical properties of pregelatinized rice flour. Food Chem. 2001;72:455–463. doi: 10.1016/S0308-8146(00)00261-2. [DOI] [Google Scholar]

- Lee HJ, Kim S, Suh HJ, Ryu D. Effects of explosive puffing process on the reduction of ochratoxin A in rice and oats. Food Control. 2019;95:334–338. doi: 10.1016/j.foodcont.2018.08.004. [DOI] [Google Scholar]

- Lee NY, Kang CS. Effects of different fertilization treatments on the physicochemical and noodle-making properties of Korean winter wheat cultivars. Food Sci Biotechnol. 2016;25:69–76. doi: 10.1007/s10068-016-0100-0. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Mariotti M, Alamprese C, Pagani MA, Lucisano M. Effect of puffing on ultrastructure and physical characteristics of cereal grains and flours. J Cereal Sci. 2006;43:47–56. doi: 10.1016/j.jcs.2005.06.007. [DOI] [Google Scholar]

- Medcalf DG, Gilles KA. Wheat starches. I. Comparison of physicochemical properties. Cereal Chem. 1965;42:558–568. [Google Scholar]

- Mir SA, Don Bosco SJ, Shah MA, Mir MM. Effect of puffing on physical and antioxidant properties of brown rice. Food Chem. 2016;191:139–146. doi: 10.1016/j.foodchem.2014.11.025. [DOI] [PubMed] [Google Scholar]

- Mondal A, Kumar KJ. Effect of thermal modification on the release characteristics of pink potato starch of Jharkhand, India. Int J Biol Macromol. 2019;140:1091–1097. doi: 10.1016/j.ijbiomac.2019.08.094. [DOI] [PubMed] [Google Scholar]

- Nakorn KN, Tongdang T, Sirivongpaisal P. Crystallinity and rheological properties of pregelatinized rice starches differing in amylose content. Starch/Stärke. 2009;61:101–108. doi: 10.1002/star.200800008. [DOI] [Google Scholar]

- Pedron T, Segura FR, da Silva FF, de Souza AL, Maltez HF, Batista BL. Essential and non-essential elements in Brazilian infant food and other rice-based products frequently consumed by children and celiac population. J Food Compos Anal. 2016;49:78–86. doi: 10.1016/j.jfca.2016.04.005. [DOI] [Google Scholar]

- Sun X, Li W, Hu Y, Zhou X, Ji M, Yu D, et al. Comparison of pregelatinization methods on physicochemical, functional and structural properties of tartary buckwheat flour and noodle quality. J Cereal Sci. 2018;80:63–71. doi: 10.1016/j.jcs.2018.01.016. [DOI] [Google Scholar]

- Thompson T. The nutritional quality of gluten-free foods. In: Gallagher E, editor. Gluten-Free Food Science and Technology. Blackwell Publishing Ltd; Oxford, UK: 2009. pp. 42–51. [DOI] [Google Scholar]

- Tie J, Yu JH, Ryu GH. Effect of moisture content and temperature on physical properties of instant puffed rice snacks. J Korean Soc Food Sci Nutr. 2012;41:846–852. doi: 10.3746/jkfn.2012.41.6.846. [DOI] [Google Scholar]

- Wang H, Xiao N, Wang X, Zhao X, Zhang H. Effect of pregelatinized starch on the characteristics, microstructures, and quality attributes of glutinous rice flour and dumplings. Food Chem. 2019;283:248–256. doi: 10.1016/j.foodchem.2019.01.047. [DOI] [PubMed] [Google Scholar]

- We GJ, Lee I, Cho YS, Yoon MR, Shin M, Ko S. Development of rice flour-based puffing snack for early childhood. Food Eng Prog. 2010;14:322–327. [Google Scholar]

- Williams PC, Kuzina FD, Hlynka I. A rapid colorimetric procedure for estimating the amylose content of starches and flours. Cereal Chem. 1970;47:411–421. [Google Scholar]

- Zapotoczny P, Markowski M, Majewska K, Ratajski A, Konopko H. Effect of temperature on the physical, functional, and mechanical characteristics of hot-air-puffed amaranth seeds. J Food Eng. 2006;76:469–476. doi: 10.1016/j.jfoodeng.2005.05.045. [DOI] [Google Scholar]

- Zhang L, Yang X, Li S, Gao W. Preparation, physicochemical characterization and in vitro digestibility on solid complex of maize starches with quercetin. LWT-Food Sci Technol. 2011;44:787–792. doi: 10.1016/j.lwt.2010.09.001. [DOI] [Google Scholar]