Abstract

With the outbreak of the 2019 novel coronavirus (COVID-19) epidemic in Wuhan, China, in January 2020, the escalating number of confirmed and suspected cases overwhelmed the admission capacity of the designated hospitals. Two specialty field hospitals—Huoshenshan and Leishenshan—were designed, built and commissioned in record time (9–12 days) to address the outbreak. This study documents the design and construction of Leishenshan Hospital. Based on data collected from various sources such as the semi-structured interviews of key stakeholders from Leishenshan Hospital, this study found that adhering to a product, organization, and process (POP) modeling approach combined with building information modeling (BIM) allowed for the ultra-rapid creation, management, and communication of project-related information, resulting in the successful development of this fully functional, state-of-the-art infectious disease specialty hospital. With the unfortunate ongoing international COVID-19 outbreak, many countries and regions face similar hospital capacity problems. It is thus expected that the lessons learned from the design, construction and commissioning of Leishenshan Hospital can provide a valuable reference to the development of specialty field hospitals in other countries and regions.

Keywords: Infectious disease field hospital construction, Wuhan Leishenshan Hospital, Building information modeling (BIM), COVID-19

Highlights

-

•

The specialty field hospital is one of the major measures to combat COVID-19.

-

•

This study documented the design and construction of the Leishenshan Hospital project.

-

•

POP modeling approach combined with BIM contributed to the rapid development of Leishenshan Hospital.

-

•

Lessons learned from the Leishenshan Hospital project can help to develop specialty field hospitals in other countries.

1. Introduction

The outbreak of novel coronavirus (COVID-19) poses a threat to the public health system in China and other countries throughout the world [1]. As of April 26, 2020, a total of 82,830 confirmed cases have been reported in China with 77,474 recoveries and 4633 deaths [2]. As the epicenter of the COVID-19 outbreak in China, over 60% of the confirmed cases were found in Wuhan. Beginning at the end of January 2020, many patients in Wuhan were unable to see a doctor and were hospitalized, and the escalating number of confirmed and suspected cases overwhelmed the admission capacity of the designated hospitals [3].

Faced with such a grim situation, the government made a quick decision to build two specialty field hospitals—Huoshenshan Hospital and Leishenshan Hospital—to quarantine and treat patients with confirmed infections. These two field hospitals were modeled on Beijing's Xiaotangshan Hospital, which treated severe acute respiratory syndrome cases in 2003 [4], and they were staffed with medical personnel from hospitals affiliated with the People's Liberation Army (PLA) Joint Logistic Support Force and medical universities from the army, navy, and air force of the PLA [5]. After Huoshenshan Hospital and Leishenshan Hospital were placed into service, the persistent shortage of hospital beds and medical supplies was eased, which was an important step toward controlling the growing epidemic and improving the recovery rate [6]. During their service period, Huoshenshan Hospital and Leishenshan Hospital admitted 3059 and 2011 patients, respectively [7].

The concept of the field hospital is not new; it originates from the battlefield and has been applied during emergencies such as natural disasters and rapidly evolving disease outbreaks [[8], [9], [10]]. However, the design and construction of Huoshenshan Hospital and Leishenshan Hospital merit special attention. First, different from general field hospitals used in battlefields or disasters (e.g., the field hospital for the 5.12 Wenchuan earthquake), Huoshenshan Hospital and Leishenshan Hospital were fully functioning field hospitals outfitted with all the medical equipment necessary to treat patients with severe symptoms. More surprisingly, the construction of Huoshenshan Hospital and Leishenshan Hospital took only 9 and 12 days, respectively. Many people witnessed their construction processes, which were livestreamed by state media [11].

The rapid and successful development of Huoshenshan Hospital and Leishenshan Hospital should be praised from both managerial and technological perspectives. For instance, key stakeholders, including the designer, main contractor, and relevant governmental departments, seamlessly collaborated with each other and allocated sufficient resources within a short timeframe; over ten thousand construction workers worked in shifts to accelerate the construction process. Regarding the technologies that facilitated the project delivery, both Huoshenshan Hospital and Leishenshan Hospital adopted prefabrication technology to avoid time-consuming in situ construction work. Moreover, the implementation of digital technologies such as building information modeling (BIM) cannot be overlooked. BIM starts with an object-based digital model that provides a digital representation of the project [12,13]. Following the product, organization, and process (POP) modeling approach, BIM incorporated organization and process information to become a shared platform for information creation, management, and communication during the development of Huoshenshan Hospital and Leishenshan Hospital.

Considering the global spread of COVID-19 and the serious shortage of hospital beds and medical supplies in many countries and regions [14], the experience of specialty field hospitals in China is expected to provide valuable information for other countries and regions to combat the COVID-19 outbreak. This research documents the design and construction experience of Leishenshan Hospital, with a particular emphasis on how BIM contributed to high-quality project delivery within a tight schedule.

The remainder of this paper is organized as follows. The next section reviews BIM implementation in hospital projects and the necessity of integrating BIM with the POP modeling approach. The third section provides details of the case study. The fourth section introduces the typical BIM applications during the development of Leishenshan Hospital. The fifth section discusses the lessons learned from the development of Leishenshan Hospital. The last section summarizes this study.

2. BIM and POP modeling

As a construction project, a hospital generally has complex design requirements that are influenced by many uncertainties, and its technical requirements can be much more complicated than other types of projects with similar scopes [15]. Previous studies have explored the use of BIM to help fulfill these technical requirements and improve the development of hospitals. Given its 3D presentation and virtual reality simulation capability, BIM can act as a technical tool that can be applied to improve design quality and productivity in a number of areas, including construction plan rehearsal and optimization, and construction site management [16]. Manning and Messner [17] reported that the application of BIM during the conceptual design stage of healthcare projects could provide instant 3D visualization and save time for quantity takeoffs. Oh et al. [18] developed an integrated design system to improve the efficiency of BIM-based collaborative design among project participants in a hospital project. They suggested that, because of its information interoperability, BIM can address several collaboration problems such as unnecessary repetitive work, and data errors and losses. For the on-site application of BIM during the construction stage, Davies and Harty [19] explored the use of “Site BIM” system that allowed site workers to use mobile tablet personal computers to access design information to assure progress and quality control. Mignone et al. [20] noted that BIM can retain information and knowledge, and encourage collaboration among project stakeholders in hospital projects. However, they also found that such effective collaboration required a structured sequential coordination process of management.

With the wide spread of BIM adoption and the complexity of healthcare facilities, researchers and practitioners have realized that BIM provides less help to the project delivery if the model contains only physical and functional product information [21]. Therefore, Product, organization, and process (POP) modeling which complements the product model with process and organization information becomes particularly effective in conjunction with BIM applications [22]. A POP model consists of three sub-models, namely: (1) a product model that contains both the geometric and non-geometric attributes of physical objects and allows for quantity takeoff, ventilation simulations, and other necessary analyses; (2) a product-process model that integrates the product model with the construction progress for seamless construction coordination and schedule management; and (3) an organization-process model that associates the specific project delivery tasks with organizational responsibilities at different project stages [23]. Through POP modeling, comprehensive data interrelationships in BIM can be constructed to establish a more interactive model for improved project planning, coordination, and visualization [24]. All these benefits contributed to the successful delivery of Leishenshan Hospital.

3. Case study details

3.1. Overview of Leishenshan Hospital

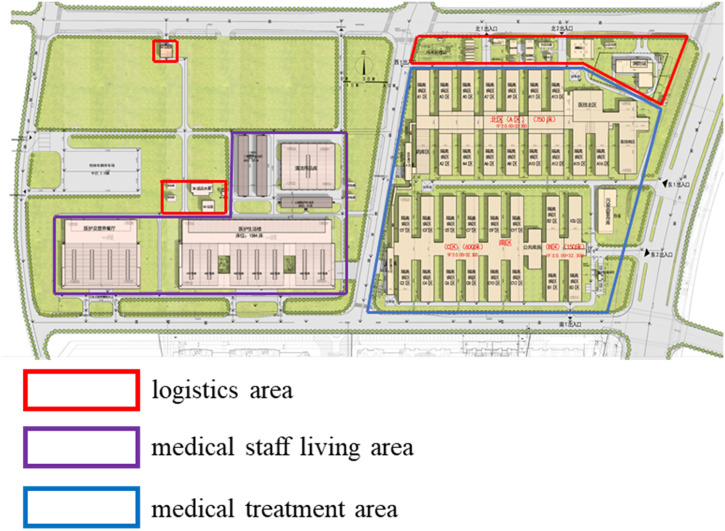

Leishenshan Hospital is located at an abandoned parking lot of the Wuhan Military Games Athletes' Village in Jiangxia District, with a site area of approximately 220,000 m2 and a total construction area of nearly 80,000 m2. Leishenshan Hospital consists of three main areas, including the medical staff living area (marked in purple in Fig. 1 ), the logistics area (e.g., supply warehouse, wastewater treatment station, trash incineration station, and ambulance decontamination area; marked in red in Fig. 1), and the medical treatment area (marked in blue in Fig. 1).

Fig. 1.

General layout of the Leishenshan Hospital. (For interpretation of the references to color in this figure, the reader is referred to the web version of this article.)

(Source: Central-South Architectural Design Institute [CSADI].)

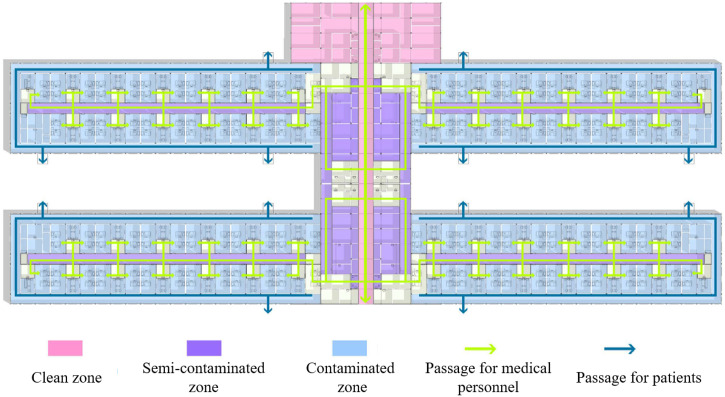

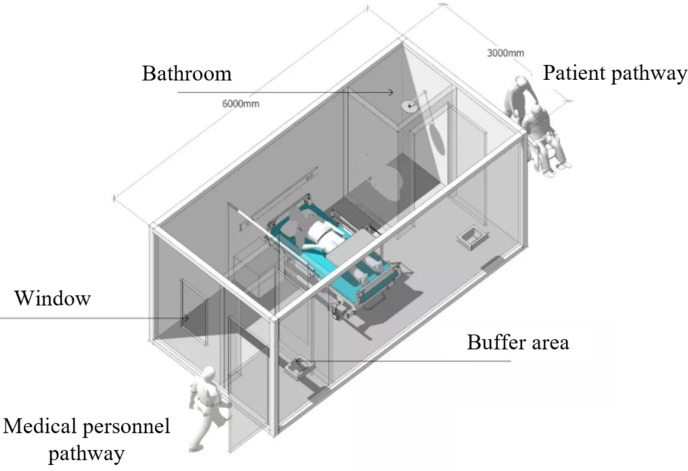

The design of the medical treatment area of Leishenshan Hospital adopted a fishbone layout, complying with the “three zones and two passages” principle and the national design code for an infectious disease hospital (see Fig. 2 ). The three zones include a clean zone, a semi-contaminated zone, and a contaminated zone; The two passages include a passage for medical personnel and a passage for the patients. Similar to other fully functioning infectious disease hospitals, the medial treatment area of the Leishenshan Hospital includes isolation wards, a medical technology facility, consultation rooms, intensive care stations, liquid oxygen stations, and other essential facilities to protect both patients and medical staff members.

Fig. 2.

Partial illustration of the “three zones and two passages”.

(Source: CSADI.)

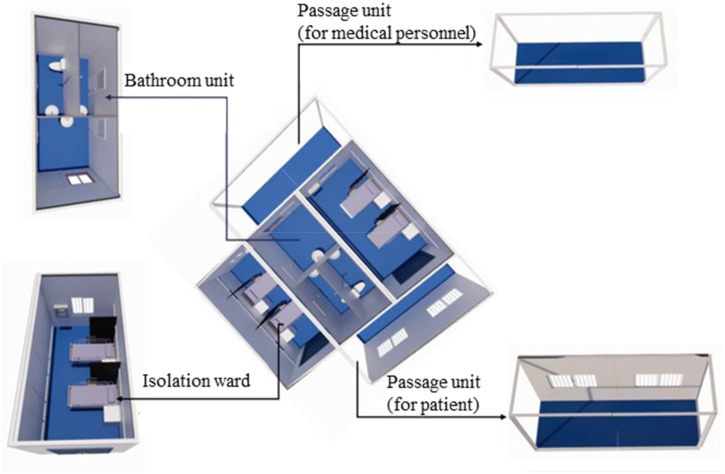

Leishenshan Hospital adopted the modular design that divided the whole hospital into individual prefabricated units. The medical treatment area consisted of over three thousand container-type prefabricated units; each unit has its own functions with a standard size of 6 m × 3 m × 2.6 m or 6 m × 2 m × 2.6 m (see Fig. 3 ). The units were produced in factories and then transported to the construction site and installed at the designated location by a mobile crane. The isolation ward was equipped with a double-sided cabinet that linked the ward to the passage; the cabinet allowed the medical personnel to deliver daily necessities or medicine to the patients without the need to enter the ward, which prevented cross-infection. In addition, the isolation wards had air conditioners, cables, televisions, and electric lights, which were installed after the prefabricated units were assembled on the construction site.

Fig. 3.

Modular design adopted for Leishenshan Hospital.

(Provided by CSADI.)

The living area for the medical personnel was adapted from the original canteen of the Athletes' Village. A total of ten buildings were newly built; among them, eight were two-story buildings with a height of 7.5 m, and two were one-story buildings. These ten buildings provided nearly 400 rooms and over 2300 beds for the medical staff of Leishenshan Hospital, and their construction also consisted of container-type prefabricated units. These prefabricated units were placed on a truss, which mitigated the need to develop a structural foundation and renovate the drainage system. Each room was equipped with a wardrobe, air conditioner, and other furnishings and appliances, as well as a private bathroom.

3.2. Data collection and analysis

In this case study of Leishenshan Hospital, both first- and second-hand data were collected from multiple sources. The first-hand data were gathered through semi-structured interviews with three of the designer's staff members (one project manager, one design director, and one BIM coordinator) and two of the main contractor's staff members (one technical manager and one BIM manager). All the interviewees oversaw and used BIM during the project delivery. Due to the physical constraints resulting from the epidemic, semi-structured interviews were conducted through telephone and online video calls, each lasting for 15 to 25 min. The interview questions were separated into parts. The first part focused on the challenges of project delivery; the second focused on how BIM was used to address these challenges. The interviewees were asked to answer questions following the designated sequences but were also allowed to discuss their BIM experience freely.

In addition to the first-hand data, second-hand data were collected from media outlets, public reports, and internal project documents from the designer, which mainly included the salient features of the Leishenshan Hospital project, the key milestones of project delivery, and the collaboration among project stakeholders. The triangulation of first- and second-hand data not only produced a comprehensive description of BIM applications at different project stages, but also revealed the necessity of leveraging the benefits of BIM acquired during the Leishenshan Hospital project that could have implications for future practices.

4. BIM-facilitated development of Leishenshan Hospital

4.1. Project delivery challenges

As reflected by the interviewees, the development of Leishenshan Hospital faced several challenges. First, it is important but extremely challenging to retain the accuracy of project information, especially the design information. Leishenshan Hospital consists of different zones, all of which have their own functions and thus should follow the corresponding design specifications. For example, the walls of the ward required additional thickness to prevent virus spread. More importantly, the time urgency of this project brought tremendous pressure to the creation of accurate information. Compared with the development of a fully functioning infectious disease hospital, which could take several months to years to complete, the construction of Leishenshan Hospital needed to be completed in 12 days. During this short period, the design was modified three times to provide 300 more beds for patients. Without accurate information, the project delivery would have been significantly delayed.

Second, design optimization can be difficult to achieve due to the complexity of the project and the limited time. The design of Xiaotangshan Hospital provided a valuable reference to support the design of Leishenshan Hospital, but significant design optimization efforts were still needed to shorten the construction time while fulfilling all the technical and functional requirements of an infectious disease hospital. For example, most of the wards were depressurized and needed an optimized ventilation system to prevent virus spread. The optimized design of Leishenshan Hospital could not have been completed based solely on designer experience.

Third, communicating information among project stakeholders can be challenging due to the large number of stakeholders involved and the inherent organizational fragmentation. Parts of the design and construction of Leishenshan Hospital were conducted in parallel, and the construction work contained more than ten cross-disciplinary processes such as site leveling, foundation engineering, pipeline embedding, anti-seepage membranes, prefabricated component assembly, and interior finishing. On the busiest construction day, there were over fifteen thousand workers and more than eight hundred construction machines working at the construction site. The main contractor had to coordinate subcontractors from different disciplines to maximize their productivity and maintain progress in accordance with the schedule.

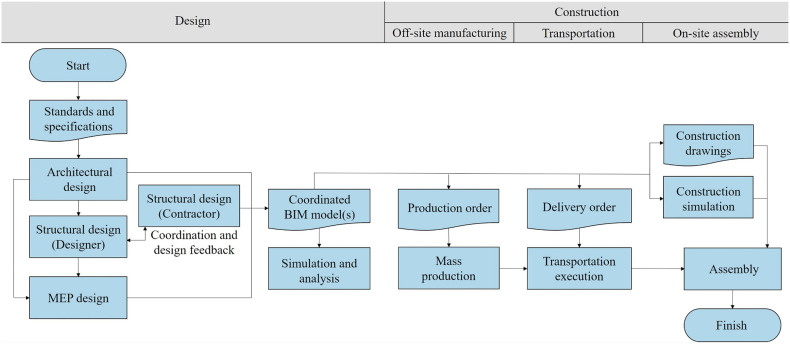

To address these challenges, the designer (Central-South Architectural Design Institute [CSADI]) and main contractor (China Construction Third Engineering Bureau Co., Ltd.) assumed strong leadership in BIM implementation for information creation, management, and communication. As shown in Fig. 4 , 2D drawings were initially created, and then the BIM model was developed. Due to the multidisciplinary characteristics of Leishenshan Hospital, not all information was stored in a single BIM model; separated models were developed. The designer and main contractor organized their own BIM teams specifically for BIM development and implementation. Following the POP modeling approach, information such as the project schedule and stakeholder responsibilities of BIM implementation were integrated into the BIM model. The level of development (LoD) of each type of BIM object, representing the general building components (e.g., a wall) and medical equipment (e.g., a hospital bed), was also specified for different BIM applications at both the design and construction stages.

Fig. 4.

Overall project delivery process for Leishenshan Hospital.

4.2. BIM implementation at the design stage

The coordinated BIM model developed at the design stage contained information on not only individual architectural, structural, and mechanical, electrical and plumbing (MEP) components, but also the functional areas and construction site. The majority of the BIM components reached a level of development (LoD) of LOD350 [25], which contained information concerning classification, size, materials, methods of operation, technical specifications, etc. With this enhanced information, BIM helped to validate and improve the design to meet the functional requirements, which were necessary to maintain the health and safety of patients, medical personnel, and the surrounding environment.

4.2.1. Optimized pathway arrangements for patients and medical personnel

A strict separation of pathways for patients and medical personnel was an essential requirement for Leishenshan Hospital. To satisfy this requirement, the pathways for patients and medical personnel were visualized in the BIM model (see Fig. 5 ). Utilizing a fishbone-shaped layout, patients entered the isolation wards through branches of the fishbone and could access bathrooms through the patient pathway. The patient pathway was also used for waste disposal at a temporary storage facility. The long middle area was a dedicated pathway for medical staff members who entered and exited the isolation ward from the buffer area by using a one-sided door. Through a route simulation of patients and medical personnel, clean supplies and waste flows were separated, and buffer areas were accurately allocated within the medical treatment area. Therefore, the chance of cross-infection to medical personnel was minimized.

Fig. 5.

Illustration of pathways for patients and medical personnel.

(Provided by CSADI.)

4.2.2. Optimized design of building service systems in the medical treatment area

Leishenshan Hospital has complex building service systems that incorporate nearly ten subsystems, including a heating, ventilation and air conditioning (HVAC) system, a water supply and drainage system, a lighting system, a weak current system, and other electrical and mechanical systems. These systems were modeled and visualized in the BIM environment. Two apparent advantages over traditional 2D drawings were noticed. First, bottlenecks among various building service systems belonging to different disciplines were detected in advance. The reduction of these bottlenecks at the design stage decreased adjustments at the construction stage, which contributed to the on-time delivery of Leishenshan Hospital. Second, the visualization of these systems in a merged BIM model helped the designer and main contractor maximize the use of interior space and establish an efficient schedule for parallel installation tasks.

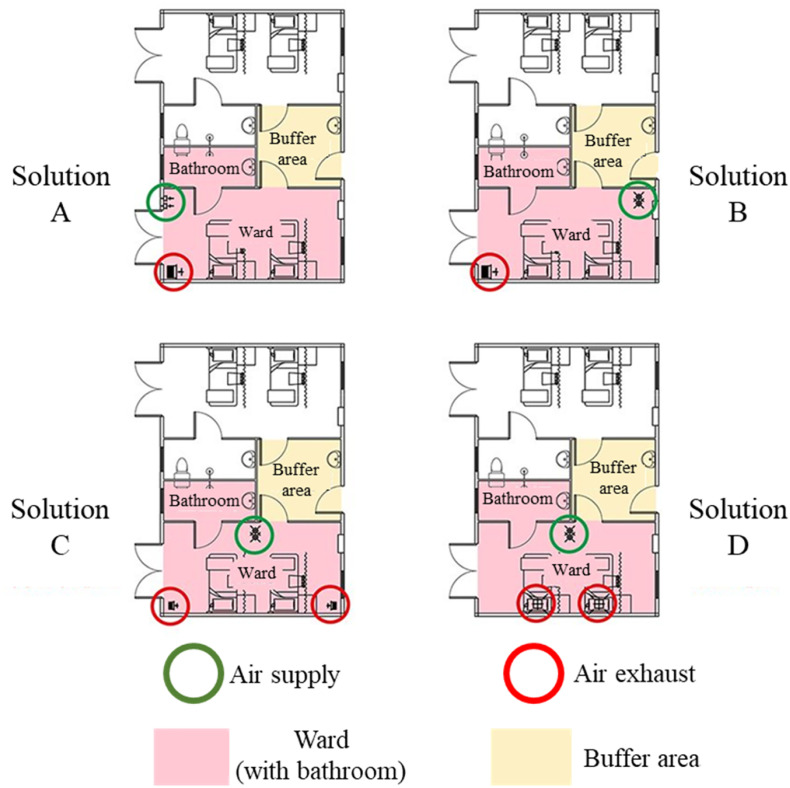

4.2.3. Ventilation simulation of isolation ward

Considering that COVID-19 is an infectious disease that can spread through breath and remain viable for several hours in the air [26], the ventilation systems of the Leishenshan Hospital followed the principle of negative pressure to isolate pathogenic microorganisms. The air pressure in the isolation ward was lower than the air pressure outside the ward. In this way, outside air flowed into the ward, and the air contaminated by patients in the ward was discharged only after special treatment; the concentration of pathogenic microorganisms in the ward was diluted by ventilation, and the area outside the ward was not contaminated. This organization of air circulation within the hospital was critically important and was carefully designed to meet relevant standards and requirements.

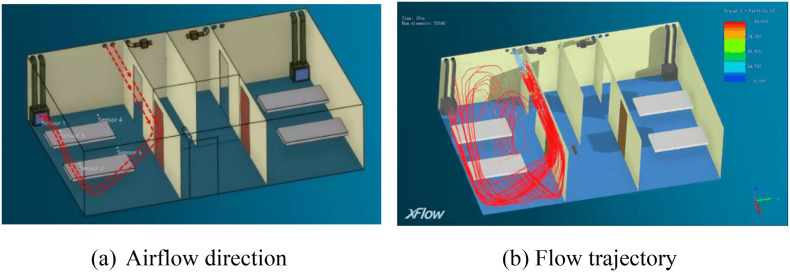

Based on the characteristics of Leishenshan Hospital, the designer generated four air supply and exhaust solutions, as shown in Fig. 6 . Then, BIM was used to simulate and analyze the air circulation and virus contamination under the four proposed solutions to select the most suitable solution for the negative pressure ward. The simulation was conducted by using SIMULIA XFlow software, a professional computational fluid dynamics software from Dassault Systèmes. Taking the analysis of Solution A as an example, monitoring points were set at the patient's and the medical personnel's breathing position, i.e., 0.75 m and 1.5 m, respectively. There were two sources for air supply, i.e., the air inlet port and the air conditioner inside the ward. The size of the air conditioner was 1.0 m × 0.4 m × 0.32 m, and the volume of its supplied air was set at a volume of 1000 m3/h, with the temperature of the supplied-air being 30 °C (in a downward direction of 45 degrees); the size of the air inlet port was Ф0.15 m, and the volume of its supplied-air was set at 250 m3/h (in the horizontal direction), with the temperature of the supplied-air being 20 °C. Additionally, the size of the air outlet port was 0.4 m × 0.4 m, and the volume of its exhausted-air was set at 700 m3/h (in the horizontal direction). Temperatures of the inner wall and outer wall were set according to the room temperature and ambient temperature, following the equal wall boundary condition. With these defined parameters, Solution A formed a U-shaped airflow inside the isolation ward. As shown in Fig. 7 , the air flows out from the air inlet port, changes its direction after arriving at the opposite wall, and flows through the position of the two patient beds to the lower area. The pressure difference between the buffer room and the ward can effectively prevent the contaminated air from spreading to the buffer room; the contaminants can be filtered and discharged through the outlet port.

Fig. 6.

Four proposed air supply and exhaust solutions for the isolation ward.

(Provided by CSADI.)

Fig. 7.

The U-shaped airflow under Solution A.

(Provided by CSADI.)

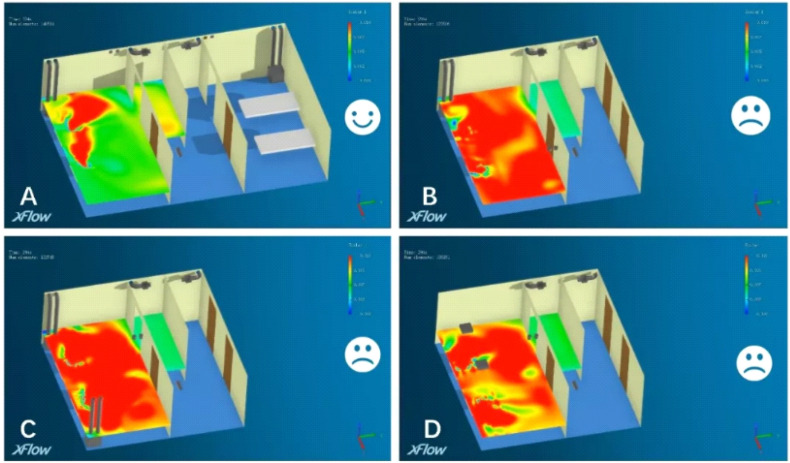

The same analysis was conducted for the other three solutions. The results of the transient moments of pollutant concentration at a certain moment are shown in Fig. 8 . The results reveal that the control of pollutant concentration in Solution A is much more effective than the other three solutions, i.e., Solutions B to D. More importantly, the concentration of the triangle area under the air inlet of the ward is observed to be high, and recommendations were made that medical personnel should stay away from this area. Therefore, with the ventilation simulation of isolation ward, feedback in the form of professional medical requirements could be provided to validate and verify whether the commingling of fresh air and polluted air was effectively avoided.

Fig. 8.

Pollutant concentration distribution under the four solutions.

(Provided by CSADI.)

4.2.4. Simulation of impacts on the surrounding environment

Although there are no residential areas around the Leishenshan Hospital, the contamination discharged from the hospital could have introduced pollution to the surrounding environment and raised serious public concerns. Therefore, in addition to the simulation of interior ventilation in the isolation ward, BIM was also used to assess the impacts of Leishenshan Hospital's contamination discharge on the surrounding environment. The building service systems contained in the BIM model provided a visualized presentation of how sewage and rainwater were collected, treated, disinfected, and then discharged into the municipal pipe networks. Moreover, the BIM model acted as a reliable information basis for the diffusion mechanism analysis that quantitatively assessed the pollution risk of contaminated air and waste gas. Necessary information, including the building shape, layout, and the location and direction of air exhaust from Leishenshan Hospital, were extracted from the BIM model and imported into the Fire Dynamic Simulator (FDS), which is an open-sourced fluid mechanics simulation software developed by the National Institute of Standards and Technology.

With the support of BIM, the simulation of contaminated air diffusion under different air exhaust arrangements, i.e., location and direction, was conducted to identify an optimal design that could meet dilution requirements. Considering that at the time of the project design, there was insufficient information on the minimum required dilution for COVID-19, this figure was set according to previous studies on the SARS virus, i.e., a 10,000-fold dilution [27]. Other details of the diffusion mechanism analysis for Leishenshan Hospital can be found in Gu et al. [28]. The simulation results showed that when the elevation of the exhaust outlet was set to 4.5 m, the relative concentration of contaminants in the air could be effectively reduced and meet the requirement of a 10,000-fold dilution. Therefore, this air exhaust arrangement was selected to ensure that the contamination emitted from Leishenshan Hospital could diffuse into the air over a short timeframe. Based on the simulation results, filtering strategies were further purposed to control the emission of contaminated air and waste gas and prevent any adverse effects of secondary pollution on the surrounding environment.

4.3. BIM implementation at the construction stage

The construction of Leishenshan Hospital also benefited from the BIM model that was supplemented with POP information. First, a seamless connection between design, production, and construction was established. The most suitable prefabrication technology for Leishenshan Hospital was selected and the coordination of prefabrication production, transportation, and assembly was established, with the main purpose of decreasing the overall construction time. Second, BIM allowed the main contractor to conduct on-site supervision and management. The timely communication of information among various trades reduced conflicts in parallel construction works, ranging from site preparation to MEP installation and interior finishing.

4.3.1. Production of prefabricated components

In view of the urgency of project delivery, before the commencement of construction, the main contractor of Leishenshan Hospital had to evaluate the different types of prefabrication technologies by considering the supply capability of various prefabricated components and the availability of relevant construction resources.

A container-type prefabricated unit was selected for the isolation ward (see Fig. 9 ). The walls of this container were made of a double-sized steel glass sandwich panel, and the skeleton was made of galvanized cold-formed steel components that were connected by bolts. Due to the difficulties in finding one supplier who had an inventory of over three thousand containers with a standard size, over ten suppliers were contracted for prefabrication production. The product information (i.e., number, type, and technical specifications of the container-type prefabricated unit) that was directly transmitted from the model to provide suppliers with accurate information for them to generate the shop drawings, schedule the production tasks, prepare the production materials, and manage the storage and logistics for each order of produced containers. During this process, the main contractor could track the production status since individual components in the BIM model had corresponding supplier information. Therefore, with the support of BIM, the communication of information between production and construction was streamlined.

Fig. 9.

Container-type prefabricated unit for the isolation ward.

(Provided by China Construction Third Engineering Bureau Co., Ltd.)

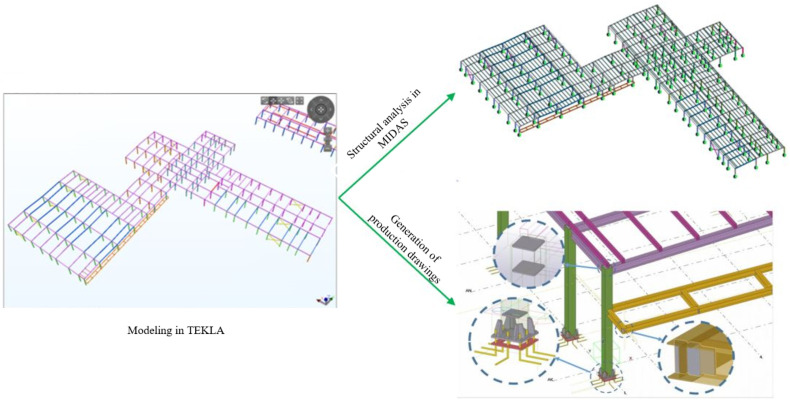

Different from the isolation ward, the medical technology facility of the Leishenshan Hospital adopted steel structure since a container-type prefabricated unit was infeasible for this building, especially for the intensive care unit (ICU) and test room. First, the building needed a large-span without structural barriers to provide more space for medical treatment. Second, the room height of the ICU and test room had to exceed 4.2 m. The production and supply of steel components for the medical technology facility were also supported by BIM. The main contractor, with collaboration from the designer, modeled the steel structure in TEKLA, a BIM software from the Trimble Co. As shown in Fig. 10 , the developed BIM model provided an information-rich visualization of the steel structure that helped reduce the types of different steel components into five main types. In addition, the model was directly used to generate production drawings, and the structural analysis, construction drawing development, and designer approval was completed almost simultaneously. This application saved a great amount of production time for the steel components and the sequential construction tasks.

Fig. 10.

Steel structure of the medical technology facility.

(Source: China Construction Third Engineering Bureau Co. Ltd.)

4.3.2. Coordination of various trades during construction

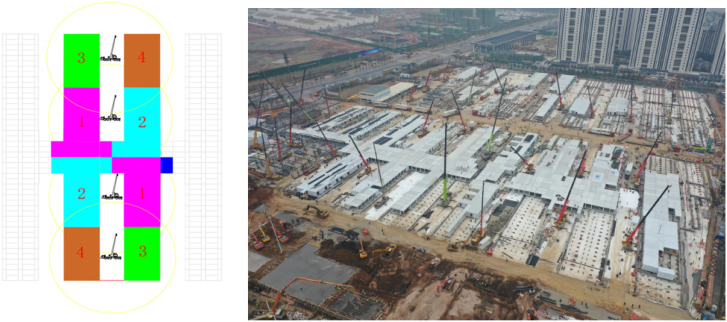

The BIM model contained organization and process information, making it easier for the main contractor to coordinate the different trades and maintain smooth construction progress. The construction site of Leishenshan Hospital was separated into five construction areas; each area was further divided into individual sections for sub-contractors to deliver parallel construction work. Within the construction site, the location of on-site material storage was carefully determined to reduce the efforts needed for transporting materials during the construction.

Taking one of the major construction tasks of Leishenshan Hospital, i.e., the assembly of container-type prefabricated units, as an example, the assembly sequence was analyzed in a virtual environment. As shown in Fig. 11 , the assembly was carried out from the central area to each branch according to the marked number, i.e., from 1 to 4. This arrangement avoided potential conflicts between the mobile cranes and improved their utilization rate. Based on the assembly plan, the required resources (e.g., mobile crane, manpower) were allocated in advance, and their usages were timely recorded by the site managers of the main contractor. The continuous monitoring of resource usage provided valuable information to avoid shortages of necessary construction resources. Once the assembly work was completed, the subsequent modification, interior facility installation, and finishing work were arranged sequentially.

Fig. 11.

On-site construction of Leishenshan Hospital.

(Provided by China Construction Third Engineering Bureau Co., Ltd.)

Similar to the assembly of container-type prefabricated units, other construction tasks also benefited from the computerization of on-site coordination and monitoring. Through the timely communication of information, actual project situations were recorded by site managers. Periodically, comparative analyses of the construction process with the confirmed BIM model were conducted. Any quality and safety issues were accurately communicated with relevant stakeholders for correction. Even when minor changes that required instant responses left no time for the corresponding stakeholders to confirm with the coordinated BIM model, the modification was first made on paper-based drawings at the construction site, and later updated in the BIM model. In this way, the entire process was closely monitored by the main contractor, and the well-organized coordination and cooperation among the different trades of the Leishenshan Hospital project were achieved.

5. Discussion

5.1. A successful implementation

Leishenshan Hospital rose from the ground in 12 days, stunning the world with its construction speed. The successful, rapid development of Leishenshan Hospital provided a ‘force of example’ [29] that showed the POP modeling approach combined with BIM implementation could greatly improve engineering efficiency, shorten engineering time, and provide precious time for fighting the epidemic. As stated by the technical manager of the main contractor (translated in English):

“According to my experience, a fully functioning infectious disease hospital with the scope of Leishenshan Hospital under normal conditions would have taken more than four months to build, but we successfully completed Leishenshan Hospital in a surprisingly short time. We believed that the faster this hospital could be developed, the more patients we could save.”

A number of BIM benefits were conservatively identified by the designer and main contractor who, among all stakeholders, played major roles in BIM implementation. First, BIM helped to improve the accuracy of information created at the early stage within a very limited time, saving much time for subsequent tasks. When each piece of information was created, it was checked in a coordinated BIM environment and modified if its accuracy was not satisfactory. The interviewed BIM coordinator of the designer suggested that (translated in English):

“With the help of BIM, the design became more accurate; bottlenecks and omissions were effectively avoided or at least reduced. We had accurate information to support in-time decision making and were ready to meet uncertainty. Let me give you an example. If additional rooms were required to accommodate medical personnel, we could refer to the BIM model and make a quick response to use the open space on the north side of the existing medical staff living area.”

Second, BIM enhanced information management at the design and construction stages. The BIM objects of Leishenshan Hospital were modeled in LOD350, indicating that these objects contained more than geometric information. Moreover, the information was structured in the BIM environment, based on which various simulations and analyses could be completed in a few hours so that decision-support information could be readily available for the designer and main contractors to select the most optimized solution from many alternatives. This benefit was evidenced by the reflections of both the designer and the main contractor: “The simulation of ventilation within the isolation ward and impacts on the external environment helped us to improve the design and guarantee the expected performance of this hospital”; “Leishenshan Hospital adopted standard-sized containers because of their availability during that period [the Chinese Spring Festival 2019]. BIM optimized the production and construction in advance to reduce construction time and cost. The BIM model can also support the alteration of Leishenshan Hospital after the COVID-19 epidemic ends.”

Third, BIM supported information communication by enabling the required information to be always available to the right person at the right time. The interoperability of BIM software that was used in the Leishenshan Hospital project allowed the information to be shared between various project stakeholders without much information loss. This improved information communication ensured that design intent could be easily understood by corresponding stakeholders, which accelerated project delivery.

“The traditional development process of a medical technology facility is: modeling and calculation by the designer—generating construction drawings—detailed drawing by the constructor—approval by the designer—factory manufacturing—site assembly. This process will obviously delay the progress of the project. Therefore, we used BIM to reengineer the whole process. Disputes in prefabrication production and construction task delivery could be solved in a timely manner, and all prefabricated components produced by different suppliers met the quality requirements.”

Although these BIM benefits were confirmed, both the designer and main contractor admitted that the implementation of BIM at Leishenshan Hospital was not an easy job. All interviewees mentioned that they had to acquire sufficient BIM resources, especially staff members with BIM skills and experience, and establish a BIM team without any delay. Fortunately, both the designer and main contractor had the experience of using BIM in developing healthcare facilities and had already nurtured their own in-house teams for BIM applications. However, not all stakeholders who were engaged in the development of Leishenshan Hospital had sufficient BIM knowledge and skills. Therefore, a mixed BIM implementation environment was actually employed. Among the specific tasks introduced in Section 4, the majority adopted a BIM-led strategy, while others, especially those requiring immediate reactions during the construction, could only adopt a BIM-assisted strategy. Such an implementation strategy did not follow the suggestions of previous studies that a pure BIM-led strategy could be more effective than BIM-assisted strategy in the hospital projects [30]. Nevertheless, the mixed BIM implementation environment was a preferable choice since the transition was more acceptable to stakeholders who had less BIM knowledge.

“The priority of the Leishenshan Hospital project was to finish this project with high quality while meeting the tight schedule, not to explore as many BIM applications as possible. If we did not have necessary BIM resources, we did not insist on purely using BIM but used the traditional paper-based methods if the overall time could be reduced.”

It is worth noting that some of the reflected benefits and challenges have been reported in previous studies examining the process and context of BIM implementation [[31], [32], [33], [34], [35], [36]]. Nevertheless, this study documents the first case study of the use of BIM in the rapid design, construction and delivery of a specialty field hospital. The experience of Leishenshan Hospital outlined here could enrich the body of knowledge concerning BIM applications in the development of healthcare facilities [[17], [18], [19], [20],37].

5.2. A replicable implementation

The emergence of COVID-19 has made it necessary to consider whether what was possible in the Leishenshan Hospital project could be possible for specialty field hospital development in other countries. Through this reported case study, the authors believe that the following preconditions should be met to address the challenges created by not only the inherent complexity of a fully functioning infectious disease hospital, but also the limited time for project completion. First, the specialty field hospital should adopt a module design and take maximum advantage of standardized prefabricated components. Second, sufficient manpower, machines, and other necessary resources should be organized quickly, and a high level of collaboration among a wide range of involved stakeholders should be established to improve the productivity of these resources. Third, the key stakeholders (such as the designer and main contractor of the Leishenshan Hospital project) should have the capability to develop and utilize the BIM model with POP information, which as reflected in this study, significantly contributed to the on-time, high-quality completion of the Leishenshan Hospital project. It is also expected that, with the increasing emphasis on computer-aided intelligent construction [38], 5G, edge computing, and other cutting-edge technologies can further enhance the information creation, management, and communication in the development of field hospitals to better combat emergency issues.

6. Concluding remarks

The unexpected COVID-19 outbreak has generated incredible pressure on public health systems. The epicenter of COVID-19—Wuhan—encountered severe challenges in the medical supply and the admission capacity of its designated hospitals. The development of two specialty field hospitals, Huoshenshan Hospital and Leishenshan Hospital, was a major strategy used to fight the COVID-19 pandemic. These two hospitals were developed in approximately ten days, saving precious time in providing high-quality medical treatment to over five thousand patients.

This study documents the experience of developing the Leishenshan Hospital project. It was found that the POP modeling approach combined with BIM benefited the design and construction of this hospital through several typical applications. First, BIM helped to improve the design by optimizing the design of building service systems and the arrangement of pathways for patients and medical personnel, and potential bottlenecks in later phases were significantly reduced. Second, BIM helped to simulate the interior ventilation within the isolation ward and the possible impacts of Leishenshan Hospital on the surrounding environment, ensuring that the infectious disease hospital met all functional requirements and technical specifications. Third, BIM helped to smooth the coordination among different trades during the construction that not only kept the progress following a tight schedule but also improved the quality of project delivery. These reported applications confirmed the capabilities of BIM to enhance information creation, management, and communication in the development of specialty field hospitals.

The experience of the Leishenshan Hospital project can be used as an important reference for other countries that are still facing the threat of COVID-19. Future studies are expected to provide more cases for investigating the use of BIM, as well as advanced information technologies, to strengthen public health systems under emergency conditions.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgement

This study is supported in part by the Fundamental Research Funds for the Central Universities under grants 2019kfyXKJC026 and 2019kfyXJJS185. The authors would like to thank the designer and main contractor of the Leishenshan Hospital project for providing valuable information for this study.

References

- 1.Sohrabi C., Alsafi Z., O’Neill N., Khan M., Kerwan A., Al-Jabir A. World Health Organization declares global emergency: a review of the 2019 novel coronavirus (COVID-19) Int. J. Surg. 2020;76:71–76. doi: 10.1016/j.ijsu.2020.02.034. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.National Health Commission of the PRC Updates on the epidemic. April 26, 2020. http://www.nhc.gov.cn/xcs/yqtb/list_gzbd.shtml (in Chinese)

- 3.Cao Y., Li Q., Chen J., Guo X., Miao C., Yang H. Hospital emergency management plan during the COVID-19 epidemic. Acad. Emerg. Med. 2020;27:309–311. doi: 10.1111/acem.13951. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Williams S. Coronavirus: how can China build a hospital so quickly? 2020. https://www.bbc.com/news/world-asia-china-51245156

- 5.XINHUA China builds new hospital in 10 days to combat coronavirus. 2020. http://www.xinhuanet.com/english/2020-02/02/c_138750288.htm

- 6.Liu W., Yue X.G., Tchounwou P.B. Response to the COVID-19 epidemic: the Chinese experience and implications for other countries. Int. J. Environ. Res. Public Health. 2020;17:2304. doi: 10.3390/ijerph17072304. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.ChinaNews Huoshenshan Hospital and Leishenshan Hospital officially closed. April 15, 2020. https://m.chinanews.com/wap/detail/zw/sh/2020/04-15/9158058.shtml (in Chinese)

- 8.Blackwell T., Bosse M. Use of an innovative design mobile hospital in the medical response to Hurricane Katrina. Ann. Emerg. Med. 2007;49:580–588. doi: 10.1016/j.annemergmed.2006.06.037. [DOI] [PubMed] [Google Scholar]

- 9.Cheng B., Shi R., Du D., Hu P., Feng J., Huang G. Mobile emergency (surgical) hospital: development and application in medical relief of “4.20” Lushan earthquake in Sichuan Province, China. Chinese Journal of Traumatology. 2015;18:5–9. doi: 10.1016/j.cjtee.2014.07.004. [DOI] [PubMed] [Google Scholar]

- 10.Bakowski J. A mobile hospital–its advantages and functional limitations. Int. J. Saf. Secur. Eng. 2016;6:746–754. doi: 10.2495/SAFE-V6-N4-746-754. [DOI] [Google Scholar]

- 11.Peng Y. Construction of 2 new Wuhan hospitals being live streamed. 2020. https://www.chinadaily.com.cn/a/202001/28/WS5e2ffebca31012821727379c.html

- 12.Sacks R., Eastman C., Lee G., Teicholz P. John Wiley & Sons; 2018. BIM Handbook: A Guide to Building Information Modeling for Owners, Designers, Engineers, Contractors, and Facility Managers. [Google Scholar]

- 13.Tan T., Chen K., Xue F., Lu W. Barriers to Building Information Modeling (BIM) implementation in China’s prefabricated construction: an interpretive structural modeling (ISM) approach. J. Clean. Prod. 2019;219:949–959. doi: 10.1016/j.jclepro.2019.02.141. [DOI] [Google Scholar]

- 14.World Health Organization Rolling updates on coronavirus disease. 2020. https://www.who.int/emergencies/diseases/novel-coronavirus-2019/events-as-they-happen

- 15.Lavikka R.H., Smeds R., Jaatinen M. Coordinating collaboration in contractually different complex construction projects. Supply Chain Manag. 2015;20:205–217. doi: 10.1108/SCM-10-2014-0331. [DOI] [Google Scholar]

- 16.Merschbrock C., Munkvold B.E. Effective digital collaboration in the construction industry–a case study of BIM deployment in a hospital construction project. Comput. Ind. 2015;73:1–7. doi: 10.1016/j.compind.2015.07.003. [DOI] [Google Scholar]

- 17.Manning R., Messner J. Case studies in BIM implementation for programming of healthcare facilities. J. Inf. Technol. Constr. 2008;13:446–457. http://www.itcon.org/2008/18 [Google Scholar]

- 18.Oh M., Lee J., Hong S.W., Jeong Y. Integrated system for BIM-based collaborative design. Autom. Constr. 2015;58:196–206. doi: 10.1016/j.autcon.2015.07.015. [DOI] [Google Scholar]

- 19.Davies R., Harty C. Implementing ‘Site BIM’: a case study of ICT innovation on a large hospital project. Autom. Constr. 2013;30:15–24. doi: 10.1016/j.autcon.2012.11.024. [DOI] [Google Scholar]

- 20.Mignone G., Hosseini M.R., Chileshe N., Arashpour M. Enhancing collaboration in BIM-based construction networks through organisational discontinuity theory: a case study of the new Royal Adelaide Hospital. Archit. Eng. Des. Manag. 2016;12:333–352. doi: 10.1080/17452007.2016.1169987. [DOI] [Google Scholar]

- 21.Kam C., Fischer M. Capitalizing on early project decision-making opportunities to improve facility design, construction, and life-cycle performance—POP, PM4D, and decision dashboard approaches. Autom. Constr. 2004;13:53–65. doi: 10.1016/j.autcon.2003.08.004. [DOI] [Google Scholar]

- 22.Chen L., Shi P., Tang Q., Liu W., Wu Q. Development and application of a specification-compliant highway tunnel facility management system based on BIM. Tunn. Undergr. Space Technol. 2020;97:103262. doi: 10.1016/j.tust.2019.103262. [DOI] [Google Scholar]

- 23.Chen L., Luo H. A BIM-based construction quality management model and its applications. Autom. Constr. 2014;46:64–73. doi: 10.1016/j.autcon.2014.05.009. [DOI] [Google Scholar]

- 24.Haymaker J., Ayaz E., Fischer M., Kam C., Kunz J., Ramsey M. Managing and communicating information on the Stanford Living Laboratory feasibility study. J. Inform. Technol. Constr. 2006;11:607–626. http://www.itcon.org/2006/42/ [Google Scholar]

- 25.AGC Level of development specification. 2019. https://bimforum.agc.org/lod/

- 26.van Doremalen N., Bushmaker T., Morris D.H., Holbrook M.G., Gamble A., Williamson B.N. Aerosol and surface stability of SARS-CoV-2 as compared with SARS-CoV-1. N. Engl. J. Med. 2020;382:1564–1567. doi: 10.1056/NEJMc2004973. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 27.Jiang Y., Zhao B., Li X., Yang X., Zhang Z., Zhang Y. Investigating a safe ventilation rate for the prevention of indoor SARS transmission: an attempt based on a simulation approach. Build. Simul. 2009;2:281–289. doi: 10.1007/s12273-009-9325-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 28.Gu D., Zhang Y., Liu H., Ma Y., Cao X., Lyu Z. A high-efficiency simulation method for analyzing the impact of exhausted air from temporary hospitals built for the treatment of novel coronavirus pneumonia. Eng. Mech. 2020:105–111. doi: 10.6052/j.issn.1000-4750.2020.02.0047. (in Chinese) [DOI] [Google Scholar]

- 29.Flyvbjerg B. Five misunderstandings about case-study research. Qual. Inq. 2006;12:219–245. doi: 10.1177/1077800405284363. [DOI] [Google Scholar]

- 30.Park J.H., Lee G. Design coordination strategies in a 2D and BIM mixed-project environment: social dynamics and productivity. Build. Res. Inf. 2017;45:631–648. doi: 10.1080/09613218.2017.1288998. [DOI] [Google Scholar]

- 31.Barlish K., Sullivan K. How to measure the benefits of BIM—a case study approach. Autom. Constr. 2012;24:149–159. doi: 10.1016/j.autcon.2012.02.008. [DOI] [Google Scholar]

- 32.Bryde D., Broquetas M., Volm J.M. The project benefits of building information modelling (BIM) Int. J. Proj. Manag. 2013;31:971–980. doi: 10.1016/j.ijproman.2012.12.001. [DOI] [Google Scholar]

- 33.Zheng L., Lu W., Chen K., Chau K.W., Niu Y. Benefit sharing for BIM implementation: tackling the moral hazard dilemma in inter-firm cooperation. Int. J. Proj. Manag. 2017;35:393–405. doi: 10.1016/j.ijproman.2017.01.006. [DOI] [Google Scholar]

- 34.Chen K., Lu W. Bridging BIM and building (BBB) for information management in construction. Engineering, Construction and Architectural Management. 2019;26:1518–1532. doi: 10.1108/ECAM-05-2018-0206. [DOI] [Google Scholar]

- 35.Dowsett R.M., Harty C.F. Assessing the implementation of BIM–an information systems approach. Constr. Manag. Econ. 2019;37:551–566. doi: 10.1080/01446193.2018.1476728. [DOI] [Google Scholar]

- 36.Papadonikolaki E., van Oel C., Kagioglou M. Organising and managing boundaries: a structurational view of collaboration with building information modelling (BIM) Int. J. Proj. Manag. 2019;37:378–394. doi: 10.1016/j.ijproman.2019.01.010. [DOI] [Google Scholar]

- 37.Lin Y.C., Chen Y.P., Yien H.W., Huang C.Y., Su Y.C. Integrated BIM, game engine and VR technologies for healthcare design: a case study in cancer hospital. Adv. Eng. Inform. 2018;36(2018):130–145. doi: 10.1016/j.aei.2018.03.005. [DOI] [Google Scholar]

- 38.Björk B.C. A unified approach for modelling construction information. Build. Environ. 1992;27:173–194. doi: 10.1016/0360-1323(92)90021-G. [DOI] [Google Scholar]