Abstract

In this study, a novel colorimetric sensor array based on chemo dyes including porphyrins and pH indicators were developed to analyse the volatile organic compounds of Chinese Baijiu with different grades. Ethyl acetate, ethyl butyrate and ethyl caproate appeared by significantly different concentration in different Baijiu grades measuring by gas chromatography and mass spectrometry and they were chosen as characteristic volatile organic components. The olfactory visualization system based on colorimetric sensor arrays was used to identify different Baijiu grades. The data were processed by building the principle components analysis, linear discriminant analysis and K-nearest neighbor classification models with the results of sensory evaluation and olfactory visualization system. This work presents a new-style colorimetric sensor using sensitive chemo dyes which has significant potential in quantitative analysis of volatile organic compounds, afterwards identifying different grades of Baijiu.

Electronic supplementary material

The online version of this article (10.1007/s10068-020-00757-z) contains supplementary material, which is available to authorized users.

Keywords: Baijiu grades, Colorimetric sensor, Principle components analysis, Linear discriminant analysis, K-nearest neighbor classification

Introduction

Baijiu is a Chinese alcoholic beverage made from grain. It is a strong distilled spirit, generally 52% alcohol by volume and enjoys a long-lasting popularity in China with a history over thousands of years (Du et al., 2011; Xiao et al., 2014). The main raw materials are the cereals, mostly sorghum, wheat, rice, and corn, with hard or soft liquor made with such yeast and moldy bran as the saccharification and fermentation agent. In the market transactions, some unscrupulous businesses are in the pursuit of the greater commercial value through adding spices to the inferior liquor, resulting in blending into a higher quality of liquor (Wang et al., 2016). Therefore, the comparative analysis of different grades of liquor has an important reference value on improving the quality of liquor and stabling the market order (Chen et al., 2014). For a long time, the discrimination of the quality grade of liquor mainly was based on the sensory evaluation (Zheng et al., 2013). The sensory analysis is usually time-consuming and requires some skilled personnel; it is also vulnerable to the impact of the physical condition, the mood of evaluators and the environment of evaluating. With respect of the reliability, accuracy, and reproducibility, the most efficient analytical methods undoubtedly depend on large equipment, including headspace solid-phase microextraction gas chromatography (Niu et al., 2016), ambient glow discharge ionization mass spectrometry (Zhen et al., 2013), headspace solid phase microextraction-mass spectrometry (Cheng et al., 2013; Cheng and Li, 2014), gas chromatography–mass spectrometry (GC–MS) (Xiao et al., 2014; Zheng et al., 2013), infrared spectroscopy (Dong et al., 2014; Li et al., 2014), electronic tongue technology (Deshmukh et al., 2015; Loutfi et al., 2015), capillary column (Zhou et al., 2014) and electrochemical technology (Jay et al., 2018). However, some unavoidable drawbacks such as complicated pretreatment, requirements for professional operation, and also high cost (Jing et al., 2014; Liu et al., 2012; Zhen et al., 2013) limit their further application and they cannot also get a comprehensive index for all the components of liquor (Peng et al., 2013). Therefore, a fast, efficient, convenient and low-cost analytical method need to be developed to identify liquor grades.

Olfactory visualization is a new concept of electronic nose, which can qualitatively and quantitatively analyse the volatile organic compounds based on the color changes before and after the exposure to the color-sensitive material (Huo et al., 2014; Stupak et al., 2017; Zhen et al., 2013). Olfactory visualization technology was first proposed by RAKOW and has achieved the visualization and digitization of the smell. At present, the technology has been used for liquor varieties, fish freshness, vinegar fermentation process, etc. (Rakow et al., 2005; Suslick, 2004; Zhang and Suslick, 2005).

In this paper, an olfactory visualization system using colorimetric sensor array was developed to characterize VOCs. The specific organic compounds which were distinguish in different Baijiu grades were analysed through GC–MS. VOCs of four quality grades of Chinese Baijiu (identified by sensory evaluation) were analysed by analysis of variance (ANOVA). And PCA, LDA and KNN models were conducted based on the results of sensory evaluation and olfactory visualization system.

Materials

Samples

There were 60 strong aromatic Baijiu samples. In the course of evaluation, each six liquor samples were a round, and three liquor critics were randomly selected from skilled ten critics. The evaluation environment would be set in the enough, soft and suitable light. The temperature was set at 25 °C, humidity at 60%, and there was no any aroma or peculiar smell.

Nine kinds of colorimetric dyes including eight kinds of porphyrins and one kind of pH indicator (The chemical name will be attached to the supplementary material) were used to determine VOCs. Four kinds of porphyrins were bought in Sigma Aldrich Co. Ltd, and four kinds of porphyrins were synthetized in laboratory. The pH indicator was bought in Sinopharm Chemical Reagent Co. Ltd. The base material used reversed-phase silica gel plate (Germany’s Merck & Co.), which can effectively avoid the impact of water vapor in the air.

Baijiu sensory evaluation

The liquor samples’ evaluation grades used the hundred-mark system as the standard of the evaluation result. Speaking in detail, the colorless and transparent sample would reach 10 scores; The national standard of the liquor aroma: When there is a long and comfortable aroma, it can reach 23–25 scores; In the system of grade evaluation, the taste score should be accounted for 50% of the total, which is the highest proportion; The liquor which has unique flavor style would get 15 scores. In short, it scored Baijiu grades considering the color, aroma, taste, and style depending on the degree of discretion.

In the production process, it mainly assessed the first-class and second-class liquor samples submitted by the workshop team workers. And between the two levels of these samples, the first batch had the colorless and transparent color, the pure and rich aroma, the sweet taste, the long aftertaste, the normal odor, scoring 90–100 scores in the hundred-mark system of the evaluation. Taking into account the evaluation of the results of the liquor tasters, there are 36 liquor samples belonging to A grade liquor products. Among these, the taste of 19 liquor samples is different from the other and contained some bitter taste, astringent taste, coke taste, mud smell, short taste, miscellaneous taste, etc., thereby they had 90–94 scores. Therefore, the 19 samples were assessed as a poor level for A− grade and the remaining 17 samples for A+ grade. The second batch of 24 samples had normal color, but less aroma, and the evaluation score of which reach 80–90 scores. And there were 15 samples with some different smell, which were treated for the degradation process and assessed as a poor level for B− grade and the remaining was scored for B+ grades.

Fabrication of colorimetric sensor array

A colorimetric sensor array is the core of the olfactory visualization technology. The steps of making colorimetric sensors were as follows: (1) Preparation of the concentration of 2 mg/mL stock solutions. We accurately weighed 10 mg of the porphyrins, respectively. Then eight kinds of porphyrins dissolved in 5 mL dichloromethane and one kind of pH indicator dissolved in 5 mL anhydrous ethanol solution; (2) By using 100 mm × 0.3 mm of capillaries respectively, we dislodged 0.1 μL colorimetric dye solutions to fixed to a piece of 3 cm × 3 cm hydrophobic reversed-phase silica gel plate. Considering the solvents were toxic and volatile, the experiment operated in the fume hood; (3) eventually we obtained 3 × 3 colorimetric sensor. Each colorimetric sensor would be stored in a sealed sample bag.

The testing processes

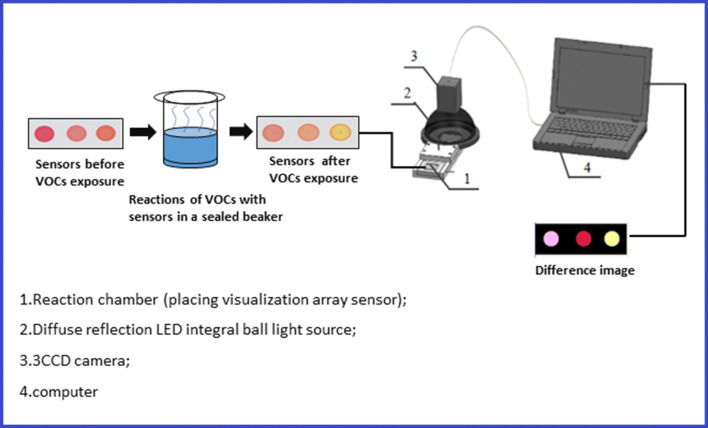

Using homemade artificial olfaction system to identify the different Baijiu grades, the diagram of artificial olfaction system was shown as Fig. 1. The test data acquisition process was as follows:

Fig. 1.

Diagram of artificial olfaction system

Before the reaction, sensor was firstly placed in the reaction chamber. The diffuse reflection LED integrated ball light source of olfactory visualization device can be uniformly reflected from the bottom of the 360-degree light emitted, which can make the light distribution evenly, and used 3CCD camera shooting silica gel Board to get the initial image. The camera’s parameters were set to: gamma value 1.00, gain value 0, exposure value 10.91.

8 mL liquor sample was removed to a beaker with a pipette. The sensor arrays silicone plate with rubber double-sided adhesive were fixed to the plastic wrap, and the cup mouth was sealed by using plastic wrap so that the sensor exposed to liquor volatile gas. The reaction was carried out in an oven at 35 °C. After the sensor was allowed to react with the volatile gas of the liquor for 15 min, the visual array sensor was taken out and the image immediately after the reaction was obtained with the camera.

Image preprocessing operations such as median filter, threshold segmentation background, morphological processing was performed on the image before and after the response of the acquired color sensor. Then the center of each sensor unit on the sensor array is centered, and the circle with a radius of 15 pixels is the region of interest for each sensor. The RGB components of the image in the ROI region before and after the reaction are obtained respectively, and we can getΔR, ΔG, ΔB components before and after the reaction. In order to make the displayed characteristic image more intuitive and clearer and the sensor signal in the same comparison range, the absolute value of the characteristic difference of ΔR, ΔG and ΔB components is normalized so that the RGB component values are mapped among 0–255. And then theΔR, ΔG, ΔB normalized are superimposed that is generated characteristic difference map before and after the sensor.

The characteristic image normalized and 27 characteristic variables (9 kinds of color sensitive materials 3 × 3 color components) are obtained. And 27 feature variables are used as the original data for pattern recognition analysis.

Data processes

The olfactory sensor array produces the corresponding difference feature image with the volatile odor components in different liquor grades. And it is necessary to use the pattern recognition method to train and predict the known samples and then construct a discriminant model to complete the identification of unknown smell. In this study, some multiple variable analysis methods were run in the MATLAB R2009b environment.

Principal component analysis (PCA) is a statistical method. A set of relevant variables are converted into a set of linearly irrelevant variables by orthogonal transform, which is called principal components (PCs) (Qin et al., 2012; Rakow and Suslick, 2000). Effective information can be extracted from a large number of original data under PCA, and it presents intuitively the trend of different grade levels of liquor samples.

Linear discriminant analysis (LDA) is an analysis method to establish the discriminant basing on several types of the known research objects, and then the observed data of grade types of known samples can be obtained. Eventually it achieved identifying and classifying the unknown types of samples (Zhao et al., 2013). Compared with PCA, LDA pays more attention to the distribution of samples in space and the distance between the samples (Chen et al., 2013; Guo et al., 2004).

K-nearest neighbor classification (KNN) is a kind of method and it stores all the sample data of the calibration set in the computer. Then the distance between each unknown sample and each training sample is calculated one by one to find the nearest k to determine and these are based on the assumption that the same kind of samples in the simulation space closing to each other (Bozin et al., 2007). KNN uses the component vector of principal component analysis as the input vector, and the corresponding liquor grade levels as the output variable, and the recognition rate of the liquor sample is used as the discriminant condition of the test of model.

Results and discussion

Sensory evaluation and composition analysis results

At present, the national testing standard for the composition analysis in Baijiu is “liquor analysis method” (GB10781.1-2006). The physical and chemical requirements for Baijiu include the amount of alcohol (% vol), total acidity (g/L in acetic acid), total ester (g/L in ethyl acetate), and solids content (g/L). Ester is an aromatic compound and takes a significant position in strong aromatic Chinese spirits, thence, ester is the main factor of the aroma formation. And especially ethyl caproate, ethyl butyrate and ethyl acetate are the important flavor of Baijiu components (Wang et al., 2015).

Volatile organic compounds (VOCs) of Baijiu with were tested by gas chromatography and mass spectrometry (GC–MS). And ethyl acetate, ethyl butyrate and ethyl caproate was chosen as characteristic volatile organic component. Combined with the results of sensory assessment, single factor analysis of variance of the three volatile organic compounds (ethyl acetate, ethyl butyrate and ethyl caproate) in 60 samples of four grades was reported. The results are shown in Table 1. It makes out that there was no significant difference in ethyl acetate between primary liquors (A+ and A−) and secondary liquors (B+ and B−) either, while significant differences were found between the two grades of B− and A. And according to ethyl butyrate and ethyl caproate, it can be clearly distinguished between primary and second level liquor.

Table 1.

Variance analysis of VOCs (mg/100L) attained by GC–MS from different grades of liquor samples

| Ethyl acetate | Ethyl butyrate | Ethyl caproate | Ethyl lactate | |

|---|---|---|---|---|

| A+ | 552a | 33a | 330a | 133a |

| A− | 512a | 29a | 367a | 129a |

| B+ | 441ab | 23b | 243b | 131a |

| B− | 413b | 21b | 214b | 134a |

A+ means first-class plus spirit; A− means first-class spirit

B+ means second-class plus spirit; B− means second-class spirit

Data represent the mean. In each row different column mean significant differences (p < 0.05)

Liquor grade discrimination

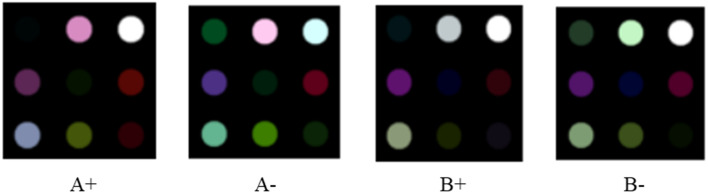

Ten mg of the selected eight kinds porphyrins and one kind of pH indicator were respectively weighed. And porphyrins were dissolved in 5 mL dichloromethane and indicator was dissolved in 5 mL anhydrous ethanol solution. Then colorimetric dye solution was spotted on 3 cm × 3 cm hydrophobic reversed-phase silica gel plate by using 100 mm × 0.3 mm of capillaries. Thereby a 3 × 3 colorimetric sensor array was gotten. The constructed array sensor was employed to discriminate the four grades of liquor, and each sample was done fifteen times in parallel. Figure 2 is the images of colorimetric sensor arrays exposure to samples, and we can see the varying degrees of color changes after the colorimetric materials reacting with volatile organic compounds of different grades of liquor. With the downgrade of Baijiu grades, the color of some sensor showed became darker and darker, that is, some of the gas content may be less and less. And some increased first and then decreased, such as No. 1-2 sensor (1 line 2 columns). The colors of the first-class grade liquor (A+ and A−) were still quite obvious, yet the color of difference image of the level B+ has been lighter. These changes correspond to the tendency of n-propanol content changing obtained by the physical and chemical experiments. Therefore, No. 1-2 sensor (TPPMnCl) is more sensitive to n-propanol. The colorimetric material TPP in No. 3-2 (3 line and 2 column), it appeared in the bright green color, with the lower level, the color change gradually become less, indicating that its sensitive volatile compounds content increased first and then decreased. The feature image can represent the fingerprint characteristics of the liquor based on the olfactory sensor, so that the aroma of the liquor is more intuitive and it is more conducive to realize the digitization of the aroma.

Fig. 2.

Characteristic images of different grades of liquor

In this study, the fabricated colorimetric sensors were developed to obtain the RGB difference data before and after reacting with the four grades of Baijiu, and it had a total of 90 samples and 1120 variables (15 samples per batch, 18 variables per sample, 9 color-sensitive materials) × R, G, B component difference).

Principal component analysis

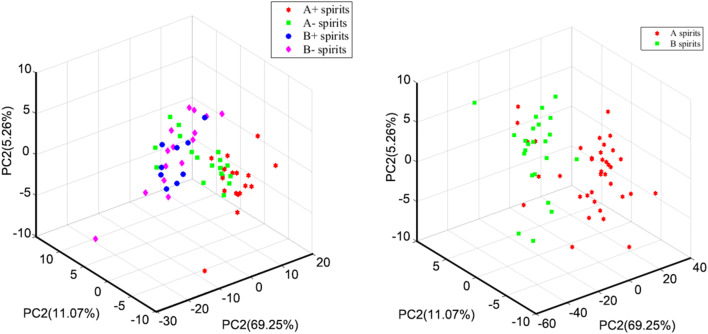

The principal component analysis was carried out using the RGB difference values as the input obtained by the reaction between the four quality grades of liquor samples (17 first-class plus spirit, 19 first-class spirit, 9 s-class plus spirit, and 15 s-class spirit) and the colorimetric sensor. Figure 3A is the diagram of three-dimensional principal component scores from the four grades of liquor. Figure 3B is the diagram of the first class (first-class plus and first-class) and second class (second-class plus and second-class) quality grades of liquors. Figure 3 shows the first three principal component scores, which embodied the projection of the sample points in the calibration set on the three-dimensional plane. It revealed the accumulated variance contribution rate reaches 85.58%. Among them, the variance contribution rate of PC1 was 69.25%; PC2 explained 11.07% variance, and PC3 also explained 5.26% variance. It can be seen from Fig. 3A, the first-class plus spirit liquor and the first-class spirit liquor can also be basically distinguished, but it is difficult to completely distinguish the two-class plus spirit liquor and the two-class spirit liquor because of the crossed projection, which may be related to differences among the storing factors of different quality grades of liquor. Storing conditions have greater impact on the quality of liquor, so there will be some differences among individuals.

Fig. 3.

Diagram of three-dimensional principal component scores from the four class grades of liquor and from the first-class and second-class quality grades of liquors

In order to eliminate the problem of unequal sample size and to further verify the application of this method in the discrimination of liquor grades, PCA model was developed directly on the first and second grade quality of liquor samples. The result is shown in Fig. 3B. As can be seen, there is a good separation between the first and second level of liquor. Even though there are several first-class grade ones overlapping the second-class, this phenomenon may be caused by random error.

Linear discriminant analysis

In order to further illustrate the characterization of the colorimetric sensor array to VOCs of liquor samples, the linear discriminant analysis (LDA) algorithm was used to discriminate the grades of the liquor quality. The LDA is a way of linear transformation to achieve the discrimination of samples, and the original data can be mapped to another lower dimension space by finding a linear transformation, therefore the ratio between the distance between groups and the distance within the group is maximized. Based on the results of the PCA analysis of the first and second grades of liquor quality, the LDA result is shown in Fig. 4. We find the recognition rate of calibration set and validation set of LDA model under different principal components. When the principal component was 15, there was the optimal LDA model of different grades. The recognition rate in the calibration set was 92.5%, and the prediction recognition rate was 90%.

Fig. 4.

The LDA of the first-class and second-class quality grades of liquors

KNN analysis

In the process of KNN discrimination model, the different PCs and the K values are the two factors. In this experiment, the number of K and PCs were both 8 (K, PC = 1, 2, …, 8), and the best principal component and the number of K were selected by the minimum error rate of discriminating the grades of liquor samples by the calibration set. In the calibration set, the discrimination rate of KNN model increased with the increase of PCs. Table 2 shows the results of KNN model for different grades of liquor samples. There was that when the PC was 3 and the K value was 1, the KNN model obtained the best result, and the discrimination rate in the calibration and prediction set were both 90.0%.

Table 2.

The performance parameter and prediction accuracy of KNN model for liquors of different quality grade

| Model | Sample | Numbers | R2 | Accuracy (%) | Total accuracy rate (%) | |||

|---|---|---|---|---|---|---|---|---|

| A+ | A− | B+ | B− | |||||

| KNN | Calibration set | 40 | 0.904 | 100 | 84.6 | 83.3 | 80 | 86.98 |

| Prediction set | 20 | 0.721 | 83.3 | 83.3 | 66.7 | 60 | 73.3 | |

The KNN model was established based on the visualization results of the four grades of liquor. Table 2 shows the performance parameters predicted by the KNN model. The R2 of the calibration set was 0.904. When the R2 value is closer to 1, the fitting result of the model is better. The KNN model has better fitting effect on the quality grade of liquor and can be used for the prediction of the liquor grade. It also can be seen from the table that the KNN model has higher accuracy in the prediction of different grades of liquor in the calibration set, which was respectively 100%, 84.6%, 83.3%, and 80%, respectively. In order to verify the predictive ability of the model to unknown grade samples, a validation set was introduced in this paper, which is not used for the construction of the model. It can be seen from Table 2, the validation accuracy of the KNN model was 83.3%, 83.3%, 66.7%, and 60%, respectively for the prediction of different grades of liquor. In addition, the model of the set R2 was 0.721, and the overall prediction accuracy was 73.3%.

Above all, through the 27 RGB difference values obtained from the colorimetric sensor array, a mathematic model (PCA, LDA, and KNN) combining with the results of sensory evaluation for the identification of liquor grade was established, and the optimal performance obtained LDA model was 92.5%. The liquor quality grade for fast, simple and intuitive identification was basically realized.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Acknowledgements

This work has been financially supported by Foundation for the National Key Technology R&D Program of China (Grant Nos. 2016YFD0401205-3, 2017YFC1600603), Foundation for the Author of National Excellent Doctoral Dissertation of the People's Republic of China (Grant No. 2015BAD19B05), Postdoctoral Science Foundation of Jiangsu Province (Grant No. 1601135B), China Postdoctoral Natural Science Foundation (2016M601746), and the Innovation Fund Designated for Graduate Students of Jiangsu Province (Project No. SJCX17_0581).

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Contributor Information

Hao Lin, Email: linhao@ujs.edu.cn.

Wen-cui Kang, Email: 1873517719@qq.com.

Hong-juan Jin, Email: 995690224@qq.com.

Zhong-xiu Man, Email: 915876161@qq.com.

Quan-sheng Chen, Email: q.s.chen@hotmail.com.

References

- Bozin B, Mimica-Dukic N, Samojlik I. Antimicrobial and antioxidant properties of rosemary and sage (Rosmarinus officinalis L. and Salvia officinalis L. Lamiaceae) essential oils. J. Agric. Food Chem. 2007;55(19):7879–7885. doi: 10.1021/jf0715323. [DOI] [PubMed] [Google Scholar]

- Cheng P, Fan W, Yan X. Quality grade discrimination of Chinese strong aroma type liquors using mass spectrometry and multivariate analysis. Food Res. Int. 2013;54:1753–1760. doi: 10.1016/j.foodres.2013.09.002. [DOI] [Google Scholar]

- Cheng JS, Li CY. Development of quality control technologies for Chinese liquor. J. Food Saf. 2248-2262 (2014)

- Chen Q, Liu A, Zhao J. Monitoring vinegar acetic fermentation using a colorimetric sensor array. Sens. Actuators B Chem. 2013;183(41):608–616. doi: 10.1016/j.snb.2013.04.033. [DOI] [Google Scholar]

- Chen H, Tan C, Wu T, Wang L, Zhu W. Discrimination between authentic and adulterated liquors by near-infrared spectroscopy and ensemble classification. Spectrochim. Acta Part A. 2014;130:245–249. doi: 10.1016/j.saa.2014.03.091. [DOI] [PubMed] [Google Scholar]

- Deshmukh S, Bandyopadhyay R, Bhattacharyya N, Pandey RA, Jana A. Application of electronic nose for industrial odors and gaseous emissions measurement and monitoring– An overview. Talanta. 2015;144:329–340. doi: 10.1016/j.talanta.2015.06.050. [DOI] [PubMed] [Google Scholar]

- Du H, Fan W, Xu Y. Characterization of geosmin as source of earthy odor in different aroma type Chinese liquors. J. Agric. Food Chem. 2011;59:8331–8337. doi: 10.1021/jf201171b. [DOI] [PubMed] [Google Scholar]

- Dong D, Zheng W, Wang W, Zhao X, Jiao L, Zhao C. A new volatiles-based differentiation method of Chinese spirits using longpath gas-phase infrared spectroscopy. Food Chem. 2014;155:45–49. doi: 10.1016/j.foodchem.2014.01.025. [DOI] [PubMed] [Google Scholar]

- Guo H, Wang T, Louie PKK. Source apportionment of ambient non-methane hydrocarbons in Hong Kong: application of a principal component analysis/absolute principal component scores (PCA/APCS) receptor model. Environ. Pollut. 2004;129:489–498. doi: 10.1016/j.envpol.2003.11.006. [DOI] [PubMed] [Google Scholar]

- Huo DQ, Song CX, Li JJ. Development of a colorimetric sensor array for rapid discrimination of Chinese liquors. Modern Food Sci. Technol. 2014;30:267–272. [Google Scholar]

- Jay NS, Dhruba KP, Badri PM, Francis PZ. Size determination of metal nanoparticles based on electrochemically measured surface-area-to-volume ratios. Anal. Chem. 2018;90:9308–9314. doi: 10.1021/acs.analchem.8b01905. [DOI] [PubMed] [Google Scholar]

- Jing Y, Meng Q, Qi P. Electronic nose with a new feature reduction method and a multi-linear classifier for Chinese liquor classification. Rev. Sci. Instrum. 2014;85:431–437. doi: 10.1063/1.4874326. [DOI] [PubMed] [Google Scholar]

- Loutfi A, Coradeschi S, Mani GK. Electronic noses for food quality: A review. J. Food Eng. 2015;144:103–111. doi: 10.1016/j.jfoodeng.2014.07.019. [DOI] [Google Scholar]

- Liu M, Han X, Tu K. Application of electronic nose in Chinese spirits quality control and flavour assessment. Food Control. 2012;26:560–570. [Google Scholar]

- Li Z, Wang PP, Huang CC. Application of Vis/NIR spectroscopy for Chinese liquor discrimination. Food Anal. Methods. 2014;7:1337–1344. doi: 10.1007/s12161-013-9755-9. [DOI] [Google Scholar]

- Niu Y, Hardy G, Agarwal M. Characterization of volatiles Tribolium castaneum (H.) in flour using solid phase microextraction-gas chromatography mass spectrometry (SPME-GCMS). FSHW 5: 24-29 (2016)

- Peng Q, Dong R, Xun S. Determination of volatile phenols in Chinese liquors by high-performance liquid chromatography associated with β-cyclodextrin and a protective barrier layer. Flavour Frag. J. 2013;28:137–143. doi: 10.1002/ffj.3139. [DOI] [Google Scholar]

- Qin H, Huo D, Zhang L. Colorimetric artificial nose for identification of Chinese liquor with different geographic origins. Food Res. Int. 2012;45:45–51. doi: 10.1016/j.foodres.2011.09.008. [DOI] [Google Scholar]

- Rakow NA, Suslick KS. A colorimetric sensor array for odour visualization. Nature. 2000;406:710–713. doi: 10.1038/35021028. [DOI] [PubMed] [Google Scholar]

- Rakow NA, Sen A, Janzen MC. Molecular recognition and discrimination of amines with a colorimetric array. Angew. Chem. 2005;117:4604–4608. doi: 10.1002/ange.200500939. [DOI] [PubMed] [Google Scholar]

- Suslick SK. A noptoelectronic nose:” seeing”smells by means of colorimetric sensor arrays. MRS Bull. 2004;29:720–725. doi: 10.1557/mrs2004.209. [DOI] [PubMed] [Google Scholar]

- Stupak M, Kocourek V, Kolouchova I. Rapid approach for the determination of alcoholic strength and overall quality check of various spirit drinks and wines using GC–MS. Food Control. 2017;80:307–313. doi: 10.1016/j.foodcont.2017.05.008. [DOI] [Google Scholar]

- Wang PP, Li Z, Qi TT, Li XJ, Pan SY. Development of a method for identification and accurate quantitation of aroma compounds in Chinese Daohuaxiang liquors based on SPME using a sol-gel fibre. Food Chem. 2015;169:230–240. doi: 10.1016/j.foodchem.2014.07.150. [DOI] [PubMed] [Google Scholar]

- Wang XL, Chen Y, Li H. Steric Hindrance Effects in the Coexistence of Varieties of Microbes: Analysis of the Causes for Flavor Difference between Solid-fermentation Baijiu and Liquid-Fermentation Baijiu. Liquor-Mak. Sci. Technol. 2016;173:212–218. [Google Scholar]

- Xiao X, Yu D, Niu Y, Chen F, Song S, Zhu J, Zhu G. Characterization of aroma compounds of Chinese famous liquors by gas chromatography–mass spectrometry and flash GC electronic-nose. J. Chromatogr. B. 2014;945–946:92–100. doi: 10.1016/j.jchromb.2013.11.032. [DOI] [PubMed] [Google Scholar]

- Zhao JW, Huang XW, Zou XB. Research on Discrimination of Dominant Spoilage Bacteria in Pork Based on Porphyrins and pH Indicators Gas-Sensing Material. J. Food Sci. Technol. (2013)

- Zhou HB, Li S. Detection of Chinese liquor by electronic nose and electronic tongue. Sci. Technol. Cereals Oils Foods. 2014;6:137–143. [Google Scholar]

- Zhang C. Suslick KS. A colorimetric sensor array for organics in water. J. Am. Chem. Soc. 127: 11548- 11549 (2005) [DOI] [PubMed]

- Zheng XX, Yu JS, Ran YZ. Analysis of liquor plasticizer incident and discussion on liquor packaging materials. Liquor-Mak. Sci. Technol. 2013;10:347–352. [Google Scholar]

- Zhen C, Zhou Y, Zhang N. Differentiation of Chinese liquors by using ambient glow discharge ionization mass spectrometry. Analyst. 2013;138:3830–3835. doi: 10.1039/c3an00074e. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.