Abstract

Surfactants role in the enhancement of the heat transfer and stability of alumina oxide – distilled water nanofluid was introduced in this research, where there are limited studies that conjugate between the stability improvement and its effect on the heat transfer coefficients. Four weight concentrations for the experiment were used (0.1, 0.3, 0.6, and 0.9%) with 20 nm particle size under a constant wall temperature. The selection of appropriate surfactants weight was tested too by implementing three weight concentrations (0.5, 1, 1.5, and 2 %) related to each nanofluid concentration via measuring their effect on the zeta potential value. The heat transfer augmentation was tested through a double horizontal pipe under a constant wall temperature at entrance region with Reynolds number range (4000–11800). The results manifested the use of nanofluid worked on enhancement the heat transfer performance better than water, and the stable nanofluid elucidated better results.

Keywords: Mechanical engineering, Fluid mechanics, Heat exchanger, Heat transfer, Nanofluidics, Nanoparticles, Satiability, Nanofluid, Constant wall temperature

Mechanical Engineering; Fluid Mechanics; Heat Exchanger; Heat Transfer; Nanofluidics; Nanoparticles; Satiability, Nanofluid, Constant wall temperature

1. Introduction

The nanofluid stability is considered one of most important properties, and many studies discussed its effect on the thermophysical properties in order to know the enhancement in the nanofluid behaviour by adding surfactants and altering the pH value of the suspension. The effect of adding two types of surfactants (SDS and PVP) on the stability and thermal conductivity with different mass fractions to the Al2O3/de-ionized water nanofluids of various volume fractions was studied by Xia and co-workers [1]. The surfactants worked on more nanoparticles dispersing in the base fluid and improved the steadiness of suspension. The best enhancement in the thermal conductivity took place at the optimum ratio of concentration of the surfactant mass fraction and the particle volume fraction, where the nanoparticles and surfactants ratio should be concerned. R. Choudhary et al. [2] studied the stability analysis of Al2O3/water nanofluid by changing the pH and sonication time in details. The results indicated that the stability influenced by the time of sonication and pH value, where the zeta potential increased as volume fraction decreased beside an increment occurred at the basic and acidic region when changing the pH value.

The thermophysical properties and the (Al2O3-EG) nanofluids performance were studied by [3] using 0.1% volume concentration and a varied temperature range (20–60 °C) and utilizing (PVP) and (SDS) as surfactants to enhance the nanofluid stability. The best stability reached with PVP surfactants, and it was noticed when the surfactants concentration increased, the thermal conductivity and viscosity increased too and then started to decrease until obtaining the best surfactant concentration. For both laminar and turbulent forced convective process, the temperature below 50 °C can be considered as efficient for the working fluids. The nonlinear increase of viscosity with particle concentration was due to the aggregation of particles [4]. Applicability of nanofluids in cooling and heating applications were working well. The paper showed that nanofluid stability had a strong relation with viscosity and thermal conductivity [5]. The heat transfer coefficient, was an important amount utilized in the calculation of heat transfer, usually used once there was a phase change between a fluid and a solid, or convection. The coefficient was not a property like specific heat or thermal conductivity, however rather a descriptive amount based mostly on fluids interacting with geometries [6].

In the present research, four samples of alumina-water nanofluid were introduced at different concentrations (0.1, 0.3, 0.6 and 0.9%) beside another four samples after selecting the optimum concentration of surfactants in order to study the effect of stability enhancement on the convective heat transfer.

2. Preparation of nanofluid

The nanofluid was prepared by utilizing the two-step method. The average particle shape and size are spherical and 20 nm, respectively as depicted in the SEM image, Figure. (1).

Figure 1.

SEM image for Al2O3 nano powder.

The required weight for the nano powder and the distilled water was estimated according to the mixing equation [4]:

| (1) |

Then, nano particles were added to the distilled water through shaking by hand for a while before making a probe ultra-sonication for one hour to break down the clusters.

Figure (2) illustrates the procedure of producing the nanofluid in the present work.

Figure 2.

Nanofluid preparation diagram.

3. Stability control

The sodium dodecyl sulfate (SDS) (NaC12H25SO4) was used as surfactants in order to reach the stable colloid nanofluid because it is directly related to the steric stabilization mechanism. The SDS structure contains a head and tail. One of these endings sticks on the particles surface to prevent them from attraction and also works as an adhesive between particles and medium [7]. Figure (3) depicts the packet of the used surfactant and the chemical structure of it. In this study, the optimum concentration of surfactants to the colloid was investigated by applying four volume fractions of SDS (0.1, 0.3, 0.6 and 0.9%) on each volume fraction of the alumina-water nanofluid. The optimum volume fraction of surfactants will appear at the highest zeta potential. The zeta potential was carried out to verify the stability level by using the Zeta Potential Analyzer (Zeta Plus) Brookhaven-USA, as shown in Figure (4). Zeta potential measurements revealed an increment in the zeta potential values as adding the additives to the nanofluid. For 0.1, 0.3 and 0.5% surfactant concentration, the best zeta potential recorded the maximum value when the amount of additives is equaled to the nano particles amount which means 1%. The zeta potential values were 45.6, 48.76 and 51.24 mV with 0.1, 0.3 and 0.5 wt.%, respectively. The nanofluid reveals degradation in the stability when increasing the amount of surfactants. The zeta potential of nanofluid with 1% was 53 mV at the 0.5% of SDS which represents the optimum mixture concentration, Figure (5).

Figure 3.

(a) The SDS surfactants can and (b) The chemical structure of the SDS.

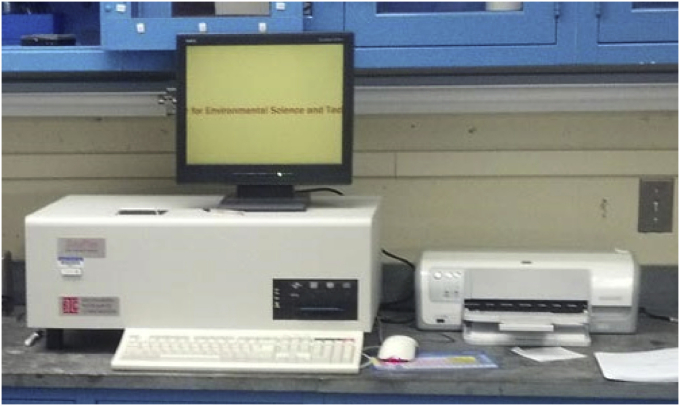

Figure 4.

Zeta potential analyzer (Zeta plus) Brookhaven.

Figure 5.

SDS weight concentration versus the zeta potential of nanofluid.

The sediment photograph capturing of the nanofluid is illustrated in Figure (6). Figure (6-a) represents the samples after preparation. The additives effect appeared obviously when the all samples still homogenized for 44 days without trace of sedimentation for 1 wt.% with 0.5 wt.% surfactants, Figure (6-b). Generally, the sedimentation period is proportional to the weight concentration [8].

Figure 6.

(a) Al2O3 Nanofluid after preparation (b) Al2O3 Nanofluid after 44 days.

4. Experimental test rig

The experimental setup is schematically represented in Figure (7), it comprises a test section (Double pipe Heat exchanger), receiving tank, condensation unit, Arduino, flow meter, heater with thermostat to keep the temperature of the nanofluid constant at the inlet, pump, bypass valve arrangement, thermocouples to read the temperatures, and personal computer. The test section includes a double pipe heat exchanger; the inner tube is from copper and has a diameter of (0.0101 m) with a length of (0.4 m), also the annulus tube is from copper and has a diameter is (0.028 m). The water/nanofluid flows throughout the inner tube via utilizing a pump. The external annular tube is the evaporator of the condensation unit. The mass flow rates for the hot fluid and the water/nanofluid are governed by the arrangements of a by-pass valve. A flow meter (Model YF-S201 working with Arduino) was utilized for measuring the hot fluid mass flow rate. Through the experiments, the hot fluid nanofluid mass flow rate was varied from (0.033 kg/s) to (0.26 kg/s). Three thermocouples were used to read the temperatures of the inlet, outlet, nanofluid and surface.

Figure 7.

The schematic diagram of experimental rig.

In order to remove the nanofluid residue from the system and displace the nano particles from the wall, a flash procedure was implemented by filling the nanofluid tank with fresh water and circulating it in the system for half hour. This will help in prepare the system to receive another concentration of nanofluid without agglomeration as possible on the wall.

5. Data reduction

The data of experiments were utilized to compute the coefficient of the convective heat transfer as well as the Nusselt no. of nanofluids with different particle volume concentrations. For the fluid flows in the heat exchanger inner tube, the rate of heat transfer of hot fluid (nanofluid Al2O3) in the inner tube can be stated as:

| (2) |

While, the mass flow rate and the heat transfer of cold fluid (R134a) for outer tube are:

| (3) |

Ha = Specific enthalpy of saturated vapor at the evaporator temperature.

Hb = Specific enthalpy at the compressor exit.

| (4) |

RE: Refrigerant effect, see Figure (8).where,

| (5) |

Figure 8.

The refrigeration cycle of cold tube.

The average heat transfer rate (Qav) utilized in the computation is estimated from the cold and hot sides as following [9]:

| (6) |

The overall heat transfer coefficient () for the nanofluid flowing in a concentric tube of heat exchanger is calculated from:

| (7) |

where, Ain = πDinL, and ΔTLM is the logarithmic mean temperature difference.

| (8) |

where,

The outside heat transfer coefficient (ho) is calculated by this Eq. (10)

| (9) |

| (10) |

where,

x = 0.75, which is the difference in dryness fraction.

And,

Therefore, the Nusselt number of the cold side can be calculated from the equation below [14].

| (11) |

The coefficient of the convection heat transfers of test fluid (hi) can be found from this equation:

| (12) |

where, Uin is the overall coefficient of heat transfer based upon the area of inside tube, (hi) and (ho) are the individual coefficients of the convective heat transfer of fluids inside and outside the tubes, respectively.

Eq. (13) below denotes the experimental Nusselt no., which is computed based upon the coefficient of heat transfer of the tube side, the hot water thermal conductivity and the tube diameter.

| (13) |

| (14) |

The losses of heat are too low and the difference between Qcold and Qhot is not more than 10% in heat exchanger; that means the experimental setup is calibrated well and it's ready for conducting the experiments with various nanofluids' concentrations.

6. Results and discussion

The heat transfer augmentation of the nanofluid was investigated experimentally under constant wall temperature at the entrance region. The inlet temperature of the nanofluid to the test section was controlled by the chilling unit that will insured to reach the targeted temperature and stopping the continued heating to the test section wall. Figures 9 and 10 demonstrate that the coefficient of heat transfer will increase with the increment of the range of Reynolds number. It's obviously noted that the coefficient of the convective heat transfer of nanofluid is more than the base fluid (water) at a specified range of Reynolds number. The outcomes are conformed to those found by SURESH, S. et al. [9]; SHARMA, K. V. et al. [10] and HERIS, et al. [11]. The improvement of heat transfer is resulted via the suspended nanoparticles and gets much noticeable with the particle volume concentration increase. The attributed reason for this improvement is also related to the as follows: (1) the nanofluid having the suspended nanoparticles will increase the mixture thermal conductivity and (2) the method of the high energy exchange resulted from the nanoparticles chaotic movement, XUAN, et al. [12]. The heat exchanger system performance can be improved via employing nanofluids at the optimal weight concentration of the anionic surfactant in addition to nanoparticles. Figures 11 and 12 reveal that when the coefficient of heat transfer will increase, the Nusselt number increases, Eq. (13) [13]. The enhancement in the Nusselt number for all nanofluid at four concentrations (0.01, 0.03,0.06 and 0.09%) were 2.6%, 3.0, 6.3% and 10.2%, respectively, and when using additive metal to the stability treatment, the enhancement became 4.9%, 6.6, 8.9% and 13.44% after the stability treatment. The maximum augmentation was 10.2% before and 13.44% after the stability treatment at 0.9%, for 11800 Reynolds number, the increment in the specific heat and thermal conductivity leads to increase the amount of the heat gained by nanofluid. Figures 13 and 14 demonstrate the Nusselt number behaviour with the volume concentration, the Nusselt increased with the nanoparticles increase [14]. Figures 15 and 16 manifest the ratio of the nanofluid Nusselt number to that of the pure water at the similar Reynolds number versus Reynolds number. One can notice that an important augmentation of the coefficient of heat transfer can be determined via suspending small quantities of the nanosized Al2O3 particles into water [15]. The better performance in heat transferring is related to the ability of nanofluid in absorbing the heat from the pipe wall due to the nanoparticles thermal conductivity improvement, this leads to increasing in the heat gain by the nanofluid and decreasing the differences between the surface temperature and transportation medium. In the present experiments, Nunf/Nuw was about 1.12 and 1.38 before and after stability treatment, respectively at 0.09% volume fraction of Al2O3 nanoparticles in water at a Reynolds number of 11800.

Figure 9.

Average coefficient of heat transfer versus Reynolds no. for distilled water and (Al2O3) nanofluid at the volume concentrations without stability treatment.

Figure 10.

Average coefficient of heat transfer versus Reynolds no. for distilled water and (Al2O3) nanofluid at the volume concentrations with stability treatment.

Figure 11.

Average Nusselt number versus Reynolds no. for distilled water and (Al2O3) nanofluid at the volume concentrations without stability treatment.

Figure 12.

Average Nusselt number versus Reynolds no. for distilled water and (Al2O3) nanofluid at the volume concentrations with stability treatment.

Figure 13.

Average Nusselt number versus volume concentrations for distilled water and (Al2O3) nanofluid at the different flow rates without stability treatment.

Figure 14.

Average Nusselt number versus volume concentrations for distilled water and (Al2O3) nanofluid at the different flow rates with stability treatment.

Figure 15.

The ratio of Nusselt no. of nanofluid to Nusselt no. of base fluid versus Reynolds no. without stability treatment.

Figure 16.

The ratio of Nusselt no. of nanofluid to Nusselt no. of base fluid versus Reynolds no. with stability treatment.

In Figure 17. The values were carefully validated comparison to the values of [16] theoretical correlation. Figure 18. The data matches well and has the same behaviour with published data for Rabienataj Darzi [17]. The results obtained are slightly higher than [17]. This may be explained by using refrigeration unit for Provide constant wall temperature and It was found that such an approach can produce good enhancement, and stable data.

Figure 17.

Nusselt number of water is compared with the values of Dittus–Boelter H.C. Brinkman [16].

Figure 18.

Comparison of present study with the [17], the effect of Reynold on Nusselt number.

7. Conclusions

Adding nanoparticles to the base fluid augmented the heat transfer rate, and this augmentation increased gradually as the concentration increased, where the maximum increment in the Nusselt number reached at the highest volume concentration. Dealing with stable nanofluid working on getting better results where adding additives to the aluminium oxide nanofluid at an optimum weight improved the suspension's stability and enhanced the heat transfer. The stability improvement was noticed by zeta potential value increase. The stable nanofluid has better thermophysical properties in comparison with the unstable nanofluid which leads to the present augmentation.

Declarations

Author contribution statement

Ali Habeeb Askar: Conceived and designed the experiments; Performed the experiments; Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data; Wrote the paper.

Saif Ali Kadham: Conceived and designed the experiments; Performed the experiments; Analyzed and interpreted the data; Wrote the paper.

Salah Hadi Mshehid: Performed the experiments; Contributed reagents, materials, analysis tools or data.

Funding statement

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Competing interest statement

The authors declare no conflict of interest.

Additional information

No additional information is available for this paper.

References

- 1.Xia Guodong. Effects of surfactant on the stability and thermal conductivity of Al2O3/de-ionized water nanofluids. Int. J. Therm. Sci. 2014;84:118–124. [Google Scholar]

- 2.Choudary Rajesh. Stability analysis of Al2O3/water nanofluids. J. Exp. Nanosci. 2017;12(1):140–151. [Google Scholar]

- 3.Zhai Yuling. Evaluation of surfactant on stability and thermal performance of Al2O3-ethylene glycol (EG) nanofluids. Powder Technol. 2019;343:215–224. [Google Scholar]

- 4.Kouloulias K. Visualisation of subcooled pool boiling in nanofluids. Fusion Eng. Des. 2019;146:153–156. [Google Scholar]

- 5.Khairul M.A. Effects of surfactant on stability and thermo-physical properties of metal oxide nanofluids. Int. J. Heat Mass Tran. 2016;98:778–787. [Google Scholar]

- 6.Belhocine Ali, Oday Ibraheem Abdullah. Similarity and numerical analysis of the generalized Levèque problem to predict the thermal boundary layer. Int. J. Interact. Des. Manuf. 2018;12(3):1015–1025. [Google Scholar]

- 7.Kong Linghui, Sun Jianlin, Bao Yueyue. Preparation, characterization and tribological mechanism of nanofluids. RSC Adv. 2017;7(21):12599–12609. [Google Scholar]

- 8.Abed H.H. Mechanical Engineering, University of Technology; 2019. Experimental Study of Heat Transfer Augmentation and Stability of Al2O3 Nanofluid. M.Sc. Thesis. [Google Scholar]

- 9.Suresh S. Experimental studies on heat transfer and friction factor characteristics of Al2O3/water nanofluid under turbulent flow with spiralled rod inserts. Chem. Eng. Process: Proc. Intensif. 2012;53:24–30. [Google Scholar]

- 10.Sharma K.V., Sundar L. Syam, Sarma P.K. Estimation of heat transfer coefficient and friction factor in the transition flow with low volume concentration of Al2O3 nanofluid flowing in a circular tube and with twisted tape insert. Int. Commun. Heat Mass Tran. 2009;36(5):503–507. [Google Scholar]

- 11.Heris S. Zeinali, Esfahany M. Nasr, Etemad, Gh S. Experimental investigation of convective heat transfer of Al2O3/water nanofluid in circular tube. Int. J. Heat Fluid Flow. 2007;28(2):203–210. [Google Scholar]

- 12.Xuan Yimin, Roetzel Wilfried. Conceptions for heat transfer correlation of nanofluids. Int. J. Heat Mass Tran. 2000;43(19):3701–3707. [Google Scholar]

- 13.John Wiley. 2008. Nanofluids Science and Technology Book. [Google Scholar]

- 14.El Becaye Maiga, Sidi Heat transfer enhancement in turbulent tube flow using Al2O3 nanoparticle suspension. Int. J. Numer. Methods Heat Fluid Flow. 2006;16(3):275–292. [Google Scholar]

- 15.Fotukian S.M., Nasr Esfahany M. Experimental investigation of turbulent convective heat transfer of dilute γ-Al2O3/water nanofluid inside a circular tube. Int. J. Heat Fluid Flow. 2010;31(4):606–612. [Google Scholar]

- 16.Brinkman H.C.W. The viscosity of concentrated suspensions and solutions. J. Chem. Phys. 1952;20(4):571–581. [Google Scholar]

- 17.Darzi AA Rabienataj, Farhadi Mousa, Sedighi Kurosh. Heat transfer and flow characteristics of Al2O3–water nanofluid in a double tube heat exchanger. Int. Commun. Heat Mass Tran. 2013;47:105–112. [Google Scholar]