Abstract

Dust masks are often confused with filtering facepiece respirators (FFR) but are not approved by NIOSH for respiratory protection against particulate exposure. This study reports the filtration performance of commercially available dust masks against submicron particles and discusses the relevance of these findings toward the filtration of nanoparticles. Seven different models of dust masks from local home improvement/hardware stores were challenged with submicron NaCl particles, and initial percentage penetration and resistance levels were measured using two test procedures. A polydisperse aerosol test (PAT) method, similar to the “worst case” conditions used in the NIOSH particulate respirator certification test protocol was used. A monodisperse aerosol test (MAT) method, which utilizes eleven different particle sizes in the range of 20–400 nm, were also used for particle penetration measurements at 30 and 85 L/min flow rates using the TSI 3160. Dust masks were designated as category low-, medium- and high-penetration dust masks based on penetration levels of <5%, 5–25% and >25%, respectively. Data collected using the PAT and the MAT methods showed <5% initial penetration levels for low-penetration dust masks, which is similar to the NIOSH-approved class-95 filtering facepiece respirators. Average penetration levels for medium- and high-penetration dust masks were between 8.9–24.2% and 74.5–96.9%, respectively. Penetration levels of MPPS particles from the MAT correlated with penetration levels from the PAT. Monodisperse MPPS penetration levels from MAT and penetration levels from PAT showed poor correlation with resistance values and no correlation with cost. The results of this study show that dust masks frequently do not provide filtration performance equivalent to that of NIOSH certified devices. Users of dust masks should be cautioned against using them for protection against particulates in the nano- or ultrafine size ranges.

Keywords: Nanoparticle, Respirator, Dust Mask, Filtration, Particle penetration

INTRODUCTION

Particles are generated by a wide variety of natural, manufacturing, domestic, and industrial activities, including construction, agriculture, and mining. There are also numerous sources of particulate that are generated in recreation or household activities such as woodworking, lawn mowing and pottery. The amount of dust emitted by these activities depends on the physical characteristics of the materials and the way these materials are handled. Humans, if unprotected, may inhale high levels of particulate when exposed to particle generation sources. Inhalation of airborne contaminants is often associated with diseases including pneumoconiosis, cancer, asthma and allergic alveolitis (WHO, 1999; Hoet et al., 2004). Respirators are often used as a means to reduce inhalation of particulate in various workplaces and in the home when engineering controls and administrative measures are insufficient.

National Institute for Occupational Safety and Health (NIOSH)-approved respirators are available at home improvement/hardware stores. NIOSH-approved respirators are tested under stringent test conditions for certification. Dust masks are also available at home improvement/hardware stores, but are not respirators and are not approved by NIOSH for respiratory protection against particulate. Dust masks may not legally be used in the workplace if respiratory protection is required (Federal Register, 1988). Dust masks are sold under different names including nuisance mask, face mask, and protective mask. Manufacturers suggest that dust masks can be used for sweeping, cleaning, gardening, pollen, etc. Some of them have warnings such as “do not use for protection against asbestos, lead-based paint, oil aerosols, vapors, gases, harmful materials or toxic chemicals”. Some dust mask models have information on filtration efficiency for 0.3–10 μm particles.

Traditionally, dust masks have been used outside the workplace by the general public engaged in home improvement projects, gardening, or recreation (e.g. pottery). These hazards typically involve larger particles (> 1000 nm). However, nanomaterials are increasingly being incorporated into commercial products (Maynard and Michelson, 2008), which increases the chances that people engaged in recreation or home activities could be increasingly exposed to aerosolized nanoparticles or ultrafine (< 100 nm) particles as they manipulate these products. The increased concern of human exposure to particles in this size range stems from recent research that indicates that nanoparticles exhibit increased biological activity compared to larger particles of the same material (Schulte et al., 2008). Furthermore, in the event of an influenza pandemic, a shortage of NIOSH-approved filtering facepiece respirators (FFRs) is possible (IOM, 2006). In such an emergency situation, workers and the general public may be tempted to substitute dust masks for NIOSH-approved products. Although the exact mechanism for transmission of infectious diseases is still subject to much debate, some scenarios involved bioaerosols in the submicrometer range and possibly even the nano- or ultrafine particle size range (Kowalski et al., 1999; Balazy et al., 2006a).

NIOSH-certified, particulate respirators are required for protection against airborne particles in workplaces that require that an Occupational Safety and Health Administration (OSHA) respiratory protection program be in place. In 1995, NIOSH issued regulations for certifying non-powered particulate respirators under 42 CFR Part 84, which replaced the older 30 CFR Part 11 (CFR, 1972). Under these regulations, three new categories of respirators replaced the previously used dust/mist (DM) and dust/fume/mist (DFM) respirators (CFR, 1972). The three particulate respirator categories are N, R, and P (based on their degradation resistance) with types 95, 99 and 100 which provide minimum filtration efficiencies of 95%, 99% and 99.97%, respectively. To adequately protect workers under different workplace conditions NIOSH recommends using a respirator selection process (NIOSH, 2004). N-series respirators are used against solid and water-based non-oil particles. For oil particles, R and P series respirators are recommended. Among the available choices for protection against particulate in workplaces, disposable N95 FFRs are commonly used because of their relatively low cost and availability.

Fibrous filters capture particles by diffusion, interception, impaction, electrostatic capture and other mechanisms. Particles greater than 300 nm are captured by interception and impaction mechanisms, while, particles smaller than 100 nm are captured efficiently by diffusion. The performance or effectiveness of all of these mechanisms is dependent on the particle velocity with respect to the fibers in the filter medium. The single fiber filtration theory predicts the existence of an intermediate particle size region, where neither the impaction/interception nor the diffusion mechanisms are dominant (Hinds, 1999). Particles in this size range are termed the most penetrating particle size (MPPS), because their penetration is higher compared to particles that are either larger or smaller in size. The MPPS can vary under different conditions because it is dependent on several factors including, filter media characteristics (fiber size, packing density, charge, etc.), filter type (mechanical, electret, etc.), and experimental conditions (flow rates and particle charge) (Lee and Liu, 1980; Lee and Liu, 1982; Martin and Moyer, 2000). Recent studies showed that the MPPS for NIOSH-approved N95 and P100 FFRs containing electret filter media is in the 40–50 nm range (Balazy et al., 2006a; Balazy et al., 2006b; Rengasamy et al., 2007; Rengasamy et al., 2008).

The filtration performance of NIOSH-approved respirators is well documented by various laboratories (Qian et al., 1998; Willeke and Qian, 1998; Richardson et al., 2006). NIOSH-approved N95 FFRs show less than 5% particle penetration when tested under NIOSH particulate respirator certification test protocols. On the other hand, surgical and other type masks that were not certified and tested by NIOSH can allow relatively high penetration levels of inert and biological particles (Chen and Willeke, 1992; Chen et al., 1994; Brosseau et al., 1997; McCullough et al., 1997). Chen and Willeke (1992) measured the penetration of particles in the 150–4000 nm range at different flow rates using a manikin fitted with a mask or respirator. For surgical and nuisance masks, penetration levels of 300 nm particles were approximately 55–85% and 70–90% at flow rates of 30 and 100 L/min, respectively. The MPPS was in the 200–500 nm range. They also reported that DM and DMF filters were much more efficient than surgical and nuisance masks. A subsequent study measured the efficiency of surgical masks, and DM and DMF respirator filters against 0.55 μm (550 nm) polystyrene latex particles at 45 L/min and Mycobacterium abscessus particles at 45 and 85 L/min flow rates (Brosseau et al., 1997). Their results showed that the efficiency level of surgical masks was less than that of DM and DMF respirators.

Recently the filtration efficiency of two surgical masks and two N95 respirators against MS2 virus particles in the 10–80 nm range was reported (Balazy et al., 2006a). Penetration levels of one model surgical mask increased with increasing particle size from 10 to 50 nm, and then remained at approximately 20% for particles up to 80 nm size at 85 L/min flow rates. A similar penetration pattern was obtained at 30 L/min flow rate, which showed a maximum penetration level of approximately 13%. Another surgical mask showed a monotonic increase in penetration with increase in particle size from 10 nm to 80 nm. The high penetration levels of surgical masks were further confirmed by a recent study that investigated the filtration performance and fit of surgical masks used in hospital and dental settings (Oberg and Brosseau, 2008). Filtration efficiencies of various surgical masks were measured using monodisperse latex spheres of 0.8, 2 and 3 μm (800, 2000, and 3000 nm) diameters at 6 L/min as well as with polydisperse NaCl aerosols of 75 nm diameter (count median diameter). Penetration levels of 0–84% and 4–90% were obtained for the three sizes of latex spheres and NaCl aerosol challenges, respectively. A detailed study on the filtration performance of dust masks using both the NIOSH particulate respirator test protocol and submicrometer sized (< 1000 nm or < 1 μm) monodisperse aerosol particles is lacking.

In this study, penetration of submicrometer sized NaCl particles through seven models of commercially available dust masks was measured using a polydisperse aerosol test (PAT) method similar to the NIOSH certification protocol and a monodisperse aerosol test (MAT) method similar to that used previously (Rengasamy et al., 2007). The filtration performance and costs of the different dust mask models were also calculated and recorded. The implications of these filtration results for protection against airborne nanoparticles were discussed.

METHODS AND PROCEDURES

Dust Masks

Dust masks from seven different manufacturers were selected based on the availability of dust masks in local home improvement/hardware stores. Only one model mask from each manufacturer was employed in the study. The manufacturer and model of the evaluated dust masks were: AOSafety (Comfort mask), Barrier (Surgical facemask), Kimberly-Clark (Dust mask), 3M (Comfort mask), MSA (Dust mask), Nation/Ruskin (PM5) and Superior. Manufacturers of dust mask models were named randomly as A, B, C, D, E, F and G in the subsequent sections of the manuscript to protect their identity. None of the dust masks are certified by NIOSH for respiratory protection.

Polydisperse Aerosol Test (PAT) Method

A TSI 8130 automated filter tester was used for polydisperse submicrometer NaCl aerosol generation and penetration measurements. Initial penetration levels of NaCl particles were measured for 1 min of loading, instead of carrying out the much longer NIOSH 42 CFR 84 test protocol (Federal Register, 1995; NIOSH, 2005). The NIOSH certification test is based upon the assumption of “worst-case” conditions for assessing filtration performance. The test uses a charge neutralized polydisperse NaCl aerosol challenge with a count median diameter (CMD) of 0.075 ± 0.02 μm (75 ± 20 nm) and a geometric standard deviation of less than 1.86. For the log normal distribution used in the test, 95% of the NaCl particles are in the range of 22–259 nm. In the PAT method, all of the particles penetrating through the filter are measured simultaneously in the TSI 8130 using a forward light scattering photometer. Percentage particle penetration and resistance (mm water) levels were measured simultaneously at 85 L/min flow rate, which represents a very high work rate not sustainable by most individuals (Janssen, 2003). Measurements were made using a Plexiglas box (20 cm × 20 cm × 10 cm) to mount each respirator for tests as described previously (Rengasamy et al., 2007).

Effect of Isopropanol Treatment on Polydisperse Aerosol Penetrations

The possibility that dust masks use electrically charged filter media to help capture particles was tested by exposing the dust masks to liquid isopropanol. Previously, researchers demonstrated that dipping electret filter media in liquid isopropanol reduced or removed electrical charges associated with fibrous filters and increased laboratory particle penetration several-fold (Martin and Moyer, 2000). This effect is not seen with filter media that rely solely upon mechanical mechanisms for filtration. Thus, this procedure is a simple, but effective approach to ascertaining whether a particular dust mask or respirator contains electret filter media. Five additional dust masks from each model were tested using the PAT method. Dust masks from manufacturer G were not included in the test because they were not available at the time. After the test, the dust masks were carefully removed from the test box to avoid physical damage. The same dust masks were dipped in isopropanol for 30 sec, removed and allowed to dry in a vacuum hood overnight. Each of these dust masks was then mounted in the test box and tested again using the PAT method.

Monodisperse Aerosol Test (MAT) Method

A different set of five masks from the same models that were employed for the PAT experiments were tested against various monodisperse NaCl particles using a TSI 3160 Fractional Efficiency Tester (TSI 3160) as described previously (Rengasamy et al., 2007). The MAT method uses a scanning mobility particle sizer to classify particles based on electrical mobility and a particle counter to measure the number of particles for each selected monodisperse particle size. The MAT method was used in this study to obtain specific information about the filtration efficiency of the dust masks against monodisperse particles less than 100 nm in size, as other studies have shown that the PAT method is limited in its ability to obtain this information (Eninger et al., 2008). Initial percentage penetration levels of eleven different monodisperse aerosols, centered at 20, 30, 40, 50, 60, 80, 100, 150, 200, 300 and 400 nm, were measured in one test run for each mask at a flow rate of 85 L/min. Another set of five samples from each model was tested at 30 L/min flow. As noted in the above discussion of the PAT method, 85 L/min was selected as a “worst-case” setting as it represents a very high work rate. The lower flow rate (30 L/min) represents a flow rate assumed to be representative of a mild work rate. Particle penetration and resistance levels were measured using the same Plexiglas box that was used for the experiments done using the PAT method.

Data Analysis

The data was analyzed using the SigmaStat® (Jandel Corporation) computer program. Average and 95% confidence interval penetration levels were calculated for each model. Correlation coefficients between variable parameters were calculated using the Pearson Product Moment Correlation method. To enable a tiered analysis of filtration performance as a function of resistance, cost, and electrostatic treatment, the evaluated dust masks were grouped into low-, medium-, and high-penetration categories based on initial penetration levels of <5%, 5–25% and >25%, respectively.

RESULTS

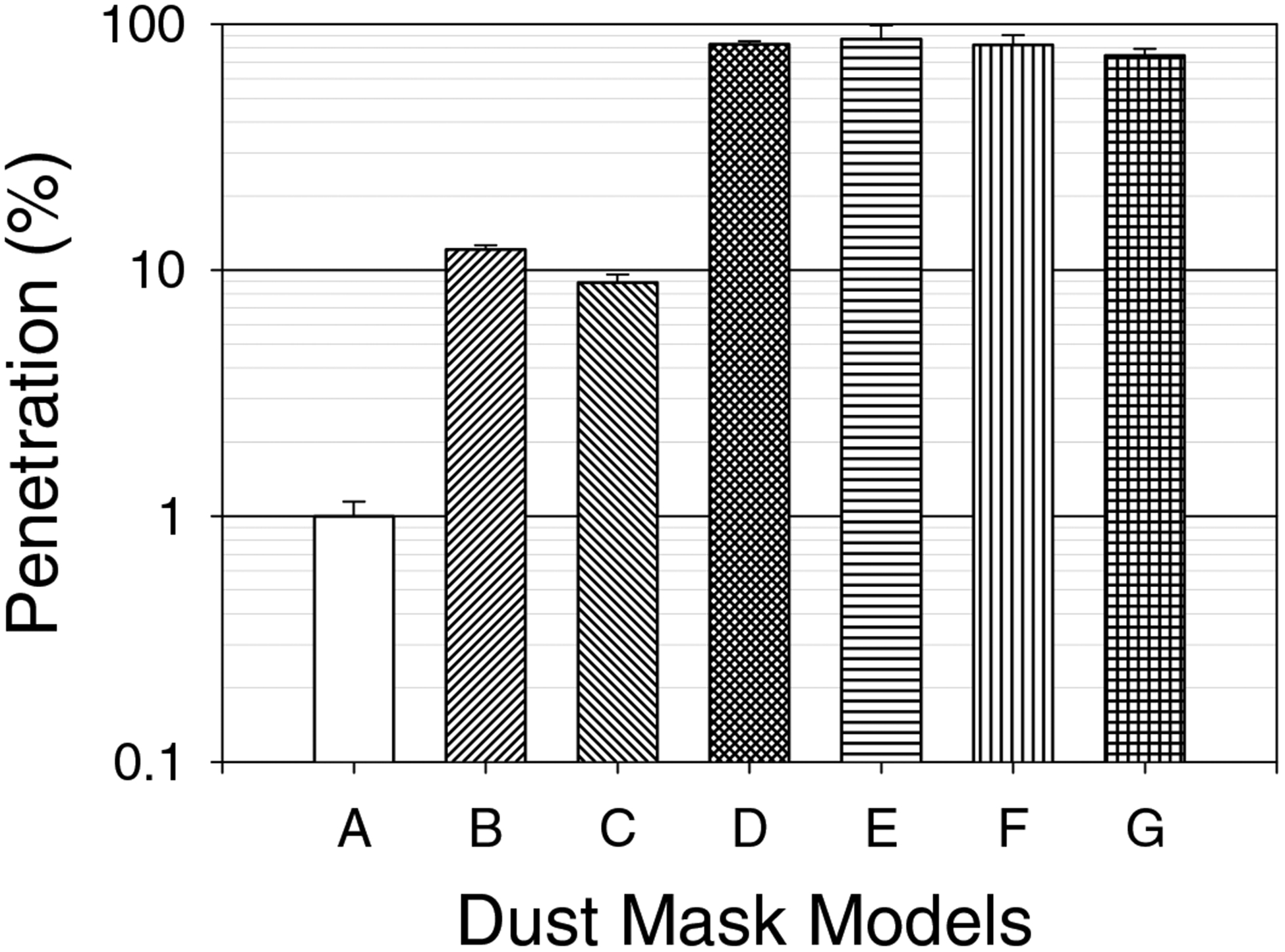

Figure 1 shows the initial percentage penetration levels from the PAT method similar to the NIOSH certification test protocol for particulate FFR at 85 L/min flow rate. Initial particle penetration levels varied between 1.0% and 87.0%. Only one low-penetration category dust mask was found, which showed an average initial penetration level of 1.0%. Two medium-penetration dust masks showed average initial penetration levels of 8.9% and 12.1%. The average initial penetration levels of the four high-penetration category dust mask models tested were between 74.5% and 87.0%.

Figure 1.

Penetration levels from the polydisperse aerosol test (PAT) method for the low (A)-, medium (B and C)-, and high (D, E, F, and G)-penetration category dust masks at 85 L/min flow rate.

Effect of Isopropanol Treatment on PAT Filtration Performance

Table I shows initial penetration levels of control and isopropanol treated dust masks. Isopropanol treatment increased the penetration levels of low-, and medium-penetration dust masks by about 100-and 6-fold, respectively. The increase in average initial penetration levels of isopropanol treated low- and medium-penetration category dust masks were significantly (P<0.05) higher than the controls, while high-penetration dust masks showed little to no effect.

Table I.

Effect of Isopropanol Treatment on Dust Mask Filtration Performance

| Category | Dust Mask Models | Average Penetration Levels from the PAT Method at 85 L/min (%) | |

|---|---|---|---|

| Control | Isopropanol-Treated | ||

| Low-penetration | A | 0.53 ± 0.12 | 55.20 ± 0.61* |

| Medium-penetration | B | 12.20± 0.70 | 75.12 ± 3.23* |

| C | 9.62 ± 1.32 | 62.30 ± 3.19* | |

| High-penetration | D | 89.20 ± 1.27 | 89.10 ± 2.92 |

| E | 85.80 ± 1.73 | 87.96 ± 2.45 | |

| F | 81.42 ± 4.72 | 86.18 ± 4.23 | |

| G | ND | ND | |

Note:

Significantly (P=<0.05) different from the control; ND = not determined.

MAT Filtration Performance

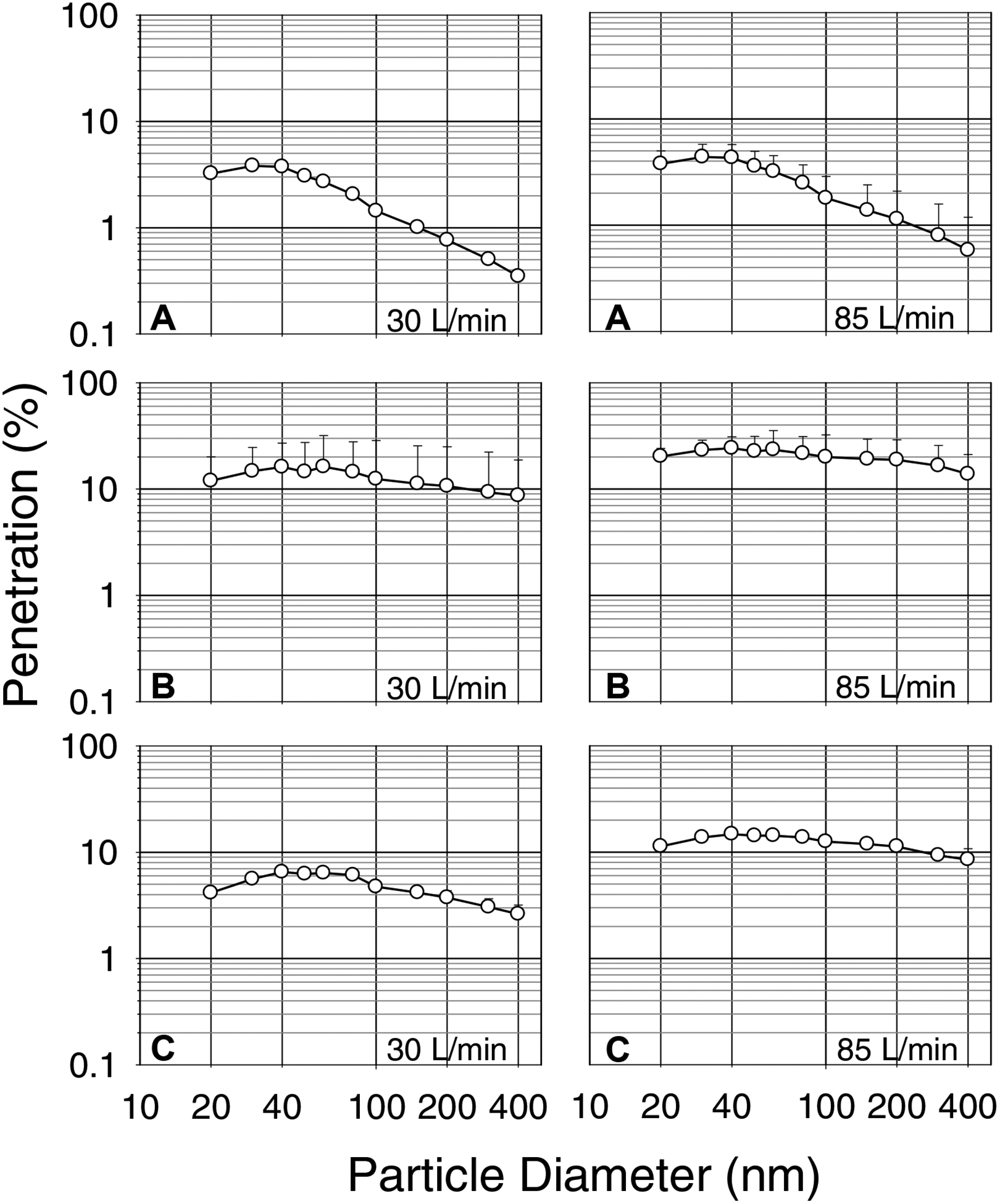

Dust masks from each manufacturer were tested against eleven different size submicrometer monodisperse aerosol particles and initial penetrations levels were measured using the MAT method at 30 and 85 L/min flow rates. For the low-penetration mask, the average initial penetration levels increased from moderate levels for 20 nm particles until reaching a maximum for 40 nm particles, and then, decreased to much lower levels for 400 nm particles at both 30 and 85 L/min flow rates (Figure 2). The MPPS was in the 40 nm range and the average penetration level for the most penetrating particles was 4.3 % at 85 L/min. A similar penetration pattern was obtained for medium-penetration category dust masks, but penetration levels were higher than 5% for 20–400 nm size particles. The MPPS was in the 40 nm range for medium-penetration category dust masks as well. The average percentage penetration of MPPS particles levels were 14.7 and 24.2 at 85 L/min flow rate. In general, the penetration levels of the MPPS were slightly less at the 30 L/min flow rate for both low- and medium-penetration category dust masks.

Figure 2.

Penetration levels at 11 different monodisperse particle sizes measured using the monodisperse aerosol test (MAT) method for one low (A)- and two medium (B)-penetration category dust mask models at 30 and 85 L/min flow rate.

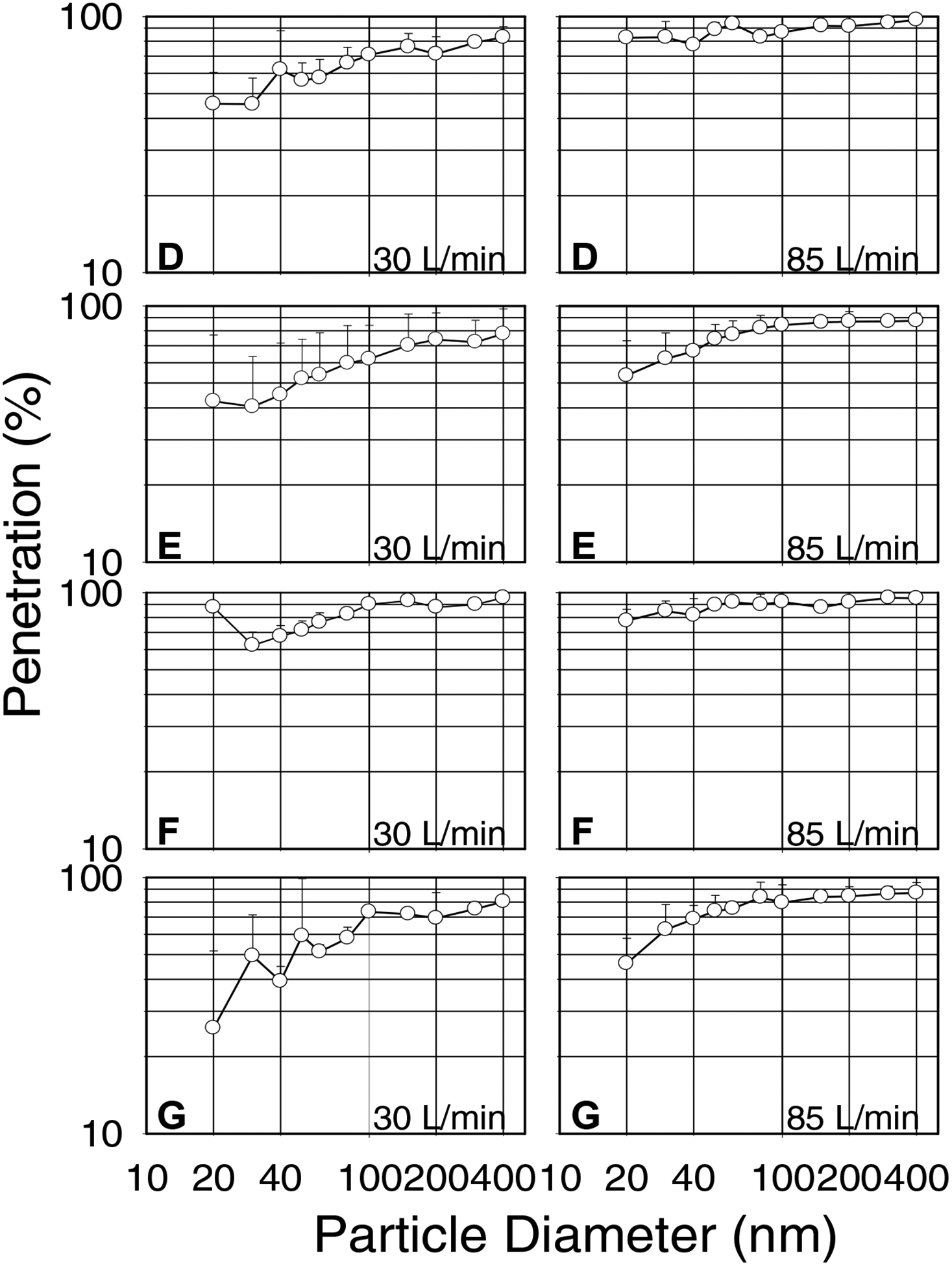

Figure 3 shows average initial penetration levels for the high-penetration category dust masks. In general, penetration levels at both 30 and 85 L/min increased with increasing particle size from 20 nm to 400 nm. Maximum penetration levels were obtained at 400 nm for all four models. Penetration levels for 20 nm particles were between 46.1% and 82.6%, and increased to levels between 87.1% and 96.8% for 400 nm particles at 85 L/min. Percentage penetrations were less at 30 L/min than at 85 L/min similar to low- and medium-penetration category dust masks.

Figure 3.

Penetration levels for 11 different monodisperse particle sizes measured using the monodisperse aerosol test (MAT) method for the four high-penetration category dust mask models (D, E, F and G) at 30 and 85 L/min flow rate.

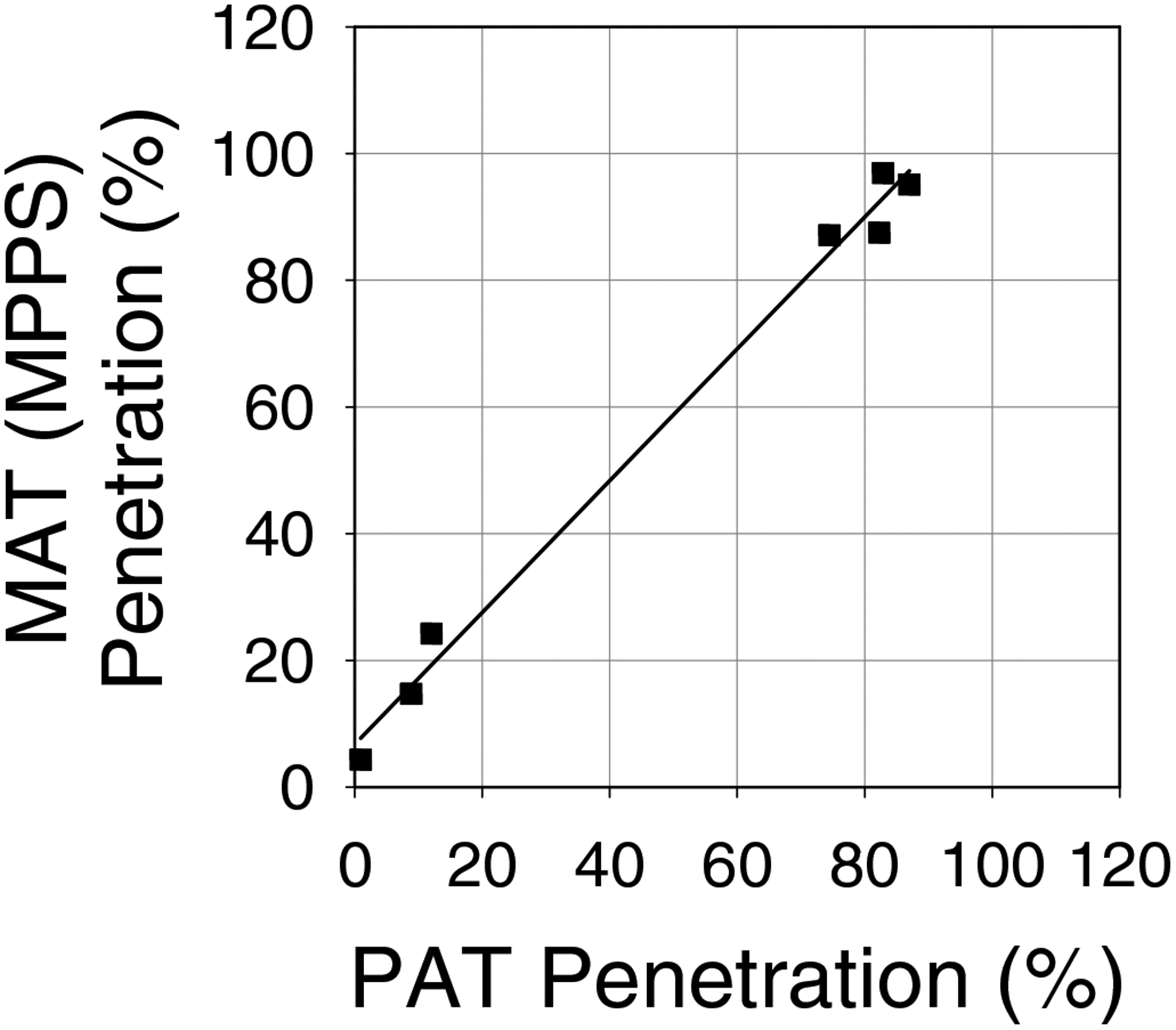

Correlation between MAT and PAT Filtration Performance

Figure 4 shows the correlation (r = 0.99) between the average percentage penetration levels from the seven dust masks in the study obtained from using the PAT method and the monodisperse MPPS aerosol particles from the MAT method. The MPPS levels used in this figure were 40 nm for low- and medium penetration category dust masks and 400 nm for high-penetration category dust masks. The dust mask models with the highest penetration levels from the PAT also showed the highest levels of monodisperse MPPS aerosol penetrations from MAT. Similarly, the models that had the smallest penetration levels using PAT showed the smallest penetration levels for the monodisperse MPPS aerosols using MAT.

Figure 4.

Correlation of the penetration levels from the polydisperse aerosol test (PAT) method and MPPS aerosol penetrations from the monodisperse aerosol test (MAT) method at 85 L/min flow rate for the seven dust mask models. (r = 0.99)

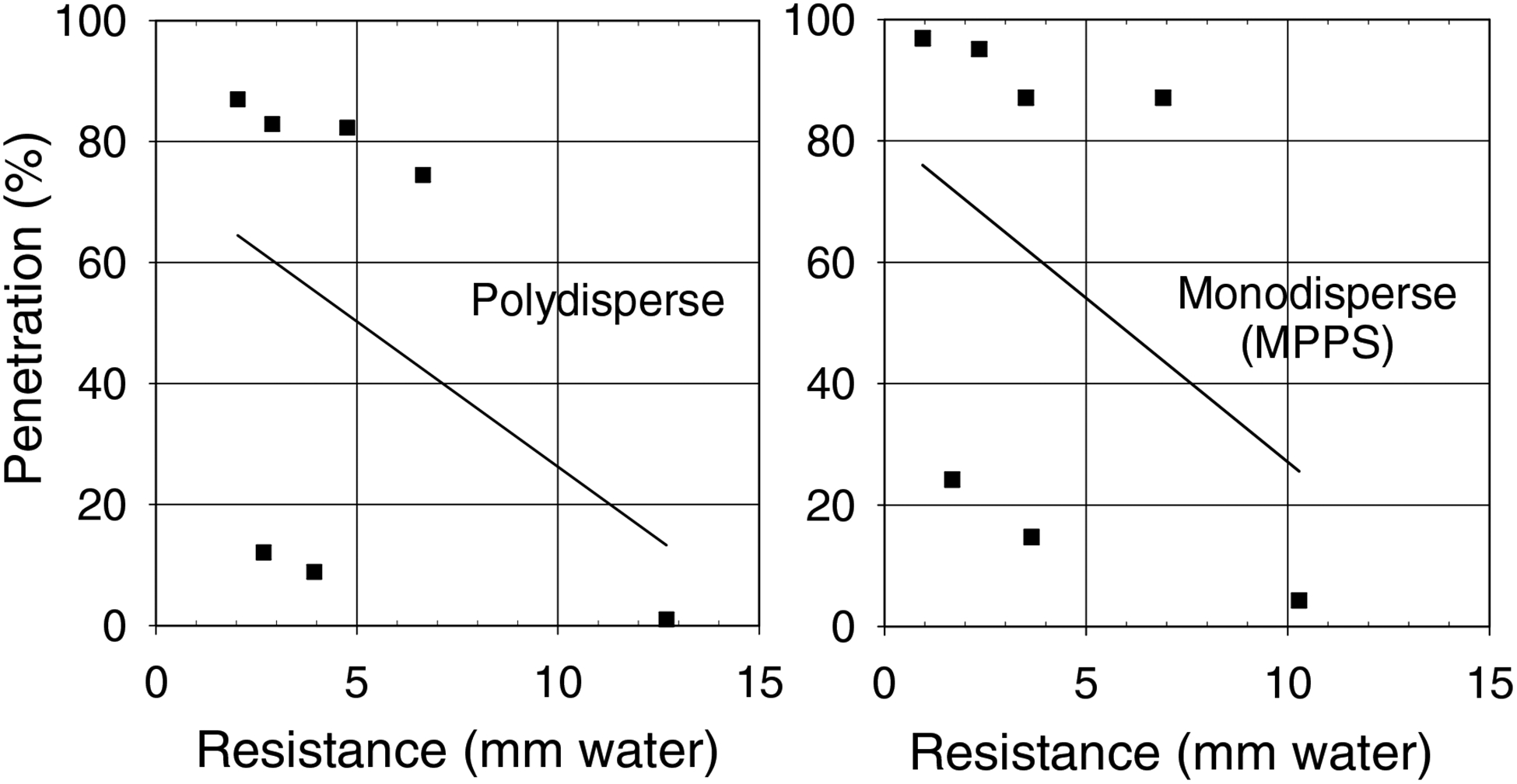

Correlation between Penetration and Resistance Levels

Resistance levels for the dust masks were measured simultaneously when testing filtration performance. Figure 5 shows resistance levels measured during the PAT and MAT experiments at 85 L/min. Using the PAT, average resistance levels for the seven different dust mask models were between 2.0 −12.7 mm water (top panel). There was no significant correlation (r = −0.44, P > 0.05) between penetration levels obtained using PAT and resistance levels. For example, the low-penetration category dust mask that had the smallest particle penetration level showed the highest resistance level also. At the same time, some high-penetration category dust masks also showed relatively high resistance levels compared to medium-penetration category dust masks. Similarly, no significant correlation (r = −0.43, P > 0.05) was obtained between monodisperse MPPS penetration using the MAT method and resistance levels (bottom panel).

Figure 5.

Penetration and resistance levels from the polydisperse aerosol test (PAT) (top panel) and monodisperse aerosol test (MAT) (bottom panel) methods at 85 L/min flow rate for the seven dust mask models. (top panel, r = −0.44; bottom panel, r = −0.43)

Correlation between Dust Mask Cost and Penetration

Table II shows the purchasing costs of the dust masks in the study and their corresponding levels of filtration performance at 85 L/min. The prices of the different models of dust masks were between $0.33 and $0.99 per piece compared to the wide variation in particle penetration level (1–87%). The costs of low- and medium-penetration dust masks were $0.65 and $0.33 to $0.65 per mask, respectively. At the same time, the costs of high-penetration dust masks were from $0.49 to $0.99 per mask. Correlation of dust mask cost with filtration performance from either the PAT method or MPPS aerosols using the MAT method showed no significant relationship (r = −0.12 and r = −0.14, respectively). The low-penetration category dust mask that exhibited the best filtration performance was moderately priced. Yet, some of the high-penetration category dust masks that showed relatively poor filtration efficiency were more costly.

Table II.

Penetration Levels and Costs of the Seven Dust Mask Models

| Category | Dust Mask Models | Average Penetration at 85 L/min (%) | Unit Price ($) | |

|---|---|---|---|---|

| PAT | MAT (MPPS) | |||

| Low-penetration | A | 1.0 | 4.3 | 0.65 |

| Medium-penetration | B | 12.1 | 24.2 | 0.33 |

| C | 8.9 | 14.7 | 0.65 | |

| High-penetration | D | 82.9 | 96.9 | 0.49 |

| E | 87.0 | 95.1 | 0.50 | |

| F | 82.3 | 87.5 | 0.51 | |

| G | 74.5 | 87.1 | 0.99 | |

DISCUSSION

Dust masks obtained from home improvement/hardware stores showed varying levels of filtration performance. Polydisperse submicrometer NaCl aerosol penetration tests (PAT) at 85 L/min flow rate, similar to the NIOSH particulate respirator test protocol, showed a wide range of filtration performance, with only one model falling into a low-penetration category (average penetration levels of <5%), two models falling into a medium-penetration category (5–25%) and four models falling into a high-penetration category (>25%). To our knowledge a dust mask with initial penetration levels less than 5% obtained using the aggressive test conditions employed in this study (e.g., 85 L/min flow rate, charge neutralized particles in the MPPS range, etc.), similar to the penetration levels seen in NIOSH-approved class-95 FFRs, has not been reported in the literature.

The results were further confirmed using the MAT method which utilized eleven different diameter size monodisperse NaCl particles in the range of 20–400 nm, at 30 and 85 L/min flow rate. Average penetration levels of monodisperse MPPS particles from the MAT method showed a significant correlation (r=0.99) with penetration levels from the PAT method. Good correlation and consistent rank ordering of the filtration performances of N95 FFRs against the same PAT method used here and 40, 100, 200, and 300 nm monodisperse aerosol tests have been observed previously (Rengasamy et al., 2007). Similar correlations have been observed for high efficiency particulate air (HEPA) filter media (Lifshutz and Pierce, 1996; Pierce, 1998). Dust masks that had smaller penetration levels for monodisperse aerosols using the MAT method also showed similar penetration levels when tested against the submicrometer polydisperse aerosols in the PAT method used in this study. Penetration levels among different dust masks were expected to vary because manufacturers employ a variety of filter media and designs. However, the wide variation in filtration efficiency for dust masks observed in the study was somewhat unexpected. The variation might be explained by the lack of standard test criteria for dust masks unlike the NIOSH certification protocol used for particulate respirators.

Among the three categories of dust masks that were identified by the PAT and MAT methods, the low-penetration category dust mask showed penetration levels similar to the levels expected for NIOSH-certified class-95 particulate FFRs. Higher penetration levels obtained for medium- and high-penetration category dust masks agree with previous studies on some dust masks (Chen and Willeke, 1992). For example, surgical and nuisance dust masks had efficiency levels of less than 50% for particles in the range of 300 nm even at a flow rate of 30 L/min. Particle collection efficiency decreased to less than 10% (i.e., > 90% particle penetration) at high flow rates such as 100 L/min. A recent study also reported the effect of high flow rate on particle penetration levels (Oberg and Brosseau, 2008). All the surgical masks tested in that study showed higher penetration levels at 84 L/min compared to that at 6 L/min. Similar findings were obtained by others for inert aerosol particles (Chen and Willeke, 1992).

Penetration measurements using the MAT method showed that the MPPS for low- and medium-penetration dust masks was in the 40 nm range. The MPPS obtained in this study agree with recent reports for NIOSH-approved FFRs (Balazy et al., 2006b; Richardson et al., 2006; Rengasamy et al., 2007). A MPPS of 50 nm was obtained for two N95 FFRs tested for penetrations using a manikin model, which employed different diameter size monodisperse NaCl particles (Balazy et al., 2006b). The results were confirmed by a recent study with additional N95 FFR models using a small box for particle filtration tests (Rengasamy et al., 2007). The MPPS for all five N95 FFR models were found to be in the 40 nm range. The reason for the shift in the MPPS from 100–400 nm as reported previously for high efficiency (HE) and other types of respirators (Stevens and Moyer, 1989), to 50 nm has been attributed to the incorporation of electret filter media featuring electrostatic particle capturing. The MPPS has been shown to vary among filters due to several factors including fiber diameter, packing density, fiber charge, aerosol flow rate and others (Lee and Liu, 1980; Lee and Liu, 1982; Martin and Moyer, 2000). Recent studies showed that the MPPS for P100 FFRs were also in the 40–50 nm range (Richardson et al., 2006; Rengasamy et al., 2008) suggesting that particle capturing by the class-P FFRs used in those studies may also involve the electrostatic mechanism. The results obtained for low- and medium-penetration category dust masks subjected to the isopropanol treatment described earlier suggest that these dust mask fibers are electrically charged since particle penetration increases substantially after isopropanol treatment. Previous studies showed that isopropanol treatment increased particle penetration by removing electric charge associated with filter fibers used in N95 and P100 filter media (Martin and Moyer, 2000). The MPPS was believed to be within 100–300 nm for mechanical class-P FFRs similar to HE filters (Stevens and Moyer, 1989). The MPPS for high-penetration category masks was in the 300–400 nm range under similar test conditions suggesting that particle capturing mechanisms are similar to non-electret mechanical filters.

Users may be tempted to select dust masks based on cost assuming that there is a direct relationship between filtration performance and cost. Unlike the very wide variation in filtration performance obtained for the different dust masks, only a marginal difference in costs was observed. For example, the one dust mask that had efficiency levels similar to NIOSH-approved class-95 FFRs, was purchased for $0.65 per piece compared to one of the poor performing high-penetration dust masks at $0.99 per piece. The negative correlation coefficients (r = −0.12 and r = −0.14, respectively) obtained between filtration performance and cost indicates no significant correlation.

Inhalation of airborne dust particles is known to cause illness and disease (WHO, 1999; Hoet et al., 2004). For example, particles such as sand and wood dust showed inflammatory response and genetoxicity in human cell lines (Wei and Meng, 2006; Bornholdt et al., 2007). House dust appears to be a potential route of heavy metal exposure in some cities (Hogervorst et al., 2007). The health effect may be attributed to particle size, chemical composition and surface area, exposure level and duration, and individual susceptibility. Emerging health hazards such as inhalation of nanoparticles and infectious bioaerosols increases the need for awareness of the protection capabilities provided by NIOSH certified respirators and non-certified dust masks and surgical masks. Workers and the general public rely on respiratory devices and dust masks for protection against harmful particulate. A better understanding of respiratory protection, fit testing, hazard exposure level and training are necessary to select respirator devices (Weissman, 2006; Sherrard and Breeding, 2007).

Only one of the dust masks evaluated in this study was found to have a penetration level low enough to be consistent with NIOSH requirements for approval at the level for class-95 FFRs. Data presented in this paper for six of the seven different dust mask models evaluated demonstrated exceedingly higher penetration levels than 5%, the NIOSH approved penetration level for class-95 FFRs. The two test methods used in this study utilize aggressive conditions and the submicrometer sized particle challenges may not be representative of actual workplace or household aerosols (Martin and Moyer, 2000). Thus, the laboratory filtration performances seen in this study provide a conservative estimate of actual filtration performance. The lack of test requirements and standardized test criteria for dust masks suggest that they may not provide predictable filtration performance against submicrometer particles, and nano-sized and ultrafine aerosols in particular.

In this study, only seven different dust mask models were tested for filtration performance against nanoparticles. This is mainly due to the availability of limited number of dust mask models in the local market at the time of investigation. The dust mask models tested in the study represent only a small sample size and may change with time. The dust masks selected may not be representative of all models available on the market. Different dust mask models may be available in other regions. These masks may have tested worse than or superior to any of the ones that were evaluated here. In addition, manufacturers constantly update dust mask models to introduce new better performing products at reduced cost.

Respiratory protection against particulate is also dependent on face seal leakage of particles in addition to filtration performance. Both dust masks and respirators need to achieve a tight face seal in order to maximize protection. Dust masks could be fit tested like NIOSH certified FFRs. Fit factor was not measured in this study, and dust masks may not give fit factor levels similar to NIOSH approved FFRs. This observation is supported by a recent study which quantitatively measured fit factors less than 10 for different surgical masks (Oberg and Brosseau, 2008). In their study, the conclusion was that none of the five surgical masks tested met the fit performance criteria for respiratory protection. Thus, even if the dust mask filter material provides acceptable levels of filtration efficiencies, it should not be assumed that they would provide respiratory protection levels similar to those provided by NIOSH approved products.

CONCLUSIONS

The average initial penetration levels for six of seven dust mask models obtained from home improvement/hardware stores exceeded 5% (the NIOSH-approved maximum initial penetration level for class-95 FFRs) as measured using two different test methods. The low-penetration category dust mask had penetration levels <5% for both test methods, while other dust masks showed significantly higher initial penetration levels. The initial penetration levels obtained using the PAT method had significant correlation with the penetration levels found with 20–400 nm monodisperse MPPS aerosols collected using the MAT method. The MPPS was found to be in the 40 nm range for low- and medium-penetration category dust masks. Isopropanol treatment markedly increased the penetration levels of low- and medium category dust masks suggesting that these models share filtration characteristics similar to NIOSH-approved N95 and P100 FFRs containing electret filter media. The filtration performance of dust masks showed no correlation with cost or breathing resistance. Dust masks are not approved by NIOSH and should not be used in workplaces for respiratory protection against particulate, because the level of protection they provide cannot be assured as evidenced by the large variability seen in tests of filtration performance. Users of dust masks should be cautioned against using them for protection against particulate in the nano- or ultrafine size ranges.

Acknowledgments

The authors acknowledge NIOSH colleagues including William Newcomb, Jeffrey Peterson, Kenneth Williams, Douglas Landsittel, and Mark Hoover for their critical review of the manuscript and suggestions.

Footnotes

Publisher's Disclaimer: Disclaimer

The findings and conclusions in this report are those of the authors and do not necessarily represent the view of the National Institute for Occupational Safety and Health. Mention of commercial product or trade names does not constitute endorsement by the National Institute for Occupational Safety and Health.

REFERENCES

- Balazy A, Toivola M, Adhikari A, Sivasubramani SK, Reponen T, Grinshpun SA. (2006a). Do N95 respirators provide 95% protection level against airborne viruses, and how adequate are surgical masks? Am J Infect Control 34:51–57. [DOI] [PubMed] [Google Scholar]

- Balazy A, Toivola M, Reponen T, Podgorski A, Zimmer A, Grinshpun SA. (2006b). Manikin-based performance evaluation of N95 filtering-facepiece respirators challenged with nanoparticles. Ann Occup Hyg 50:259–269. [DOI] [PubMed] [Google Scholar]

- Bornholdt J, Saber AT, Sharma AK, Salolainen K, Vogel U, Wallin H. (2007). Inflamatory response and geneotoxicity of seven wood dusts in the human epithelial cell line A549. Mut Res/Gen Toxicol Environ Mutagen 632:78–88. [DOI] [PubMed] [Google Scholar]

- Brosseau LM, McCullough NV, Vesley D. (1997). Mycobacterial aerosol collection efficiency of respirator and surgical mask filters under varying conditions of flow and humidity. App Occup Environ Hyg 12:435–445. [DOI] [PubMed] [Google Scholar]

- Code of Federal Regulations (CFR). (1972). Respiratory protective devices. In Title 30 CFR Part 11. U.S. Government Printing Office, Office of the Federal Register, Washington, DC. [Google Scholar]

- Chen CC, Willeke K. (1992). Aerosol penetration through surgical masks. Am J Infect Control 20:177–184. [DOI] [PubMed] [Google Scholar]

- Chen SK, Vesley D, Brosseau LM, Vincent JH. (1994). Evaluation of single-use masks and respirators for protection of health care workers against mycobacterial aerosols. Am J Infect Control 22:65–74. [DOI] [PubMed] [Google Scholar]

- Eninger RM, Honda T, Reponen T, McKay R, Grinshpun SA. (2008). What Does Respirator Certification Tell Us About Filtration of Ultrafine Particles?. J Occup Environ Hyg 5 286–295. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Register Federal. (1988). Respiratory protection. Occupational Safety and Health Administration. In. U.S. Government Printing Office, Office of Federal Register, Washington, D.C. pp 1152–1300. [Google Scholar]

- Register Federal. (1995). Respiratory Protective Devices. Final Rules and Notice. 60:30335–30398. [Google Scholar]

- Hinds WC. (1999). Properties, behavior, and measurement of airborne particles. New York, New York: Wiley-Interscience Publication, John Wiley & Sons, Inc. 182–205 pp. [Google Scholar]

- Hoet PH, Bruske-Hohlfeld I, Salata OV. (2004). Nanoparticles - known and unknown health risks. J Nanobiotechnol 2:12. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Hogervorst J, Plusquin M, Vangronsveld J, Nawrot T, Cuypers A, Hecke EV, Roels HA, Carleer R, Staessen JA. (2007). House dust as possible route of environmental exposure to cadmium and lead in the adult general population. Environ Res 103:30–37. [DOI] [PubMed] [Google Scholar]

- Janssen L (2003). Principles of physiology and respirator performance. Occup Health & Safety 72:73. [PubMed] [Google Scholar]

- Kowalski WJ, Bahnfleth WP, Whittam TS. (1999). Filtration of Airborne Microorganisms: Modeling and Prediction ASHRAE Trans: Res 105:4–17 [Google Scholar]

- Lee KW, Liu BYH. (1980). On the minimum efficiency and the most penetrating particle size for fibrous filters. Air Pollution Cont Assn 30:377–381. [Google Scholar]

- Lee KW, Liu BYH. (1982). Experimental study of aerosol filtration by fibrous filters. Aero. Sci. Tech 1:35–46. [Google Scholar]

- Lifshutz N, Pierce M. (1996). A general correlation of MPPS penetration as a function of face velocity with the model 8140 using the CertiTest 8160 In: Proceedings of the 24th DOE/NRC Nuclear Air Cleaning and Treatment Conference. Portland, Orgeon. pp 698–706. [Google Scholar]

- Martin SB Jr., Moyer ES. (2000). Electrostatic respirator filter media: filter efficiency and most penetrating particle size effects. Appl Occup & Environl Hyg. 15:609–617. [DOI] [PubMed] [Google Scholar]

- Maynard A, Michelson E. (2008). The Nanotechnology Consumer products inventory. Project on Emerging Nanotechnologies at the Woodrow Wilson Center for Scholars The Pew Charitable Trusts. [Google Scholar]

- McCullough NV, Brosseau LM, Vesley D. (1997). Collection of Three Bacterial Aerosols by Respirator and Surgical Mask Filters under Varying Conditions of Flow and Relative Humidity. Ann Occup Hyg 41:677–690. [DOI] [PubMed] [Google Scholar]

- National Institute for Occupational Safety and Health (NIOSH). (2004). NIOSH Respirator Selection Logic. DHHS (NIOSH) Publication No. 2005–100. Cincinnati, Ohio. [Google Scholar]

- National Institute for Occupational Safety and Health (NIOSH). (2005). Procedure No. RCT-APR-STP-0057, 0058, 0059, Revision 1.1. In: DHHS, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, National Personal Protective Technology Laboratory, Pittsburgh, Pennsylvania. [Google Scholar]

- Oberg T, Brosseau LM. (2008). Surgical mask filter and fit performance. Am J Infect Cont. 36:276–282. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Pierce M (1998). HEPA filter media testing: 1950–2000. In: Proceedings of the 25th DOE/NRC Nuclear air Cleaning and Treatment Conference. Minneapolis, Minnesota. pp 72–78. [Google Scholar]

- Qian Y, Willeke K, Grinshpun SA, Donnelly J, Coffey CC. (1998). Performance of N95 respirators: filtration efficiency for airborne microbial and inert particles. Am Indust Hyg Assoc J 59:128–132. [DOI] [PubMed] [Google Scholar]

- Rengasamy A, Verbofsky R, King WP, Shaffer RE. (2007). Nanoparticle penetration through NIOSH-approved N95 filtering-facepiece respirators. J Int Soc Res Prot 24:49–59. [Google Scholar]

- Rengasamy S, King WP, Eimer B, Shaffer RE. (2008). Filtration performance of NIOSH-approved N95 and P100 filtering-facepiece respirators against 4–30 nanometer size nanoparticles. J Occup Environ Hyg (in press). [DOI] [PubMed] [Google Scholar]

- Richardson AW, Eshbaugh JP, Hofacre KC, Gardner PD. (2006). Respirator filter efficiency against particulate and biological aerosols under moderate to high flow rates. In: U.S. Army Edgewood Chemical Biological Center Report for Contract No. SP0700–00-D-3180, Task No. 335, ECBCCR-085. [Google Scholar]

- Schulte PA, Geraci C, Zumwalde R, Hoover M, Kuempel E. (2008). Occupational risk management of engineered nanoparticles. J Occup Environ Hyg 5:239–249. [DOI] [PubMed] [Google Scholar]

- Sherrard LJ, Breeding DC. (2007). The Ins and Outs of Voluntary Respirator Use. Occup Health Safety November Issue. [PubMed] [Google Scholar]

- Stevens GA, Moyer E. (1989). “Worst case” aerosol testing parameters: I. Sodium chloride and dioctyl phthalate aerosol filter efficiency as a function of particle size and flow rate Am Indust Hyg Assoc J 50:257–264. [DOI] [PubMed] [Google Scholar]

- Wei A, Meng Z. (2006). Induction of chromosome aberrations in cultured human lymphocytes treated with sand dust storm fine particles (PM2.5). Toxicol Lett 166:37–43. [DOI] [PubMed] [Google Scholar]

- Weissman BR. (2006). Dust masks, filtering facepieces, respirators: What’s what and who’s who? Occup Health Safety October Issue. [Google Scholar]

- World Health Organization (WHO). (1999). Hazard prevention and control in the work environment: Airborne dust. World Health Organization Occupational Health WHO/SDE/OEH/99.14, http://www.who.int/occupational_health/publications/airdust/en. [Google Scholar]

- Willeke K, Qian Y. (1998). Tuberculosis control through respirator wear: performance of National Institute for Occupational Safety and Health-regulated respirators. Am J Infect Control 26:139–142. [DOI] [PubMed] [Google Scholar]