Abstract

Mediated fuel cells are electrochemical devices that produce power in a manner similar to that of conventional proton exchange membrane fuel cells (PEMFCs). They differ from PEMFCs in their use of redox mediators dissolved in liquid electrolyte to conduct oxidation of the fuel or reduction of the oxidant, typically O2, in bulk solution. The mediators transport electrons (and often protons) between the electrode and the catalysts or chemical reagents in solution. This strategy can help overcome many of the challenges associated with conventional fuel cells, including managing complex multi-phase reactions (as in O2 reduction) or the use of challenging or heterogeneous fuels, such as hydrocarbons, polyols and biomass. Mediators are also commonly used in enzymatic fuel cells, where direct electron transfer from the electrode to the enzymatic active site can be slow. This review provides a comprehensive survey of historical and recent mediated fuel cell efforts, including applications using chemical and enzymatic catalysts.

Graphical Abstract

1. Introduction

1.1. Proton-exchange-membrane fuel cells (PEMFCs) and redox flow batteries (RFBs): Context for mediated fuel cells (MedFCs).

Growing worldwide energy demands continue to motivate the exploration and development of diverse energy storage1 and conversion2 technologies that could support broader use of renewable energy sources, such as solar, wind, hydroelectric, and biomass.3 Electrochemical technologies are a major focus of these efforts, with prominent examples including solid-state4–7 and redox flow batteries,8,9 supercapacitors,10,11 and (photo)electrochemical production of chemicals, ranging from hydrogen (H2) to carbon-based molecules (formic acid, syn gas, MeOH, among others).12,13 Chemicals produced from the latter processes may be stored or transported to other locations for power generation, ideally with fuel cells to leverage their higher energy efficiency relative to conventional combustion-based power generation.14 This review article surveys historical and recent advances in mediated (or “indirect”) electrochemical processes for power generation. These processes are conceptually related to proton exchange membrane fuel cells (PEMFCs) and redox flow batteries (RFBs) (Figure 1), while incorporating features distinct from these established technologies.

Figure 1.

General schematic of an A) PEM fuel cell, B) flow battery in discharge mode with [A] representing the anodic (e.g. low potential) redox couple and [C] representing the cathodic (e.g. high potential) redox couple, and C) mediated fuel cell with mediators for both anode and cathode.

PEMFCs are the most common class of fuel cells for low-temperature power generation.15 These devices convert energy from chemical bonds into electricity by oxidizing a chemical fuel at the anode and reducing an oxidant at the cathode. Conventional PEMFCs use H2 as the fuel16 and O2 as the oxidant. The electrons from H2 are transported from the electrode through the electrical circuit, while the protons are transported through a membrane electrolyte, consisting of a sulfonated fluoropolymer (e.g., Nafion®), to the cathode where they combine with O2 and the electrons to produce water (Figure 1A). A related class of fuel cells, anion exchange membrane fuel cells (AEMFCs), utilize membrane electrolytes that conduct anions, such as Cl− or OH−, and have been the focus of growing interest.17

Water management is a key challenge in conventional PEMFCs.18 Water must be present within the ionic polymer membrane to support efficient proton transport from the anode to the cathode,19 and this requirement is met by using humidified sources of H2 and O2 gases. Meanwhile, the water generated at the cathode from O2 reduction must be removed to avoid flooding of the catalyst. The issues related to water management limit the temperature range available for effective operation of PEMFCs (typical operation ≤ 100 °C). Membrane-electrode assemblies20 and bipolar plates21 have been engineered to address these challenges, while ensuring effective delivery of gases to the catalyst surface, efficient coupling of the catalytic reactions of H2 and O2 with the proton- and electron-transport processes, and precise management of water. Fuel cell technologies continue to improve, with recent advances enabling access to current and power densities of ≥ 2.5 A/cm2 and 1.2 W/cm2, respectively.22

The requirement for high loadings of Pt catalyst at the cathode to achieve optimal performance represents one of the most significant impediments to conventional PEMFCs.23 Pt catalysts are also used at the anode, but the higher catalytic rates for H2 oxidation relative to O2 reduction mean that much less catalyst is required at the anode. Advances have been made in the development of non-platinum group metal (non-PGM) catalysts for O2 reduction;24–26 however, these catalysts typically have lower intrinsic activity than Pt and, therefore, require higher catalyst loadings to achieve the similar current densities. The higher catalyst loading introduces additional limitations associated with the increased electrical resistance from the thicker catalyst layer and restricted mass transport of O2 and water through the electrode. Consequently, commercial applications of non-PGM cathode catalysts have thus far been restricted to low power-density applications, in which the complications arising from higher catalyst loadings are less problematic.27,28

Alongside the development of PEMFCs that use H2 as a fuel, considerable effort has been directed toward the development of fuel cells capable of using liquid fuels. Such devices avoid challenges associated with the storage, transport, and distribution of H2. Direct methanol fuel cells (DMFCs),29 which oxidize MeOH (supplied as a concentrated aqueous solution) to CO2 at the anode, are among the most prominent applications of liquid fuel cells. The lower rates of MeOH oxidation relative to H2 oxidation, however, leads to considerably lower power densities in DMFCs (< 120 mW/cm2).30 The use of fuels more complex than MeOH, such as sugars or other biomass-derived molecules, and limitations on the practical concentrations of these fuels in the aqueous solutions delivered to the anode, can further constrain catalytic rates and power densities in liquid fuel cells.31 Liquid fuel cells must be operated under conditions that avoid cathode flooding, which can arise from transport of water from the fuel solution through the membrane as protons are transported from the anode to the cathode. Complications of the type described here account for the limited commercial application of PEMFCs with fuels other than hydrogen.

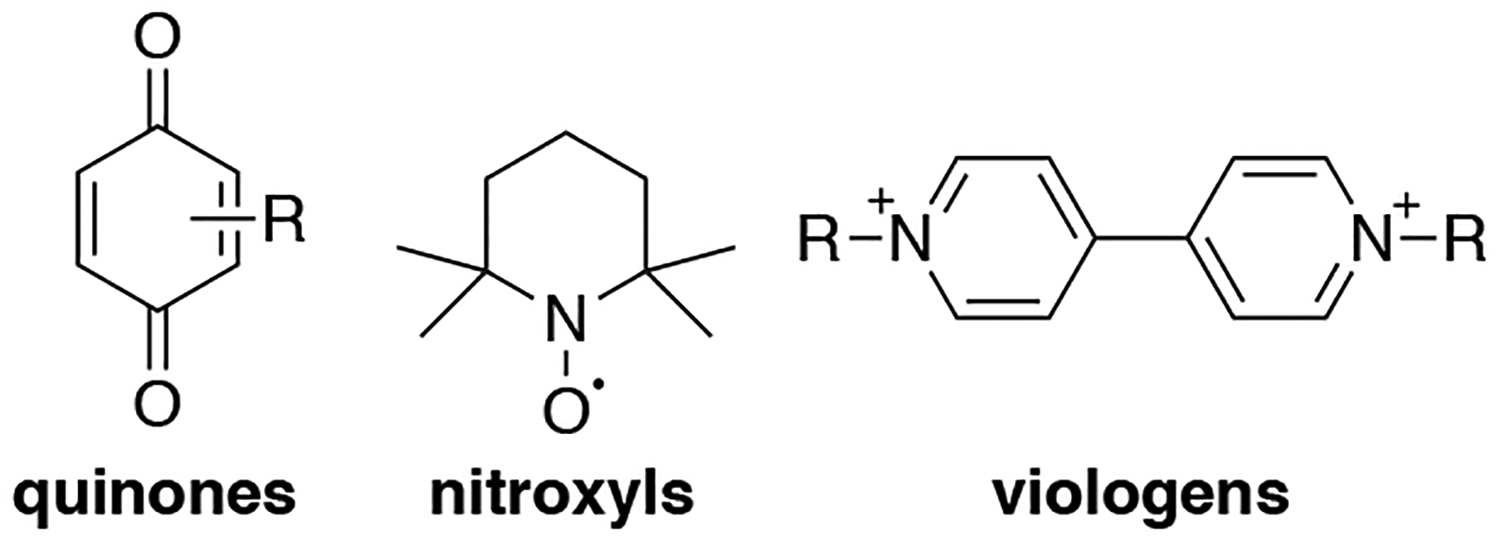

Redox flow batteries (RFBs) represent the second class of electrochemical devices directly relevant to the subject matter of this review article. RFBs store electrical energy by transferring electrons to and from molecules or ions dissolved in solution (Figure 1B). Typical systems feature two tanks of redox couples, one containing a cathodic species that has a high reduction potential and the other with an anodic, low-potential species. Electrical energy is stored and generated by flowing the redox couple solutions through the cathode and anode compartments, which are separated by a semi-permeable membrane that enables selective transfer of protons or other ions while preventing mixing of the mediators. The underlying concepts of redox flow batteries were first demonstrated in the late 1800s,32 with significant technological development beginning in the 1960s.33 Commercial installations have emerged in recent years.34 Examples of the redox couples at the anode/cathode used in commercial systems include Cr/Fe, Zn/Br, and V/V.8 The systems using Fe, Cr, Zn and Br species benefit from the low cost of the chemicals, but the all-vanadium redox flow batteries exhibit the longest lifetimes and are the most widely used. Challenges associated with these technologies include the high toxicity and corrosivity of the electrolyte (particularly for V- and Br-based systems), the limited number of redox couples that operate near the limiting potentials for H+/H2O reduction and H2O/OH− oxidation for aqueous electrolytes, and the limited material supply and high cost of V. All-organic redox species have been the focus of much recent attention as a means to address these limitations. Examples include derivatives of quinones, nitroxyls, and viologens (Figure 2).9,35 The synthetic modularity of these molecules, which allows their redox potentials and other physical properties (e.g., solubility, stability) to be tuned, greatly expands the scope of possible compounds that may be considered. Water-soluble redox couples are especially appealing because water is low-cost solvent with inherently low solvent resistivity;36–38 however, non-aqueous RFBs have also been the focus of major research efforts.39

Figure 2.

Structures of representative organic mediators examined for redox flow battery applications.

1.2. Mediated fuel cells (MedFCs): Overview and opportunities.

The above discussion of PEMFC and RFB technologies provides the relevant context for the introduction of mediated fuel cells (MedFCs, Figure 1C), which are the focus of this review article. The latter devices feature dissolved mediators analogous to the mediators used in RFBs; however, catalytic regeneration of the mediators in an off-electrode compartment enables sustained production of electricity analogous to the operation of PEMFCs. Mediator regeneration is achieved by supplying a fuel to reduce the low-potential mediator and O2 to oxidize the high potential mediator, typically employing a catalyst for both processes. Mediated fuel cell systems are distinct from RFBs because they can operate continuously, as long as the supplies of fuel and oxidant are maintained.

Several factors impact the utility of redox mediators for use in mediated fuel cells. First, the redox potential of the mediator should be as close as possible to the formal potential of the fuel or the oxidant. For a “conventional” system using H2 as the fuel and O2 as the oxidant, the anode mediator should have a redox potential near 0.0 V vs. RHE (Reversible Hydrogen Electrode; i.e., adjusting for the pH of the system), and the cathodic mediator a redox potential near 1.23 V vs. RHE. Additionally, the redox mediator should display fast electron transfer kinetics, to minimize any overpotentials caused by kinetic losses in the system, it needs to be stable in both oxidized and reduced states to enable long-term performance, and it must be highly soluble in aqueous solution for the cell to maximize the current densities.

MedFCs have several potential advantages over conventional fuel cells that warrant their consideration for further development. These features include the following:

1). Enabling the use of “challenging” fuels.

By moving fuel oxidation away from the anode, a greater number of fuel options could become available, and more diverse catalysts may be considered. For example, the use of H2 feeds containing carbon monoxide, sulfur-, or nitrogen-based contaminants has been demonstrated,40 and this advantage was one of the original motivations for investigating MedFCs.41 Another advantage is that fuels that are too complicated to oxidize at an electrode under mild conditions (<150 °C) may be considered. Examples of these alternatives include alcohols more complicated than MeOH and heterogeneous fuel sources, such coal or biomass-derived cellulose or lignin, which are challenging fuels for direct activation at an electrode.

2). Overcoming challenges with the oxygen reduction reaction (ORR).

A major motivation in previous studies of mediated fuel cells has been the replacement of Pt, which is required in relatively high loading in conventional PEM cathodes, with non-PGM alternatives.42 The high loadings of Pt are necessary to achieve sufficiently high activity within the narrow spatial dimension at the gas-diffusion electrodes. By moving the catalytic O2 reduction process into an off-electrode compartment, the ORR may be optimized independently of the electrochemistry. The lower intrinsic activity of non-PGM catalysts relative to Pt is less problematic in this configuration. For example, mass-transport restrictions are significantly reduced when the catalyst does not need to be in direct contact with the electrode and membrane, and higher mass loadings of the non-PGM catalyst may be integrated in an off-electrode reactor in a manner that does not impede system performance. The electrochemical reaction of the mediator features a simpler two-phase (liquid/solid) system at the electrode, rather than the more complicated three-phase (gas/liquid/solid) system present in conventional fuel cells. While there is still a three-phase reaction occurring at the off-electrode catalyst, many of the engineering and materials constraints are relaxed. For example, it is not essential to use a conductive catalyst support, and there are fewer limitations on the amount of catalyst that can be used, allowing higher loadings of less active and less expensive catalysts than Pt to be used.

3). Opportunities to improve overall system performance.

At first glance, mediated fuel cells appear to increase the complexity of a fuel cell stack, due to the requirement for extra plumbing and pumps to operate the mediator-regeneration loop. In fact, however, they can simplify the balance of plant accessories. PEMFCs are typically limited to operating at or below 100 °C and require humidification of the gases to avoid dehydration of the membrane. Since mediated fuel cells use aqueous mediator solutions, the membrane remains well-hydrated and gas humidification is unnecessary. Additional benefits arise from using aqueous solutions, which can absorb heat generated from the oxidation and reduction reactions, thereby facilitating temperature control of the fuel cell stack. Finally, mediated cathode systems are ideally suited for pairing with liquid fuels, including both conventional and mediated anode processes, because they are not susceptible to the flooding from water convection that can occur with gas-diffusion cathodes in PEMFCs.

4). Reduced performance losses from activation polarization.

Activation polarization is the loss in cell voltage at low current densities due to the kinetic barriers for electron transfer to the species to be oxidized or reduced. The particularly high kinetic barriers associated with catalytic reduction of O2 leads to substantial losses in the cell potential when O2 is directly reduced at an electrode. Similar issues arise at the anode, when using fuels more complex than H2, such as methanol. Redox mediators, on the other hand, may be selected to have fast electrochemical kinetics and thereby minimize activation polarization losses.

1.3. Scope of coverage and notes on nomenclature and symbolic notation used in this review.

Redox mediators have been employed in a wide range of electrochemical devices and applications, many of which have been the subject of previous review. Important examples include electrochemical synthesis of organic and inorganic chemicals,43–46 in addition to diverse energy-based technologies beyond flow batteries,8,9 including dye-sensitized solar cells,47,48 solid-state batteries (e.g., “redox targeting”),49,50 decoupled water splitting,51 electrochemical capacitors,52 and solar flow batteries.53 This review covers mediated fuel cells (MedFCs) that feature a mediated cathode for O2 reduction, a mediated anode for H2, alcohol, or biomass oxidation, or a doubly mediated system, wherein mediators are used for both half-reactions of the fuel cell. Some aspects of these reactions have been reviewed previously;41,42,54 however, significant advances in recent years, together with the partial coverage of these previous reviews, provided motivation to prepare this comprehensive survey. Only systems that are designed or intended to produce power (galvanic cells) are covered in depth, though reference is occasionally made to relevant electrolysis systems. Most of the examples consist of full fuel cells, but relevant half-cell studies are also discussed. Enzymatic fuel cells55–57 using soluble mediators are included, but microbial fuel cells58,59 are not presented. While microbial fuel cells feature certain advantages, including the capability to produce their own mediators and potential for genetic engineeringfor enhanced performance,60 their added complexity makes it is difficult to compare them directly to the other systems.

Historically, mediated fuel cells have been given the name “chemically regenerable redox fuel cells”, or CRRFCs,41,42,54,61–64 to distinguish them from “redox fuel cells”, which are now typically called redox flow batteries (RFBs). With the shift in the flow battery nomenclature, we have chosen to adopt the simplified term “mediated fuel cell” or “MedFC” for these systems (avoiding the term “MFC”, which is commonly employed for microbial fuel cells).

To simplify the notation used to describe mediated fuel cell systems, we have adopted the following notation: fuel|anode catalyst|anode mediator||cathode mediator|cathode catalyst|oxidant, whereby the double bar (||) refers to the membrane separating the anode and anode compartments and the single bar (|) separates the different components within the mediated anode or cathode systems. Certain studies only investigated one of the half-cell systems, or a system was conducted in the absence of a mediator or catalyst. In such cases, certain components are omitted from the symbolic notation. The distinction between a “mediator” and a “catalyst” is not always well defined in multi-component electrochemical mediator systems. We have attempted to be consistent in use of the term “mediator” for the major redox-active species that undergoes electron-transfer at the electrode, and the term “catalyst” for the species that undergoes the redox reaction with the fuel or oxidant in a redox cascade. Ambiguities can arise, for example, in single-component mediator systems in which the “mediator” also serves as the “catalyst”. A table containing information for all reported mediated fuel cells using chemical catalysts is given in Appendix I. All reports of mediated fuel cells using enzymatic catalysts is provided in Section 3.2.

2. The Cathode: Oxygen Reduction

The reduction of O2 is the predominant cathodic reaction for fuel cell technology, owing to the availability of O2 and formation of water as a benign product. State-of-the-art catalysts in PEMFCs and DMFCs are composed of Pt or Pt alloys that exhibit the best combination of high activity, low overpotential, long-term stability, and selectivity for 4 e− reduction of O2 to H2O.65,66 While optimal performance is achieved with these Pt-based catalysts, their high costs continues to be a limiting factor in PEMFC commercialization. The cost of Pt has been forecasted to account for over 40% of the stack cost.67 Eliminating or decreasing the loading of Pt or Pt-group metals is a high priority, and heterogeneous electrocatalysts such as Pt-alloys and non-PGM electrocatalysts, including metal-free carbon-based materials, have been developed.68,69 The first commercial PEMFC system utilizing non-PGM catalysts was announced in 2017.28 Nonetheless, no catalysts have thus far achieved the activity and stability metrics of Pt or Pt alloys, and alternate solutions continue to be the focus of active study. Mediated O2 reduction was the focus of considerable historical investigation, and new advances have emerged in recent years. The following sections survey the different mediators that have been reported for mediated ORR, including historical and recent examples, and systems implemented in fuel cell devices and fundamental studies.

2.1. Br−/Br2 mediator

The bromide/bromine redox couple has been widely used in flow battery research due to its high redox potential (1.06 V vs. NHE), fast electrode kinetics, and high solubility of the relevant species in different redox states. The potential is within 200 mV of the thermodynamic potential for O2 reduction to H2O and, therefore, could provide a low-overpotential strategy for mediated ORR. Fuel cells reported with bromine-based mediators for the ORR are shown in Table 1.

Table 1.

Reported systems using Br mediators for O2 reduction

The first report of a MedFC utilizing bromine-based cathode mediators was published in 1955 by Posner.70 In this work, other cathodic mediators were examined, but they exhibited low cell potentials. A variety of catalysts and mediators were screened, and the use of bromine in combination with NO2 showed promise (Figure 3). The anode contained chars, coke, or coal as the fuel and a variety of metal ions were tested as anodic mediators. Tests were also performed without NOx/O2-based regeneration, and the results showed that Br2 at the cathode shows minimal polarization (<0.05 V) up to a cell current density of >50 A/ft2 (i.e., ~54 mA/cm2) with 1.2 N Br2 and 0.7 N HBr in 3 N HCl. Challenges with long-term stability of the cathode system was acknowledged, but >8 h of sustained activity was demonstrated.

Figure 3.

Redox sequence for bromine-mediated cathode with a NOx-based catalyst (||Br2|NOx|O2). For relevant studies, see references 40, 70–73.

In the same year, Posner and Merton-Bingham studied the mechanism of NOx-catalyzed autoxidation of HBr.71 The authors proposed a 6-step sequence (Figure 4A), with the slow step involving the reaction of NOBr in solution with an unknown, gas-phase species resulting from the reaction of HNO2 and HBr (species “X” in Figure 4A). Later studies by Reneke noted reproducibility problems with the analytical techniques for bromine quantification employed by Posner and Merton-Bingham.72 Reneke also suggested that the mechanism of Posner and Merton-Bingham was unnecessarily complex and proposed an alternative 3-step mechanism (Figure 4B). Calculations from Reneke’s report propose that a 10-kW fuel cell using this system to regenerate Br2 would require a regeneration tower over 130 ft in height and 1.5 ft in diameter. These dimensions likely prevent large-scale implementation of this technology; however, the report from Posner, as well as subsequent studies, show that fuel cell operation is possible.

Figure 4.

Proposed mechanisms for HBr oxidation to Br2 by NOx catalysts.

In 1959, Carson and Feldman from the General Electric Company described a 100 W fuel cell stack, using seven cells connected in series.40 The cathodic mediator was Br2/Br−, again using nitric oxide to promote aerobic regeneration of Br2. The fuel was H2, which reduced a TiIV mediator to TiIII (i.e., TiO2+/Ti3+) using Pd-black as an off-electrode catalyst (H2|Pt|TiO2+||Br2|NOx|O2) (see Section 3.1.2 for discussion of the anode performance). The cells were operated at 80 °C, and an open-circuit potential of around 0.95 V was obtained. Continuous operation of the system was demonstrated for over 16 days, but the regeneration of the mediators was not sufficient to operate the system at its peak activity for longer than a few minutes. Additionally, the overall efficiency was low, due to high internal resistance of the cell, and the overall device was quite large, due to a complicated liquid delivery system to each cell. Carson and Feldman noted that, while this system demonstrated technical feasibility, several improvements would be necessary for commercialization, including the use of non-volatile mediators/catalysts on the cathode.

In 1964, Juda, at Ionics, Inc., patented a fuel cell using bromine-based mediators.73 H2 oxidation at a heterogeneous Pt electrode was used as the anodic reaction. The cathode compartment contained a solution of KBr, HBr and Br2 with NO2 as the catalyst. An open circuit potential of 0.98 V and an operating potential of 0.7 V at 10 mA/cm2 at room temperature were obtained. Juda compared these results to a system using similar loadings of KI, HI, and I2 without a catalyst, which generated an open circuit potential of 0.5 V and an operating potential of 0.3 V at a current density of 10 mA/cm2. No sustained operation of these cells was reported.

2.2. Vanadyl and vanadium-containing polyoxometalate cathodic mediators

The VO2+/VO2+ redox couple is the most widely studied cathodic mediator in mediated fuel cells. Some major advantages of this system include the high redox potential (~1.0 V vs. NHE), its non-volatile nature, good stability, and reasonably high solubility (> 2 M). These features underlie the widespread implementation of the same mediator system for redox flow battery applications.74 A catalyst is required to increase the rate of VO2+ reoxidation by O2. Both NOx-based catalysts and heteropolyacids (HPAs; also called polyoxometalates, POMs) have been used for this purpose. Table 2 lists the various implementations reported for cathodic vanadium mediators.

Table 2.

Reported fuel cell systems using V-based mediators for O2 reduction.

| fuel | catalyst | mediator | mediator | catalyst | ref |

|---|---|---|---|---|---|

| H2 | Pt | – | VO2+/VO2+ | HCl | 75 |

| – | – | V2+/V3+ | NOx | 79 | |

| H2 | Pt | Ti3+/TiO2+ | 80 | ||

| CH4, ethylene glycol, coal | Pt | Fe2+/Fe3+ | 82–84 | ||

| biomass | – | Fe2+/Fe3+ | 85, 86 | ||

| sugars | Pt | V3+/VO2+ | Pt | 81 | |

| H2 | Pt | H4SiW12O40 | POM | 76–78 | |

| Pt | – | V-containing POM | 63, 95–102,104 | ||

| Pt/C | AQ | 105 | |||

| sugars | POM | Fe2+/Fe3+ | 110 | ||

| biomass | POM | 107, 111, 112 | |||

| alcohols | 108 | ||||

| lignin | 113 | ||||

| coal | 109 | ||||

The first example of VO2+/VO2+ mediators for electrocatalytic O2 reduction was patented by Schaefer and Kordesch at Union Carbide Corporation in 1966.75 While details of the invention are somewhat limited, they described a cell using an H2 gas anode and NaVO3 dissolved in a strong HCl electrolyte (19–39% by weight). When the cathode was supplied with O2, it was operated for over 24 h at 80 °C and sustained a potential between 1.5 and 1.7 V vs. cadmium (conversion to a standardized reference was not given) at a current density of 50 mA/cm2. An HCl electrolyte was necessary for regeneration; when H2SO4 was used as the electrolyte, addition of HBr and HNO3 was necessary to achieve sustained activity.

Oei, working at Ford, reported the use of a VO2+/VO2+ mediated cathode. The initial report investigated the performance of various electrolytes in a RFB context (i.e., no regeneration of either redox couple by O2 or a fuel): VO2+/VO2+ as the cathodic redox couple and Sn2+/Sn4+, Fe2+/Fe3+, or Cu/Cu2+ as the anodic redox couples.63 Initial tests optimized the flow-field configuration and electrode materials. The different electrode materials displayed similar performance for the vanadium redox process, but substantially different activity for the Sn2+/Sn4+ redox couple. Later in the same year, Kummer and Oei reported a mediated cathode system with VO2+ and POMs as the mediator/catalyst composition (POM = H3PMo12O40 or H5PMo10V2O40). A silicon-containing POM was used as the anodic mediator (H2|Pt|Si-POM||VO2+|POM|O2; see Section 3.1.4 for discussion of anodic performance).76–78 Polarization curves were obtained using 0.8 M VOSO4 and 0.28 M H3PMo12O40 at a pH 0.75 (Figure 5). The highest power density obtained was ~38 mW/cm2. Reasonable iR-free voltages were obtained, but the internal resistance of the cell contributed to significant losses in cell potential (0.83 V with iR-correction vs. 0.55 V without iR-correction at ~80 mA/cm2). Slow regeneration of the cathode mediator system caused the potential of the cathode compartment to drop from 468 mV to 330 mV over 900 minutes of operation. A pH change was observed in the cathode compartment, which was attributed to vanadium migration through the membrane. The authors commented that long-term performance would be determined by the size of the regenerators, and to achieve reasonable rates, the regenerator would be too large for commercial vehicle use. For example, a 20-kW engine would weigh over 5,000 pounds.

Figure 5.

Redox sequence proposed for V-mediated cathode with POM catalyst for O2 reduction (||VO2+|POM|O2). For relevant systems using this mediated cathode, see references 76–78.

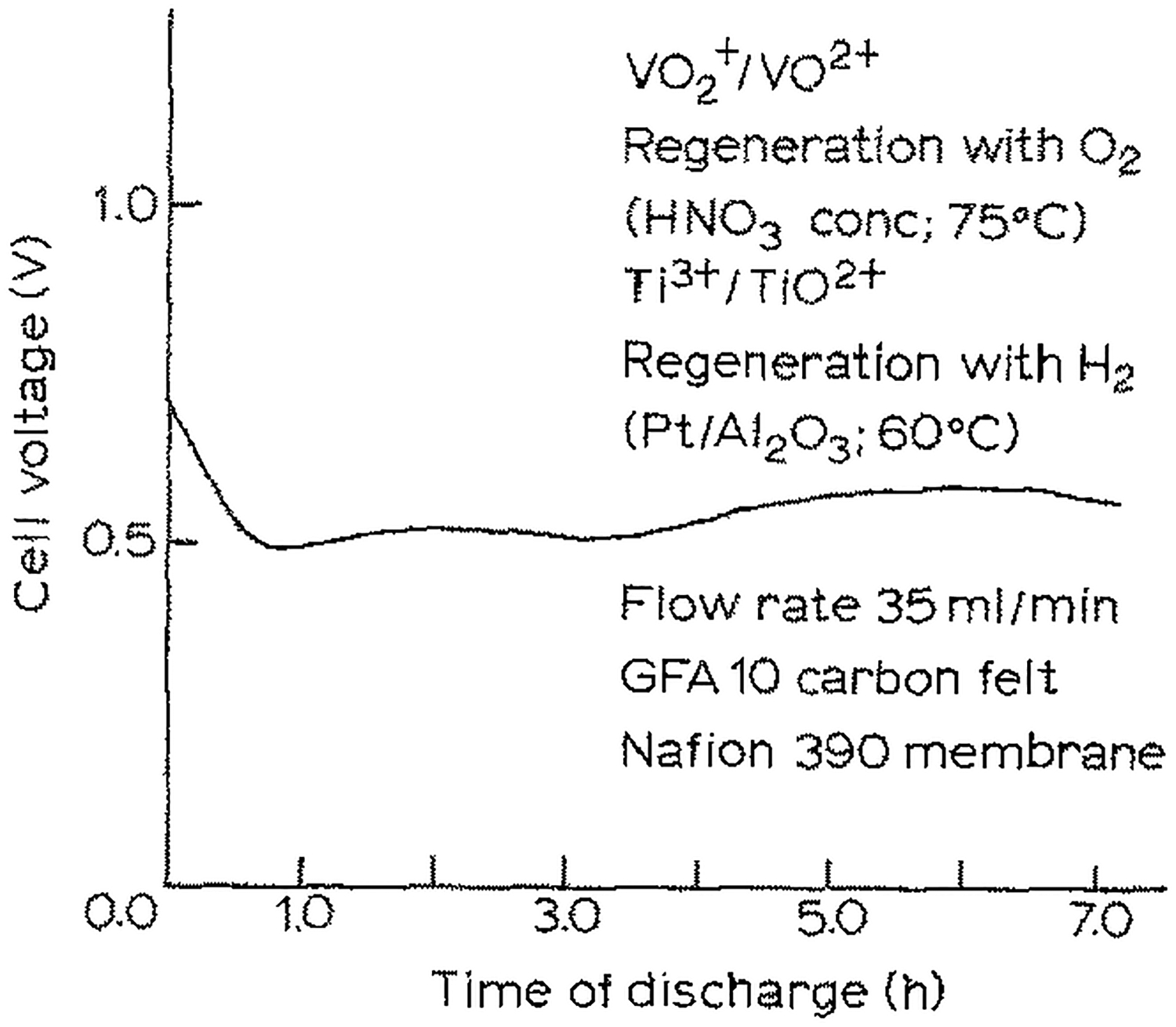

In 1985, Kummer and Oei reported further optimization of their mediated fuel cell design.79 To avoid the substantial performance decreases observed in VO2+ oxidation catalyzed by POMs, they shifted to the use of NOx gases as a catalyst (Figure 6A). Over a 12 h experiment, the cathodic performance remained nearly constant (Figure 6B), showing more stable performance than previous reports.63 To prevent loss of NOx species, a static pressure of O2 was used without bubbling gas into the cathode solution. When using a V2+/V3+ anode solution, power densities of 73.5 mW/cm2 were achievable.

Figure 6.

(A) Redox sequence for vanadium-mediated cathode with NOx catalyst for O2 reduction (||VO2+|NOx|O2). For systems featuring this mediated cathode, see references 79–86. (B) Sustained performance curve of a mediated cathode utilizing a VO2+/VO2+ redox mediator, reoxidized with NOx-based catalysts. The anode solution contained a V2+/V3+ redox mediator which was not regenerated during the experiment (V3+||VO2+|NOx|O2). Cell was discharged through a 5-ohm external load with a flow rate of 230 mL/min. Adapted from ref. 79. Copyright 1985, Chapman and Hall Ltd.

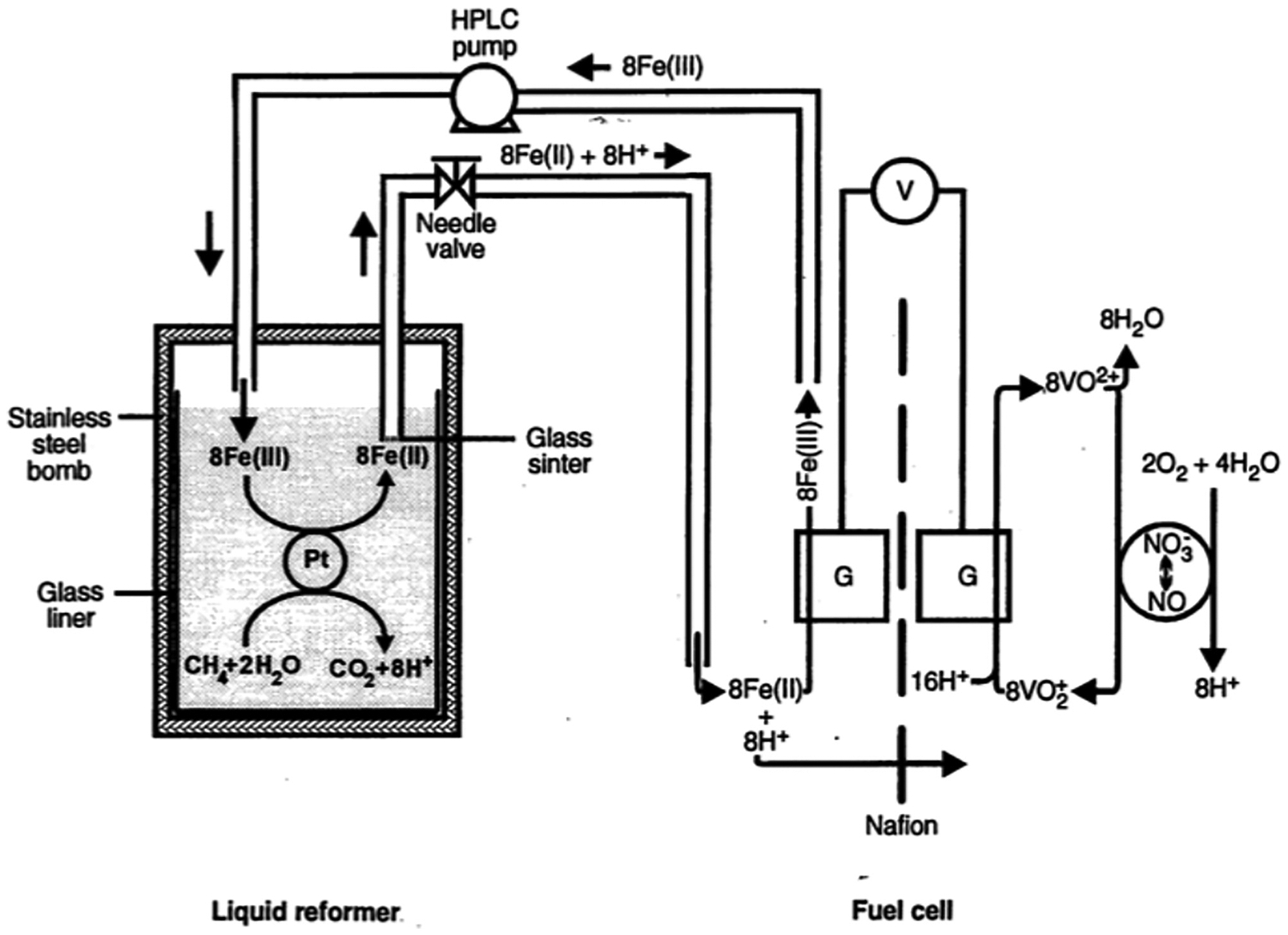

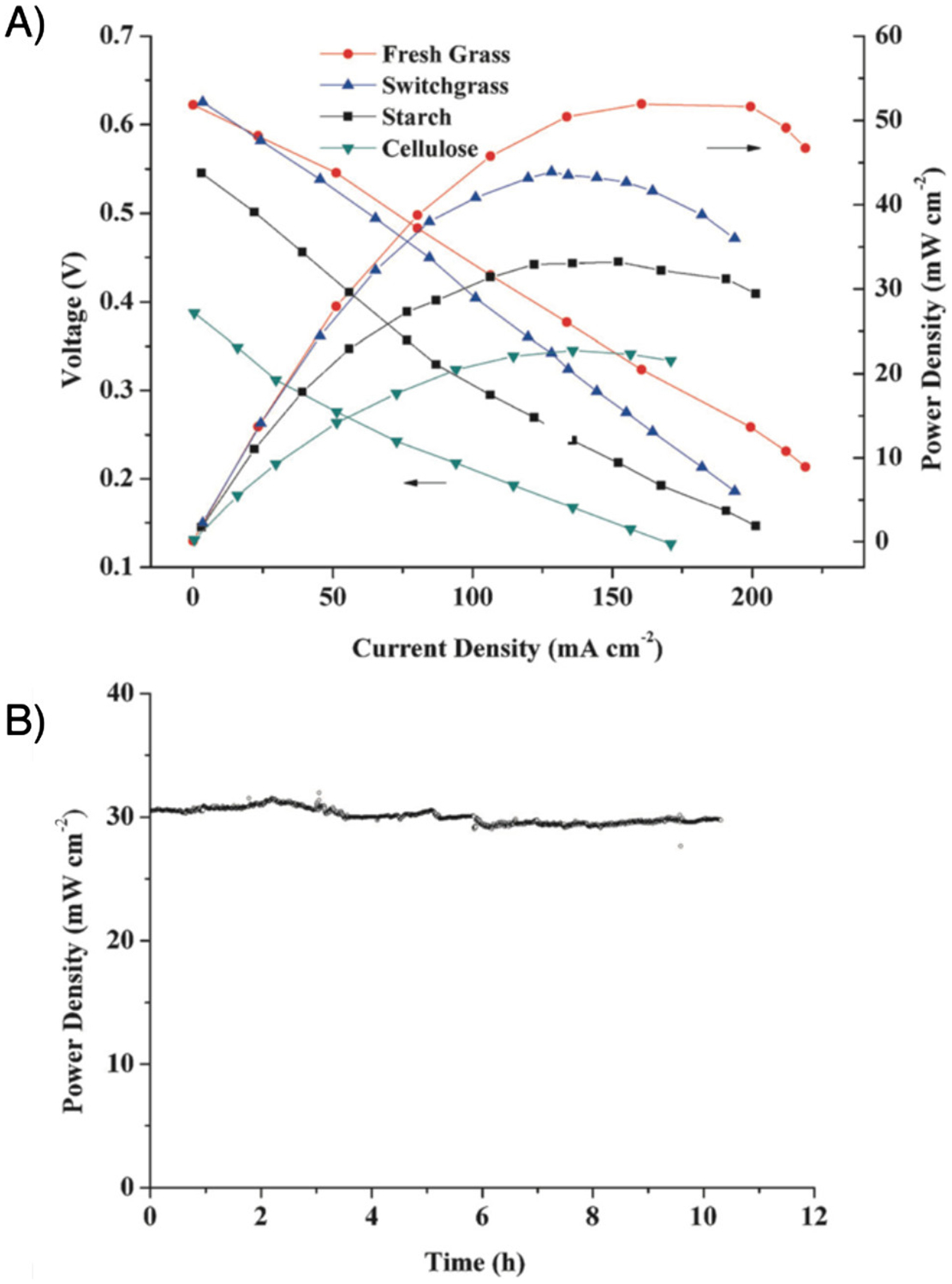

The VO2+/VO2+ redox couple has been adopted by other groups in various fuel cell studies focused on anodic reaction chemistry. Folkesson constructed a cell using a VO2+/VO2+ redox mediator regenerated aerobically using NOx as a catalyst with a variety of anode redox mediators for H2 oxidation (see Sections 3.1.2, 3.1.3, and 3.1.7 for further discussion of the anodic chemistry).80 Folkesson demonstrated reasonably stable cell performance generating around 15 mW/cm2 using the VO2+/VO2+ and Ti3+/TiO2+ redox couples. A later report mentions the aerobic oxidation of VO2+ catalyzed by Pt for a fuel cell using a V3+/VO2+ anode for the oxidation of sugars in a fuel cell stack capable of producing 10 kW of power; however, no evidence for the aerobic oxidation of VO2+ was presented.81 Whitesides and coworkers have used vanadyl-based mediators paired with NOx catalysts in a variety of applications (c.f. Figure 6A). Their initial report focused on the use of methane as a fuel, mediated by Fe2+/Fe3+ and catalyzed by Pt black (CH4|Pt|Fe2+||VO2+|NOx|O2; see Section 3.1.3 for further discussion of the anode).82 Methane oxidation occurred under forcing conditions in a high-pressure reactor (120 °C, 54 atm CH4), and the Fe2+ in the resulting aqueous reaction mixture was oxidized at the anode (Figure 7). Polarization curves were obtained, but the performance of the overall system was low, due to engineering difficulties in cell construction and the large potential losses associated with use of the Fe2+/Fe3+ redox couple as the anodic redox mediator (~600 mV difference between thermodynamic potential of methane oxidation to CO2 and the Fe2+/Fe3+ redox potential). This approach was later extended by Whitesides and coworkers to the use of ethylene glycol as a fuel, generating a power density of 9.9 mW/cm3,83 and to the use of solid carbonaceous fuels, including coal (see Section 3.1.3 for further discussion).84

Figure 7.

Schematic of doubly mediated fuel cell (CH4|Pt|Fe2+||VO2+|NOx|O2) using methane as fuel developed by Whitesides and coworkers. Adapted from ref. 82. Copyright 1994, American Association for the Advancement of Science.

Deng and coworkers reported a fuel cell using VO2+/VO2+-based mediators and an HNO3 catalyst to mediate O2 reduction on the cathode paired with an Fe2+/Fe3+ anodic mediator for biomass (wheat straw) oxidation.85 Power densities of over 100 mW/cm2 were achieved with 10 g of wheat straw in 100 mL of electrolyte (10 mL HCl and 30 g FeCl3 in H2O), and a stable current density of 320 mA/cm2 was achieved at a voltage of 0.3 V for over 12 h (see Section 3.1.3 for discussion of the anode). Further studies by Deng and coworkers compared the performance of a mediated cathode utilizing a VO2+/VO2+ mediator with HNO3 as a catalyst with the performance of a mediated cathode using an H12P3Mo18V7O85 POM mediator (see section 3.1.4 for discussion of the relevant anode).86 Glucose and other biomass sources were used as the fuel with an FeCl3 anodic mediator (glucose|Fe3+||VO2+|NOx|O2 vs. glucose|Fe3+||POM|O2). The cell utilizing the vanadium/NOx system achieved a maximum power density of approximately 90 mW/cm2, whereas the POM-mediated cell only achieved a maximum power density of approximately 35 mW/cm2. This difference was attributed to the higher open circuit potential achieved by the vanadium-based system compared to the POM-based system.

As discussed above, Oei demonstrated that mixtures of POMs and VO2+ undergo aerobic oxidation. POM/VO2+ reactions with O2 have been intensely studied for decades, particularly for Mo/V-containing POMs.87–94 These reactions are quite complex, due to the complicated speciation of POMs in acidic solutions. This complexity can be observed in the 31P and 51V NMR spectra of H12P3Mo18V7O85, in which a multitude of different POM isomers and structures are observed (Figure 8).

Figure 8.

31P and 51V NMR spectra of 0.25 M solution of H12P3Mo18V7O85. Numerals 1, 2, 3, and 4 correspond to collection of lines of HPA-x Keggin POMs H3+xPMo12-xVxO40, where x = 1–4, see reference 87. Adapted from ref. 91. Copyright 2008, Elsevier B.V.

Starting in the mid-2000s, Acal Energy Ltd., a company based in the UK, filed numerous patents describing the use of POMs as combined mediator/catalysts for the electrocatalytic ORR for fuel cells. In contrast to the Oei work discussed above, Acal used a conventional Pt/C H2 anode. POMs have a variety of promising characteristics, including their inexpensive components, ability to operate at high potentials, and thermodynamic stability.95,96 Several POM species with promising activities were identified. Higher vanadium incorporation into the vanadium-substituted phosphomolybdate (H3+xPMo12-xVxO40, 0<x<6) led to enhanced activity, as did the inclusion of sodium ions (NaxH3PMo12-xVxO40, 0<x,6).97 Addition of 0.15 M VO2+ (as V2O4) as an additional mediator to a solution of 0.3 M H3Na3PMo9V3O40 gave higher sustained voltages when the fuel cell was run at 400 mA/cm2. A cell voltage of ~0.5 V was observed with no added V2O4 and ~0.58 V with added V2O4.98 In a later patent application, Acal disclosed that a mediated fuel cell with 0.3 M Na4H3PMo8V4O40, operated at 80 °C and an ambient pressure, achieved sustained performance over 40 min at approximately 0.4 V and 1.5 A/cm2.99 In 2019, Knuckey, Creeth, and coworkers disclosed the role of elevated temperatures and air pressures on POM reoxidation.100 Using H7PMo8V4O40, they tested the rate of open-circuit potential (OCP) recovery after cell discharge at 0.8 V. At a regenerator temperature of 80 °C and atmospheric pressure using air, it took over 4000 s for the OCP to increase to 0.88 V. In contrast, at 120 °C and 2 barg (air), the same OCP was reached in under within 300 s.

Building on the work of Acal, Matsui, Eguchi, and coworkers published a systematic study of three POMs as fuel cell cathode mediators: H3PMo12O40, H5PMo10V2O40, and H6PMo9V3O40.101 Polarization curves examining the influence of POM identity, concentration (0.01–0.3 M), and cell temperature (20, 40, or 80 °C) were reported using a conventional Pt/C H2 anode (Figure 9). The vanadium-containing POMs displayed higher activity than the all-molybdenum POM, and increased performance was observed at higher mediator concentrations and higher temperatures. The aerobic regeneration activity of the three POMs during fuel cell operation was examined. Using 0.01 M solutions at either 25 °C or 80 °C and purged with either Ar or O2, the voltage of the cell was monitored as a function of time at a current density of 5.36 mA/cm2. The voltage using the all-Mo H3PMo12O40 mediator decayed identically under O2 or Ar, indicating that the aerobic oxidation of the reduced mediator was slow. H5PV2Mo10O40 showed similar behavior under O2 and Ar at 25 °C, indicating slow aerobic reoxidation; however, steady currents under O2 at 80 °C indicated that the POM was oxidized at a sufficient rate for sustained activity at elevated temperature. H6PV3Mo9O40 is oxidized at both temperatures, yielding stable voltages over the course of the experiment. The maximum power density obtained (measured by polarization curves) was approximately 40 mW/cm2, obtained with 0.3 M H6PV3Mo9O40 at 20 °C or with 0.1 M H6PV3Mo9O40 at 80 °C.

Figure 9.

Voltage time-courses of POM-mediated cathodes (H2|Pt||POM|O2) at a current density of 5.36 mA/cm2 at either 25 °C or 80 °C under O2 or Ar for 0.01 M solutions of (a) H3PMo12O40, (b) H5PV2Mo10O40, and (c) H6PV3Mo9O40. Adapted from ref. 101. Copyright 2016, American Chemical Society.

Davies and coworkers published a separate study of the use of a H6PV3Mo9O40 POM (HV3) solution as the cathodic mediator, again utilizing a conventional Pt/C H2 anode (Figure 10).63 Many of the reaction parameters of the cathode were examined. A primary focus in this report was the influence of the concentration of reduced vanadium (VO2+) on the performance of the cell and examination of the “regenerator efficiency” to probe how well the reduced mediator undergoes oxidation by O2. The authors reported the performance of the cell at various VO2+ fractions (i.e., the amount of reduced vanadium relative to total vanadium): 0.05 (almost fully oxidized), 0.25, 0.45, 0.65, and 0.85 (mostly reduced). As expected, the highest OCP values were obtained with the most oxidized solution (0.05 VO2+), and a maximum power density of nearly 1 W/cm2 was achieved with 95% oxidized 0.3 M H6PV3Mo9O40 at 80 °C. Regeneration experiments, however, indicated that only approximately half of the VIV can be aerobically oxidized to VV, which will limit overall performance. Based on their regeneration data and the polarization curves, the authors predicted the steady-state performance of the combined system, and the results indicated that the steady-state performance will be similar to the results observed with the 0.85 VO2+ (mostly reduced) fraction. This result indicated that the regeneration ability of their system was too low to reach optimal power densities. The authors compared their calculated steady state results, as well as their data at 0.05 and 0.65 VO2+ fractions, to state-of-the-art conventional PEMFCs and to other mediated cathode fuel cells (Table 3). Their result at 0.05 VO2+ fraction was above that for state-of-art PEMFCs and far above those reported for other cathode-mediated systems, while the 0.65 VO2+ fraction and the calculated steady state performance were below that of traditional PEMFCs, with a maximum sustainable power density estimated to be 0.38 W/cm2.

Figure 10.

Schematic of POM-mediated cathode fuel cell (H2|Pt||POM|O2) reported by Davies and coworkers. Adapted from ref. 63. Copyright 2017, Elsevier B.V.

Table 3.

Performance comparison of a reported conventional PEM fuel cell, previously reported mediated cathode fuel cell systems, and results from Davies and coworkers.63

| System | Cathode material | Cathode reaction | Liquid Electrolyte | OCP (V) | Cell voltage @ 0.2 A/cm2 (V) | Cell voltage @ 1 A/cm2 (V) | Max power (W/cm2) | Ref. |

|---|---|---|---|---|---|---|---|---|

| Conventional PEMFC | Pt/C | O2 + 4 e− + 4 H+ → 2 H2O | None | 0.96 | 0.81 | 0.67 | ≥ 0.83 | 23 |

| Mediated cathode (HNO3) | N-doped carbon | NO3− + 2 e− + 2 H+ → NO2− + H2O | 5 M HNO3 | 1.04 | 0.95 | 0.46 | 0.51 | 129 |

| Mediated cathode (POM) | carbon | VO2+ + e− → VO2+ | 0.45 M POMa | 0.83 | 0.68 | 0.46 | 0.51 | 96 |

| Mediated cathode (POM) | carbon | VO2+ + e− → VO2+ | 0.3 M HV3 @ 0.05 VIV | 0.99 | 0.9 | 0.72 | 1 | 63 |

| Mediated cathode (POM) | carbon | VO2+ + e− → VO2+ | 0.3 M HV3 @ 0.65 VIV | 0.78 | 0.72 | 0.5 | 0.58 | 63 |

| Mediated cathode (POM) | carbon | VO2+ + e− → VO2+ | 0.3 M HV3 @ steady stateb | 0.81 | 0.73 | – | 0.36 | 63, 102 |

| Mediated cathode (POM) | carbon | VO2+ + e− → VO2+ | 0.3 M NaV4 @ steady stateb | 0.80 | 0.75 | 0.53 | 0.58 | 63, 102 |

POM identity was not disclosed

Steady-state data was calculated from regeneration rates and cell data

In a follow up report, Davies and coworkers examined four different POM species in the same manner described above,102 with the four POM solutions labeled HV3 (empirical formula H6PV3Mo9O40), HV4 (empirical formula H7PV4Mo8O40), NaV3 (empirical formula Na3H3PV3Mo9O40), and NaV4 (empirical formula Na4H3PV4Mo8O40). The “protonic” HV3 and HV4 POMs displayed higher open circuit voltages at all VIV fractions relative to the sodiumcontaining solutions, due to the lower pH of the protonic solutions. Polarization curves using almost fully oxidized HV3 or HV4 (5% VIV) displayed power densities of over 1 W/cm2. However, the HV3 composition underwent oxidative regeneration much more slowly than the other POM compositions, leading to poor extrapolated steady-state performance. The authors predicted the steady-state performance for each POM identity based on the polarization curves at different VIV fractions and the regeneration data, and they then projected the expected steady-state polarization curves for each POM (Figure 11). Due to its poor reoxidation, HV3 had the lowest estimated performance at steady-state. The two V4 POMs had nearly identical performance, with NaV4 displaying slightly higher maximum power density (578 mW/cm2; see also, last entry in Table 3). The authors pointed out that the regenerator performance continued to be a limiting factor in achieving maximal power densities and cite an Acal patent describing the formation of “microbubbles” to enhance POM oxidation.103 A steady-state durability test was performed using the NaV4 POM at a current density of 0.4 A/cm2, and no loss in activity was detected over a 200 h run.

Figure 11.

Projected (a) i-V and (b) power density curves generated from simulated steady state performance for HV3, HV4, NaV3, and NaV4 POM solutions (H2|Pt||POM|O2). Adapted from ref. 102. Copyright 2017, Elsevier B.V.

In 2018, Ward and Davies published a study investigating the role of temperature and catholyte concentration of a POM-mediated cathode.104 Using both HV4 and NaV4 POM compositions, the temperatures tested ranged from 40–90 °C and catholyte concentrations ranged from 0.2–0.45 M. Increases in temperature led to a slight decrease in the redox potential of the catholyte, while an increase in concentration led to larger increases in the catholyte redox potential. The authors also examined the role of temperature and concentration on the pH and conductivity of the catholyte and observed that increasing temperature and concentration both led to decreases in the pH and increases to the conductivity. Polarization curves with different concentrations of HV4 (95% oxidized) showed a 25% increase in maximum power density when shifting from 0.2 M POM to 0.3 M POM at 80 °C, but only a 6% increase when shifting from 0.3 M POM to 0.45 M POM. The minimal improvement at high concentrations was attributed to an increase in cell ohmic resistance as the catholyte concentration increased, perhaps due to VO2+ and VO2+ incorporation into the membrane. For NaV4 catholyte solutions, the best results at 80 °C were obtained using a 0.3 M concentration of the POM, which also corresponded to the lowest observed ohmic cell resistance. Increasing the temperature of both 0.3 M HV4 and NaV4 solutions resulted in enhanced performance at low current densities due to decreased activation losses, as expected; however, detrimental effects were observed at 90 °C at high current densities. The authors suggested that the poorer performance arose from anode effects, e.g., a decrease in electrochemical Pt surface area and decreased exchange current densities. POM regeneration data, collected using the same procedure as in previous reports, indicated that NaV4 has an increased rate of reoxidation relative to HV4. Concentration had only a minor impact on the rate of regeneration. Increasing the temperature typically led to higher reoxidation rates, with an exception observed upon increasing from 80 °C to 90 °C with highly reduced (>60 % reduced) NaV4 samples. The authors attributed a decreased reoxidation rate in this case to decreased O2 solubility and mass transport constraints. Steady-state experiments for each condition were performed at 1 A/cm2, and the highest voltage (0.47 V) was obtained with 0.45 M NaV4 at 90 °C. Very similar performance, however, was obtained using 0.3 M NaV4 at 80 °C, with only a 10 mV drop in cell voltage relative to the more forcing conditions. The authors concluded that the optimal conditions for fuel cell performance are 80 °C with 0.3 M NaV4 and estimated that a steady state peak power density of approximately 510 mW/cm2 could be achieved.

Stahl and coworkers reported a double MedFC using Na4H3PMo8V4O40 as a cathodic mediator paired with a mediated anode consisting of a Pt/C catalyst and anthraquinone mediator to mediate H2 oxidation.105 In initial tests using the mediated anode with a conventional cathode consisting of a Pt/C electrocatalyst, low power densities were obtained due to flooding of the cathode. Significantly higher power densities (up to 528 mW/cm2 with iR-correction) were obtained when a POM-mediated cathode was used instead (see Section 3.1.6 for further discussion of the mediated anode).

Recently, analogous vanadium-containing POMs have been used as cathodic mediators for ORR in various biomass-based fuel cells. A different set of lower-potential POMs were used as mediators for anodic biomass oxidation.106 The relevant anodic chemistry is discussed in Section 3.1.4. The selection of POMs used in the cathode was expanded beyond the Keggin-type POMs typically used by Acal and others described above, inspired by the fundamental POM/O2 reactivity reported by Zhizhina and Odyakov.91

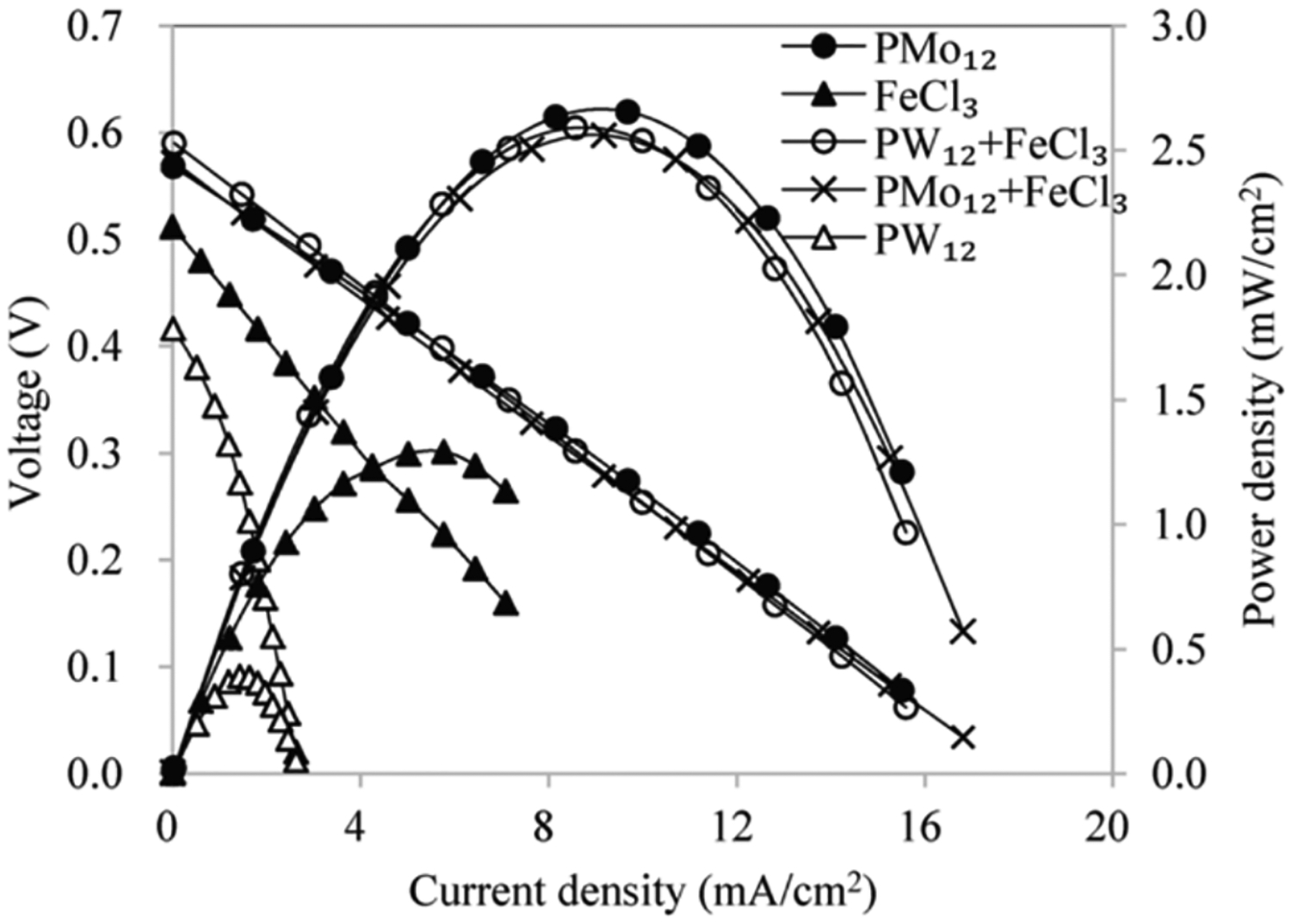

The first example was reported by Deng and coworkers in 2014,107 describing a cell capable of using fresh grass, switchgrass, starch, or cellulose as the anodic fuels (Figure 12). A 0.3 M solution of H12P3Mo18V7O85 (or the di- or tri-sodium salt thereof) was used as the cathodic mediator solution, and H3PW11MoO40 was used as the anodic mediator. Stable power densities of 30 mW/cm2 were obtained for 10 h of operation at 80 °C. Consistent with the high loading of vanadium in the cathodic POM mediator, a very high potential (> 1.0 V vs. NHE) was achieved, even with multiple reduced vanadium centers in the POM. The influence of concentration and degree of reduction on the rate of aerobic oxidation was investigated. The degree of reduction was defined as the average number of electrons each POM complex had collected, and the highest rate of oxidation was reached at a high degree of reduction (>1.8 e−/POM) and at intermediate concentrations (~0.15 M). Analyses of anodic reactions are presented in Section 3.1.4.

Figure 12.

A) Schematic for the doubly mediated fuel cell using POM-I as mediator for biomass oxidation and POM-II as mediator for O2 reduction (biomass|POM-I||POM-II|O2). B) Further details showing electrode reactions and regeneration reactions of POM-I and POM-II. Adapted from ref. 107. Copyright 2014 Wiley-VCH Verlag GmbH & Co.

Several additional studies have employed cathodes with V-containing POM mediators or mediated systems using both VO2+ and POMs in efforts primarily focused on processes at the anode (i.e., thorough analysis of the cathode performance was not conducted). These studies will be elaborated in Section 3, but are briefly noted here. Deng and coworkers described a fuel cell using alcohol-based fuels, such as methanol, glycerol, or glucose, using H12P3Mo18V7O85 as a cathodic POM mediator. Maximum power densities of over 30 mW/cm2 with sorbitol as the alcohol, based on single-scan polarization curves with a fully oxidized mediator at the cathode (i.e., without steady-state POM regeneration by O2).108 The same group later reported a fuel cell system utilizing the same POM mediator in the cathode and using low-rank coal as the fuel.109 The same cathodic POM mediator was subsequently utilized by Li and coworkers in a fuel cell utilizing glucose, cellulose, or starch as a fuel.110 Deng and coworkers utilized sewage sludge as the fuel in their system using H3PMo12O40 as the anodic mediator and H12P3Mo18V7O85 as the cathodic mediator.111 Chao, Deng, and coworkers reported a biomass fuel cell using sugars treated photochemically and thermally with H3PMo12O40 at the anode and H12P3Mo18V7O85 at the cathode.112

A fuel cell using lignin as a fuel and H3PMo12O40 as the anodic mediator was reported by Zhao and Zhu,113 with several cathode variations. Examples included (a) a traditional Pt/C gas-diffusion cathode with O2 as the oxidant, (b) carbon electrodes with PMo12O40 or K5PV2Mo10O40 as POM mediators with O2, and (c) a carbon electrode with KMnO4 as a stoichiometric oxidant. Open circuit potentials and maximum power densities were measured at 90 °C and are summarized in Table 4. In general, the power densities were higher with solution-phase oxidants versus a conventional O2 cathode. Continuous operation of the cell at 90 °C with each oxidant was examined. The cathodes using O2 at Pt/C (current density ~ 0.4 mA/cm2) and the mediated H3PMo12O40|O2 system (current density ~ 0.5 mA/cm2) displayed reasonably stable behavior, while the current density decreased substantially for cathodes utilizing KMnO4 or K5PV2Mo10O40|O2.

Table 4.

Performance of various cathode chemistries on fuel cell performance using lignin as fuel.

| Oxidanta | OCP (mV) | Maximum Power Density (mW/cm2) |

|---|---|---|

| O2 @ Pt/C | 350 | 0.96 |

| O2 + 0.1 M H3PMo12O40 | 690 | 5 |

| 0.2 M KMnO4 | 900 | 45.1 |

| O2 + 0.1 M K5PV2Mo10O40 | 330 | 0.41 |

: 1 atm O2

2.3. Fe2+/Fe3+ mediator

The Fe2+/Fe3+ redox couples, including those from aqueous Fe salts, [Fe(CN)6]4/3−, and ferrocene derivatives, have been the subject of substantial interest from the flow battery community.8 The electrode kinetics can be rapid, and these mediators have low cost and toxicity. On the other hand, the redox potential of free Fe2+/Fe3+ (~0.7 V) is relatively low compared to the thermodynamic potential for O2, even while ancillary ligands may be used to access higher potentials. The various mediated cathode systems using this mediator for O2 reduction are summarized in Table 5.

Table 5.

Reported systems using iron-based mediators for O2 reduction.

In 1931, Lamb and Elder studied the aerobic oxidation of FeSO4 in acidic solutions catalyzed by various substances, with the goal of utilizing this redox mediator in a fuel cell application.114 The rate of oxidation of Fe2+ was monitored by measuring the potential of the solution during the oxidation. The reaction rate was found to be first order in pO2, second order in [FeSO4], and independent of [H2SO4] above 0.23 M, but the reaction rate increased rapidly below this H2SO4 concentration. CuSO4 was found to accelerate the oxidation, and it was noted that in the presence of CuSO4 the oxidation of FeSO4 accelerated with increasing acid concentration. Additionally, charcoal accelerated the reaction rate with a roughly first order dependence, and Pt black accelerated the reaction rate in a non-linear fashion, which the authors attributed to catalyst poisoning. The authors then constructed a working cathode solution with a Zn/ZnSO4 anode to study the behavior of the mediated cathode under electrochemical conditions. Comparison of O2 consumption in their kinetic studies with data obtained from the electrochemical studies show good agreement. In the electrochemical studies, the authors measured a current density of 21.5 mA/cm2 while operating at a potential of 0.606 V.

In 1953, Posner published a pair of papers examining the oxidation of Fe2+ in concentrated HCl solutions with no catalyst and in dilute HCl solutions catalyzed by charcoal.115,116 At high concentrations of HCl (> 4.0 N), Fe2+ was rapidly autoxidized, while below this value, the reaction was slow, consistent with the previous observations of Lamb and Elder. At the high concentrations of acid, the rate of Fe2+ oxidation was first order in [Fe2+], approximately first order in [HCl] between 6–8 N, and first order in pO2. Posner proposed that the rate of oxidation increases at high [HCl] due to the formation of an Fe2+-HCl complex, the oxidation of which bypasses formation of superoxide and proceeds directly to HO2•. When H2SO4 is used as the acid, no acceleration of the autoxidation rate is observed at high concentrations, suggesting that the active complex is not formed with this acid. At lower acid loadings, with charcoal as a catalyst, the autoxidation rate was first order in the catalyst loading, pO2, and [H+], and proportional to [Fe2+]/([Fe2+]+[Fe3+]). The use of iron as a mediator for the ORR was not pursued further, however, due to its low potential.70 Efforts were made to identify ligands that could increase the Fe2+/Fe3+ potential.117 No suitable ligands were identified, however, and use of Fe2+/Fe3+ as ORR cathode mediators were abandoned for many years.

Iron-based mediators reemerged in the mid- to late-2000s, when Acal Energy Ltd. published a series of patents using various iron-based mediators in fuel cell cathodes. A patent application118 described a MedFC using a conventional Pt/C H2 anode paired with a mediated cathode system containing K3Fe(CN)6 and KOH. The use of both a cationic- and anionic-selective membrane was required for optimal performance. In a separate experiment, they disclosed the aerobic regeneration of K3Fe(CN)6 from K4Fe(CN)6 using a solution containing 0.02 M EDTA and 0.01 M MnSO4. However, there was no integration between the aerobic regeneration studies and the fuel cell experiments. In subsequent patents, ferrocene (Fc) species were described as mediators using iron complexes to catalyze aerobic oxidation of the reduced mediator.119–122 Examples include the use of Fc(CH2SO3H)2 as a cathodic mediator and [Fe(trilen-(SO3Na)3)]2+ as the catalyst at pH 2 (Figure 13). A fuel cell was constructed incorporating a conventional Pt/C H2 anode (i.e., H2|Pt/C||Fc(CH2SO3H)2|[Fe(trilen-SO3Na)3)]2+|O2), and the mediator was partially oxidized by bubbling O2 through a solution of the mediator and catalyst (10 mM mediator and 1.0 mM catalyst). A polarization curve was measured with this cell. This system exhibited an open-circuit potential of approximately 0.78 V, but the potential decreased rapidly with increasing current, resulting in a current density of only 16 mA/cm2 at a cell voltage of 0.2 V. The authors confirmed that the mediator undergoes regeneration during fuel cell operation by monitoring the open-circuit potential vs. time. Fc derivatives with the cyclopentadienyl rings linked together by an alkyl tether exhibit increased stability relative to unlinked derivatives at pH 2.5.123 In spite of these improvements, subsequent efforts by Acal emphasized polyoxometalate mediators (cf. Section 2.2).

Figure 13.

Ligand used with Fe2+ (trilen-SO3Na)3 and to oxidize Fc(CH2SO3H)2 mediator.

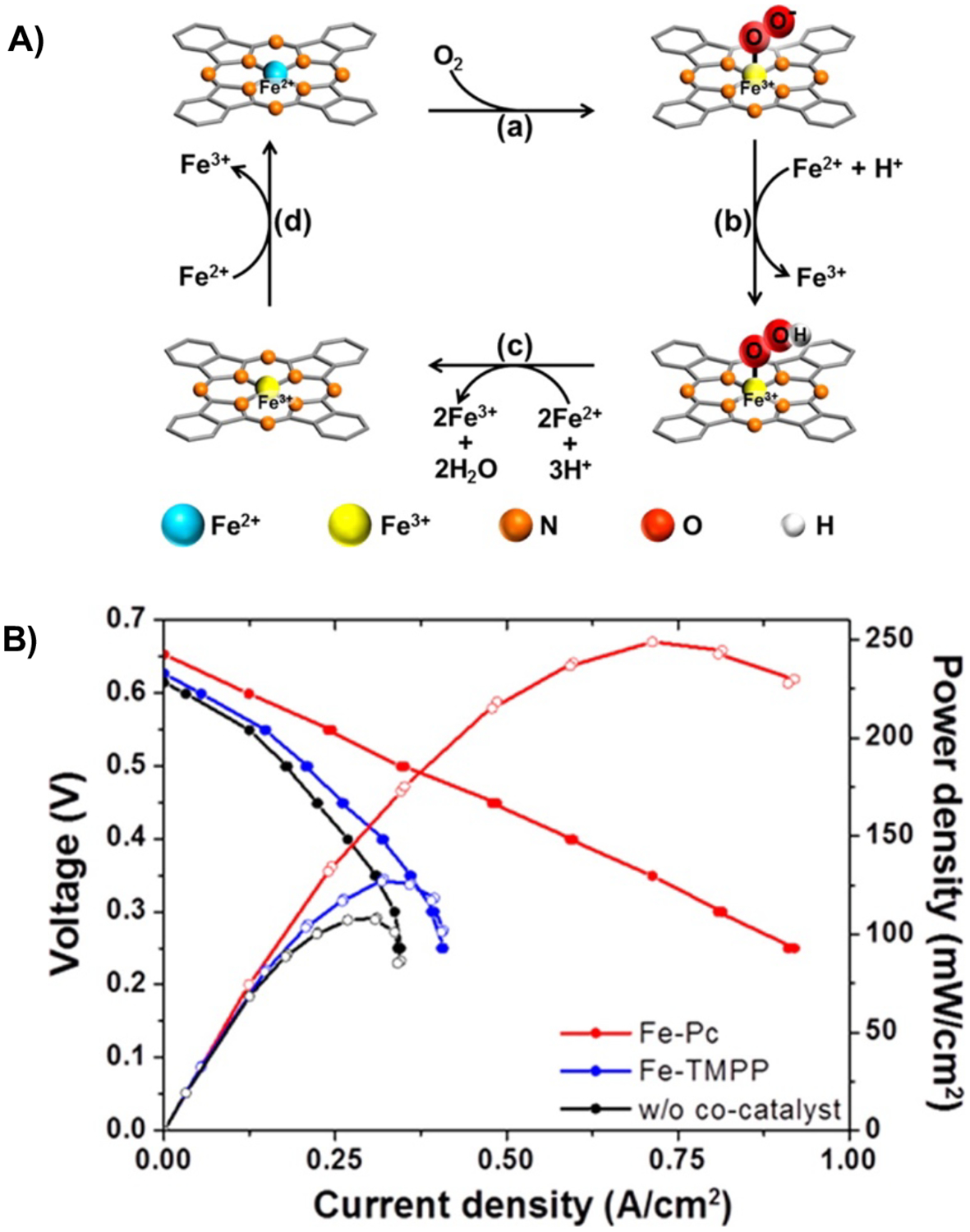

In 2016, Park and coworkers reported the use of iron phthalocyanine, Fe(pc), as a catalyst for the aerobic oxidation of Fe2+ in the context of a MedFC.61 They studied the kinetics of Fe2+ [as Fe(SO4)] oxidation by O2 (1 atm) in 1 M H2SO4 catalyzed by 0.25 mM Fe(pc) or [FeIII(tetra(4-OMephenyl)porphyrin)]Cl. Fe(pc) was a more effective catalyst with >90% conversion of Fe2+ to Fe3+ after 5 h. This reaction was proposed to proceed via O2 binding to the iron macrocycle in the FeII oxidation state and subsequent reduction of O2 to water with H2SO4 and aqueous Fe2+ ions as the source of protons and electrons (Figure 14A). The authors then measured polarization curves for the three oxidized solutions (0.5 M FeSO4 plus 1.0 M H2SO4 and (i) no catalyst, (ii) Fe(pc), or (iii) [FeIII(tetra(4-MeOphenyl)porphyrin)]Cl). They found the best performance for the solution containing Fe(pc), stemming from the much higher conversion of Fe2+ to Fe3+ (Figure 14B). In this study, the cell was held at 80 °C and H2 was supplied as the fuel to a Pt/C anode (H2|Pt/C||Fe2+|Fe(pc)|O2). The solution containing Fe(pc) as the catalyst led to a peak power density of ~250 mW/cm2, which was over three-fold higher than the other two solutions (65 mW/cm2 for the uncatalyzed solution and 76.8 mW/cm2 for the solution containing the Fe-porphyrin catalyst). However, no sustained electrolysis data was included to provide evidence for efficient on-stream regeneration of the mediator during fuel cell operation. The authors noted that further adoption of mediated cathode systems would require higher potential mediators, as well as more active catalysts for the mediator oxidation.

Figure 14.

(A) Proposed mechanism for Fe2+ oxidation by O2 catalyzed by Fe(pc). (B) Polarization curves measured using 0.5 M FeSO4 + 1.0 M H2SO4 solutions after oxidation at 80 °C with O2 for 5 h in the presence of no catalyst (black traces), [FeIII((4-OMephenyl)porphyrin)]Cl (Fe-TMPP) as catalyst (blue traces), or Fe(Pc) as catalyst (red traces). H2 was used as the fuel at a Pt/C electrode (H2|Pt/C||Fe2+|Fe(pc)|O2). Adapted from ref. 61. Copyright 2016 American Chemical Society.

In order to study Fe complexes similar to those reported by Acal, Metz and coworkers used computational methods to calculate the reduction potential of a variety of different Fe complexes bearing chelating nitrogen ligands (Figure 15).62 Using experimental E1/2 values for [Fe(II)trilen (R = H/Cl/SO3Na)-OH2]2+ and Fe(II)N4Py(R = H/CH3)-OH2]2+, the authors calculated the difference between potential energy surfaces by the self-consistent field method, ΔE(SCF), and found good agreement between these values. The authors used these benchmarks to estimate the redox potential of [Fe(II)trilen (R = CH3/CF3/CN)-OH2]2+ and [Fe(II)TFM-trilen(R = H/SO3Na)-OH2]2+. The complex [Fe(II)TFM-trilen(R = SO3Na)-OH2]2+ was expected to have a redox potential of nearly 1 V, which would increase the open-circuit potential by ~25% relative to the highest previous Fe complex studied experimentally. A synthetic route to this complex was proposed, but it wasn’t prepared. Thus, experimental validation of these results, including assessment of mediator stability and aerobic regeneration, awaits further study.

Figure 15.

Ligands studied computationally by Metz and coworkers to determine the redox potentials of the Fe complexes.62 Experimentally determined redox potentials are shown in red, while the calculated redox potentials are shown in black.

2.4. NOx mediators

In previous sections, NOx species have been utilized as catalysts for aerobic oxidation of a mediator. HNO3 has also been utilized as a single-component mediator/catalyst system. Both HNO3 and HNO2 have high reduction potentials to NO, 0.957 V and 1.028 V vs. NHE, respectively. These values are close to the formal reduction potential of O2 to H2O, 1.23 V, and it is possible to access high concentrations of HNO3 that support high current densities. The systems using NOx species derived from HNO3 as cathode mediator/catalysts for O2 reduction are given in Table 6.

Table 6.

Reported systems using NOx species as mediators for O2 reduction.

In the early 1960s, research into the use of HNO3-mediated ORR was conducted by researchers at Esso Research and Engineering Company in New Jersey.124 Alcohols, such as methanol or ethylene glycol, were targeted as the fuels for this system. In the initial report, low concentrations of HNO3 (approximately 1 wt% in H2SO4) gave substantially higher currents than O2 alone. The researchers studied the mechanism of electroreduction of HNO3 and proposed an autocatalytic mechanism with a rate-limiting step involving the reaction of HNO3 with nitric oxide (NO) to form nitrous acid (HNO2).125 The latter was proposed as the electroactive species. Engineering of the external regenerator allowed up to 30 cycles of HNO3 turnover, measured by comparing the total charge passed to stoichiometric redox equivalents available from HNO3.126 A challenge with this system was the loss of NO or other NOx species to the gas phase, but further development of the MeOH-HNO3/O2 fuel cell enabled power densities of 44 mW/cm2 at 0.34 V using a new Pt/C-based catalyst at the cathode. A maximum power density of 19 mW/cm2 was obtained during continuous operation for over 180 h using a standard Pt mesh cathode.127

The use of NOx-based mediators for fuel cell cathodes was revisited in 2011, when Park and coworkers reported a fuel cell using the NO2−/NO3− as a cathodic redox mediator using a nitrogen-doped carbon-felt electrode.128 The reduction of NO3− to NO2− has a formal potential of 0.94 V, and aerobic oxidation of NO2− is facile. The authors prepared an Fe-N/C catalyst by treatment of iron nitrate and melamine with carbon black and annealing of the resultant powder at 700 °C under N2. This electrode showed enhanced activity for nitrate reduction relative to commercial Pt/C catalysts. Specifically, polarization curves using a conventional Pt/C H2 anode and 5 M HNO3 as the oxidant in the cathode compartment showed higher current densities with Fe-N/C than with Pt/C cathodes (325 mA/cm2 vs. 250 mA/cm2, respectively) at 0.9 V. To monitor the stability of the cathode materials, the power density at 0.8 V was measured over the course of 100 h with an operating temperature of 80 °C. The Fe-N/C electrode showed minimal drop in activity, while the performance of the Pt/C cathode dropped dramatically. This decrease in activity was attributed to Pt dissolution. The selectivity of NO3− reduction using the Fe-N/C electrode was measured, and a 98.3% selectivity for formation of NO2− was observed, with the remainder forming N2 and NO. No data describing aerobic regeneration of NO3− was presented, though the authors suggested that this should be achievable.

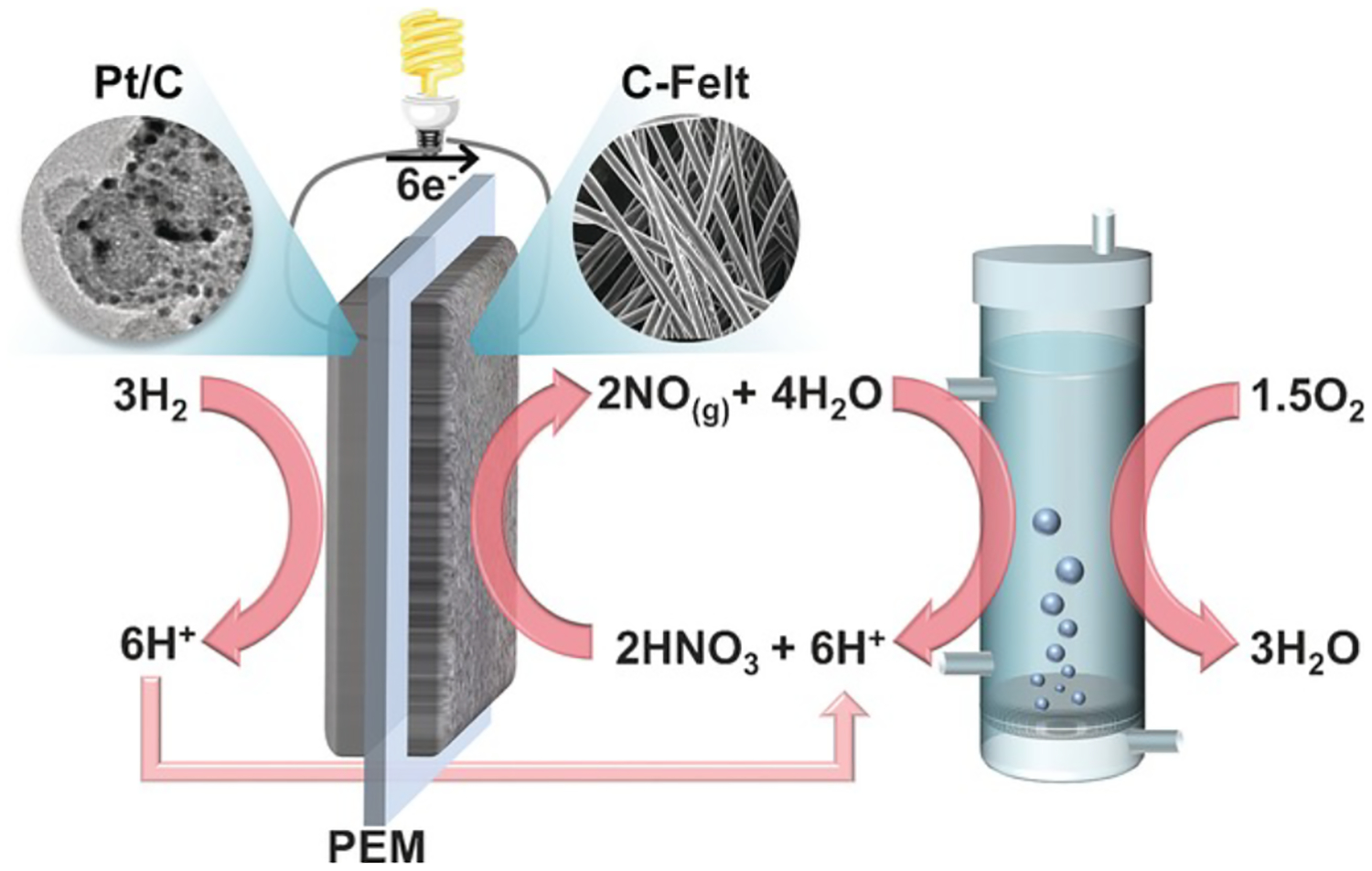

In 2017, Park and coworkers reported an H2/O2 fuel cell using a Pt/C anode and a heteroatom-doped cathode with an HNO3/NO mediator (Figure 16).129 Nitrogen-doped carbon felt, prepared by treatment of commercial carbon felt at 700 °C under an atmosphere of NH3, proved to be an efficient electrode material to facilitate the reduction of NO3− to NO. Polarization curves using 5 M HNO3 were collected at a variety of temperatures, and at 80 °C a power density of over 0.5 W/cm2 was achieved at a potential of 0.8 V. To examine the long-term activity of this system, the fuel cell performance was monitored by holding the cell at a potential of 0.8 V for 30 days with circulation of the 5 M HNO3 solution supplied with 1 atm O2 (H2|Pt/C||HNO3|O2). A slow linear decline in performance was observed during the experiment, falling to approximately 0.3 W/cm2 after 30 days of operation (Figure 17); however, replacement of the cathode solution with fresh HNO3 caused the cell performance to return to its original values. The authors calculated a “regeneration efficiency” of approximately 93%. With no O2 supply, the system was capable of producing power for only 4 days, reflecting the redox capacity of the HNO3 in the cathode solution.

Figure 16.

Schematic of a mediated fuel cell using the NO3−/NO redox mediator to mediate O2 reduction. Adapted from ref. 129. Copyright 2017 Wiley-VCH Verlag GmbH & Co. KGaA.

Figure 17.

Long term stability test of HNO3-mediated cathode with nitrogen-doped carbon-felt electrode. Cell run at 80 °C with H2 anode. Adapted from ref. 129. Copyright 2017 Wiley-VCH Verlag GmbH & Co. KGaA.

A direct ethanol fuel cell utilizing a PtSn alloy anodic catalyst and a HNO3-based catholyte mediator was reported in 2018 by Park and coworkers (Figure 18).130 The system achieved a maximum power density of 68 mW/cm2 and an open-circuit potential of ~0.85 V. In contrast, a system using direct O2 reduction on a commercial Pt/C catalyst on the cathode achieved a maximum power density of 34 mW/cm2 and an open-circuit potential of ~0.65 V. No NO2 regeneration data was presented in this work.

Figure 18.

Schematic of a direct ethanol fuel cell using an HNO3 mediated cathode. Adapted from ref. 130. Copyright 2018 Hydrogen Energy Publications LLC.

2.5. Nitroxyl/Oxoammonium mediators

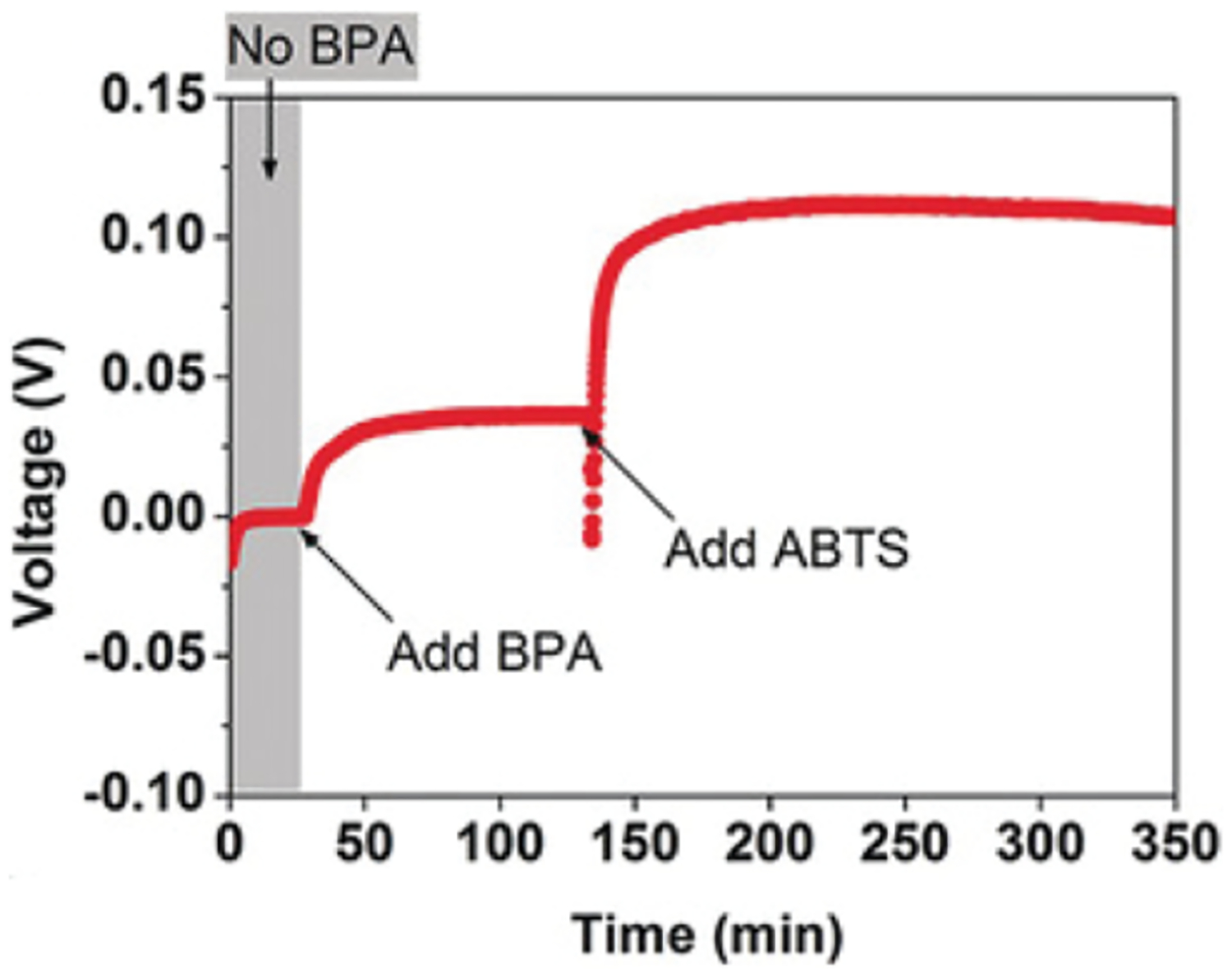

Organic aminoxyls, such as TEMPO (2,2,6,6-tetramethylpiperidine N-oxyl), are organic radicals that can undergo 1 e− oxidation to an oxoammonium species. They have been used as mediators in a wide variety of alcohol oxidation reactions, including under electrochemical46,131 and aerobic132,133 reaction conditions. The use of NOx co-catalysts in the latter reactions provided the starting point for a fundamental study by Gerken and Stahl to investigate the ORR with an aminoxyl/NOx mediator/catalyst system (Figure 19A).134 Cyclic voltammetry and controlled-potential electrolysis experiments highlighted the cooperative redox behavior of this system. A series of different nitroxyl mediators (TEMPO, ACT, 3-CARP, and ABNO; Figure 19B) were examined. TEMPO/TEMPO+ electrochemistry was facile, but TEMPO did not react efficiently with O2 (Figure 19C, blue trace). NO, generated by addition of acid to a solution of NaNO2, reacted rapidly with O2, but the NO2 product exhibited poor electrochemical behavior (Figure 19C, black trace). The combination of both mediators led to a significant and sustained increase in the observed currents (Figure 19C, red trace). Other aminoxyl mediators (ABNO, ACT, and 3-CARP) yielded similar results (Figure 19D), and the operating potential correlates with the potential (vs. Fc+/0) of the aminoxyl/oxoammonium redox couple.

Figure 19.

A) Simplified scheme for TEMPO-mediated O2 reduction using a NOx-based catalyst B) Different nitroxyls examined in the study. C) Controlled-potential electrolysis traces in the presence and absence of mediator and/or catalyst (TEMPO and NOx, respectively). D) Controlled-potential electrolysis traces in the presence of NOx and various nitroxyl mediators (red = TEMPO; black = ACT; blue = ABNO; green = 3-CARP). Adapted from ref. 134. Copyright 2015 American Chemical Society.

The thermodynamic potential for O2 reduction under these reaction conditions was determined by measuring the H+/H2 open-circuit potential under the non-aqueous conditions and applying the relevant corrections.135,136 The highest potential mediator, ACT, was shown to feature an ORR overpotential of roughly 300 mV, similar to overpotentials associated with the onset of ORR with conventional Pt catalysts. This system was not well suited for practical application (e.g., due to the use of an organic solvent and loss of NOx species to the gas phase), but it provides some of the most thorough insights to date into the mechanisms of electrochemical O2 reduction with NOx and mixed aminoxyl/NOx mediator systems.

Park and coworkers reported a MedFC using aqueous acidic conditions with TEMPO as a mediator in the absence of a redox catalyst (Figure 20A).137 The authors report the redox potential of TEMPO to be 0.76 V and used a conventional Pt/C H2 anode (H2|Pt/C||TEMPO|O2). A fuel cell test with a cathode flow rate of 2 mL/min produced a maximum power density of 90 mW/cm2 (Figure 20B). A constant potential experiment was conducted at 0.4 V, and the current was observed to go to zero in approximately 190 minutes (Figure 20C). A rough analysis of the total charge passed suggests that no regeneration of TEMPO occurs with O2, consistent with previous observations (e.g., Figure 20B). The reduced TEMPO mediator will be present as TEMPOH2+ under these conditions and will not undergo facile reactions with O2.138

Figure 20.

A) Schematic of mediated cathode fuel cell using TEMPO mediator. B) Polarization curve of the mediated fuel cell using TEMPO as a cathodic mediator and a conventional H2 anode. Conditions: 0.3 M TEMPO and 1 M H2SO4 in the cathode, fuel cell temperature 30 °C. C) Time-on-stream test using a TEMPO-mediated cathode. Inset shows original color of TEMPO solution (left) and solution color after time-on-stream experiment (right). Adapted from ref. 137. Copyright 2018, Elsevier B.V.

2.6. Quinone/Hydroquinone mediators

Quinones have a rich redox chemistry. They undergo both electron-transfer or proton-coupled electron transfer, they are used in dehydrogenation and other oxidation reactions with organic molecules, and they serve as cocatalysts in aerobic oxidation reactions.139,140 The last of these roles has direct relevance to the ORR because hydroquinone (H2Q) reacts with activated oxygen species in the reduction of O2 with a molecular Co(salophen) catalyst.141 Stahl and Anson showed that the use of H2Q as an “electron-proton transfer mediator” led to a change in ORR product selectivity from H2O2 (two-electron reduction) to H2O (four electron reduction) during electrocatalytic O2 reduction.142 Cyclic voltammetry and bulk electrolysis experiments further showed that H2Q led to an enhanced rates and lower overpotentials for the Co(salophen)-catalyzed ORR in organic solvent (N,N-dimethylformamide, with acetic acid as the proton source; Figure 21). The conditions for the Co(salophen)/H2Q study reflected those used in the prior aerobic oxidation reactions, but the results have implications for more-conventional ORR effort by showing that a mediator could participate in a cooperative, inner-sphere mechanism and thereby influence the rate and/or selectivity of the reaction.

Figure 21.

Simplified scheme for quinone-mediated O2 reduction utilizing Co(salophen) as a soluble catalyst. Adapted from ref. 142. Copyright 2017, American Chemical Society.

The first demonstration of hydroquinone-mediated ORR under PEMFC-like conditions was reported by Stahl and coworkers in 2018, using a water-soluble quinone mediator paired with an off-electrode heterogeneous Co-N/C catalyst.143 Water-soluble high-potential quinones containing sulfonate groups have been utilized in flow-battery applications144 (Compounds A-C, Figure 22), but the previously reported materials rapidly decomposed and had inadequate stability for fuel cell operation. To address this limitation, a new tetra-substituted quinone bearing four alkylsulfide-linked sulfonate groups was designed and synthesized (Compound D, Figure 22). This mediator exhibited substantially improved stability with a half-life over >5000 h. Various M-N/C catalysts were tested for their ability to oxidize the corresponding hydroquinone to the quinone under fuel cell relevant conditions (1 M H2SO4 and 60 °C), and a Co-N/C catalyst using 1,10-phenanthroline as the nitrogen source during the pyrolytic catalyst preparation was identified as the most effective catalyst. A fully integrated fuel cell was constructed using a conventional Pt/C H2 anode (H2|Pt/C||quinone|Co-N/C|O2) and a Nafion membrane between the anode and cathode (Figure 23A). The cathodic solution contained 0.1 M quinone in 1 M H2SO4. This solution was circulated between the fuel cell cathode, where the oxidized mediator was reduced, and a packed-bed reactor, where the mediator was oxidized by O2 using the Co-N/C catalyst. An iR-corrected peak power density of 251 mW/cm2 (161 mW/cm2 uncorrected) was obtained (Figure 23B). Under steady-state conditions, a stable current output was observed for over 8 h at a constant potential of 0.5 V (Figure 23C). Control experiments showed that a decrease in current density occurred when O2 flow was shut off to the packed bed reactor, and the current density returned to its previous value when O2 flow was resumed. It was noted that development of stable higher potential mediators would enable the fuel cell performance to match or exceed that of conventional fuel cells.

Figure 22.

Stability of quinone structures previously tested for flow battery applications, A-C, and new tetrasubstituted quinone D. The stability was assessed by 1H NMR, and the half-lives were calculated by assessing the first-order rate constant for quinone decomposition. Conditions: 0.1 M quinone concentration in 0.5 M D2SO4 + 0.05 M CH3SO3H in D2O at 60 °C. Adapted from ref. 143. Copyright 2018, Elsevier B.V.

Figure 23.

A) Schematic of mediated cathode utilizing quinone mediator and Co-Phen/AC catalyst, H2|Pt/C||quinone|Co-phen/AC|O2. B) Polarization curves and C) time-on-stream performance for quinone-mediated fuel cell cathode with a Co-N/C catalyst. Conditions: 0.1 M quinone mediator, 1 M H2SO4, 60 °C, H2 fuel with Pt/C anode, MWCNT-coated carbon paper cathode, Nafion 117 membrane, 5 g Co-N/C catalyst in packed bed reactor. Time-on-stream experiment conducted at a constant potential of 0.5 V. Adapted from ref. 143. Copyright 2018, Elsevier B.V.

2.7. 2,2’-Azino-bis(3-ethylbenzothiazoline-6-sulphonate) mediator

2,2’-Azino-bis(3-ethylbenzothiazoline-6-sulfonate), ABTS2−, is a water-soluble, redox-active organic molecule that has been used as a mediator for O2 reduction with various enzymes at the cathode of enzymatic fuel cells (Figure 24). Mediators have found widespread use in enzymatic fuel cells to facilitate electron transfer between the electrode and the active site of an enzyme, which can be buried within the enzyme. A more detailed discussion of the role of mediators in enzymatic fuel cells is provided in Section 3.2 in the context of anodic reactions, and a review of O2 reduction in enzymatic biofuel cells, including both mediated and direct electrochemical approaches, was recently published.145 In general, mediated fuel cells employing enzymatic catalysts achieve power densities that are much lower (often, by two or three orders of magnitude) than those described in the previous sections.

Figure 24.

(A) Structure of ABTS2− and (B) redox sequence for ABTS2−-mediated cathode with enzymes as catalyst. For systems using this mediated cathode, see references 146–154.

The first use of ABTS2− in this context was reported by Palmore and Kim in 1999, using fungal laccase from Pyricularia oryzae as the enzyme catalyst.146 Many laccases reduce O2 at very high potentials, though prior reports using direct electrochemical methods displayed very low current densities. The outer-sphere electron-transfer reactivity of laccase accommodates a wide array of mediators. The authors considered mediators with an array of redox potentials, with the hope of identifying one close to the formal potential of the enzyme (E°’ = 0.539 V vs. SCE at pH 4.0, at which the formal potential for the reduction of O2 to H2O is 0.723 V vs. SCE). ABTS2− was selected due to its high potential (E°’ = 0.440 V vs. SCE at pH 4.0), good solubility and reasonable stability.

The authors investigated the aerobic oxidation of ABTS2− to ABTS•− catalyzed by laccase. Lower pH values favored higher laccase activity, and the stoichiometry of ABTS2− oxidized to O2 reduced was found to be 4:1, consistent with full reduction of O2 to water. A fuel cell employing a pH 4, 0.2 M acetate buffer was constructed with a Pt-gauze anode under 1 atm H2 and a glassy carbon or Pt-foil cathode containing both laccase and ABTS2− under 1 atm O2 (H2|Pt||ABTS2− |laccase|O2). The anode and cathode compartments were separated by a Nafion membrane. Polarization curves were obtained, and this system showed both a higher open-circuit potential and lower polarization relative to a Pt/O2 or carbon/O2 cathode system (Figure 25A). For example, at a current density of 25 μA/cm2 the biocathode exhibits a potential of 0.50 V vs. SCE, while the Pt/O2 and carbon/O2 system have potentials of 0.04 V and −0.29 V, respectively. Measured power densities were substantially higher for the biocathode, with the mediator system achieving a power density of approximately 40 μW/cm2, compared to ~15 μW/cm2 for a Pt cathode and ~3 μW/cm2 for a carbon cathode (Figure 25B). The performance of mediated laccase cathodes decreases at pH > 5. A biofuel cell pairing ABTS2− and fungal laccase at the cathode was reported to achieve a max power density of 99.8 μW/cm2 at a pH 4.0, with a decrease to 2.0 μW/cm2 at a pH 7.147

Figure 25.

A) Polarization curves of a fuel cell constructed with a laccase/ABTS2− biocathode (dotted line with open circles), Pt cathode (solid line with filled triangles), or carbon cathode (solid line with filled circles). B) Power density for the mediated fuel cell (dotted line with open circles) compared with a Pt cathode (solid line with filled triangles) and a carbon cathode (solid line with filled circles). Adapted from ref. 146. Copyright 1999 Elsevier Science S.A.

A pair of studies investigating the use of ABTS2− as a mediator at pH 7 were published by Ikeda and coworkers in 2001. The initial study explored electrocatalytic reduction of O2 with bilirubin oxidase from M. verrucaria as the catalyst and ABTS2− as the mediator.148 Cyclic voltammetry studies indicated catalytic O2 reduction occurred under these conditions, with a half-wave potential of 490 mV vs. Ag/AgCl, which is close to the thermodynamic potential for O2 reduction to H2O (615 mV vs. Ag/AgCl at pH 7.0; Figure 26). The mediator was found to decompose via disproportionation of ABTS•− to ABTS2− and ABTS0, which is unstable under these conditions. In a subsequent study, a biofuel cell with an ABTS2−/bilirubin oxidase cathode system was paired with Desulfovibrio vulgaris bacteria and methyl viologen for H2 oxidation at the anode.149 A pH of 7 was maintained in each compartment, which were separated by an anion-exchange membrane. Results from this study showed that the cathode compartment exhibited good activity and stability, but the overall power output was limited by the anodic chemistry.

Figure 26.

Cyclic voltammagrams of: A) pH 7.0 phosphate buffer, B) pH 7 phosphate buffer and 0.25 mM ABTS2–, and C) pH 7 phosphate buffer, 0.25 mM ABTS2–, and 0.11 mM BOD. Scan rate was 10 mV/s, working electrode was glassy carbon, and a Pt disk was used as the counter electrode Adapted from ref. 148. Copyright 2001 Elsevier Science B.V.