Abstract

Introduction

Military aviation inventory management systems are a vital tool for air forces to reduce operating costs whilst improving fleet readiness, aircraft serviceability, and availability, and the safety measurements of the country.

Objective

This paper aims to establish a local, affordable, high quality, reliable, and adaptive inventory management system which manages and improves inventory in the military aviation industry (Air forces). The aim of the new system is to improve aircraft fleet serviceability, reliability, and readiness in order to enhance the operational status and level of readiness at the least possible costs.

Methods

This study designs, proposes, and implements a highly reliable customized Microsoft Access software as a powerful, simple, user-friendly. Affordable software that supports the on-time availability of the air force inventory of spare parts. The system will have full capability of integrating maintenance management systems (M.M.S.) and will address aircraft inventory challenges.

Results

The proposed system provides high-quality reports that improve supply chain management and processes that help collate maintenance, supply chain, and logistics information that reduces stock to the minimum. This will result in improved components, increased serviceability, availability, and reliability, decreased costs, and decreased Aircraft on Ground (A.O.G.).

Keywords: Aerospace engineering, Industrial engineering, Safety engineering, Air quality, Natural hazard, Public health, Quality of life, Occupational health, Health economics, Public administration, Inventory management system, Aircraft on ground, Supply chain, Access software, Military aviation

Aerospace engineering; Industrial engineering; Safety engineering; Air quality; Natural hazard; Public health; Quality of life; Occupational health; Health economics; Public administration; Inventory management system; Aircraft on ground; Supply chain; Access software; Military aviation

1. Introduction

People have been selling and buying things for centuries. Therefore, stock management has always existed, and it had a profound impact during the Industrial Revolution reflected on both the goods cost and market share, “supply” is considered to be of strategic significance (Houlihan, 1988).

The supply chain is defined as a “set of companies that pass materials forward, several independent product manufacturing firms and placing it in the hands of the end-user in a supply chain” (La Londe and Masters, 1994). The key purpose of supply chain management is to manage and integrate the sourcing, control, and steady flow of materials (Monczka et al., 2002). The supply chain consists of raw material and component suppliers and producers, product assemblers, wholesalers, vendors, distributors, and transportation organizations (La Londe and Masters, 1994). Supply chain management refers to planning and carrying out these activities, aiming to best meet the goals of a supply chain's shareholders (Peltz et al., 2012). According to Stevens (1989), supply chain management also aims to harmonize customer requirements with the materials flow from its sources, therefore achieving an equilibrium between competing customer service and priorities, at reasonable components cost and availability, since the Supply chain management performs and manage the complete material resources and flow (Jones and Riley, 1985). An empirical study by Lee and Nam (2016) identified individual supply chain orientation (S.C.O.) and showed that organizational and information technology .C.O.S.C.O. has a significant influence on strategic S.C.M.

The Royal Jordanian Air Force (RJAF) was established on 22 July 1948 and is charged with the air defense missions of territorial integrity, the close support of the army, and tactical bombing and the airlifting of troops and supplies. The RJAF has six airbases and 35 different aircraft and related systems for different fleets, including f-16, F-5, C-119, C-130, Mirage F-1s, F-5Es, and F-5Fs. The RJAF's main aim is to maintain the operational fleet state and a high level of serviceability and reliability at the least possible costs, which increases the challenges for both maintenance and inventory management personnel. According to Snyder and Mills (2004), the transition emphasizes the usefulness of devising fast and logical techniques and systems for defining the entire support necessary to air forces organizations having different platforms and infrastructures. Like others, RJAF maintenance, supply chain experts face significant problems in fulfilling the requirements of the different aircraft fleets, and makes it difficult for them to find the reasons behind low quality and reliability in a timely and less costly manner. Inventory management systems in aviation are very closely related to maintenance management systems, as there is no use of materials unless maintenance is taking place. However, there may be maintenance action with no materials required, which can be observed in the case of daily inspections (i.e., pre-flight, through-flight, and -post-flight), which are carried out without any abnormal findings. Even these daily inspections necessitate some rags and chamois leather pieces for cleaning canopy transparency. The typical life cycles of military equipment, tools, and apparatuses and the acquisition cycles for weapon systems run anywhere between (8 and 12) years. Wynn (1992) adds that primary and major systems can remain in the inventory up to 30 years and maybe more. The RJAF has many inventory issues in supporting fleet, including:

-

1.

The accumulation of surplus, unused spares

-

2.

The accumulation of expired items

-

3.

Budget shortages, which lead to additional high requirements not being met.

-

4.

Expansion in the use of different platforms because of political and imposed regional threats

-

5.

Expiry of the warranty period caused by not closely monitoring warranty items.

Therefore, there is an identified need for an adaptive inventory management system (AIMS), which eliminates any shortcomings in the current inventory system and which is cheap and user-friendly. The system should also reduce inventory costs and the chances of A.O.G. through ensuring the practical usage of needed items based on maintenance requirements, improving the process of predicting spare parts, and ultimately maintaining the fleet, operational state, and high levels of serviceability and reliability at the least possible costs. Therefore, this study aims to develop an adaptive inventory system, which meets the annual needs, and the budget of the RJAF achieves the highest degree of aircraft serviceability, reduces the surplus of unneeded spares, and eliminates A.O.G. cases. The proposed system will also have full capability of integrating maintenance management systems (M.M.S.) and will help overcome the inventory as mentioned above issues.

Moreover, there is a need for a new adaptive inventory management system that establishes a database for trusted vendors versus untrusted ones based on their performance. Still, which is not limited to specific aspects such as lead time, priority in dealing with hot issues, the way components original manufacturers fulfill warranty claims, the way they deal with supply deficiency reports (S.D.R), and returned items. The new system should also have an analytical tool for some items that might be helpful in engineering redesign based on a high rate of failure and reducing the chances of Aircraft on Ground (A.O.G.) due to supply. The system should purchase the correct amount and quantity needed, from the right seller, merchant or vendor, at the ideal time, with the most reasonable and least expensive price:—many methods used for improving inventory. Supply chain methods have evolved rapidly like the Spares Acquisition Integrated with Production (SAIP) and Rapid Acquisition of Manufactured Parts (RAMP) methods, both used during the various, and particular stages of the procurement procedure, all of them require satisfactory and detailed accurate planning to guarantee an appropriate use (Aven and Root, 1980; Balwally, 1991). A few commercial software have covered these problems, including COMPASS, developed by Aven and Root (1980), and OPUS10 SYSTECON-AB, developed by The Air Force Institute of Technology, AFIT, Wright-Patterson AFB OH School of Systems and Logistics (Tysseland, 2009). However, the OPUS10 SYSTECON-AB software is costly and has more options than those requested for the RJAF.

2. Literature review

Item or resource stock is defined as Inventory. The literature identifies four types of inventory management systems based on inventory functions: manufacturing, distribution, and retail inventories, and inventory of services (Jacobs et al., 2014). An inventory management system is defined as a group of rules and controls that detect, manage, and maintain inventory levels (Jacobs et al., 2014). Relph and Milner (2015) emphasized the importance of the inventory planning process, which determines the optimal level, inventory management, and control methods and tools, to better manage the integrity of the stock, and inventory balancing, between demand and supply, also mentioned that the inventory cost comes from five sources, namely unit cost, ordering cost, setup cost, holding cost, and risk cost.

Many researchers believe that eliminating, or at least significantly reducing, the role of inventories in modern supply chains would mean a significant reduction in logistics costs and improved satisfaction (Amling et al., 2005). The office of Federal Procurement Policy stated that inventory management caters to different items and spare parts, which are repairable, consumable, and acquired for use in the scheduled and on non-scheduled maintenance, servicing, and major periodic inspections of the aircraft (Donaldson, 1989). Stated that the management of the maintenance inventory should include all aircraft or systems components, including the minor shelf items, stocks up to significant components with necessary tools, and it excludes some items categorized by the maintenance and supply organization for each system or aircraft. Examples include power plants, general airplane systems (landing gear, hydraulic, flight controls, oxygen, and air-conditioning systems, avionics and communication, Instrument and electrical systems, and weapons, and armaments systems. Spare parts can be consumable, repairable, or significant components reference (Graham, 1988). Sometimes, repairable parts such as hydraulic pumps, generators, and valve assemblies are spare parts that can be fixed in case they stop working, or they can be sent to a pre-set rework cycle and then sent back to the inventory (Tracy, 1985). Service inventory maintenance is important for aviation inventory due to the difficulty in predicting the needed spares where the service organization is devoted to providing aftermarket expendables to the aviation industry. According to Tracht et al. (2013), The optimum inventory shall be subject to a minimum level of service level constraint in the event that a minimum service level is set as a constraint within the the calculation.

Aviation inventory management is unique compared to other industry inventory management, whereby there is a need to balance the inventory system (i.e., maintain a balance between maintenance demand and order) and keep costs as low as practical while maintaining the level of readiness necessary for completing the mission. Further, equipment non-availability could result in severe consequences, and the challenges of having the required aviation spare components are unlimited (Wynn, 1992), and the location of aviation inventories is crucial. Aircraft spare parts providers focus on the needs of customers to balance their inventory levels without interrupting their services. The purpose of aviation inventory management is to monitor the movements of stock as the basis for daily stock position and levels for procurement purposes. The main aim of any aviation inventory management system is to maintain a balance in the aviation inventory system, and this is realized by two criteria: the order quantity and the time of placing an order. As for air force, the primary objective is to defend the country's space and territory by a set of defensive and offensive air operations, whilst the secondary objective is to carry out training to achieve the primary objective at the lowest expenses. A perfect aviation inventory management system should have specific capabilities, which include maximizing the reliability and serviceability of the fleet, minimizing the capital hold by unnecessary inventory, identifying the frequently used items, identifying the critical items, and identifying the low demand items. Military aviation inventory systems suffer from many issues ranging from the accumulation of unneeded items, shortages resulting in aircraft on ground (A.O.G.), absence of minimum stock levels, and just-in-time (J.I.T.) components. A.O.G. is defined as parts that keep the aircraft from being released to service, and spares ordered on the A.O.G. basis are delivered in under 24 h but at three times the cost from the nearest vendor (Kent, 2001). A.O.G. is also used to describe critical shipments for parts or materials for out-of-service aircraft in specific locations. All major air carriers have an A.O.G. desk manage obsolescence issues and the expiry of life-limited items.

Perpetual minimum stock level systems play a significant role in inventory management and defined as a method used by companies for managing inventory by using the concept of the minimum quantity or minimum stock levels; it consists of having a continuous inventory of a specific number of inventory items (minimum level) set by the organization based on their needs. Other methods like the just-in-time (J.I.T.) method, or the zero inventory production system (ZIPS), beside the minimum inventory production system (MIPS), Kanban production, Kaizen production, stockless production, pull-through production, and Quick Response (Q.R.) inventory system (Biggart and Gargeya, 2002). JIT highly dependent on the ability of the company and the suppliers to deliver on time and is used to deliver the exact quantity of inventory needed to the production floor right on the time that it is needed. The J.I.T. based on three basic principles: elimination of waste, continuous quality improvement, and encouragement of worker participation planning and execution (Kent, 2001). Supply Chain methods models aim and intend to optimize stock levels of components spare parts for better availability and lower prices to improve fleet readiness with fewer constraints on service level. Peltz et al. (2005) identified several factors affecting inventory performance, including item cost, mobility demand pattern, and transition costs. The inventory holding cost consists of the spare component cost (stock cost) along with the interest rate that includes the (capital cost and inventory risk cost) besides losses regarding the life limit items (Lambert et al., 2006) (Lambert et al., 2006; Oskarsson et al., 2013; Storhagen, 2003). Besides this, the stock out cost is considered as a penalty and lost revenue (Chelbi and Rezg, 2006). Sherbrooke (2006) and Louit et al. (2009) have used maintenance costs in their models and have included both overhaul and repair costs. Meanwhile (Louit et al., 2009), did not consider the overhaul cost in their model calculations, and they equate maintenance costs to repair costs. Transportation costs are only considered as the cost of shipping between the different locations (Fritzsche, 2012).

Fortuin and Martin (1999) and Botter and Fortuin (2000) split components spare parts into two different categories: repairable spare parts, which are divided into non-interchangeable parts and rotables, and the spare part that cannot be used when it fails (non-repairable spare parts). Repairable spare parts have proper management in the military organization since most of the time, they are costly components and have an extended delivery lead time, as well as other industries with considerable and valuable resources and organizations with high readiness levels (Duran and Perez, 2014). According to Sherbrooke (2006), In general, the repairable spare parts receive more consideration than non-repairable spare parts components, as repairable parts may impact a .A.F.R.A.F. readiness due to unavailability of spare parts in a timely manner.

Aviation systems are involved, as they require many spare parts and include multifaceted problems in comparison to the problems faced in controlling finished inventories. The first complex problems are severe in forecasting, harmful stock-outs, valued spare components and extended delivery lead times, and high inventory investments are undesirable in all warehouses (Botter and Fortuin, 2000). Researchers like Storhagen (2003) and Fortuin and Martin (1999) explored the impact of both low and erratic demand. They found that inaccurate results and forecasts might lead to decreased and faulty inventory control and harmful stock-outs. Spare parts are critical because stock-outs may have severe consequences on the system (Fortuin and Martin, 1999). Organization readiness and performance affected by the stock out of spare parts, the vital low cost and Bench stocks like standard hardware, nuts, bolts, washers must always be available and bought with large quantities, (Lorentz et al., 2011; Storhagen, 2003). Extended delivery lead times, refers to the period of time between the initiation of the need for a product or service and the delivery of that product or service, is another factor affecting the inventory management (Oskarsson et al., 2013). Low-demand parts also pose challenges on air forces Such as those to reduce the cycle time of procurement, increasing supply Stock supply, and reduced purchase and maintenance costs of goods, Especially when parts with low demand are used in larger, more expensive applications (Fortuin and Martin, 1999). Low-demand items can be defined as items which are not requested more than six times a year (Chenoweth et al., 2010).

Cannibalization methodology used extensively as a routine fast repair technique for aircraft and aircraft maintenance strategy to maintain and improve the air forces high readiness, especially with scarcity of supply sources of high-value components, or have an extended lead time where maintenance personnel removes serviceable components and parts, from one aircraft usually grounded for more than one reason or needed spare parts, to render another aircraft operational, at the same time Cannibalization adversely affect maintenance personnel morals and increase the maintenance cost and repeated workload (Cassady et al., 2003; Salman et al., 2007 Cassady et al., 2003, Salman et al., 2007).

Logistics and delivery services are vital in preventing A.O.G. occurrence and improving the availability of aircraft. Storhagen (2003), stated that “logistics is all about the economy and utilizing resources in the best possible way”; for now, the factors indirectly influence the logistics environment, such as time and flexibility, should be considered in order for a company to reach its goals (Mattsson and Jonsson, 2005). According to Oskarsson et al. (2013), stated that logistics aim to provisional best delivery services include flexible workflows, suppliers, and seller collaboration, service introduced 24/7 with the least possible cost. Storhagen (2003) stated that a firm's revenue depends heavily on the quality and delivery services (Mattsson and Jonsson, 2005; Oskarsson et al., 2013). Oskarsson et al. (2013), defined the excellent delivery service that should include the availability, precision, reliability, and flexibility, Parameters.

Furthermore, prediction and forecasting play a vital role in inventory management systems. According to Ghobbar and Friend (2002), the forecasting method Additive Winter (A.W.) suggest that the seasonal effects are of constant and persistent size, whilst Multiplicative Winter (M.W.) suggest the effects as continuous and proportional in size to the local, personalized mean level (Makridakis et al., 1998; Winters, 1960). Single exponential smoothing (S.E.S.) related to forecasting in situations of low and alternating demand, whilst the seasonal regression model (S.R.M.) is used in time series for modeling data with seasonal effects (Ragsdale and Plane, 2000). Weighted calculation of demand rates (WCDR) refers to dividing the aggregate demand for a spare part component during an experience period by the total activity of the aircraft during the same period, in order to obtain an average forecast rate (Adams et al., 1993). Forecasting in environments of low and irregular aircraft spare parts demand affects the quality of inventory management strategy (Croston, 1972). In double exponential smoothing (D.E.S.) and trend adjusted exponential smoothing (TAES), forecasting time series data have a linear trend (Pfunder, 1986). The service life limit of aircraft components can be calculated and adjusted from historical data, usage intervals, design of experiment methodology, and reliability probability functions. Exponentially weighted moving average is a useful forecasting tool for time series data that exhibit a linear trend (Makridakis et al., 1998).

The innovation of a tailored inventory management system forR.A.F. originated from many reasons, including the fact that Jordan is a high threat environment live in a high-threat environment, Jordan's commitment to support the U.N. strategic national policies, the need to maximize both the limited budget performance and the qualified human resource constraints, and the need to overcome old inventory management systems issues.

3. Inventory management system programming architecture methodology

This inventory management system (I.M.S.) is a computer-based inventory management system which tracks inventories, forecasts demands, generates reorder points, and ordering sizes, as well as tracking the costs and expenditures of inventory. Analyzing data could help in identifying any material deficiencies that might be attributed to premature failure due to the materials, design, vendor, or storage conditions. Apart from this, the I.M.S. can closely monitor inventory and send out alert messages to avoid any consequences related to using such items and monitor the warranty items so that they are operated and tested well before the warranty period expires. Microsoft software Access was used for creating this system.

In the current research, we customized a local inventory management system (I.M.S.) using the Microsoft Access 2016 application, which is one of the Microsoft Office 2016 packages, the detailed information on the tailored Inventory Management System Architecture shown in the appendix. The application is used to handle databases efficiently for personal and corporate uses. Unlike other Microsoft Office products, learning and utilizing the benefits of Microsoft Access 2016 requires prior understanding of but not limited to the following: (I) relational database fundamentals (primary keys, foreign keys, records, fields) (ii) data types (dates, text, numbers), and (iii) Boolean logic (AND, OR, and NOT). The need to write lengthy codes is reduced significantly, as the Access 2016 packages contain many built-in functions that meet the ordinary requirements for our daily activities. However, Access 2016 also has a wide range of options and capabilities for people with high programming skills in Visual Basic. More functionality details will be explained later in this section.

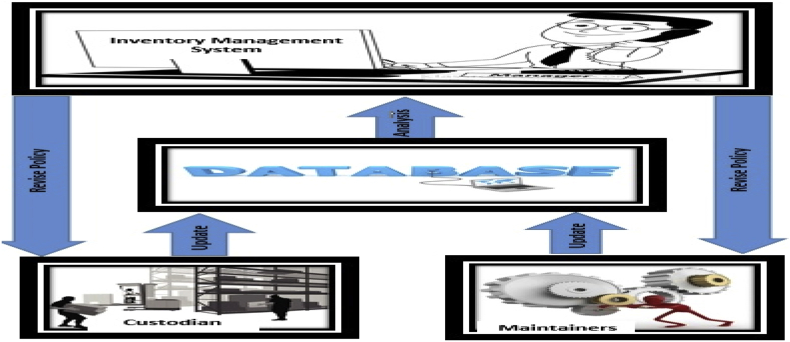

The system in the present study was used to manage all types of inventory from military aircraft components from the last two years. We successfully fulfilled our local requirements saving significant time, evaluating inventory through improving inventory exactness, and improving the monitoring of standard stock items (availability and shortages) and customized reports with updated forms. The introduced I.M.S. also saved much money in comparison to most other aircraft I.M.S.s, which are very expensive and complicated and require regular costly updates. Furthermore, the introduced I.M.S. can act as a long-term problem-solving support system. Through the I.M.S. protocol, we can set standard operating procedures, standardize the documentation processes, and ultimately provide real-time aircraft and inventory status. As shown in Figure 1, the conceptual design of the I.M.S. consists of three critical players: the maintainers perform the maintenance actions, the custodians perform inventory management, and both send status and updates through the database system in order for the analysis to be performed to adjust the whole situation.

Figure 1.

General I.M.S.

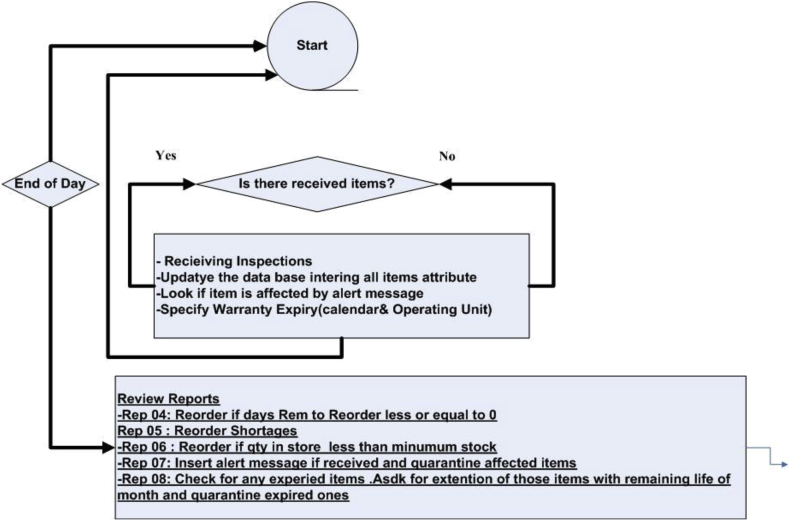

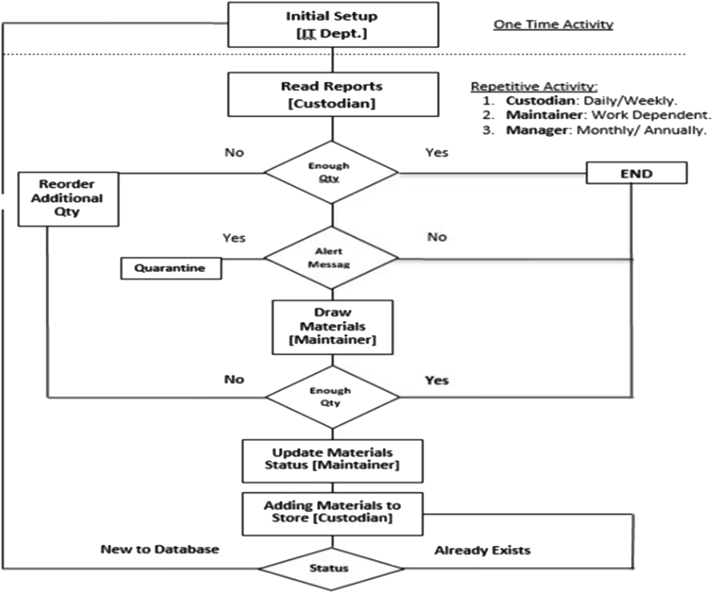

The maintainers are responsible for pulling the exact needed parts, looking for any constraints, and updating the database by entering the quantity used and the case it was used for. The data provided by the maintainers form the basis for later analysis, which greatly helps determine the consumption rate. Further investigation can reveal if this higher consumption rate is associated with a specific type of maintenance, technician, and/or the type and specific aircraft serial. Figure 2 displays a flow chart of the maintainers' tasks. Custodian tasks and responsibilities include keeping inventory physically, as well as updating the database of the physical inventory status, as shown in Figure 3.

Figure 2.

Maintainers task flow chart.

Figure 3.

Custodian task flow chart.

Finally, the I.M.S. Managerial Section Scope of Work window provides full data statistics to the responsible professionals for extra analysis. The section scope of work is shown in Figure 4, and Figure 5 below indicates clearly how the process of I.M.S. functions.

Figure 4.

I.M.S. Flow chart.

Figure 5.

The process of I.M.S.

The I.M.S. is constructed using basic logic. The first logic is to calculate the daily usage rate for each part by counting the number of days between the first and the last order then dividing it by the number of parts ordered in this period. A daily usage rate helps in calculating the used quantities per day, which, in return, indicated the number of days left until the next order. The second logic is to obtain the average delivery time using Eq. (1). After obtaining the daily usage rate and the average delivery time, the third logic is to obtain the number of days left until the next order using Eq. (2). Eq. (2) can be used to obtain the number of days needed to consume the quantity in store, and Eq. (3) can be used to obtain the deadline by which the quantity of the part will be zero. Finally, we can obtain the number of days left until the next order using Eq. (4). The three critical performers in the inventory management system (I.M.S.) are the custodian staff, the maintainers (who are the inventory end users), and the I.M.S. manager. Each player has a set of tasks and responsibilities which ensure that an efficient outcome of the I.M.S. is achieved.

| (1) |

| (2) |

| (3) |

| (4) |

Responsibility and accessibility to the data and the way actual daily activities are executed are identified. The access and privileges are identified as manager privileges (PM), custodian privileges (CM), and maintainer privileges (MM). Manager privileges are those awarded to the person with full access to all screens to provide overall monitoring and management of the database, whilst custodian privileges are those awarded to the person who monitors the daily transactions (in/out) of the store, monitors stock levels, follows up with aircraft periodic maintenance calendar due items, and ensures that parts are available when or before needed. Finally, maintainer privileges are those awarded to the person who draws items and parts to carry out technical work on the aircraft and who is concerned with finding the right part when needed.

The software has been designed in such a way that the managers only receive the data they need. This is because, as observed from my experience, most managers receive much more data than they can absorb. The new system's main screen is shown in Figure 6.

Figure 6.

Main screen.

However, the data presented above is used as an example of purposes only. Specific focus has been placed on user data privacy aspects. By hitting on the Data Entry button, the user is directed towards the screen to enter and update daily transactions and order status and to look at material details, photos, dates of expiry (if applicable), and available stock. By clicking on the Reports button, the user is then directed to the reports, with summaries of the most common requirements, as shown in Figure 7.

Figure 7.

Reports screen.

Furthermore, based on the results of this project, any data can be used through the I.M.S. system reporting outputs. The reports in the reports screen, shown in Figure 8, can be exported locally or to an external drive in the “Pdf” format if needed. By clicking on the forecast button, the user is directed to a spreadsheet for ad-hoc queries on the projected items due for replacement in the next 100 h–300 h. By clicking on the warranty follows ups button, the manager receives access to the warranty status of the item under warranty terms.

Figure 8.

The “Warranty” screen.

The reports include data selected, sorted, and grouped according to the user's desire, as every manager or user has his or her way of organizing data and reports. A considerable number of reports can be produced, with each report customized in its contents and layout. Pivot tables are the cross-tabulation display of two parameters: their summation, averages, or counting the number of records.

The “Warranty” screen is another tool that quickly develops a better picture of the status of items under warranty to operate and make use of the warranty terms before the item/component is out of this privilege, as shown in Figure 8.

The proposed system also provides a specific screen for components forecasts to give decision-makers a better picture of fleet readiness in the future. The forecast is another tool that utilizes the power of Access to quickly develop a better picture of the status of a fleet of aircraft within the near future, as shown in Figure 8. The following report indicates daily consumption, which is also helpful in forecasting. The RJAF develops its spare parts forecasting depending on historical data and Original Manufacturer (O.E.M) data and recommendations from statistical (econometric) models that explain and incorporate daily usage that can help maintenance and inventory managers in the future. The primary goal of the integration of I.M.S. and .M.S.M.M.S. is to monitor both forecast and warranty Items for the efficient utilization of assets, as shown in Figure 9, Figure 10, and Figure 11.

Figure 9.

Forecast (pivot table).

Figure 10.

Forecast screen Details.

Figure 11.

Integration of inventory management system (I.M.S.) & maintenance management system (M.M.S.).

4. Conclusion and future work

The main contribution of this paper has been to explain how a free I.M.S. can be developed for the maintenance of a complex engineering system like military aircraft. The innovation of a tailored inventory management system for RJAF originated from many reasons, including the fact that Jordan is a high threat environment in a high-threat environment, Jordan's commitment to support the U.N. strategic national policies, the need to maximize both the limited budget performance and the qualified human resource constraints, and the need to overcome old inventory management systems issues. The I.M.S. program will prove to be a very efficient tool in inventory management for several reasons.

Firstly, it will provide increased efficiency for the inventory management system by providing an estimate of the requirements that is unbiased and not based on guesswork. Secondly, it is adaptable, as it is capable of forecasting the needs for different lengths of time and providing accurate inventory management, allowing the organization to track inventory accurately. Thirdly, it will eliminate A.O.G. cases, especially on low dollar value items, where inaccurate inventory management can lead to lost sales. According to John and Robert (2004), inventory management is a great time-saving tool. Fourthly, if properly analyzed, it is a perfect tool for calculating the exact quantity of inventory needed and highlighting issues such as the need to replace certain O.C. items on specific intervals or reduce the frequency at which some O/H or scrap items are replaced. This makes it easier to prevent product shortages and allows the organization to keep just enough inventories on hand without having too much (John and Robert, 2004). Fifthly, it will prove useful for highlighting material deficiencies related to a specific vendor, lot number, etc.

This program works to reduce the surplus of unneeded inventory items, and a decision made by users at the directorate of maintenance and directorate of supply may be made to trade low demand items for other required items. Another feature of the program is the comprehensive monitoring of limited life items by utilizing items with the earliest expiry date first. Moreover, the program monitors inventory, which impacts the safety or has some constraints on its use. Sometimes a need for an Air force deployment to other locations. Using this program provides a close estimate of the number of spares needed to fulfill force deployment needs. These estimates are based on the number of aircraft, period of operation, and mission needs. One of the principal analyses that might seem out of the I.M.S. software is to monitor the percentage of items replaced on unscheduled maintenance, as this might highlight item deficiencies.

Further analysis may attribute this deficiency either to the vendor, material, design, misuse, improper storage conditions, and the installation procedures. By eliminating the surplus of unneeded items, the I.M.S. will be of great importance in calculating the value of inventory left after the platform becomes out of service. This is likely to help in the trading of these items to other users as soon as this becomes practical, hence minimizing the loss of value.

The I.M.S. program will not be rendered useful without a well-trained and objective oriented workforce. Further, continuous improvement is vital, as there is always room for improvement to enhance theI.M.S. capabilities, make it more handy for users, make it easier to interpret, and enhance the reliability of the data analysis. Such improvements make the I.M.S. an accountable program which can help decision-makers carry out their work. In the future, the capabilities of the I.M.S. can be integrated with flight activity by linking a separate sub-database remotely (distributed database), making it possible to track flight activities and link this information with the quantities of materials/items needed for any specific period and to develop a personnel availability (man-load) plan. Such a plan would be helpful to the owner or operator of the platform and could be of great help for the platform O.E.M. in production continuation improvement.

Declarations

Author contribution statement

Hesham Almomani: Conceived and designed the experiments; Wrote the paper.

Osama Al Meanazel, Ehsan Kwaldeh & Ahmad Qamar: Performed the experiments; Analyzed and interpreted the data.

Abdallah Alaween: Contributed reagents, materials, analysis tools or data.

Atif Khasaleh: Performed the experiments; Wrote the paper.

Funding statement

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Competing interest statement

The authors declare no conflict of interest.

Additional information

No additional information is available for this paper.

Appendix A. Supplementary data

The following is the supplementary data related to this article:

References

- Adams J.L., Abell J.B., Isaacson K.E. 1993. Modeling and Forecasting the Demand for Aircraft Recoverable Spare Parts. Retrieved from. [Google Scholar]

- Amling A., Post G., Zamsky D., Rankin K., Marcus S., Woods B. Google Patents. 2005. Systems and methods for integrated global shipping and visibility. [Google Scholar]

- Aven W.M., Root D.R. 1980. A Study of the Computational Requirements for Spares in the USAF A-10 SAIP Program. Retrieved from. [Google Scholar]

- Balwally N.M. 1991. Forecasting Digital Microcircuit Obsolescence. Retrieved from. [Google Scholar]

- Biggart T.B., Gargeya V.B. Impact of .I.T.J.I.T. on inventory to sales ratios. Ind. Manag. Data Syst. 2002 [Google Scholar]

- Botter R., Fortuin L. Stocking strategy for service parts–a case study. Int. J. Oper. Prod. Manag. 2000 [Google Scholar]

- Cassady C., Mendoza A., Ormon S., Schneider K., Rainwater C., Carrasco M.…Honeycutt J. 2003. Quantifying the Impact of Aircraft Cannibalization. Retrieved from. [Google Scholar]

- Chelbi A., Rezg N. Analysis of a production/inventory system with randomly failing production unit subjected to a minimum required availability level. Int. J. Prod. Econ. 2006;99(1-2):131–143. [Google Scholar]

- Chenoweth M.E., Arkes J., Moore N.Y. 2010. Best Practices in Developing Proactive Supply Strategies for Air Force Low-Demand ServiceParts. Retrieved from. [Google Scholar]

- Croston J.D. Forecasting and stock control for intermittent demands. J. Oper. Res. Soc. 1972;23(3):289–303. [Google Scholar]

- Donaldson S.A. Section six of the office of federal procurement policy act amendments of 1988: a new ethical standard in government contracting. Cumberl. Law Rev. 1989;20:421. [Google Scholar]

- Duran O., Perez L. Paper Presented at the International Conference on Computational Science and its Applications. 2014. Optimization of the multiechelon system for repairable spare parts using swarm intelligence combined with a local search strategy. [Google Scholar]

- Fortuin L., Martin H. Control of service parts. Int. J. Oper. Prod. Manag. 1999 [Google Scholar]

- Fritzsche R. Cost adjustment for single item pooling models using a dynamic failure rate: a calculation for the aircraft industry. Transport. Res. E Logist. Transport. Rev. 2012;48(6):1065–1079. [Google Scholar]

- Ghobbar A.A., Friend C.H. Sources of intermittent demand for aircraft spare parts within airline operations. J. Air Transport. Manag. 2002;8(4):221–231. [Google Scholar]

- Graham R. 1988. Life Cycle Costing in Spare Parts Procurement: a Decision Model. Retrieved from. [Google Scholar]

- Houlihan J.B. International supply chains: a new approach. Manag. Decis. 1988;26(3):13–19. [Google Scholar]

- Jacobs F.R., Chase R.B., Lummus R.R. McGraw-Hill/Irwin; New York, NY: 2014. Operations and Supply Chain Management. [Google Scholar]

- John B., Robert T.P. 2004. Material Requirement Planning in Aircraft Maintenance. [Google Scholar]

- Jones T.C., Riley D.W. Using inventory for competitive advantage through supply chain management. Int. J. Phys. Distrib. Mater. Manag. 1985 [Google Scholar]

- Kent G. Black Publishers Ltd; 2001. Global Logistics Management-A Competitive Advantage for the New Millennium. [Google Scholar]

- La Londe B.J., Masters J.M. Emerging logistics strategies. Int. J. Phys. Distrib. Logis. Manag. 1994 [Google Scholar]

- Lambert D., Stock J.R., Ellram L.M., Grant D. First European Edition. McGraw-Hill; 2006. Fundamentals of Logistics Management. [Google Scholar]

- Lorentz H., Shi Y., Hilmola O.P., Srai J., de Souza R., Tan A.W.K.…Garg M. A proposed framework for managing service parts in the automotive and aerospace industries. Benchmark Int. J. 2011 [Google Scholar]

- Louit D., Pascual R., Banjevic D. Optimal interval for major maintenance actions in electricity distribution networks. Int. J. Electr. Power Energy Syst. 2009;31(7-8):396–401. [Google Scholar]

- Makridakis S., Wheelwright S., Hyndman R. Jhon Wiley & Sons. In: Inc; New York: 1998. Forecasting Methods and Applications. [Google Scholar]

- Mattsson S.-A., Jonsson P. Studentlitteratur, Lund. 2005. Logistik: Läran om effektiva materialflöden. [Google Scholar]

- Monczka R.M., Trent R.J., Handfield R.B. South-Western Pub; 2002. Purchasing and Supply Chain Management. [Google Scholar]

- Oskarsson B., Aronsson H., Ekdahl B. 2013. Modern Logistik: För Ökad Lönsamhet: Liber. [Google Scholar]

- Peltz E., Robbins M., McGovern G. 2012. Integrating the Department of Defense Supply Chain. Retrieved from. [Google Scholar]

- Peltz E., Robbins M.L., Girardini K.J., Eden R., Halliday J.M., Angers J. 2005. Sustainment of Army Forces in Operation Iraqi Freedom: Major Findings and Recommendations. Retrieved from. [Google Scholar]

- Pfunder K. Paper Presented at the APICS-Fall Seminar Proceedings, Orlando, FL. 1986. Selecting the right approach to establish .R.O.M.R.O. Stocking levels. [Google Scholar]

- Ragsdale C.T., Plane D.R. On modeling time series data using spreadsheets. Omega. 2000;28(2):215–221. [Google Scholar]

- Relph G., Milner C. Kogan Page Publishers; 2015. Inventory Management: Advanced Methods for Managing Inventory within Business Systems. [Google Scholar]

- Salman S., Cassady C.R., Pohl E.A., Ormon S.W. Evaluating the impact of cannibalization on fleet performance. Qual. Reliab. Eng. Int. 2007;23(4):445–457. [Google Scholar]

- Sherbrooke C.C. Vol. 72. Springer Science & Business Media; 2006. (Optimal Inventory Modeling of Systems: Multi-Echelon Techniques). [Google Scholar]

- Snyder D., Mills P. 2004. Supporting Air and Space Expeditionary Forces: A Methodology for Determining Air Force Deployment Requirements. Retrieved from. [Google Scholar]

- Stevens G.C. Integrating the supply chain. Int. J. Phys. Distrib. Mater. Manag. 1989 [Google Scholar]

- Storhagen N.G. 2003. Logistik: Grunder Och Möjligheter: Liber Ekonomi. [Google Scholar]

- Lee Taehee, Nam Hyunjeong. An empirical study on the impact of individual and organizational supply chain orientation on supply chain managemen. Asian J. Ship. Logist. 2016;32(Issue 4):249–255. [Google Scholar]

- Tracht K., von der Hagen F., Schneider D. Applied repairable-item inventory modeling in the aviation industry. Procedia CIRP. 2013;11:334–339. [Google Scholar]

- Tracy E.A. 1985. Component Obsolescence: Presentation of a Decision Process for Assessing and Selecting Alternative Solutions Applicable to Major Weapon Systems Production. Retrieved from. [Google Scholar]

- Tysseland B.E. Spare parts optimization process and results: OPUS10 cases in the Norwegian Defence. Int. J. Phys. Distrib. Logist. Manag. 2009;39(1):8–27. [Google Scholar]

- Winters P.R. Forecasting sales by exponentially weighted moving averages. Manag. Sci. 1960;6(3):324–342. [Google Scholar]

- Wynn M.E., III . Naval postgraduate school; 1992. Spare parts non-availability: the identification of impediments to spares acquisition. 1992. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.