Abstract

Peroxisome proliferator-activated receptor alpha (PPARα) is expressed in retinal Müller cells, endothelial cells, and in retinal pigment epithelium, and agonism of PPARα with genetic or pharmacological tools ameliorates inflammation, vascular leakage, neurodegeneration, and neovascularization associated with retinal diseases in animal models. As such, PPARα is a promising drug target for diabetic retinopathy and age-related macular degeneration. Herein, we report proof-of-concept in vivo efficacy in an STZ-induced vascular leakage model (rat) and preliminary pharmacokinetic assessment of a first-generation lead 4a (A91). Additionally, we present the design, synthesis, and evaluation of second-generation analogs, which led to the discovery of 4u and related compounds that reach cellular potencies <50 nM and exhibit >2,700-fold selectivity for PPARα over other PPAR isoforms. These studies identify a pipeline of candidates positioned for detailed PK/PD and pre-clinical evaluation.

Keywords: PPARα, age-related macular degeneration, diabetic retinopathy, PPAR selectivity, structure-based design

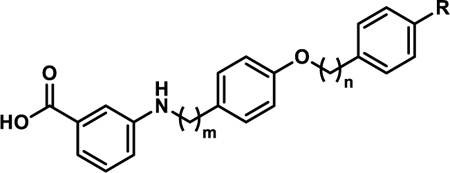

Graphical Abstract

INTRODUCTION

Diabetic retinopathy (DR) is a common complication of diabetes (~30% of diabetics) and is the leading cause of blindness in the working population.1 Currently, >40% of the patient population fails to respond to the gold-standard treatment, direct intraocular injection of vascular endothelial growth factor (VEGF) antibodies.2 New therapies that are superior or complementary to current approaches would be of great value to patients, especially for those that remain refractory to current options. Ideally, unlike current treatment options, new approaches should be non-invasive (to the eye), affordable, and not reliant on specialized facilities.

The promise of peroxisome proliferator-activated receptor alpha (PPARα) agonism as a novel strategy for treating DR has been confirmed in two independent human clinical trials (FIELD and ACCORD), wherein orally administered Fenofibrate (Feno), a clinically used drug for hyperlipidemia, demonstrated robust protective effects against DR and retinal neovascularization (NV) in type 2 diabetic patients.3–4 This protection greatly reduced the need for patients to undergo disease modifying laser photocoagulation therapy. Since the report of these results, mechanistic and genetic studies have determined that the protective effects of Feno are unrelated to its lipid-lowering activity, but rather result from agonism of PPARα by the Feno metabolite fenofibric acid (FenoFA).5–6 Feno/FenoFA however, suffer from low ocular distribution, low affinity and selectivity for PPARα, and dose-limiting toxicities, all of which will likely limit its use as a DR therapy. Proof-of-concept, however, for targeting retinal PPARα with systemically available small molecules has been established with Feno and revealed that small molecule agonists with improved PK/PD profiles have high promise to become first-in-class non-invasive treatment options for DR and related ocular conditions (e.g., age-related macular degeneration and retinopathy of prematurity).7–8

As important members of the nuclear receptor superfamily, PPARs play essential roles in regulating cellular differentiation, development, metabolism, and tumorigenesis of higher organisms. Thus, these receptors have been considered attractive targets for treating metabolic disorders and inflammatory conditions.9–10 PPARs consist of 3 subtypes: PPARα, PPARγ and PPARδ/β. Although the ligand-binding domains share high sequence similarity (60–70%), the isoforms exhibit distinct tissue distribution, biological functionality, and can be targeted selectively.11 Within this family, PPARα has been implicated in hyperlipidemia, diabetes and inflammatory disorders; and agonism of this isoform provides pharmacological benefits for these conditions.12–13 Only recently, however, have the roles of PPARα in regulating VEGF, inflammation, mitochondrial function, apoptosis, and NV in diabetic retinae been revealed, thus elucidating a new avenue for PPARα agonists as therapeutics for oculovascular diseases.14–15 Specifically, previous studies demonstrate that PPARα knockout alone results in retinal mitochondrial dysfunction, a declined electroretinogram (ERG) response, and retinal cell apoptosis.16 Furthermore, PPARα levels in the retina are decreased in diabetic animal models and in diabetic humans and that agonism of PPARα restores balance.14–15 Although PPARα agonism was intensely investigated in the 1990s as a therapeutic approach for dyslipidemia, and numerous potent agonists exist in literature, none of the known chemotypes have been evaluated in animal models for efficacy against retinal conditions. Rather than attempting to repurpose known compounds, often lacking full disclosure of physicochemical and PK/PD profiles, we decided to embark on a discovery process to identify and develop novel PPARα agonistic chemotypes as new compositions for DR and AMD leads.

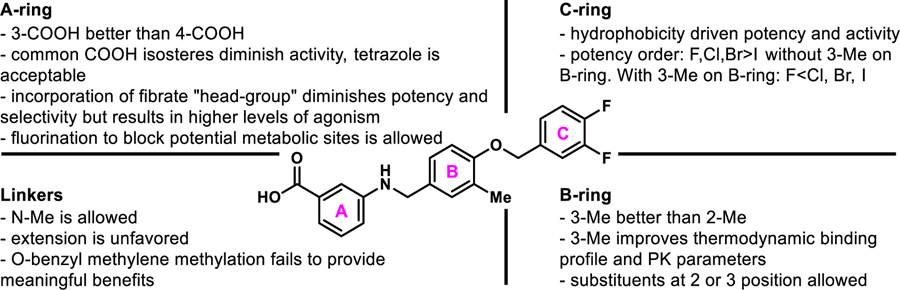

Recently, we published first-generation structure activity relationship (SAR) studies on a new PPARα agonistic chemotype, 4-carboxy-2-phenylquinolines, represented by Y-0452 (Figure 1).17 Guided by in-silico studies, we proposed that deconstruction of the rigid quinoline core would provide a more synthetically tractable and flexible scaffold, expected to exhibit improved complementarity to the U-shaped ligand binding pocket. Based on this design strategy, we developed the 4-benzyloxy-benzylamino chemotype to assess our hypothesis. In general, this small molecule family exhibits improved potency and selectivity over both Y-0452 (initial hit) and FenoFA, thus validating our rationale for further development of this chemotype and pursuing proof of concept studies. Compound A91 (Figure 1), a representative analogue from this series was advanced through rigorous biochemical evaluation to demonstrate typical downstream responses of PPARα agonism including PPARα upregulation, induction of target genes (e.g., Acadm, Cpt1a, Fabp3, and Slc25a20) and attenuation of cell migration.17 Having identified a new class of PPARα agonists and demonstrating useful SAR, the purpose of the work presented herein was to assess the preliminary PK and in vivo protection against vascular leakage of A91 to establish proof-of-concept and develop second-generation derivatives aimed at improving potency and selectivity of this chemotype.

Figure 1.

Overall strategy for hit optimization and the objective of the studies presented herein.

RESULTS AND DISCUSSION

PK/PD Profile of First-Generation Lead.

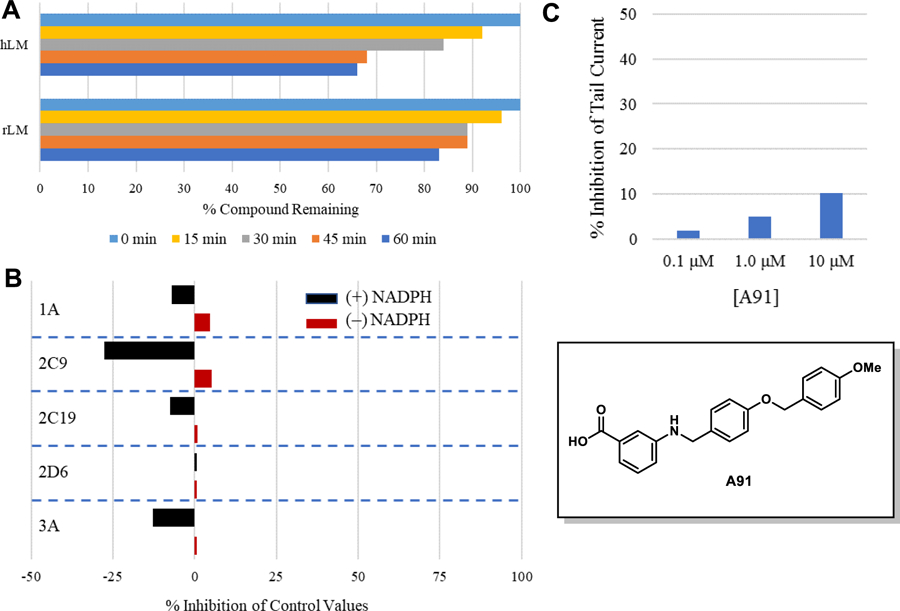

To gain insight about the metabolic stability and rate of clearance, both of which influence bioavailability, A91 was assessed for intrinsic clearance in human and rat (Sprague-Dawley) liver microsomes. As shown in Figure 2A, compound A91 proved to be rather stable, with the mean half-life (t1/2) exceeding 60 minutes in both human and rat microsomes. These results indicate that this chemotype is likely to exhibit low clearance and that phase-I hepatic metabolism is unlikely to limit bioavailability.

Figure 2. Pharmacokinetic profile of A91.

(A) Stability in liver microsomes. A91 was pre-incubated with pooled liver microsomes in phosphate buffer (pH 7.4) for 5 min at 37 °C. The system was activated by the addition of an NADPH-regenerating system and incubated for 0, 15, 30, 45, and 60 min before being quenched with an acetonitrile/methanol mixture. Samples were processed and analyzed by HPLC-MS/MS to determine the peak area remaining. Experiments completed in duplicate and mean values are depicted. (B) Assessment of A91 (10 μM) for irreversible inhibition of the major CYP450 drug metabolizing isoforms. Peak areas corresponding to the metabolite of known substrates for each isoform are recorded. The percent of control activity was calculated by comparing the peak area obtained in the presence of A91 to that obtained in the absence of A91. Percent inhibition was calculated by subtracting the percent control activity from 100. Time-dependent CYP inhibition is demonstrated if the percent inhibition from samples pre-incubated with the NADPH-regenerating system is larger than those without NADPH-regeneration. Negative values are a reflection of the variability in the background noise of the experiment. Experiments completed in duplicate and mean values are depicted. (C) Assessment of A91 for inhibition of the hERG channel. The degree of inhibition (%) was obtained by measuring the tail current amplitude, which is induced by a one-second test pulse to −40 mV after a two-second pulse to +20 mV, before and after drug incubation. Experiments completed in duplicate and mean values are depicted.

In parallel, A91 was assessed for evidence of time-dependent inhibition against the major drug metabolizing cytochrome P450 isoforms (i.e., 1A, 2C9, 2C19, 2D6, and 3A). In this assay, peak areas corresponding to the metabolite of control substrates were recorded in the presence or absence of A91. This analysis was completed in the presence and absence of NADPH, to reveal time-dependence of inhibition. Test compounds which exhibit higher inhibition of metabolite formation in the absence of NADPH are deemed time-dependent inhibitors. As shown in Figure 2B, A91 exhibits no evidence of time-dependent inhibition for any of the CYP450s evaluated. This observation is especially important for CYP3A, as this family is responsible for the metabolism of statins, a drug class required for a majority of diabetics. These results indicate that CYP drug-drug interactions due to irreversible or tight binding are unlikely with this chemotype.

Lastly, A91 was evaluated for inhibition of the human ether-á-go-go (hERG) potassium channel. Inhibition of this channel is a flagship sign of cardiac toxicity. For this experiment, the automated whole cell patch-clamp (Qpatch 48) technique was used to record outward potassium currents from a single cell in the presence and absence of the compound of interest. As shown in Figure 2C, compound A91 exhibits low potency for the hERG channel (compounds that exhibit ≥50% inhibition at 10 μM are flagged as toxic), indicating that this chemotype is unlikely to exhibit hERG-related cardiotoxicity, especially if potency for PPARα is improved. It is also worth noting that A91 exhibits no measurable cytotoxicity in the retinal pigment epithelium photoreceptor cell-line 661W at concentrations as high as 200 μM as measured in a colorimetric enzyme coupled LDH detection cytotoxicity assay (supplementary).

In vivo Efficacy of First-Generation Lead.

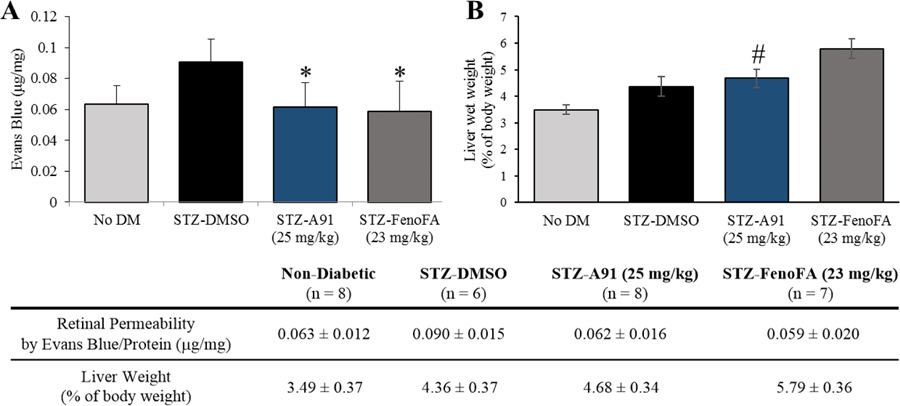

With a promising initial PK profile, and cellular potency and selectivity surpassing FenoFA, we advanced A91 to proof-of-concept in vivo efficacy studies in a well-established streptozotocin (STZ)-induced rat model of DR, which assesses the ability of a compound of interest to attentuate retinal vascular leakage—a major culprit behind diabetic macular edema and consequential vision loss. As shown in Figure 3A, systemic administration (i.p.) of compound A91 reduces retinal vascular leakage in diabetic rats to the range of the non-diabetic cohort at relatively the same dose as FenoFA. Of interesting note, A91 seems to lack signs of hepatomegaly (Figure 3B), a common side-effect of Feno/FenoFA observed in rodent models but not in humans. These in vivo results paired with the initial PK assessment, demonstrate that A91 1) exhibits in vivo efficacy in a relevant DR model following systemic administration, 2) crosses the blood-retinal barrier and reaches the retina, 3) is bioavailable, 4) survives first-pass metabolism and clearance mechanisms well enough to maintain efficacy, and 5) demonstrates a relatively safe profile (no observable toxicity) after daily i.p. injection for one-month.

Figure 3.

(A) Effects on retinal permeability and (B) liver phenotype for compound A91 in comparison to FenoFA. 7–8 week-old male Brown Norway rats were injected with streptozotocin (STZ, 55 mg/kg) to induce diabetes. Two weeks after STZ injections, daily treatment (i.p. injection) with compound A91 or FenoFA commenced and lasted for 28 days. Student’s t-test was used to compare groups for statistical significance and values are mean ± SD, # P<0.05 (vs. FenoFA), Retinal permeability was measured using Evans blue as tracer and normalized by total retinal protein. *P<0.05 (vs. STZ-DMSO).

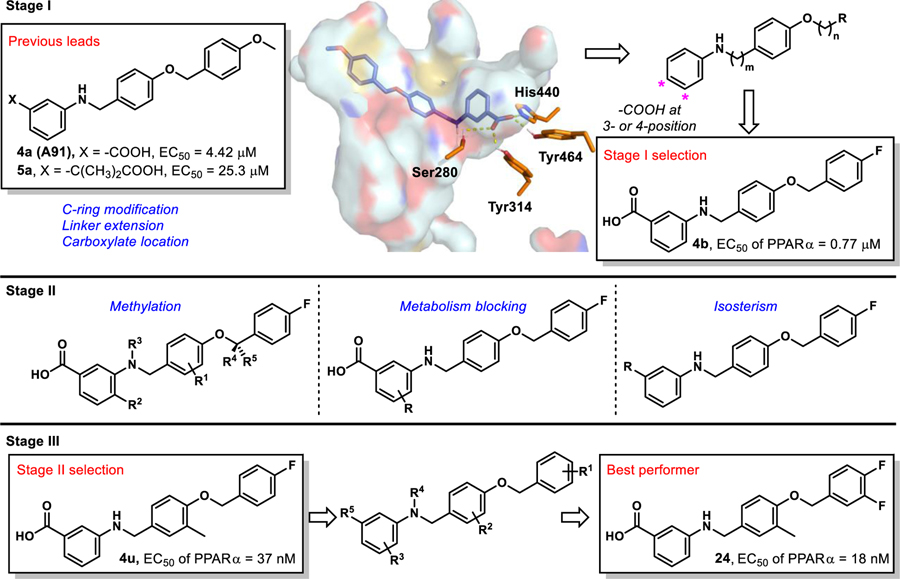

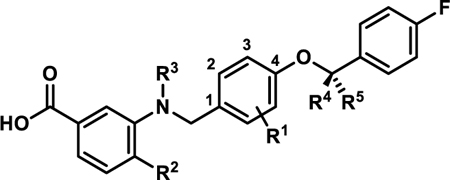

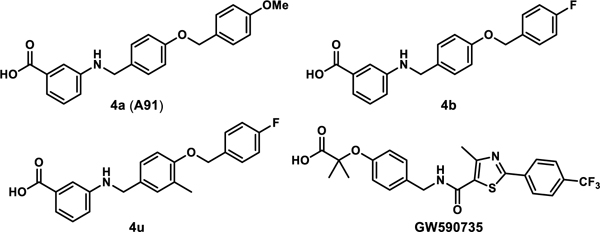

Inspired by promising PK and in vivo results for A91, we commenced second-generation SAR studies with an aim of enhancing potency and isoform selectivity of this chemotype for PPARα. Since no co-crystal structure of A91 existed at the onset of this work, we developed an in-silico model using the Schrodinger Drug Discovery Suite to gain insight into the putative binding mode and guide our evolution of this chemotype. For these studies we selected PDB 2P54, a co-crystal structure of a known PPARα selective agonist GW590735 bound to human PPARα (hPPARα). To validate our docking approach, constraints, and parameters, GW590735 was extracted, exposed to MM2 energy-minimization, and re-docked into the hPPARα ligand binding domain to ensure that the results reproduced the bound conformation of the ligand. The overlay of co-crystallized and docked GW590735 showed excellent congruence (RMSD = 0.155 Å). Maintaining the same constraints and parameters, A91 was docked into hPPARα and the results were visually inspected for strategies to improve or introduce key interactions. Since our gatekeeper assay is a cell-based assessment and thus not based on direct binding affinity, scores were not used to prioritize ligands at this stage. Instead, visual inspection and structural modification hypotheses dictated the prioritization of derivatives selected for synthesis and assessment.

Our approach focused on three key principles. First, maintain a suitably positioned carboxylate (or isostere) to capture key hydrogen bonding interactions. Previous studies demonstrate the significance of hydrogen bond interactions between hPPARα Ser280, Tyr314, His440, and Tyr464 on the AF-2 helix and the carboxylate of known PPARα ligands.18–25 The ability to interact with all four of these residues is believed to be responsible for triggering full agonism of hPPARα.19 Poorer agonists tend to only interact with some of these hydrogen-bonding partners. It is worth noting that while historical PPARα literature suggests a carboxylic acid is required for activity (a pharmacophore), examples of PPARα agonists lacking this functionality have been reported,13, 26 demonstrating the -COOH motif can be altered. Secondly, we wanted to maintain the N-benzyl linkage to provide a complementary geometry for the U-shaped architecture of the ligand-binding domain. Third, our in-silico studies consistently predicted the aryl tail (C-ring) to bind a hydrophobic pocket comprised of helices 6 and 7 and defined by Ile241, Leu247, Ala250, Leu254, and Ala333. Literature precedence demonstrates that improvement of this interaction with other PPARα chemotypes has proven beneficial to enhancing ligand potency and selectivity.23–25

Stage I SAR: Linker Extension, C-Ring Modification, Carboxylate Location.

The first stage of our SAR (Figure 4) focused on assessing various hydrophobic substituents on the C-ring, probing the effects of linker extension, and determining optimal location for the carboxylate motif (or isostere).

Figure 4.

Multi-stage approach to structural improvement of A91. Model depicts 4a (A91) docked to PDBID 2P54.

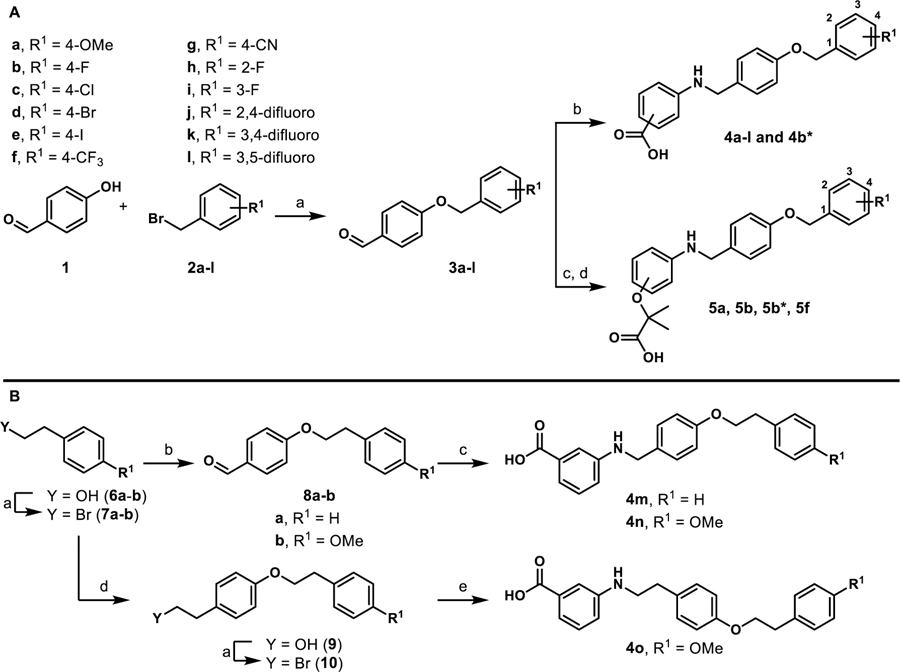

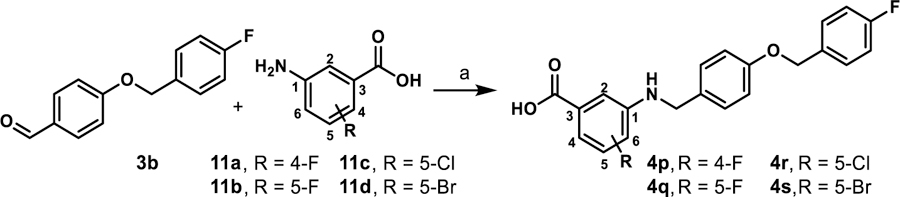

To generate stage I analogues, 4-hydroxybenzaldehyde (1) was coupled with various benzyl bromides (2a-l) to yield the corresponding 4-benzyloxy-benzaldehydes 3a-l (Scheme 1A). These precursors were then coupled with 3-aminobenzoic acid (or 4-aminobenzoic acid in the case of 4b*) via reductive amination to obtain 4a-4l and 4b*. Following a similar synthetic approach, 5a, 5b, 5b*, and 5f that include the typical fibrate head-group were synthesized (Scheme 1A). The only difference in the generation of 5a, 5b, 5b* and 5f was that the carboxylate remained protected as the ethyl ester until being revealed in the final step following saponification. Our previous studies indicated that the 4-benzyloxy-benzylamino chemotype deviates from the fibrates in that incorporation of the classical α-gem-dimethyl carboxylate “head-group” leads to pan-agonism and decreases potency. While these affects are obviously opposite to our goals, these analogues were generated to determine if this trend continued to propagate through this series.

Scheme 1.

Synthesis of stage I analoguesa

aReagents and conditions: A) (a) K2CO3, DMF; (b) i) 3-aminobenzoic acid or 4-amino benzoic acid, toluene, 130 °C, 2–3 h; ii) NaBH(OAc)3, acetic acid, THF, 12 h, 32–97%; (c) i) ethyl 2-(3-aminophenoxy)-2-methylpropanoate or ethyl 2-(4-aminophenoxy)-2-methylpropanoate, toluene, 130 °C, 2–3 h; ii) NaBH(OAc)3, acetic acid, THF, 12 h; (d) LiOH·H2O, THF/CH3OH/H2O, 12 h, 14–60%. B) (a) PBr3, diethyl ether; (b) 4-hydroxybenzaldehyde, K2CO3, DMF, 40–65%; (c) 3-aminobenzoic acid, toluene, 130 °C, 2–3 h; ii) NaBH(OAc)3, acetic acid, THF, 12 h, 96%; (d) tyrosol, K2CO3, DMF, 26%; (e) 3-aminobenzoic acid, Et3N, DMF, 25%. All yields reported are unoptimized. Asterisks indicate the -COOH motif is attached para instead of meta.

To generate derivatives with extended linkers the synthesis began with the transformation of primary alcohols 6a-b into the corresponding alkyl bromides 7a-b (Scheme 1B). These precursors were then utilized to O-alkylate 4-hydroxybenzaldehyde to generate 8a-b, which were coupled with 3-aminobenzoic acid through reductive amination to provide 4m and 4n that included an extra –CH2– between the B and C-rings (Scheme 1B). Analogue 4o with an additional –CH2– between the A and B rings and the B and C rings was also generated. Chemoselective alkylation of tyrosol with 7b afforded 9, which was converted to the corresponding alkyl bromide 10 that was used to N-alkylate 3-aminobenzoic acid (Scheme 1B).

Stage I derivatives were evaluated for in vitro human PPARα (hPPARα) agonism in a commercially available hPPARα luciferase cell reporter assay (Indigo Biosciences). This assay utilizes non-human mammalian cells engineered to express hPPARα with the luciferase reporter gene functionally linked to a PPARα-response promoter. Thus, quantifying changes in luciferase expression in compound treated reporter cells provides a sensitive method to quantify changes in PPARα activity. As an initial first-pass assessment, all compounds were evaluated at two concentrations, 5 μM and 50 μM. This two-concentration approach is a cost-effective means to provide insight into 1) rough estimates of potency, 2) therapeutic window, and 3) relative levels of agonism. A 5:50 ratio <<1.0 indicates the compound is much more active at 50 μM than 5 μM, meaning the compound has poor potency. A 5:50 ratio ~1.0 indicates equal activity at both concentrations, meaning the EC50 is <5 μM and is non-cytotoxic to the cells at a 10-fold higher concentration, as cell death results in a decrease in luminescence production. As one would presume, a 5:50 ratio of >1.0 indicates a potency <5 μM, but also demonstrates toxicity at 50 μM. Therefore, 5:50 ratios of ~1.0 are desirable. GW590735, a highly selective (≥500-fold over PPARγ and PPARδ) PPARα partial agonist was employed as a positive control.24

In line with our hypothesis, the incorporation of lipophilic or electron withdrawing substituents on the C-ring of the benzoic acid chemotype (4b-l) provides an improvement in cellular activity in comparison to A91 (4a). Most analogues in the 4b-l series exhibit 5:50 ratios >0.5, indicating EC50 values <5 μM (Table 1). Comparison of 4b and 4b* demonstrates that the 3-carboxylate is favored over the 4-carboxylate. Within this class, we advanced 8 derivatives to multi-point dose-response analysis in the same luciferase assay. Compounds were chosen based on a combination of interest, 5:50 ratio, and level of agonism. As shown in Table 1, the 4-F (4b), 4-Br (4d), 2,4-difluoro (4j), and 3,4-difluoro (4k) analogues all exhibit submicromolar activity and are ~2–3 fold more active than the 4-I (4e) and 4-CF3 (4f). This result was somewhat forecasted by our in-silico results, which predicted that substituents larger than a bromine at the 4-position would be problematic. Even though the 3-F (4i) is less active than the 4-F (4b), it was still more active than A91. Thus, it is not surprising that inclusion of fluorine at both the 3- and 4-positions (4k) of this scaffold results in additive properties and is the most potent compound of this series. Inclusion of the typical fibrate head-group (5a, 5b, 5b*, and 5f) once again leads to decreased potency (Table 2) but often higher levels of agonism than the benzoic acid relatives (5a vs A91, 5b vs 4b, and 5f vs 4f). As shown in Table 3, analogs containing extended linkers 4m–4o exhibited poor potency (4m and 4n) or poor activation (4o) in comparison to related non-homologated derivatives.

Table 1.

In vitro Activity of 4a-la

| |||||||

|---|---|---|---|---|---|---|---|

| Compound | R | Ratio (5/50)b | Fold-Signalc | EC50 hPPARα (μM)d | EC50 hPPARγ (μM) | EC50 hPPARδ (μM) | SIe |

| 4a (A91) | 4-OMe | 0.5 | 1.4 | 4.43±0.01 | >100 | >100 | >20 |

| 4b | 4-F | 0.8 | 1.3 | 0.77±0.03 | >100 | >100 | >125 |

| 4b* | 4-F | 0.3 | 0.4 | ||||

| 4c | 4-Cl | 0.6 | 1.5 | 0.83±0.04 | |||

| 4d | 4-Br | 0.8 | 1.3 | 0.97±0.14 | |||

| 4e | 4-I | 0.7 | 1.1 | 1.45±0.02 | |||

| 4f | 4-CF3 | 0.9 | 0.9 | 0.96±0.11 | |||

| 4g | 4-CN | 0.6 | 1.0 | ||||

| 4h | 2-F | 0.8 | 1.0 | ||||

| 4i | 3-F | 0.9 | 1.2 | 1.18±0.05 | |||

| 4j | 2,4-difluoro | 1.2 | 1.2 | 0.54±0.09 | >100 | >100 | >175 |

| 4k | 3,4-difluoro | 1.1 | 1.2 | 0.36±0.01 | |||

| 4l | 3,5-difluoro | 1.1 | 1.1 | ||||

| GW590735 | 1.0 | 1.0 | 0.015±0.002 | ||||

| Rosiglitazone | 0.28±0.3 | ||||||

| GW0742 | 0.0019±0.002 | ||||||

All analogues contain the carboxylate head-group at the meta-position of the A-ring unless otherwise indicated.

indicates a para-carboxylate.

Ratio of relative light unit (RLU) signal at 5 μM and 50 μM compound concentrations.

Ratio of maximal signal strength observed for the compound of interest to that obtained with GW590735.

EC50 values represent the mean ± SEM of atleast two separate experiments performed in triplicate.

SI = EC50 (PPARγ or PPARδ) / EC50 (PPARα). Blank cells indicate compound was not selected for testing in the corresponding assay.

Table 2.

All analogues contain the carboxylate head-group at the meta-position of the A-ring unless otherwise indicated.

indicates a para-carboxylate.

Ratio of relative light unit (RLU) signal at 5 μM and 50 μM compound concentrations.

Ratio of maximal signal strength observed for the compound of interest to that obtained with GW590735.

Table 3.

In vitro Activity of 4m-o

Ratio of relative light unit (RLU) signal at 5 μM and 50 μM compound concentrations.

Ratio of maximal signal (RLU) strength observed for the compound of interest to that obtained with GW590735.

From the stage I cohort, analogues 4b and 4j were selected to move forward to selectivity assessment, wherein equivalent luciferase assays were conducted on isogenic cell-lines engineered to overexpress either hPPARγ or hPPARδ. Neither compound produced significant levels of hPPARγ or hPPARδ agonism up to 100 μM compound concentration, indicating a selectivity of >125-fold (4b) and >175-fold (4j) for hPPARα. Rosiglitazone, a known selective PPARγ agonist, and GW0742, a known selective PPARδ agonist, were employed as positive controls in these isogenic cell-lines.

Stage II SAR: Strategic Methylation, Metabolism Blocking, Carboxylate Isosteric Replacement.

From the stage I results, compound 4b was selected as the base structure from this family for advancement. Three strategies were leveraged to advance the SAR in stage II 1) methylation at strategic positions within the scaffold that were expected to enhance complementarity with the shape and hydrophobicity of the PPARα ligand binding pocket; 2) blockage of predicted sites of metabolism; and 3) isosteric replacement of the carboxylate.

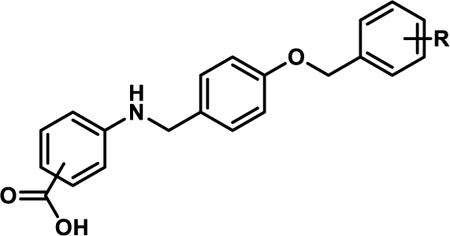

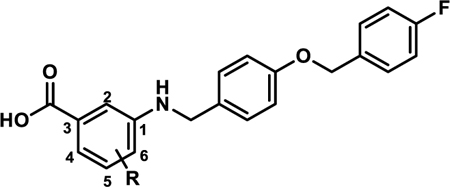

In silico prediction of major sites of metabolism for A91 with Schrodinger’s P450 Site of Metabolism software identified the A-ring as a potential liability for CYP450 oxidation (supplementary). As such, we synthesized 4p and 4q (Scheme 2) to interrogate the effects of fluorine blockage on activity. These two analogues were generated by coupling 3b to 5-amino-2-fluorobenzoic acid (11a) or 5-amino-3-fluorobenzoic acid (11b) to produce 4p and 4q, respectively. The 5-fluoro variant (4q) exhibits a ~3-fold improvement in activity over the 4-fluoro derivative (4p) and is nearly equipotent to 4b (Table 4). Interestingly, incorporation of a chlorine at the 5-position of the A-ring (4r) greatly decreases potency (5:50 ratio = 0.11), while incorporation of a bromine at the 5-position (4s) maintains potency in comparison to 4b but introduces apparent cytotoxicity at elevated concentrations (5:50 ratio = 1.3). These results suggest that fluorine incorporation should be a viable strategy to block sites on the A-ring if proven to be problematic as this series progresses through development.

Scheme 2.

Synthesis of 4p-4sa

aReagents and conditions: (a) i) 11, toluene, 130 °C, 2–3 h; ii) NaBH(OAc)3, acetic acid, THF, 25 °C, 12 h, 78–86%.

Table 4.

In vitro Activity of 4p-s

| |||||||

|---|---|---|---|---|---|---|---|

| Compound | R | Ratio (5/50)a | Fold-Signalb | EC50 hPPARα (μM)c | EC50 hPPARγ (μM) | EC50 hPPARδ (μM) | SId |

| 4p | 4-F | 0.8 | 1.2 | 1.61±0.06 | |||

| 4q | 5-F | 1.1 | 1.1 | 0.58±0.04 | >100 | >100 | >170 |

| 4r | 5-Cl | 0.1 | 1.1 | ||||

| 4s | 5-Br | 1.3 | 1.4 | 1.12±0.08 | >100 | >100 | >100 |

Ratio of relative light unit (RLU) signal at 5 μM and 50 μM compound concentrations.

Ratio of signal maximal signal (RLU) strength observed for the compound of interest to that obtained with GW590735.

EC50 values represent the mean ± SEM of atleast two separate experiments performed in triplicate.

EC50 (PPARγ or PPARδ) / EC50 (PPARα). Blank cells indicate compound was not selected for testing in the corresponding assay.

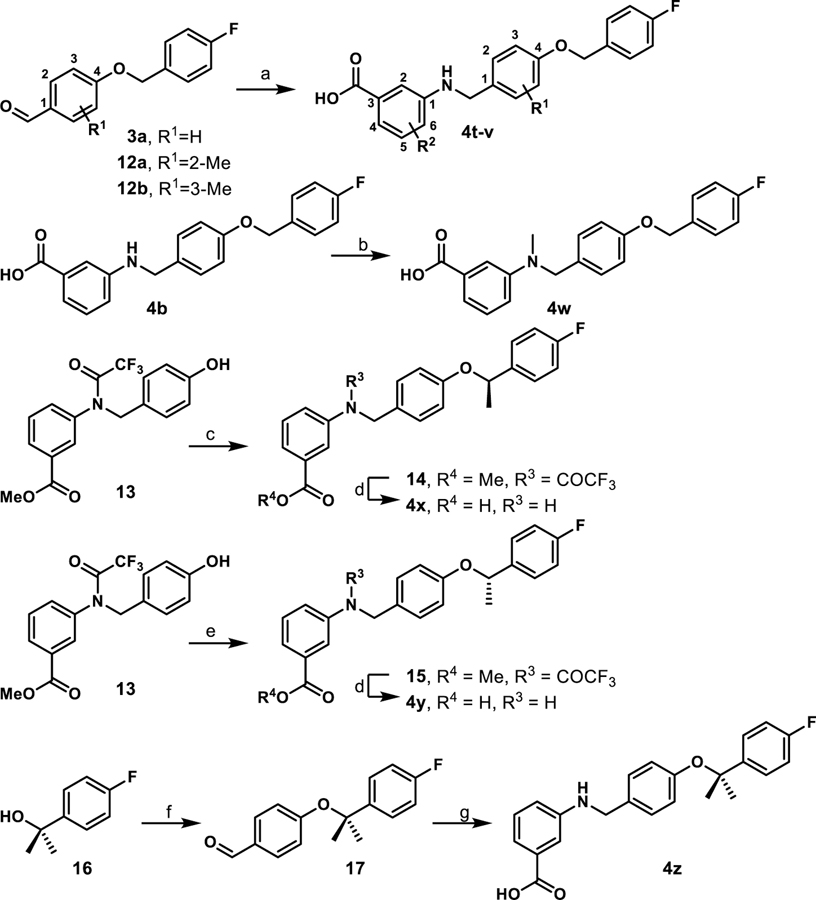

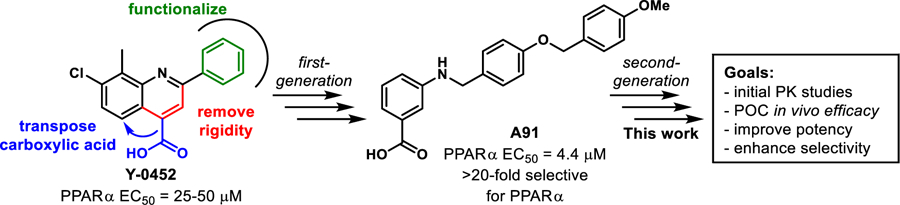

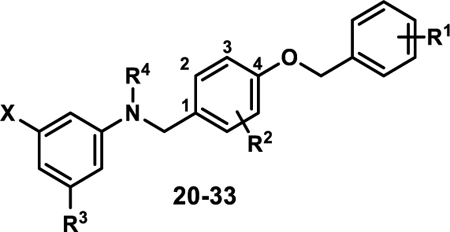

Inspired by frequently reported methyl effects in drug discovery,27 analogues containing one or two methyl groups at different positions were synthesized (Scheme 3) using variations of chemistry discussed in Schemes 1 and 2 and evaluated in the luciferase assay (4t-z, Table 5). Specifically, we interrogated the effects of methylation on the 2- and 3-position of the B-ring, the 4-position of the A-ring, the nitrogen linker, and all possible variations on the benzylic position of the linker between the B- and C-rings (another predicted site of metabolic liability). Interestingly, installation of a methyl group at the 3-position of B-ring (4u) resulted in a drastic improvement in cellular activity, dropping the EC50 to ~40 nM, a ~21-fold improvement from the des-methyl relative, 4b, and improving the selectivity for the PPARα isoform to >2,700-fold (Figure 5). However, methylation at alternate sites (4t and 4v-z) failed to induce similar effects on the activity, indicating that the improvement observed with 4u is not likely to arise from an increase in general hydrophobicity but rather from improving aspects of target engagement.

Scheme 3.

Synthesis of methylated derivatives 4t-za

aReagents and conditions: (a) i) 3-aminobenzoic acid or 3-amino-4-methylbenzoic acid, toluene, 130 °C, 2–3 h; ii) NaBH(OAc)3, acetic acid, THF, 25 °C, 12 h, 70–92%; (b) paraformaldehyde, NaBH(OAc)3, EtOH, reflux 2 h, 25 °C, 12 h, 43%; (c) (R)-1-(4-fluorophenyl)ethan-1-ol, di-tert-butyl azodicarboxylate, PPh3, toluene; (d) LiOH·H2O, THF/CH3OH/H2O, 25 °C, 12 h, 65–75%.; (e) (S)-1-(4-fluorophenyl)ethan-1-ol, di-tert-butyl azodicarboxylate, PPh3, toluene; f) 4-hydroxybenzaldehyde, TFAA, DBU, CuCl2, MeCN, 8%; (g) i) 3-aminobenzoic acid, toluene, 130 °C, ii) NaBH(OAc)3, AcOH, THF, 12 h, 25%. All yields reported are unoptimized.

Table 5.

In vitro Activity of 4t-z

| |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Compound | R1 | R2 | R3 | R4 | R5 | Ratio (5/50)a | Fold-Signalb | EC50 hPPARα (μM)c | SId |

| 4t | 2-Me | H | H | H | H | 0.8 | 1.2 | 1.45±0.06 | |

| 4u | 3-Me | H | H | H | H | 1.4 | 1.2 | 0.037±0.01 | >2700 |

| 4v | H | Me | H | H | H | 0.2 | 0.3 | ||

| 4w | H | H | Me | H | H | 0.8 | 1.7 | 0.90±0.08 | |

| 4x | H | H | H | Me | H | 0.1 | 0.6 | 25.6±3.5 | |

| 4y | H | H | H | H | Me | 0.2 | 1.6 | ||

| 4z | H | H | H | Me | Me | 0.2 | 0.8 | 8.52±1.83 | |

| 4a (A91) | 0.5 | 1.4 | 4.43 ± 0.01 | >20 | |||||

| 4b | 0.8 | 1.3 | 0.77 ± 0.03 | >125 | |||||

| GW590735 | 1.0 | 1.0 | 0.015±0.002 | ||||||

Ratio of relative light unit (RLU) signal at 5 μM and 50 μM compound concentrations.

Ratio of signal maximal signal (RLU) strength observed for the compound of interest to that obtained with GW590735.

EC50 values represent the mean ± SEM of atleast two separate experiments performed in triplicate.

EC50 (PPARγ or PPARδ) / EC50 (PPARα). Blank cells indicate compound was not selected for testing in the corresponding assay.

Figure 5.

Dose-response curves for 4u (blue squares, solid line) against PPARα, PPARδ, and PPARγ. Respective controls are provided as black circles/dashed line.

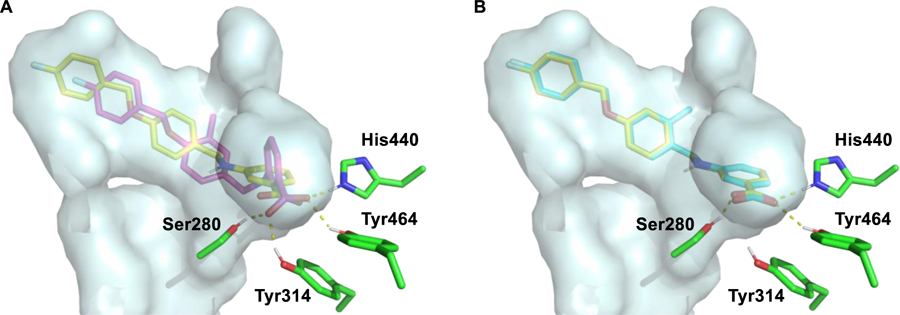

While the reason for the drastic improvement in activity arising from incorporation of the methyl group at the 3-position of the B-ring is not obvious, we have interrogated this phenomenon briefly by in silico methods. Results from these studies suggest that methylation at the 3-position (4u) results in a binding shift that allows for improved hydrogen bonding with the Ser280, Tyr314, His440, and Tyr464 tetrad (Figure 6A). Additionally, 4u is predicted to bind with the aromatic ring of the benzoic acid perpendicular to His440 thus allowing for T-shaped edge-to-face pi-interactions (Figure 6A). Methylation at the 2-position (4t), however, produces no such shift and 4t overlays very well with the des-methyl analogue 4b (Figure 6B). As such, it is not surprising that the activity of 4t and 4b are relatively similar.

Figure 6.

Predicted binding modes of 4b, 4t, and 4u, demonstrating the possible effects of methyl installation on the 2- or 3-position of the B ring. (A) Overlay of the predicted binding poses for 4b (yellow) and 4u (magenta). (B) Overlay of the predicted binding poses for 4b (yellow) and 4t (cyan). PDBID: 2P54. The pdb file of the docking model is included in the Supporting Information.

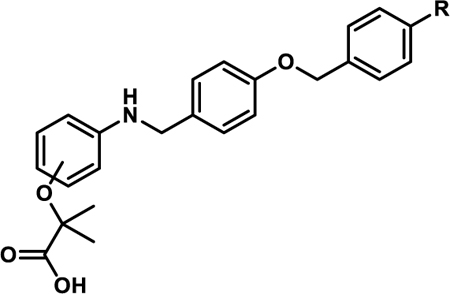

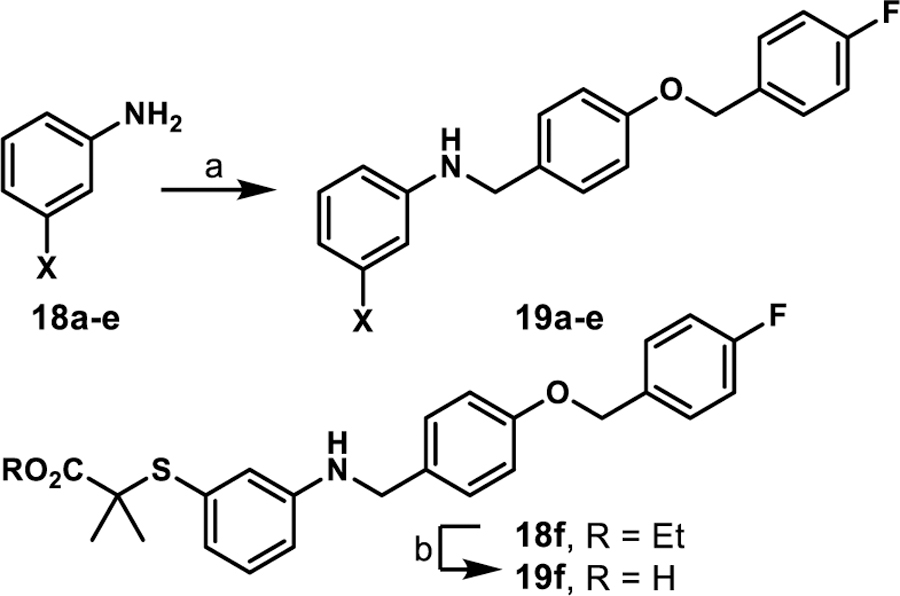

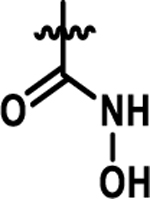

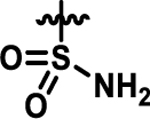

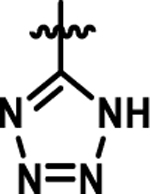

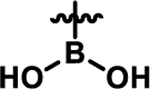

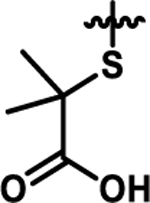

Coupling 3b to a variety of anilines containing carboxylic acid surrogates (18a-e) allowed us to assess the effect of isosteric replacement on PPARα agonistic activity (19a-e, Scheme 4). As seen in Table 6, replacement of the carboxylate with any of the isosteres resulted in dramatic decreases in activity, as noted by either a low 5:50 ratio or low overall signal. The exception being the tetrazole (19d), which exhibits decreased potency but comparable activation levels to the original carboxylate. This result confirms that the carboxylic acid is a key contributor to triggering PPARα agonism but can indeed be modified. As part of this series, the thio-variant of the fibrate head-group was also synthesized and assessed (19f). Interestingly, this derivative exhibits an attenuated level of agonism compared to the parent analogue, 5b. Differences in agonism levels now observed between the benzoic acid, fibrate head-group, and the thio-fibrate head-group strongly suggest that manipulation of this motif may provide a useful means to tune the level of agonism induced by a chemotype. This could be important as it is still unknown what level of stimulation (partial or full-agonism) is optimal for PPARα to have a therapeutic effect in the retina.

Scheme 4.

Synthesis of isostere containing derivatives 19a-fa

aReagents and conditions: (a) 3b, toluene, 130 °C, 2–3 h; ii) NaBH(OAc)3, acetic acid, THF, 25 °C, 12 h, 8–80%; (b) LiOH·H2O, THF/CH3OH/H2O, 12 h, 13%.

Table 6.

In vitro Activity of Carboxylate Isosteres

| Compound | X | Ratio (5/50)a | Fold-Signalb |

|---|---|---|---|

| 19a |  |

1.0 | 0.1 |

| 19b |  |

0.5 | 0.6 |

| 19c |  |

1.2 | 0.1 |

| 19d |  |

0.4 | 1.6 |

| 19e |  |

0.9 | 0.1 |

| 19f |  |

0.2 | 1.1 |

| 4b |  |

0.8 | 1.3 |

| GW590735 | 1.0 | 1.0 | |

Ratio of relative light unit (RLU) signal at 5 μM and 50 μM compound concentrations.

Ratio of signal maximal signal (RLU) strength observed for the compound of interest to that obtained with GW590735.

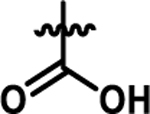

Additional Assessment of 4u.

As the most potent analogue identified in stages I and II, 4u was selected for additional assessment. To confirm target engagement, evaluate binding potency, and provide some insight into selectivity in a relevant human retinal cell line (MIO-M1, Müller cells) we subjected 4u to a CETSA (cellular thermal shift assay).28–29 Unlike the luciferase assay, MIO-M1 cells are not engineered to specifically report engagement with PPARα and thus provide a more realistic picture of compound behavior in a disease related cell setting. In an initial heat gradient, non-ligand associated PPARα displayed a temperature-dependent decay, with Tagg(50) and Tagg(75) at 40.8 °C and 45.5 °C, respectively (Figure 7A). In a subsequent test, dose-dependent potency of the PPARα agonists, A91 and 4u were tested at 45.5 °C, the temperature point at which 75% of free PPARα protein melted. As shown in Figure 7B, A91 improved PPARα stability incrementally with an EC50 of 0.3 μM. On the other hand, 4u rescued PPARα stability by 3-fold with an EC50 of 93 nM. The results for 4u correlate well with the EC50 value obtained from the luciferase assay (EC50 = 37 nM), demonstrating consistency of this compound within different contexts and eluding to excellent intracellular selectivity.

Figure 7.

Cellular thermal shift assay results for A91 and 4u. (A) Thermal melting profile of PPARα. (B) Dose-dependent stabilization of PPARα by A91 and 4u. Experiment was run at 45.5 °C, the Tagg(75).

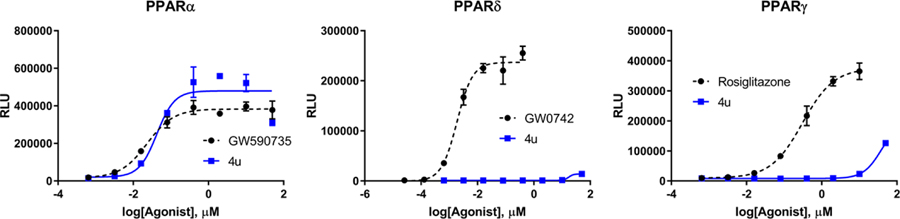

Compound 4u was assessed in the same PK studies as 4a (A91). As seen in Figure 8, this analogue exhibits significantly improved stability in human and rat liver microsomes (Figure 8A), shows no signs of irreversible inhibition of the major drug metabolizing CYP450s (Figure 8B) and is not considered a hERG liability (Figure 8C). It is important to note that while this compound exhibits 10% inhibition of hERG at 10 μM (the same as A91), this analogue is ~20-fold more potent than A91.

Figure 8. Pharmacokinetic profile of 4u.

(A) 4u was pre-incubated with pooled liver microsomes in phosphate buffer (pH 7.4) for 5 min at 37 °C. The system was activated by the addition of an NADPH-regenerating system and incubated for 0, 15, 30, 45, and 60 min before being quenched with an acetonitrile/methanol mixture. Samples were processed and analyzed by HPLC-MS/MS to determine the peak area remaining. Experiments completed in duplicate and mean values are depicted. (B) Assessment of 4u (10 μM) for irreversible inhibition of the major CYP450 drug metabolizing isoforms. Peak areas corresponding to the metabolite of known substrates for each isoform are recorded. The percent of control activity was calculated by comparing the peak area obtained in the presence of 4u to that obtained in the absence of 4u. Percent inhibition was calculated by subtracting the percent control activity from 100. Time-dependent CYP inhibition is demonstrated if the percent inhibition from samples pre-incubated with the NADPH-regenerating system is larger than those without NADPH-regeneration. Negative values are a reflection of the variability in the background noise of the experiment. Experiments completed in duplicate and mean values are depicted. (C) Assessment of 4u for inhibition of the hERG channel. The degree of inhibition (%) was obtained by measuring the tail current amplitude, which is induced by a one-second test pulse to −40 mV after a two-second pulse to +20 mV, before and after drug incubation. Experiments completed in duplicate and mean values are depicted.

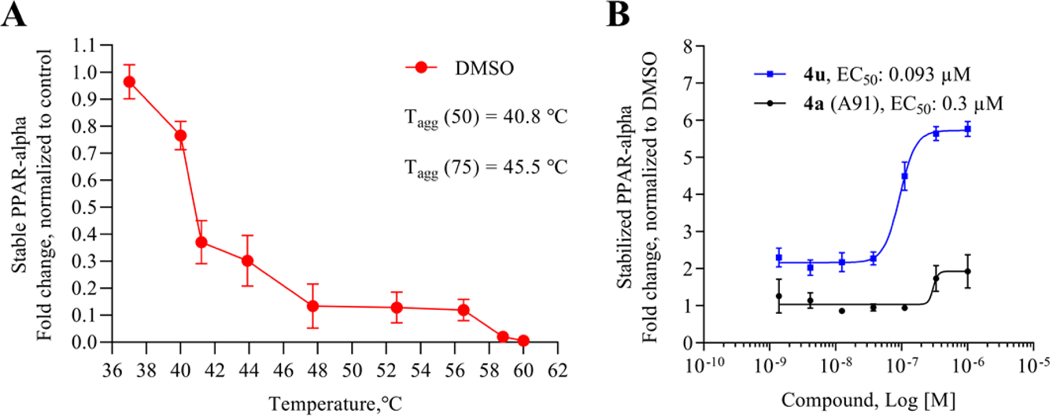

Stage III SAR: Combining Lessons Learned.

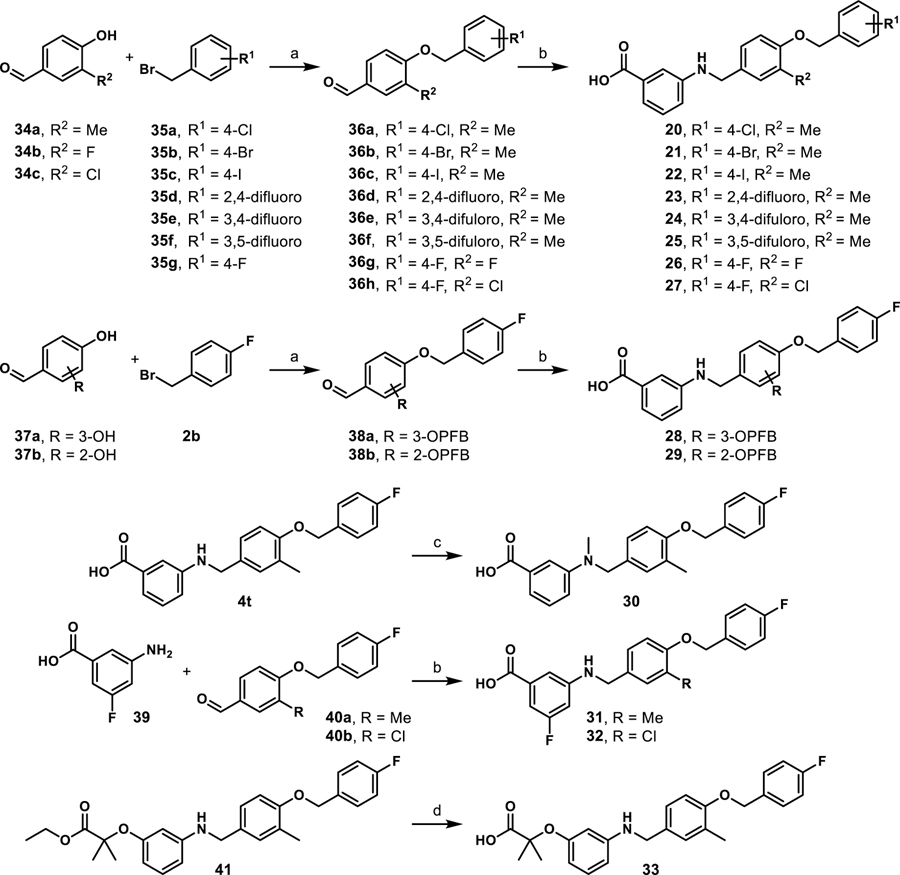

Due to information gained from the stage I and II cohorts we designed and synthesized a series that combined beneficial features from each stage. Utilizing established synthetic routes, compounds 20-33 were synthesized and evaluated in similar fashion to stage I and II derivatives (Scheme 5). As shown in Table 7, all stage III analogues exhibit submicromolar activity in the cell luciferase assay, with many derivatives revealing EC50 values under 50 nM. Comparison of 24–29 to the corresponding des-methyl relatives demonstrates that the methyl effect is ~10–20-fold more potent for each derivative and thus exhibits exquisite consistency. Most notably, 22, which contains an iodine at the 4-position on the C-ring, exhibits a 50-fold improvement in activity in comparison to the des-methyl B-ring relative. Based on the predicted shift in the binding pocket (Figure 6) we suspect that room in the C-ring pocket is subsequently freed, allowing space for the larger iodine substituent that is not as easily accommodated with the des-methyl compound, 4e. Consistent with the effect observed between 4w and 4b, N-methylation of the linker results in ~2-fold decrease in potency (4u vs. 30). Furthermore, comparison of 4u and 31 reveals that incorporation of the 3-F on the A-ring results in a maintenance in potency, a phenomenon first observed between 4b and 4q. Overall, the results from stage III analogues confirm trends seen in stages I and II, corroborate in silico docking predictions, and provide compelling evidence that the SAR for this chemotype is consistent, a desirable yet often elusive property in lead optimization.

Scheme 5.

Synthesis of Stage III Analogues 20–33a

aReagents and conditions: (a) K2CO3, DMF; (b) i) 3-aminobenzoic acid or 4-amino benzoic acid, toluene, 130 °C, 2–3 h; ii) NaBH(OAc)3, acetic acid, THF, 12 h, 36–84%; (c) paraformaldehyde, NaBH(OAc)3, EtOH, reflux 2 h, 25 °C, 12 h, 44%; (d) LiOH·H2O, THF/CH3OH/H2O, 12 h, 32%.

Table 7.

In Vitro Activity of Stage III Analogues

| ||||||||

|---|---|---|---|---|---|---|---|---|

| Compound | X | R1 | R2 | R3 | R4 | Ratio (5/50)a | Fold-Signalb | EC50 hPPARα (μM)c |

| 20 | COOH | 4-Cl | 3-Me | H | H | 1.2 | 1.2 | 0.029±0.001 |

| 21 | COOH | 4-Br | 3-Me | H | H | 1.2 | 1.3 | 0.031±0.008 |

| 22 | COOH | 4-I | 3-Me | H | H | 1.8 | 1.5 | 0.027±0.003 |

| 23 | COOH | 2,4-difluoro | 3-Me | H | H | 1.2 | 1.4 | 0.056±0.007 |

| 24 | COOH | 3,4-difluoro | 3-Me | H | H | 1.4 | 1.6 | 0.018±0.001 |

| 25 | COOH | 3,5-difluoro | 3-Me | H | H | 1.1 | 1.6 | |

| 26 | COOH | 4-F | 3-F | H | H | 0.7 | 1.7 | |

| 27 | COOH | 4-F | 3-Cl | H | H | 1.1 | 1.5 | |

| 28 | COOH | 4-OPFB | 3-OPFB | H | H | 1.0 | 1.4 | 0.81±0.17 |

| 29 | COOH | 4-OPFB | 2-OPFB | H | H | 0.9 | 1.2 | 0.93±0.02 |

| 30 | COOH | 4-F | 3-Me | H | Me | 0.8 | 2.1 | 0.067±0.01 |

| 31 | COOH | 4-F | 3-Me | F | H | 0.9 | 1.5 | 0.040±0.001 |

| 32 | COOH | 4-F | 3-Cl | F | H | 1.1 | 1.8 | 0.052±0.011 |

| 33 | OC(CH3)2COOH | 4-F | 3-Me | H | H | 1.0 | 1.6 | 0.74±0.04 |

| 4b | 0.8 | 1.3 | 0.77±0.03 | |||||

| 4a (A91) | 0.5 | 1.4 | 4.43±0.01 | |||||

| GW590735 | 1.0 | 1.0 | 0.015±0.002 | |||||

Ratio of relative light unit (RLU) signal at 5 μM and 50 μM compound concentrations.

Ratio of signal maximal signal (RLU) strength observed for the compound of interest to that obtained with GW590735.

EC50 values represent the mean ± SEM of atleast two separate experiments performed in triplicate. OPFB = para-fluorobenzyl. Numbering shown is based on the name of the resulting products. Blank cells indicate compound was not selected for testing in the corresponding assay.

Thermodynamic Binding Profiles.

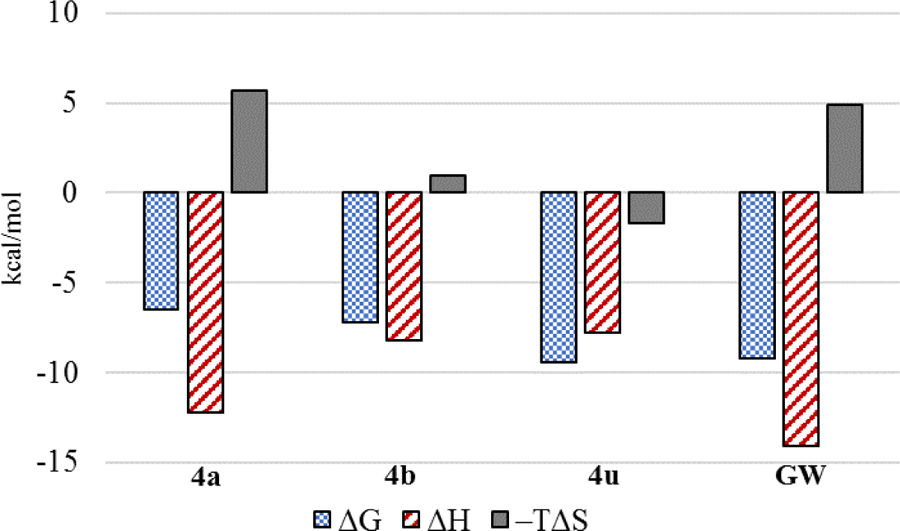

To determine thermodynamic parameters relating to the formation of PPARα/ligand complexes, we subjected structurally related 4a, 4b, and 4u along with GW590735 (as a known agonist) to isothermal titration calorimetry (ITC). These analogues were selected, as they only differ in single functionalities that produce significant changes in cellular activity and thus allowed for the correlation of binding thermodynamics to specific molecular features. Replacement of the C-ring 4-OMe (4a) with a 4-F (4b) produces a ~3-fold improvement in binding affinity, an observation consistent with cellular activity. Based on the thermodynamic profile (Figure 9, Table 5), the observed improvement in binding affinity is likely due to a 4.73 kcal/mol lower entropic penalty of binding for 4b. Introduction of a methyl group on the B-ring (4u) dramatically improves (~38-fold) the binding affinity, also consistent with cellular results. As depicted in Figure 9, the incorporation of the methyl group at the 3-position of the B-ring produces a favorable –TΔS term while also maintaining a favorable ethalpic contribution. The full thermodynamic binding profile of 4u reveals enthalpically driven binding to PPARα, helping to explain the significant jump in affinity.

Figure 9.

Thermodynamic binding profiles of select ligands.

Combined, these results suggest that the observed improvements in the cellular luciferase assay are likely due to improved binding profiles and not alterations in cellular permeability, solubility, or other physicochemical properties that may affect activity. Likewise, the proximities of Kd and EC50 values provides compelling evidence that this chemotype exhibits high specificity for PPARα. Attempts to obtain a Kd and thermodynamic binding profile for the fibrate headgroup containing member of this series (5b) failed to produce reproducable data due to solubility issues under assay conditions.

2.9. Conclusion

In conclusion, we have advanced our initial studies on the 4-benzyloxy-benzylamino chemotype as a novel PPARα agonistic scaffold by providing proof-of-concept in vivo efficacy, preliminary pharmacokinetic assessment and the design, synthesis, and evaluation of second-generation analogues that provide highly potent and isoform selective leads. The data demonstrate that systemic A91 (4a) treatment (i.p. injection) reduces retinal vascular leakage in diabetic rats to the level of non-diabetic controls at relatively the same dose as FenoFA, without signs of hepatomegaly. A full PK profile of this chemotype has yet to be determined (due to resource limitations), limiting PK/PD correlations for the in vivo data in comparison to FenoFA. However, embedded in these results is confirmation that A91 1) exhibits in vivo efficacy in a relevant DR model following systemic administration, 2) crosses blood-retinal barrier and reaches the retina, 3) is bioavailable, 4) survives first-pass metabolism and clearance mechanisms well enough to reach the site of disease and maintain efficacy, and 5) demonstrates a relatively safe profile (no observable toxicity) after daily intraperitoneal injection for one-month.

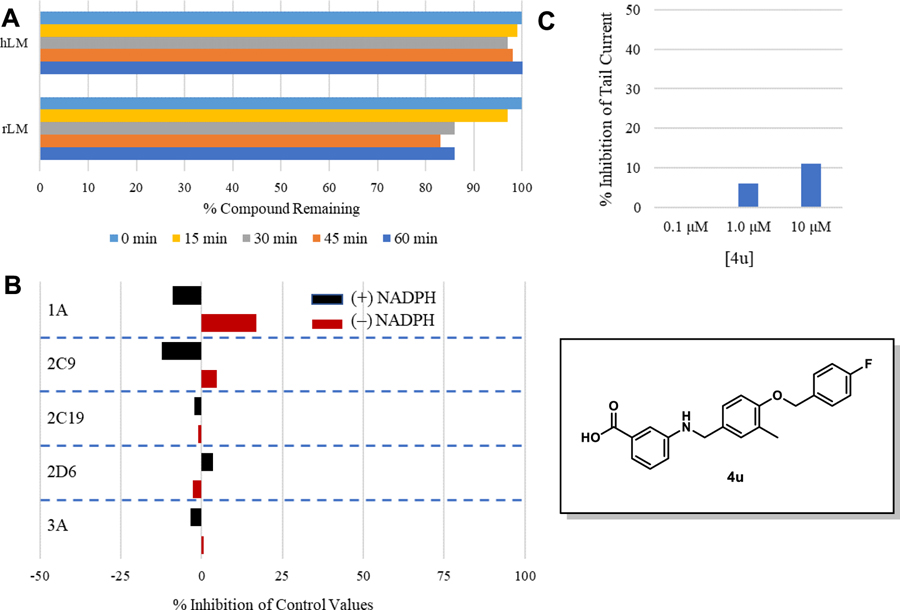

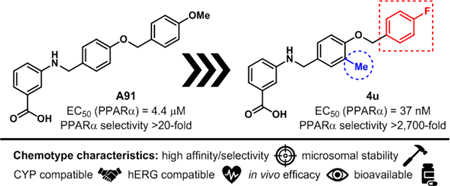

Utilizing A91 as a template we leveraged structure-guided design to develop second generation derivatives focused on improving the potency, affinity, and selectivity for PPARα (Figure 10). These efforts led to the discovery of 4u and related compounds that reach cellular potencies <50 nM and exhibit >2,700-fold selectivity for PPARα over other PPAR isoforms. Importantly, we discovered that incorporation of a methyl at the 3-position of the B-ring leads to dramatic improvements in target engagement, selectivity, and cellular activity. Cellular thermal shift analysis confirms tight binding of the top candidates to hPPARα and isothermal titration calorimetry further confirms a much-improved binding affinity and thermodynamic profile for 4u in comparison to A91 (4a). Initial pharmacokinetic assessment of 4u reveals microsomal stability in both human and rat microsomes, no evidence of irreversible inhibition of major drug metabolizing CYP450 enzymes, and a low risk for hERG interactions at relevant concentrations.

Figure 10.

Summary of current SAR on the 4-benxyloxy-benzylamino chemotype for PPARα agonism.

Detailed determination of a full PK/PD profile of this chemotype and advanced in vivo studies are ongoing and will be communicated in due time. Priority studies moving forward will focus on determining drug exposure in the retina after systemic administration and determining a more comprehensive metabolic profile, including phase-II conjugations. The data reported within, however, emphasize the promise of the 4-benzyloxy-benzylamino chemotype as a PPARα agonistic family with efficacy in the retina after systemic administration and identify a pipeline of candidates positioned for detailed PK/PD and pre-clinical evaluation.

EXPERIMENTAL SECTION

General Synthetic Information.

Starting materials, ACS grade DCM, methanol, ethyl acetate, toluene, anhydrous DMF, THF were purchased from TCI Chemicals, Oakwood, Alfa Aesar, Boron Molecular, Fisher Scientific or Sigma-Aldrich. All reactions requiring anhydrous conditions were run under a nitrogen atmosphere. NMR were collected on a 400, 500, and 600 MHz (specified below) Varian VNMRS Direct Drive spectrometer equipped with an indirect detection probe. NMR data were collected at 25 °C unless otherwise indicated. Pulse sequences were used as supplied by Varian VNMRJ 4.2 software. All NMR data was processed in MestReNova v11.0. High resolution mass spectrometry was obtained from and analyzed by the Mass Spectrometry Facility at the University of Oklahoma. All analogues evaluated in biological assays were >95% purity based on HPLC and NMR analyses.

Purity Analysis of Final Analogues.

Ultra-high-pressure liquid chromatography (UPLC) separation of samples (25 uM) was performed using an Agilent 1290 UPLC system equipped with an Agilent Zorbax Eclipse Plus reverse-phase column (ODS-18; 50 mm x 2.1 mm, 1.8− μm particle size). Mobile phase A consisted of 100% Optima® LC/MS submicron filtered water (Fisher Scientific). Mobile phase B consisted of 100% Optima® LC/MS acetonitrile. A binary gradient at 0.65 mL/min flow rate was applied as follows: 100% solvent A from 0 to 1 min linear gradient to 20% solvent B, linear gradient to 80% solvent B from 1 to 8 min, linear gradient to 100% solvent B from 8 to 9.1 min, 100% solvent B from 9.1 to 10.3 min, and linear gradient to return the mobile phase to 100% solvent A from 10.3 to 10.4 min, which was maintained for an additional 3 min before the next sample was injected. The UPLC column eluent was introduced into an Agilent 1290 Infinity Diode Array Detector. Absorbance was scanned from 190 to 400 nm. Absorbance intensity at 154 nm was quantitated by area integration. For accurate mass confirmation the eluent traveled in series from the DAD to an Agilent 6545 UHD Accurate Mass QTOF device equipped with an electrospray ionization source operated in negative ion mode. Nitrogen was used as a nebulizing gas (40 pounds/inch2) and a drying gas (325 °C and 10 L/min flow rate). Fragmentor, skimmer, and capillary voltages were 180, 45, and 2500 V, respectively. Data was collected with Mass Hunter Acquisition (B.08.00) and analyzed with Mass Hunter Qualitative (B.07.00).

General Procedure A (Reductive amination).

Requisite aniline (1.0 eq.) was dissolved in toluene (30 mL), and the requisite aldehyde (1.02 eq.) was added. The reaction mixture was heated for 2 h under reflux using a Dean–Stark trap. Subsequently, the solvent was evaporated under reduced pressure. The crude product was dissolved in THF (0.1 M) and cooled to 0 °C prior to the addition of neat sodium triacetoxyborohydride (2.0 eq.). The resulting reaction mixture was stirred for 15 min, after which acetic acid (0.01 eq.) was added to the reaction. The mixture was then allowed to stir for 12 h at 25 °C while monitoring by TLC. Upon complete consumption of the aniline, the reaction was quenched through slow addition of water. The mixture was extracted three times with EtOAc, the organic layers were combined and washed with brine. The organic layer was dried over anhydrous sodium sulfate, filtered, and evaporated under vacuum. The product was purified by column chromatography (SiO2) using dichloromethane/methanol (99.5:0.5) as the eluent.

General Procedure B (Ester saponification).

To a stirred solution of the requisite ethyl ester (1.0 eq.) in THF/MeOH/H2O mixture (0.1 M, 3:1:1) was added lithium hydroxide monohydrate (5.0 eq.) and the reaction mixture was stirred for 12 h at 25 °C. The reaction mixture was concentrated to remove organic solvents. The aqueous layer was acidified to pH 2.0 with 1 N aq. HCl and then extracted with EtOAc. The organic layer was washed with water and brine. The resulting organic layer was dried over anhydrous Na2SO4, filtered, and evaporated under vacuum. The product was purified by column chromatography (SiO2) using dichloromethane/methanol (99:1) as the eluent.

3-((4-((4-methoxybenzyl)oxy)benzyl)amino)benzoic acid (4a):

Reaction scale: 100 mg (0.73 mmol) of 3-amino benzoic acid. Compound 4a was prepared following General Procedure A with aldehyde 3a (0.74 mmol). The product was purified by flash column chromatography (SiO2, CH2Cl2/CH3OH, 99.5:0.5) to give a white amorphous solid (210 mg, 80% yield). 1H NMR (400 MHz, Chloroform-d) δ 7.46 (d, J = 7.7 Hz, 1H), 7.36 (d, J = 9.2 Hz, 3H), 7.27 (q, J = 6.3, 4.1 Hz, 4H), 6.94 (dd, J = 14.6, 8.1 Hz, 4H), 6.84 (d, J = 8.3 Hz, 1H), 4.99 (s, 2H), 4.30 (s, 2H), 3.82 (s, 3H) ppm; 13C NMR (101 MHz, Chloroform-d) δ 171.8, 159.6, 158.4, 148.3, 131.1, 130.2, 129.4, 129.3 (2C), 129.1, 128.9 (2C), 119.4, 118.2, 115.2 (2C), 114.2 (2C), 114.0, 70.0, 55.4, 47.8 ppm. HRESI m/z: 364.1449 (C22H21NO4 + H+ requires 364.1543).

3-((4-((4-fluorobenzyl)oxy)benzyl)amino)benzoic acid (4b):

Reaction scale: 50 mg (0.36 mmol) of 3-amino benzoic acid. Compound 4b was prepared following General Procedure A with aldehyde 3b 0.37 mmol). The product was purified by flash column chromatography (SiO2, CH2Cl2/CH3OH, 99.5:0.5) to give a white amorphous solid (40 mg, 32% yield). 1H NMR (600 MHz, DMSO-d6) δ 7.48 (dd, J = 8.3, 5.5 Hz, 2H), 7.27 (d, J = 8.2 Hz, 2H), 7.21 (dd, J = 9.3, 8.9 Hz, 2H), 7.16 (dd, J = 1.9 Hz, 1H), 7.13 (dd, J = 7.7 Hz, 1H), 7.09 (d, J = 7.6 Hz, 1H), 6.96 (d, J = 8.7 Hz, 2H), 6.82 – 6.60 (m, 1H), 6.44 (t, J = 6.0 Hz, 1H), 5.04 (s, 2H), 4.21 (d, J = 5.8 Hz, 2H). 13C NMR (151 MHz, DMSO-d6) δ 167.8, 161.7 (d, J = 243.5 Hz), 157.1, 148.7, 133.4 (d, J = 3.1 Hz), 131.9, 131.4, 129.8 (d, J = 8.4 Hz, 2C), 128.8, 128.3 (2C), 116.6, 116.3, 115.2 (d, J = 21.3 Hz, 2C), 114.6 (2C), 112.9, 68.4, 45.7. TOFMSESI m/z: 352.1357 (C21H18FNO3 + H+ requires 352.1304).

4-((4-((4-fluorobenzyl)oxy)benzyl)amino)benzoic acid (4b*): Reaction scale: 50 mg (0.36 mmol) of 4-amino benzoic acid. Compound 4b* was prepared following General Procedure A with aldehyde 3b (0.37 mmol). The product was purified by flash column chromatography (SiO2, CH2Cl2/CH3OH, 99.5:0.5) to give a white amorphous solid (60 mg, 52% yield). 1H NMR (400 MHz, Methanol-d4) δ 7.75 (d, J = 8.8 Hz, 2H), 7.45 (dd, J = 8.5, 5.5 Hz, 2H), 7.27 (d, J = 8.5 Hz, 2H), 7.13 – 7.04 (m, 2H), 6.95 (d, J = 8.6 Hz, 2H), 6.59 (d, J = 8.8 Hz, 2H), 5.04 (s, 2H), 4.30 (s, 2H). 13C NMR (101 MHz, Methanol-d4) δ 170.8, 168.3 (d, J = 244.5 Hz), 168.1, 166.5, 162.6, 159.3, 154.4, 133.0 (d, J = 3.2 Hz), 132.6 (2C), 130.7, 130.6 (2C), 129.6 (d, J = 8.6 Hz, 2C), 118.5, 116.3 (d, J = 21.6 Hz, 2C), 116.0 (2C), 112.5 (2C), 70.3, 47.3. TOFMSESI m/z: 352.1357 (C21H18FNO3 + H+ requires 352.1304).

3-((4-((4-chlorobenzyl)oxy)benzyl)amino)benzoic acid (4c):

Reaction scale: 100 mg (0.73 mmol) of 3-amino benzoic acid. Compound 4c was prepared following General Procedure A with aldehyde 3c (0.74 mmol). The product was purified by flash column chromatography (SiO2, CH2Cl2/CH3OH, 99.5:0.5) to give a white amorphous solid (203.3 mg, 76% yield). 1H NMR (400 MHz, Methanol-d4) δ 7.41 (d, J = 8.5 Hz, 2H), 7.36 (d, J = 8.5 Hz, 2H), 7.29 (d, J = 6.3 Hz, 2H), 7.28 (s, 1H), 7.25 (dt, J = 7.6, 1.3 Hz, 1H), 7.15 (t, J = 7.8 Hz, 2H), 6.93 (d, J = 8.6 Hz, 1H), 6.82 (ddd, J = 8.0, 2.5, 1.1 Hz, 1H), 5.03 (s, 2H), 4.26 (s, 2H). 13C NMR (101 MHz, Methanol-d4) δ 169.3, 157.6, 148.8, 136.3, 133.1, 132.0, 131.0, 128.7 (2C), 128.5, 128.2 (2C), 128.1 (2C), 117.6, 117.0, 114.5 (2C), 113.2, 68.7, 46.5. TOFMSESI m/z: 366.0897 (C21H18ClNO3 - H+ requires 366.0902).

3-((4-((4-bromobenzyl)oxy)benzyl)amino)benzoic acid (4d):

Reaction scale: 50 mg (0.36 mmol) of 3-amino benzoic acid. Compound 4d was prepared following General Procedure A with aldehyde 3d (0.37 mmol). The product was purified by flash column chromatography (SiO2, CH2Cl2/CH3OH, 99.5:0.5) to give a white amorphous solid (96 mg, 65% yield). 1H NMR (600 MHz, DMSO-d6) δ 12.68 (s, 1H), 7.57 (d, J = 8.5 Hz, 2H), 7.39 (d, J = 8.0 Hz, 2H), 7.27 (d, J = 8.2 Hz, 2H), 7.18 (dd, J = 2.0 Hz, 1H), 7.13 (dd, J = 7.6 Hz, 1H), 7.10 (ddd, J = 7.5, 1.5 Hz, 1H), 6.95 (d, J = 8.8 Hz, 2H), 6.78 (ddd, J = 8.0, 1.8 Hz, 1H), 6.44 (s, 1H), 5.05 (s, 2H), 4.21 (s, 2H). 13C NMR (151 MHz, DMSO-d6) δ 168.3, 157.4, 149.1, 137.1, 132.5, 131.9, 131.8 (2C), 130.2 (2C), 129.3, 128.8 (2C), 121.3, 117.1, 116.7, 115.1 (2C), 113.4, 68.8, 46.2. TOFMSESI m/z: 412.0512 (C21H18BrNO3 + H+ requires 412.0543).

3-((4-((4-iodobenzyl)oxy)benzyl)amino)benzoic acid (4e):

Reaction scale: 100 mg (0.73 mmol) of 3-amino benzoic acid. Compound 4e was prepared following General Procedure A with aldehyde 3e (0.74 mmol). The product was purified by flash column chromatography (SiO2, CH2Cl2/CH3OH, 99.5:0.5) to give a white amorphous solid (210 mg, 80% yield).1H NMR (600 MHz, DMSO-d6) δ 7.74 (d, J = 8.3 Hz, 2H), 7.27 (d, J = 8.4 Hz, 2H), 7.24 (d, J = 8.0 Hz, 2H), 7.17 (dd, J = 1.9 Hz, 1H), 7.14 (dd, J = 7.7 Hz, 1H), 7.13 – 7.07 (m, 1H), 6.94 (d, J = 8.6 Hz, 2H), 6.78 (ddd, J = 8.3, 1.7 Hz, 1H), 5.03 (s, 2H), 4.20 (s, 2H). 13C NMR (151 MHz, DMSO-d6) δ 167.7, 157.0, 148.6, 137.2 (2C), 137.0, 132.0, 131.2, 129.8 (2C), 128.8, 128.3 (2C), 116.7, 116.4, 114.6 (2C), 112.9, 93.7, 68.4, 45.7. TOFMSESI m/z: 460.0424 (C21H18INO3 + H+ requires 460.0404).

3-((4-((4-(trifluoromethyl)benzyl)oxy)benzyl)amino)benzoic acid (4f):

Reaction scale: 100 mg (0.73 mmol) of 3-amino benzoic acid. Compound 4f was prepared following General Procedure A with aldehyde 3f (0.74 mmol). The product was purified by flash column chromatography (SiO2, CH2Cl2/CH3OH, 99.5:0.5) to give a white amorphous solid (170 mg, 58% yield). 1H NMR (600 MHz, DMSO-d6) δ 12.60 (s, 1H), 7.75 (d, J = 8.1 Hz, 2H), 7.65 (d, J = 8.1 Hz, 2H), 7.28 (d, J = 8.7 Hz, 2H), 7.16 (dd, J = 2.6, 1.9 Hz, 1H), 7.13 (dd, J = 8.5, 7.7 Hz, 1H), 7.09 (ddd, J = 7.6, 1.6 Hz, 1H), 6.98 (d, J = 8.7 Hz, 2H), 6.78 (ddd, J = 8.1, 2.6, 1.2 Hz, 1H), 6.45 (t, J = 6.0 Hz, 1H), 5.20 (s, 2H), 4.21 (d, J = 5.8 Hz, 2H). 13C NMR (151 MHz, DMSO-d6) δ 167.8, 156.9, 148.7, 142.1, 132.1, 131.3, 128.8, 128.4 (2C), 128.2 (q, J = 29.2, 30.8, 33.0 Hz), 127.9 (2C), 125.3 (q, J = 3.6 Hz, 2C), 124.2 (q, J = 271.2, 271.8, 272.3 Hz), 116.6, 116.3, 114.6 (2C), 112.8, 68.2, 45.7. TOFMSESI m/z: 400.1139 (C22H18F3NO3 - H+ requires 400.1166).

3-((4-((4-cyanobenzyl)oxy)benzyl)amino)benzoic acid (4g):

Reaction scale: 100 mg (0.73 mmol) of 3-amino benzoic acid. Compound 4g was prepared following General Procedure A with aldehyde 3g (0.74 mmol). The product was purified by flash column chromatography (SiO2, CH2Cl2/CH3OH, 99.5:0.5) to give a white amorphous solid (110 mg, 42% yield). 1H NMR (600 MHz, DMSO-d6) δ 12.63 (s, 1H), 7.84 (d, J = 8.2 Hz, 2H), 7.62 (d, J = 7.9 Hz, 2H), 7.28 (d, J = 8.3 Hz, 2H), 7.19 (dd, J = 2.0 Hz, 1H), 7.14 (dd, J = 7.7 Hz, 1H), 7.12 (d, J = 8.7 Hz, 1H), 7.00 – 6.90 (m, 2H), 6.79 (dt, J = 7.8, 2.0 Hz, 1H), 6.45 (s, 1H), 5.18 (s, 2H), 4.22 (s, 2H). 13C NMR (151 MHz, DMSO-d6) δ 167.9, 156.8, 148.7, 143.0, 132.4 (2C), 132.2, 131.3, 128.9, 128.4 (2C), 128.0 (2C), 118.8, 116.7, 116.4, 114.7 (2C), 112.9, 110.4, 68.2, 45.8. TOFMSESI m/z: 359.1406 (C22H18N2O3 + H+ requires 359.1390).

3-((4-((2-fluorobenzyl)oxy)benzyl)amino)benzoic acid (4h):

Reaction scale: 50 mg (0.36 mmol) of 3-amino benzoic acid. Compound 4h was prepared following General Procedure A with aldehyde 3h (0.37 mmol). The product was purified by flash column chromatography (SiO2, CH2Cl2/CH3OH, 99.5:0.5) to give a white amorphous solid (122 mg, 97% yield). 1H NMR (600 MHz, DMSO-d6) δ 12.60 (s, 1H), 7.54 (t, J = 7.4 Hz, 1H), 7.41 (q, J = 6.4 Hz, 1H), 7.29 (d, J = 8.2 Hz, 2H), 7.24 (d, J = 10.1 Hz, 1H), 7.22 (d, J = 7.4 Hz, 1H), 7.18 (s, 1H), 7.14 (t, J = 7.7 Hz, 1H), 7.10 (d, J = 7.6 Hz, 1H), 6.98 (d, J = 8.5 Hz, 2H), 6.79 (d, J = 7.8 Hz, 1H), 6.44 (s, 1H), 5.10 (s, 2H), 4.22 (d, J = 4.4 Hz, 2H). 13C NMR (151 MHz, DMSO-d6) δ 167.8, 160.4 (d, J = 245.9 Hz), 157.1, 148.7, 132.1, 131.3, 130.6 (d, J = 4.1 Hz), 130.3 (d, J = 8.3 Hz), 128.9, 128.4 (2C), 124.5 (d, J = 3.5 Hz), 123.9 (d, J = 14.7 Hz), 116.7, 116.3, 115.4 (d, J = 21.1 Hz), 114.6 (2C), 112.9, 63.5 (d, J = 3.4 Hz), 45.8. TOFMSESI m/z: 374.1169 (C21H18FNO3 + Na+ requires 374.1163).

3-((4-((3-fluorobenzyl)oxy)benzyl)amino)benzoic acid (4i):

Reaction scale: 50 mg (0.36 mmol) of 3-amino benzoic acid. Compound 4i was prepared following General Procedure A with aldehyde 3i (0.37 mmol). The product was purified by flash column chromatography (SiO2, CH2Cl2/CH3OH, 99.5:0.5) to give a white amorphous solid (96 mg, 65% yield). 1H NMR (600 MHz, DMSO-d6) δ 12.61 (s, 1H), 7.46 – 7.38 (m, 1H), 7.29 – 7.28 (m, 2H), 7.28 – 7.27 (m, 1H), 7.26 – 7.24 (m, 1H), 7.20 – 7.17 (m, 1H), 7.16 – 7.14 (m, 1H), 7.14 – 7.12 (m, 1H), 7.13 – 7.08 (m, 1H), 6.99 – 6.95 (m, 2H), 6.81 – 6.75 (m, 1H), 6.44 (t, J = 5.8 Hz, 1H), 5.10 (s, 2H), 4.21 (d, J = 4.4 Hz, 2H). 13C NMR (101 MHz, DMSO-d6) δ 167.8, 162.2 (d, J = 243.5 Hz), 157.0, 148.7, 140.2 (d, J = 7.3 Hz), 132.0, 131.3, 130.4 (d, J = 8.3 Hz), 128.9, 128.4 (2C), 123.4 (d, J = 2.8 Hz), 116.7, 116.4, 114.7 (2C), 114.5 (d, J = 20.9 Hz), 114.1 (d, J = 21.9 Hz), 112.9, 68.3, 45.8. TOFMSESI m/z: 352.1360 (C21H18FNO3 + H+ requires 352.1343).

3-((4-((2,4-difluorobenzyl)oxy)benzyl)amino)benzoic acid (4j):

Reaction scale: 50 mg (0.36 mmol) of 3-amino benzoic acid. Compound 4j was prepared following General Procedure A with aldehyde 3j (0.37 mmol). The product was purified by flash column chromatography (SiO2, CH2Cl2/CH3OH, 99.5:0.5) to give a white amorphous solid (100 mg, 70% yield). 1H NMR (600 MHz, DMSO-d6) δ 12.62 (s, 1H), 7.60 (ddd, J = 8.6, 6.7 Hz, 1H), 7.32 – 7.27 (m, 1H), 7.29 – 7.26 (m, 2H), 7.17 (dd, J = 1.9 Hz, 1H), 7.14 (d, J = 7.7 Hz, 1H), 7.13 – 7.11 (m, 1H), 7.10 – 7.09 (m, 1H), 6.98 (d, J = 8.6 Hz, 2H), 6.83 – 6.73 (m, 1H), 6.46 (t, J = 6.3 Hz, 1H), 5.07 (s, 2H), 4.22 (d, J = 4.7 Hz, 2H). 13C NMR (151 MHz, DMSO-d6) δ 167.8, 161.4 (dd, J = 4.0, 12.6 Hz), 161.4 (dd, J = 12.1, 499.9 Hz), 157.0, 148.7, 132.2, 132.1 (dd, J = 5.7, 10.1 Hz), 131.3, 128.8, 128.4 (2C), 120.4 (dd, J = 3.4, 14.4 Hz), 116.7, 116.3, 114.6 (2C), 112.9, 111.5 (dd, J = 3.8, 21.3 Hz), 104.0 (t, J = 25.8 Hz), 63.1 (d, J = 2.9 Hz), 45.7. TOFMSESI m/z: 392.1085 (C21H17F2NO3 + Na+ requires 392.1069).

3-((4-((3,4-difluorobenzyl)oxy)benzyl)amino)benzoic acid (4k):

Reaction scale: 50 mg (0.36 mmol) of 3-amino benzoic acid. Compound 4k was prepared following General Procedure A with aldehyde 3k (0.37 mmol). The product was purified by flash column chromatography (SiO2, CH2Cl2/CH3OH, 99.5:0.5) to give a white amorphous solid (106 mg, 79% yield). 1H NMR (600 MHz, DMSO-d6) δ 12.61 (s, 1H), 7.51 (ddd, J = 11.6, 7.8, 2.0 Hz, 1H), 7.44 (ddd, J = 10.8, 8.4 Hz, 1H), 7.30 (d, J = 4.0 Hz, 1H), 7.27 (d, J = 8.4 Hz, 2H), 7.16 (dd, J = 1.9 Hz, 1H), 7.13 (dd, J = 7.7 Hz, 1H), 7.09 (ddd, J = 7.6, 1.3 Hz, 1H), 6.96 (d, J = 8.7 Hz, 2H), 6.77 (ddd, J = 8.0, 2.6, 1.2 Hz, 1H), 6.45 (t, J = 6.1 Hz, 1H), 5.06 (s, 2H), 4.21 (d, J = 5.7 Hz, 2H). 13C NMR (151 MHz, DMSO-d6) δ 167.8, 156.9, 149.3 (dd, J = 12.7, 245.6 Hz), 148.9 (dd, J = 12.4, 245.3 Hz), 148.7, 135.0 (dd, J = 3.6, 5.8 Hz), 132.1, 131.3, 128.8, 128.3 (2C), 124.4 (dd, J = 3.5, 6.5 Hz), 117.5 (d, J = 17.1 Hz), 116.7 (d, J = 17.5 Hz), 116.6, 116.3, 114.6 (2C), 112.9, 67.8, 45.7. TOFMSESI m/z: 370.1238 (C21H17F2NO3 + H+ requires 370.1249).

3-((4-((3,5-difluorobenzyl)oxy)benzyl)amino)benzoic acid (4l):

Reaction scale: 100 mg (0.73 mmol) of 3-amino benzoic acid. Compound 4l was prepared following General Procedure A with aldehyde 3l (0.74 mmol). The product was purified by flash column chromatography (SiO2, CH2Cl2/CH3OH, 99.5:0.5) to give a white amorphous solid (196 mg, 73% yield). 1H NMR (600 MHz, DMSO-d6) δ 12.61 (s, 1H), 7.28 (d, J = 8.3 Hz, 2H), 7.19 (dd, J = 2.4, 9.1 Hz, 1H), 7.17 (dd, J = 1.8 Hz, 2H), 7.15 (d, J = 3.7 Hz, 1H), 7.13 (d, J = 7.7 Hz, 1H), 7.10 (ddd, J = 1.4, 7.6 Hz, 1H), 6.97 (d, J = 8.6 Hz, 2H), 6.78 (ddd, J = 1.2, 2.5, 8.0 Hz, 1H), 6.45 (t, J = 5.8 Hz, 1H), 5.11 (s, 2H), 4.22 (d, J = 5.1 Hz, 2H). 13C NMR (151 MHz, DMSO-d6) δ 167.8, 162.4 (dd, J = 13.0, 246.5 Hz, 2C), 156.7, 148.7, 141.9 (t, J = 9.2 Hz), 132.2, 131.3, 128.8, 128.4 (2C), 116.7, 116.3, 114.7 (2C), 112.9, 110.3 (dd, J = 5.2, 20.3 Hz, 2C), 103.0 (t, J = 25.8 Hz), 67.8, 45.7. TOFMSESI m/z: 368.1120 (C21H17F2NO3 - H+ requires 368.1104).

3-((4-phenethoxybenzyl)amino)benzoic acid (4m):

Reaction scale: 50 mg (0.36 mmol) of 3-amino benzoic acid. Compound 4m was prepared following General Procedure A with aldehyde 8a (0.37 mmol). The product was purified by flash column chromatography (SiO2, CH2Cl2/CH3OH, 99.5:0.5) to give a white amorphous solid (121 mg, 96% yield). 1H NMR (600 MHz, Methanol-d4) δ 7.39 (s, 1H), 7.28 (t, J = 2.0 Hz, 1H), 7.27 (s, 2H), 7.26 (d, J = 3.5 Hz, 2H), 7.24 (s, 2H), 7.19 (h, J = 4.1 Hz, 1H), 7.14 (t, J = 7.8 Hz, 1H), 6.84 (d, J = 8.6 Hz, 2H), 6.81 (dd, J = 1.9, 8.4 Hz, 1H), 4.23 (s, 2H), 4.13 (t, J = 6.9 Hz, 2H), 3.02 (t, J = 6.9 Hz, 2H). 13C NMR (151 MHz, Methanol-d4) δ 169.3, 157.9, 148.8, 138.5, 131.6, 131.1, 128.6 (2C), 128.5, 128.2 (2C), 128.0 (2C), 125.9 (2C), 117.6, 117.0, 114.2, 113.3, 68.5, 46.7, 35.3. TOFMSESI m/z: 346.1443 (C22H21NO3 - H+ requires 346.1449).

3-((4-(4-methoxyphenethoxy)benzyl)amino)benzoic acid (4n):

Reaction scale: 50 mg (0.36 mmol) of 3-amino benzoic acid. Compound 4n was prepared following General Procedure A with aldehyde 8b (0.37 mmol). The product was purified by flash column chromatography (SiO2, CH2Cl2/CH3OH, 99.5:0.5) to give a white amorphous solid (130 mg, 96% yield). 1H NMR (600 MHz, Methanol-d4) δ 7.28 (d, J = 2.2 Hz, 1H), 7.25 (d, J = 8.1 Hz, 2H), 7.25 (s, 1H), 7.18 (d, J = 8.2 Hz, 2H), 7.14 (t, J = 7.8 Hz, 1H), 6.84 (d, J = 8.8 Hz, 2H), 6.83 (d, J = 8.7 Hz, 2H), 6.83 – 6.78 (m, 1H), 4.24 (s, 2H), 4.09 (t, J = 6.9 Hz, 2H), 3.75 (s, 3H), 2.96 (t, J = 6.9 Hz, 2H). 13C NMR (151 MHz, Methanol-d4) δ 170.7, 159.8, 159.4, 150.3, 133.0, 132.5, 131.8, 130.9 (2C), 129.9, 129.6 (2C), 119.0, 118.4, 115.7 (2C), 114.9 (2C), 114.8, 70.1, 55.7, 48.1, 35.9. TOFMSESI m/z: 378.1709 (C23H23NO4 + H+ requires 378.1700).

3-((4-(4-methoxyphenethoxy)phenethyl)amino)benzoic acid (4o):

3-amino benzoic acid (50 mg, 0.36 mmol) and compound 10 (113 mg, 0.37 mmol) were dissolved in DMF. Triethylamine (102 uL, 0.72 mmol) was added at 25 °C and the reaction was stirred for 12 h upon which the reaction was deemed complete by TLC. The reaction was quenched with aq. 1N HCl (3 mL). The solution was diluted with EtOAc (30 mL). The organic layer was washed with water (3 × 20 mL) and brine (3 × 20 mL). The organic layer was dried over Na2SO4, filtered, and concentrated under vacuum. The product was purified by flash column chromatography (SiO2, CH2Cl2/CH3OH, 99.5:0.5) to give a white amorphous solid (36 mg, 25% yield). 1H NMR (500 MHz, Methanol-d4) δ 7.36 – 7.29 (m, 1H), 7.27 (ddd, J = 7.7, 1.6, 1.1 Hz, 1H), 7.19 (d, J = 6.6 Hz, 2H), 7.17 (d, J = 6.7 Hz, 2H), 7.14 (d, J = 7.7 Hz, 1H), 6.90 (ddd, J = 8.0, 2.4, 1.1 Hz, 1H), 6.84 (t, J = 2.0 Hz, 2H), 6.83 (t, J = 2.1 Hz, 2H), 4.41 (t, J = 6.9 Hz, 2H), 4.09 (t, J = 6.9 Hz, 2H), 3.75 (s, 3H), 2.97 (t, J = 7.0 Hz, 2H), 2.96 (t, J = 6.9 Hz, 2H). 13C NMR (126 MHz, Methanol-d4) δ 168.5, 159.8, 159.1, 149.3, 132.2, 131.8, 131.4, 131.0 (2C), 130.9 (2C), 130.1, 120.8, 119.8, 116.7, 115.7 (2C), 114.8 (2C), 70.1, 66.8, 55.6, 35.9, 35.3. TOFMSESI m/z: 392.1870 (C24H25NO4 + H+ requires 392.1856).

2-fluoro-5-((4-((4-fluorobenzyl)oxy)benzyl)amino)benzoic acid (4p):

Reaction scale: 50 mg (0.32 mmol) of 5-amino-2-fluorobenzoic acid (11a). Compound 4p was prepared following the General Procedure A with aldehyde 3b (0.33 mmol). The product was purified by flash column chromatography (SiO2, CH2Cl2/CH3OH, 99.5:0.5) to give a white amorphous solid (98 mg, 82% yield). 1H NMR (600 MHz, DMSO-d6) δ 7.48 (dd, J = 8.5, 5.7 Hz, 2H), 7.26 (d, J = 8.4 Hz, 2H), 7.21 (t, J = 8.9 Hz, 1H), 7.01 – 6.97 (m, 1H), 7.00 – 6.93 (m, 3H), 6.75 (dt, J = 8.8, 3.5 Hz, 1H), 6.31 (s, 1H), 5.05 (s, 2H), 4.17 (s, 2H). 13C NMR (151 MHz, DMSO-d6) δ 165.6, 161.7 (d, J = 243.5 Hz), 157.1, 152.9 (d, J = 244.7 Hz), 144.9, 133.4, 131.8, 129.9 (d, J = 8.2 Hz, 2C), 128.4 (2C), 117.3 (d, J = 7.4 Hz), 116.9 (d, J = 23.3 Hz, 2C), 115.3, 115.1, 114.7 (2C), 113.7, 68.4, 46.2. TOFMSESI m/z: 368.1093 (C21H17F2NO3 - H+ requires 368.1104).

3-fluoro-5-((4-((4-fluorobenzyl)oxy)benzyl)amino)benzoic acid (4q):

Reaction scale: 50 mg (0.32 mmol) of 3-amino-5-fluorobenzoic acid (11b). Compound 4q was prepared following the General Procedure A with aldehyde 3b (0.33 mmol). The product was purified by flash column chromatography (SiO2, CH2Cl2/CH3OH, 99.5:0.5) to give a white amorphous solid (102 mg, 86% yield). 1H NMR (400 MHz, Methanol-d4) δ 7.45 – 7.37 (m, 2H), 7.26 (d, J = 8.4 Hz, 2H), 7.11 (t, J = 1.8 Hz, 1H), 7.10 – 7.00 (m, 2H), 6.96 – 6.89 (m, 2H), 6.87 (dt, J = 9.1, 1.9 Hz, 1H), 6.47 (dt, J = 11.4, 2.3 Hz, 1H), 4.98 (s, 2H), 4.22 (s, 2H). 13C NMR (101 MHz, Methanol-d4) δ 169.4 (d, J = 3.3 Hz), 165.1 (d, J = 241.1 Hz), 163.8 (d, J = 244.7 Hz), 159.2, 152.0 (d, J = 11.1 Hz), 134.8 (d, J = 3.2 Hz), 134.1 (d, J = 9.9 Hz), 132.8, 130.6 (d, J = 8.1 Hz, 2C), 129.6 (2C), 116.2, 116.0 (2C), 111.1 (d, J = 2.0 Hz), 104.5 (d, J = 24.0 Hz, 2C), 103.9 (d, J = 26.0 Hz), 70.3, 47.8. TOFMSESI m/z: 368.1096 (C21H17F2NO3 - H+ requires 368.1104).

3-chloro-5-((4-((4-fluorobenzyl)oxy)benzyl)amino)benzoic acid (4r):

Reaction scale: 50 mg (0.29 mmol) of 3-amino-5-chlorobenzoic acid (11c). Compound 4r was prepared following the General Procedure A with aldehyde 3b (0.30 mmol). The product was purified by flash column chromatography (SiO2, CH2Cl2/CH3OH, 99.5:0.5) to give a white amorphous solid (88 mg, 78% yield). 1H NMR (500 MHz, Methanol-d4) δ 7.42 (dd, J = 8.4, 5.4 Hz, 2H), 7.26 (d, J = 8.3 Hz, 2H), 7.17 (dt, J = 16.7, 1.7 Hz, 2H), 7.07 (t, J = 8.8 Hz, 2H), 6.93 (d, J = 8.5 Hz, 2H), 6.75 (t, J = 2.1 Hz, 1H), 5.00 (s, 2H), 4.23 (s, 2H). 13C NMR (101 MHz, DMSO-d6) δ 166.6, 161.7 (d, J = 243.5 Hz), 157.2, 150.1, 133.7, 133.3 (d, J = 3.0 Hz), 133.0, 131.3, 129.9, 129.8, 128.4 (2C), 115.5, 115.3, 115.1, 114.8, 114.7 (2C), 112.0, 68.5, 45.6. TOFMSESI m/z: 384.0812 (C21H17ClFNO3 - H+ requires 384.0808).

3-bromo-5-((4-((4-fluorobenzyl)oxy)benzyl)amino)benzoic acid (4s):

Reaction scale: 50 mg (0.23 mmol) of 3-amino-5-bromobenzoic acid (11d). Compound 4s was prepared following the General Procedure A with aldehyde 3b (0.23 mmol). The product was purified by flash column chromatography (SiO2, CH2Cl2/CH3OH, 99.5:0.5) to give a pale amorphous solid (85 mg, 86% yield). 1H NMR (400 MHz, Methanol-d4) δ 7.42 (dd, J = 8.5, 5.4 Hz, 2H), 7.29 (d, J = 1.7 Hz, 1H), 7.26 (d, J = 8.3 Hz, 2H), 7.21 (t, J = 1.8 Hz, 1H), 7.07 (t, J = 8.8 Hz, 2H), 6.93 (d, J = 8.4 Hz, 2H), 6.91 (t, J = 2.1 Hz, 1H), 5.00 (s, 2H), 4.23 (s, 2H). 13C NMR (101 MHz, Methanol-d4) δ 169.1, 165.0, 161.9 (d, J = 146.3 Hz), 159.3, 151.5, 134.8, 134.2, 132.7, 130.6 (d, J = 8.2 Hz), 129.6 (2C), 123.7, 120.9, 119.9, 116.2, 116.04, 116.01 (2C), 113.6, 70.29, 47.67. TOFMSESI m/z: 428.0295 (C21H17BrFNO3 - H+ requires 428.0303).

3-((4-((4-fluorobenzyl)oxy)-2-methylbenzyl)amino)benzoic acid (4t):

Reaction scale: 50 mg (0.36 mmol) of 3-amino benzoic acid. Compound 4t was prepared following General Procedure A with aldehyde 12a (0.37 mmol). The product was purified by flash column chromatography (SiO2, CH2Cl2/CH3OH, 99.5:0.5) to give a white amorphous solid (100 mg, 70% yield). 1H NMR (400 MHz, DMSO-d6) δ 12.53 (s, 1H), 7.48 (dd, J = 8.5, 5.7 Hz, 2H), 7.25 – 7.16 (m, 2H), 7.18 (s, 1H), 7.17 (d, J = 4.0 Hz, 1H), 7.14 (d, J = 7.6 Hz, 1H), 7.11 (dt, J = 7.6, 1.5 Hz, 1H), 6.86 (d, J = 2.6 Hz, 1H), 6.79 (td, J = 8.6, 2.3 Hz, 2H), 6.31 – 5.95 (m, 1H), 5.05 (s, 2H), 4.15 (d, J = 4.5 Hz, 2H), 2.30 (s, 3H). 13C NMR (101 MHz, DMSO-d6) δ 167.7, 157.1, 148.8, 148.1 (d, J = 330.2 Hz), 137.3, 133.4 (d, J = 2.9 Hz), 131.3, 129.7, 129.6, 129.4, 128.7 (d, J = 7.3 Hz, 2C), 116.7, 116.5, 116.1, 115.1 (d, J = 21.4 Hz, 2C), 112.5, 111.6, 68.3, 44.2, 18.7. TOFMSESI m/z: 364.1360 (C22H20FNO3 - H+ requires 364.1354).

3-((4-((4-fluorobenzyl)oxy)-3-methylbenzyl)amino)benzoic acid (4u):

Reaction scale: 100 mg (0.72 mmol) of 3-amino benzoic acid. Compound 4u was prepared following General Procedure A with aldehyde 12b (0.73 mmol). The product was purified by flash column chromatography (SiO2, CH2Cl2/CH3OH, 99.5:0.5) to give a white amorphous solid (200 mg, 75% yield). 1H NMR (600 MHz, DMSO-d6) δ 7.49 (dd, J = 8.5, 5.7 Hz, 2H), 7.21 (dd, J = 8.9 Hz, 2H), 7.17 (dd, J = 2.0 Hz, 1H), 7.15 (d, J = 2.4 Hz, 1H), 7.14 (s, 1H), 7.11 (s, 1H), 7.10 (ddd, J = 7.5, 1.4 Hz, 1H), 6.95 (d, J = 8.3 Hz, 1H), 6.82 – 6.67 (m, 1H), 5.06 (s, 2H), 4.17 (s, 2H), 2.16 (s, 3H). 13C NMR (151 MHz, DMSO-d6) δ 167.7, 161.6 (d, J = 243.3 Hz), 155.1, 148.7, 133.7 (d, J = 2.9 Hz), 131.5, 131.2, 129.5, 129.4 (d, J = 8.2 Hz, 2C), 128.8, 125.8, 125.6, 116.6, 116.3, 115.2 (d, J = 21.3 Hz, 2C), 112.8, 111.6, 68.5, 45.8, 16.2. TOFMSESI m/z: 388.1328 (C22H20FNO3 + Na+ requires 388.1319).

3-((4-((4-fluorobenzyl)oxy)benzyl)amino)-4-methylbenzoic acid (4v):

Reaction scale: 50 mg (0.33 mmol) of 3-amino-4-methylbenzoic acid. Compound 4v was prepared following the General Procedure A with aldehyde 3b (0.34 mmol). The product was purified by flash column chromatography (SiO2, CH2Cl2/CH3OH, 99.5:0.5) to give a white amorphous solid (111 mg, 92% yield). 1H NMR (600 MHz, Methanol-d4) δ 7.44 (t, J = 6.7 Hz, 2H), 7.31 (d, J = 8.1 Hz, 2H), 7.26 (s, 1H), 7.21 (d, J = 7.8 Hz, 1H), 7.08 (t, J = 8.6 Hz, 2H), 7.01 (d, J = 7.7 Hz, 1H), 6.95 – 6.91 (m, 2H), 5.02 (s, 2H), 4.36 (s, 2H), 2.18 (s, 3H). 13C NMR (101 MHz, DMSO-d6) δ 168.4, 161.7 (d, J = 243.6 Hz), 157.0, 145.9, 133.4 (d, J = 3.0 Hz), 132.2, 129.9, 129.8, 129.4, 128.0 (2C), 127.9, 126.2, 117.1, 115.3, 115.0, 114.6 (2C), 114.4, 110.0, 68.4, 45.7, 17.8. TOFMSESI m/z: 364.1342 (C22H20FNO3 - H+ requires 364.1354).

3-((4-((4-fluorobenzyl)oxy)benzyl)(methyl)amino)benzoic acid (4w):

Paraformaldehyde (5 mg, 0.16 mmol), compound 4b (30 mg, 0.08 mmol), sodium triacetoxyborohydride (6.2 mg, 0.096 mmol) and 2 mL of ethanol were combined in a 10 mL of round bottom flask with a reflux condenser. The mixture was heated for 2 h at 100 °C and subsequently cooled to 25 ° for 12 h. The solvent was removed under vacuum and the residue was dissolved in EtOAc (60 mL). The organic layer was washed with aq. 1N HCl (20 mL), water (20 mL), and brine (20 mL). The organic layer was dried over Na2SO4, filtered, and concentrated under vacuum. The compound was purified by flash column chromatography (SiO2, CH2Cl2/CH3OH, 99.5:0.5) to give a white amorphous solid (13 mg, 43% yield). 1H NMR (400 MHz, Methanol-d4) δ 7.4 (d, J = 5.5 Hz, 1H), 7.4 – 7.4 (m, 2H), 7.3 (dt, J = 1.3, 7.6 Hz, 1H), 7.2 (t, J = 7.9 Hz, 1H), 7.1 (d, J = 8.6 Hz, 2H), 7.1 (t, J = 8.8 Hz, 2H), 7.0 (ddd, J = 1.1, 2.8, 8.3 Hz, 1H), 6.9 (d, J = 8.7 Hz, 2H), 5.0 (s, 2H), 4.5 (s, 2H), 3.0 (s, 3H). 13C NMR (101 MHz, Methanol-d4) δ 170.7, 163.8 (d, J = 244.4 Hz), 159.2, 151.1, 134.8 (d, J = 3.3 Hz), 132.4, 132.3, 130.6 (d, J = 8.3 Hz, 2C), 130.0, 129.2 (2C), 118.8, 118.2, 116.1 (d, J = 21.7 Hz, 2C), 116.0 (2C), 114.5, 70.3, 56.8, 38.9. TOFMSESI m/z: 388.1328 (C25H26FNO4 + H requires 388.1319). TOFMSESI m/z: 366.1509 (C22H20FNO3 + H+ requires 366.1500).

(R)-3-((4-(1-(4-fluorophenyl)ethoxy)benzyl)amino)benzoic acid (4x):

Compound 13 (53 mg, 0.15 mmol), (S)-1-(4-fluorophenyl)ethan-1-ol (21 mg, 0.15 mmol), and PPh3 (39 mg, 0.15 mmol) were dissolved in toluene (2.5 mL) and cooled to 0 °C. A solution of DtBAD (35 mg, 0.15 mmol) in toluene (5 mL) was added dropwise to the mixture. The reaction was warmed to 25 °C and stirred at for 12 h, at which time the reaction was deemed complete by TLC. The solvent was removed under reduced pressure. The residue was purified by flash column chromatography (SiO2, hexanes/ethyl acetate = 2: 1) to provide the desired product 14 as colorless oil. The resulting product 14 (50 mg, 0.114 mmol) was dissolved in a THF/MeOH/H2O (3:1:1) mixture and LiOH·added was (mmol 0.57, mg 24) H2O. The reaction stirred at 25 °C for 12 h upon which the reaction was deemed complete by TLC. The reaction was quenched with aq. 1N HCl (3 mL) and extracted with EtOAc (3 × 10 mL). The organic layers were combined dried over Na2SO4, filtered and concentrated by vacuum. The product 4x was purified by flash column chromatography (SiO2, CH2Cl2/CH3OH, 99.5:0.5) to give a white amorphous solid (25 mg, 65% yield). [α]20D = +22.0 (c = 9.1 mg/mL, l = 0.5 dm, MeOH). 1H NMR (400 MHz, Methanol-d4) δ 7.35 (dd, J = 8.6, 5.4 Hz, 2H), 7.29 – 7.24 (m, 1H), 7.26 – 7.23 (m, 1H), 7.19 – 7.15 (m, 2H), 7.15 – 7.09 (m, 1H), 7.01 (t, J = 8.8 Hz, 2H), 6.80 (d, J = 6.6 Hz, 2H), 6.79 – 6.75 (m, 1H), 5.33 (q, J = 6.4 Hz, 1H), 4.17 (s, 2H), 1.54 (d, J = 6.4 Hz, 3H). 13C NMR (101 MHz, Methanol-d4) δ 170.7, 163.5 (d, J = 243.8 Hz), 158.2, 150.2, 140.7 (d, J = 3.1 Hz), 133.1, 132.4, 129.9, 129.5 (2C), 128.7 (d, J = 8.3 Hz, 2C), 119.0, 118.4, 117.1 (2C), 116.1 (d, J = 21.7 Hz, 2C), 114.7, 76.4, 48.0, 24.7. TOFMSESI m/z: 364.1363 (C22H20FNO3 - H+ requires 364.1354).

(S)-3-((4-(1-(4-fluorophenyl)ethoxy)benzyl)amino)benzoic acid (4y):

Compound 13 (60 mg, 0.17 mmol), (R)-1-(4-fluorophenyl)ethan-1-ol (24 mg, 0.17 mmol), and PPh3 (45 mg, 0.17 mmol) were dissolved in toluene (2.5 mL) and cooled to 0 °C. A solution of DtBAD (39 mg, 0.17 mmol) in toluene (5 mL) was added dropwise to the mixture. The reaction was warmed to 25 °C and stirred at for 12 h, at which time the reaction was deemed complete by TLC. The solvent was removed under reduced pressure. The residue was purified by flash column chromatography (SiO2, hexanes/ethyl acetate = 2: 1) to provide the desired product 15 as colorless oil. The resulting product 15 (24 mg, 0.05mmol) (23 mg, 0.049 mmol) was dissolved in a THF/MeOH/H2O (3:1:1) mixture and LiOH·added was (mmol 0.25, mg 10) H2O. The reaction stirred at 25 °C for 12 h upon which the reaction was deemed complete by TLC. The reaction was quenched with aq. 1N HCl (3 mL) and extracted with EtOAc (3 × 10 mL). The organic layers were combined, dried over Na2SO4, filtered, and concentrated by vacuum. The product 4y was purified by flash column chromatography (SiO2, CH2Cl2/CH3OH, 99.5:0.5) to give a white amorphous solid (14 mg, 75% yield). [α]20D = −22.0 (c = 9.1 mg/mL, l = 0.5 dm, MeOH). 1H NMR (600 MHz, Methanol-d4) δ 7.40 – 7.34 (m, 2H), 7.28 – 7.24 (m, 1H), 7.27 – 7.22 (m, 1H), 7.21 – 7.16 (m, 2H), 7.13 (t, J = 7.8 Hz, 1H), 7.02 (t, J = 8.8 Hz, 2H), 6.82 – 6.80 (m, 2H), 6.79 (ddd, J = 8.1, 2.5, 1.0 Hz, 1H), 5.36 (q, J = 6.4 Hz, 1H), 4.19 (s, 2H), 1.55 (d, J = 6.4 Hz, 3H). 13C NMR (151 MHz, Methanol-d4) δ 170.8, 163.7 (d, J = 243.9 Hz), 158.3, 150.4, 140.9 (d, J = 2.9 Hz), 133.3, 132.5, 130.0, 129.7 (2C), 128.8 (d, J = 8.4 Hz, 2C), 119.2, 118.6, 117.3 (2C), 116.3 (d, J = 21.6 Hz, 2C), 114.8, 76.5, 48.2, 24.8. TOFMSESI m/z: 364.1365 (C22H20FNO3 - H+ requires 364.1354).

4-((2-(4-fluorophenyl)propan-2-yl)oxy)benzaldehyde (17):

To a solution of compound 16 (1.5 g, 8.2 mmol) in MeCN (10 mL) at 0 °C was added DBU (3.7 g, 24.6 mmol). TFAA (1.14 mL, 8.2 mmol) was added dropwise and the solution was stirred for 30 min. Then the mixture was added dropwise to a solution of compound 1 (1 g, 8.2 mmol) and CuCl2·H2O (1.4 mg, 0.0082 mmol) in MeCN (10 mL) over a period of 5 min at 0 °C. The mixture was allowed to warm to 25 °C and stir for 12 h. The solvent was removed under reduced pressure and the residue was diluted in DCM (40 mL). The organic layer was washed sequentially with aq. 1N HCl (2 × 20 mL), aq. 1N NaOH (2 × 20 mL), sat. aq. NaHCO3 (2 × 20 mL), and brine (20 mL). The organic layer was dried over Na2SO4, filtered, and concentrated in vacuo. Compound 17 was purified by silica gel chromatography (SiO2, hexanes/ethyl acetate = 20:1) to provide the desired product as colorless oil. Yield: 8%. 1H NMR (500 MHz, Chloroform-d) δ 9.81 (s, 1H), 7.68 – 7.62 (m, 2H), 7.44 – 7.36 (m, 2H), 7.10 – 7.01 (m, 2H), 6.78 – 6.69 (m, 2H), 1.78 (s, 6H). 13C NMR (126 MHz, Chloroform-d) δ 190.9, 162.1 (d, J = 246.5 Hz), 161.6, 141.3 (d, J = 3.4 Hz), 131.4, 129.8, 126.9 (d, J = 8.0 Hz), 119.1, 115.7 (d, J = 21.4 Hz), 81.1, 29.8.

3-((4-((2-(4-fluorophenyl)propan-2-yl)oxy)benzyl)amino)benzoic acid (4z):

Compound 4z was prepared following the General Procedure A with aldehyde 17 (0.62 mmol). The desired product was purified by flash column chromatography (SiO2, CH2Cl2/CH3OH, 99.5:0.5) to give a white amorphous solid (60 mg, 25% yield). 1H NMR (500 MHz, DMSO-d6) δ 8.4 (s, 1H) 7.53 – 7.45 (m, 2H), 7.22 – 7.13 (m, 2H), 7.14 (d, J = 2.3 Hz, 1H), 7.16 – 7.08 (m, 2H), 7.12 – 7.05 (m, 1H), 7.07 (s, 1H), 6.70 (dt, J = 6.2, 2.9 Hz, 1H), 6.62 – 6.55 (m, 2H), 6.26 (t, J = 5.9 Hz, 1H), 4.13 (d, J = 5.4 Hz, 2H), 1.63 (s, 6H). 13C NMR (101 MHz, DMSO-d6) δ 168.4, 161.1 (d, J = 243.0 Hz), 154.1, 148.6, 142.3 (d, J = 3.1 Hz), 132.8, 128.5, 127.9 (2C), 127.3 (d, J = 8.0 Hz, 2C), 119.9 (2C), 116.8, 115.5, 115.0 (d, J = 21.0 Hz, 2C), 112.9, 102.2, 79.4, 45.8, 29.1 (2C). TOFMSESI m/z: 402.1482 (C23H22FNO3 + Na+ requires 402.1476).

2-(3-((4-((4-Methoxybenzyl)oxy)benzyl)amino)phenoxy)-2-methylpropanoic acid (5a):