By late spring 2020 the Covid-19 pandemic had caused virtually all international conferences and exhibitions to be canceled or postponed to the following year. As a result MPR is able to give more space to important but as yet unreported contributions from 2019.

One such instance played an important part across two sessions of the EPMA 2019 Annual Congress, where experts in the fields of hard materials and additive manufacturing jointly studied the interlocking status of their respective arts.

The problem

So what is so special about AM-HM?

The typical raw material for additive manufacturing, colloquially ‘3D printing,’ is plastic or metallic, melts within a small temperature range and welds strongly to the previously melted material. Hardmetals, on the other hand, comprise two wildly different materials: particles of hard and wear-resistant ceramic, typically but not exclusively tungsten carbide (WC), embedded in a tough metallic matrix such as cobalt (Co). The ceramic WC melts at nearly 2800 °C, whilst the melting point of pure cobalt is about 1500 °C. In traditional PM, moreover, the WC doesn’t melt, but partially dissolves and reprecipitates from the matrix during liquid-phase sintering. At just above the WC melting point, pure Co is vaporized.

No wonder that hardmetal AM has been so long in coming, and rated not one but two special sessions at the EPMA Maastricht event. The first of these concentrated on fusion processes whilst the second trained its sights on more indirect methods. Most of the papers described relatively simple WC/Co alloys, but there were exceptions looking at more complex compositions. They are reviewed in order of presentation.

Part One: HM and AM fusion processes

“Thermal post-treatment of additively manufactured WC/Co processed by laser powder bed fusion” presented by Tobias Schwanekamp of the Institute of Manufacturing and Tooling Technology, Cologne University of Applied Sciences

In his introduction, the author explained that the increased design freedom offered by AM processes such as laser powder bed fusion (LPBF) offered significant benefits in developing innovative cutting tool concepts, such as lightweight design and increased functionality. The ability to fabricate customized coolant channel systems inside the tool was of particular interest. (Your reviewer, by contrast, considers the immediate future of AM-HM to lie in the manufacture of complex wear parts – KJAB)

The LPBF process, the presenter said, was completely different from conventional sintering, the classical method for producing WC/Co. The laser energy was focused on a very small spot a few tens of microns in diameter, moving along the powder surface. Depending on process parameters and the powder material, LPBF offered heating and cooling rates between 103 and 108 K/s, leading to the possibility of developing non-equilibrium phases. However, high temperature gradients induced residual stresses in the parts being produced. These stresses imposed serious limitations to the quality of the laser molten material, causing deformation and thermal cracks.

Significant improvement in the quality of laser molten WC/Co was achieved by high-temperature preheating of the baseplate. With preheating temperatures of 800 °C, thermal cracking was prevented within a wide range of parameters, porosity substantially reduced and minimum laser energy for solidification reduced. With this, undesired W2C and eta-phase transformation could be reduced to values closer to the detection limit of X-ray diffraction (XRD). However, even with high-temperature preheating, material properties were poorer than those of conventionally sintered WC/Co. Hence additional measures such as thermal post-processing (sinter-HIP) of L-PFB processed material were required.

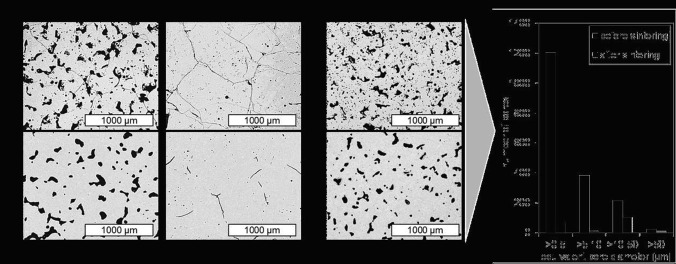

For this research project, initial tests employed specimens from WC/Co 88/12 and 83/17 powders subjected to thermal post-processing in cooperation with GKN Sinter Metals Engineering. Due to limitations in the available plant, sintering conditions could not be optimized for WC/Co material. Maximum temperature of the sintering furnace was limited to 1400 °C and the sintering process was conducted under vacuo. Nevertheless, small-sized pores and cracks of specimens generated from WC/Co 83/17 were reduced significantly, as shown in Figure 1 . All samples generated by LPBF without preheating (Figure 1a) showed a network of cracks and, depending on the energy input, a characteristic amount of residual pores. With the follow-up sinter process, small-sized pores vanished and cracks partially healed. Samples generated with 800 °C preheating produced residual pores rather than cracks but for very low laser energy inputs (Figure 1b). Subsequent sinter processing significantly reduced the porosity. Reduction of pores was most significant for equivalent pore diameters below 10 µm, as shown in the diagram.

Figure 1.

Reduction of small-sized pores and cracks achieved by conventional sintering of specimens generated by LPBF from WC/Co 83/17 with different specific energy inputs EV.

Promising results in the initial tests were followed by experiments focused on reducing remaining defects by sinter-HIP post-treatment, with temperature and pressure profiles similar to those of conventional WC/Co sintering. This main study used agglomerated and presintered WC/Co thermal spray powder. Table 1 gives an overview of the powder specifications as provided by the factory certification test report from Durum Verschleiss-Schutz. (The table indicates a substantial excess of carbon in the powder, probably because of its original intended use in thermal spraying. For these experiments, perhaps a composition closer to stochiometric from a sintered hardmetal manufacturer might have been a better initial choice. Stoichiometric carbon content based on 83% WC would be 5.08 rather than 5.46%, so a value nearer to this might have given less likelihood of performance-lowering free graphite in the final microstructure - KJAB)

Table 1.

Material data of processed WC/Co thermal spray powder.

| DURMAT | WC/Co | Co wt % |

C wt % |

W wt % |

Particle size µm | WC grain size µm | Bulk density g/cm3 |

|---|---|---|---|---|---|---|---|

| 102.007 | 83/17 | 17.04 | 5.46 | 77.5 | −45 + 22 | 2.5 | 4.9 |

All samples were built on a Renishaw AM 250 system under inert gas atmosphere (nitrogen 5.0) at an elevated preheating temperature of the baseplate of 800 °C. A standard meander scan pattern was applied using a 200 W fiber laser with a focal diameter of df = 75 µm. Layer thickness was kept to a constant value of 30 µm. Different test series are illustrated in Figure 2 .

Figure 2.

Sample geometries for parameter screening (DoE) and detailed analysis of density, residual stresses and phase composition.

In the first test setup, simple cubic specimens were generated under wide variation of laser power from Pmin 36 W to Pmax 200 W, scan velocity from Vmin 36 mm/s to Vmax 200 mm/s and hatch distance from hmin 36 µm to hmax 200 µm. To reduce experimental effort a central composite ‘design of experiments’ (DoE) was chosen.

Effects of thermal post-treatment on sample properties were analyzed; thermal cracking and pores by microscopic examination of polished cross-sections, elemental composition and microstructure by SEM and energy dispersive X-ray spectroscopy (EDX), hardness as HV3 and transverse rupture strength by conventional three-point bending.

In a second step three different parameter settings were selected for more detailed analysis, representing low (196 J/mm3), medium (278 J/mm3) and high (476 J/mm3) specific energy input EV. Larger cubic specimens were generated by LPBF with each edge ground to 21 mm length. As a thermal post-treatment, the laser molten samples were subjected to a sinter-HIP process normally applied for sintering of conventional WC/Co tools. These experiments were carried out by Seco Tools in Sweden. The impact of sinter-HIP on phase composition was evaluated by X-ray diffraction before and after sintering. Volume shrinkage was calculated from increase in density during sinter-HIP.

The impact of sinter-HIP on porosity was evaluated over a wide range of LPBF parameter settings, as shown in Figure 3 . Unfortunately, relatively low magnification displays only macro- rather than microstructure. It seems to have come as a surprise to the experimenters that even very large pores and highest porosities were reduced to near zero by sinter-HIP, and that the overall porosity of samples thus post-treated was hardly affected by the previous LPBF parameters. However, such a result would be expected by any experienced hardmetal manufacturer. The initial laser heating would melt only the cobalt binder, which would hold the WC particles together in the desired configuration on resolidification during normal liquid-phase sintering. Though the carbide particles would not melt, they would fracture on a micro scale due to imposed thermal stresses. Subsequent conventional sinter-HIP would induce liquid-phase sintering (with change of Co to a Co/WC pseudo-eutectic), closure of porosity, shrinkage and densification.

Figure 3.

Impact of sinter-HIP on the porosity of samples generated by LPBF from WC/Co 83/17 with variations in P, V and h; polished cross sections (left) and main effects plots (right).

Density measurements after sinter-HIP indicated a reduction of sample volume between 2.5 and 3.5% and an increase of density, as shown in Figure 4 . The most significant effect was achieved for the sample with the lowest energy input during LPBF. Mass differences measured before and after sinter-HIP were negligibly small. Density values above those of conventional WC/Co 83/17 were measured for all post-treated samples, due to the loss of Co by evaporation during the laser AM process. This evaporation effect strongly depended on the LPBF process parameters P, V and h, respectively the energy input EV. In the current study, there was no significant effect of sinter-HIP on Co content within the limit of measurement uncertainties, which would be expected because the evaporation temperature of Co is not reached during sinter-HIP.

Figure 4.

Results of density measurement.

More detailed XRD phase analysis of the large cubic samples before and after sinter-HIP also indicated no significant impact on phase formation. Beside the original WC and Co phases from the powder, undesired phases such as W2C and eta-phase were not detected in any of the samples. (but these would only be seen in low-carbon compositions. Was any check made for free carbon, which is also an ‘undesired phase’? If the quoted composition was correct, we know it was in the raw material. – KJAB).

All patterns of the sinter-HIP samples showed significantly lower “noise” and more pronounced peaks in comparison with the non-treated samples. This is an indicator for a higher grade of crystallization, since the noise in XRD is increasing with increasing amount of amorphous structures. This is indicated by SEM micrographs, shown in Figure 5 . The post-treated samples all exhibit a clear separation between the Co matrix (black) and the WC grains (light gray). For the non-treated LPBF samples the Co matrix is highly saturated with tungsten being visible by the gray interspersion of the matrix. For the sample with the high energy input (476 J/mm3), some dark gray regions are also found between the WC grains of the sinter-HIP microstructure (encircled). These regions are most likely traces of eta-phases, too less to be detected by XRD. Visual analysis of the micrographs suggests, that the WC grain growth during sinter-HIP increases with the amount of residual binder. However, the measurement equipment within this study does not allow for a quantitative comparison between grain size distributions of the investigated samples. More detailed analysis will be required for confirmation.

Figure 5.

SEM (BSE) images of WC/Co microstructure after LPBF and LPBF + sinter-HIP.

Even though the microstructure was obviously affected by sinter-HIP, a significant effect on the average Vickers hardness was not found during tests on all DoE samples. However, for the untreated samples, volumetric defects such as pores can cause a significant degradation of the material resistance against the Vickers indent. This led to large variations in measured HV3 values. A significant reduction of the standard deviation in Vickers hardness was subsequently achieved by sinter-HIP, due to lower porosity.

Besides Vickers hardness, transverse rupture strength (TRS) was considered to be another important quality feature, especially for cutting tool applications. A comparison of the results between untreated and post-treated samples in the parameter range of the DoE indicated that a significant increase in maximum TRS values was not achieved by sinter-HIP. This was shown in the main effects plot of Figure 6 . However, the optimum parameter settings for maximizing TRS value were shifted towards parameter sets with lower energy inputs. For those parameter settings, the adverse effect of Co evaporation and eta-phase formation was the lowest. Nevertheless, these parameter settings also caused the highest porosities, resulting in significant decrease in TRS of the untreated samples.

Figure 6.

Main effects plots – impact of sinter-HIP on the TRS of samples generated by LPBF from WC/Co 83/17 with variations in P, v and h.

The elimination of those pores through sinter-HIP led to a significant increase in the TRS. Based on the results and trends, shown in Figure 3, Figure 6, sinter-HIP was expected to allow further reduction of energy input during LPBF as well as an increase of maximum TRS. Future work would therefore probably focus on an investigation of maximum porosity values, which could still be reduced by sinter-HIP. For this purpose, minimum energy input for solidification of WC/Co during LPBF should also be taken into account.

For some of the samples, considerable geometrical distortions were observed after sinter-HIP. This was particularly evident in the large cubic samples, shown in Figure 7 a. Such deformations are crucial for grinding of tools (see Figure 7b), since they provoke unacceptably high grinding allowances or, at worst, rejection of the tool. The deformations are particularly sensitive to shrinkage effects, especially the reduction of volume by elimination of pores. In the investigation, residual stresses in the samples were measured and compared to untreated reference samples. The results of these tests are shown in Figure 7c. Since the residual stresses in the first 0.25 mm of drilling depth might be affected by surface grinding, this area was excluded from the analysis. The highest residual stresses occurred in the sample with the high energy input of 476 J/mm3 during LPBF. Understandably, the stresses were significantly reduced after sinter-HIP. However, this stress release led to the highest deformation of all samples. Low energy input (LPBF 196 J/mm3) generally led to lower residual stresses and therefore to less deformation after sinter-HIP.

Figure 7.

Deformation of samples after sinter-HIP; cubic samples (a) and tool bodies (b), residual stresses in laser molten WC/Co samples before and after sinter-HIP (c).

Summaries

The author refers to “laser molten” WC/Co on numerous occasions, but it seems doubtful to this reviewer that more than a tiny fraction, if any, would have reached the exceptionally high melting point of WC without evaporating most or all of the low-boiling-point cobalt. Nevertheless, I’ve used the author’s terminology in case he has unpublished research to prove my supposition incorrect. However, this is only terminology and does not affect the actual investigation and the results included in the paper.

The WC/Co produced in this investigation was characterized by several material deficits, which precluded any industrial application such as additive manufacturing of innovative WC/Co cutting tools. Of course one problem was that the investigators chose compositions with nominal Co contents higher than almost any commercial hardmetal cutting tool. A significant improvement to the WC/Co material quality was achieved by high-temperature preheating of the base-plate during LPBF and a sinter-HIP post-treatment was applied to further eliminate remaining defects such as pores.

The author summarized his main findings as follows:

-

•

Sinter-HIP significantly reduces the porosity inside laser molten WC/Co. Even large pores beyond 50 µm in equivalent diameter can almost be eliminated. Relative densities close to 100% can be achieved. Therefore sinter-HIP offered the option to significantly reduce the energy input during LPBF. Consequently, the evaporation of binder, the formation of undesired phases and the induction of thermal stresses is reduced.

-

•

The overall residual binder content and the phase composition inside the laser molten WC/Co material is not significantly affected by sinter-HIP. However, sinter-HIP leads to recrystallization of WC, dissolved within amorphous regions of the binder matrix.

-

•

Some samples were drastically deformed after sinter-HIP. Correspondence between residual stresses after LPBF and the grade of deformation after sinter-HIP is related to the results of residual stress measurements. High laser energy inputs lead to higher stresses after LPBF and consequently to higher deformation after sinter-HIP.

Based on the results, a reduction of laser energy input in LPBF in combination with sinter-HIP post-treatment is considered as a promising measure to improve the material quality of laser molten WC/Co. Further work should focus on the identification of maximum porosity values, which can still be closed by sinter-HIP as well as the minimum energy input which is required for solidification of WC/Co during LPBF. Another important aspect is the reduction of WC grain growth, since hardness and toughness are significantly degraded with increasing grain sizes. The results indicate a potential correlation between the amount of binder and the grain growth during sinter-HIP. Furthermore, a detailed investigation of the impact factors on deformation during sinter-HIP must be conducted, since those deformations provoke unacceptably high grinding allowances in tool manufacturing.

My own summary is a little different:

-

•

The research appears to show that AM can in principle be substituted for conventional pressing of complex hardmetal shapes prior to conventional processing by sinter-HIP. It might also be possible to use conventional sintering (in vacuo, carbon-rich or hydrogen atmosphere) without added pressure, after AM.

-

•

Initial proof-of-concept testing has been carried out on high-cobalt, high-carbon, coarse-grain WC/Co powder mixes optimized for spraying rather than sintering. It is suggested that at least some of further research be carried out on lower-carbon (nearer to but still greater than stoichiometric), lower-cobalt, fine-grain powder mixes, also containing chromium-based grain-growth inhibitor, optimized for sintering. Another possibility (which I would prefer) might be 92(W/Ti/Ta/Nb)C/8Co with tough solid-solution rounded carbide grains of about 1 micrometer nominal grain size and much better mechanical and thermal properties than simple WC/Co – but regrettably it is most unlikely to be available today in research quantities.

“Investigation of metallurgical reactions between tungsten titanium carbide and Ni and Fe alloys in PTA weld pool” presented by Petr Fiala, Oerlikon Metco (Canada), Fort Saskatchewan, Canada

This paper described research to develop a new or extended application for an existing industrial product, titanium tungsten carbide (Ti,W)C, used successfully as a hard phase with a Ni or Fe base matrix as a PTA (plasma transferred arc) hardfacing feedstock. But the paper doesn’t even mention additive manufacturing, though it was presented in a session devoted to AM in a hard materials context. Nonetheless, it may provide a clue or two for the investigating AM of hard materials and the congress organizers clearly thought it worthy of inclusion.

Because the alloy systems mentioned are extremely complex and reaction-time sensitive, I’ve given rather more detail than I’d normally include in a review. However, the alternative would be to suggest accessing the original to any interested reader, which would be distinctly less useful.

Plasma Transferred Arc (PTA) is a common deposition method for creating carbide-based wear-resistant overlays, which are mostly used in mining operations. The PTA process injects a blend of carbide powder and matrix material into a weld pool formed on the surface of a substrate. During this process, the matrix is melted and the carbide is dispersed throughout the matrix. Some carbide particles may dissolve into the matrix and reprecipitate as various phases. The make-up of these precipitates depends upon which alloying elements are present in the matrix. Typical feedstock material is tungsten carbide blended with a nickel self-fluxing alloy. Tungsten carbide is either stoichiometric WC or low-carbon so-called cast tungsten carbide W2C/WC. The W2C/WC has a lamellar eutectoid microstructure of W2C and WC. Such microstructure is able to resist a compressive mechanical load without fracturing but possesses a lower dissolution resistance compared to the stoichiometric WC. However, W2C is metastable under 1250 °C which increases reactivity with the matrix. The high thermal diffusivity of tungsten carbide also results in increased particle dissolution in the weld pool. Another disadvantage of tungsten carbide is its high enthalpy of formation ΔHf = −38.5 kJ/mol, compared for example to TiC with ΔHf = −185.6 kJ/mol, which makes WC more easily dissolved by molten metals. It is possible to modify these characteristics of tungsten carbide by alloying it with titanium carbide. (Ti,W)C has a density of 9.8–10.1 g/cm3, which is close to the density of nickel- or iron-based matrices and helps it to disperse evenly in the matrix. The addition of TiC stabilizes the WC phase and allows it to exist as a metastable phase at room temperature while increasing carbide microhardness to 2700–3000 HV0.1. Moreover, this carbide has a higher dissolution, corrosion and oxidation resistance compared to tungsten carbide. These properties help an overlay made with this hard phase to retain its hardness. (Note: higher microhardness does not necessarily imply higher abrasion resistance. – KJAB)

Relatively commonplace to hardmetal manufacturers since the early days of steelcutting carbide tools, (Ti,W)C was developed for PTA to meet requirements which tungsten carbide was said not to address. These included wear applications in corrosive environments and less-expensive overlays with iron-based matrices. Both of these required better dissolution resistance of the carbide in nickel superalloys or in any type of iron-base alloy. For these reasons, (Ti,W)C development was focused on two combinations: (Ti,W)C in an Inconel 625 type matrix and (Ti,W)C in a stainless steel 316L type matrix. Since W2C/WC could not be welded in alloyed matrices in the same way as (Ti,W)C, for performance comparison of (Ti,W)C with cast tungsten carbide (W2C/WC) it was decided to PTA deposit both in the most commonly used W2C/WC matrix alloy, Ni3B3Si, with as few variables as possible. Unfortunately it was still impossible to compare these two material systems under identical conditions, the most serious problem being the formation of porosity in the (Ti,W)C + Ni3B3Si overlays (see Figure 8 ). In contrast, the W2C/WC + Ni3B3Si overlay had no apparent porosity, but this seems to have been after examination at only 15x magnification, much too low to confirm zero porosity.

Figure 8.

Pores in (Ti,W)C + NiBSi overlay.

The speaker noted that W2C/WC carbide might also occasionally produce overlays with some porosity, often with the cause being difficult to determine. In the case of (Ti,W)C it was first suspected that factors such as moisture in the powder, unsuitable deposition parameters, lot-to-lot variability or free carbon in the carbide were culprits. Further unspecified testing did not confirm any of these potential causes and were eventually rejected. It was not possible to establish a reproducible correlation between amount of porosity and amount of any of the matrix alloying elements. It was therefore decided to perform several more PTA deposition tests combined with RAD (Rapid Alloy Development) software modeling and EDS analysis. At the same time, a series of dissolution tests of W2C/WC and (Ti,W)C in Ni self-fluxing alloy and steel was performed.

Overlay samples were deposited by PTA (Plasma Transferred Arc) on ASTM A516 Carbon Steel, Grade 70, using a Stellite Starweld 400A PTA system with an Excalibur torch. All powders used for the PTA welding test were used in a ratio of 60 wt.% carbide and 40 wt.% matrix. The matrix materials were pure Ni, MetcoClad 625 (Inconel 625 type composition), XPT 734 (NiBSi), MetcoClad 316L-Si (steel 316L type composition), and martensitic alloy Metco 1030A. All alloys were produced and supplied by Oerlikon Metco and their compositions are listed in Table 2 . Substrates were cleaned by grit blasting with 20 mesh Metcolite C that consists of 3.5 wt.% TiO2, balance Al2O3.

Table 2.

Compositions of individual components in wt.%.

| Powders | Ni | Fe | Cr | Si | Ti | W | Mo | Mn | Nb | B | C |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Pure Ni | Bal. | ||||||||||

| XPT 734 | Bal. | 3 | 3 | ||||||||

| Metco 14E | Bal. | 2.8 | 11 | 3.9 | 2.25 | 0.45 | |||||

| MetcoClad 625 | Bal. | 4 | 22 | 9 | 0.4 | 4 | |||||

| MetcoClad 316L-Si | 12 | Bal. | 17 | 2.3 | 2.5 | 1.0 | 0.03 | ||||

| Metco 1030A | Bal. | Proprietary martensitic alloy | |||||||||

| (Ti,W)C | 22.7 | Bal. | 8.8 | ||||||||

| W2C/WC | Bal. | 3.9 | |||||||||

The RAD (Rapid Alloy Development) software platform was used for evaluating the compositional space of individual compositions in broad ranges of concentrations and temperatures. The RAD modeling used an interface model where carbide of a fixed composition was dissolved in matrix material from 0 to 50 wt.% in increments of 1 wt.%. Temperature range was 1000–3000 K in increments of 50 K. The influence of substrate chemistry was also taken into consideration.

RAD calculations were also used to develop a criterion to assess the dissolution resistance of W2C/WC and (Ti,W)C in metal matrices. Dissolution resistance was determined by the amount of primary carbides which could resist dissolution in a liquid matrix at a specific temperature. Primary carbides were regarded as the original carbide phases in W2C/WC and TiC, ie MC, cubic MC and M2C-type phases. M6C (eta carbides), M7C3, M23C6 and other carbides formed from matrix or dissolution products were not viewed as primary carbides. The dissolution behaviors of carbides with compositions covering a section of the Ti-W-C ternary system were analyzed for two different metal matrices: a Ni self-fluxing alloy matrix (Metco 14E) and an Fe-based matrix (MetcoClad 316L-Si). Their compositions are also provided in Table 2.

In parallel with the RAD calculations, a simple experiment to evaluate the dissolution resistance of carbides in molten alloys was carried out. Powder mixtures containing 20 mol% carbide +63/−150 µm (W2C/WC or (Ti,W)C1−X) and 80 mol% matrix +53/−125 µm (Metco 14E or MetcoClad 316L-Si) were placed in an alumina crucible then heated in argon atmosphere to 1400 °C and kept at this temperature for 30 min. The material combinations are listed in Table 3 . To compare the dissolution resistance of carbides having different densities, the same mole ratio carbide/matrix (20:80) for all the powder mixtures was used (higher carbide contents led to problems with a carbide wettability by the matrix). The carbide particles, matrix and dissolution products were characterized by SEM and EDS analysis and the results compared to the RAD calculation results.

Table 3.

Powder blends for the dissolution tests in mol%

| Carbide mol% |

Matrix mol% |

||

|---|---|---|---|

| W2C/WC | (Ti,W)C | Metco 14E | MetcoClad 316L-Si |

| 20 | 80 | ||

| 20 | 80 | ||

| 20 | 80 | ||

| 20 | 80 | ||

Table 4 summarizes all overlays and indicates which ones contained porosity. The amount of porosity fluctuated in those overlays and no clear correlation between porosity and deposition parameters was found. Even though W2C/WC + XPT 734 overlays did not contain porosity in this instance, it is known to occasionally occur with this combination of components. Cross-sections of some of the overlays are illustrated in Figure 9 .

Table 4.

Characterization of overlays.

| Material compositions | Pores | Graphite* |

|---|---|---|

| W2C/WC + XPT 734 | No | Yes |

| (Ti,W)C + XPT 734 | Yes | Yes |

| (Ti,W)C + MetcoClad 625 | No | No |

| (Ti,W)C + MetcoClad 316L-Si | No | No |

| (Ti,W)C + Metco 1030A | No | No |

| (Ti,W)C + Ni | Yes | Yes |

| W2C/WC + XPT 734 + 1 wt.% Metcolite C | No | Yes |

| (Ti,W)C + XPT 734 + 1 wt.% Metcolite C | Yes | Yes |

Identified by RAD software.

Figure 9.

Overlay cross-sections, optical light microscopy, 15x magnification, (a) (Ti,W)C + XPT 734, (b) W2C/WC + XPT 734, (c) (Ti,W)C + Metco 1030A.

(Ti,W)C + 40 wt% Ni3B3Si overlay originally contained a significant amount of porosity but when the experiment was repeated, no porosity was detected. In this respect this composition behaved in an unpredictable way. However, (Ti,W)C + XPT 734 + 1 wt.% Metcolite C overlays contained noticeable amounts of porosity in a range of deposition parameters. RAD modeling identified the formation of TiB2, Ni-Si-W matrix and graphite throughout the evaluated range of (Ti,W)C dissolution. The temperature interval of graphite presence in molten alloy reached 900 K (see Figure 3a) and provided carbon with enough time to react with oxygen. (W,Ni)2B formed up to about 18% dissolution, WC started forming above 14% and (Ti,W)C above 25% dissolution. If dilution with the substrate were considered then Fe partially replaced Ni and formed (W,Fe,Ni)3B2 for dissolution up to 23% and (Ni,Fe)3B up to 13%. The balance of Fe remains in the Ni-Fe-Si-W matrix. The amount of dissolved Fe did not affect graphite formation in any significant way. Graphite formation temperature was reached above 2350 K (see Figure 3a), explaining the possibility of reducing alumina blasting grit together with all other less stable oxides and forming CO bubbles. This possibility has been confirmed by a follow-up RAD calculation.

W2C/WC + 40 wt.% Ni3B3Si overlays contained very few pores no matter which deposition parameters were used or whether the blend was doped with 1 wt.% of Metcolite C grit. RAD modeling identified the formation of Ni-Si-W matrix and (Ni,W)2B in the whole evaluated range of W2C/WC dissolution. Graphite forms in a 15–35 wt.% concentration range of dissolved W2C/WC (see Figure 3b), and it always forms after (W,Ni)2B. Ni3B is formed only up to about 20 wt.% of dissolved W2C/WC and WC is formed for concentrations above 23 wt.% of dissolved W2C/WC. If WC forms in the melt at high temperature it could cause a step increase in the graphite content between 1500 and 1450 K. Some of its W would dissolve in the Ni-Si-W matrix and the remaining C would form graphite. Since this change occurred at a temperature close to the matrix solidus and no evidence for it was observed, it was assumed that this transformation did not happen and WC remained stable to room temperature. Formation temperature of graphite was <1800 K for any dissolved content of W2C/WC (see Figure 10 b) and hence graphite was not able to reduce alumina or titania in the embedded blast media. If dilution with the substrate were considered, Fe could be found in the Ni-W-Fe-Si matrix, (W,Ni,Fe)2B, (W,Fe,Ni)3B2 and (W,Ni,Fe)6C phases.

Figure 10.

(Column a) (Ti,W)C + XPT734, (column b) W2C/WC + XPT734, (column c) (Ti,W)C + Ni, the secondary alloy is (Ti,W)C; melt graphite content is in mol%; formation temperature of graphite is in K.

(Ti,W)C + 40 wt% Ni overlays contained porosity. The amount of porosity decreased with increasing shielding gas flow (argon 12–14 liters per minute) and switching the center and powder feed gas from Ar to the reducing Ar/5H2. A complete elimination of porosity was achieved by increasing the welding current from 140 to 160 A. The RAD modeling identified formation of graphite above the matrix solidus in the dissolution range of 7–37 wt.% (Ti,W)C (see Figure 10).

In overlays made from (Ti,W)C + 40 wt% Metcoclad 625, (Ti,W)C + 40 wt% Metcoclad 316L-Si, and (Ti,W)C + 40 wt% Metco 1030A, porosity was absent form blends no matter which deposition parameters were used. RAD modeling did not identify graphite formation at temperatures above the matrix solidus for these compositions.

RAD calculations were also used to assess the dissolution resistance of W2C/WC and (Ti,W)C in Ni- and Fe-based matrices. Figure 11 a shows the effect of Ti content on the dissolution resistance of primary carbide fraction of Ti-W-C carbides in a NiCrSiB matrix (MetcoClad 14E) at 1400 °C. In general, higher Ti content increases carbide dissolution resistance up to a maximum close to pure TiC, close to 48Ti/2W/50C in at.% in Figure 11a. This composition could retain about 17.1 mol% of the primary carbide of the original 20 mol%. By comparison, pure WC and W2C/WC compositions had lower dissolution resistance, especially W2C/WC (62 W/38C in at.%), where the presence of a large fraction of metastable W2C accounts for this behavior. As shown in Figure 12 , W2C/WC particles were drastically dissolved after the dissolution test. Only some WC phase was still present inside the primary carbides. EDS analysis of the primary tungsten carbide particle after the test revealed a higher Ni content (≈30 wt.%) within the carbide particle, which is higher than the tungsten content, thus confirming the high dissolution level. By contrast, even if the surface of (Ti,W)C carbides is transformed into (Ti,W,Cr)CX carbide, the particle core is virtually unaffected (see Figure 6). EDS analysis of the particle core revealed that Ti and W were the main elements together with C. This result shows that (Ti,W)C carbides have a better dissolution resistance in NiCrBSi than W2C/WC which is also evidenced by RAD calculations.

Figure 11.

RAD calculations of dissolution resistance of WC, W2C/WC, and (Ti,W)C in (a) NiCrBSi and (b) 316L type matrix. Primary carbide fraction and compositions are in mol% and at.%, respectively.

Figure 12.

(a and b) – Microstructure of W2C/WC in NiCrBSi (Metco 14E) matrix after 30 min at 1400 °C.

Figure 11b illustrates the dissolution resistance of (Ti,W)C carbides in a stainless steel matrix (MetcoClad 316L-Si) as a function of Ti content. TiC once again increased the dissolution resistance of (Ti,W)C. Dissolution of both types of carbide was more severe in the Fe-based matrix than in the Ni-based matrix. In fact, pure cast tungsten carbide W2C/WC dissolved completely in the MetcoClad 316L-Si molten bath at 1400 °C. These results were in good agreement with the RAD calculations since no pure WC or W2C were detected by EDS analysis among the resulting phases in the W2C/WC + 80 mol% MetcoClad 316L-Si melted sample. (Ti,W)C carbide retention was lower in the Fe-based compared to the Ni-based matrix, 12 mol% compared with 15.5 mol% from the original 20 mol%. Unlike W2C/WC, some primary (Ti,W)C carbides were found in the MetcoClad 316L-Si matrix after the dissolution test.

Summary

Although (Ti,W)C variants were developed for crater-resistant steelcutting hardmetals many years ago, they seem to be new in PTA blends. These have better corrosion and dissolution resistance than tungsten carbide, enabling them to be used in corrosion applications in combination with highly alloyed nickel and iron matrices. In hardfacing, high quality (Ti,W)C overlays can be deposited with appropriate changes in technique. For example, (Ti,W)C needs to be deposited with higher heat input and avoiding Ni self-fluxing alloys.

RAD modeling results seem to correlate well with experimental results with regard to bubble formation in overlays as a result of graphite formation. Only overlays with a thermodynamically favored formation of graphite in a molten matrix may form bubbles. In order for bubbles to form, two reactants must coexist at the same temperature, typically graphite and oxygen or a reducible oxide. If any of the two conditions is not met there are no bubbles formed. Since compositions such as (Ti,W)C + 40 wt% Metcoclad 625, (Ti,W)C + 40 wt% Metcoclad 316L-Si, and (Ti,W)C + 40 wt% Metco 1030A do not form graphite in the melt they also do not form CO gas induced porosity.

Feedstock material may contain a thin surface oxide layer, substrate may have an oxidized surface layer or there may be embedded alumina grit from grit blasting. Alumina’s melting temperature is above 2000 °C and carbon can reduce alumina at temperature just below its melting point. If these and other variables are tightly controlled and the occurrence of oxygen or oxides is minimized, it is still possible to deposit porosity-free overlays even if graphite is present in the melt.

EDS analysis identified various phases in tested overlays which according to the RAD calculations should exist only at different dissolution concentrations of the primary carbide but not together. The author’s explanation was that dissolving carbide was likely to create a concentration gradient around itself and therefore phases calculated to exist at the highest dissolution concentrations would exist in the close vicinity of the primary carbide and phases calculated for lower dissolution concentrations would exist at a greater distance from the primary carbide. To which I would add that this research looked at time- and temperature reactions as well as metastable compounds in brain-bogglingly multidimensional phase diagrams. RAD calculations may have shown good correlation with EDS, but this is necessarily simplified analysis because of the number of constituents and operational parameters involved.

The RAD calculations also showed good agreement with the dissolution tests with regard to the better dissolution resistance of (Ti,W)C in Ni self-fluxing alloy and stainless steel matrices compared to tungsten carbide. However, various titanium-tungsten carbides had become established in the hardmetals industry (in the popular S and F grades, for example) some years before I became involved in manufacture in the early 1950s. However, we (though not most other companies) had replaced all by solid-solution tungsten-titanium-tantalum-niobium carbide grades (with cobalt binders) with much greater resistance to chemical dissolution at high temperatures.

Oerlikon Metco is an important international company within the powder metallurgical industrial sector. Though the Metco part of the organization is best known for its expertise in hardfacing products and processes, it also offers “tested and qualified nickel, titanium, cobalt and stainless steel metal powders with the technical support required for additive manufacturing.” The work described in this paper certainly opens up new possibilities in metal spray hardfacing, but whether it will also do so in 3D printing or even conventional hard materials PM is problematic. But it’s certainly interesting in the context of an EPMA congress session.

“Influence of laser energy input on the microstructure development of additively manufactured WC/Co hardmetal” presented by Sofia Fries of Institute for Materials Applications in Mechanical Engineering RWTH, Aachen University, Germany

Laser Powder Bed Fusion (LPBF) is a technology-spanning application, employed in additive manufacturing from prototyping to the production of small batch sizes. Process parameters for various steels, nickel-based alloys and other non-ferrous materials, are already fully developed.

Composite materials of tungsten carbide and cobalt, the most popular cemented carbides (WC/Co), or hardmetals, are essential for the tool manufacturing industry, with a wide range of other applications. Adjustment of hardness, fracture toughness and wear resistance is mainly achieved by variation of WC grain size and cobalt content. However, at least when this paper was compiled, WC/Co could not be successfully processed by LPBF. First attempts to build crack-free dense parts were conducted in the early 2000s.

Process parameters like energy input had been found to be crucial to obtain high material density. However, higher energy input promoted WC grain growth and resulted in lower hardness. Several problems had been identified that prevented reliable production of LPBF WC/Co parts, including brittle eta-phases and W2C in LPBF samples. In addition, cobalt evaporation during the process led to local lower binder contents. Arguably the main problem with AM of WC/Co was that the high melting point of WC is combined with the low evaporation temperature of Co, yet both materials must be reacted to obtain the well-known benefits of liquid-phase sintering (Figure 13 ).

Figure 13.

(a and b) Microstructure of (Ti,W)C in NiCrBSi (Metco 14E) matrix after 30 min at 1400 °C.

This paper reported the effects of high-energy powder-bed preheating on densification. Preheating temperatures of 800–950 °C were combined with varying laser energy input to produce sintered WC/Co samples. Porosity, hardness and phase compositions were investigated.

Raw material was Amperit 526 tungsten carbide-cobalt powder produced by H.C. Starck. The powder had a composition of 83 wt% WC and 17 wt% Co, see Table 5 . Depending on what is represented by ‘other,’ there could be up to 0.3% free carbon (graphite) in the mix, because the stoichiometric corresponding to 78% W is about 4.77% C (Table 6 ).

Table 5.

Chemical composition of WC/17Co according to manufacturer.

| Element | Co | C total | W | Fe | Other |

|---|---|---|---|---|---|

| Wt% | 16,9 | 5.07 | 78 | 0.0 | <0.5 |

Table 6.

Process parameters for parameter study.

| Process parameter | Unit | Abbreviation | Value |

|---|---|---|---|

| Laser power | W | PL | 140–260 |

| Scan speed | mm/s | vs | 400; 500 |

| Hatch distance | Μm | dH | 60 |

| Layer thickness | Μm | dL | 30 |

| Beam diameter | Μm | dB | 80 |

| Preheating temperature | °C | TP | I: 950; II: 900; III: 850; IV: 800 |

| Exposure strategy | – | – | stripe |

| Hatch rotation | – | – | 33° |

Agglomerated and presintered powder is normally used for thermal spraying processes. Particle size distribution of the agglomerate was measured by laser diffraction (Horiba LA 950) giving a d50 value of 35 μm. WC grain size ranged from 0.5 to 3.0 μm, classified as coarse by the researchers. WC/17Co agglomerates with a rough surface are shown in Figure 14 a), carbides (light gray) embedded in Co binder phase (gray). Internal porosity can be seen in Figure 14b). Additionally, inhomogeneous binder distribution was observed adjacent to some powder particles. The build platform for the LPBF process was sand-blasted AISI 316L austenitic stainless steel of 55 mm diameter and 10 mm thickness.

Figure 14.

Agglomerated and sintered WC-17Co powder: (a) powder morphology; (b) cross-section of a powder agglomerate.

Samples for this study were produced using the LPBF (Laser powder bed fusion) machine ‘Aconity MIDI’ (Aconity3D, Herzogenrath). The LPBF machine is equipped with a fiber laser system YLR-1000-WC (IPG Photonics, Burbach) with maximum output of 1 kW emitted at a wavelength of 1070 nm. An integrated inductive heating device allowed substrate preheating to 1200 °C. An argon atmosphere (<10 ppm oxygen) with an overpressure of approx. 80 mbar compared to ambient was maintained throughout the build cycle.

All specimens with final dimensions of approx. 10 × 10 × 10 mm3 were manufactured using a ‘stripe’ exposure pattern with hatch rotation of 33° between each layer, Figure 15 a). For all specimens, hatch and contouring exposure parameters were identical. In addition the preheating temperature was reduced stepwise from the initial temperature of 950 °C by 50 °C every 80 layers during the build cycle in order to further vary process conditions and thus the conditions for microstructural evolution.

Figure 15.

(a) Schematic exposure strategy, (b) variation of powder bed preheating temperature during the LPBF process along the specimen, (c) schematic thermal history for the different sections during the LPBF process.

The resulting sections were labeled according to Figure 15b) (sections I–IV). The schematic thermal history for the different sections is shown in Figure 15c). Build cycle duration, as the sum of build and cooling times, was approximately 165 minutes. Each section was built in about 30 minutes. To reduce build platform temperature, the process was interrupted between each section for approximately 15 minutes to allow free cooling. During this time, the inert atmosphere with overpressure remained in the build chamber. Specimens were separated from the build platform by wire EDM after cooling to room temperature.

Microstructural analysis was carried out by light microscopy on polished cross-sections, with etching by Murakami reagent. Porosity was determined at unetched samples using open source image analysis software. Phase analysis was performed using XRD and Vickers hardness (HV 10) was measured in the regular way

Volume energy density within the specimens, a function of laser power, scan speed, layer thickness and hatch distance, was varied between 194 and 361 J/mm3. However, energy input resulting from powde-bed preheating had not yet been detailed in the literature. Thus, for describing energy input; a combination of volume energy density EV and preheating energy was used, for example 194 J/mm3 II (at 900 °C powder-bed preheating temperature). The material in sections I-IV experienced a different thermal history, see Figure 15c). Besides temperature and volume energy density, time is an important factor, as with all WC/.Co sintering processes. In these AM experiments, process time was regarded as the sum of the build and cooling times.

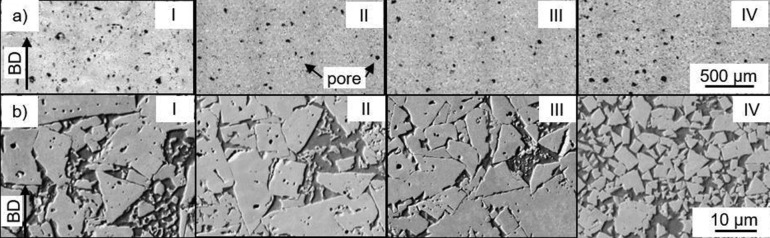

Microstructural examination of polished and etched cross-sections identified those parts of the specimen with the lowest Ev in this study, in Figure 16 a). There was no visible distinction between sections I, II and III. However, microstructure was strongly influenced by decrease of preheating temperature from 850 to 800 °C. The amount of porosity between 950 and 850 °C (I–III) was similar, whereas section IV was distinguished by pronounced porosity. Spherical pores appeared in I–III, presumably gas pores, as compared with pore networks found in IV. However, section I was exposed to additional heating of 800–900 °C for at least two hours, whereas section IV was only preheated to 800 °C for the time taken to build 80 layers, about 30 minutes. This might be the reason for the reduced porosity of approx. 1%.

Figure 16.

Microstructure of sections I–IV (EV = 194 J/mm3) (a) optical microscopy, combination of 16 single images per section, (b) SEM images, detail 1: precipitation during sintering; detail 2: unmelted region.

In the sample examination of Figure 16, a combination of low porosity and small WC grain size was found in section I, 194 J/mm3 and 950 °C. In previous studies, cobalt binder accumulations with a fine dispersed dendritic or polygonal phase were found in the microstructure. It was assumed that this phase was related to reprecipitation of W and C from binder alloy during cooling. The experimenters were uncertain whether it was W2C or eta-phase (but could it have been Co-base pseudo-eutectic, as is usual in conventional WC/Co sintering? – KJAB). Similarly, the reprecipitated polygonal phase was found in the section II, detail 1 in Figure 16b). By contrast, unmelted agglomerates were present in section IV, detail 2, due to insufficient energy input by the preheating system.

In Figure 17 , the microstructure of the specimen with the maximal Ev of 361 J/mm3 is shown. Spherical pores were found in all sections. In respect of porosity, similar densification was found regardless of the preheating temperature. However, the overall energy input was too high in sections I – III. The shape of WC grains was irregular, and pores were found within WC grains. It was presumed that decomposition of WC was induced by the high temperature during the process. Concerning the size and the shape of the WC grains, section IV was distinguished by the regular prismatic shape and the smallest grain size in this sample. The combination of 361 J/mm3 and 800 °C was therefore seen as a trade-off between densification and WC grain growth.

Figure 17.

Microstructure of sections I–IV (EV = 361 J/mm3) (a) optical microscopy, combination of 12 single images per section, (b) SEM images.

As with regular sintered WC/Co, Vickers hardness of the samples was influenced by porosity, WC grain size and cobalt content. Good correlation between porosity and hardness was found for both samples, Table 7 records some of the experimental results. For conventionally produced cemented carbides with coarse WC grain size and 15 wt% cobalt, hardness of 1050 ± 50 HV10 would be expected. Besides porosity, lower hardness in LPBF samples could certainly be explained by the large WC grain size, with scattering of values due to inhomogeneous carbide distribution and cobalt agglomerations. In sections I–III, 850–950 °C, there was no significant effect of volume energy density EV on hardness. In sections I of both samples hardness was strongly dependent on porosity.

Table 7.

Porosity and hardness for various combinations of EV and preheating temperature.

| Ev J/mm3 | Section | T °C |

Porosity % |

Hardness HV10 |

|---|---|---|---|---|

| 194 | IV | 800 | 36.5 | 199 ± 9.2 |

| 194 | III | 850 | 1.02 | 981 ± 39 |

| 194 | II | 900 | 1.20 | 950 ± 69 |

| 194 | I | 950 | 0.68 | 1023 ± 49 |

| 361 | IV | 800 | 3.74 | 779 ± 101 |

| 361 | III | 850 | 0.79 | 952 ± 81 |

| 361 | II | 900 | 1.50 | 985 ± 17 |

| 361 | I | 950 | 1.12 | 913 ± 1.7 |

Dispersed eta-phases, indicating substantial loss of carbon during processing, dominated the microstructure after etching with Murakami reagent (Figure 18 ). The author suggested several possible reasons for lack of carbon and thus for the occurrence of η-phases. Firstly, the carbon/tungsten atomic ratio [C/W] in the initial powder was 0.995 and thus lower than 1, the stoichiometric value. Second, with decreasing cobalt content due to evaporation, eta-phases are said to occur at lower deviations from the ideal C/W value.

Figure 18.

Microstructure of LPBF sample (361 J/mm3) after etching with Murakami reagent.

Summary

This study investigated the influence of laser energy input EV and preheating temperature of the build platform on the microstructure of LPBF additively manufactured WC/Co hardmetal. Densification of the cemented carbides during the LPBF build cycle depended on EV and the preheating temperature. For low EV values combined with high preheating temperatures of 900–950 °C, porosity of approximately 1% was found. For high EV values, irregularly shaped WC grains, eta-phases and W2C were found. Further reduction of porosity was achieved by subsequent heat treatment, in particular sinter-HIP. The author considered the formation of eta-phases was irreversible, so the combination of a low laser energy input and a high preheating temperature of 950 °C was recommended. However, eta-phase formation is by no means irreversible and in traditional cemented carbide production can be reversed through diffusion, by sintering in a carburising environment. Conventional sinter-HIP in a neutral atmosphere obviously won’t help. I certainly agree with the presenter that, In further studies, carbon content of the LPBF samples should be investigated in greater depth. As the speaker suggested, possible approaches are to increase the carbon content in the initial powder or in process or post-treatment atmospheres.

It should be noted that AM researchers frequently put forward the idea of indexable hardmetal inserts or solid carbide rotary tooling with integral cooling passages as potentially important objects for 3D printing. However, in this and other studies they typically choose 87WC/13Co and similar compositions for their research when, even if the research were successful, poor performance would make the product difficult if not impossible to optimize for the intended application. Moreover, high-quality extruded carbide with precision straight or helical coolant passages has been readily available for years.

“Characterization of commercially available WC/Co powders used for laser-based powder bed fusion” presented by Mario Schafnitzel of Fraunhofer IGCV, Augsburg, Germany

As mentioned in the introduction to this session review, the additive manufacturing of cemented carbides is attracting increasing attention in research and industry. Focus is on the manufacturing process, parameters used and effects occurring in the produced components. Earlier researchers discussed the conflict between minimizing porosity and simultaneously reducing cobalt content by vaporization at large energy input. A number of (optimistic) approaches had been devised to improve the properties of WC/Co processed by LPBF and align it with conventionally produced WC/Co, including post-laser exposure with moderate energy density to reduce porosity. Other investigators had used platform heating from 650 to 800 °C to increase component density and reduce cracking. In addition, thermal post-treatments, like vacuum sintering, hot isostatic pressing (HIP) and sinter-HIP, were regarded as possibilities to reduce cracks, pores and brittle eta-phase. Nevertheless, for reasons I discussed at the beginning of this feature, no LPBF-based process chain for the production of commercial-grade WC/Co, had yet been developed.

As raw materials for AM hardmetals, most LPBF researchers choose agglomerated and partially sintered powders produced for thermal spraying. These were also initially chosen for the production of test specimens by LPBF. However, the input powders eventually became central to this research. One investigator, for instance, had produced powders adapted for LPBF in the hope of reducing the internal porosity left from thermal spraying powders. Elsewhere, VC and Cr3C2 were successfully added to reduce grain growth. Somewhat surprisingly, however, an addition of carbon black did not reduce the occurrence of brittle η-phase. (Could this have been because sufficient oxygen was trapped in the highly porous powder particles tooxidizeall the available free carbon – and more?)

Besides nominal chemical composition, other powder-related properties had been examined for relevance to LPBF. They had been categorized into powder properties (e.g., morphology, particle size distribution), particle density), bulk powder behavior (eg flowability, powder packing) and in-process performance (e.g., rakeability and beam-powder-interaction process efficiency). Detailed investigation of such powder properties, focusing on WC/Co and LPBF, had not been carried out previously.

WC/Co powders specifically produced for additive manufacturing had recently become commercially available and were already used for binder jetting. Thus for this paper it was possible to compare for LPBF processing four powders produced for different purposes (additive manufacturing, thermal spraying) and from different manufacturing processes (agglomerated and sintered, sintered and crushed). Instead of the usual application-oriented processability of WC/Co, powder properties were investigated in greater depth and their effects on processing up to powder coating estimated. With this analysis it was hoped to improve selection criteria for future studies of powders and applications.

Concept

For examining the suitability of a WC/Co powder, several properties were critical at different processing stages (Figure 19 ). First of all, particle morphology, influenced by the manufacturing process, affected other properties like bulk density and flowability and was important for further estimations and understandings. Nevertheless, general assumptions about flowability based on morphology were not possible, as adhesive forces also influenced flow properties. Examination of particle size distribution (PSD) was necessary to check whether powders could be used for LPBF in the intended powder layer thickness. PSD (narrow or wide) also provided an initial assessment of flow properties and powder bed density. Sufficient flow behavior, bulk density and layer homogeneity were ultimately important to obtain a deposited layer with good powder bed density. The final question was whether the different powders had different reflectivity due to the properties previously described.

Figure 19.

Concept for the selection of important powder properties for WC/Co processing at LPBF.

Experimental

Those responsible for this sensible and comprehensive project rolled out a substantial array of state-of-art apparatus for carefully selected tests on the four chosen WC/Co powders. Among others, they included a Malvern Mastersizer 3000E laser diffraction particle size analyzer; Hitachi TM3030-plus SEM with back-scattered electrons and 1000x magnification for morphological examination of powders; Freeman FT4 powder rheometer to measure flow properties, conditioned bulk density, powder stability (by so-called ‘Stability Method’), agglomeration and segregation; and a Keyence VK9700K laser-scanning microscope to examine rakeability of the different powders, check powder layer homogeneity and measure surface roughness.

WC/Co powders are marketed in a wide range of variants. The powders used in this investigation are listed and described in Table 8 . Interestingly, what I would judge to be some of the most important measurements were not included in the list, most notably chemical compositions (especially carbon content) of the specific powder batches as-received and also of the variously processed powders and products. Such information is necessary to make sense of such data as density, indentation hardness and volume percentages of eta-phases. Somewhat surprisingly, according to the tabulation, every one of the as-received commercial products where nominal carbon contents were supplied was sub-stoichiometric

Table 8.

Left column: Examined commercially available WC/Co powders for LPBF with manufacturer’s specifications for chemical composition and PSD measured by laser diffraction. Middle column: SEM images of powder particles. Right column: SEM images of polished cross-sections of powder particles.

|

AM WC701 containing 12% cobalt was the only powder in this study produced specifically for additive manufacturing. It mainly showed (see Table 8) spherical particles with a mix of open and closed pores (see cross-section) and the narrowest PSD compared to the other powders. The porosity of the particles seemed comparatively low and promised high bulk density. Amperit 515.001, like WC-559 and Woka 3201 powders, is produced for thermal spraying. The Amperit powder was sintered and broken, resulting in a non-spherical shape, with angular edges, and high particle density. The irregular particle shape was expected to cause unstable flowability, as particles agglomerate and wedge. At the same time, high particle density might result in higher bulk density. WC-559 is an agglomerated and plasma densified powder with cobalt content of about 17 %, which should have promoted higher toughness and impact strength but noticeably poorer wear resistance. Plasma densification was expected to result in higher particle density and spherical particle shape to improve flow properties. Nevertheless, this powder apparently showed higher porosity than the other powders investigated. Woka 3201, an agglomerated and sintered powder with 17% cobalt, offered lower porosity than WC-559 and larger particle size than the other studied powders.

Test results

Results of the rheometer measurements are shown in Figure 20 and Table 9 . The stability method indicates that all powders produced for thermal spraying should show stability and robustness, with stability indices from 0.94 to 1.10. However, AM WC701 showed a stability index of 1.22 and thus suggested possible effects such as agglomeration. Basic flowability energy (BFE) corresponds to the energy required to generate a certain flow pattern, shows the influence of various factors and is also an indicator of good flow properties. It showed that for the measurement of powders WC-559 and Woka 3201 lower energies were necessary and thus better flow behavior could be expected. Specific energy (SE) values indicated cohesion in the powder and showed how the powder behaved in a low-stress environment, for example when powder was filled into a coater. All powders showed relatively low and comparable cohesion. Woka 3201 showed the lowest specific energy, possibly due to lower density with 17% cobalt content instead of 12%, a larger particle size and thus lower cohesion. In addition, the variable flow rate method was applied to evaluate suitability for changing flow rates. All powders seemed to be relatively insensitive to flow rate by showing a low flow rate index (FRI), especially WC-559 and Woka 3201. Interpretation of the results for AM WC701 were limited by the previously determined instability, but also showed low FRI.

Figure 20.

Plots of stability and variable flow rate tests with Freeman FT4 powder rheometer.

Table 9.

Results of stability and variable flow rate tests with Freeman FT4 powder rheometer.

| Powder | Stability index | Basic flowability energy mJ |

Specific energy mJ/g |

Flow rate index | Conditioned bulk density g/ml |

|---|---|---|---|---|---|

| AM WC701 | 1.22 | 1398.62 | 2.88 | 1.20 | 6.50 |

| Amperit 515.001 | 1.10 | 1095.67 | 2.70 | 1.16 | 6.31 |

| WC-559 | 0.94 | 605.31 | 2.27 | 1.03 | 4.06 |

| Woka 3201 | 0.99 | 712.10 | 1.90 | 1.01 | 5.45 |

Results of the conditioned bulk density (CBD) measurements were obtained for comparable conditions. As expected, powders AM WC701 and Amperit 515.001 with comparatively low porosity had the highest bulk densities and the quite porous WC-559 the lowest. It was assumed that density in the applied powder layer correlated with the bulk density. For LPBF, it was also agreed that powder layer density should be as high as possible.

Rheometer measurements were facilitated by applying the powder layers with the byko-drive automatic film applicator. 100 µm layers were coated for comparison purposes. Images from the laser-scanning microscope (Figure 21 ) illustrated the homogeneity of the powder layer. AM WC701 had a clearly homogeneous powder layer, also seen in the surface roughness value Rz, significantly below that of the other powders (Table 10 ). It seemed that the comparably small and spherical particles were more uniformly coated. (It’s worth mentioning here that the apparent accuracy of the surface roughness measurements – 5 significant figures or better than one part in 100,000 – is borderline meaningless, like claiming to measure the length of a football field to the nearest millimeter. A two-significant-figure mean value with a plus/minus range would be realistic and more sensible – KJAB).

Figure 21.

Images of the surface morphology of the powder layers taken with the laser-scanning microscope.

Table 10.

Surface roughness Rz of powder layers measured by laser scanning microscope.

| Powder | RZ |

|---|---|

| AM WC701 | 103.44 |

| Amperit 515.001 | 160.69 |

| WC-559 | 151.57 |

| Woka 3201 | 164.27 |

Processing powders produced primarily for thermal spraying resulted in significantly higher roughness and inhomogeneous layers. In particular, Amperit 515.001 displayed highly uneven areas where particles accumulated or were missing. Non-spherical particles resulted in numerous friction surfaces and entanglement possibilities, causing inconsistent powder coating. Powders WC-559 and Woka 3201 powders showed similar tendencies, but to a lesser extent.

When a layer of WC/Co hardmetal powder is applied in LPBF, the cobalt-based binder is melted and resolidifies. Particle size and morphology seemed to influence the relative reflectivity of the powders at different wavelengths (Figure 22 ). Woka 3201 had the highest relative reflection (19.2% at 1064 nm), which may have been related to the large particles and correlated angle of incidence. The influence of the cobalt was not significant, as the 17% cobalt binder had both the highest and the lowest reflection. The results for WC559 were explained by open porosity and rough surface that allowed reflection and absorption by adjacent powder particles. WC-559 showed 15.45% relative reflection at 1064 nm. AM WC701 and Amperit 515.001 had similar results, reflecting 18.06% and 17.55% respectively at 1064 nm wavelength. As a next step in their research, the author’s team proposed to make transmission measurements for different WC/Co powders in order to compare absorption rates.

Figure 22.

Relative reflection at 1064 nm wavelength.

Conclusions

After previous research on LPBF of tungsten carbide and WC/Co had concentrated on the manufacturing process, a variety of powders currently used for this purpose were discussed in this paper. Four commercially available mixes were compared, one produced for AM and the others for thermal spraying. In order to compare the materials with regard to processability and various powder properties such as morphology, PSD, flow properties, bulk density and laser reflection were measured.

These are the key results, according to the author:

The powders show different porosities and bulk densities. Especially the powder AM WC701 and the sintered and crushed powder Amperit 515.001 show the lowest porosity and highest bulk density.

Almost all powders, with exception of AM WC701, exhibit a stable flow behavior. Especially WC559 and Woka 3201 show good flow properties due to the low BFE. The FRI also shows that all powders react to changing flow rates in a generally stable manner.

In terms of powder layer homogeneity, AM WC701 shows significantly lower roughness and better homogeneity than the compared powders. Nevertheless, all powders have continuous powder layers, which enable processing by LPBF.

The relative reflection at a wavelength of 1064 nm is between 15.45% (WC-559) and 19.20 % (Woka 3201). Morphology and the resulting surface roughness and particle size with different angles of incidence lead to different results.

From these results, a basic suitability of all powders for the processing up to the powder coating in LPBF can be determined. Nevertheless, the powder AM WC701 produced for AM has the highest bulk density, a sufficient stable flow behavior and a homogeneous powder layer as well as a reflection comparable to other powders. In order to assess the overall processability of LPBF, the different powders can be processed and compared in following studies.

And here is my report and review (KJAB:)

It seemed particularly noteworthy to this reviewer that all the tests carried out were physical or to some extent metallurgical, with a virtually complete absence of vital chemical analyses. Maybe the talented investigators were all physicists, but it should not have been too difficult to discover that cemented carbide raw materials and intermediates, especially for WC/Co, are extremely sensitive to alloy content, especially carbon and adsorbed oxygen (which together react to form CO and/or CO2 before disappearing into the local atmosphere). Pure cobalt has a low melting point but also a low boiling point, not too dissimilar to the melting point of WC, but in conventional liquid-phase sintering they react together and densify via volume shrinkage to almost zero porosity. As well as being temperature-reliant, the sintering operation is time-critical and extremely sensitive to chemical composition, impurities, powder preparation methods and even shipping and storage environments. Additive manufacturers like to talk about opportunities for 3D-printed hardmetal cutting inserts, but how many of them realize that, in addition to all of the above, most cutting inserts must, as a final stage of manufacture, accept from one up to perhaps 2000 ultra-thin layers of performance-enhancing ceramic coatings.

The superfast non-equilibrium nature of laser-based reactions in the AM environment and the difficulties of specifying, measuring and controlling whatever reactions may be taking place make investigation of the AM techniques described in this paper far from simple. As just one example, it is important to avoid sub-stoichiometric carbon content, which by definition is not even sufficient carbon to change all the W to WC. The resultant embrittlement would cancel out any enhanced toughness promised by the initially high cobalt content. But three of the powders tested were, according to their supplier’s data, already sub-stoichiometric as-received, and not even a guess was proferred for the carbon content of the other product tested, in spite of the importance of this value. But what about the cobalt content of the finished material? Some Co will have vaporized, but we have no idea of this parameter’s typical value or batch-to-batch reproducibility.

So how should we mark this paper? Good try, without a doubt, but could do much better. The author will probably do so in the next exam, after some intensive homework on the basics of WC-base hardmetals.