Summary

Thermoelectric generators (TEGs) offer cost-effective and sustainable solid-state energy conversion mechanism from wasted heat into useful electrical power. Thermoelectric (TE) materials based upon bismuth telluride (BiTe) systems are widely utilized in applications ranging from energy generation to sensing to cooling. There is demand for BiTe materials with high figure of merit (zT) and TEG modules with high conversion efficiency over intermediate temperatures (25°C–250°C). Here we provide fundamental breakthrough in design of BiTe-based TE materials and utilize them to demonstrate modules with outstanding conversion efficiency of 8%, which is 40% higher compared with state-of-the-art commercial modules. The average zT of 1.08 for p-type and 0.84 for n-type bismuth telluride alloys is obtained between 25 and 250°C. The significant enhancement in zT is achieved through compositional and defect engineering in both p- and n-type materials. The high conversion efficiency accelerates the transition of TEGs for waste heat recovery.

Subject Areas: Energy Engineering, Materials Science, Energy Materials

Graphical Abstract

Highlights

-

•

Significant improvement in design of bismuth telluride alloys is demonstrated

-

•

High peak and average zT are obtained in both p- and n-type bismuth telluride alloys

-

•

Thermoelectric generator with conversion efficiency of 8% is fabricated

-

•

High efficiency accelerates the transition of TEGs for waste heat recovery

Energy Engineering; Materials Science; Energy Materials

Introduction

It is estimated that ~70% of the energy produced worldwide is rejected into the environment mostly in the form of waste heat (Forman et al., 2016). A sustainable, cost-effective, and efficient way to recover some fraction of the wasted heat would have great impact on overall renewable energy production and in reducing carbon footprint. One of the promising ways to recover thermal energy is through thermoelectric generators (TEGs). TEGs are silent solid-state devices with no moving parts and utilize environmentally sustainable materials (Bell, 2008; Snyder and Toberer, 2008). The challenge with TEGs has been their low conversion efficiency, which is one of the main obstacles in their widespread application. The theoretical conversion efficiency () of TEGs is expressed by Equation (1) (Goldsmid, 1995):

| (Equation 1) |

where TC and TH are cold and hot side temperatures, respectively, and (zT)avg is the average thermoelectric (TE) materials figure-of-merit. zT is a dimensionless materials-dependent component that is defined by Equation (2):

| (Equation 2) |

where σ, S, κ, and T are electrical conductivity, Seebeck coefficient, total thermal conductivity (including electronic [κElectronic], lattice [κLattice], and bipolar [κBipolar] thermal conductivities), and absolute temperature, respectively (Snyder and Toberer, 2008). The term σS2 is known as power factor (PF). It is known that high PF is an important factor toward enhancing the output power of a TEG (Liu et al., 2016; He et al., 2016); however, it is not sufficient to improve TEG's conversion efficiency, which is mainly dependent on zT.

In the literature, the primary research focus has been on improving the peak zT, i.e., (zT)peak, by manipulating electron and phonon transport properties through different techniques such as nanoinclusions (Nozariasbmarz et al., 2016; Kang et al., 2020), band gap engineering (Pei et al., 2012; Zhu et al., 2018), formation of resonant dopant states (Chen et al., 2017; Tan et al., 2015), energy filtering effect (Liang et al., 2017), all-scale hierarchical architectures (Biswas et al., 2012), and mitigation of lattice strain (Chen et al., 2015). These techniques do not assure high conversion efficiency of TEGs mainly due to the low (zT)avg or high device contact resistance. In general, the efficiency of a TEG can be improved by (1) high (zT)avg of TE materials (Equation 1), (2) large temperature gradient (Equation 1), (3) appropriate TEG design to minimize the heat loss (Rowe and Min, 1996; Kishore et al., 2020), and (4) small electrical and thermal contact resistances at the junction of TE materials and substrate mainly controlled by the quality of contact metallization of the TE materials, device fabrication process, soldering/brazing material, and interconnect electrodes (Bjørk, 2015; Nozariasbmarz et al., 2019a). All these factors should be considered in the design and fabrication of the TEGs with high efficiency. Fabrication of reliable low-resistance electrical contacts between TE legs and headers has been difficult to accomplish in TE device fabrication (Joshi and Poudel, 2016; Feng et al., 2013). At the device level, thermal contact resistance at the TE leg/metal interconnect junction and metal interconnect/ceramic substrate, as well as the thermal conductivity of the ceramic substrate affects the temperature distribution and drop across the TEG (Liu and Bai, 2019). Thus, a comprehensive strategy is required for designing high-efficiency TEGs that comprises materials for TE legs, soldering/brazing, metallization, interconnects, and headers (Kishore et al., 2020). This article addresses these aspects ranging from materials to TE modules. We demonstrate p- and n-type bismuth telluride (BiTe) alloys with high (zT)avg leading to efficient module performance for waste heat recovery application in the temperature range of 25 to 250°C.

Results

Theoretically, the conversion efficiency of TEGs is enhanced by augmented temperature difference (ΔT) and (zT)avg (Figure 1A). In ideal conditions, at a ΔT of 230°C, the of a module with (zT)avg equal to 0.8, 1, 1.2, and 1.4 is 7.9%, 9.3%, 10.4%, and 11.5%, respectively. However, there is a deviation between the theoretical and experimental values of the efficiency mainly due to the parasitic losses through the TE legs and junctions. Also, the deviation arises because the actual TE leg temperature is lower than the measured external temperature of hot and cold side headers. Figure 1B shows the schematic of a single couple TEG module investigated in this study. Top and bottom headers are made of aluminum nitride (AlN), which has high thermal conductivity but low electrical conductivity, to efficiently conduct the heat from heater to TEG. The copper (Cu) interconnects provide the series electrical connection. The joining material makes electrical and thermal conduction between legs and headers; and finally, there are p- and n-type TE legs. The sample IDs, compositions, and synthesis process of the TE legs are defined in Table S1 (see Transparent Methods). Type (I) module is constructed using Type (I)-p (Bi0.5Sb1.5Te3) and Type (I)-n (Bi2Te2.7Se0.3S0.01) materials, and Type (II) module is constructed using Type (II)-p (Bi0.4Sb1.6Te3) and Type (II)-n (Bi2Te2.7Se0.3S0.01Cu0.01) materials.

Figure 1.

Conversion Efficiency, Output Power, and Components of Customized Single Couple TEG Module

(A) Theoretical conversion efficiency () of TEGs versus temperature difference (ΔT) for different (zT)avg values. The black dashed arrow shows ΔT = 230°C.

(B) Schematic drawing of different components of customized single couple TEG module.

(C) Conversion efficiency of the fabricated BiTe modules compared with commercial and state-of-the-art modules (Kuroki et al., 2014; Hao et al., 2016). The error bar indicates uncertainty of the conversion efficiency measurement. The inset is the actual fabricated single couple TEG module.

(D) Output power density of the fabricated BiTe modules compared with commercial and state-of-the-art modules (Kuroki et al., 2014; Hao et al., 2016). The error bar indicates uncertainty of the output power measurement.

(E) Comparison of the output power of single couple and full module (18 couples). The inset shows top and side views of the full module.

See also Figures S1 and S4 and Table S1.

To validate the performance of synthesized materials, single couple modules were fabricated using Type (I) and Type (II) materials (inset of Figure 1C). The performance of our modules is compared with a single couple fabricated using commercial p- and n-type materials acquired from Crystal Ltd. Type (II) module demonstrates 8% efficiency and 2.1 W/cm2 power density at ΔT = 230°C, which is among the highest values reported in the literature for BiTe modules (Figures 1C and 1D). The efficiency and power of Type (I) module is found to be 6.7% and 0.92 W/cm2, respectively. The efficiency of both modules is ~15% less than theoretical estimation (Figure 1A). Type (II) TEG module (inset of Figures 1C, S1, and S4) demonstrates 40% and 15% higher conversion efficiency compared with the commercial crystalline materials and the best literature value, respectively. A full TEG module comprises 18 couples, i.e., 36 p- and n- TE legs, thus it will exhibit 18× higher power compared with the single couple made using similar p- and n-type legs. Results in Figure 1E clearly demonstrate the quality of the module fabrication process where output power for full TEG module is found to be close to ~18× that of single couple over the wide temperature range.

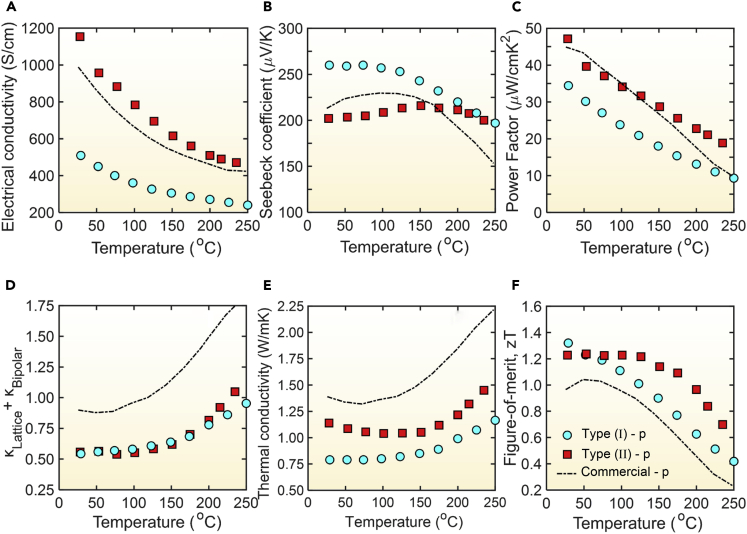

Figure 2 compares the TE properties of Type (I)-p, Type (II)-p, and commercial p-type BiTe alloys as function of temperature. The TE properties of commercial alloy are shown as a reference (Poudel et al., 2008). The electrical conductivity of all samples (Figure 2A) decreases with temperature due to the reduction of Hall mobility as a result of the electron-phonon scattering at high temperature. The electrical conductivity of Type (II)-p is higher than that of Type (I)-p in all temperature ranges, which is due to the higher carrier concentration (Figures 2B and S2A). The difference between two samples compensates at higher temperatures. Carrier concentration in BiTe alloys is controlled through vacancies and antisite defects, wherein Bi and Sb vacancies donate 3 holes and Te contributes 2 electrons, Bi on Te-site antisite defect donates one hole, and Te on Bi-site contributes one electron (Stterthwaite and Ure, 1957; Horak et al., 1986).

Figure 2.

Temperature-Dependent Thermoelectric Properties of the Synthesized p-Type Materials

(A) Electrical conductivity.

(B) Seebeck coefficient.

(C) Power factor (PF).

(D) Lattice + bipolar thermal conductivity.

(E) Total thermal conductivity.

(F) zT for Type (I)-p, Type (II)-p, and commercial p-type BiTe alloys. The TE properties of commercial p-type alloy are shown for comparison.

See also Figure S2A.

The Seebeck coefficient of Type (I)-p is higher up to ~200°C; after that it converges to similar values as that of Type (II)-p (Figure 2B). At lower temperatures, due to lower carrier concentration in Type (I)-p, the electrical conductivity is lower as well. Higher carrier concentration generally results in lower absolute value of Seebeck coefficient and higher electrical conductivity. Carrier concentration of Type (II)-p is higher than that of Type (I)-p up to 175°C as Type (II)-p has higher doping. This explains why the Seebeck coefficient of Type (II)-p is lower than that of Type (I)-p in this temperature range (Figures 2B and S2A). The PF of Type (II)-p is larger than Type (I)-p over all temperature ranges, which is due to its significantly larger electrical conductivity (Figure 2C). This difference is constant at all temperature ranges. Type (II)-p and Type (I)-p samples have the maximum PF of 47 μW/cmK2 and 34 μW/cmK2, respectively. As shown in Figure 1D, the module fabricated from high-PF materials results in high output power.

The combination of lattice and bipolar thermal conductivity (κLattice + κBipolar) of the samples is approximately similar up to 200°C, and then it deviates at high temperature (Figure 2D). The overall reduction of the total thermal conductivity of Type (II)-p up to 150°C is due to the phonon scattering (Tritt, 2004), and it increases at higher temperatures due to the bipolar thermal conduction (Figure 2E). However, in Type (I)-p, the bipolar effect has shifted to room temperature and the total thermal conductivity monotonically increases with temperature. The notable drop in thermal conductivity of Type (I)-p is due to the reduction in electronic part of thermal conductivity. This agrees with higher Seebeck coefficient, i.e., reduced dopant concentration in Type (I)-p. The thermal conductivity of both samples is less than that of commercial p-type alloy in all temperature ranges.

Figure 2F shows the comparison of the zT values versus temperature. Above 50°C, zT of Type (II)-p is higher than that of Type (I)-p, and only at room temperature, Type (I)-p has higher zT. The (zT)peak of Type (I)-p and Type (II)-p is 1.3 and 1.25, respectively. The magnitude of zT~1.2 is maintained in a broad temperature range up to 150°C in Type (II)-p resulting in high (zT)avg. Better TE properties above room temperature make this material suitable for low-grade waste heat recovery application, such as energy harvesting from hot-water pipes (Kishore et al., 2020). Type (I)-p with higher (zT)peak and lower thermal conductivity at room temperature is appropriate for specific applications that involve high heat sink/source contact resistance such as body heat harvesting (Nozariasbmarz et al., 2019a; 2020a, 2020b; Suarez et al., 2016) and body cooling (Kishore et al., 2019).

Figure 3 compares the TE properties of the synthesized Type (I)-n and Type (II)-n BiTe alloys as function of temperature. The TE properties of a commercial n-type alloy are also shown for comparison (Hu et al., 2016). Similar to p-type samples, the electrical conductivity of both n-type samples (Figure 3A) decreases with temperature due to the reduction of Hall mobility as a result of the electron-phonon scattering at high temperatures. The electrical conductivity of Type (II)-n is higher than that of Type (I)-n in all temperature ranges (Figure 3A) due to the higher carrier concentration in Type (II)-n as shown in Figure S2B. This confirms the donor behavior of Cu dopant. In n-type BiTe alloys, Se enhances Te vacancies, resulting in higher electronic contribution. Cu atoms can also enter the interstitial sites among four Te atoms, resulting in lattice expansion along <001> direction (Liu et al., 2011). Below 200°C, Type (I)-n has higher absolute value of Seebeck coefficient than Type (II)-n. Beyond 200°C, their values converge (Figure 3B). The Seebeck coefficient of Type (II)-n barely changes with temperature. Carrier concentration of Type (II)-n is higher than Type (I)-n up to 175°C. Type (II)-n has higher dopant concentration, which results in lower absolute value of Seebeck coefficient compared to Type (I)-n in the temperature range considered here (Figures 3B and S2B).

Figure 3.

Temperature-Dependent Thermoelectric Properties of the Synthesized n-Type Materials

(A) Electrical conductivity.

(B) Seebeck coefficient.

(C) Power factor (PF).

(D) Lattice + bipolar thermal conductivity.

(E) Total thermal conductivity.

(F) zT for Type (I)-n, Type (II)-n, and commercial n-type BiTe alloys. The TE properties of commercial n-type alloy are shown for comparison.

See also Figure S2B.

Both n-type samples have almost similar PF up to 100°C. Above 100°C, Type (II)-n has larger PF, mainly due to the higher electrical conductivity at elevated temperatures (Figure 3C). The maximum PF of both n-type samples is ~30 μW/cmK2, which is smaller than those of commercial n-type and all p-type samples. The magnitude of κLattice + κBipolar for the synthesized samples is similar at room temperature, and then it deviates at higher temperatures due to the shifting of bipolar conduction to lower temperatures in Type (I)-n (Figure 3D). Addition of dopants shifts the onset temperature for bipolar effect to higher temperature by preventing the generation of minority carriers. The low κLattice of Type (II)-n is mainly due to the solid solution alloying with sulfur and copper, which results in thermal conductivity reduction through point defect mechanism that induces localized strains and mass fluctuations (Liu et al., 2013; Hu et al., 2014). As shown in Figure 3E, the total thermal conductivity of the synthesized samples is lower than that of commercial n-type alloy in all temperature ranges. The thermal conductivity of Type (I)-n is smaller than that of Type (II)-n up to 125°C, after which it rapidly increases due to the strong bipolar effect. Although dopants are mainly used to tune the Fermi level by optimizing the carrier concentration, the alloying elements in Type (II)-n provide atomic mass and size contrast compared with Bi-Te-Se matrix alloy, resulting in smaller thermal conductivity at high temperature.

Figure 3F demonstrates zT comparison of n-type samples versus temperature. Type (I)-n has higher zT up to 75°C due to the smaller thermal conductivity in this temperature range. Above 100°C, zT of Type (II)-n is higher due to the high PF and low thermal conductivity. The (zT)peak of Type (I)-n and Type (II)-n is 0.92 and 0.9, respectively. In Type (II)-n, zT~0.9 is maintained in a broad temperature range from 50°C to 150°C, which results in high (zT)avg in this material. Type (I)-n has lower thermal conductivity and higher Seebeck coefficient and zT at room temperature, which makes this material appropriate for applications that require large contact resistance between TE and heat source/sink at room temperature such as wearable electronics (Nozariasbmarz et al., 2019a, 2019b; 2020a, 2020b). However, comparatively Type (I)-n is not the best candidate for power generation at high temperature due to its zT degradation. Instead, Type (II)-n is a more suitable candidate for TE power generation due to its high performance over the entire temperature range.

The magnitude of (zT)avg for Type (II)-p and Type (II)-n materials is found to be 1.08 and 0.84, respectively (Figure 4A), which is 50% and 30% higher than that of commercial materials and among the best reported (zT)avg values for BiTe alloys. It should be noted that compared with Type (I) materials that have higher (zT)peak, Type (II) materials have ~20% higher (zT)avg, which results in 20% improvement in device conversion efficiency. These results confirm the importance of search for TE materials with high (zT)avg to achieve elevated efficiencies in TEGs. Figure 4B shows the comparison of the X-ray diffraction (XRD) patterns of Type (I)-p, Type (II)-p, Type (I)-n, and Type (II)-n materials. All materials are pure, and the XRD patterns are approximately similar except for minor peak shifting due to the p- or n-type doping. Transmission electron microscopic (TEM) image of Type (II)-p reveals microstructure consisting of high dislocation density (Figures 4C and S3A). The arrays of dislocations are shown by yellow arrows in Figure S3A. In p-type BiTe alloys, in addition to point defects, dislocations also contribute to transport properties by suppressing thermal conductivity (Poudel et al., 2008; Kim et al., 2015). TEM image of Type (II)-n shows a dislocation-free microstructure with sharp grain boundaries (Figures 4D and S3B). As mentioned earlier, one of the mechanisms for zT enhancement in n-type BiTe is through increase of point defect density, which is created through alloying elements, i.e., sulfur and copper. For example, Cu atom increases the distance between two BiTe layers that are weekly bonded by van der Waals force (Liu et al., 2011; Bludska et al., 2004). The fringes on the surface of the grains in Type (II)-n are due to the lattice distortion and strain (Liu et al., 2011).

Figure 4.

(zT)avg, Phase Identification, and Microstructure of the Synthesized Materials

(A) Comparison of the (zT)avg of the synthesized Type (I) and Type (II) materials along with commercial materials.

(B) XRD patterns of Type (I)-p, Type (II)-p, Type (I)-n, and Type (II)-n materials.

(C) TEM image of Type (II)-p material.

(D) TEM image of Type (II)-n material. Enlarged view of TEM images are shown in Figure S3.

Discussion

We report synthesis of p- and n-type BiTe materials and utilize them to demonstrate high-performance TEG modules for waste heat recovery application. Both p- and n-type BiTe alloys with high average and peak zT were synthesized via a combination of defect engineering and substitutional alloying. A record 8% conversion efficiency and 2.1 W/cm2 power density in BiTe alloy-based modules was achieved. The TEG modules with high average zT-based BiTe alloys exhibit 40% higher efficiency compared with the commercial crystalline materials and 15% higher efficiency than the values reported in literature. This study reveals that high average zT and module design variables are critical factors in enhancing the efficiency of TEGs.

Limitations of the Study

As literature and commercial thermoelectric generators have used different sizes of TE modules and TE leg sizes, accurate comparison of all different modules is limited. In addition, whereas efficiency measurement of a single couple module is relatively simple and can be standardized, measuring the efficiency of large-size modules is challenging mostly due to the inaccurate heat flow measurement.

Resource Availability

Lead Contact

Further information and requests for resources should be directed to and will be fulfilled by the Lead Contact, Amin Nozariasbmarz (aln192@psu.edu).

Materials Availability

This study did not generate new unique materials.

Data and Code Availability

Data in this study will be provided upon request from the corresponding author.

Methods

All methods can be found in the accompanying Transparent Methods supplemental file.

Acknowledgments

B.P. and W.L. acknowledge the financial support from the DARPA MATRIX program (NETS). A.N. acknowledges the financial support through NSF-CREST grant number HRD 1547771. B.P. acknowledges the financial support from the National Science Foundation through I/UCRC Program. H.B.K. and S.P. acknowledge the financial support through Office of Naval Research through award number N00014-20-1-2602.

Author Contributions

A.N. and B.P. conceived the idea; A.N. and B.P. designed and conducted the experiments; H.Z. performed the XRD measurements; S.P. supervised the research; All authors contributed to the discussions and writing of the manuscript.

Declaration of Interests

The authors declare no competing interests.

Published: July 24, 2020

Footnotes

Supplemental Information can be found online at https://doi.org/10.1016/j.isci.2020.101340.

Contributor Information

Amin Nozariasbmarz, Email: aln192@psu.edu.

Shashank Priya, Email: sup103@psu.edu.

Supplemental Information

References

- Bell L.E. Cooling, heating, generating power, and recovering waste heat with thermoelectric systems. Science. 2008;321:1457–1461. doi: 10.1126/science.1158899. [DOI] [PubMed] [Google Scholar]

- Biswas K., He J.Q., Blum I.D., Wu C.I., Hogan T.P., Seidman D.N., Dravid V.P., Kanatzidis M.G. High-performance bulk thermoelectrics with all-scale hierarchical architectures. Nature. 2012;489:414–418. doi: 10.1038/nature11439. [DOI] [PubMed] [Google Scholar]

- Bjørk R. The universal influence of contact resistance on the efficiency of a thermoelectric generator. J. Electron. Mater. 2015;44:2869–2876. [Google Scholar]

- Bludska J., Karamazov S., Navratil J., Jakubec I., Horak J. Copper intercalation into Bi2Te3 single crystals. Solid State Ionics. 2004;171:251–259. [Google Scholar]

- Chen L., Gao S., Zeng X., Dehkordi A.M., Tritt T.M., Poon S.J. Uncovering high thermoelectric figure of merit in (Hf,Zr)NiSn half-Heusler alloys. Appl. Phys. Lett. 2015;107:041902. [Google Scholar]

- Chen L., Liu Y., He J., Tritt T.M., Poon S.J. High thermoelectric figure of merit by resonant dopant in half-Heusler alloys. AIP Adv. 2017;7:065208. [Google Scholar]

- Feng S.P., Chang Y.H., Yang J., Poudel B., Yu B., Ren Z., Chen G. Reliable contact fabrication on nanostructured Bi2Te3-based thermoelectric materials. Phys. Chem. Chem. Phys. 2013;15:6757–6762. doi: 10.1039/c3cp50993a. [DOI] [PubMed] [Google Scholar]

- Forman C., Muritala I.K., Pardemann R., Meyer B. Estimating the global waste heat potential. Renew. Sust. Energ. Rev. 2016;57:1568–1579. [Google Scholar]

- Goldsmid H.J. Conversion efficiency and figure-of-merit. In: Rowe D.M., editor. CRC Handbook of Thermoelectrics. CRC Press; 1995. pp. 19–26. [Google Scholar]

- Hao F., Qiu P., Tang Y., Bai S., Xing T., Chu H.-S., Zhang Q., Lu P., Zhang T., Ren D. High efficiency Bi2Te3-based materials and devices for thermoelectric power generation between 100 and 300 ºC. Energy Environ. Sci. 2016;9:3120–3127. [Google Scholar]

- He R., Kraemer D., Mao J., Zeng L., Jie Q., Lan Y., Li C., Shuai J., Kim H.S., Liu Y. High power factor and power density in NbFeSb. PNAS. 2016;113:13576–13581. doi: 10.1073/pnas.1617663113. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Horak J., Cermak K., Koudelka L. Energy formation of antisite defects in doped Sb2Te3 and Bi2Te3 crystals. J. Phys. Chem. Sol. 1986;47:805–809. [Google Scholar]

- Hu L., Zhu T., Liu X., Zhao X. Point defect engineering of high-performance bismuth-telluride-based thermoelectric materials. Adv. Funct. Mater. 2014;24:5211–5218. [Google Scholar]

- Hu X., Jood P., Ohta M., Kunii M., Nagase K., Nishiate H., Kanatzidis M.G., Yamamoto A. Power generation from nanostructured PbTe-based thermoelectrics: comprehensive development from materials to modules. Energy Environ. Sci. 2016;9:517–529. [Google Scholar]

- Joshi G., Poudel B. Efficient and robust thermoelectric power generation device using hot-pressed metal contacts on nanostructured half-heusler alloys. J. Electron. Mater. 2016;45:6047–6051. [Google Scholar]

- Kang H.B., Poudel B., Li W., Lee H., Saparamadu U., Nozariasbmarz A., Kang M.G., Gupta A., Heremans J.J., Priya S. Decoupled phononic-electronic transport in multi-phase n-type half-heusler nanocomposites enabling efficient high temperature power generation. Mater. Today. 2020;36:63–72. [Google Scholar]

- Kim S.I., Lee K.H., Mun H.A., Kim H.S., Hwang S.W., Roh J.W., Yang D.J., Shin W.H., Li X.S., Lee Y.H. Dense dislocation arrays embedded in grain boundaries for high-performance bulk thermoelectrics. Science. 2015;348:109–114. doi: 10.1126/science.aaa4166. [DOI] [PubMed] [Google Scholar]

- Kishore R.A., Nozariasbmarz A., Poudel B., Priya S. Ultra high-performance thermoelectric generators for field deployments. ACS Appl. Mater. Inter. 2020;12:10389–10401. doi: 10.1021/acsami.9b21299. [DOI] [PubMed] [Google Scholar]

- Kishore R.A., Nozariasbmarz A., Poudel B., Sanghadasa M., Priya S. Ultra-high performance wearable thermoelectric coolers with less materials. Nat. Comm. 2019;10:1765. doi: 10.1038/s41467-019-09707-8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kuroki T., Kabeya K., Makino K., Kajihara T., Kaibe H., Hachiuma H., Matsuno H., Fujibayashi A. Thermoelectric generation using waste heat in steel works. J. Electron. Mater. 2014;43:2405–2410. [Google Scholar]

- Liang Z.M., Boland M.J., Butrouna K., Strachan D.R., Graham K.R. Increased power factors of organic-inorganic nanocomposite thermoelectric materials and the role of energy filtering. J. Mater. Chem. A. 2017;5:15891–15900. [Google Scholar]

- Liu W., Bai S. Thermoelectric interface materials: a perspective to the challenge of thermoelectric power generation module. J. Materiomics. 2019;5:321–336. [Google Scholar]

- Liu W., Kim H.S., Jie Q., Ren Z. Importance of high power factor in thermoelectric materials for power generation application: a perspective. Scripta Mater. 2016;111:3–9. [Google Scholar]

- Liu W., Lukas K.C., McEnaney K., Lee S., Zhang Q., Opeil C.P., Chen G., Ren Z. Studies on the Bi2Te3–Bi2Se3–Bi2S3 system for mid-temperature thermoelectric energy conversion. Energy Environ. Sci. 2013;6:552–560. [Google Scholar]

- Liu W.-S., Zhang Q., Lan Y., Chen S., Yan X., Zhang Q., Wang H., Wang D., Chen G., Ren Z. Thermoelectric property studies on Cu-doped n-type CuxBi2Te2.7Se0.3 nanocomposites. Adv. Energy Mater. 2011;1:577–587. [Google Scholar]

- Nozariasbmarz A., Roy P., Zamanipour Z., Dycus J.H., Cabral M.J., LeBeau J.M., Krasinski J.S., Vashaee D. Comparison of thermoelectric properties of nanostructured Mg2Si, FeSi2, SiGe, and nanocomposites of SiGe-Mg2Si, SiGe-FeSi2. Apl. Mater. 2016;4:104814. [Google Scholar]

- Nozariasbmarz A., Kishore R.A., Poudel B., Saparamadu U., Li W., Cruz R., Priya S. High power density body heat energy harvesting. ACS Appl. Mater. Inter. 2019;11:40107–40113. doi: 10.1021/acsami.9b14823. [DOI] [PubMed] [Google Scholar]

- Nozariasbmarz A., Krasinski J.S., Vashaee D. N-type bismuth telluride nanocomposite materials optimization for thermoelectric generators in wearable applications. Materials. 2019;12:1529. doi: 10.3390/ma12091529. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Nozariasbmarz A., Collins H., Dsouza K., Polash M.H., Hosseini M., Hyland M., Liu J., Malhotra A., Ortiz F.M., Mohaddes F. Review of wearable thermoelectric energy harvesting: from body temperature to electronic systems. Appl. Energ. 2020;258:114069. [Google Scholar]

- Nozariasbmarz A., Suarez F., Dycus J.H., Cabral M.J., LeBeau J.M., Öztürk M.C., Vashaee D. Thermoelectric generators for wearable body heat harvesting: material and device concurrent optimization. Nano Energy. 2020;67:104265. [Google Scholar]

- Pei Y.Z., Wang H., Snyder G.J. Band engineering of thermoelectric materials. Adv. Mater. 2012;24:6125–6135. doi: 10.1002/adma.201202919. [DOI] [PubMed] [Google Scholar]

- Poudel B., Hao Q., Ma Y., Lan Y., Minnich A., Yu B., Yan X., Wang D., Muto A., Vashaee D. High-thermoelectric performance of nanostructured bismuth antimony telluride bulk alloys. Science. 2008;320:634–638. doi: 10.1126/science.1156446. [DOI] [PubMed] [Google Scholar]

- Rowe D.M., Min G. Design theory of thermoelectric modules for electrical power generation. IEE Proc. - Sci. Meas. Technology. 1996;143:351–356. [Google Scholar]

- Snyder G.J., Toberer E.S. Complex thermoelectric materials. Nat. Mater. 2008;7:105–114. doi: 10.1038/nmat2090. [DOI] [PubMed] [Google Scholar]

- Stterthwaite C.B., Ure R.W., Jr. Electrical and thermal properties of Bi2Te3. Phys. Rev. 1957;108:1164. [Google Scholar]

- Suarez F., Nozariasbmarz A., Vashaee D., Öztürk M.C. Designing thermoelectric generators for self-powered wearable electronics. Energy Environ. Sci. 2016;9:2099–2113. [Google Scholar]

- Tan G.J., Shi F.Y., Hao S.Q., Chi H., Zhao L.D., Uher C., Wolverton C., Dravid V.P., Kanatzidis M.G. Codoping in SnTe: enhancement of thermoelectric performance through synergy of resonance levels and band convergence. J. Am. Chem. Soc. 2015;137:5100–5112. doi: 10.1021/jacs.5b00837. [DOI] [PubMed] [Google Scholar]

- Tritt T.M. Springer; 2004. Thermal Conductivity: Theory, Properties, and Applications. [Google Scholar]

- Zhu H., He R., Mao J., Zhu Q., Li C., Sun J., Ren W., Wang Y., Liu Z., Tang Z. Discovery of ZrCoBi based half Heuslers with high thermoelectric conversion efficiency. Nat. Commun. 2018;9:2497. doi: 10.1038/s41467-018-04958-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Data Availability Statement

Data in this study will be provided upon request from the corresponding author.