Abstract

Decoctions of ambang (Xymalos monospora) leaves are claimed to have therapeutic potentials but they are seasonal and highly perishable because of its high moisture content. To improve on the use of this plant, drying studies were carried out on its leaves in an effort to produce a green tea. Green tea was produced under 3 different drying conditions including shade, sun and electric drying. The effects of drying method and temperature (50, 60 and 70 °C) on the kinetics, proximate composition and total phenolic content of the teas were analyzed. Drying method had a significant effect on the drying kinetics and quality of the green tea produced. Drying occurred entirely in the falling rate period suggesting that the principal mechanism of drying was by diffusion. Kinetics of the drying processed were modeled successfully by the Page and Modified Page equations. Activation energy for the drying process as determined using K-values from the modified page equation was 27.89 kJ/mol. Significant differences were observed in the quality parameters of teas produced. Protein, carbohydrate and total phenolic content were also dependent on the type of solvent used for extraction. The green tea produced at 60 °C had most of its properties comparable to the commercial green tea used as a reference in the study. It is recommended that to produce good quality tea from ambang leaves, drying should be done at 60 °C for 6 h to obtain a tea with the following composition; moisture content (6.56 ± 0.01), total polyphenols (8.29 ± 0.08), Proteins (2.99 ± 0.13), ash (8.40 ± 0.15) and fiber content (20.43 ± 2.60).

Keywords: Activation energy, Drying, Green tea, Polyphenol, Xymalos monospora

Introduction

Sub-saharran Africa habours a plethora of multipurpose tree and plant species that has played primordial roles for centuries as food and in medicines. The processing and sale of some of these plants represent significant income earning activities for the stakeholders. One of such multipurpose plant species is Xymalos monospora commonly called ambang. The plant is distributed in countries such as Cameroon and Equitorial Guinea eastward to southern Sudan, Uganda and Kenya and southward to Zimbabwe, Mozambique, South Africa Swaziland. It has been introduced in India where it is cultured sporadically (Mojeremane 2012). In Cameroon this plant species grows in the wild in the highland regions of the North West region. Empirical observations in the field in Momo Division of the North West region(6°20′ N 10°30′ E / 6.33° N 10.500° E of Cameroon indicated that some consumers claim to use decoctions from the leaves of X. monospora in the management of high blood pressure, diabetes and to stimulate the heart. Inhabitants of this area also consume these leaves as a vegetable. Equally, in Burundi and Tanzania, leaf decoctions are drunk for cough and whooping cough and are also added to drinking water meant for cattle consumption to cure East Coast fever (Mojeremane 2012).

The consumption of these leaves is highly limited because it is seasonal and very perishable due to its high moisture content at harvest (> 80 g/100 g) on wet basis. One way of extending its shelf-life is to process the leaves into a green tea which can be consumed out of the growing area and out of the production season for the intended claimed health and nutrition benefits.

Tea is made from the young tender shoots (flushes) of Camellia sinensis (L) and it is the most commonly consumed non-water beverage in the world due to its refreshing and mildly stimulating effects (Langat et al. 2015).Tea beverage has continued to be considered medicine since the ancient times because of its polyphenols. Research on humans has shown that tea provides naturally healthy diets that included plant-derived polyphenols (Karorl et al. 2007). Tea can be categorized into three main types depending on the level of oxidation: green (unfermented), oolong (partially fermented) and black (fermented) tea (Lan-Sook et al. 2014). Green tea has more catechins than the other two types of tea and in addition it contains certain minerals and vitamins which increases its anti-oxidant potentials (Cabreca et al. 2006).

Recent studies have equally shown that green tea may contribute to a reduction in the risk of cardiovascular disease and some forms of cancers as well as the promotion of oral health and other physiological functions such as anti-hypertensive effects, body weight control, antibacterial and antivirasic activity, solar ultraviolet protection, bone mineral density increase, antifibrotic properties and neuroprotective power (Karorl et al. 2007). From the preceding analysis, it is preferable to consume green tea in other to derive the maximum possible benefits. This manuscript is focused on the production of a green tea from ambang leaves.

Amongst the various unit operations involved in the production of green tea, drying is one of the key operations because of the important role it plays on the quality and shelf-life of the tea. To the best of our knowledge, there is no literature information on green tea production from X. monospora leaves. This work is therefore based on the production of a green tea from ‘ambang’ leaves with focus on the drying process and its influence on some quality attributes of the teas produced.

Material and methods

Plant identification and sample collection

The plant was harvested together with the leaves, flowers and seeds and taken to the natural herbarium in Yaounde Cameroon which after marching the plant with google photos identified it as Xymalos monspora. Leaves from the entire plant were collected from Teze in Ngie Sub-division Northwest region of Cameroon (5.4301 N and 9.5510 E), and transported to the laboratory on the same day of harvest. In the laboratory, the first four shoots of the plant were selected, washed under running water and allowed to drain over night for processing the following morning.

Determination of moisture content of leaves

About 10–15 g of fresh sample was placed in an electric oven (DHG-9101-1SA, SEARCHTECH INSTRUMENTS, China) and dried at 105 °C for 24 h. After drying, the sample was removed and placed in a desiccator to cool and the final mass was weighed using an electronic balance (XY200S,). This was done in triplicates. Moisture content was expressed as a percentage loss in mass on wet basis.

Evaluation of the drying kinetics of the green tea

Preparation of the green tea

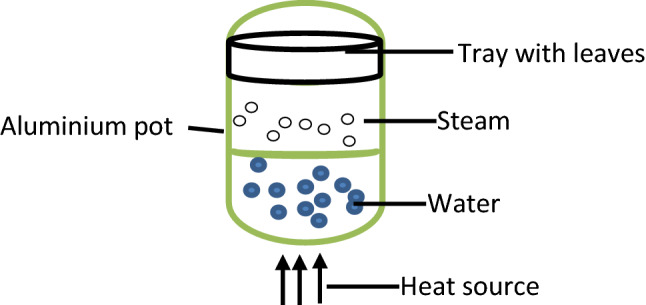

The method used in this work was adopted from Agnieszka and Wilfried (2014) for the preparation of the Japanese type green tea with slight modifications as follows: The leaves were fixed by putting about 120 g of the leaves in a cylindrical and non-perforated aluminum tray of 40 cm diameter. The tray was then suspended over a 20 l cylindrical aluminium pot containing 3 l of water and measuring 40.5 × 24 × 1.4 cm for the diameter, height and thickness respectively. The steam produced from the pot was used to heat the leaves without the leaves having direct contact with the boiling water (Fig. 1). Steaming was done for 12 min with stirring at 2 min intervals to ensure uniform heating. After steaming, the leaves were spread on a laboratory bench to cool to room temperature (about 25 °C). The purpose of steaming is to reduce or prevent oxidation from oxidative enzymes and remove unwanted scents without damaging the flavor of the tea significantly. Fixing was followed by the rolling step. 30–40 g of the cooled or fixed leaves were placed on a chopping board and a manual roller made from wood was used to press the leaves on the chopping board with to and fro movements while ensuring that the pressure exerted on the leaves did not grind them but rather ruptured the cell walls of the plant tissues to facilitate drying. Rolling was done in batches and at the end, all the rolled leaves were thoroughly mixed for uniformity and the moisture content of the rolled leaves determined as earlier described. The rolling process equally helps to regulate the release of the natural substances and flavor during the steeping process (Shimelis 2015).

Fig. 1.

Sketch of the steam cooking process

Collection of drying kinetics data

Three drying techniques, shade drying, open Sun drying and oven drying (50, 60 and 70 °C) were used in this study. For the oven drying, three drying trays each measuring 12 × 16 cm and of a known mass were used to load about 30 g of rolled leaves into each of them. The loss in mass over time (drying kinetics) of each of the trays was recorded. Measurements were done at predefined time intervals until the mass of the produce being dried became constant. For the shade drying, trays having the same dimension as those used in the oven were made from wire gauze and were mounted on a stand about 75 cm high. Poles were pinned around the stand and covered with a polyethylene plastic to provide the needed shade. A similar set up was made for open sun drying but for the fact that it was not shaded. Drying kinetics for these treatments were then carried out as described for the oven drying. All experiments were carried out in triplicates.

At the end of drying, part of the green tea sample was used to determine the residual moisture content of the dried leaves. The remaining portion was ground using a manual hand grinding machine and passed through a 450 µm pore size sieve to obtain a powder which was packaged in transparent polyethylene material and stored in a freezer (SG 2016 0324 60,365, supper general, China) at − 10° C for further analysis.

Analysis of the drying data

Moisture content at time t for all the drying runs was evaluated from the equation

| 1 |

Xt is % moisture content at time t, Mt is mass of product at time t and M0 is the initial mass of the product being dried, X0 is the initial moisture content of the product.

Drying rate was calculated using Eq. 2.

| 2 |

Drying profiles and drying rate curves were then plotted to evaluate the influence of the drying methods and temperature on the drying behavior of the leaves.

Modeling of the drying kinetics

The data obtained was fitted into six thin-layer linearized drying models namely: Newton or Lewis, Page, Modified Page, Henderson, two term exponential and Logarithmic equations as shown on Table 1. Model coefficients were determined through multiple linear regressions on Microsoft excel. These models were chosen because they are simple and have been consistently used in the literature to model drying data of leafy vegetables.

Table 1.

Equations used for modeling the drying data

| Model number | Model name | Original equation | Linearized form | References |

|---|---|---|---|---|

| 1 | Newton or Lewis | Onwude et al. (2016) | ||

| 2 | Page | Shukla et al. (2014) | ||

| 3 | Modified page | Qinqin et al. (2015) | ||

| 4 | Handerson and Pabis | Kadam et al. (2011) | ||

| 5 | Two Term Exponential | Mujaffar and Lee Loy (2016) | ||

| 6 | Logarithmic | Deepak and Gattumane (2015) |

Validation of the models

The models were validated using R2 obtained from regression analysis of the respective equations as well as the Chi-square (χ2) and root mean square error (RMSE) values calculated from Eqs. 3 and 4 (Kadam et al. 2011). The mean relative deviation error (MRDE) was calculated using Eq. 5.

| 3 |

| 4 |

| 5 |

where, and are the measured and calculated moisture ratios at observation x respectively, n represents number of measured data points, and z is number of constants in model.

Calculation of activation energy

The activation energy involved in the oven drying of the tea leaves was evaluated from the Arrhenius equation (Lam et al. 2014) using data obtained at 50, 60 and 70 °C as shown in Eq. 6.

| 6 |

where, A0 is the pre-exponential factor of the Arrhenius equation (m2/s); Ea is the activation energy (kJ/mol); R is the universal gas constant (KJ/mol K), and T is the temperature (K). Ea was obtained from the linearized form of Eq. 6 as presented in Eq. 7.

| 7 |

Evaluation of the quality of the green tea produced

Some parameters of the quality of the ground tea were analyzed by standard methods as follows: Total carbohydrates, and polyphenols were quantified by the methods described by Annabelle et al. (2014), proteins were determined according to Gerardo et al. (2011) while crude fiber and ash followed the method of Tiencheu et al. (2016). Methanol, phosphate buffer and ethanol extracts of the tea were also produced and analysed for total polyphenols, proteins and carbohydrates respectively.

The results obtained were compared with those extracted in water. A commercial tea was obtained from a supermarket in Bamenda (5.9631° N, 10.1591° E) market and analyzed alongside the produced teas and used as a control in the study.

Statistical analysis

The comparison of the various quality parameters analyzed were achieved using the one-way analysis of variance (ANOVA) and where there were significant differences the means were separated by the DUNCAN multiple range test on Statgraphics centurion XVIII. Figures as well as R2, χ2, mean relative deviation error (MRDE) and RMSE-values were generated on microsoft Excel.

Results and discussion

Drying kinetics of Xymalos monospora leaves

Moisture content of the leaves

The average of initial moisture content of the fresh (unprocessed) X. monospora leaves was 85.60 ± 0.81 g/100 g. Similar results were indicated by Sheetal et al. (2013) as they reported that the moisture content of fresh leafy vegetables have values between 85 and 92 g/100 g. Moreover, Eme-Okafor (2012) reported that the moisture content of green leafy vegetables ranged between 90 and 95 g/100 g. On the other hand, the moisture content of leaves after the rolling process was 81.54 ± 0.71 g/100 g.

The values for moisture lost after the rolling process was far lower than values reported by Selena and John (2013) who indicated that about 40 g/100 g moisture is lost during the fixing process of tea.

Influence of drying on the drying kinetics of Xymalos monospora

Influence of drying method

From Fig. 2a it can be observed that while there was no significant difference between the different treatments in the early period of drying (first 0–100 min) drying became significantly faster for samples that underwent sun drying compared to electric drying at 50 °C and drying under shade in the later drying period (100–400 min). The slow drying process observed for the shade drying is attributable to the low temperatures and high relative humidities of the air observed during the drying processes. This is in agreement with studies conducted by Ahmad et al. (2016) as they realized that at low air temperatures, the relative humidity is higher, slowing down the drying process and as a result increases the drying time. Drying was unexpectedly faster under ambient conditions (about 30 °C) compared to oven drying at 50 °C. This is attributed to the high wind speed and low relative humidity of the ambient drying air compared to the oven drying conditions, since the electric oven was not ventilated.

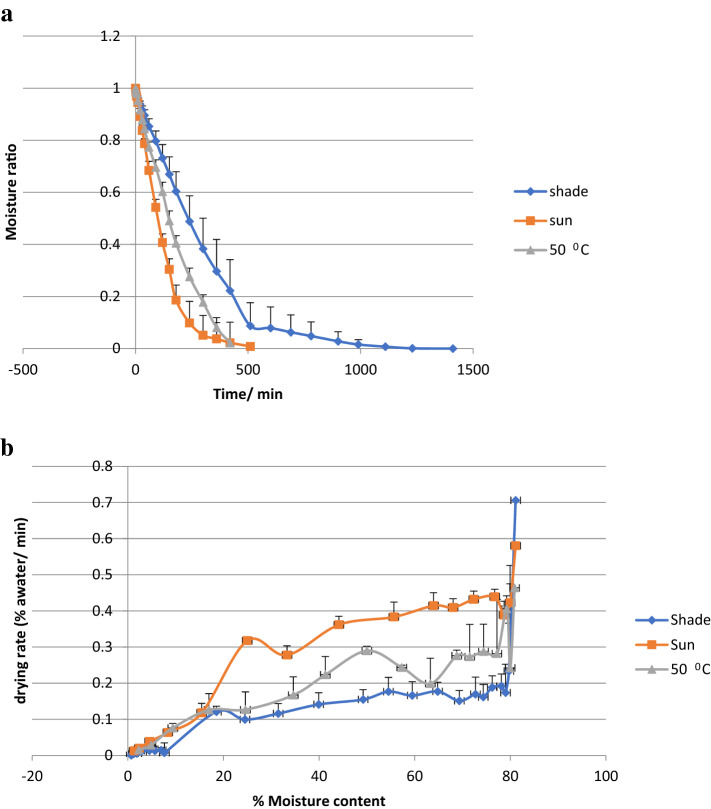

Fig. 2.

a Influence of drying method on moisture loss of the leaves. b The influence of drying method on the drying rate

Figure 2b confirms that sun drying was the fastest drying method compared to shade and 50 °C. This is in disagreement with studies made by Sahari and Driscoll (2013) who reported that the drying rate of a product is mainly affected by the drying air temperature and the thickness of the material and that air velocity had little effect on drying rate.

Influence of drying temperature

From Fig. 3a, it is observed that in the beginning and at the end of the drying process, there was no significant difference (p < 0.05) in the moisture loss. But between 40 and 360 min of drying, there was a significant difference between drying at 50 °C and 70 °C. In fact drying time was dependent on process temperature, as increasing.

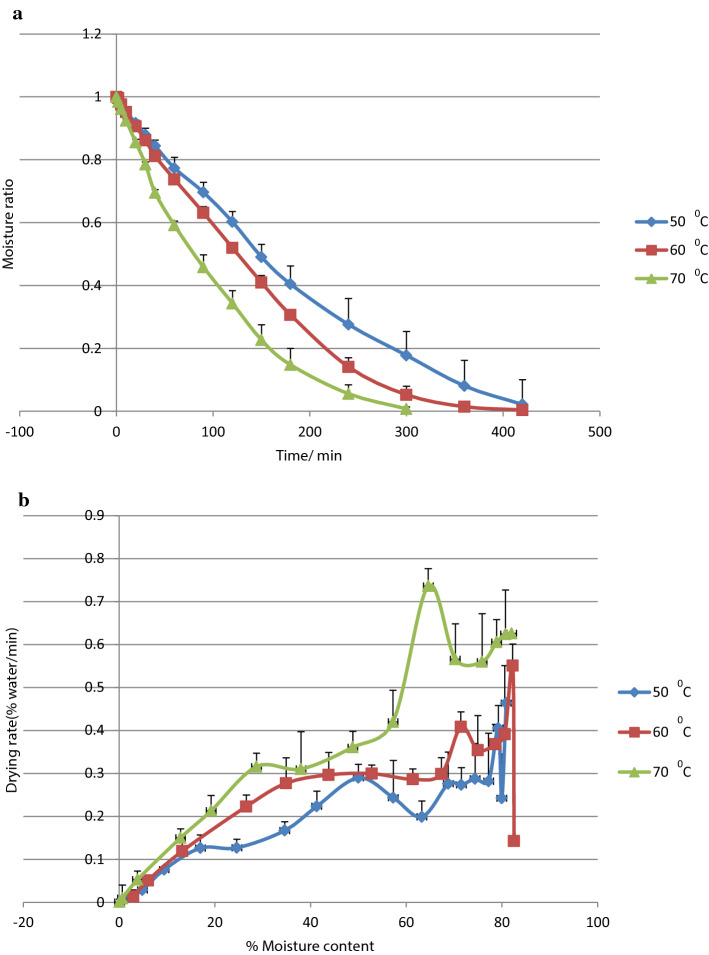

Fig. 3.

a The influence of temperature on the drying kinetics of leaves. b The influence of drying temperatures on the drying rate

This is in line with the studies of Coradi et al. (2014) and Prasad and Prasad (2013) as they indicated that the increase in air temperature significantly reduced the drying time of lemon grass and spinach leaves respectively.

Figure 3b presents the drying rate curves of the green teas as a function of temperature which confirms the temperature effect on drying as earlier explained. Generally, from the drying rate curves, we notice the absence of the temperature attainment and the constant rate periods, indicating that drying occurred mainly in the falling rate period. The absence of the constant rate falling period here can be attributed to the moisture loss that occurred between harvest, transportation and during the rolling process prior to drying.

Modeling of drying kinetics.

From Table 2, it can be seen that the Page and Modified Page equations could better model the drying behavior of X. monospora leaves based on their high R2-values across the respective treatments when compared with those of the other models. The Chi-square (χ2) and RMSE values were therefore calculated for these models to ascertain their validities to model the drying of X. monospora leaves. From Table 2, it is seen that the χ2 and RMSE are very low while the R2-values for all the treatments are very close to 1 for the Page and Modified Page models. These models were therefore validated for describing the drying process of the leaves of X. monospora. Plots of measured versus calculated moisture content ratios for the selected equations gave a very close distribution of the points around the diagonal with R2-values of 0.998 and 0.997 respectively, thereby confirming their suitability in describing the drying process of the green teas.

Table 2.

Model constants and R2 for the six different treatments

| Model name | Shade | Sun | 50 °C | 60 °C | 70 °C | ||

|---|---|---|---|---|---|---|---|

| 1 | Newton | R2 | 0.968 | 0.708 | 0.661 | 0.663 | 0.913 |

| K | 0.004 | 0.013 | 0.016 | 0.024 | 0.017 | ||

| 2 | Page | R2 | 0.972 | 0.985 | 0.957 | 0.968 | 0.987 |

| K | 0.004 | 0.004 | 0.003 | 0.002 | 0.006 | ||

| N | 0.979 | 1.111 | 1.148 | 1.323 | 1.142 | ||

| χ2 | 0.0022 | 0.0004 | 0.0050 | 0.0106 | 0.0032 | ||

| MRDE | 12.180 | 1.195 | 6.232 | 13.217 | 3.908 | ||

| RMSE | 0.0453 | 0.0201 | 0.06642 | 0.0965 | 0.0526 | ||

| 3 | Modified Page | R2 | 0.972 | 0.985 | 0.957 | 0.968 | 0.987 |

| K | 0.004 | 0.008 | 0.006 | 0.008 | 0.011 | ||

| N | 0.979 | 1.111 | 1.148 | 1.323 | 1.142 | ||

| χ2 | 0.0042 | 0.0010 | 0.0032 | 0.0045 | 0.0024 | ||

| MRDE | 12.107 | 12.998 | 22.77 | 13.222 | 3.099 | ||

| RMSE | 0.0620 | 0.0293 | 0.0533 | 0.0631 | 0.0456 | ||

| 4 | Henderson and Pabis | R2 | 0.968 | 0.708 | 0.661 | 0.663 | 0.913 |

| K | 0.004 | 0.013 | 0.016 | 0.024 | 0.017 | ||

| A | 1.214 | 2.123 | 3.181 | 3.785 | 1.542 | ||

| 5 | Two term exponential | R2 | 0.968 | 0.708 | 0.661 | 0.663 | 0.913 |

| K | 0.004 | 0.013 | 0.016 | 0.024 | 0.017 | ||

| A | − 0.2141 | − 1.1234 | − 2.1804 | − 2.785 | − 0.542 | ||

| 6 | Logarithmic equation | R2 | 0.968 | 0.708 | 0.661 | 0.663 | 0.913 |

| K | 0.004 | 0.013 | 0.016 | 0.024 | 0.017 | ||

| Ac | 1.214 | 2.123 | 3.18 | 3.785 | 1.542 |

Activation Energy

Activation energy calculated using the Modified page model was 27.89 kJ/mol. Fernando et al. (2011) reported that once considering agricultural products, the value for activation energy ranges from 12.7 to 110 kJ mol−1. With this result, the activation energy from this study was in line with their findings. But Coradi et al. (2014) carried out studies and saw that the activation energy for liquid diffusion of lemon grass plant was 62.84 kJ/mol which was higher than the results obtained in this study. The relatively low activation energy is a pointer to the fact that energy requirements for the drying of ambang leaves could be relatively low thereby reducing the processing cost.

Quality of the green tea

Moisture contents of various types of green tea as given by Xiaoli et al. (2012) were within the range (3–45 g/100 g). On the contrary, Muhammed et al. (2013) stated that the moisture content of the green tea they studied ranged between 4.93 and 7.47 g/100 g. Our tea treatments except the one produced at 70 °C with a moisture content of 6.65 g/100 g was out of this range (Table 3). Shimelis (2015) reported that the moisture content of green tea was 11.8 ± 0.55 g/100 g. Manisha and Narayan (2017) reported that the moisture content of the green leafy vegetables they dried under the sun ranged between 4.71 and 7.06 g/100 g which was lower than those obtained in this study under similar conditions (10.61 g/100 g). The moisture content of the various green teas obtained in this work were less than that of reference commercial green tea indicating that in terms of moisture content our teas presented good storage properties.

Table 3.

Proximate and total polyphenol composition of samples (g/100 g)

| Parameter/sample | Extraction solvent | Shade | Sun | 50 °C | 60 °C | 70 °C | Reference |

|---|---|---|---|---|---|---|---|

| Moisture content | 10.48d ± 0.01 | 10.61e ± 0.04 | 7.77b ± 0.87 | 8.96c ± 0.00 | 6.56a ± 0.01 | 12.41f ± 0.04 | 10.48d ± 0.01 |

| Total polyphenol | Water | 3.53Ia ± 0.29* | 5.04Ib ± 0.13 | 5.58Ib ± 0.77 | 8.29Ic ± 0.08 | 4.85Ib ± 0.34 | 12.26Id ± 0.37 |

| Methanol | 1.89IIa ± 0.15** | 1.39IIa ± 0.07 | 2.39IIb ± 0.04 | 3.01IIc ± 0.09 | 1.21IIa ± 0.08 | 10.19IId ± 0.67 | |

| Proteins | Water | 2.57Ia ± 0.02 | 2.31Ia ± 0.03 | 2.73Ia ± 0.15 | 2.99Ia ± 0.13 | 2.57Ia ± 0.05 | 5.93Ib ± 0.08 |

| Phosphate buffer | 2.76IIa ± 0.05 | 2.92IIa ± 0.11 | 3.09IIab ± 0.01 | 3.32IIb ± 0.08 | 3.20IIb ± 0.09 | 5.00IIc ± 0.14 | |

| Carbohydrate | Water | 1.84Ib ± 0.07 | 1.54Ib ± 0.12 | 1.59Ib ± 0.05 | 1.67Ib ± 0.02 | 0.91Ia ± 0.07 | 4.03Ic ± 0.00 |

| Ethanol | 6.16IIc ± 0.41 | 7.23IId ± 0.09 | 4.80IIa ± 0.07 | 6.28IId ± 0.16 | 5.29IIb ± 0.16 | 13.32IIe ± 0.01 | |

| Ash | 7.53b ± 0.13 | 7.32b ± 0.11 | 8.18c ± 0.01 | 8.40c ± 0.15 | 8.41c ± 0.02 | 4.50a ± 0.12 | |

| Fiber | 25.44b ± 1.28 | 7.79a ± 0.52 | 16.84a ± 1.46 | 20.43a ± 2.60 | 20.57a ± 4.91 | 19.00a ± 2.26 | |

| Fats | 9.59bc ± 4.24 | 10.43c ± 0.00 | 8.74b ± 0.70 | 8.46b ± 2.83 | 9.59bc ± 2.83 | 6.48a ± 2.12 |

*Different Superscript roman numerals indicate significant difference (p < 0.05) as a result of the extraction solvent for a particular quality parameter (polyphenol, proteins and carbohydrates) and a particular drying treatment

**Different superscript letters on the same row indicate significant difference (p < 0.05) as a result of the drying

From Table 3, it can be seen that, extractions with boiling water for 10 min gave significantly (p < 0.05) higher concentrations of polyphenol than extraction with methanol for all treatments. For a given solvent, the quantity of polyphenol extracted varied significantly with the drying treatment given to the sample and was highest for the commercial green tea which was used as a control in these studies. Green tea dried in an oven at 60 °C gave the highest polyphenol value (8.29 ± 0.08 g/100 g) amongst the prepared teas which was however significantly lower than that of the reference tea (12.26 ± 0.37 g/100 g). The concentrations of polyphenols obtained from both extraction media (water and ethanol) for the sample dried at 60 °C were in the range of the values reported by Stankovic et al. (2010). The variation of quantity of polyphenol with temperature was consistent in water and methanol extracts where polyphenol content increased up to 60 °C and then decreased at 70 °C and was attributed to browning reactions. Sharma et al. (2015) observed the increased of polyphenol content of onion with heating temperature and attributed it to browning reactions during the heating process.

Similar to polyphenols and carbohydrate contents, extraction medium had a significant effect on the protein content. In both extraction media (water and phosphate buffer) treatment method had no significant difference on the protein contents of the tea prepared in this study which however were significantly lower than that of the reference tea. Protein values from this study are in agreement with studies carried out by Rajeswari (2010) who reported that green leafy vegetables have protein values between 2 and 7 g/100 g which gets concentrated on dehydration. The protein content of the leaves is non-negligible.

The extraction medium had a significant effect (p < 0.05) on the quantity of carbohydrates of the different samples. More carbohydrates were extracted in ethanol compared to water. For the water extracted samples, carbohydrate content was lowest in the oven dried treatment at 70 °C and highest for the reference sample. There were no significant differences in the carbohydrate contents of the other teas after water extraction. In ethanol, the reference tea again had the highest quantity of carbohydrates.

All tea samples studied had significantly higher ash content (7.32 ± 0.11- 8.41 ± 0.02 g/100 g) compared to the reference green tea (lipton) (4.50a ± 0.12 g/100 g) and ash content value of 4.7 ± 0.01 g/100 g for green tea (from Camellia sinensis) as reported by Shimelis (2015). Mohammed and Sulaiman (2009), reported in their study that the green teas they studied had values between 4.9 and 7.5 g/100 g which were comparable to those obtained in this study.

The tea dried in the shade gave the highest concentration of fiber (25.44 ± 1.28 g/100 g) compared to the other treatments and the reference tea (19.00 ± 2.26 g/100 g). From studies conducted by Jayawardhane et al. (2016) on six different kinds of green tea, they realized that the fiber content of the teas was within the range of 10.9–19.5 g/100 g comparable to the teas obtained after oven drying at 50 °C and in the sun as well as the reference tea. Courage (2015) reported that the fiber content of a composite tea made from Cymbopogon citratus, Lippia multiflora and Ganoderm alucidum was 77.06 ± 0.33 which was far higher than the results obtained from this study. These differences could be due to the fact that the tea produced from this study was made using only one plant as opposed to that of Courage (2015) who used 3 different plants. Rabia et al. (2014) reported that green tea fiber content to be 15.35 ± 1.05 g/100 g which was significantly lower than the highest value obtained in this study.

Akande et al. (2011) reported that fat content of green tea was 6.09 ± 0.01 g/100 g which was lower than the range (8.46–8.59 g/100 g) reported in this study. Fat content of the reference green tea was significantly lower than those obtained in this work. This was true only for the control green tea whose value was closed to that reported by Akande et al. (2011). The significantly higher amounts of fats observed in this study could be due to the complete omission of fermentation as often done in tea processing (Muhammad et al. 2013). Based on the analysis, it can be said that X. monospora is rich in fats compared to other sources treatment given to the samples.

Conclusion

Green tea can be produced from the leaves of X. monospora under different drying conditions. The drying of X. monospora leaves occurs mostly in the falling rate period and gives rise to only one drying constant for each treatment. The Modified Page equation is the best equation to describe the drying kinetics of X. monospora leaves. Activation energy as determined using k-values from the modified page equation is 27.89 kJ/mol. Drying method has a significant effect on the quality of the tea produced (p < 0.05). Extraction solvent has a significant influence on the protein, total phenol and carbohydrate contents. The green tea produced from oven drying at 60 °C with the following composition total polyphenol (8.29 ± 0.08), Proteins (2.99 ± 0.13), ash (8.40 ± 0.15) and fiber content (20.43 ± 2.60) is recommended.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- Agnieszka K, Wilfried A (2014) Antioxidant capacity of tea: effect of processing and storage. In: Preedy V (ed) Processing and impact on antioxidants in beverages, pp 109–120. 10.1016/C2012-0-02151-5

- Ahmad F, Chan HY, Habibis S, Dayang FB, Mohd HR, Rado Y, Ari PD, Rahmadeniand KS. Activation energy of thin-layer drying kinetics of belimbingdayak fruit (Baccaurea angulata) Res J Appl Sci Eng Tech. 2016;13(4):295–300. doi: 10.19026/rjaset.13.2945. [DOI] [Google Scholar]

- Akande IS, Samuel TA, AgbazueOlowolagba UBL. Comparative proximate analysis of ethanolic and water extracts of Cymbopogon citratus (lemon grass) and four tea brands. Plant Sci Res. 2011;3(4):29–35. [Google Scholar]

- Annabelle LP, Hyeyoung L, Kevin C, Daniela B. Rapid quantification of functional carbohydrates in food products. Food Nutr Sci. 2014;5:71–78. [Google Scholar]

- Cabreca C, Artacho R, Gimenez R. Beneficial effects of green tea—a review. J Am Coll Nutr. 2006;25(2):79–99. doi: 10.1080/07315724.2006.10719518. [DOI] [PubMed] [Google Scholar]

- Coradi PC, Melo EC, Rocinely PR. Mathematical modeling of the drying kinetics of the leaves of lemon grass (Cymbopogon citratus Stapf) and its effects on quality. IDESIA. 2014;32(4):43–56. doi: 10.4067/S0718-34292014000400006. [DOI] [Google Scholar]

- Courage SD. Sensory performance, proximate and antioxidant activity of tea from composite formulation of cymbopogon citratus, lippiamultiflora and ganoderma lucidum. JFood Nutr Sci. 2015;3(3):131–138. [Google Scholar]

- Deepak S, Gattumane MM. Drying kinetics and mathematical modeling of Casuarina equisetifolia wood chips at various temperatures. Periodica Polytechnica Chem Eng. 2015;59(4):288–295. doi: 10.3311/PPch.7855. [DOI] [Google Scholar]

- Eme-Okafor EP (2012) Effect of drying methods on the nutrient and phytochemical properties of some cultivated and wild leafy vegetables. MSc. Dissertation, University of Nigeria, Nsukka, Nigeria, pp 1–60

- Fernando MB, Paulo CC, André LDG, Márcio AM, Felipe EAM, Sílvia CC. Periods of constant and falling-rate for infrared drying of carrot slices. Revista Brasileirade EngenhariaAgrícola e Ambiental. 2011;15(8):845–852. doi: 10.1590/S1415-43662011000800012. [DOI] [Google Scholar]

- Gerardo J, Marianne LS, Leonisa Y, Nancy LL, Julita R. Determination of the sensitivity range of Biurett for undergraduate biochemistry experiments. E J Sci Technol. 2011;5(6):77–83. [Google Scholar]

- Jayawardhane SADPS, Madushanka KPC, Mewan KM, Jayasinghe SK, Karunajeewa DGNP, Edirisinghe ENU (2016) Determination of quality characteristics in different green tea products available in Sri Lankan supermarkets 6th symposium on plantation crop research, Colombo, Sri Lanka, 57–68

- Kadam DM, GoyalGupta RKMK. Mathematical modeling of convective thin layer drying of basil leaves. J Med Plants Res. 2011;5(19):4721–4730. [Google Scholar]

- Karorl S, Wachlra F, Wanyoko J, Nguro R. Antioxidant capacity of different types of tea products. Afr J Technol. 2007;6(19):2287–2296. [Google Scholar]

- Lam VM, Takahiro O, Shoji K, Yoshiki M, Akio T. Effect of different drying methods on physical and chemical attributes of blanched green bell pepper. Food Sci Technol Res. 2014;20(4):775–783. doi: 10.3136/fstr.20.775. [DOI] [Google Scholar]

- Lan-Sook L, Sang-Hee K, Young-Boong K, Young-Chan K. Quantitative analysis of major constituents in green tea with different plucking periods and their antioxidant activity. Molecules. 2014;19:9173–9186. doi: 10.3390/molecules19079173. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Langat N, Thomas T, John W, Jeremiah K, Brian P, John A. Models and experiments for energy consumption and quality of green tea drying. Energy Sci Eng. 2015;3(1):43–50. doi: 10.1002/ese3.49. [DOI] [Google Scholar]

- Manisha S, Narayan P. Effect of drying methods on ash contents and moisture content of leafy vegetables. Intl J Sci Res. 2017;6(8):936–938. [Google Scholar]

- Mohammed MI, Sulaiman MA. Proximate, caffeine and tannin analyses in some brands of tea consumed in Kano metropolis, Nigeria. Bayero J Pure Appl Sci. 2009;2(2):19–21. [Google Scholar]

- Mojeremane W (2012) Xymalosmonospora (Harv.)Baill.Ex Warb. [internet] Record from PROTA4U. In: Lemmens RHMJ, Louppe D, Oteng-Amoako AA (eds) PROTA (Plant Resources of tropical Africa / Ressourcesvegetales de l`AfriqueTropicale), Wageningen, Netherlands. http://www.prota4u.org/search.asp. Accessed 24 Jan 2018

- Muhammad A, Asif A, Anwaar A, Nauman K, Imran H, Iftikhar A. Chemical composition and sensory evaluation of tea (Camellia sinensis) Pak J Bot. 2013;45(3):901–907. [Google Scholar]

- Mujaffar S, Lee Loy A. Drying kinetics of microwave-dried vegetable amaranth (Amaranthus dubius) leaves. J Food Res. 2016;5(6):33–44. doi: 10.5539/jfr.v5n6p33. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Onwude DI, Hashim N, Janius RB, Nawi N, Abdan K. Evaluation of a suitable thin layer model for drying of pumpkin under forced air convection. Intl Food Res J. 2016;23(3):1173–1181. [Google Scholar]

- Prasad A, Prasad K. Studies on kinetics of moisture removal from spinach leaves. Int J Agric Food Sci Technol. 2013;4(4):303–308. [Google Scholar]

- Qinqin C, Jinfeng B, Xinye W, Jianyong Linyan Z, Yuhan Z. Drying kinetics and quality attributes of jujube (Zizyphus jujuba Miller) slices dried by hot-air and short- and medium-wave infrared radiation. Food Sci Technol. 2015;64:759–766. [Google Scholar]

- Rabia SA, Masood SB, Nuzhat H, Tauseef SM, Muhammad UA, Zarina M, Farhan S. Quantitative and qualitative portrait of green tea catechins (GTC) through HPLC. Int J Food Prop. 2014;17(7):1626–1636. doi: 10.1080/10942912.2012.723232. [DOI] [Google Scholar]

- Rajeswari R (2010) Dehydration of green leafy vegetables and its effect on quality. Master of Home Science Dissertation, University of Agricultural Sciences, Dharwad, India, p 70

- Sahari Y, Driscoll RH (2013) Thin layer drying of agricultural products: a review. In: 3rd Malaysian postgraduate conference (MPC). Sydney, Australia, 2013, 8–21

- Selena A, John RS (2013) Green tea: plants, processing, manufacturing and production. In: Tea in health and disease prevention, pp 19–31. 10.1016/B978-0-12-384937-3.00002-1

- Sharma K, Ko EY, Assefa AD, Ha S, Nile SH, Lee ET, Park SW. Temperature-dependent studies on the total phenolics, flavonoids, antioxidant activities, and sugar content in six onion varieties. J Food Drug Anal. 2015;23(2):243–252. doi: 10.1016/j.jfda.2014.10.005. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sheetal G, Gowri B, Jyothi L, Jamuna P. Retention of nutrients in green leafy vegetables on dehydration. J Food Sci Technol. 2013;50(5):918–925. doi: 10.1007/s13197-011-0407-z. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Shimelis S (2015) Optimization and characterization of antioxidant activity from green tea (Camellia sinensis) and evaluation of its preservative effect—a thesis. MSc. Dissertation, Addis Ababa Institute of Technology Addis Abba, Ethiopia, p 77

- Shukla RN, Priyadarshini, Atul AM. An experimental study and mathematical modeling of microwave drying of green peas. Intl J Adv Eng Technol. 2014;6(6):2618–2624. [Google Scholar]

- Stankovic MS, Topuzovic M, Mihailovic SSV. Antioxidant activity and concentration of phenols and flavonoids in the whole plant and plant parts of Teucrium chamaerdys L. var. glanduliferum Haussk. J Med Plants Res. 2010;4(20):2092–2098. [Google Scholar]

- Tiencheu B, Ufuan AA, Tatsinkou BF, Tenyang N, Tiepma EFN, Womeni HM. Formulation and nutritional evaluation of instant weaning foods processedfrom maize (zea mays), pawpaw (carica papaya), red beans (phaseolus vulgaris) and mackerel fish meal (Scombers combrus) Am J Food Sci Technol. 2016;4(5):149–159. [Google Scholar]

- Xiaoli L, Chuanqi X, Yong H, Zhengjun Q, Yancho Z. Characterising the moisture content of tea with diffuse reflectance spectroscopy using wavelet transform and multivariate analysis. J List Sens (Basel) 2012;12(7):9847–9861. doi: 10.3390/s120709847. [DOI] [PMC free article] [PubMed] [Google Scholar]