Abstract

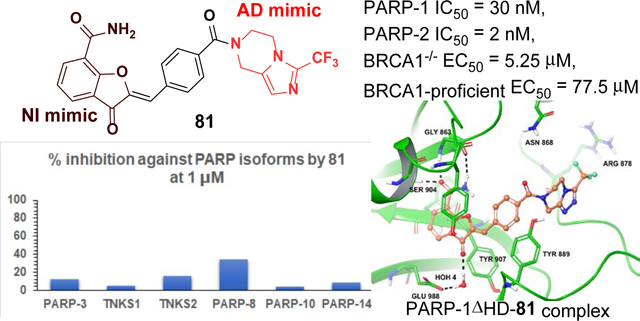

Poly(ADP-ribose) polymerase (PARP) inhibitors are a class of anticancer drugs that block the catalytic activity of PARP proteins. Optimization of our lead compound 1 ((Z)-2-benzylidene-3-oxo-2,3-dihydrobenzofuran-7-carboxamide; PARP-1 IC50 = 434 nM) led to a tetrazolyl analogue (51, IC50 = 35 nM) with improved inhibition. Isosteric replacement of the tetrazole ring with a carboxyl group (60, IC50 = 68 nM) gave a promising new lead, which was subsequently optimized to obtain analogues with potent PARP-1 IC50 values (4 nM – 200 nM). PARP enzyme profiling revealed that the majority of compounds are selective toward PARP-2 with IC50 values comparable to clinical inhibitors. X-ray crystal structures of the key inhibitors bound to PARP-1 illustrated the mode of interaction with analogue appendages extending toward the PARP-1 adenosine-binding pocket. Compound 81, an isoform-selective PARP-1/−2 (IC50 = 30 nM/2 nM) inhibitor, demonstrated selective cytotoxic effect toward BRCA1-deficient cells compared to isogenic BRCA1–proficient cells.

Graphical Abstract

INTRODUCTION

Exogenous and endogenous genotoxic injuries lead to DNA single strand breaks (SSBs) and DNA double strand breaks (DSBs), which collectively trigger the DNA damage response (DDR) in cells. In cancer cells, SSBs occur at a frequency of up to 10,000 per cell each day.1 While SSBs are repaired by base excision repair (BER),2 repair of DSBs requires a functional homologous recombination (HR) or non-homologous end joining (NHEJ) repair mechanism.3, 4 Computational analyses indicated the involvement of approximately 400 proteins in the regulation of the DDR process.5, 6 Poly(ADP-ribose) polymerase-1 (PARP-1) plays an important role in BER-mediated DNA damage repair as well as other pathways7 by binding to the damaged DNA through the coordinated action of its N-terminal zinc finger motifs. The C-terminal catalytic site of PARP-1 hydrolyzes NAD+ substrate into ADP-ribose and nicotinamide (NI). Branched and linear chains of ADP-ribose units are covalently transferred onto a wide range of target proteins such as DNA polymerases, histones, DNA ligases, p53 and topoisomerase I/II (heteromodification), and onto PARP itself (automodification).8 Thus, PARP-1 acts as a “writer” of poly (ADP-ribosylation) (PARylation).9 PARylation has been shown to play a role in cellular processes such as DNA damage repair, maintaining genomic stability, regulation of transcription, and cell death.10, 11 PARylation of PARP-1 is necessary for non-covalent recruitment of DNA repair proteins, including DNA ligase III, DNA polymerase β (pol β) and XRCC1 to the sites of DNA breaks.12–14 PARylation of PARP-1 is also thought to promote its dissociation from DNA damage sites to allow repair.15, 16 Therefore, targeting PARP-1 with small molecule inhibitors is an attractive strategy to enhance antitumor effect.17–23

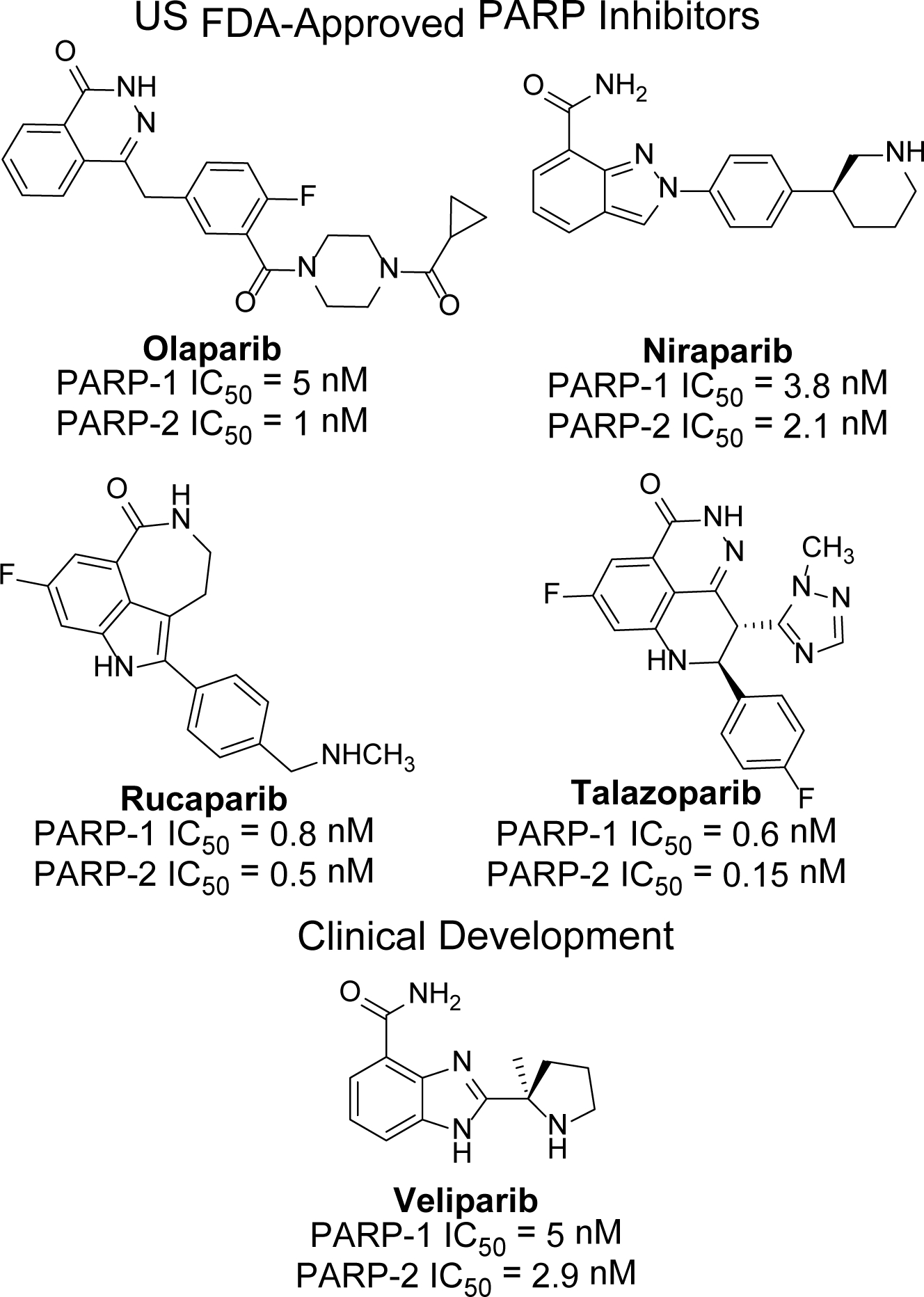

Synthetic lethality is a strategy that exploits gene defects in cancer for therapeutic benefit.24 The foremost example of synthetic lethality as a targeted cancer therapy is the use of PARP inhibitors in the treatment of cancer in individuals with germline mutations in BRCA1 or BRCA2. In addition to blocking the catalytic activity of PARP proteins, some PARP inhibitors (niraparib, olaparib, rucaparib and talazoparib) act at least in part by trapping PARP on damaged DNA.23 This trapping interferes with DNA replication causing double stranded breaks that cannot be repaired in HR-defective tumor cells. PARP-1 inhibitors as single agents are, therefore, efficacious in treating tumors deficient in HR components, including BRCA1/2, but are of limited utility in tumors with normal or restored function of HR repair mechanism.25–29 Consequently, the use of FDA approved PARP-1 inhibitors such as olaparib,30 niraparib,31 rucaparib32 and talazoparib33 has mainly focused on their therapeutic role as a monotherapy to treat BRCA-deficient tumors based on the concept of synthetic lethality.23 These drugs and another PARP-1 inhibitor, veliparib,34 are also currently undergoing advanced clinical trials as combination and/or single agents in cancer therapy (Figure 1).35 Clinical PARP-1 inhibitors are also useful for the treatment of other cancers with DNA DSB repair deficiency such as those with BRCAness.36 Taking these factors into consideration, PARP-1 remains an attractive target for anticancer drug development.

Figure 1.

Structures and PARP-1/PARP-2 inhibitory activity of clinical compounds either US FDA approved or undergoing Phase III clinical trials.

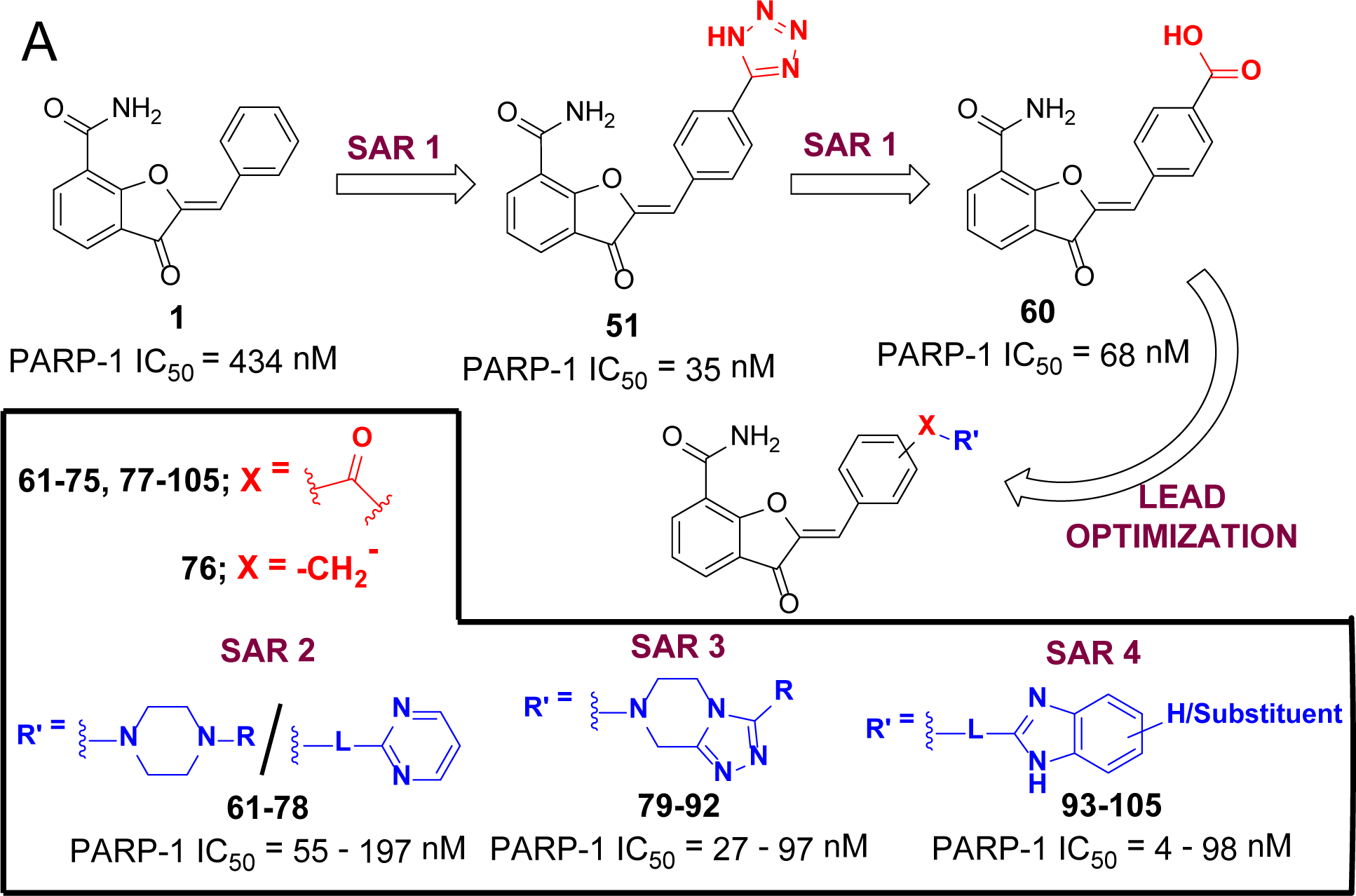

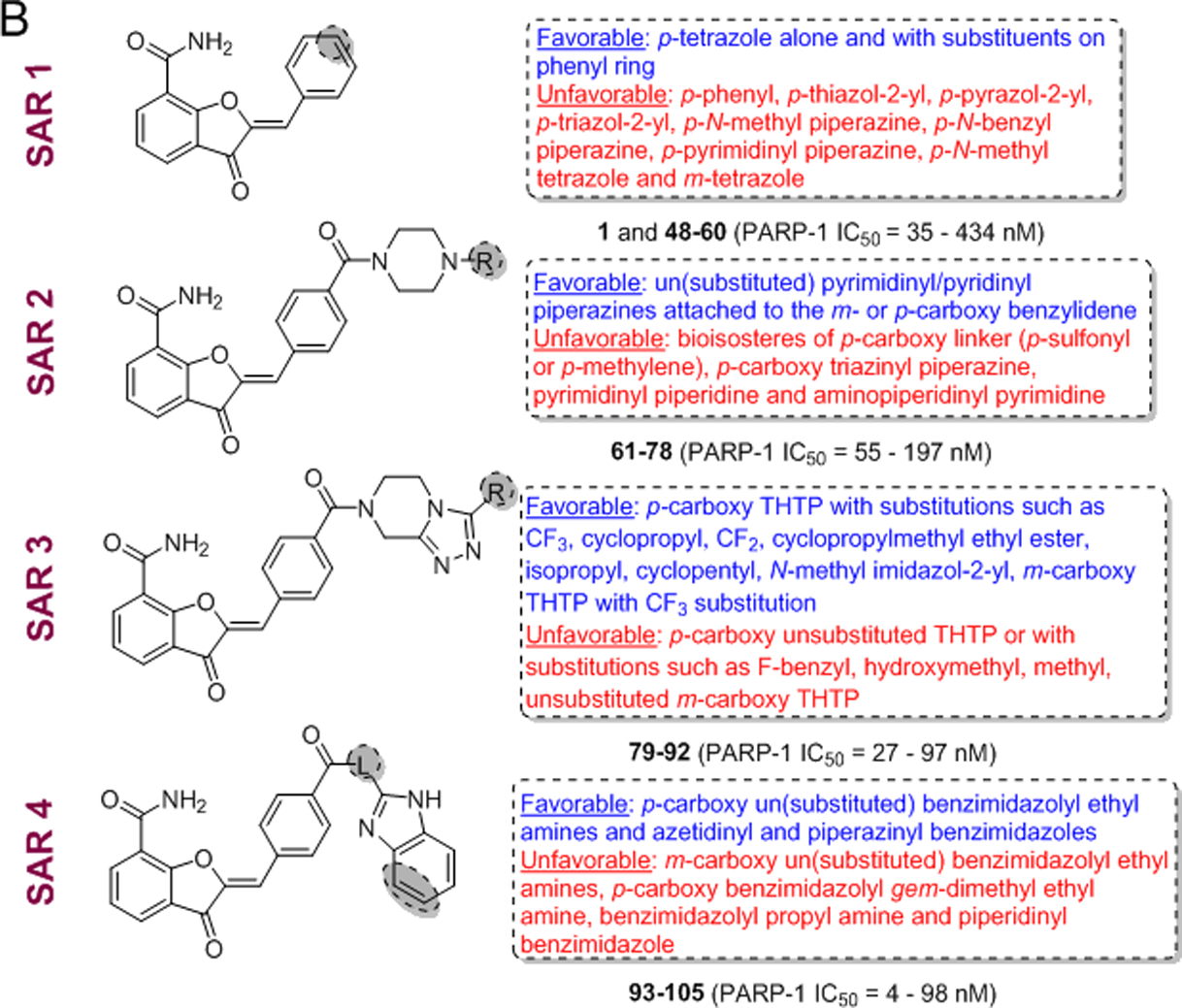

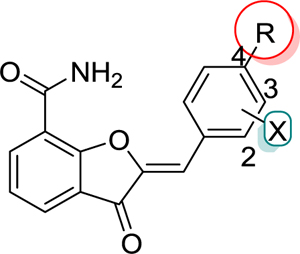

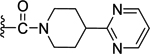

In this article, we report the design, synthesis, structure-activity relationship (SAR), and in vitro evaluation of our previously published lead compound 1,37 thereby leading to the identification of several unique PARP-1 inhibitors (Figure 2A and 2B). Compound 1 binds to the NI pocket of the PARP-1 catalytic fold. Based on previous structural data,37 we hypothesized that installation of a 4’-carboxyl group in compound 1 is an ideal vector to facilitate the incorporation of a wide range of substituents (pyridine, pyrimidine, pyrazine, 1,3,5-triazine, 1,3,4-thiadiazole, 5,6,7,8-tetrahydro-[1,2,4]triazolo[4,3-a]pyrazine (THTP), and benzimidazole) directed toward engaging the adenosine-binding pocket (ABP) of PARP-1 with the goal of developing PARP-1 inhibitors with improved potency and a unique mode of engaging the PARP-1 active site. Indeed, we show that these new compounds act as potent inhibitors of PARP-1 and PARP-2 with desirable (low nM) IC50 values. Key target compounds showed high selectivity toward PARP-1 and PARP-2 over other catalytic PARP isoforms and specifically inhibited growth of BRCA1-mutant cells, thus providing refined leads for further optimization to produce preclinical candidates.

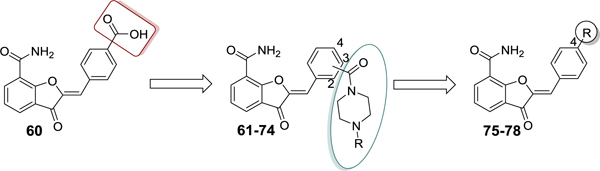

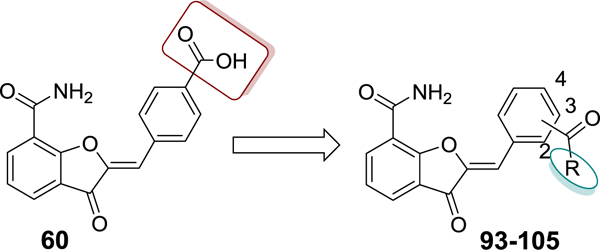

Figure 2.

(A) Design strategy for sequential optimization of high nanomolar inhibitory lead 60. (B) Favorable and unfavorable substitutions outlined for the four phases of SAR (Linkers in the structures are abbreviated as ‘L’).

RESULTS AND DISCUSSION

Chemistry.

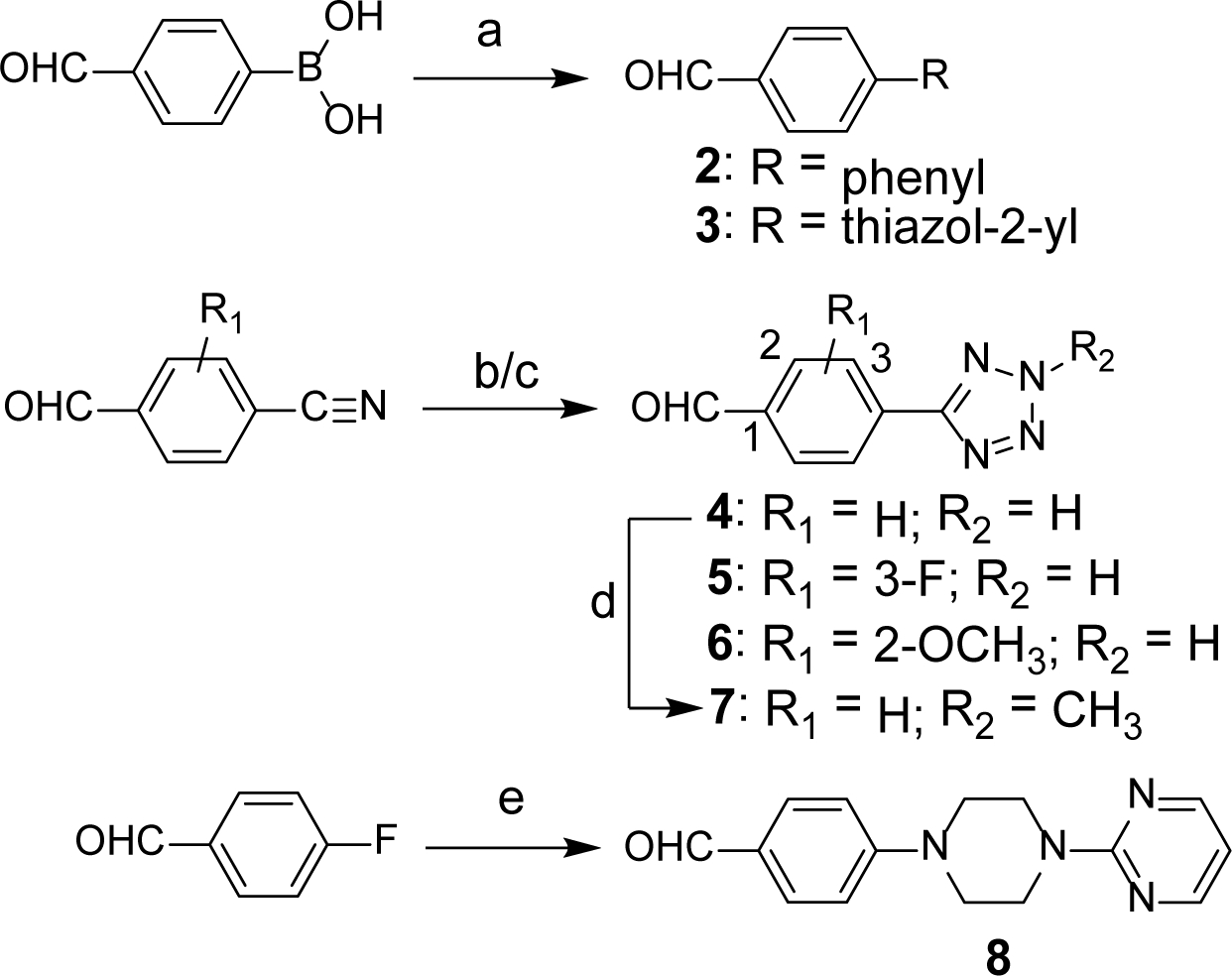

Benzaldehyde derivatives and the other intermediates as precursors to the synthesis of target compounds were prepared according to Schemes 1–4.

Scheme 1. Synthesis of Benzaldehyde Intermediates 2–8a.

aReagents and conditions: (a) bromobenzene for 2 and 2-chlorothiazole for 3, Pd(PPh3)4, K2CO3, H2O, THF, 80°C, 12 h; (b) NaN3, Et3N, DMF, 180°C, overnight for 4; (c) NaN3, Et2NH.HCl, toluene, reflux, 24 h for 5 and 6; (d) 4, CH3I, K2CO3, DMF, rt, 4 h; (e) pyrimidin-2-yl-piperazine, K2CO3, DMF, 130°C, 24 h.

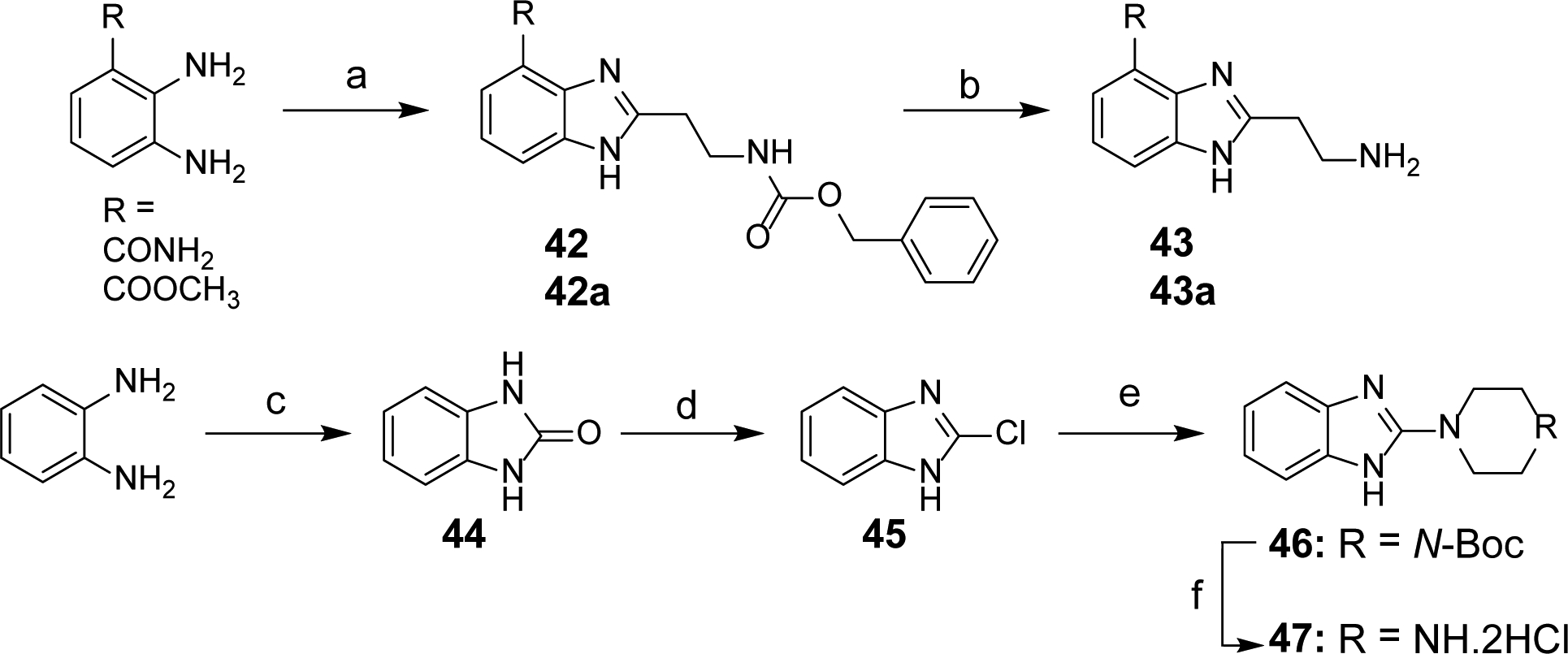

Scheme 4. Synthesis of Intermediates 43, 43a and 47a.

aReagents and conditions: (a) Benzyl 3-oxopropylcarbamate, NH4OAc, DMF, 80°C, 6 h (for 42); benzyl 3-oxopropylcarbamate, HCTU, EtN(i-Pr)2, DMF, rt to reflux, 10 h (for 42a); (b) H2, Pd/C, CH3OH, rt, 5 h; (c) 1,1′-carbonyldiimidazole, THF, rt, 22 h; (d) POCl3, 95°C, 16 h; (e) N-Boc piperazine, toluene, MW, 150°C, 6h; (f) 4N HCl, dioxane, rt, overnight.

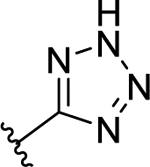

Synthesis of Benzaldehyde Intermediates 2–8 (Scheme 1).

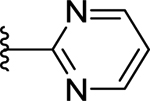

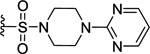

Scheme 1 represents the synthesis of substituted benzaldehydes. For the synthesis of 4-phenyl or 4-thiazol-2-yl benzaldehydes 2 and 3, reported Suzuki coupling conditions were utilized.38, 39 The [2+3] cycloaddition reaction of 4-cyanobenzaldehyde with sodium azide in the presence of triethylamine produced tetrazolyl derivative 4.40 An alternate procedure (sodium azide/diethylamine hydrochloride/toluene)41 was used for conversion of 4-cyano-3-fluorobenzaldehyde and 4-cyano-2-methoxybenzaldehyde to corresponding tetrazolyl substituted benzaldehydes 5 and 6 because the conditions used for the synthesis of 4 proved unsuccessful. N-Methyl derivative 7 was prepared from benzaldehyde 4 using iodomethane.42 Further, SNAr reaction of 4-fluorobenzaldehyde with pyrimidin-2-yl-piperazine yielded benzaldehyde derivative 8.43 These benzaldehyde intermediates (2-8) and the other commercially available benzaldehydes (see experimental) served as precursors for the synthesis of target compounds shown in Table 1.

Table 1.

Initial Optimization of Lead Compound 1

|

||||||

|---|---|---|---|---|---|---|

| Compd | X | R | PARP-1 IC50 (nM)a | pIC50 ± S.D (nM) | PARP-2 IC50 (nM)a | pIC50 ± S.D (nM) |

| 1 | H | -H | 434 | 6.41 ± 0.20 | NT | - |

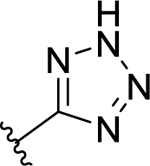

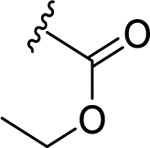

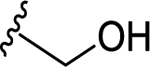

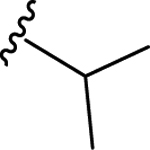

| 48 | H |  |

>50 (2%b) | - | NT | - |

| 49 | H |  |

>50 (7%) | - | NT | - |

| 50 | H |  |

>50 (5%) | - | NT | - |

| 51 | H |  |

35 | 7.50 ± 0.20 | 2.1 | 8.69 ± 0.01 |

| 52 | H |  |

>50 (4%) | - | NT | - |

| 53 | 3-

|

-H | >50 (14%) | - | <50 (76% c) | - |

| 54 | H |  |

>50 (7%) | - | NT | - |

| 55 | H |  |

>50 (10%) | - | NT | - |

| 56 | H |  |

>50 (19%) | - | <50 (56%) | - |

| 57 | 3-F |  |

56 | 7.28 ± 0.14 | <50 (100%) | - |

| 58 | 2-OCH3 |  |

47 | 7.33 ± 0.07 | 1.6 | 8.80 ± 0.05 |

| 59 | H |  |

>50 (4%) | - | NT | - |

| 60 | H | -COOH | 68 | 7.17 ± 0.08 | NT | - |

| Olad | - | - | 1.2 | 8.93 ± 0.07 | 0.5 | 9.40 ± 0.30 |

| Vele | - | - | 1.5 | 8.83 ± 0.06 | 100% @ 10 nM | - |

Data shown are mean values obtained from two independent experiments performed in duplicates.

% inhibition screening at a single concentration (50 nM unless otherwise specified) was performed in duplicates and data shown is an average of two independent experiments;

% inhibition screening of PARP-2, was performed at 50 nM concentration, in duplicates by one experiment;

Olaparib;

Veliparib;

Not tested (NT).

Synthesis of Benzaldehyde Intermediates 9–17 and 20–28 (Scheme 2).

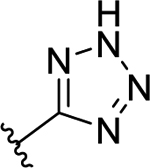

Scheme 2. Synthesis of Benzaldehyde Intermediates 9–17 and 20–28a.

aReagents and conditions: (a) substituted commercial piperazine or piperidine or 4-aminopiperidine or synthesized piperazine 19 (see scheme in inset), HCTU, HOBt, EtN(i-Pr)2, DCM, 0°C to rt, overnight; (b) N-Boc piperazine, K2CO3, CH3CN, reflux, overnight; (c) 4N HCl, dioxane, rt, overnight; (d) pyrimidin-2-yl-piperazine, Et3N, DCM, 0°C to rt, 12 h; (e) pyrimidin-2-yl-piperazine, K2CO3, CH3CN, reflux, overnight.

Benzaldehyde intermediates 9-17 were prepared by coupling commercially available N4-substituted piperazines with commercially available 4-carboxybenzaldehyde in the presence of HCTU, HOBt and N,N-diisopropylethylamine (DIPEA).44 Ester 18 was synthesized by SNAr reaction on methyl 2-chloropyrimidinyl-5-carboxylate using N4-Boc protected piperazine as the nucleophile.37, 45 The Boc protection was then removed with 4N HCl in dioxane to obtain the hydrochloride salt 19. Piperazinyl derivative 19 was next coupled with 4-carboxybenzaldehyde in the presence of HCTU, HOBt and DIPEA to produce benzaldehyde intermediate 20. Benzaldehydes 21-24 were prepared using commercially available N4-substituted piperazines and 3- or 4-carboxybenzaldehyde in the presence of previously mentioned peptide coupling conditions. Similarly, intermediates 25 and 26 were prepared by coupling commercially available piperidine or aminopiperidine with 4-carboxybenzaldehyde. Intermediate 27 was obtained by reacting commercially available 4-formylbenzene sulfonyl chloride with pyrimidin-2-yl-piperazine in the presence of triethylamine.37 Intermediate 28 was obtained via an SN2 reaction using commercially available 4-bromomethyl benzaldehyde and pyrimidin-2-yl-piperazine.37 These benzaldehyde intermediates were used for the preparation of target compounds shown in Table 2.

Table 2.

The Effect of Substituted Piperazine/Piperidine Substituents on the Phenyl Portion of Benzylidene Moiety

| |||||

|---|---|---|---|---|---|

| Compd | Position | R | PARP-1 IC50 (nM)a | pIC50 ± S.D (nM) | PARP-2 IC50 (nM)a |

| 51 | - | - | 35 | 7.50 ± 0.20 | 2.1 |

| 60 | - | - | 68 | 7.17 ± 0.08 | NT |

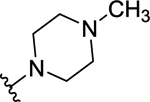

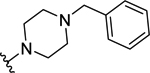

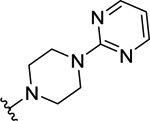

| 61 | 4- |  |

>50 (19%b) | - | NT |

| 62 | 4- |  |

66 | 7.18 ± 0.01 | NT |

| 63 | 4- |  |

55 | 7.27 ± 0.10 | <50 (89%c) |

| 64 | 4- |  |

77 | 7.12 ± 0.04 | <50 (89%) |

| 65 | 4- |  |

>50 (8%) | - | NT |

| 66 | 4- |  |

>50 (22%) | - | NT |

| 67 | 4- |  |

>50 (10%) | - | NT |

| 68 | 4- |  |

66 | 7.18 ± 0.04 | NT |

| 69 | 4- |  |

66 | 7.18 ± 0.05 | <50 (92%) |

| 70 | 4- |  |

>50 (34%) | - | NT |

| 71 | 4- |  |

>50 (36%) | - | <50 (98%) |

| 72 | 3- |  |

58 | 7.24 ± 0.06 | <50 (89%) |

| 73 | 3- |  |

>50 (32%) | - | <50 (96%) |

| 74 | 3- |  |

>50 (16%) | - | <50 (88%) |

| 75 | 4- |  |

197 | 6.71 ± 0.08 | NT |

| 76 | 4- |  |

>50 (NA) | - | <50 (51%) |

| 77 | 4- | 112 | 6.95 ± 0.01 | NT | |

| 78 | 4- |  |

>50 (3%) | - | >50 (21%) |

| Olad | - | - | 1.2 | 8.93 ± 0.07 | 0.50 ± 0.30 |

| Vele | - | - | 1.5 | 8.83 ± 0.06 | 100% @ 10 nM |

Data shown are mean obtained from two independent experiments performed in duplicates.

% inhibition screening at a single concentration (50 nM unless otherwise specified) was performed in duplicates and data shown is an average of two independent experiments;

% inhibition screening of PARP-2, was performed at 50 nM concentration, in duplicates by one experiment;

Olaparib;

Veliparib;

No activity (NA);

Not tested (NT).

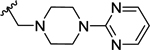

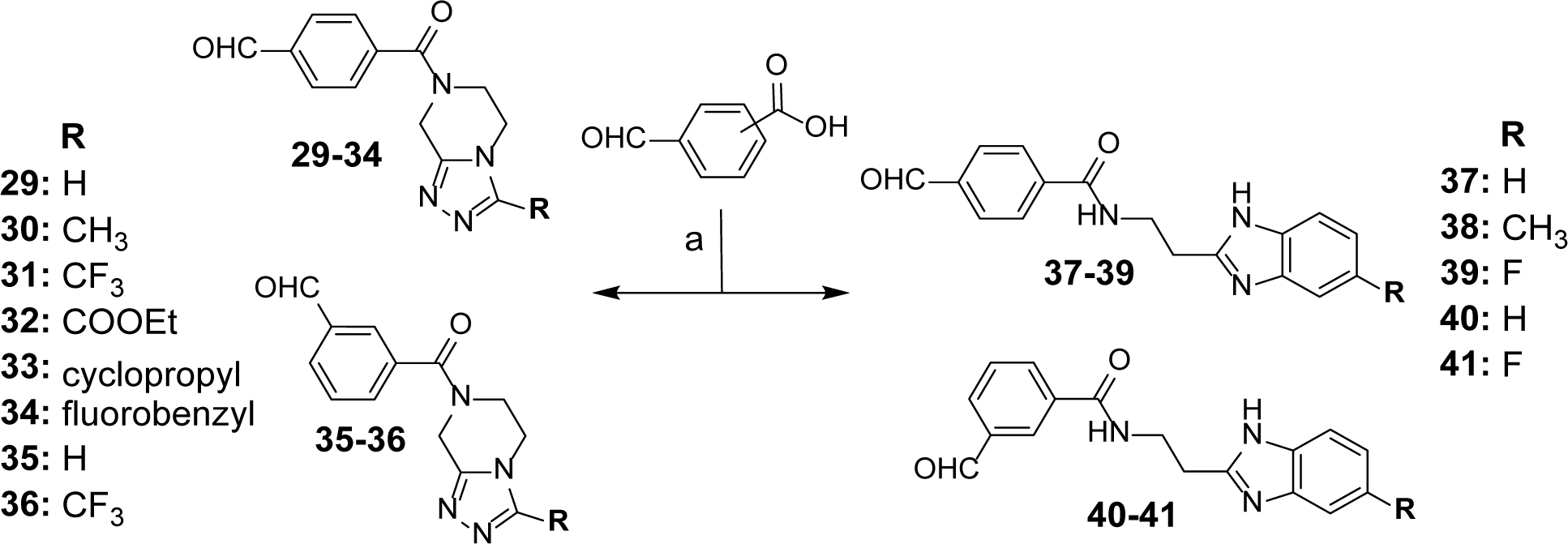

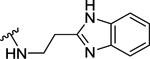

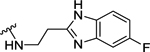

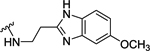

Synthesis of Benzaldehyde Intermediates 29–41 (Scheme 3).

Scheme 3. Synthesis of Benzaldehyde Intermediates 29–41a.

aReagents and conditions: (a) 4-formylbenzoic acid or 3-formylbenzoic acid, appropriate (un) substituted THTP or benzimidazole-2-yl-ethylamine, HCTU, HOBt, EtN(i-Pr)2, DCM, 0°C to rt, overnight.

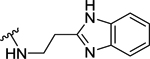

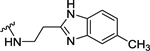

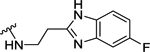

Scheme 3 depicts the preparation of benzaldehyde intermediates 29-41, which were utilized to synthesize target compounds listed in Tables 3 and 4. The 3-carboxy or 4-carboxy benzaldehydes were coupled with commercially available (un)substituted THTPs to obtain intermediates 29-36 or (un)substituted benzimidazole-2-yl-ethylamines for intermediates 37-41 in the presence of HCTU/HOBt coupling conditions.44

Table 3.

The Effect of 1,2,4-Triazolopiperazine Amide Substituents on the Phenyl Ring of Benzylidene Moiety

|

||||||

|---|---|---|---|---|---|---|

| Compd | Position | R | PARP-1 IC50 (nM)a | pIC50 ± S.D (nM) | PARP-2 IC50 (nM)a | pIC50 ± S.D (nM) |

| 51 | - | - | 35 | 7.50 ± 0.20 | 2.1 | 8.69 ± 0.01 |

| 60 | - | - | 68 | 7.17 ± 0.08 | NT | - |

| 79 | 4- | -H | 97 | 7.02 ± 0.10 | >10 (18%c) | - |

| 80 | 4- | -CH3 | 81 | 7.10 ± 0.09 | <10 (55%) | - |

| 81 | 4- | -CF3 | 30 | 7.53 ± 0.07 | 2 | 8.80 ± 0.01 |

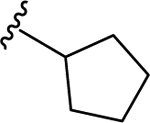

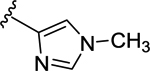

| 82 | 4- |  |

40 | 7.42 ± 0.12 | 3.7 | 8.44 ± 0.03 |

| 83 | 4- |  |

27 | 7.57 ± 0.05 | 1.9 | 8.72 ± 0.02 |

| 84 | 4- |  |

>50 (25%b) | - | <10 (59%) | - |

| 85 | 4- | -CHF2 | 30 | 7.52 ± 0.01 | 3 | 8.52 ± 0.03 |

| 86 | 4- |  |

47 | 7.33 ± 0.06 | 3.5 | 8.46 ± 0.04 |

| 87 | 4- |  |

>50 | - | <10 (61%) | - |

| 88 | 4- |  |

42 | 7.43 ± 0.21 | 4.6 | 8.34 ± 0.02 |

| 89 | 4- |  |

37 | 7.48 ± 0.22 | 3.9 | 8.42 ± 0.05 |

| 90 | 4- |  |

32 | 7.55 ± 0.22 | 3.3 | 8.48 ± 0.01 |

| 91 | 3- | -H | >50 (13%) | - | >10 (6%) | - |

| 92 | 3- | -CF3 | 42 | 7.38 ± 0.01 | >10 (47%) | - |

| Olad | - | - | 1.2 | 8.93 ± 0.07 | 0.5 | 9.40 ± 0.30 |

| Vele | - | - | 1.5 | 8.83 ± 0.06 | <10 nM | - |

Data shown are mean values obtained from two independent experiments performed in duplicates.

% inhibition screening at a single concentration (50 nM unless otherwise specified) was performed in duplicates and data shown is an average of two independent experiments;

% inhibition screening of PARP-2, was performed at 10 nM concentration, in duplicates by one experiment.

Olaparib;

Veliparib.

Not tested (NT).

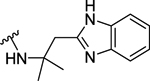

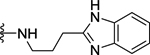

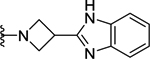

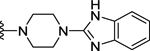

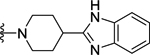

Table 4.

Effect of Benzimidazolylethyl/ Benzimidazolylazetidine/ Benzimidazolylpiperazine Amide Substituents on the Phenyl Ring of Benzylidene Moiety

|

||||||

|---|---|---|---|---|---|---|

| Compd | Position | R | PARP-1 IC50 (nM)a | pIC50 ± S.D (nM) | PARP-2 IC50 (nM)a | pIC50 ± S.D (nM) |

| 51 | - | - | 35 | 7.50 ± 0.20 | 2.1 | 8.69 ± 0.01 |

| 60 | - | - | 68 | 7.17 ± 0.08 | NT | - |

| 93 | 4- |  |

36 | 7.45 ± 0.10 | ~10 (50%c) | - |

| 94 | 4- |  |

22 | 7.66 ± 0.02 | 5 | 8.32 ± 0.12 |

| 95 | 4- |  |

51 | 7.31 ± 0.14 | >10 (33%) | - |

| 96 | 3- |  |

88 | 7.07 ± 0.10 | >10 (18%) | - |

| 97 | 3- |  |

97 | 7.02 ± 0.07 | >10 (24%) | - |

| 98 | 4- |  |

28 | 7.55 ± 0.02 | >10 (44%) | - |

| 99 | 4- |  |

4 | 8.41 ± 0.11 | 0.7 | 9.19 ± 0.03 |

| 100 | 4- |  |

>50 (33%b) | - | >10 (22%) | - |

| 101 | 4- |  |

>50 (49%) | - | >10 (48%) | - |

| 102 | 4- |  |

30 | 7.54 ± 0.10 | >10 (44%) | - |

| 103 | 4- |  |

18 | 7.77 ± 0.15 | 4 | 8.40 ± 0.08 |

| 104 | 4- |  |

58 | 7.24 ± 0.05 | >10 (28%) | - |

| 105 | 4- |  |

98 | 7.01 ± 0.02 | NT | - |

| Olad | - | - | 1.2 | 8.93 ± 0.07 | 0.5 | 9.40 ± 0.30 |

| Vele | - | - | 1.5 | 8.83 ± 0.06 | <10 nM | - |

Data shown are mean values obtained from two independent experiments performed in duplicates.

% inhibition screening at a single concentration (50 nM unless otherwise specified) was performed in duplicates and data shown is an average of two independent experiments;

% inhibition screening of PARP-2, was performed at 10 nM concentration, in duplicates by one experiment.

Olaparib;

Veliparib.

Not tested (NT).

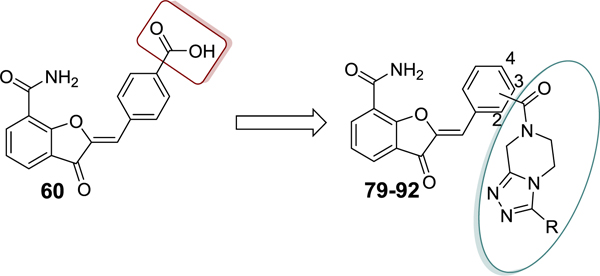

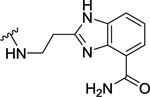

Synthesis of Intermediate Amines 43, 43a and 47 (Scheme 4).

Scheme 4 represents the synthesis of key amine intermediates as precursors to obtain target compounds shown in Table 4. The 2,3-diaminobenzamide or methyl 2,3-diaminobenzoate were condensed with benzyl 3-oxopropylcarbamate leading to cyclized intermediates 42 or 42a, which were subjected to hydrogenolysis to obtain amines 43 or 43a. To synthesize piperazine intermediate 47, ortho-phenylenediamine was reacted with 1,1′-carbonyldiimidazole to generate a cyclic urea compound 44, followed by a chlorination reaction using neat POCl3 to obtain 2-chlorobenzimidazole 45. The chloro group in compound 45 was then replaced via microwave assisted SNAr reaction by N-Boc piperazine to obtain 46 and a subsequent Boc-deprotection using 4N HCl/dioxane mixture gave 47 as a di-hydrochloride salt.

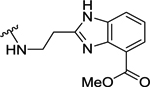

Preparation of Target Compounds 48–105 (Scheme 5).

Scheme 5. Synthesis of Target Compounds 48–105a.

aReagents and conditions: (a) synthesized or commercial benzaldehydes, NH4OAc, toluene, reflux, 4–12 h; (b) appropriately substituted commercially obtained amines or synthesized amines 43, 47 and 43a HCTU, HOBt, EtN(i-Pr)2, DCM, 0°C to rt, overnight.

Target compounds were synthesized using the key intermediate 3-oxo-2,3-dihydrobenzofuran-7-carboxamide (I) (Supporting Information, Scheme S1 for details regarding synthesis of I). Scheme 5 depicts the synthesis of target compounds 48-84 and 91-97, using modified Knoevenagel condensation reaction of intermediate I with various synthesized or commercially obtained benzaldehydes.37 Target compounds 85-90, 98, 100-102 and 104 were prepared by coupling 60 with commercially obtained amines whereas target compounds 99, 103 and 105 were respectively prepared using synthesized amines 43, 47 and 43a in the presence of HCTU/HOBt coupling conditions.

Structure-Activity Relationship.

The present SAR study is based on our lead compound 1 ((Z)-2-benzylidene-3-oxo-2,3-dihydrobenzofuran-7-carboxamide), which showed PARP-1 inhibitory activity at a sub-micromolar concentration (IC50 = 434 nM) in PARP-1 enzyme assay. We began optimizing lead 1 to obtain a new and potent PARP-1 inhibitory series of dihydrobenzofuran-7-carboxamide (DHBF) compounds. This lead optimization program led to four innovative SAR phases as outlined in Tables 1–4. All newly synthesized compounds, along with positive controls, olaparib and veliparib, were tested using PARP-1 and PARP-2 chemiluminescence assay to obtain IC50 and pIC50 values (Supporting Information Figure S1 and S2 indicate PARP-1 and PARP-2 IC50 dose-response curves of representative compounds). Our IC50 values for the positive controls, olaparib and veliparib, were comparable to the reported values.30, 34

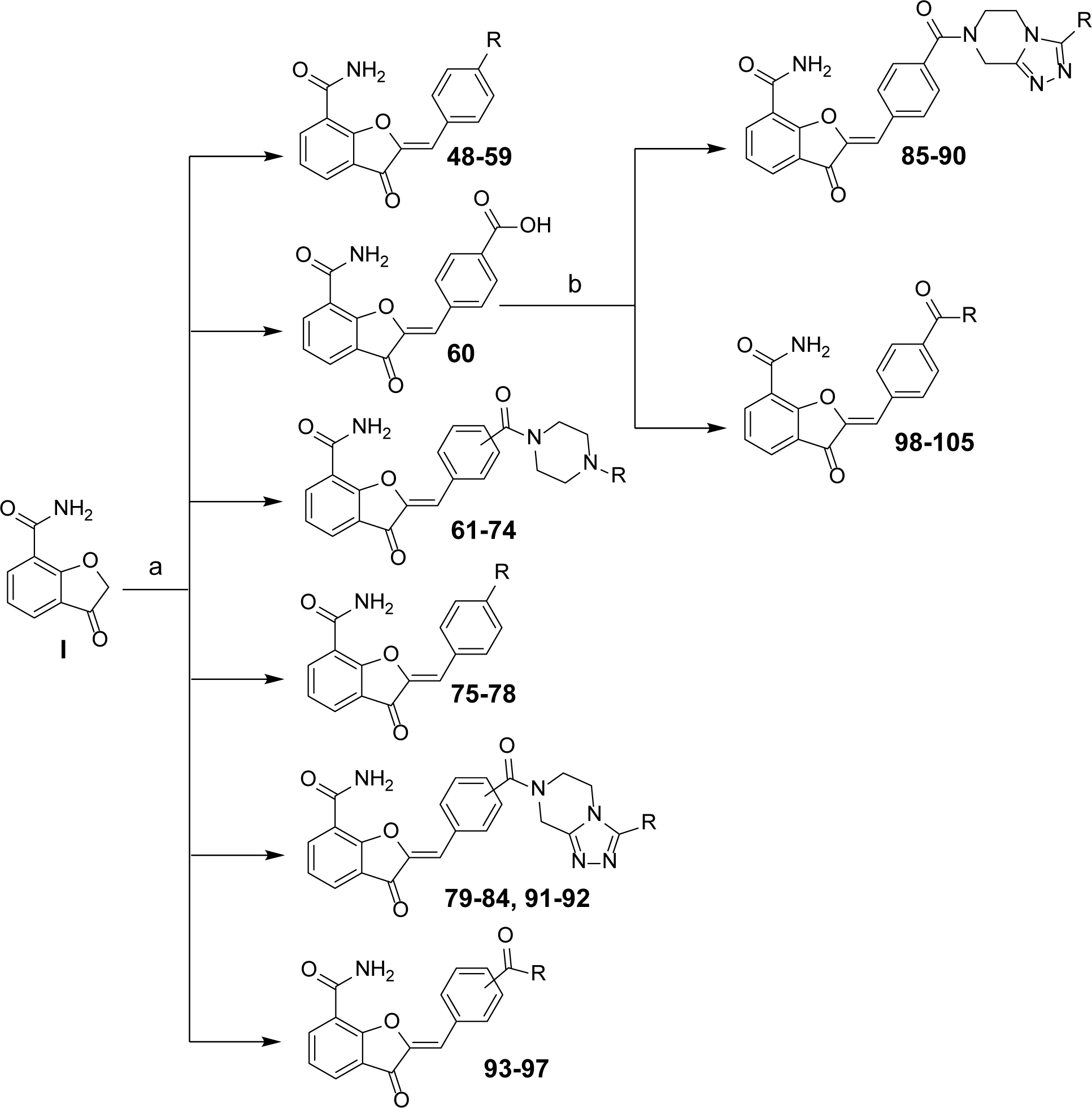

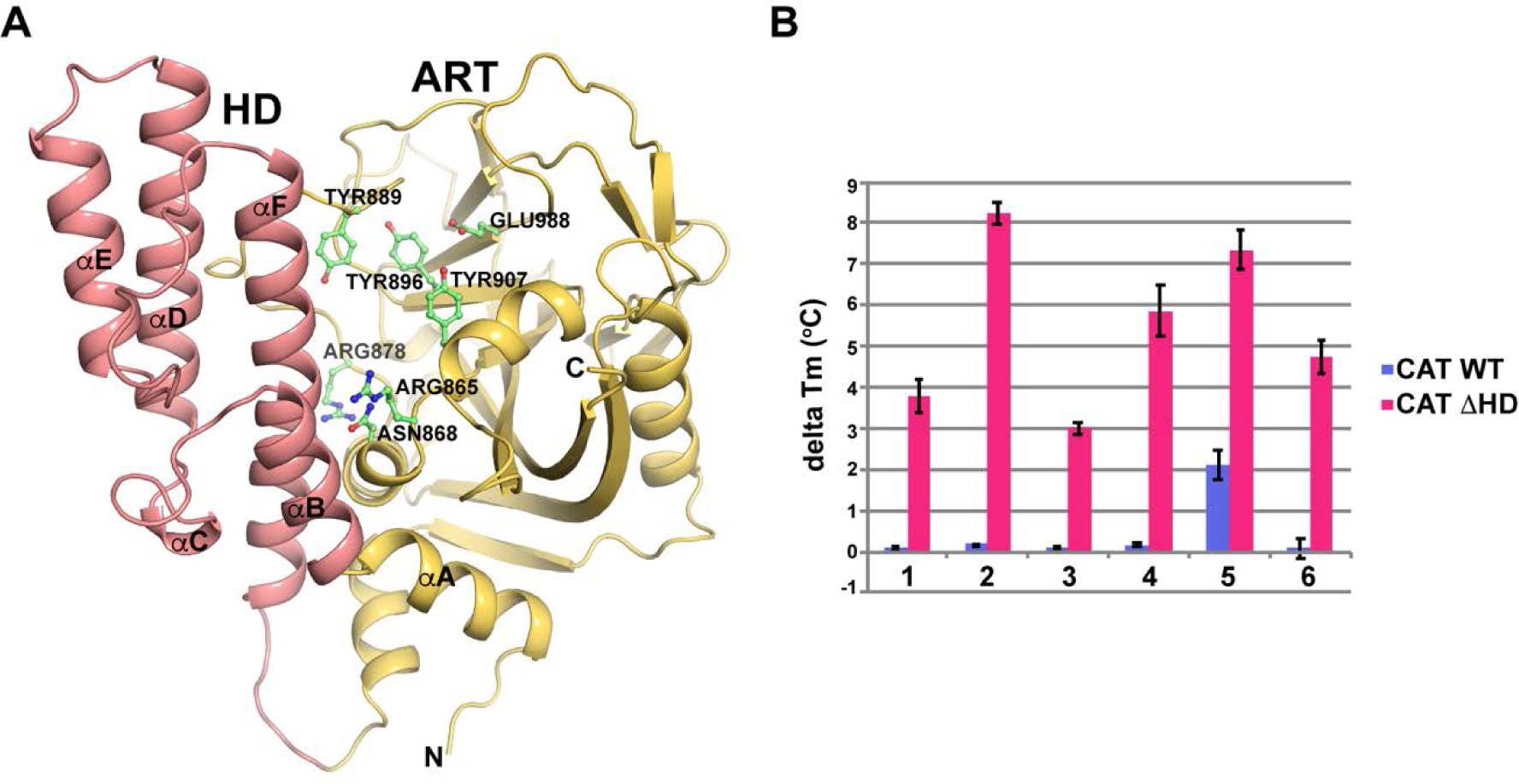

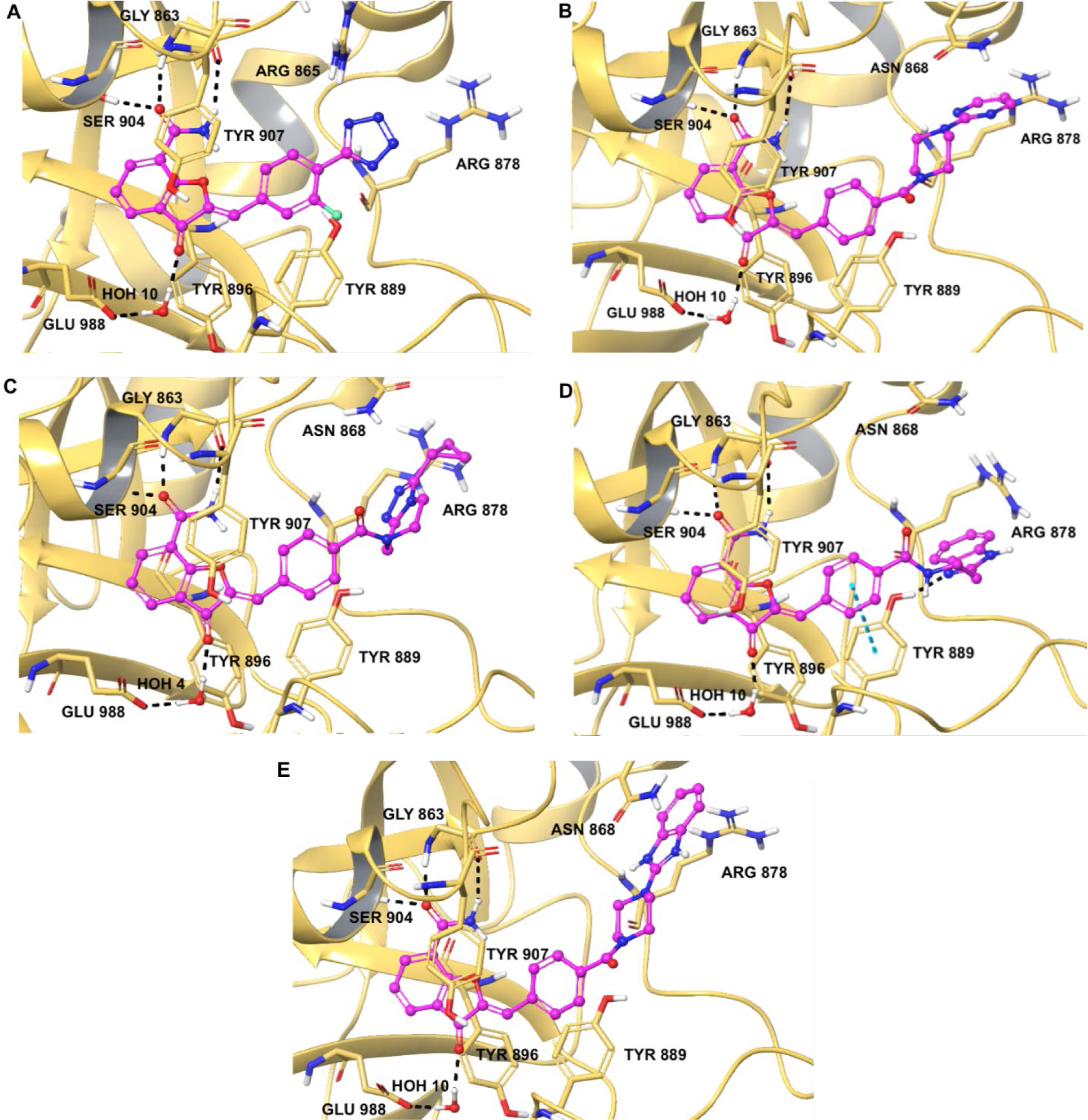

From each of the four SAR studies, X-ray crystal structures were determined for key target compounds in complex with the minimal ADP-ribosyltransferase (ART) fold of human PARP-1, representing a constitutively active form of PARP-1.46 ART interaction with NAD+ is primarily mediated through a NI-binding site and ABP. Attached to the ART fold is an autoinhibitory helical domain (HD) that acts to selectively block access to substrate NAD+ by interfering with the ABP (Figure 3A).46, 47 Upon binding to damaged DNA, the N-terminal regulatory domains of PARP-1 assemble in a way that leads to unfolding of the HD, thus relieving autoinhibition and allowing for binding of NAD+ to the active site.46–48 Our initial binding analysis of the newly synthesized compounds by differential scanning fluorimetry (DSF) revealed that most of these compounds were unable to bind to the catalytic domain (CAT) in the presence of a folded HD, but they successfully bound to the CAT with the deleted helical domain (CATΔHD) (Figure 3B). These compounds thus behave similar to the NAD+ analogue benzamide adenine dinucleotide (BAD), which can only bind to PARP-1 when the HD is deleted, or unfolded in the presence of DNA damage.47 This biophysical study suggests that our compounds may display increased efficacy and cancer cell specificity while showing reduced cytotoxicity in normal cells. Moreover, the binding analysis indicated that the designed extensions to compound 1 were likely to engage the ABP. Based on these data, the CATΔHD construct was used for crystallographic analysis. Five structures were determined using X-ray diffraction data extending to resolutions between 1.5 to 2.2 Å (Supporting Information Table S1 and Figure S3 and Figure 4). Each of the bound inhibitors exhibited hydrogen bonding interactions with key amino acid residues in the NI-binding site such as Ser904 and Gly863 and a water-mediated hydrogen bond with the catalytic residue Glu988. The crystal structures helped to understand the molecular basis of PARP-1 inhibition and allowed us to rationalize the observed SAR trends, as described in the sections below.

Figure 3.

Inhibitor binding to the PARP-1 catalytic domain. (A) Ribbon representation of the PARP-1 catalytic domain (CAT) using PDB code 3gjw.71 The HD and ART domains are indicated in red and orange, respectively. Several residues are labeled and numbered, and the N-terminus (labelled as N) and C-terminus (labelled as C) are noted. (B) DSF was used to assess the capacity of inhibitors to bind to the catalytic domain of PARP-1 (CAT), or the catalytic domain with the HD deleted (CATΔHD). The change in melting temperature (delta TM) of PARP-1 CAT and CATΔHD in the presence of the indicated PARP inhibitors was measured. The delta TM was calculated by subtracting the TM values of CAT or CATΔHD alone from the values obtained in the presence of inhibitor. The averages of three experiments are shown, and the error bars represent the standard deviations. Note: (1) pyrimidinyl piperazine analogue 63; (2) tetrazolyl analogue 57; (3) benzimidazole-2-yl-ethylamine analogue 93; (4) cyclopropyl THTP analogue 83; (5) benzimidazole-2-yl-piperazine analogue 103; (6) benzamide adenine dinucleotide.

Figure 4.

X-ray crystal structures of selected PARP inhibitors bound to CATΔHD of PARP-1. Structures in case of inhibitors are represented in the form of ball and stick model and in case of amino acid residues as tube model. Nitrogen and oxygen atoms are represented in blue and red colors respectively. Carbons in case of inhibitors are represented in magenta color whereas amino acid residues are shown in faded orange color. Hydrogen bond interactions are shown as broken black lines and pi-pi stacking interactions are shown as blue broken lines. (A) Representation of tetrazolyl analogue 57 bound to PARP-1; (B) representation of pyrimidin-2-yl-piperazine analogue 63 bound to PARP-1; (C) representation of cyclopropyl THTP analogue 83 bound to PARP-1; (D) representation of benzimidazole-2-yl-ethylamine analogue 93 bound to PARP-1 and (E) representation of benzimidazole-2-yl-piperazine analogue 103 bound to PARP-1.

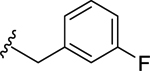

Exploration of para-/meta-Aryl/Heteroaryl Substituted Benzylidene Analogues of Lead 1 (SAR 1).

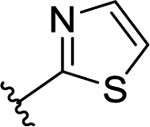

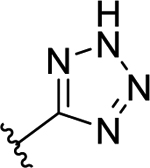

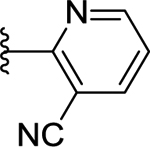

Table 1 represents various substituents at C2-position of DHBF scaffold (I, see Scheme 5). The initial optimization efforts were mainly focused on exploring simplified substitution of various aryl/heteroaryl ring systems at the para-position of the benzylidene moiety present in lead 1. A biphenyl analogue 48 failed to show any PARP-1 inhibition at the tested concentration of 50 nM. Therefore, we replaced the para-phenyl ring with various saturated and unsaturated heterocyclic rings with the intention of capturing hydrogen bonding and/or ionic interactions within the ABP of PARP-1. Amongst the unsaturated heterocycles (49-52) such as thiazole, 1,2,4-triazole, 2H-tetrazole, and 1H-pyrazole, only the tetrazolyl analogue, 51, gave a promising enzyme inhibition with an IC50 value of 35 nM. Encouragingly, 51 showed ~12-fold improvement in inhibition as compared to lead 1. The 4-position was optimal for the tetrazole ring as moving it to the meta-position of the benzylidene moiety (53) proved detrimental to the activity. Next, the distal aromatic/heteroaromatic ring in the above-mentioned analogues was replaced with basic saturated heterocycle such as substituted piperazine. The N-methylpiperazine analogue 54, showed loss of activity as compared to 51. Replacing the N-methylpiperazine of 54 with bulky and hydrophobic N-benzylpiperazine and pyrimidin-2-yl-piperazine yielded compounds 55 and 56; however, both proved inferior to 51. Having established 51 as the best inhibitor from this series, we conducted a limited SAR on 51 by introducing electron-withdrawing 3-fluoro (57, IC50 = 56 nM) and electron-donating 2-methoxy (58, IC50 = 47 nM) substituents, both of which gave a degree of PARP-1 inhibition comparable to that of 51. X-ray crystallographic analysis revealed favorable localization of the tetrazole moiety of a representative analogue 57 in the vicinity of active site residue Arg865 as shown in Figure 4A. This observation was also corroborated by the detrimental result obtained by replacing the acidic tetrazole proton with a methyl group as observed in 59.

Since the tetrazole ring is not amenable for further chemical optimization, we sought to determine if the tetrazole ring can be isosterically replaced with a carboxyl group, because the carboxyl derivative could further be efficiently derivatized to improve potency similar to what has been done during the development of olaparib.30 Toward this goal, we prepared a 4-carboxybenzylidene analogue (60, IC50 = 68 nM) and noted appreciable inhibitory potency, suggesting this compound would serve as a refined lead for subsequent SAR studies. To further confirm the role of acidic group at the para-position of a benzylidene moiety, we replaced the carboxyl group with a cyano substituent and as expected, it showed decreased activity as compared to 60 (data not shown). We found that replacement of a carboxyl group in 60 with a primary carboxamide group resulted in the retention of activity (data not shown), which prompted us to explore further SAR using various alicyclic amines such as N4-heteroaryl substituted piperazines, un(substituted) THTPs and un(substituted) benzimidazoles with various linkers.

Exploration of the Vector Addressing ABP of PARP-1 with Heteroaryl Piperazine/Piperidine Motifs (SAR 2).

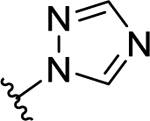

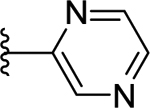

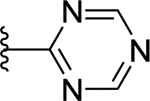

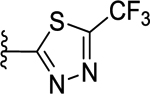

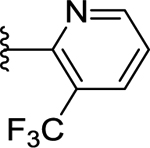

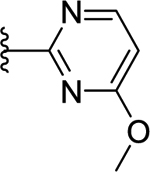

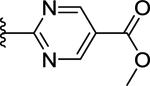

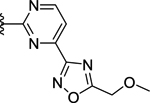

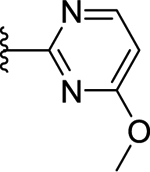

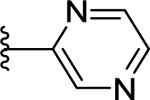

Compounds displayed in Table 2 were designed to extend carboxyl group of the newly identified lead 60 to capture additional interactions within the ABP of PARP-1. The activities of analogues in this series were also compared to compound 51, which was the best compound from SAR 1. To obtain more potent compounds, first we coupled the pendant carboxyl group in 60 with an N-phenylpiperazine moiety to obtain 61, which showed a detrimental effect on activity compared to 60. We next replaced the hydrophobic phenyl ring with polar isosteric heteroaromatic rings to obtain potent inhibitors. For example, pyridin-2-yl (62), pyrimidin-2-yl (63), and pyrazin-2-yl (64) derivatives showed tolerance for heteroaryl-piperazine extensions with IC50s ranging from 55 nM to 77 nM. X-ray crystal structure of 63 bound to CATΔHD PARP-1 demonstrated extension of pyrimidine moiety in the vicinity of Asn868 and the ABP residue Arg878 as shown in Figure 4B. The 1,3,5-triazin-2-yl (65) and 5-trifluoromethyl-1,3,4-thiadiazol-2-yl (66) analogues were found inferior compared to 63. Because pyridin-2-yl (62) and pyrimidin-2-yl (63) analogues gave appreciable enzyme inhibition, we decided to determine the influence of electron-withdrawing groups (67, 68, 70, and 71) or electron-donating group (69) on pyridine or pyrimidine rings. While 3-trifluoromethylpyridin-2-yl analogue (67) was inferior, the 3-cyanopyridin-2-yl analogue (68, IC50 = 66 nM) was as active as unsubstituted analogue 62. Amongst small to large substituents, 4-methoxy substitution on pyrimidine ring (IC50 = 66 nM) showed appreciable inhibition as evidenced from analogue 69, whereas, analogues 70 and 71 with an ester and methoxymethyl oxadiazolyl substitutions led to a moderate inhibition. Having established a favorable role of heteroaryl substituted piperazine motifs at the para-position of the benzylidene, we next determined whether these motifs could be tolerated at the meta-position. Toward this objective, we made meta-counterparts of 63, 69, and 64 to obtain 72-74, which were not well tolerated except for analogue 72 (IC50 = 58 nM). To investigate the significance of a carbonyl group in the disposition of a pyrimidin-2-yl-piperazine moiety in 63, compounds 75 and 76 were prepared. Compound 75, a non-classical rigid sulfone isostere, showed ~3.5-fold decreased enzyme inhibition as compared to 63. Similarly, compound 76, a non-classical flexible methylene isostere, also led to decreased activity. These results underscore the contribution of a carbonyl group in directing the pyrimidin-2-yl-piperazine moiety toward the amino acid residues located within ABP (Figure 4B). Next, we sought to explore the role of the piperazine ring in 63 by replacing it with a 4-aminopiperidine ring (77, IC50 = 112 nM) and found that this substitution resulted in two-fold loss of activity. We replaced the piperazine linker in 63 with a piperidine linker to obtain 78, which also showed a detrimental effect on potency as compared to 63 indicating the requirement of terminal piperazine ring nitrogen for an improved inhibition. Because substitutions on pyrimidin-2-yl- or pyridin-2-yl-piperazines failed to give us better enzyme inhibition than analogue 51, we decided to generate a new series with a fused bicyclic ring system containing sp2 N atoms with the expectation of obtaining potent inhibitors.

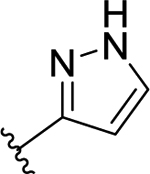

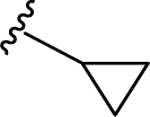

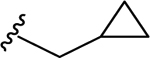

Exploration of THTP Amides Linked to the meta- or para-Position of Benzylidene Moiety (SAR 3).

SAR 3 optimization involved extension of carboxyl group toward ABP of PARP-1 by coupling with THTP as a rigid isostere of pyrimidinylpiperazine moiety as shown in Table 3. Unsubstituted THTP analogue (79) gave appreciable enzyme inhibition (IC50 = 97 nM). To enhance productive interactions with residues from ABP of PARP-1, we inserted functional groups at the 3-position of THTP ring with varying molecular size and electronic properties such as electron neutral (methyl, isopropyl, cyclopropylmethyl, cyclopentyl and -CH2OH), electron-withdrawing (-CHF2, -CF3, -COOEt, 3-flurobenzyl, and N-methyl imidazole) and pi-electron donor (cyclopropyl). These efforts led to a series of target compounds (80-90, and 92) with improved inhibitory profile as compared to SAR 2 analogues. The C3-methyl substitution on THTP (80) resulted in a slight improvement in enzyme inhibition as compared to 79. Similarly, C3-trifluoromethyl analogue (81) gave a 3-fold improvement in the activity as compared to unsubstituted analogue 79 and methyl analogue 80. The C3-ethyl ester analogue (82, IC50 = 40 nM) was also well tolerated, which indicates the favorable contribution of moderately sized electron-withdrawing groups at C3- position of THTP. Based on the recent review on versatile role of a cyclopropyl ring in medicinal chemistry,49 next we added a cyclopropyl group at C3-position to obtain analogue 83 (IC50 = 27 nM) with the best enzyme inhibition of the THTP series. X-ray structure of 83 bound to CATΔHD PARP-1 revealed localization of a cyclopropyl ring in the vicinity of Asn868 and ABP residue Arg878 (Figure 4C). Increasing the steric bulk and hydrophobicity at C3-position of THTP with meta-fluorobenzyl substituent yielded 84 with unfavorable enzyme inhibition. Replacing the trifluoromethyl group at C3-position of THTP in 81 by a difluoromethyl group (85, IC50 = 30 nM) was well tolerated. Insertion of a methylene bridge between the C3 of a THTP ring and a cyclopropyl ring in 83 gave 86 (IC50 = 47 nM) with considerable retention of the activity of 83. A polar C3-hydroxymethyl substituent (87) proved to be a weak inhibitor. Substitution of an isopropyl group, noncyclic isostere of a cyclopropyl ring, at C3-position of THTP (88, IC50 = 42 nM) was well tolerated. Replacement of a cyclopropyl ring in 83 with cyclopentyl (89, IC50 = 37 nM) or 1-methylimidazol-4-yl (90, IC50 = 32 nM) also showed comparable potency to that observed for 83. Based on the inhibition profile of various substitutions at C3-position of THTP, it is evident that smaller substituents with electronegative property improve inhibition by interacting with polar residues in ABP of PARP-1.

The evaluation of the effect of moving THTP from para- to the meta-position led to two representative analogues. For example, meta-version of 79 led to a loss of activity as exemplified by 91. However, meta-version of 81 produced 92 (IC50 = 42 nM) with retention of inhibitory activity. In summary, this SAR study revealed favorable impact of THTP scaffold on PARP-1 inhibition as compared to the lead compounds 51 and 60.

Exploration of Benzimidazoles with Various Linkers as ABP Motifs, Coupled to the meta- or para-Position of Benzylidene Moiety (SAR 4).

Table 4 shows the extension of a carboxyl group of 60 for ligand occupancy within the ABP of PARP-1. Carboxyl group of 60 was subjected to coupling with various (un)substituted benzimidazolyl ethylamines as novel ABP-motifs. An initial lead from this series, compound 93 (IC50 = 36 nM) with no substituent on the benzimidazole ring, had set the stage for obtaining potent PARP-1 inhibitors. Further SAR work on lead 93 involved exploration of different substituents on the benzimidazole ring with electronic properties such as electron neutral (CH3) and electron withdrawing (F) groups as exemplified by 94 (IC50 = 22 nM) and 95 (IC50 = 51 nM), respectively. As anticipated, moving benzimidazole ethylamine moiety in 93 and 95 to the meta-position produced 96 (IC50 = 88 nM) and 97 (IC50 = 97 nM) with a 2-fold decreased potency. Introducing electron donor methoxy group at 5-position of the benzimidazole moiety led to 98 (IC50 = 28 nM) with comparable activity to analogue 93. These results conclude that 4-position of the benzylidene moiety is the ideal vector to access and produce productive interactions within ABP of PARP-1. Replacement of the benzimidazole ring in 93 with benzimidazole-4-carboxamide led to 99 (IC50 = 4 nM) with 9-fold improvement in potency compared to 93. Further SAR involved modification of the ethyl linker and, toward this goal, we synthesized analogues with a gem-dimethyl50 substitution (100) which led to a slight decrease in activity. Replacement of the ethyl linker in 93 with the propyl linker produced 101 with marginally decreased activity compared to 93.

Finally, we explored the impact of replacing flexible ethylamine linker with azetidine, piperazine or piperidine linkers to limit the conformational flexibility and allow for entropically favorable binding within the ABP of PARP-1. These efforts led to the synthesis of azetidine analogue 102 (IC50 = 30 nM), piperazine analogue 103 (IC50 = 18 nM) and piperidine analogue 104 (IC50 = 58 nM) amongst which 103 exhibited the best inhibition. Since benzimidazole-4-carboxamide in 99 serves as an excellent NI mimic, we decided to elucidate whether DHBF-7-carboxamide or benzimidazole-4-carboxamide binds to the NI site. Toward this objective, we synthesized a methyl ester analogue 105 (PARP-1 IC50 = 98 nM) and observed a 25-fold decrease in activity as compared to 99, and thus, validated the switched positioning of benzimidazole-4-carboxamide and DHBF-7-carboxamide, respectively, within NI and ABP of PARP-1 active site. Further biophysical characterization of 99 and 105 will confirm above-mentioned observation. In summary, SAR 4 revealed potent analogues such as 99 and 103 with 108- and 24-fold increase in activity, respectively, as compared to lead 1.

X-ray crystal structures of 93 and 103 in complex with CATΔHD PARP-1 revealed that the benzimidazole portion was directed toward Arg878 of ABP (Figure 4D and 4E). Additionally, compound 93 exhibited pi-pi stacking and hydrogen bonding interactions with the side chain of Tyr889.

Investigation of PARP-2 Enzyme Inhibition by Selected Target Compounds.

PARP-2, via physical interaction or PARylation of various target proteins, plays an important role in a wide range of cellular processes that are dysregulated in tumorigenesis.51 PARP-2−/− mice are highly sensitive to alkylating agents as well as ionizing radiation.52, 53 Further, both PARP-1 and PARP-2 are required for efficient BER as evidenced from global decrease in PARP activity upon PARP-2 depletion.54 Because the C-terminal catalytic domains of PARP-1 and PARP-2 exhibit ~69% homology,55 it is not surprising that clinically utilized PARP inhibitors potently inhibit both PARP-1 and PARP-2 (Figure 1). We, therefore, conducted a screen of highly active PARP-1 inhibitors against PARP-2 as shown in Tables 1–4. The tetrazolyl and piperazinyl analogues 51, 53, and 56-58 from SAR 1 (Table 1) demonstrated potent PARP-2 inhibition (IC50 = 2.1 nM, 76%, 56%, 100% at 50 nM and IC50 = 1.6 nM, respectively). Compound 58 showed a 29-fold greater potency against PARP-2 as compared to PARP-1 and its PARP-2 IC50, was comparable to that observed for olaparib (PARP-2 IC50 = 0.5 nM). PARP-2 inhibition profiles of representative compounds 63, 64, 69, 71-74 and 76 from SAR 2 (Table 2) also showed greater selectivity toward PARP-2 compared to PARP-1 as evidenced by 51–98% inhibition of PARP-2 at 50 nM concentration. We further investigated the inhibition profile of THTP analogues, from SAR 3 (Table 3), in PARP-2 enzyme assay at 10 nM concentration. Compound 51 displayed potent PARP-2 inhibition (IC50 = 2.1 nM) and it was used for comparison in Tables 3 and 4. Compounds 81 (IC50 = 2 nM) and 83 (IC50 = 1.9 nM) both displayed high potency against PARP-2 with IC50s comparable to that of olaparib and with a 15- and 14-fold selectivity, respectively, as compared to PARP-1 inhibition. Compounds 80, 84 and 87 inhibited PARP-2 by 55–61% at 10 nM concentration and thus demonstrate higher potency toward PARP-2 as compared to PARP-1. Analogues 82, 85, 86, and 88-90 also exhibited potent inhibition of PARP-2 with IC50 values ranging from 3 – 4.6 nM. PARP-2 screening of compounds 93, 98, and 101 from Table 4 at 10 nM concentration showed 44–50% inhibition. Compounds 94 (IC50 = 5 nM), 99 (IC50 = 0.7 nM) and 103 (IC50 = 4 nM) also exhibited potent PARP-2 inhibition and moderate selectivity toward PARP-2 over PARP-1. Modest PARP-2 inhibitory activity was observed for the meta-analogues 96 and 97. Overall, most of these compounds exhibited selectivity toward PARP-2, which is a common trend for the FDA approved drugs olaparib, niraparib, rucaparib and talazoparib. However, the extent of the selectivity for the compounds toward PARP-2, in the current study, is greater than that observed for the clinically used PARP inhibitors.

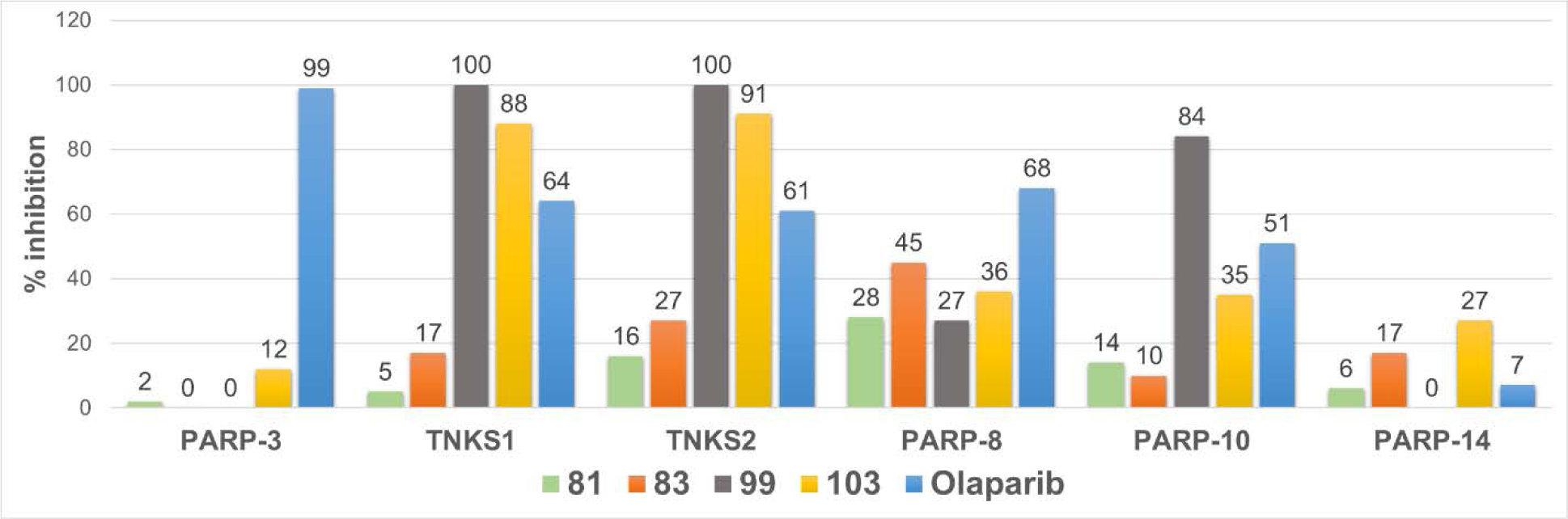

PARP-Isoform Profiling for Selected Target Compounds.

Discovery of isoform-selective inhibitors is at the forefront of medicinal chemistry and chemical biology research.56 Because the majority of clinically validated PARP-1 inhibitors show a wide spectrum of inhibitory activity toward catalytically active PARP-isoforms,57, 58 we obtained selectivity profiles of our four best PARP-1 inhibitors (81, 83, 99 and 103) at 500 nM concentration against a panel of six catalytic PARP-isoforms (Figure 5). Based on this data, compounds 81 and 83 will serve as high affinity chemical probes for PARP-1 and PARP-2 without interfering with other catalytic PARP-isoforms (PARP-3, TNKS1, TNKS2, PARP-8, PARP-10 and PARP-14). Further evaluation of compound 81 at 1 μM concentration against above mentioned catalytic PARP-isoforms led to minimal inhibition (12%, 5%, 16%, 34%, 4% and 9%, respectively). Thus, compound 81 demonstrated >33 and 500-fold selectivity toward PARP-1 and PARP-2 compared to the other catalytic PARP-isoforms.

Figure 5.

Inhibitory profile of selected PARP inhibitors against several PARP isoforms at 500 nM concentration. Screening was performed in duplicates and % inhibition was represented as the average of obtained values.

Since compounds 99 and 103 showed significant inhibition of anticancer targets TNKS1 and TNKS2 at 500 nM concentration, we obtained their IC50 values (Table 5). Compound 99 inhibited TNKS1 and TNKS2 with IC50 values of 6.3 nM and 8.8 nM, respectively, which was comparable to TNKS-selective analogue XAV939.59 Compound 99 thus inhibits clinically significant isoforms of PARP (PARP-1, PARP-2, TNKS1 and TNKS2) with low nM IC50 values (Table 5). Compound 103, however, moderately inhibited TNKS1 and TNKS2 with 131 nM and 198 nM IC50 values, respectively (Supporting Information, dose-response curves of 99 and 103 toward TNKS1 and TNKS2). It may be concluded that a bicyclic ring system attached to a flexible linker is important for the inhibition of TNKS1 and TNKS2 as evidenced from flexible analogue 99 and rigid analogues 81 and 103. Inhibition data of 81 against PARP-1, PARP-2, TNKS1 and TNKS2 is also shown in Table 5 for comparison.

Table 5.

Inhibition Data for Compounds 81, 99 and 103 against PARP-Isoforms

| Compd | PARP-1 IC50 (nM) a |

PARP-2 IC50 (nM) a |

TNKS1 IC50 (nM) a |

TNKS2 IC50 (nM) a |

|---|---|---|---|---|

| 81 | 30 | 2 | >1000b | >1000b |

| 99 | 4 | 0.7 | 6.3 | 8.8 |

| 103 | 18 | 4 | 131 | 198 |

| Olaparib | 1.2 | 0.5 | NT | NT |

| XAV939 | NT | NT | 4.2 | 2.1 |

Data shown are mean values obtained from two independent experiments performed in duplicates.

% inhibition of 81 was 5% and 16% at 1000 nM for TNKS1 and TNKS2, respectively.

Investigation of the Cellular Activity of PARP Inhibitors in BRCA1-mutant Cells.

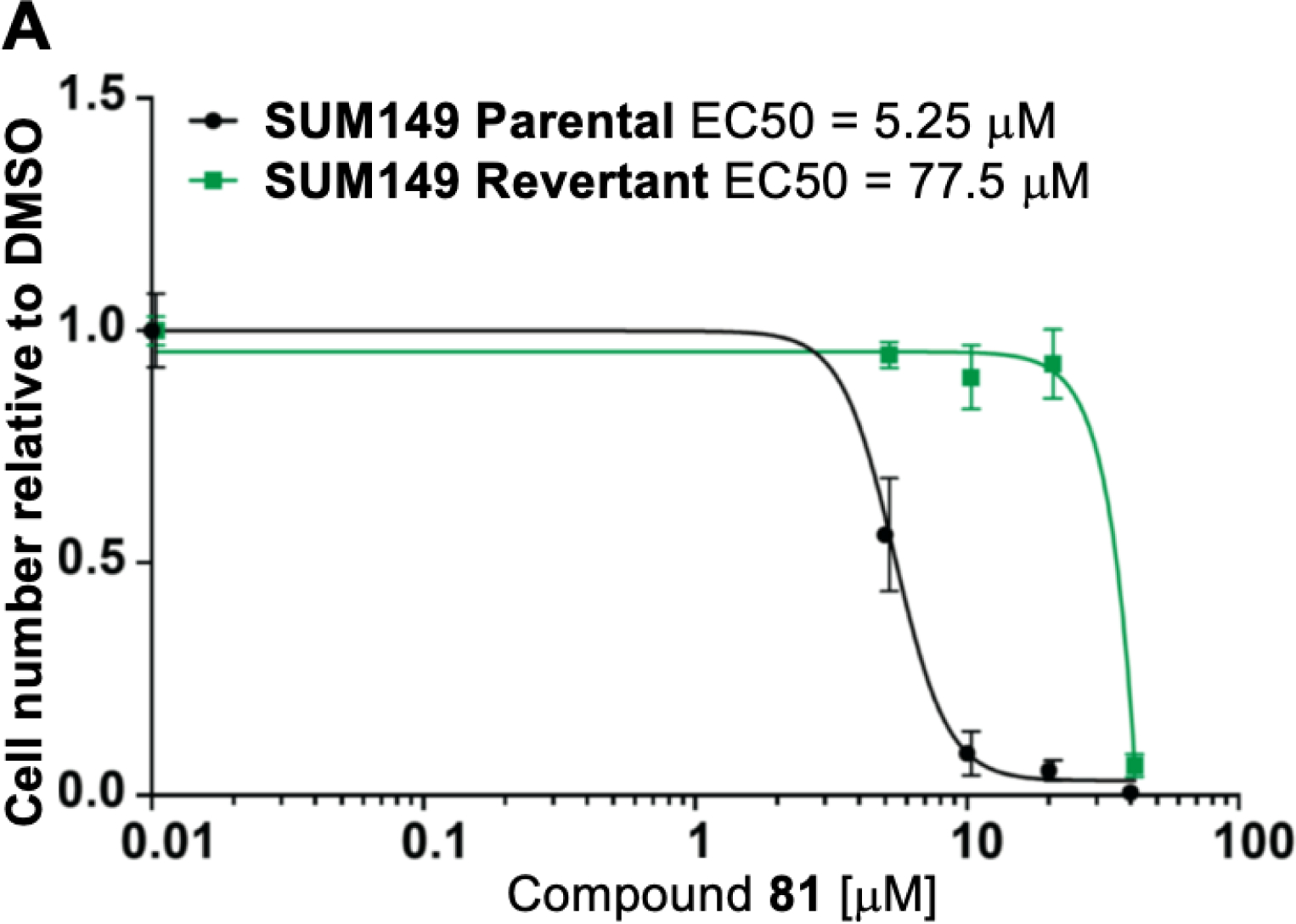

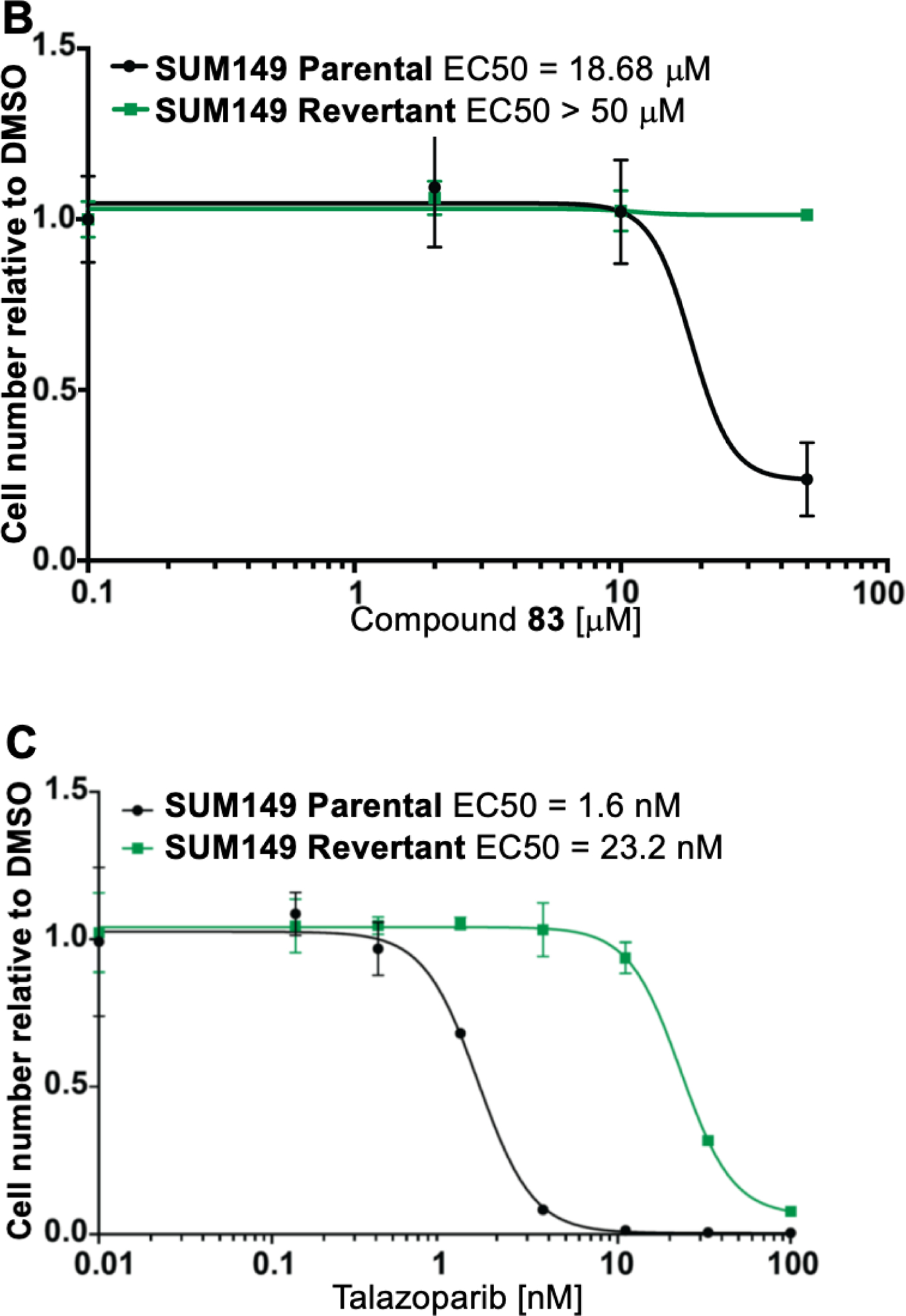

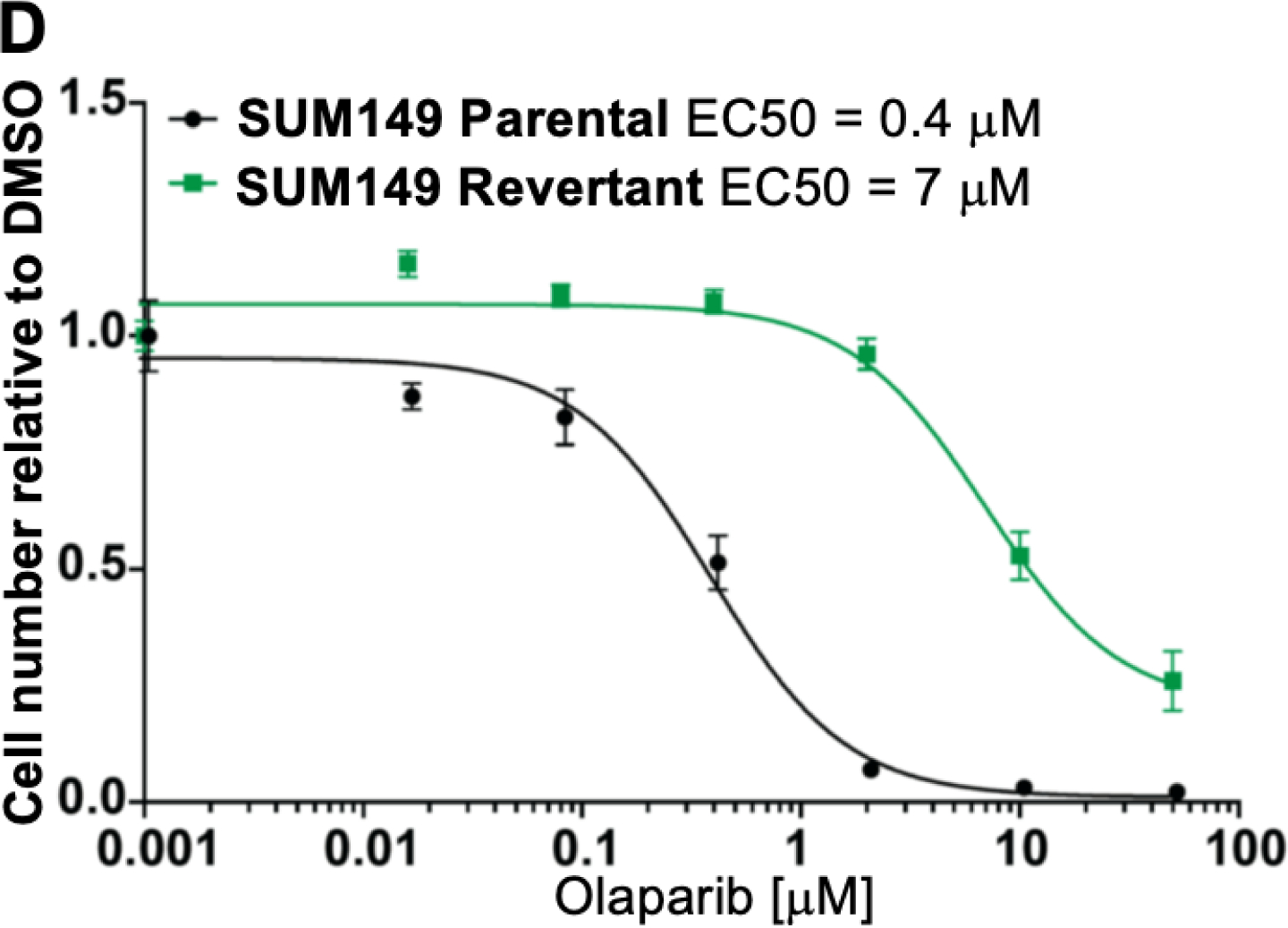

Extensive preclinical and clinical data have established that loss of BRCA1 or BRCA2 is associated with increased sensitivity to small molecule inhibitors targeting PARP-1/−2 (PARPi).23 To determine whether compounds 81 and 83, the most selective PARP-1/−2 inhibitors of the series, demonstrate specific cytotoxicity, we tested them in a pair of isogenic BRCA1-deficient and -proficient SUM149 breast cancer cell lines.60 We found that BRCA1-mutant cells are >10-fold more sensitive to both compounds 81 and 83 when compared to BRCA1-proficient cells (Figure 6A, 6B and Supporting Information Figure S4). This differential sensitivity was similar to talazoparib or olaparib treatment (Figure 6C and 6D). This finding suggests that compounds 81 and 83 have PARP-specific cytotoxicity in the context of BRCA1 loss.

Figure 6.

Dose-response survival curves for SUM149 parental (BRCA1−/−, black line) and SUM149 corrected/revertant (BRCA1-proficient, green line) cells treated with (A) compound 81, (B) compound 83, (C) Talazoparib and (D) Olaparib at the indicated concentrations. Data were normalized to vehicle treated cells and error bars indicate standard deviation derived from technical replicates (n=3).

CONCLUSIONS

A series of dihydrobenzofuran-7-carboxamides was designed, starting from the X-ray crystal structure of moderately active lead 1 (Z-2-benzylidene-3-oxo-2,3-dihydrobenzofuran-7-carboxamide, PARP-1 IC50 = 434 nM) in complex with a full length multi-domain PARP-1.37 In this study, four different SARs were explored at the meta- or para-position of the benzylidene portion of lead 1 to identify effective adenosine-binding motifs. For example, the 4-tetrazole motif yielded analogues with PARP-1 IC50 values of 35 nM - 56 nM. The pyridinyl/pyrimidinyl piperazine motifs displayed IC50 values ranging from 55 nM - 197 nM. Modifications on THTP motif demonstrated IC50 values of 27 nM - 97 nM and benzimidazolyl ethylamine/piperazine /azetidine/piperidine motifs also gave desirable IC50s in the range of 4 nM - 98 nM. Additionally, most of the compounds in the series were PARP-2 selective and their IC50s were similar to clinically utilized PARP inhibitors as exemplified by compounds with <5 nM IC50s against PARP-2. Differential scanning fluorimetry (DSF) of selected compounds from each of the SARs revealed that these compounds are unable to bind to the CAT domain in the presence of a folded helical domain; however, they efficiently bound to the CAT with the helical domain deleted (CATΔHD). Therefore, we propose that these compounds can bind to PARP-1 either with HD deleted or unfolded potentially as a result of DNA damage. X-ray crystal structures of selected compounds from four different SARs in complex with CATΔHD PARP-1 provided insights into the binding mechanism and will form the basis for optimization efforts in the future. Compounds 81 and 83 showed selective inhibition of PARP-1 and PARP-2 over other catalytic PARP-isoforms such as PARP-3, TNKS1, TNKS2, PARP-8, PARP-10, and PARP-14. Compound 99 exhibited single digit nM IC50 values against clinically significant PARP-isoforms (PARP-1, PARP-2, TNKS1 and TNKS2). PARP-isoform selective compounds 81 and 83 demonstrated BRCA1-dependent cytotoxic effect in the SUM149 cell line suggesting that they are promising lead compounds for further optimization.

EXPERIMENTAL

Chemical Synthesis.

Materials and Instrumentation.

All chemicals were procured from Accela Chembio (San Diego, CA), Aldrich Chemical Co. (Milwaukee, WI), Alfa Aesar (Ward Hill, MA), Arkpharm, Inc. (Arlington Heights, IL), Chem-Impex Int. Inc. (Wood Dale, IL), Combi-Blocks Inc. (San Diego, CA), Enamine LLC (Monmouth Jct., NJ), Oakwood Products (West Columbia, SC), Oxchem Corporation (Wood Dale, IL), Synthonix (Wake Forest, NC) and were used without additional purification. Qualitative analysis of reactions was performed by thin layer chromatography (TLC) with silica gel G as the adsorbent (250 microns) on aluminum backed plates (Agela Technologies) and Ultraviolet (UV) light at 254 nm or 365 nm for visualization purposes. 1H NMR experiments were performed using a Bruker 400 Ultrashield™ spectrometer (1H at 400 MHz and 13C at 100 MHz) equipped with a z-axis gradient probe. 1H NMR chemical shifts were reported downfield from tetramethylsilane (TMS as an internal standard) in parts per million (δ ppm) for majority of the intermediates and all the target compounds. The 1H NMR data are depicted as: chemical shift (multiplicity s (singlet), bs (broad singlet), d (doublet), t (triplet), dd (doublet of doublets), ddd (doublet of doublets of doublets), dq (doublet of quartets), dt (doublet of triplets), tt (triplet of triplets), td (triplet of doublets), h (hextate), m (multiplet), qd (quartet of doublets), number of protons and coupling constant). Column chromatography purifications were performed using silica gel (40–63 μm) purchased from Silicycle Inc. (Quebec City, CANADA) and flash chromatography was conducted using Reveleris® X2 flash chromatography system (BUCHI Corporation, New Castle, DE). Preparative TLC was performed using Silica Gel GF 1000 μm 20×20 cm glass backed plates procured from Analtech (Miles Scientific, Newark, DE). Purity analysis for target compounds 48-78 and mass analysis of all the target compounds was performed on an Agilent 1260 infinity series liquid chromatography (LC) system connected with Agilent 6120 quadrupole mass spectrometer (MS) (Agilent, Santa Clara, CA). Purity analysis of compounds 79-105 were carried out using Agilent 1260 infinity series HPLC system (Agilent, Santa Clara, CA). Purity and mass analysis was performed using Agilent Eclipse plus C18, 3.5 μm, 4.6 mm × 100 mm column and the runs were monitored at 254 nm. All target compounds were analyzed to be ≥ 95% pure (based on major peak area/total area of combined peaks). Acetonitrile (ACN) and water (0.1% formic acid) mixtures were used as mobile phase for purity analysis of compounds 48-78. For analogues 48 and 52, a 12 min gradient run was performed with 30 – 70% ACN in water. For analogue 50, a gradient run was performed with 60 – 40% ACN in water over 8 min. For analogues 51, 56, 57, 60, 61, 63 – 75, 77 and 78, a gradient run was performed with 40 – 60% ACN in water over 8 min. For analogue 54, an 8 min isocratic run was performed with 60% ACN in water. The flow rate was 0.5 mL/min for analysis of all the above-mentioned target compounds. For mass analysis of compounds 79-92, an 8 min gradient run of 70–90% ACN in water was used with a flow rate of 0.5 mL/min and for compounds 93-105, the flow rate was increased to 1 mL/min. For the purity analysis of compounds 49, 53, 58, 59, 62, 76, 79-105, ACN (0.1% DEA) and water (0.1% DEA) combination was used as the mobile phase. A gradient run with 10% ACN to 90% ACN in water over 8 min (flow rate of 1 mL/min) was used as the mobile phase. The elemental analyses (C, H, and N) were carried out by Atlantic Microlabs, Inc., (Norcross, GA), and the observed values were within ± 0.4% of the calculated values.

Synthesis.

Procedures for synthesizing the key intermediate I and conditions for Knoevenagel condensation to obtain the target compounds were adapted from our previously reported work.37 Target compounds obtained via Knoevenagel condensation were either washed with methanol and water, thereby resulting in pure compounds or were purified using chromatographic techniques such as preparative TLC or flash chromatography.

General Procedure for Suzuki Coupling Reaction (A).

Reactions were performed using conditions reported in previously published studies.38, 39

[1,1’-Biphenyl]-4-carbaldehyde (2).

Intermediate 2 was obtained by Suzuki coupling (procedure A) of 4-formylphenylboronic acid (500 mg, 3.34 mmol) with bromobenzene (0.35 mL, 3.34 mmol), as a pale yellow solid (485 mg, 80% yield).61 1H NMR (400 MHz, CDCl3; TMS) δ 9.93 (s, 1H), 7.82 (d, J = 8.2 Hz, 2H), 7.61 (d, J = 8.2 Hz, 2H), 7.54 – 7.48 (m, 5H).

4-(Thiazol-2-yl)benzaldehyde (3).

Intermediate 3 was synthesized using procedure A and 4-formylphenylboronic acid (500 mg, 3.34 mmol) and 2-chlorothiazole (0.29 mL, 3.34 mmol), as a pale brown solid (424 mg, 67% yield); 1H NMR (400 MHz, DMSO-d6; TMS) δ 10.11 (s, 1H), 8.13 (d, J = 7.8 Hz, 2H), 8.01 (d, J = 3.1 Hz, 1H), 7.97 (d, J = 7.6 Hz, 2H), 7.90 (d, J = 3.2 Hz, 1H).

4-(2H-Tetrazol-5-yl)benzaldehyde (4).

To a solution of 4-formylbenzonitrile (1 g, 7.63 mmol) dissolved in N,N-dimethylformamide (DMF), triethylamine (2.13 mL, 15.25 mmol) was added with subsequent addition of sodium azide (1.49 g, 22.88 mmol) and ensuing reaction mixture was heated to 180°C for overnight. The reaction mixture was then vacuum dried on a rotary evaporator to remove majority of DMF. The resulting crude mixture was then partitioned between 1N aqueous HCl and ethyl acetate and the organic layer was collected and further extracted 3X with brine to remove the residual DMF from the organic layer. Later, ethyl acetate layer was dried over MgSO4, filtered and evaporated to obtain brown solid, which was suspended in ethyl acetate and washed with ethyl acetate to yield pure compound 4 as a cream colored solid (897 mg, 67% yield). 1H NMR (400 MHz, DMSO-d6) δ 10.11 (s, 1H), 8.31 (d, J = 7.3 Hz, 2H), 8.13 (d, J = 7.3 Hz, 2H).

General Procedure for Preparation of Substituted 2H-tetrazol-5-yl benzaldehyde Intermediates (B).

These intermediates were prepared by slightly modifying reported procedure,41 wherein sodium azide and diethylamine hydrochloride were added to a solution of the appropriate benzonitrile in toluene. The reaction mixture was then allowed to reflux in an inert condition for a period of 24 h. Thereafter, toluene was evaporated and subsequently extracted with 1X 1N aqueous HCl and ethyl acetate. Ethyl acetate layer was then dried over MgSO4 and evaporated to obtain the crude benzaldehyde derivative that was purified by flash chromatography.

3-Fluoro-4-(2H-tetrazol-5-yl)benzaldehyde (5).

Intermediate 5 was obtained using the general procedure B, by reacting 2-fluoro-4-formylbenzonitrile (500 mg, 3.35 mmol) with sodium azide (371 mg, 5.7 mmol) and diethylamine hydrochloride (625mg, 5.7 mmol), as a white solid (173 mg, 27% yield). 1H NMR (400 MHz, DMSO-d6) δ 10.09 (s, 1H), 8.32 (t, J = 7.4 Hz, 1H), 8.03 – 7.95 (m, 2H).

2-Methoxy-4-(2H-tetrazol-5-yl)benzaldehyde (6).

Intermediate 6 was prepared using the general procedure B, by reacting 3-methoxy-4-formylbenzonitrile (500 mg, 3.10 mmol), sodium azide (343 mg, 5.27 mmol) and diethylamine hydrochloride (578 mg, 5.27 mmol) as a white solid (520 mg, 82% yield); 1H NMR (400 MHz, DMSO-d6) δ 10.40 (s, 1H), 7.93 – 7.83 (m, 2H), 7.75 (dt, J = 8.0, 1.1 Hz, 1H), 4.04 (s, 3H).

4-(2-Methyl-2H-tetrazol-5-yl)benzaldehyde (7).

Intermediate 7 was obtained by reacting tetrazole intermediate 4 (250 mg, 0.57 mmol), as described in a reported procedure,42 as a yellow solid (196 mg, 73% yield). 1H NMR (400 MHz, DMSO-d6; TMS) δ 10.10 (s, 1H), 8.29 (d, J = 8.3 Hz, 2H), 8.10 (d, J = 8.0 Hz, 2H), 4.47 (s, 3H).

4-(4-(Pyrimidin-2-yl)piperazin-1-yl)benzaldehyde (8).

Intermediate 8 was obtained using a reported procedure43 by reacting 4-fluorobenzaldehyde (1 g, 8.06 mmol) with pyrimidin-2-yl-piperazine (2.16 g, 8.06 mmol) and potassium carbonate (2.23 g, 16.11 mmol), as a white solid (1.575 g, 73% yield). 1H NMR (400 MHz, CDCl3; TMS) δ 10.05 (s, 1H), 8.32 (d, J = 4.8 Hz, 2H), 7.95 (d, J = 8.2 Hz, 2H), 7.59 (d, J = 8.0 Hz, 2H), 6.55 (t, J = 4.7 Hz, 1H), 4.00 – 3.75 (m, 6H), 3.53 – 3.39 (m, 2H)

General Procedure for Peptide Coupling Reactions (C).

To a suspension of appropriate carboxylic acid [(3-carboxy or 4-carboxy benzaldehyde or 60) 1 eq] in dichloromethane, HCTU (1.5 eq) and HOBt (1.5 eq) were added and the temperature was brought down to 0°C while the reaction was stirring. To this mixture, DIPEA was added (2 eq) and the resultant mixture was left stirring at 0°C for 15 min. Subsequently, the amine (1.1 eq) was added as such or by dissolving in a minimum volume of dichloromethane (for amines which were liquids at rt) to the reaction mixture and the reaction was stirred at rt for overnight. The reaction was then diluted with DCM and washed 3X with small portions of water. Resultant organic phase was dried over MgSO4, filtered and evaporated to yield crude coupled products, which were either used as obtained or purified by flash chromatography using gradient DCM and methanol combinations as the mobile phase, wherein the concentration of methanol in dichloromethane was varied from 1–8% based on the nature of product to be purified.

4-(4-Phenylpiperazine-1-carbonyl)benzaldehyde (9).

Intermediate 9 was prepared using the general procedure C, where 4-formylbenzoic acid (500 mg, 3.33 mmol) was reacted with 1-phenylpiperazine (594 mg, 3.66 mmol), as a brown solid (724 mg, 74% yield). 1H NMR (400 MHz, CDCl3; TMS) δ 10.01 (s, 1H), 7.92 (d, J = 7.9 Hz, 2H), 7.57 (d, J = 7.8 Hz, 2H), 7.27 (t, J = 7.8 Hz, 2H), 6.96 – 6.81 (m, 3H), 4.01 – 3.86 (m, 2H), 3.60 – 3.46 (m, 2H), 3.31 – 3.18 (m, 2H), 3.18 – 3.03 (m, 2H).

4-(4-(Pyridin-2-yl)piperazine-1-carbonyl)benzaldehyde (10).

Intermediate 10 was synthesized using general procedure C, by reacting 4-formylbenzoic acid (500 mg, 3.33 mmol) with pyridin-2-yl-piperazine (598 mg, 3.66 mmol), as a brown oil (638 mg, 65% yield) that was used as such in the next step; 1H NMR (400 MHz, CDCl3; TMS) δ 10.02 (s, 1H), 8.20 – 8.13 (m, 1H), 7.92 (dd, J = 8.2, 2.1 Hz, 2H), 7.57 (dd, J = 8.3, 2.0 Hz, 2H), 7.49 (ddd, J = 10.6, 6.5, 2.0 Hz, 1H), 6.65 (dd, J = 7.5, 4.8 Hz, 2H), 4.02 – 3.82 (m, 2H), 3.66 – 3.43 (m, 6H).

4-(4-(Pyrimidin-2-yl)piperazine-1-carbonyl)benzaldehyde (11).

Intermediate 11 was obtained by using general procedure C, where 4-formylbenzoic acid (500 mg, 3.33 mmol) was treated with pyrimidin-2-yl-piperazine (602 mg, 3.66 mmol), as an off-white solid after flash purification (838 mg, 85% yield); 1H NMR (400 MHz, DMSO-d6; TMS) δ 10.08 (s, 1H), 8.39 (d, J = 4.8 Hz, 2H), 8.00 (d, J = 8.3 Hz, 2H), 7.67 (d, J = 7.9 Hz, 2H), 6.68 (t, J = 4.7 Hz, 1H), 3.96 – 3.64 (m, 6H), 3.45 – 3.30 (m, 2H).

4-(4-(Pyrazin-2-yl)piperazine-1-carbonyl)benzaldehyde (12).

12 was synthesized by using 4-formylbenzoic acid (500 mg, 3.33 mmol), pyrazin-2-yl-piperazine (602 mg, 3.66 mmol) and the general procedure C, as a brown oil that was used as such without any purification for subsequent synthesis; 1H NMR (400 MHz, CDCl3; TMS) δ 10.04 (s, 1H), 8.20 – 8.14 (m, 1H), 8.13 – 8.05 (m, 1H), 7.96 (d, J = 7.9 Hz, 2H), 7.87 (d, J = 2.7 Hz, 1H), 7.61 (d, J = 7.9 Hz, 2H), 3.98 – 3.83 (m, 2H), 3.78 – 3.66 (m, 2H), 3.65 – 3.49 (m, 4H).

4-(4-(1,3,5-Triazin-2-yl)piperazine-1-carbonyl)benzaldehyde (13).

Aldehyde 13 was prepared using the general procedure C, where 4-formylbenzoic acid (500 mg, 3.33 mmol) was reacted with triazin-2-yl-piperazine (605 mg, 3.66 mmol), as a brown oil (738 mg, 75% yield) that was as such subjected to the next step; 1H NMR (400 MHz, CDCl3; TMS) δ 10.04 (s, 1H), 8.52 (s, 2H), 7.98 (d, J = 7.9 Hz, 2H), 7.63 (d, J = 7.9 Hz, 2H), 4.05 – 3.94 (m, 2H), 3.92 – 3.80 (m, 4H), 3.55 – 3.44 (m, 2H).

4-(4-(5-(Trifluoromethyl)-1,3,4-thiadiazol-2-yl)piperazine-1-carbonyl)benzaldehyde (14).

Aldehyde 14 was prepared by using general procedure C, where 4-formylbenzoic acid (500 mg, 3.33 mmol) was treated with 2-(piperazin-1-yl)-5-(trifluoromethyl)-1,3,4-thiadiazole (503 mg, 3.66 mmol), as a pale yellow solid (838 mg, 85% yield), after evaporating the organic layer and washing the crude solid with ethyl acetate; 1H NMR (400 MHz, DMSO-d6; TMS) δ 10.08 (s, 1H), 8.02 (d, J = 8.2 Hz, 2H), 7.68 (d, J = 8.1 Hz, 2H), 3.89 – 3.41 (m, 8H).

4-(4-(3-(Trifluoromethyl)pyridin-2-yl)piperazine-1-carbonyl)benzaldehyde (15).

Intermediate 15 was prepared via general procedure C by using 4-formylbenzoic acid (500 mg, 3.33 mmol) and 1-(3-(trifluoromethyl)pyridin-2-yl)piperazine (847 mg, 3.66 mmol) as a dark brown oil (757 mg, 63% yield), which was directly used as obtained for subsequent synthesis; 1H NMR (400 MHz, CDCl3; TMS) δ 10.06 (s, 1H), 8.48 (dd, J = 5.0, 1.9 Hz, 1H), 8.00 – 7.96 (m, 2H), 7.93 (dd, J = 7.8, 1.9 Hz, 1H), 7.65 – 7.58 (m, 2H), 7.18 – 7.10 (m, 1H), 3.99 – 3.90 (m, 2H), 3.60 – 3.52 (m, 2H), 3.39 – 3.31 (m, 2H), 3.26 – 3.21 (m, 2H).

2-(4-(4-Formylbenzoyl)piperazin-1-yl)nicotinonitrile (16).

Aldehyde 16 was prepared using the general procedure C, where 4-formylbenzoic acid (500 mg, 3.33 mmol) was allowed to react with 2-(piperazin-1-yl)nicotinonitrile (689 mg, 3.66 mmol) as a brown oil (638 mg, 60% yield) that was directly used as obtained for subsequent synthesis; 1H NMR (400 MHz, CDCl3; TMS) δ 10.06 (s, 1H), 8.38 (dd, J = 4.9, 2.0 Hz, 1H), 7.97 (d, J = 7.8 Hz, 2H), 7.84 (dd, J = 7.7, 2.1 Hz, 1H), 7.60 (d, J = 7.8 Hz, 2H), 6.89 (dd, J = 7.6, 4.9 Hz, 1H), 4.01 – 3.92 (m, 2H), 3.85 – 3.77 (m, 2H), 3.68 – 3.62 (m, 2H), 3.62 – 3.52 (m, 2H).

4-(4-(4-Methoxypyrimidin-2-yl)piperazine-1-carbonyl)benzaldehyde (17).

Aldehyde 17 was synthesized by using 4-formylbenzoic acid (250 mg, 1.67 mmol) and 4-methoxy-2-(piperazin-1-yl)pyrimidine (356 mg, 1.83 mmol) as per the general procedure C as a dark yellow oil, which was used as obtained for subsequent synthesis; 1H NMR (400 MHz, CDCl3; TMS) δ 10.04 (s, 1H), 8.00 (dd, J = 23.9, 6.7 Hz, 3H), 7.63 (d, J = 7.8 Hz, 2H), 6.03 (d, J = 5.7 Hz, 1H), 3.99 – 3.90 (m, 2H), 3.90 – 3.77 (m, 7H), 3.52 – 3.43 (m, 2H).

Methyl 2-(4-(tert-butoxycarbonyl)piperazin-1-yl)pyrimidine-5-carboxylate (18).

Intermediate 18 was prepared according to reported procedures.37, 45 To a solution of N-Boc piperazine (270 mg, 1.45 mmol) in acetonitrile, potassium carbonate (400 mg, 2.9 mmol) and methyl 2-chloropyrimidine-5-carboxylate (250 mg, 1.45 mmol) were added and the suspension was allowed to reflux for overnight. Subsequently, the solvent was evaporated and the residue was subjected to extraction with ethyl acetate and water. The organic phase was then dried over MgSO4 and was further vacuum dried to obtain the N-Boc intermediate 18 as an off-white solid (413 mg, 88% yield). 1H NMR (400 MHz, CDCl3; TMS) δ 8.86 (s, 2H), 3.99 – 3.91 (m, 4H), 3.90 (s, 3H), 3.59 – 3.46 (m, 4H), 1.51 (s, 9H).

Methyl 2-(piperazin-1-yl)pyrimidine-5-carboxylate hydrochloride (19).

Intermediate 19 was prepared by using the N-Boc piperazine 18 (413 mg, 1.28 mmol) and dissolving it in dioxane, followed by lowering the temperature of the reaction to 0°C, using ice. Further, 4N aqueous solution of HCl (4.7 mL, 12.81 mmol) was added drop wise and the reaction mixture was stirred at rt for overnight. The solvent was then evaporated and the resultant semi-solid mass was triturated with a small amount of methanol to obtain a white suspension, which was filtered and dried to obtain 19 (278 mg, 88% yield) as a hydrochloride salt. 1H NMR (400 MHz, D2O) δ 8.70 (s, 2H), 4.05 – 3.98 (m, 4H), 3.77 (s, 3H), 3.30 – 3.24 (m, 4H).

Methyl 2-(4-(4-formylbenzoyl)piperazin-1-yl)pyrimidine-5-carboxylate (20).

Intermediate 20 was synthesized using general procedure C and by reacting 4-formylbenzoic acid (125 mg, 0.83 mmol) with intermediate 19 (237 mg, 0.92 mmol) as a white solid (185 mg, 63% yield); 1H NMR (400 MHz, DMSO-d6; TMS) δ 10.08 (s, 1H), 8.82 (s, 2H), 8.01 (d, J = 7.9 Hz, 2H), 7.68 (d, J = 7.9 Hz, 2H), 4.10 – 3.68 (m, 9H), 3.51 – 3.37 (m, 2H).

4-(4-(4-(5-(Methoxymethyl)-1,2,4-oxadiazol-3-yl)pyrimidin-2-yl)piperazine-1-carbonyl)benzaldehyde (21).

Aldehyde 21 was prepared using the general procedure C, where 4-formylbenzoic acid (130 mg, 0.87 mmol) was allowed to react with 5-(methoxymethyl)-3-(2-(piperazin-1-yl)pyrimidin-4-yl)-1,2,4-oxadiazole (250 mg, 0.95 mmol) as a cream colored solid (189 mg, 53% yield), by washing the crude solid with ethyl acetate; 1H NMR (400 MHz, CDCl3; TMS) δ 10.07 (s, 1H), 7.98 (d, J = 8.1 Hz, 1H), 7.61 (d, J = 8.1 Hz, 1H), 7.54 (d, J = 8.4 Hz, 2H), 7.46 (d, J = 8.4 Hz, 2H), 4.79 (s, 2H), 4.12 – 3.97 (m, 2H), 3.97 – 3.79 (m, 4H), 3.60 – 3.47 (m, 5H).

3-(4-(Pyrimidin-2-yl)piperazine-1-carbonyl)benzaldehyde (22).

Intermediate 22 was prepared by using general procedure C, where 3-formylbenzoic acid (500 mg, 3.33 mmol) was treated with pyrimidin-2-yl-piperazine (602 mg, 3.66 mmol) as a dark yellow oil (812 mg, 82% yield) that was directly used for subsequent synthesis without additional purification; 1H NMR (400 MHz, CDCl3; TMS) δ 10.05 (s, 1H), 8.33 (d, J = 4.7 Hz, 2H), 8.03 – 7.92 (m, 2H), 7.74 (d, J = 7.6 Hz, 1H), 7.65 (t, J = 7.8 Hz, 1H), 6.58 (t, J = 4.7 Hz, 1H), 4.02 – 3.76 (m, 6H), 3.61 – 3.46 (m, 2H).

3-(4-(4-Methoxypyrimidin-2-yl)piperazine-1-carbonyl)benzaldehyde (23).

Aldehyde 23 was synthesized by using 4-formylbenzoic acid (250 mg, 1.67 mmol) and 4-methoxy-2-(piperazin-1-yl)pyrimidine (356 mg, 1.83 mmol) and as per the general procedure C as a brown oil (338 mg, 62% yield) that was directly used in the subsequent step without additional purification; 1H NMR (400 MHz, CDCl3; TMS) δ 10.03 (s, 1H), 8.03 (d, J = 5.7 Hz, 1H), 7.97 – 7.92 (m, 2H), 7.70 (dt, J = 7.6, 1.5 Hz, 1H), 7.61 (t, J = 7.9 Hz, 1H), 6.02 (d, J = 5.6 Hz, 1H), 3.97 – 3.74 (m, 9H), 3.57 – 3.41 (m, 2H).

3-(4-(Pyrazin-2-yl)piperazine-1-carbonyl)benzaldehyde (24).

Intermediate 24 was prepared using the general procedure C, where 3-formylbenzoic acid (500 mg, 3.33 mmol) was allowed to react with pyrazin-2-yl-piperazine (602 mg, 3.66 mmol) as a brown oil (753 mg, 76% yield), which was used as obtained in the subsequent step; 1H NMR (400 MHz, CDCl3; TMS) δ 10.03 (d, J = 1.3 Hz, 1H), 8.15 (d, J = 1.6 Hz, 1H), 8.07 (dt, J = 3.2, 1.6 Hz, 1H), 7.98 – 7.92 (m, 2H), 7.89 (dd, J = 2.8, 1.3 Hz, 1H), 7.71 (dq, J = 7.7, 1.6 Hz, 1H), 7.62 (t, J = 7.4 Hz, 1H), 3.99 – 3.81 (m, 2H), 3.76 – 3.48 (m, 6H).

4-(4-(Pyrimidin-2-yl)piperidine-1-carbonyl)benzaldehyde (25).

Aldehyde 25 was prepared by using general procedure C, where 4-formylbenzoic acid (250 mg, 1.67 mmol) was treated with 2-(piperidin-4-yl)pyrimidine (299 mg, 1.83 mmol) as a yellow oil (364 mg, 74% yield), which was used in the subsequent synthesis without additional purification; 1H NMR (400 MHz, CDCl3; TMS) δ 10.05 (s, 1H), 8.72 (d, J = 4.9 Hz, 2H), 7.95 (d, J = 7.7 Hz, 2H), 7.58 (d, J = 7.9 Hz, 2H), 7.25 (t, J = 5.0 Hz, 1H), 4.85 – 4.71 (m, 1H), 3.82 – 3.63 (m, 4H), 3.27 – 3.16 (m, 4H).

4-Formyl-N-(1-(pyrimidin-2-yl)piperidin-4-yl)benzamide (26).

Intermediate 26 was synthesized by using 4-formylbenzoic acid (500 mg, 3.33 mmol) and 1-(pyrimidin-2-yl)piperidin-4-amine (653 mg, 3.66 mmol) as per general procedure C as a pale yellow solid (666 mg, 64% yield); 1H NMR (400 MHz, CDCl3; TMS) δ 10.02 (s, 1H), 8.27 (d, J = 4.8 Hz, 2H), 7.95 (d, J = 8.3 Hz, 2H), 7.88 (d, J = 8.3 Hz, 2H), 7.04 (d, J = 7.9 Hz, 1H), 6.46 (t, J = 4.8 Hz, 1H), 4.78 – 4.66 (m, 2H), 4.31 – 4.19 (m, 1H), 3.98 – 3.68 (m, 2H), 3.10 – 2.99 (m, 2H), 2.11 – 2.02 (m, 2H).

4-((4-(Pyrimidin-2-yl)piperazin-1-yl)sulfonyl)benzaldehyde (27).

Intermediate 27 was prepared using procedure from our previously published work,37 where pyrimidin-2-yl-piperazine (201 mg, 1.22 mmol) was reacted with triethylamine (0.34 mL, 2.44 mmol) in dichloromethane, followed by drop wise addition of 4-formylphenyl sulfonyl chloride (dissolved in dichloromethane) under 0°C and brought to rt after which it was left stirring for a period of 12 h. The solvent was later evaporated, and the mixture was purified by flash chromatography to yield 27 as a white solid (286 mg, 70% yield). 1H NMR (400 MHz, DMSO-d6) δ 10.11 (s, 1H), 8.34 (d, J = 4.7 Hz, 2H), 8.14 (d, J = 7.9 Hz, 2H), 7.97 (d, J = 7.9 Hz, 2H), 6.64 (t, J = 4.7 Hz, 1H), 3.88 – 3.78 (m, 4H), 3.04 – 2.96 (m, 4H).

4-((4-(Pyrimidin-2-yl)piperazin-1-yl)methyl)benzaldehyde (28).

Intermediate 28 was prepared according to our previous report.37 To a solution of pyrimidin-2-yl-piperazine (454 mg, 2.76 mmol) in acetonitrile, potassium carbonate (694 mg, 5.02 mmol) and 4-bromomethyl benzaldehyde (500 mg, 2.51 mmol) were added and the suspension was allowed to reflux for overnight. Subsequently, the solvent was evaporated followed by extraction of the reaction mass with ethyl acetate and water. Ethyl acetate layer was then dried over MgSO4 and was further purified using flash chromatography to obtain 28 as a yellow solid (536 mg, 76% yield). 1H NMR (400 MHz, CDCl3; TMS) δ 10.00 (s, 1H), 8.30 (dd, J = 4.8, 0.7 Hz, 2H), 7.86 (d, J = 8.0 Hz, 2H), 7.55 (d, J = 8.0 Hz, 2H), 6.48 (td, J = 4.7, 0.7 Hz, 1H), 3.88 – 3.79 (m, 4H), 3.62 (s, 2H), 2.56 – 2.45 (m, 4H).

4-(5,6,7,8-Tetrahydro-[1,2,4]triazolo[4,3-a]pyrazine-7-carbonyl)benzaldehyde (29).

Intermediate 29 was synthesized using general procedure C, by reacting 4-formylbenzoic acid (275 mg, 1.83 mmol) with 5,6,7,8-tetrahydro-[1,2,4]triazolo[4,3-a]pyrazine (250 mg, 2.01 mmol) as a white solid (213 mg, 45% yield), after purification using flash chromatography with DCM and methanol as the mobile phase; 1H NMR (400 MHz, CDCl3; TMS) δ 10.08 (s, 1H), 8.25 (s, 1H), 7.99 (d, J = 8.0 Hz, 2H), 7.64 (d, J = 7.8 Hz, 2H), 5.01 (bs, 2H), 4.34 – 4.03 (m, 4H).

4-(3-Methyl-5,6,7,8-tetrahydro-[1,2,4]triazolo[4,3-a]pyrazine-7-carbonyl)benzaldehyde (30).

Intermediate 30 was synthesized using general procedure C and by reacting 4-formylbenzoic acid (247 mg, 1.65 mmol) with 3-methyl-5,6,7,8-tetrahydro-[1,2,4]triazolo[4,3-a]pyrazine (250 mg, 1.81 mmol) as a white solid (236 mg, 53% yield), after purification using flash chromatography with DCM and methanol as the mobile phase; 1H NMR (400 MHz, CDCl3; TMS) δ 10.07 (s, 1H), 7.98 (d, J = 8.3 Hz, 2H), 7.63 (d, J = 8.0 Hz, 2H), 4.84 (bs, 2H), 4.36 – 3.78 (m, 4H), 2.43 (s, 3H).

4-(3-(Trifluoromethyl)-5,6,7,8-tetrahydro-[1,2,4]triazolo[4,3-a]pyrazine-7-carbonyl)benzaldehyde (31).

Intermediate 31 was synthesized using general procedure C and by reacting 4-formylbenzoic acid (178 mg, 1.19 mmol) with 3-(trifluoromethyl)-5,6,7,8-tetrahydro-[1,2,4]triazolo[4,3-a]pyrazine (251 mg, 1.3 mmol) as a pale yellow solid (259 mg, 67% yield) after purification using flash chromatography with DCM and methanol as the mobile phase; 1H NMR (400 MHz, CDCl3; TMS) δ 10.05 (s, 1H), 7.97 (d, J = 7.8 Hz, 2H), 7.66 (d, J = 7.7 Hz, 2H), 5.01 (bs, 2H), 4.42 – 3.91 (m, 4H).

Ethyl 7-(4-formylbenzoyl)-5,6,7,8-tetrahydro-[1,2,4]triazolo[4,3-a]pyrazine-3-carboxylate (32).

Intermediate 32 was synthesized using general procedure C and by reacting 4-formylbenzoic acid (174 mg, 1.16 mmol) with ethyl 5,6,7,8-tetrahydro-[1,2,4]triazolo[4,3-a]pyrazine-3-carboxylate (250 mg, 1.27 mmol) as off-white solid (234 mg, 62% yield) after purification using flash chromatography with DCM and methanol as the mobile phase; 1H NMR (400 MHz, CDCl3; TMS) δ 10.06 (s, 1H), 7.99 (d, J = 7.9 Hz, 2H), 7.68 (d, J = 7.8 Hz, 2H), 5.03 (bs, 2H), 4.48 – 4.39 (m, 4H), 4.03 – 3.78 (m, 2H), 1.43 – 1.38 (m, 3H).

4-(3-Cyclopropyl-5,6,7,8-tetrahydro-[1,2,4]triazolo[4,3-a]pyrazine-7-carbonyl)benzaldehyde (33).

Intermediate 33 was synthesized using general procedure C and by reacting 4-formylbenzoic acid (208 mg, 1.39 mmol) with 3-cyclopropyl-5,6,7,8-tetrahydro-[1,2,4]triazolo[4,3-a]pyrazine (250 mg, 1.52 mmol) as a white solid (209 mg, 51% yield) after purification using flash chromatography with DCM and methanol as the mobile phase; 1H NMR (400 MHz, DMSO-d6) δ 10.09 (s, 1H), 8.08 – 7.97 (m, 2H), 7.74 (d, J = 7.9 Hz, 2H), 4.77 (bs, 2H), 4.20 – 3.98 (m, 3H), 3.83 – 3.65 (m, 1H), 2.00 – 1.82 (m, 1H), 1.02 – 0.81 (m, 4H).

4-(3-(3-Fluorobenzyl)-5,6,7,8-tetrahydro-[1,2,4]triazolo[4,3-a]pyrazine-7-carbonyl)benzaldehyde (34).

Intermediate 34 was synthesized using general procedure C and by reacting 4-formylbenzoic acid (147 mg, 0.98 mmol) with 3-(3-fluorobenzyl)-5,6,7,8-tetrahydro-[1,2,4]triazolo[4,3-a]pyrazine (250 mg, 1.08 mmol) as a white solid (178 mg, 50% yield) after purification using flash chromatography with DCM and methanol as the mobile phase; 1H NMR (400 MHz, CDCl3; TMS) δ 10.03 (s, 1H), 7.98 – 7.90 (m, 2H), 7.60 (d, J = 7.8 Hz, 2H), 7.29 (td, J = 7.9, 5.9 Hz, 1H), 7.05 – 6.87 (m, 3H), 4.91 (bs, 2H), 4.16 (s, 2H), 3.98 – 3.62 (m, 3H), 3.31 – 3.01 (m, 1H).

3-(5,6,7,8-Tetrahydro-[1,2,4]triazolo[4,3-a]pyrazine-7-carbonyl)benzaldehyde (35).

Intermediate 35 was synthesized using general procedure C and by reacting 3-formylbenzoic acid (275 mg, 1.83 mmol) with 5,6,7,8-tetrahydro-[1,2,4]triazolo[4,3-a]pyrazine (250 mg, 2.01 mmol) as a white solid (268 mg, 57% yield) after purification using flash chromatography with DCM and methanol as the mobile phase; 1H NMR (400 MHz, CDCl3; TMS) δ 10.05 (s, 1H), 8.04 – 7.97 (m, 2H), 7.92 (s, 1H), 7.82 – 7.73 (m, 1H), 7.67 (t, J = 7.4 Hz, 1H), 4.93 (bs, 2H), 4.44 – 3.97 (m, 4H).

3-(3-(Trifluoromethyl)-5,6,7,8-tetrahydro-[1,2,4]triazolo[4,3-a]pyrazine-7-carbonyl)benzaldehyde (36).

Intermediate 36 was synthesized using general procedure C and by reacting 3-formylbenzoic acid (178 mg, 1.19 mmol) with 3-(trifluoromethyl)-5,6,7,8-tetrahydro-[1,2,4]triazolo[4,3-a]pyrazine (251 mg, 1.3 mmol) as a colorless oil (242 mg, 63% yield) after purification using flash chromatography with DCM and methanol as the mobile phase; 1H NMR (400 MHz, CDCl3; TMS) δ 10.03 (s, 1H), 7.81 – 7.74 (m, 2H), 7.60 – 7.52 (m, 1H), 7.44 (t, J = 7.9 Hz, 1H), 4.81 (s, 2H), 4.16 – 3.73 (m, 4H).

N-(2-(1H-Benzo[d]imidazol-2-yl)ethyl)-4-formylbenzamide (37).

Intermediate 37 was synthesized by reaction of 4-formylbenzoic acid (212 mg, 1.41 mmol) with 2-(1H-benzo[d]imidazol-2-yl)ethan-1-amine (250 mg, 1.55 mmol) using general procedure C, where the ethyl acetate extract was subjected to evaporation and the crude residue was washed further with ethyl acetate to obtain 37 as an off-white solid (257 mg, 62% yield); 1H NMR (400 MHz, DMSO-d6) δ 12.33 (bs, 1H), 10.08 (s, 1H), 8.94 (t, J = 5.6 Hz, 1H), 8.06 – 7.95 (m, 4H), 7.54 – 7.42 (m, 3H), 7.17 – 7.09 (m, 3H), 3.75 (q, J = 7.0 Hz, 2H), 3.12 (t, J = 7.3 Hz, 2H).

4-Formyl-N-(2-(5-methyl-1H-benzo[d]imidazol-2-yl)ethyl)benzamide (38).

Aldehyde 38 was synthesized by reaction of 4-formylbenzoic acid (195 mg, 1.30 mmol) with 2-(5-methyl-1H-benzo[d]imidazol-2-yl)ethan-1-amine (250 mg, 1.43 mmol) using general procedure C, where the ethyl acetate extract was subjected to evaporation and the crude residue was washed further with ethyl acetate to obtain 38 as a pale yellow solid (283 mg, 71% yield); 1H NMR (400 MHz, DMSO-d6; TMS) δ 12.16 (bs, 1H), 10.08 (s, 1H), 8.92 (s, 1H), 8.09 – 7.90 (m, 4H), 7.48 – 7.12 (m, 2H), 6.95 (t, J = 9.1 Hz, 1H), 3.73 (q, J = 6.8 Hz, 2H), 3.08 (t, J = 7.4 Hz, 2H), 2.39 (s, 3H).

N-(2-(5-Fluoro-1H-benzo[d]imidazol-2-yl)ethyl)-4-formylbenzamide (39).

Intermediate 39 was synthesized by reaction of 4-formylbenzoic acid (190 mg, 1.27 mmol) with 2-(5-fluoro-1H-benzo[d]imidazol-2-yl)ethan-1-amine (249 mg, 1.39 mmol) using general procedure C, where the ethyl acetate extract was subjected to evaporation and the crude residue was washed further with ethyl acetate to obtain 39 as an off-white solid (271 mg, 69% yield); 1H NMR (400 MHz, DMSO-d6) δ 12.44 (bs, 1H), 10.08 (s, 1H), 8.91 (d, J = 7.6 Hz, 1H), 8.06 – 7.97 (m, 4H), 7.57 – 7.39 (m, 1H), 7.30 (ddd, J = 36.5, 9.6, 2.6 Hz, 1H), 7.05 – 6.91 (m, 1H), 3.73 (q, J = 6.8 Hz, 2H), 3.10 (td, J = 7.3, 3.6 Hz, 2H).

N-(2-(1H-Benzo[d]imidazol-2-yl)ethyl)-3-formylbenzamide (40).

Aldehyde 40 was synthesized by reaction of 3-formylbenzoic acid (212 mg, 1.41 mmol) with 2-(1H-benzo[d]imidazol-2-yl)ethan-1-amine (250 mg, 1.55 mmol) using general procedure C, where the ethyl acetate extract was subjected to evaporation and the crude residue was washed further with ethyl acetate to obtain 40 as a brown solid (209 mg, 51% yield); 1H NMR (400 MHz, DMSO-d6) δ 12.31 (bs, 1H), 10.08 (s, 1H), 8.95 (t, J = 5.6 Hz, 1H), 8.39 (t, J = 1.8 Hz, 1H), 8.16 (dt, J = 7.8, 1.5 Hz, 1H), 8.07 (dt, J = 7.7, 1.3 Hz, 1H), 7.71 (t, J = 7.7 Hz, 1H), 7.61 – 7.36 (m, 2H), 7.13 (dd, J = 6.2, 3.0 Hz, 2H), 3.75 (q, J = 6.8 Hz, 2H), 3.12 (t, J = 7.3 Hz, 2H).

N-(2-(5-Fluoro-1H-benzo[d]imidazol-2-yl)ethyl)-3-formylbenzamide (41).

Intermediate 41 was synthesized by reaction of 3-formylbenzoic acid (190 mg, 1.27 mmol) with 2-(5-fluoro-1H-benzo[d]imidazol-2-yl)ethan-1-amine (249 mg, 1.39 mmol) using general procedure C, where the ethyl acetate extract was evaporated and the crude residue was further purified by preparative TLC with DCM and 7N ammonia in methanol solution as the solvent system to obtain 41 as a brown solid (229 mg, 58% yield); 1H NMR (400 MHz, CDCl3; TMS) δ 9.91 (s, 1H), 8.62 (t, J = 5.7 Hz, 1H), 8.30 (s, 1H), 8.08 (d, J = 7.6 Hz, 1H), 7.92 (d, J = 7.7 Hz, 1H), 7.50 (t, J = 7.7 Hz, 1H), 7.45 – 7.34 (m, 1H), 7.14 (ddd, J = 8.9, 4.1, 2.2 Hz, 1H), 6.95 – 6.80 (m, 1H), 4.03 – 3.92 (m, 2H), 3.28 (t, J = 6.4 Hz, 2H).

Tert-butyl (2-(4-carbamoyl-1H-benzo[d]imidazol-2-yl)ethyl)carbamate (42).

To a solution of 500 mg of 2,3-diaminobenzamide (3.30 mmol) in DMF, benzyl 3-oxopropylcarbamate (754 mg, 3.64 mmol) and ammonium acetate (382 mg, 4.96 mmol) were added, followed by heating the mixture at 60°C for a period of 6 h. The resulting mixture was then dissolved in ethyl acetate and extracted 3X with saturated NaHCO3 and 3X with brine solution. The resultant organic layer is dehydrated using MgSO4 and concentrated under vacuum to obtain 42 as an orange colored oil (457 mg, 45% yield), which was used as obtained in the next step. 1H NMR (400 MHz, DMSO-d6; TMS) δ 12.79 (s, 1H), 9.30 (s, 1H), 7.85 – 7.60 (m, 3H), 7.50 (s, 1H), 7.38 – 7.22 (m, 6H), 5.02 (s, 2H), 3.56 – 3.45 (m, 2H), 3.07 (t, J = 7.1 Hz, 2H).

Methyl 2-(2-(((benzyloxy)carbonyl)amino)ethyl)-1H-benzo[d]imidazole-7-carboxylate (42a).

Intermediate 42a was prepared according to a reported procedure62 by dissolving methyl 2,3-diaminobenzoate (500 mg, 3.01 mmol) in DMF, followed by adding HCTU (2490 mg, 6.02 mmol) and DIPEA (0.79 mL, 4.52 mmol) to the mixture. The reaction was then allowed to stir for 4 h at room temperature. Subsequently, the mixture was subjected to reflux conditions for a period of 6 h. Reaction was then subjected to evaporation under vacuum and purified using a preparative TLC using 3% of 2.33 M NH3 containing methanol in DCM to obtain 42a as a brown solid (212 mg, 20% yield). 1H NMR (400 MHz, DMSO-d6) δ 12.29 (s, 1H), 7.84 (d, J = 7.8 Hz, 1H), 7.77 (d, J = 7.5 Hz, 1H), 7.47 – 7.41 (m, 1H), 7.38 – 7.29 (m, 5H), 7.26 (t, J = 7.8 Hz, 1H), 5.02 (s, 2H), 3.94 (s, 3H), 3.50 (q, J = 6.7 Hz, 2H), 3.08 (t, J = 7.1 Hz, 2H).

Methyl 2-(2-aminoethyl)-1H-benzo[d]imidazole-7-carboxylate (43a).

Intermediate 43a was prepared from 42a (200 mg, 0.57 mmol) by following similar protocol used for preparation of 43 as a white solid (56 mg, 45% yield). 1H NMR (400 MHz, DMSO-d6) δ 7.94 – 7.75 (m, 4H), 7.30 (t, J = 7.8 Hz, 1H), 3.95 (s, 3H), 3.42 – 3.33 (m, 2H), 3.24 (t, J = 6.7 Hz, 2H).

2-(2-Aminoethyl)-1H-benzo[d]imidazole-4-carboxamide (43).

Intermediate 42 (300 mg, 0.99 mmol) was dissolved in methanol and catalytic amounts of palladium over carbon was added to the solution followed by transferring the mixture into a Parr-hydrogenation apparatus. The apparatus was purged (3X) with nitrogen and then evacuated followed by introduction of hydrogen into the vessel to attain a pressure of 60 psi. The reaction was monitored for the consumption of hydrogen and approximately after 5 h, the reaction was stopped, filtered on celite bed to remove palladium. This was followed by subjecting the reaction mixture to column chromatography using DCM and 2.33M ammonia in methanol mixture to obtain amide 43 as a white solid (120 mg, 60% yield). 1H NMR (400 MHz, DMSO-d6; TMS) δ 9.35 (s, 1H), 8.06 – 7.95 (m, 4H), 7.84 (d, J = 7.3 Hz, 1H), 7.68 (s, 1H), 7.28 (t, J = 7.9 Hz, 1H), 3.19 – 3.10 (m, 2H), 2.98 (t, J = 5.7 Hz, 2H).

1,3-Dihydro-2H-benzo[d]imidazol-2-one (44).