Abstract

Although there have been enormous reports on the microplastic pollution from different plastic products, impacts, controlling mechanisms in recent years, the surgical face masks, made up of polymeric materials, as a source of microplastic pollution potential in the ecosystem are not fully understood and considered yet. Current studies are mostly stated out that microplastics pollution should be a big deal because of their enormous effect on the aquatic biota, and the entire environment. Due to the complicated conditions of the aquatic bodies, microplastics could have multiple effects, and reports so far are still lacking. In addition to real microplastic pollutions which has been known before, face mask as a potential microplastic source could be also researching out, including the management system, in detail. It is noted that face masks are easily ingested by higher organisms, such as fishes, and microorganisms in the aquatic life which will affect the food chain and finally chronic health problems to humans. As a result, microplastic from the face mask should be a focus worldwide.

Keywords: Covid-19, Medical face mask, Plastic production, Microplastics pollution, Disposable plastics

Graphical abstract

Highlights

-

•

The surgical face mask has been using for the control of Covid-19 pandemics transmissions.

-

•

The surgical face masks production rates are rising due to fast transmissions of the positive cases.

-

•

However, the face mask as solid waste macroplastic, and ends up with the microplastic pollutions makes raise environmental threats.

-

•

The face masks waste management systems attract attention.

-

•

Microplastic research from the face mask and awareness creation should be a focus worldwide successful to eradicate the problem.

1. Backgrounds and knowledge gaps

The use of plastic polymers has huge societal benefits, but the microplastic (MP) fragments depends on the plastic age comes with problems for health, and environmental impacts. This issue is due to the improper handling of plastic waste as part of the solid wastes. The mismanagements, also with the high production capacity of plastic products, on the plastic solid waste, raise a prosperity study validates that MP has universally permeated to the aquatic ecosystem nowadays. Because of the huge plastic solid wastes released in the littering as well as aquatic bodies, MP ingestion by aquatic biotas has been increased. Surly, plastics waste in the aquatic system originates from solid waste, also could be from the municipal effluents, and the runoffs across the littering in the cities (Wagner et al., 2014).

Even if the research on MP pollution originated from plastic wastes has been conducted, and limited awareness created by many scholars, there are immense gaps of knowledge regarding medical face masks that are manufactured from plastic polymers and could be a potential source of MP pollution. As like that of the conventional plastic products (bottles, caps, etc.…) as a relevant source for MPs, and have environmental, the surgical face masks should be investigated as a big source of MPs. Therefore, MPs from the face masks are for aquatic system contaminants of emerging concern, and researches should be conducted to assess the environmental risk, comprehensive data on their abundance, fate, sources, and biological effects are needed, and awareness creation is also very important.

2. History of COVID-19 and face masks

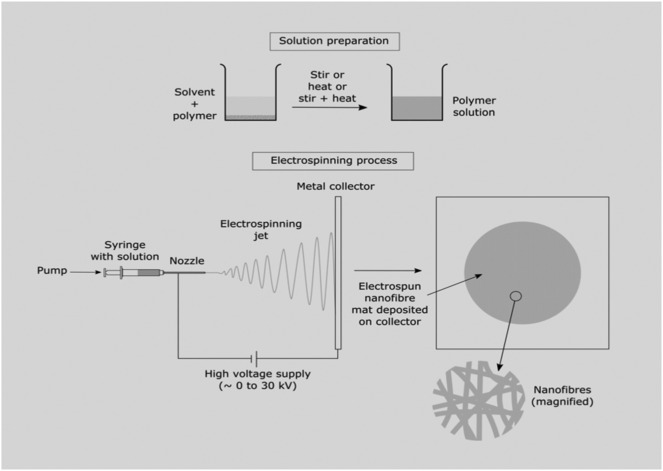

Many residents in the industrialized world, such as china, Beijing, have been using disposable face masks in an attempt to protect their health from high particulate matter (PM) concentrations so far. Mostly, face masks for selling may or may not be certified to the nation or WHO standards, but their shelf life performance may not deliberate (Wcherrie et al., 2018). Even if the developed countries have been using extensively face masks since the emergence of COVID-19 all over the world including developing countries are using in mass. World Health Organization (WHO) detected Covid-19 in China in December 2019 and its declaration as a pandemic and various measures have been put in place in different all over the world to control the virus further spread (Xu and Li, 2020). The idea of lockdown (staying at home), travel restriction and isolation is the most successful preventive measure. But, the governments afraid that the world economy will pull down and the crisis will occur. Thus, the peoples as well the governments of different countries are forced to release the lockdown and uses other options. The mass wearing of disposable face masks together with implementing social distancing, good hand hygiene (washing of hands), and avoiding public or crowded spaces (Tran et al., 2020). Although the disposable face masks were primarily made for the protection of health-care professionals, who are skills how to use and dispose of, to prevent occupational hazards, untrained professionals also use of face masks during the outbreak of SARS in 2003 and COVID-19 in 2019 (Elachola et al., 2020; Yang et al., 2011). The use of these face masks by unprofessional, lead to a severe problem in the environment as a solid waste problem and as microplastic pollution in the marine as well as freshwater ecosystems. In the case of the COVID-19 pandemic, researchers and scientists have promoted the use of face masks in mass until the mode of transmission of Covid-19 is fully understood which already adopted from the influenza pandemic scenario (Schuchat et al., 2011). It has too been contended that it can offer assistance in decreasing the number of times an individual touch the face/mouth/nose with unwashed hands, which can significantly diminish the chance of contamination. The presentation of face masks (H. Liang Wu et al., 2020) as one of the prudent measures to moderate down the transmission rate of Covid-19 from individual to individual has come about in a worldwide deficiency for the foremost respected gather, which are the health care experts (Wu et al., 2020). As per the estimate of WHO, nearly 89 million procedural masks were needed to control COVID 19 each month (WHO, 2020). This has brought about a phenomenal rise within the worldwide productions of medical masks produced from Polymeric Nanofibers. At this time, not only the medical masks but also non-medical masks have been producing, for those who can't able to buy, from different materials including cotton, silks, etc.… which are uncertified by WHO. Major players in face mask production have in this manner scaled up their capacities. The production capacities expected to increase as a COVID-19 infection case will increase globally (Phan and Ching, 2020). For example, China produces 200 million face masks a day as of June 2020 which is more than twenty times the amount it made at the start of February 2020. Besides, because many countries are decreasing lockdown restriction, it could lead to a drastic increase in infection correspondingly will increase the face mask production capacities. Surgical face masks (use and dispose of) can be manufactured from different polymeric materials. Such as polypropylene, polyurethane, polyacrylonitrile, polystyrene, polycarbonate, polyethylene, or polyester depending on the order of the customers. Those polymeric materials, exactly, have been using as a raw material for different plastic product productions. Disposable masks consist of three layers; an inner layer which is a fibrous material, middle layer (melt gusted filter part), and an outer layer (nonwoven, which are water-resistant and colored). The main filtering layer of the mask is produced by the conventional fabrication fibers, which can be nanofiber and/or microfiber depending on the target particulate matter size with an electrospinning technology (Dutton, 2009). The polymer melt materials are electrically charged then after the melted polymer subjected to the electrical field where the polymeric material is removed and ‘cropped’ from the source in fine structures which form nanofibers (Leung and Sun, 2020). Fig. 1 shows the Schematics of the electrospinning process for face mask production (SalehHudin et al., 2018). There may exist some variations in the formation of the products from one brand to the others shown in Table 1 . But, in general, the medical face mask is manufactured from nanofiber plastic materials. Different nations have been upgrading general production capacity due to the increase in the utilization of surgical face masks.

Fig. 1.

Schematic diagram of electrospinning processing steps for the fabrication of nanofibre (SalehHudin et al., 2018).

Table 1.

Ten different kinds/brands of the surgical mask with respective characteristics (THE ONLINE MEDICAL DEVICE EXHIBITION, 2020).

| Brands | Basic characteristics | |

|---|---|---|

| 1 | Non-woven surgical mask FM-04 |

|

| 2 | Non-woven surgical mask/type II/disposable/3-ply |

|

| 3 | Disposable surgical mask/3-ply/non-woven/non-sterile |

|

| 4 | Type II surgical mask/polypropylene/disposable/non-woven |

|

| 5 | Type IIR surgical mask SMSK001l |

|

| 6 | Type II surgical mask |

|

| 7 | Non-woven surgical mask/disposable/3-ply HHAO MEDI |

|

| 8 | 3-ply surgical mask/non-woven/2-ply TK-9249 |

|

| 9 | Type II surgical mask/disposable/non-woven MP211 |

|

| 10 | Type I surgical mask |

|

3. Observation and fates of surgical face mask

The COVID-19 has created another sort of flare-up: a worldwide resurgence in single-use plastic and a downpour of for the most part unrecyclable personal protective equipment littering city lanes, clogging sewage channels, indeed turning up profound underneath the waves. The environmentalist and other campaigners have long worried within the rise of a current environmental challenge, by adding to the bulk plastics as solid waste and correspondingly microplastics particularly within the aquatic environment. These face masks within the littering surface are washed into water bodies through surface flooding and canals adding to the nearness of a macroplastics then after a microplastics within the oceanic medium. Particularly in Africa, this can be the rainy season, from May to October, makes the freshwater and marine environment stacked with microplastics. For instance, the present author observes faces masks of different kinds, colors, and textures in the Lake Tana, from Bahir Dar city littering (Fig. 2 A) as well as in channel in the town. Also, in the globe, organization advocacy and research on marine pollution reported in February 2020, loads of face masks in an ocean in Hong Kong. Also, a French environmental NGO that assesses and taken out different surgical masks amid a later plunge to the Mediterranean seabed around the resort town of Antibes as shown in Fig. 2B reported on June 22, 2020. The massive use of face masks by the emergency of COVID-19 gives evidence on the environmental disorder both in the terrestrial and aquatic environment and that the global pandemic has not reduced the challenge of increasing plastic pollution in the environment. The massive use of face masks by the emergency of COVID-19 gives evidence on the environmental disorder both in the terrestrial and aquatic environment and that the global pandemic has not reduced the challenge of increasing plastic pollution in the environment.

Fig. 2.

Collection of various Covid-19 face masks of different types and colors (A) from Bahir Dar city littering and coasts of Lake Tana (photo credits by the present author) (B) from Mediterranean ocean-bed Photo credit: Mediterranean ocean-bed (NEWS18, BUZZ).

Use and through polymeric (polystyrene, polypropylene etc.…) materials have been identified so far as a significant source of macroplastics and microplastic particulate pollution in the environment (Schnurr et al., 2018). For instance, different packaging plastic materials, a bottling plastic materials (especially bottled water), and containers from the food processing industries are principal sources for microplastics pollution as a form of fibers and/or particulate matter in the ocean, freshwater and marine environment globally (Rios Mendoza and Balcer, 2019). These polymeric materials will get into the water bodies in different ways, such as leaching, flooding, and by the wind. Similarly, disposable face masks, which made up of polymeric materials, have been getting into the environment first as disposal in landfill and dumpsites or littering at public spaces then after into the freshwater, oceans as a new emerging source of microplastic fibers. These face masks are degrading/fragmenting into pieces of particles with various environmental conditions (temperature, humidity, saline etc.…), commonly less than 5 mm (Schmidt et al., 2018).

4. Experimental validation by chemical structure and thermal analysis

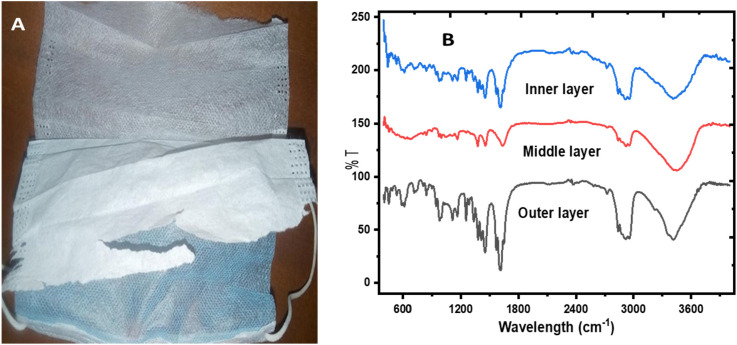

4.1. FTIR spectral analysis

The chemical structural illustrations the three parts in the face mask fabric based on their stretching vibration with the corresponding photos were examined by using Fourier transformation infrared (FTIR) spectroscopy as shown in Fig. 3(a) and (b). The FTIR spectral determination was found as the critical supporting information of the face masks chemical functional groups as plastic polymer materials. The experiment was done using a JASCO-6600 spectrometer with a scanning range of 400–4000 cm−1. Separately the three layers in the surgical faces mask were sized reduced, and ground using mortar-pestle mechanical pressing with potassium bromide (KBr) powder. The peak at 611 cm−1 for the outer and inner layer, not the middle, attributes the phenyl vibration absorption (Zhang et al., 2013). But the bands at 886 cm−1 for only the inner and outer parts of the face mask is the stretching of carbonyl functional groups (Nam et al., 2016). The peaks around 1100 cm−1 are assignments for the glucose rings stretching in the fiber for the three parts of the face mask. The peaks at 1253 cm−1 for the outer and inner layer attributes for the C—O stretches. The outer (non-woven) the inner (pure polystyrene) and the middle layers exhibit two characteristic peaks around 1454 and 1380 cm−1 are ascribed to the symmetry deformation of methyl (–CH2–) groups (Zhang et al., 2013). The small spectral peaks at 1369, 1338, 1319 cm−1 on the outer, and inner layers are the assignments of the methyl deformation and others. A similarly FTIR spectral characteristics on PS/non-woven, pure polystyrene, and non-woven fabrics reported by (Diao et al., 2017). The peaks around 1619 and 1545 cm − 1 attributed to the C O stretching of the primary amide and C—N stretching, and N—H bends to the secondary amide in the polypropylene for the inner and outer layer of the surgical face mask, respectively. However, no spectra peaks of the N—H bending to the secondary amide for the middle layer due to the structures from the fabrics have been removed by the melting process (Chen and Sun, 2005). A similar report on polypropylene infrared spectral analysis was found by (Liu et al., 2019). The broad and clear peaks for the three layers around 3414 and 2945 cm−1atributes the celluloses O—H stretching, asymmetric and/or symmetric aliphatic C—H stretching, respectively. The functional groups stretching vibration in the spectra provide a piece of information that face masks have been produced from polymeric materials, particularly from polypropylene tells that it a huge source of microparticles pollution in the aquatic ecosystem.

Fig. 3.

Disassembled photo (photo credit by the present author) of the three-layer face mask (A) and the corresponding FTIR spectra (B)

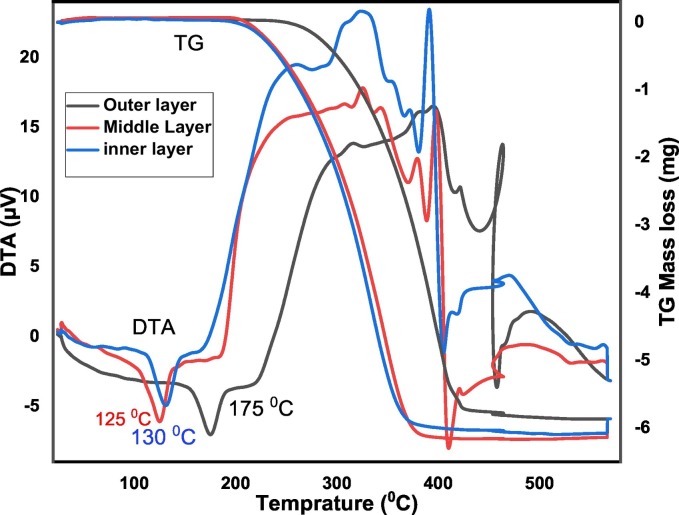

4.2. Thermogravimetric analysis

The thermogravimetric/differential thermal analysis (TGA/DTA) was used. Separately, the three (inner, middle, and outer) layers were heated from 25 to 600 °C with a heating rate of 15 °C/min in the atmosphere control at a sampling cycle. A 6.3 mg mass was used for the three layers. The empty crucible used as a reference. The complete thermal analysis was 38 min. The endothermic phase transition heat flows and peak temperatures of low-density polymeric plastics are different. The phase transition flow value of polyethylene, polypropylene, polyethylene terephthalate, polyester, polyamide, polyvinyl chloride, and polyurethane are around 100 °C, 160 °C, 250 °C, 216 °C, 260 °C, 270 °C, and 290 °C, respectively (Majewsky et al., 2016). The mass loss and an endothermic event appear as endothermic (negative) peak are shown in the TGA/DTA thermograms. The present author hypothesizes that the different negative thermal peaks of the three layers would have appeared. As shown in Fig. 4 the inner, middle, and outer layers of the face mask have 130, 125, and 175 °C endothermic peak temperatures, respectively. This tells us that the surgical face masks are fabricated using polypropylene (PP) plastic polymers which coincide with the studies on microplastic determinations of different polymers (Majewsky et al., 2016). The other endothermic and exothermic peaks after from 300 to 450 °C temperatures could be the deformational or melt agglomerate transition phase. Besides, the ash content remains after thermogravimetric analysis were measured to calculate the organic matters decomposed. I found that 94% of the decomposed organics (remain ash = 6%) up to 600 °C temperature. That is the mass loss was recorded as 5.9 mg out of the initial 6.3 mg masses.

Fig. 4.

Thermogravimetric/differential thermal analysis of the three layers surgical face mask.

5. Implications on the socio-economy and environment

The severe impacts of plastic as a solid waste and microplastics contamination in the environment have been investigated, validated, and demonstrated by different researchers in various publications (Wu et al., 2019; Galloway et al., 2017; Rist et al., 2018). Microplastics contain toxic chemicals as an additive like phthalate, organotin, nonylphenol, polybrominated biphenyl ether, and triclosan. Those toxic chemicals can be released during the degradation processes (either chemically or biologically) of plastic polymers in the open environment. Generally, the consequences are both the fauna and flora of the environments. Some of the treats include aquatic lives, such as fishes which a major food web to human existence. Fishes tend to swallow microplastics intentionally on non-intentionally which can reach into foods meant for human consumption, raising a concern on global food safety final will be a consequence in the food scarcity (Fadare et al., 2020). In the tourism industry, lounges coastal areas are very important for countries' currency. But, once the shore environments have been polluted with plastics and plastic particles, which reduces aesthetic and recreational value thus, impacts to human social and mental stability. The other important aspect of environmental deterioration and degradation up to climate change. The occurrence of plastics and plastic particles in the environment will contribute a drought then after global warming due to carbon emission and disaster risk management will become difficult (Reid et al., 2019; Shen et al., 2020).

Beyond the socio-economy and environmental impacts of face masks as a source of microplastic pollution, the face mask can act as a medium for COVID-19 out breaking. Because the nature of plastic particles tends to proliferate microbes thus, it will disseminate in the food chain and/or direct attacks.

The big deal is also arising nowadays as microplastics as a niche for microbial and developing biofilms. The microbial constituents may significantly different as compared with the natural freely living microorganism communities in the surrounding aquatic environment (Yang et al., 2020). This can affect microbial habitual and the environmental processes in aquatic ecosystems. Microplastic abundance in the globe increases dramatically makes the ecological function consequences for the overall ecosystem and animal health, including humans are under question.

6. Regulations so far on plastic pollutions

Various governance strategies and regulations have been enacted over the years to reduce the sources of plastic pollution in aquatic environments. The first global legislation is the International Convention for the Prevention of Pollution from Ships (MARPOL 73/78) signed in 1973 by 134 countries. But, legislation by itself is not enough and has not effectively reduced the plastic pollution in the aquatic ecosystem. This may be, due to the conflict of economic interests across the countries. Also, recently the G7 and EU communities have taken a committed action to sustainable plastic waste management practice by increasing its reusability, and recycling strategies. The UN Environment Programme has established strategies and guidelines to increase the global awareness of plastic pollution and recycling and global plastic waste management. But, the initiatives are not more conceptualized and are under scrutiny. Thus, they should be accompanied by project and research incentives to increase understanding of the microplastic persistence in the open water system and develop controlling and/or remediation plans (Carole Excell, 2019).

Particularly, the State Economic and Trade Commission (SETC) proclaimed on the production and use of disposable foam plastic tableware (SETC, 2001). The General Office of the State Council (GOSC) restricted the production, sale, and use of plastic shopping bags; banned too small plastic bags (b0.025 mm), and implemented charges for the use of other plastic bags in the market places beginning (GOSC, 2007). Also, the GOSC broadcasted a new regulation on waste import on the different Import of 24 types of waste that has been banned from daily use (GOSC, 2017).

Besides the environmentalist, some countries government have been worried and putting in place strict measures to control the persistent proliferation of plastics as solid waste right now. For instance, the National Oceanic and Atmospheric Administration (NOAA) under their project on the Marine Waste actions act approved the European Commission. This project is expected to promote awareness towards plastic particle pollution through the public education program (Li et al., 2020). Different countries have made national plastic bags regulations. But, some of the countries have not made plastic bag regulations. Even some are withdrawn from their plastic bag regulations after a certain time. World resource reported on March 11, 2019, that 127 Countries have adopted some form of legislation to regulate plastic gag ban as of July 2018 reviewed by the UN environment. The legislation may absolute ban, partial ban to progressively phase-outs, and incentivizes the use of reusable bags. 15 countries in Africa, South Africa were firstly introduced in 2003, have been declared that the plastic bags should either banned them completely or charge a tax on them. Asian countries including Bangladesh, Cambodia, Hong Kong, India, Indonesia, Malaysia, and Taiwan have a regulation on the ban on all thin plastic bags and began requiring retailers to charge a tax on thicker bags starting from 2008, but does not explicitly restrict their production. Australia hasn't a regulation of ban on the plastic bag, but some states, such as South Australia, and Tasmania have begun to put bans legislation. Almost all European countries have a regulation on the plastic bag bans, and actively fighting against it. Denmark was the first European country which has been begun charging a tax on plastic bags in 1994. Also, Ireland has been begun the charging of customers for plastic bags in 2002. Recently, England, Germany, Italy, Scotland, and wales have put in place their banning regulation. Some of the North American countries, such as the US have not yet put bans in plastic bags, but Mexico and Canada have banned. South American countries, such as Argentina, Brazil, Chile, and Colombia have not absolute bans but, have measures mechanisms to reduce plastic bag use as only biodegradable bags are allowed recycling programs. Eighty-nine countries we reviewed opted for partial bans or restrictions on plastic bags instead of full bans. For example, France, India, Italy, Madagascar, and several other countries, but they do ban or tax plastic bags that are fewer than 50 μm in thickness (Carole Excell, 2019).

Irregular uses of plastic bags in the black market system make the efficacy of bans and taxes hard to pin down, especially, the African, and Asia countries. For example, the plastic bag use in South Africa dropped 90% after the ban regulation.

Even though face masks are one of the plastic solid waste material after use, placing ban regulations on it remains the least option right now. The reason may be considering its positive than the negative impacts in the ongoing global controlling mechanisms against the Covid-19 spreading. Furthermore, strengthening critical thinking in research to provide eco-friendly alternatives for sustainable and effective face mask waste management systems to combat plastic pollution is not timely. This means that mobilization and awareness of Covid-19 prevention, control, and eradication are intensive than plastic pollution across the globe. The present author afraid that the microplastic pollution, being adding face masks together, maybe the next worldwide pandemic. Thus, I suggest that it will indeed be creditable if the awareness on safeguarding our environment through reduction and proper management of our disposable face masks can as well be carried outside by side as like that of COVID-19 prevention mobilization.

7. Conclusion

Microplastics attract recent attention due to it is the emerging contaminants. The occurrence, abundance, and quantity microplastics originated from different personal care produced, but not the face masks, were reported worldwide. However, there are no studies, and knowledge about face masks are plastic polymers which end up as microplastic and/or nanofiber contaminants in water systems. This study evaluates the surgical face mask is a potential source for microplastic contaminants in the littering as well as the water systems. Illustrations on the electrospinning manufacturing processes and the raw materials used for the productions of surgical face mask together with different brand codes were given The three layers of the face mask were experimented and validated by chemical structure, endothermic phase transition analysis as it is manufactured from plastic polymers, especially from polypropylene. Thus, the analytical instrumental techniques are important possible approaches for the identifications of microplastic in microplastic pollutions research. The three layers in surgical face mask are disassembled and have confirmed that they account a slight chemical and thermal characteristics though all are plastic polymers. This short communication on the face mask can significantly progress our understanding of the environmental problem and more for the establishment/enforcement of legislation and regulations in the future.

Credit author statements

Tadele Assefa Aragaw: Conceptualization, Methodology, Data analysis, writing the original draft preparation, Visualization, Investigation, Final reviewing and editing.

Declaration of competing interest

The author declares that they have no known competing for financial interests or personal relationships that could influence the work reported in this paper.

Acknowledgments

I would like to thank those organizations, and individuals whom I have used previously published materials. The author apologizes to all people, and organizations whose contribution to the field of microplastic pollution may have been reviewed by the fault or not adequately acknowledge.

References

- Carole Excell No title [WWW document] World Resour. Inst. 2019 https://www.wri.org/blog/2019/03/127-countries-now-regulate-plastic-bags-why-arent-we-seeing-less-pollution URL. retrieved on July 2020. [Google Scholar]

- Chen Z., Sun Y. Antimicrobial polymers containing melamine derivatives. II. Biocidal polymers derived from 2-vinyl-4,6-diamino-1,3,5-triazine. J. Polym. Sci. Part A Polym. Chem. 2005;43:4089–4098. doi: 10.1002/pola.20906. [DOI] [Google Scholar]

- Diao Z., Wang L., Yu P., Feng H., Zhao L., Zhou W., Fu H. Super-stable non-woven fabric-based membrane as a high-efficiency oil/water separator in full pH range. RSC Adv. 2017;7:19764–19770. doi: 10.1039/C7RA01603D. [DOI] [Google Scholar]

- Dutton K.C. Overview and analysis of the meltblown process and parameters. J. Text. Apparel Technol. Manag. 2009;6:2008. [Google Scholar]

- Elachola H., Ebrahim S.H., Gozzer E. COVID-19: facemask use prevalence in international airports in Asia, Europe and the Americas, March 2020. Travel Med. Infect. Dis. 2020;35 doi: 10.1016/j.tmaid.2020.101637. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Fadare O.O., Wan B., Guo L.H., Zhao L. Microplastics from consumer plastic food containers: are we consuming it? Chemosphere. 2020;253 doi: 10.1016/j.chemosphere.2020.126787. [DOI] [PubMed] [Google Scholar]

- Galloway T.S., Cole M., Lewis C. Interactions of microplastic debris throughout the marine ecosystem. Nat. Ecol. Evol. 2017;1:1–8. doi: 10.1038/s41559-017-0116. [DOI] [PubMed] [Google Scholar]

- GOSC . General Office of the State Council; 2007. Notice of the General Office of State Council on Restricting the Production, Sale and Use of Plastic Shopping Bags.www.shanghai.gov.cn [Google Scholar]

- GOSC . General Office of the State Council; 2017. Notice of the general office of the state council on issuing the implementa- tion plan for prohibiting the entry of foreign garbage and advancing the reform of the solid waste import administration system.http://www.isri.org/docs/default-source/int'l-trade/170727chinaannouncement-en.pdf [Google Scholar]

- Leung W.W.F., Sun Q. Charged PVDF multilayer nanofiber filter in filtering simulated airborne novel coronavirus (COVID-19) using ambient nano-aerosols. Sep. Purif. Technol. 2020;250:116886. doi: 10.1016/j.seppur.2020.116887. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Li C., Busquets R., Campos L.C. Assessment of microplastics in freshwater systems: a review. Sci. Total Environ. 2020;707 doi: 10.1016/j.scitotenv.2019.135578. [DOI] [PubMed] [Google Scholar]

- Liu C., Dai Z., Zhou R., Ke Q., Huang C. Fabrication of polypropylene-g-(diallylamino triazine) bifunctional nonwovens with antibacterial and air filtration activities by reactive extrusion and melt-blown technology. J. Chem. 2019;2019 doi: 10.1155/2019/3435095. [DOI] [Google Scholar]

- Majewsky M., Bitter H., Eiche E., Horn H. Determination of microplastic polyethylene (PE) and polypropylene (PP) in environmental samples using thermal analysis (TGA-DSC) Sci. Total Environ. 2016;568:507–511. doi: 10.1016/j.scitotenv.2016.06.017. [DOI] [PubMed] [Google Scholar]

- Nam S., Slopek R., Wolf D., Warnock M., Condon B.D., Sawhney P., Gbur E., Reynolds M., Allen C. Comparison of biodegradation of low-weight hydroentangled raw cotton nonwoven fabric and that of commonly used disposable nonwoven fabrics in aerobic Captina silt loam soil. Text. Res. J. 2016;86:155–166. doi: 10.1177/0040517514551468. [DOI] [Google Scholar]

- Phan T.L., Ching C.T.S. A reusable mask for coronavirus disease 2019 (COVID-19) Arch. Med. Res. 2020;51:455–457. doi: 10.1016/j.arcmed.2020.04.001. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Reid A.J., Carlson A.K., Creed I.F., Eliason E.J., Gell P.A., Johnson P.T.J., Kidd K.A., MacCormack T.J., Olden J.D., Ormerod S.J., Smol J.P., Taylor W.W., Tockner K., Vermaire J.C., Dudgeon D., Cooke S.J. Emerging threats and persistent conservation challenges for freshwater biodiversity. Biol. Rev. 2019;94:849–873. doi: 10.1111/brv.12480. [DOI] [PubMed] [Google Scholar]

- Rios Mendoza L.M., Balcer M. Microplastics in freshwater environments: a review of quantification assessment. TrAC Trends Anal. Chem. 2019;113:402–408. doi: 10.1016/j.trac.2018.10.020. [DOI] [Google Scholar]

- Rist S., Carney Almroth B., Hartmann N.B., Karlsson T.M. A critical perspective on early communications concerning human health aspects of microplastics. Sci. Total Environ. 2018;626:720–726. doi: 10.1016/j.scitotenv.2018.01.092. [DOI] [PubMed] [Google Scholar]

- SalehHudin H.S., Mohamad E.N., Mahadi W.N.L., Muhammad Afifi A. Multiple-jet electrospinning methods for nanofiber processing: a review. Mater. Manuf. Process. 2018;33:479–498. doi: 10.1080/10426914.2017.1388523. [DOI] [Google Scholar]

- Schmidt N., Thibault D., Galgani F., Paluselli A., Sempéré R. Occurrence of microplastics in surface waters of the Gulf of Lion (NW Mediterranean Sea) Prog. Oceanogr. 2018;163:214–220. doi: 10.1016/j.pocean.2017.11.010. [DOI] [Google Scholar]

- Schnurr R.E.J., Alboiu V., Chaudhary M., Corbett R.A., Quanz M.E., Sankar K., Srain H.S., Thavarajah V., Xanthos D., Walker T.R. Reducing marine pollution from single-use plastics (SUPs): a review. Mar. Pollut. Bull. 2018;137:157–171. doi: 10.1016/j.marpolbul.2018.10.001. [DOI] [PubMed] [Google Scholar]

- Schuchat A., Bell B.P., Redd S.C. The science behind preparing and responding to pandemic influenza: the lessons and limits of science. Clin. Infect. Dis. 2011;52:S8–S12. doi: 10.1093/cid/ciq007. [DOI] [PubMed] [Google Scholar]

- SETC . State Economic and Trade Commission; 2001. On an emergency notice to immediately stop production of disposable foam plastic tableware.http://www.gov.cn/gongbao/content/2001/content_60799.htm [Google Scholar]

- Shen M., Ye S., Zeng G., Zhang Y., Xing L., Tang W., Wen X., Liu S. Can microplastics pose a threat to ocean carbon sequestration? Mar. Pollut. Bull. 2020;150:110712. doi: 10.1016/j.marpolbul.2019.110712. [DOI] [PubMed] [Google Scholar]

- THE ONLINE MEDICAL DEVICE EXHIBITION Surgical masks [WWW document]. ONLINE Med. DEVICE Exhib. 2020. https://www.medicalexpo.com/medical-manufacturer/surgical-mask-45498.html URL.

- Tran T.T., Pham L.T., Ngo Q.X. Forecasting epidemic spread of SARS-CoV-2 using ARIMA model (case study: Iran) Glob. J. Environ. Sci. Manag. 2020;6:1–10. doi: 10.22034/GJESM.2019.06.SI.01. [DOI] [Google Scholar]

- Wagner M., Scherer C., Alvarez-Muñoz D., Brennholt N., Bourrain X., Buchinger S., Fries E., Grosbois C., Klasmeier J., Marti T., Rodriguez-Mozaz S., Urbatzka R., Vethaak A.D., Winther-Nielsen M., Reifferscheid G. Microplastics in freshwater ecosystems: what we know and what we need to know. Environ. Sci. Eur. 2014;26:1–9. doi: 10.1186/s12302-014-0012-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Wcherrie J., Apsley A., Cowie H., Steinle S., Mueller W., Lin C., Horwell C.J., Sleeuwenhoek A., Loh M. Effectiveness of face masks used to protect Beijing residents against particulate air pollution. Occup. Environ. Med. 2018;75:446–452. doi: 10.1136/oemed-2017-104765. [DOI] [PMC free article] [PubMed] [Google Scholar]

- WHO . Who; 2020. Shortage of Personal Protective Equipment Endangering Health Workers Worldwide. [Google Scholar]

- Wu P., Huang J., Zheng Y., Yang Y., Zhang Y., He F., Gao B. Environmental occurrences, fate, and impacts of microplastics. Ecotoxicol. Environ. Saf. 2019;184 doi: 10.1016/j.ecoenv.2019.109612. [DOI] [PubMed] [Google Scholar]

- Wu H. Liang, Huang J., Zhang C.J.P., He Z., Ming W.K. Facemask shortage and the novel coronavirus disease (COVID-19) outbreak: reflections on public health measures. Clin. Med. 2020 doi: 10.1016/j.eclinm.2020.100329. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Xu S., Li Y. Beware of the second wave of COVID-19. Lancet. 2020;395:1321–1322. doi: 10.1016/S0140-6736(20)30845-X. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Yang P., Seale H., Raina MacIntyre C.R., Zhang H., Zhang Z., Zhang Y., Wang X., Li X., Pang X., Wang Q. Mask-wearing and respiratory infection in healthcare workers in Beijing, China. Braz. J. Infect. Dis. 2011;15:102–108. doi: 10.1590/S1413-86702011000200002. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Yang Y., Liu W., Zhang Z., Grossart H.P., Gadd G.M. Microplastics provide new microbial niches in aquatic environments. Appl. Microbiol. Biotechnol. 2020 doi: 10.1007/s00253-020-10704-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zhang W., Shi Z., Zhang F., Liu X., Jin J., Jiang L. Superhydrophobic and superoleophilic PVDF membranes for effective separation of water-in-oil emulsions with high flux. Adv. Mater. 2013;25:2071–2076. doi: 10.1002/adma.201204520. [DOI] [PubMed] [Google Scholar]