Graphical abstract

Keywords: Hexavalent chromium, Water pollution, Chemical reduction, Metal nanoparticles, Nanocatalysis

Abstract

Hexavalent Chromium [Cr(VI)] is a highly carcinogenic and toxic material. It is one of the major environmental contaminants in aquatic system. Its removal from aqueous medium is a subject of current research. Various technologies like adsorption, membrane filtration, solvent extraction, coagulation, biological treatment, ion exchange and chemical reduction for removal of Cr(VI) from waste water have been developed. But chemical reduction of Cr(VI) to Cr(III) has attracted a lot of interest in the past few years because, the reduction product [Cr(III)] is one of the essential nutrients for organisms. Various nanoparticles based systems have been designed for conversion of Cr(VI) into Cr(III) which have not been critically reviewed in literature. This review present recent research progress of classification, designing and characterization of various inorganic nanoparticles reported as catalysts/reductants for rapid conversion of Cr(VI) into Cr(III) in aqueous medium. Kinetics and mechanism of nanoparticles enhanced/catalyzed reduction of Cr(VI) and factors affecting the reduction process have been discussed critically. Personal future insights have been also predicted for further development in this area.

1. Introduction

Hexavalent chromium [Cr(VI)] has hazardous effects on organisms and its removal from soil and water bodies has gained a considerable attention in last few decades (Zhou et al., 2016; Veerakumar et al., 2017). Cr(VI) is known as highly toxic, non-biodegradable and cancer causing material. It is found as an environmental contaminant in soil, surface and ground water. Cr(VI) is a cause of various diseases in human beings like dermatitis, lung and nasopharynx cancer on inhaling (Costa and Klein, 2006; Katz and Salem, 1993). It is enlisted as one of the priority water pollutants by United State Environmental Protection Agency (USEPA). It is being used extensively in various fields including wood preservation, electroplating, finishing of metals, textile industry, leather tanning industry and stainless steel production because of its specific characteristics. That is why, Cr(VI) is present in industrial wastewater as pollutant. It is urgent to develop various methodologies for elimination of Cr(VI) from water bodies. Various methodologies such as adsorption (Ali and Gupta, 2006; Maponya et al., 2020), membrane filtration (Kaya et al., 2016), solvent extraction (Venkateswaran and Palanivelu, 2004), electrochemical precipitation (Sun et al., 2015), coagulation (Golbaz et al., 2014), bioremediation (Beller et al., 2013; Benazir et al., 2010), ion exchange (Xiao et al., 2016) and catalytic reduction (Saikia et al., 2017) in addition to some traditional strategies (Barrera-Díaz et al., 2012; Malaviya and Singh, 2011) based on reduction followed by precipitation have been employed for removal of Cr(VI) from aqueous medium. Although adsorption technology is an in-expensive and green methodology and does not involve formation of any side products. Multistep preparation of adsorbent and incomplete removal of Cr(VI) from aqueous medium are few main limitations of adsorption technology. In ion-exchange method of water purification, Cr(VI) ions present in water are exchanged with ions of another metal electrostatically held on exchanger. The incomplete removal of Cr(VI) ions is one of the main limitations of ion exchange methodology. Ultrafiltration is also used to remove Cr(VI) from aqueous medium but membrane fouling, high operational cost and re-contamination of water during backwashing are few drawbacks of ultrafiltration methodology. Bioremediation of Cr(VI) is an in-expensive and green methodology for removal of pollutants from water but Cr(VI) is not easily degradable by microbes. Moreover bioremediation is a time taking process. Chemical method like chemical reduction of Cr(VI) to Cr(III) is one of the economical approaches used for complete elimination of Cr(VI) from aqueous medium. Reduction of Cr(VI) is thermodynamically feasible but kinetically sluggish reaction. The rate of reduction of Cr(VI) can be increased by using some inorganic nanoparticles as reductants or catalysts. Reduction of Cr(VI) by inorganic nanoparticles is termed as enhanced reduction while reduction of Cr(VI) by some suitable reducing agent in the presence of inorganic nanoparticles (nano-catalysts) is known as catalytic reduction. The use of inorganic nanoparticles as reductants (Fazlzadeh et al., 2017; Lv et al., 2017; Qian et al., 2017; Su et al., 2016; Zhou et al., 2020) as well as catalysts (Lv et al., 2020; Shao et al., 2017; Zhang et al., 2018) for Cr(VI) reduction has become the subject of interest due to high efficiency, low cost, environment friendly approach, applicability on industrial scale and no harmful byproduct formation in comparison to organic matter where re-oxidation may occur (Wang et al., 2019). In this treatment, Cr(VI) is completely converted into Cr(III) which has low mobility as compared to Cr(VI) (Li et al., 2016a). Reduction product [Cr(III)] is one of the essential nutrients for organisms. Although inorganic nanoparticles based materials used for Cr(VI) reduction may have some toxic effects on aquatic life but the reduction of Cr(VI) has been usually carried out in the presence of monometallic and bimetallic nanoparticles of some noble metals like Pt, Pd and Ag which do not have any significant toxic effects on aqueous environment. However, monometallic and bimetallic nanoparticles of some non-noble metal like Ni and Co have some toxic effects on aqueous organisms but their concentration is usually kept low to avoid their toxic effects on aquatic life.

Various reviews on removal of Cr(VI) from aqueous medium are available in literature but present review is totally different from already published reviews (Barrera-Díaz et al., 2012; Cheung and Gu, 2007; Jobby et al., 2018; Miretzky and Cirelli, 2010; Maitlo et al., 2019; Wang et al., 2016). For example, Cheung and Gu (2007) presented an overview of mechanism of Cr(VI) detoxification by microorganisms and concluded that microorganisms may convert Cr(VI) to Cr(III). Therefore reduction of Cr(VI) by microorganism is not a part of present review. Two years ago, removal of Cr(VI) by biosorption and biotransformation has been reviewed by Jobby et al. (2018). Similarly Miretzky and Cirelli (2010) have reviewed removal of Cr(VI) and Cr(III) from aqueous solution by raw and modified lignocellulosic materials using adsorption methodology. To avoid repetition, removal of Cr(VI) by biosorbents or lignocellulosic based adsorbents has not been discussed in present review. Barrera-Díaz et al. (2012) have reviewed reduction of Cr(VI) by biological and electrochemical methods. Maitlo et al. (2019) have recently reviewed adsorptive potential of various types of nanomaterials for treatment of wastewater contaminated with Cr(VI) in term of their adsorption capacity, removal efficacy and partition coefficient. Photocatalytic reduction of Cr(VI) within the metal-organic framework has been reviewed by Wang et al. (2016). However detailed discussion on the reduction of Cr(VI) in the presence of nanoparticles (used as reductants or catalysts) was not a part of aforementioned reviews. That is why, we are going to review Cr(VI) reduction by inorganic nanoparticles (reductants or catalysts) without any discussion on electrochemical and biological reduction of Cr(VI). Versatile nanoparticles have been developed for reduction of Cr(VI) to Cr(III) but to the best of our knowledge, the progress of reduction of Cr(VI) in the presence of inorganic nanoparticles has not been reviewed in the academic literature.

In present work, we have reviewed reduction of Cr(VI) into Cr(III) using different inorganic nanomaterials as catalysts and reducing agents but main attention has been given to nano-catalyzed reduction of Cr(VI). Recent developments in methodologies adopted for synthesis, stabilization and characterization of nanoparticles reported for reduction of Cr(VI) has been presented.

The review is divided into various sections. Section 1 is an introduction of the topic. Classification of various nanomaterials documented for Cr(VI) reduction has been elaborated in section 2. Section 3 presents critical overview of synthesis and stabilization of nanoparticles used for Cr(VI) reduction. Summary of the characterization techniques is given in section 4. Chemistry of catalytic reduction of Cr(VI) by different reductants has been discussed in sections 5. Study of catalytic reduction using spectrophotometry has been described in section 6. Factors affecting catalytic reduction of Cr(VI) to Cr(III) have been discussed in section 7. Section 8 gives an overview of catalytic recycling. In the last section (section 9), personal perspective on future work is given as guidelines for new researchers.

2. Classification of inorganic nanoparticles reported for Cr(VI) reduction

A wide variety of inorganic nanoparticles has been utilized for reduction of Cr(VI). They have been classified here on the basis of their function, nature and morphology.

2.1. Classification of nanoparticles on the basis of their function

Inorganic nanoparticles may be classified into two different categories on the basis of their function/role in reduction of Cr(VI) to Cr(III). Some inorganic nanoparticles have ability to act as reducing agent to convert Cr(VI) to Cr(III). Zerovalent iron (Zhao et al., 2020), iron sulfide (Yu et al., 2020), iron oxide (Yi et al., 2020) and iron based bimetallic (Ruan et al., 2020) nanoparticles have been reported as reducing agents for reduction of Cr(VI) to Cr(III). Iron exists in low oxidation state in such kind of nanoparticles and is oxidized simultaneously during Cr(VI) reduction. Such kind of nanoparticles have poor stability over the time, particularly in aqueous or air medium. They are consumed in reduction process and cannot be recycled easily. Some inorganic nanoparticles do not directly involved in reduction process but speed up the reduction of Cr(VI) with some suitable reducing agent. Monometallic nanoparticles of Pd (Tripathi and Chung, 2020; Dorosti et al., 2020), Pt (Sivaranjan et al., 2020) and Ag (Chen et al., 2018a) and their bimetallic (Bao et al., 2020; Mahar et al., 2019) nanoparticles have been widely used as catalysts for reduction of Cr(VI) with some suitable reducing agent. Such kind of nanoparticles are relatively stable and can be easily recovered for their re-use in Cr(VI) reduction.

2.2. Classification on the basis of nature of nanoparticles

Inorganic nanoparticles reported for Cr(VI) reduction on the basis of their nature may be classified as metallic nanoparticles, non-metallic nanoparticles and iron sulfide nanoparticles. Metallic nanoparticles may be further classified as nanoparticles with reducing properties and nanoparticles with catalytic properties. Bimetallic nanoparticles is another class of metallic nanoparticles that may have two catalytic active components (Mahar et al., 2019) or one catalytic active component along with a reducing metal component (Shi et al., 2019). Detailed discussion on aforementioned nanoparticles is given below.

2.2.1. Metallic nanoparticles

Various monometallic and bimetallic nanoparticles have been used for Cr(VI) reduction to Cr(III). A brief overview of different metallic nanoparticles used for Cr(VI) reduction has been presented here.

Zerovalent iron (Fe0) nanoparticles have been proven to be eco-friendly candidates for reduction of Cr (VI) into Cr (III). Use of Fe nanoparticles in Cr(VI) reduction has been widely reported in literature due to high abundance, low cost, easy availability and high reducing ability of iron metal (Fazlzadeh et al., 2017; Lv et al., 2017; Qian et al., 2017; Su et al., 2016; Zhou et al., 2020; Chen et al., 2018b). Zerovalent iron is oxidized to Fe2+/Fe+3 in process of Cr(VI) reduction to Cr(III) and then Fe(III) is co-precipitated with Cr(III). Fe0 nanoparticles are superiors to bulk zerovalent iron due to their high reactive surface area as well as good injectability (Fu et al., 2013). But Fe nanoparticles are highly prone to aggregation which results in loss of their activity. Therefore, fabrication of Fe nanoparticles is necessarily followed by their stabilization to keep them active for their application in Cr(VI) removal from aqueous medium. Various stabilizing systems have been developed to stop aggregation of iron nanoparticles to be used in reduction of Cr(VI) into Cr(III) in aqueous medium. For example, Shao-Feng et al. (Shao-feng et al., 2005) have studied the removal of Cr(VI) from aqueous system using Fe0 nanoparticles. Starch was utilized as stabilizer to avoid aggregation of Fe0 nanoparticles to be utilized for reduction of Cr (VI) into Cr(III). Starch is a good stabilizer to stop aggregation of Fe nanoparticles but chances of oxidation of Fe nanoparticles cannot be totally eliminated. Similarly, Petala et al. (Petala et al., 2013) used Fe0 NPs stabilized on mesoporous silica material known as MCM-41 for reduction of Cr(VI). This MCM-41 system was proved to be suitable candidate for stabilization of active Fe nanoparticles because of its porous structures with narrow pore size distribution. Bentonite supported Fe0 nanoparticles have been used for Cr(VI) reduction to Cr(III) (Diao et al., 2016). Bentonite material does not only stabilize Fe nanoparticles but also enhances their reactivity towards Cr(VI) reduction. Role of bentonite in enhancement of reactivity of Fe nanoparticles towards Cr(VI) reduction is not clear and needs further investigation. Cr(VI) removal from waste water by chemical reduction method using zerovalent iron (ZVI) nanoparticles stabilized on multi-walled carbon nanotubes has been also reported (Lv et al., 2011). The nanocomposite made of ZVI nanoparticles and carbon nanotubes was found to be more active system in comparison to the un-supported ZVI nanoparticles and ZVI nanoparticles supported on activated carbon for Cr(VI) reduction. Fe nanoparticles can be supported and stabilized on multi-walled carbon nanotubes to obtain nanocomposite with excellent ability of reduction of Cr(VI) to Cr(III) but further work is needed to be carried out for understanding of mechanistic pathway of removal of Cr(VI) by the nanocomposite. Fe0 nanoparticles supported on Fe3O4 have been also used for elimination of Cr(VI) from aqueous solutions by reduction method (Wu et al., 2009). In Fe3O4-supported Fe0 system, Fe nanoparticles are attached on the surface of Fe3O4 particle and cannot aggregate with each other. Graphene is widely used supporting system of Fe0 nanoparticles because of its high surface to volume ratio, low manufacturing cost and good mechanical strength in comparison to many of other supporting systems. Graphene nanosheets supported Fe0 nanoparticles have been also utilized for the efficient elimination of Cr(VI) from water using chemical methodology (Li et al., 2016a). The immobilization of ZVI nanoparticles onto graphene nanosheets enhances their stability and ability of electron transfer. The reduction of Cr(VI) into Cr(III) by zerovalent iron nanoparticles is an in-expensive method but stabilization of iron nanoparticles in zerovalent state is a difficult job. Therefore a lot of efforts have been made to stabilize Fe0 nanoparticles for Cr(VI) reduction using various stabilizing systems and readers are referred to literature for further studies (Fazlzadeh et al., 2017; Lv et al., 2017; Qian et al., 2017; Su et al., 2016; Zhou et al., 2020; Chen et al., 2018b; Fu et al., 2013; Shao-feng et al., 2005; Petala et al., 2013; Diao et al., 2016; Lv et al., 2011; Wu et al., 2009).

Pd is a noble metal and nanoparticles of Pd can be stabilized more easily in comparison to Fe nanoparticles using suitable stabilizing systems. Moreover Pd at nanoscale has an excellent potential to catalyze a large variety of chemical reactions including reduction of Cr(VI) (Nasrollahzadeh et al., 2020). Use of Pd nanoparticles have been extensively studied for reduction of Cr(VI) into Cr(III) but role of Pd nanoparticles is different from that of Fe nanoparticles. Fe nanoparticles are highly reactive and act as reductant in reduction of Cr(VI) and are oxidized from zero oxidation state to higher oxidation states (Fe+2 and Fe+3) as described in section 2.1. However reduction of Cr(VI) in the presence of noble metal nanoparticles like Pd, an additional reducing agent is needed while noble metal nanoparticles act as catalyst to speed up the reduction of Cr(VI). Catalytic reduction of Cr(VI) using Pd nanoparticles stabilized by different supporting systems has been widely documented in literature (Veerakumar and Lin, 2020). For example, Omole et al. (2007) have reported palladium nanoparticles in N,N-dimethylformamide for catalytic reduction of Cr (VI) using formic acid as hydrogen source. The use of unsupported palladium nanoparticles as catalyst in Cr(VI) reduction is not an economical method of elimination of Cr(VI) because they are not only unstable, their recovery from reaction mixture for re-use is also difficult. To stop their aggregation, palladium nanoparticles were stabilized in polyamic acid to obtain recoverable and reusable catalytic system with excellent catalytic activity. Polyamic acid itself has some toxic effects. It is important to replace toxic stabilizers with some environmentally benign supporting materials. Recently activated carbon supported palladium nanoparticles have been stabilized by ingredients derived from garlic skin for reduction of hexavalent chromium with formic acid (Veerakumar et al., 2017). The detailed discussion on synthesis of Pd nanoparticles will be given in section 3. High catalytic efficiency of the system may be attributed to the immobilization of palladium nanoparticles on porous surface of activated carbon.

Pd nanoparticles can be incorporated in mesoporous metal oxides and then can be used as catalysts but poisoning of the catalyst surface and difficulty in recovery and reusability of the catalyst are problems associated to use of such kind of catalytic systems. To overcome above mentioned problems, catalyst can be used as a thin film made of porous metal oxide loaded with Pd nanoparticles. For example, Dandapat et al. (2011) has reported glass substrate immobilized mesoporous-Al2O3 thin film loaded with Pd nanoparticles as an efficient and recyclable catalyst for reduction of Cr (VI) to Cr (III). Porosity of the metal oxide facilitates the diffusion of reactants to the Pd surface and its benign nature makes this system environment friendly. Catalyst can be obtained using small amount of precursor salt. Moreover, immobilization of catalyst film on glass substrate makes this system easily recoverable and reusable. Oxides of metalloids may also be used as mesoporous support of Pd nanoparticles. The immobilizing ability and stability of Pd nanoparticles on the surface of metalloid oxide can be enhanced by amine-functionalization of oxide surface. For example, Celebi et al. (2016) has reported highly stable Pd NPs supported on amine-functionalized silica (SiO2) for reduction of Cr(VI). The approach used for immobilization and stabilization of Pd nanoparticles on amine-grafted silica was simple but not environmentally benign. Stabilization of Pd nanoparticles using hydrophilic polymeric material as support is more facile and economical approach. Hydrophilic polymeric system does not only stabilize Pd nanoparticles but also enhances their dispersity in water to easily carryout reaction in aqueous medium. Stabilization of Pd nanoparticles within electro spun polyethyleneimine (PEI) and polyvinyl alcohol (PVA) nanofibers crosslinked with glutaraldehyde for reduction of Cr(VI) into Cr(III) in aqueous medium has been reported by Huang et al. (2012). Facile approach, easy handling, small nanoparticles fabrication with uniform size distribution, large inter-particle distance, good stability, excellent catalyst dispersibility in water, good recoverability, reusability and high efficiency with complete Cr(VI) conversion into Cr(III) are fascinating features of the designed catalytic system. Pd nanoparticles supported on various organic and inorganic stabilizing systems for reduction of Cr(VI) have been widely studied. It is not possible to discuss all reports in detail in this review. Therefore readers are referred to the literature for further study (Tripathi and Chung, 2020; Veerakumar and Lin, 2020; Sadik et al., 2014; Gao et al., 2018; Yang et al., 2014; Sadeghi et al., 2019).

Platinum nanoparticles have been also proved an efficient catalyst for Cr(VI) conversion to Cr(III). Pt nanoparticles can be easily stabilized using suitable stabilizing material. Pt NPs have excellent catalytic activity but their use as catalyst for reduction of Cr(VI) is not encouraged due to high cost of Pt metal. However few reports are available on use of Pt nanoparticles as catalyst in reduction of Cr(VI). For instance, Dandapat et al. (2017) have immobilized well dispersed Pt nanoparticles on Bismuth oxyhalide-alumina composite film using ethanol as reductant and used resulting material as catalyst to convert Cr(VI) into Cr(III). The presence of Bismuth oxyhalide (BiOX) increases rate of reduction of Cr(VI) but role of BiOX in enhancement of rate of reduction of Cr(VI) is not clear. Although catalytic system was found to be recoverable and re-usable but recovery of catalyst from reaction mixture after completion of the reaction was difficult. Pt based catalytic systems having additional magnetic material can be easily recovered by using external magnetic field. For example, Mai et al. (2017) have developed uniform bifunctional Fe3O4/mesoporous silica core/shell system for fabrication of Pt NPs by reduction of Pt precursor in the internal channels for reduction of Cr(VI). The catalytic system was found to be separable by using external magnet due to presence of Fe3O4 as core within the system.

Silver nanoparticles have gained attention as catalysts for various reduction reactions (Begum et al., 2019, 2017; Naseem et al., 2019; Begum et al., 2016) but their utility as nano-catalyst for Cr(VI) reduction is limited (Chen et al., 2018a; Liu et al., 2016a). Low stability of Ag nanoparticles as compared to other noble metal (Pt and Pd etc.) nanoparticles may be one of the possible reasons behind this limitation. Silver nanoparticles cannot catalyze dehydrogenation of formic acid to produce hydrogen for Cr(VI) reduction. This is another reason of avoiding application of Ag nano-catalyst in reduction of Cr(VI) with formic acid. Silver oxide layer formation around Ag nanoparticles and their high rate of aggregation because of their high surface energy, are other reasons of avoiding their use as catalyst in Cr(VI) reduction. Moreover, toxic reducing agents and expensive capping agents are needed for fabrication and stabilization of silver nanoparticles respectively for their use in catalysis. Therefore only two reports are available on catalytic application of silver nanoparticles towards reduction of Cr(VI) to Cr(III) in aqueous medium (Chen et al., 2018a; Liu et al., 2016a). Chen et al. (2018a) have reported magnetic carbonized polydopamine spheres decorated with silver nanoparticles by pyrolysis without using any reductant. The resulted catalytic system was used as a magnetically recyclable catalyst for catalytic reduction of Cr(VI) into Cr(III) using formic acid as hydrogen source. Mechanism of silver nanoparticles catalyzed Cr(VI) reduction is different from Cr(VI) reduction occurring in the presence of Pt and Pd nanoparticles and will be discussed in section 5. Recovery of silver ions from waste water or soil for synthesis of silver nanoparticles and their use as catalyst for removal of toxic materials from water may result in two-fold environmental application. For example, Liu et al., (2016) extracted Ag+ ions from aqueous medium by biomass and then converted Ag+ ions into silver nanoparticles by pyrolysis of biomass without using any external reductant and capping agent during nanoparticles fabrication. The resultant hybrid material (Ag@Biochar) was utilized as catalyst for Cr(VI) reduction to Cr(III).

Nickel nanoparticles are well known for their catalytic potential towards different reactions but to the best of our survey, only few reports are available on their use in reduction of Cr(VI) to Cr(III) with formic acid (Zhu et al., 2019; Bhowmik et al., 2014; Akram et al., 2019). Although Ni is non-noble metal like Fe but it cannot reduce Cr(VI) without additional source of hydrogen. For example, Akram et al. (2019) have reported thermally expanded reduced graphene oxide (TERGO) decorated with nickel carbide-nickel nanoparticles (Ni3C-NiNPs) to obtain (TER/Ni3C-NiNPs) nano-catalytic system with excellent catalytic potential towards Cr(VI) reduction to Cr(III) in aqueous medium. No additional reducing agent and capping agent was used for nanocomposite fabrication. Graphene extended structure itself acts as stabilizer to stop aggregation of nickel nanoparticles. Good catalytic activity was attributed to the unique combination of Ni3C-Ni NPs and TERGO. High conductivity, good adsorption ability, large surface area, porosity and specific electronic properties of reduced graphene extended structure also contribute in high catalytic activity of nickel nanoparticles. By inspiration of above mentioned supportive properties of reduced graphene oxide, Bhowmik et al. (2014) also fabricated highly stable nickel nanoparticles loaded in reduced graphene oxide and reported that RGO cannot only stabilize nickel nanoparticles without any additional capping agent but also makes the catalytic system easily recoverable. Nickel-reduced graphene oxide nanocomposite can effectively reduce Cr(VI) to Cr(III) in the presence of formic acid as reducing agent at room temperature

N-doped carbon material loaded with transition metal nanoparticles has gained attention as catalyst for various reduction reactions but its use in Cr(VI) reduction has been rarely reported. This material may be highly useful for reduction of Cr(VI) due to prevention of corrosion of metal, promotion of electron transfer because of modification of electronic structure of surface carbon layer upon N-doping and high catalytic activity of transition metal. Zhu et al. (2019) have reported 3D N-doped graphene carbon nanotube network loaded with nickel nanoparticles (Ni@N-CNTs/N-G) by using Nickel-metal organic frame work and melamine as precursors. The resulting hybrid material was utilized for rapid Cr(VI) reduction to Cr(III) with formic acid.

2.2.2. Bimetallic nanoparticles

Various monometallic nanoparticles reported for Cr(VI) reduction have been described in previous section (2.1.1). According to above discussion, noble metal nanoparticles have excellent catalytic activities towards reduction of Cr(VI) but expensive nature of their precursor salts limits their use as catalyst at large scale. Nanoparticles of non-noble metal like zerovalent iron are highly unstable. They may lose their activity as result of their aggregation or due to oxide layer formation around them during synthesis, storage or even during catalytic reaction (Petala et al., 2013; Diao et al., 2016). Fabrication of bimetallic nanoparticles for catalytic reduction of Cr(VI) gives solution of problems associated to catalysis by both noble and non-noble metal nanoparticles. Moreover catalytic activity of bimetallic nanoparticles has been found much higher than that of monometallic counterparts because of synergistic effect (Saikia et al., 2017). Variation in electronic interactions between re-hybridized metal orbital in a bimetallic nanoparticle also may be the cause of enhancement of catalytic activity (Vellaichamy and Periakaruppan, 2016). For example, mixing a small amount of another metal having catalytic potential such as Ni, Cu, Pt and Pd (more noble than Fe) to zerovalent iron to form bimetallic nanoparticles does not only give more stability to zerovalent iron but also increases the activity of the system. Zhou et al. (2016) have reported fabrication of Fe/Ni by chemical reduction of precursor salts of both metals with KBH4 in ethanol. Resulting bimetallic nanoparticle system was used for reduction of Cr(VI) to Cr(III) in the presence of ultra-sound. Rate of reduction of Cr(VI) in the presence of Fe/Ni bimetallic nanoparticles was found to be much higher than that in the presence of individual monometallic nanoparticles under similar reaction conditions. Jiang et al. (2018) used Fe-Cu bimetallic nanoparticles supported on chitosan for removal of Cr(VI) from wastewater using chemical reduction methodology. The reducing ability of the bimetallic composite system (chitosan-Fe/Cu) was found to be much higher than that of zerovalent iron nanoparticles of same size in case of Cr(VI) reduction. The enhanced catalytic potential of Cu-Pd alloy nanoparticles was also explored by Saikia et al. (2017) for reduction of nitroaromatics and hexavalent chromium. Hexavalent chromium has also been effectively reduced with formic acid using Au-Ag bimetallic nanoparticles catalyst stabilized by reduced graphene oxide (Vellaichamy and Periakaruppan, 2016). The uniformly distributed high contents of metal nanoparticles within RGO sheets has significant impact on catalytic activity of the system (Li et al., 2018). Catalytic activity of bimetallic system may be further improved by using N-doped reduced graphene oxide as support. Li et al. (2018) have reported reduction of Cr(VI) by using Pt-Pd bimetallic nanoparticles supported on N-doped RGO. High catalytic performance of Pt-Pd bimetallic nanoparticles was attributed to synergistic effect as well as specific structure of N-doped RGO. Hu et al. (2017) have presented environmentally benign fabrication of Pt-Au nanospheres stabilized by theophylline at RGO with enhanced catalytic efficiency towards Cr(VI) reduction. Recyclable Pt-Pd nanoparticles stabilized on procyanidin-grafted eggshell membrane have also been reported for the reduction of hexavalent chromium in literature (Liang et al., 2014). Pt-Pd nanoparticles were stabilized on polyphenol grafted eggshell membrane (ESM) for reduction of Cr(VI). ESM is an in-expensive and environmentally benign supporting system for stabilization of Pt-Pd bimetallic nanoparticles. Synthesis of bimetallic nanoparticles using ESM as support will be discussed in section 3.

2.2.3. Metal sulfide nanoparticles

Metal sulfides can also be used for reduction of Cr(VI). They are highly effective at their nanoscale levels. For example nanoscale iron sulfide (FeS) is highly useful for removal of Cr(VI) from water and soil. They do not only have good ability to extract Cr(VI) ions from soil/water by adsorption but are also good reductants. FeS nanoparticles stabilized by different supporting agents for reduction of Cr(VI) have attracted much attention of scientists due to formation of insoluble chromium precipitates during process of remediation which can be easily separated out (Wang et al., 2019; Lyu et al., 2017, 2018; Gong et al., 2016; Wu et al., 2017). So process of remediation involves three steps called adsorption, reduction and co-precipitation. Wang et al. (2019) have used chitosan supported FeS nanoparticles for in-situ removal of Cr(VI) from groundwater and saturated soil. The mechanism of removal of Cr(VI) from ground water by iron sulfide nanoparticles involves more than one steps including adsorption of Cr (VI) ions on the surface of FeS nanoparticles and reduction of adsorbed Cr(VI) ions followed by precipitation.

2.2.4. Non-metallic (metal free) nanoparticles

Metal free reduction of Cr(VI) to Cr(III) may be carried out but only two reports are available in literature on reduction of Cr (VI) catalyzed by non-metallic nanoparticles (Gong et al., 2015; Tripathi et al., 2018). For example Triphathi et al. (Tripathi et al., 2018) have reported fabrication of protein stabilized zerovalent sulfur nanoparticles with narrow size distribution and spherical shape using F. benghalensis leaf extract and applied them as catalyst for reduction of Cr(VI).

2.3. Classification on the basis of morphology of nanoparticles

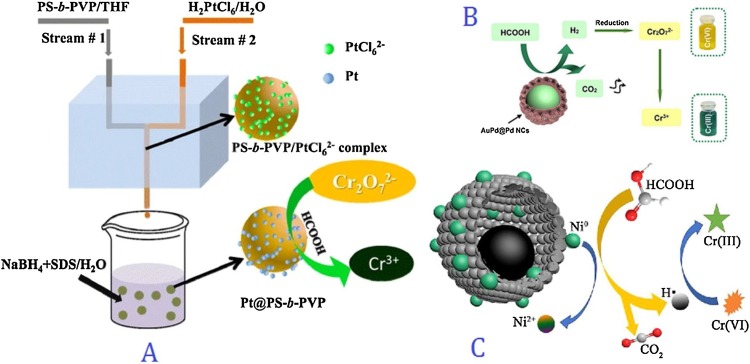

Inorganic nanoparticles used for reduction of Cr(VI) may be classified as homogeneous, core-shell, yolk-shell and nanoparticles attached on surface of microspheres on the basis of their morphology. Simple monometallic nanoparticles have same composition throughout the structure and are made of a large number of atoms of the same metal. These nanoparticles may be treated as homogeneous nanoparticles. Similarly, non-metallic nanoparticles like sulfur nanoparticles or iron sulfide nanoparticles have also same composition throughout the particle dimension and are also termed as homogeneous inorganic nanoparticles. However sometimes, monometallic nanoparticles are attached on the surface of another nanomaterial. Resulting system as whole may be treated as heterogeneous system. For example Chen et al. (2018a) stabilized silver nanoparticles on the surface of carbonized polydopamine nanospheres filled with Fe3O4 nanoparticles for reduction of Cr(VI). Fe3O4 nanospheres have been also decorated with zerovalent iron nanoparticles for chemical reduction of Cr(VI) but system is not recyclable due to consumption of zerovalent iron in reduction of Cr(VI) (Wu et al., 2009). Similarly Pd nanoparticles decorated lignin based phenolic microspheres have been recently reported for Cr(VI) reduction to Cr(III) (Chen et al., 2020). Low amount of precursor and negligible diffusional barrier are the main advantages of use of such kind of morphology of catalytic systems. polystyrene-b-poly(4-vinylpyridine) nanospheres decorated with Pt nanoparticles (Pt@PS-b-PVP) shown in Fig. 1 (A) have been applied for reduction of Cr(VI). Detail of method of Pt nanoparticles fabrication will be described in section 3. Pd nanoparticles attached on outer region of Fe3O4 nanocubes encapsulated in a thin layer of N-doped carbon shell of cubical shape have been also documented for reduction of Cr(VI) (Tian et al., 2020). Shell does not only protect Pd nanoparticles from oxidation and agglomeration but also facilitates the electron transfer for speedy reduction of Cr(VI). Shell region of N-doped carbon is porous and does not significantly affects diffusion of reactant molecules to the catalyst surface. Iron-iron sulfide core-shell nanoparticles with Fe0 core and FeS shell have been reported for reduction of Cr(VI). Cr(VI) ions are adsorbed on FeS shell surface to get reduce by Fe+2 and Fe+2 changes its oxidation state from +2 to +3 but F(III)-Cr(III) hydroxides are precipitated on the surface of core-shell nanoparticles to slow down the process of reduction of Cr(VI) to Cr(III) (Gong et al., 2017). Core-shell system with Fe0 core and SiO2 shell has been also used for reduction of Cr(VI) but in this system, zerovalent iron core acts as reductant and mesoporous SiO2 shell protects iron nanoparticles from aggregation and oxidation but allows diffusion of reactant molecules from bulk to Fe nanoparticles through its porous structure (Li et al., 2012). Similarly, bimetallic nanoparticles have atoms of two different metals in a nanoparticle. It is very difficult to get bimetallic nanoparticles with exactly uniform distribution of atoms of both metals throughout a nanoparticle. In case of nano alloys, atoms of both metals are present in the whole nanostructure but both metals have its own characteristics. Therefore, bimetallic nanoparticles cannot be treated as homogeneous nanoparticles. Bimetallic nanoparticles with different morphologies have been reported for reduction of Cr(VI). For example Au-Pd@Pd core shell catalytic system with Au-Pd alloy core and Pd shell have been fabricated by one-pot co-reduction methodology for highly efficient reduction of Cr(VI) in aqueous medium as shown in Fig. 1 (B) (Shao et al., 2017). Yolk-shell morphology is rare in nano-catalytic systems reported for reduction of Cr(VI) to Cr(III). Three-dimensional yolk-shell morphology of metal organic framework derived Ni-C system for reduction of Cr(VI) to Cr(III) has been recently reported by Lv et al. (2020) as shown in Fig. 1 (C).

Fig. 1.

Pt nanoparticles decorated on the surface of polystyrene-b-poly(4-vinylpyridine) nanospheres (Pt@PS-b-PVP) (A) adopted with permission from reference Zhang et al. (2018) (Copyright Springer 2018), Core-shell morphology of trimetallic nanoparticles with Au-Pd core and Pd shell (B) adopted with permission from reference (Shao et al., 2017) (Copyright Elsevier 2017), Nickel nanoparticles embedded carbon based yolk-shell system derived from Ni-MOF (C) adopted with permission from reference Lv et al. (2020) (Copyright Elsevier 2020) for Cr(VI) reduction to Cr(III).

3. Synthesis of nanoparticles for Cr (VI) reduction

Different inorganic nanoparticles including monometallic (Fe, Pt, and Pd, Ag and Ni), bimetallic (Fe-Ni, Pt-Pd, Pt-Au, Fe-Cu, Au-Ag etc.) and metal sulfide nanoparticles have been utilized for Cr(VI) reduction. Selection of method of fabrication of nanoparticles depends upon type of required nano-system. In general, two different methodologies (top down and bottom up approaches) are applied for the fabrication of all types of inorganic nanoparticles. The breaking of bulk material into nanoparticles by some mechanical means is known as top down approach while ions/atoms/molecules are combined together to form nanoparticles in bottom up approach (Petala et al., 2013; Hoeppener et al., 2002). Bottom up is superior because of easy control on shape, size and size uniformity of nanoparticles during their fabrication, low energy consumption and good dispersity and stability of nanoparticles in solvent. Most of the above mentioned nanoparticles have been fabricated using bottom approach. Naked inorganic nanoparticles are not stable because of their high surface energies. They may aggregate quickly to catalytically in-active bulk material. Therefore, synthesis of all type of inorganic NPs is carried out within the dispersion of some suitable stabilizer/support. Fabrication and stabilization of inorganic nanoparticles reported for Cr(VI) reduction has been described in the following sections in detail.

3.1. Synthesis of zerovalent iron nanoparticles

Fe° nanoparticles are usually fabricated by bottom up approach using some suitable stabilizing system. Starch, SiO2, multi-walled carbon nanotubes, bentonite and magnetite (Fe3O4) are generally used as supporting materials for fabrication and stabilization of zerovalent iron nanoparticles (Fu et al., 2013; Shao-feng et al., 2005; Wu et al., 2009; Diao et al., 2016; Lv et al., 2011; Wu et al., 2009). Bentonite is extensively utilized as support for immobilizing zerovalent iron nanoparticles because of its high abundance, good chemical stability and excellent adsorption capability. Fe° nanoparticles supported on bentonite have been reported by Shi and co-workers (Shi et al., 2011) who used liquid-phase reduction approach for synthesis of zerovalent iron nanoparticles. FeCl3.6H2O was dispersed in ethanol-water solvent system in the presence of required amount of bentonite. Sodium borohydride (NaBH4) solution was injected into reaction vessel to reduce Fe(III) ions to zerovalent iron (Fe°) nanoparticles. Similarly synthesis of zerovalent iron nanoparticles in the inner surface of MCM-41 has been also reported using same reduction methodology with slight modification (Petala et al., 2013). For this purpose, ferric chloride (FeCl3·6H2O) dissolved in ethanol was poured on the mesoporous material. The solvent was evaporated by heating the mixture at ∼80 °C and resulting solid material was grinded into powder and dispersed into absolute ethanol to carry out reduction of iron salt by addition of sodium borohydride to obtain zerovalent iron nanoparticles. Fabrication of iron nanoparticles by chemical reduction method has been also reported in aqueous medium. For example, Lv et al. (2011) loaded Fe nanoparticles in multi-walled carbon nanotubes using chemical reduction of precursor salt in aqueous medium. Ferrous sulfate (FeSO4.7H2O) and carbon nanotubes were dispersed in deionized water by ultrasound and then NaBH4 solution was injected into the mixture under N2 purging and stirring to convert Fe+2 into Fe° according to the following reaction.

| [Fe(H2O)6]+2 + 2BH4− →Fe0 + 2B(OH)3 + 7H2 |

Wu et al. (2009) used exactly same methodology of fabrication of zerovalent Fe nanoparticles in aqueous medium using Fe3O4 as stabilizer/support instead of carbon nanotube to get magnetically separable Fe nanoparticle based catalytic system.

In addition to chemical reduction of iron salt described above, microwave assisted synthesis (González‐Arellano et al., 2008), decomposition of iron carbonyls (Vollmer and Janiak, 2011), decomposition of {Fe(N[Si(CH3)3]2}2 in the presence of hydrogen (Dumestre et al., 2004), thermal decomposition of Fe-metal organic framework (Zhang et al., 2016), chemical reduction of iron oxides (Hisano and Saito, 1998), vapor phase condensation (Stefaniuk et al., 2016), mechanical treatment (Ambika et al., 2016), method based on micro-organisms (Ravikumar et al., 2018), Laser ablation method (Okazoe et al., 2018) and carbo-thermal method (Wang et al., 2018) have also been reported for fabrication of iron nanoparticles but Fe nanoparticles prepared by these methods have not been reported yet for reduction of Cr(VI). Therefore, discussion on these methods is out of the scope of present review. Detailed discussion on method of synthesis of iron nanoparticles can be found in already published reviews (Stefaniuk et al., 2016; Zhao et al., 2016).

3.2. Synthesis of palladium nanoparticles

Palladium nanoparticles used as catalyst for Cr(VI) conversion to Cr(III) are usually synthesized by chemical reduction of palladium precursor using bottom up technique. For example Omole et al. (2007) have reported fabrication of palladium nanoparticles by chemical reduction method in non-aqueous solvent [N, N-dimethylformamide (DMF)] using palladium acetate as precursor. Palladium acetate was reduced with sodium borohydride in DMF at ambient temperature. Concentrated H2SO4 was added into stirred reaction mixture to form palladium colloidal particles. The un-reacted sodium borohydride was removed by microfiltration of acidified palladium colloid using water and DMF. Polyamic acid was used to stabilize Pd nanoparticles to be used as catalyst for Cr(VI) reduction to Cr(III). Dandapat et al. (2011) prepared Pd nanoparticles on mesoporous ɤ-Al2O3 film as a reusable catalyst for reduction of Cr(VI) to Cr(III). Mesoporous ɤ-Al2O3 film coated on glass substrate was dipped in PdCl2 solution to load metal ions in it. Hydrogen-argon system (H2/Ar) was used to reduce palladium salt into palladium nanoparticles. Pd-ɤ-Al2O3 film was used as catalyst for reduction of K2Cr2O7 with formic acid. Same strategy of Pd nanoparticles fabrication has been reported by Celebi et al. (2016) who initially functionalized SiO2 with amine groups by adding 3-aminopropyltriethoxysilane [H2N(CH2)3Si(OC2H5)3] into ethanol containing SiO2 and then reduced palladium(II) nitrate dihydrate [Pd(NO3)2·2H2O] with sodium borohydride in aqueous medium to get Pd nanoparticles for reduction of Cr(VI). The donor-acceptor interactions between amino groups attached with SiO2 surface and Pd nanoparticles give long term stability to Pd nanoparticles. Huang et al. (2012) used in-situ reduction approach for loading of catalytically active Pd nanoparticles on electrospun poly polyethyleneimine/polyvinyl alcohol (PEI/PVA) nanofibers. In this work, aqueous dispersion of PVA and PEI was electrospun and then crosslinking was caused by glutaraldehyde vapors to enhance the water stability of the system. Crosslinked nanofibers were loaded with potassium tetrachloropallidate (K2PdCl4). [PdCl4]−2 ions were diffused into the polymer matrix due to electrostatic attraction between positively charged nitrogen of PEI and metal precursor anion. Then NaBH4 solution was used to reduce Pd+2 into zerovalent Pd nanoparticles. The pictorial diagram describing the whole story of Pd nanoparticles fabrication in PEI/PVA matrix is shown in Fig. 2 .

Fig. 2.

Immobilization of palladium nanoparticles in electrospun polyethyleneimine and polyvinyl alcohol (PEI/PVA) nanofibers crosslinked by glutaraldehyde using in-situ reduction of K2PdCl4 with NaBH4 in aqueous medium. Reproduced with permission from reference Huang et al. (2012). Copyright American Chemical Society 2012.

In all above schemes of Pd nanoparticles fabrication, NaBH4 have been used as reducing agent which itself is highly toxic. To avoid the use of NaBH4, chemical reduction may be replaced by thermal reduction but chemical reduction can be carried out at room temperature while thermal reduction needs high temperature. Veerakumar et al. (2017) have reported synthesis of Pd nanoparticles by thermal reduction and stabilized them by Garlic (Allium sativum L.) skin biomass. For this purpose, Garlic raw material was grinded, dried and then activated by mixing it with aqueous solution of zinc chloride in a Teflon-coated flask under microwave irradiation at 100°C. Resulting slurry was air dried at 100 °C and then it was graphitized in the presence of N2 at 600−900 °C. Resulting carbonaceous material was cooled and washed with HCl. After pyrolysis at 400°C in CO2 flow, the carbonaceous material (GAC) loaded with PdNO3 was subjected to thermal reduction at 900°C in the presence of N2 to obtain Pd@GAC.

3.3. Synthesis of platinum nanoparticles

Preparation of platinum nanoparticles (Pt NPs) using bottom up methodology for Cr(VI) conversion to Cr(III) has been reported in the presence of different supports (Dandapat et al., 2017; Mai et al., 2017). Dandapat et al. (2017) used bismuth oxyhalides (BiOX) to synthesize Pt nanoparticles within mesoporous Al2O3 in the form of a nanocomposite film. Ethanol was used as reducing agent to reduce metal ions into Pt nanoparticles in the presence of BiOX which acts as catalyst for oxidation of ethanol. In this way, metal ions can be successfully converted into metal nanoparticles without using any conventional reducing agent. Mai et al. (2017) fabricated Pt nanoparticles in bi-functionalized magnetic mesoporous silica using in-situ reduction method. The schematic illustration of fabrication of Pt nanoparticles in bi-functionalized Fe3O4/mesoporous silica core/shell nanoparticles is shown in Fig. 3 . For preparation of Fe3O4/mesoporous silica core/shell structures, aqueous dispersion of Fe3O4 having triethanolamine (TEA) was charged with Tetraethyl orthosilicate (TEOS). Outer modification was carried out to functionalize SiO2 shell surface with thiol groups (-SH). Then template was removed before inner modification for functionalization of inner surface with amine groups (-NH2). Resulting Fe3O4@SH-SiO2-NH2 material was loaded with chloroplatinic acid hexahydrate (H2PtCl6·6H2O). Negatively charged [PtCl6]2− ions were attracted by protonated amino groups (-NH3 +) present in inner surface and repelled by negatively charged thiol group present on outer surface. As a result, [PtCl6]2− ions are loaded on the inner side of channels. The inner surface with abundant –NH2 group can chelate with metal ions by replacing chloride ions. After loading metal ions, sodium borohydride was added to reduce platinum ions into Pt nanoparticles as shown in Fig. 3. Zhang et al. (2018) have documented fabrication of Pt nanoparticles on the surface of polystyrene-b-poly(4-vinylpyridine) (PS-b-PVP) nanospheres using the technique of flash nanoprecipitation. For this purpose, PS-b-PVP/THF dispersion was mixed in a compartment with H2PtCl6/H2O coming from different stream to load [PtCl6]2−into PS-b-PVP surface through chelation. [PtCl6]2- ions attached on PS-b-PVP surface were then reduced to Pt nanoparticles using NaBH4 as reductant in the presence of sodium dodecyl sulfate (SDS) as shown in Fig. 1 (A).

Fig. 3.

Synthesis of platinum nanoparticles by in-situ reduction of [PtCl6]2− with NaBH4 in bi-functional Fe3O4/mesoporous silica core/shell nanoparticles (FMSNs) modified by thiol groups (-SH) on their outer surfaces and amine groups in their inner surfaces. Reproduced with permission from reference Mai et al. (2017). Copyright Elsevier 2017.

3.4. Synthesis of silver nanoparticles

Ag nanoparticles reported for catalytic reduction of Cr(VI), are synthesized by chemical reduction of silver salt usually silver nitrate. Chen et al. (2018a) have synthesized Ag nanoparticles based catalytic system for reduction of Cr(VI) into Cr(III) using chemical reduction approach. For this purpose, dopamine was self-polymerized in the presence of iron salt (FeCl3.6H2O) to obtain Fe-PDA complex and then silver nitrate solution was added to load silver ions on the surface of polydopamine complex spheres. Polydopamine acts as reductant to convert silver ions into silver nanoparticles. Heat treatment of silver nanoparticles decorated Fe-PDA spheres results in magnetic nanoparticles loaded carbonaceous material as shown in Fig. 4 . The resulting hybrid material was used as magnetically separable catalytic system for Cr(VI) reduction to Cr(III) with formic acid. Chemical reduction approach for the fabrication of silver nanoparticles has been also reported by Liu et al. (2016a) who extracted silver ions from aqueous medium using fir sawdust (FSD) obtained from a local timber treatment plant as adsorbent. Biomass loaded with silver ions was subjected to pyrolysis in the presence of N2 without adding any additional reducing agent and capping agent. Bio-oil was separated from resulting mixture and Ag nanoparticles loaded biochar was cooled and stored as solid residue for its further use as catalyst for Cr(VI) reduction to Cr(III).

Fig. 4.

Synthesis of silver nanoparticles decorated magnetic carbonized spheres obtained from self-polymerization of dopamine in the presence of iron salt. Reproduced with permission from reference Chen et al. (2018a). Copyright Elsevier 2018.

3.5. Synthesis of nickel nanoparticles

Nickel nanoparticles were loaded on the surface of reduced graphene oxide by hydrothermal method using molecular hydrogen as reductant (Bhowmik et al., 2014). The schematic illustration of synthesis route is shown in Fig. 5 . In the first step, graphene oxide (GO) was prepared and then GO was dispersed in aqueous solution of precursor salt (NiCl2·6H2O) and hexamethylenetetramine by ultrasonic and then sealed in an autoclave for hydrothermal reaction for fabrication of Ni(OH)2−GO at 120°C. Ni(OH)2−GO composite was heated at 350 °C in the presence of H2 under inert atmosphere of N2 to get Ni NPs loaded on RGO sheets as shown in Fig. 5. Reduced graphene oxide does not only stabilize Ni nanoparticles but also enhances their catalytic activity towards reduction of Cr(VI). Fabrication and stabilization of Ni nanoparticles in the form of Ni3C-Ni on thermally expanded reduced graphene oxide (TERGO) has been also reported by Akram et al. (2019).

Fig. 5.

Synthesis of nickel nanoparticles (Ni NPs) embedded in reduced graphene oxide (RGO) by hydrothermal method. Reproduced with permission from reference Bhowmik et al. (2014). Copyright American Chemical Society 2014.

Transition metal nanoparticles loaded into nitrogen doped carbon (M-N-C system) has gained attention as efficient catalysts for various reduction reactions. Nickel nanoparticles M-N-C catalytic systems have been used for this purpose because of their unique structure and surface properties. For example Zhu et al. (2019) have synthesized Ni-N-C system for reduction of Cr(VI). Ni-MIL and melamine were dispersed in ethanol and then reaction mixture was subjected to centrifugation to separate out solid material. Resulting solid material was initially pyrolyzed at 600 °C in the presence of argon and then heated at 800 °C to get Ni-N-C catalyst for reduction of Cr(VI).

3.6. Synthesis of bimetallic nanoparticles

Bimetallic nanoparticles utilized for reduction of Cr(VI) have been usually synthesized by chemical reduction method almost similar to the method described for synthesis of monometallic nanoparticles in previous sections. Although a wide variety of methods of preparation of bimetallic nanoparticles have been reported in literature but our discussion is limited to synthesis of those bimetallic nanoparticles that have been used for reduction of Cr(VI) (Peng et al., 2008; Sankar et al., 2012; Liu et al., 2014). Different attempts have been made into order to synthesize bimetallic nanoparticles based catalytic systems for reduction of Cr(VI). To the best of our knowledge, chemical reduction is one of the mostly reported methodologies. For example, Saikia et al. (2017) have prepared copper-palladium (Cu-Pd) bimetallic nanoparticles by simultaneous reduction of CuCl2.2H2O and PdCl2 using hydrazine as reducing agent in slightly basic pH medium in the absence of any external capping agent but the reduction process was carried out in aqueous medium at 120°C in an autoclave which is generally known as hydrothermal method. It is very difficult to store CuPd bimetallic nanoparticles without any stabilizing agent. Moreover use of CuPd based catalytic system for reduction of Cr(VI) is not cost effective due to presence of palladium metal in bimetallic system. Fabrication of bimetallic nanoparticles using precursors of in-expensive metals for Cr(VI) reduction is the best strategy. Zhou et al. (2016) have prepared cost effective iron-nickel (Fe-Ni) bimetallic nanoparticles for the removal of Cr(VI) from aqueous medium. Aqueous solution of KBH4 was added to precursor salts of Ni and Fe (NiSO4.6H2O and FeCl3.6H2O) dissolved in ethanol to carry out reduction of both metal ions to form Fe-Ni bimetallic nanoparticles at room temperature under N2 atmosphere. It is almost impossible to stabilize Fe-Ni bimetallic particles for long time without strong capping agent because both metals especially on nanoscale are prone to oxidation/aggregation. Therefore freshly prepared Fe-Ni system has good activity for Cr(VI) reduction but cannot be stored for long time. Jiang et al. (2018) have prepared Fe-Cu bimetallic nanoparticles capped by chitosan with relatively better stability over the time for removal of Cr(VI) from waste water. Functionalities of chitosan like hydroxyl and amine groups bind with zerovalent metal nanoparticles to give them long term stability. FeSO4.7H2O and CuSO4.5H2O salts were simultaneously reduced with NaBH4 in the presence of chitosan to obtain bimetallic nanoparticles with homogeneous distribution of atoms of both metals while core-shell Fe-Cu bimetallic nanoparticles with Fe core and Cu shell were obtained by step-wise reduction process. For synthesis of Fe-Cu core-shell system, Fe nanoparticles were initially synthesized by reduction of FeSO4.7H2O with NaBH4 in the presence of chitosan and then Fe nanoparticles were used as seed particles for fabrication of copper shell around Fe nanoparticles by reduction of CuSO4.5H2O with same reducing agent in the same stabilizer. Size of core and thickness of shell can be controlled by controlling concentration of precursor salts. Colloidal stability of Fe-Cu bimetallic nanoparticles was found to be dependent on stabilizer contents. Aggregation of Fe-Cu nanoparticles can be controlled by chitosan but chances of oxidation cannot be totally avoided. Bimetallic nanoparticles made of two noble metals capped with suitable stabilizers can be easily stabilized for long term without oxidation. For example, Hu et al. (2017) have synthesized Au-Pt bimetallic nanoparticles by reducing H2PtCl2 and HAuCl4 salts on reduced graphene oxide with hydrazine hydrate in theophylline simultaneously. Au-Pt bimetallic nanoparticles were found to be stable over the time and proved to have high activity for reduction of Cr(VI). Fabrication of RGO supported bimetallic nanoparticles for reduction of Cr(VI) has been widely reported in literature using same methodology as described above with slight modifications and can be found in recent literature (Vellaichamy and Periakaruppan, 2016; Li et al., 2018; Yao et al., 2020; Lu et al., 2017).

3.7. Synthesis of iron sulfide nanoparticles

Synthesis of FeS nanoparticles to be used for reduction of Cr(VI) is different from synthetic methods reported for metal nanoparticles. FeS nanoparticles reported for reduction of Cr(VI) are prepared by displacement reaction instead of reduction reaction in a suitable solvent under inert atmospheric condition. FeS nanoparticles are also unstable like above mentioned inorganic nanoparticles. Therefore, they are fabricated in the presence of a stabilizing system. Synthesis of FeS nanoparticles in the presence of various stabilizing agents has been widely reported in recent literature but general synthetic scheme is almost similar and has been described here (Wang et al., 2019; Yu et al., 2020; Lyu et al., 2017; Wu et al., 2017; Li et al., 2017; Wang et al., 2011; Tan et al., 2020). For example, Li et al. (2017) have reported synthesis of FeS nanoparticles using carboxymethyl cellulose (CMC) as stabilizer in aqueous medium by displacement reaction between FeSO4.7H2O and Na2S in aqueous medium under N2 atmosphere. FeSO4.7H2O solution was added into CMC solution at pH ≥ pKa of CMC (5.3) to form Fe2+-CMC complex. Formation of Fe2+-CMC complex was the result of donor-acceptor interaction between Fe2+ ions and COO− groups of CMC. Then stoichiometric amount of Na2S solution was added into dispersion of Fe2+-CMC complex to form FeS nanoparticles as a result of electrostatic attraction between Fe2+ and S2-ions. FeS nanoparticles were found stable over the time and were used for enhanced reduction of Cr(VI) in aqueous medium.

3.8. Synthesis of Non-metallic nanoparticles

Synthesis of non-metallic nanoparticles is different from that of metallic nanoparticles. Our discussion is limited to synthesis of those non-metallic nanoparticles which have been reported for reduction of Cr(VI). Sulfur nanoparticles have been used as catalyst for reduction of Cr(VI) (Tripathi et al., 2018). Synthesis of sulfur nanoparticles is a subject of broad interest and has been reviewed in literature (Rai et al., 2016; Suleiman et al., 2013). Synthesis of sulfur nanoparticles used for Cr(VI) reduction has been discussed here. Tripathi et al. (2018) have reported biogenic synthesis of sulfur nanoparticles to be used as catalyst for reduction of Cr(VI). For this purpose, F. benghalensis leaf extract dispersion was added into sodium thiosulfate pentahydrate solution in deionized water. The precipitation reaction was initiated by addition of citric acid into the reaction mixture. Elemental sulfur nanoparticles were collected using the process of centrifugation and were found stable for catalytic reduction of Cr(VI). Various functionalities present in F. benghalensis leaf extract do not only act as capping agents but also are helpful in dispersing sulfur nanoparticles in aqueous medium.

4. Characterization techniques

Catalytic activity of inorganic nanoparticles towards reduction of Cr(VI) depends upon their nature, shape, size and size distribution and nature and morphology of the supporting material used. Therefore, a broad spectrum of techniques has been applied for the characterization of catalytic systems (inorganic nanoparticles along with stabilizers) used for the Cr(VI) reduction. The UV–vis spectrophotometry (UV–vis) (Tripathi et al., 2018; Kalwar et al., 2013), Fourier transform infrared spectroscopy (FTIR) (Lv et al., 2020; Tripathi et al., 2018; Kalwar et al., 2013), X-ray diffraction (XRD) (Shao et al., 2017; Chen et al., 2020), Transmission electron microscopy (TEM) (Lv et al., 2020; Zhang et al., 2018; Chen et al., 2020; Tian et al., 2020), Field emission scanning electron microscopy (FESEM) (Tian et al., 2020), dynamic light scattering (DLS) (Zhang et al., 2018), Thermogravimetric analysis (TGA) (Lv et al., 2020; Chen et al., 2018a; Tian et al., 2020), X-rays photoelectron spectroscopy (XPS) (Shao et al., 2017; Chen et al., 2018a, 2020; Tian et al., 2020; Wu et al., 2020), Atomic force microscopy (AFM) (Wu et al., 2020), Raman spectroscopy (RS) (Lv et al., 2020; Chen et al., 2018a; Wu et al., 2020), Brunauer Emmett-Teller (BET) (Lv et al., 2020; Chen et al., 2018a; Liu et al., 2016a), Magnetometeric analysis (MA) (Chen et al., 2018a) Elemental mapping (EM) (Chen et al., 2020) and scanning electron microscopy-energy dispersive spectrometry (SEM-EDS) (Shao et al., 2017; Wu et al., 2020) are frequently used for characterization as well as for investigation of catalysis process.

Theoretical details of characterization techniques used for analysis of inorganic nanoparticles is beyond the scope of this review. Only purpose of physical techniques used for characterization of inorganic nanoparticles without mathematical background has been described here. Catalysis is surface phenomenon and catalytic reduction of Cr(VI) needs surface to get reduce. Surface morphologies of the nanoparticles and their supports are investigated by SEM. Surface area of inorganic nanoparticles depends upon their surface to volume ratios. Shape, Size and size distribution of inorganic nanoparticles used for Cr(VI) reduction is measured by TEM. DLS is used for the same purpose in case of liquid dispersion of inorganic nanoparticles. UV–vis spectrophotometry has become a useful tool for characterization of noble metal nanoparticles and their use in catalysis. Size, size distribution and shape of Plasmonic nanoparticles may be predicted on the basis of UV–vis spectra of their dispersion. UV–vis spectrophotometry is widely used to monitor the progress of conversion of Cr(VI) to Cr(III). Catalytic reduction of Cr(VI) is affected by the ratio of content of catalyst to that of its support. Contents of true catalyst in composites are determined by AAS or ICP or EA. Metal nanoparticles used in catalytic reduction of Cr(VI) may change their oxidation state during reaction as a result of some reaction. The change in their oxidation state is confirmed by EDX and XPS. Information regarding oxidation state of catalyst and degree of crystallinity of inorganic nanoparticles is determined from XRD. The recoverability of catalyst by magnetic field is measured by magnetometry. Catalytic systems to be utilized for reduction of Cr(VI) should be stable in temperature window of the reaction and their stability as a function of temperature is judged by TGA. TGA is also useful for determination of content of inorganic material present in catalytic composite system. FTIR and Raman spectroscopies are used for investigation of interaction betweencatalyst and support of the catalyst. Porosity of the support and inorganic material plays a significant role in catalysis and is investigated by BET.

5. Chemistry of Cr(VI) reduction

Cr(VI) reduction to Cr(III) with various reducing agents has been reported in literature but our discussion is limited to only those reductants which have been used in inorganic particles induced/catalyzed reduction of Cr(VI). Mechanism of reduction depends upon nature of reducing agent and catalyst. Therefore chemistry of the reduction of Cr(VI) on the basis of reducing agent used has been divided into following sections.

5.1. Inorganic nanoparticles catalyzed Cr(VI) reduction

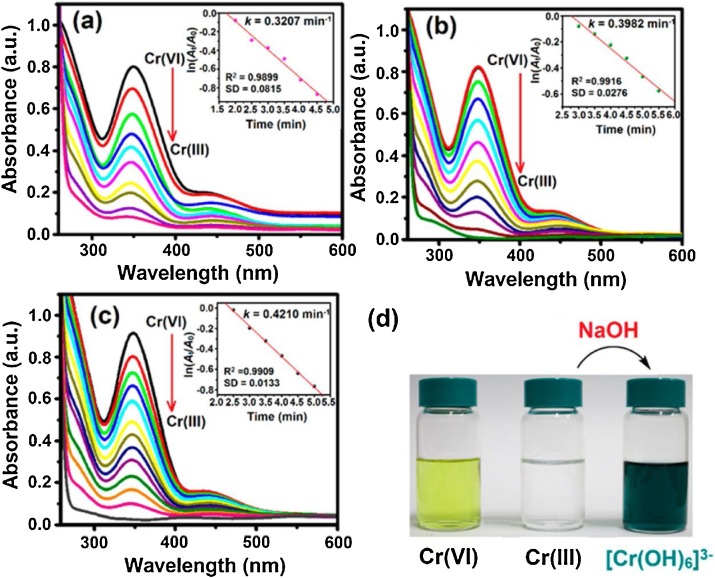

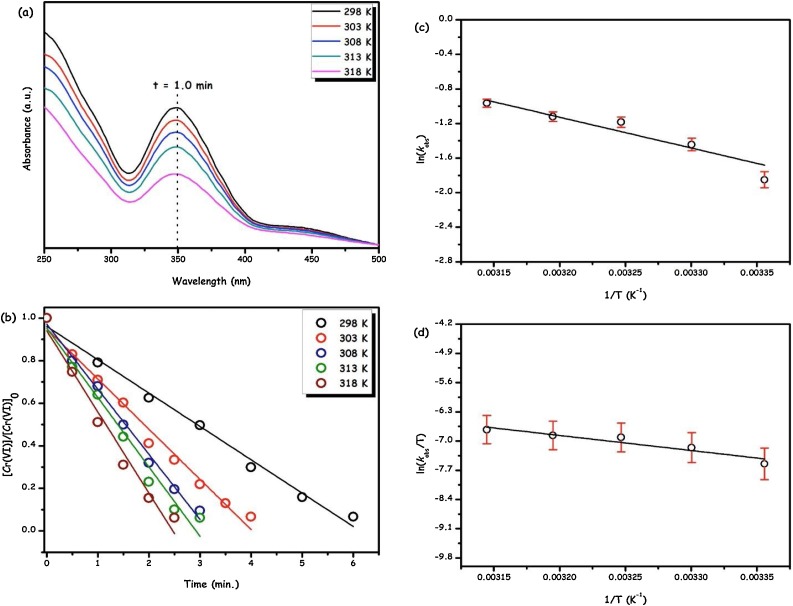

5.1.1. Cr(VI) reduction by formic acid/sodium formate

Cr(VI) reduction to Cr(III) catalyzed by inorganic nanoparticles is usually carried out using formic acid as reductant. Chemistry of catalytic reduction of Cr(VI) with formic acid depends upon nature of inorganic nanoparticles used as catalyst. There are two mechanistic possibilities of catalytic conversion of Cr(VI) on the surface of noble metal nanoparticles like Pt and Pd nanoparticles. In case of first possibility, formic acid molecules diffuse to Pd surface, get adsorbed and then get dehydrogenated into CO2 and H2. In-situ produced H2 adsorbed on active sites of Pd acts as reducing agent and converts already adsorbed Cr(VI) to Cr(III). Cr(III) desorbs from catalyst surface and diffuses out from surface region to the bulk region. The schematic illustration of the above description is given in Fig. 6 A.

Fig. 6.

Schematic illustration of two possible mechanisms of catalytic Cr(VI) reduction to Cr(III).

In the second mechanistic possibility, decarbonylation of formic acid occurs on the surface of Pd nanoparticles and CO and H2O are produced as products in the first step. In the second catalytic step, CO adsorbed on Pd surface may act as reductant to convert Cr(VI) to Cr(III) on the surface of Pd nanoparticles as shown in Fig. 6 B. Second mechanistic possibility was ruled out by Li et al. (2016b) on experimental basis using Pd nanoparticles encapsulated in metal organic frame work (Pd-ZIF-67). In controlled experiments, catalytic Cr(VI) reduction to Cr(III) with commercially available H2 under acidic conditions on the same catalytic system was found to be lower than that with in-situ produced H2 under similar reaction conditions which reflected that in-situ produced H2 is more reactive than commercially available H2. Reaction was found to be very slow in case of reduction of C(VI) with external CO in the presence of same catalyst under same reaction conditions which eliminated the possibility of second mechanism. Therefore first possibility has been accepted as true mechanism of catalytic reduction of Cr(VI) with formic acid in the presence of Pd and Pt and has been reported in various publications (Liang et al., 2014; Li et al., 2016b; Yadav and Xu, 2013). For example, exactly same mechanism of catalytic reduction of Cr(VI) with formic acid in the presence of Pt metal nanoparticles has been reported by Mai et al. (2017) and has shown in Fig. 7 . Formic acid is dehydrogenated into CO2 and H2 on Pt nanoparticle surface. H2 is used to reduce Cr2O7 −2 to Cr(III) [See color change in reaction mixture from yellow to colorless in inset of Fig. 7]. Formation of Cr(III) from Cr(III) was confirmed by addition of sodium hydroxide solution into solution of product which was changed from colorless to green due to conversion of Cr(III) to [Cr(H2O)6]+3 (See change in color in inset of Fig. 7). Omole et al. (2007) have reported same mechanism for Cr(VI) reduction with formic acid in the presence of palladium nanoparticles stabilized by polyamic acid. Reaction was not found to be occurred in the absence of any one of the catalyst and formic acid.

Fig. 7.

Schematic illustration of mechanism of catalytic Cr(VI) reduction to Cr(III) with formic acid (HCOOH) using supported Pt nanoparticles. Reproduced with permission from reference Mai et al. (2017). Copyright Elsevier 2017.

It is worth mentioning that mechanism of catalytic reduction of Cr(VI) with formic acid in the presence of silver nanoparticles is different from scheme described above. Dehydrogenation of formic acid cannot occur on the surface of silver nanoparticles. Therefore a different mechanism has been proposed for Cr(VI) reduction in the presence of silver nanoparticles (Chen et al., 2018a; Liu et al., 2016a). In catalytic reduction of Cr(VI), formic acid is initially decomposed into CO and H2O on the surface of silver nanoparticles. Activated silver-carbonyl complex is generated as a result of activation of CO by silver nanoparticles which attracts Cr(VI) towards silver surface to form silver-carbonyl-Cr(VI) complex. In acidic medium, Cr(VI) in the complex is then reduced to Cr(III) with CO produced in first step through various intermediate transformations. A brief picture of the mechanism of silver nanoparticles catalyzed reduction of Cr(VI) with formic acid is given in Fig. 8 .

Fig. 8.

Mechanism of catalytic Cr(VI) reduction to Cr(III) with formic acid (HCOOH) using silver nanoparticles as catalyst.

Catalytic Cr(VI) reduction with H2 was carried out in the presence of silver nanoparticles but no significant reaction progress was observed which signified that Cr(VI) reduction with H2 cannot occurs in the presence of silver nanoparticles. Moreover in-situ produced CO was found to be more effective reductant in comparison to commercially available CO under similar conditions.

The mechanism of catalytic Cr(VI) reduction with formic acid in the presence of Au-Ag bimetallic nanoparticles is similar to that described for Ag catalyzed process in Fig. 8 but rate of reduction has been found to be higher in case of bimetallic nanoparticles (Vellaichamy and Periakaruppan, 2016) while Pt-Pd bimetallic catalyzed process follows mechanism of monometallic Pd catalyzed reduction of Cr(VI) as described above in Fig. 6 A.(Li et al., 2018; Hu et al., 2017). Reduction of Cr(VI) with formic acid in the presence of Au-Pd@Pd (Shao et al., 2017), Pt-Au (Hu et al., 2017), Cu-Ni (Borah et al., 2014), Pd-Cu (Trivedi et al., 2016) bimetallic nanoparticles is also occurred according to mechanism given in Fig. 6 B.

Kaining et al. (Gong et al., 2015) have reported molybdophosphate catalyzed reduction of Cr(VI) with formic acid via electron transfer but electron transfer mechanism in case of molybdophosphate catalysis needs further investigation and must be explored in future studies. However in case of reduction of Cr(VI) with formic acid in the presence of non-noble metal nanoparticles, electron transfer mechanism has been proposed on the basis of experimental observations. Bhowmik et al. (2014) have reported redox mechanism of reduction of Cr(VI) using Ni nanoparticles supported on reduced graphene oxide in which formic acid adsorbed on Ni surface is initially decomposed to CO2 and nascent hydrogen •through redox process and oxidation state of nickel is changed from zero to +2. Surface atoms of nickel gets oxidized to NiO. Presence of NiO was confirmed by XRD and Raman analysis of recovered sample of the composite. The nascent hydrogen is highly reactive and reduces Cr(VI) to Cr(III).

Catalytic reduction of Cr(VI) with formic acid catalyzed by inorganic nanoparticles is one of the best strategies for removal of Cr(VI) from aqueous medium because of low toxicity, high stability and easy storage of reducing agent (formic acid). Formic acid also provides acidic medium which is favorable for reduction of Cr(VI). Moreover, no solid or liquid side product is formed in this process. Only CO2 is produced during reduction reaction which may poison the surface of catalyst. But CO2 is a gas and may be extracted from reaction mixture for useful purpose without releasing it into the atmosphere. Additionally formic acid is inexpensive and is available in local market.

Cr(VI) reduction to Cr(III) may be carried out using metal formate as hydrogen source. For example sodium formate (Li et al., 2016c; Yang et al., 2010) and mixture of formic acid and sodium formate (Celebi et al., 2016) has been reported as reductant for Cr(VI) conversion to Cr(III). Yang et al. (2010) reduced K2Cr2O7 by sodium formate in the presence of viral templated Pd nanoparticles and reported that sodium formate acts electron donor in acidic environment. The chemical changes occurring during catalytic reduction of Cr(VI) by sodium formate under acidic condition may be summarized in the form of following ionic equations:

| Cr2O72− +14H3O+ +6e- → 2Cr+3 +21 H2O |

| HCOO− + H2O → CO2 +H3O +2e− |

5.1.2. Cr(VI) reduction by oxalic acid

Catalytic Cr(VI) reduction by oxalic acid in the presence of inorganic nanoparticles has been also reported in literature (Mahar et al., 2019) but mechanism of catalytic process is almost similar to that described in case of catalytic reduction of Cr(VI) with formic acid. Mahar et al. (Mahar et al., 2019) have recently reported Cr(VI) reduction by oxalic acid in the presence of Pt-Pd bimetallic nanoparticles supported on Indian tin oxide. It has been observed that oxalic acid is converted into H2 and CO2 on the surface of Pt-Pd nanoparticles. Nascent hydrogen produced acts as reducing agent to convert Cr(VI) into Cr(III) according to mechanism described in section 5.1 (Fig. 6).

5.1.3. Cr(VI) reduction by sodium borohydride

Sodium borohydride may be used as reducing agent for Cr(VI) reduction to Cr(III) in the presence of inorganic nanoparticles but Cr(VI) reduction by sodium borohydride has been rarely reported in literature. Toxicity, instability and basic nature of NaBH4 are the major obstacles in its use as reductant for Cr(VI) reduction to Cr(III). Kalwar et al. (2013) have reported Cr(VI) reduction by sodium borohydride (NaBH4) in aqueous medium in the presence of Ni nanoparticles stabilized by l-Cysteine. Catalytic Cr(VI) reduction to Cr(III) by sodium borohydride was monitored using UV–vis spectrophotometry by measuring the decrease in absorbance at 372 nm as a function of time. It is worth mentioning that usually catalytic Cr(VI) reduction to Cr(III) under acidic conditions is monitored by measuring the value of absorbance at 350 nm. NaBH4 is basic in nature. Its addition to the mixture containing Cr(VI) increases the pH of the medium. As result, λmax value of Cr(VI) is shifted from 350 nm to 372 nm due to conversion of [Cr2O7]−2 to [CrO4]−2 before Cr(VI) conversion to Cr(III). Chemistry of catalytic Cr(VI) reduction to Cr(III) using Ni nanoparticles as catalyst has been described in the form of following chemical equation.

| 2K2Cr2O7 + 2NaBH4 → 2Cr2O3 + 4KOH +2NaOH + 2B (OH)3 |

Non noble metal nanoparticles may lost their catalytic activity over storage due to their oxidation or aggregation. Utility of freshly prepared metal nanoparticles may result in an excellent catalytic efficiency. Loading of Cr(VI) into solution of metal precursor before nanoparticles fabrication leads to quick use of nanoparticles as catalyst for Cr(VI) conversion to Cr(III). For example Liu et al. (2016b) have reduced Cr(VI) by the addition of FeCl3 and NaBH4 into aqueous solution of K2Cr2O7. According to their findings, zerovalent iron nanoparticles are produced by reduction of iron salt by sodium borohydride. In-situ produced Fe0 nanoparticles have two fascinating features. They may act as catalyst to provide active sites for Cr(VI) reduction by NaBH4. Zerovalent iron nanoparticles are highly reactive and may also act as reductant for Cr(VI) conversion to Cr(III).

Using aforementioned concept, reduction of Cr(VI) to Cr(III) by NaBH4 in the presence of fly ash leachate (FAL) has been reported by Zhao et al. (2017). They reported that NaBH4 reduces metal ions present in FAL to metal nanoparticles which act as catalyst for reduction Cr(VI) by NaBH4. A comparison of catalytic reduction of Cr(VI) by formic acid and NaBH4 in the presence of Ni nanoparticles supported on graphene oxide has been presented by Bhowmik et al. (Bhowmik et al., 2014) who reported that reduction ability of formic acid is much higher than that of NaBH4 because reaction mixture has pH = 2 in case of Formic acid and pH = 7–8 in case of sodium borohydride. Cr(VI) reduction to Cr(III) is highly pH dependent according to step-II of mechanism of catalytic Cr(VI) reduction given in Fig. 6 A.

5.1.4. Cr(VI) reduction by H2

Pt, Pd and Pd-Pt nanoparticles catalyzed Cr(VI) reduction with formic acid discussed in section 5.1 describes that in-situ produced H2 acts as reducing agent for Cr(VI) reduction. Therefore commercially available H2 must be able to act as reductant in Pt/Pd nanoparticles catalyzed Cr(VI) reduction. The reduction must be carried out in acidic medium to fulfill the requirement of step-II of mechanism given in Fig. 6 A.

However silver nanoparticles are not good catalysts for efficient Cr(VI) reduction to Cr(III) due to poor adsorption of H2 on the surface of silver nanoparticles. The Cr(VI) reduction ability of different reductants on the surface of silver nanoparticles reported by Liu et al. (Liu et al., 2016a) has been found in the order of HCOOH > CO>H2.

5.1.5. Cr(VI) reduction by CO

Silver nanoparticles catalyzed Cr(VI) reduction with formic acid discussed in section 5.1 describes that CO produced acts as reducing agent for Cr(VI) reduction. Therefore commercially available CO gas can be used as reductant in inorganic nanoparticles catalyzed Cr(VI) reduction. The reduction must be carried out in acidic medium to fulfill the requirement of step-II of mechanism given in Fig. 8. Liu et al. (2016a) carried out Cr(VI) reduction with commercially available CO in the presence of H2SO4 on the surface of biomass stabilized silver nanoparticles. It was found that CO can reduce Cr(VI) to Cr(III) on the surface of silver nanoparticles but reduction efficiency was found to be low in comparison to in-situ produced CO (by dehydration of formic acid) under similar conditions. The same observation has been reported by Chen et al. (2018a).

5.2. Inorganic nanoparticles enhanced Cr(VI) reduction

5.2.1. Cr(VI) reduction by iron sulfide nanoparticles

Ferrous sulfide is a widely used material (both in bulk and nanoparticles forms) for remediation of Cr(VI) contaminated soil and ground water due to its good adsorbing ability and reducing power(Wang et al., 2019; Gong et al., 2016; Wu et al., 2017; Li et al., 2017). Our discussion is limited to the use of FeS nanoparticles as reductant for conversion of Cr(VI) to Cr(III). FeS nanoparticles are highly reactive in comparison to bulk FeS, due to their high surface to volume ratio and have gained considerable attention as active materials for Cr(VI) reduction in last few years (Lyu et al., 2017, 2018; Wu et al., 2017; Gong et al., 2017; Wu et al., 2020; Du et al., 2016; Chen et al., 2019). Chemistry of Cr(VI) reduction by FeS nanoparticles is simple. FeS nanoparticles do not only provide the surface for adsorption of Cr(VI) but also act as highly reactive reducing agent. Fe+2 is oxidized to Fe+3 by converting Cr(VI) to Cr(III) with simultaneous conversion of S−2 to SO3 −2/SO4 −2. Wang et al. (2019) have reported Carboxymethyl cellulose (CMC) stabilized FeS nanoparticles for reductive removal of Cr(VI) from ground water and soil. The schematic illustration of the process is shown in Fig. 9 . FeS nanoparticles have ability to reduce adsorbed Cr(VI) as well as aqueous Cr(VI). The reduced [Cr(III)] and oxidized [Fe(III)] species both are precipitated in the form of their hydroxides in solid phase as shown in Fig. 9.

Fig. 9.

Process of reductive removal of Cr(VI) from Soil using FeS nanoparticles as reductant. Reproduced with permission from reference Wang et al. (2019). Copyright Elsevier 2019.

Gong et al. (2017) have reported adsorption of Cr(VI) followed by reduction and precipitation by FeS using core-shell nanoparticles with zerovalent iron core and FeS shell for Cr(VI) removal from ground water. Procedure of fabrication of FeS@Fe° core-shell nanoparticles is different from synthesis of FeS nanoparticles but mechanism of Cr(VI) removal from ground water is almost similar to that reported by Wang et al. (2019) and is shown in Fig. 10 .

Fig. 10.