Abstract

The waste from end-of-life electrical and electronic equipment has become the fastest growing waste problem in the world. The difficult-to-treat waste-printed circuit boards (WPCBs), which are nearly 3–6 wt % of the total electronic waste, generate great environmental concern nowadays. For WPCB treatment and recycling, the mechanical–physical method has turned out to be more technologically and economically feasible. In this work, the mechanical–physical treatment and recycling technologies for WPCBs were investigated, and future research was directed as well. Removing electric and electronic components (EECs) from WPCBs is critical for their crushing and metal recovery; however, environmentally friendly and high-efficiency removal techniques need be developed. Concentrated metals rich in Cu, Al, Au, Pb, and Sn recovered from WPCBs need be further refined to add to their economic values. The low value-added nonmetallic fraction of waste-printed circuit boards (NMF-WPCBs) accounts for approximately 60 wt % of the WPCBs. From the perspective of environmental management, a zero-waste approach to recycling them should be developed to gain values. Preparing polymer composites and geopolymers offers many advantages and has potential applications in various fields, especially as construction and building materials. However, the mechanical and thermal properties of NMF-WPCBs composites should be further improved for preparing polymer composites. Surface modification or filler blending could be applied to improve the interfacial comparability between NMF-WPCBs and the polymer matrix. The NMF-WPCBs shows potential in preparing cement mortar and geological polymers, but the environmental safety resulting from metals needs to be taken into account. This study will provide a significant reference for the industrial recycling of NMF-WPCBs.

1. Introduction

The rapid development of technology innovations and consequent frequent replacement of electrical and electronic equipment (EEE) have resulted in shorter and shorter lifespans for electronic products. The waste from end-of-life EEE, also known as electronic waste (e-waste), has become one of the fastest growing waste problems worldwide.1,2 The updated report “Global e-waste monitor 2017: Quantities, flows, and resources” demonstrated that 44.7 million metric tons (Mt) of e-waste was generated worldwide in 2016, and this amount will reach 52.2 Mt by 2021.3 Printed circuit boards (PCBs) are an important component of EEE, and the resulting waste PCBs (WPCBs) have become almost 3–6 wt % of the total e-waste generated. The WPCBs with various sizes and models usually originate from EEE manufacturers, PCB manufacturers, and e-waste recycling plants. Meanwhile, they have significant amounts of precious metals, as compared with the natural ores (Table 1). D’Adamo et al.4 estimated the economic potential of WPCBs and suggested that they could create striking economic benefits if totally recycled, and the net present value could reach 63.0 million € for high-grade ones. Temporary stacking or landfilling of WPCBs will result in not only a waste of resources but also a release of heavy metals, as well as organic pollutants such as brominated flame retardants (BFRs). Simple combustion might generate high amounts of particulate matters, carbon oxides, and HBr, causing significant environmental pollution. Therefore, many technologies such as pyrometallurgy, hydrometallurgy, bioleaching, supercritical fluid, and physical separation had been developed to facilitate their treatment and recycling. Among them, pyrometallurgy offers significant volume reduction and substantial energy recovery but requires high energy consumption and easily causes secondary pollution. Hydrometallurgy is a low-cost treatment; however, it consumes large amounts of chemicals and generates a huge amount of wastewater. Bioleaching is a simple, lower cost, and eco-friendly technology, but it is time-consuming or has a relatively low efficiency. The mechanical–physical method, including dismantling, crushing, and separating processes, has been extensively applied in recycling plants worldwide. In this work, the mechanical–physical treatment and recycling technologies for WPCBs were analyzed, and future research was directed as well.

Table 1. Value Distributions of Metals Contained in WPCBsa.

| WPCBs type | Ag | Co | Mo | Sn | Ni | Cu | Zn | Pb | Al | Mn | Si |

|---|---|---|---|---|---|---|---|---|---|---|---|

| price ($/ton) | 528558 | 66500 | 16000 | 19775 | 11295 | 6761 | 3197 | 2474 | 2033 | 1850 | 1825 |

| central processing units | 16.83 | 6.34 | 0.67 | 8.71 | 9.99 | 50.52 | 0.2 | 0.5 | 2.54 | 0.03 | 4.27 |

| mobile phone PCBs | 25.34 | - | - | 15.18 | 1.03 | 46.3 | 0.97 | 0.9 | 3.84 | 0.31 | 5.61 |

| computer PCBs | 13.9 | - | - | 5.7 | 0.85 | 61.51 | 0.63 | 0.13 | 7.71 | 0.14 | 9.41 |

| CPCBs with wire | 4.9 | - | - | 12.7 | 0.29 | 73 | 2 | 1.1 | 3.6 | 0.02 | 2.3 |

| television PCBs | 10.38 | - | - | 32.58 | 1.24 | 44.58 | 3 | 2.46 | 3.84 | 0.05 | 1.79 |

| copy machine PCBs | 22.6 | - | - | 16.55 | 1.33 | 48.09 | 0.99 | 1.07 | 3.43 | 0.23 | 5.7 |

| fax machine PCBs | 23.07 | - | 0.05 | 18.75 | 2 | 44.32 | 1.26 | 1.36 | 3.89 | 0.29 | 5.02 |

Units: %.

2. Mechanical–Physical Treatment

2.1. Dismantling

PCBs are designed for a durability of 500 000 h, while the average end-of-life for EECs is 20 000 h, only 4% of its designed lifespan, which means there are still many EECs functioning even at the time of discard. Without dismantling, the EECs present might hinder the subsequent treatment of WPCBs. The dismantling could not only promote the recovery of those hazardous but valuable components (e.g., resistors, transistors, capacitors, and even solder) for reutilization but also simplify the recovery of precious metals and nonmetallic fractions. Therefore, it has become an initial and indispensable process for WPCB recycling.

Over the past few decades, manual dismantling has always been the dominant method and might still be applied in some developing countries, for example, China, India, and South Africa. For this primitive method, workers usually use a coal-heated plate to melt solders on WPCBs and then remove EECs, which has drawbacks of low efficiency and environmental pollution. The emission of toxic gas during the desoldering process, such as hexabromocyclododecane, polybrominated diphenyl ethers, polychlorinated biphenyls, and tetrabromobisphenol A, will pose a threat to the health of workers.

In order to recover EECs using a nondestructive, ecofriendly, and economically feasible method, extensive research has been conducted. The mechanical dismantling is promising from the prospect of economy and environment. The current techniques of EEC removal could basically be divided into two types. The first process is removing solder joints which bonds the base board and components. To reach the melting temperature of solder, which is around 225–250 °C, technologies such as melting by infrared rays, a heat transfer medium like hot air or liquids, and dissolution by chemical reagents have been applied. Specifically, IR heat lamps (mostly incandescent lamps) are used for IR heating, and the wavelength of IR radiation varies from 700 nm to 1 mm depending on the temperature of the emitting body. In hot air heating, hot air is used to melt solders between components and base boards, thus removing EECs. Chen et al.5 proposed a device that accomplished ideal disassembly efficiency with the incubation period of 2 min, preheating temperature of 120 °C, and heating source temperature of 260 °C. As for liquid medium, its further processing such as treating with the used hot fluid and washing WPCBs and EECs is complex. In that case, it is more suitable to use an infrared ray and hot air to melt solders for the operation line among the welding methods, but only the low-temperature hot-melt tin can achieve the dismantling of EECs without damage and pollution. The second process is recovering components. For the reason that EECs usually present as through a hole device (THD) and a surface mounting device (SMD) (Figure 1), different external forces such as cutting and drawing are applied, and various techniques such as mechanical sweep, gas jet, and centrifugation are developed to dislodge different types of components efficiently. Yang et al.6 quantitatively analyzed the minimum disassembly external force and minimum acceleration under different conditions, providing a quantitative analysis of the development of disassembly equipment for WPCBs. Wang et al.7 designed a pilot-scale EEC disassembling system, which completely removes solder in the condition that the temperature, rotating speed, and incubation time are 265 °C, 10 rpm, and 8 min, respectively. An automatic disassembling apparatus has been gradually established recently, taking the place of manual operation and presenting a promising perspective; however, higher integrated components bring more challenges to the disassembly work. Thus, a “design for manufacturing, assembly, and disassembly” has been appealed in the manufacturing aspect, to simplify the whole recycling process.

Figure 1.

Mechanical structure of printed circuit boards.

2.2. Crushing

The WPCBs without EECs are mainly composed of thermoset polymers and the attached solder, copper foil, and others, with high hardness and toughness. In order to facilitate the subsequent recovery of both metal and energy, crushing becomes the key for most recycle treatments of WPCBs, which is used for the liberation of different fractions and determines the recovery rate and purity of materials. Generally, the crushing can be grouped into coarse and fine crushing. A lot of crushers are designed for these purposes, and we present some conventional ones (Figure 2).

Figure 2.

Case of some conventional WPCB crushers.

In the process of coarse crushing, the jaw crusher and hammer crusher are the most common machines, which could control the size of WPCB scraps into 1–10 mm. However, both of them have low efficiency, and most of the WPCB particles of size larger than 9 mm still remain after the crushing process. Though a disk crusher with peeling and grinding action endows better crushing performance, which could enable the fraction of PCB scrap to be less than 12 mm,30 it is still difficult to recycle materials. Estrada-Ruiz et al.8 found that MF remains attached in part to the NMF-WPCBs in particles with sizes of 3.37 mm, while it is sufficiently liberated in particles with sizes of 840 μm using optical microscopy, which is consistent with the view that the particle size suitable for separation in industrial applications is 0.6–1.2 mm. Thus, fine crushing which could control the particle size to less than 1 mm is needed. Currently, a two-step crushing process (shredder–hammer mill) was put forward to allow materials to be liberated completely. What’s more, high voltage electrical pulses and coheating swelling with organic solvent are designed to strip metals from WPCBs sufficiently. After crushing, the total metal concentration increased apparently, whereas ceramic components decreased, which indicates that we could obtain more value and benefits.

2.3. Separation

Separation is the essential process of the mechanical–physical recycling process of WPCBs, which could result in metallic materials with high purity and low pollution in the treatment. Technically, separation methods could sort out the metallic materials from the nonmetallic materials based on the difference of the physical properties of various particles (e.g., density, particle size, electrical conductivity, magnetic permeability), mainly involving density and magnetoelectric separation. Gravity separation/density separation is according to the distinction in density and particle size among different materials. Miscellaneous particles are then layered by the fluid dynamics and mechanical forces. Magnetoelectric separation enables the separation of a metal and nonmetallic mixture based on the differences in magnetism or electricity. As the result of separation, copper is found be the most concentrated metal, and Ag, Au, and Cu occupy the highest value percentages.

2.3.1. Gravity Separation (GS)/Density Separation (DS)

GS/DS technology is used for the separation of WPCB particles based on the distinction in terminal kinematic velocity among various particles in the viscous gas or liquid. The GS could be divided into dry and wet GS according to different separation agents, and the separation equipment generally includes a wind separator, air table, pulsating air separation device, cyclone separator, and fluidized bed. Among them, the vertical air classifier is a typical dry GS device with an upward flow of air inside (Figure 3a). The light particles (powder consisting of glass fiber and Resin) would escape from the top of the container, while heavy particles were retained at the bottom. Zhang and Forssberg9 reported that density-based separation is feasible to separate metals from plastics, light plastics, and glass fiber reinforced resins, as well as light metals and heavy metals. Zhang et al.10 used a vibrated gas–solid fluidized bed to separate metals, and the highest metal recoveries of 86.39% were accomplished for particle fraction sizes between 0.5 and 1 mm. Meng et al.11 used supergravity separation to separate metals and found that the concentration of precious metals in said alloy and residue is greatly influenced by the temperature as well as gravity coefficient. The total recovery values of Cu, Zn, Pb, and Sn were up to 93.23%, 80.86%, 94.54%, and 97.67%, respectively, when the temperature is 1300 °C and gravity coefficient is 1000. For wet GS, shaking tables are commonly used in the current separation process, as it solved air and noise problems as well as recycled water. Duan et al.12 reported that the Falcon separator gave a concentrated product graded 92.36% metal with a recovery of 97.05%; the reverse water pressure was 0.05 MPa; the speed transducer frequency was set at 30 Hz; and the feed density was 20 g/L.

Figure 3.

WPCBs separating: (a) gravity separation and (b) electronic separation

2.3.2. Magnetic Separation (MS)

MS uses magnets to attract magnetic materials, achieving the separation of metallic particles from a mixture. As a result of magnet influence, the magnetic particles are drifted with the movement of the drums. However, the agglomeration of the particles could result in a low separation efficiency in the process because of the attraction of some nonferrous fractions attached to the ferrous ones. Those techniques are usually combined together for a better separation effect. Veit et al.13 used MS and ES to separate MF, obtaining a fraction of concentrated metals containing more than 50% on average of Cu, 24% of Sn, and 8% of Pb. Zhang et al.14 proposed TES to enhance GS and obtained a improved metal recovery from 76.39% to 81.41%. Zhu et al.15 combined magnetic and gravity separation, and the respective recovery of Cu and Fe is 82.33% and 74.15% when treating with particle size less than 0.5 mm and 79.22% and 90.44% for 1–0.5 mm.

2.3.3. Electrostatic Separation (ES)

ES involves three typical separation techniques, i.e., corona electrostatic separation (CES), triboelectric separation (TES), and eddy current separation (ECS). CES is regarded as the most effective separation technique for separating MF and NMF (Figure 3b). In a high voltage electrostatic field which is applied using a corona and electrostatic electrode, the nonconductive particles are charged and adhered on the drum, and thus the conductive particles could be separated under the combined force of centrifugal force and gravity. In the process, the capability of CES depends on the difference in polarity and the amount of charge acquired by the separated particles, and the distance of the corona electrode, the electrostatic electrode, high-voltage supply, and roll speed are significant to optimize metal recovery from WPCBs. Xue et al.16 concluded that conductor and nonconductor, semiconductor, and nonconductive separation obtained good performance using higher voltage levels, and the separation efficiency was up to 82.5% for conductors and 88% for semiconductors with their proposed integrated process.

TES is used to separate organic and inorganic in NMF-WPCBs because organic components and fiberglass in WPCB charged the opposite charge, and the biggest difference was found using the poly(methyl methacrylate) charger because this material has a higher charge that can enhance the electric field force. In addition, the inorganic content of each size fraction was found to increase with the decrease in size during this process. Zhang et al.17,18 reported that TES can effectively remove inorganics of NMF-WPCBs, especially SiO2 and Al2O3. Li et al.19 used the computer simulation in the separation of heavy and light particles, and their study validated that the resin and fiberglass powder had different detached trajectories in the same conditions. Yang et al.20 designed a novel TES device which can effectively recycle OM from the NMFs, and the OM content was up to 85.12% in the positive plate product when the feed rate, rotation speed, and voltage were 12.96 kg/h, 500 r/min, and 50 kV, respectively.

ECS is usually applied to separate light metal (aluminum) from WPCBs at a high frequency alternating magnetic field. In the current ECS industry, the magnet roller diameter is commonly 300 mm, and its maximum revolution is up to 3000 rpm. The belt width ranges from 450 to 1250 mm, and its speed can reach 1.0 m/s. The handling capacity ranges between 2 and 2.6 tons. The theoretical model of particle trajectory was analyzed, and the optimum separation effect was achieved with the feeding belt velocities of 1.18 m/s, magnetic roller rotating speeds of 3000 rpm, and particle radius of 8.44 mm. The separation efficiency was up to 95.54% in a practical experiment.

3. NMF-WPCB Recycling

A certain purity of MFs and NMFs could be obtained after enrichment operation. The metallic materials are welcomed by recycling industries, and their recovery has become one of the most profitable businesses. However, nonmetallic materials, which consist of 40% organic substances and 60% inorganic substances, draw less attention due to their complex recovery and lower economic benefits, even though they account for 60–70 wt % of the WPCBs. A large quantity of NMF-WPCBs would generate immense waste of resources as well as pose a huge challenge to the environment if discarded or disposed of inproperly. Therefore, seeking a proper disposal technique for NMF-WPCBs is urgent, and its recycle technology requires further study.

3.1. Chemical Components

First, the composition of NMFs is complicated, including organic materials (epoxy resin, BFRs, curing agents, etc.) and inorganic materials (glass fiber made from SiO2, CaO, and Al2O3), and resin and glass fiber are the main compositions. In a former study, the glass fiber and cured epoxy resin accounted for 65 and 32 wt %, and the impurities of copper and solder were less than 3 and 0.1 wt %, respectively. The chemical components of NMF-WPCBs were further analyzed; although the compositions of different types of WPCBs are different, the organic materials (OMs) commonly make up most of the sample, followed by the elements of Si, Cu, Al, and Ca (Figure 4). Wang et al.21 revealed that the content of metals of their sample could be up to 16.68 wt %, suggesting current separating techniques need to be improved. Also, their research revealed that fractions of various sizes were significantly different. The results show that the OM content decreases as the particle size decreases, and the metal concentration increases suddenly when the particle size is less than 0.125 mm. It is suggested that different recycle processes should be applied for different size fractions. In another sample, the high content (nearly 26 wt %) of bromine is presented, which could be attributed to the existence of BFRs.

Figure 4.

Chemical components of NWF-WPCB samples

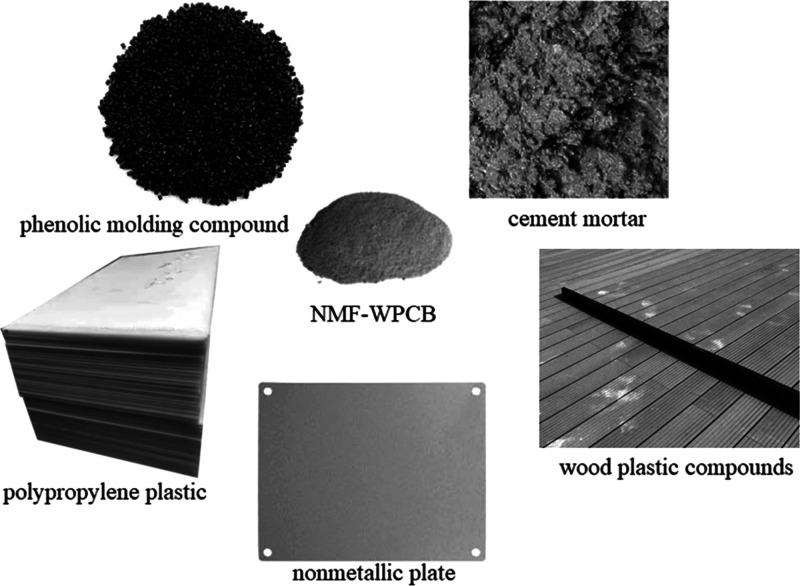

The primary raw materials of NMFs show the possibility of the potential application as a substitute; for instance, the composition of resin demonstrates that it has a good compatibility with the matrix, and the glass fiber could reinforce the performance of the polymer composite. At present, a lot of work has been done, such as the preparation of phenolic molding compounds, cement mortar, polypropylene plastic, nonmetallic plate, and wood plastic compounds (Figure 5). However, the inorganics in NMFs, especially glass fibers, have poor compatibility with other materials, easily forming high stress concentration points, thus significantly affecting the performance of recycle products, causing the critical problem. Duan et al.22 warn that the threat of environmental pollution of recycled products exists, mainly from the composition of heavy metals, BFRs, and secondary persistent organic pollutants, particularly dioxins.

Figure 5.

Wide applicable scenarios of NWF-WPCBs.

3.2. Preparation of Composite Materials

A polymer composite is a multiphase material integrated by reinforcing fillers and the polymer matrix. Its synergistic mechanical properties cannot be achieved from any other component. For polymers in the conventional PCBs, thermosetting composites are always used as filler or glass fiber reinforced epoxy resin, while paper reinforced phenolic resin with a bonded copper foil or silicone substrates is used for preparing chips and circuits. Based on the attributes of NMF-WPCBs mentioned before, the addition of the NMF powder could replace some raw material and can hopefully be reutilized to prepare composite materials by using them as fillers. Until now, the NMF-WPCBs have been reported to successfully replace wood flour filling into a phenolic molding compound (PMC), wood plastic compounds (WPCs), polypropylene plastic (PP), and other composite materials. For PMCs, the addition of NMFs improved the tensile and bending strength. The optimal added content of NMFs is 20 wt %, resulting in flexural strength, charpy notched impact strength, heat deflection temperature, dielectric strength, and rasching fluidity of 70 MPa, 2.4 kJ/m2, 168 °C, 3.9 MV/m, and 103 mm, respectively. For WPC, the addition of NMFs improved the flexural strength, tensile strength, and charpy impact strength and reduced the screw withdrawal strength. They were reported to reach 25.8 MPa, 9.8 MPa, 3.4 kJ/m2, and 121/115 N/mm, respectively, for a hollow WPC with 15% nonmetals (H-15-WPC) before the aging process. Also, Guo et al.23 prepared a nonmetallic plate (NMP), added resin paste as a bonding agent, and found the polymer composite to have excellent mechanical properties with a flexural strength of 68.8 MPa and a charpy impact strength of 6.4 kJ/m2 when the nonmetallic material content was 20 wt % and the particle size was less than 0.07 mm, indicating the NMF-WPCBs could be reused as an alternative for wood flour in PMC and WPC. Zheng et al.24 prepared a novel NMF-WPCBs/PP composite and found the tensile strength, tensile modulus, bending strength, and flexural modulus of the PP composites increased by 28.4%, 62.9%, 87.8%, and 133.0%, respectively, and suggested as much as 30 wt % NMFs could be added in PP composites without violating the environmental regulations. Rajagopal et al.25 produced sustainable composite panels, and the flexural and tensile modulus of the 80/20 (waste automotive plastics/nonmetallic PCB) panel could increase by nearly 50% and 280%, compared to the original waste automotive plastics. Additionally, the addition of NMFs is found to significantly improve the physical and chemical properties of composite materials. Incorporating WPCBP into high-density polyethylene (HDPE)–wood composites improved the notched impact strength, water absorption rates, and rheological properties. The improvement of mechanical properties was confirmed to have a higher aspect ratio and strong interfacial adhesion through scanning electron microscopy studies. For example, unsaturated polyester (UP) composites showed better tensile strength, flexural strength, and heat distortion temperature than the UPE matrix when incorporated with a suitable content of NMFs. Also, the WPCB–UP composite plate shows a potential when applied in sound insulation, and the maximum weighted sound reduction index of the composite plate with particle size less than 0.71 mm was reported up to 28.4 dB.

Sometimes, direct use of NMFs to prepare polymer composites might create problems such as poor dispersion and toughness between the filler and matrix, and the surface modification of NMF or filler blending could be the solution. According to studies, the NMFs modified by a silane coupling agent KH-550 improved the dispersion and compatibility of fillers in a matrix when preparing recycled polycarbonate, and the tensile and flexural strength could achieve 84.68 and 118.3 MPa. Also, the addition of KH-550 and PE-g-MAH improved the interfacial adhesion between fillers and the HDPE matrix; meanwhile, they improved the tensile strength and notched impact strength of the composites which were enhanced by 64.4% and 66.1% compared to the original samples. All the composite materials containing modifiers represent better storage modulus and interfacial adhesion with respect to the original composites. Regarding the environmental affect, the composition of NMFs contains heavy metal and BFRs, and the organic additives such as phenolic resin, unsaturated resin, and styrene are used widely during composite preparation. Therefore, it is important to monitor pollutant emission during composite preparation and to analyze metal leaching from composites during daily use. Guo et al.26 investigated the volatile organic compounds (VOCs) and metal leaching from different kinds of NMF-WPCBs composites including PMC, WPC, and NMP. The results showed that VOC emission from composite products derives from the added organic compounds in the process of manufacturing: phenol primarily originated from phenolic resin, and benzaldehyde, octanal, and d-limonene were emitted in relatively low concentrations from wood flour. The analysis of metal concentrations in leachates indicated that the concentrations of other heavy metals were within the limit except of Cu (average = 893 mg/L; limit = 100 mg/L). The environmental assessment based upon VOC tests and leaching characteristics indicated that the composite materials have a chance to be friendly to the environment.

3.3. Preparation of Geopolymers

NMF-WPCBs can also be used as raw materials to prepare geological polymers and cement mortar. Geopolymer is a product of inorganic polymerization, which was first proposed by Davidovits in 1978. He put forward that an alkaline liquid could be used to react with Si and Al in a source material of geological origin or byproduct materials to produce binders. It is generally prepared by mixing aluminasilica sources with activating solutions and then activating the mixture via temperature curing. Janardhanan and Ramasamy27 utilized NMFs as a partial replacement for fine aggregates in geopolymer concrete. It was observed that up to 30% replacement of NMFs and the mechanical properties improved, indicating that using NMFs in concrete could reduce the requirement for conventional fine aggregates as well as help to immobilize the toxic substance like heavy metals. Regarding the cement mortar, Premur et al.28 determined the possibility of incorporation of NMFs in concrete products for aggregates on an industrial scale, after adding 5, 10, 15, and 20 wt % NMFs to mineral filler. Ban et al.29 proved that the maximum expansion rates in water for WPCB particle size from 0.08 to 0.30 mm satisfied the necessary condition as an alternative additive for cement mortar as a substitute for sand. Wang et al.30 applied them in cement mortar as an admixture, resulting in an increase in air content, improvement of the water-retention property for fresh mortar, and reduction of the bulk density for hardened mortar. At the same time, the leaching behavior from heavy metals in geopolymer also rouses concern, and evaluating its possible noxious effects on the environment is necessary. The environmental impacts of recycled products have been studied, showing no heavy metal was leached from the cement mortar, which could result from the fixation effect of cement hydrates. From the above studies, we see that preparing geopolymers using NMF-WPCBs can improve their mechanical properties. In addition, the metals present in NMF-WPCBs can be immobilized by geopolymers, which will reduce the environmental concern.

4. Conclusions

The WPCBs have drawn more attention recently, and their recovery is important for both economic and environmental issues. Among different recycling techniques, mechanical–physical treatment is a feasible and environmentally friendly method. However, concentrated metals rich in Cu, Al, Au, Pb, and Sn recovered from WPCBs need to be further refined to add to their economic values. Currently, the recovery of MF could bring huge economic benefits, while NMF-WPCBs remains a challenge. Because they are mainly composed of resin and glass fiber, they have the possibility to replace some raw materials in various fields, especially as construction and building materials or as filler of composites or geopolymers. Many studies indicated that incorporating NMF-WPCBs could improve the physical and thermal performance of regenerated products, such as PMC, WPC, and PP based composites. However, direct use as raw materials might cause poor dispersion and toughness problems between the filler and matrix and affects the final performance of the products. In this case, surface modification or filler blending are alternative solutions. The modifiers KH-550 and PE-g-MAH are commonly used. In addition, the product reliability and potential environmental risks need be taken into account because of the present metals and BFRs. In this case, for the fate of metals and BFRs, the life cycle assessment of regenerated products need to be conducted.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (21906144) and Zhejiang Provincial Natural Science Foundation of China (Grant no. LY19B070008).

Biographies

Dr. Qin Wang received her Ph.D. from Zhejiang University, China. Her current research interests are solid waste treatment and recycling.

Mr. Baogui Zhang received his M.Sc. from China Academy of Space Technology, Beijing. His current research interests are digital circuit design and solid waste treatment.

Mr. Shaoqi Yu received his B.Tech from Zhejiang University of Science and Technology, China. His current research interests are solid waste treatment and recycling.

Ms. Jingjing Xiong received her B.Tech from Guilin University of Technology, China. Her current research interests are solid waste treatment and recycling.

Prof. Zhitong Yao received his Ph.D. from Zhejiang University, China. His current research interests are solid waste treatment and recycling.

Dr. Baoan Hu received his Ph.D. from Tianjin University, China. His current research interests are solid waste treatment and recycling.

Prof. Jianhua Yan received his Ph.D. from Zhejiang University, China. His current research interests are solid waste treatment and recycling.

The authors declare no competing financial interest.

References

- Yao Z.; Ling T.-C.; Sarker P.; Su W.; Liu J.; Wu W.; Tang J. Recycling difficult-to-treat e-waste cathode-ray-tube glass as construction and building materials: A critical review. Renew. Renewable Sustainable Energy Rev. 2018, 81, 595–604. 10.1016/j.rser.2017.08.027. [DOI] [Google Scholar]

- Yu S.; Su W.; Wu D.; Yao Z.; Liu J.; Tang J.; Wu W. Thermal treatment of flame retardant plastics: A case study on a waste TV plastic shell sample. Sci. Total Environ. 2019, 675, 651–657. 10.1016/j.scitotenv.2019.04.264. [DOI] [PubMed] [Google Scholar]

- Baldé C.; Forti V.; Gray V.; Kuehr R.; Stegmann P.. The Global E-waste Monitor-2017; United Nations University (UNU); International Telecommunication Union (ITU) & International Solid Waste Association (ISWA), Bonn/Geneva/Vienna. ISBN Electronic Version, 2017; pp 978–992. [Google Scholar]

- D’Adamo I.; Ferella F.; Gastaldi M.; Maggiore F.; Rosa P.; Terzi S. Towards sustainable recycling processes: Wasted printed circuit boards as a source of economic opportunities. Resour. Conser. Recy. 2019, 149, 455–467. 10.1016/j.resconrec.2019.06.012. [DOI] [Google Scholar]

- Chen M.; Wang J.; Chen H.; Ogunseitan O. A.; Zhang M.; Zang H.; Hu J. Electronic waste disassembly with industrial waste heat. Environ. Sci. Technol. 2013, 47 (21), 12409–12416. 10.1021/es402102t. [DOI] [PubMed] [Google Scholar]

- Yang J.; Xiang D.; Wang J.; Duan G.; Zhang H. Removal force models for component disassembly from waste printed circuit board. Resour. Conser. Recy. 2009, 53 (8), 448–454. 10.1016/j.resconrec.2009.03.007. [DOI] [Google Scholar]

- Wang J.; Guo J.; Xu Z. An environmentally friendly technology of disassembling electronic components from waste printed circuit boards. Waste Manage. 2016, 53, 218–224. 10.1016/j.wasman.2016.03.036. [DOI] [PubMed] [Google Scholar]

- Estrada-Ruiz R.; Flores-Campos R.; Gamez-Altamirano H.; Velarde-Sanchez E. Separation of the metallic and non-metallic fraction from printed circuit boards employing green technology. J. Hazard. Mater. 2016, 311, 91–99. 10.1016/j.jhazmat.2016.02.061. [DOI] [PubMed] [Google Scholar]

- Zhang S.; Forssberg E. Optimization of electrodynamics separation for metals recovery from electronic scrap. Resour. Conver. Recy. 1998, 22, 143–162. 10.1016/S0921-3449(98)00004-4. [DOI] [Google Scholar]

- Zhang G.; He Y.; Wang H.; Zhang T.; Wang S.; Yang X.; Xia W. New technology for recovering residual metals from nonmetallic fractions of waste printed circuit boards. Waste Manage. 2017, 64, 228–235. 10.1016/j.wasman.2017.03.030. [DOI] [PubMed] [Google Scholar]

- Meng L.; Guo L.; Zhong Y.; Wang Z.; Chen K.; Guo Z. Concentration of precious metals from waste printed circuit boards using supergravity separation. Waste Manage. 2018, 82, 147–155. 10.1016/j.wasman.2018.10.024. [DOI] [PubMed] [Google Scholar]

- Duan C.; Wen X.; Shi C.; Zhao Y.; Wen B.; He Y. Recovery of metals from waste printed circuit boards by a mechanical method using a water medium. J. Hazard. Mater. 2009, 166 (1), 478–482. 10.1016/j.jhazmat.2008.11.060. [DOI] [PubMed] [Google Scholar]

- Veit H. M.; Diehl T. R.; Salami A. P.; Rodrigues J. d. S.; Bernardes A. M.; Tenório J. A. S. Utilization of magnetic and electrostatic separation in the recycling of printed circuit boards scrap. Waste Manage. 2005, 25 (1), 67–74. 10.1016/j.wasman.2004.09.009. [DOI] [PubMed] [Google Scholar]

- Zhang G.; He Y.; Feng Y.; Zhang T.; Wang H.; Zhu X. Recovery of residual metals from fine nonmetallic fractions of waste printed circuit boards using a vibrated gas-solid fluidized bed. Sep. Purif. Technol. 2018, 207, 321–328. 10.1016/j.seppur.2018.06.017. [DOI] [Google Scholar]

- Zhu X.; Nie C.; Wang S.; Xie Y.; Zhang H.; Lyu X.; Qiu J.; Li L. Cleaner approach to the recycling of metals in waste printed circuit boards by magnetic and gravity separation. J. Cleaner Prod. 2020, 248, 119235. 10.1016/j.jclepro.2019.119235. [DOI] [Google Scholar]

- Xue M.; Yan G.; Li J.; Xu Z. Electrostatic separation for recycling conductors, semiconductors, and nonconductors from electronic waste. Environ. Sci. Technol. 2012, 46 (19), 10556–10563. 10.1021/es301830v. [DOI] [PubMed] [Google Scholar]

- Zhang G.; He Y.; Wang H.; Zhang T.; Yang X.; Wang S.; Chen W. Application of triboelectric separation to improve the usability of nonmetallic fractions of waste printed circuit boards: removing inorganics. J. Cleaner Prod. 2017, 142, 1911–1917. 10.1016/j.jclepro.2016.11.093. [DOI] [Google Scholar]

- Zhang G.; Wang H.; Zhang T.; Yang X.; Xie W.; He Y. Removing inorganics from nonmetal fraction of waste printed circuit boards by triboelectric separation. Waste Manage. 2016, 49, 230–237. 10.1016/j.wasman.2015.12.022. [DOI] [PubMed] [Google Scholar]

- Li J.; Jiang Y.; Xu Z. Eddy current separation technology for recycling printed circuit boards from crushed cell phones. J. Cleaner Prod. 2017, 141, 1316–1323. 10.1016/j.jclepro.2016.09.144. [DOI] [Google Scholar]

- Yang J.; Wang H.; Zhang G.; Bai X.; Zhao X.; He Y. Recycling organics from non-metallic fraction of waste printed circuit boards by a novel conical surface triboelectric separator. Resour. Conser. Recy. 2019, 146, 264–269. 10.1016/j.resconrec.2019.03.008. [DOI] [Google Scholar]

- Wang H.; Zhang G.; Hao J.; He Y.; Zhang T.; Yang X. Morphology, mineralogy and separation characteristics of nonmetallic fractions from waste printed circuit boards. J. Cleaner Prod. 2018, 170, 1501–1507. 10.1016/j.jclepro.2017.09.280. [DOI] [Google Scholar]

- Duan H.; Hu J.; Yuan W.; Wang Y.; Yu D.; Song Q.; Li J. Characterizing the environmental implications of the recycling of non-metallic fractions from waste printed circuit boards. J. Cleaner Prod. 2016, 137, 546–554. 10.1016/j.jclepro.2016.07.131. [DOI] [Google Scholar]

- Guo J.; Li J.; Rao Q.; Xu Z. Phenolic molding compound filled with nonmetals of waste PCBs. Environ. Sci. Technol. 2008, 42 (2), 624–628. 10.1021/es0712930. [DOI] [PubMed] [Google Scholar]

- Zheng Y.; Shen Z.; Cai C.; Ma S.; Xing Y. The reuse of nonmetals recycled from waste printed circuit boards as reinforcing fillers in the polypropylene composites. J. Hazard. Mater. 2009, 163 (2–3), 600–606. 10.1016/j.jhazmat.2008.07.008. [DOI] [PubMed] [Google Scholar]

- Rajagopal R. R.; Rajarao R.; Cholake S. T.; Sahajwalla V. Sustainable composite panels from non-metallic waste printed circuit boards and automotive plastics. J. Cleaner Prod. 2017, 144, 470–481. 10.1016/j.jclepro.2016.12.139. [DOI] [Google Scholar]

- Guo J.; Jiang Y.; Hu X.; Xu Z. Volatile organic compounds and metal leaching from composite products made from fiberglass-resin portion of printed circuit board waste. Environ. Sci. Technol. 2012, 46 (2), 1028–1034. 10.1021/es2029558. [DOI] [PubMed] [Google Scholar]

- Janardhanan T.; Ramasamy V. Improvements in the microstructural and mechanical properties of geopolymer concrete containing NMF’s of e-wastes as partial replacement of aggregates. Eur. J. Environ. Civ. En. 2017, 1–12. 10.1080/19648189.2017.1357869. [DOI] [Google Scholar]

- Premur V.; Vučinić A. A.; Melnjak I.; Radetić L. Reuse of the recycled nonmetallic fraction from waste printed circuit boards in pavement industry. Environ. Eng. Manage. J. 2018, 17 (11), 2719–2729. 10.30638/eemj.2018.271. [DOI] [Google Scholar]

- Ban B. C.; Song J. Y.; Lim J. Y.; Wang S. K.; An K. G.; Kim D. S. Studies on the reuse of waste printed circuit board as an additive for cement mortar. J. Environ. Sci. Health, Part A: Toxic/Hazard. Subst. Environ. Eng. 2005, 40 (3), 645–656. 10.1081/ESE-200046618. [DOI] [PubMed] [Google Scholar]

- Wang R.; Zhang T.; Wang P. Waste printed circuit boards nonmetallic powder as admixture in cement mortar. Mater. Struct. 2012, 45 (10), 1439–1445. 10.1617/s11527-012-9843-0. [DOI] [Google Scholar]