Abstract

Threatened by the energy crisis and environmental pollution, most countries in the world are vigorously developing new energy vehicles to promote low-carbon environmental protection and boost a green transportation system. Based on the intelligent manufacturing standard system, this study constructed a new energy vehicle intelligent manufacturing development-influencing factor model. Taking the intelligent manufacturing development ability as the dependent variable, taking external environment factors, commonalities among the new energy vehicle enterprises, and industry progress as independent variables, five hypotheses are proposed. This study used a structural equation model to test the hypotheses and reveal the mechanism of how factors influence the new energy vehicle intelligent manufacturing. The results show that external environment factors and industry progress directly and positively affect the development capability of intelligent manufacturing of new energy vehicles, while the commonalities among the NEV enterprises have an indirect effect through industry progress on intelligent manufacturing of new energy vehicles. Based on the analysis, this study puts forward some suggestions for better development of new energy vehicle intelligent manufacturing.

1. Introduction

Nowadays, the main energy resource consumed by the economic and social development sectors of all countries in the world is petroleum, but petroleum is nonrenewable energy, and the proven reserves are limited. Due to the very limited proven reserves of petroleum, the present energy consumption structure will probably cause a worldwide energy crisis in the future.1 Therefore, clean and green energy has attracted the world’s attention. China’s regional development of the new energy is uneven.2 Traditional fuel vehicles not only consume much petroleum, but also pollute the environment severely, through greenhouse gas emissions, which has caused global warming and posed a threat to the welfare of human beings.3 As new energy technologies boom all across the world, the new energy vehicle (NEV) sector has developed greatly and it could be seen that there is a trend for NEV to replace the traditional fuel vehicles.4 Some European countries, such as Norway and Germany, have drawn up a schedule to phase out traditional fuel vehicles.5 China shows similar interest in the NEVs during the transition from high-speed growth to medium-to-high speed of growth and finally to medium-to-high level of development. This forces the automobile industry to produce vehicles that are greener and smarter. Intelligent manufacturing (IM) is the focus of the Made in China 2025 plan, and NEVs, especially the connected and smart vehicles, are listed as one of the top 10 industries to be supported by the authorities.6 Along with a new round of scientific and technological revolutions and industrial changes, industrial internet, artificial intelligence, and 5G technologies have been gradually popularized. As a booming industry, the NEV sector should utilize the new-generation information technologies to accelerate industry upgradation and IM.

Studies on the NEVs started earlier in foreign countries, and foreign scholars have done more in-depth research on the development of NEVs. Kinoshita reported that the U.S. Department of Energy began to fund electric vehicles as early as 1993, providing financial support for the research on advanced rechargeable batteries and fuel cells.7 Kimble et al. believed that the top priority for emerging commercial formats represented by NEVs is innovation, and more attention should be paid to technological innovation to improve the level of intelligence.8 Åhman believed that the government played an essential role in developing alternative fuel vehicles.9 Hermans proposed that the NEV intelligent transportation system had made progress as a result of the development of NEV IM, and it is important to improve the level of intelligence to ensure market competitiveness.10 Tabor believed that a high level of IM could shorten the transformation cycle of new energy vehicles and reduce initial cost.11 Kassen et al. proposed that the electric vehicle market would grow by 40% year-on-year in 2018.12 Only with independent research and development, safe and reliable manufacturing to produce traction motors and other core components can have the core competitiveness of IM.13

Chengpeng believed that the Made in China 2025 plan had made it clear that the development strategy of China’s NEVs was to vigorously develop pure electric vehicles and fuel cell vehicles.14 Peihong et al. divided the IM of automobiles into two parts: the IM process and the IM results and believed that the IM of automobiles was still in the initial stage.15 He proposed that in the manufacturing process of NEVs, we should focus on the construction of key parts of the production lines and combine artificial intelligence and other modern technologies to make them intelligent, so as to promote the development of IM of NEVs.16 Yufeng et al. analyzed the current situation of intelligent development of NEVs from three aspects of NEV components, vehicle, and vehicle networking system.17 Mei believed that the lack of core technology and weak independent R&D capability were the bottlenecks restricting the development of China’s NEVs to a high level.18 Under the background of transformation and upgradation of the automobile industry in the new era, the development of NEV IM urgently needs relevant professional talents. Wang Bin pointed out that the automobile professional talents trained in China’s colleges and universities were insufficient, the training positioning was conservative, and the training mode of automobile professional talents needed to be innovated.19 Yang et al. found that China’s “dual-credit system” policy was in the leading position in the world, which is of great significance to enhance the international competitiveness of China’s NEV industry.20

To sum up, the previous studies focused on three aspects: First, the current development of NEVs; second, the problems existing in the development of IM of NEVs; and third, the prediction of the development trend of intelligent NEVs. There are relatively few research studies on the influencing factors of the development ability of NEV IM. In this study, through the construction of the NEV IM development system, we put forward the hypotheses and establish the main influencing factor model of the NEV IM development. Based on the huge NEV market in China, the questionnaire data were collected, and the second-order structural equation model was used to test the hypotheses. It fills the gap in this research field. Empirical analysis has established the relationship between the influencing factors and the development ability of NEV IM. It has clarified the key influencing factors and influencing mechanism of the factors on the development ability of NEV IM and put forward reasonable suggestions for promoting the development of NEV IM.

2. Theory and Hypotheses

2.1. Theoretical Background

With the supply side structural reform and industrial upgradation and development, IM has gradually become the development trend of the future manufacturing industry, which is also an important measure to enhance international competitiveness and to accelerate the transformation of China from a big manufacturing power to a strong manufacturing power. As the pillar industry of the national economy, the implementation of IM is an inevitable way to make the automobile industry bigger and stronger. Whether it is the modification of NEV products themselves, or the manufacturing and driving of NEV, it is easier to manufacture intelligent vehicles than traditional fuel vehicles. In the Guidelines for the Construction of National Intelligent Manufacturing Standard System (2018 Edition), a national Intelligent Manufacturing standard system has been established from three aspects of commonalities among the NEV enterprises, key technology, and industry application.21 In this study, a NEV IM development capability system framework is constructed with reference to the national standard system, which provides theoretical support for empirical analysis, as shown in Figure 1.

Figure 1.

Development capability system architecture of NEV IM.

According to the different organizational structure of production activities, the system layer divides the IM process of NEVs into different links, which are equipment layer, unit layer, workshop layer, enterprise layer, and collaborative layer. The equipment layer is the layer that uses various instruments and equipment to sense and operate the physical process in the IM process. The unit layer is used to process various internal information and monitor and control the physical process. The workshop layer mainly realizes the production management of the NEV IM workshop. The enterprise layer is oriented to the operation and management of the NEVs. At the collaborative layer, the internal and external information of the NEV IM enterprises is interconnected. The life cycle of NEVs includes R&D and design, production and manufacturing, logistics transfer, operation and sales, and product service. In the stage of R&D and design, the corresponding intelligent design technology is selected according to the characteristics of the NEVs to simulate and optimize the products. Production and manufacturing is the process of IM of NEVs that uses intelligent information, process means, and production methods. Logistics transfer is the process of transferring NEVs from the production place to the sales place in combination with the new-generation information technology. Operation and sales is to use the Internet, big data, and other ways to achieve NEV sales. Product service is based on cloud platform, big data, 5G, and so on to realize remote, personalized, customized services, etc. Intelligent features are based on 5G, artificial intelligence, and other new-generation information technologies. IM of NEVs is mainly reflected in five aspects: resource elements, interconnection, merger and sharing, system integration, and emerging cultural formats. Resource elements are the necessary intelligent workshop and digital model for the production of NEVs. Interconnection is to use the modern communication technology in the terminal, production, control, management, and other links to achieve information exchange. Merger and sharing is based on big data, cloud platform, and other collaborative analysis of information under the premise of interconnection. System integration is to integrate multiple intelligent modules such as production line and digital workshop into the whole IM of NEVs. The emerging industry is the value chain integration of NEVs in the environment of industrial upgradation.

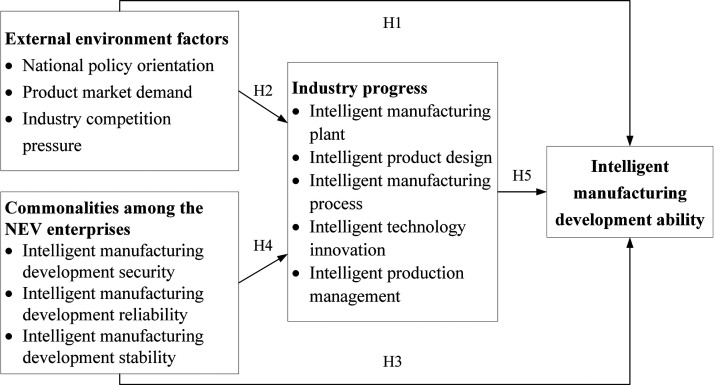

The innovation and contribution of this study are based on: the national intelligent manufacturing standard system, the established development capability system architecture of NEV IM, and the influencing factor model of NEV IM development capability. The first step is to study all kinds of IM application systems, extract their common and abstract features, and build a three-dimensional IM system architecture composed of a system layer, a life cycle and an intelligent feature, so as to clarify the intelligent manufacturing object and boundary. The second step is based on the in-depth analysis of the standardization requirements and the integration of the NEV IM development ability as the dependent variable, external environment factors, commonalities among the NEV enterprises, and industry progress as independent variables. The third step is to decompose and refine the NEV IM standard architecture, refine the items that affect each variable, and build the influencing factor model of new energy vehicle intelligent manufacturing development capability (Figure 2).

Figure 2.

Influencing factor model of the NEV IM development capability.

According to the characteristics of NEV IM across industries, fields, and specialties, this study constructs an IM standard system that meets the development needs of the NEV industry and promotes the overall improvement of the development capability of NEV IM. Accelerating the promotion of intelligent manufacturing is an important area of focus to accelerate the deep integration of industrialization and informatization of NEV manufacturing enterprises and promote the supply side structural reform of the NEV manufacturing industry, which is of great significance to reshape the new competitive advantages of the NEV manufacturing enterprises.

2.2. Hypotheses

Through sorting out the system architecture of NEV IM development capability, on the basis of previous research, this study considered many factors that may affect the development ability of new energy vehicle intelligent manufacturing and puts forward three hypotheses: external environment factors, commonalities among the NEV enterprises, and industry progress. Further study of the influence of various factors on the development ability of NEV IM is required.

2.2.1. External Environment Factors

As a new industry, NEVs need government support to develop smoothly. Many countries have introduced relevant policies to promote reform of the automobile industry, such as tax relief, car purchase subsidies, and research and development subsidies.20 Germany has done the best in this regard followed by China, the United States, and Japan.22 Policy and market integration is essential for the NEV industry, and the NEV market should be more inclusive, so as to create a healthy development environment.23 Many countries are adopting different strategies to stimulate consumers’ acceptance of NEVs, and the demand for NEVs in China has shown a sharp growth trend in recent years.24 The development of NEVs has become China’s national strategy. The competition and substitution between NEVs and traditional fuel vehicles are affecting the reconstruction of the automobile industry pattern.25

To sum up, in terms of external environment factors, national policy orientation, product market demand, and industry competition pressure are selected as the influencing factors, and the following assumptions are proposed:

H1: The external environment factors have a direct positive impact on the development ability of IM of NEVs;

H2: The external environment factors have a direct and positive impact on the development of the NEV industry and indirectly affect the development ability of NEV IM.

2.2.2. Commonalities among the NEV Enterprises

IM plays an important role in the industrial revolution 4.0 and is widely used in various fields and promotes the development of the industrial revolution.26 The development of IM of NEVs can reduce production costs, meet user needs, and save energy and environmental protection. However, there is no perfect legal system to ensure the safety of IM of vehicles at the same time.15 IM needs an open and safe platform and should be on-demand service-oriented, but there are also processing challenges and cross domain problems such as reliability, availability, and adaptability.27 The sustainable development ability of IM enterprises determines the vitality of enterprises, and the survival and growth of enterprises is affected by enterprise leaders, enterprise institutions, and external environment factors.28 The IM enterprises need to have good organizational management ability to deal with unknown risks and maintain competitive advantages in a complex environment.29

To sum up, in terms of commonalities among the NEV enterprises, the development security, reliability, and stability of IM are selected as the influencing factors, and the following assumptions are proposed:

H3: Commonalities among the NEV enterprises have a direct positive impact on the development ability of IM of NEVs;

H4: Commonalities among the NEV enterprises have a direct and positive impact on the development of NEV industry and indirectly affect the development ability of NEV IM.

2.2.3. Industry Progress

Under the promotion of the Energy Saving and NEV Industry Development plan (2012–2020), the Made in China 2025 plan, and other policies, the IM of NEVs has also ushered in various advantages, and the development prospect of the industry is worth looking forward to. The Internet of things and artificial intelligence gave birth to an intelligent chemical plant, promoted the innovation of IM technology, and improved the efficiency of production and manufacturing,30 and the NEV manufacturing enterprises have also realized the intelligent production workshop.31 The R&D personnel of NEVs often face the pressure of reducing the development cost and time, which requires the help of powerful computer-aided designs.32 IM plays an important role in mass customization and efficient production,26 and this is also the future development trend of manufacturing enterprises.33 The development of NEVs is based on technological innovation. Technological R&D is the source of innovation and the fundamental driving force of enterprise competitiveness.34 The success of the enterprise benefits from good management. In the era of industry 4.0, the whole process of manufacturing system is optimized with a new digital scheme, and lean management of the production system is implemented.35

To sum up, in terms of industry progress, the IM plant, intelligent product design, IM process, intelligent technology innovation, and intelligent production management are selected as the influencing factors, and the following assumption is proposed:

H5: The development of the industry has a direct positive impact on the development ability of IM of NEVs.

2.3. Research Design

Based on the previous theories and assumptions, this study further refined the influencing factor model of the NEV IM development ability by consulting references and intuitively produced the scale of factors influencing the development ability of IM of NEVs, as shown in Table 1.

Table 1. Scale of Factors Influencing the Development Ability of IM of NEVs.

| facets | variable | item |

|---|---|---|

| external environment factors (EEF) | national policy orientation (ZC) | purchase NEVs and enjoy national and local policy subsidies (ZC1) |

| exemption of vehicle and ship tax and purchase tax for the purchase of NEVs (ZC2) | ||

| NEV IM enterprises enjoy high-tech tax preference (ZC3) | ||

| unrestricted travel and purchase of NEVs (ZC4) | ||

| product market demand (SC) | NEV product model diversity (SC1) | |

| NEV IM product portfolio relevance (SC2) | ||

| intelligent degree of NEV products (SC3) | ||

| industry competition pressure (JZ) | competitive pressure of traditional fuel vehicles (JZ1) | |

| competitive pressure of foreign enterprises and joint ventures (JZ2) | ||

| improvement in the IM level of new energy automobile industry (JZ3) | ||

| improvement in the cost control ability of IM of NEVs (JZ4) | ||

| commonalities among the NEV enterprises (CANE) | IM development security (AQ) | IM information system and data security (AQ1) |

| equipment functional safety for IM (AQ2) | ||

| personnel safety in all links of IM (AQ3) | ||

| IM development reliability (KK) | plan, organize, coordinate, and supervise the IM system (KK1) | |

| guide and verify the IM system in terms of technical methods (KK2) | ||

| effective detection of IM system and products (KK3) | ||

| IM development stability (WD) | establish an index system to evaluate the performance and results of IM implementation (WD1) | |

| evaluation standard for maturity of IM capability (WD2) | ||

| implementation strategy of IM development and improvement of IM ability (WD3) | ||

| industry progress (IP) | IM plant (GC) | modeling and simulation for the overall design of the NEV manufacturing plant (GC1) |

| digital management of the NEV manufacturing plant construction process (GC2) | ||

| establish a big data management platform for the NEV IM industry (GC3) | ||

| Intelligent product design (SJ) | digital design and simulation of NEVs with computer-aided tools (SJ1) | |

| establish PDM of an NEV product data management system (SJ2) | ||

| product life cycle management for NEVs (SJ3) | ||

| IM process (LC) | simulation of the NEV production process with computer-aided tools (LC1) | |

| automatic production line has been equipped with IM equipment such as industrial robots (LC2) | ||

| intelligent recognition and sensing are widely used in manufacturing (LC3) | ||

| making full use of the human–computer interaction system for data and information processing in a manufacturing process (LC4) | ||

| intelligent technology innovation (JS) | high proportion of R&D investment in the IM technology of NEVs (JS1) | |

| high proportion of innovative R&D personnel for the IM of NEVs (JS2) | ||

| AI is widely used in innovative design, collaborative research, and development (JS3) | ||

| intelligent production management (GL) | using an ERP system to optimize the resource management of the NEV IM enterprise (GL1) | |

| establish an MES system to realize the whole process management of IM of NEVs (GL2) | ||

| using industrial big data, 5G, and cloud platform to provide intelligent decision-making for business management (GL3) | ||

| IM development ability (ZZ) | intelligent level of NEVs (ZZ1) | |

| IM of NEVs to reduce costs and increase efficiency (ZZ2) | ||

| shorten R & D cycle of NEV new products (ZZ3) | ||

| enterprises can perceive the IM information of NEVs and optimize the precise implementation in time (ZZ4) | ||

3. Computational Methods

3.1. Basic Data

In this study, data were collected by questionnaire, and a Likert scale was used to design the questionnaire of the factors influencing the development ability of NEV IM. The Likert scale is a common questionnaire method, which usually has a 5-point scale, a 7-point scale, and a 10-point scale. Based on the scale method of Förster and Gopal in the field of automobile,36,37 as well as the 10-point Likert scale of Dadamo,38 the questionnaire is divided into 10 levels for each item, and 10 points is the highest and 1 point is the lowest. As one of the key points of China’s industrial structure adjustment, NEVs undertake the task of upgrading from traditional industries to IM. The subjects of the questionnaire are mainly managers, technicians, and researchers in related fields of NEV manufacturing enterprises. A total of 600 questionnaires was sent out and 585 were recovered. After 57 invalid questionnaires were eliminated, 528 remained as valid questionnaires with an effective recovery rate of 88%.

3.2. Reliability and Validity Test

The data collected through the questionnaire need to have enough reliability and validity to ensure the correctness and validity of the analysis results.39 Therefore, before the empirical analysis, we first tested the reliability and validity of the questionnaire data.

The reliability analysis is mainly used to evaluate the stability or reliability of the questionnaire data. In this study, the Cronbach’s α method is used to test the original data. According to the opinion of most scholars, it is generally considered that the Cronbach’s α coefficient is acceptable when it is greater than 0.7. SPSS 22.0 software was used to analyze the reliability of the questionnaire data. The results are shown in Table 2. The overall Cronbach’s α coefficients of external environment factors, commonalities among the NEV enterprises, industrial development, and IM development ability are 0.877, 0.952, 0.969, and 0.893, respectively. The Cronbach’s α coefficients of variables are all within the acceptable range, and the Cronbach’s α coefficients are not improved after an item is deleted, so data reliability is very good.

Table 2. Reliability Test of Influencing Factors.

| facets | variable | item | Cronbach’s α | Cronbach’s α of deleted item | |

|---|---|---|---|---|---|

| external environment factors(EEF) | ZC | ZC1 | 0.877 | 0.791 | 0.738 |

| ZC2 | 0.749 | ||||

| ZC3 | 0.737 | ||||

| ZC4 | 0.736 | ||||

| SC | SC1 | 0.742 | 0.783 | ||

| SC2 | 0.656 | ||||

| SC3 | 0.634 | ||||

| JZ | JZ1 | 0.846 | 0.815 | ||

| JZ2 | 0.808 | ||||

| JZ3 | 0.829 | ||||

| JZ4 | 0.762 | ||||

| commonalities among the NEV enterprises(CANE) | AQ | AQ1 | 0.952 | 0.868 | 0.859 |

| AQ2 | 0.795 | ||||

| AQ3 | 0.779 | ||||

| KK | KK1 | 0.919 | 0.892 | ||

| KK2 | 0.85 | ||||

| KK3 | 0.905 | ||||

| WD | WD1 | 0.896 | 0.827 | ||

| WD2 | 0.829 | ||||

| WD3 | 0.894 | ||||

| industry progress(IP) | GC | GC1 | 0.969 | 0.907 | 0.905 |

| GC2 | 0.853 | ||||

| GC3 | 0.828 | ||||

| SJ | SJ1 | 0.88 | 0.82 | ||

| SJ2 | 0.806 | ||||

| SJ3 | 0.863 | ||||

| LC | LC1 | 0.925 | 0.909 | ||

| LC2 | 0.911 | ||||

| LC3 | 0.881 | ||||

| LC4 | 0.908 | ||||

| JS | JS1 | 0.924 | 0.905 | ||

| JS2 | 0.854 | ||||

| JS3 | 0.909 | ||||

| GL | GL1 | 0.908 | 0.811 | ||

| GL2 | 0.85 | ||||

| GL3 | 0.903 | ||||

| IM development ability(IMDA) | ZZ1 | 0.893 | 0.848 | ||

| ZZ2 | 0.884 | ||||

| ZZ3 | 0.857 | ||||

| ZZ4 | 0.859 | ||||

Validity analysis refers to the consistency between the results of the questionnaire and the content to be studied. In this study, the KMO test and the Bartlett spherical test were used to verify the validity of the data collected by the scale. Generally speaking, the validity is acceptable when the value of KMO is greater than 0.6. From the results of validity analysis shown in Table 3, it can be seen that the KMO values of external environment factors, commonalities among the NEV enterprises, industry progress, and IM development ability are all above 0.8, and the validity is very good. The Sig. value corresponding to the Bartlett spherical test is 0, less than 0.05, which can be further analyzed.

Table 3. Validity Test of Influencing Factor Variables.

| variable | KMO | chi-square | df | sig. |

|---|---|---|---|---|

| EEF | 0.87 | 359.043 | 55 | 0 |

| ZC | 0.676 | 43.476 | 36 | 0 |

| SC | 0.651 | 50.478 | 48 | 0 |

| JZ | 0.777 | 111.198 | 37 | 0 |

| CANE | 0.931 | 511.771 | 76 | 0 |

| AQ | 0.727 | 94.727 | 56 | 0 |

| KK | 0.747 | 141.701 | 33 | 0 |

| WD | 0.737 | 116.947 | 47 | 0 |

| IP | 0.904 | 1138.674 | 120 | 0 |

| GC | 0.731 | 130.49 | 35 | 0 |

| SJ | 0.736 | 101.371 | 39 | 0 |

| LC | 0.832 | 198.844 | 46 | 0 |

| JS | 0.741 | 147.498 | 53 | 0 |

| GL | 0.711 | 138.552 | 51 | 0 |

| IMDA | 0.834 | 146.431 | 36 | 0 |

According to the needs of the research hypotheses, this study conducted a correlation analysis on IM development ability, external environmental factors, commonalities among the NEV enterprises, and industry progress, as shown in Table 4. The results show that external environment factors, commonalities among the NEV enterprises, industry progress, and IM development ability have significant positive correlation. This proves the feasibility of the hypotheses to some extent. In order to further explore the relationship between variables, a second-order structural equation is used for testing.

Table 4. Correlation Test of Influencing Factor Variables.

| variable | 1 | 2 | 3 | 4 |

|---|---|---|---|---|

| external environment factors | 0.924 | |||

| commonalities among the NEV enterprises | 0.892c | 0.917 | ||

| industry progress | –0.099a | 0.899c | 0.927 | |

| IM development ability | 0.437b | 0.677b | 0.651b | 0.818 |

Indicates significant correlation at 0.05 level.

Indicates significant correlation at 0.01 level.

Indicates significant correlation at 0.001 level, and the diagonal is the square root of AVE.

3.3. Confirmatory Factor Analysis

In order to ensure the accuracy and efficiency of the analysis, before the structural equation model analysis of the factors affecting the development of IM of NEVs, the degree of fitting of each facet of the structural equation model is tested, and then the overall fit of the model is tested. Structural equation model checking can be divided into two parts: measurement model analysis and structural model analysis.

Generally speaking, the method of confirmatory factor analysis is used for the measurement model analysis. In this study, software Amos 25.0 is used for the confirmatory factor analysis, and the results are shown in Table 5. The results show that the fitting index of each measurement model basically reaches the standard of the acceptable value.

Table 5. Analysis Results of Structural Equation Measurement Model of Influencing Factors of NEVs.

| fitting index | CMIN/DF | RMSEA | GFI | AGFI | IFI | TLI | CFI | PNFI | PCFI |

|---|---|---|---|---|---|---|---|---|---|

| acceptable value | < 3 | < 0.05 | > 0.9 | > 0.9 | > 0.9 | > 0.9 | > 0.9 | > 0.5 | > 0.5 |

| external environment factors | 1.968 | 0.023 | 0.926 | 0.920 | 0.905 | 0.939 | 0.918 | 0.590 | 0.656 |

| commonalities among the NEV enterprises | 1.098 | 0.039 | 0.914 | 0.938 | 0.995 | 0.993 | 0.995 | 0.634 | 0.664 |

| industry progress | 2.015 | 0.026 | 0.965 | 0.960 | 0.917 | 0.892 | 0.916 | 0.665 | 0.717 |

| IM development ability | 0.662 | 0.016 | 0.990 | 0.952 | 0.991 | 0.974 | 0.914 | 0.633 | 0.653 |

Generally speaking, a path analysis is used in the structural model analysis, which is verified by the load value of each path factor. The standardized factor load results are shown in Table 6. The structural equation model is based on data driving, and there is no uniform standard for the critical value of the factor load. This study refers to the view of the structural equation model and its application, and a factor load above 0.45 can be accepted.40 It can be seen from Table 6 that the load of each facet factor is far greater than 0.45, and the fitting degree of the model is good.

Table 6. Structural Equation Model Factor Load of Influencing Factors.

| facets | variable | factor loads | item | factor loads | facets | variable | factor loads | item | factor loads |

|---|---|---|---|---|---|---|---|---|---|

| EEF | ZC | 0.59 | ZC1 | 0.65 | IP | GC | 0.84 | GC1 | 0.80 |

| ZC2 | 0.69 | GC2 | 0.82 | ||||||

| ZC3 | 0.72 | GC3 | 0.91 | ||||||

| ZC4 | 0.74 | SJ | 0.96 | SJ1 | 0.84 | ||||

| SC | 0.89 | SC1 | 0.58 | SJ2 | 0.89 | ||||

| SC2 | 0.87 | SJ3 | 0.80 | ||||||

| SC3 | 0.72 | LC | 1.00 | LC1 | 0.87 | ||||

| JZ | 1.00 | JZ1 | 0.76 | LC2 | 0.90 | ||||

| JZ2 | 0.76 | LC3 | 0..9 | ||||||

| JZ3 | 0.71 | LC4 | 0.87 | ||||||

| JZ4 | 0.86 | JS | 0.86 | JS1 | 0.86 | ||||

| CANE | AQ | 0.91 | AQ1 | 0.78 | JS2 | 0.96 | |||

| AQ2 | 0.83 | JS3 | 0.87 | ||||||

| AQ3 | 0.89 | GL | 0.87 | GL1 | 0.94 | ||||

| KK | 1.00 | KK1 | 0.88 | GL2 | 0.91 | ||||

| KK2 | 0.93 | GL3 | 0.79 | ||||||

| KK3 | 0.87 | IMDA | ZZ | 1.00 | ZZ1 | 0.79 | |||

| WD | 0.95 | WD1 | 0.89 | ZZ2 | 0.71 | ||||

| WD2 | 0.87 | ZZ3 | 0.82 | ||||||

| WD3 | 0.83 | ZZ4 | 0.81 |

3.4. Overall Test of the Structural Equation Model

After testing, the questionnaire data have good reliability and validity, and the confirmatory factor analysis of each facet model shows convergence state, which can further test the overall fit of the structural equation model. Software Amos 25.0 is used to test the structural equation model of the influencing factors of NEV IM development capability; the fitting index of the first validation measurement model is shown in Table 7, and the analysis results of the structural model are shown in Figure 3. The test results show that the fitting index of the measurement model does not fully meet the standard of the acceptable value. In the structural model analysis, the factor load coefficient of the three paths from external environment factors to industry progress, external environment factors to IM development capability, and commonalities among the NEV enterprises to industry progress is less than 0.45, which is not up to the standard of the acceptable value. According to the suggestion of software and the references, the structural equation model of the influencing factors on the development ability of the IM of NEVs is modified properly.

Table 7. Fitting Index of Measurement Model for Influencing Factors of IM Development Ability of NEVs.

| fitting index | CMIN/DF | RMSEA | GFI | AGFI | IFI | TLI | CFI | PNFI | PCFI |

|---|---|---|---|---|---|---|---|---|---|

| acceptable value | < 3 | < 0.05 | > 0.9 | > 0.9 | > 0.9 | >0.9 | > 0.9 | > 0.5 | > 0.5 |

| model fitting results | 2.131 | 0.053 | 0.842 | 0.846 | 0.837 | 0.803 | 0.825 | 0.544 | 0.670 |

| correction of fitting results | 2.126 | 0.042 | 0.924 | 0.941 | 0.927 | 0.902 | 0.922 | 0.545 | 0.672 |

Figure 3.

Validation analysis results of structural model of influencing factors of IM development ability of NEVs.

The factor load of the two paths from external environment factors to industry progress and from commonalities among the NEV enterprises to NEV IM development capability is far less than 0.45, indicating that the influence of variables is not significant. These two paths are deleted to modify the structural equation model under the original assumption, and then software Amos 25.0 is used to test the modified structural equation model of the influencing factors of NEV IM development capability. The fitting index of the measurement model and the analysis results of the structural model are shown in Table 5 and Figure 4, respectively. The fitting index and the factor load of the modified structural equation measurement model are all acceptable, and the fitting degree of the model is good.

Figure 4.

Structure model validation analysis results of factors influencing the development ability of IM of NEVs after modification.

4. Results and Discussion

The hypothesis test results of the factors influencing the development ability of IM of NEVs are summarized as follows:

H1: The external environment factors have a significant positive impact on the development ability of IM of NEVs (β = 0.463, p < 0.01), and the original hypothesis is established;

H2: The external environment factors have no significant impact on the development of new energy automobile industry (β = −0.099, p = 0.152), and the original hypothesis is not true;

H3: Commonalities among the NEV enterprises have no significant impact on the development ability of NEV IM (β = 0.105, p = 0.677), and the original hypothesis is not true;

H4: Commonalities among the NEV enterprises have a significant positive impact on the development of the NEV industry and indirectly affect the development ability of NEV IM (β = 0.886, p < 0.01), and the original hypothesis is established;

H5: Industry progress has a significant positive impact on the development of NEV IM (β = 0.695, p < 0.01), and the original hypotheses is established.

Ever since the concept of IM was first established, scholars have worked greatly to develop the relevant theories. Yu et al. have put forward a five-layer system in which the IM is characterized by independent intelligent sensing, interconnection, collaboration, learning, analysis, decision-making, control, etc.44 Based on the IM standard system set by the Guidelines for the Construction of National IM Standard System (2018 Edition),21 this research creates a new analysis system for NEV IM, from three aspects of system level, life cycle, and intelligent characteristics.41 The theory of enterprise development was formed in the 1960s, and the design school represented by the SWOT analysis model believes that the external environment factors play a decisive role in the development of enterprises.42 The positioning school represented by the Porter’s five force model suggests that the factors affecting the competitive state of enterprises include five aspects: competitors, potential entrants, substitutes, buyers, and suppliers.43 This study fully considers the factors that may affect the development ability of NEV IM and puts forward relevant hypotheses, which are tested by empirical analysis.

Since China launched the 10 Cities and 1000 Vehicles plan in 2009, it has accelerated the commercialization process of NEVs.44 In recent years, NEVs have occupied a leading position in China’s automobile market and developed rapidly due to government subsidies, tax preferences, technical support, and other policy factors.45 However, with the gradual weakening impact of policies, the sustainable development of NEVs will depend mainly on technological innovation and infrastructure improvement.25 In the future, consumers’ demand for NEVs will be technological and intelligent.46 Internal competition in the industry will also result in the origin of demand, and the development of IM such as intelligent interconnection and automatic driving will become the commanding point of competition.47 Therefore, affected by policy changes, the impact of external environment factors on the development of NEV industry is declining, and the impact on the development ability of NEV IM will continue to increase.

At present, China has become the largest market of NEVs, and the policy focus of the Chinese government has begun to change from industrial expansion to technological innovation.48 Safety, reliability, and stability, as the basic elements of the development system of IM, are also the basis for evaluating the development level of IM of NEVs.49 Keeping data information and IM equipment safe can ensure the safety of personnel in all links.50 Based on advanced technology and methods to effectively detect products, a reliable IM system is established.51 It has established a perfect index system and mature evaluation standards and has a stable development implementation strategy.52 All of the above promote the development of new energy automobile industry to different degrees. The study shows that commonalities among the NEV enterprises directly promote the development of NEV industry and indirectly improve the development ability of NEV IM.

In other previous studies, Zhao et al. summarized the studies on the key technologies in the development of new energy automobile industry and briefly introduced the development objectives of related industries.53 Gang pointed out that the emerging intelligent technologies lead the development direction of China’s new energy automobile industry.6 The intelligent development of the new energy automobile industry is reflected in the manufacturing plant, product design, manufacturing process, technological innovation, production management, and other aspects. Innovation drives the new energy automobile industry to move toward high-quality development. The study found that the industry progress has a positive impact on the development ability of IM of NEVs.

5. Conclusions and Implications

5.1. Conclusions

Based on the structural equation model, this study analyzes the main factors that influence the development ability of IM of NEVs. The empirical analysis indicates that the external environment factors and industry progress are the main factors affecting the development ability of NEV IM; commonalities among the NEV enterprises indirectly affect the development ability of NEV IM through industry progress. Among the three, the IP has the greatest impact on the development of NEV IM, not only a direct effect but also as a bridge to transmit the effect from commonalities among the NEV enterprises to NEV IM.

The external environment factors have a direct positive effect among which the impact of competition pressure is the largest, market demand is the second, and the national policy guidance is the least. Unlike the hypotheses, it is revealed that the external environment factors have no significant effect on the industry progress. After more than 10 years of rapid development, China’s new energy automobile industry has reached a bottleneck period. The main challenge it is facing currently is how to boost innovation and intelligent development.

The industry progress has a direct positive effect on the development ability of IM of NEVs. The influencing factors sorted by impact from high to low are intelligent processing, intelligent designing, intelligent management, technology innovation, and intelligent equipment. The factor of industry progress spans the system level and life cycle dimensions of the NEV IM development capability system architecture. It not only meets the specific requirements of the industry, but also meets the common needs of the external environment factors and foundation. Promoting intelligent development has a very significant positive effect on the development ability of IM of NEVs.

The commonalities among the NEV enterprises have no significant direct effect on the development ability of NEV IM. However, the security, reliability, and stability of IM development are closely related to the industry progress. Therefore, it has a direct and positive effect on the industry progress and then indirectly affects the development ability of NEV IM.

5.2. Implications

According to the empirical analysis results, this study makes some suggestions to promote the development of NEV IM from three aspects: government, industry, and enterprise:

Government: The authorities should provide preferential policies to promote the restructuring of the traditional vehicle industry and support the NEV enterprises’ mergers and reorganization, as well as market competition. The original intention of stimulating the consumption of NEVs through subsidy policies has been basically achieved. It is a general trend to shift from policy-driven to market-oriented. Industrialization and informatization should be deeply integrated to make breakthroughs in NEV IM. The bottleneck of NEV development, such as battery size and endurance ability, needs to be solved as soon as possible. At present, all countries in the world are competing for the market of NEVs, so it is necessary to provide infrastructure for construction and promote the development of IM. In addition to technological innovation and upgradation, infrastructure for construction and improvement in supporting facilities are still the key to a better market prospect of NEVs. It is suggested that the infrastructure must be improved through strengthening the collaborative innovation of industrial chain, accelerating the upgradation of infrastructure, gradually completing the intelligent upgradation of production line based on the concept of green development, optimizing process management using big data and Internet thinking, and accelerating the construction of intelligent charging piles.

5.2.1. Industry

From the perspective of an industrial development situation, NEVs have passed the initial stage of development. High quality development is the general trend. The NEV industry should be transformed from quantity to quality. At present, there are obvious low-end overcapacity and low-end capacity problems in the NEV industry. It is suggested that the NEV industry should be rational, pay attention to quality, and speed up the shift to high-quality development. First, rational investment is required, from attracting investment to strengthening competition. Second, attention should be paid to research and development to improve the intelligence, safety, and reliability of the products. The third is to speed up the supplement of short boards such as smart chips and controllers.

5.2.2. Enterprise

At present, the threshold of government subsidies is constantly increasing, and the indicators of existing policies are also inclined to intelligence, safety, and reliability. It is suggested that the NEV manufacturers should review the situation and adjust their development strategies. First, close attention should be paid to the technical indicators and adjustment trend of the current policy system. Second, they should aim at the market demand, the cutting-edge technology, and the product layout after the withdrawal of subsidies in advance. Third, they should do a good job in fund guarantee, strengthen the coordinated development of the industrial chain, and establish a risk-sharing mechanism for the industrial chain.

Acknowledgments

This research was funded by the National Social Science Fund of China [grant number No. 16BJY078] and the Heilongjiang Soft Science Project [grant number No. GC16D102].

Author Contributions

F.M. and X.J. conceived the study; F.M. and X.J. proposed the methodology; J.C. and W.Z. performed software analysis; J.C. and W.Z. conducted validations; X.J. conducted a formal analysis; X.J. and M.L. conducted the investigation; X.J. and M.L performed data curation; X.J. prepared the original draft; and F.M. wrote the manuscript, reviewed, and edited it.

The authors declare no competing financial interest.

References

- Bilgen S. Structure and environmental impact of global energy consumption. Renew. Sustain. Energ. Rev. 2014, 38, 890–902. 10.1016/j.rser.2014.07.004. [DOI] [Google Scholar]

- Jin X.; Li M.; Meng F. Comprehensive Evaluation of the New Energy Power Generation Development at the Regional Level: An Empirical Analysis from China. Energies 2019, 12, 4580. 10.3390/en12234580. [DOI] [Google Scholar]

- Granovskii M.; Dincer I.; Rosen M. A. Economic and environmental comparison of conventional, hybrid, electric and hydrogen fuel cell vehicles. J. Power Sources 2006, 159, 1186–1193. 10.1016/j.jpowsour.2005.11.086. [DOI] [Google Scholar]

- Geng W.; Ming Z.; Lilin P.; Ximei L.; Bo L.; Jinhui D. China′s new energy development: Status, constraints and reforms. Renew. Sustain. Energ. Rev. 2016, 53, 885–896. 10.1016/j.rser.2015.09.054. [DOI] [Google Scholar]

- Vassileva L.; Campillo J. Adoption barriers for electric vehicles: Experiences from early adopters in Sweden. Energy 2017, 120, 632–641. 10.1016/j.energy.2016.11.119. [DOI] [Google Scholar]

- New energy technology and intelligent development lead the major changes in the automotive industry. Available online: http://en.foresight-energy.cn/content/?121.html (accessed on 16 April 2020).

- Kinoshita K.Exploratory technology research program for electrochemical energy storage. Lawrence Berkeley National Lab: CA (United States)1992. [Google Scholar]

- Kimble C.; Wang H. China’s new energy vehicles: value and innovation. J. Bus. Strategy 2013, 34, 13–20. 10.1108/02756661311310413. [DOI] [Google Scholar]

- Åhman M. Government policy and the development of electric vehicles in Japan. Energy Policy 2006, 34, 433–443. 10.1016/j.enpol.2004.06.011. [DOI] [Google Scholar]

- Hermans J.Energy survival guide: insight and outlook. Leiden University Press; 2011. [Google Scholar]

- Tabor D. P.; Roch L. C. M.; Saikin S. K.; Kreisbeck C.; Sheberla D.; Montoya J. H.; Dwaraknath S.; Aykol M.; Ortiz C.; Tribukait H.; Aspuru-Guzik A. Accelerating the discovery of materials for clean energy in the era of smart automation. Nat. Rev. Mater. 2018, 3, 5. 10.1038/s41578-018-0005-z. [DOI] [Google Scholar]

- Kassen A. G.; White E. M. H.; Hu L.; et al. Novel mechanisms for solid-state processing and grain growth with micro structure alignment in alnico-8 based permanent magnets. AIP Adv. 2018, 8, 056206–056207. 10.1063/1.5007850. [DOI] [Google Scholar]

- Liu C.; Gao X.; Ma W.; Chen X. Research on regional differences and influencing factors of green technology innovation efficiency of China’s high-tech industry. J. Comput. Appl. Math. 2019, 369, 112597. 10.1016/j.cam.2019.112597. [DOI] [Google Scholar]

- Chengpeng S. NEVs will become the vehicles of the future. China Awards Sci. Tech. 2015, 6, 41–42. [Google Scholar]

- Peihong X. Y. Z.; Xianzhong M. The future of China’s automobile intelligent manufacturing. Tsinghua Bus. Rev. 2018, Z1, 90–93. [Google Scholar]

- He Y. On the development of NEVs and intelligent manufacturing. Sci. Technol. Innov. 2017, 3, 101. [Google Scholar]

- Yufeng H. J. L.; Chao S. Intelligent Development and Trends for NEVs. Automot. Digest 2019, 8, 14–21. [Google Scholar]

- Jiang C.; Zhang Y.; Bu M.; Liu W. The Effectiveness of Government Subsidies on Manufacturing Innovation: Evidence from the New Energy Vehicle Industry in China. Sustainability 2018, 10, 1692. 10.3390/su10061692. [DOI] [Google Scholar]

- Bin W. Research on the Training of Application-oriented Automobile Professionals in the Background of Intelligent Manufacturing. J. Vocat. Educ. 2018, 692, 150–154. [Google Scholar]

- Yang D. Y.; Xu; Tianshu P.; Peng Z. Research on Development Strategy for China’s Powerful Automobile Industry. Strat. Study CAE 2018, 20, 37–44. [Google Scholar]

- Notice of the two departments on printing and distributing the construction guide of national intelligent manufacturing standard system (2018 version). Availabe online: http://www.gov.cn/xinwen/2018-10/16/content_5331149.htm (accessed on 16 April 2020).

- Ma Y.; Shi T.; Zhang W.; Hao Y.; Huang J.; Lin Y. Comprehensive policy evaluation of NEV development in China, Japan, the United States, and Germany based on the AHP-EW model. J. Cleaner Prod. 2019, 214, 389–402. 10.1016/j.jclepro.2018.12.119. [DOI] [Google Scholar]

- Hu Z.; Yuan J. China’s NEV market development and its capability of enabling premium NEV: Referencing from the NEV market performance of BMW and Mercedes in China. Transp. Res. Part A Policy Pract. 2018, 118, 545–555. 10.1016/j.tra.2018.10.010. [DOI] [Google Scholar]

- Zhou Y.; Wang M.; Hao H.; Johnson L.; Wang H. Plug-in electric vehicle market penetration and incentives: a global review. Mitig. Adapt. Strateg. Glob. Chang. 2015, 20, 777–795. 10.1007/s11027-014-9611-2. [DOI] [Google Scholar]

- Sun S.; Wang W. Analysis on the market evolution of new energy vehicle based on population competition model. Transp. Res. Part D Transp. Environ. 2018, 65, 36–50. 10.1016/j.trd.2018.08.005. [DOI] [Google Scholar]

- Zhong R.; Xu X.; Klotz E.; Newman S. T. Intelligent Manufacturing in the Context of Industry 4.0: A Review. Engineering 2017, 3, 616–630. 10.1016/J.ENG.2017.05.015. [DOI] [Google Scholar]

- Wang J.; Zhang L.; Duan L.; Gao R. X. A new paradigm of cloud-based predictive maintenance for intelligent manufacturing. J. Intell. Manuf. 2017, 28, 1125–1137. 10.1007/s10845-015-1066-0. [DOI] [Google Scholar]

- Chen S.-H. The Influencing Factors of Enterprise Sustainable Innovation: An Empirical Study. Sustainability 2016, 8, 425. 10.3390/su8050425. [DOI] [Google Scholar]

- Davies A.; Brady T. Organisational Capabilities and Learning in Complex Product Systems: Towards Repeatable Solutions. Res. Policy 2000, 29, 931–953. 10.1016/S0048-7333(00)00113-X. [DOI] [Google Scholar]

- Hu L.; Miao Y.; Wu G.; Hassan M.; Humar I. iRobot-Factory: An intelligent robot factory based on cognitive manufacturing and edge computing. Future Gener. Comput. Syst. 2018, 90, 569. 10.1016/j.future.2018.08.006. [DOI] [Google Scholar]

- Zhou K.; Liu T.; Zhou L.. Industry 4.0: Towards future industrial opportunities and challenges; 2015; 2147–2152, 10.1109/FSKD.2015.7382284pp. [DOI] [Google Scholar]

- Hirz M.; Dietrich W.; Gfrerrer A.; Lang J.. Integrated Computer-Aided Design in Automotive Development; 2013; 10.1007/978-3-642-11940-8. [DOI] [Google Scholar]

- Wang L.; Törngren M.; Onori M. Current status and advancement of cyber-physical systems in manufacturing. J. Manuf. Syst. 2015, 37, 517–527. 10.1016/j.jmsy.2015.04.008. [DOI] [Google Scholar]

- Filippetti A. Innovation modes and design as a source of innovation: A firm-level analysis. Eur. J. Innov. Manag. 2011, 14, 5–26. 10.1108/14601061111104670. [DOI] [Google Scholar]

- Enke J.; Glass R.; Kreß A.; Hambach J.; Tisch M.; Metternich J. Industrie 4.0 – Competencies for a modern production system. Procedia Manuf. 2018, 23, 267–272. 10.1016/j.promfg.2018.04.028. [DOI] [Google Scholar]

- Förster B. Technology foresight for sustainable production in the German automotive supplier industry. Technol. Forecast. Soc. Change 2015, 92, 237–248. 10.1016/J.TECHFORE.2014.09.010. [DOI] [Google Scholar]

- Gopal P. R.; Thakkar J. Sustainable supply chain practices: an empirical investigation on Indian automobile industry. Prod. Plan. Control 2016, 27, 49–64. 10.1080/09537287.2015.1060368. [DOI] [Google Scholar]

- Dadamo I.; Gastaldi M.; Rosa P. Recycling of end-of-life vehicles: Assessing trends and performances in Europe. Technol. Forecast. Soc. Change 2020, 152, 119887. 10.1016/j.techfore.2019.119887. [DOI] [Google Scholar]

- Carmines E.; Zeller R. Reliability and Validity Assessment. Basic Measure. 1985, 1–58. [Google Scholar]

- Jietai H.Structural equation model and its application. In Structural equation model and its application, Education Science Press: 2004. [Google Scholar]

- Li B.; Hou B.-C.; Yu W.-T.; Lu X.-B.; Yang C.-W. Applications of artificial intelligence in intelligent manufacturing: a review. Front. Inform. Technol. Electron. Eng. 2017, 18, 86–96. 10.1631/FITEE.1601885. [DOI] [Google Scholar]

- Andrews K. R. Directors’ responsibility for corporate strategy. Harv. Bus. Rev. 1980, 58, 30–42. [Google Scholar]

- Pervan M.; Curak M.; Pavic Kramaric T. The Influence of Industry Characteristics and Dynamic Capabilities on Firms’ Profitability. Int. J. Financial Stud. 2017, 6, 4. 10.3390/ijfs6010004. [DOI] [Google Scholar]

- Gong H.; Wang M.; Wang H. New energy vehicles in China: Policies, demonstration, and progress. Mitig. Adapt. Strateg. Glob. Chang. 2012, 18, 207. 10.1007/s11027-012-9358-6. [DOI] [Google Scholar]

- Li W.; Long R.; Chen H. Consumers’ evaluation of national new energy vehicle policy in China: An analysis based on a four paradigm model. Energy Policy 2016, 99, 33–41. 10.1016/j.enpol.2016.09.050. [DOI] [Google Scholar]

- Tingting H. L. B. Three key words of automobile demand in 2014: new energy, technology and intelligence. Financial World 2014, 8, 97. [Google Scholar]

- Ye X.Research on the Development Trend of Intelligent Vehicle; 2017; 10.2991/ammsa-17.2017.88. [DOI] [Google Scholar]

- Jinan Z. The development trend and restricting factors of NEVs in China. Auto Time 2019, 4, 87–88. [Google Scholar]

- Meng F.; Jin X. Evaluation of the Development Capability of the New Energy Vehicle Industry: An Empirical Study from China. Sustainability 2019, 11, 2635. 10.3390/su11092635. [DOI] [Google Scholar]

- Pan X.; Chen W.; Wu L. Mobile User Location Inference Attacks Fusing with Multiple Background Knowledge in Location-Based Social Networks. Mathematics 2020, 8, 262. 10.3390/math8020262. [DOI] [Google Scholar]

- Lee J.; Bagheri B.; Kao H.-A. A Cyber-Physical Systems architecture for Industry 4.0-based manufacturing systems. SME Manuf. Lett. 2014, 3, 18. 10.1016/j.mfglet.2014.12.001. [DOI] [Google Scholar]

- Dong X.; Wang B.; Yip H. L.; Chan Q. N. CO2 Emission of Electric and Gasoline Vehicles under Various Road Conditions for China, Japan, Europe and World Average—Prediction through Year 2040. Appl. Sci. 2019, 9, 2295. 10.3390/app9112295. [DOI] [Google Scholar]

- Zhao H.; Li G.; Wang N.; Zheng S.; Yu L.; Gao Y. Research Status of Several Key Technologies for the Development of Electric Vehicles. Appl. Mech. Mater. 2012, 160, 361–365. 10.4028/www.scientific.net/AMM.160.361. [DOI] [Google Scholar]