Abstract

Sigumjang is a traditional Korean fermented barley bran consumed in the Gyungsang-do area. In this study, pork loin was marinated with sigumjang, and its physicochemical and textural properties were investigated. Sigumjang-marinated pork loin (SMPL) displayed an attractive yellowish-brown overall color. SMPL’s pH marginally increased during storage and finally equilibrated to the pH of sigumjang, 5.5, on day 14. The amino-type nitrogen content of SMPL increased linearly during the marination period. Due to the lower extractability and higher pH compared to the control, the volume of myofibrillar fragments in SMPL decreased during the marination period. SMPL showed an increase in free amino acids related to umami (Asp and Glu) and sweet (Ser, Thr, Ala and Gly) tastes compared to the control. These may indicate improvement of sensory qualities of SMPL. The results also provide valuable information for the use of sigumjang in the development of novel meat products.

Keywords: Sigumjang (fermented barley bran), Marinated meat, Umami taste, Pork loin

Introduction

Sigumjang is a traditional Korean fermented barley bran consumed in the Gyungsang-do area. The appearance, taste, and flavor of sigumjang differ from those of traditional Korean doenjang (fermented bean pastes). Unlike other traditional Korean fermented foods that contain over 10% sodium, sigumjang contains a low sodium level of less than 3%, as well as a less distinctive taste and odor. Therefore, sigumjang has the potential to be applied to various foods, including meat (Jeong et al., 2016). In South Korea, pork is the most commonly consumed meat, and its consumption has gradually increased in recent years (KMTA, 2014). However, consumers show a unique consumption pattern and a stronger preference for high-fat belly or Boston butt compared to low-fat loin or ham (Cho et al., 2007; Ngapo et al., 2007; Oh and See, 2012). This unique consumption pattern has led to an imbalance between supply and demand for pork belly, resulting in a substantial dependence on imports from other countries. Thus, adequate processing techniques for unattractive pork cuts are required (Jin and Kim 2004). Meat marination is a widespread precooking method for improving meat characteristics, such as taste, texture, juiciness, and flavor, while reducing the creation of potentially harmful compounds (Kuttappan et al., 2016; Perlo et al., 2010; Saha et al., 2009b). The Japanese often use miso, a traditional fermented soy sauce, not only for soups or as a seasoning, but also as a marinade for meat and fish due to its low salt content and mild properties. Marinated pork loin using miso (miso-pickled pork) is consumed not only in Japan, but worldwide. Unfortunately, it is not popular to use traditional Korean Jang (doenjang) as a marinade for meat due to its high salt content and unique odor. Therefore, in this study, we marinated pork loin with sigumjang and investigated its physicochemical and textural properties, as well as the optimal marination time.

Materials and methods

Preparation of sample

Fresh pork loins, 48 h post-mortem, were obtained from a local livestock packaging center in 2017, and the samples were sliced into 1.5 cm thick pieces. Sigumjang was prepared according to the general method used previously (Jeong et al., 2016). Briefly, sigumjang meju was made with steamed barley bran and water, mixed with B. amyloliquefaciens MFST KCCM11719P (KCCM, Seoul, Korea), and then fermented at 25 °C for 2 weeks. Subsequently, the sigumjang meju was blended with barley, water (1:1:0.5), and NaCl (3% of total volume) and fermented at 25 °C for 5 days to obtain sigumjang. After removing visible connective tissue and fat, the pork loins were soaked in sigumjang at a ratio of 1:1 for marination. The marination was carried out for 14 days at 4 °C and sampled on days 1, 7, and 14 for the designed experiments. The excess sigumjang from the pork loin samples was thoroughly removed with Kimwipes. All assays were done in triplicate.

Color

The sample’s color was measured using a chroma meter (CR-200, Minolta, Osaka, Japan). The results are shown as Hunter’s L, a, and b: L* (black-white component), and the chromatic coordinates a* (+ red to − green component) and b* (+ yellow to − blue component).

pH and amino type nitrogen

Five grams of sample meat was roughly sliced and mixed with 45 mL of distilled water. A slurry was then made using a homogenizer (AM-11; Nihonseiki Kaisha Ltd., Tokyo, Japan). The pH was measured using a pH meter (ORION 3 STAR; Thermo Electron Co., Waltham, MA, USA). The amino type nitrogen was measured by the Formal method (AOAC, 1990).

Myofibril fragmentation index (MFI)

Myofibrils from the sample meat were obtained according to the method of Olson et al. (1976) and suspended in a buffer (pH 7.0, 100 mM KCl, 20 mM potassium-phosphate, 1 mM NaN3, 1 mM EDTA). An aliquot of the myofibril suspension was diluted with the buffer to obtain a protein concentration of 0.5 mg/mL, and the absorbance of this suspension was measured using a spectrophotometer (UV-1240, Shimadzu Co., Kyoto, Japan) at 540 nm.

MFI scores were calculated as follows: MFI = Optical density at 540 nm × 200

Cooking loss

Each marinated pork loin was cut into about weight 50 ± 5 g. Then it was placed into a polypropylene bag, boiled for 30 min at 75 °C in a water bath, and cooled to room temperature. The percentage of cooking loss was obtained by measuring the weight change of the sample before and after cooking.

Composition of free amino acids

Free amino acids from the sample were measured using an amino acid analyser (L-8800, GMI Co., Ramsey, MN, USA). Prior to analysis, 15 g of each sample was blended with 100 mL of distilled water and 15 mL of 20% trichloroacetic acid (Sigma-Aldrich, St. Louis, MO, USA). In order to remove the precipitated protein, the samples were centrifuged at 1811 × g for 20 min. The supernatant was mixed with ethyl ether to separate the lipids, after which the separated water layer was evaporated. The water layer concentrate was dissolved in 0.2 M citrate buffer (pH 2.2) and filtered through a 0.22 μm membrane (Millipore, Billerica, MA, USA).

Statistical analysis

Data from individual experiments are expressed as the mean ± standard deviation. All statistical analyses were performed using Statistical Package for the Social Sciences version 20 for Windows software (SPSS, Chicago, IL, USA). One-way ANOVA analysis of variance was conducted to examine if the treatment effect was significant. Duncan’s multiple range test was followed to identify which treatment yields significant different mean from the others. The treatment effect and group differences were considered significant when p < 0.05.

Results and discussion

Color and pH

The color of meat is a key factor for consumer satisfaction with regards to meat products (Huidobro et al., 2005). Figure 1 and Table 1 show the change in the color of sigumjang-marinated pork loin (SMPL) during storage at 4 °C. The changes in color were mostly related to marination or non-marination, and not the storage period. SMPL showed lower lightness (L*) and redness (a*), but higher yellowness (b*) compared to non-marinated pork loin during storage. The yellowness of SMPL slowly decreased with time but was still almost two-fold higher than that of the non-marinated sample. The dark-yellow color of SMPL could be attributed to the brownish color of sigumjang. Kim et al. (2014) indicated that an increase in the sodium chloride concentration of a marinade could linearly reduce the lightness in the color of meat.

Fig. 1.

Appearance of marinated pork loin with sigumjang. Day 0 describes the non-marinated pork loin. Days 1-14 describes the pork loin marinated with sigumjang at 4 °C

Table 1.

Changes in the surface meat color (L*-, a*-, and b*-values) of pork loin marinated with sigumjang during storage at 4 °C

| Storage days | Color | ||

|---|---|---|---|

| L(lightness) | a(redness) | b(yellowness) | |

| 0 | 46.09 ± 1.39a | 15.51 ± 0.47a | 4.38 ± 0.40c |

| 1 | 31.52 ± 0.82bc | 12.21 ± 0.56b | 9.87 ± 0.31a |

| 7 | 30.82 ± 2.57c | 9.57 ± 0.77c | 8.25 ± 0.41b |

| 14 | 33.54 ± 1.03b | 9.38 ± 0.33c | 8.02 ± 0.55b |

All values are mean ± the standard deviation of three replicates. Means in the same column with different superscript letters are significantly different (p < 0.05)

There were no dramatic changes in pH during marination; the pH of SMPL marginally increased with time and was finally equilibrated to pH 5.5, which is the pH of sigumjang (not presented). Therefore, the pH of SMPL was affected by sigumjang. It was previously reported that the pH of beef jerky cured with soybean paste was also affected by the curing ingredient (Lim et al., 2014).

Amino type nitrogen, myofibril fragmentation index (MFI), and cooking loss

The content of amino type nitrogen in aged or cured foods is an important index for the degree of aging and is related to taste quality (Ku et al., 2014). The amino type nitrogen content of SMPL increased linearly with marination time (p < 0.05), as shown in Table 2. There was a similar report showing that pH and amino type nitrogen increase during the curing period (Cho et al., 2000). MFI has been widely used to explain the degree of myofibrillar protein fragmentation (Wilhelm et al., 2010; Yu et al., 2005). However, in this study, the MFI of SMPL was reduced during the marination period. This could be explained by the lower extractability of SMPL and higher pH compared to non-marinated pork loin. The MFI reflects changes in meat pH with age, and the MFI of aged pork loin was shown to be lowest at a pH between 5.5 and 6.5 (Watanabe et al., 1996). During marination, moisture from the SMPL leaked into the sigumjang due to osmotic activity, with the result of the SMPL being tougher than the non-marinated pork loin. SMPL resisted the gentle homogenization required for the preparation of myofibrillar protein, resulting in low myofibrillar protein extraction, regardless of the weakening Z-line proteins. MFI measures the fragility of myofibrils, which is due to the weakening of Z-line proteins. Consequently, when meat is gently homogenized, myofibrils break into increasingly small segments (Watanabe et al., 1996). Kim et al. (2014) suggested that the difference in MFI was not reflected in meat tenderness when surveying the quality of chicken breast during post-mortem storage. In order to determine the freshness of SMPL during storage (Crespo et al., 1978; Lee and Lee, 2014), we estimated its volatile basic nitrogen (VBN) content. We could not find any significant differences in VBN regardless of marination time; it was maintained below 6 mg/% for 14 days (data not shown).

Table 2.

Changes in pH, amino type nitrogen, MFI and cooking loss of pork loin marinated with sigumjang during storage at 4 °C

| Storage days | pH | Amino nitrogen (mg%) | MFI value | Cooking lose (%) |

|---|---|---|---|---|

| 0 | 5.31 ± 0.11d | 280.28 ± 1.37d | 47.33 ± 0.50a | 26.12 ± 0.28a |

| 1 | 5.38 ± 0.01c | 371.37 ± 3.47c | 36.20 ± 0.26b | 20.43 ± 0.19d |

| 7 | 5.41 ± 0.01b | 378.38 ± 0.95b | 35.40 ± 0.20bc | 22.87 ± 0.51c |

| 14 | 5.48 ± 0.11a | 462.46 ± 3.63a | 34.73 ± 0.33bc | 25.22 ± 0.37b |

All values are mean ± the standard deviation of three replicates. Means in the same column with different superscript letters are significantly different (p < 0.05)

Table 2 shows the cooking loss results for SMPL during marination at 4 °C. The cooking loss value of SMPL decreased on day 1 but increased from day 7, almost reaching that of non-marinated pork loin on day 0. Marination increased the water-holding capacity (WHC) of the SMPL due to the salt content. Curing or marination partially solubilizes proteins, which increases the WHC (Kim et al., 2011). However, too long margination periods caused shrinkage and leakage of intracellular water in SMPL. As expected, this may result in an increased cooking loss from day 7 onwards.

Free amino acid composition

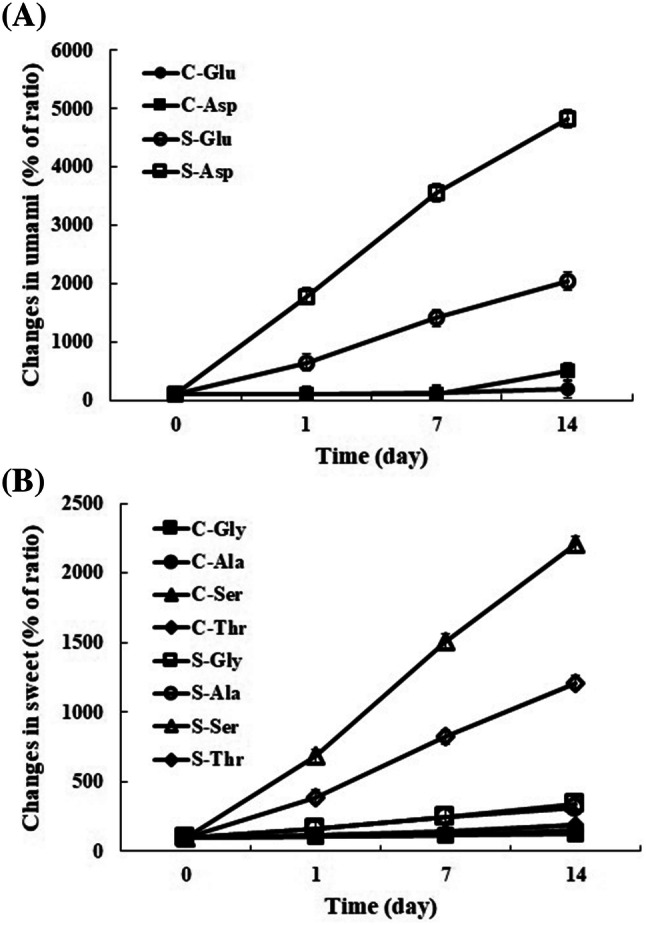

During storage, free amino acids related to umami taste and sweet taste, were more abundant in SMPL compared to those in non-marinated pork loin (Fig. 2). Glutamic and aspartic acids, which are amino acids that give a pleasant fresh taste (umami taste), were analysed in the present work (Rotola-Pukkila et al., 2015; Sasaki et al., 2007). These free amino acids, as well as serine and threonine, were more abundant in SMPL compared to free amino acids related to a bitter taste. The intensity of the umami taste plays an important role in the taste of meat, even though the taste of meat is a combination of all five taste dimensions (Rotola-Pukkila et al., 2015). The reasonably high free amino acid content of SMPL was due to enzymatic activity originating from sigumjang and the moderately salty marination conditions. In our previous study, Bacillus amyloliquefaciens subsp. in sigumjang showed high protease, cellulase, and amylase activities (Jeong et al., 2016). There are several reports suggesting that the levels of free amino acids that possess bitter, monosodium glutamate-like, tastes are elevated after curing (Sforza et al., 2006; Zhao et al., 2005).

Fig. 2.

Changes in the free amino acids of the pork loin marinated with sigumjang during storage at 4 °C. C-amino acid means amino acid for control group and S-amino acid for SMPL group. The vertical bars indicate standard deviations

In conclusion, the marination of pork loin with sigumjang contributes to a reduction of cooking loss, and an increase in free amino acids related to umami taste. Such physicochemical changes may indicate the improvement of sensory quality, which result in increase in consumer liking. Future studies should include systematic sensory studies to investigate how these changes influence perceived sensory characteristics and acceptability of marinated pork. Altogether, these results indicate that the marination of pork loin with sigumjang can improve its quality. The results also provide valuable information for the use of sigumjang in the development of novel meat products.

Acknowledgements

This research was supported by Korea Institute of Planning and Evaluation for Technology in Food, Agriculture, Forestry (IPET) through High Value-added Food Technology Development Program, funded by Ministry of Agriculture, Food and Rural Affairs (MAFRA) (114009-02-1-HD020).

Compliance with ethical standards

Conflict of interest

The authors declare no conflict of interest.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Contributor Information

Hojeong Jeong, Email: jeonghjkr@naver.com.

Soohyung Lee, Email: jellybenus@naver.com.

Gi Dong Han, Email: gdhan1@ynu.ac.kr.

References

- AOAC. Official Methods of Analysis of AOAC Intl. 15th ed. Method 920.55. Association of Official Analytical Chemists, Washington DC, USA (1990)

- Cho S, Park B, Ngapo T, Kim J, Dransfield E, Hwang I. Effect of meat appearance on South Korean consumer’s choice of pork chops determined by image methodology. J. Sens. Stud. 2007;22:99–114. doi: 10.1111/j.1745-459X.2007.00098.x. [DOI] [Google Scholar]

- Cho YJ, Song MW, Im YS, Choi YJ. Estimation of amino-nitrogen content in salt-fermented sand lance sauce. J. Fish Mar. Sci. Edu. 2000;12:91–101. [Google Scholar]

- Crespo FL, Millan R, Moreno AS. Chemical changes during ripening of a Spanish dried sausage, 3: Changes in water-soluble nitrogen compounds. Archivos de Zootecnia. 1978;27:105–116. [Google Scholar]

- Huidobro E, Miguel Blázquez B, Onega E. A comparison between two methods (Warner–Bratzler and texture profile analysis) for testing either raw meat or cooked meat. Meat Sci. 2005;69:527–536. doi: 10.1016/j.meatsci.2004.09.008. [DOI] [PubMed] [Google Scholar]

- Jeong H, Lee S, Yoon J, Chung H, Han GD. Characteristics of Sigumjang, fermented barley bran paste, usually consumed in Gyeongsang-do Area of South Korea and Isolation of its useful Strains. Emir. J. Food Agric. 2016;28:303–310. doi: 10.9755/ejfa.2015-10-900. [DOI] [Google Scholar]

- Jin S, Kim I. Developments of fermented meat and Yakibua products using pork parts of low-preference. Korea: Research report of Ministry of Agri. Seoul; 2004. pp. 1–17. [Google Scholar]

- Kim HW, Hwang KE, Song DH, Kim YJ, Lim YB, Choi JH, Choi YS, Kim HY, Kim CJ. Effects of soy sauce on physicochemical and textural properties of tumbled chicken breast. Poult. Sci. 2014;93:680–686. doi: 10.3382/ps.2012-02930. [DOI] [PubMed] [Google Scholar]

- Kim HW, Choi JH, Choi YS, Kim HY, Han DJ, Kim TH, Lee SK, Kim CJ. Effects of salt concentration in soybean sauce on the physicochemical properties of pre-rigor ground Hanwoo muscle. Korean J. Food Sci. An. 2011;31:389–397. doi: 10.5851/kosfa.2011.31.3.389. [DOI] [Google Scholar]

- Korea Meat Trade Association (KMTA). Available from: http://website.informer.com/visit?domain=kmta.or.kr. Accessed Jul. 25, 2014

- Ku KH, Park K, Kim HJ, Kim Y, Koo M. Quality Characteristics of Doenjang by Aging Period. J. Korean Soc. Food Sci. Nutr. 2014;43:720–728. doi: 10.3746/jkfn.2014.43.5.720. [DOI] [Google Scholar]

- Kuttappan VA, Gunsaulis VB, Mauromoustakos A, Meullenet JF. Owens, CM. Effect of pre- and post-marination aging on meat quality attributes of early deboned (2 h postmortem) broiler breast fillets. Poult. Sci. 11: 2690-2695 (2016) [DOI] [PubMed]

- Lee HJ, Lee JJ. Effects of various kinds of salt on the quality and storage characteristics of tteokgalbi. Korean J. Food Sci. Anim. Resources. 2014;34:604–613. doi: 10.5851/kosfa.2014.34.5.604. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Lim HJ, Kim GD, Jung EY, Seo HW, Joo ST, Jin SK, Yang HS. Effect of curing time on the physicochemical and sensory properties of beef jerky replaced salt with soy sauce, red pepper paste and soybean paste. Asian-Australas J. Anim. Sci. 2014;27:1174–1180. doi: 10.5713/ajas.2013.13853. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ngapo T, Martin JF, Dransfield E. International preferences for pork appearance: I. Consumer choices. Food Qual. Prefer. 2007;18:26–36. doi: 10.1016/j.foodqual.2005.07.001. [DOI] [Google Scholar]

- Oh SH, See MT. Pork preference for consumers in China, Japan and South Korea. Asian Australas J. Anim. Sci. 2012;25:143–150. doi: 10.5713/ajas.2011.11368. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Olson DG, Parrish FC, Jr, Stromer MH. Myofibril fragmentation and shear resistance of three bovine muscles during postmortem storage. J. Food Sci. 1976;41:1036–1041. doi: 10.1111/j.1365-2621.1976.tb14384.x. [DOI] [Google Scholar]

- Perlo F, Bonato P, Fabre R, Teira G, Tisocco O. Meat quality evaluation of broiler breast fillets affected by aging time and marination. Int. J. Poult. Sci. 2010;9:1063–1068. doi: 10.3923/ijps.2010.1063.1068. [DOI] [Google Scholar]

- Rotola-Pukkila MK, Pihlajaviita ST, Kaimainen MT, Hopia AI. Concentration of umami compounds in pork meat and cooking juice with different cooking times and temperatures. J. Food Sci. 2015;80:2711–2716. doi: 10.1111/1750-3841.13127. [DOI] [PubMed] [Google Scholar]

- Saha A, AVS Perumalla Y, Lee, J F Meullenet, CMO Wens. Tenderness, moistness, and flavor of pre- and postrigor marinated broiler breast fillets evaluated by consumer sensory panel. Poult. Sci. 88:1250-1256 (2009) [DOI] [PubMed]

- Sasaki K, Motoyama M, Mitsumoto M. Changes in the amounts of water-soluble umami-related substances in porcine longissimus and biceps femoris muscles during moist heat cooking. Meat Sci. 2007;77:167–172. doi: 10.1016/j.meatsci.2007.02.025. [DOI] [PubMed] [Google Scholar]

- Sforza S, Galaverna G, Schivazappa C, Marchelli R, Dossena A, Virgili R. Effect of extended aging of parma dry-cured ham on the content of oligopeptides and free amino acids. J. Agric. Food Chem. 2006;13:9422–9429. doi: 10.1021/jf061312+. [DOI] [PubMed] [Google Scholar]

- Watanabe A, Daly CC, Devine CE. The effects of the ultimate pH of meat on tenderness changes during ageing. Meat Sci. 1996;42:67–78. doi: 10.1016/0309-1740(95)00012-7. [DOI] [PubMed] [Google Scholar]

- Wilhelm AE, Mahanhini MB, Hernández-Blazquez FJ, Ida EI, Shimokomaki M. Protease activity and the ultrastructure of broiler chicken PSE (pale, soft, exudative) meat. Food Chem. 2010;119:1201–1204. doi: 10.1016/j.foodchem.2009.08.034. [DOI] [Google Scholar]

- Yu H, Lee ES, Jeong JY, Paik HD, Choi JH, Kim CJ. Effects of thawing temperature on the physicochemical properties of pre-rigor frozen chicken breast and leg muscles. Meat Sci. 2005;71:375–382. doi: 10.1016/j.meatsci.2005.04.020. [DOI] [PubMed] [Google Scholar]

- Zhao GM, Zhou GH, Tian W, Xu XL, Wang YL, Luo X. Changes of alanyl aminopeptidase activity and free amino acid contents in biceps femoris during processing of Jinhua ham. Meat Sci. 2005;71:612–619. doi: 10.1016/j.meatsci.2005.05.006. [DOI] [PubMed] [Google Scholar]