Abstract

Hydrogel plays a vital role in cell-laden three dimensional (3D) bioprinting, whereas those hydrogels mimic the physical and biochemical characteristics of native extracellular matrix (ECM). The complex microenvironment of the ECM does not replicate from the traditional static microenvironment of the hydrogel, but the evolution of the 3D bioprinting facilitates to accommodate the dynamic modulation and spatial heterogeneity of the hydrogel system. Selection of hydrogel for 3D bioprinting depends on the printing techniques including microextrusion, inkjet, laser-assisted printing, and stereolithography. In this review, we specifically cover the 3D printable hydrogels where cells can be encapsulated without significant reduction in the cell viability. The recent research highlights of the most widely used hydrogel materials are elucidated in terms of stability of the hydrogel system, cross-linking method, support cell types and their post-printing cell viability. Also, the techniques used to improve the mechanical and biological properties of the hydrogels, such as adding various organic and inorganic materials and making microchannels, are discussed. Furthermore, the recent advances in vascularized tissue construct and scaffold-free bioprinting as a promising method for vascularization are covered in this review. The recent trends in four-dimensional (4D) bioprinting as a stimuli-responsive formation of new organs, and 3D bioprinting based organ-on-chip systems are also discussed.

Keywords: Hydrogel, Bioprinting, Microextrusion, Dynamic modulation, Vascularization

1. Introduction

Tissue engineering is one of the promising technique to alleviate the organ shortage crisis in the world by developing artificial tissue and organs [1]. In general, tissue engineering utilizes three elements to generate functional tissue construct: (i) cells alone, (ii) biomaterials alone, and (iii) combination of both cells and materials in the form of scaffolds [2]. The conventional scaffold fabrication techniques, such as solvent casting, gas forming, membrane lamination, salt leaching, and fiber binding [3–5] have limitations including intrinsic inability to mimic the complex microstructure of biological tissues [6]. As a solution to this problem, another tissue engineering approach called modular tissue engineering was investigated to mimic the complex microstructural features of the organ [7,8] before the development of 3D bioprinting techniques. Furthermore, 3D bioprinting based on three approaches: biomimicry, autonomous self-assembly, and mini-tissue building blocks [9]; offers the unprecedented capability and versatility to deliver cells and materials in complex microstructure with superior spatial distribution [10]. So, researches are developing the 3D bioprinting techniques to fabricate 3D human organs with similar biological and mechanical properties to the actual organs. Also, 3D bioprinting allows us to design and produce structures intraoperatively, especially for bone injuries and defects where imaging based bioprinting with the assist of magnetic resonance imaging (MRI) or computed tomography (CT) can be utilized to print scaffolds/grafts that can precisely fit into bone defects [11].

Bioprinting is defined as the spatial patterning of living cells and other biologies such as growth factors by stacking and assembling them using a computer-aided layer by layer deposition technique for fabrication of living tissue and organs [12,13]. However, 3D printing of bioinert materials without biological component cannot be considered as bioprinting [12]. Four types of techniques widely used for the bioprinting, namely, (i) extrusion-based, (ii) inkjetbased, (iii) laser-assisted, and (iv) stereolithography [1,11,17,24]. Inkjet bioprinters are also known as a drop on demand bioprinters. Recently, this drop on demand bioprinters further classified into four groups according to their droplet generation mechanisms, namely inkjet (thermal, piezoelectric or electrostatic) bioprinters, acoustic droplet election, electro-hydrodynamic jetting, and micro-valve bioprinting [21]. In-depth details of these three techniques were extensively studied or reviewed by many researchers [1,12,17,21,24–26], and therefore, we are not going to discuss the details on these techniques in this review paper. The summarized details of each bioprinter type and their basic features are shown in Table 1. The conventional 3D printing involves the printing of synthetic or natural polymer or combination of both using extreme conditions such as heating, prolonged chemical crosslinking, and photocrosslinking. The most used polymers in the 3D printing techniques are the followings: poly(ε-caprolactone) (PCL) [27–29]. poly(lactic acid) (PLA) [30–33], poly(lactic-co-glycolic acid) (PLGA) [34–36], hydrogel-based polymers such as alginate, gelatin, and poly(ethylene glycol) (PEG) based materials (will be discussed in the section 3). Incorporation of inorganic substances such as hydroxyapatite (HA) [37], graphene oxide (GO) [38], β-tricalcium phosphate (β-TCP) [39], and calcium phosphate [30] into thermoplastic polymers was also investigated as a method to improve hydrophilicity and bioactivity.

Table 1.

Comparison of bioprinter types.

| Bioprinter type |

Stereolithography | Refs. | |||

|---|---|---|---|---|---|

| Drop on demand (inkjet) | Microextrusion | Laser-assisted | |||

| Material viscosities | 3.5–12 mPa/s | 30 mPa/s to above 6 × 107 mPa/s | 1–300 mPa/s | No limitation | [1,9,14,15,16] |

| Print speed | Fast | Slow | Medium | Fast | [1,9,12,17] |

| Resolution or droplet size | High | Moderate | High | High | [1,9,18] |

| Printer cost | Low | Medium | High | Low | [1,9,17,19] |

| Cell viability | 80–95% | 40–90% | <85% | >85% | [1,17,20,21] |

| Cell densities | Low < 106 cells/ml | High (cell spheroids) | Medium, 108 cells/ml | Medium | [9,17] |

| Preparation time | Low | Low to medium | High | Low | [22,23,18] |

| Materials used in bioprinting | Alginate, collagen | Alginate, GelMA, PEGDMA, PEGDA | Collagen, Martigel | Hyaluronic acid Alginate, PEG based acrylates | [1,18] |

Many review papers addressed the 3D printing technologies and materials used as a bioink, including thermosets, hydrogels, and inorganic nanocomposites. However, those reviews mostly focused on the printability and cytotoxicity of the materials, and there is a shortage of comprehensive reviews on cell encapsulated hydrogel systems. There are a lot of essential requirements which have to be addressed when we select a hydrogel-based material for cell encapsulated printng (bioprinting). Therefore, In this review paper, we will discuss the natural and synthetic material systems, which can be used for bioprinting with cells. This paper also reviews the hydrogel structure, stability, and their properties, including, shear-thinning, self-healing, and encapsulated cell viability. The sections are categorized according to the type of hydrogel material such as aliginate, gelatin, and PEG, where the limitations and strength of each bioink materials are elucidated, and different printing techniques are elaborated accordingly. The type of cells and their viability after printing will be discussed with the addition of specific applications. Also, the recent trends in bioprinting such as scaffold-free bioprinting 4D bioprinting, and bioprinting of organ-on-chip systems will be discussed with a focus on the materials perspective rather than the cells. Finally, this paper provides the reader with current and future perspective of bioprintable materials and their limitations.

2. Hydrogel structure, stability, and properties

Hydrogels, a 3D network of molecules composed of hydrophilic polymer chains, can be designed into any shape, size or form, and have the ability to absorb up to a thousand times their dry weight in a water-rich environment [40,41]. Hydrogel-based systems have become a prime candidate for many applications as carriers for cells in various tissue engineering applications, and as molecule or drug delivery vehicles in stem cell and cancer research due to the recent advances in 3D bioprinting techniques [42]. More controlled physicochemical properties of hydrogels have been achieved in the past couple of years due to the advances in chemical methods- such as click chemistry, gelation mechanisms, and mixing with nanoparticles. However, the biomedical engineering related applications, such as tissue engineering, stem cell therapy for cancers, and immunomodulation; require more than mechanical and chemical versatility from hydrogels, require cell compatibility and mimicking the ECM environment for cellular activities. The traditional static and normal microenvironment of hydrogels do not replicate the complexity of the biological tissues since most of the biological processes are heterogeneous in nature. Therefore, a variety of innovative fabrication techniques were evolved not only to cater the dynamic modulation of hydrogels, which attributed to the changing their shapes gradually in the predefined path; but also to control spatial heterogeneity, which determines the tissue integration, localized cell behavior, and cell-material interactions [40–43].

Hydrogels are formed by cross-linking of polymer chains in an aqueous medium through various mechanisms such as physical entanglement, ionic interaction, chemical crosslinking. Physical entanglement or physical gelation mostly depends on the intrinsic properties of the polymers and therefore, the ability to control the microenvironment is limited. However, these gelation processes do not require the complex chemical modification to the chains, and also these processes are generally reversible. In contrast to the physical approach, chemical approach always requires controlled process conditions, but this controllable and precise crosslinking procedures are beneficial to develop more accurate and hierarchically complex microenvironment.

2.1. Physical crosslinking

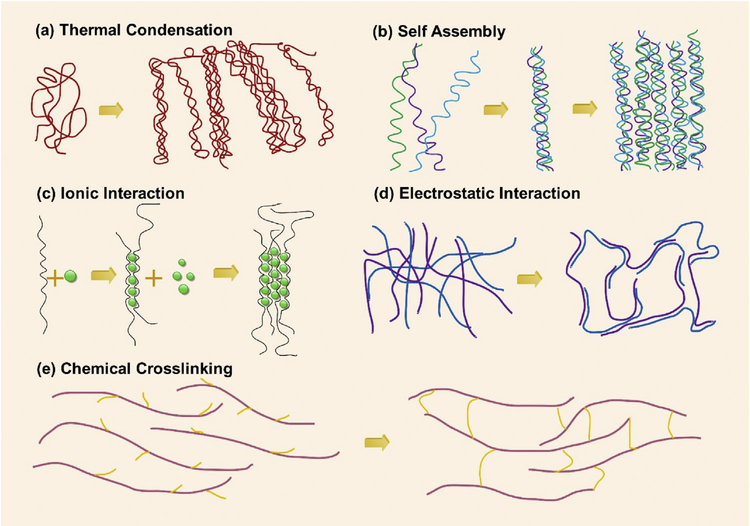

2.1.1. Thermal condensation

Most of the seaweed-derived natural polysaccharides, including agarose, carrageenan, and some animal-derived protein, including gelatin, elastin, and collagen, make the thermally driven hydrogels [44]. Thermal condensation or gelation (Fig. 1(a)) occurs at either increasing temperature or decreasing temperature, in which the transition temperatures are defined as the upper critical solution temperature (UCST), where above this temperature water and polymer are miscible; and lower critical solution temperature (LCST), where below this temperature water and polymer are miscible [41,44,45]. Three types of possible interactions are taken place when a polymer is dissolved in water, namely polymer-polymer, polymer-water, and water-water [46]. For polymer exhibiting an LCST, temperature increase makes polymer-water interaction unfavorable, making the other two interactions more favorable, which results in negative free energy (ΔG). This negative free energy is attributed to the higher entropy term (ΔS) with respect to the increase in the enthalpy term (ΔH) according to the thermodynamic relation ΔG = ΔH-TΔS. In this type of system, water-water interaction is the governing force and hence the entropy of water is increased. This phenomenon is known as the “hydrophobic effect". It is noteworthy to mention that LCST is an “entropy driven" effect while UCST is an “enthalpy driven" effect [44–46]. Compared to the LCST driven polymers, very few UCST driven polymers have been found to date [47].

Fig. 1. Crosslinking of hydrogels.

(a)-(d) Physical crosslinking: (a) Thermal condensation, (b) Molecular self-assembly, (c) Ionic gelation, (d) Electrostatic interaction; and (e) Chemical crosslinking.

2.1.2. Self-assembly

Molecular self-assembly is the other form of physical gelation process. Self-assembly is driven by the noncovalent, weak bonding mechanisms such as hydrogen bonds, hydrophobic interactions, electrostatic interactions, and it is mainly dominated by the peptide and protein-based hydrogels (Fig. 1(b)) [48]. Recent advances in supramolecular chemistry have opened the door for development of an increasing number of bioinspired hydrogel systems. These systems have two distinct properties which are essential for 3D printed hydrogels and injectable gels; they are shear thinning, show viscous flow under shear stress and self-healing, ability to recover when the stress is removed. However, the major challenge in this type of system is the prolonged time for self-healing, which adversely affects the cell encapsulation. Despite these drawbacks, several biomimetic supramolecular systems have been developed utilizing host-guest or receptor-ligand pairs, and dock-and-lock protein structures [49,50].

2.1.3. Ionic interaction

The hydrogel can also be formed either chelation (Fig. 1(c)) or electrostatic interaction (Fig. 1(d)), facilitating spontaneous physical gelation due to the presence of electrically charged species. These polymers are known as polyelectrolytes: contain net charged along the polymer backbone, and crosslink to form insoluble complexes when combined with multi-valent cations or anions according to the charge of the polymer. The reason for the insolubility of these polyelectrolyte complexes in the water is the scarcity of the charged groups of the polymer, which are mutually shielded by the complex formation [44]. This types of physical hydrogels are also known as ionotropic hydrogels [51]. Most of the natural polymers are negatively charged, such as alginate, carrageenan, and hyaluronic acid due to the presence of carboxyl or sulfate groups. However, the presence of the amino groups in the polymer backbone make positively charged polymers like chitosan and gelatin. Calcium alginate is a prominent example for ionotropic hydrogel. Alginate is composed of α-L-guluronic acid (G units) and β-D-mannuronic acid (M units) monomers, which vary in amount and depending on the source of alginate [52,53]. The presence of divalent cations such as Ca2+ and Ba2+ facilitate binding between the G-units of the adjacent alginate chains in an “egg-box" form. In contrast to the natural polymers, polyelectrolytes from synthetic polymers offer a wide range of controllable electrostatic properties. The most common example for the synthetic ionotropic hydrogel is the poly (L-lysine) (PLL) and poly (acrylic acid) (PAA) pair [6,54].

2.2. Chemical crosslinking

The most stable and tunable hydrogels can be obtained through the chemical cross-linking (covalently bound hydrogels) (Fig. 1(e)) as compared to the physical cross-linking. Conventional crosslinking mechanisms include radical polymerization, crosslinking through complementary groups such as aldehydes, condensation reactions between hydroxyl or amine groups with carboxylic acids or derivatives, high energy irradiation, and enzyme-enabled crosslinking [55]. Recent developments in the click chemistry provide extremely selective and orthogonal reactions that proceed with high efficiency and under a variety of mild conditions, which enables the biological functionalities within the hydrogel during processing. Furthermore, these advances facilitate well-defined microenvironment for assaying cell functions where single cues can be introduced, and subsequent effects individually elucidated [56,57]. Click chemistry based reactions have been widely used for hydrogel formation in recent years due to the challenges associated with the conventional chemical crosslinking methods such as extreme reaction conditions, prolonged reaction time, and low yield, which adversely affect to the use of cells with the material [41]. Apart from click chemistry, in the past decade, Michael addition has been widely exploited as a bioorthogonal reaction tool, including thiol-based vinyl sulfones, acrylamides, and maleimides. Also, the azide-alkyne cycloaddition reaction was studied as an appropriate cellular encapsulation system [58]. Thiolene reactions are radically mediated polymerization, which requires the creation of initial radicals either thermally or photochemically. Despite, photochemically driven radical formation provides additional benefits to fabricate cell encapsulated matrices: (i) the ability to spatiotemporally control the chemistry, (ii) rapid reaction rate at a lower radical dose, and (iii) lack of oxygen inhibition, thereby facilitating the incorporation of cells and biochemical cues [59].

2.3. Hydrogel properties

Hydrogels that exhibit orthogonal control of multiple properties in cellular microenvironment should meet several physical and biological requirements to apply in 3D bioprinting. The main requirement is the biocompatibility of the materials. Biocompatibility refers to the “ability of a material to perform with an appropriate host response in a specific situation" [60]. Also, the hydrogel should be immunocompatible, which does not facilitate significant inflammatory response at in vivo microenvironments. Most of the naturally derived polymers including alginate, chitosan, gelatin, hyaluronic acid, and cellulose always show good biocompatibility and few synthetic polymers such as polyethylene glycol (PEG) and its derivatives also demonstrate good biocompatibility in both in vitro and in vivo conditions. Hydrogels fabricated through the click chemistry, Michael addition reactions, and thiolene reactions using synthetic polymers always generate small molecules such as unreacted monomers, initiators, and crosslinkers. Therefore, it is essential to remove those byproducts, or it is necessary to select minimal cytotoxic materials in both in vitro and in vivo microenvironment at the design stage. Apart from biocompatibility, several other factors have to be considered, including mass transport, biodegradability, target microenvironment, mechanical properties, and effect of crosslinking reaction to the cell viability. First considering the mass transport, it is a vital requirement for cell encapsulation, since the continuous exchange of gases (O2 and CO2), nutrients, proteins and waste product into, and out of or within the hydrogel is important for viability and proliferation of encapsulated cells. Also, the ability to transfer hydrophobic/hydrophilic molecules is beneficial as some therapeutic techniques requiring controlled drug release (i.e., tumor chemotherapy) [40,58].

Biodegradation is an essential aspect for a biomedical application that requires controlled resorption in vivo, and the degradation mainly depends on the bulk dissolution based on several mechanisms such as hydrolysis (ester or enzymatic), photolysis, disentanglement, and combination of these mechanisms [40,58]. The degradation of the material creates more space for cell proliferation, migration, and also for the infiltration of the blood vessels. The development of a spatiotemporal aspect of this type of hydrogel is still a challenge [61,62]. Material-specific degradation will be further discussed in Section 3. However, the ability to mimic the dynamic nature of the ECM is considered as a major challenge in the hydrogel synthesis. The spatiotemporal control of the biological interaction at the material-cell interface including mediate cell proliferation, migration, adhesion, and receptor-ligand binding is challenging due to the complexity of the ECM microenvironment, which includes plethora of structural proteins; such as collagen, laminin, fibronectin, elastin; polysaccharides and various growth factors, enzymes, and inhibitors [58]. This type of biodirectional crosstalk between the microenvironment and the cells is known as “dynamic reciprocity," and multiple tissue engineering approaches have been developed to generate matrices which are capable of this reciprocity [63].

The ability to create a cell-laden hydrogel matrix is greatly dependent on the severity of the crosslinking reaction and the cytotoxicity of the byproducts and unreacted substances. The monomers, initiators, and free radical generated from the reactions can be damaging to the cells, and such effects diminish the efficacy of the 3D microenvironment in both in vitro and in vivo. Furthermore, the photoinitiated polymerization reactions which use ultraviolet (UV) radiation or blue light radiation to generate free radicals can be harmful to the encapsulated cells if subjected to the prolonged exposure. Apart from these general properties, viscosity is an essential property for the hydrogels which are subjected to 3D bioprinting or commonly known as the printability of the hydrogel. If viscosity is too high, high pressure should be applied, and the resulting high mechanical forces and shear stresses may damage the cells. In contrast, low viscosity may hamper structural integrity and the resolution of the printed structure [64]. The internal diameter of the nozzle also affects to the post-printing cell viability as a larger diameter nozzle requires low pressure, which subjected to lower shear stress and having good cell viability and vice versa.

Another main consideration of developing the hydrogel system is mechanical stability. In some situations, tissue formation can greatly depend on the mechanical properties of the hydrogels. As an example, the matrices which use in the load-bearing application should withstand until cells have produced their own functional ECM. It is widely known that the mechanical properties of the hydrogel, specifically stiffness, influence the cell adhesion, proliferation, and differentiation. Distcher and coworkers demonstrated that the mesenchymal stem cell differentiates into specific lineages according to the matrix stiffness. Soft matrices that mimic brain meant to be neurogenic, stiffer matrices that mimic muscles became myogenic, and comparatively rigid matrices that mimic collagenous bone prove to be osteogenic [65,66]. However, conventional hydrogels possess low mechanical properties and hence widely used in soft tissue applications. Alternatively, hydrogels, synthesized from hybridization with nanomaterials, by mixing multiple components, or via crystallite crosslinking proved to possess good mechanical properties [41]. These techniques will be further discussed in Section 3.

3. Materials for 3D printable hydrogels

3.1. Alginate-based hydrogels

As previously mentioned alginate is a polyanionic, hydrophilic polysaccharide which consists of linear (l-4)-linked β-Dmannuronic acid (M blocks) and its C5-epimer α-L-guluronic acid (G blocks) residues and the G block content varies between 30% and 70% depending on the species and part of the seaweed where alginate is extracted [67]. The M blocks and G blocks are separated by MG regions, and G blocks increase the gel formation while MG and M blocks increase the flexibility of the gel [68]. The presence of divalent cations results in the gelation of the alginate through G blocks because of the affinity for the alkaline earth metals (except Mg2+). The affinity for the cations varies in an increasing manner as Ca2+< Sr2+< Ba2+ [69]. Though the gelation process of the alginate in the presence of divalent cations is not fully understood, it is reported that the gelation takes place in an “egg-box" form, where the ions that are locked in between the surrounded pair of helical chains [70]. Pore size, which is in the range of 5 and 200 nm, is an essential parameter related to the cell viability, proliferation, therapeutic drug delivery and it is also crucial for the mass transport such as nutrients, waste products. The largest pore size can be found in the high G block contained alginate. In general, viscosity and elasticity of the gel depending on the concentration of alginate, molecular weight, and the G block content [67,68,71].

Due to the excellent printability and versatility of the material, calcium alginate-based hydrogels are one of the most studied hydrogel systems in the field of 3D bioprinting. Most widely used 3D printing techniques for the alginate-based bioinks are extrusion assisted bioprinting, and the inkjet assisted bioprinting [72]. Natural alginate is a bioinert material with limited degradation [73]. The enzymes that needed to breakdown the alginate polymer chains are not available in mammals and therefore limit the use of alginate for in vivo tissue generation [74]. The degradation rate of the alginate was increased in a controllable manner without altering the gelation ability with Ca2+ by the Mooney’s group using the oxidation of alginate in the presence of sodium periodate [75]. Ying Mei’s team studied the effect of oxidation percentage of alginate and the viscosity of the solution on human adipose-derived stem cells (hADSCs). According to their findings, 5% oxidation percentage and 10% and 15% (w/v) concentrations of alginate are best for the hADSCs proliferation. The optimal viscosity requirement for the consistent printability of alginate is in the range of 400–3000mm2 s−1 [73]. The increasing viscosity of the alginate adversely affects the cell viability as previously reported in the number of studies [76,77]. Wenmiao Shu’s team reported a method to improve the stability of the 3D printed alginate structures by using the three-stage crosslinking method; where partial crosslinking with Ca2+ was done to achieve the printability, the second crosslinking with Ca2+ was done immediately after the printing for rigidity, and final crosslinking with Ba2+ was done for long term stability in the tissue culture media; without significantly altering the cell viability [78].

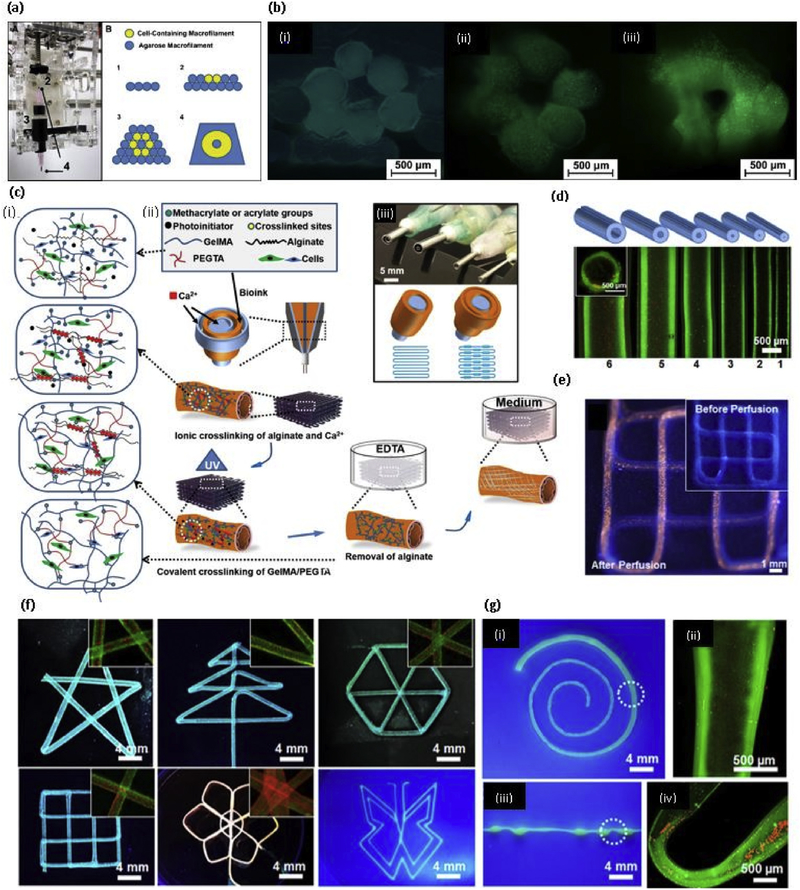

Making a 3D vascularized structure or organ remains a major challenge in the tissue engineering field. This type of vascularized structure supports cell viability because of enhanced nutrient delivery and oxygen perfusion. A novel coaxial nozzle strategy or core/ shell model has been developed in recent years in order to print blood vessel-like microchannels in the cell-laden structures using alginate by Ozbolat’s team [79]. The reason for using alginate in this coaxial nozzle strategy was mainly due to their capacity in regulating cell behavior and structural integrity in cell culture. The inner diameter of these nozzles should be carefully selected according to the requirement as the diameter of the microchannels are depending on this factor. In this study, Ozbolat’s team selected two coaxial nozzle assemblies: (i) an assembly with 26 gauge (230 μm inner diameter (ID), 457 μm outer diameter (OD)) inner needle and 18 gauge (840 μm ID, 1270 μm OD) outer needle; (ii) an assembly with 23 gauge (330 μm ID, 650 μm OD) inner needle and 18 gauge outer needle in order to understand the effect of wall thickness on cell viability. Later, the same team developed another system to print blood vessel-like channel structure using cartilage progenitor cell encapsulated Ca-alginate gel system [80]. Liang Ma’s team developed the same coaxial nozzle method to print microchannels (Fig. 2(a) and (b)) with the addition of external CaCl2 immersion while printing to improve stability. They were able to print different structures (Fig. 2(c)) using perfusable microchannels (Fig. 2(d)) and also they reported the enhanced cell viability in structures with microchannels compared to the structure without microchannels using mouse fibroblast cells [77]. Selvaganapathy’s team were able to print hollow channels with a diameter in the range of 500 μm - 2 mm by changing the flow rate or varying the speed of the print heads by using the same method mentioned above [81]. The same coaxial nozzle system was developed to obtain cell-laden core with a mechanically stable shell to create vascular structure known as core-shell model by the Jing Yang’s team. This strategy provided several advantages as the cell contained core does not directly expose to the crosslinking agents, and therefore, high cell viability can be obtained. Also, mechanical stability can be achieved by the robust crosslinking of outer shell material [82]. After this method was proposed by the Ozbolat’s team, Several studies were done using a different type of hydrogel materials. Those studies will be discussed in the relevant section of hydrogel material.

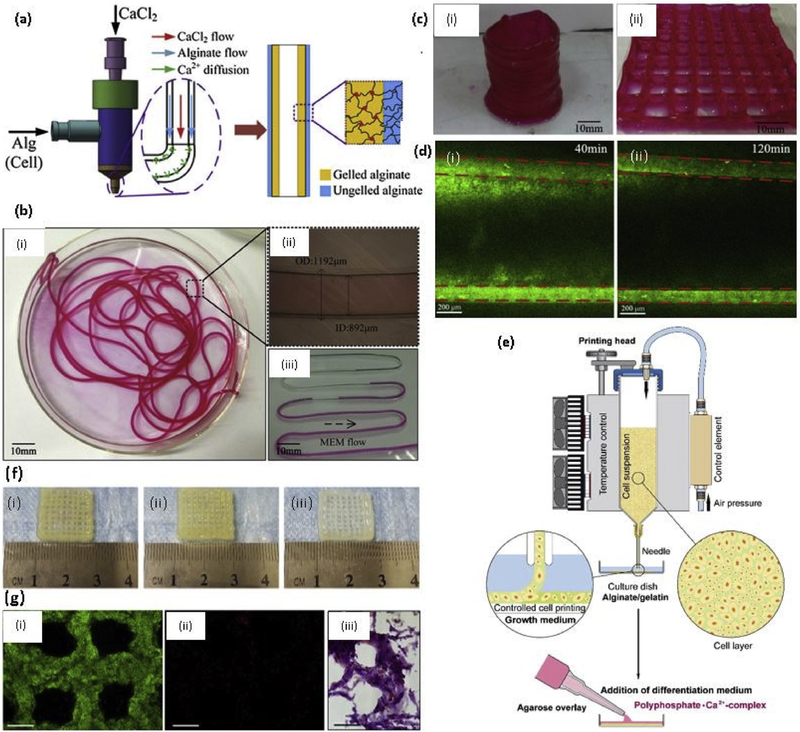

Fig. 2. Natural Polymer based 3D printed hydrogels.

(a) Coaxial needle used to make hollow tubes, where CaCl2 flows through core nozzle and alginate extrudes through outer nozzle; (b) (i) Printed alginate hollow filaments; (ii) The filament under an inverted microscope; (iii) Perfusion of cell culture media (MEM); (c) Printed 3D alginate structures with built-in microchannels: (i) Hollow cylinder; (ii) Grid; (d) Diffusion mass transfer of EGFP from microchannel into calcium alginate matrix (i) 40min (ii) 120 min [77] with permission from Elsevier, copyright 2015; (e) Sketch of the procedure of 3D cell printing of scaffolds subsequently covered with an agarose overlay using the 3D-Bioplotter [86] with permission from Elsevier, copyright 2014; (f) 3D bioprinting of chondrocytes encapsulated (i) Sodium alginate (ii) Sodium alginate/agarose (4:1) (iii) Sodium alginate/collagen (4:1) [102] with permission from Elsevier, copyright 2018; and (g) 3D bioprinted hyaluronic acid and gelatin matrix with hCMPCs (i) Live-dead assay performed 2h after printing showed the vast majority of hCMPCs to be alive (green) and (ii) Only a few were dead (red), scale bar1000 μm (iii) Hematoxylin and eosin staining 1 day after printing showed the homogenous distribution of the printed hCMPCs, scale bar 20 μm [111] with permission from Elsevier, copyright 2015. (For interpretation of the references to colour in this figure legend, the reader is referred to the web version of this article.)

The incorporation of other natural and synthetic polymers, and inorganic materials into the alginate hydrogels was extensively studied and found enhanced biological and mechanical properties. Nanocellulose was incorporated into calcium alginate hydrogel system deliver the human nasoseptal chondrocytes (hNCs) for cartilage tissue regeneration [83]. Nanocellulose fibers are incorporated to alginate due to their good mechanical properties, hydrophilicity, and biocompatibility. The compressive stress of the scaffolds was in the range of 25–40 kPa, and the addition of a different amount of nanocellulose did not significantly increase the compressive stress. In another study, Lin Li’s team incorporated methylcellulose (MC) into calcium alginate hydrogel system in order to increase the thixotropic property, extrudability, and stackability. The viscosity of the alginate/ MC blend hydrogel system is contributed by the MC, and the viscosity of the hydrogel decreased with increasing shear rate, indicating the shear-thinning behavior. The average compression modulus of the bulk and two-layered alginate/ MC hydrogels were reported as 11.11 and 7.17 kPa respectively. Also, they have used a trisodium citrate treatment to increase the interfacial bonding between printed layers with the presence of mouse fibroblasts, and 95% post printing cell viability was achieved [84]. Gelatin was incorporated into alginate to increase the long term structural integrity with two-step mechanism combining the thermosensitive property of gelatin and chemical crosslinking of calcium alginate. In this study, hydroxyapatite (HA), the main mineral component of the natural bone, was also incorporated into the gel system in addition to the human mesenchymal stem cells (hMSCs, 85% post printing cell viability), where HA favors the use of this hydrogel system for bone tissue engineering. Three different scaffold types - 8% HA, 4% HA, and no HA- were tested for Young’s modulus. As expected, Young’s modulus of the hydrogel systems increased with the increasing HA content, where 36 ± 3 kPa, 32 ± 2 kPa, and 29 ± 2 kPa of post-printing modulus at day 0 were reported for 8% Ha, 4% HA, and no HA scaffolds respectively. No significant difference was observed at day 3 after swelling, where all the modulus values were around 30–32 kPa range for all three groups [85]. Muller’s team reported that bonerelated SaOS-2 cells in the sodium alginate/gelatin hydrogel are in the non-proliferating state. They found out that the addition of an overlay onto bioprinted system consisting of agarose and calcium salt of polyphosphate (Poly.Ca2+) as shown in Fig. 2(e) increases cell proliferation and mineralization of the cell while increasing the Youngs modulus of the scaffold system. Reduced Young’s modulus (RedYM) of the alginate system was reported as 2.5 kPa after two day incubation period, and this value further reduced to 0.8 kPa at day 5. The addition of 100 μM of Poly.Ca2+ complex increased the RedYM to 22 kPa at 5 day incubation period. However, the presence of SaOS-2 cells in the hydrogel reduced this RedYM value to 3.2 kPa at five-day incubation, indicating the degradation and metabolization of the complex by the cells [86]. In another study, calcium alginate/ polyvinyl alcohol (PVA)/ HA hydrogel system with encapsulation of mouse calvaria 3T3-E1 (MC3T3) cells showed sufficient integrity and mechanical properties over 14 days incubation period without diminishing the cell viability [87].

Kim’s team reported the alternative printing layers of poly (ε caprolactone) (PCL) and MC3T3 cell encapsulated calcium alginate hydrogel system showed significantly improved mechanical properties and 84% of cell viability after 25 days of cell culture. Two different scaffold orientations were made as one alginate strut between PCL struts, and two alginate struts between PCL struts. Tensile modulus values were completely dependent on the PCL strut volume fraction, where 15.4 MPa and 8.3 MPa tensile modulus values were reported for high PCL struct volume scaffold and lower PCL struct volume fraction scaffolds respectively [88]. Calcium alginate containing transforming factor-β (TGF-β) and chondrocytes were printed using a layer by layer technique with the combination of PCL by Cho’s group, where enhanced cartilage tissue and type II collagen formation was observed in both in vitro and in vivo experiments. Mechanical stability of the scaffold was achieved through the PCL, and alginate acted as a cell carrier [89]. Bone morphogenic protein-2 (BMP-2) loaded gelatin microparticles incorporated calcium alginate scaffolds showed enhanced osteogenic differentiation and the controlled release of BMP-2 in the goat multipotent stromal cell (gMSCs) encapsulated system. Gelatin microparticles (MPs) are suitable for BMP-2 delivery, where 30% of the BMP-2 shows burst release at the beginning and the remaining amount released in a controlling manner due to the enzymatic degradation of the gelatin. The presence of BMP-2 in gelatin MPs led to osteogenic differentiation in vitro and in vivo, and higher release of BMP-2 was observed in vivo conditions due to the higher enzymatic activity. However, after 4 weeks of subcutaneous implantation of the scaffolds in mice, BMP-2 was still available in the implanted scaffolds [90]. Ouyang’s team developed alginate/HA scaffolds having an anti-inflammatory function via the addition of atsttrin; a progranulin derived engineered protein, to reduce the effect of proinflammatory tumor necrosis factor- α (TNF-α). High expression of TNF-α adversely affects to the BMP-2 induced osteoblastic differentiation, and atsttrin exerts an antagonistic effect on TNF-α function [91].

3.2. Collagen-based hydrogels

Collagen is one of the major components in all the connective tissues, making one of the most studied biomolecules of the ECM, with a triple helix structure. Collagen represents approximately 25% of the total dry weight of mammals [12,92]. Even though collagen can be extracted from almost every living animal, the source for tissue engineering applications include porcine skin, bovine skin and tendons, and rat tail among others. Collagen types I, II, III, V, and XI are only known for making collagen fibers out of 29 distinct collagen types up to date. Apart from all the collagen types, type I collagen (Col-I) is the mostly (only) studied collagen type in 3D bioprinting due to its ability to undergo self-assembly to form fibrous hydrogels [93]. Type I collagen stays in liquid form at low temperatures while increasing temperature (37ºC) or remaining at neutral pH forms fibrous hydrogels. However, Col-I has an intrinsic limitation due to the slow gelation, whereas it takes half an hour to form gel at 37 °C. Because of this slow gelation, the required structural stability cannot be achieved after bioprinting. Also, the slow gelation reduces homogeneity of the cells in the hydrogel, since the cells move downwards and stabilize in the bottom due to the gravity. So, collagen cannot be used alone without a support material due to its weaker mechanical properties and slow gelation rates. Several studies were reported the successful incorporation of collagen into a different type of natural and synthetic hydrogel systems.

Cho’s team developed a 3D structure which mimics the osteochondral tissue by incorporating human chondrocytes, derived from human septal cartilage, and osteoblasts (MG63 cells), derived from human osteosarcoma. They studied the overall behaviors of chondrocytes and osteoblasts on Col-I and alginate-based hyaluronic acid (HLA) gel system. Both chondrocytes and osteoblasts were better in their native ECMs, HLA, and ColI respectively. HLA, mixed with alginate and then crosslinked with CaCl2, has shown Young’s modulus of 21.4 ± 5.7 kPa. Col-I, crosslinked by increasing temperature, has shown Young’s modulus of 4.3 ± 1.4 kPa. Chondrocytes encapsulated collagen hydrogel system, and osteoblasts encapsulated HLA/ alginate hydrogel system had shown 90% of cell viability and growth up to 14 days in vitro for osteochondral tissue generation. [94].Hyung Kim’s team investigated the previously mentioned core/shell model to encapsulate hADSCs in the core with collagen hydrogel, and the shell of calcium alginate without cells using a coaxial nozzle system. Collagen is a good cell carrier because of its role as a natural ECM material, but due to its weak stability and prolonged crosslinking time diminish the ability to use Col-I as a 3D printable hydrogel. In this study, Col-I was covered with a calcium alginate shell, which gives mechanical support during the printing process [95]. High-density collagen hydrogel was used to overcome the low mechanical stability of the construct by Bonassar’s team. The equilibrium compression modulus of the printed tissue constructs increased linearly with increasing collagen concentration and 2 fold increase of modulus was observed from 10 mg/ml to 20 mg/ml collagen concentration. Modulus of 30kPa was obtained at the highest printable collagen concentration of 17.5 mg/ml, where 20 mg/ml concentration was not suitable due to the clogging and precross-linked of the collagen inside the tip. They have reported good cell viability and maintained cell growth of primary meniscal fibrochondrocytes for cartilage repair. Cell viability of the printed construct did not significantly vary with the density of the collagen (from 12.5 mg/ml to 17.5 mg/ml), and no reduction in the cell viability was observed over 10 days in culture [96]. The same team studied the effect of riboflavin photocrosslinking through blue light, and the effect of pH on the primary articular chondrocytes encapsulated Col-I-based hydrogel system. However, the cell viability approximately decreased from 95% to 75% due to the addition of blue light-activated riboflavin crosslinking [97]. The reduction of cell viability was due to the addition of higher concentration of riboflavin (0.5 mM) and as previously reported, 0.25 mM of riboflavin was the optimum concentration to prevent the reduction of cell viability. In contrast, low concentration reduces the mechanical stability of the hydrogel while blue light-activated crosslinking also reduces the cell viability [98]. Soker’s team developed an in situ 3D bioprinting technology to treat a full-thickness skin wound in nu/nu mice using fibrin-collagen gel system. They reported that the amniotic fluid-derived stem cells (AFSCs) treated wounds have shown enhanced microvessel density and capillary diameter compared to the bone marrow-derived stem cells treated wounds [99]. Boland’s team developed a 3D printed fibrin-collagen I based dermo-epidermal graft for skin wound using the ink-jet printer. Three types of cells, namely neonatal human dermal fibroblasts, human dermal microvascular endothelial cells, and neonatal human epidermal keratinocytes were encapsulated into the hydrogel system and near identical to natural skin of athymic nude mice with microvessels was obtained [100]. Similarly, Reimers’s team developed laser-assisted bioprinting (LaBP) to coat a thin layer of fibroblasts and keratinocytes encapsulated collagen hydrogel system on top of the stabilizing matrix (Matriderm®) for full-size skin wound in nude mice [101]. Recently, collagen was incorporated into sodium alginate gel system to deliver the chondrocytes without altering the gelling mechanism of sodium alginate. They have made porous scaffolds; which are having good post printing resolution; with sodium alginate, sodium alginate with agarose, and sodium alginate with collagen type I as shown in Fig. 2(f)[102]. Collagen type I and macromolecule-based polyvinylpyrrolidone (PVP) bioink was developed to deliver fibroblasts using a novel single step drop on demand (DOD) bioprinting strategy [103].

3.3. Chitosan-based hydrogels

Chitosan, a natural cationic copolymer of β-(l-4) linked 2-acetamino-2-deoxy-D-glucopyranose and 2-amino-2deoxy-Dglucopyranose, is a deacetylated form of chitin derived from shells of crustaceans [104,105]. Cell-laden 3D printed structure using chitosan-based hydrogels are not extensively studied due to the acidity of the gel. Chitosan dissolved only in the weak acids such as acetic acid, and the pH (around 4.0) of the solution is not favorable for living cells. Several studied were performed to encapsulate cells in the chitosan-based scaffolds using different techniques such as mixing with other natural and synthetic hydrogel systems and neutralizing the pH. Recently, one research group was able to print cell-laden chitosan-based scaffolds using a glycerol phosphate disodium salt as an ionic crosslinker while adding NaOH to increase the pH up to 7.0 after dissolving the chitosan in acetic acid. They incorporated HA and MC3T3-E1 cells with the chitosan gel and compared to the cell viability and differentiation of alginate/HA scaffolds. Enhanced cell functions were reported in the chitosan/ HA hydrogel compared to the alginate/ HA gel system [106]. Jia-Kuo Yu’s group developed a thermoresponsive chitosan gel system by mixing the chitosan which dissolved in 0.1 M acetic acid with a βglycerolphosphate solution. This system remains in the liquid form at 4ºC starts sol-gel transition at 37 °C. This team developed a hybrid scaffold with PCL to deliver BMP-2 and the rabbit bone marrow derived MSCs in to a mice cranial defect. The compressive strength of the chitosan thermoresponsive gel, and PCL incorporated hybrid system was reported as 200 kPa, and 6.7 MPa (similar to human cancellous bone) respectively [107]. It was reported that the pore size greater than 300 μm are beneficial for enhanced angiogenesis and osteogenesis, while small pores favored hypoxic conditions and would induce chondrogenesis [107,108]. Several authors have reported the use of carboxymethyl chitosan, water soluble chitosan derivative, as a successful candidate to make cell-laden 3D printed scaffolds with the combination of other natural or synthetic polymers [109].

3.4. Hyaluronic acid-based hydrogels

Hyaluronic acid (HLA), a linear non-sulfated glycosaminoglycan (GAG), is a polysaccharide with the repeating disaccharide, β-1,4D-glucuronicacid, β-1,3-N-acetyl-D-glucosamine [21,110]. HLA is a major ECM component of cartilage and ubiquitously find in almost all connective tissues. To use HLA as a 3D printable bioink, chemical modifications and mixing with other polymers are often carried out to enhance the rheological and mechanical properties. HLA and gelatin-based gel system with human cardiac-derived progenitor cells (hCMPCs) were used to print a cardiac patch, which has shown enhanced cardiac and vascular differentiation in a mouse model. As shown in Fig. 2(g), very high post-printing cell viability, and homogeneous distribution of the hCMPCs were obtained. [111]. Doyle’s team developed a thermoresponsive HLA and MC blend to deliver sheep adipose-derived mesenchymal stem cells [112]. Rajaram’s team investigated the addition of polyethyleneimine (PEI), a polycation which stabilizes the alginate molecular structure through the formation of polyelectrolyte, into the HLA/alginate hydrogel with ATDC-5 chondrogenic cells. They have found reduced cell viability with increasing PEI concentrations, and Young’s modulus of the 0.1% PEI and 0.5% PEI scaffolds were reported as 1.4kPa and 1.6kPa respectively [113]. Burdick’s team developed a methacrylated HLA (MeHA), which facilitates the UV photocuring through the addition of 4-(2-hydroxyethoxy)phenyl(2-propyl)ketone (Irgacure 2959) photoinitiator. The stability of the hydrogel system further enhanced through the guest-host mixture, where adamantine act as a guest and β-cyclodextrin as a host, separately coupled to the MeHA mixture [114]. The use of HLA in the other polymer based hydrogel systems will be discussed in the appropriate sections.

3.5. Gelatin and methacrylated gelatin-based hydrogels

Gelatin, a partially hydrolyzed form of collagen, is a water soluble and biodegradable polypeptide. The gelling properties of the gelatin depend on the origin of the source, such as mammalian derived gelatin, fish-derived gelatin. The use of gelatin in tissue engineering applications is limited due to its higher enzymatic degradation rates and poor mechanical stability because of the high solubility in the physiological environment [115]. Several studies were done on gelatin only scaffolds, but the prolonged crosslinking period at extreme conditions have restricted the use of cells [116,117]. However, gelatin-based hydrogels have been extensively studied in the field of tissue engineering by incorporating natural and synthetic polymers, and inorganic materials to increase the stability of the system. Butcher’s group developed calcium alginate and gelatin-based hydrogel system to develop valve conduits, which can deliver dual cell types in a region-specific manner, with anatomical architecture. They incorporated aortic root sinus smooth muscle cells (SMCs) and aortic valve leaflet interstitial cells (VICs) in the alginate/gelatin gell system. The mechanical stability of the gel system reduced over time in the cell culture media, where ultimate tensile strength of cell-free hydrogel reduced from 0.84 ± 0.07 MPa to 0.40 ± 0.04 MPa after 7 day immersion, and elastic modulus decreased from 1.44 ±0.3 MPa to 0.96 ±0.08 MPa at 7 day immersion [118]. In another study, compressive modulus of the alginate/gelatin hydrogel was reported. The increasing concentrations of alginate and gelatin increased the compressive modulus while reducing the cell viability due to the higher pressure and shear stress subjected to the cells during extrusion-based bioprinting. The compression modulus of the 5% (w/v) alginate/6% (w/v) gelatin and 7% alginate/ 8% gelatin were reported as 29.8 ± 2.49 kPa, and 48.0 ± 5.74 kPa respectively [119]. Shah’s team investigated a multi-polymer hydrogel system based on gelatin. They have developed 35 formulations of extrudable bioink systems with multi crosslinking, consist of gelatin type A, gelatin methacrylate, fibrinogen, and modified PEG (amine-carboxylic coupling; PEGX, X = sucinimidyl valerate) by changing the composition of each material and varying the crosslinking degree. They have incorporated hMSCs, human dermal fibroblasts (hDFs) and TGFβ into the gel, and 2-hydroxy-4-(2-hydroxyethoxy)-2-methylpropiophenone was used as the photoinitiator for gelatin methacrylate [120]. The teams lead by the Atala have developed several hydrogel systems based on gelatin and various synthetic and natural polymers. A hydrogel consists of glycerol, fibrinogen, gelatin, and HLA with the addition of Pluronic F-127 as a sacrificial material, and PCL as a supporting material was used to bioprint various vascularized tissue construct with various cell types. C2C12 myoblasts encapsulated skeletal muscle construct, hAFSCs encapsulated human mandible bone structure, and rabbit primary auricular chondrocytes laded human ear structure were successfully fabricated using the extrusion-based integrated tissue-organ printer (ITOP) [121]. Similarly, HLA and gelatin-based hydrogel system were developed with two crosslinkers and 2 stage polymerization [122]. They have developed various bioink formulation systems consist of thiol-modified gelatin (Gelin-S), thiol-modified HLA (Heprasil), PEG diacrylate (PEGDA), 4-Arm PEG acrylate, 8-Arm PEG alkyne, 4-Arm PEG alkyne, Irgacure 2959 as a photoinitiator, and unmodified gelatin and HLA was added to improve the shear thinning and extrusion properties (Fig. 3 (a)). This bioink system was used to incorporate primary human liver hepatocytes (as liver spheroids) (Fig. 3(b)), a well known cell type for its difficulty to maintain in vitro.

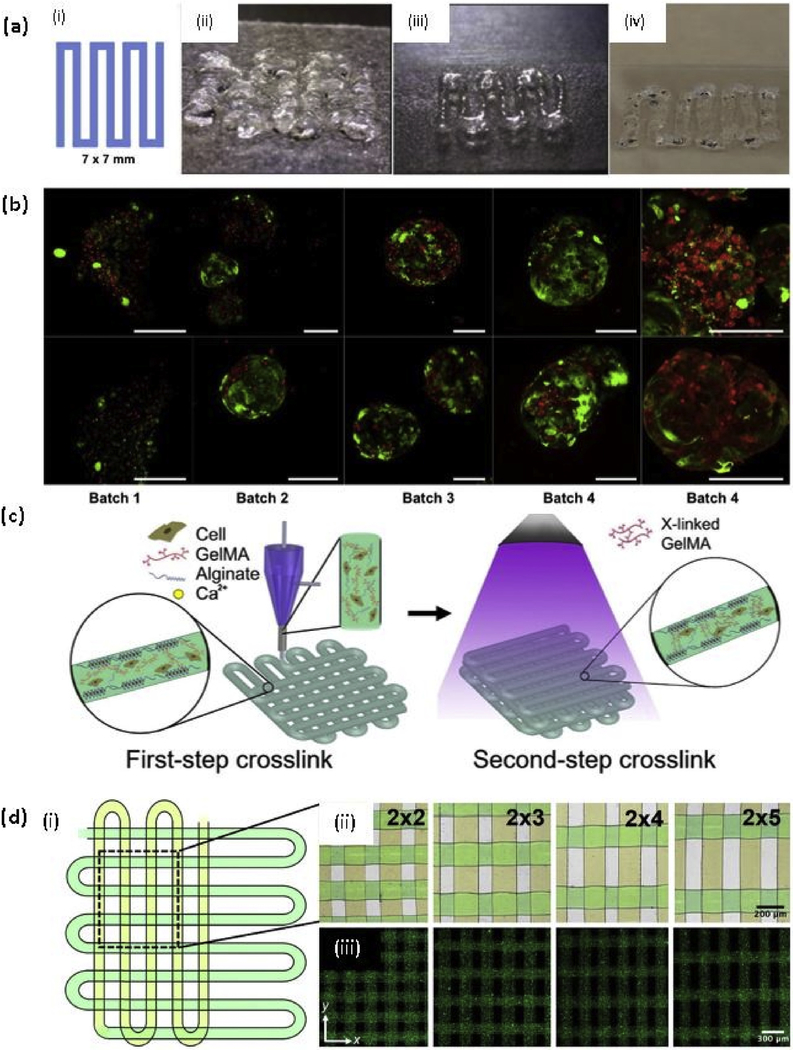

Fig. 3. Gelatin and methacrylated gelatin based bioprinting.

(a) Testing of bioinks, (i) A 7 × 7 mm pattern used for bioink deposition. (ii) An initial formulation of a PEGDA and 4-arm PEG alkyne containing bioink. (iii) Improved extrusion and end structure smoothness after addition of unmodified HA and gelatin to improve shear thinning and material smoothing. (iv) Extruded hydrogel bioink formulation using 8% PEGDA and 8% 8-arm PEG alkyne crosslinkers; (b) Demonstration of bioprinting parameter optimization and associated viability of liver spheroids bioprinted in the liver-specific hydrogel bioink resulted in high cell viability as depicted using LIVE/DEAD viability assay (batch 1–4). In contrast, gelatin-based gels that were printed in parallel under optimal environmental conditions yielded extremely poor viability (batch 5). Green - calcein AM-stained viable cells; Red - ethidium homodimer-stained dead cells. Scale bars - 200 μm [122] with permission from Elsevier, copyright 2015; (c) Schematic diagrams showing the two-step crosslinking process, where the alginate component is first physically crosslinked by the CaCl2 followed by chemical crosslinking of the GelMA component using UV illumination; and (d) (i)Top view single-layer schematic of the design of the bioprinted microfibrous scaffold and corresponding (ii) Brightfield (pseudocolored to match the schematic) and (iii) Fluorescence micrographs showing the bioprinted scaffolds with different aspect ratios of unit grids [131] with permission from Elsevier, copyright 2016. (For interpretation of the references to colour in this figure legend, the reader is referred to the web version of this article.)

Methacrylated gelatin was first introduced in early 2000 by Etienne H. Schacht and coworkers and known as gelatin methacrylamide [123]. The addition of functional groups to the gelatin backbone increases the degree of control of hydrogel design and properties through a crosslinking process, which either uses photoradical initiation or enzymatic crosslinking. Most of the reported literature used photo-initiated radical formation as it provides more temporal and spatial control over the enzymatic crosslinking process [124,125]. Substitution of the amine groups in gelatin can be done by using several chemicals, such as methacrylol chloride, glycidyl methacrylate, methacrylic anhydride, but the use of methacrylic anhydride is the most efficient process and resulting in a more stable product [126]. Therefore, the most widely used method for synthesizing methacrylated gelatin is the mixing gelatin with the methacrylic anhydride, but the final product is being called by three different names, gelatin methacrylate, gelatin methacrylol, and gelatin methacrylamide, and used same acronym GelMA.

After 2010, GelMA is extensively using as a 3D printable bioink for different tissue engineering applications with the incorporation of different cell types. It is reported that 5–15% (w/v) concentration of GelMA hydrogel can support the cell spreading and 7–15% (w/v) of GelMA is required to achieve successful bioprintability with hepatocarcinoma (HepG2) cells and NIH 3T3 Cells by using extrusion-based printing [127]. Khademhosseni’s group extensively studied the use of GelMA in tissue engineering applications using Irgacure 2959 as a photoinitiator. The compressive modulus of the GelMA depends on the methacrylation degree and the concentration of the GelMA, where the compressive modulus of GelMA with higher methacrylation degree was reported in the range of 5–30 kPa from lower concentration to higher concentration respectively [128]. In another study, they have reported that the degree of methacrylation of GelMA can be used to modulate the cellular behavior and the extent of vascular network formation both in vitro and in vivo. Also, the cell spreading, organization, and proliferation depend on the methacrylation degree, where softer hydrogels, with lower methacrylation degree, are more lenient than the stiffer hydrogels, with higher methacrylation degree. 1 M GelMA showed superior vascularization than 10 M GelMA when encapsulated with human blood-derived endothelial colony-forming cells (ECFCs). Monoculture of ECFCs was not able to proliferate or spread in GelMA while coculture with hMSCs showed spreading of ECFCs [129]. In a recent study, a novel strategy to bioprint cell-laden GelMA in lower concentration (3%) was proposed using GelMA physical gels (GPGs), where the GelMA was subjected to the cooling process (4° C) before printing [130]. As expected, the viability of the human umbilical vein endothelial cells (hUVECs) was reduced with increasing GelMA concentrations. In another study, a novel hybrid strategy to fabricate endothelialized myocardium on-a-chip platform was investigated using a mixture of GelMa and sodium alginate with hUVECs. Previously described coaxial nozzle method was used to print hollow tubular structure with the incorporation of the two steps crosslinking as shown in Fig. 3(c), where CaCl2 was delivered through the core of the nozzle to crosslink the alginate component of the gel mixture ionically. After printing, post-crosslinking was done using UV light for the 30 s, and human-induced pluripotent stem cells (hiPSCs)-cardiomyocytes were seeded to the scaffold. The scaffolds with different aspect ratios were printed, as shown in Fig. 3(d), and fluorescent microbeads were added to the bioink to distinguished the distance between microfibers. The system was kept in the microfluidic perfusion bioreactor and proposed to use as a platform for cardiovascular drug screening. The perfusion greatly affects the viability of both hUVECs and hiPSCs-cardiomyocytes, as shown in Fig. 4(a)–(d) [131].

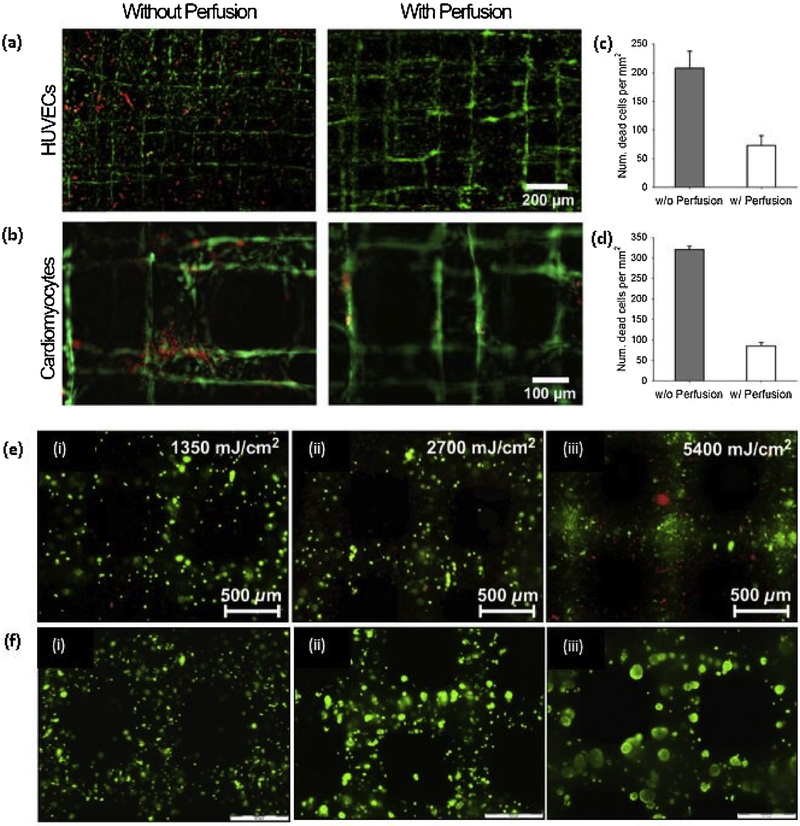

Fig. 4. GelMA based bioprinting.

(a, b) Live/dead micrographs and quantified cell morbidity of bioprinted endothelialized scaffolds without and with perfusion in the bioreactors; (c, d) Live/dead micrographs and quantified cell morbidity of bioprinted cardiac organoids without and with perfusion in the bioreactors [131] with permission from Elsevier, copyright 2016; (e) HepG2-gelatin constructs were cured using 12959 and an irradiation dose of (i) 1350, (ii) 2700, and (iii) 5400mJ/cm2. After 24h, cell survival was evaluated using a LIVE/DEAD assay. Scale bar indicates 500 μm; (f) HepG2-gelatin constructs, cured using the VA-086 photo initiator with irradiation dose of 1800mJ/cm2, Cell viability within the scaffold was evaluated at (i) Day 1, (ii) Day 7, and (iii) Day 14 using a live/dead stain; (scale bar 500 μm) [132] with permission from Elsevier, copyright 2014.

Dubruel’s team investigated the use of photoinitiator, 2–2'azobis[2-methyl-N-(2-hydroxyethyl)propionamide] (VA-086) as a substitution for conventional Irgacure 2959 photoinitiator. The porous scaffold structure was bioprinted with HepG2 cells using 10% (w/v) GelMA without adding viscosity-enhancing additives. More than 97% of cell viability was obtained with VA086 photoinitiator (Fig. 4(e) and (f)), and the maintained expression of liver-specific functions was observed [132]. Instead of 365 nm UV irradiation, Kim’s team proposed quick blue light laser photocuring at 405 nm wavelength using VA-086 due to the high cell viability after crosslinking compared to the Irgacure 2959, which can not be activated at wavelengths above 370 nm. The optimum cell viability was achieved through 250 mW laser power and 10 s crosslinking time using 10% GelMA. Over 90% cell viability of NIH 3T3 cells was reported at day 0 post-printing, and cells elongated inside the microenvironment of gel at 2 days of culture [133]. Chen and the coworkers developed a patient-specific hepatic model to personalized in vitro drug screening, and disease study with the incorporation of hiPSC derived hepatic progenitor cells (hiPSC-HPCs) using a stereolithography technique based on a custom-built digital micromirror device (DMD). Methacrylated HLA (GMHA), a product synthesize through the reaction of HLA with glycidyl methacrylate, and GelMA were used as bioinks with a photoinitiator, lithium phenyl-2,4,6-trimethyl benzoyl phosphinate (LAP) [134]. In a recent study; two steps crosslinking strategy, rapid reversible crosslinking of gelatin, and irreversible photocrosslinking of GelMA; was used to achieve the printability through the reduction of GelMA concentration, which adversely affects to the cell viability and spreading of cells. In this method, they were able to print viscosity similar to 30% (w/v) GelMA, using 5% GelMA and 8% gelatin, without affecting to the cell viability and mechanical stability [135].

The main concern related to the GelMA hydrogel is the poor mechanical strength, which adversely affects the load-bearing applications such as bone and cartilage repair. To address this problem, several methods have been used, including alternated printing with PCL and making a support structure using thermoplastic materials. In one study, reinforced cell encapsulated GelMA soft hydrogel with organized high porosity microfiber network of PCL was investigated. The hydrogel was later printed to the etched PCL fiber network, where etching with NaOH increases the stiffness of the composite and more responsive to the mechanical loading. Instead of photocrosslinking, a combination of two chemical crosslinkers ammonium persulfate/tetramethylenediamide (APS/TEMED) was used to stabilize the gel. The stiffness of the GelMa crosslinked with 12.5 mM, and 25 mM APS/TEMED was reported as 7.1 ± 0.5 kPa and 7.5 ± 1.0 kPa respectively. The stiffness of the porous PCL hydrogel composite scaffolds was significantly increased to 214 ± 24 kPa and 405 ± 68 kPa in 12.5 mM and 25 mM APS/TEMED crosslinked sample respectively. Human chondrocytes were incorporated to the GelMA/APS mixture before crosslinking, where over 80% of cell viability was achieved at day 1, and cell viability closer to the 80% also maintained up to 7 days of culture [136]. Malda’s team also investigated the alternating printing of PCL, as a supporting material, and a mixture of GelMA and HLA hydrogel, where HLA acts as a viscosity enhancer, encapsulated with chondrocytes. They have reported cartilaginous matrix formation at 4 weeks and improved mechanical moduli (5–180 kPa) [137].

3.6. Poly(ethylene glycol) (PEG) based hydrogels

PEG is one of the most widely studied hydrogels in tissue-engineered scaffolds for cell studies and drug delivery [138]. PEG is a hydrophilic, biocompatible, and nonimmunogenic polymer due to its intrinsic molecular structure, where PEG diol surround with two hydroxyl end groups, which can be converted into other functional groups such as carboxyl, methoxyl, thiol, amine, vinyl sulfane, azide, acetylene, and acrylate [139,140]. Photopolymerization is the most common strategy to make PEG hydrogel, which allows more spatial and temporal control for the fabrication of scaffolds in situ. PEG diacrylate (PEGDMA), PEG dimethacrylate (PEGDMA). and multiarm PEG acrylates (n-PEG-Acr) are the major type of PEG macromers used in photopolymerization to PEG hydrogels, which are not naturally biodegradable. The addition of degradable segments, including poly (propylene fumarate) (PPF), polyester, acetal, and disulfide enhances the degradation rate of PEG-based hydrogels.

Prestwich and the co workers investigated the use of tetrahedral PEG tetracrylates (TertraPACs) in cell encapsulation. They were able to bioprint a vessel like constructs using thiolated HLA crosslinked with TetraPACs, where NIH 3T3 cells were encapsulated, by adding the agarose microfilaments, as shown in Fig. 5(a) and (b). Two 4-arm PEG derivatives with different PEG chain lengths (TetraPEG8 and TetraPEG13) were synthesized from tetrahedral pentaerythritol derivatives.This PEG hydrogel has shown significantly high shear modulus compared to the PEGDA hydrogel and good cell viability up to 4 weeks [141]. In another study, a perfusable construct with a hollow interior vessel-like structure was developed using a multilayered coaxial extrusion system. The hydrogel system consists of GelMA, sodium alginate, and 4-arm PEG-tetra acrylate (PEGTA) with the addition of hUVECs and hMSCs. The hollow structure was achieved through the initial ionic crosslinking with the Ca2+ (flows through core nozzle) during the printing, and the final covalent photocrosslinking of GelMA and PEGTA was done after printing (Fig. 5(c)). The varying diameter of hollow tubes were printed by changing the diameter of nozzles, as shown in Fig. 5(d). Significantly higher compressive modulus was observed with compared to that of GelMA only scaffolds as increasing PEGTA concentration increased the modulus, where 50.7 ± 3.0 kPa compressive modulus was observed in 3% (w/v) PEGTA scaffolds. Fig. 5(e) shows a printed structure before and after perfusion, and this technique can be used to print continuous hollow tubes with complex shapes (Fig. 5(f)) and also hollow tubes with varying diameters (Fig. 5(g)) [142]. Bertassoni’s group developed a perfusable microchannel system in different PEG derivatives using agarose as a removable material to create microchannels. These microchannels were successfully embedded in to GelMA, star PEG-co-lactide acrylate (SPELA), PEGDMA, and PEGDA based hydrogel systems, but the cell encapsulation was only done in GelMA system, where MC3T3 cells were mixed with GelMA and hUVECs were injected to the created microchannels, and successful completion of endothelial monolayer was observed [143].

Fig. 5. PEG based bioprinting.

(a) The custom microcapillary tube adaptor and printing protocol for building a cellularized tubular structure, consisting of depositing hydrogel macrofilaments in a stacked manner; (b) (i) Immediately after printing (ii) At 14 days, and (iii) At 28 days of culture using LIVE/DEAD staining to highlight viable and dead cells [141] with permission form Elsevier, copyright 2010; (c) (i) Schematic diagram showing two step crosslinking processes of the bioink, (ii) Schematics showing the procedure of bioprinting perfusable hollow tubes with the bioink (iii) The designed multilayered coaxial nozzles; (d) Fluorescence micrographs showing the bioprinted perfusable tubes displaying different outer diameters; (e) Fluorescence photographs before (inset) and after injection with red fluorescent microbeads into the lumen of the single, continuous bioprinted tube (f) Fluorescence photographs showing bioprinted perfusable tubes with various shapes; and (g) Photographs showing single tubes bioprinted with a gradually increasing size (i) and periodically varying sizes (iii) the high-magnification fluorescence micrographs in (ii and iv) clearly show the varying diameters at selected locations indicated in (i and iii), respectively [142] with permission from Elsevier, copyright 2016. (For interpretation of the references to colour in this figure legend, the reader is referred to the web version of this article.)

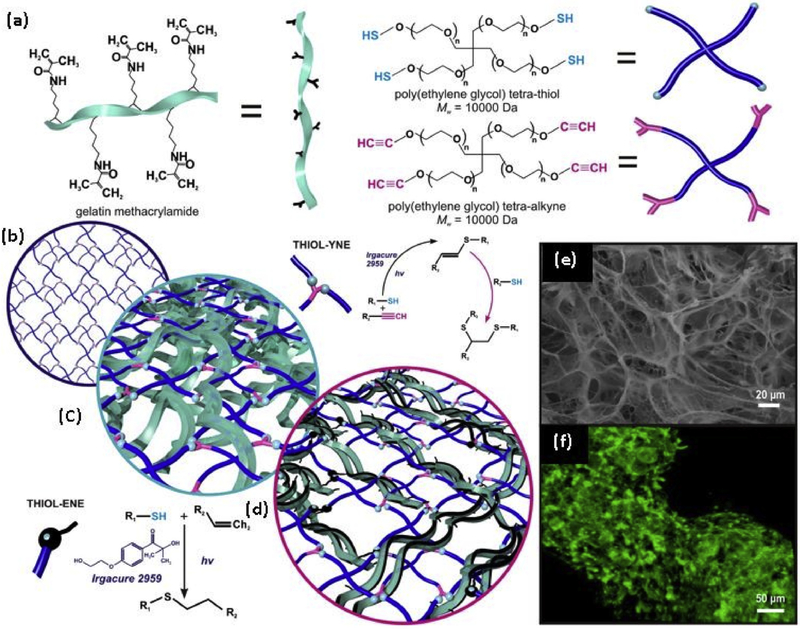

A eosin Y based photoinitiator, 2',4',5',7'-tetrabromflurescein disodium salt, was used to make covalent bonds in a hydrogel mixture of GelMA and PEGDA through a visible light (514 nm) radiation, where 85% of NIH 3T3 cell viability was observed up to 5 days [144]. Xiaofeng Cui’s team developed a number of 3D printed (inkjet-based) PEG-based hydrogel systems to be used in bone and cartilage tissue engineering. In one study, nanoparticles of bioactive glass (BG) and HA were separately incorporated into the PEGDMA hydrogel to investigate the effect of BG and HA on cell viability and mechanical strength. Highest cell viability (86.62 ± 6.02%) of hMSCs was observed in HA incorporated PEGDMA hydrogel, and alkaline phosphatase activity (ALP) and gene expression by quantitative PCR was shown that PEGDMA-HA was better compared to the PEGDMA-BG group [145]. Also, in another study, acrylated arginylglycyl-aspartic acid (RGD), and acrylated matrix metalloproteinase (MMP) sensitive peptide were synthesized and incorporated into the PEGDMA hydrogel system with hMSCs. Hydrogel with PEG peptides showed high expression of collagen type X and MMP13, and the system strongly stimulated the endochondral bone formation [146]. A mixture of PEGDMA and GelMA showed 80% cell viability of encapsulated hMSCs and enhanced osteogenic and chondrogenic expression were shown in PEGDMA/GelMA system compared to PEGDMA alone system [147]. Kaplan’s team studied the incorporation of the physical gelation of silk fibroin protein at 37°C to 3D bioprinting with PEG. They have found that the system was compatible with the hMSCs and surprisingly, higher silk concentration gels (10%) supported the better cell growth than lower concentration gels. Mouse fibroblasts encapsulated scaffolds were subcutaneously implanted in the mice, and the scaffolds maintained the shape and structure after 6 weeks while maintaining the viability of a significantly higher number of cells [148]. In a recent study, PEG microgels were prepared via off-stoichiometry thiol-ene click chemistry using 4-arm PEG-norbornene (PEG-Nb) and PEG-dithiol (PEG-DT). The microgels were prepared using electrospraying technique, and the PEG-Nb encapsulated with hMSCs were printed using an extrusion-based printer, where LAP and PEGDT were added to the printed structure to photocrosslinking [149]. Ligler’s team developed a bio/synthetic interpenetrating network (BioSINx) containing GelMA and PEG, where GelMA polymerized within a PEG framework. The PEG network was formed by thiolyne coupling, and GelMA was integrated using a thiol-ene coupling reaction. The schematic representation of the reactions is shown in Fig. 6. They successfully made microfilament encapsulated with endothelial cells by using the hydrodynamic method. This hydrogel system can be successfully developed into a 3D bioprintable bioink [150]. The summary of advantages and disadvantages of each hydrogel type we have discussed in this section is shown in Table 2.

Fig. 6. Fabrication of bio/synthetic interpenetrating network.

(BioSIN) of (a) Gelatin methacrylamide and poly(ethylene glycol) via concurrent photoinitiation of thiol-ene and thiolyne coupling. The click-functionalized macromer precursors undergo multi-mode crosslinking to form an interlocking 3D hydrogel; (b) The well-defined network architecture of TYC-formed PEG hydrogels were intertwined with either; (c) Physically-incorporated gelatin (BioSINP) or; (d) Covalently crosslinked gelatin methacrylamide (BioSINx) in which the gelatin methacrylamide reacts with both itself and the PEG network.; (e) The architectural heterogeneity emulated native extracellular matrix; (f) Superior physiochemical properties were able to support the continued proliferation of encapsulated cells, where cytoskeletal F-actin fiber staining illustrates the density and interaction of encapsulated cells [150] with permission from Elsevier, copyright 2014.

Table 2.

The advantages and disadvantages of each hydrogel type with their respective application in the biomedical field.

| Hydrogel type | Advantages | Disadvantages | Applications | References |

|---|---|---|---|---|

| Alginate | Viscosity can be easily manipulated by changing the concentration Comparatively short cross-linking time CaCl2 does not significantly reduce the cell viability Compatible with a lot of cell types |

Mechanically unstable for prolonged culture Low degradation rates Does not enhance the cell proliferation |

Vascular tissue Cartilage tissue Bone tissue |

[81] [83,89] [85,90] |

| Collagen | Natural ECM material Act as a good cell carrier Can easily mix with other hydrogels, such as alginate, GelMA, PEG-based derivatives |

Low mechanical stability and cannot be used alone Prolonged crosslinking time |

Cartilage tissue Skin tissue |

[94,96] [99–101] |

| Chitosan | Natural material Shows relatively good mechanical stability Can easily mix with other hydrogel materials |

Acidity reduces the cell viability Neutralization of the solution is required. Can not be used alone |

Bone tissue | [107] |

| Hyaluronic acid | A major component of the ECM Act as a good cell carrier Facilitates cell proliferation Can easily modify and mix into different hydrogel systems to increase mechanical stability and cell viability |

Low mechanical stability and cannot be used alone | Cardiovascular tissue Cartilage tissue |

[111] [113] |

| Gelatin | Consists of natural ECM components Have thermo-responsive property Good cell viability Can use as cell carrier or fugitive bio-ink |

Low mechanical stability Not stable at physiological temperature |

Vascular tissue Liver tissue |

[118,121] [122] |

| Gelatin methacrylate | Derived from modification of gelatin, and consists of natural ECM component Light polymerizable into the stable hydrogel Short cross-linking time Compatible with many cell types |

Low mechanical stability Cell viability depends on the photocrosslinking time, the intensity of the light and photoinitiator |

Vascular tissue Myocardium-on-chip Liver tissue Cartilage tissue |

[129] [131] [132,134] [137] |

| PEG-based derivatives | Properties of the PEG-based derivatives can be easily manipulated using chemical modification techniques Good mechanical stability can be achieved Shows relatively good mechanical stability Mostly light polymerizable material within a short time |

Synthetic material Does not provide biological cues for cell proliferation Cell viability depends on the photocrosslinking time, the intensity of the light, and photoinitiator |

Vascular tissue Bone tissue Cartilage tissue |

[142,143] [145,146,147] [145,147] |

4. Recent trends in bioprinting technology

4.1. Scaffold-free bioprinting

The scaffold-based bioprinting has been explored widely in the past decade, where scaffold-based tissue construct provide mechanical and molecular cues to promote cell adhesion, cell proliferation, and promote ECM production [151]. However, there are several adverse effects created by the polymers and exogenous matrix-based tissues, such as necrosis at the tissue core due to the poor nutrient diffusion in vivo, interfere with direct cell-cell interaction, and toxic degradation products [23,151,152]. Because of the reasons mentioned above, as an alternative, 3D printing based scaffold-free tissue engineered construct have been explored. To eliminate the creation of 2D monolayer and cell-substrate interference, low (or none) adherence substrate or plates or hanging droplets can be utilized [72]. The cardiac patch was created using cardiomyocytes, endothelial cells (both human umbilical vein and embryonic stem cell-derived endothelial cells), and fibroblast to avoid core necrosis in vivo, where low attachment plates were used in vitro. The patches survived in implantation in vivo, and the performed human microvessels anastomosed with the rat host coronary circulation [152]. In another study, the non-adherent substrate was used to create vascularized human liver-like tissue structure with human induced pluripotent stem cells (hiPSCs) [153]. The liver buds created in vitro were transplanted into the mice became functional within 48 h by connecting to the host vessels.

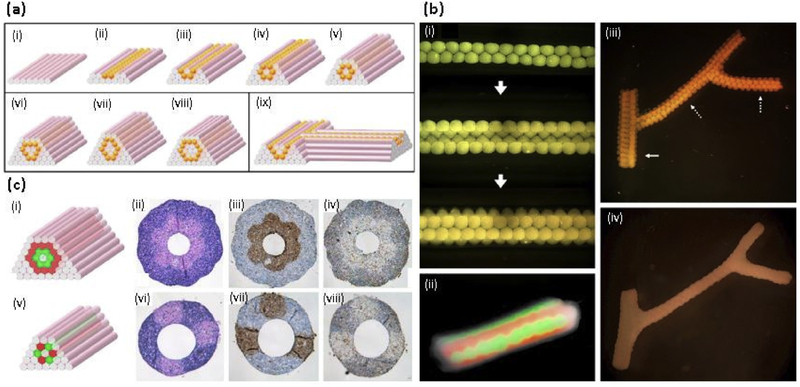

Scaffold-free bioprinting is explored to synthesized hollow tube structures where vascularization is required. Scaffold-free vascular construction was printed layer by layer with agarose rods, used as a non-adhering molding template (Fig. 7(a)). Human skin fibroblasts (HSF) and human umbilical vein smooth muscle cells (hUVSMCs) aggregated into discreet units either as multicellular spheroids or as cylinders of controlled diameter (Fig. 7(b)). Also, multicellular cylinders composed of hUVSMCs and HSF were made, as shown in Fig. 7(c) [23]. In another study, low adherent agarose mold was used to print tissue spheroids, make from alginate-based microdroplets, containing endothelial cells and smooth muscle cells. It is reported that the cell-secreted collagen type I plays a critical role in promoting cell-cell adhesion, tissue formation, and maturation [151]. Overhang structure of sodium alginate hydrogel was successfully fabricated using inkjet printing with fibroblasts (3T3 cells), where this method can be applied to make blood vessels [154]. The conventional coaxial nozzle system also can be used to make scaffold-free bioprinted structures. Articular cartilage tissue strands were made using alginate-based hydrogel system with the ability to assemble into different shapes [155]. Apart from vessel-like structures, laser-assisted tissue graft was printed using alginate and ethylenediaminetetraacetic acid (EDTA) with porcine-derived MSCs, where good osteogenic and chondrogenic differentiation was observed after culturing in vitro [156].

Fig. 7. Scaffold-free bioprinting.

(a) Design template for tubular structures. (i-v) Deposition scheme for the smallest diameter tube that can be built of agarose rods (pink) and multicellular spheroids (orange) of the same diameter. (vi-viii) More complex tubular structures. (ix) Scheme for a branching structure. (b) Fusion patterns of multicellular spheroids assembled into tubular structures. (i) HSF spheroids assembled according to the template. (ii) Fusion pattern after 7 days of a tube assembled from fluorescently labeled red and green sequences of CHO spheroids. (iii) Branched structure built of 300 mm HSF spheroids with branches of 1.2 mm (solid arrow) and 0.9mm (broken arrows). (iv) The fused branched construct after 6 days of deposition. (c) Building a double-layered vascular wall; i,v. HUVSMC and HSF multicellular cylinders were assembled according to specific patterns (HUVSMC: green; HSF: red). Panels ii-iv and vi-viii show the results of histological examination of the respective structures in i and v after 3 days of fusion: H&E (ii,vi), smooth muscle a-actin (brown; iii,viii) and Caspase-3 (brown; iv,viii) stainings are shown. Note that the more complex construct in the upper row requires more time to fuse [23] with permission from Elsevier, copyright 2009. (For interpretation of the references to colour in this figure legend, the reader is referred to the web version of this article.)

4.2. Four-dimensional (4D) bioprinting

4D printing inspired by the natural shape morphing systems, such as nastic plant motions; where external environmental stimuli, including humidity, light or touch causes a shape change in leaves, flowers, bracts and tendrils [157]. Simply, a fourth dimension, time is introduced to the 3D printed structure; where their shape and or function can change over time due to an applied external stimuli, such as moisture [157], light [158], temperature [159], pH [160], magnetic field [161], or electric impulse [162], 4D printing is considered as printing of stimuli-responsive material, known as a smart material, that can be physically or chemically changed in response to external stimuli [72]. In addition to the above definition, the 4D bioprinting is considered as the printing of microengineered tissue construct with the cells, where the time dimension that is related to maturation of tissue construct through self-organization of the cellular process such as cell communication and cell interaction, plays a significant role [163]. Shape memory polymers and the hydrogels are the best candidates used in 4D bioprinting [72,163]. Up to date, cell encapsulated 4D bioprinting is not widely studied, and, therefore, here we will discuss some of the new natural and synthetic hydrogel system used in 4D printing in recent years with the addition of cell encapsulated 4D bioprinting. This stimuli-responsive shape morphing of the hydrogels categorized into different sections based on stimuli such as temperature-responsive shape morphing, moisture responsive shape morphing, magnetic field-responsive shape morphing, and light-responsive shape morphing.

Several researchers have investigated temperature-responsive shape morphing hydrogel systems in recent years. A nanocomposite hydrogel consists of poly (N-isopropylacrylamide) (PNIPAM), and synthetic hectorite clay undergoes a fluid-gel transition in response to the temperature increment up to 80ºC due to the phase transition [159]. PNIPAM is widely used in thermo-responsive shape morphing systems. Alginate and PNIPAM based hydrogel system were used to make a hydrogel that exhibits a large reversible volume transition at the critical temperature, Tc (=32 to 35 ºC) [164]. In a recent study, Laponite, a synthetic clay, was used to synthesize thermo-responsive hydrogel through mixing that with agarose and acrylamide, where physical crosslinking of agarose and photocrosslinking of acrylamide give the stability to the hydrogel (Fig. 8(c)). Laponite increases the shear-thinning properties and stability of the post-printing structure and also showed higher mechanical properties compared to agarose only and acrylamide only gels [165].

Fig. 8. 4D bioprinting.