Abstract

Digital twin has the potential to be an important concept for achieving smart manufacturing. However, there remains a lot of confusion about the concept and how it can be implemented in real manufacturing systems, especially among small-to-medium-sized enterprises. This paper synthesizes the different perspectives that have been reported on the digital twin to identify the key characteristics that must be understood when developing a digital twin for a specific use case. Example applications are provided and the need for a standardized framework, such as the one under development as ISO 23247 (Digital Twin Manufacturing Framework), is motivated. This framework can enable context-dependent implementations and promote composability and reusability of digital twin components.

Keywords: Smart manufacturing, Digital twin, Framework

1. Digital Twins in Manufacturing

The digitalization of manufacturing systems is the foundation of smart manufacturing. Recent technology advancements, such as smart sensors, Internet of Things (IoT), cloud computing, machine learning, and artificial intelligence (AI), have enabled digitalization and facilitated the development of digital twins in manufacturing [1]. A recent Gartner survey reveals that 75 % of organizations implementing IoT already use digital twins or plan to within a year. By 2022, over two-thirds of these companies are anticipated to have deployed at least one digital twin in production [2].

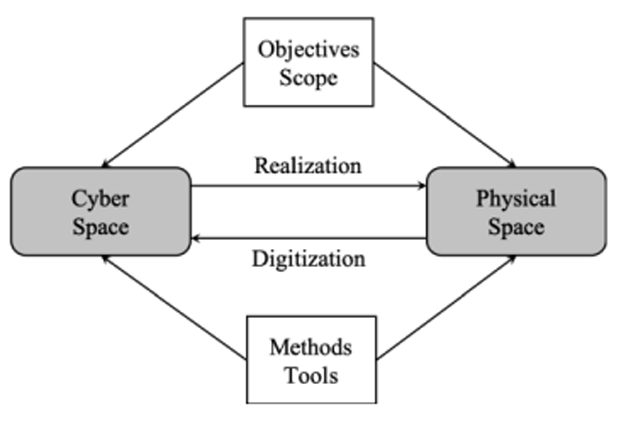

Grieves and Vickers [3] originally defined the digital twin as “a digital informational construct of a physical system as an entity on its own.’ “Twin” in this context implies that this digital information would be linked to the physical system throughout its entire lifecycle. Applying this concept to manufacturing allows manufactures to create fit-for-purpose digital representations of their production systems and processes using collected data and information to enable analysis, decision making, and control for a defined objective and scope (see Figure 1). However, many companies, especially small-to-medium-sized enterprises (SMEs), often do not have the expertise or resources required to implement digital twins effectively. Efforts can be further complicated by the lack of consensus on the digital twin concept and the different standards, technologies, and procedures that can be used to implement digital twins. The goal of this paper is to synthesize these different perspectives on the digital twin to guide the development of a standardized framework that enables manufacturers to develop digital twins for specific objectives more easily, cheaply, and quickly.

Figure 1:

An overview of the digital twin concept (adapted from Hedberg et al. [4])

2. Perspectives on the Digital Twin

Many ways have been proposed to differentiate the digital twin from more traditional notions of modeling and simulation. For example, some research has identified real-time visualization as a key innovation with digital twins while other research has focused on the digital twin as a virtual duplicate of a physical system. Table 1 summarizes some of these perspectives based on the proposed definition, relevant viewpoint (i.e., product, process, or system), fidelity of the digital representation (i.e., complete or partial representation), and temporal integration (e.g., real-time or offline) of a digital twin. Note that an offline digital twin describes the case where real-time communication is not critical. Rather, an offline digital twin would connect to the physical system periodically. This periodic connection is an important distinction between an offline digital twin and a traditional simulation model.

Table 1:

Summary of Different Perspectives on the Digital Twin

| Reference | Definition | Viewpoint | Fidelity | Temporal Integration |

|---|---|---|---|---|

| GE [5] | Software representation | Product, Process | Complete | Offline |

| Siemens [6] | Virtual representation | Product, Process | Complete | Offline |

| Shao and Kibira [7] | Integrated model | Process, System | Partial or Complete | Real-time |

| Tao and Zhang [8] | Reference model | Product | Complete | Offline |

| Coronado et al. [9] | Digital model | System | Complete | Near real-time or Offline |

| Ahuett-Garza and Kurfess [10] | Cyber-physical system | System | Partial | Real-time |

| Negri et al. [11], Kritzinger et al. [12] | Virtual or computerized counterpart | System | Partial | Real-time |

| Garetti et al. [13] | Virtual representation | System | Partial | Real-time |

| Haag and Anderl [14] | Digital representation | Product | Complete | Offline |

| Boschert and Rosen [15] | Data and model | Product, Process, System | Partial | Real-time or Offline |

Based on the perspectives in Table 1, we argue that the digital twin concept depends on the context and viewpoint required for a specific use case, i.e., the digital twin is a fit-for-purpose digital representation. Thus, a digital twin need only collect the data relevant for the use case of interest rather than all available data from the physical system. Similarly, there should be no one digital twin of a physical system but rather a variety of digital twins depending on their use. Realizing a digital twin requires a good understanding of the scope and constraints of the digital twin to avoid the enormous costs described by West and Blackburn [16]. Assessing the scope and constraints of a digital twin will depend on three key factors:

Application: The specific application of the digital twin determines whether it needs to support real-time or offline updating as well as the fidelity needed to support the decision or control action that is desired. The scope and objectives of the digital twin decides which aspects should be included. The usefulness of a digital twin is determined by accuracy not complexity. Avoiding unnecessary components and functionalities saves time and effort and limits potential errors.

Viewpoint: The viewpoint of the desired decision or control action determines whether a product, process, or system twin is needed. Similarly, the viewpoint determines the methods and tools required, such as if the digital twin should mimic the observable behavior of the system (i.e., emulation) or if it should model the state of the system (i.e., simulation) [17].

Context: The context needed to support a viewpoint determines how information should be provided by the digital twin. For example, visualization (while powerful) may not be needed based on the requirements of the use case and constraints on time and budget. Similarly, the relevant viewpoint can influence the types of information that form the context provided by the digital twin.

3. Example Uses of Digital Twins in Manufacturing

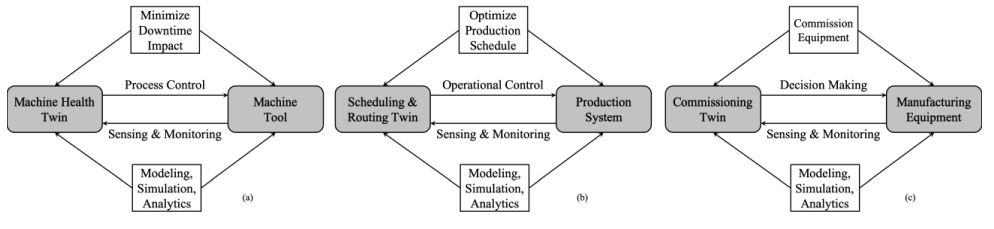

There are a number of potential ways that a product, process, or system digital twin may be used at all levels of manufacturing (e.g., machine, cell, line, facility, or supply chain). Figure 2 highlights three examples described below:

Figure 2:

Three examples of the use of digital twins in manufacturing

Minimizing the impact of equipment downtime: A “machine health twin” can use process and equipment data to monitor, troubleshoot, diagnose, and predict faults and failures in manufacturing equipment. The knowledge can then inform the control of the equipment itself.

Optimizing production planning and scheduling: A “scheduling and routing twin” can collect data from shop-floor systems, such as production equipment, manufacturing execution systems (MES) and enterprise resource planning (ERP) systems, to analyze the current status of the production system and any fluctuations in customer demand, inventory, and resources. This knowledge can then enable demand-driven, on-time delivery, resource (i.e., material, labor, and equipment) optimization, cycle-time reduction, and inventory-cost reduction.

Enabling virtual commissioning: A “commissioning twin” can use information from the vendor and data collected by monitoring new equipment performance during commissioning to enable system optimization and continuous improvement. This knowledge can allow manufacturers to discover and resolve issues before investment and avoid the need for costly adjustments during or after installation.

4. Standardized Framework for the Digital Twin in Manufacturing

A standardized framework can help enable manufacturers leverage digital twins for decision making and control by providing the means to navigate the complex set of standards, technologies, and procedures that can be used for implementation. It should be generic, reusable, and customizable irrespective of implementation so that it can support multiple relevant use cases. Such a framework should include guidelines, methods, and best practices. Using the framework consistently in a company can facilitate the composability of models and interoperability among modules and provide examples of data collection, modeling and simulation, communication, integration, and applications of relevant standards. It can also enable the generation and management of common data and model components to enable the reuse of these components, e.g., a model components library or model templates may be useful for reusing and composing model components.

The ISO 23247 (Digital Twin Manufacturing Framework) standard is currently under development at the committee draft (CD) stage. The goal of this effort is to provide a generic development framework for the use of digital twin in manufacturing that can be instantiated for case-specific implementations. There are four parts that have been proposed for the standard: (1) overview and general principles, (2) reference architecture, (3) digital representation, and (4) information exchange. These four parts will provide guidelines and procedures for analyzing modeling requirements, defining scope and objectives, promoting common terminology usage, specifying a generic reference architecture that enables the instantiation of a digital twin for a specific use case, and supporting information modeling of the physical system and information synchronization between a digital twin and physical system.

Further work is required to continue the development of ISO 23247 including defining the reference architecture and testing, verifying, and validating the standard through implementations for different use cases. These activities can help provide the feedback necessary to complete and improve the standard and help mature the digital twin concept in manufacturing from infancy to a value-generating tool that improves production processes and operations.

Footnotes

Disclaimer

Certain commercial systems may be identified in this paper. Such identification does not imply recommendation or endorsement by NIST. Nor does it imply that the products identified are necessarily the best available for the purpose.

References

- [1].Bolton D 2016. “What Are Digital Twins and Why Will They Be Integral to The Internet of Things?”, Connected World, November 2, 2016. [Google Scholar]

- [2].Gartner. 2019. Gartner Survey Reveals Digital Twins Are Entering Mainstream Use. https://www.gartner.com/en/newsroom/press-releases/2019-02-20-gartner-survey-reveals-digital-twins-are-entering-mai

- [3].Grieves M and Vickers J 2016. “Digital Twin: Mitigating Unpredictable, Undesirable Emergent Behavior in Complex Systems (Excerpt)”, DOI: 10.13140/RG.2.2.26367.61609, https://www.researchgate.net/publication/307509727_Origins_of_the_Digital_Twin_Concept. [DOI] [Google Scholar]

- [4].Hedberg T Jr., Helu M, Sprock T (2018) A standards and technology roadmap for scalable distributed manufacturing systems. Proceedings of the ASME 2018 Manufacturing Science and Engineering Conference, V003T02A019 DOI: 10.1115/MSEC2018-6550. [DOI] [Google Scholar]

- [5].GE. 2018. What is Digital Twin? https://www.ge.com/digital/applications/digital-twin

- [6].Siemens. 2018. Digital Twin, https://www.plm.automation.siemens.com/global/en/our-story/glossary/digital-twin/24465

- [7].Shao G and Kibira D 2018. “Digital Manufacturing: Requirements and Challenges for Implementing Digital Surrogates.” Proceedings of the 2018 Winter Simulation Conference, edited by Rabe M, et al. 1226–1237. Piscataway, New Jersey: Institute of Electrical and Electronics Engineers, Inc. [Google Scholar]

- [8].Tao F and Zhang M 2018. Digital Twin Shop-Floor: A New Shop-Floor Paradigm Towards Smart Manufacturing. IEEE Access, Special Section on Key Technologies for Smart Factory of Industry 4.0. Doi 10.1109/ACCESS.2017.2756069. [DOI] [Google Scholar]

- [9].Coronado PDU, Lynn R, Louhichi W, Parto M, Wescoat E, and Kurfess T 2018. Part data integration in the shop floor digital twin: mobile and cloud technologies to enable a manufacturing execution system. Journal of Manufacturing Systems 48 (2018) 25–33. [Google Scholar]

- [10].Ahuett-Garza H and Kurfess T 2018. A brief discussion on the trends of habilitating technologies for industry 4.0 and smart manufacturing. Manufacturing Letters 15 (2018) 60–63. [Google Scholar]

- [11].Negri E, Fumagalli L, Macchi M 2017. A review of the roles of Digital Twin in CPS-based production systems. Procedia Manufacturing 11(2017) 939–948. [Google Scholar]

- [12].Kritzinger W, Karner M, Traar G, Henjes J, and Sihn W 2018. Digital twin in manufacturing: a categorical literature review and classification. IFAC papersOnLine 51-11 (2018) 1016–1022. https://d1keuthy5s86c8.cloudfront.net/static/ems/upload/files/tcrze_0370_FI.pdf [Google Scholar]

- [13].Garetti M Rosa P and Terzi S 2012. Life cycle simulation for the design of product-service systems. Computers in Industry, 63(2012) pp361–369. doi: 10.1016/j.compind.2012.02.007. [DOI] [Google Scholar]

- [14].Haag S and Anderl R 2018. Digital Twin - Proof of concept. Manufacturing Letters 15 (2018) 64–66. [Google Scholar]

- [15].Boschert S, Rosen R. 2016. Digital Twin - The Simulation Aspect In: Hehenberger P, Bradley D, editors. Mechatronic Futures. Cham: Springer International Publishing. [Google Scholar]

- [16].West TD and Blackburn M, 2017. Is Digital Thread/Digital Twin Affordable? A Systemic Assessment of the Cost of DoD’s Latest Manhattan Project. Procedia computer science, 114, pp.47–56. [Google Scholar]

- [17].Brooks B, Davidson A, and Gregor I 2014. “The Evolving Relationship between Simulation and Emulation: Faster than Real-Time Controls Testing.” Proceedings of the 2014 Winter Simulation Conference, edited by Tolk A, et al. 4240–4249. Piscataway, New Jersey: Institute of Electrical and Electronics Engineers, Inc. [Google Scholar]