Abstract

Oxygen reduction reaction (ORR) plays significant roles in electrochemical energy storage and conversion systems as well as clean synthesis of fine chemicals. However, the ORR process shows sluggish kinetics and requires platinum-group noble metal catalysts to accelerate the reaction. The high cost, rare reservation, and unsatisfied durability significantly impede large-scale commercialization of platinum-based catalysts. Single-atom electrocatalysts (SAECs) featuring with well-defined structure, high intrinsic activity, and maximum atom efficiency have emerged as a novel field in electrocatalytic science since it is promising to substitute expensive platinum-group noble metal catalysts. However, finely fabricating SAECs with uniform and highly dense active sites, fully maximizing the utilization efficiency of active sites, and maintaining the atomically isolated sites as single-atom centers under harsh electrocatalytic conditions remain urgent challenges. In this review, we summarized recent advances of SAECs in synthesis, characterization, oxygen reduction reaction (ORR) performance, and applications in ORR-related H2O2 production, metal-air batteries, and low-temperature fuel cells. Relevant progress on tailoring the coordination structure of isolated metal centers by doping other metals or ligands, enriching the concentration of single-atom sites by increasing metal loadings, and engineering the porosity and electronic structure of the support by optimizing the mass and electron transport are also reviewed. Moreover, general strategies to synthesize SAECs with high metal loadings on practical scale are highlighted, the deep learning algorithm for rational design of SAECs is introduced, and theoretical understanding of active-site structures of SAECs is discussed as well. Perspectives on future directions and remaining challenges of SAECs are presented.

1. Introduction

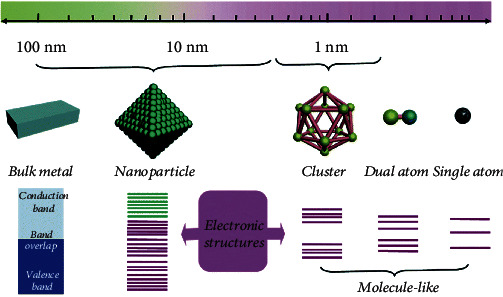

Energy plays crucial roles in the development of human civilization. Most energy-related process involves catalytic reactions by using catalysts to accelerate the reaction rate and elevate the product selectivity [1]. The phenomenon of catalysis has been recognized since ancient times, whereas the cognition of the essence merely began in the 18th century [2]. Catalysts are commonly divided into heterogeneous catalysts and homogeneous catalysts. Heterogeneous catalysts are composed of supported metal nanoparticles. Only a small part of metal atoms exposed on the surface participate in the reaction, whereas other metal atoms nonaccessible by the reactants are inert or even cause undesirable side reactions. Homogeneous catalysts possess tunable active-site structure, which enables them exhibiting ultrahigh activity and unique selectivity for specific reactions [3]. However, unsatisfactory stability and poor recyclability limit their applications. Coupling the merits of both homogeneous and heterogeneous catalysts is the ultimate goal in catalysis science. In this context, atomically isolated metal atoms embedded in suitable supports generate a new kind of catalysts, which patches up the gap between homogeneous and heterogeneous catalysis. The dispersion of metal on an atomic scale generates maximum utilization efficiency (nearly 100%), remarkable quantum size effect, unsaturated coordination environment, and strong metal-support interaction, as shown in Figure 1 [4], which enables metal atoms dramatically boosted activity, selectivity, and stability. Furthermore, recent progress in advanced characterization techniques makes it possible to confirm the exact geometric structure of the active centers due to their simplicity and homogeneity, which provides an ideal platform for establishing theoretical calculation models and deeply understanding catalytic mechanisms at the atomic-scale level to elucidate the fundamental synthesis-structure-performance correlations for rational design of catalysts for targeted reactions. This novel kind of catalysts was, for the first time, named as “single-atom catalysts (SACs)” by Qiao and coworkers in 2011 after precisely anchoring atomically isolated Pt atoms on FeOx [5]. Since then, study on SACs experienced an explosive growth and SACs have been used in various reactions including propane dehydrogenation [6], n-hexane isomerization [7], C-H bond activation [8], Suzuki coupling [9], and CO oxidation [5]. Especially, the introduction of SACs in electrochemical reactions, including hydrogen evolution reaction (HER) [10], oxygen evolution reaction (OER) [11, 12], oxygen reduction reaction (ORR) [13], carbon dioxide reduction reaction (CO2RR) [14], and nitrogen reduction reaction (NRR) [15], boosts the great progress on synthesis, characterization, reaction mechanism, and structure-performance relationship of single-atom electrocatalysts (SAECs) due to the high detection sensitivity and low catalyst loadings for electrochemical reactions.

Figure 1.

Electronic energy level changes in reducing the metal size. Reproduced from [4].

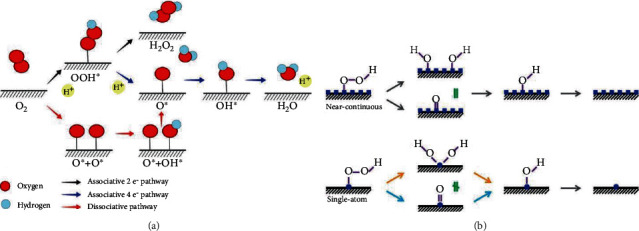

Among various electrochemical reactions catalyzed by SAECs, ORR plays significant roles in electrochemical energy storage and conversion technologies as well as clean synthesis of fine chemicals [16]. Hydrogen peroxide (H2O2) is regarded as one of the most widely used fine chemicals for water treatment and chemical synthesis [17]. The industrial demand for hydrogen peroxide has reached 4 million tons per year. The clean production of H2O2 through selectively electrochemical reduction of oxygen molecules involves the oxygen reduction reaction. The ideal catalysts for H2O2 synthesis should exhibit high ORR activity, high selectivity, and low reduction reaction activity toward H2O2. However, traditional bulk metal catalysts and metal nanoparticle catalysts show poor selectivity for H2O2 due to the cleavage of O-O bond by adjacent atom sites [18]. SAECs featuring with atomically isolated active sites promoted the adsorption of O2 adopting the end-on type other than peroxo configuration, lowering the probability of O-O bond cleavage. Therefore, SAECs would be an ideal catalyst for H2O2 production via ORR. Moreover, ORR is widely involved in the discharging process of various metal-air batteries, such as Li-O2 battery and zinc-air battery, as well as low-temperature fuel cells, like anion exchange membrane fuel cells (AEMFCs), proton exchange membrane fuel cells (PEMFCs), and microbial fuel cells (MFCs) [19]. The ORR rate significantly determines the output power density of these advanced electrochemical energy storage and conversion devices. Normally, the ORR process shows sluggish kinetics and requires platinum-group noble metal (PGNM) catalysts to accelerate the reaction. However, the scarce reservation, high cost, and poor durability significantly impede the large-scale commercialization of PGNM catalysts [20]. US Department of Energy (DOE) reported that PGNM electrocatalysts account for 55% cost of the fuel cell stack used for automobiles [21], barricading the commercialization of fuel cell technologies. To address these difficult problems, intensive efforts have been devoted to develop noble metal-free ORR catalysts with low cost and high activity in the past decades including metal-free carbon-based electrocatalysts [22], SAECs [23], metal nitride electrocatalysts [24], and metal alloy electrocatalysts [25]. Among these reported noble metal-free ORR catalysts, single-atom electrocatalysts (denoted as M-Nx-Cy, M=metal) show great potential to substitute PGNM catalysts because of their high intrinsic activity and tunable support structures [26].

Tremendous advantages and outstanding performance of SAECs in oxygen reduction reactions as well as ORR-related applications have intrigued substantial growth of research interest in the past several years [27]. In this review, recent advances of synthesis, characterization, ORR performance of SAECs, and their applications in ORR-related H2O2 production, metal-air batteries, and low-temperature fuel cells were systematically summarized. Relevant progresses on SAECs with binary metal centers, binary ligands, and unique architecture supports were also reviewed. For practical applications, general strategies to synthesize SAECs with high metal loadings on large scale are highlighted, the deep learning algorithm for highly efficient design of SAECs is introduced, and theoretical understanding of the active-site structure of SAECs and the structure-performance relationship is discussed. Finally, challenges and perspectives for SAECs are present to spotlight the future direction for further optimizing ORR performance.

2. Synthetic Methods for SAECs

SAECs are not directly available; in that, the individual metal atoms are prone to aggregate into nanoclusters or nanoparticles in the synthetic process to reduce surface energy. For the synthesis of SAECs, the following critical criteria should be considered: (i) uniform dispersion of active sites over the support, (ii) strong interaction between isolated metal atoms and adjacent coordination atoms, (iii) promotion of mass and electron transport as well as active-site accessibility, and (iv) high activity and durability. Various strategies for the synthesis of SAECs have been developed, including wet chemical methods, high-temperature pyrolysis methods, vapor deposition method, and atom trapping methods. For practical applications, some general methods for the synthesis of SAECs with high metal loadings on a large scale have also been developed.

2.1. Wet Chemical Methods

Wet chemical methods, including impregnation, modular coordination, colloidal strategy, electrochemical deposition, low-temperature reduction, and ion exchange, are of ease to operate and have been widely used for production on a large scale. The isolated metal atoms show strong interaction with the support, which ensures that the isolated metal atoms are dispersed on the surface of the support and prevents their aggregation. The key points to prepare high-performance SAECs include selecting suitable precursor materials and controlling the synthetic procedure.

2.1.1. Impregnation

For impregnation method, the first and most important thing is to construct suitable anchoring sites to immobilize and disperse single-atom metal precursors. The commonly used anchoring sites include the defect sites on the metal oxides, the coordination atoms (such as B, N, P, O, S) doped in the carbon skeleton, the π-π interaction, and the covalent tethering.

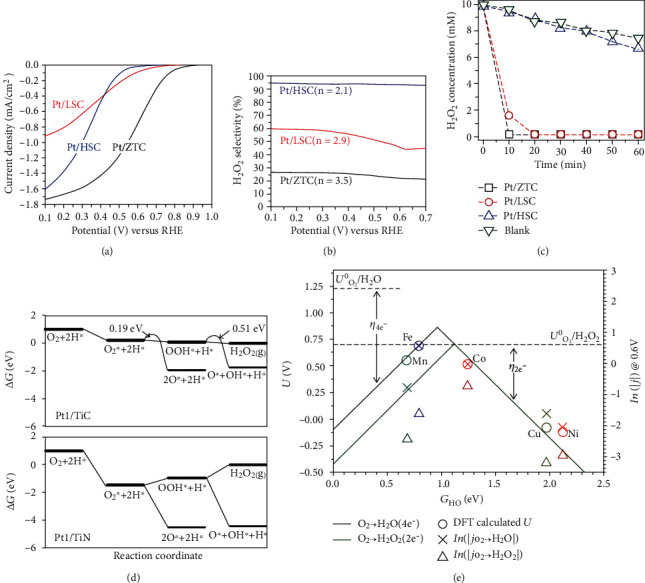

By pyrolyzing a core shell-structured SiO2@melamine-resorcinol-formaldehyde polymer spheres, followed by HF etching, N-doped porous carbon spheres could be prepared. Then, a single-atom Co catalyst with CoN5 active sites was obtained by impregnating the N-doped carbon spheres into a cobalt phthalocyanine (CoPc) solution [33]. N atoms doped in the carbon matrix coordinated with the central Co atom of CoPc in the axial direction and firmly anchored the CoPc molecules on the carbon spheres. The same method could also be used to prepare Fe, Ni, and Cu single-atom catalysts by replacing CoPc with FePc, NiPc, and CuPc. Choi and coworkers prepared sulfur-doped zeolite-templated carbon (HSC) support with a high sulfur loading of 17 wt% [34]. By impregnating HSC into H2PtCl6 solution, the strong interaction between Pt and S could anchor isolated Pt atoms on the HSC support. After H2 reduction, a single-atom Pt/HSC catalyst with a high Pt loading of 5 wt% was successfully prepared. EXAFS and HAADF-STEM identified the generation of individual Pt2+ species coordinated with four S-moieties. By grinding sodium hypophosphite with the graphite carbon nitride (g-C3N4) nanosheets followed by thermal treatment at 300°C under inert atmosphere, Cao et al. prepared phosphor-decorated g-C3N4 nanosheets (PCN) [35]. By impregnating the obtained PCN in a RuCl3 solution at 70°C for 5 h, followed by thermal treatment at 300°C under argon atmosphere, a single-atom Ru catalyst (Ru-N-C) was prepared.

By mixing CoPc with CNTs in DMF associated with the assistance of magnetic stirring and sonication, CoPc molecules could be immobilized on the surface of CNTs to form the single-atom CoPc/CNT catalyst by the strong π-π interaction [36]. With the same method, amino functionalized CoPc (CoPc-NH2) could also be anchored onto the surface of CNTs to synthesize single-atom CoPc-NH2/CNT catalyst [37]. However, under harsh electrochemical reaction conditions, this kind of immobilization approach usually causes the exfoliation of the active CoPc molecules. Cao et al. reported a covalent tethered method to immobilized Fe phthalocyanine (FePc) onto single-walled carbon nanotubes (CNTs) to prepare single-atom Fe electrocatalyst (FePc-Py-CNTs) for ORR [38]. Firstly, purified CNTs were functionalized by reaction with 4-aminopyridine (4-AP) to prepare the Py-CNT support. Then, Py-CNTs were impregnated into a FePc solution and FePc molecules were tethered onto Py-CNTs by axial coordination. Compared with the π-π interaction, covalent tethering shows better stability.

In most cases, the synthesis of SAECs by impregnation is conducted in aqueous solutions, which limits the choice of precursors to water-soluble metal salts, preventing the use of organometallic metal salts containing organic ligands. Hutchings's group recently reported a facile synthesis of active carbon-supported precious metal-based (Pd, Pt, Ru, Au, etc.) single-atom catalysts in organic solvents with low-polarity and low-boiling-point solvent, such as ultradry acetone [39]. By simple impregnation, stabilized single cationic metal species were anchored on active carbon supports in the obtained single-atom catalysts. The substitution for water with organic solvents avoids the utilization of strongly oxidizing aqueous solutions and reduces the catalyst drying temperature, which prevent sintering of the highly dispersed metal species.

2.1.2. Modular Coordination Method

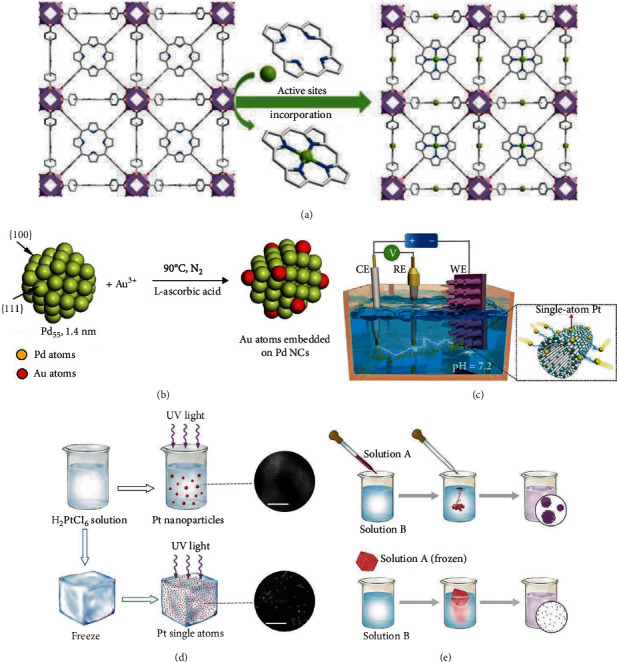

Metal organic frameworks (MOFs) consisting of organic linkers bonded with metal nodes show unique properties of tunable pore size, large specific surface area, and uniform structure. By incorporating porphyrin rings in the organic linkers, the obtained MOFs could be used as the host to coordinate with various metal cations due to the strong coordination properties of the porphyrin rings. The as-prepared materials show atomically dispersed single-atom metal sites with totally uniform structures and high loadings. The popularity of isolated metal atoms and the pore size of MOFs could be easily tuned by constructing different organic linkers. With zirconium chloride and tetrakis(4-carboxyphenyl) porphyrin as the precursor, a porphyrin-based MOF (MOF-525) was prepared [28]. Then, MOF-525 powders were immersed into a cobalt nitrate solution in DMF. The coordination of Co cations with the porphyrin rings in the MOF-525 matrix could anchor Co cations and form single-atom MOF-525-Co catalyst, as illustrated in Figure 2(a). In a similar way, a single-atom MOF-525-Zn catalyst was also prepared. For the first time, Sawano and coworkers synthesized a triaryl-phosphine-derived tricarboxylate linker, which was used to prepare a Zr-based MOF (P1-MOF) [40]. Postsynthetic metalation of P1-MOF with [Ir(OMe)(cod)]2 or [RhCl(nbd)]2 afforded single-atom P1-MOF-Rh or P1-MOF-Ir with controllable metal loadings. The strong coordination of isolated monophosphine sites in the P1-MOF matrix with metal precursors inhibits the mobilization of metal precursors and generates single-atom catalysts. With organic dicarboxylic acid and AlCl3 as the precursors, Zhou and coworkers synthesized a microporous MOF-253 [41]. By immobilizing a platinum complex (cis-Pt(DMSO)2Cl2) onto the 2,2′-bipyridine units, a single-atom MOF-253-Pt catalyst was prepared.

Figure 2.

Wet chemical methods for the synthesis of SAECs. (a) Incorporation of active sites into a porous framework. Reproduced from [28]. (b) Schematic illustration of the deposition of single Au atoms on Pd mother clusters by the successive reduction method using L-ascorbic acid as the reducing reagent. Reproduced from [29]. (c) Schematic diagram of the electrochemical deposition of single-atom Pt onto CoP nanotubes. Reproduced from [30]. (d) Schematic illustration the iced-photochemical process for the preparation of atomically dispersed Pt catalysts. Reproduced from [31]. (e) Illustration of the syntheses of atomically dispersed metals. Reproduced from [32].

By replacing porphyrin with metalloporphyrin in the organic linkers, this kind of SAECs could be directly synthesized in one step. Zuo et al. reported a surfactant-stabilized coordination strategy towards two-dimensional single-atom Pt catalysts with a Pt loading as high as 12.0 wt% by embodying presynthesized Pt-porphyrin molecules into Cu-based MOF nanosheets [42]. This modular coordination is an ideal method to synthesize SAECs with uniform active-site structure and high metal loadings. However, the conductivity of the obtained SAECs is unsatisfactory, which inhibits the overall electrochemical catalytic efficiency.

2.1.3. Colloidal Strategy

A series of colloidal single-atom catalysts were synthesized by embedding metal A atoms on another metal B nanoclusters with the successive reduction, simultaneous reduction, or galvanic replacement reactions. As illustrated in Figure 2(b), with the PVP-protected Pd nanoclusters as the mother support, the successive reduction of HAuCl4 produced a colloidal Au single-atom catalyst [29]. EELS measurements showed that Au clusters were located on several areas across the surface of the Pd55 nanoclusters. A golden single-atom Pt electrocatalyst (Pt4Au96) was prepared by reducing H2PtCl6 (4%) and HAuCl4 (96%) simultaneously in the mixture of oleylamine and ethylene glycol in one pot [43]. The individual Pt atoms were surrounded and stabilized by Au atoms of the bimetal nanocrystals. A PVP-protected colloidal isolated Au atom on Pd nanocluster catalyst was prepared by a galvanic replacement reaction method [44]. The Pd atoms at the top positions of Pd nanoclusters reacted with Au3+ ions and replaced by the formed Au atoms. This approach could also be used to synthesize trimetallic catalysts with isolated Au sites on IrPd bimetal nanoclusters [45].

2.1.4. Electrochemical Deposition

MXenes, a new class of two-dimensional transition metal carbides/nitrides, feature exceptional properties: (i) excellent electronic conductivity with efficient charge transport, (ii) catalytically active basal planes with exposed metal sites, (iii) hydrophilic surface functionalities, and (iv) unique layered structure consisting of conductive transition metal carbides or nitrides. These attractive properties render MXenes as superior substrate for facilitating various electrocatalysts. For instance, electrochemically exfoliation Mxene nanosheets (Mo2TiC2Tx) containing large quantities of exposed basal planes could generate abundant Mo vacancies, which could be used as the anchoring site to electrochemically deposit single-atom Pt [10].

As shown in Figure 2(c), Zhang et al. developed an electrochemical method to deposit single-atom Pt onto CoP nanotubes [30]. Firstly, they prepared a CoP nanotube arrays on Ni foams (NT-NF). Then, NT-NF, Pt foil, and saturated calomel electrode were assembled in a standard three-electrode filling with N2-saturated 1 M phosphate-buffered solution. After 5000 potential cycles, the single-atom PtSA-NT-NF electrocatalyst was obtained.

Very recently, Zhang et al. developed a general electrochemical deposition strategy, which could be applied in a wide range of metals and supports for the preparation of SAECs [46]. The deposition process was carried out on both anode and cathode. A glassy carbon electrode loaded with Co(OH)2 nanosheets was used as the working electrode and a diluted H2IrCl6 (100 μM) solution was used as the metal precursor and the electrolyte. The depositing process started from 0.10 to -0.40 V in cathodic deposition and from 1.10 to 1.80 V in anodic deposition. The scanning cycle was repeated for three times to obtain A-Ir1/Co(OH)2 from the anode and ten times to obtain C-Ir1/Co(OH)2 from the cathode. More than 30 kinds of different SAECs (Fe, Ni, Co, Zn, Cu, Cr, V, Ag, Mn, Ru, Ir, Pd, Rh, Pt, Au, etc.) are prepared from anodic or cathodic deposition by changing supports and metal precursors.

2.1.5. Low-Temperature Reduction Method

The ice lattice possesses natural confining effect. If an aqueous solution is frozen rapidly at ultralow temperature, an ice layer containing a homogeneous concentration of isolated metal atoms will be formed. Assisted with wet chemical or photochemical reduction, this strategy was used to synthesize SAECs with the frozen ice providing spatial confining environment. Wei and coworkers reported an ice-based photochemical reduction method to prepare Pt-based SAECs [31]. As illustrated in Figure 2(d), H2PtCl6 solution was rapidly frozen in liquid nitrogen followed by irradiation with UV lamp. After the H2PtCl6 ice was warmed to room temperature, a solution containing Pt single atoms was prepared. The obtained Pt single atoms in solution could be transferred onto multiwalled carbon nanotubes, mesoporous carbon, graphene, ZnO, and TiO2 by simple impregnation. This ice-based photochemical reduction method could also be used to prepare single-atom Ag- and Au-based catalysts. The most important factor to be precisely controlled is to guarantee the frozen state of the H2PtCl6 solution in the photoreduction process. Furthermore, this iced photoreduction method was extended to ice melting wet chemical reduction method with NaBH4 as the reducing reagent [32]. As shown in Figure 2(e), firstly, AgNO3 aqueous solution was rapidly frozen in liquid nitrogen. The ice was submerged into the NaBH4 solution and naturally melted with magnetic stirring at 0°C. After approximately one hour, the ice was partially melted, the remaining ice was removed. By collecting the mixed solution, the atomically dispersed Ag solution was prepared. The obtained single Ag atoms could also be supported onto mesoporous carbon. To be highlighted, this ice melting reduction method could be extended to fabricate other single-atom metal solutions including Co, Ni, Cu, Rh, Ru, Pd, Os, Ir, Pt, and Au. In a similar way, this liquid reduction method was used to prepare single-atom Co electrocatalyst (Co/NMC-LT900) at ultralow temperature of -60°C [47]. A CoCl2 solution (Solution A) and an alkaline N2H5OH and KOH solution (Solution B) were cooled down to -60°C, respectively. Then, Solution A was added dropwise into Solution B by a syringe pump. For the following reducing, anchoring, rinsing, and filtering process, the temperature was finely controlled at -60°C. After drying and annealing at 900°C for 1 h, single-atom Co/NMC-LT900 catalyst was prepared. Compared with traditional solution-phase reduction at room temperature, a sluggish nucleation rate and a higher energy barrier are required at ultralow reduction temperature to inhibit nuclei formation. As a result, single-atom cobalt catalysts are synthesized.

2.1.6. Ion Exchange Method

With monodisperse Cu1.94S nanoparticles as the support, a redox-based ion exchange method was developed to prepare single-atom Pt catalysts (h-Pt1-CuSx) [48]. Firstly, H2PtCl6 solution was injected into a cyclohexane dispersion containing Cu1.94S nanoparticles. Then, Cu1.94S nanoparticles reacted with H2PtCl6. During the reaction, H2PtCl6 was reduced to Pt0 atoms, which were further embedded into the surface of the Cu1.94S nanoparticles to form single-atomic Pt sites in CuSx. The strong Pt-S interaction ensured that Pt atoms would selectively coordinate with S without the generation of Pt clusters. The interior of Cu1.94S was further oxidized and removed, finally yielding hollow CuSx nanoparticles with rich isolated Pt sites (h-Pt1-CuSx). The Pt loading reaches as high as 24.8 at%. Kim et al. used a typical incipient wetness impregnation method to synthesize the atomically isolated Pt on antimony-doped tin oxide (ATO) [49]. Owing to the strong interaction of ATO with Pt, single-atom Pt was successfully anchored on ATO (Pt1/ATO) by substituting Sb sites with Pt atoms. The Pt loading is as high as 8 wt%.

2.2. High-Temperature Pyrolysis Methods

In 1964, Jasinski found that macrocyclic compounds with an MN4 center showed ORR activities [50], which opens up the avenue for preparation of SAECs by pyrolyzing C and N containing organic precursors (such as MOFs, melamine, dicyandiamide, ethylene diamine, polyaniline, phenanthroline, polypyrrole, phthalocyanine, porphyrin) together with transition metals (such as Fe, Co, Ni, Cu, Zn, Cr, Mn, Mo, Mg, Pt, Pd, Rh, Ir, Os) at high temperatures. Without chemical control, this high-temperature pyrolysis method usually causes the formation of metal nanoclusters/nanoparticles or metal oxides/carbides/nitrides, which makes the identification of the active-site structure a great challenge. In recent years, several effective strategies based on high-temperature pyrolysis have been revealed to synthesize SAECs with uniformly dispersed active sites.

2.2.1. MOF-Based Encapsulation Pyrolysis

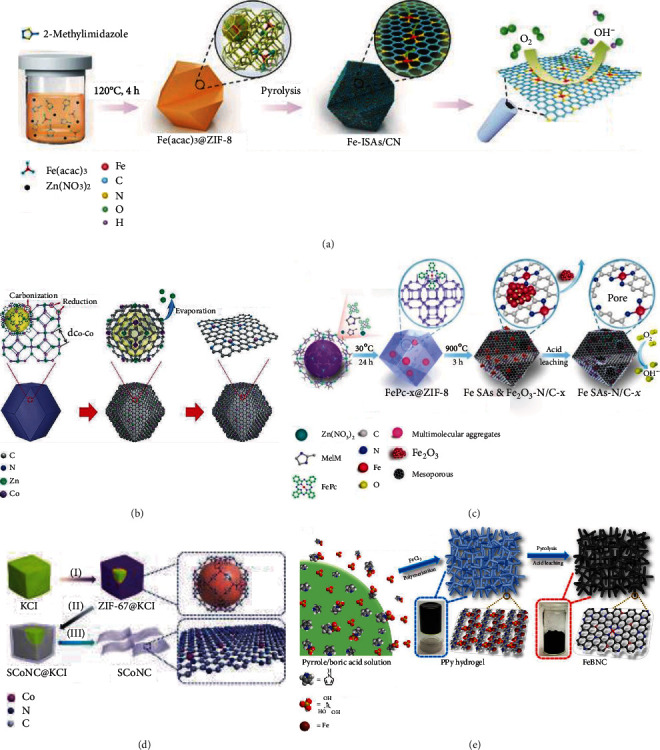

To uniformly disperse active sites on atomic scale, metal organic frameworks (MOFs) are often used to synthesize the SAECs by pyrolysis at high temperatures. After heating treatment, the organic precursors were converted into N-doped porous carbon framework with isolated metal atoms. The catalytic activity of the resulting SAECs is of high sensitivity to the synthetic factors, such as the organic linker forms, the loadings of metal precursors, pyrolyzing atmosphere, and the temperature profiles. The utilization of MOFs together with a low content of metal precursors contributes to inhibit the migration and aggregation of metal species, resulting in the generation of dense single-atom metal sites. One of the most widely used MOFs is zeolitic imidazolate frameworks (ZIFs), especially ZIF-8. The nanocavity diameter of ZIF-8 is approximately 11.6 Å, which is large enough to encapsulate metal complexes such as Fe(acac)3 [51], Fe-Phen [56], and ferrocene (Fc) [57]. By enlarging the nanocavity size of ZIF-8, huge iron(II) phthalocyanine (FePc) molecules could be incorporated [53], as shown in Figure 3(c). After pyrolysis at 900°C under inert atmosphere, single-atom Fe-N-C catalysts were prepared. With FeCl2 and Zn(NO3)2 as the metal precursors, 2-methylimidazole as the organic ligand, and KI as the reducing reagent, Gu et al. prepared a Fe-doped ZIF-8 under nitrogen atmosphere [14]. After pyrolysis at 900°C, a single-atom Fe3+-N-C electrocatalyst was obtained. Compared with other methods conducted under ambient conditions, this approach under anaerobic conditions could synthesize a single-atom catalyst with Fe3+ ion center coordinated with pyrrolic N atoms of N-doped carbon support. It was found that the pyrrolic N ligands prefer to stabilize Fe3+, while the pyridinic N ligands are prone to coordinate with Fe2+. By ball-milling Fe(OAc)2, 1,10-phenanthroline, and ZIF-8, Li et al. prepared a FePhenMOF precursor [58]. Different from traditional one-step pyrolyzing under inert atmosphere, they proposed a two-step pyrolyzing approach: (i) Firstly, FePhenMOF was pyrolyzed under inert atmosphere (denoted as FePhenMOF-Ar). (ii) Then, FePhenMOF-Ar was further thermally treated under NH3 atmosphere (denoted as FePhenMOF-ArNH3). The second pyrolysis in NH3 maintains the active-site structure but remarkably elevating the density of available ORR sites by increasing the porosity directly contacting with the electrolyte and substrates. This MOF-based pyrolysis method could also be used to prepare binary metal SAECs. For instance, a binary metal Fe,Mn-N/C catalyst was prepared by adsorbing FeSO4 and manganese(II) 2,4-pentanedionate (C10H14MnO4) into the pores of ZIF-8 followed by pyrolyzing at 900°C [59]. The as-prepared Fe,Mn-N/C contains two types of M-Nx active site decorated in the carbon matrix.

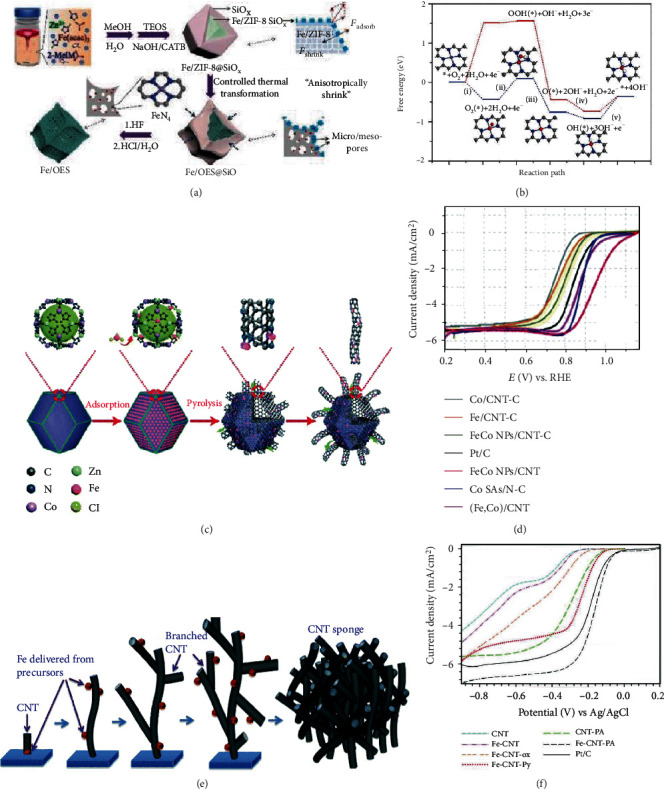

Figure 3.

High-temperature pyrolysis methods for the synthesis of SAECs. (a) MOF encapsulation to synthesize Fe-based SAECs. Reproduced from [51]. (b) The synthesis of Co SAs/N-C. Reproduced from [52]. (c) The synthesis of single-atom Fe SAs-N/C-20. Reproduced from [53]. (d) The synthesis of the single-atom SCoNC catalysts with KCl molten salt method. Reproduced from [54]. (e) The synthetic procedure of single-atom FeBNC catalysts. Reproduced from [55].

The composition and morphology of SAECs could be modulated by coating ZIF-8 nanocrystals with customized layers. For example, by coating with PZS layers, an N, P, and S codoped Fe-SAs/NPS-HC catalyst was prepared [60]. In Fe-SAs/NPS-HC, the atomically dispersed Fe atoms coordinated with near-range nitrogen atoms and interacted with long-range sulfur and phosphorus atoms. Furthermore, with the silica coating layers, an overhang-eave structure anchored with isolated Fe atoms (Fe/OES) could be prepared [61]. Silica-coated MOFs could generate an outward adsorption force, which induces the MOF precursors toward anisotropic thermal shrinkage. As a result, the edge fringes of ZIF-8 were reserved, while the dodecahedron planar facets collapsed in the pyrolyzing process. Compared with traditional bulk carbon structure-supported single-atom Fe catalysts, the resulting Fe/OES catalyst showed edge-rich structure that processes much three-phase boundaries, which could enhance mass transport of substrates and improve the active-site accessibility. Surfactants were also used to coat MOF nanocrystals to prepare single-atom Co catalyst [62]. In comparison with cationic surfactant CTAB, anionic surfactant SDS, and nonionic surfactant PVP, nonionic triblock copolymer F127 showed strong interaction with Co-ZIF-8 nanocrytals by coordinating hydrophilic groups of F127 with Zn2+ and Co2+ sites on the surface of ZIF-8. During the subsequent pyrolysis, the F127 layers were firstly carbonized to form a carbon layer on the Co-ZIF-8 nanocrystals and showing significant confinement effect to inhibit the agglomeration of Co atoms. As a result, a single-atom Co catalyst was successfully prepared.

Zn cations in ZIF-8 could be gradually substituted with Co cations from 0 to 100 atom% with the ZIF structure unchanged. Yin et al. designed and prepared a Zn/Co bimetallic MOF with the molar ratio of Zn/Co above 1 : 1 [52]. By directly pyrolyzing the Zn/Co bimetallic MOF, a single-atom Co catalyst was obtained with Zn atoms evaporated away. As illustrated in Figure 3(b), the introduction of Zn atoms lengthened the distance between Co atoms and thus prevented the aggregation of Co species in the pyrolyzing process. The subsequent evaporation of Zn atoms could generate enriched porosity and high specific surface in the carbon matrix. With the Co doping content of 20 atom%, the obtained catalyst possessed the maximum density of isolated Co sites and exhibited the highest ORR activity [63].

While a large number of ZIF-8-derived SAECs have been prepared in recent years, high pyrolyzing temperatures above 900°C are usually needed to remove Zn from the carbon framework. The high-temperature treatment constantly leads to the formation of metal nanoclusters or nanoparticles. Suppressing the migration and aggregation of single-atom sites could preferentially increase the active-site popularity. The utilization of zinc limits the pyrolyzing conditions, especially pyrolyzing temperatures, in the optimization of ORR performance. Al-Zoubi and coworkers reported that by replacing Zn with a low-boiling-point Cd in the MOF, the pyrolyzing temperature could be dramatically dropped to 750°C [64]. In this protocol, firstly, with terephthalic acid and DABCO as the N-containing organic ligand, cadmium nitrate as the metal node, and iron nitrate as the Fe precursor, a binary-ligated Cd-Fe-DABCO-TPA MOF was prepared. Then, the as-made Cd-Fe-DABCO-TPA MOF and 1,10-phenanthroline were ball-milled for 2 h. After pyrolyzing at 750°C under NH3 atmosphere, a single-atom Fe-C-N750 was obtained. ICP-AES measurements demonstrated that most of Cd has been removed after the pyrolysis and the residual of Cd is only 0.4 wt% in the synthesized Fe-C-N750 catalyst. In contrast, 15.4 wt% of Zn was left in the ZIF-8-derived sample. The discrepancy in boiling point between Cd and Zn results in the residual amount of sacrificed metal in the produced catalyst.

With 2-amino terephthalic acid (H2BDC-NH2) as the organic linker, Wang and coworkers prepared an UiO-66-NH2 MOF [65], which contains lots of uncoordinated -NH2 groups. The strong interaction between Ru3+ and amine groups could guarantee the isolated Ru atoms to be confined in the pores of MOFs and prevent their aggregation in the pyrolyzing process. In the absence of amine groups, Ru atoms tend to aggregate with Ru clusters formed on the porous carbon. The same strategy could also be used to prepare single-atom W catalyst with WCl5 as the W precursor [66]. Liu et al. prepared an Mg-based MOF (Mg-HMT) by reacting MgCl2 with hexamethylenetetramine in a mixed solvent of water and alcohol [67]. After pyrolysis, the impurities were removed by diluted HCl solution. It should be mentioned that suitable drying conditions for the precursor play a decisive role in maintaining the high ORR activity. This is the first example to synthesize main-group-based SAECs by high-temperature pyrolysis.

2.2.2. Molten Salt-Assisted Pyrolysis

Although SAECs derived from MOF precursors can preserve the original microstructures, this strategy also offers low yields and requires complex steps (especially the synthesis of precursors and post treatment). Therefore, for large-scale production and application of SAECs, it is a highly desirable task to propose simple and economical synthetic methods. Molten salts, including LiCl, NaCl, KCl, ZnCl2, and their mixtures, are soluble in water and could be easily removed after synthesis. As the template, molten salts could be used to synthesize nitrogen-doped porous carbon with a high specific area. More importantly, at high temperatures, the strong polarizing force of molten salts facilitates to break the ionic bonds in oxides and release free ions from solid oxides. After being trapped by N-doped carbon matrix, free ions were converted into isolated single-atom sites. In molten salts, the free migration of metal species could be inhibited, which is highly desired to form isolated metal sites at high temperature. For example, as shown in Figure 3(d), a KCl-assisted method was developed to prepare single-atom Co catalyst [54], in which a thin layer of ZIF-67 containing Co precursor grew on the surface of KCl particles, followed by annealing under argon at 750°C for 2 h and washing with diluted HCl and H2O to remove KCl template. With NaCl as the template, glucose as the carbon source, and FeCl3 as the Fe precursor, Zhang et al. prepared a single-atom Fe1-HNC-500-850 catalyst [68–70]. By mixing NaCl, glucose, and FeCl3 in water followed by freeze drying, grinding, and pyrolyzing under NH3 at 500°C and Ar at 850°C, single-atom FeN4 sites were anchored on honeycomb-like nanosheets (Fe1-HNC-500-850). Similarly, Ni1-HNC-500-850 and Co1-HNC-500-850 catalysts could also be prepared with this NaCl-assisted strategy.

The molten salt-assisted strategy makes it possible to utilize ordinary metal oxides (such as Fe2O3 and Co2O3) and small organic molecules (such as adenine) as precursors to produce carbon-supported SAECs [71]. Firstly, the molten salt (ZnCl2 and NaCl with a mass ratio of 1 : 1), adenine, and Fe2O3 were ground by ball mill. The obtained sample was thermally treated at 900°C under inert atmosphere. After removal of the impurities, the single-atom Fe-SAC/NC catalyst was obtained. The strong polarizing force of molten salts plays critical roles in dissolving oxides, releasing free metal ions, and forming N-doped carbon framework to trap generated metal ions. In addition, the molten salt could also modulate the structure of the carbon framework; in that, ZnCl2 with a boiling point of 732°C will be evaporated at high temperatures above 800°C and can act as a suitable pore-forming agent. In contrast to traditional thermal treatment, the pyrolysis of small organic molecules in molten salts could suppress the direct decomposition of these molecules and promote the carbonization process.

2.2.3. Polymer Pyrolysis

Polymers are a kind of macromolecules and consist of repeated subunits. By selecting suitable subunits, coordination atoms including N, S, and P could be incorporated into polymers. Corresponding polymers could be used as the precursors of carbon matrix and doped heteroatoms. Various synthetic or natural polymers, such as polypyrrole [55], pyrrole-thiophene copolymer [72], poly(2-fluoroaniline) [73], chitosan [74], polydopamine [75], and cocoon silk [76], have been successfully used to synthesize SAECs. For example, with pyrrole, phytic acid, and FeCl3 as the precursor, Yuan et al. prepared a binary nitrogen and phosphorus-coordinated single-atom iron catalyst (Fe-N/P-C) [77]. Firstly, polypyrrole (PPy) hydrogel was synthesized by the polymerization of pyrrole with phytic acid and FeCl3. Then, the PPy hydrogel was thermally treated under inert atmosphere. After leaching with diluted sulfuric acid, nitrogen and phosphorus binary-coordinated iron active sites decorated on carbon nanosheets were prepared. As shown in Figure 3(e), by replacing phytic acid with boric acid, this pyrolysis method based on polypyrrole (PPy) hydrogel could also be used to prepare B-doped Fe-N-C catalyst (FeBNC) containing boron centers and atomically dispersed Fe-Nx sites [55].

With polypyrrole and FeCl3-coated carbonaceous nanofibers (CNF@PPy) as the precursor and SiO2 as the protecting layer, a single-atom Fe-N-doped carbon nanofiber catalyst (Fe-N-CNF) was synthesized [78]. In the absence of the SiO2-protected shell, Fe species tends to aggregate to form inactive nanoparticles in the pyrolyzing course. The silica-protected shell plays important roles in suppressing the aggregation of iron species and trapping volatile chemicals in the pyrolysis process. As a result, the obtained Fe-N-CNF catalysts showed optimized surface functionalities and porous structures. By coating poly(2-fluoroaniline) (P2FANI) onto FeO-(OH) nanorods followed by controlled pyrolysis at high temperatures, Zhang et al. synthesized a mesoporous Fe-N/C catalysts. The FeO-(OH) nanorods serve as both the hard template to suppress the shrinkage of P2FANI in the carbonization process and the pore-forming agent to increase the porosity in the carbonized framework. The obtained Fe-N/C possesses a specific surface area as high as 934.8 m2 g−1.

By introducing metal precursors during the in situ condensation process of formamide, atomically dispersed dense metal sites coordinated with multiple N-dentate ligands formed. After pyrolysis, SAECs could be obtained [79]. This approach could produce seven kinds of monometallic (Fe, Co, Ni, Mn, Zn, Mo, and Ir), one kind of bimetallic (FeCo), and one kind of trimetallic (ZnFeCo) SAECs. In addition, all of the resulting SAECs could be transferred onto various substrates (graphene oxide, CNTs, active carbon, and silica) as ultrathin layers. Among the prepared catalysts, the pyrolysis-free Fe and Ni single-atom electrocatalysts supported onto CNTs exhibited excellent ORR performance.

Very recently, controlled shockwaves with high temperatures were introduced to synthesize single-atom catalysts. This technique operates at very high temperatures (1500-2000 K) and features with a periodic on-off heating process [80]. Firstly, small amounts of metal salts were dissolved in ethanol to form a diluted solution (0.1-0.5 mmol L−1). The resultant solution was transferred onto the carbon nanofiber (CNF) film with a loading of 20-100 μL cm−2 (in total ~0.01 μmol cm−2). The precursor-loaded CNF films were then treated with a programmed electrical pulse under inert atmosphere. The on-state high temperature offers energy to overcome the activation barrier for atom dispersion and form thermodynamically favorable metal-defect bonds, while the off-state guarantees the stabilization, especially for the substrate. The as-prepared single-atom catalysts show superior thermal stability and could be used as durable catalysts. This shockwave method could be used to prepare Pt, Ru, and Co single atoms on various substrates including carbon, C3N4, and TiO2. In a similar way, Bi and coworkers developed an arc-discharge method to prepare single-atom Pt1/MoC catalyst. The high temperature of up to 4000°C overcomes the energy barrier for Pt atom dispersion and overall stability by forming thermodynamically favorable metal-support interactions, which enables the Pt1/MoC catalyst exhibiting ultrahigh thermal stability [81].

2.2.4. Metal Organic Complexes Pyrolysis

Metal organic complexes contain metal atoms and organic ligands simultaneously. Different organic ligands contain different coordination atoms, show different molecular sizes, and exhibit different decomposition temperatures. Commonly used organic ligands include porphyrins, phthalocyanines (Pc), 1,10-phenanthroline (Phen), bipyridine, and acetylacetone (acac). To be highlighted, some metal organic complexes such as metal (iron, cobalt, and manganese) porphyrins and phthalocyanines could be directly used as the electrocatalysts for ORR [50]. In most cases, metal organic complexes serve as the precursors of metal, C, and other heteroatoms to synthesize SAECs by pyrolysis. With Fe-porphyrin complexes as the metal precursor and carbon nanotubes (CNT) as the support, Sa et al. developed a general “silica-protective-layer-assisted” method that can preferentially generate the catalytically FeN4 sites doped in CNT walls while inhibiting the formation of inactive Fe-based particles [82]. Firstly, iron porphyrin precursors were adsorbed onto CNTs followed by silica layer overcoating and high-temperature pyrolysis. After removal of silica layer by acid etching, thin layer porphyrinic carbon coating on CNT catalysts (CNT/PC) was prepared. Temperature-controlled in situ X-ray absorption spectroscopy in the synthetic process of CNT/PC reveals that the interaction between the silica protecting layers and the FeN4 moieties prevents to form large Fe-based nanoparticles. Compared with the CNT/PC prepared without silica protective layers, the CNT/PC catalyst contains higher density of FeN4 sites. This silica-protected-layer-assisted approach could be extended to prepare other carbon-supported SAECs including Ketjen black, reduced graphene oxides, acetylene black, and Vulcan. By diluting metalloporphyrin (MTPP) containing target metals with tetraphenylporphyrin (TPP) diluents followed by pyrolysis, twenty-four kinds of single-atom electrocatalysts including noble and nonnoble metals (such as Pt, Pd, Ru, Rh, Au, Ag, Ir, Ti, V, Cr, Mn, Fe, Co, Ni, Cu, Ga, Zr, Mo, W, Cd, In, Sn, Er, Bi) could be prepared [83, 84]. It should be noted that this high-temperature pyrolysis method requires expensive equipment and consumes high energy, which must be considered for commercial applications.

2.3. Vapor Deposition Method

2.3.1. Atomic Layer Deposition (ALD)

The atomic layer deposition (ALD) technology is based on cyclically sequential self-terminating reactions between gas-phase precursor molecules and a solid surface. In a typical ALD process, the precursor molecules are introduced to contact with the solid surface and then react with specific sites on the solid surface. In case all reactive sites have been consumed, the growth process stops. The self-limiting feature of ALD provides controllable and accurate means to synthesize SAECs.

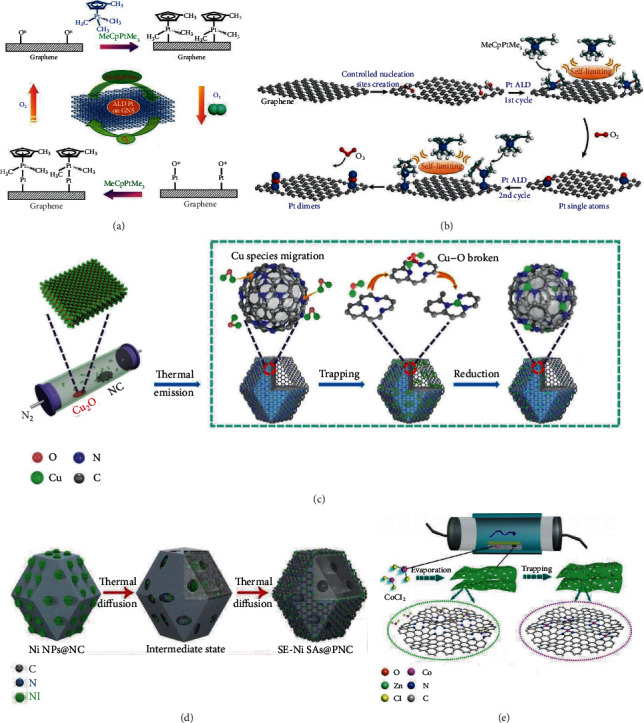

A single-atom Pt/Graphene catalyst was prepared through the atomic layer deposition (ALD) method with (methylcyclopentadienyl)-trimethyl platinum (MeCpPtMe3) and oxygen molecules as the precursors [85]. As shown in Figure 4(a), MeCpPtMe3 firstly reacted with oxygen atoms of the graphene sheets to form Pt-containing monolayer, which further reacted with oxygen molecules to prepare single-atom Pt sites coordinated with oxygen atoms. The popularity of Pt atoms on graphene substrate can be precisely tuned by controlling the cycle numbers. For instance, after 50 ALD cycles, the Pt loading was as high as 1.52 wt% and the deposited Pt species consisted of isolated Pt atoms as well as small fraction of Pt nanoclusters. With graphene oxide sheets replaced by nitrogen-doped graphene nanosheets (NGNs), this ALD method could be used to prepare single-atom Pt/NGNs catalysts [90]. In a similar way, palladium hexafluoroacetylacetate (Pd(hfac)2) and bis(cyclopentadienyl) cobalt (Co(Cp)2) could also be used as the metal precursors to prepare corresponding SAECs with the ALD technique [91, 92]. Yan et al. further found that Pt2 dimers could also be deposited on graphene with ALD technology [86]. As shown in Figure 4(b), phenol-related oxygen species on graphene function as anchor sites to immobilize Pt and the Pt2 dimers are likely in the oxidized Pt2Ox form. It must be mentioned that expensive apparatus and low yields limit the application of this ALD method on a large scale.

Figure 4.

Vapor deposition and atom-trapping methods for the synthesis of SAECs. (a) Synthesis of atomically isolated Pt on graphene nanosheets with the ALD method. Reproduced from [85]. (b) Preparation of Pt2/graphene catalysts. Reproduced from [86]. (c) Synthesis of single-atom Cu catalyst with the atom trapping method. Reproduced from [87]. (d) Synthesis of single-atom Ni catalyst from Ni NPs. Reproduced from [88]. (e) Synthesis of single-atom Co catalyst. Reproduced from [89].

2.3.2. Chemical Vapor Deposition (CVD)

Chemical vapor deposition (CVD) techniques have been widely utilized to produce two-dimensional materials [93, 94]. However, the application of this CVD technique to synthesize SAECs has remained less popular. Qiu et al., for the first time, developed a CVD method to embed isolated Ni atoms in graphene nanosheets [95]. By treating Ni30Mn70 alloy with (NH4)2SO4 aqueous solution, they prepared nanoporous Ni substrates, followed by a CVD process to coat graphene layers. After removal of the Ni substrate with 2.0 M HCl solution, single-atom Ni decorated in porous graphene nanosheets was obtained. The Ni atoms are physically adsorbed on the hollow centers of graphene. Furthermore, by replacing benzene with pyridine, they synthesized single Ni atoms/clusters immobilized in N-doped nanoporous graphene using this CVD process [96], in which N atoms were firstly predoped followed by Ni deposition. In the resultant catalyst, the total Ni loading was up to 23 wt%, including isolated atoms and clusters. The atomically dispersed Ni atoms were stabilized by both Ni-N bonds and Ni-C bonds.

2.4. Atom Trapping Method

Atom trapping method is a newly developed strategy to synthesize SAECs. At high temperatures, metal nanoparticles (Pt, Pd, Au, Rh, and Ni nanoparticles) [88, 97, 98], metal bulks (Pt net, Au foil, Pd bulk, Nb bulk, Cu foam, Co foam, and Ni foam) [99–101], metal oxides (Fe2O3, Co2O3, Cu2O, SnO2, and MoO3) [87], and metal salts (CoCl2, H2PtCl6, H2PdCl4, HAuCl4, and H2IrCl6) [89, 102] could release metal atom vapor, which could be trapped by various substrates placed in the downstream and form corresponding SAECs. For example, Nb atom vapor released by arc discharge of Nb bulk could be trapped by carbon and formed the single-atom Nb-in-C catalyst [99]. As shown in Figure 4(c), under nitrogen atmosphere, the surface of commercial Cu2O could be evaporated to form volatile species at 1273 K and the volatile species could be trapped and reduced by N-doped carbon, N-doped reduced graphene oxide, and N-doped carbon nanotubes to generate single-atom Cu-based catalysts [87]. In a similar way, Sn-based and Mo-based single-atom catalysts were also prepared by using SnO2 and MoO3 as the metal precursors. This approach avoids the usage of corrosive NH3 and is suitable for the large-scale production and practical application. Wei and coworkers directly observed the transformation of Pt, Pd, and Au nanoparticles into their corresponding single atoms in the presence of N-doped carbon above 900°C in an inert atmosphere by in situ environmental TEM [98]. DFT calculations suggested that the high-temperature conversion of noble metal nanoparticles to N-coordinated single-atom catalysts was driven by the formation of more thermal dynamically stable M-N4 (M=Pt, Pd, and Au), while migrating noble metal atoms were trapped by the defect sites on N-doped carbon substrates. They also found that besides nanoparticles, bulk metals (such as Cu, Co, and Ni foam) could react with NH3 at high temperatures to form Cu(NH3)X, Co(NH3)X, and Ni(NH3)X species [100]. After trapped by N-doped carbon framework originated from ZIF-8 by pyrolysis, single-atom catalysts were obtained. To be highlighted, this strategy is suitable to practical applications.

Feng et al. reported a general strategy to disperse active carbon-supported Rh nanoparticles into single-atom Rh catalyst [103]. Firstly, active carbon-supported RhCl3 was thermally treated under nitrogen atmosphere at 300°C for 2 h. The residual was reduced with hydrogen at 300°C for 2 h to obtain the fresh 5 wt% Rh catalyst with Rh nanoparticle size of 4 nm (RhNP/AC). The RhNP/AC was transformed into the single-atom Rh1/AC catalyst by heating at 240°C for 6 h in a CO/CH3I mixture. It was found that CO molecules and in situ generated I radicals promoted the breakage of Rh-Rh bonds to form mononuclear Rh(CO)3I complexes, which were trapped by oxygen-containing active carbon to form the single-atom Rh(CO)3I(O-AC) catalyst. This approach could also be used to transform active carbon-supported Ru, Pd, Ag, Ir, and Pt nanoparticles to corresponding single-atom catalysts.

Besides evaporation at high temperatures, synthesis of SAECs with the atom trapping method at low temperatures is also realized. Zhang and coworkers developed a synergistic micropore trapping and nitrogen anchoring method to prepare Pt single-atom catalysts (Pt1/hNCNC) [102]. Both DFT calculations and experiments suggest that the micropores decorated with nitrogen atoms (especially pyridinic N) on the edge are favorable for the dispersion of platinum atoms; in that, H2PtCl6 could react with amino group to form stable [Cx(NH)2]2+[PtCl6]2- via the electrostatic interaction, followed by the spontaneous dechlorination upon heat treatment at 70°C. This method could also be successfully applied to construct Pd-, Au-, and Ir-based SAECs.

2.5. General Synthetic Methods for SAECs with High Metal Loadings on Practical Scale

SAECs exhibit tremendous potential in electrocatalysis. However, the scalable synthesis of SAECs with high density of active sites is of great challenge, due to the balance between single-atomic dispersion and loading in the formation of M-N-C sites at high temperatures. For practical applications, the synthesis of SAECs on a large scale with generality is highly required. In very recent years, great progress has been made [104]. For example, the loading of isolated metal atoms has been as high as 18 wt% [105], the general method has been extended to synthesize SAECs for more than 34 types [102], and the production of SAECs on a kilogram scale has been realized [106]. Finally, the introduction of the deep learning algorithm together with big data technology will greatly speed up the screening process and start up a new direction of rational design and modification for complicated SAECs with expected electrochemical catalytic performance.

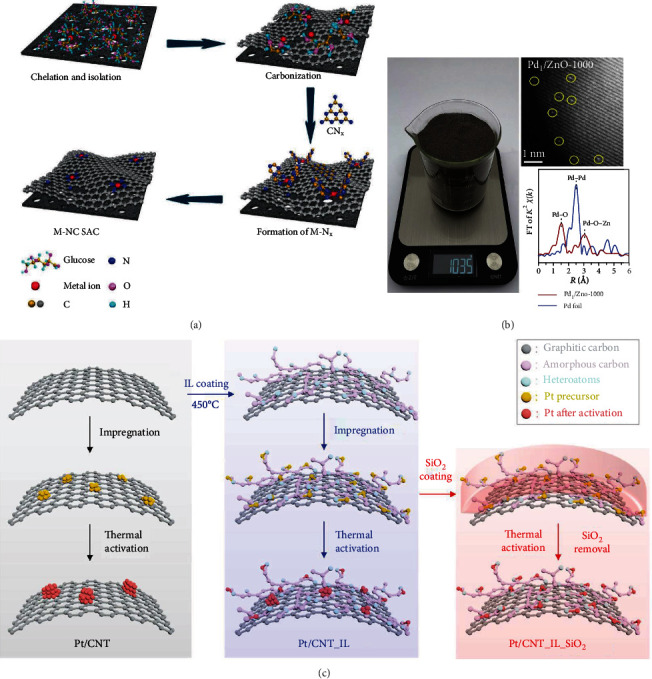

As shown in Figure 5(a), a cascade anchoring strategy was developed for the mass production of a series of M-N-C SAECs (M=Mn, Fe, Co, Ni, Cu, Mo, Pt) with a metal loading up to 12.1 wt% [107]. Firstly, glucose molecules chelate with metal ions and bind to O-rich carbon support. Excessive glucoses were used to isolate glucose-metal complexes on the carbon substrate. Then, the chelated metal complexes release metal atoms in the pyrolysis process at high temperatures, which were captured by decomposed CNx species from melamine to generate M-Nx moieties and embed into the carbon matrix to form SAECs. By reacting Ir(CO)2(acac) with O-containing groups on the reduced graphene aerogel (rGA), atomically isolated iridium complexes could be immobilized on rGA. The rGA substrate provides highly effective bonding sites for metal anchoring superior to those of metal oxides, due to the merits of uniformity and high density. This approach could prepare a single-atom Ir catalyst with remarkably high Ir loading up to 14.8 wt% [109]. With carbon cloth- (CC-) supported NiO (NiO/CC) as the support, Wang et al. prepared a single-atom Ir catalysts with the Ir loading as high as 18 wt% [105]. Firstly, a piece of NiO/CC was immersed into a chloroiridic acid ethanol solution for 10 min and then dried at 80°C. Subsequently, the dried sample was calcined at 350°C for 2 h in air, cooled down, and washed with water. The Ir-NiO/CC catalyst was obtained after dried in air. It was observed that atomically dispersed Ir-atoms are anchored at the outermost surface of NiO and are stabilized by covalent Ir-O bonding, which induces the isolated Ir atoms to form a favorable Ir(IV) oxidation state.

Figure 5.

General synthetic methods for the synthesis of SAECs on practical scale. (a) The preparation of M-NC SACs with the cascade anchoring strategy. Reproduced from [107]. (b) Preparation of Pd1/ZnO on kilogram scale. Reproduced from [106]. (c) Synthesis of single-atom Pt/CNT_IL_SiO2. Reproduced from [108].

A general precursor dilution strategy was developed to prepare SAECs. Firstly, metalloporphyrin (MTPP) containing target metals copolymerized with tetraphenylporphyrin (TPP). The TPP molecules were used as diluents to separate metal atoms. After pyrolysis at high temperatures, carbon-supported single-atom catalysts (M1/N-C) were obtained [83]. By using this method, twenty-four kinds of single-atom catalysts including noble and nonnoble metals (such as Pt, Pd, Ru, Rh, Au, Ag, Ir, Ti, V, Cr, Mn, Fe, Co, Ni, Cu, Ga, Zr, Mo, W, Cd, In, Sn, Er, and Bi) were successfully prepared. This method could also be extended to prepare bimetallic Pt1-Sn1/N-C single-atom catalysts. Furthermore, a general electrochemical deposition strategy applicable to a wide range of metals and supports was developed to prepare SAECs. In a standard three-electrode device, a glassy carbon electrode loaded with Co(OH)2 nanosheets were used as the working electrode and a diluted H2IrCl6 solution was used as the metal precursor and the electrolyte. The depositing process started from 0.10 to -0.40 V in cathodic deposition and from 1.10 to 1.80 V in anodic deposition. The scanning cycle was repeated for three times to obtain A-Ir1/Co(OH)2 from the anode and ten times to obtain C-Ir1/Co(OH)2 from the cathode. More than 30 kinds of different SAECs (Fe, Ni, Co, Zn, Cu, Cr, V, Ag, Mn, Ru, Ir, Pd, Rh, Pt, Au, etc.) are prepared from anodic or cathodic deposition by changing supports and metal precursors [46].

With carbon black as the support, 1,10-phenanthroline (Phen) as the N-containing ligand, and transition metal salts as the metal precursor, a general ligand-mediated strategy was developed to prepare transition metal-based SAECs on a large scale [110]. Firstly, nickel(II) acetate coordinated with 1,10-phenanthroline in ethanol to form Ni-Phen complexes. Then, Ni-Phen complexes were adsorbed onto carbon black support. After pyrolysis under argon atmosphere, single-atom Ni-SAC catalyst was obtained. The Ni loading could be as high as 5.3 wt%. By changing the metal precursors, Mn-, Fe-, Co-, Zn-, Cr-, Cu-, Ru-, and Pt-based SAECs and Fe/Co-, Ru/Fe-, Ru/Co-, and Ru/Ni-based binary SAECs were also successfully prepared. To be highlighted, this synthetic approach could be enlarged to produce carbon-based SAECs on a kilogram scale. By ball-milling iron(II) acetate, 1,10-phenanthroline (Phen), and ZIF-8, Sun et al. prepared a FePhenMOF precursor [39]. After thermal treatment of FePhenMOF under Ar and NH3 atmosphere, a single-atom FePhenMOF-ArNH3 could be prepared. This ball-milling method could be easily scaled up to synthesize gram-level SAECs in one pot depending on the size of furnace and ball-milling machine. Furthermore, this method was extended to prepare ZnO- and CuO-supported Pd-based single-atom catalysts on a kilogram scale [106]. As shown in Figure 5(b), firstly, the mixture of Pd(acac)2 and Zn(acac)2 with a weight ratio of 1 : 400 was thoroughly grounded. After calcination at 400°C for 2 h in air, the single-atom Pd1/ZnO catalyst was obtained. With the same method, ZnO-supported Rh- and Ru-based single-atom catalysts were also prepared on a kilogram scale.

With the high-speed development of artificial intelligence, the deep learning algorithm attracted more and more attention in a broad research field. Sun et al. for the first time used the deep learning algorithm to develop graphdiyne-supported SAECs with zero-valenced central metal atoms [111]. By quantifying the electron transfer ability and zero-valence stability between metals and graphdiyne support, it was found that among all transition metals, Co, Pd, and Pt showed exceptional stability of zero-valence SAECs based on the evident energy barrier difference between losing electrons and gaining electrons. This novel deep learning algorithm together with big data technology starts up a new direction of rational design and modification for complicated SAECs with expected electrochemical catalytic performance.

3. Characterizations

Compared with nanoclusters and nanoparticles, single-atom electrocatalysts possess well-defied ORR active sites, which simplifies the model construction for theoretical calculations and improves the deeply understanding of the interaction between active sites and substrate species. Conversely, the understanding of fundamental reaction mechanism further directs the design of more highly efficient ORR catalysts by tuning the geometric configurations and coordination environments at the atomic level. Experimentally, the characterization and identification of single-atom sites can be completed with advanced techniques including synchrotron-based X-ray absorption spectroscopy, Mossbauer spectroscopy, scanning tunneling microscopy, and scanning transmission electron microscopy. The atomic-level structure information, including the chemical state, the coordination environment, the spin state of metal centers, and electronic properties, could be elucidated. The combination of these advanced characterization techniques with DFT calculations can clarify the structure-performance relationship, enabling precise rational design of customized SAECs. The characterization techniques for SAECs in this review include scanning tunneling microscopy (STM), sub-angstrom-resolution aberration-corrected scanning transmission electron microscopy (AC-STEM) equipped with EDX and EELS accessories, synchrotron-based X-ray absorption spectroscopy (XAS) including XANES and EXAFS, Mössbauer spectroscopy, X-ray diffraction (XRD), X-ray photoelectron spectroscopy (XPS), Fourier-transform infrared spectroscopy (FTIR), nuclear magnetic resonance (NMR), inductively coupled plasma atomic emission spectrometry (ICP-AES), elemental analysis, and density functional theory (DFT) calculation. ORR performance of SAECs is usually tested on rotating disc electrode (RDE) or rotating ring disc electrode (RRDE) in various oxygen-saturated electrolytes, such as 0.1 M alkaline KOH solution, 0.05 M neutral phosphate-buffered solution (PBS), 0.5 M acidic H2SO4 solution, and 0.1 M acidic HClO4 solution.

3.1. X-Ray Diffraction

X-ray diffraction (XRD) is the most commonly used indirect characterization technology to prejudge the formation of SAECs [30, 51, 56]. The principle is based on the following: (i) If diffraction peaks ascribed to the metal-related species (including metal, metal oxides, metal carbides, metal nitrides, metal sulfides, metal phosphides) are detected, the obtained catalysts could not be called single-atom electrocatalysts. (ii) If the single-atom catalysts are successfully synthesized, no diffraction peaks ascribed to the metal-related species mentioned above could be detected. But this prejudgment is insufficient, because no diffraction peaks might be attributed to the low metal loading (<2 wt%) or the very small particle size (<4 nm). Some other advanced characterization technologies should be further conducted.

3.2. Scanning Tunneling Microscopy

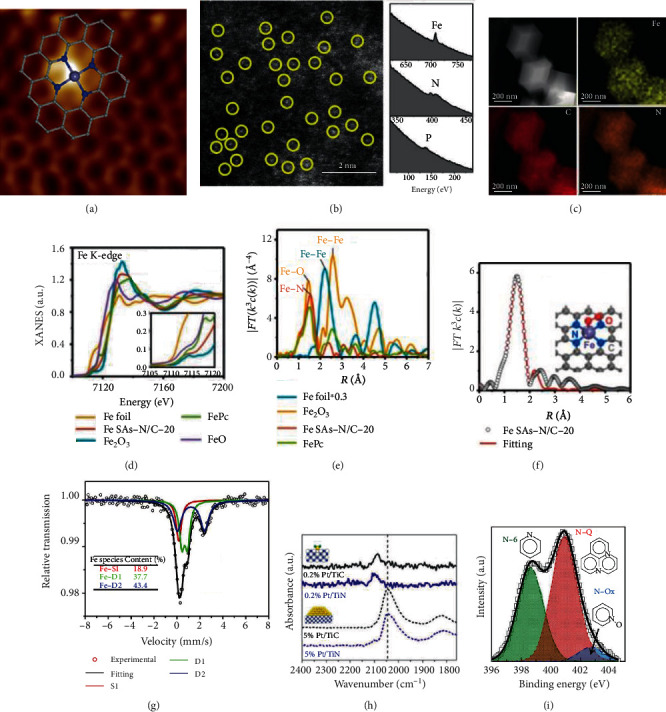

Scanning tunneling microscopy (STM) is an ultrahigh-resolution instrument and commonly used to observe the surface structure at the atomic level. With a conducting tip approaching to the substrate surface, a bias voltage will be exerted. Meanwhile, the generation of a tunneling current occurs. By recording the current as the tip scanning across the surface, the structure information of the substrate surface can be detected. As shown in Figure 6(a), in a low-temperature STM image of N-doped graphene-based single-atom Fe catalyst, the isolated Fe site was observed, which resolved as a brighter spot and coordinated with four nitrogen atoms embedded in the graphene matrix [112]. Patera and coworkers used an in situ high-speed STM to directly monitor the catalytic behavior of single Ni atoms at the Klein (k) and Zigzag (z) edges of a graphene flake during real growth process [115]. They found that Ni atoms reside longer in the kink sites of graphene accompanied by C dimer attachment nearly, which suggests that single Ni atoms play the catalytic roles for the graphene growth.

Figure 6.

Characterization techniques for SAECs. (a) STM image of single-atom FeN4/GN-2.7 (2 nm × 2 nm). Reproduced from [112]. (b) AC-STEM image of Fe-N/P-C-700 and corresponding EELS atomic spectra of Fe, N, and P elements from the bright dots shown in the yellow circle. Reproduced from [77]. (c) HAADF-STEM image and element mapping of single-atom Fe catalyst. Reproduced from [51]. (d) XANES spectra of Fe K-edge. Reproduced from [53]. (e) FT k3-weighted EXAFS spectra. Reproduced from [53]. (f) Fitting curves of FT-EXAFS. Reproduced from [53]. (g) Mössbauer spectrum of 57Fe. Reproduced from [77]. (h) Diffuse reflectance FT-IR spectra of adsorbed CO. Reproduced from [113]. (i) XPS spectra of N 1 s. Reproduced from [114].

3.3. Aberration-Corrected Scanning Transmission Electron Microscopy

In recent years, the resolution of an aberration-corrected scanning transmission electron microscopy (AC-STEM) has been increased to sub-angstrom of 0.5 Å, which makes it capable to distinguish isolated single atoms. AC-STEM image provides the most effective method to directly observe isolated metal atoms anchored on the supports based on the Z-contrast imaging. By focusing electron beam on the sample and collecting electrons that scatter out to an annular dark field detector, Z-contrast images can be obtained, where Z represents the atomic number of the observed atom. The electron beam energy might induce the dynamic hopping and movement of isolated atoms, which leads to inaccurate atomic images. When we carry out AC-STEM experiments, we should guarantee that the tested samples could tolerate to the electron beam and take measures to mitigate the negative effect of electron beam. Accompanied by energy-dispersive X-ray spectrometry (EDX) and electron energy loss spectroscopy (EELS), element composition and distribution at the atomic level can be obtained [14, 90]. In 1996, Nellist and Pennycook for the first time resolved the position of the isolated metal atom from substrates by using the Z-contrast atomic resolution imaging [116]. By means of in situ environmental transmission electron microscopy, Wei and coworkers directly observed the process of converting Pd nanoparticles into isolated Pd atoms at high temperatures in the presence of N-doped carbon support [98].

3.4. X-Ray Absorption Spectroscopy

Electron microscopy enables the direct observation of isolated single atoms. However, the visual range with this technology is limited and only specific local area can be selected. Synchrotron-radiated X-ray absorption spectroscopy (XAS) is a more powerful technique to confirm the overall detailed atomic and electronic information of selected single atoms. XAS relies on the oscillatory structure in the X-ray absorption coefficient above an X-ray absorption edge. These signals precisely reflect the structure information of the materials, including the oxidation state, the coordination number, and the coordination environments. Therefore, XAS is an effective technology to confirm the chemical state and the local atomic structure of isolated atoms. Generally, X-ray absorption near-edge spectroscopy (XANES) and extended X-ray absorption fine structure (EXAFS) are two typical measurement regimes of XAS. XANES measures the oxidation state and coordination environment (e.g., tetrahedral, hexahedral, octahedral coordination) of the selected atoms, while EXAFS provides information on the distance, coordination number, and species of the neighbor elements of the absorbing atoms. With XANES and EXAFS, the structures of series of SAECs, such as FeN4, CoN4, CoN2+2, NiN2O2, MoN1C2, WN4, WN1C3, and WN2C2, have been successfully confirmed [53, 62, 66, 74, 117]. In addition, the structures of CoN2, CoN3, CoN4, and CoN5 have also been synthesized and characterized [33, 118]. With in situ XAS techniques, Li et al. identified the Fe2+-N4 moieties with nonplanar configuration embedded in carbon matrix as the highly efficient ORR active sites [58]. This nonplanar Fe2+-N4 configuration could reversibly transform to an in-plane Fe3+-N4 moiety axially coordinated with oxygen adsorbates when the applied potential crosses the Fe2+/3+ redox potential anodically. The density of the active sites could be modulated by the redox potential. With the assistance of in situ XAS technologies, Sasaki et al. observed the deactivation mechanism of Pt nanoparticle catalysts during the ORR process, which follows the oxidation of the outermost Pt atoms and then the dissolution caused by carbon corrosion and the OER process [119]. Kaito et al. revealed that the Pt-Pt bond length dominates the intrinsic ORR activity [120]. Yoshida et al. confirmed that the oxygen evolution reaction occurs at the domain edge of NiO6 octahedra of the nickel borate electrocatalyst [121]. These findings are totally different from previously reported results based on ex situ techniques.

3.5. Mössbauer Spectroscopy

Mössbauer spectroscopy is a Mössbauer effect-based characterization technique. Mössbauer spectroscopy is composed of the nearly recoil-free emission and absorption of nuclear gamma rays in solids. Three typical nuclear interactions may be detected: the isomer shift generated by differences in nearby electron densities, quadrupole splitting produced by atomic-scale electric field gradients, and magnetic Zeeman splitting created by nonnuclear magnetic fields. Mössbauer spectroscopy featuring with high energy and narrow line widths of nuclear gamma rays is a highly sensitive technique to detect the energy changes in 1011 resolution. Based on 57Fe-based Mössbauer technique, Fe-based SAECs have been precisely characterized owing to their ultrasensitivity to the coordination environment and electronic configuration of the central Fe ions in the complicated materials [58].

Mössbauer spectroscopy is a more powerful technique to detect the purity of Fe-based SAECs. For instance, Kramm et al. fount that Fe-based SAECs prepared by pyrolyzing Fe-porphyrin complexes at 800°C showed three doublets (D1, D2, and D3) and a singlet [122]. Three doublets could be attributed to FeN4 sites with a ferrous low-spin (D1) and to two ferrous mid-spin (D2 and D3) sites. D1 with in-plain low-spin (S = 0) ferrous FeN4 sites is regarded as the active center for 4e− ORR in acidic electrolytes. The difference between D2 sites and D3 sites lies in their local environments, i.e., D2 resembling iron phthalocyanine (FePc) and D3 similar to porphyrins. D2 offers negligible contribution to the ORR activity due to the axial coordination with adjacent N atoms of FePc molecules, which inhibits the adsorption and activation of oxygen molecules. D3 is stabilized by carbon frameworks. The singlet is belonging to superparamagnetic iron, i.e., very small iron nanoparticles without magnetic ordering. The appearance of the singlet indicates the formation of impurities in Fe-based SAECs. After purification by conducting a second thermal treatment of the resultant catalysts in the forming gas with a subsequent HCl leaching, the singlet disappeared and only doublets remained in the Mössbauer spectroscopy, demonstrating the formation of single-atom FeN4 electrocatalysts with high purity.

Mössbauer spectroscopy could also be used to analyze the structure of Fe-based binary metal SAECs and binary ligand-coordinated Fe-based SAECs. Wang et al. prepared a Fe-based single-atom catalyst (Fe SAs/N-C) and a Fe-Co binary metal single-atom catalyst ((Fe,Co)/N-C) [123]. The Mossbauer spectrum of Fe SAs/N-C is composed of three doublets (D1, D2, and D3) that could be attributed to square-planar Fe(II)N4 configuration with Fe(II) in a high-, low-, and intermediate-spin state, respectively, while the Mossbauer spectrum of (Fe,Co)/N-C could be fitted with three FeN4 centers similar to those of the Fe SAs/N-C and a singlet. The singlet demonstrates the presence of Fe-Co bond in (Fe,Co)/N-C.

Yuan et al. prepared binary N and P-coordinated single-atom Fe catalysts (Fe-N/P-C-700) with FeN3P configuration as the active site [77]. As shown in Figure 6(g), the Mossbauer spectrum of Fe-N/P-C-700 was composed of one singlet assigned to Fe-P and two doublets (D1, D2) ascribed to Fe-Nx moieties. The D1 and D2 doublets are belonging to square planar Fe-N4 configurations. In the Mössbauer spectrum, no sextets were detected, indicating the absence of iron carbides in Fe-N/P-C-700 and all Fe species are atomically dispersed.

3.6. Fourier-Transform Infrared Spectroscopy

One of the most important features of single-atom catalysts is the absence of nanoclusters and nanoparticles. AC-STEM could directly observe the dispersion of single atoms. However, the existence of nanoclusters and nanoparticles could not be excluded. Fourier-transform infrared spectroscopy (FTIR) can resolve and record the vibration mode of adsorbed probe molecules on catalyst surfaces, which could be used to distinguish the differences between single-atom sites and nanoparticle sites [5, 124]. With CO as the probe molecules, in situ FTIR provides a powerful tool to identify the absence of nanoclusters and nanoparticles by monitoring the highly sensitive vibration mode of the adsorbed CO molecules. As shown in Figure 6(h), for single-atom Pt catalysts, such as Pt1/FeOx, Pt1/TiC, and Pt1/TiN, only linearly adsorbed CO molecules at 2080 cm−1 could be detected, while for Pt catalysts with nanoclusters and nanoparticles, bridge-bonded CO molecules at 1820 cm−1 were observed [113]. The bridge-bonded configuration of CO molecules needs two adjacent Pt atoms and can only be detected on Pt nanoparticles. Therefore, the bridge-bonded CO peak could be used to exclude the presence of nanoclusters and nanoparticles. With O2 as the probe molecule, a low-temperature FTIR experiments showed that single nuclear Fe1-N-C sites mainly show a superoxo-like vibration with a O-O bond length of 1.34 Å, while binuclear Fe2-N-C are dominated with peroxo-like adsorption with a O-O bond length of 1.48 Å, suggesting that Fe2-N-C provides more favorable adsorption configuration to activate oxygen molecules and shows high intrinsic ORR activity [125].

3.7. Nuclear Magnetic Resonance

In nuclear magnetic resonance (NMR) measurements, when nuclei in a strong constant magnetic field are perturbed by a weak oscillating magnetic field, a responding electromagnetic signal with a frequency characteristic of the magnetic field at the nucleus will form. If the oscillation frequency matches the intrinsic frequency of the nuclei, this process occurs near resonance. It should be noted that the oscillation frequency relies on the strength of the chemical environment, the static magnetic field, and the magnetic properties of the involved isotope. In a 27Al solid-state magic-angle spinning NMR spectroscopy, Kwak and coworkers found that the pentacoordinate Al3+ sites (Al3+penta) formed on the (100) facets of γ-Al2O3 by dehydration and dehydroxylation at elevated temperatures and the coordinatively unsaturated Al3+penta sites function as the anchoring position to bind Pt atoms [126]. With the Pt loadings lower than 1 wt%, each Al3+penta interacts with exact one Pt atom and forms atomically dispersed Pt/γ-Al2O3 catalysts.

3.8. X-Ray Photoelectron Spectroscopy

X-ray photoelectron spectroscopy (XPS) is a commonly used surface analysis technology to detect the element oxidation state. For SAECs, the central metal element generally coordinates with adjacent heteroatoms (such as N, O, P, S) to decrease the surface energy and form stabilized single-atom configuration. During the course, the central metal would transfer charges into coordinated heteroatoms and show some oxidative states due to the relatively low electronegativity of the central metal. This oxidative state of the central metal in SAECs could be detected by XPS analysis [114]. For example, Han et al. observed that after the formation of single-atom Fe-Nx-C catalyst, the central Fe atom shows higher binding energy than metallic iron and lower binding energy than Fe2O3 [56], which indicates that the charge transfer from central Fe to adjacent N occurs. Generally, XPS analysis is accompanied with XANES measurements to further confirm the oxidative state of the central metal element.

By using the synchronous illumination X-ray photoelectron spectroscopy (SI-XPS) and the synchronous illumination diffuse reflectance Fourier-transform infrared spectroscopy (SI-DRIFTS), Zhang et al. detected the charge transfer as well as chemical bond evolution of single-atom Pt/C3N4 under light irradiation [127]. Upon photo-induced charge excitation and transfer, the dynamic variations of Pt-N bond cleavage into Pt0 and C-N bond transformation into C=N bond of C3N4 can be experimentally observed. Such dynamic changes designate Pt0 and C3N4 as the sites for reduction and oxidation reactions separately. However, these transformations could not be detected on the Pt nanoparticles decorated on C3N4 catalyst. This work highlights the importance of synchronous illumination spectroscopic characterizations to understand the dynamic evolution of catalysts.

3.9. Inductively Coupled Plasma Atomic Emission Spectroscopy

Inductively coupled plasma atomic emission spectroscopy (ICP-AES) is a trace analytical technique used to measure the content of chemical elements. The plasma acts as a high-temperature source to excite atoms and ions to emit electromagnetic radiation, which is unique to a specific element. The intensity of the emissions from different wavelengths is proportional to the element contents in the sample. ICP-AES is one of the most commonly used technologies to measure the accurate mass loading of the central metal atoms in SAECs [51, 56]. It must be mentioned that before ICP-AES measurements, suitable methods should be adapted to digest the SAEC samples to guarantee the complete dissolution of solid samples.

3.10. Elemental Analysis

Elemental analysis is a commonly used analytical technique to measure certain element contents in organic compounds, such as H, C, and N. Firstly, a sample is burned completely in excess oxygen. Then, the combusted products, such as carbon dioxide, water, and nitric oxide, were collected by various traps. By calculating the masses of these combustion products, the composition of the unknown sample could be obtained. Modern advanced elemental analyzers are competent to measure the content of sulfur along with CHN simultaneously. The elemental analysis technology is usually used to measure the content of N and S in SAECs [128, 129].

3.11. Density Functional Theory Calculations

Compared with nanoparticles and nanoclusters, single-atom catalysts possess simple, uniform, and well-defined structures. Therefore, density functional theory (DFT) calculations show great potential in confirming the optimized configuration of single-atom catalysts, elucidating the interaction between active sites and substrate species, and illustrating the specific reaction mechanism. For example, single-atom Fe-N-C catalyst showed high ORR activity with a half-wave potential up to 0.900 V [51]. The 4e− ORR reaction mechanism in the alkaline medium is as follows, where ∗ represents the active site:

O2(g) + ∗⟶O2∗

O2∗+H2O(l) + e−⟶∗OOH + OH−

∗OOH + e−⟶∗O + OH−

∗O + H2O(l) + e−⟶∗OH + OH−

∗OH + e−⟶OH− + ∗

DFT calculations show that step (v), i.e., charging of the adsorbed ∗OH to form OH−, is the rate determining step and compared with Fe nanoparticles the higher activity of Fe-N-C stems from the facile electron transfers from Fe single atom to the adsorbed ∗OH species. The DFT calculation results matched well with that of the electronic chemical potential calculations. Single-atom Zn-N-C catalyst exhibited competitive ORR activity and better ORR durability than that of Fe-N-C in both acidic and alkaline electrolytes. DFT calculation demonstrated that different from Fe-N-C, the pyridinic-N in Zn-N-C was less prone to be protonated in the acidic solutions [130]. Meanwhile, DFT calculation also reveals that the Zn-N4 moiety is more electrochemically stable than the Fe-N4 in the ORR process. Therefore, Zn-N-C with a high Zn loading of 9.33 wt% shows excellent ORR performance. Atomically dispersed Zn-Co bimetallic catalyst (Zn/Co-N-C) shows a theoretical overpotential of 335 mV during ORR process. DFT calculations reveal that compared with Zn-N-C and Co-N-C, bimetallic Zn/Co-N-C shows superior oxygen binding ability, which greatly lengthens the O-O bond from 0.123 to 0.143 nm and promotes the cleavage of O-O bond [131].

Han and coworkers systematically calculated the adjacent effect between two neighboring Fe-N-C sites of isolated single-atom FeNx (x = 3 or 4) sites on ORR performance [132]. It was found that the adsorption energies of O2 and OH are closely relevant to the density, the reactant coverage, and the active-site coordination. Due to the electron transfer from two Fe atoms to O2, the adsorption of O2 or OH is enhanced by the adjacent FeN3 site. Shortening the Fe-Fe distance results in stronger binding and activation of O2. The increased FeN3 density decreases the activation energy barrier of the ORR potential determining step (PDS). In contrast, the adjacent effect is weaker on FeN4, except for the extremely dense FeN4-FeN4 (4.1 Å) model. The reason for the difference between FeN3 and FeN4 is that FeN3 sites show stronger magnetic exchange interaction and stronger intersite communication than those of FeN4 sites. Further investigation on the impact of active-site density on the kinetics of ORR with Fe-N-C single-atom catalysts is highly expected.

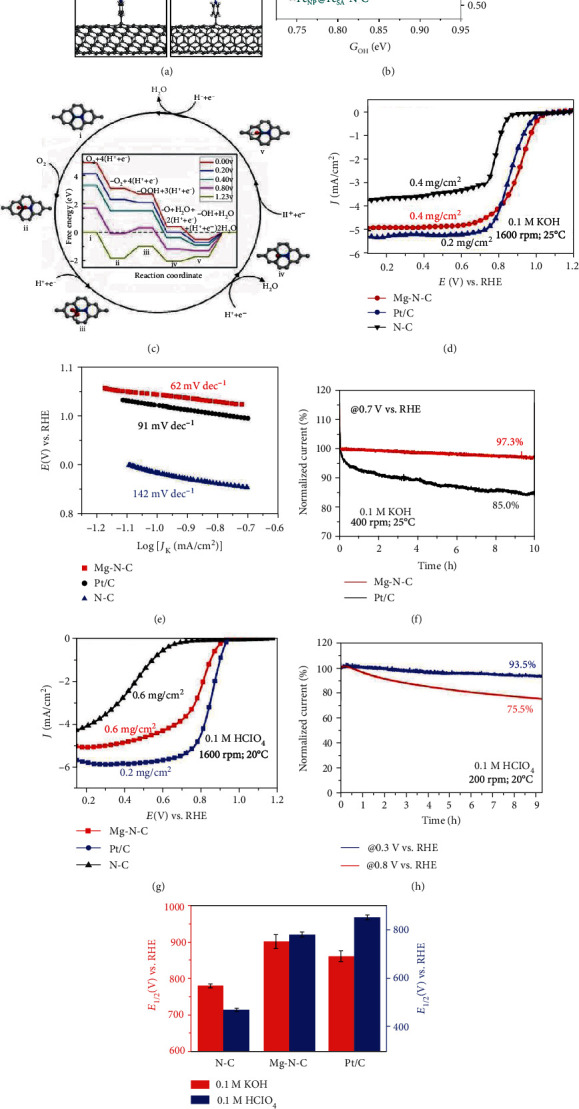

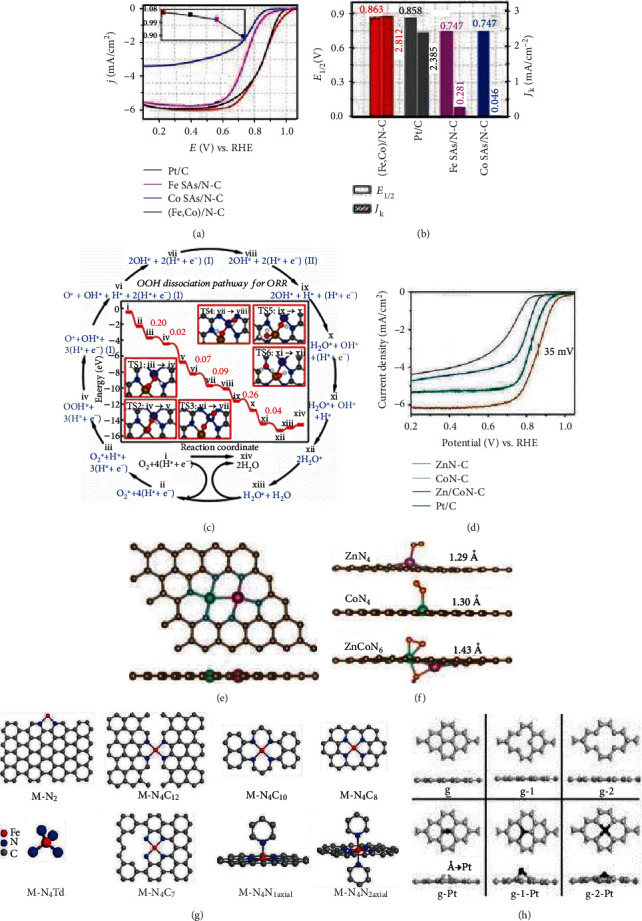

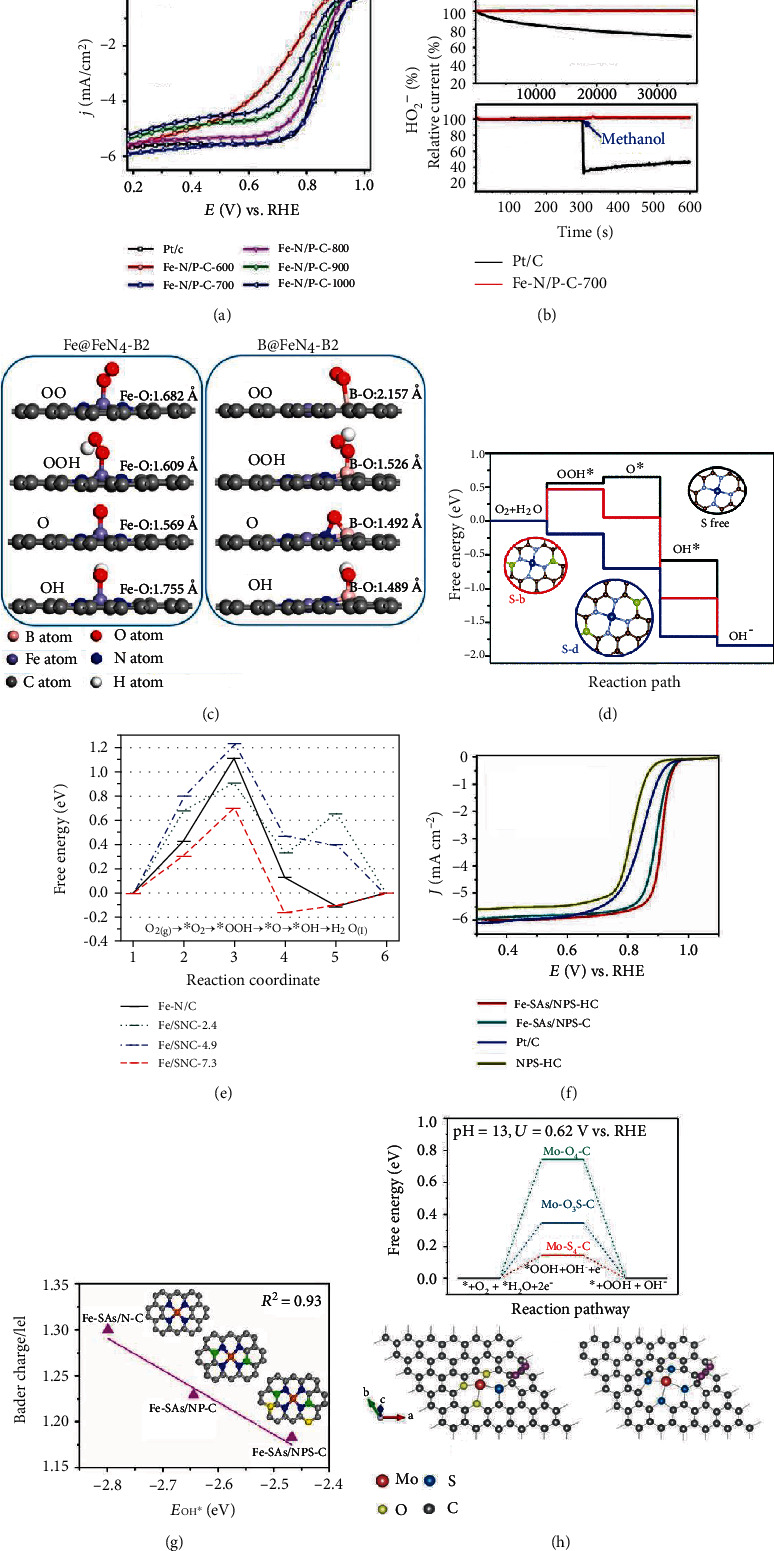

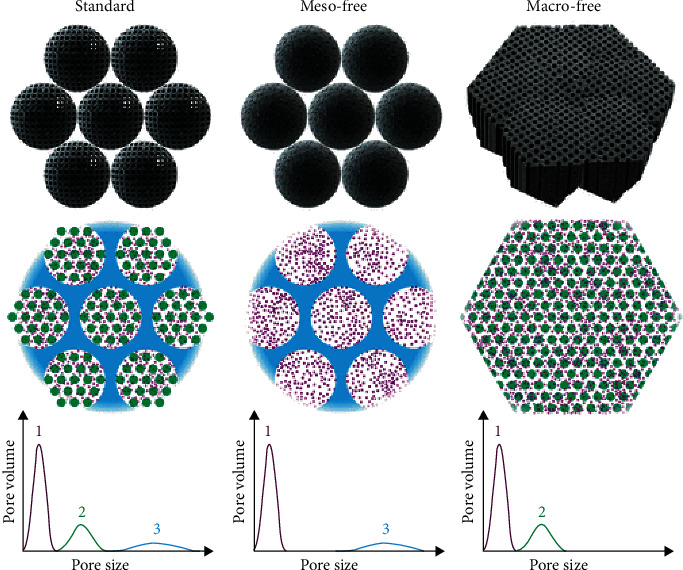

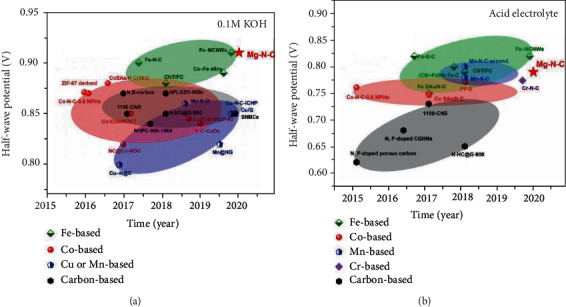

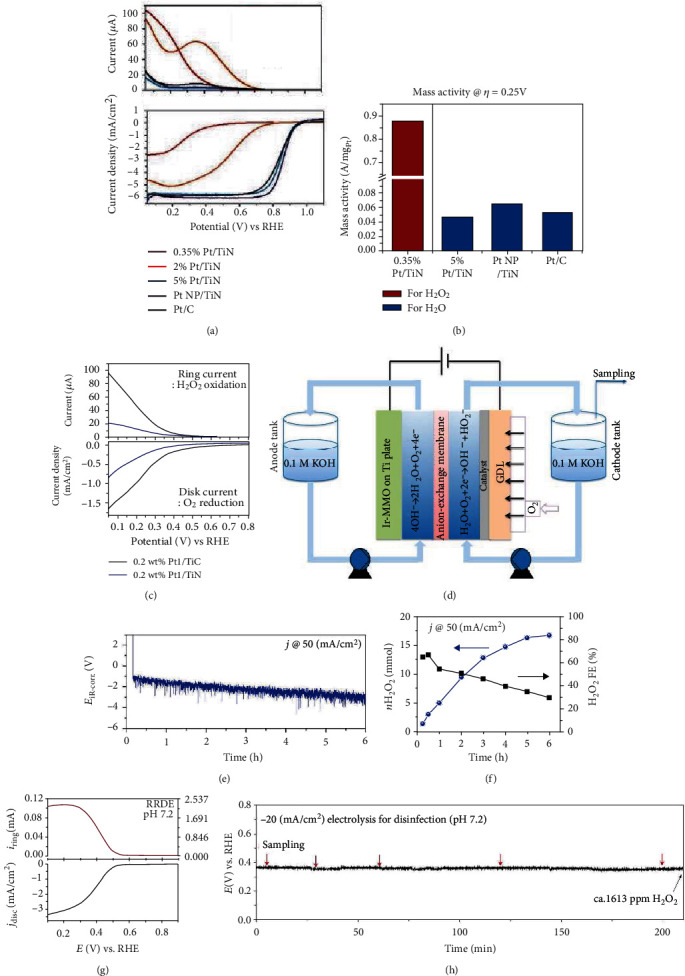

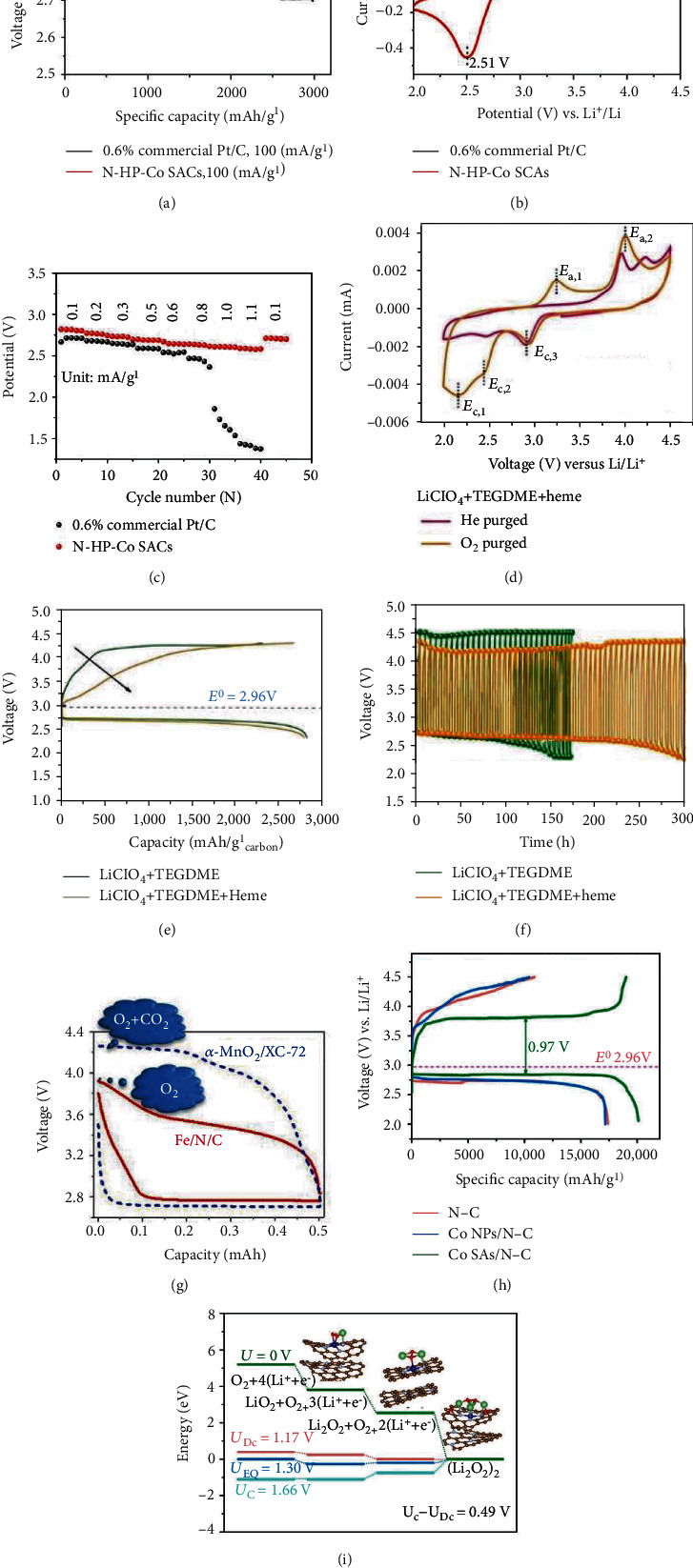

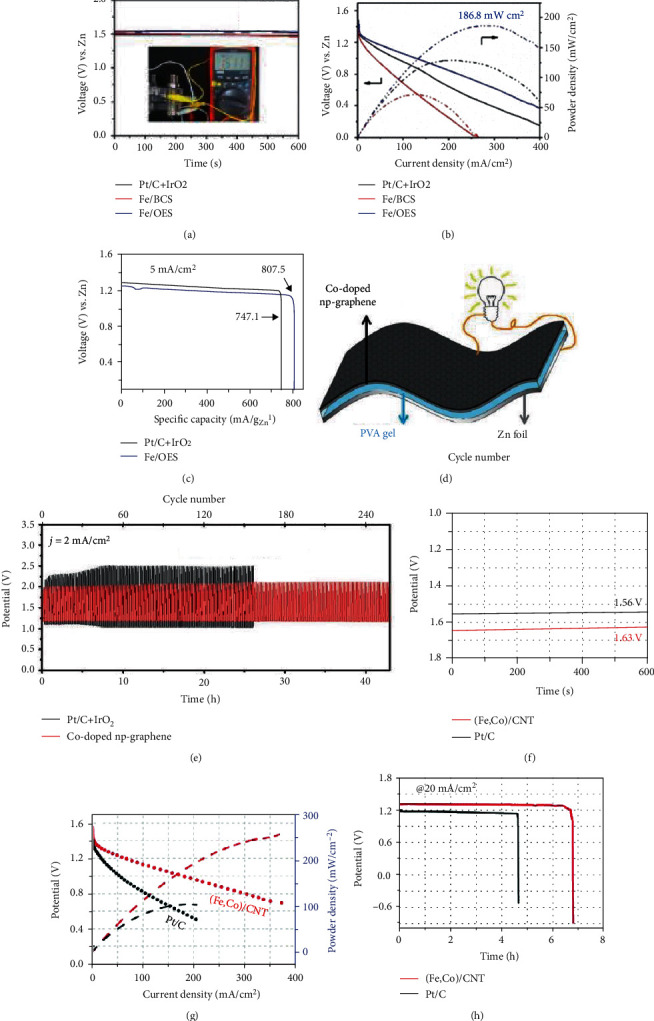

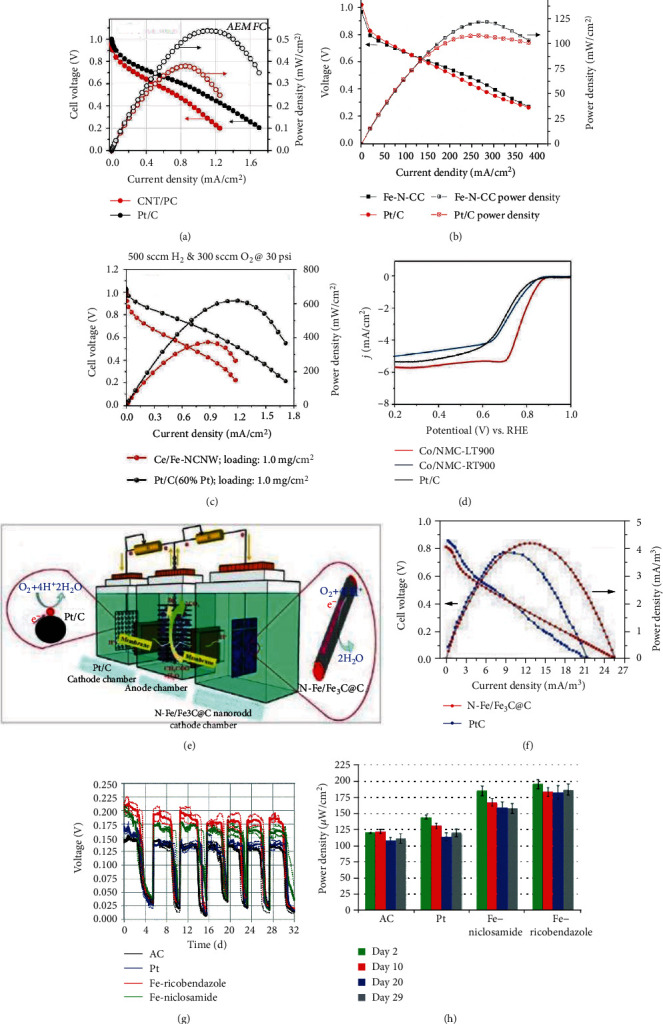

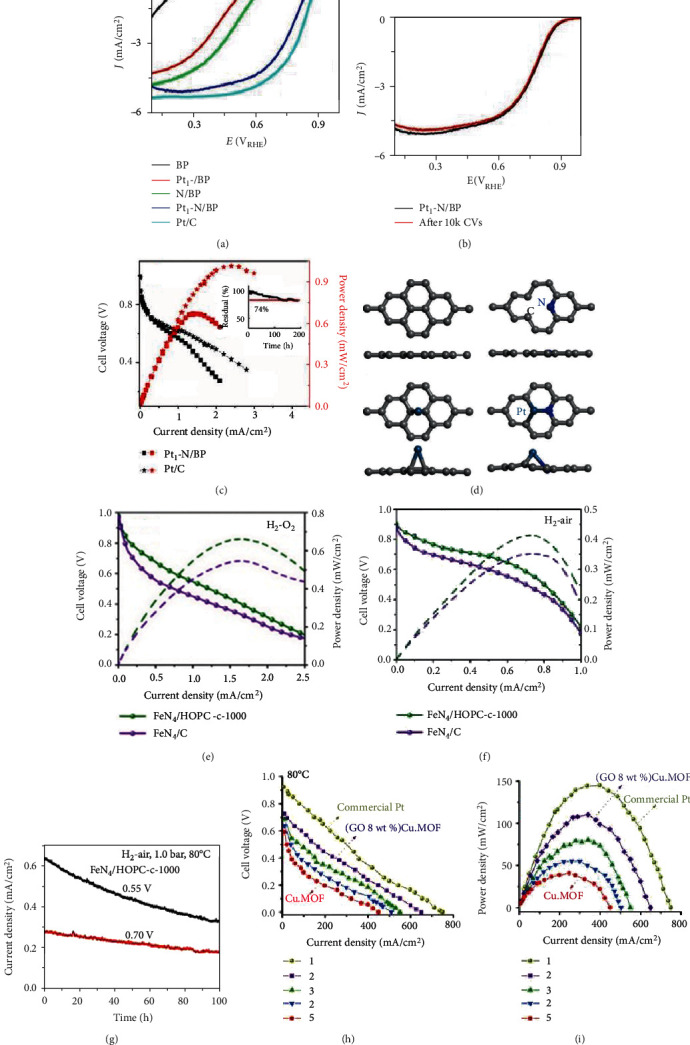

4. SAECs for Oxygen Reduction Reactions