Abstract

There is growing interest in the application of natural ingredients to replace chemical dough improvers in bread formulations in order to meet consumer demands of clean label products. The goal of this study was to evaluate the dough quality and baking quality of hard red spring (HRS) wheat flour blends to replace commercial dough improvers. Hard red winter (HRW) wheat flour is commonly used in bread and diner roll formulations. In this study, doughs were prepared by adding 10%, 20%, 30%, and 40% of HRS wheat flour to HRW wheat base-flour to compare the dough quality and baking quality relative to different levels of commercial improvers. Additional to commercial HRS flour, two commonly grown HRS wheat varieties (Glenn and Linkert) were included in the study. All of the HRS wheat flour blends had significantly (p < 0.05) higher farinograph stability and extensograph resistance at 135 min than doughs containing most of the commercial additives. Bread flour with 40% Glenn and 40% Linkert showed the highest loaf volumes of 920 cm3 and 950 cm3, respectively with the firmness of 1553.50 and 1525.50 mN, respectively. Baking quality of HRS wheat flour blends also showed significant (p < 0.05) correlation with dough rheology but commercial additives did not have the correlations. Therefore, HRS wheat flour may be used as a replacement for dough improvers, as it had better dough and bread properties compared to commercial additives and provides a great alternative for “clean-label” bread products.

Keywords: Clean label, Dough improvers, Dough conditioners, Dough strengtheners, Bread formulations

Introduction

Bread is one of the most important sources of carbohydrates in the human diet (Dewettinck et al. 2008). The major ingredients used in bread formulations are flour, water, yeast, salt, sugar and the major components of flour are protein, carbohydrates, and lipid. The storage proteins of flour develop gluten network during hydration and the visco-elastic properties of gluten network are unique for breadmaking properties. Besides protein, starch also plays an important role in the rheological characteristics of dough by strengthening this network as they begin to swell upon heating (Zeleznak and Hoseney 1986).

Besides the major ingredients, there are some minor ingredients used in bread formulations for overall quality improvement. Among minor ingredients, bakery improvers are used to aid production and improve certain quality factors of bread. These bakery improvers include dough conditioners, dough strengtheners, crumb softeners, emulsifiers, and surfactants (Pyler and Gorton 2008). Dough strengtheners may bind with the gluten to improve the machinability and gas retention of dough which subsequently affect loaf volume, symmetry, texture and grain of bread. Moreover, they bind with the starch to retard the rate of staling (Dubois 1979).

Dough strengtheners are typically oxidants, reductants, and surfactants. Surfactants interact with gluten to strengthen the dough and help the gluten matrix becomes more elastic and extensible. Surfactants also can form a clathrate with amylose, thus limiting swelling of starch and amylose leaching (Science of Baking 2010). Oxidants facilitate the interchange between the thiols and disulfide bonds in protein, inhibit the protease enzyme, oxidize thiols group, and affect protein aggregation to improve dough rheology and bread quality (Pyler and Gorton 2008).

Food products made using these chemicals often confuse consumers rather enlighten and the judgment of food choice mainly depends on the available information on the label (Aoki et al. 2010). Many of these chemicals are also associated with health controversies, for example, potassium bromate was a much-discussed subject since 1990 (Pyler and Gorton 2008) due to its carcinogenic effects (Kurokawa et al. 1990). In addition, azodicarbonamide irritates eyes and the respiratory tract (CDC 2015), and DATEM is found to be a cause of heart fibrosis and adrenal overgrowth in rats. Considering all of these issues, many bakeries have already eliminated potassium bromate and azodicarbonamide upon consumer demand for clean label (Pyler and Gorton 2008). Although there is no official definition of the term clean label, it generally means using natural ingredients, no artificial ingredients, no artificial preservatives, no high fructose corn syrup and no artificial colors in food processing (Hutt and Sloan 2015).

In this experiment, HRS wheat flour with high protein content (13–16%) was selected as a clean label ingredient. The high protein content and superior gluten quality of HRS what flour among the bread wheats make their extensive use as a blending wheat to increase the gluten strength in batches of flour (U.S. HRS crop quality report, 2017). Maghirang et al. (2006) compared the HRS and HRW wheat flour qualities and found that the quantity of gliadin proteins, farinograph stability, loaf volume and crumb grain score were higher for HRS wheat flour, whereas HRW wheat flour had higher soluble polymeric proteins, free polar lipids content, alveograph P/L ratio and falling number. They also concluded that HRS wheat generally exceeds the grain and flour quality of HRW even in the similar range of protein content. Therefore, using HRS wheat flour as a dough strengthening ingredient, would provide a natural ingredient as well as a solution for the consumers to avoid the above stated chemical dough improvers.

The objective of this study was to replace commercially available dough improvers with HRS wheat flour during bread making in order to provide a clean label.

Materials and methods

Materials

Hard red winter (HRW) wheat flour, and two types hard red spring (HRS) wheat flour samples were obtained from commercial sources. HRS wheat cultivars (Glenn and Linkert) were collected from different research field of North Dakota, USA then cleaned and milled separately using Buhler laboratory mill.

The HRW wheat flour was used as base flour and HRS wheat flours were used to compare dough strengthening ability with ten commercially available dough additives. The chemical dough additives were potassium bromate (PB), azodicarbonamide (ADA), ascorbic acid (AA), sodium stearoyl lactylate (SSL), calcium stearoyl lactylate (CSL), diacetyl tartaric acid esters of mono- and diglycerides (DATEM), and ethoxylated mono- and diglycerides (EMG). Moreover, three additional ingredients: nonfat dry milk (NFDM), vital wheat gluten (VWG) and fat were also investigated.

Analysis of flours, dough and bread crumbs

The moisture and protein content of each of the flour, dough and bread samples were determined with air-oven drying at 135 °C (AACC method 44-19.01 1999) and with a LECO FP 528 nitrogen/protein analyzer (LECO, St. Joseph, MI, USA) (AACCI method 46–30.01), respectively.

Dough preparation

The doughs were prepared by blending 10, 20, 30 and 40% (w/w) of each of the HRS wheat flour with respective 90, 80, 70 and 60% (w/w) HRW wheat flour. Additional, doughs were prepared by adding 50 ppm SSL,50 ppm CSL, 25 ppm DATEM, 0.50% EMG, 150 ppm AA, 30 ppm ADA, 10 ppm PB, 5% VWG, 2% Fat, and 2% NFDM to 100% HRW wheat flour.

Dough quality

Water absorption and dough mixing properties of the samples were investigated by farinograph (C. W. Brabender Instruments, Hackensack, NJ, USA) according to the AACC method 54-21.02 (2011). Dough extensibility was measured using an Extensigraph (C.W. Brabender Instruments Inc., Hackensack, NJ) according to AACC method 54-10.01 (1999).

Bread baking and quality

Bread (100 g pup loaves) was baked using straight dough method according to AACCI approved method with the following modifications: fungal α-amylase (15 SKB) and instant yeast (1.0%) instead of dry malt powder and compressed yeast, respectively as well as the addition of 10 ppm ammonium phosphate. A 2-h fermentation schedule with two punches was used for bread baking (AACC method 10-09.01 1999).

After baking, bread loaf volume was measured in a volumeter by rapeseed displacement (AACC method 10-05.01 1999). The bread was then evaluated for crust color, crumb color, crumb grain, and symmetry using a scale of 1–10, with ten being the best and one being the worst. The firmness of the bread slice was done after 1 day of baking using texture analyzer (Texture Technologies Corp., Scarsdale, NY) attached with an acrylic probe of 2.5 cm diameter (AACC method 74–09.01 1999).

Statistical analysis

The experimental design was randomized complete block design (RCBD) with three replications. Statistical analysis was performed using the SAS statistical methods (Version 9.3, SAS Institute; Cary, NC). An analysis of variance (ANOVA) was performed to assess the effect of treatments on quality characteristics and treatment means were separated by least significant difference (LSD) test at P = 0.05.

Results and discussion

Proximate analysis of flour

Before dough rheology and baking experiments were conducted, proximate analysis was performed for the flours used in this study. All of the flours were tested for their moisture and protein content (Table 1). HRW wheat flour had protein content of 9.25% and moisture of 12.7%. Among the HRS wheat flours, HRS 2 showed the highest protein content of 14.8% whereas HRS 4 showed the lowest of 13.0%. However, HRS 4 showed the highest and HRS 3 showed the lowest moisture content. Protein is likely the most important quality determining the factor of HRS wheat, and the average protein content of North Dakota grown HRS wheat flour is 13.8% (14% mb) and average moisture content of grain is 12.6%, respectively (U.S. HRS Regional Quality Report 2017).

Table 1.

Proximate compositions of flours

| Sample ID | Source | Moisture | Protein (14% MB) |

|---|---|---|---|

| (%) | (%) | ||

| Base flour | Commercial HRW wheat | 12.7 | 09.11 |

| HRS1 | Commercial HRS wheat | 12.4 | 13.35 |

| HRS2 | Cultivar ‘Glenn’ | 12.8 | 14.60 |

| HRS3 | Cultivar ‘Linkert’ | 12.1 | 13.99 |

| HRS4 | Commercial HRS wheat | 12.9 | 12.84 |

MB moisture basis, HRW hard red winter, HRS hard red spring

Effect of HRS wheat blends and additives on dough quality

Dough quality of each of the flour blends was studied by farinograph and extensograph, and presented in Table 2. For the farinograph parameters, the 40% HRS 2 and 40% HRS 3 showed significantly (P < 0.05) higher water absorption and stability than even their respective 30% blends. There is a positive correlation between dough strength and glutenin proteins (Barak et al. 2013) and HRS flour is adding glutenin to the blends. There was also an increasing trend in stability with increasing percentages of HRS wheat flour for all the HRS blends in stability, and in peak time for most of the HRS wheat flour blends. Both the 30% and 40% blends of HRS 3 and HRS 4 showed significantly (P < 0.05) lower mixing tolerance index (MTI) than HRW wheat flour. Dough stability is positively corelated to the loaf volume whereas MTI indicates the degree of softening. A high-water absorption with a low degree of softening indicates good quality flour (Hadnadev et al. 2011). Among the oxidants, AA resulted in significantly (P < 0.05) lower water absorption and significantly (P < 0.05) higher stability compared to HRW wheat flour. The ADA resulted in higher water absorption and stability than slow acting PB and AA because ADA exerted most of its effect during mixing whereas PB has no effect during mixing. Similar results are indicated by previous studies (Tsen 1963; Bushuk and Hlynka 1960). Among the surfactants, EMG caused significantly (P < 0.05) higher peak time and stability than HRW wheat flour by reacting with gluten (Science of Baking 2010); however, rest of them react with starch to improve machinability of dough (Pyler and Gorton 2008) which was not shown in farinograph. Therefore, almost all of the HRS wheat flour blending showed significantly (P < 0.05) higher water absorption, peak time, and stability than commercial dough improvers except VWG. Blending stronger gluten and/or add more glutenin of HRS wheat flour to weak HRW wheat flour even better than strengthening actions of commercial dough improvers on the gluten protein of HRW wheat flour. This can be more explained by the results of VWG which also has stronger gluten and/or add more glutenin to weak flour rather reacting weak flours protein to make it stronger.

Table 2.

Dough rheology of HRS wheat flour blends and dough additives

| FAB | FPT | FST | MTI | FQN | EXT045 | ERS045 | EAR045 | EXT135 | ERS135 | EAR135 | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| (14%mb) | (min) | (min) | (BU) | (mm) | (cm) | (BU) | (cm2) | (cm) | (BU) | (cm2) | |

| HRW | 53.7 | 1.5 | 8.1 | 23.0 | 69.0 | 11.8 | 476.3 | 79.0 | 10.6 | 686.7 | 96.3 |

| HRS wheat flour blends | |||||||||||

| HRS1/HRW | |||||||||||

| 100/0 | 61.7 | 13.0 | 21.3 | 14.7 | 247.3 | 17.1 | 679.0 | 145.7 | 12.7 | 1011.3 | 170.0 |

| 10/90 | 55.9 | 1.6 | 10.6 | 11.7 | 112.0 | 13.6 | 408.7 | 78.7 | 11.4 | 639.3 | 98.7 |

| 20/80 | 56.4 | 6.8 | 13.5 | 21.0 | 139.3 | 13.8 | 455.0 | 85.3 | 11.5 | 694.7 | 107.3 |

| 30/70 | 58.3 | 6.4 | 13.7 | 16.7 | 146.0 | 13.8 | 459.3 | 84.7 | 12.1 | 723.0 | 116.0 |

| 40/60 | 58.2 | 7.8 | 13.9 | 21.7 | 148.0 | 14.5 | 490.0 | 95.0 | 12.0 | 779.7 | 131.7 |

| HRS 2/HRW | |||||||||||

| 100/0 | 63.6 | 10.3 | 20.1 | 8.0 | 285.3 | 17.3 | 660.0 | 143.3 | 13.5 | 1124.7 | 208.0 |

| 10/90 | 54.3 | 7.2 | 13.7 | 26.0 | 136.3 | 13.0 | 495.3 | 89.3 | 11.7 | 686.7 | 106.7 |

| 20/80 | 55.0 | 7.6 | 14.5 | 19.0 | 152.3 | 13.1 | 543.7 | 97.7 | 11.6 | 760.0 | 117.7 |

| 30/70 | 56.5 | 7.3 | 15.3 | 16.7 | 156.7 | 14.2 | 516.7 | 99.0 | 12.2 | 815.3 | 133.3 |

| 40/60 | 57.2 | 6.9 | 16.5 | 15.0 | 177.7 | 14.2 | 556.3 | 106.3 | 11.8 | 947.3 | 145.7 |

| HRS 3/HRW | |||||||||||

| 100/0 | 62.3 | 8.2 | 27.6 | 13.3 | 250.3 | 16.8 | 677.7 | 146.0 | 14.0 | 1115.7 | 208.7 |

| 10/90 | 55.9 | 1.6 | 11.8 | 13.7 | 118.7 | 13.2 | 447.3 | 82.0 | 11.1 | 612.7 | 91.7 |

| 20/80 | 56.3 | 7.2 | 14.6 | 20.3 | 155.0 | 13.4 | 453.0 | 82.7 | 11.6 | 714.0 | 109.3 |

| 30/70 | 57.3 | 7.0 | 14.6 | 19.3 | 151.0 | 14.1 | 518.3 | 98.3 | 11.2 | 812.0 | 120.0 |

| 40/60 | 58.2 | 7.2 | 16.3 | 13.3 | 168.7 | 14.4 | 534.3 | 101.7 | 11.6 | 868.3 | 132.0 |

| HRS 4/HRW | |||||||||||

| 100/0 | 62.2 | 15.2 | 19.8 | 21.3 | 220.3 | 14.3 | 928.0 | 164.7 | 7.9 | 1500.0 | 138.0 |

| 10/90 | 55.7 | 7.7 | 12.4 | 25.0 | 133.7 | 12.3 | 533.0 | 89.3 | 10.1 | 796.3 | 106.7 |

| 20/80 | 56.5 | 9.1 | 13.0 | 31.0 | 140.3 | 12.9 | 579.7 | 98.0 | 9.1 | 946.7 | 110.7 |

| 30/70 | 57.2 | 9.9 | 13.6 | 30.3 | 147.3 | 12.1 | 639.0 | 102.3 | 8.5 | 1142.3 | 121.7 |

| 40/60 | 57.4 | 11.1 | 15.0 | 27.3 | 164.7 | 13.0 | 597.3 | 98.3 | 7.4 | 1186.7 | 104.0 |

| 100% HRW + additives | |||||||||||

| 50 ppm SSL | 54.6 | 1.4 | 5.3 | 44.7 | 28.3 | 13.5 | 418.7 | 80.3 | 12.2 | 591.3 | 97.7 |

| 50 ppm CSL | 54.7 | 1.9 | 7.5 | 29.3 | 32.3 | 12.2 | 435.3 | 76.0 | 11.1 | 570.3 | 87.0 |

| 25 ppm DATEM | 55.6 | 1.5 | 6.7 | 30.7 | 41.0 | 12.5 | 438.7 | 75.3 | 11.6 | 591.3 | 91.7 |

| 0.50% EMG | 55.4 | 5.5 | 9.1 | 37.7 | 96.0 | 12.7 | 413.0 | 74.0 | 10.7 | 572.0 | 83.0 |

| 150 ppm AA | 52.3 | 1.6 | 10.2 | 23.3 | 86.0 | 10.9 | 663.3 | 95.3 | 7.1 | 1263.7 | 105.7 |

| 30 ppm ADA | 56.1 | 1.7 | 5.8 | 26.3 | 56.3 | 7.8 | 763.3 | 72.3 | 6.7 | 763.7 | 60.7 |

| 10 ppm PB | 54.5 | 1.6 | 9.3 | 16.3 | 94.7 | 12.3 | 462.3 | 80.7 | 11.1 | 715.0 | 106.3 |

| 5% VWG | 62.3 | 7.9 | 17.6 | 18.3 | 182.7 | 13.7 | 551.7 | 99.0 | 9.5 | 1034.0 | 122.3 |

| 2% Fat | 53.9 | 1.5 | 11.0 | 7.0 | 115.7 | 12.2 | 451.7 | 78.3 | 11.3 | 635.0 | 97.7 |

| 2% NFDM | 56.0 | 1.9 | 10.6 | 11.0 | 113.0 | 13.1 | 354.3 | 68.0 | 11.9 | 534.0 | 89.0 |

| LSD | 0.5 | 1.0 | 1.3 | 7.9 | 27.1 | 1.4 | 84.3 | 15.6 | 1.4 | 102.7 | 19.1 |

FAB farinograph water absorption, FPT farinograph peak time, FST farinograph stability, FQN farinograph quality number, EXT 045 extensograph extensiblity at 45 min, ESR 045 extensograph resistance at 45 min, EAR 045 extensograph area at 45 min, EXT 135 extensograph extensiblity at 135 min, ESR 135 extensograph resistance at 135 min, EAR 135 extensograph area at 135 min

For the extensograph data, the extensibility at 45 min increased as the amount of HRS in the blend increased, although the increases were not determined to be significant (P < 0.05). All of the blends showed trends of increasing resistance at 45 min and 135 min with increasing amount of HRS wheat flour. The 30% and 40% of HRS 2 as well as 30% and 40% of HRS 3 blends showed much better extensograms than their other respective blends. Extensograph is function of both gliadin and glutenin, therefore adding more gluten to flour blends shoed better results even than their other respective blends. Among oxidants, AA and ADA showed significantly (P < 0.05) higher resistance at 45 min, and AA showed significantly (P < 0.05) higher extensibility at 135 than HRW wheat flour. Resistance is function of gliadin and extensibility is the function of glutenin (Barak et al. 2013; Wang et al. 2006; Wieser, 2007), only AA react with both of them. Among the surfactants, only SSL showed significantly higher extensibility both at 45 min and 135 min than HRW wheat flour; however, there were no other significant (P < 0.05) differences within the surfactants as well as between surfactants and HRW wheat flour. Surfactants react with starch which is not obvious in farinogragh because farinogragh deal with gluten (Wang et al. 2006; Wieser 2007

These findings clearly indicate that both the 30% and 40% HRS 3 as well as 30% and 40% HRS 4 blends showed significantly (P < 0.05) higher results for almost all the parameters than commercial dough improvers excepting VWG. VWG add gliadins and glutenins to the dough that increase both extensibility and resistance (Wang et al. 2006; Wieser 2007). HRS wheat flours contained higher protein contents and strong gluten quantities than HRW wheat flour, which add more gluten as well as balanced glutenin/gliadin to HRW wheat flour and helps to show better dough properties in farinograph and extensograph than commerical improvers.

Correlation between farinograph and extensograph data

Farinograph absorption, stability, and FQN showed significant (P < 0.05) correlation with all the extenosgraph results, except the extensibility at 135 min for the flour blends. On the other hand, there was no significant (P < 0.05) correlation among almost all the parameters of farinograph and extensograph for the commercial dough additives, whereas only EAR was significantly (P < 0.05) correlated with farinograph stability (Table 3).

Table 3.

Correlation between farinograph and extensograph data of HRS wheat blends and dough additives

| FAB | FPT | FST | MTI | FQN | |

|---|---|---|---|---|---|

| HRS wheat flour blends | |||||

| EXT 045 | 0.854*** | 0.413NS | 0.830*** | − 0.628** | 0.877*** |

| ERS 045 | 0.720*** | 0.856*** | 0.694*** | 0.148NS | 0.717*** |

| EAR 045 | 0.886*** | 0.788*** | 0.872*** | − 0.171NS | 0.899*** |

| EXT 135 | 0.238NS | − 0.284NS | 0.348NS | − 0.728*** | 0.315NS |

| ERS 135 | 0.718*** | 0.854*** | 0.663*** | 0.193NS | 0.702*** |

| EAR 135 | 0.857*** | 0.529* | 0.898*** | − 0.411NS | 0.918*** |

| Dough additives | |||||

| EXT 045 | 0.282NS | 0.363NS | 0.407NS | 0.030NS | 0.305NS |

| ERS 045 | 0.064NS | 0.019NS | 0.009NS | − 0.027NS | 0.032NS |

| EAR 045 | 0.319NS | 0.468NS | 0.633* | − 0.079NS | 0.485NS |

| EXT 135 | − 0.032NS | − 0.105NS | − 0.091NS | 0.050NS | − 0.112NS |

| ERS 135 | 0.134NS | 0.276NS | 0.492NS | − 0.176NS | 0.408NS |

| EAR 135 | 0.286NS | 0.375NS | 0.693* | − 0.270NS | 0.558NS |

FAB farinograph water absorption, FPT farinograph peak time, FST farinograph stability, FQN farinograph quality number, EXT 045 extensograph extensiblity at 45 min, ESR 045 extensograph resistance at 45 min, EAR 045 extensograph area at 45 min, EXT 135 extensograph extensiblity at 135 min, ESR 135 extensograph resistance at 135 min, EAR 135 extensograph area at 135 min. NS non-significant

*P ≤ .05, **P ≤ .01, ***P ≤ .001

Quality traits of the bread made of HRS wheat flour blends and additives

Bread baking qualities are characterized by baking absorption, dough handling properties, bread loaf volume, specific volume, crust and crumb score, and firmness (Table 4). In this experiment, most of the HRS wheat flour blends showed significantly (P < 0.05) higher baking absorption than commercial dough improvers whereas VWG showed significantly (P < 0.05) higher baking absorption than all most all of the HRS wheat flour blends. Due to high protein content, HRS wheat flour and blends had significantly (P < 0.05) higher baking absorption than HRW wheat flour. Maghirang et al. (2006) also found similar results. However, there is no significant (P < 0.05) difference in mixing time among the HRS wheat flour blends as well as among most of the dough additives.

Table 4.

Baking quality characteristics of the bread made from HRS blends and dough additives

| BAB | MT | DS | OS | LV | SV | SY | CRC | CT | CBC | FM | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| (%) | (Min) | (0–10) | (cm) | (cc) | (0–10) | (0–10) | (0–10) | (0–10) | (0–10) | mN | |

| HRW | 60.1 | 3.6 | 8 | 1 | 605 | 4.7 | 3 | 4.5 | 4 | 4.5 | 3179 |

| HRS wheat flour blends | |||||||||||

| HRS1/HRW | |||||||||||

| 100/0 | 69.8 | 5 | 9 | 4.2 | 1002.5 | 7.7 | 8 | 10 | 7 | 10 | 1293.5 |

| 10/90 | 62.5 | 4.5 | 9 | 2.3 | 785 | 6.1 | 5.5 | 8 | 6 | 8 | 2306.5 |

| 20/80 | 63 | 4.4 | 9 | 2.9 | 847.5 | 6.6 | 6.5 | 9 | 6 | 9 | 2083.5 |

| 30/70 | 65 | 4.5 | 9 | 3.1 | 875 | 6.8 | 6.5 | 10 | 7 | 10 | 1781 |

| 40/60 | 65.8 | 4.6 | 10 | 2.9 | 870 | 6.7 | 7 | 10 | 7 | 10 | 1658 |

| HRS 2/HRW | |||||||||||

| 100/0 | 72 | 5 | 8 | 4.1 | 1055 | 7.9 | 8.5 | 10 | 8 | 10 | 690.5 |

| 10/90 | 60.8 | 4 | 9 | 2.1 | 757.5 | 5.8 | 5.5 | 8.5 | 6 | 8.5 | 2163.5 |

| 20/80 | 63.1 | 4.1 | 9 | 2.7 | 815 | 6.3 | 6.5 | 9.5 | 6 | 9.5 | 1943.5 |

| 30/70 | 63.9 | 4.4 | 9 | 3 | 875 | 6.7 | 7 | 10 | 7 | 10 | 1599.5 |

| 40/60 | 65 | 4.4 | 9.5 | 3.5 | 920 | 7.1 | 7.5 | 10 | 7.5 | 10 | 1553.5 |

| HRS 3/HRW | |||||||||||

| 100/0 | 72 | 5.3 | 8 | 4.1 | 1065 | 8.2 | 8 | 10 | 8 | 10 | 919.5 |

| 10/90 | 63.5 | 4.3 | 9 | 2.7 | 802.5 | 6.2 | 5.5 | 8.5 | 6.5 | 8.5 | 2018.5 |

| 20/80 | 64 | 4.4 | 9.5 | 2.8 | 837.5 | 6.5 | 6.5 | 9 | 7 | 9 | 1971.5 |

| 30/70 | 65 | 4.5 | 9.5 | 3 | 905 | 7 | 7.5 | 10 | 8 | 10 | 1641.5 |

| 40/60 | 66 | 4.5 | 10 | 3.7 | 950 | 7.3 | 7.5 | 10 | 8 | 10 | 1525.5 |

| HRS 4/HRW | |||||||||||

| 100/0 | 69.4 | 5 | 8 | 3.7 | 992.5 | 7.5 | 8 | 9.5 | 7.5 | 9.5 | 1197.5 |

| 10/90 | 62.5 | 4.3 | 9 | 2.9 | 715 | 5.4 | 5 | 8 | 6 | 8 | 2222.5 |

| 20/80 | 63.8 | 4.5 | 9 | 2.3 | 762.5 | 5.7 | 6 | 9.5 | 6.5 | 9.5 | 2141.5 |

| 30/70 | 64.5 | 4.6 | 9 | 2.4 | 815 | 6.2 | 6.5 | 10 | 7 | 10 | 2034.5 |

| 40/60 | 65.2 | 4.6 | 10 | 3 | 807.5 | 6.1 | 7 | 10 | 7.5 | 10 | 1900.5 |

| 100% HRW + additives | |||||||||||

| 50 ppm SSL | 61 | 4.4 | 9 | 1.5 | 720 | 5.5 | 5 | 6 | 6 | 6 | 2149.5 |

| 50 ppm CSL | 61.1 | 5.1 | 8.5 | 1.2 | 615 | 4.8 | 3 | 4 | 5 | 4 | 2931.5 |

| 25 ppm DATEM | 62 | 4.3 | 9 | 2.2 | 712.5 | 5.5 | 4.5 | 7 | 6.5 | 7 | 2678 |

| 0.50% EMG | 62.8 | 4.1 | 8.5 | 2.7 | 812.5 | 6.3 | 5.5 | 8 | 6 | 8 | 1708 |

| 150 ppm AA | 61.2 | 4.3 | 9.5 | 2 | 712.5 | 5.5 | 4 | 7.5 | 6.5 | 7.5 | 2777 |

| 30 ppm ADA | 58.8 | 3.5 | 5 | 0 | 450 | 3.5 | 0 | 1 | 0.5 | 1 | 10,072.50 |

| 10 ppm PB | 62.4 | 4.5 | 8.5 | 1.9 | 707.5 | 5.4 | 5.5 | 6 | 6.5 | 6 | 2793.5 |

| 5% VWG | 70.4 | 4.4 | 9 | 2.5 | 850 | 6.1 | 6.5 | 9 | 7.5 | 9 | 1734.5 |

| 2% Fat | 60.3 | 3.6 | 8 | 1.9 | 677.5 | 5.2 | 4 | 6 | 5.5 | 6 | 2586.5 |

| 2% NFDM | 63.1 | 4.1 | 8.5 | 1.4 | 727.5 | 5.5 | 5.5 | 8 | 7.5 | 8 | 2602 |

| LSD | 2.6 | 0.5 | 1.1 | 0.7 | 45.5 | 0.4 | 1 | 1.2 | 0.9 | 1.2 | 1818.9 |

LSD least significant difference at P = 0.05, HRS hard red spring wheat flour, HRW hard red winter Wheat flour, BAB baking absorption, MT mixing time, DS dough score, OS oven spring, LV loaf volume, SV specific volume, SY symmetry, CRC crust color, CT crumb texture, CBC crumb color, FM firmness, SSL sodium steroyl lactylate, CSL calcium steroyl lactylate, DATEM diacetyl tartaric acid ester of mono and diglycerides, EMG ethoxylated monoglycerides, AA ascorbic acid, ADA azodicarbonamide, PB potassium bromate, VWG vital wheat gluten, NFDM nonfat dry milk, DS commercially available dough strengtheners

There was trend of increasing oven spring, loaf volume and specific volume with increasing percentage of HRS wheat flour for all of the HRS wheat flour blends (Table 4). Almost all of the HRS wheat flour blends showed significantly (P < 0.05) higher oven spring than almost all of the commercial dough additives. The increasing percentages of HRS wheat flour is adding more protein and loaf volume is a function of flour protein which increase with increasing protein content and protein quality for pan breads (Finney and Barmore 1948; Finney 1984). Specific volumes also showed very similar increasing trends of loaf volume. The highest specific volume among the blends showed by bread with HRS 3 blend, and that was significantly (P < 0.05) higher than the highest specific volume given by bread made of commercial dough additives. Among surfactants, there was no significant (P < 0.05) difference in the loaf volume between SSL and DATEM; however, CS showed significantly (P < 0.05) lower loaf volume and EMG showed significantly (P < 0.05) higher loaf volume than SSL and DATEM. Similar loaf volume increasing action of DATEM and SSL were found in a previous study (Rogers and Hoseney 1983). In another study, EMG showed highest loaf volume followed by SSL and DATEM with 0.50% treatments (Junge and Hoseney 1981). Besides surfactants, there was no significant (P < 0.05) difference in loaf volume between PB and AA; however, ADA was significantly (P < 0.05) lower than those two oxidants. The differences in the loaf volume are due to rate of activity of the oxidants. The ADA is a fast acting, and completed the action during mixing; however, the ascorbic acid is medium acting and PB is slow acting, and these can exert most of the effects after mixing (Pyler and Gorton 2008). Bread made with the HRS wheat flour blends showed significantly (P < 0.05) higher loaf volume than HRW wheat flour, and all the commercial dough improvers except EMG and VWG. The 30% and 40% of HRS 2 as well as 30% and 40% of HRS 3 blends showed significantly (P < 0.05) higher volume than respective blends of HRS 1 and HRS 4. The 30% and 40% of HRS 2 as well as 30% and 40% HRS 3 showed significantly (P < 0.05) higher loaf volume than the highest loaf volume (850 cc) among the dough additives given by VWG.

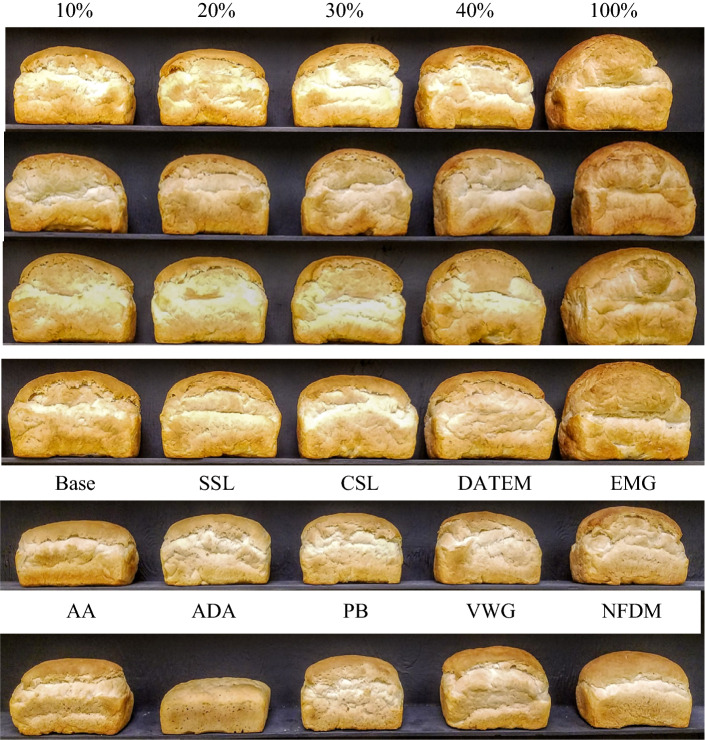

Increase in crumb firmness is the most widely used indicator of bread staling (Gray and Bemiller 2003) which directly affects the consumer preference (He and Hoseney 1990). In this experiment, bread with the HRS wheat flour blends showed lower firmness then all the commercial dough additives, except EMG and VWG. There was also a trend of decreasing firmness with increasing amount of HRS wheat flour percentages for all the HRS wheat flour blends. Among HRS wheat flour blends, the lowest firmness of 1525 mN and 1553 mN were obtained for 40% HRS 3 and 40% HRS 2, respectively. We found that bread firmness decreased with higher protein content and previous research has also shown that there is a negative correlation between gluten index and firmness (Barak et al. 2013). Although there was no significant differences in firmness between commercial additives; EMG showed the lowest firmness whereas ADA showed the extremely high firmness of 10,072 mN. In addition, emulsifiers (except CSL) showed lower firmness than oxidants (Fig. 1). Emulsifiers are more efficient in reducing bread firmness by forming a complex with amylose, and monoacylglycerols had higher than DATEM. Both SSL and DATEM exerted similar crumb softening complex forming power effect due to the presence of a stearic acid in their structure (Eduardo et al. 2016)

Fig. 1.

Bread loves made from HRS blends (HRS 1, HRS 2, HRS 3, and HRS 4, respectively) and commercial dough strengtheners. CSL calcium steroyl lactylate, DATEM diacetyl tartaric acid ester of mono and diglycerides, EMG ethoxylated monoglycerides, AA ascorbic acid, ADA azodicarbonamide, PB potassium bromate, VWG vital wheat gluten, NFDM nonfat dry milk

For the crust color, crumb color, and crumb texture of bread, almost all the HRS wheat flour blends showed better values than commercial dough strengtheners. Bread with 30% and 40% of HRS wheat flour blends showed the highest color values of 10 on the scale of 0 to 10, which are significantly (P < 0.05) higher that all the dough additives. Bread with the 30% and 40% of HRS wheat flour blends also showed much better symmetry and texture than all other HRS wheat flour blends and significantly (P < 0.05) higher values than most of the dough improvers. Among the surfactants, EMG showed significantly (P < 0.05) higher than CSL and SSL for symmetry, color and texture values; however, among oxidants, AA and PB showed significantly (P < 0.05) higher symmetry, color and texture value than ADA. Among the additional ingredients, NFDM showed significantly (P < 0.05) higher symmetry, color and texture value than all of the surfactants and oxidants, excepting EMG.

Correlation between dough rheology and bread quality characteristics

For HRS wheat flour blends, all the farinograph parameters excepting MTI showed significant (P < 0.05) correlation with all baking quality characteristics except dough score. The farinograph stability showed significant (P < 0.05) and positive correlation with loaf volume (r = 0.894); however, significant (P < 0.05) and negative correlation with firmness (r = − 0.882). These findings are very similar to a previous study (Barak et al. 2013). Similar to farinogragh, most of the extensograph parameters showed significant (P < 0.05) correlation with all baking quality characteristics except dough score. However, ERS045 was not correlated with crumb color and texture, and ERS135 did not show any significant correlation with baking quality characteristics (Table 5). For the commercial dough additives, there was no significant (P < 0.05) correlation between almost all the dough quality characteristics and baking quality characteristics. The farinograph stability showed significant (P < 0.05) and positive, but not strong correlation with loaf volume (r = 0.62). Only EXT045 and EAR135 showed significant (P < 0.05) correlation between almost all the dough quality characteristics.

Table 5.

Correlation coefficients between dough and bread qualities among HRS blends and chemical dough strengtheners

| BAB | MT | DS | OS | LV | SV | SY | CRC | GT | CBC | FM | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| HRS blends | |||||||||||

| FAB | 0.982*** | 0.922*** | − 0.310NS | 0.826*** | 0.896*** | 0.866*** | 0.815*** | 0.559** | 0.672*** | 0.837*** | − 0.878*** |

| FPT | 0.634** | 0.680*** | 0.008NS | 0.663*** | 0.598** | 0.560** | 0.700*** | 0.622** | 0.453* | 0.671*** | − 0.660*** |

| FST | 0.901*** | 0.843*** | − 0.237NS | 0.858*** | 0.894*** | 0.883*** | 0.814*** | 0.605** | 0.634** | 0.891*** | − 0.882*** |

| MTI | − 0.411NS | − 0.241NS | 0.226NS | − 0.363NS | − 0.481* | − 0.500* | − 0.323NS | − 0.089NS | − 0.360NS | − 0.342NS | 0.389NS |

| FQN | 0.944*** | 0.860*** | − 0.244NS | 0.886*** | 0.912*** | 0.885*** | 0.867*** | 0.635** | 0.662*** | 0.938*** | − 0.930*** |

| EXT045 | 0.875*** | 0.770*** | − 0.205NS | 0.809*** | 0.887*** | 0.881*** | 0.776*** | 0.515* | 0.581** | 0.837*** | − 0.847*** |

| ERS045 | 0.697*** | 0.681*** | − 0.340NS | 0.607** | 0.602** | 0.564** | 0.587** | 0.385NS | 0.357NS | 0.664*** | − 0.637** |

| EAR045 | 0.881*** | 0.811*** | − 0.390NS | 0.774*** | 0.810*** | 0.780*** | 0.738*** | 0.463* | 0.483* | 0.842*** | − 0.817*** |

| EXT135 | 0.290NS | 0.122NS | − 0.170NS | 0.297NS | 0.395NS | 0.429* | 0.224NS | 0.097NS | 0.157NS | 0.347NS | − 0.335NS |

| ERS135 | 0.703*** | 0.724*** | − 0.207NS | 0.596** | 0.591** | 0.546** | 0.629** | 0.469* | 0.471* | 0.668*** | − 0.634** |

| EAR135 | 0.897*** | 0.771*** | − 0.330NS | 0.796*** | 0.859*** | 0.842*** | 0.746*** | 0.501* | 0.542** | 0.925*** | − 0.863*** |

| Additives | |||||||||||

| FAB | 0.850*** | 0.106NS | − 0.031NS | 0.241NS | 0.387NS | 0.233NS | 0.344NS | 0.306NS | 0.199NS | 0.045NS | − 0.033NS |

| FPT | 0.857*** | 0.137NS | 0.183NS | 0.563NS | 0.634* | 0.538NS | 0.494NS | 0.524NS | 0.321NS | 0.279NS | − 0.289NS |

| FST | 0.845** | 0.063NS | 0.336NS | 0.537NS | 0.620* | 0.501NS | 0.569NS | 0.638* | 0.535NS | 0.441NS | − 0.405NS |

| MTI | − 0.164NS | 0.277NS | 0.088NS | 0.026NS | 0.020NS | 0.093NS | − 0.076NS | − 0.123NS | − 0.159NS | − 0.038NS | − 0.004NS |

| FQN | 0.759** | − 0.155NS | 0.165NS | 0.478NS | 0.564NS | 0.451NS | 0.530NS | 0.588NS | 0.438NS | 0.297NS | − 0.285NS |

| EXT045 | 0.593NS | 0.487NS | 0.809** | 0.700* | 0.833** | 0.819** | 0.897*** | 0.774** | 0.864*** | 0.904*** | − 0.922*** |

| ERS045 | − 0.138NS | − 0.354NS | − 0.544NS | − 0.416NS | − 0.497NS | − 0.545NS | − 0.622* | − 0.464NS | − 0.609* | − 0.687* | 0.734* |

| EAR045 | 0.573NS | 0.198NS | 0.454NS | 0.428NS | 0.435NS | 0.364NS | 0.333NS | 0.411NS | 0.349NS | 0.368NS | − 0.307NS |

| EXT135 | 0.091NS | 0.312NS | 0.457NS | 0.321NS | 0.396NS | 0.430NS | 0.550NS | 0.338NS | 0.517NS | 0.588NS | − 0.644* |

| ERS135 | 0.321NS | − 0.022NS | 0.180NS | 0.163NS | 0.144NS | 0.090NS | 0.021NS | 0.211NS | 0.096NS | 0.033NS | 0.045NS |

| EAR135 | 0.672* | 0.337NS | 0.759** | 0.638* | 0.707* | 0.646* | 0.739** | 0.693* | 0.751** | 0.773** | − 0.728* |

BAB baking absorption, MT mixing time, DS dough score, OS oven spring, LV loaf volume, SV specific volume, SY symmetry, CRC crust color, GT crumb texture, CBC crumb color, FM firmness, FAB farinograph water absorption, FPT farinograph peak time, FST farinograph stability, FQN farinograph quality number, EXT extensograph extensiblity, ESR extensograph resistance, EAR extensograph area, NS non-significant

*P ≤ .05, **P ≤ .01, ***P ≤ .001

These results suggested that there is good correlation between dough rheological measurements and baking performance for the wheat flour blends but not for commercial dough additives. Many researchers have attempted to predict bread quality by measuring dough rheological characteristics, especially grain quality, flour quality, and dough quality (Autio et al. 2001; Lee et al. 2006; Dowell et al. 2008). Therefore, a very good correlation between dough rheology and bead quality characteristics is desirable.

Conclusion

In this study, HRS wheat flour blends used as a replacement for dough improvers had better characteristics than commercial additives for both the dough and bread properties. Dough quality charateristics of almost all of the HRS flour blends showed significantly (P < 0.05) higher value than most of the commercial dough additives. There were also positive and significant correlations between farinograph and extensograph parameters for only the HRS flour blends. Poor dough rheological properties of bread flour influence the bakers to add dough additives to facilitate the bread manufacturing process; however, these results indicate that HRS flour blends had better rheological properties than available dough additives. The 30% and 40% of both Linkert and Glenn flour blends showed higher loaf volume and lower firmness than all the commercial dough additives, besides those the highest loaf volume and the lowest firmness were shown by 40% Linkert followed by 40% Glenn. For the crust and crumb color, almost all of the blends showed better values than the additives. There was no significant (P < 0.05) correlation between the dough quality characteristics and baking quality characteristics for the commercial dough additives whereas HRS wheat flour blends showed significant (P < 0.05) correlation between almost all the dough quality characteristics and baking quality characteristics. Higher loaf volume and lower firmness are two most important bread quality parameters and the most influential factors for dough additives, our results indicate that we can get better bread quality by using HRS wheat flour blends. Therefore, we can conclude that addition of 40% HRS wheat flour to HRW wheat flour can be used as a clean label ingredient to replace almost all of the commercial strengtheners in bread production.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- AACC International (1999) Approved methods of the American Association of Cereal Chemists International. Method 44-19.01 (Moisture—Air Oven Method), Method 46-30.01 (Crude Protein—Combustion Method), Method 54-10.01 (Extensigraph Method), Method 10-09.01 (Basic Straight-Dough Bread-Baking Method-Long Fermentation), Method 10-05.01 (Measurement of volume by rapeseed displacement), Method 74-09.01 (Measurement of bread firmness by universal testing machine), AACC International, St. Paul, MN, USA.

- AACC International (2011) Approved methods of the American Association of Cereal Chemists International. Method 54-21.02. Rheological Behaviour of Flour by Farinograph: Constant Flour Weight Procedure. AACC International, St. Paul, MN, USA.

- Aoki K, Shen JY, Saijo T. Consumer reaction to information on food additives: evidence from an eating experiment and a field survey. J Econ Behav Organ. 2010 doi: 10.1016/j.jebo.2009.11.007. [DOI] [Google Scholar]

- Autio K, Flander L, Kinnunen A, Heinonen R. Bread quality relationship with rheological measurements of wheat flour dough. Cereal Chem. 2001;78:654–657. doi: 10.1094/cchem.2001.78.6.654. [DOI] [Google Scholar]

- Barak S, Mudgil D, Khatkar BS. Relationship of gliadin and glutenin proteins with dough rheology, flour pasting and bread making performance of wheat varieties. LWT-Food Sci Technol. 2013;51:211–217. doi: 10.1016/j.lwt.2012.09.011. [DOI] [Google Scholar]

- Bushuk W, Hlynka I. The bromate reaction in dough.1. Kinetic studies Cereal Chem. 1960;37:141–150. [Google Scholar]

- CDC (2015) Azodicarbonamide. https://www.cdc.gov/niosh/ipcsneng/neng0380.html. Accessed 02 Oct 2018

- Dewettinck K, Van Bockstaele F, Kuhne B, de Walle DV, Courtens TM, Gellynck X. Nutritional value of bread: Influence of processing, food interaction and consumer perception. J Cereal Sci. 2008;48:243–257. doi: 10.1016/j.jcs.2008.01.003. [DOI] [Google Scholar]

- Dowell FE, Maghirang EB, et al. Relationship of bread quality to kernel, flour, and dough properties. Cereal Chem. 2008;85:82–91. doi: 10.1094/cchem-85-1-0082. [DOI] [Google Scholar]

- Dubois DK. Dough strengtheners and crumb softeners. I. Definition and classification. Tech Bull Am Inst Bak. 1979;1:1–4. [Google Scholar]

- Eduardo M, Svanberg U, Ahrné L. Effect of hydrocolloids and emulsifiers on the shelf-life of composite cassava-maize-wheat bread after storage. Food Sci Nutr. 2016;4:636–644. doi: 10.1002/fsn3.326. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Finney KF. An optimized, straight-dough, bread-making method after 44 years. Cereal Chem. 1984;61:20–27. [Google Scholar]

- Finney KF, Barmore MA. Loaf volume and protein content of hard winter and spring wheats. Cereal Chem. 1948;25:291–312. [Google Scholar]

- Gray JA, Bemiller JN. Bread staling: molecular basis and control. Compr Rev Food Sci F. 2003;2:1–21. doi: 10.1111/j.1541-4337.2003.tb00011.x. [DOI] [PubMed] [Google Scholar]

- Hadnadev DT, Pojic M, Hadnađev M, Torbica A. The role of empirical rheology in flour quality control. In: Akyar I, editor. Wide spectra of quality control, 1st edn. Europe: InTech; 2011. pp. 335–360. [Google Scholar]

- He H, Hoseney R. Changes in bread firmness and moisture during long-term storage. Cereal Chem. 1990;67:603–605. [Google Scholar]

- Hutt CA, Sloan AE (2015) Coming clean: what clean label means for consumers and industry. https://www.globalfoodforums.com/wp-content/uploads/2015/04/Natural-to-Non-GMO-Regulators-Consumers-C.Adams_.pdf Accessed 02 Oct 2018

- Junge RC, Hoseney RC. A mechanism by which shortening and certain surfactants improve loaf volume in bread. Cereal Chem. 1981;58:408–412. [Google Scholar]

- Kurokawa Y, Maekawa A, Takahashi M, Hayashi Y. Toxicity and carcinogenicity of potassium bromate—a new renal carcinogen. Environ Health Persp. 1990;87:309–335. doi: 10.2307/3431039. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Lee KM, Shroyer JP, Herrman TJ, Lingenfelser J. Blending hard white wheat to improve grain yield and end-use performances. Crop Sci. 2006;46:1124–1129. doi: 10.2135/cropsci2005.07-0184. [DOI] [Google Scholar]

- Maghirang EB, Lookhart GL, et al. Comparison of quality characteristics and breadmaking functionality of hard red winter and hard red spring wheat. Cereal Chem. 2006;83:520–528. doi: 10.1094/cc-83-0520. [DOI] [Google Scholar]

- Pyler EJ, Gorton LA. Baking science and technology: volume I: fundamentals and ingredients. Kansas City: Sosland Publishing Co; 2008. [Google Scholar]

- Rogers DE, Hoseney RC. Breadmaking properties of DATEM Baker's Digest. 1983;57:12–16. [Google Scholar]

- Science of Baking . Module 2: ingredient technology. Manhattan: American Institute of Baking; 2010. [Google Scholar]

- Tsen CC. The reaction mechanism of azodicarbonamide in dough. Cereal Chem. 1963;40:638–647. [Google Scholar]

- U.S. HRS crop quality report (2017) https://www.uswheat.org/cropQuality/doc/4DB84BAFA206D2F9852581C2006F0C4D/$File/cqr2017-en.pdf?OpenElement, Accessed 02 Oct 2018

- Wang YG, Khan K, Hareland G, Nygard G. Quantitative glutenin composition from gel electrophoresis of flour mill streams and relationship to breadmaking quality. Cereal Chem. 2006;83:293–299. doi: 10.1094/cc-83-0293. [DOI] [Google Scholar]

- Wieser H. Chemistry of gluten proteins. Food Microbiol. 2007;24:115–119. doi: 10.1016/j.fm.2006.07.004. [DOI] [PubMed] [Google Scholar]

- Zeleznak KJ, Hoseney RC. The role of water in the retrogradation of wheat-starch gels and bread crumb. Cereal Chem. 1986;63:407–411. [Google Scholar]