Abstract

The effects of ozone treatment on microorganism and volatile substances of wheat bran, as well as on the quality of fresh noodles made from wheat flour supplemented with ozone treated wheat bran were studied in this paper. Results showed that the optimized condition of ozone treatment was 50 min treatment time and optimized condition of bran properties were 15% moisture content, 15 mesh particle size. Under the optimized condition microbial contents in the wheat bran can be reduced more than 90% after ozone treatment. There was no significant increase in microbial contents of treated wheat bran during storage, whereas the types of volatile substances were gradually decreased. After the ozone treated wheat bran was added back to wheat flour and used for fresh noodles preparation, there were relatively few changes in the quality of the fresh noodles but the shelf life was prolonged as compared to the untreated bran.

Keywords: Wheat bran, Ozone treatment, Storage, Microbial content, Volatile substance, Noodles quality

Introduction

Wheat is one of the earliest cultivated cereal crops in the world. Among the world's total grain output, wheat ranks first. China is the major producer of wheat and the amount of wheat per year has been exceeded 120 million tons at present. Wheat bran is the main processing by-product of wheat flour mills, and its annual output can reach more than 20 million tons, but most of the wheat bran has been used for feed (Hemdane et al. 2016), which reduced the value-added of the wheat bran (Prückler et al. 2014). Wheat bran is rich in dietary fiber, protein, vitamin, minerals and bioactive compounds, so it has important nutritional and health functions (Hemdane et al. 2016). Therefore, the investigation of the quality of pan bread (Gómez et al. 2003), steamed bread (Shu-Guo et al. 2008), biscuits (Sudha et al. 2007), spaghetti (Chillo et al. 2008) and Asian noodles (Inglett et al. 2005) after addition of the wheat bran are increasing.

As the outer epidermis of wheat grains, bran contacted more closely with the environment compared to other part of grains. Therefore, the microorganisms count currently found in wheat bran are relatively high. The microorganisms currently found in wheat are mainly bacteria of the genera Pseudomonas, Micrococcus, Lactobacillus and Bacillus, and molds such as Aspergillus, Penicillium, Streptomyces and their mycotoxins. These microorganisms are mainly found on the surface of the grains, and only a few microbial species appear in the interior of grain seeds via embryos or due to mechanical damage (Olson and Nottingham 1980). The important nutrient composition, microbial status and pesticide residues of wheat bran have analyzed by Santala et al. (2011), Berghofer et al. (2003), Kolberg et al. (2011), respectively, they found that microorganisms mainly exist in the wheat epidermis. Excessive microbiological content will affect the application of wheat bran in foods. Therefore, it is necessary to find an economical, efficient and convenient method to reduce the microorganisms in wheat bran.

Owing to the highly reactive and the strong oxidizing property, ozone can cause an increase in reactive oxygen species in living cells, which in turn lead to oxidative stress in cells. Therefore, it is one of the most effective disinfectants (Bai et al. 2017; Li et al. 2013). In addition, in aqueous solution, ozone can decompose rapidly (half-life of 20–50 min) to molecular oxygen without leaving a toxic residue under ambient temperature and pressure (Chittrakorn 2008), so ozone treatment is a green, safe method of sterilization. The application of ozone technology in flour processing can effectively reduce the amount of microorganisms in the flour, but there would be an existence irritating odor (Li et al. 2013). There have been several researches about ozone treatment on wheat flour (Min et al. 2017), wheat bran and wheat germ (Li et al. 2013; Zhu 2018). Alexandre et al. (2018) reported that ozone treatment was a possible method for reducing mycotoxins in wheat bran yet did not affect the nutritional quality such as total phenolic content and antioxidant capacity of the bran. Noodles are one of the main traditional foods in China, and account for about 30–35% of the total consumption of wheat flour (Chen et al. 2011). In recent years, fresh noodles are more popular among consumer due to their rich nutrition and high chewiness quality. The application of the wheat bran in the fresh noodles was limited because of the high microbiological contents. The objectives of this work were to study the effect of ozone treatment on microorganism and volatile substance in wheat bran. In addition, the quality and shelf-life of fiber-rich fresh noodles made from wheat flour supplemented with ozone treated bran were also discussed.

Materials and methods

Materials

The sample was hard wheat named Yannong 19 which purchased from Anhui Golden Land Electronics Co., Ltd. These samples were ground in a laboratory mill (Model MLU-202, Bühler) to obtain wheat bran according to AACC (2000) method after tempering for 24 h at 16% moisture content for hard wheat. The flour extraction rate was about 70%. The remained bran fraction (30% of wheat weight) was collected and used as raw material in the following sections.

The contents of moisture, ash, crude fat, crude starch, crude protein, phytic acid, total dietary fiber and soluble dietary fiber were 10.16%, 4.67%, 3.57%, 22.76%, 17.41%, 4.47%, 31.79% and 2.15% on a dry basis of the whole wheat bran, respectively, they were analyzed according to the AACC methods (AACC 2000). Wheat flour was purchased from Tiandi Flour Industry Co., Ltd, Zhengzhou, China.

Ozone treatment

The moisture content of the wheat bran with particle size of 20 meshes was adjusted to 10%, 15%, 20%, 25% and 30%, respectively by a humidifier through spraying water vapor and treated for 40 min to investigate the effect of moisture content. In the case of the effect of particle size, the wheat bran with varied particle sizes (8 mesh, 15 mesh, 20 mesh and 40 mesh), which was obtained by passing through different mesh sieves, was adjusted to 20% moisture content and treated for 40 min. To investigate the effect of treating time, the condition of particle size and moisture was fixed at 20 meshes and 20% moisture content, the wheat bran was treated at different times (20 min, 30 min, 40 min, 50 min and 60 min, respectively). The ozone gas treatment was conducted using an ozone generator (Model OPV-Y 100 s, Shandong, China) with a production of 10 g/h. About 80 g wheat bran was placed in an automatic revolving evaporation bottle (Model RE 52-99, Shanghai, China) to ensure a homogeneous contact between bran and ozone during the reaction with a constant airflow rate of 5 L/min for a preset time. Two silicone hoses were connected to the bottle with one for importing the ozone gas and the other for exhausting the waste gas to the outside. There were two single samples exposed for the next analysis. After treated with ozone, the wheat bran was spread on a small tray and placed in a fume cupboard at room temperature for further analysis.

Determination of microorganisms

The microorganisms of samples were analyzed periodically by using microbiological test kit (Oasis Biochemical Co., Ltd, Guangdong, China). About 25 g of the sample was removed and placed into 225 mL 0.85% aseptic physiological saline, and the mixture was homogenized using an emulsification isotropic machine (Model FSH-2A, China) for 2 min. A series of tenfold dilution were made using aseptic physiological saline, and 1 mL of the appropriate dilutions was poured onto the test kit to determine the total plate count, Escherichia coli, molds and yeasts, respectively. The total plate count test kit and the Escherichia coli test kit were incubated at 36 °C for 24 h. The molds and yeasts test kit was incubated at 28 °C for 48 h. Analyses were run in triplicate.

Volatile compound analysis

Solid phase microextraction (SPME)

An aliquot of 1.0 g of the wheat bran was hermetically sealed in a 20 mL screw top amber vial with a polypropylene hole cap, and before sampling, each fiber was eluted for 1 h in the gas chromatography (GC) injector port at 230 °C, then the fiber was used to extract the volatile organic compounds at 40 °C for 35 min. The SPME was immediately inserted into the gas chromatography-mass spectrometer (GC–MS) injector and desorbed for 3 min.

The GC–MS determination results were searched by the NIST 08. L mass spectrometry library through the Chem Station data processing system. Qualitative analysis was performed on components with a peak area matching degree of more than 80% to determine the volatile components and the peak area normalization method was used to calculate the relative content of each component.

GC–MS conditions

The gas chromatography separation was performed on a 30 m DB-WAX fused silica capillary column with 0.25 mm inner diameter and 0.25 μm film thickness. The column was maintained at 40 °C for 3 min after injection, then increased at 5 °C min−1 to 80 °C, and then raised to 230 °C at 10 °C min−1, maintained for 7 min. Splitless injection was performed with helium as the carrier gas with a constant flow rate of 1 mL min−1. Injector, transfer line temperature and ion-source temperature were 230, 280 and 200 °C, respectively. All mass spectra were acquired in electron-impact (EI) mode.

Noodles preparation and storage

Fresh noodle samples were prepared according to SB/T10137-93 (1993) with some modification. All equipment (flour mixer, roller and cutter) was sterilized with 75% alcohol (ethyl alcohol) before used. The fresh noodles were made according to the following dough formulation: the total mass of the flour was 100 g, wheat flour were 90, 85, 80, and 75 g, the wheat bran were 10, 15, 20 and 25 g respectively corresponding to the amount of the total flour. The water amount of all the flour-bran blend were adjusted to 33% (total flour basis) by adding distilled water (T = 30 °C). All ingredients were mixed in the flour mixer (JHMZ 200, East Fude Technology Development Center, Beijing) for 7 min at the speed of 104 rpm. The obtained dough crumbles were resting in a sterilized and resalable plastic bag for 20 min at room temperature (25 °C). After that, the dough was sheeted eight times using a roller (JMTD-168/140, Beijing Laboratory Equipment Instrument Technology Co., LTD, Beijing, China). The roll gap was 2 mm at the first pass, and then adjusted the roll gap to 3.5 mm, the doubled folded dough passed through the second time. Following that, there were more than five passes to make until the gap progressively reduced to 1 mm. Finally, the noodles with 10 or 18 mm length and 2 mm wide was made by cutting the sheeted dough using a cutter and then placed the noodles in a vacuum pack bag, and before cooking, the noodles were stored at room temperature (25 °C) and cold temperature (4 °C), respectively, for no longer than 24 h.

Noodles quality evaluation

There were 500 mL tap water in a small aluminum pan (diameter of 20 cm), and the water was boiled in a 2000 W electric stove. The fresh noodle samples which prepared before were added to the pot and then cooked to the optimum cooking time (the time required for the opaque central core of the noodle to disappear when squeezed gently between two glass plates) (Suhendro et al. 2000). After that, the noodles were taken out immediately and washed about 10 s with flowing distilled water, then the samples were put in the bowl for the sensory evaluation. The sensory evaluation standard was based on SB/T10137-93. All samples with randomized numbers were tested by a taste panel consisted of five experts at the same time. They are scored in terms of color (10 points), appearance (10 points), palatability (20 points), toughness (25 points), stickiness (25 points), smoothness (5 points) and taste (5 points) for a total score of 100 points.

For texture profile analysis (TPA) and tensile test, noodles (20 strips, 10 cm in length for a compressive test; 12 strips, 18 cm in length for tensile test) were cooked in 500 mL of boiling distilled water for 4 min. Then, the cooked noodles were placed in 200 mL water (20 °C) for 1 min and drained for 30 s, immediately followed by compressive tests using the TA-XT 2i texture analyzer (Scarsdale, NY, USA; Stable Micro Systems, Surrey, UK).

Texture profile analysis of cooked noodles was performed with the HDP/PFS probe. The optimal test conditions were the following: the compression mode was trigger type, auto-5 g; the pretest speed, post-test speed, and test speed were 2.0 mm/s, 0.8 mm/s, 0.8 mm/s, respectively; the strain was 75% and the interval between two compressions was 5 s. Five texture parameters of the force distance curves can be obtained: hardness (g), springiness, cohesiveness (g), chewiness (g) and resilience. Six determinations were conducted, with the high and low values discarded, so that data were the means for four strands (Lu et al. 2009).

The tensile test of cooked noodles was performed with the A/SPR probe. The conditions of the test were the following: the extension mode was trigger type, auto-0.5 g; the pretest speed, post-test speed and test speed were 2.0 mm/s, 10.0 mm/s, 2.0 mm/s, respectively. For each sample, six determinations were conducted, with the high and low values discarded, so that data were the means for four strands.

The cooking process of noodles for water absorption and the cooking loss test was similar to that for TPA test, except that 200 mL distilled water and 20 g noodles was used. After the optimum cooking time, the cooked noodles were washed with distilled water, drained in the gauze for 5 min and weighted immediately. The cooking water was collected and its volume adjusted to 500 mL with distilled water. An aliquot (50 mL) of the diluted cooking water was then transferred to a beaker (pre-dried to a constant weight) and dried in an air oven at the 105 °C until to constant weight.

Water uptake (g/g) was calculated by subtracting the initial sample weight from the cooked sample weight and dividing by the initial sample weight. Cooking loss was calculated by dividing the weight of dry solids left in the beaker after cooking by the initial sample weight.

Statistical analysis

The results were expressed as mean value ± standard deviations of the individual measurements. Analysis of variance (ANOVA) was performed using SPSS ver. 20.0 for Windows (SPSS Institute, Cary, NC). Significance of differences was defined at P < 0.05 with Duncan’s multiple range test.

Results and discussion

Effect of ozone treatment on microbial quantity of wheat bran

The content of the total plate count Escherichia coli, yeasts and molds in the raw material Yannong 19 wheat bran were 1.98 × 104 CFU/g, 8.76 × 103 MPN/g, 4.21 × 103 CFU/g and 2.41 × 103 CFU/g, respectively, and the contents of microorganism were within the range which proposed by Berghofer et al. (2003).

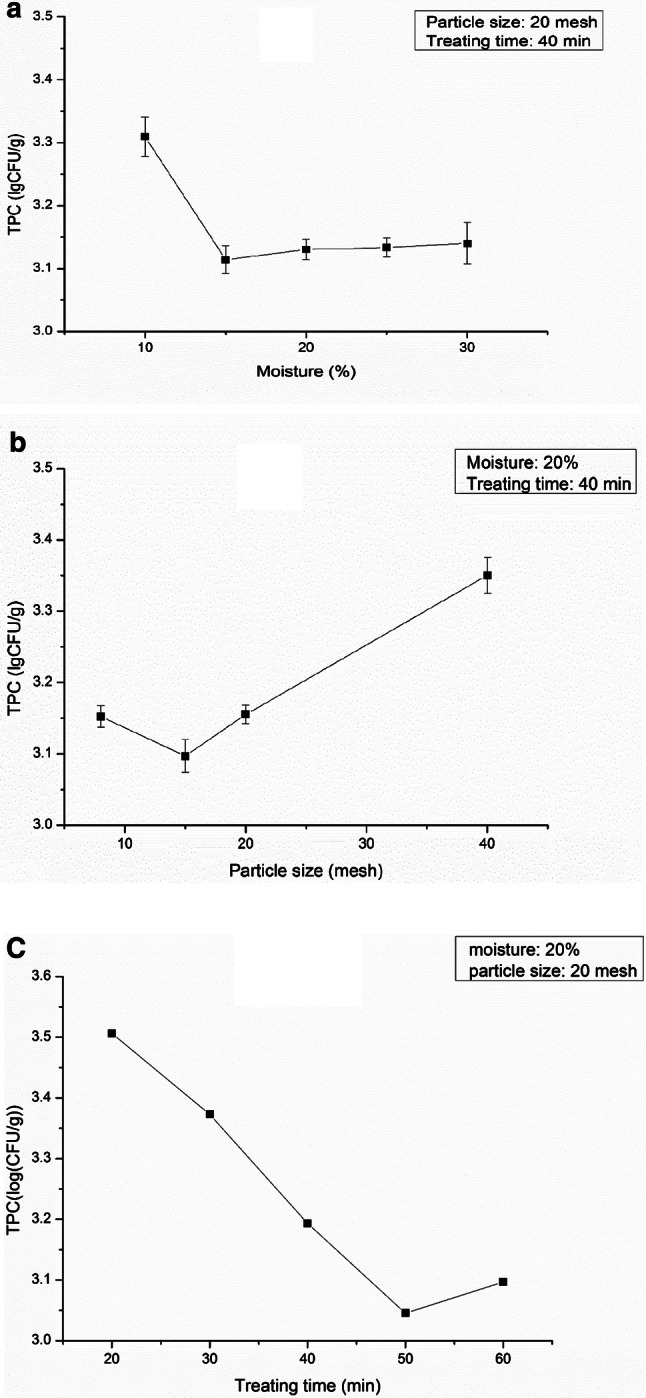

The effect of wheat bran moisture, particle size and ozone treating time used for ozone treatment for the total plate count of wheat bran are shown in Fig. 1. As shown in Fig. 1a, with the increase of the moisture content in the bran, the total plate count decreased first and then increased slightly. When the moisture content was 15%, the total plate count was the lowest. The decrease tendency of total plate count of bran as moisture content increased could be attributed to that ozone decomposed in aqueous solution to hydrogen peroxide, superoxide and hydroxyl radicals which can take part in a secondary reaction (Zorlugenç et al. 2008) and enhance the sterilization intensity. In addition, ozone was thought to kill microorganisms by oxidation of polyunsaturated fatty acids to acid peroxides and oxidation of cellular components such as sulfhydryl groups, amino acids of enzymes, proteins and peptides (Young and Setlow 2010; Zorlugenç et al. 2008). The cell membrane of the bacteria was easily swelled and thinned in high moisture contents, unsaturated lipids of the cell membrane were degraded by ozone, result in cell disruption and subsequent leakage of cellular contents (Elif et al. 2006). The slight increase of the total plate count after the moisture content exceed 15% may be due to the formation of some lumps at the higher water content which prevent the entry of ozone into the interior of lump.

Fig. 1.

The effect of wheat bran moisture, particle size and ozone treating time during ozone treatment on the total plate count

According to Fig. 1b, the total plate count decreased first and then increased as the bran particle size decreased. This might be due to the fact that the particle size of wheat bran has a direct impact on the contact area between ozone and bran, thus affecting the sterilization effect of ozone on bran. Too large size would lead to a small specific surface area of wheat bran, which was disadvantageous for sterilization, while too small size would lead to the formation of lumps, resulting in the prevention of ozone entering the interior of wheat bran effectively (Wang et al. 2018).

Figure 1c showed that the total plate count of the bran decreased with the increase of treating time, and after 50 min of the ozone treatment, the total plate count tended to be stable. The results implied that most of the microbes on the surface of the bran have been killed during treating, while a certain amount of living bacteria inside the bran were difficult to be killed.

From the above experiments, the optimal ozone treatment condition was 50 min treatment time and optimized condition of bran properties were 15% moisture content, 15 mesh particle size. The total plate count of wheat bran after ozone treatment decreased from 1.98 × 104 to 9.06 × 102 CFU/g.

Microbial changes of ozone-treated wheat bran during storage

As a strong oxidizing agent, ozone has been used in the food industry, since it can penetrate cell membranes and cause damage to cells, ozone has none-thermal, lethal effects on microorganisms (Li et al. 2012). Figure 2 showed the total plate count changed in ozone treated wheat bran during storage for one month. As shown in Fig. 2, microbial content, including total plate count, Escherichia coli, mold and yeast of wheat bran decreased rapidly after ozone treatment and then had a slight but not significant increase with the extension of storage time. The change in microbial content may be due to the fact that under ambient temperature and pressure the ozone can decompose into oxygen (Min et al. 2017), resulting in a decrease of bacteriostatic effect and thus reproduction of microorganisms. Results confirmed that the ozone treatment can effectively reduce the microbial content in the bran, and the microbial content did not increase significantly after the storage of one month.

Fig. 2.

Variation of microbial content in ozone treated wheat bran during storage (unit: the total plate count, molds and yeasts were CFU/g; coliform group was MPN/g)

Volatile compound of ozone-treated wheat bran during storage

Ozone treatment may impart some unpleasant smell to wheat bran due to the unique odor itself, this severely affects the sensory qualities of wheat bran and its further use in foods. Li et al. (2012) reported that ozone-treated wheat flour also produced this odor, and the odor was increased with the increase of treating time. To identify the main compounds associated with the odor changes induced by ozone treatment, the volatile compounds of wheat bran were adsorbed onto the extraction fiber syringes by headspace solid-phase microextraction and analyzed by GC–MS (Table 1).

Table 1.

The main volatile compound of ozone treated wheat bran during storage

| Retention Time/min | Molecular formula | Compounds | Relative content (%) | |||

|---|---|---|---|---|---|---|

| Control | 1d | 7d | 30d | |||

| 3.36 | C6H12O | Hexanal | – | 55.48 | 37.76 | 34.19 |

| 5.18 | C6H14O | Hexanol | 14.49 | – | – | – |

| 7.85 | C7H6O | Benzaldehyde | 2.86 | – | – | – |

| 8.82 | C12H26 | 2,2,4,6,6-pentamethylheptane | 6.27 | – | – | – |

| 9.98 | C9H16O | (Z)-2-nonenal | – | 0.18 | 0.26 | 1.58 |

| 10.91 | C4H9NO2 | Butyl nitrite | – | – | – | 11.97 |

| 11.05 | C8H14O | Trans-2-octenal | 1.45 | 2.43 | 3.78 | – |

| 11.44 | C6H12O2 | Hexanoic acid | – | 2.77 | – | – |

| 12.31 | C10H22 | N-decane | 2.89 | – | – | – |

| 12.39 | C9H18O | Nonanal | 35.3 | 12.35 | 27.78 | 25.56 |

| 13.66 | C9H16O | (E)-Nonal | 1.62 | 2.49 | 2.2 | 0.83 |

| 14.42 | C12H26 | 2-methylundecane | 7.8 | 0.28 | 0.09 | – |

| 14.53 | C12H24O | Dodecaldehyde | 0.72 | 3.30 | 3.82 | 1.12 |

| 15.915 | C9H18O2 | Tannic acid | – | 0.850 | 1.43 | 1.93 |

| 16.295 | C14H28O | 1,2-epoxytetradecane | 3.67 | 0.310 | 0.51 | 0.26 |

GC–MS results showed that the type and content of volatile substances in wheat bran can be changed by ozone treatment. A total of 67 volatile compounds was detected from the ozone-treated wheat bran and control group. There were 29, 34, 30, and 24 species detected in untreated samples and treated samples stored for 1 days, 7 days and 30 days, respectively. As shown in Table 1, partial alcohols and alkanes were oxidized into aldehydes, ester and acids due to the strong oxidizing property of ozone, which increased the total kinds of volatile compounds collected in the samples. Similar conclusion also reported by Obadi et al. (2017) for bread products made from ozonized wheat flour. However, with the prolongation of storage time, the type of volatile substances was significantly reduced. This result was in agreement with that of Chittrakorn et al. (2008).

Volatile nonanal, hexanol, 2-methylundecane and 2, 2, 4, 6, 6-pentamethylheptane were found to be the major compounds in untreated wheat bran. After 1 day and 7 days’ storage, obvious changes in the types of major volatile compounds were detected in ozone treated samples, and hexanal, nonanal and dodecanal became the major compounds. After 30 days’ storage, the major compounds were hexanal, nonanal and butyl nitrite. The strong oxidizing property and instability of ozone during storage changed the flavor substance and composition in wheat bran, and the largest change was found for hexaldehyde, which has a strong irritating odor. Therefore, the irritating smell of ozone treated wheat bran might be positively related to hexaldehyde. With the prolongation of storage time, the content of hexaldehyde decreased gradually, and the butyl nitrite was easy to decompose. Compared to the beginning of the process, the smell has decreased after 30 days of storage.

Quality of noodles made by flour supplemented with ozone-treated wheat bran

The ozone-treated wheat bran was added back to the wheat flour. Thereafter, the bran-rich wheat flour was used to prepare the fresh noodles and their qualities were evaluated. The tensile properties of the noodles were shown in Table 2. With the increase of the amount of untreated bran, the breaking force and stretching distance increased first and then decreased. When the added amount was 15%, the stretching distance was the largest and the extension of the noodles was the best. This may be due to the fact that there was an appropriate amount of dietary fiber. During the cooking process, the dietary fiber absorbs water and expands, making the starch granules and protein gluten network tightly integrated, which reinforced the network structure and increased the tensile index of the noodles. Dietary fiber has high water holding capacity and can compete for free water with starch and protein in the dough matrix (Tsilo et al. 2013). Nevertheless, excessive competition, along with increasing ozone-treated wheat bran, can lead to the incomplete hydration of starch and protein and thus hinder the formation of the gluten network (Li et al. 2016a, b), therefore, the quality of the noodles was affected.

Table 2.

TPA and tensile properties of fresh noodles supplemented by wheat bran with and without ozone treatment

| Sample | Hardness (g) | Springiness | Adhesiveness (g) | Chewiness (g) | Resilience | Tensile force (g) | Stretch distance (mm) | |

|---|---|---|---|---|---|---|---|---|

| Process mode | Additive amount (%) | |||||||

| Untreated | 10 | 4242.21 ± 22.92 g | 0.77 ± 0.03a | 0.58 ± 0.02a | 1962.35 ± 22.90b | 0.27 ± 0.02ab | 8.53 ± 0.19c | 28.78 ± 0.26d |

| 15 | 4669.02 ± 13.61f | 0.64 ± 0.03d | 0.51 ± 0.00bcd | 1481.59 ± 18.24f | 0.23 ± 0.01ab | 9.12 ± 0.09b | 31.23 ± 0.24b | |

| 20 | 4960.61 ± 17.37e | 0.67 ± 0.03 cd | 0.48 ± 0.02 cd | 1583.07 ± 14.11e | 0.23 ± 0.01ab | 6.63 ± 0.08f | 26.77 ± 0.15e | |

| 25 | 5340.14 ± 15.54c | 0.71 ± 0.01bc | 0.50 ± 0.00bcd | 1961.59 ± 36.39b | 0.26 ± 0.01ab | 5.48 ± 0.12 g | 23.96 ± 0.06f | |

| Ozone treatment | 10 | 4924.10 ± 15.75e | 0.73 ± 0.01ab | 0.55 ± 0.02ab | 1896.62 ± 6.54c | 0.28 ± 0.00a | 7.70 ± 0.19d | 30.00 ± 0.19c |

| 15 | 5119.71 ± 24.61d | 0.63 ± 0.01d | 0.53 ± 0.05abc | 1741.58 ± 24.64d | 0.27 ± 0.05ab | 10.40 ± 0.36a | 34.65 ± 0.16a | |

| 20 | 5561.15 ± 33.37b | 0.75 ± 0.02ab | 0.54 ± 0.01abc | 2256.57 ± 7.01a | 0.27 ± 0.00a | 7.43 ± 0.23d | 28.62 ± 0.18d | |

| 25 | 5764.19 ± 36.97a | 0.74 ± 0.01ab | 0.45 ± 0.01d | 1934.74 ± 21.60bc | 0.22 ± 0.00b | 6.98 ± 0.06e | 23.54 ± 0.36 g | |

Different letters in the same column are significantly different (P < 0.05). Mean ± SD is calculated from six measurements

Under the same added amount of wheat bran, noodles made from ozone-treated wheat bran had high extension distance (except the amount of 25%) and tensile force (except the amount of 10%). It had been shown that an increase in the amount of disulfide bonds cross-linking of protein polymers by sulphydryl group oxidization would strengthen the gluten matrix (Chittrakorn 2008; Li et al. 2012; Obadi et al. 2016; Zhu 2018). Furthermore, by significantly affecting the molecular properties of proteins in wheat bran, ozone leads to profound changes in the rheological properties of the obtained dough (Gozé et al. 2017), which in turn increased the breaking force and stretching distance of noodles.

Textural qualities are important concerns of consumers for noodle products (Liu et al. 2014). Table 2 shows the effect of supplementation of different proportion of ozone-treated and untreated bran on noodle texture characteristics (TPA). As can be seen from Table 2, the noodles prepared from flour added with ozone-treated wheat bran had higher hardness, when the additive amount of the bran was 15% and 20%, chewiness has a similar tendency with hardness. It had been shown that wheat bran can increase the hardness of noodles. This might be due to the fact that the addition of dietary fiber-rich bran could change the distribution of moisture in the dough and then change the secondary structure of gluten by the increase of β-sheet structure, which probably strengthened the hardness of the noodles (Wen et al. 2018). What’s more, compared to untreated bran, after ozone treatment, the increase of hardness may also be due to the cross-linking of bran proteins to form macromolecule polymers and these polymers strengthened the gluten network (Mudgil et al. 2016). Chewiness is the energy needed to break down the noodles to the swallowing state, which is related to the hardness and cohesiveness. It is an indicator that a texture analyzer simulates a person’s feeling when chewing noodles. A better taste of noodle needs moderate chewiness. It can be seen from the Table 2 that the chewiness of the noodles with ozone-treated bran was decreased first and then increased, the decrease may be due to the fact that the gluten structure was destroyed by the wheat bran. On the contrary, with the increase of bran content, the increase in chewiness may be because the increasing effect of wheat bran itself on chewiness exceeded its destructive effect on gluten protein.

The effect of supplement of ozone-treated and untreated bran on water absorption, cooking loss, and sensory score characteristics of noodles were summarized in Table 3. Results showed that the addition of a low proportion of ozone-treated bran increased the water absorption of the noodles and decreased the cooking loss, and an opposite trend occurred when a high proportion of ozone-treated bran was added. When the added amount of ozone-treated bran was relatively low, the increase of the water absorption of the noodles may be due to the higher hydrophilicity of dietary fiber in the bran, and the strong oxidation of ozone may strengthen the gluten network and cause a better encapsulation of starch granules, which inhibited the swelling of starch granules, thereby reducing the cooking loss of noodles. When the added amount of ozone-treated bran was relatively high, a large amount of dietary fiber in wheat bran would destroy the structure of gluten network, and the exposing of the starch outside of the gluten increased the cooking loss of noodles, the result was in agreement with earlier reports (Çatal and İbanoğlu 2014).

Table 3.

Water absorption, cooking loss and sensory score of fresh noodles supplemented by wheat bran with and without ozone treatment

| sample | Water absorption (%) | Cooking lost rate (%) | Sensory score | |

|---|---|---|---|---|

| Process mode | Additive amount (%) | |||

| Untreated | 10 | 100.11 ± 0.57b | 8.54 ± 0.03a | 78.25 ± 3.71ab |

| 15 | 75.93 ± 0.01e | 5.73 ± 0.15e | 77.20 ± 0.95ab | |

| 20 | 88.43 ± 1.88d | 6.00 ± 0.03de | 74.08 ± 3.75bcd | |

| 25 | 103.67 ± 1.29a | 6.77 ± 0.08c | 69.53 ± 3.84cd | |

| Ozone treatment | 10 | 103.96 ± 0.47a | 6.16 ± 0.15d | 79.93 ± 4.77a |

| 15 | 93.78 ± 0.24c | 5.67 ± 0.14e | 77.28 ± 1.54ab | |

| 20 | 91.95 ± 1.19cd | 6.53 ± 0.43cd | 74.45 ± 1.24bc | |

| 25 | 93.69 ± 0.26c | 7.01 ± 0.12b | 70.75 ± 1.01cd | |

Different letters in the same column are significantly different (P < 0.05). Mean ± SD is calculated from two measurements

The sensory score of noodles was decreased with the increasing amount of ozone treated bran, which may be due to the fact that the addition of bran destroyed the gluten network causing the deterioration of the quality of the noodles. The supplement of ozone-treated bran made flour has irritating odor, however, there was no significant difference in sensory score compared to noodles from untreated bran, indicating that the cooking process further reduces the irritating odor substances to a consumer-acceptable level.

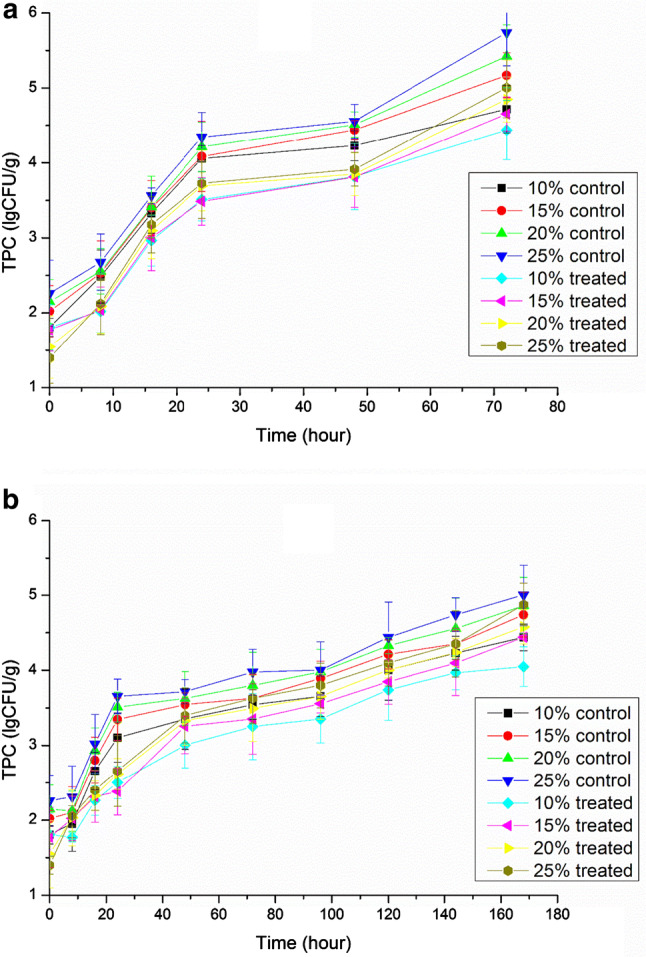

The shelf life of fresh noodles

Figure 3 showed the results of microbial changes in fresh noodles during storage at room temperature (25 °C) and low temperature (4 °C). As can be seen from Fig. 3, the total plate count in noodles was proportional to the amount of wheat bran added. Under the same treatment conditions, when the total plate count reached 104 CFU/g, the storage period of fresh noodles with added 10% ozone-treated wheat bran reached 7 days at 4 °C (Fig. 3b), while 2 days at 25 °C (Fig. 3a). Therefore, low temperature further inhibited the growth of microorganisms. Results showed that the total plate count of ozone treated bran supplemented noodles was lower than those of noodles supplemented with untreated bran during the storage, and the decreasing amplitude was nearly 1.0 log CFU/g. Therefore, the ozone treatment of wheat bran can significantly inhibit the growth of microorganisms in fresh noodles supplemented with wheat bran. The result of inhibiting the microorganism growth of ozone was in accordance with the findings of Bai et al. (2017), who studied the effect of aqueous ozone on the initial microbial counts of newly produced semi-dried buckwheat noodles, and reported that an initial TPC reduction of 1.8 log CFU/g after 50 min aqueous ozone treatment.

Fig. 3.

Changes of the total plate count in bran-rich fresh noodle during storage. a for room temperature (25 °C) and b for 4 °C

Conclusion

The treatment conditions such as moisture content, particle size and treatment time all had an important impact on the modified effect of ozone on wheat bran. The ozone treatment can significantly reduce the microbial content in wheat bran and the degree of reduction was nearly 90%. After storage for 30 days, there was no significant increase in the count of microorganisms. Volatile substances increased immediately after ozone treatment, but the species decreased during the storage and it was found that the irritating odor might be related to the production of hexanal, which might be removed during the cooking process of the noodles. Compared with the untreated bran, the ozone treatment of wheat bran had little effect on the quality of fresh noodles supplemented with treated wheat bran, especially for the sensory scores, while the ozone treatment could significantly prolong the shelf life of these fresh noodles.

Acknowledgements

This work was supported by the National Natural Science Foundation of China (No. U1604235), the Special Fund for Henan Agriculture Research System (No. S2017-01-G06) and the Key Scientific and Technological Research Projects of Henan Education Department (No. 13B550948).

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- AACC . Approved methods. USA: American Association of Cereal Chemists; 2000. [Google Scholar]

- Alexandre APS, Velaparedes RS, Santos AS, Costa NS, Canniattibrazaca SG, Caloridomingues MA, Augusto PED. Ozone treatment to reduce deoxynivalenol (DON) and zearalenone (ZEN) contamination in wheat bran and its impact on nutritional quality. Food Addit Contam A. 2018;35:1189–1199. doi: 10.1080/19440049.2018.1432899. [DOI] [PubMed] [Google Scholar]

- Bai YP, Guo XN, Zhu KX, Zhou HM. Shelf-life extension of semi-dried buckwheat noodles by the combination of aqueous ozone treatment and modified atmosphere packaging. Food Chem. 2017;237:553–560. doi: 10.1016/j.foodchem.2017.05.156. [DOI] [PubMed] [Google Scholar]

- Berghofer LK, Hocking AD, Miskelly D, Jansson E. Microbiology of wheat and flour milling in Australia. Int J Food Microbiol. 2003;85:137–149. doi: 10.1016/S0168-1605(02)00507-X. [DOI] [PubMed] [Google Scholar]

- Çatal H, İbanoğlu Ş. Effect of aqueous ozonation on the pasting, flow and gelatinization properties of wheat starch. LWT Food Sci Technol. 2014;59:577–582. doi: 10.1016/j.lwt.2014.04.025. [DOI] [Google Scholar]

- Chen JS, Fei MJ, Shi CL, Tian JC, Sun CL, Zhang H, Ma Z, Dong HX. Effect of particle size and addition level of wheat bran on quality of dry white Chinese noodles. J Cereal Sci. 2011;53:217–224. doi: 10.1016/j.jcs.2010.12.005. [DOI] [Google Scholar]

- Chillo S, Laverse J, Falcone PM, Protopapa A, Nobile MAD. Influence of the addition of buckwheat flour and durum wheat bran on spaghetti quality. J Cereal Sci. 2008;47:144–152. doi: 10.1016/j.jcs.2007.03.004. [DOI] [Google Scholar]

- Chittrakorn S (2008) Use of ozone as an alternative to chlorine for treatment of soft wheat flours. Dissertations and Theses, Gradworks

- Elif D, Candan Gürakan G, Alev B. Effect of controlled atmosphere storage, modified atmosphere packaging and gaseous ozone treatment on the survival of Salmonella Enteritidis on cherry tomatoes. Food Microbiol. 2006;23:430–438. doi: 10.1016/j.fm.2005.08.002. [DOI] [PubMed] [Google Scholar]

- Gómez M, Ronda F, Blanco CA, Caballero PA, Apesteguía A. Effect of dietary fibre on dough rheology and bread quality. Eur Food Res Technol. 2003;216:51–56. doi: 10.1007/s00217-002-0632-9. [DOI] [Google Scholar]

- Gozé P, Rhazi L, Lakhal L, Jacolot P, Pauss A, Aussenac T. Effects of ozone treatment on the molecular properties of wheat grain proteins. J Cereal Sci. 2017;75:243–251. doi: 10.1016/j.jcs.2017.04.016. [DOI] [Google Scholar]

- Hemdane S, Langenaeken NA, Jacobs PJ, Verspreet J, Delcour JA, Courtin CM. Study of the intrinsic properties of wheat bran and pearlings obtained by sequential debranning and their role in bran-enriched bread making. J Cereal Sci. 2016;71:78–85. doi: 10.1016/j.jcs.2016.08.003. [DOI] [Google Scholar]

- Inglett GE, Peterson SC, Carriere CJ, Maneepun S. Rheological, textural, and sensory properties of Asian noodles containing an oat cereal hydrocolloid. Food Chem. 2005;90:1–8. doi: 10.1016/j.foodchem.2003.08.023. [DOI] [Google Scholar]

- Kolberg DI, Prestes OD, Adaime MB, Zanella R. Development of a fast multiresidue method for the determination of pesticides in dry samples (wheat grains, flour and bran) using QuEChERS based method and GC–MS. Food Chem. 2011;125:1436–1442. doi: 10.1016/j.foodchem.2010.10.041. [DOI] [Google Scholar]

- Li M, Zhu K-X, Wang B-W, Guo X-N, Peng W, Zhou H-M. Evaluation the quality characteristics of wheat flour and shelf-life of fresh noodles as affected by ozone treatment. Food Chem. 2012;135:2163–2169. doi: 10.1016/j.foodchem.2012.06.103. [DOI] [PubMed] [Google Scholar]

- Li M, Peng J, Zhu K-X, Guo X-N, Zhang M, Peng W, Zhou H-M. Delineating the microbial and physical–chemical changes during storage of ozone treated wheat flour. Innov Food Sci Emerg. 2013;20:223–229. doi: 10.1016/j.ifset.2013.06.004. [DOI] [Google Scholar]

- Li Q, Liu R, Wu T, Zhang M. Soluble dietary fiber fractions in wheat bran and their interactions with wheat gluten have impacts on dough properties. J Agr Food Chem. 2016;64:8735–8744. doi: 10.1021/acs.jafc.6b03451. [DOI] [PubMed] [Google Scholar]

- Li Q, Liu R, Wu T, Wang M, Zhang M. Soluble dietary fiber fractions in wheat bran and their interactions with wheat gluten have impacts on dough properties. J Agric Food Chem. 2016;64(46):8735–8744. doi: 10.1021/acs.jafc.6b03451. [DOI] [PubMed] [Google Scholar]

- Liu C, Li L, Hong J, Zheng X, Bian K, Sun Y, Zhang J. Effect of mechanically damaged starch on wheat flour, noodle and steamed bread making quality. Int J Food Sci Tech. 2014;49:253–260. doi: 10.1111/ijfs.12306. [DOI] [Google Scholar]

- Lu Q, Guo S, Zhang S. Effects of flour free lipids on textural and cooking qualities of Chinese noodles. Food Res Int. 2009;42:226–230. doi: 10.1016/j.foodres.2008.11.007. [DOI] [Google Scholar]

- Min JL, Mi JK, Han SK, Lim ST, Sang SK. Effects of ozone treatment on physicochemical properties of Korean wheat flour. Food Sci Biotechnol. 2017;26:435–440. doi: 10.1007/s10068-017-0059-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Mudgil D, Barak S, Khatkar BS. Optimization of textural properties of noodles with soluble fiber, dough mixing time and different water levels. J Cereal Sci. 2016;69:104–110. doi: 10.1016/j.jcs.2016.02.015. [DOI] [Google Scholar]

- Obadi M, Zhu KX, Peng W, Ammar AF, Zhou HM. Effect of ozone gas processing on physical and chemical properties of wheat proteins. Trop J Pharm Res. 2016;15:2147. doi: 10.4314/tjpr.v15i10.13. [DOI] [Google Scholar]

- Obadi M, Zhu KX, Peng W, Sulieman AA, Ali MA, Mohammed K, Zhou HM. Shelf life characteristics of bread produced from ozonated wheat flour. J Texture Stud. 2017 doi: 10.1111/jtxs.12309. [DOI] [PubMed] [Google Scholar]

- Olson JC, Nottingham PM. International commission on microbiological specifications of foods. Microb Ecol Foods Factors Affecting Life Death Micro-org. 1980;1:1–37. [Google Scholar]

- Prückler M, Siebenhandl-Ehn S, Apprich S, Höltinger S, Haas C, Schmid E, Kneifel W. Wheat bran-based biorefinery 1: composition of wheat bran and strategies of functionalization. LWT Food Sci Technol. 2014;56:211–221. doi: 10.1016/j.lwt.2013.12.004. [DOI] [Google Scholar]

- Santala O, Lehtinen P, Nordlund E, Suortti T, Poutanen K. Impact of water content on the solubilisation of arabinoxylan during xylanase treatment of wheat bran. J Cereal Sci. 2011;54:187–194. doi: 10.1016/j.jcs.2011.02.013. [DOI] [Google Scholar]

- SB/T10137-93 (1993) Code of industrial standard of China, Wheat flour used for noodles

- Shu-Guo LI, Chen H, Xue-Mei LI, Wei CJ, Zhao WH. Preparation of micronized wheat bran fiber and its effect on quality of Chinese steamed bread and noodle. Cereals Oils. 2008;9:27–30. [Google Scholar]

- Sudha ML, Vetrimani R, Leelavathi K. Influence of fibre from different cereals on the rheological characteristics of wheat flour dough and on biscuit quality. Food Chem. 2007;100:1365–1370. doi: 10.1016/j.foodchem.2005.12.013. [DOI] [Google Scholar]

- Suhendro EL, Kunetz CF, Mcdonough CM, Rooney LW, Waniska RD. Cooking characteristics and quality of noodles from food sorghum. Cereal Chem. 2000;77:96–100. doi: 10.1094/CCHEM.2000.77.2.96. [DOI] [Google Scholar]

- Tsilo TJ, Simsek S, Chao S, Anderson JA. Genetic mapping of QTL associated with flour water absorption and farinogram related traits in bread wheat. Euphytica. 2013;194:293–302. doi: 10.1007/s10681-013-0906-2. [DOI] [Google Scholar]

- Wang H, Liu Y, Chen L, Li X, Wang J, Xie F. Insights into the multi-scale structure and digestibility of heat-moisture treated rice starch. Food Chem. 2018;242:323–329. doi: 10.1016/j.foodchem.2017.09.014. [DOI] [PubMed] [Google Scholar]

- Wen H, Ma S, Li L, Zheng X, Wang X. Rheological properties of gluten and gluten: tarch model doughs containing wheat bran dietary fibre. Int J Food Sci Tech. 2018;53:1–7. doi: 10.1111/ijfs.13702. [DOI] [Google Scholar]

- Young SB, Setlow P. Mechanisms of Bacillus subtilis spore resistance to and killing by aqueous ozone. J Appl Microbiol. 2010;96:1133–1142. doi: 10.1111/j.1365-2672.2004.02236.x. [DOI] [PubMed] [Google Scholar]

- Zhu F. Effect of ozone treatment on the quality of grain products. Food Chem. 2018;264:358–366. doi: 10.1016/j.foodchem.2018.05.047. [DOI] [PubMed] [Google Scholar]

- Zorlugenç B, Zorlugenç FK, Öztekin S, Evliya IB. The influence of gaseous ozone and ozonated water on microbial flora and degradation of aflatoxin B in dried figs. Food Chem Toxicol. 2008;46:3593–3597. doi: 10.1016/j.fct.2008.09.003. [DOI] [PubMed] [Google Scholar]