Abstract

On‐land transport/storage of fresh fishery products (FFP) for up to 3 days in ‘tubs’ of three‐layered poly‐ethylene filled with freshwater and ice was compared to the currently authorised practice (fish boxes of high‐density poly‐ethylene filled with ice). The impact on the survival and growth of biological hazards in fish and the histamine production in fish species associated with a high amount of histidine was assessed. In different modelling scenarios, the FFP are stored on‐board in freshwater or seawater/ice (in tubs) and once on‐land they are ‘handled’ (i.e. sorted or gutted and/or filleted) and transferred to either tubs or boxes. The temperature of the FFP was assumed to be the most influential factor affecting relevant hazards. Under reasonably foreseeable ‘abusive’ scenarios and using a conservative modelling approach, the growth of the relevant hazards (i.e. Listeria monocytogenes, Aeromonas spp. and non‐proteolytic Clostridium botulinum), is expected to be < 0.2 log10 units higher in tubs than in boxes after 3 days when the initial temperature of the fish is 0°C (‘keeping’ process). Starting at 7°C (‘cooling‐keeping’ process), the expected difference in the growth potential is higher (< 1 log10 for A. hydrophila and < 0.5 log10 for the other two hazards) due to the poorer cooling capacity of water and ice (tub) compared with ice (box). The survival of relevant hazards is not or is negligibly impacted. Histamine formation due to growth of Morganella psychrotolerans under the ‘keeping’ or ‘cooling‐keeping’ process can be up to 0.4 ppm and 1.5 ppm higher, respectively, in tubs as compared to boxes after 3 days, without reaching the legal limit of 100 ppm. The water uptake associated with the storage of the FFP in tubs (which may be up to 6%) does not make a relevant contribution to the differences in microbial growth potential compared to boxes.

Keywords: Fish tubs, fish boxes, transport, storage, fresh fishery products, biological hazards, histamine

Summary

Following a request from the European Commission, the EFSA Scientific Panel on Biological Hazards (BIOHAZ) was asked to provide a scientific opinion on the use of fish tubs compared to fish boxes for transporting and storing fresh fishery products (FFP) upon their arrival at the first on‐land establishment.

In Term of Reference 1 (ToR1), EFSA was requested to compare the impact that transport and storage of FFPs in on‐land establishments in tubs, when compared to currently authorised practices (fish boxes), could have on the survival and growth of biological hazards and the production of histamine in fish species associated with a high amount of histidine. The ToR2 was to estimate the impact that transport and storage in tubs have on the water content of the fish meat compared to boxes and on its consequences on the survival and growth of biological hazards.

It was clarified that the tubs are composed of three‐layered poly‐ethylene (PE) and filled with freshwater and ice while the boxes are composed of high density poly‐ethylene (HDPE) and are filled with layers of fish and ice. Fish are expected to be kept in tubs for a maximum of 3 days, with an exceptional maximum duration of 5 days.

The FFP should have been transported on‐board using tubs filled with fresh or seawater and ice. Upon the arrival at the first on‐land establishment, the FFP may be gutted and/or filleted before on‐land transport/storage as whole, gutted or filleted fish. The assessment compared the following conditions:

Baseline or current condition: the FFP are unloaded and transferred to boxes with ice, where they are kept during transport and storage on‐land until dispatched and/or marketed;

Alternative condition: the FFP are unloaded and transferred to tubs with freshwater and ice, where they are kept during transport and storage on‐land until dispatched and/or marketed.

Good practice with handling fish catches as well as the use of enough ice and re‐icing was assumed. It was also assumed that the initial status of the fish (e.g. intrinsic characteristics, conditions on‐board, hygienic status) was common for the two conditions, and thus, the relative impact during the on‐land transport and storage in boxes or tubs would be equivalent.

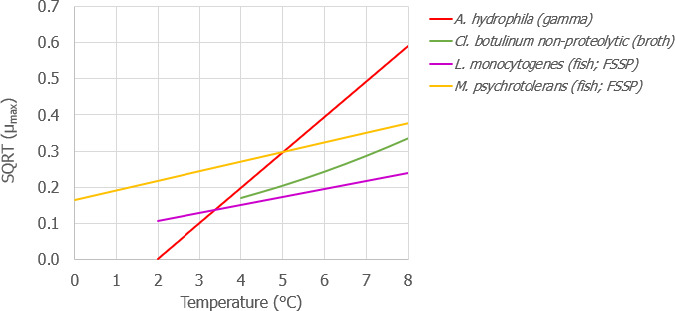

The relevant biological hazards were identified from the literature, considering their ability to cause human illness associated with FFP and to grow and/or survive on FFP within the temperature range of −3°C to 7°C. The hazards of interest may be present on the fish surface, fish meat or intestines. The relevant biological hazards for growth on FFP at refrigeration temperatures < 7°C are Aeromonas spp., non‐proteolytic Clostridium botulinum and Listeria monocytogenes, while those relevant for survival (no change or reduction) are pathogenic Escherichia coli, Salmonella, Staphylococcus aureus, Vibrio spp. and Nematodes (Anisakis spp.). The relevant histamine‐producing bacteria in FFPs are Enterobacter spp., Morganella spp. and Photobacterium spp.

Due to the scarcity of data on fish temperatures comparing both conditions, heat transfer modelling was used. The temperature of the fish surface was considered the main impacting factor. Two processes were considered:

the capacity of maintaining (i.e. ‘keeping’) the temperature when fish from tubs on‐board are transferred to either boxes or tubs for transport and storage on‐land, assuming no change of the fish temperature during such transfer, and

the ‘cooling’ capacity when the fish is handled (e.g. gutting and/or filleting) after landing, which causes an increase of the fish temperature to 7°C, and are then transferred to either boxes or tubs for transport and storage on‐land (i.e. ‘cooling‐keeping’).

In an ‘ideal’ scenario with proper practices and assuming that the initial fish temperature is 0°C and the fish is in perfect contact with ice in boxes and with a perfect mixing of water and ice in tubs, the temperature of the fish surface would be equal for both types of containers and equivalent to the temperature of melting ice (i.e. 0°C) throughout the transport/storage period.

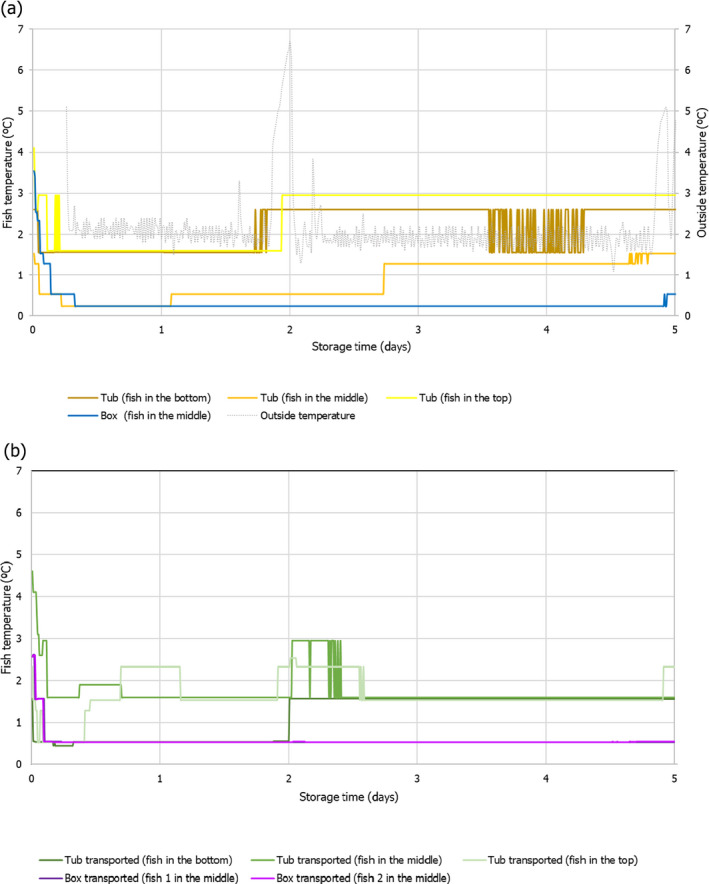

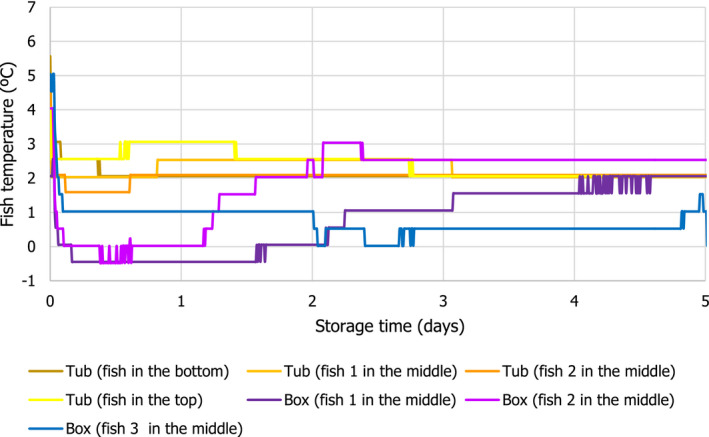

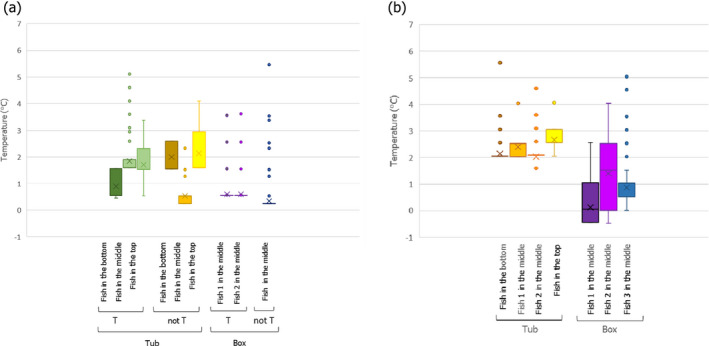

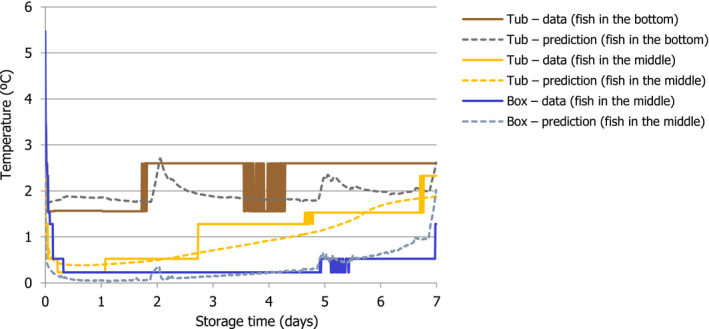

Only two experiments using lean small fish (plaice) provided ‘observed’ time–Temperature (t/T) profiles of fish upon storage/transport in both type of containers. The fish temperature fluctuated and relevant differences were observed depending on the location of the fish within the containers, which can be related to the distance from the ice layer as well as to the container walls. Overall, the median fish temperature was about 1.0°C higher when transported/stored in tubs compared to boxes, but after the short initial cooling stage, fish temperature never exceeded 3.1°C during the subsequent storage/transport.

The heat transfer model predicted fish surface temperatures under reasonable foreseeable ‘abusive’ scenarios of the outside temperature where temperature is mostly at 2°C but including some abusive peaks up to 6°C, assuming that in boxes, fish are surrounded by two layers of ice, and in tubs, fish are in water below an ice layer without mixing. The model provided satisfactory outputs when compared with observed data, for both types of containers. The model was then applied to generate the fish surface t/T profiles for both processes using both type of containers under the same conditions of transport/storage, considering the size of the fish (e.g. small flat fish such as plaice vs. bigger fish with a broad oval cross section, such as salmon) and their fat content (1–4% vs. 10–20%). The fat content and the dimensions of the fish have only limited impact on the t/T profiles as compared to the impact of the initial fish temperature and outside temperature of the chilling room where tubs and boxes are stored, or transported. The fish surface temperatures depend on the location of the fish within the containers, with fish located in positions more distant from the ice (the centre between ice layers in a box and the bottom of the tub) and closer to the walls of the container being the worst‐case scenario (warmest). It is important to note that, at earlier stages of storage, fish cools down faster in boxes than in tubs. Later, as the ice melts, the capacity to keep the temperature low is less in boxes than in tubs, which can be related to the insulating properties of the tubs.

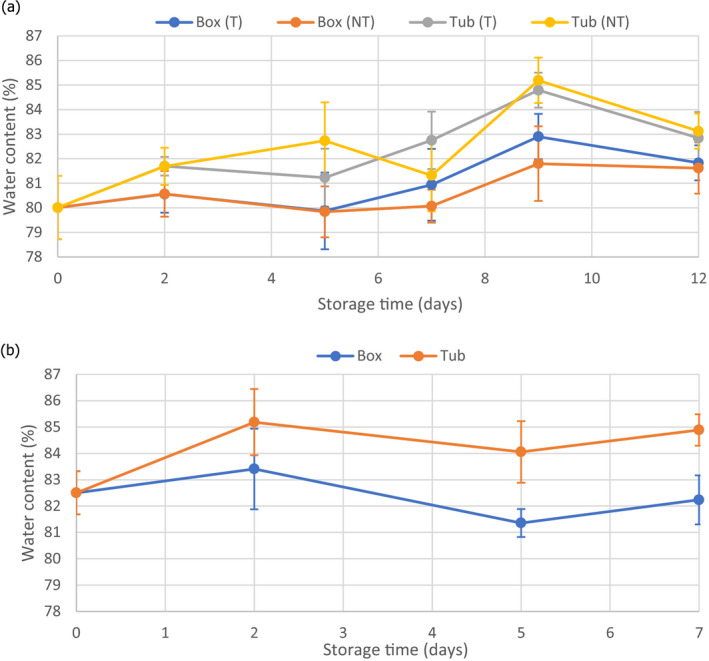

The impact of the transport and storage of FFP in tubs and boxes on the water content of the fish meat was assessed through review of the available published data in the scientific literature as was the impact on the physico‐chemical characteristics of the FFP relevant for microbial behaviour. From available data on water and salt content of fish, the water phase salt (WPS) content was calculated. FFP stored/transported in tubs with fresh water and ice may increase the water content from 0% to 6%, causing a reduction of the WPS concentration (%) ranging from 0 to 0.019 units in comparison with the FFP transferred to boxes.

The impact of the fish temperature on the growth or survival of the identified hazards during the transport and storage of FFP in tubs in comparison with boxes was assessed applying available predictive models for specific pathogens and histamine accumulation. t/T profiles from observed data and predicted through heat transfer modelling were used as input. The impact of the WPS change due to potential water uptake upon storage of FFP in tubs was assessed by changing this input factor in the predictive models. The impact of other factors (e.g. pH, initial concentration of histamine producing bacteria, lag phase, oxygen availability, internalisation) was considered in the uncertainty analysis. When no predictive models were available for a particular hazard, its behaviour was assessed using the evidence obtained through the literature review.

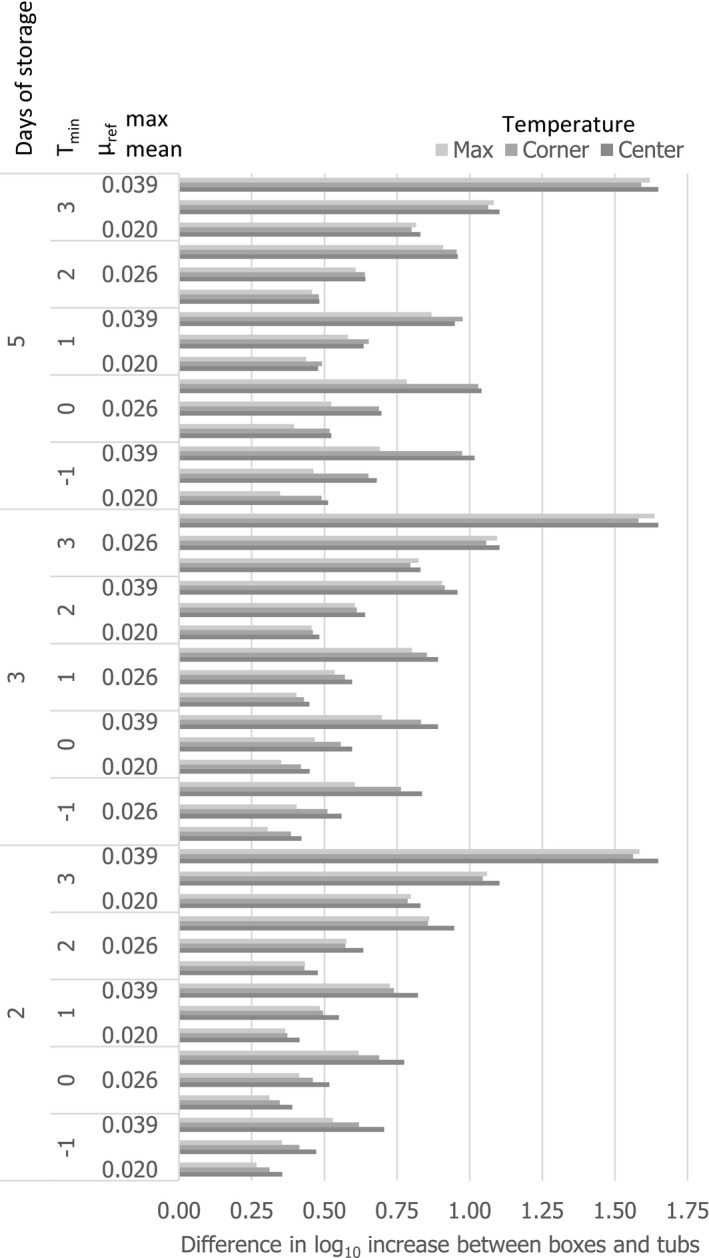

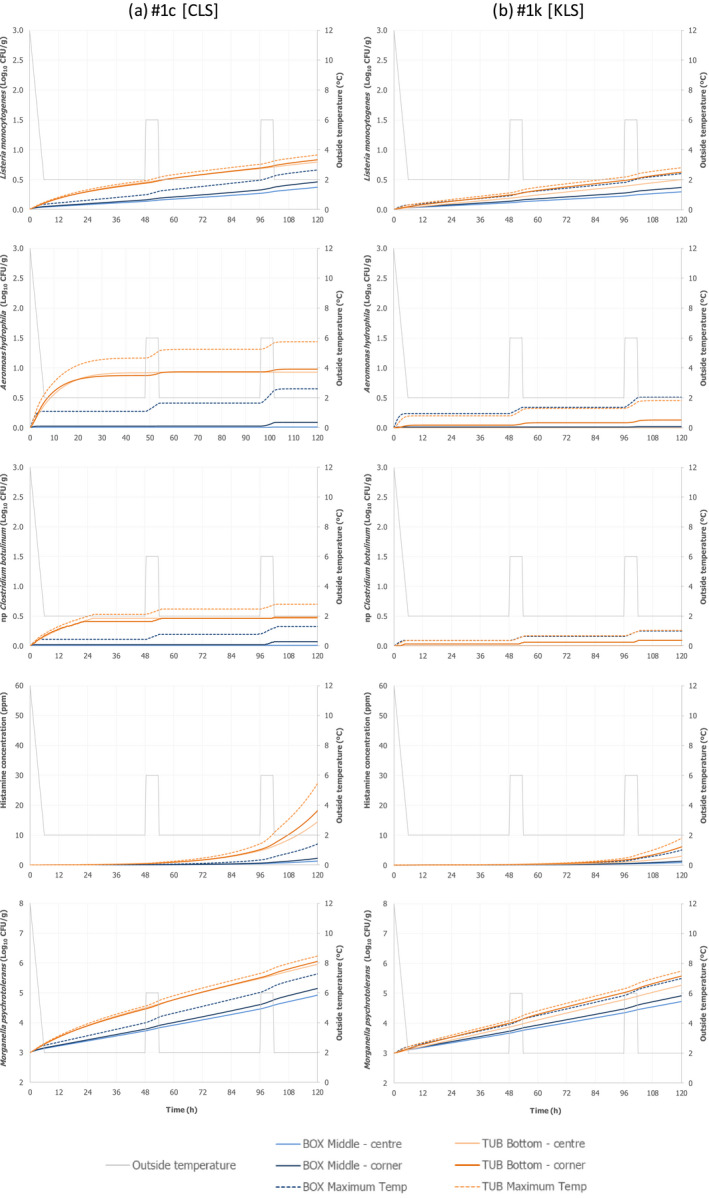

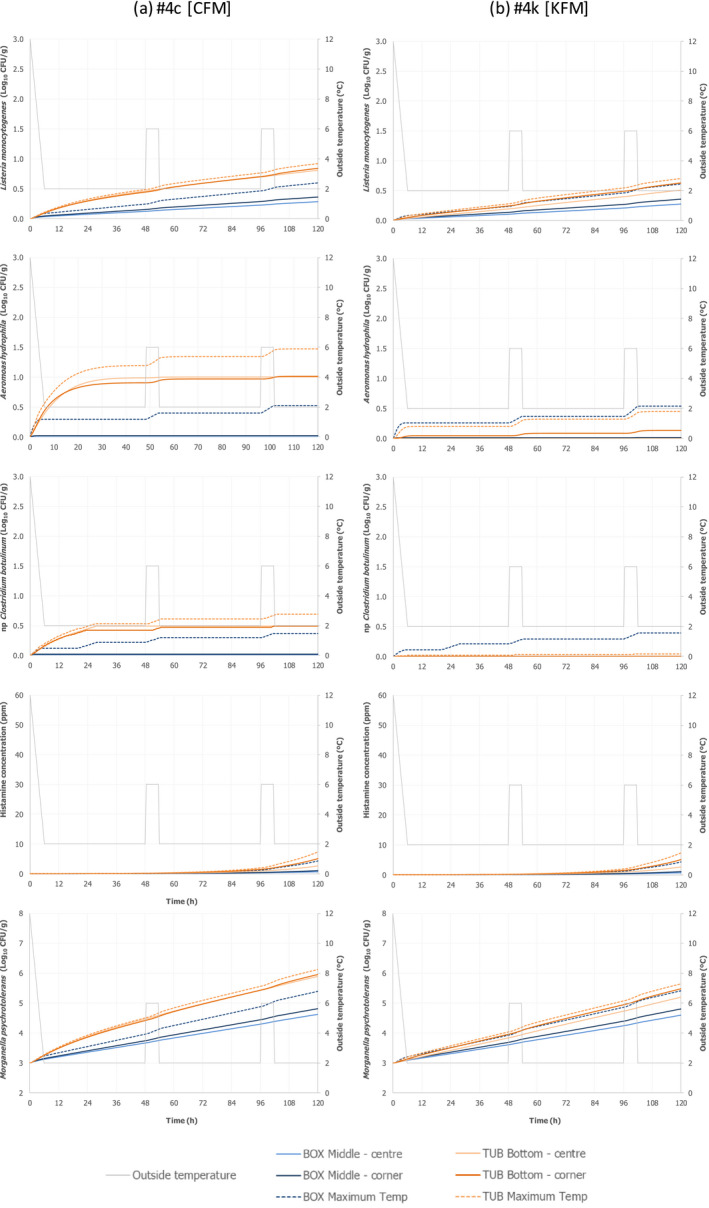

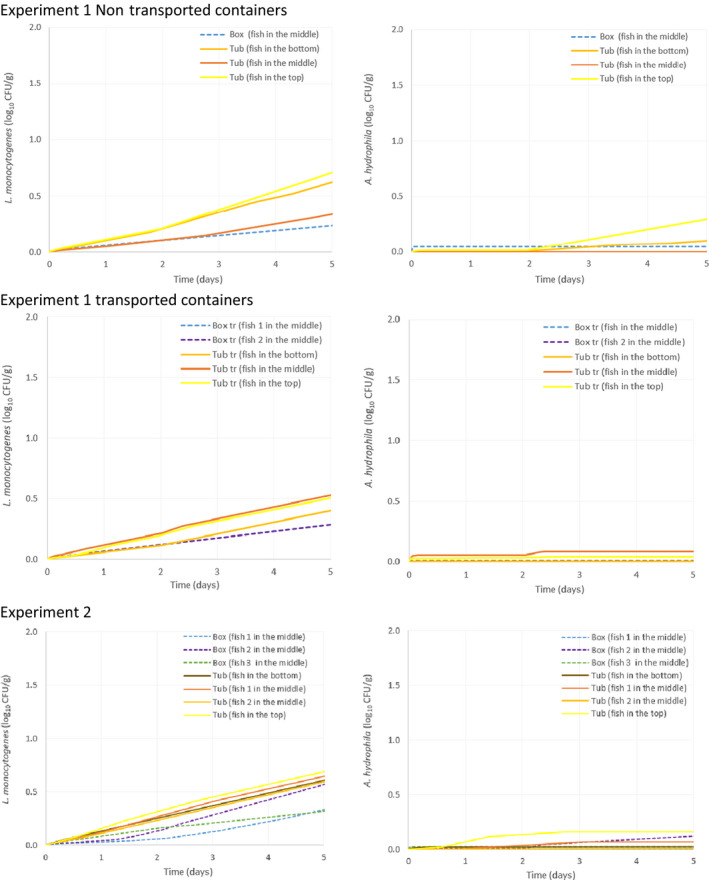

Under an ‘ideal’ scenario described above, there is no difference in the growth potential of Aeromonas spp., non‐proteolytic Cl. botulinum and L. monocytogenes in FFP when transported/stored in tubs compared to boxes as FFP temperature is maintained at 0°C throughout the storage/transport. Under ‘reasonably foreseeable abusive’ scenarios (referred to ‘abusive’ scenarios), the initial fish temperature when transferring the FFP to the tub or box needs to be considered. If the initial fish temperature equals 0°C (referred to as ‘keeping’ process), the growth potential (log10 increase) of the relevant hazards (i.e. A. hydrophila, L. monocytogenes or non‐proteolytic Cl. botulinum) is up to 0.12 log10 units, 0.17 log10 units, and 0.27 log10 units higher in tubs than in boxes after 2 days, 3 days, and 5 days, respectively. Instead, if the initial fish temperature is equal to 7°C (referred to as ‘cooling‐keeping’ process), the difference in the growth potential (log10 increase) of the relevant hazards is of a higher magnitude compared to the ‘keeping’ process mainly as a result of the poorer cooling capacity of water with ice (in tubs) compared to ice (in boxes). More specifically, for A. hydrophila, L. monocytogenes, and non‐proteolytic Cl. botulinum growth, the log10 increase is up to 1 log10 units, 0.5 log10 units and 0.5 log10 units higher in tubs than in boxes, respectively, after 3 days of storage/transport. An exceptional duration of the storage/transport of 5 days would result in a limited additional increase (≤ 0.1 log10) of the differences in the growth potential of the relevant hazards between boxes and tubs. Under the conditions of the assessment based on the fish t/T profiles that may occur under ‘abusive’ conditions of transport/storage of FFP, no substantial differences in the magnitude of reduction of pathogens between boxes and tubs are expected.

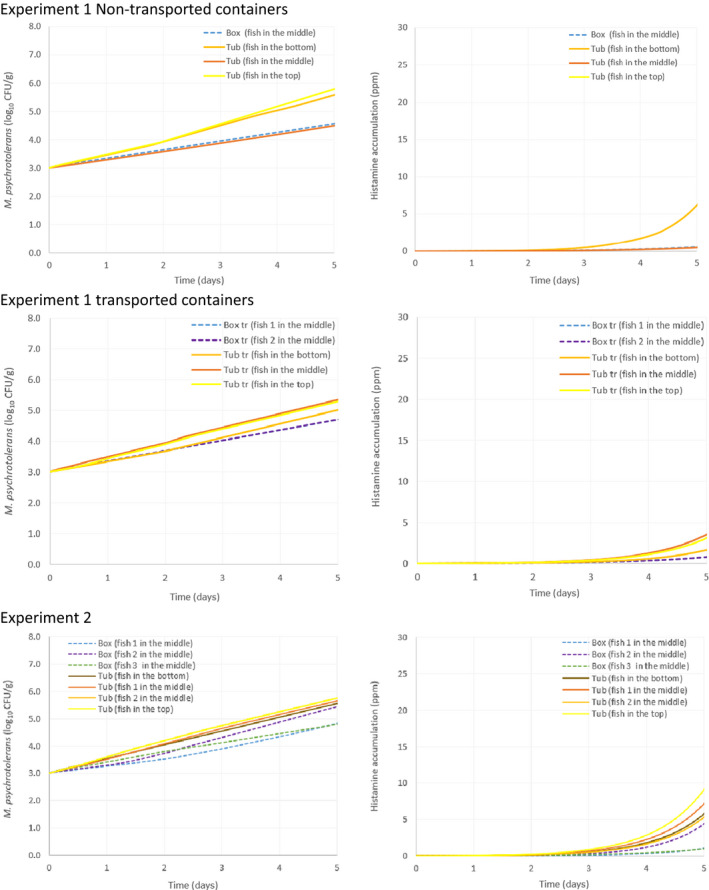

As for growth of the histamine‐producing hazards, under the ‘ideal’ scenario, there is no difference in the growth potential of M. psychrotolerans on FFP and on histamine accumulation when transported/stored in tubs compared to boxes. Under ‘abusive’ scenarios, when the initial fish temperature at transfer to the tub or box equals either 0°C or 7°C (referred to as ‘keeping process’ or ‘cooling‐keeping’ process), the histamine formation due to the growth of M. psychrotolerans can be up to 0.4 and 1.5 ppm higher, respectively, in tubs compared to boxes after 3 days. After the exceptional maximum duration of 5 days, the maximum difference can be up to 16 ppm and in any case the limit of 100 ppm histamine as defined in Commission Regulation (EC) 2073/200510 is not reached. Though it was not possible to quantify the temperature‐dependent growth and histamine production by Enterobacter spp. and Photobacterium spp, for the present assessment, these two histamine‐forming bacteria are considered less relevant than M. psychrotolerans because they have a lower histamine‐producing potential.

As the t/T profile is only slightly affected by the size and fat content of the fish, so is the associated growth potential of the relevant hazards. The location of the fish within the container impacted the t/T profile and thus the associated microbial growth.

The foreseeable decrease in WPS due to the uptake of water when fish is stored/transported in tub (in water and ice) has a negligible impact on the growth rate of all identified biological hazards and, consequently, on the growth potential of relevant pathogens, and on the histamine formation in FFP stored/transported in tubs compared to boxes.

In principle, any condition leading to more growth (log10 increase) of the relevant hazards would increase the public health risk. A higher histamine accumulation in tubs compared to boxes would be increase the public health risk, only if the threshold benchmark dose is exceeded. Quantification of the risk to public health associated with the storage/transport in tubs compared to boxes would require a quantitative microbial risk assessment (QMRA), including an exposure assessment taking into account subsequent steps of the FFP supply chain including the consumer handling and consumption habits as well as the dose–response relationship for each relevant hazard. Such a model is not available, and its development was beyond the scope of the present mandate.

Several recommendations for the sector for limiting the growth of pathogens when using tubs filled with water and ice are included, such as using precooled tubs made of insulating material and with a lid. To fill the tubs with sufficient water at a temperature as close to 0°C as possible and with enough ice on top to cover the whole surface of the tubs, making sure that all fish are below the ice layer, as well as to keep the temperature of the chilling room close to the melting ice temperature throughout the whole period of storage and transport. During transport and storage, with an absolute maximum duration of 5 days, it is recommended to re‐ice if needed and to circulate water inside the tubs to achieve uniform temperatures within the container. At last, tubs have to be transport and stored (as for boxes) in a cool environment.

1. Introduction

1.1. Background and Terms of Reference as provided by the requestor

In accordance with Annex III, Section VIII, Chapter III point A of Regulation (EC) No 853/20041, when chilled, unpackaged [fishery] products are not distributed, dispatched, prepared or processed immediately after reaching an establishment on‐land, they must be stored under ice in appropriate facilities. Re‐icing must be carried out as often as necessary.

The same point A states that containers (fish boxes) used for the dispatch or storage of unpackaged prepared fresh fishery products stored under ice must ensure that melt water does not remain in contact with the products. However, whole and gutted fresh fishery products may be transported and stored in cooled water on board vessels. They may also continue to be transported in cooled water after landing, and be transported from aquaculture establishments, until they arrive at the first establishment on‐land carrying out any activity other than transport or sorting.

The industry claims that fish boxes are keeping the upper fish cool, while the bottom ones are pressed together and the required temperature is difficult to reach in those conditions, as the ice prevents full surface contact. In addition, the use of ice boxes causes mechanical damage to the fish and enhances the formation of bacterial ‘slime’.

According with a study published by ILVO (Research Institute for Agriculture, Fisheries and Food) an internationally recognized scientific institute part of the Government of Flanders,2 commissioned by the Flemish Fish Auctions, the preservation of fish in tubs (large plastic containers measuring 1 × 1 × 1 meters (or 1 × 1 × 0.5 meters), filled with ice and water) was excellent and even slightly better than in fish boxes (polystyrene boxes3 where the fish is placed under ice, normally used by the industry), but storage in tubs also affected the water content of the fish. The temperature differences and fluctuations proved limited in tubs. Based on this research, ILVO formulated recommendations for the use of tubs.

The study demonstrated that, during a shelf life experiment, a temperature difference within the same tub of up to 2.8°C was recorded. The threshold level of 4°C for the fish temperature was never exceeded despite some fluctuations in the ambient temperature. Although the fish in tubs reached slightly higher temperatures than the fish in the boxes, this had no effect on the quality of the fish. The sensory and chemical analyses showed that plaice in tubs even had a longer shelf life than plaice in boxes. Although the microbiological parameters were also better in the tubs than in the boxes, these differences were not significant. Transport did not affect any parameter. The storage in tubs did have an effect on the water content of the fish meat. This effect was evident already after 2 days of storage: fish in tubs clearly had higher water content than in boxes.

EFSA is asked to provide a scientific opinion on the use of “tubs” compared to fish boxes for transporting and storing fresh fishery products in on‐land establishments. In particular, EFSA is requested:

Terms of Reference (ToR) 1: To compare the impact that transport and storage of fresh fishery products in on‐land establishments in “tubs”, when compared to currently authorised practices (fish boxes), could have on:

-

a)

the survival and growth of biological hazards.

-

b)

the production of histamine in fish species associated with a high amount of histidine.4

ToR 2: To estimate the impact that transport and storage in tubs have on the water content of the fish meat compared to currently authorised practices (fish boxes) and its consequences on the survival and growth of biological hazards.

1.2. Interpretation of the Terms of Reference

The term ‘fishery products’ as defined by Regulation (EC) No 853/20041, Annex I, comprises all seawater and freshwater animals (except for live bivalve molluscs, live echinoderms, live tunicates and live marine gastropods, and all mammals, reptiles and frogs) whether wild or farmed and including all edible forms, parts and products of such animals. In Annex I, ‘fresh fishery products’ (FFP) are defined as unprocessed fishery products, whether whole or prepared, including products packaged under vacuum or in a modified atmosphere, that have not undergone any treatment to ensure preservation other than chilling. However, as the current mandate is restricted to unpackaged FFP, with packaged FFP being beyond the scope of this assessment. It was clarified that the specific FFP to which the ToR apply also include ‘prepared fishery products’, in particular unprocessed fishery products that have undergone an operation affecting their anatomical wholeness, such as gutting, heading and filleting. The FFP considered in the assessment are derived from the marine and land‐based environment.

The assessment focuses on the EU/EEA regarding the transport and storage of unpackaged FFP (referred to as ‘FFP’ throughout the rest of the document) from the first on‐land establishments onwards using ‘boxes’ (as authorised practice) in comparison with ‘tubs’ (as alternative practice) until they are marketed or processed. The terms ‘box’ and ‘tub’ encompass plastic containers (Figure 1) made of different materials and with different dimensions depending on its use on‐board or on‐land. Tubs are large containers which are usually filled with ice and seawater (only on‐board) or ice and freshwater (on‐board or on‐land). Boxes are filled with layers of fish and ice.

Figure 1.

Example of a fish box (white) and a tub (red) (Source of picture: Visfederatie, 2020)

The tubs to be considered for on‐land use are composed of three‐layered poly‐ethylene (PE) and are filled with ice and freshwater. The boxes are composed of high‐density poly‐ethylene (HDPE) and are filled with layers of fish and ice. Polystyrene boxes are not to be evaluated, as the focus of interest is mainly on business to business transport. Fish were expected to be kept in tubs for a maximum of 3 days. However, the absolute and exceptional maximum duration considered was 5 days.

It was clarified with the requestor that FFP transported on‐board using tubs (filled with fresh or seawater and ice) should be considered for the assessment, so the use on‐board of boxes (with ice) is beyond the scope of this opinion.

It was agreed with the requestor to assume that the freshwater and seawater as well as the ice (made either from fresh or seawater) used to fill the tubs and/or boxes comply with the legal standard. Thus, when either potable water or clean seawater are used, according to their definitions in Regulation (EC) 852/20045 , 6, they should not be a source of microbiological contamination of the fish. The growth and survival of spoilage microorganisms as well as quality traits (e.g. sensory, commercial value etc.) are also beyond the scope of this mandate.

The term ‘impact’ of a given condition on the growth or survival of a biological hazard (including accumulation of histamine) was interpreted as the change of the concentration of the hazard, e.g. microorganism log10 concentration change or histamine concentration change. Subsequently, the requestor clarified that in case of any evidence of a different survival or growth of biological hazards in FFP submitted to the alternative practice in comparison with the baseline, to indicate if this could represent a potential risk for public health.

ToR 2 is considered implicitly included in ToR 1 as the output of ToR 2 is needed to answer ToR 1. Therefore, as the two ToRs are interlinked, it was agreed to combine the conclusions for both ToRs.

Based on the interpretations described above, the following assessment questions (AQs) were formulated in order to address the ToR.

AQ 1: What is the reduction potential (i.e. log10 decrease) or growth potential (i.e. log10 increase) of relevant biological hazards when FFP, initially stored in freshwater or seawater/ice (in tubs) on board, are subsequently ‘handled’ (i.e. sorted or gutted and/or filleted) at the first on‐land establishment and then transferred to freshwater/ice (in three‐layered PE tubs) compared to being transferred to ice (in HDPE boxes) for further transport and storage on‐land for a maximum duration of 3 days with an exceptional maximum duration of 5 days? Is there a potential increased risk for public health as a result of using tubs compared to boxes?

AQ 2: What is the magnitude of histamine accumulation in fish species associated with a high amount of histidine when FFP, initially stored in freshwater or seawater/ice (in tubs) on board, are then ‘handled’ (i.e. sorted or gutted and/or filleted) at the first on‐land establishment before being transferred to freshwater/ice (in three‐layered PE tubs) compared to ice (in HDPE boxes) for further transport and storage on‐land for a maximum duration of 3 days with an exceptional maximum duration of 5 days? Is there a potential increased risk for public health as a result of using tubs compared to boxes?

AQ 3: What is the contribution of the water content change of the fish meat on previous AQs outcomes when FFP, first stored in freshwater or seawater/ice (in tubs) on board, are ‘handled’ at the first on‐land establishment and then transferred to freshwater/ice (in three‐layered PE tubs) compared to ice (in HDPE boxes) for further transport and storage on‐land for a maximum duration of 3 days with an exceptional maximum duration of 5 days?

1.3. Additional information

1.3.1. Additional background information

1.3.1.1. Previous EFSA scientific opinions and reports

In 2015, EFSA published a report on the assessment of the temperature conditions, including a possible tolerance, to be applied for storage and transport of packaged FFP, gutted or entire, including some parts of them, at retail level where icing is not possible. The main temperature‐dependent hazards identified were histamine as well as the psychrotrophic Listeria monocytogenes, Clostridium botulinum and Yersinia enterocolitica. It was concluded that it is possible to store packaged FFP at refrigeration temperatures above 0°C (e.g. 3–5°C) and still be compliant with the current EU and international regulated microbiological criteria. For this, the storage time and the concentration of CO2 in the packaging headspace need to be adjusted accordingly. The report provides several scenarios equivalent to storage at 0°C, consisting of combinations of storage temperature, shelf‐life and CO2 concentration in the package (EFSA, 2015).

Also in 2015, EFSA published a scientific opinion of the Panel on Biological Hazards (BIOHAZ) and the Panel on Contaminants in the Food Chain (CONTAM) on the minimum hygiene criteria to be applied to clean seawater and on the public health risks and hygiene criteria for bottled seawater intended for domestic use. It was concluded that the comprehensiveness of the sanitary survey, the stringency of microbiological criteria and the need for treatment depend on the relative exposures associated with the different uses of seawater. For uses with low exposure to microbiological hazards, a basic sanitary survey and microbiological criteria based on the Directive 2006/7/EC7 are considered appropriate. For uses with a higher exposure, a more comprehensive sanitary survey, mandatory water treatment and microbiological criteria based on Council Directive 98/83/EC8 with an additional criterion for Vibrio spp. are considered appropriate (EFSA BIOHAZ and CONTAM Panel, 2015). Low exposure could be considered when using seawater to fill the tubs on‐board, while high exposure could be considered when seawater is in contact with prepared, processed and/or ready‐to‐eat (RTE) fishery products.

In 2017, EFSA assessed the incidents of histamine intoxication in some EU countries that were linked to consumption of tuna and were notified through the Rapid Alert System for Food and Feed (RASFF). All incidents of histamine intoxication were evaluated to highlight common factors in the food distribution chain that potentially contributed to the human cases, and to verify the possible correlation upstream in the food supply chain through the food business operators (FBO) involved. Due to the nature of histamine and the conditions that favour its production, it was concluded that it is likely that several concurrent factors have occurred in several stages along the food chain. It was recommended to maintain adequate chilling rates, carefully manage the cold chain and ensure hygienic conditions at each step of the supply chain of this product (EFSA, 2017).

1.3.1.2. Legal background

According to food safety requirements of the Regulation (EC) 178/20029, food shall not be placed on the marked if it is unsafe, i.e. if it is considered to be injurious to health and/or unfit for consumption (e.g. due to spoilage) taking into account the normal conditions of use at each stage of production, processing distribution and the consumer.

Regulation (EC) No 853/20041 lays down specific rules on the hygiene of food of animal origin for FBOs and supplements Regulation (EC) No 852/20045 on the hygiene of foodstuffs. Section VIII of Annex III of Regulation (EC) No 853/20041 deals with fishery products. It states that clean water may be used for the handling and washing of fishery products and the production of ice used to chill fishery products. It supplements the requirements of Annex II, Chapter VII to that Regulation stating that clean water may be used with whole fishery products. When clean water is used, adequate facilities and procedures are to be available for its supply to ensure that such use is not a source of contamination for the foodstuff.

Regulation (EC) 852/20045 defines ‘clean seawater’ as natural, artificial or purified seawater or brackish water that does not contain microorganisms, harmful substances or toxic marine plankton in quantities capable of directly or indirectly affecting the health quality of food. ‘Potable water’ means water meeting the minimum requirements laid down in Council Directive 98/83/EC of 3 November 19988 on the quality of water intended for human consumption; ‘clean water’ includes clean seawater and freshwater of a similar quality.

Relevant information from the Chapters in Annex III, Section VIII of the Regulation (EC) No 853/20041 is summarised here. Chapter I states that vessels designed and equipped to preserve fishery products for more than 24 h must be equipped with holds, tanks or containers for the storage of fishery products at the temperatures laid down in Chapter VII (see below). Holds and containers must ensure that melt water does not remain in contact with the products. In vessels equipped for chilling fishery products in cooled clean seawater, tanks must incorporate devices for achieving a uniform temperature throughout the tanks, reaching, after loading, not more than 3°C and not more than 0°C within 6 h and 16 h, respectively, and must allow monitoring/recording of temperatures.

Chapter II defines the requirements during and after landing. It specifies that, when it is not possible to refrigerate them on board vessels, FFPs shall be refrigerated as soon as possible after their landing and stored at a temperature close to that of melting ice. It also states that FBOs displaying FFPs for sale must ensure their refrigerated storage.

Chapter III defines the requirements for establishments, including vessels, which handle fishery products. It states that:

Where chilled, unpackaged products are not distributed, dispatched, prepared or processed immediately after reaching an establishment on land, they must be stored under ice in appropriate facilities. Re‐icing must be carried out as often as necessary. Packaged FFPs must be chilled to a temperature approaching that of melting ice.

Operations such as heading and gutting must be carried out hygienically and as quickly as possible after the products have been caught or landed. The products must be washed thoroughly immediately after these operations.

Operations such as filleting and cutting must be carried out so as to avoid contamination or spoilage of fillets and slices. Fillets and slices must not remain on the worktables beyond the time necessary for their preparation and must be wrapped and, where necessary, packaged and must be chilled as quickly as possible after their preparation.

Containers used for the dispatch or storage of unpackaged prepared FFPs stored under ice must ensure that water from melted ice does not remain in contact with the fish.

Whole and gutted FFPs may be transported and stored in cooled water on‐board vessels. They may also continue to be transported in cooled water after landing, and be transported from aquaculture establishments, until they arrive at the first establishment on land carrying out any activity other than transport or sorting.

Chapter V states that FBOs must ensure that the limits with regard to histamine are not exceeded. These limits are defined in Commission Regulation (EC) 2073/200510 as food safety criteria (FSC) in two different types of fishery products placed on the market during their shelf‐life:

In fishery products from fish species associated with a high amount of histamine (particularly fish species of the families Scombridae, Clupeidae, Engraulidae, Coryfenidae, Pomatomidae and Scombresosidae), out of n = 9 units comprising the sample, c = 2 units may have a histamine concentration between m = 100 and M = 200 mg/kg, none may be > M, and the mean value observed should be ≤ m.

The second type comprises fishery products from the same fish species that have undergone enzyme maturation treatment in brine. Out of the n = 9 units comprising the sample, c = 2 units may have a histamine concentration between m = 200 and M = 400 mg/kg, while none may be > M.

Chapter VI states that containers in which FFPs are kept on ice must be water resistant. Chapter VII states that FFPs must be maintained at a temperature approaching that of melting ice during their storage while Chapter VIII states that this also applies during their transport and reiterates that melt water must not remain in contact the FFPs, when kept under ice.

1.3.1.3. Fresh fishery products, production and supply chains

Fish can originate from aquaculture or be caught in the wild either from the sea or from freshwater environments. Fish exist at the ambient temperature of their environment, so their initial temperature is generally above 0°C. Seawater and freshwater temperatures vary significantly depending on many factors (e.g. season, latitude, depth, freshwater sources or oceanographic currents) and EU waters range from ~ 4°C (north) to 25°C or higher (south) (EFSA, 2015).

The handling of fishery products on‐board depends on the fish species and aims to assure the quality of the catch fish to be marketed (Huss, 1995; Mai et al., 2010; Valtýsdóttir et al., 2010; Matis, 2017). Small fish, such as herring or mackerel, are stored without bleeding or gutting, while bigger fish such as cod or salmon are bled after slaughtering and gutted as soon as possible thereafter (Borderías and Sánchez‐Alonso, 2011; Matis, 2017). However, a delay of up to 24 h for gutting can be applied for bigger fish provided that they are rapidly chilled. As stated by the current regulation (see Section 1.3.1.2), fish, which are bled or gutted, are washed before being stored on‐board.

Cooling and careful handling at all stages of the fish supply chain are key factors to assure good quality, maximum shelf‐life and high value of fishery products. Additional factors which can affect the quality of the fishery products are fishing season, area, fishing and handling equipment, nutritional status and age, rigor mortis as well as handling before and after processing. Once the fish are caught, they are chilled to achieve a temperature close to that of melting ice. The chilling methods used include immersion in ice slurry, refrigerated seawater (RSW) or flake ice. For instance, flake ice is widely used to reduce the temperature of fresh fish down to final levels slightly above 0°C; slurry ice (a mixture of small ice crystals suspended in water) is often used for superchilled products because it allows the product temperature to be reduced to just below the initial freezing temperature (−0.5°C to −2.8°C) (Stonehouse and Evans, 2015; Laguerre et al., 2018). The resultant temperature gradient brings the fish surfaces in contact with ice close to 0°C relatively rapidly, while the core temperature drops more slowly. Factors which may affect the rate of cooling include the ratio of fish to ice, contact of fish with ice, the size and the initial temperature of the fish, the type and temperature of the ice, the type of containers (including their insulating properties), the temperature outside the container and, for longer fishing trips, the frequency of re‐icing (Huss, 1995; Shawyer and Pizzal, 2003). On‐board, the stowage can be in fish boxes or tubs with ice, in fish tubs with a mixture of seawater or freshwater and ice and also by other means such as on shelves in the ship hold covered with ice or in RSW/chilled sea water (CSW) tanks (Stonehouse and Evans, 2015; Laguerre et al., 2018).

As a consequence of the heat transfer from the fish to the ice, the ice melts. Whilst the temperature of slush‐ice mixture arguably approaches that of melting ice, the efficacy of icing to maintain the cold chain is optimised by replacing melted ice (re‐icing) and removing water (melted ice) in contact with fish, making use of the drainage holes on the containers. Melted ice replacement also helps to remove organic matter and some of the microbial contamination carried by the water (Huss, 1995; Adams and Moss, 2006).

FFP going directly to the fish processing plant are kept in the same container from the catching ground to the processing plant. Otherwise, after landing fish is usually sorted and transferred to new containers (boxes) in fish auction centres. Throughout the subsequent distribution chain, transport and storage of FFP on‐land are carried out in ice and away from water (from melted ice) whilst in boxes. Tubs made with insulating material are also being used to keep fish in ice (Seafish Fact Sheet, 2008; Margeirsson et al., 2010; Margeirsson, 2012).

1.3.2. Approach to answer the ToR

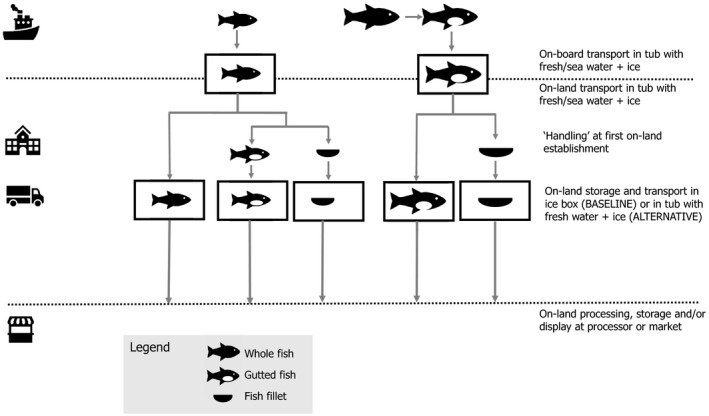

A conceptual map of the conditions to be addressed in the current assessment is depicted in Figure 2. Upon arrival at the first on‐land establishment, the conditions to be compared in the assessment include:

Baseline or current condition: the FFP are unloaded and transferred to boxes with ice, where they are kept during transport and storage on‐land until dispatched and/or marketed; and

Alternative condition: the FFP are unloaded and transferred to tubs with freshwater and ice, where they are kept during transport and storage on‐land until dispatched and/or marketed.

Figure 2.

General flow diagram of the transport and storage of fresh fishery products

For the present assessment, either whole or gutted FFP are transported on‐board using tubs filled with freshwater or seawater and ice. As fish filleted on‐board are always frozen, fish filleted on‐board is out of the scope of this assessment. Once on‐land, the FFP may be gutted and/or filleted at the first establishment before the on‐land transport/storage as whole, gutted or filleted fish in boxes with ice (baseline) or in tubs with freshwater and ice (alternative condition). Good practice when handling fish catches as well as the use of sufficient ice and re‐icing was assumed. It was also assumed that the initial status of the fish (e.g. intrinsic characteristics, conditions on‐board, hygienic status) was common for the two conditions, and thus, the relative impact during the on‐land transport and storage in boxes or tubs would be equivalent.

To address the AQs to answer the ToRs, the following steps were undertaken:

The relevant biological hazards (including histidine‐decarboxylase bacteria and the consequent histamine accumulation) were identified from the literature, considering their ability to cause human illness associated with FFP and to grow and/or survive (either no change or reduction) on FFP considering the temperatures encountered during transport and storage in boxes and tubs. The hazards of interest are those that may be present on the fish surface or within fish meat or intestines.

-

The temperature of the fish surface was considered to be the main factor impacting the growth and/or survival of the identified hazards during the storage and transport of FFP in tubs as compared to boxes. Due to scarcity of data for fish temperatures in both conditions, heat transfer modelling was used to assess:

the capacity for maintaining (i.e. ‘keeping’) the temperature when fish from tubs on‐board are transferred to either boxes or tubs for transport and storage on‐land, assuming no change of the fish temperature during such transfer, and

the ‘cooling’ capacity when the fish handling (e.g. gutting and/or filleting) after landing causes an increase of the fish temperature which are then transferred to either boxes or tubs for transport and storage on‐land.

The impact of the transport and storage of FFP in tubs and boxes on the water content of the fish meat was assessed through literature and subsequently, its impact on the physico‐chemical characteristics of the FFP (relevant for microbial behaviour) was assessed. From available data on water and salt content of fish, the water phase salt (WPS) content was derived.

The impact of the fish temperature on the behaviour (growth or survival) of the identified hazards during the transport and storage of FFP in tubs compared to boxes was assessed applying available predictive models for specific pathogens and histamine accumulation using as input temperature profiles from observed data and predicted through heat transfer modelling. The impact of the WPS change due to potential water uptake upon storage of FFP in tubs was assessed by changing this factor in the predictive models. The impact of other factors (e.g. pH, initial concentration of histamine producing bacteria, lag phase) was considered in the uncertainty analysis. When no predictive models were available for a particular hazard, its behaviour was assessed through literature review.

For the quantification of the potential risk to public health, a quantitative microbial risk assessment (QMRA) model would be needed, integrating the level of exposure of the relevant hazards due to the consumption of FFP and a dose–response (DR) relationship for each considered hazard. Such a QMRA was not available and its development would require the collection of a large data set and information which was out of the scope of the present mandate. Consequently, the potential risk to public health was not quantified, but factors that would need to be included in such assessment were described.

2. Data and methodologies

2.1. Hazard identification

The listing of the biological hazards (including histidine‐decarboxylase bacteria and the consequent histamine accumulation) associated with FFP was based on the scientific opinion (EFSA BIOHAZ and CONTAM Panel, 2015) and report (EFSA, 2015) summarised in Section 1.3.1.1 and considered hazards potentially present in FFP, including fishes, crustacea, cephalopods and sea urchins. Bivalve shellfish were not considered as they are sold either live or frozen. For the selection of hazards relevant for FFP, the compiled list was screened considering first the evidence of these hazards to cause human illness (i.e. report of human cases or outbreaks) associated with fishery products that had not been further processed (e.g. salted, marinated, smoked etc.). Cl. botulinum was included in the screening for its potential for growth under anaerobic conditions that may occur in specific niches within fishery products. For Cl. botulinum, evidence of human illness associated with products other than canned fish was considered.

The hazards complying with this first criteria were then evaluated for their ability to grow and/or to survive in raw fishery products, considering a temperature range of the fish (from −3°C to 7°C11) that encompassed the reasonably foreseeable temperatures in boxes or tubs during storage and transport, including temperature increases associated with ‘handling’, such as gutting and/or filleting. In literature screening of the ability of the hazards to grow and/or to survive in raw fishery products, growth and reduction were considered relevant when an increase or decrease ≥ 0.5 log10 units was reported. This criterion was defined in agreement with the reliability (circa 0.5 log10) generally attributed to quantitative enumeration methods on the basis of early studies (Jarvis et al., 1977; Kramer and Gilbert, 1978), and confirmed by the analysis of measurement uncertainty (median: 0.6 log10 CFU/g) associated with microbiological methods for specific organisms count (Jarvis et al., 2007). Furthermore, the threshold of ≥ 0.5 log10 units was considered conservative compared to other values (i.e. ≥ 1.0 log10 units) in some instances adopted as a measure of significant variation in food microbiology.

Other physio‐chemical parameters (such as pH and WPS) relevant for growth and/or survival were not considered at screening level. Compared to EFSA (2015), additional analysis was performed to consider the survival (as no change or reduction in the concentration) of the hazards. The strategy for conducting the literature searches and screening is provided in Appendix A.

2.2. Description of the conditions of the assessment

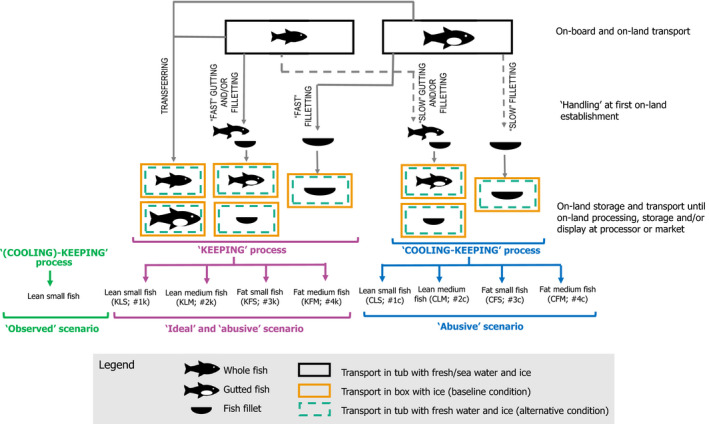

The baseline condition (i.e. box filled with fish in ice) and the alternative condition (i.e. tub filled with fish in freshwater and ice) for transport/storage were compared by assessing (i) the temperature‐related processes regarding the initial fish temperature; (ii) the type of fish and (iii) different potential scenarios as described below and depicted in Figure 3.

Figure 3.

Conceptual map showing the scenarios and case studies to be assessed for transport/storage of fresh fishery products comparing the baseline condition (i.e. box filled with fish in ice) and the alternative condition (i.e. tub filled with fish in freshwater and ice)

Temperature‐related processes:

Keeping the chill temperature of the fish (referred to as ‘keeping’ process), which applies to whole fish (either ungutted or gutted on‐board), not ‘handled’ after landing other than transferring to a new container, being either a tub or a box. This process also includes fish that is gutted and/or filleted on‐land fast enough to not cause a temperature increase of the fish before its transfer to a tub or a box. The initial fish temperature is assumed equal to the temperature inside the tubs (i.e. 0°C) upon arrival at the first on‐land establishment.

Cooling and then keeping the chill temperature of the fish (referred to as ‘cooling‐keeping’ process), which apply when fish gutting and/or filleting at the first on‐land establishment causes an initial increase of the fish temperature up to 7°C. This initial temperature is considered, assuming that the fish temperature upon arrival at the first on‐land establishment is in the range from 0°C to 3°C, increases 3–4°C for every half an hour of ‘handling’, the time for ‘handling’ is maximum 30 min (Margeirsson et al., 2010; Valtýsdóttir et al., 2010), and then, the handled fish is transferred to a tub or a box.

Two major criteria were considered to define the type of fish for the assessment:

The fat content of the fish was considered by selecting fish with a low (such as plaice having a fat and water content of 1–4% and 79–81%, respectively) and high (such as Atlantic salmon having a fat and water content of 10–20% and 60–70%, respectively) fat content, referred to as ‘lean’ fish and ‘fat’ fish.

Two different dimensions and geometries were considered, i.e. small flat fish vs. bigger fish with a broad oval cross section. These were categorised as follows; ‘small’ fish (e.g. a plaice of a size class 4 having a weight of 150–300 g) and ‘medium‐sized’ fish (e.g. salmon with a length of 50 cm). The size of the latter was restricted by the size of the fish box. Whole or gutted fish was considered to have the same geometric dimension, while fillets would be at least half of the dimension in one of the three axes. The inclusion of two different dimensions accounts for the variety of sizes of whole (including gutted) or filleted fish within the assessed range.

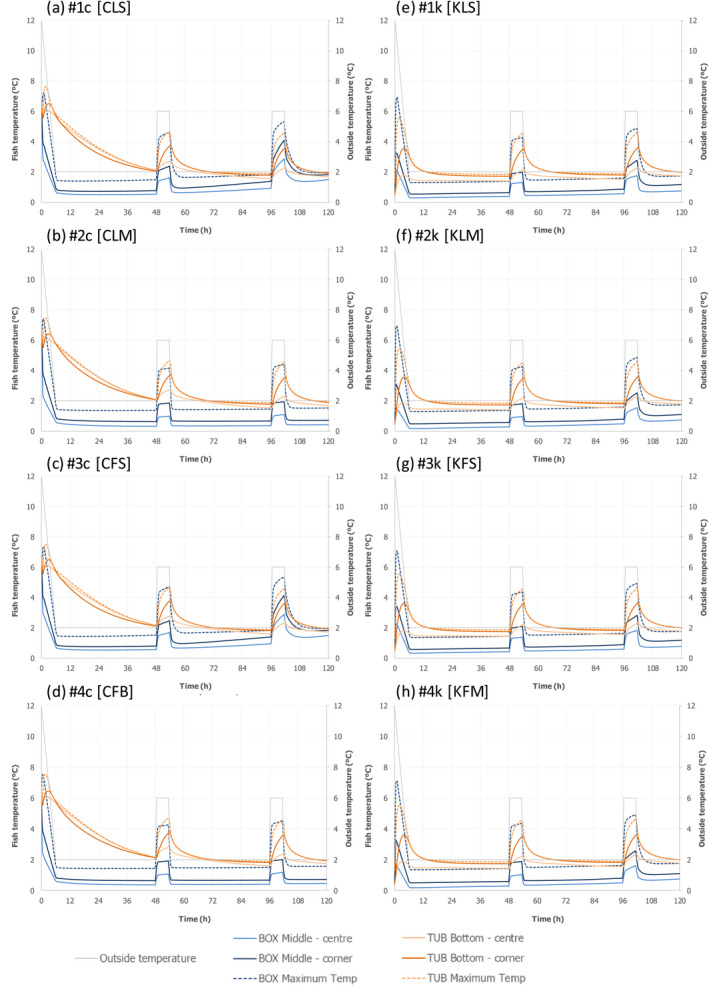

For each process and type of fish, three potential scenarios were assessed based on the initial fish temperature and outside temperature (i.e. the temperature of the room/chamber/truck in which the fish containers (boxes/tubs) will be transported/stored) and the configuration inside the container:

the ‘ideal’ scenario: it assumes that the initial fish temperature equals the temperature inside the tubs (i.e. 0°C) upon arrival at the first on‐land establishment and the fish temperature does not increase when transferred to the on‐land container because in case of a box, the fish is surrounded by ice with perfect contact with fish surface; while in case of a tub, the fish is surrounded by water in equilibrium with ice and there is perfect mixing by aeration. Under this scenario, the gutting and/or filleting of the fish is considered fast enough so as not to cause a temperature increase in the fish. The outside temperature is low enough to avoid a temperature increase inside the container (box or tub). Therefore, the fish temperature is constant and equal to 0°C during the whole ‘keeping’ process, irrespectively of the type of fish and type of container. This scenario is not applicable to the ‘cooling‐keeping’ process.

the ‘observed’ scenario: based on experimental data of the fish temperature records of the experiments of the ‘Qualitubfish’ project (Section 2.3.1) dealing with small lean fish, which included a short cooling period followed by keeping the chill temperature. It is referred to as a ‘(cooling)‐keeping’ process.

-

the last scenario is applicable to the ‘keeping’ and ‘cooling‐keeping’ process and takes into account reasonably foreseeable abuse of the following factors (‘abusive’ scenarios):

-

(a)

for the ‘keeping’ process, the initial fish temperature equals the temperature inside the tubs (i.e. 0°C) upon arrival at the first on‐land establishment. For the cooling‐keeping’ process, the fish temperature rises to 7°C during its handling.

-

(b)

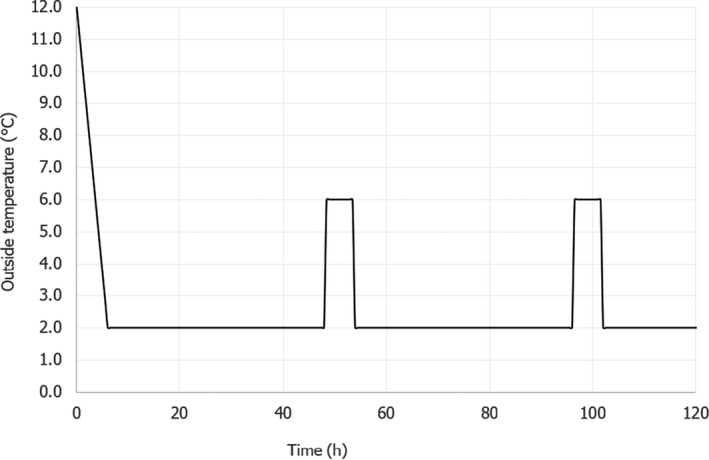

the outside temperature (i.e. temperature in the chamber or truck where the container is stored/transported) follows the profile shown in Figure 4, starting from 12°C, decreasing to 2°C in 6 h, then following 48‐h time/Temperature (t/T) cycles, including abusive temperatures, consisting of: 42 h at 2°C, increase from 2°C to 6°C in 30 min, 5 h at 6°C, decrease from 6°C to 2°C in 30 min. This was based on expert opinion considering the t/T profiles derived from the ‘Qualitubfish’ project (Bekaert et al., 2016a) and as described in Thordarson et al. (2017).

-

(c)

for boxes, fish is surrounded by air and two layers of ice (bottom and top); while for tubs, fish is in water below an ice layer on the top of the tub without mixing.

-

(a)

For these scenarios, the fish t/T profiles were obtained from heat transfer modelling (Section 2.3.2) for the combinations shown in Figure 3. Among the entire set of modelled temperatures, the temperature of fish located in the ‘warmest spot’ within the container was considered to assess microbial growth. For boxes, the temperature of two fish located in the middle of the box was used, i.e. one fish in the centre and one in the corner close to the box wall. For tubs, the temperature was extracted for two fish located in the bottom of the tub, i.e. one in the centre and the other in the corner.

Figure 4.

For all cases, the duration of the transport and storage in the tub/box on‐land would be constrained by the time of on‐board transport and in the first on‐land establishment. For modelling purposes, it was considered that the total duration of the transport/storage on‐land would be maximum 5 days in accordance with the exceptional absolute maximum duration assessed. However, fish is expected to be kept in a tub for a maximum up to 3 days (see Section 1.2 and Table 3 in Section 2.5.2).

Table 3.

Input values used for assessing the growth of hazards through the application of selected predictive models

| Variables and parameters affecting microbial growth, accounted for by the models | Background information | Final selection of input values for modelling | Data sources and/or reasoning for selected input values |

|---|---|---|---|

| Temperature of fish surface | Refer to assumptions about t/T profiles that may occur during ‘cooling‐keeping’ and/or ‘keeping’ processes (Sections 1.3.2 and 2.3) | Data shown in Section 3.2.1 | ‘Observed’ scenarios: data from the ‘Qualitubfish’ experiments 1 and 2 |

| Data shown in Section 3.2.3 | ‘Abusive’ scenarios: data from the heat transfer model (for boxes and tubs), which was validated against the observed ‘Qualitubfish’ data and considered reliable for simulating the keeping and cooling profiles | ||

| WPS (%) |

Median = 0.3711 Mean = 0.513 SD = 0.474 Min = 0.143 Max = 1.739 n = 10 |

0.37 (A. hydrophila, Cl. botulinum and M. psychrotolerans) 0.6% (L. monocytogenes, as this is the minimum level accepted by FSSP tool) |

Median of n = 10 values for fresh fish of different species was extracted from scientific papersa |

| pH |

Median = 6.5 Mean = 6.4 SD = 0.27 Min = 5.78 Max = 6.89 n = 31 |

6.5 | Median of n = 31 values for fresh fish of different species was extracted from scientific papersb |

| Oxygen availability or aerobic/anaerobic conditions | – |

Aerobic (A. hydrophila, L. monocytogenes, M. psychrotolerans) Anaerobic (Cl. botulinum) |

Applies to obligatory anaerobic hazards that may multiply under the anaerobic gut environment, where these organisms reside |

| Lag time | Relative lag time (RLT; ho) for FSSP; physiological state (ao) for ComBase | No lag time | For the uncertainty analysis, comparisons were carried out between (sub‐) selected growth simulations without and with lag time, associated with different (assumed) initial physiological states. The subselected simulations were those of t/T scenarios that showed the maximum log10 increases without lag |

| Lactic acid (endogenous origin) | Up to 1% (10,350 ppm) Yellowfin tuna Emborg et al. (2005) | 0.7% (7,000 ppm) lactate in water phase | Mejlholm et al. (2010) |

| Initial concentration of histidine |

Median = 5,000 Mean = 5,915 SD = 3,917 Min = 1,187 Max = 13,970 n = 15c |

10,750 ppm | High enough so it is not the limiting factor for histamine formation (e.g. from 10,750 ppm of histidine, up to 7,700 ppm of histamine could be formed) (EFSA, 2015) |

| Initial concentration of M. psychrotolerans | 10; 100; 10,000 CFU/gd | 1,000 CFU/g | The level of 1,000 CFU/g was chosen as a rather conservative initial level, i.e. not very high as 10,000 CFU/g, but not such low that would probably mask the differences in histamine accumulation between boxes and tubs for the t/T conditions of the current assessment. The same levels was also tested in the previous EFSA report (EFSA, 2015) |

| Initial concentration of histamine | 0 ppm | Assuming fresh fish with no relevant histidine‐decarboxylase activity before fish lands | |

| Time points of interest for the assessment e | 1 and 2 days | Possible durations as below the realistic maximum duration according to the clarification with the requestor and in agreement with the ‘Qualitubfish’ data (in 82% of the 61 surveyed fish transport/storage the duration was ≤ 2 days). The duration of 2 days also approximately corresponds with the end of cooling | |

| 3 days | The realistic maximum duration according to the clarification with the requestor and in agreement with the ‘Qualitubfish’ data (duration of ≤ 3 days for 97% of transported/stored fish surveyed) | ||

| 5 days | The exceptional absolute maximum duration according to the clarification with the requestor and in agreement with the ‘Qualitubfish’ data (duration below 5 days for all 61 surveyed transported/stored fish) |

WPS: Water phase salt; t/T: time/Temperature.

Based on values reported in (Emborg et al., 2005; Magnússon et al., 2010; Valtýsdóttir et al., 2010; Digre et al., 2011; Thordarson et al., 2017).

Based on values reported in (Ruiz‐Capillas and Moral, 2001; Gimenez et al., 2002; Baixas‐Nogueras et al., 2003; Pons‐Sanchez‐Cascado et al., 2006; Erkan, 2007; Kilinc et al., 2007; Olsson et al., 2007; Sallam, 2007; Emborg and Dalgaard, 2008; Hernandez et al., 2009; Magnússon et al., 2010; Khalafalla and El‐Sayed, 2015).

Based on (Abe, 1983; Fletcher et al., 1995; Antoine et al., 1999; Shirai et al., 2002; Kanki et al., 2004; Ruiz‐Capillas and Moral, 2004; Emborg et al., 2005).

Low initial concentrations (≤ 10 CFU/g) can be expected in the skin and gills of FFP. Higher concentrations can be found in the intestines and contaminate the FFP when handheld either on‐board and on‐land (Emborg et al., 2005; Emborg and Dalgaard, 2008). An exceptional worst‐case scenario of initial concentration of M. psychrotolerans was assumed to be 10,000 CFU/g.

For the ‘observed’ scenario, the objective of the ‘Qualitubfish’ experiments was to evaluate the shelf‐life of fish in a tub, so the maximum duration monitored (i.e. 12 days and 7 days) is not considered a realistic practice. Therefore, the actual assessed time for these t/T profiles was cut to 5 days in accordance with the exceptional maximum duration that fish could be kept in a tub.

2.3. Fish temperature in boxes and tubs

A literature search was conducted to retrieve data comparing fish temperature profiles when transporting or storing (either keeping or cooling) fish in tubs (with freshwater and ice) or boxes (with ice), keeping the other conditions fixed such as the outside temperature, type of fish and conditions before transport or storage. Two studies compared the t/T profile of fish when kept in such boxes and tubs. Both studies were conducted in the frame of the ‘Qualitubfish’ project and consisted of storing/transporting lean small fish (plaice) in boxes and tubs under the same external temperature conditions mimicking the foreseeable conditions of on‐land transport and storage. The studies have been described in two reports. In the first experiment described in Bekaert et al. (2016a), the fish were stored for 3 days on ice in boxes on‐board a fishing vessel before the start of the experiment, while in the second experiment (Bekaert et al., 2016b), storage was for 8 days on ice before the start.

Otherwise, studies are limited to the currently authorised practices, both for use of tubs and boxes. That is the transport of fish in boxes after the first on‐land establishment, and the on‐board transport of fish in tubs. For example, studies are available on the use of tubs with ice, dry ice, slurry ice or gel/ice packs but without water, or with seawater but not freshwater, thus not covering the conditions to be assessed in the present mandate.

Due to the lack of experimental data, thermodynamic models were developed enabling the comparison of the impact on the fish temperature of current authorised practice (baseline condition, using boxes) and alternative condition (using tubs) for on‐land transport or storage under the same conditions of initial fish temperature and outside temperature.

The temperature dynamics in boxes and tubs were modelled considering the processes, type of fish and scenarios described in Figure 3. When data were available (as in the ‘(cooling)‐keeping’ process for lean small fish), the heat transfer model was validated (Section 2.3.2.2).

2.3.1. Recorded time/temperature profiles during storage/transport

Temperature data gathered in the first experiment of the ‘Qualitubfish’ project (Bekaert et al., 2016a) were used (i) to assess the dynamics of the fish temperature in boxes with ice and in tubs with freshwater and ice (Section 3.2.1), (ii) to validate the thermodynamic models (Section 3.2.2) and (iii) to assess the behaviour of selected relevant hazards through the application of predictive models (Section 3.4). In this experiment, plaice (Pleuronectes platessa) of size class 4 (having a weight of 150–300 g) were stored for 3 days on ice in boxes on‐board a fishing vessel before being transferred on‐land to tubs or boxes. The PE tubs were filled with 400 kg of fish, 110 L of freshwater at 2.7°C and 20 kg of flake ice. The HDPE boxes were filled with 40 kg of fish and 15 kg of flake ice on the bottom, in the middle and on top of the boxes. The temperature of fish was recorded by inserting temperature loggers into the core of the fish through the gutting cut. The temperature monitored fish were marked with a strap and placed in different zones of two tubs, namely on the bottom, in the middle and on top. Logged fish were also placed in the middle of four different boxes. One tub and three boxes were immediately stored for 12 days in a cold storage room (non‐transported). One tub and three boxes were also transported by truck to the Netherlands and back the next day to be further stored in the same cold storage. After 7 days of storage, boxes and tubs were re‐iced. The temperature of the cold storage (outside temperature) was also monitored.

In the second experiment of the ‘Qualitubfish’ project (Bekaert et al., 2016b), plaice of the same size class were stored for 8 days on ice in boxes on‐board and transported with trucks to the auction before being transferred on‐land to tubs or boxes. One PE tub was filled with 400 kg of fish, water was added to cover all fish and a layer of ice was put on top. HDPE boxes were filled with ~ 40 kg of fish and 15 kg of flake ice (layer of ice on top, in the middle and on the bottom). Both the tub and boxes were further stored for 7 days in a cold storage room. The temperature of the fish inside tubs and boxes was registered as in the previous experiment. The outside temperature was not available and therefore not allowing validation of the thermodynamic model, but allowing to assess the dynamics of the fish temperatures and behaviour of selected relevant hazards as the first experiment.

For the assessment of the behaviour of selected biological hazards, the actual t/T profiles from both experiments were cut to 5 days in accordance with the maximum duration to be assessed (see Section 1.2).

As part of the study described in the report (Bekaert et al., 2016a), a total of 61 tubs were followed from the auction in Belgium to the filleting company in the Netherlands. In most cases, the fish was processed on the same day (n = 16 tubs; 26.2%) or on the next day (n = 29 tubs; 47.5%). For the rest of the tubs, the duration before processing was 2 days, 3 days and 4 days for n = 5 (8.2%), n = 9 (14.8%) and n = 2 (3.3%) tubs, respectively.

2.3.2. Modelling of fish temperature dynamics in boxes and tubs

The heat transfer modelling was applied to estimate the fish surface temperature under the process of cooling and/or keeping fish in ice (in boxes) vs. in water and ice (in tubs) under the same conditions of transport/storage. Figure 3 shows the considered conditions regarding the fat content of the fish, its dimensions and initial temperature. The outside temperature depends on the scenario of ‘ideal’ or ‘abusive’.

As mentioned in Section 2.2, for the ‘ideal’ scenarios, temperatures inside containers can be predicted without the use of mathematical models assuming ideal conditions, like perfect contact of ice with fish (in boxes) and perfect mixing of water and ice (in tubs).

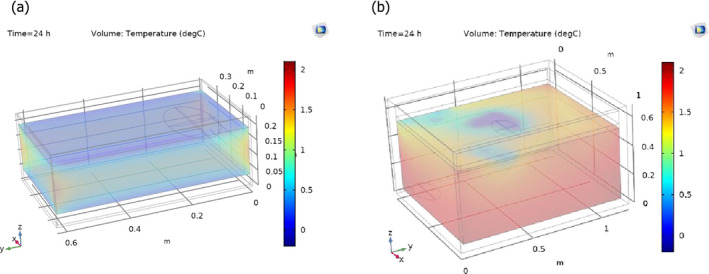

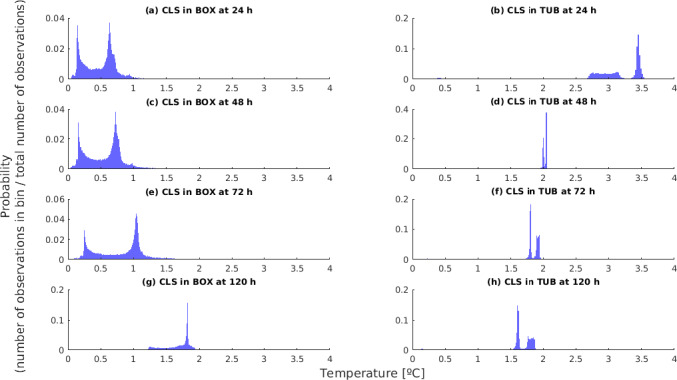

For ‘abusive’ scenarios, the t/T profiles inside the containers were modelled using mathematical heat transfer models. For each container, the model consists of a partial differential equation simulating the temperature dynamics (along the time) and distribution (on space) with different thermodynamic parameters for each considered material (e.g. air, water, ice, lean/fat fish, PE container material). Therefore, the model required to define geometries and positions for each of the materials (referred to as ‘domains’), mesh these domains (spatial discretisation of the partial differential equation) and evaluate the resulting equations in each of the elements of the mesh. The partial differential equation was solved using the software COMSOL® (COMSOL Multiphysics Reference Manual, version 5.4”, COMSOL, Inc, www.comsol.com). More details about numerical methods, discretisation in time and space and further details about the simplifications and assumptions can be found in Appendix B. In short, the model, named the Temperature Simulator of Fish Stored in Tubs and Boxes (FishT‐TaB Simulator), relies on the following simplifications and assumptions:

-

1

Heat transfer by conduction is simulated, disregarding any other type of heat transfer phenomena;

-

2

The phase change from ice to water is simulated using the ‘apparent heat capacity method’ in which the latent heat is included as an additional term in the heat capacity;

-

3

Only two fish, assuming an ellipsoid geometry, were explicitly modelled in each container. For the contribution of the other fish in the same container, a matrix of water/fish in tubs and air/fish in boxes is simulated using the standard approximations for modelling porous materials;

-

4

Among all the modelled fish surface temperatures distributed in space, three t/T profiles were retrieved for each container. The highest temperatures were selected as follows:

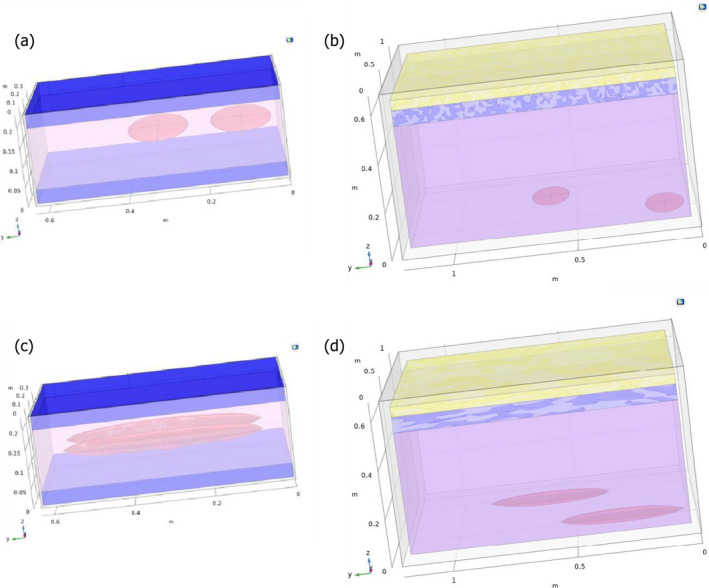

-

For boxes, the maximum temperatures (Tmax) are expected in the centre (in the vertical and horizontal axis), i.e. the furthest location from both ice layers on the top and bottom. Therefore, the selection was (see Figure 5 for illustration):

Tmax on the surface of a fish located in the centre of the box;

Tmax on the surface of a fish located in the centre, but close to the box wall; and

the maximum overall temperature in the food/air matrix.

-

For tubs, from the thermodynamic principles, Tmax is expected on the bottom (i.e. the furthest vertical location from the top ice layer); selected temperatures were:

Tmax on the surface of a fish located in the bottom centre of the tub;

Tmax on the surface of a fish located in the bottom corner of the tub; and

Tmax obtained for each time within the whole food/water matrix.

-

For the validation of the heat transfer model, the temperature locations are selected based on the position of the hardware sensors in the ‘Qualitubfish’ project experiments (Bekaert et al., 2016a) with some adjustments due to modelling only two ice layers, whereas the experiments were carried out with three layers (see Section 2.3.2.2 for details). The fish temperatures modelled for the validation consisted of the average temperature of the whole fish, as data loggers were inserted into the fish through the gutting cut.

-

5

Convective heat flux was considered with the usual heat transfer coefficient without air flow;

-

6

Initial conditions were assumed homogenous in space, i.e. with the same temperatures for all the points in the same domain; and

-

7

Whenever a parameter, initial condition or boundary condition may be case‐dependent, the usual practice was considered. Assumed values, such as the container‐specific characteristics of the tubs and boxes, are described in Table 1. The fish‐specific characteristics are provided in Table 2.

Figure 5.

Geometries and configuration of the container (box: a and c; tub: b and d) considered for modelling the surface temperature of (a) lean small fish in boxes with ice, (b) lean small fish in tubs with ice and water, (c) lean medium fish in boxes with ice and (d) lean medium fish in tubs with ice and water

- Blue, yellow and grey domains represent ice, air and container material, respectively. Domains are scaled to represent cooling conditions (63 and 15 kg of ice in tubs and boxes, respectively). The pink domain is the air/fish matrix in boxes and the water/fish matrix in tubs. The red ellipsoids represent the fish where the temperature was captured and used to simulate the hazard behaviour. The box is open on the top without any lid, while the tub is closed with the same foam. Note that the orientation of small and medium fish is different to accommodate the medium fish inside the container

Table 1.

Container‐specific characteristics of the boxes and tubs

| Parameter | Boxes | Tubs |

|---|---|---|

| Container outer dimensions (L × W × H) | 80 × 45 × 27 cma | 120 × 100 × 79 cmb |

| Container inner dimensions (L × W × H) | 62 × 37 × 23 cma | 111–115 × 91–95 × 60.5–61.5 cmc |

| Container thickness | 0.5 cm | 4.6 cm |

| Container material | HDPEc | Triple‐walled with a PE structure of the outer walls and PE core of the container (3.6 cm PE foam core in between 0.5 cm HDPE skin)c , d |

| Container weight | 4.18 kga | 55 kgb |

| Container volume | 60 La | 630 Lb |

| Fish added in the container | 30 kge | 440 kgf |

| Ice added in the container | 15 kg (for ‘keeping’ and ‘cooling‐keeping’ processes)e | 38 kg (‘keeping’ process) and 63 kg (‘cooling‐keeping’ process)f |

| Water added in tubs | NA | 100 kg (‘keeping’ process) and 100 kg (‘cooling‐keeping’ process)f |

| Type of water used | NA | Freshwater without salt added |

| Type of ice and arrangement | Top and bottom layers of ice | Water with ice on top |

HDPE: high‐density polyethylene; NA: not applicable; PE: polyethylene.

Based on the ‘180° fish box ‐ 800 × 450 × 270 mm ‐ solid base and walls ‐ 2 open handholes’.10

Based on the ‘Seaplast 630 Insulated Storage Bulk Container’.11

Considered having following properties (as of PE skin): thermal conductivity of 0.44 W/(m·°C), density of 930 kg/m3 and heat capacity of 1.64 kJ/(kg·°C) at constant pressure.

Considered having following properties (as of PE foam of the core of the container): thermal conductivity of 0.05 W/(m·°C), density of 70 kg/m3 and heat capacity of 2.3 kJ/(kg·°C) at constant pressure.

Considered having following properties: thermal conductivity of 0.035 W/(m·°C), density of 31 kg/m3 and heat capacity of 1.28 kJ/(kg·°C) at constant pressure.

For boxes, the amount of fish and ice considered the practice applied in the ‘Qualitubfish’ project (Bekaert et al., 2016a,b) and relied on the ice/fish ratio of 1/2 according to (Graham et al., 1992). Smaller quantities of ice with respect to fish have been also reported (Thordarson et al., 2017; Laguerre et al., 2019), which may lead to an earlier need of re‐icing to ensure the presence of ice in the container.

For tubs, the amount of fish and water was based on the practice applied in the ‘Qualitubfish’ project (Bekaert et al., 2016a,b), while the amount of ice was estimated through the ice calculator for tubs that can be retrieved at https://isreiknir.matisprojects.com/ (Ragnarsson, 2017). Convection on both sides of the wall was not considered and it assumed that the container is closed and is similar to 660 L‐PE. The calculations were made to ensure ice was not completely melted when the tub would be stored for 7 days at 2°C (with safety margin of 2 days). It assumed an initial fish and water temperature of 0°C and 3°C, respectively, for the ‘keeping’ process. It assumed an initial fish and water temperature of 7°C and 0.5°C, respectively, for the ‘cooling‐keeping’ process.

Table 2.

Fish‐specific characteristics

| Fish temperature | ||

|---|---|---|

| Initial temperature | 0°C or 7°C depending on the scenario (see Section 2.2) | |

| Small fish (e.g. plaice)a | Medium fish (e.g. salmon)b | |

| Fish dimensions: length | 29 cm | 50 cm |

| Fish dimensions: height | 15.5 cm | 10.7 cm |

| Fish dimensions: thickness | 0.85 cm | 5 cm |

| Lean fish (e.g. haddock/cod) c | Fat fish (e.g. salmon) d | |

| Thermal conductivity (k) | 0.43 W/m°C | 0.41 W/m°C |

| Specific heat capacity (Cp) | 3.73 kJ/kg°C | 3.50 kJ/kg°C |

| Density (ρ) | 1,054 kg/m3 | 1,025 kg/m3 |

Average length for Atlantic salmon is 70–75 cm and its average weight is 3.5–5.5 kg. The maximum reported length for Atlantic salmon is 150 cm and a maximum reported weight of 46.8 kg (https://www.fws.gov/fisheries/freshwater-fish-of-america/atlantic_salmon.html). The salmon with a length of 50 cm would correspond to a weight of around 1.4 kg.

Representative of a plaice of a size class 4 having a weight of 150–300 g (https://lv.vlaanderen.be/nl/visserij/cijfers-marktoverzichten/prijsnoteringen).

Based on Margeirsson et al. (2012).

2.3.2.1. ‘Cooling’ and ‘cooling‐keeping’ processes of fish in boxes and tubs

Figure 5 illustrates the geometries applied when modelling the temperature of the fish surface for the cooling and ‘cooling‐keeping’ processes of lean small or medium fish in boxes and tubs. Each domain is represented with a different colour. The red ellipsoids represent the fish that has been considered for recording its surface temperature to assess the hazard behaviour (Sections 2.5.2 and 2.5.3).

For fat fish, domains were recalculated to maintain the same ratios of fish/water/ice in tubs and fish/air/ice in boxes (Table 1) considering that the fat fish density is slightly lower than that of the lean fish (see Table 2). For the ‘keeping’ process, the domains were scaled to have 38 kg instead of 63 kg of ice in tubs. For boxes, no changes were required as the same amount of ice was used for ‘keeping’ and ‘cooling‐keeping’ process.

The water or air used inside the containers was considered precooled at 0.5°C for the ‘cooling‐keeping’ process, but not for the ‘keeping’ process, in which the value measured in the ‘Qualitubfish’ experiment (i.e. 2.7°C) was used. For both ‘keeping’ and ‘cooling‐keeping’ process, 1.5°C was used for the material of the container and −0.5°C for ice (see modelling assumption 2 for justification).

2.3.2.2. Validation of the heat transfer model

To validate the predictive performance of the heat transfer model, predicted and observed data from the first experiment of the ‘Qualitubfish’ project were compared. Some parameters and initial conditions were different from those in the case studies described for the ‘abusive’ scenarios. In these cases, the parameter value used was based on the actual measurements carried out in the project experiments. Details are shown in Appendix B.

The first experiment evaluated temperatures of one fish in a box and three fish on the bottom, middle and top of a tub. The top fish was subjected to higher temperatures than expected as it was not fully covered with ice and this location (fish between ice and air domains) could not be simulated with the model; therefore, this record was excluded for the validation.

For the other temperatures, the following locations were assumed:

Fish in the box was modelled by placing the fish close to the box wall and just below the ice layer. The position close to the ice was selected because in the experiments, boxes were filled with three layers of ice (top, middle and bottom), whereas only two layers were assumed (top and bottom) for modelling (as a worst case). Total amounts of ice were the same in the experiments and modelling;

Fish in the tub bottom was simulated by placing the fish on the bottom close to the corner; and

Fish in the tub middle was simulated by placing the fish in the centre of the horizontal plane (x–y axis) but just behind the ice layer for the vertical (z axis). Results for a fish located on the centre in the vertical (z axis) showed higher temperatures than in the experiments. It should be noted that the exact location of the fish in the experiment is unknown and the fish with the temperature logger might move up at some point.

To make the temperatures reported by the model and the loggers placed inside the fish more comparable, average temperatures inside each of the fish were calculated. It should be noted that using the same approach as for the case studies, i.e. Tmax in each of the containers or Tmax on the fish surface, would have significantly overestimated the observed temperatures.

2.4. Water absorption and consequences on fish WPS

A literature search was performed to gather scientific publications, reports and official documents relevant to the water absorption in fish stored under different conditions. Focusing on publications between 1965 and 2019 (inclusive) and relying on expertise in the WG (e.g. relevant peer reviewed papers, scientific reports, book chapters), this was further developed using ‘footnote chasing’ until sufficient coverage of the subject area was achieved.

According to water sorption isotherms, at the high aw values of fresh fish, the increase of water content has little impact on aw. Furthermore, the inaccuracy of the water sorption isotherms at the upper extreme (aw > 0.90) is high as the studies usually focus on the desorption isotherm (built for drying or dehydrating products with aw < 0.96) and do not represent the sorption isotherm representing the intake of water by fresh fish that has not been dried before. It was decided to use instead the WPS as a parameter for assessing the impact of fish water uptake on the behaviour of relevant hazards. The WPS can be derived from the salt and water content of foods. For foods without added salt, the percentage of endogenous salt in the WPS is calculated by dividing the salt content by the water content multiplied by 100, to express it as percentage.

The potential impact of the storage conditions of FFP in water and ice (in tubs) on parameters relevant for bacterial growth (e.g. oxygen availability, internalisation) was assessed from literature review.

2.5. Behaviour of relevant hazards

The impact of the fish temperature on the behaviour (survival or growth) of the identified hazards during the transport and storage of FFP in tubs compared to boxes was assessed applying predictive models, when available, for specific pathogens and histamine accumulation using as input the observed t/T profiles and those derived through heat transfer modelling. For the latter, the following was used: (i) the ‘observed’ scenarios through the fish t/T recorded in the ‘Qualitubfish’ experiment as detailed in Section 2.3.1 and/or (ii) the ‘abusive’ scenarios from predicted surface t/T profiles from the heat transfer model in boxes and tubs considering different processes (‘cooling‐keeping’ and ‘keeping’), fat content and dimensions of fish (Section 2.3.2, Figure 3).

When no predictive models were available for a particular hazard, its behaviour was assessed using the relevant studies selected from the literature review (Section 2.1) reporting data on the levels of the hazards during the storage of FFP at different temperatures. Survival was considered either as no change or as a reduction of the concentration of relevant selected hazards. The potential impact of factors other than temperature associated with the storage/transport of FFP in tubs with water and ice was taken into account in the uncertainty analysis.