Abstract

A multi‐country outbreak of Listeria monocytogenes ST6 linked to blanched frozen vegetables (bfV) took place in the EU (2015–2018). Evidence of food‐borne outbreaks shows that L. monocytogenes is the most relevant pathogen associated with bfV. The probability of illness per serving of uncooked bfV, for the elderly (65–74 years old) population, is up to 3,600 times greater than cooked bfV and very likely lower than any of the evaluated ready‐to‐eat food categories. The main factors affecting contamination and growth of L. monocytogenes in bfV during processing are the hygiene of the raw materials and process water; the hygienic conditions of the food processing environment (FPE); and the time/Temperature (t/T) combinations used for storage and processing (e.g. blanching, cooling). Relevant factors after processing are the intrinsic characteristics of the bfV, the t/T combinations used for thawing and storage and subsequent cooking conditions, unless eaten uncooked. Analysis of the possible control options suggests that application of a complete HACCP plan is either not possible or would not further enhance food safety. Instead, specific prerequisite programmes (PRP) and operational PRP activities should be applied such as cleaning and disinfection of the FPE, water control, t/T control and product information and consumer awareness. The occurrence of low levels of L. monocytogenes at the end of the production process (e.g. < 10 CFU/g) would be compatible with the limit of 100 CFU/g at the moment of consumption if any labelling recommendations are strictly followed (i.e. 24 h at 5°C). Under reasonably foreseeable conditions of use (i.e. 48 h at 12°C), L. monocytogenes levels need to be considerably lower (not detected in 25 g). Routine monitoring programmes for L. monocytogenes should be designed following a risk‐based approach and regularly revised based on trend analysis, being FPE monitoring a key activity in the frozen vegetable industry.

Keywords: Listeria monocytogenes, growth, blanched frozen vegetables, public health risk, risk factors, control options, food safety management systems

Summary

Following a request from the European Commission, the Scientific Panel on Biological Hazards (BIOHAZ) was asked to provide a scientific opinion on the public health risk posed by Listeria monocytogenes and, if considered relevant by EFSA, other pathogens that may contaminate fruit, vegetables and herbs (FVH) which are processed (e.g. blanched) prior to being placed on the market frozen. It was clarified that fruit and herbs are out of scope of the assessment, as these are typically not blanched while some or all groups of vegetables may be blanched. These will be referred to as blanched frozen vegetables (bfV).

In particular, EFSA was asked to provide an estimation of the public health impact of L. monocytogenes contamination, and if considered relevant also of other pathogens in bfV, compared with other known pathogen–food combinations (Term of Reference 1; ToR1). Based on the number of human cases involved in the food‐borne outbreaks (FBOs) in the European Union (EU) (2005–2018), L. monocytogenes is the most relevant pathogen in bfV for public health. Therefore, the public health impact of L. monocytogenes contamination of bfV was compared with the better‐known risk of food‐borne illness associated with ready‐to‐eat (RTE) foods such as RTE meat products, dairy products and/or fishery products. Comparison was done using data on strong FBOs at EU/EEA level from 2008 to 2018 related to L. monocytogenes for the whole population. The ‘dairy’ food category was responsible for five outbreaks by L. monocytogenes involving 47 cases, while ‘fish and seafood’ and ‘meat and meat products’ caused nine and 16 outbreaks involving 63 and 190 cases, respectively. Cases linked to bfV were reported only in 2018 and involved 46 persons (all hospitalised) and five deaths. Also, a quantitative microbiological risk assessment (QMRA) model was used to estimate the listeriosis risk associated with the consumption of bfV by the elderly population of the age group 65–74 years old. The bfV were separated into two subcategories to encompass the range of consumer habits in relation to the mode of use/consumption; namely those consumed uncooked or cooked (i.e. boiled, fried or microwave heated). The estimated individual risk, i.e. the probability of illness per serving, is lower for bfV than for any of the RTE food subcategories evaluated, i.e. cold‐smoked fish, hot‐smoked fish, gravad fish, cooked meat, sausage, pâté and soft and semi‐soft cheese. It is up to 3,600 times greater for bfV consumed uncooked rather than cooked and judged to be very unlikely (5–10%) to be higher for bfV consumed uncooked than for soft and semi‐soft cheese. The estimated public health impact, i.e. the annual number of cases for elderly females in the EU, taken as an example, is less than two cases per year, which is, considering also the uncertainty, lower than any of the evaluated RTE food categories. The public health impact of bfV is dominated by the proportion of total servings consumed uncooked.

The main risk factors of contamination and growth of L. monocytogenes in bfV from processing until consumption were assessed in ToR 2. The production steps considered started from the receipt of the raw material at the processing plant, while the consumption steps included storage after thawing, food preparation and consumption habits. The main factors that may increase the contamination and/or growth of L. monocytogenes in bfV during processing are: (i) the hygiene status of the incoming raw materials; (ii) the hygienic conditions of the food processing environment (FPE), including food contact surfaces (FCSs) and non‐FCSs; (iii) the microbiological quality of the process water; and (iv) the time/Temperature (t/T) combinations used for storage, washing, blanching, cooling and freezing. Blanching (depending on t/T applied in the process) and water disinfection (to maintain the microbiological quality of process water) can reduce the contamination of L. monocytogenes in bfV at processing level. The main factors affecting contamination and/or growth of L. monocytogenes in bfV after processing are: (i) the intrinsic characteristics of the bfV (e.g. pH, aw, nutrients, presence of antimicrobial compounds and natural microbiota); (ii) the t/T profiles during thawing and storage; and (iii) the cooking conditions applied, including the cooking method and equipment.

In ToR 3, recommendations were requested on possible control options that may be implemented by food business operators (FBOp) during the production process of bfV. Control options are based on prerequisite programmes (PRPs), including good hygiene practises (GHP), good manufacturing practices (GMP) and operational PRPs (oPRPs), as well as procedures based on the hazard analysis and critical control points (HACCP) principles. Analysis of the hazards and activities of the target FBOp suggest that PRPs are sufficient to reduce contamination and the application of a complete HACCP plan is either not possible or would not further enhance food safety. In total, 11 PRP categories were identified, which, if implemented together, are very likely (95–99%) to reduce the probability of contamination of bfV by L. monocytogenes. Hygienic design of equipment, cleaning and disinfection of the processing environment and water control are of utmost importance to reduce the probability of introduction, survival and growth of L. monocytogenes. Additionally, t/T combinations applied during washing, blanching, cooling and freezing must be controlled to prevent the potential for any surviving L. monocytogenes to grow. Four different oPRPs are suggested as control measures and linked to seven different processing stages including: (i) equipment and processing environment (oPRP1: cleaning and disinfection); (ii) processing steps where water is used (oPRP2: water control); (iii) washing (oPRP3: t/T control); (iv) blanching (also oPRP3: t/T control); (v) cooling (also oPRP3: t/T control); (vi) freezing (also oPRP3: t/T control); and (vii) consumer practices (oPRP4: product information and consumer awareness). Additional control measures which the aim to reduce or eliminate L. monocytogenes in the product or on food process surfaces have been identified. However, not all of these measures are commercially available. In addition, their efficacy is not yet fully validated in industrial settings.

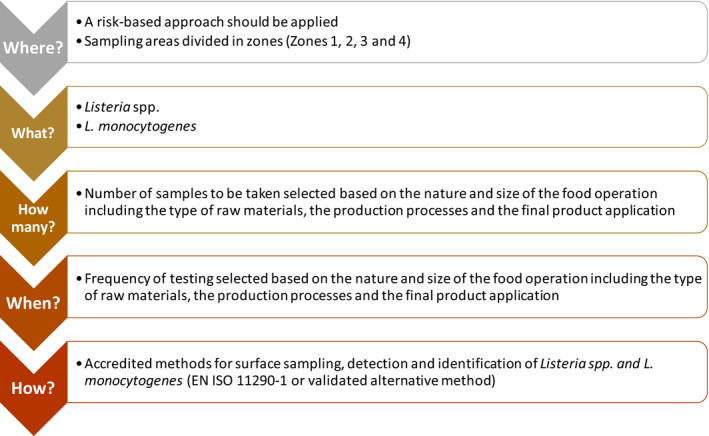

In ToR 3, recommendations were requested on routine monitoring for L. monocytogenes in the bfV processing environment and final product. This was carried out by critically appraising available guidelines for the industry. It was clarified that sampling and monitoring recommendations have the purpose to verify that the food safety management system (FSMS) implemented by the FBOp is well designed and has the appropriate control measures. Environmental monitoring (EM) can be used to validate or verify specific PRPs or as a strategy to monitor the environment for unhygienic conditions. An EM program should establish the sampling strategies and microbiological methods for L. monocytogenes detection most appropriate for maximising the identification of sources and routes of L. monocytogenes contamination in the FPE. Well‐established routine EM programmes should be designed on a risk‐based approach, considering the nature and size of the food operation and reflecting aspects related to the raw materials, the production processes and the final product application, but they also need to be regularly revised based on trend analysis. To establish a routine monitoring program, the FBOp should consider the following criteria: (i) the identification of the sampling points; (ii) the target microorganisms; (iii) the sample size; (iv) the frequency of testing; and (v) the selection of sampling, detection and quantification methods. It is not possible to give specific advice regarding the sampling sites that should be selected or the number of samples and frequency of sampling because these must be chosen on a case‐by‐case basis and established on a risk‐based approach and trend analysis. Sampling, detection and enumeration methods should follow validated methods. Subtyping of L. monocytogenes isolates by molecular methods (such as whole genome sequencing; WGS) is necessary to establish whether the isolates belong to a persistent clone.

It was clarified that, if the FBO decides to establish an intermediate level of L. monocytogenes concentrations in bfV at the end of the production process (i.e. performance objective; PO) compatible with the food safety objective (FSO) of 100 CFU/g at the moment of consumption without cooking, the PO would need to be estimated considering reasonably foreseen storage conditions (e.g. 48 h 12°C). This was mainly inferred from a study that considered the potential growth of L. monocytogenes in different bfV during storage for a maximum of 120 h at 5 to 12°C. It was concluded that the occurrence of relatively low levels of L. monocytogenes at the end of the production process, e.g. < 10 CFU/g (detection limit of the quantification method), would be compatible with that limit of 100 CFU/g as long as any labelling recommendations given are strictly followed (i.e. 24 h at 5°C). However, considering reasonably foreseeable conditions of use by the consumers beyond the labelling instructions (i.e. 48 h at 12°C), levels need to be considerably lower, even below the detection sensitivity of the current available standard analytical procedure/methods (not detected in 25 g) for those vegetables that best support pathogen growth. Microbiological criteria, set by the risk manager, can be used as a tool to verify that the threshold of the L. monocytogenes concentration in bfV at the end of production (compatible with the limit) is not exceeded. Sampling plans should be designed to take into consideration the expected heterogeneity of the contamination, the specificity and the sensitivity of the analytical methodology as well as the statistical confidence required for acceptance or rejection of non‐compliant lots. The impact of possible food safety criteria (FSC) on public health and/or on product compliance would be useful information to support risks managers’ decisions in this respect.

Consumer education and standardised label information are recommended to promote better understanding by consumers. It is also recommended to raise the awareness of the public health risks associated with the consumption of uncooked bfV, particularly by susceptible population groups. It is also recommended to perform subtyping of L. monocytogenes isolates detected during the routine monitoring program in FPE by molecular methods (e.g. WGS) and to improve collection and reporting of data on human listeriosis, including underlying conditions.

1. Introduction

1.1. Background and Terms of Reference as provided by the requestor

A multi‐country outbreak of Listeria monocytogenes ST6 that caused 53 cases and 10 deaths over the period 2015–2018, was linked in 2018 to frozen vegetables. The processing of such vegetables included a blanching step before their freezing. The outbreak was detected using very specific molecular analytical methods, facilitating the linkage between human and food isolates. Environmental contamination of a freezing plant was indicated as the source of the persistence of the strain causing the outbreak from 2015 until 2018. At the request of the Commission EFSA published, on 3 July 2018, recommendations on the sampling strategies and established microbiological methods for maximising the sensitivity of detection of L. monocytogenes in processing water and the environment of premises producing frozen fruit, vegetables or herbs (FVH) as well as on the final food produced. Recommendations were also provided on the identification of critical sampling sites for environmental monitoring (EM) of L. monocytogenes.

Outbreak investigations conducted showed that some frozen FVH can be defrosted and used as such in salads by consumers or as ingredients in other ready‐to‐eat (RTE) products subsequently sold to consumers without undergoing any process to eliminate or reduce the level of pathogens. If such defrosted FVH are stored for a prolonged period at refrigeration temperature, the potential growth of L. monocytogenes could represent a serious public health risk.

Commission Regulation (EC) No 2073/20051 lays down the microbiological criteria for certain micro‐organisms, their toxins or metabolites and the implementing rules to be complied with by food business operators (FBOp). In particular, different L. monocytogenes food safety criteria have been laid down for RTE foods, depending on their ability to support the growth of this pathogen. While L. monocytogenes does not grow in frozen foods and therefore, a threshold of 100 CFU/g has been accepted for such products, such criteria might not sufficiently protect the consumer if defrosted FVH are stored for a certain period, even at refrigeration temperatures, before consumption.

Following a major outbreak of Shiga toxin‐producing Escherichia coli (STEC) O104:H4 in Germany in 2011, EFSA issued seven scientific opinions on pathogens in food of non‐animal origin, including an opinion providing outbreak data analysis and risk ranking of food/pathogen combinations, adopted on 6 December 2012. No combination of L. monocytogenes with food of non‐animal origin were included in that ranking, due to both the absence of reported L. monocytogenes outbreaks implicating food of non‐animal origin and the criteria considered in the ranking tool.

Prevention of contamination of FVH with pathogens is based on hygiene requirements and implementation of the HACCP principles, to be respected by FBOp at all stages of the food production chain and laid down in general in Regulation (EC) No 852/2004 on the hygiene of foodstuffs.2 Recommendations on the specific application of these requirements in the production and storage of frozen FVH may further reduce the risk from the potential contamination of such food with foodborne pathogens.

In view of the above, there is a need to evaluate and recommend specific control measures to reduce public health risks arising from the consumption of frozen FVH.

EFSA is asked to issue a scientific opinion on the public health risk posed by L. monocytogenes and, if considered relevant by EFSA, by other pathogens that may contaminate fruit, vegetables and herbs which are processed (e.g. blanched) prior to be placed on the market frozen. More specifically, EFSA is asked to:

-

provide an estimation of the public health impact of L. monocytogenes contamination, and if considered relevant of other pathogens of frozen fruit, vegetables and herbs blanched before freezing. For this purpose, EFSA should make a semi‐quantitative estimation of the risk posed by the “Listeria/pathogen – frozen fruit, vegetables and herbs” combination by comparing such risk with better known risks, for example:

-

–

with the risk of L. monocytogenes from other food such as meat products, dairy products and/or fishery products, or

-

–

with the risk of food of non‐animal origin/pathogen combination, as done in the previous EFSA scientific opinion on the risk posed by pathogens in food of non‐animal origin. Part 1 (outbreak data analysis and risk ranking of food/pathogen combinations), adopted on 6 December 2012.

-

–

assess the main risk factors of contamination and growth of pathogens in frozen FVH during all stages from processing (excluding at primary production) until consumption (including e.g. storage after thawing, food preparation and consumption habits).

-

provide recommendations:

-

a)

on possible control options that may be implemented by FBOp during the production process of frozen FVH and assess their efficacy to reduce public health risks, and

-

b)

on routine monitoring for L. monocytogenes in frozen FVH taking into account good hygiene practises (GHP) and procedures based on the HACCP principles.

-

a)

1.2. Interpretation of the Terms of Reference

It was clarified that, for the three ToRs, the assessment was exclusively for the commercial production of blanched frozen FVH. Based on the information kindly provided by the European Association of Fruit and Vegetable Processors (PROFEL; Appendix A), no fruit groups and typically no herbs are blanched while some or all groups of vegetables may be blanched. Therefore, fruit and herbs are out of scope of the assessment. Frozen meals (e.g. vegetables with meat) were also beyond the scope of the assessment but mixtures of frozen vegetables were to be considered.

For some products, the blanching process depends on the customer requirements, factory or process. Mostly, hot water blanching and steam blanching are applied in freezing plants in the EU and these technologies will be addressed in the assessment.

In a previous scientific opinion (EFSA BIOHAZ Panel, 2013), a categorisation of foods of non‐animal origin (FoNAO) was made to permit a risk ranking among different commodities with respect to the main biological hazards covered in the assessment. This categorisation of FoNAO is compatible with the definition of the food commodities used in EU food‐borne outbreaks (FBOs) and food consumption databases and followed the conventional categories of botanical groups (e.g. citrus fruit, stone fruit, apples and related fruit, berries, melon, tomatoes, leafy vegetables, roots and tubers, etc). In this opinion, the same categorisation is followed, and fruiting vegetables/vegetable fruits are considered vegetables.

The frozen products may have undergone a size reduction (e.g. cut, sliced and diced) but shall not be smashed or juiced (e.g. into smoothies and purees) before freezing. However, the frozen vegetables can be thawed and used for example in smoothies. New specialities include frozen vegetables that have been grilled or coated, but these have not been considered within this opinion.

It was agreed that after the identification of the relevant pathogens for frozen vegetables blanched before freezing in the ToR1, answers to ToR2 and ToR3 would be elaborated considering the selected pathogens in ToR1.

Based on the above, ToR 1 aims to provide an estimation of the public health impact of L. monocytogenes contamination of blanched frozen vegetables (bfV). If considered relevant, other pathogens associated with bfV could be considered.

After discussion with the European Commission, several points were clarified for ToR 1 as follows:

-

–

The criteria to be used for considering another pathogen as relevant are to be defined by EFSA.

-

–

Also, the bfV as one group or as subgroups are to be defined by EFSA depending on their importance and available data to distinguish such subgroups.

-

–

The methodology to be used is to be defined by EFSA. It could be qualitative, semi‐quantitative, or quantitative depending on the available data.

ToR 1 was reformulated as assessment questions (AQs):

Which are the pathogen(s) (in addition to L. monocytogenes) in bfV of relevance for public health/illness in the EU?

What is the public health risk posed by L. monocytogenes/pathogen – bfV (subgroups) in comparison with other known pathogen–food combinations using the methodology best suited based on the available data?

For ToR 2, it was clarified that:

-

–

Both bfV and non‐bfV are processed in the same company using the same processing lines and steps. Therefore, if the processing of non‐blanched products is a risk factor for blanched products, non‐blanched products will also be considered.

-

–

Although frozen vegetables are traditionally considered as non‐RTE products, these products may be consumed uncooked. According to the British Frozen Food Federation (BFFF, 2018), historically frozen vegetables have not been represented as RTE and ready‐to‐defrost‐and‐eat (RTDE) foods. However, changing consumer behaviour towards ‘healthy’, ‘on‐the go’, ‘convenience’ meals has changed consumer perception meaning that frozen vegetables can be treated by consumers as safe to eat without cooking. Also a recent internal review of products in the frozen market made by that Federation (BFFF, 2018) identified variation in the labelling information, with some products clearly stating that they are RTE, others implying the need to cook, and others being unclear. Additionally, in several informative leaflets and websites of companies manufacturing frozen vegetables, the FBOp explicitly suggests eating them directly after thawing, without cooking.

-

–

The risk factors for contamination are interpreted as sources of contamination (increasing the prevalence and/or the level of contamination) and those affecting growth (increasing growth and thus the level of contamination). Cross‐contamination at the consumer level is not considered.

The ToR 2 has been reformulated as (AQs):

What are the main factors affecting contamination and/or growth of the pathogens defined in ToR 1 in bfV during processing (i.e. until the product is released to retail/packaged)?

What are the main factors affecting contamination of the product and/or growth of pathogens defined in ToR 1 in bfV after processing and until consumption (including e.g. storage after thawing, food preparation and consumption habits)?

For ToR 3, it was clarified that:

-

–

Food businesses are obliged to develop and implement food safety management systems (FSMS) including prerequisite program (PRP) activities and hazard analysis and critical control point (HACCP) principles. For this reason, control options will be based on prerequisite programmes (PRPs; e.g. cleaning and disinfection), and operational prerequisite programmes (oPRPs) and, if possible, control points (CPs) and critical control points (CCPs; i.e. the steps at which control can be applied and is essential to prevent or eliminate a food safety hazard or reduce it to an acceptable level). PRPs are preventive practices and conditions needed prior to and during the implementation of HACCP and which are essential for food safety. However, some prerequisites, typically linked to the production process, may be identified as essential to control the likelihood of the introduction, survival and/or proliferation of food safety hazards in the product(s) or in the processing environment. These are referred to as oPRPs.

-

–

The control options are to be compared based on their efficacy (i.e. reducing the L. monocytogenes occurrence or levels on the final product), but the impact of this reduction cannot necessarily be translated to public health.

-

–

The starting point will be the receipt of the raw material at the processing plant.

-

–

Recommendations on routine EM program for L. monocytogenes in bfV processing environment and final product included in this scientific opinion have the purpose to verify that the FSMS implemented by the FBOp is well designed and has the appropriate control measures. The aim of the EM program is to establish the sampling strategies and microbiological methods for L. monocytogenes detection most appropriate for maximising the identification of sources and routes of L. monocytogenes contamination in the FPE.

-

–

L. monocytogenes concentrations in bfV at the end of the production process compatible with 100 CFU/g would need to be estimated based on the potential growth of L. monocytogenes at reasonably foreseen storage conditions. This would help if the FBOp decides to establish an intermediate level to guarantee that the limit of 100 CFU/g is not exceeded at the moment of consumption without cooking.

ToR 3 has been reformulated as (AQs):

Which possible control options can be recommended to be implemented by the FBOp during the production process of bfV, along with their efficacy to reduce contamination (prevalence and/or levels) of L. monocytogenes, within the frame of procedures based on the HACCP principles and GHP (as part of the PRPs)?

What is the L. monocytogenes concentration in bfV at the end of the production process as performance objective (PO)3 that would be compatible with the food safety objective (FSO)4 of 100 CFU/g at the moment of consumption without cooking, for different times and temperatures of storage once the frozen vegetable is removed from the freezer.

What routine monitoring for L. monocytogenes in bfV processing environment and final product can be recommended to verify the correct application of GHP and/or within the frame of procedures based on the HACCP principles?

1.3. Additional information

1.3.1. Additional background information

1.3.1.1. Previous EFSA scientific opinions and reports

After the major FBO of STEC O104:H4 in Germany in 2011, EFSA was asked to identify and rank specific food/pathogen combinations most often linked to human cases, including frozen fruits and vegetables. Based on a semi‐quantitative model, the top‐ranking food/pathogen combination was Salmonella spp. and leafy greens eaten raw followed by (in equal rank) Salmonella spp. and tomatoes, Salmonella spp. and melons, Salmonella spp. and bulb and stem vegetables, and pathogenic Escherichia coli and fresh pods, legumes or grains. Among the limitations of the model, it was highlighted that more efforts should be given to collect additional data, even in the absence of reported FBOs, as well as to enhance the quality of the EU‐specific data. In addition, to assist future microbiological risk assessments (MRA), consideration should be given to the collection of additional information on how food has been processed, stored and prepared as part of the above data collection exercises (EFSA BIOHAZ Panel, 2013).

In the scientific opinion on L. monocytogenes contamination of RTE foods and the risk for human health in the EU, time series analysis for the 2008–2015 period in the EU/EEA indicated an increasing trend of the monthly notified incidence rate of confirmed human invasive listeriosis for the over 75 age groups and female age group between 25 and 44 years old (probably related to pregnancies). A conceptual model was used to identify factors in the food chain as potential drivers for L. monocytogenes contamination of RTE foods and listeriosis. Factors considered likely to be responsible for the increasing trend in cases are the increased population size of the elderly and susceptible population except for the 25–44 female age group. For the increased incidence rates and cases, the likely factor is the increased proportion of susceptible persons in the age groups over 45 years old for both genders. Quantitative modelling suggests that more than 90% of invasive listeriosis is caused by ingestion of RTE food containing > 2,000 CFU/g, and that one‐third of cases are due to growth of the organism in the consumer phase (EFSA BIOHAZ Panel, 2018). In this opinion, three EFSA outsourcing activities under ‘Closing gaps for performing a risk assessment on L. monocytogenes in RTE foods’ are summarised, including: an extensive literature search and study selection with data extraction on L. monocytogenes in a wide range of RTE foods (Pérez‐Rodríguez et al., 2017); a quantitative risk characterisation on L. monocytogenes in RTE foods, starting from the retail stage (Pérez‐Rodríguez et al., 2017); and the comparison of isolates from different compartments along the food chain, and in humans using whole genome sequencing (WGS) analysis (Møller Nielsen et al., 2017).

In 2018, EFSA and ECDC published the multi‐country outbreak report on L. monocytogenes serogroup 4b, multi‐locus sequence type (MLST) 6, infections linked to frozen corn and possibly to other frozen vegetables (EFSA and ECDC, 2018). This FBO of invasive L. monocytogenes infections confirmed by WGS had been ongoing in Austria, Denmark, Finland, Sweden and the United Kingdom since 2015. As of 15 June 2018, 47 cases were reported, and nine patients died.5 Cases were detected in Finland (23 cases), United Kingdom (11 cases), Sweden (7 cases), Denmark (4 cases) and Austria (2 cases). The median age of cases was 72 years (interquartile range 56–85), 26 (55%) cases were females. Information on hospitalisation was available for 16 patients, who were all hospitalised. WGS analysis of 29 non‐human L. monocytogenes isolates found them to be closely related to the multi‐country human cluster of L. monocytogenes serogroup 4b, MLST 6. The non‐human isolates were obtained from frozen corn, frozen vegetable mixes including corn, frozen spinach products, frozen green beans and two environmental samples. Traceability information for the contaminated products pointed to the source of contamination in a Hungarian freezing plant. It is possible that frozen vegetables other than corn processed in this plant could also be a vehicle of human infection. The maximum concentration found was 1,400 CFU/g in one frozen corn batch. However, the strain was not related to the FBO. L. monocytogenes 4b, ST6, but matches the outbreak strain in frozen corn and other frozen vegetables produced in the 2016, 2017 and 2018 production seasons at the plant of the Hungarian company A. This suggests, according to the report, that the strain was persisting in the processing environment after standard cleaning and disinfection procedures carried out in conjunction with periods of inactivity in the plant, as well as the rotation of the processed products. Production sites were also sampled in the Hungarian company A. The first positive sample was taken after the grinding stage which occurs after blanching (96°C for 110 s) and cooling of spinach.

Based on the consumption information included in the multi‐country outbreak report, no information on consumption as RTE (without cooking) of the implicated foods was provided. However, consumers may have eaten these thawed products without having cooked them properly or at all. For example, foods cooked in the microwave may still have cold spots where the bacteria could survive. Moreover, it was stated that ‘the consumption of thawed corn and thawed vegetables without cooking them is not an unusual practice (e.g. in salads, smoothies, etc.).’ and ‘In order to reduce the risk of L. monocytogenes infection due to the consumption of contaminated non ready‐to‐eat frozen vegetables, consumers should thoroughly cook these products before consumption, as it is not unusual for them to be consumed without being cooked (e.g. in salads, smoothies)’.

In 2018, EFSA provided scientific and technical assistance for the design of sampling and testing strategies for the detection of L. monocytogenes in the processing plants of frozen FVH. This was expected to support the competent authorities (CA) and FBOp in the, at that moment ongoing, multi‐country outbreak investigation mentioned above. Recommendations to the European Commission were provided on the sampling strategies and established microbiological methods most appropriate for maximising the sensitivity of detection of L. monocytogenes for microbial source tracking (MST) to identify the point of origin of microbial contamination in a food processing environment (FPE) including raw vegetables, processing water and the environment of premises producing frozen FVH as well as on the final food produced. Seven steps were defined for a fit‐for‐purpose sampling strategy, including the identification of critical sampling sites (CSSs) for EM of L. monocytogenes, which is expected to support food‐borne outbreak investigations where frozen FVH are implicated. The relevant CSSs can be defined based upon critical inspection inside a freezing plant and the background information described in the report. The international standards EN ISO 11290‐1:20176 and EN ISO 11290‐2:20177 were recommended for L. monocytogenes detection and enumeration. It was concluded that characterisation of L. monocytogenes isolates using well‐established molecular techniques is needed to establish links between isolates from humans and from implicated FVH (EFSA, 2018).

This FBO triggered PROFEL to take steps as a sector association together with DG SANTE. Two actions were agreed: (a) Investigate the risks associated with frozen vegetables – the growth rate of L. monocytogenes in five products (challenge tests) and the subsequent recommendation for on‐pack instructions and guidance to consumers; (b) Develop an industry guide to good hygiene practices, which will be used to raise awareness and improve standards across the industry. In collaboration with the Commission and EU MS, the guidelines aim to meet the requirements of Regulation (EC) No 852/20042 in order to obtain recognition as EU community guides for the production and food safety management of quick‐frozen FVH, starting from the receipt of raw materials and ending with the packed end products ready for next step in the food supply chain, business to business (B2B), business to consumer (B2C). The target is that FBOp active in the commercial production and/or trade of quick‐frozen FVH may use the guidelines as a starting point for their own FSMS, helping on the elaboration of good practices, PRPs and HACCP principles. The scope for the challenge tests is frozen FVHs, categorised to identify the most relevant products based on pH, sugar content, anti‐bacterial compounds, nutrient level and structure/texture of the product. From each category, a model product was chosen on which challenge tests were performed to identify the risk of possible L. monocytogenes growth. The selected products were white cabbage, sweetcorn kernels, sweet potatoes, peas and parsnips. The draft hygienic guidelines were submitted to DG SANTE by the end of October 2019 and have simultaneously been shared for consultation with broader interested stakeholder organisations representing suppliers or users of frozen FVH and other relevant interest groups (farmers, HORECA/catering, food and drink industry, consumer organisations, retailers, etc.) and with EFSA (see documentation provided to EFSA). These will be referred to as draft PROFEL guidelines in this document.

1.3.1.2. Production of bfV

Information kindly provided by PROFEL indicates that around 3.8 million tonnes of frozen vegetables were produced in the EU in 2017, which corresponds to data from 16 Member States (MS). Table 1 shows the production values for the different MS. In the draft PROFEL guidelines (PROFEL, 2019), the EU annual production of quick‐frozen vegetables8 is estimated at 4 million tonnes, including all MS.

Table 1.

Production of frozen vegetables in the EU (tonnes) as provided by Mrs. Nele Cattoor (General Secretary at PROFEL) by e‐mail on 28 June 2019 (Cattoor, 2019b)

| Country | 2014 | 2015 | 2016 | 2017 |

|---|---|---|---|---|

| Belgium, the Netherlands, Germany, UK | 1,481,105 | 1,415,079 | 1,442,825 | 1,511,392 |

| Portugal, Spain | 603,100 | 666,700 | 703,600 | 843,400 |

| Austria, Czechia, Denmark, Finland, Italy, Sweden | 394,384 | 351,211 | 317,132 | 377,328 |

| Poland | 404,000 | 449,800 | 585,600 | 707,000 |

| France | 391,324 | 399,535 | 381,000 | 321,015 |

| Hungary | 70,629 | 70,150 | 62,587 | 36,950 |

| Greece | 30,000 | 30,000 | 30,000 | 30,000 |

| Total | 3,374,542 | 3,382,475 | 3,522,744 | 3,827,085 |

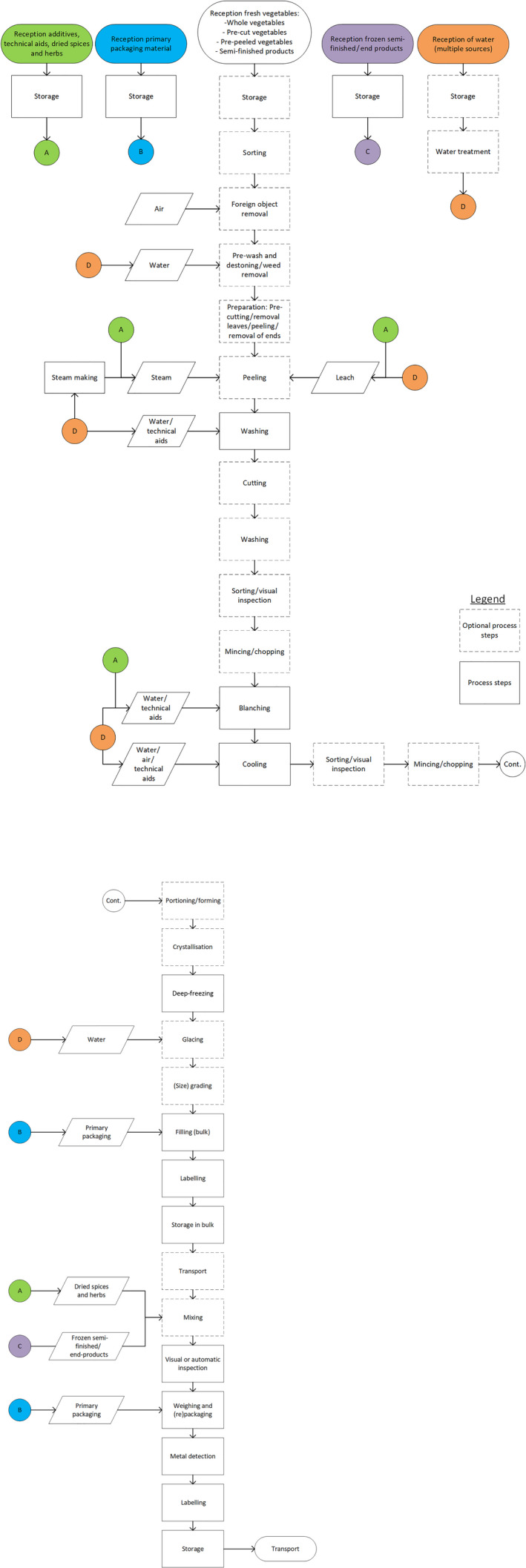

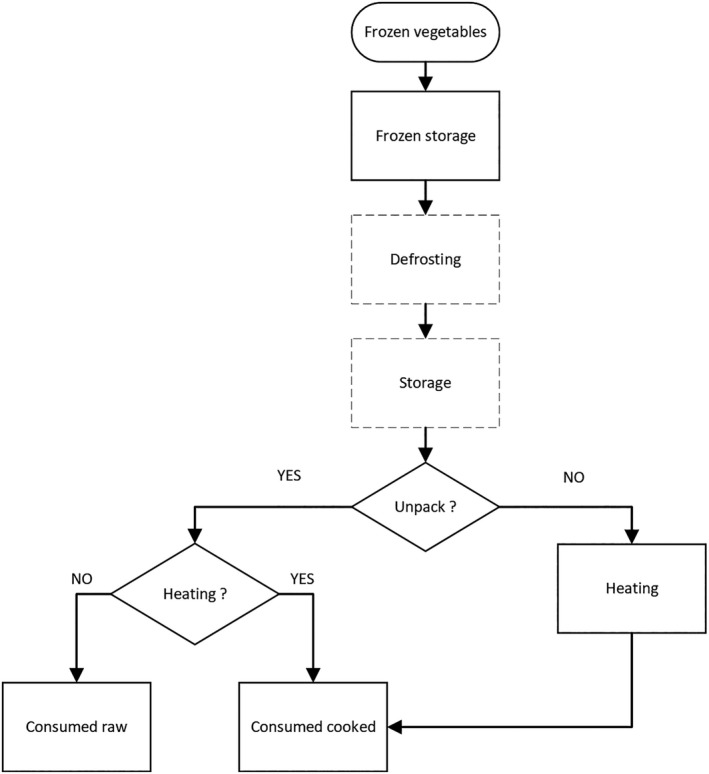

In the previous EFSA report (EFSA, 2018), the production of frozen FVH has been described in detail. As this assessment is restricted to bfV, the flow charts have been revised and are presented in Figures 1a and b. They provide a general description of the process to produce bfV from the moment of receipt of the fresh vegetables/ingredients at the freezing plant and/or handling facilities. It should be noted that the details of this flow chart might vary between companies.

Figure 1.

General flow chart for the production of blanched frozen vegetables from the moment of receipt of the fresh vegetables at the freezing plant and/or handling facilities

- This flow chart might vary between companies and only represents a general description of the process.

1.3.1.3. Legal background

Food safety criteria (FSC) for L. monocytogenes in RTE foods have been applied from 2006 onwards (Commission Regulation (EC) 2073/20051). This Regulation requires the following:

-

–

In RTE foods intended for infants and RTE foods for special medical purposes, L. monocytogenes must not be detected in 25 g of sample (n = 10 sample units);

-

–

In RTE foods that are unable to support the growth of the bacterium, other than those intended for infants and for special medical purposes, L. monocytogenes must not exceed 100 CFU/g during the shelf‐life (n = 5 sample units); and

-

–

In RTE foods that are able to support the growth of the bacterium, other than those intended for infants and for special medical purposes:

-

○

L. monocytogenes must not be detected in 25 g of sample before they have left the immediate control of the producing FBOp (n = 5 sample units), when the FBOp is not able to demonstrate, to the satisfaction of the CA, that the product will not exceed the limit of 100 CFU/g throughout the shelf‐life; and

-

○

L. monocytogenes must not exceed 100 CFU/g during the shelf‐life (n = 5 sample units) when the FBOp is able to demonstrate, to the satisfaction of the CA, that the product will not exceed the limit of 100 CFU/g throughout the shelf‐life.

-

○

In this Regulation, RTE food is defined, as Food intended by the producer or the manufacturer for direct human consumption without the need for cooking or other processing effective to eliminate or reduce to acceptable level microorganisms of concern.

1.3.2. Approach to answer the ToR

Term of reference 1

To answer to ToR 1, the pathogen(s), in addition to L. monocytogenes, in bfV of relevance for public health in the EU were identified and defined based on data of FBOs and of the Rapid Alert System for Food and Feed (RASFF). The information kindly provided by PROFEL (Appendix A) was used to distinguish the vegetables that are usually blanched before the freezing process. Then, the blanched vegetable subgroup(s) of interest were chosen considering the pathogens selected and the available data. Finally, the public health impact of L. monocytogenes contamination of bfV was compared with the better‐known risk of food‐borne illness associated with RTE foods such as RTE meat products, dairy products and/or fishery products. This was done using data on FBOs at EU/EEA level from 2008 to 2018 related to L. monocytogenes for the whole population and using a QMRA model to estimate the listeriosis risk with the consumption of bfV by the elderly population of the age group 65–74 years old. This population category was selected because it represents a higher risk than the younger population, but it does not represent the worst‐case scenario (population over 75 years old). For the modelling approach, bfV were separated into two different food subcategories to encompass the range of consumer habits in relation to the mode of use/consumption. Namely those consumed uncooked (i.e. consumed without any cooking step able to eliminate L. monocytogenes) and those consumed cooked (i.e. boiled, fried or microwave heated, as recommended by most of the producers). Since full cooking of vegetables would result in negligible risk, the latter subcategory also includes heat treatments that would not result in the elimination of L. monocytogenes.

Term of Reference 2

The approach taken to answer to ToR 2 was to identify the main factors affecting contamination and growth of the pathogen(s) in bfV during the production and consumption stages. The production steps started from the receipt of the raw material at the processing plant (excluding primary production), while the consumption steps included e.g. storage after thawing, food preparation and consumption habits.

Term of Reference 3

The approach taken to answer to ToR 3 was to identify the food safety management options during the production process, based on the outcome of ToR 2 regarding factors affecting contamination and growth. These control options include PRPs, including GHP, good manufacturing practices (GMP) and oPRPs, as well as procedures based on the HACCP principles. Also, alternative methods reported by the scientific literature as potential intervention options for the inactivation of L. monocytogenes and, in most cases, not implemented by the industry were considered. Considering that control options are based on preventive measures, the efficacy of the establishment of specific PRPs on the reduction of contamination in the product cannot be assessed. Recommendations on routine monitoring for L. monocytogenes in the bfV processing environment and final product were carried out by critically appraising available guidelines for the industry taking into account that sampling and monitoring recommendations have the purpose to verify that the FSMS implemented by the FBOp is well designed and has the appropriate control measures. The growth of L. monocytogenes in different bfV after different holding periods under reasonably foreseeable conditions of use by the consumers was calculated, using data on growth kinetic parameters and growth potential, to estimate the L. monocytogenes concentration at the end of the production process that would be compatible with the FSO of 100 CFU/g.

2. Data and methodologies

2.1. Data

2.1.1. Data request through EFSA's Microbiological Risk Assessment network

The Microbiological Risk Assessment (MRA) network was requested to provide information about:

the presence and concentration of pathogens (incl. L. monocytogenes) in frozen vegetables and, if available, their link to human cases (e.g. FBOs);

the risk factors and possible control options (and efficacy) from processing until consumption;

the growth of L. monocytogenes in thawed vegetables; and

the consumer behaviour for handling frozen vegetables (e.g. temperature/time conditions of thawing; % consuming uncooked; % thawed beforehand) and consumption (e.g. importance of industrially frozen vs. fresh vegetables).

2.1.2. Data on pathogens of public health relevance in bfV

2.1.2.1. Food‐borne outbreaks

Within the framework of the EU Zoonoses Directive 2003/99/EC,9 the EU MS are required to submit data on the occurrence of zoonoses, zoonotic agents, antimicrobial resistance and FBOs. EFSA, in collaboration with ECDC, coordinates the collation and analysis of these data to produce the annual EU One Health Zoonoses Report10 which include data on FBOs. The latter represents the most comprehensive set of data available at an EU level for assessing the burden of FBOs in the EU/EEA and the related contributing risk factors. The technical specifications for harmonised reporting of FBOs through the EU reporting system, in accordance with the aforementioned EU Zoonoses Directive can be found in EFSA (2014).

For the identification of pathogens of public health relevance in bfV, data on ‘strong and weak evidence’ FBOs from the years 2005–2018 were extracted from the EFSA zoonoses database on 29 July 2019.

To compare the vehicles involved in the outbreaks related to L. monocytogenes, only data on ‘strong’ FBOs at EU/EEA level from 2008 to 2018 were considered and were extracted from the EFSA zoonoses database on 29 July 2019.

2.1.2.2. EU Rapid Alert System for Food and Feed data

Commission Regulation (EU) No 16/201111 lays down the implementing measures for the requirements of Regulation (EC) No 178/200212 around the RASFF.13 This is established as a system facilitating the notification of food and feed safety alerts among the CAs of MS. Although, the RASFF system is primarily a communication facility and cannot be considered to be an epidemiological surveillance system as explained previously (EFSA BIOHAZ Panel, 2018), RASFF data were used in this assessment to provide information about the hazards present in frozen vegetables. A search was conducted on 1 August 2019 of the RASFF database using as product category ‘food’, as the hazard category ‘pathogenic microorganisms’, as the product categories ‘fruits and vegetables’ or ‘herbs and spices’ and as subject ‘frozen’ or ‘freezing’. No time restriction was applied. Manual screening was performed to gather information about the product being a frozen vegetable not being smashed or juiced before freezing.

2.1.3. Data on L. monocytogenes in frozen vegetables

2.1.3.1. EFSA monitoring data

The monitoring data collected by EFSA on L. monocytogenes in RTE food are mainly food chain control data (official monitoring) and are collected by the CA conducting investigations to verify whether the FBOp implement correctly the FSC (see Section 1.3.1.3). As stated by Boelaert et al. (2016) and EFSA (EFSA BIOHAZ Panel, 2018), L. monocytogenes belongs to a second category of monitoring data that are less harmonised compared to a first category of fully harmonised and comparable data. Although the matrices sampled are harmonised and the sampling and analytical methods for L. monocytogenes are harmonised to a certain extent, the sampling objectives, the place of sampling and the sampling frequency vary or are interpreted differently between MS and according to food types. Data on the occurrence of pathogens on frozen vegetables were extracted (matrix level 3) for the years 2008–2018. Only the data retrieved using detection methods (presence/absence) were used as these are considered to have a higher sensitivity compared to the L. monocytogenes enumeration method. Data were summarised considering the sampling units (single units and batches), sampling stages (processing and retail stages), sampling context (e.g. surveillance, monitoring) and sampling strategy (e.g. ‘census sampling’, ‘convenience sampling’ and ‘objective sampling’ vs. ‘suspect sampling’, ‘selective sampling’).

2.1.3.2. Data from scientific literature and outsourcing activities

The strategy for conducting the literature searches is provided in Appendix B. Two searches were conducted in Web of Science™ Core Collection (1975–present), CABI: CAB Abstracts® (1910–present) and PubMed on 8 April 2019. The search aimed to retrieve information on hazards in frozen FVH (first search) and related to L. monocytogenes in frozen FVH (second search).

The records were complemented with relevant records from the report by Jofré et al. (2016). In that report, the results of an extensive literature search considering the time span 1990–2015, is described with the aim to gather information on the occurrence and levels of contamination of L. monocytogenes in different foods (i.e. RTE foods, leafy greens and melons and traditional meat products) and risk factors for L. monocytogenes contamination of various foods. Information was extracted about the study, type of product (population) and analytical methodology, risk factors (exposure and comparators) and results (outcomes) about prevalence and concentration of L. monocytogenes. Also, data obtained through the MRA network and extracted from the monitoring data were assessed (see Section 2.1.1).

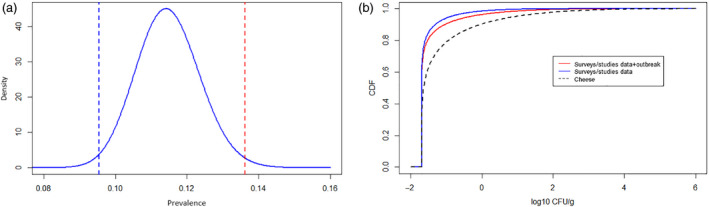

Prevalence data were included considering random sampling taking place after 2010 from Europe and North America, covering retail or processing plants (data obtained from one plant being repeatedly sampled was avoided), independent of analytical method, and for ‘frozen vegetables’ or ‘mixed vegetables’ which according to Appendix A are always, or may be, blanched. Concentration data, in most cases left‐censored, were extracted from the subset of prevalence studies reporting this and were fitted to a beta‐general distribution.

2.1.3.3. Multi‐country outbreak report

To complement the limited concentration data, quantitative results from sampling and analysis of frozen vegetables were extracted from the previously mentioned multi‐country outbreak report (EFSA and ECDC, 2018) where possible.

2.1.4. Consumption data

To estimate the serving size of bfV, the acute food consumption data (considering the consuming days only) were extracted from the EFSA Comprehensive European Food Consumption Database14 for the elderly (65–74 years old) age group for a representative set of vegetables that are commonly blanched and used as frozen products. The vegetables were: carrots, peas, beans, broccoli, corn and asparagus. Data were available from 19 MS and 23 surveys. The most recent survey per MS was considered to estimate summary statistics. Thus, data were considered from 19 surveys. The survey starting dates ranged from 2000 to 2015.

To estimate the consumption of bfV and consequently the number of servings, data were extracted by considering those vegetables in the FoodEx2 list that are (i) always blanched, (ii) always or sometimes blanched and (iii) always or sometimes blanched but without potatoes. Potential blanching was based on Appendix A. For the estimations, it was assumed that about 8% of the total consumption events would have been derived from industrially frozen vegetables. This figure was derived from a recent Belgian survey on home consumption in 2018, in which the total vegetable consumption per capita was 45 kg, of which the frozen vegetables accounted for 3.6 kg.15 This proportion is in agreement with the figure of 8.2% on average (interquartile range (IQR) = 5.4–11.2%) derived from data available in the EU Data Food Networking (DAFNE16) databank, the Eurostat report about the fruit and vegetable sector (201917) and the PROFEL production data.18 The surveys available from 28 countries indicate that, on average 16% (IQR = 11–22%) of the total vegetable consumption comes from the category ‘processed vegetables’, including frozen, tinned and others (such as pickled, dried, ready meals, etc). Assuming that frozen and canned vegetables represent approximately 75% of the processed vegetable production, while the group of others representing 25% (Eurostat). Overall, the production of frozen vegetables is double that of canned, but there are exceptions: France, where it is the opposite and Poland that produces about eightfold more frozen than canned vegetables (PROFEL data).

2.2. Methodologies

2.2.1. ToR 1

2.2.1.1. Identification of pathogens of public health relevance in bfV

The identification of pathogens, in addition to L. monocytogenes, in bfV of relevance for public health/illness in the EU was performed using data on ‘strong and weak evidence’ FBOs from the years 2005–2018 as explained in Section 2.1.2.1. The vehicle category ‘Vegetables and juices and other products thereof’ was selected. Manual screening of the ‘vehicle info fields’ and ‘rescom’ fields was performed to gather information about the vehicle being a frozen vegetable.

2.2.1.2. Public health impact based on food‐borne outbreak data

The data on ‘strong’ FBOs at EU/EEA level from 2008 to 2018 related to L. monocytogenes were used to compare the number of outbreaks, number of human cases, number of hospitalised cases and number of fatal cases for the food vehicles involved in the outbreaks.

2.2.1.3. Public health impact based on a QMRA

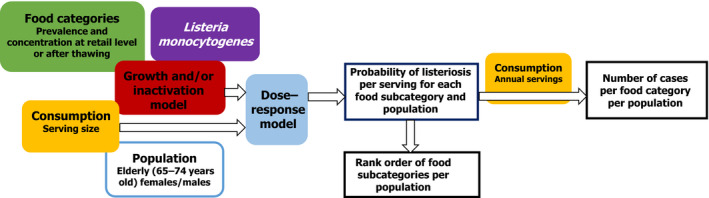

The estimation of the public health risk posed by L. monocytogenes and bfV in comparison with other known pathogen–food combinations was performed using a model that was developed based on the generic QMRA (gQMRA) as described in a previous scientific opinion (EFSA BIOHAZ Panel, 2018). This model is called generic because users can add food categories and their own data. A revision of the model was needed since that model aimed to estimate the risk associated with consumption of different RTE food categories (e.g. cold‐smoked fish, hot‐smoked fish, gravad fish, cooked meat, sausage, pâté and soft and semi‐soft cheese) for all age and gender groups. The food categories were subcategorised by the type of atmosphere packaging (i.e. normal atmosphere packaging (NAP) or reduced oxygen packaging (ROP)), except for soft and semi‐soft cheese, resulting in 13 RTE food subcategories. Furthermore, the model does not distinguish risk associated with the different foods, only total risk and did not include the bfV as food category. Thus, a revised model, named the modified generic Quantitative Microbiological Risk Assessment (mgQMRA), was developed using blocks from the gQMRA as a starting point (Figure 2).

Figure 2.

Overview of the mgQMRA developed to assess the risk associated with blanched frozen vegetables (two subcategories, with or without cooking) and 13 ready‐to‐eat food subcategories (based on type of atmosphere packaging)

The objective of the mgQMRA is to estimate and rank the mean probability of listeriosis per serving of the different food categories for the elderly population. The 13 RTE food subcategories defined above were supplemented with two subcategories of bfV considering the mode of use/consumption, being either cooked (i.e. consumed after cooking at variable extent) or uncooked (i.e. consumed as a RTE product). Public health impact was also estimated by comparing the predicted annual number of listeriosis cases. The model scripts were implemented in R version 3.5.1 (R Core Team, 2018, Appendix C). The input data for bfV are shown in Table 2 whereas for the 13 RTE food subcategories, it can be found in EFSA BIOHAZ Panel (2018), which sourced data from Pérez‐Rodríguez et al. (2017).

Table 2.

Summary of the generic Quantitative Microbiological Risk Assessment (mgQMRA) input data for blanched frozen vegetables (bfV) consumed with or without cooking for the baseline scenario and best‐case and worst‐case uncertainty scenarios

| Parameter | Distributiona | Input parameters | Baseline scenario | Input parameters for best‐case uncertainty scenario | Input parameters for worst‐case uncertainty scenario | Comments or percentiles used for best‐case and worse‐case |

|---|---|---|---|---|---|---|

| Prevalence of L. monocytogenes in bfV | Beta |

alpha = (147 + 1) beta = (1,288‐147 + 1) |

p = 0.114 | p = 0.098 | p = 0.133 | 2.5th and 97.5th percentiles |

| Initial concentration of L. monocytogenes in bfV (log10 CFU/g) – surveys/studies + FBO data | Beta‐general |

Min = −1.69 Max = 5 Shape 1 = 0.094 Shape 2 = 2.839 |

Used as baseline |

Shape 1 = 0.121 Shape 2 = 3.819 |

Shape 1 = 0.073 Shape 2 = 2.217 |

2.5th and 97.5th percentiles |

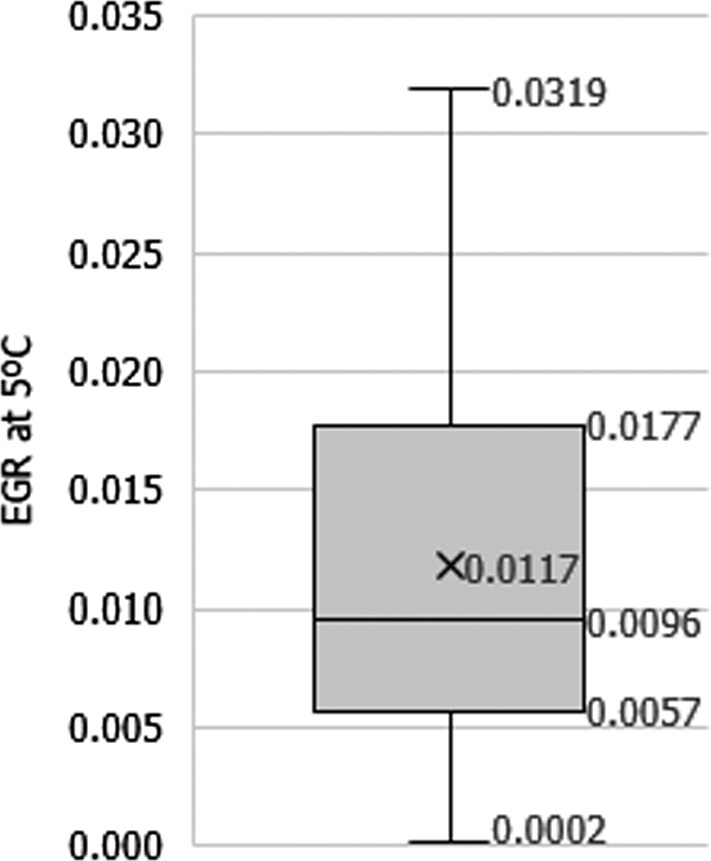

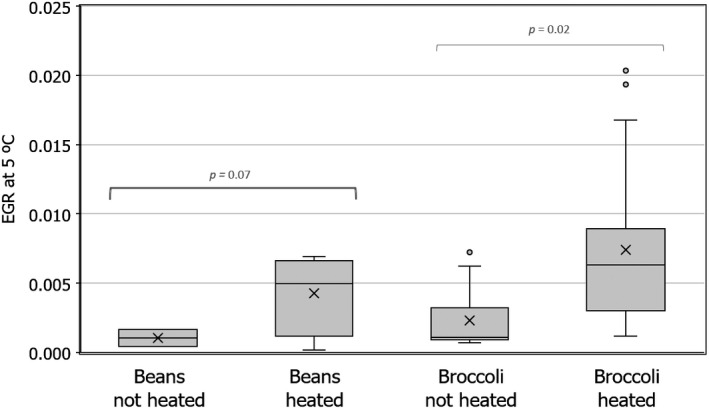

| Exponential growth rate (expressed as log10 /h) of L. monocytogenes in heat‐treated vegetables at a reference temperature of 5°C (EGR5°C) | Lognormal |

Mean = 0.0117 SD = 0.00816 Max = 0.0319 |

All scenarios | All scenarios | All scenarios | Not evaluated in the uncertainty analysis |

| Serving size of vegetables (g) | Constant | Mean = 49 | Used as baseline | 31 g | 106 g | 20th and 80th percentiles, respectively |

| Maximum population density (log10 CFU/g) of L. monocytogenes in vegetables | Constant | Mean = 7.83 | Used as baseline | 5.43 | 9.78 | Minimum and maximum Nmax |

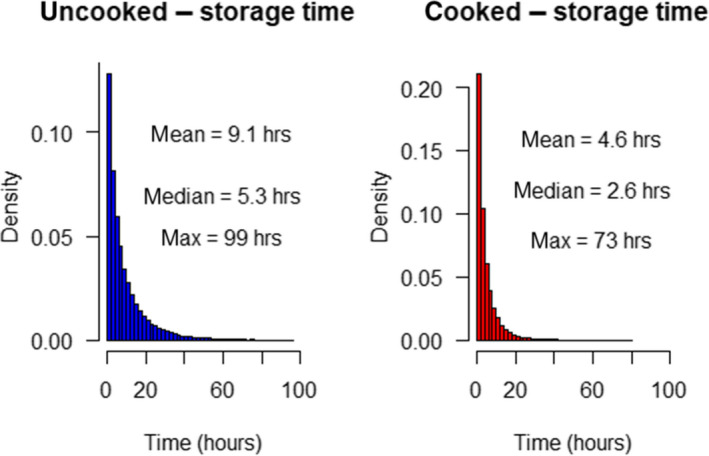

|

Consumer storage time outside the freezer = (remaining shelf‐life × proportion being used) Remaining shelf‐life (h) Proportion being used |

Exponential with rate = 1/mean shelf‐life Beta‐Pert |

Mean shelf‐life = 12 h (‘cooked’ vegetables) Mean shelf‐life = 24 h (‘RTE’ vegetables) Max = 96 h Minimum = 0 Most likely = 0.3 Maximum = 1.1 |

All scenarios | All scenarios | All scenarios | Not evaluated |

| Storage temperature at consumer fridge (°C) | Truncated Normal |

Mean = 5.9°C SD = 2.9°C Lower = −2°C Upper = 15°C |

All scenarios | All scenarios | All scenarios | Not evaluated – same for all foods |

| Reduction of L. monocytogenes in the event of cooking (log10 units) | Beta‐Pert |

Min = 1 log10 Most likely = 5 log10 Maximum = 9 log10 |

Used as baseline | Same as baseline | Most likely = 3 | Reasonable assumptions |

| Dose response of L. monocytogenes for the elderly population | Log‐normal exponential model |

Females: Mean = −13.7020 SD = 1.6154 Males: Mean = −13.5598 SD = 1.6154 |

All scenarios | All scenarios | All scenarios | Not evaluated‐ The same uncertainty over all food categories so less important for the uncertainty related to the comparison |

| Annual number of servings of bfV for the elderly population | Constant | 2.65 × 109 (females); 2.28 × 109 (males) | Baseline | 1.63 × 109 (females); 1.38 × 109 (males) | 3.15 × 109 (females); 2.74 × 109 (males) | Public health impact evaluated in scenario analysis |

| Proportion of servings of bfV consumed cooked or uncooked by the elderly population | Constant | Cooked = 50, 60, 70, 80, 90, 100 and uncooked = 50, 40, 30, 20, 10, 0 | Proportions based on label information Willis et al. (2019): cooked: 96%; uncooked = 4% | Proportions based on label information Willis et al. (2019): cooked: 77%, uncooked = 23% | Different proportions were evaluated in separate scenario analyses |

The same distributions as used in the gQMRA in EFSA BIOHAZ Panel (2018), except for the log10 reduction for cooking which was not included in that model.

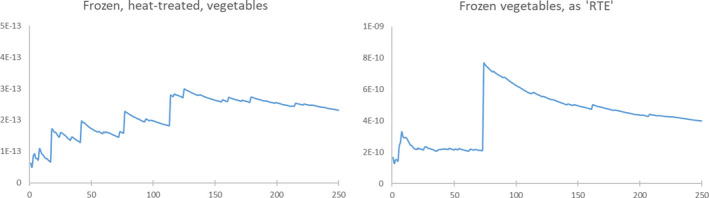

The exposure was estimated based on the prevalence and initial contamination of L. monocytogenes level at retail, taking potential growth during storage and inactivation during cooking, and serving sizes for the population of interest into consideration (Figure 2). The exposure was then combined with an exponential dose response (DR) model to estimate the mean probability of listeriosis per serving using the model parameters for the elderly population developed in EFSA BIOHAZ Panel (2018). Distributions were used to describe the variability of model parameters and to estimate the mean probability of illness following consumption of a contaminated serving. This estimate was multiplied by the mean prevalence of L. monocytogenes in the food subcategories to obtain the risk per any serving. To achieve a sufficient number of iterations and consistent ranking of food subcategories, multiple simulations were run (250 simulations) each involving 2 × 105 iterations (Figure C.1; Appendix C). Ranking of risk per serving was based on the mean probability of illness per serving (Pérez‐Rodríguez et al. (2017)).

Figure C.1.

The estimated mean probability of illness per serving as a function of the number of simulations for the two scenarios; thawed frozen vegetables consumed after cooking or without cooking (i.e. as RTE food)

- The impact of random high‐risk iterations resulting in higher risk simulations is illustrated. The impact is decreasing with the number of simulations and 250 simulations were selected as a balance between the required precision and the execution time.

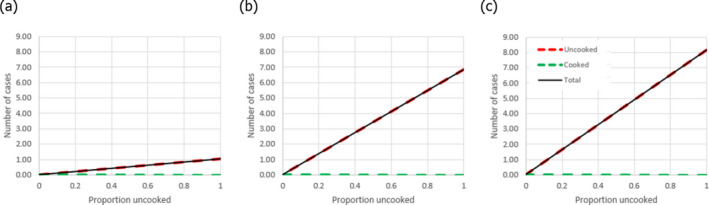

The public health impact of bfV in terms of the number of cases per year in the female/male elderly age group was evaluated by combining the predicted mean probability of illness per serving with the number of servings per year in the EU/EEA. The estimation of the total number of bfV servings in the EU/EEA is described in Section 2.1.4, and scenarios of different proportions of servings consumed uncooked or cooked were evaluated. The predicted number of cases for bfV was compared with the predicted number of cases associated with the seven RTE food categories mentioned above.

As mentioned above, the L. monocytogenes contamination of the RTE food categories was characterised by the prevalence and concentration at retail. The uncertainty in the prevalence estimation was described by a beta‐distribution as in the gQMRA model (EFSA BIOHAZ Panel, 2018). Very sparse concentration data were available representing bfV and these data were mostly reported as below the limit of detection of the plate count procedure (e.g. < 10 CFU/g to < 100 CFU/g depending on the analytical methodology used). The concentration data were fitted to a beta‐general distribution using the fitdistrplus package in R (Delignette‐Muller and Dutang, 2015). A non‐parametric bootstrap resampling method was applied to estimate uncertainty in the parameters of the distribution fitted to the data. The 95% confidence interval (CI; 2.5th and 97.5th percentiles) for the parameters is reported in Table 2 and were used in the evaluation of uncertainty. Two distributions were developed, one based on the literature data and the other one supplementing these data with concentration data from the multi‐country outbreak report (EFSA and ECDC, 2018).

A weighted mean serving size of bfV was estimated from the mean serving sizes derived as reported in Section 2.1.4. As the number of consuming days in the various surveys varied, the reported mean serving sizes were weighted by the number of consuming days of the respective survey in order to obtain a weighted mean serving size. The three estimates of the total number of servings of bfV described in Section 2.1.4, representing uncertainty, were assumed to represent a baseline (always or sometimes blanched but without potatoes), best‐case (always blanched) and worst‐case scenario (always or sometimes blanched with potatoes). The potential public health impact was evaluated by assuming different proportions of the total number of servings being consumed uncooked (as RTE) and cooked, respectively.

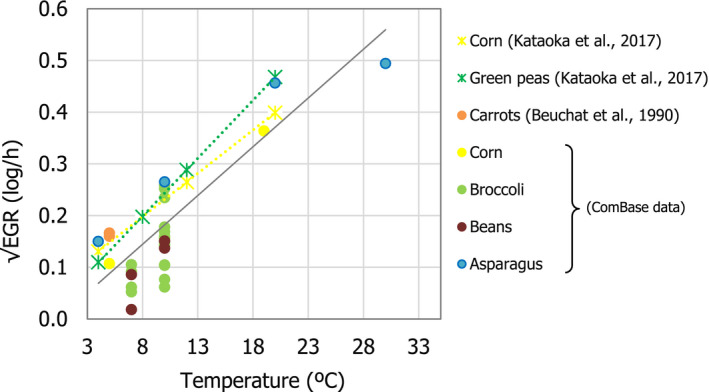

Changes in L. monocytogenes levels were described by estimating growth using the same approach as in EFSA BIOHAZ Panel (2018). The exponential growth rate (EGR) of one specific strain or a pool of L. monocytogenes strains (up to a 12‐strain mixture) was obtained from scientific literature for different vegetables including corn, green peas, carrots, broccoli, beans, asparagus (Beuchat and Brackett, 1990; Kataoka et al., 2017) and records available in ComBase.19 Experiments using vegetables previously heated (e.g. blanched or an equivalent heat treatment) were also considered as the pathogen seems able to grow faster in heat‐treated vegetables (see Section 3.3.2). EGR values collected were either reported in the scientific article or estimated by primary growth model fit using the DMFit tool from ComBase. The EGR values at specific storage temperatures were standardised to 5°C (EGR5°C) using the square‐root‐based secondary model for bacterial growth using Tmin = −1.18°C as in FDA and FSIS (2003) and EFSA BIOHAZ Panel (2018). The variability of EGR5°C of L. monocytogenes was assumed to be log‐normally distributed and the mean, standard deviation and truncated maximum rate (mean + 2 standard deviations) considered (Table 2). No lag time was included in the growth simulation; this assumption may overestimate growth and the associated risk. The mean and standard deviation of the maximum population density of L. monocytogenes as result of growth (MPD) was extracted from the data in the same studies used to extract the EGR. The minimum and maximum MPD (MPDmin and MPDmax) was used in the best‐ and worst‐case scenario, respectively (Table 2).

Different heat treatment intensities (t/T combinations) have been considered for cooking, varying between very strong heat treatments (i.e. fully cooking) to lesser heat treatments (i.e. slight microwaving). The impact of cooking on the exposure to L. monocytogenes, in terms of log‐reduction, was modelled as a beta‐pert distribution, assuming a reduction between 1 and 9 log10 units, with 5 log10 as the most likely value (equivalent to the minimum required for a fully cooking treatment of food (NACMCF, 2006). The parameters of this distribution were based on considerations of potential heat treatments, as well as the variability of heat resistance of L. monocytogenes reported by the meta‐analysis carried out by van Asselt and Zwietering (2006). That study reported a mean decimal reduction time (D‐value) at 70°C (D70°C) of 0.09 min and an upper 95% prediction interval, used as a conservative estimation D70°C = 0.52 min, and the thermal resistance constant z = 4–11°C (EURL‐L. monocytogenes and ANSES, 2019b). To address the uncertainty with this assumption, a most likely value of 3 log10 units was evaluated representing a higher risk scenario associated with less effective heating methods than cooking in boiling water.

The remaining shelf‐life in the consumer refrigerator was modelled as an exponential distribution with a rate described by 1/mean shelf‐life. The mean shelf‐life was assumed 0.5 day for cooked vegetables and 1 day for vegetables consumed uncooked. The maximum remaining shelf‐life resulting from the exponential distribution was assumed 4 day. The actual consumer storage time is calculated as the remaining shelf‐life multiplied by a proportion of remaining shelf‐life at which time consumption takes place. The proportion is described by a beta‐pert distribution, with a minimum, mode and maximum proportion of 0, 0.3 and 1.1 as in the previous scientific opinion (EFSA BIOHAZ Panel, 2018). For bfV, this time represents the delay between vegetables being thawed and consumed (uncooked subcategory) or between being thawed and cooked (cooked subcategory). Storage temperature was assumed to follow a normal distribution among consumers but constant during the storage period for a given consumer (EFSA BIOHAZ Panel, 2018).

In the previous scientific opinion (EFSA BIOHAZ Panel, 2018), the number of cases of the seven RTE food categories were calculated based on the probability of illness per type of packaging (i.e. NAP or ROP), using data on the proportions of food with each packaging produced and consumed. For bfV, the proportion of consumption as cooked and uncooked (as RTE) was needed. Since there are limited data on this, different proportions were assumed and used in scenarios to evaluate total number of cases based on estimates of 1) the probability of illness per serving and 2) the total number of servings of bfV. In addition, the number of cases was also predicted based on the reported proportions of bfV with information on the label to cook or not before consumption (Willis et al., 2019).

The same DR model and parameters developed in the previous scientific opinion were used for the elderly female and male age groups (EFSA BIOHAZ Panel, 2018). The r‐value is the key parameter in this DR model and represents the probability that one single cell will survive the different barriers in the human intestinal tract and multiply in the human host. This value depends on the susceptibility of the host and the virulence of the L. monocytogenes strain.

2.2.2. ToR 2

First, the stages from processing (excluding primary production in the field) until consumption (including e.g. storage after thawing and consumption habits) of bfV were identified based on the EFSA technical report (EFSA, 2018) and combined with expert knowledge on the current industrial practices thanks to the exchange of information between the WG and PROFEL regarding the type of products subjected to blanching (Appendix A) as well as the processing steps involved in the production chain (draft PROFEL guidelines). Secondly, scientific papers retrieved by the literature search described in Section 2.1.3.2 (including ComBase) as well as the knowledge and expertise of the WG members were considered to identify the main factors affecting contamination and/or growth of L. monocytogenes in bfV during the production and consumption stages.

2.2.3. ToR 3

Scientific papers as well as the knowledge and expertise of the WG members were considered to identify possible control options that may be implemented by FBOp during the production process of bfV. The proposal for control options highlights the most critical steps to be considered by the industry taking into account prerequisite programmes (PRPs) and procedures based on the HACCP principles. The identification of PRPs, oPRP or CCP was performed based on the Commission Notice on the implementation of FSMS covering PRPs and procedures based on the HACCP principles, including the facilitation/flexibility of the implementation in certain food businesses (Commission Notice (EC) No 2016/C 278/0120).

The control measures considered are based on preventive measures, and for this reason, the efficacy of the establishment of specific preventive measures on the reduction of contamination in the product cannot be assessed. Reviewed research papers, focussing on additional technologies (which in most cases are not fully implemented by the industry), have been retrieved by the literature search. Recommendations on routine monitoring for L. monocytogenes in bfV processing environments and final product were carried out by critically appraising available guidelines for the industry taking into account that sampling and monitoring recommendations have the purpose to verify that the FSMS implemented by the FBOp is well designed and has the appropriate control measures. Key documents were selected based on WG discussion. These included the EURL Lm‐ANSES ‘Guidelines on Sampling the Food Processing Area and Equipment for the Detection of Listeria monocytogenes’ (EURL‐L. monocytogenes and ANSES, 2019a), the international standard EN ISO 18593:2018,21 the document from the Food and Drug Administration ‘Testing Methodology for Listeria species or L. monocytogenes in Environmental Samples’ (FDA, 2015), and the ‘Environmental Monitoring Handbook for the Food and Beverage Industries’ published by the University of Cornell in collaboration with 3M (3M and Cornell, 2019). For frozen vegetables produced as RTE, the draft guidance from the Food and Drug Administration/Center for Food Safety and Applied Nutrition ‘Control of Listeria monocytogenes in Ready‐To‐Eat Foods: Guidance for Industry’ (FDA‐CFSAN, 2017), among others, were considered for the assessment. Information provided by the draft PROFEL guidelines (PROFEL, 2019) has been included.

To estimate L. monocytogenes concentrations at the end of production process compatible with the FSO of 100 CFU/g, L. monocytogenes growth in different bfV was calculated considering the period between the removal of the product from the freezer and the subsequent storage for a certain period of time under reasonably foreseeable conditions of use by the consumers (8–12°C for a maximum of 120 h). For this, the growth kinetic parameters of a 12‐strain cocktail of L. monocytogenes in frozen–thawed corn and green peas were obtained from the predictive models developed specifically for these vegetables by Kataoka et al. (2017), which included a rapid thawing process of the 25 g portions used in the experiment. In addition, the growth potential during thawing and storage at 9°C for 24 and 48 h obtained in the challenge tests reported in the draft PROFEL guidance of 200 g portions of different types of frozen vegetables, were taken into consideration.

2.2.4. Uncertainty

Based on the EFSA guidance on uncertainty analysis in scientific assessments (EFSA Scientific Committee, 2018b), and the scientific opinion on the principles and methods behind EFSA's guidance on uncertainty analysis in scientific assessment (EFSA Scientific Committee, 2018a), special attention was given to: (i) the interpretation of the ToRs, i.e. framing of the mandate and the AQs, (ii) identifying sources of uncertainty and (iii) their impact on the outcome of the assessment. The identified assumptions and other sources of uncertainty were listed.

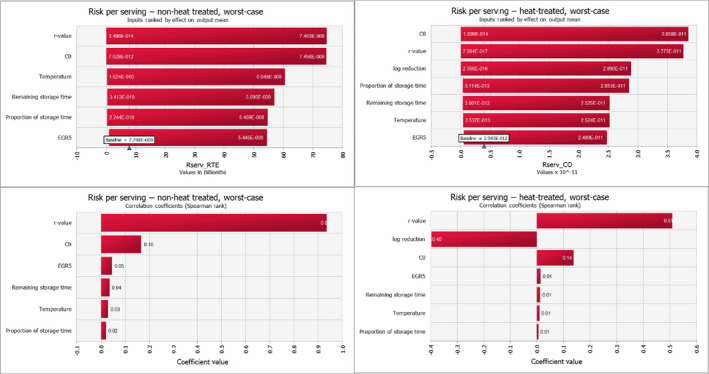

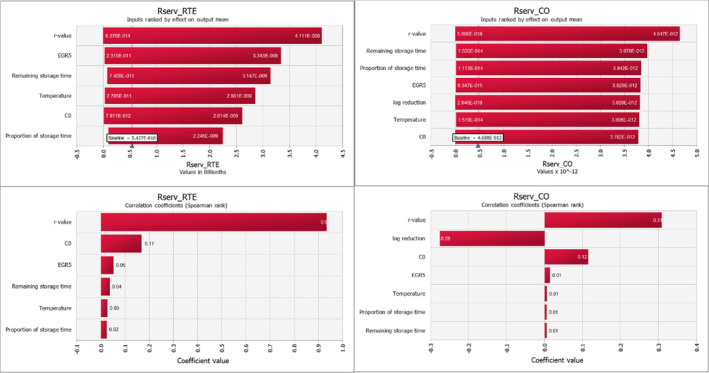

For ToR1, the uncertainty of the rankings based on comparisons to other known risks using the mgQMRA model was evaluated by running a baseline and two uncertainty scenarios, termed a best‐ and worst‐case scenario. This resulted in 19 different outcomes for the food subcategories and scenarios being evaluated and ranked; 13 RTE food subcategories and 2 subcategories of bfV each with three scenarios. For the predicted number of cases, scenarios with different estimates of the total number of servings of bfV and proportions of consumer behaviour in terms of consuming uncooked or cooked were evaluated. The identified sources of quantified and non‐quantified uncertainties and the outcomes of the best and worst‐case scenarios were used to estimate the overall uncertainty in the response to ToR1. In support of this analysis, the mgQMRA model was implemented in the @Risk Analysis Add‐in (version 7.5.0, Palisade Corporation) for Excel. First, sensitivity and scenario analyses were carried out for the effect of variability in input parameters on the variability of the output mean risk per serving for the separate scenarios. Second, a sensitivity analysis of the uncertain parameters serving size, prevalence, initial concentration and MPD was evaluated by changing one parameter at the time (in Table 2) using the Simtable function in @Risk. A total of 200,000 iterations of the model per simulation were used in the sensitivity analyses.

For ToR2 and 3, uncertainties may result in the incomplete identification or misclassification of (1) factors of contamination or growth of L. monocytogenes in bfV; (2) control options; and (3) recommendations on routine monitoring. The following were considered:

Incompleteness: some factors/control options/recommendations may be missed in the identification process and so would be considered non‐existent or not relevant.

Misclassified: some factors of contamination/control options/recommendations may be wrongly included in the list of an outcome table without being relevant factor.

The uncertainty analysis was limited to the quantification of the probability of incompleteness or misclassified factors/control options/recommendations. For the incompleteness of factors/control options/recommendations, the expert knowledge was elicited on the probability that at least one factor/control option/recommendation was missed in the outcome table. For the misclassification, the experts elicited the probability that each factor/control option/recommendation included in the outcome table was correctly included.

3. Assessment

3.1. Pathogens of public health relevance in bfV

3.1.1. Evidence from food‐borne outbreaks

An overview of the FBOs in the EU/EEA where frozen vegetables were implicated as reported in EFSA's zoonoses database (2005–2018) can be found in Table D.1 in Appendix D. Before 2018, two outbreaks were reported with 17 cases, no hospitalisations or deaths, implicating frozen vegetables. The Staphylococcus aureus outbreak22 in frozen beans took place at a school or kindergarten in Belgium in 2009 and caused 14 cases. It was reported that storage time/Temperature (t/T) abuse was a contributory factor (i.e. a fault or circumstance that singly or in combination led to the FBO). Based on Appendix A, the beans were likely to have been blanched.

Table TableD.1.

Summary of food‐borne outbreaks (FBOs) in the EU/EEA where frozen vegetables were implicated as reported in EFSA's zoonoses database (2005–2018)

| Year | Causative agent | Countrya | Number of human cases | Number of hospitalised cases | Number of deaths | Food vehicleb | Blanchedc | Place of exposured | Contributory factorh | Nature of evidence |

|---|---|---|---|---|---|---|---|---|---|---|

| 2009 | Staphylococcus aureus | BE | 14 | 0 | 0 | Frozen beans | Probably | School or kindergartene | Storage t/T abuse | Laboratory detection in implicated food |

| 2015 | Clostridium perfringens | DE | 3 | 0 | 0 | Frozen onions | Likely not | Canteen or workplace cateringf | Inadequate chilling | Detection of causative agent in food vehicle or its component – Symptoms and onset of illness pathognomonic to causative agent |

| 2018 | Listeria monocytogenes | DK | 4 | 4 | 0 | Frozen corn and other frozen vegetables | Yes | Multiple places of exposure in more than one countryg | Unprocessed contaminated ingredient | Detection of causative agent in food vehicle or its component – Detection of indistinguishable causative agent in humans; Detection of causative agent in food chain or its environment – Detection of indistinguishable causative agent in humans; Descriptive epidemiological evidence |

| 2018 | Listeria monocytogenes | FI | 30 | 30 | 3 | Frozen corn | Yes | Multiple places of exposure in more than one countryf | Inadequate heat treatment before consumption | Product‐tracing investigations; Descriptive environmental evidence; Detection of causative agent in food vehicle or its component – Detection of indistinguishable causative agent in humans; Descriptive epidemiological evidence |

| 2018 | Listeria monocytogenes | UK | 12 | 12 | 2 | Frozen sweetcorn | Yes | Multiple places of exposure in more than one countryf | Inadequate heat treatment before consumption | Detection of causative agent in food vehicle or its component – Detection of indistinguishable causative agent in humans; Descriptive epidemiological evidence |

FBOs: food‐borne outbreaks; t/T: time/Temperature.

BE: Belgium; DE: Germany; DK: Denmark; FI: Finland; UK: the United Kingdom.

Food (or foodstuff) that is suspected of causing human cases.