Abstract

Recent national strategic plans in China have set renewable energy targets for rural household energy programs, including those that advance the production of densified biomass fuels (e.g. pellets, briquettes) for use in household cooking and heating stoves. There is presently very little information on potential barriers to the successful development of densified biomass for household cooking and heating in China, but such knowledge may be informative in settings that aim to replace unprocessed coal and other polluting fuels with renewable, cleaner-burning energy sources. We designed a case study to coordinate data-gathering efforts at rural field sites in southwestern Sichuan province and northeastern Jilin and Heilongjiang provinces, where production of densified biomass fuels is under development for household end-users. We conducted interviews with factory personnel, local administrative leaders, and sector experts involved in the production and distribution of densified fuel, including pellets and briquettes, for household use. Results from our qualitative textual data analysis yielded several recommendations for improving development of densified biomass fuels for household end-use. These included reducing heterogeneity of feedstocks, increasing financial support for operational costs (e.g. collection, transport, and storage of raw materials; storage and distribution of final products), improving household perceptions of and subsequent demand for densified biomass fuels, and increasing enforcement of national and provincial policies banning the use of coal and open-field biomass burning. Collection and storage of raw materials and the final densified fuel product were consistently noted as critical challenges to scaling up production at all three sites. Finally, the perspectives of factory managers and local village administrators that we present also indicated that production of densified biomass fuels would most likely be more successful and reproducible in places where national-level policies are viewed as obligatory.

1. Introduction

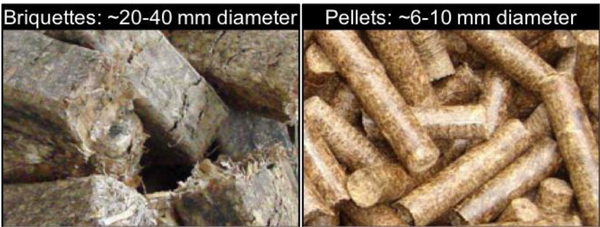

A large fraction of the Chinese population is exposed to high levels of ambient fine particulate matter (PM) air pollution,1 and fine particulate matter from household use of solid fuels.2–4 These air pollution exposures adversely impact public health and climate.5–7 Outdoor air pollution in China is often higher than the World Health Organization recommended interim target of an annual average of 25 μg-m−3,8 with contributions from both outdoor (e.g. industry, traffic) and indoor (e.g. cooking),9 that vary over fine spatial and temporal scales.10 National efforts to improve air quality have led to air pollution policies across multiple sectors.2,11,12 Rural energy policies target two common activities: open-field biomass burning to dispose of agricultural waste13,14 and household combustion of unprocessed solid fuels (including unprocessed biomass, as well as coal) for cooking and heating.3,15–20 The development of renewable biomass resources has emerged as a strategy to reduce crop burning and yield a densified biomass fuel (Figure 1) that is a suitable fuel alternative to coal and other polluting fuels.21,22 Densified biomass fuels can be directly burned inside stoves designed for in-home gasification,23 or in both gasifier and traditional heating stoves. There remain fundamental knowledge gaps related to variability and predictors of emissions performance of densified biomass fuels in traditional and gasifier stove technology, especially for home heating. A small number of field-based studies have demonstrated lower air pollution emissions from gasifier stoves burning biomass pellets compared with traditional stoves burning unprocessed biomass,24–27 although emissions of some harmful components of PM (e.g. polycyclic aromatic hydrocarbons, elemental carbon), which are harmful to health, may be comparable for gasifier and traditional wood-burning stoves.27–30

Figure 1.

Examples of briquettes (left) and pellets (right) pressed from biomass feedstocks (e.g. agricultural residues, wood logs).

Biomass utilization and renewable energy development has been a field of inquiry for several decades in China amid growing concerns about energy security and China’s global impact on carbon dioxide (CO2) emissions. Multiple national-level policies directly or indirectly promote biomass reutilization, including the Renewable Energy Law (2005), the Medium and Long-Term Development Plan for Renewable Energy (2007), the Provisional Procedures for Management of the Subsidiary Fund for Energy Utilization of Straws (2008), and the Twelfth Five-Year Plan of Biomass Energy Development (2012), among others. Past studies document the successful development of renewable biomass energy at large, centralized scales; characterized the diverse geographical distribution and abundance of biomass and agricultural resources available;31–34 described and evaluated the development of technologies and industries to enhance centralized utilization of these resources;35–38 and modeled potential trade-offs and co-benefits of policy frameworks intended to enhance national biomass utilization trajectories for global development and climate goals.39 These policies are summarized in Shan et al. (2016),22 which further recommends smaller-scale, decentralized development of densified biomass fuels to extend this fuel supply to rural households as end-users. A recent review of China-based studies that evaluated household factors influencing adoption of clean fuels, including compressed biomass, indicated that technological and expertise barriers, among others, may limit expansion of densified biomass fuels. Synthesizing these and other studies, we conclude that decentralized provision of biomass pellet and briquette fuels to widely dispersed end-users is very nascent in China.22,40 Better characterization of the technological factors and the rural administrative context affecting development of these fuels at smaller, more decentralized scales would potentially contribute new guidance for their development in diverse regions of China.

Specifically, we sought to answer the following question: from the perspective of industry and community stakeholders, what factors are important for the development of densified biomass fuels for direct use in Chinese households? To address this question, we carried out a single case study with embedded sub-units and investigated regional perspectives on factors (e.g. technological, financial) associated with the production of densified biomass pellet fuel in China. We conducted interviews with stakeholders and sector experts in three provinces (Heilongjiang, Jilin, and Sichuan) where production of densified biomass fuel for household use is being pursued. We also synthesized information from relevant, publicly available Chinese production records, peer-reviewed studies, and policy documents.

2. Methods, sources, and approach

2.1. Overview of methods

Our phenomenon of interest was the development of renewable biomass resources (i.e. wood, crop residue) into densified biomass fuels for Chinese households, which we defined as a single case. We further defined embedded subunits of analysis41,42 (i.e. sites) because our prior knowledge of this topic indicated regional variations in the perceptions of stakeholders and sector experts and the contexts in which they operate.22 The case study was well suited for qualitative methods, given the perspectives of multiple stakeholder types we investigated and sought to synthesize. Specifically, we pursued a grounded theory analytic approach, as described elsewhere,43 because the case of interest presently lacks a prevailing explanatory theory but is amenable to formulating such a theory through inductive synthesis of multiple perspectives and data sources. These sources included semi-structured, in-depth interviews; electronic documents and archival records; and direct observations by the research team. We brought these sources of information together using an iterative approach to data analysis, following approaches described for grounded theory analysis,43,44 to propose a prevailing, coherent interpretation of our results in response to our governing research question (stated above, Section 1).45,46

2.2. Study area

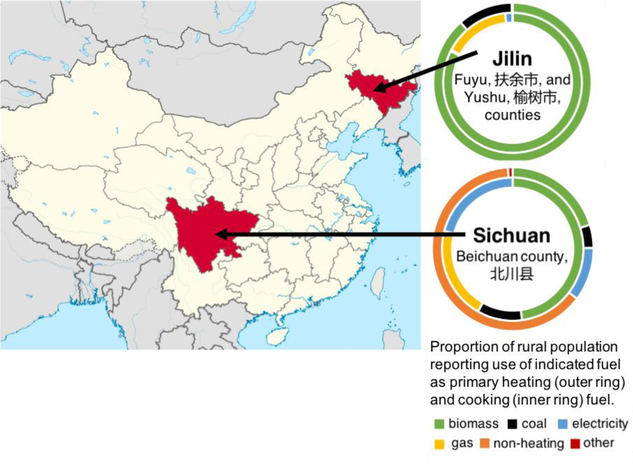

Site selection was based on the following criteria: 1) knowledge of planned or existing densified biomass production for at least one household energy program; 2) access to the biomass processing facility by the research staff; and 3) identification of at least one factory manager and one local administrative leader to interview. We identified one site in southwestern China (Beichuan county (北川县), Sichuan Province) and two sites in northeastern China (Fuyu county (扶余市) and Yushu county (榆树市), Jilin province) (Figure 2). For context, 68% of the Jilin provincial population (30 million) lives in rural areas;47 the fraction of rural Jilin residents reporting use of solid fuel as their primary cooking or heating fuel is 82% and 93%, respectively.48

Figure 2.

Interview sites in China, shown with their respective primary heating (outer ring) and primary cooking (inner ring) fuel distributions, adapted from Duan et al. (2014)

In Sichuan, 44% of the nearly 90 million residents live rurally,47 and, of those, 79% (31 million) report using solid fuel as their primary cooking fuel; 38% (15 million) report primarily using solid fuel for space heating.48 Beichuan county has a temperate climate and is the site of a rural household energy demonstration project in ~200 homes comprising a gasifier cookstove and an annual supply of pelletized biomass fuel.25,49 The biomass processing facility is envisioned to be locally managed and operated to produce biomass pellets from local wood and agricultural residues from the fruit trees that local residents cultivate for part of their income22. The gasifier stove is designed for stand-alone cooking and water-heating, iteratively incorporating user feedback throughout the design process.24

In Jilin province, Fuyu and Yushu counties have severely cold winters,50 imposing a substantial household heating demand during approximately half of the year (mean annual heating degree days ~3000).50–52 Biomass compressing factories in these two counties currently produce briquettes that are primarily for commercial end-use, but are also suitable for use in commercially available gasifier stoves that would otherwise burn coal. Feedstocks include locally available crop residues (e.g. corn, wheat). Local governments are thus exploring several very preliminary rural household energy programs. These programs are less mature than the one in Beichuan county (Sichuan province) but also aim to link local biomass processing facilities with households, who have the potential to be both providers of biomass feedstock materials (given their agricultural livelihoods) and end-users of densified biomass fuels.

All of these programs are nascent, and there are few documented examples of small- to medium-scale industries developing densified biomass fuels for end-use in local households. At each site, the factory producing pellets or briquettes had been in existence 5 years or less. In each county, we interviewed at least one factory manager and one local administrative leader.

2.3. Semi-structured, in-depth interviews

We conducted semi-structured, in-depth interviews using a series of framing questions that were tailored to the stakeholder type (see Supporting Information for interview guides, Section S1 and S2). We conducted interviews at a location suggested by the respondent (typically, their offices). We maintained an open, flexible framework to facilitate focused yet conversational communication,53,54 instructing the respondent to ask questions when needed. We also directed the interviewer to ask follow-up questions that probed for more detailed, contextual data from the respondent and allowed them to follow topical trajectories in the conversation that may have strayed from the interview guide.41,54 Interviews were conducted in Mandarin-Chinese by two native speakers on the research team. In Sichuan, we hired a third interviewer who spoke the local dialect and could assist with translation to Mandarin-Chinese as needed. The interview protocol was reviewed by the Institutional Review Board at Colorado State University (#107–18H). Respondents provided informed verbal consent to participate in the interview and to permit the interview to be audio-recorded.

In total, we completed 12 individual interviews with four factory personnel, five local administrative leaders, and three sector experts. Interviews lasted at least one hour. All respondents were male, except for the female research director at the Heilongjiang Institute for Energy and Environment. Demographic and employment characteristics of the respondents are provided in Supporting Information (Table S1).

2.4. Textual data preparation and analysis

2.4.1. Transcription and translation

All interviews were audio-recorded. Recordings were transcribed in Chinese using an intelligent verbatim approach, where the transcriber chooses which pauses and annotation (e.g. notes about non-verbal communication) are relevant, but ensures that the exact wording of the dialogue is documented. We did not record nonverbal or background sounds (e.g., laughter, sighs) or filler words (i.e., zhege “this” and nage “that”). Mispronounced words or incorrect use of grammatical structures were transcribed as the individual said them. Slang, grammatical errors, or misuse of words or concepts were kept, but if an incorrect or unexpected pronunciation decreased comprehension, the transcriber sought to infer the correct word or phrase. The transcriber proofread all transcripts against the audio recording and revised the file accordingly. All transcripts were audited for accuracy by the interviewer(s). Two professional translators with expertise in academic translation independently translated transcripts from Chinese to English.

2.4.2. Text coding

We read and re-read the translated transcripts to become familiar with the respondents’ use of language and terminology, according to first cycle coding methods.55 For second cycle coding and subsequent data analysis, we used open, inductive approaches that were consistent with the grounded theory approach.43–46 This approach facilitates inductive coding, e.g., allows key concepts to emerge during analysis rather than from predefined conceptual categories to minimize the influence of the researcher’s suppositions.55 Using this coding process (sometimes termed “axial coding”),56 we identified emergent core categories and, through constant comparison, refined the assignment of discrete attributes (as sub-code categories) to those emergent themes.43,44,56–59 We continued the process of constant comparison, aiming to reach conceptual saturation (i.e. no new conceptual categories and attributes of core categories emerged).60 To generate conceptual maps of respondent perspectives, we calculated the proportion of coded text assigned to each theme for all interviewees and aggregated by both interviewee type (e.g., factory managers, local administrators) and field site to enhance data visualization and to qualitatively assess differences or similarities across groups.

2.4.4. Quality assurance and quality control

Two members of the research team coded textual data. Both members read all interview transcripts during first cycle coding, and then independently coded two randomly selected transcripts (~17% of transcripts) using the approach described in Section 2.4.2. The independent coding systems were iteratively discussed and revised to reach consensus on the number, scope, and differentiation of core themes that emerged.55,61 This allowed us to develop consistency between the two coders.59,62 One coder then served as the primary coder for all transcripts, and developed the open and axial coding system. Once established, the second coder used the same system to independently code a randomly selected ~20% of contiguous text from each transcript. To approach the concept of inter-rater reliability, we compared results from the resulting two coding systems.61–64 Specifically, we used the proportion of text assigned to each core theme relative to all segments coded across all themes (within the same interview) to evaluate consistency between the two coders, as defined by Krippendorf’s alpha.65 This was done only for text sections that were evaluated equally by both coders (~20% of total text).

2.5. Supplemental data sources

We reviewed electronic documents, archival records, and peer-reviewed literature that closely related to the development of renewable biomass resources into densified biomass fuels for Chinese households. Specifically, we note that the Sichuan-based household energy program included in this case study has formed the basis for multiple baseline and post-intervention studies of air pollution emissions,25 indoor and outdoor air quality,15,20,66 personal exposure,66 health,67–69 and iterative stove design, development, and adoption.24,49 We also searched for supplemental data sources within academic databases and publicly-available government reports and data records. Finally, we conducted several supplemental interviews with densified biomass production sector experts (e.g. academic and government researchers, national ministry directors). These interviews were conducted in Heilongjiang province at the Heilongjiang Institute of Energy and Environment, and in Beijing at the Chinese Ministry of Agriculture, and Tsinghua University, respectively.

3. Results

Our text analysis of interview transcripts generated 113 sub-code categories (Table S2), which we iteratively aggregated into eight emergent core categories55 with the following names: village infrastructure; factory infrastructure and operation; organizational philosophy; household factors; market, policy, and financial factors (i.e. the “enabling environment”);24,70 raw materials; production; final product.

3.1. Respondent perspectives by field site and role in the biomass processing sector

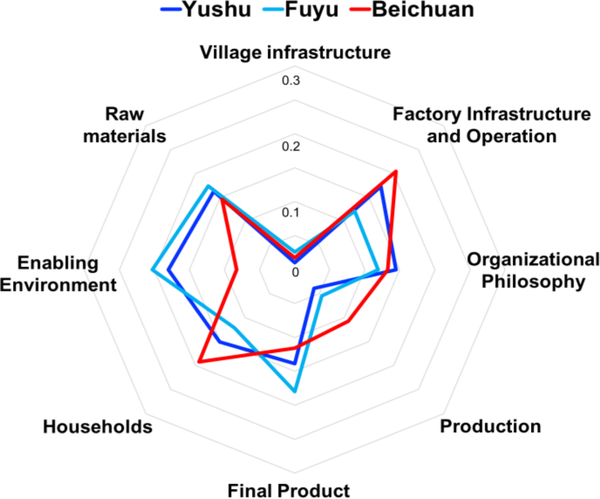

Responses were similar across field sites (Figure 3), despite considerable site-level differences in climate, geography, factory size, thermal efficiency, and biomass feedstocks. The factories in Jilin were focused on commercial sector end-users and working to diversify their end-user portfolio by considering households, whereas the factory in Sichuan was initiated at a village-scale for household end-users. Thus, the scale of operation of the factories in Jilin was larger than in Sichuan. Recommendations made across all three sites for improving the development of densified biomass fuel for household end-use were congruent. These included reducing heterogeneity of feedstocks, increasing financial support for operational costs (e.g. collection, transport, and storage of raw materials; storage and distribution of final products), improving household perceptions of and demand for densified biomass fuels, and increasing enforcement of national and provincial policies banning use of coal and open-field biomass burning. Seasonal collection of raw materials and storage of those materials were noted at all three sites as critical challenges to scaling up production. Factory managers at all sites suggested that obtaining more and higher-quality large machinery for field collection of crop residues would constitute an important first step toward addressing seasonal raw material collection. In addition to these two challenges, recommendations by factory personnel and local administrators also included provision of financial and technological support for updating and maintaining machinery, more extensive training to develop factory staff expertise, and a stronger financial investment at higher administrative levels (e.g. country, province) in rural household energy programs.

Figure 3.

Proportion of coded segments assigned to each of eight emergent core thematic areas, by site.

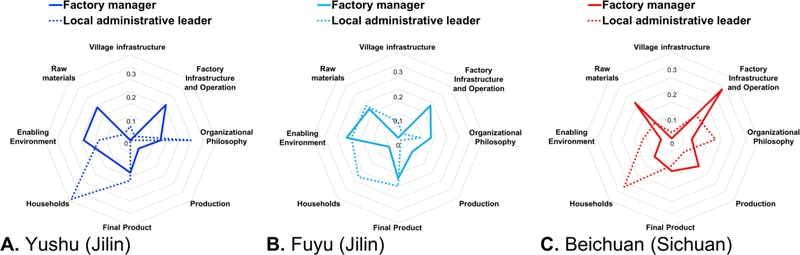

Consistent with their societal roles, factory personnel were more apt to discuss raw materials and factory infrastructure and operation, while local administrators focused on household factors and organizational philosophy (Figure 4). Specifically, local administrative leaders seemed more attentive to 1) current and projected rural household energy practices (e.g. frequent emphasis on space heating); 2) acceptance of and attitudes towards stove technologies; and 3) repair and maintenance of stove technologies (Supporting Information, Table S2). Factory personnel and local administrative leaders noted several final product characteristics that currently limit the scalability of densified biomass fuels for household end-use. For example, most respondents suggested that the energy density of densified biomass fuels for heating would need to approach that of coal and that, for cooking, densified biomass fuels were competing with liquefied and gaseous fuels and electricity. Factory personnel further recommended that the development of technology and machinery for drying raw material needed to advance, as it would yield a final product with higher energy density. Factory personnel discussed a broader range of ‘enabling environment’ topics, including market, policy, and financial factors, while local administrators focused primarily on policy factors. For example, local administrative officials cited local and national regulation and enforcement of bans on agricultural and household coal burning as key drivers of rural household energy practices, and thus, discussed the financial subsidies invested, required, or desired to support those policies. Factory personnel also recommended increased financial investment in 1) machinery upgrades and inventory expansion to support rapid raw material collection (and address seasonal pressures) and 2) infrastructure to support transport of raw materials from the fields and distribution of the densified biomass fuels to households. The topic of village contribution (rather than the factory or company contribution) to infrastructure—including machinery, technological expertise, financial tools, and programmatic innovation—was least discussed, but may represent an opportunity for further development if financial resources can be directed to villages for this purpose.

Figure 4.

Proportion of coded segments assigned to each of eight emergent core thematic areas by respondent category (solid line for factory personnel; dotted line for local administrative leaders) in Yushu county (A), Fuyu county (B), and Beichuan county (C).

3.2. Physical infrastructure

We documented estimates of factory and rural household energy program scales, as well as physical infrastructure procurement and costs (Table 1). Land for building the biomass processing facilities was acquired through the local government by purchase or through a long-term lease. The cost of land acquisition was not available at each site, but the estimate provided for Sichuan was ~5% of the estimated combined construction costs for the buildings, road, and power (electricity) infrastructure needed for the factory. When reported, building construction costs were similar across sites. Respondents indicated that within the constraints of cost that limited construction, the facilities were sized to accommodate as much storage of raw materials as possible. In Sichuan, the raw materials periodically exceeded the storage area and were thus stored outdoors, subsequently requiring longer drying times before processing. Electricity consumption costs, normalized per tonne of densified biomass fuel produced, were highest for the Sichuan factory, likely because of the slow rate of pellet compression achievable with the available (out-of-date) technology. In Yushu (Jilin), the factory manager observed variability in factory power consumption relative to dampness of raw materials, with more damp raw materials being associated with higher electricity costs because of the heat needed to dry the materials sufficiently.

Table 1.

Characteristics of factory infrastructure for biomass pellet production for rural households.

| Yushu (Jilin) | Fuyu (Jilin) | Beichuan (Sichuan) | |

|---|---|---|---|

| Factory productiona | approx. 1000 tonnes produced in 2017 for rural households; factory designed to reach 200 tonnes/day production rate and 50,000 tonnes/year 50% (target) for rural household use |

approx. 15,000 tonnes in 2017; approx. 10% for rural household use | less than 50 tonnes produced from 2014–2016 (no production in 2017). 100% (target) for rural household use |

| Rural household energy program scale | approx. 100 households in winter 2016; approx. 350 households in 2017 | approx. 3 households in winter 2016; intent to increase to approx. 100 households by 2017 | approx. 30 households in winter 2015; approx. 170 households by 2016 |

| Land acquisition | Land area (approx. 3,000 m2) purchased from village in 2012 by factory manager; price not provided. | Land rented from the government in the form of yi zheng dai zu;b recurring rental fee not provided. | Land area (approx. 400 m2) bought by town government for 20,000 RMBc. |

| Construction | One 500 m2 building (steel), reported to cost approx. 150,000 RMB. One 360 m2 building (brick-concrete), reported to cost less than 200,000 RMB. |

Not provided. | Single building (less than 400 m2); reported to cost approx. 200,000 RMB. Additional 100,000 RMB needed for road construction to factory. |

| Power and operating costs attributable to power use | Grid-based electricity provides approx. 90% of power; approx. 10% from burning cast-off briquettes. Reported average operating cost approx. 120 RMB/tonne-produced.d |

Estimated average operating coste approx. 40 RMB/tonne-producedf | ∼90,000 RMB to set up power supply (electricity) infrastructure. Estimated average operating cost approx. 200 RMB tonne-produced |

using most recent annual total production volume (tonnes) as a measure of scale

the village committee contracts with a farmer to rent their land for construction, rather than agricultural, production

standard Chinese currency, renminbi (RMB); 1 USD approximately equivalent to 6–7 RMB

when electricity usage classified for agricultural use, rather than if it were for commercial use

respondent (factory manager) reported monthly electricity costs and annual production (tonnes)

Fuyu factory reported being charged industrial power consumption prices, but has applied for agricultural rates

3.3. Technological infrastructure

Factory personnel and local administrative leaders focused on technological barriers to successful conversion of raw biomass materials into densified biomass fuels. Reported machinery needs spanned all stages of biomass processing, including the collection of raw materials; drying; shredding, chipping, and sieving; compression; and packaging for shipment. At times, respondents discussed specific machines, noting performance limitations, quality shortcomings, and cost. Imported machinery from Germany, the United States, and South Korea were four to five times more expensive than domestically produced equivalents. Imported machinery was generally viewed as being more durable, but repairs were costly and had long turnaround times. Several examples emerged from factory personnel interviews that showcased the efforts made within the factory to overcome technological barriers to profitable production of densified biomass fuel. Two examples follow.

In Yushu (Jilin), the factory manager led research and development to build customized machinery to dry raw materials, which is critical to achieving the target energy density (i.e. kilojoule of energy per kilogram of fuel; kJ/kg). The manager observed that reducing raw material moisture content to less than 15% was critical to production of biomass fuel with high energy density (approximately 17,000 kJ/kg) that was on par with coal (approximately 14,000 to 30,000 kJ/kg). To achieve this, the manager invested in design, development, and customization of machinery that could safely dry large volumes of locally-available raw materials (e.g. corn crop residue) that usually have moisture content greater than 15%.

The factory manager in Fuyu (Jilin) was less concerned with fuel energy density, but did express concerns about machine durability and repair. In response to the frequent and costly maintenance and repair needs of the biomass compression machine, the manager developed in-house machinery expertise by hiring a small team that was exclusively focused on rapid machinery repair. Not only did this innovation reduce machinery repair times and cost, the factory manager also noted that the expertise developed internally by his team became a desired service among other companies in the biomass processing sector. At the time of this study, the company was exploring several business models to offer their service as a novel revenue-generating activity.

3.4. Financial perspectives

Respondents discussed several financial models related to the costs, prices, and exchange of raw materials and end-products. Overall, the financial and business models did not appear to have stabilized on a pricing structure for the raw materials or for the final product, which may limit business viability and warrants further study as this sector matures over time. Financial compensation was not always attached to exchange of raw material or exchange of end-product pellets or briquettes (Table 2). In Fuyu (Jilin), for example, an exchange program allowed rural households to trade 3 tonnes of raw material for 1 tonne of biomass briquettes. In the same village, however, some households sold their raw materials in exchange for a cash payment that exceeded the value of 1 tonne of densified biomass briquettes. The local administrative leader suggested that these two arrangements could co-exist if two conditions were met: 1) disposal of agricultural residues was more time- and resource-intensive to some village residents than to others; and 2) alternatives to densified biomass fuel were affordable and permissable. In Sichuan, households that participated in the energy intervention program received the biomass pellet fuel at no cost for at least one year. A small fraction of homes were compensated for provision of collected agricultural residues during a period when, according to the factory manager, there was a time-sensitive need for a larger volume of raw materials for pellet production. Most residents collected their agricultural waste without compensation and paid a nominal fee (several RMB, or less than 1 USD) for pick-up at their home and transport to the factory (approximately 5–10 km).

Table 2.

Estimated expenses for raw materials and final products.

| Raw materials (prices paid to farmers by factory) | Final products (prices charged by factory) | |

|---|---|---|

| Yushu (Jilin) | no paymenta to 200 RMBb/tonne for agricultural residues | to farmers: 450–800c RMB/tonne |

| Fuyu (Jilin) | 190–230d RMB/tonne for peanut shells OR no payment to 200 RMB/tonne for straw residues |

to farmers: 450b RMB/tonne OR to power plants: 370 RMB/tonne |

| Beichuan (Sichuan) | no payment to 200 RMB/tonne for straw residues | to farmers: no charge |

excludes labor and transportation costs incurred by the factory; farmers do not receive compensation for their straw residues (because the removal of those residues is considered a no-charge service)

standard Chinese currency, renminbi (RMB), equivalent to approximately 6–7 USD

range discussed by factory manager; for specific project, per-tonne price was 600 RMB (450 from farmers, 150 from government)

depends on moisture and ash content; higher price for lower moisture content and lower ash content

The factory manager in Yushu (Jilin) noted that raw materials are abundant but constrained by other factors, as indicated in the quote below:

“In our industry, such a raw material (corn stalk)…It’s really available everywhere. But it’s too seasonal. Once the season is over, there isn’t any left. I’m referring to free raw materials. In other industries, raw materials can be bought at any time, so long as you are willing to pay for it. But straw isn’t like that. Therefore, every year… we have to collect the raw materials from the fields within a month or even 15 days, or maybe a month and a half, and then stack them all in the storage yard for further processing. As a manufacturer, first you have to… particularly the collection, storage, and transportation systems for corn stalk, you have to invest, invest in factories, and invest in equipment. You won’t survive if you start a price war before you get everything ready. So, it’s not like just selling products. If you are just selling products, then you just need to sell. But this, you have to go through manufacturing stages. Purchasing corn stalk will only make the market price [of corn stalk] go higher. I believe that… this is my opinion on doing business… if you can buy raw materials, I can buy raw materials, too. Unless you can save more than I do on the entire production processes, say I spend 200 and you can manage within 100. The rules are the same.”

Purchase prices for raw materials varied less than those for the end-products (i.e. pellets, briquettes) (Table 2). Biomass pellet and briquette prices were compared to commercially available alternative heating fuels. In Jilin, the per-tonne prices for the final products, as sold to local residents, was competitive with the local price of coal. In Beichuan (Sichuan), although households were not charged for the biomass pellets they received, the estimated cost to produce 500 grams of biomass pellets at the village factory was 2 RMB (less than 1 USD). This would yield a break-even price of 4000 RMB/tonne (approximately 620 USD), which is more than 4 times the price of pellets produced commercially elsewhere in the Sichuan province (800–900 RMB/tonne; approximately 132 USD). This finding demonstrated a clear need for innovation in production efficiency, which could be achieved with updated pellet compression machinery capable of higher hourly yield rates.

3.5. Future perspectives and policy incentives

All sites are impacted by current and emerging national policy and regulation. The two policies that were most discussed by respondents and that appear to have the most direct influence on their business and government administrative decisions were the ban on open-field biomass and crop residue burning and the ban on combustion of coal in small, inefficient boilers (i.e. household coal heating stoves and boilers). Respondents in Jilin—where these policies are more strongly enforced due to greater household coal use—projected a more positive outlook on the biomass processing industry and its potential to meet energy needs in the rural residential sector compared with respondents in Beichuan (Sichuan province) (Table 3).

Table 3.

Respondent quotes related to organizational goals and planning.

| Site | Respondent quotes |

|---|---|

| Yushu (Jilin) | Factory manager: “But among all the businesses that I have done so far, I am most optimistic about this one [densified biomass]. Because it’s a source of energy. It’s beneficial to the country and the people. It’s not just a company that is earning money, from a more advanced perspective; it’s a course for the benefit of the country and the people …So, we do this business… at least from my personal perspective, doing this business is not purely for money.” Factory manager: “Mr. Xi, the General Secretary of the Communist Party, said… the one sentence that impressed me most was the one in his speech at the 13th Five-year Plan meeting on December 21, [2016]. The first point he made was related to heating in Northern China. He said that, “you have to ensure a safe winter to farmers in the northern areas” [the actual words were “Promoting clean winter heating in northern areas has a bearing on people’s warmth in Northern China, and also on whether the number of smoggy days can be reduced”]. What’s the purpose [of the speech]? My understanding is that it’s a national appeal to ban the use of coal. However, [detailed] measures [regarding the implementation of the ban] should be formulated by local governments. You can [only] ban the use of coal when you have a substitute product. Without a substitution, wouldn’t the people just freeze to death if you just banned the use of coal in Northeast China?” Factory manager: “In the future, it won’t be just targeting the market of Yushu; our products will be targeting the three provinces in Northeast China, and will be sold in other regions of the country, too. We have to make these kinds of plans. At the end of the day, why did I choose to do this business, to produce fuel briquettes out of corn stalk? It’s because I’m optimistic about this business. Households don’t need to change [stoves]; they can all be my customers! I will still be there. My position [in the market] will still be there.” Local village administrator: “It is not very possible that it [biomass utilization] will not be implemented, because the conversion of corn straw pellets is very urgent. Because if you do not convert it, the people must have heating during the winter, and if they do not burn the pellets, they will have to burn corn stalks. It will be either these two things. They must have heating; without heating, it will be unbearable.” |

| Fuyu (Jilin) | Factory manager: “[We] believe that this [product] has a huge potential in China’s future market. After all, there is currently no listed price for this product as there is for other [related] products. But sooner or later, be it new energy or renewable energy, there will surely be a unified listed price in China. By that time, there will be relatively more businesses producing the product. So, the first person who dares to eat crabs will be the first one who obtains the first pot of gold.” Factory manager: “Our goal, the greater goal, is to be the China Shenhua Group [the number one listed coal company in China], of the fuel briquettes industry, where the suggested retail price is the standard price of the products in the industry. [We hope] that in the renewable energy and fuel briquettes industry, our listed price will be the standard price for the corresponding products for Jilin Province. That’s our expected future direction, because in the next few years, or even the next 10 years, 15 years, there’s bound to be standardized prices for fuel briquettes.” Local village administrator: “Well, [the results] can meet, how shall I put it, the standards of environmental protection, and temperature requirements. Burning this [type of fuel] does not create smoke. In addition, it can reach… The indoor temperature [generated by the heating stove] has met the requirements. We also have that plan for the future. What’s our plan? We are going to sign contracts with the farmers. The farmers plant corn. They supply free corn stalk to us, and in exchange, we give them fuel briquettes. They [the fuel] are easier to stock, and they burn better. The Development and Reform Commission has been talking about subsidies, but we haven’t ever received any. If there are government subsidies, good; if there aren’t any subsidies, we’ll still work on it. You have to sign purchase orders with them [village residents] village by village. We have really thought about this, thought about [how to promote the program] in the future. You have to go and sign contracts with, say 200 households, sign contracts with 200 households in a village, sign one-year, two-year, three-year exchange contracts, so that they send [raw materials] to you, then, they will try their best to send raw materials. If this was really implemented, then, there wouldn’t ever be any field burning. We did think about that.” Local village administrator: “Well, the coal… now, they don’t allow you to use coal, the government has stipulated that using coal is not permitted. It’s forcing you to take this path [use biomass fuel[. That’s the reason that this business is promising; it has a prosperous future. You can’t burn [coal]. It’ll violate the law.” |

| Beichuan (Sichuan) | Factory manager: “Because we know the quality of pellets machine—it runs bad—we don’t make a goal [of] how many pellets we must produce.” Interviewer: “Ideally, if the machine works well, how much would do you want to produce per month or year?” Factory manager: “As many as possible.” Former village party secretary: “For the villagers, the current status is thus: The improved stoves are still used by some people because they think the improved stoves are easier to use than the previous two batches of stoves. In contrast, other people do not use the improved stoves… We hope the improved stoves will be used by more people. After all, they are very environmentally friendly, and serve to utilize waste materials and fruit tree branches fully. However, the primary concern is to make improvements to the stoves, for example, reduce the cost of fuel production.” Former village party secretary: “Now, the project has fallen into a state of paralysis. First of all, the machinery in the factory is extremely old, and cannot operate normally. The equipment can smash straw easily, but the fuel made from it burns out quickly. In addition, the equipment is unable to smash extremely thin or thick tree branches.” Local dialect interpreter: “Do you understand? He means that the equipment is very old and may encounter various problems. For example, straw can be smashed thoroughly, but the fuel made from it burns out quickly. In addition, some fruit tree branches are very large while other fruit tree branches are very tiny. Various problems are encountered in the production process. He wants to express this meaning.” Current village party secretary: “In the future, if the fuel processing becomes the villages’ responsibility, it won’t be easy to manage. [This is because] the number of people per household is limited, and so is their consumption of fuel. If using a small amount of fuel requires so many processes… This problem could only be resolved through unified production. So, it’s not realistic to ask each household to process their own fuel in the future. An enterprise and [the management team of] the village should lead [the further development of] this project.” Current village party secretary: “I think this project is good. Why? Because aren’t we forbidden to burn waste wood now? Burning firewood generates too much pollution; the changes in air [quality] and climate are all related to pollution. So, if the government could issue some supporting policies that could facilitate our use in the future, to reduce people’s expenses related to the production and use of [biomass fuel], then the project would remain sustainable in its development.” Current town party secretary: “At present, the stoves are mainly used for cooking rice. In the future, the stoves can also be used for other purposes, for example, warming, cooking, and boiling water. In some rural tourist resorts, cooking and warming mainly rely upon firewood. I think the biomass fuel can replace the firewood… I have a plan for the future. Specifically, when [our] Village develops its tourism industry [especially rural tourist resorts], biomass fuel can be used instead for warming. I think this plan is feasible.” |

From our review of supplemental documents and reports, we determined that the number of non-wood biomass densification sites throughout China has increased by an order of magnitude over the last decade (Figure S1; from less than 100 to more than 1000). This increase is consistent with the recent introduction of national-level policies that directly or indirectly promote biomass reutilization, including those noted above, and summarized by Shan et al. (2016).22 Our interviews with sector experts at Tsinghua University, the Ministry of Agriculture, and the Heilongjiang Institute of Energy highlighted major financial investments in biomass utilization in support of these policies. For instance, at a national level, annual investments on the order of 100 million RMB (~16M USD) in renewable energy programs and biomass utilization have been recently introduced (2016-present) into 12 provinces: Heilongjiang, Jilin, Liaoning, Inner Mongolia, Hebei, Shanxi, Shandong, Henan, Jiangsu, Anhui, Shaanxi, Sichuan.

3.6. Summary of key findings from the Sichuan-based cookstove intervention study

For the Sichuan field site, a rural household energy demonstration project was carried out through a partnership between Tsinghua University and the village-level government, with financial support from national and provincial levels. This multi-year project supported extensive research and evaluation of a gasifier stove designed to burn locally-produced biomass pellets for cooking and water-boiling.24 The emissions performance of the gasifier stove and biomass pellet fuel was evaluated in the field under conditions of actual use (i.e. cooking and water-boiling) and performed at the Tier 4 ISO level.24,25 Among homes enrolled in the household energy demonstration program who received the gasifier stove and biomass pellet fuel (n=113), self-reported uptake and adoption (continued use in some capacity 5–10 months after initial uptake) were high (79% and, of those, 92%, respectively).49 However, daily use was modest initially (mean 40.4% [95% CI 34.3, 46.6] days in use per month) and declined over time, with most homes continuing to regularly use their traditional wood chimney stoves after intervention (77%).49 Mean daily indoor PM2.5 was highest in homes combining the use of both wood and clean fuel stoves (122 μg m−3), followed by exclusive use of wood stoves (106 μg m−3) and clean fuel stoves (gasifiers: 65 μg m−3; gas (biogas or liquefied petroleum gas)/electric: 55 μg m−3).71 Equivalent information on heating stove design, emissions performance, and household uptake and use has not yet been evaluated in the northern sites, or elsewhere in China to our knowledge, given the nascent introduction of government support for rural household heating energy programs in these regions.

4. Discussion and Conclusions

We discuss our main findings below and propose a set of planning recommendations that, while not exclusive to densified biomass production, could guide its development and production as a household fuel.

There is a shared expectation across stakeholder groups that household use of biomass pellet and briquette fuels is still very nascent in China, but could increase with expansion of technological and policy frameworks that favor development of these fuels more broadly. To date, national-level policies have linked biomass resource development to multiple sustainability objectives (e.g. improved air quality, better health, increased renewable energy resources) through the establishment of national targets for biomass utilization32,33,35 and for reductions in open-field biomass and household coal burning.72,73 Sociopolitical pressure to eliminate these banned practices is greatest in northeastern regions of China,3,17 which may explain, in part, why we observed greater investment in Jilin in the physical and technological infrastructure needed for production of high-density biomass fuels. However, financial investment may also be a function of scale, with smaller-scale initial operation in Sichuan relative to Jilin. Greater investment in densified biomass production enterprises in northeastern provinces, like Jilin, may also relate to the regional abundance of predictable, annual, agricultural and crop residues, which constitute the primary source of raw materials for this sector.31,32,35,38,74 Overall, we found that, although policy instruments were regarded as highly influential, they have not yet addressed barriers to cost-effective collection, transportation, storage, and processing of raw materials. Furthermore, financial mechanisms to facilitate market development for densified biomass fuels among rural households were described as underdeveloped in Jilin and unsustainable in Sichuan by local administrative leaders. Our work revealed several critical weaknesses in the policy framework for sustainable development of household biomass energy at the household level that warrant future work and research.

Our case study design aimed to characterize perspectives of local administrative leaders and densified biomass factory managers, which complements the perspectives of rural household end-users that are reported in other studies. For example, local administrative leaders, who typically governed and represented 50 – 1000 households in a single rural village, expressed concern for fuel reliability, cost, and quality. Technological maturity for this sector was noted by most respondents as essential, although not sufficient, to achieve these attributes in a fuel supply. Biomass factory managers and sectors experts we interviewed indicated that technology for processing and compressing biomass to produce pellet and briquette fuels has been maturing more rapidly in China than machinery and processes for large-scale collection of dispersed raw materials. Fuel reliability at a household level relies on consistent and sufficient upstream feedstocks.75–78 Addressing lags in technological development for raw material collection and storage, as noted above, may also improve fuel reliability in rural applications.22,40 For example, we learned that the Sichuan factory periodically purchased raw materials at great cost and distance from the factory to avoid low supply and raising concerns among households that this fuel supply was not stable. This practice could have been obviated if the collection of wood and agricultural residues in the local area were more efficient and technologically feasible.

We also learned that the technological advances achieved by mid- and large-scale biomass processing industries have some application for smaller-scale biomass processing, but they are likely limited. Instead, sector experts emphasized the need for development of design standards tailored to small-scale operations and training programs specific to local labor markets that are currently lacking. They also cited inconsistent and unskilled use of existing technologies, machinery, and processes as barriers to achieving reliable, affordable, high-quality densified biomass fuels for household end-users. Coordinated research and development efforts in engineering, economic, and business fields could be immediately impactful, and harmonize infrastructure development between villages and factories, which our study showed was under-exploited.

Our study joins a larger body of work examining sustainable rural energy development and production and delivery of new and renewable energy technologies and fuels. Although electricity and low-polluting gaseous fuels like liquefied petroleum gas (LPG) are projected to fully or nearly displace solid fuels for cooking within a decade,79,80 heating fuel modernization trends have progressed much more slowly and less completely.80 Biomass pellet and briquette production has been under consideration in China to address the need for affordable household heating fuels in rural areas. The cases we examined in two Jilin counties and one Sichuan county represented very early adopters and implementers of this potential form of rural energy development. This work, in context with that of several other recent case studies,46,87 may guide future, larger-scale work. We propose a set of questions from which future household energy programs, in China or even elsewhere, may benefit from addressing early on in their development:

What national-level policies are in place to incentivize use of densified biomass fuels and dis-incentivize the use of traditional solid fuels they would replace?

To what extent do national- and provincial- policy frameworks incorporate and support households as end-users of the densified biomass fuels developed (i.e. pellets and/or briquettes)?

What local management structures and/or policy instruments are needed for local implementation of biomass utilization policies to relate directly to households as end-users?

What opportunities exist for factories and villages to jointly overcome technological and financial barriers to feedstock, machinery, labor, and expertise needs in support of densified biomass fuels for households?

What technological and resource-based challenges exist locally that would limit production yields, reliability, costs, and final product quality with respect to household preferences?

What are anticipated local drivers of household transitions to novel household energy supplies, given the local culture and economic development trends?

What are the conditions and measures needed to support sustainable utilization of densified biomass fuel in households without (or only minor) financial subsidy or administrative interference?

How will distributional impacts to energy, environment, and living condition improvement at various levels be measured and quantified over the short- and long-term?

Who is tasked with developing and monitoring benchmarks for biomass utilization among rural households?

How should programmatic and market-based benchmarks evolve over time to address sustainability of densified biomass fuel production and use by rural households?

Our study provides a present-day snapshot of China’s quickly evolving rural energy sector. As designed, our case study relied on qualitative research and data collection methods that may be subject to biases such as researcher bias or over-reliance on one source. To mitigate the possible effects of some of these biases, we fully documented our systematic approach to data collection and analysis to allow other researchers to assess potential bias. To increase study robustness and validity of results, we sought to evaluate perspectives from multiple sources. This approach led to identification of several key challenges: 1) heterogeneity of feedstocks that limits pellet and briquette energy density, 2) high operational costs for seasonally-varying collection, transport, and storage of raw materials, 3) high operational costs for storage and distribution of final products, 4) limited household demand for densified biomass fuels, and 5) inconsistent enforcement of national and provincial policies banning use of coal and open-field biomass burning. Future research efforts may be best directed toward first identifying, implementing, and evaluating technological, economic, and policy-based solutions for densified biomass development more broadly, and then tailoring those solution to the rural household energy sector, taking into consideration provincial and local context.

Supplementary Material

Highlights.

Factory and rural administrative stakeholders shared complementary recommendations for extending production of densified biomass fuel for rural households in China, with an emphasis on heating fuels.

Respondents indicated need for technology advances to collect and move dispersed seasonal feedstocks.

Business and financial models for transactions between households and factories have not stabilized.

Stakeholders suggested that LPG and electricity may be better sources of energy for cooking, although the same may not be true for space and water heating, than densified solid fuels.

Some factory managers may pursue development of densified biomass fuels for rural households in addition to their industrial-scale end-users and find this adds complexity to their business models.

6. Acknowledgements

This work was supported in part through the Clean Cooking Implementation Science Network (ISN) with funds from the United States National Institutes of Health Common Fund program for Global Health. This work was also supported by the Wellcome Trust (UK, grant103906/Z/14/Z).

Footnotes

Publisher's Disclaimer: This is a PDF file of an unedited manuscript that has been accepted for publication. As a service to our customers we are providing this early version of the manuscript. The manuscript will undergo copyediting, typesetting, and review of the resulting proof before it is published in its final form. Please note that during the production process errors may be discovered which could affect the content, and all legal disclaimers that apply to the journal pertain.

References

- (1).Apte JS; Marshall JD; Cohen AJ; Brauer M Addressing Global Mortality from Ambient PM2.5. Environ. Sci. Technol 2015, 49 (13), 8057–8066. [DOI] [PubMed] [Google Scholar]

- (2).Zhang Q; He K; Huo H Policy: Cleaning China’s Air. Nature 2012, 484 (7393), 161–162. [DOI] [PubMed] [Google Scholar]

- (3).Liu J; Mauzerall DL; Chen Q; Zhang Q; Song Y; Peng W; Klimont Z; Qiu X; Zhang S; Hu M; et al. Air Pollutant Emissions from Chinese Households: A Major and Underappreciated Ambient Pollution Source. Proc. Natl. Acad. Sci 2016, 113 (28), 7756–7761. [DOI] [PMC free article] [PubMed] [Google Scholar]

- (4).Cheng M; Zhi G; Tang W; Liu S; Dang H; Guo Z; Du J; Du X; Zhang W; Zhang Y; et al. Air Pollutant Emission from the Underestimated Households’ Coal Consumption Source in China. Sci. Total Environ 2016. [DOI] [PubMed] [Google Scholar]

- (5).Brauer M; Freedman G; Frostad J; van Donkelaar A; Martin RV; Dentener F; van Dingenen, R.; Estep K; Amini H; Apte JS; et al. Ambient Air Pollution Exposure Estimation for the Global Burden of Disease 2013. Environ. Sci. Technol 2016, 50 (1), 79–88. [DOI] [PubMed] [Google Scholar]

- (6).Lim SS; Vos T; Flaxman AD; Danaei G; Shibuya K; Adair-Rohani H; AlMazroa MA; Amann M; Anderson HR; Andrews KG; et al. A Comparative Risk Assessment of Burden of Disease and Injury Attributable to 67 Risk Factors and Risk Factor Clusters in 21 Regions, 1990–2010: A Systematic Analysis for the Global Burden of Disease Study 2010. The Lancet 2012, 380 (9859), 2224–2260. [DOI] [PMC free article] [PubMed] [Google Scholar]

- (7).Bond TC; Doherty SJ; Fahey DW; Forster PM; Berntsen T; DeAngelo BJ; Flanner MG; Ghan S; Kärcher B; Koch D; et al. Bounding the Role of Black Carbon in the Climate System: A Scientific Assessment. J. Geophys. Res. Atmospheres 2013, 118 (11), 5380–5552. [Google Scholar]

- (8).World Health Organization. WHO Guidelines for Indoor Air Quality: Selected Pollutants; 2010. [PubMed]

- (9).Liu S; Tao S; Liu W; Dou H; Liu Y; Zhao J; Little MG; Tian Z; Wang J; Wang L; et al. Seasonal and Spatial Occurrence and Distribution of Atmospheric Polycyclic Aromatic Hydrocarbons (PAHs) in Rural and Urban Areas of the North Chinese Plain. Environ. Pollut 2008, 156 (3), 651–656. [DOI] [PubMed] [Google Scholar]

- (10).Zheng M; Salmon LG; Schauer JJ; Zeng L; Kiang CS; Zhang Y; Cass GR Seasonal Trends in PM2.5 Source Contributions in Beijing, China. Atmos. Environ 2005, 39 (22), 3967–3976. [Google Scholar]

- (11).Zheng Y; Xue T; Zhang Q; Geng G; Tong D; Li X; He K Air Quality Improvements and Health Benefits from China’s Clean Air Action since 2013. Environ. Res. Lett 2017, 12 (11), 114020. [Google Scholar]

- (12).Beijing City Government. 13th Five-Year Energy Development Plan. 2016.

- (13).National Development and Reform Commission of People’s Republic of China. Medium and Long-Term Development Plan for Renewable Energy in China (Abbreviated Version, English Draft). 2007b.

- (14).China Ministry of Agriculture; US Department of Energy. Assessment of Biomass Resources Availability in China. China Environmental Science Press, Beijing, in Chinese. China Environmental Science Press; 1998. [Google Scholar]

- (15).Archer-Nicholls S; Carter E; Kumar R; Xiao Q; Liu Y; Frostad J; Forouzanfar MH; Cohen A; Brauer M; Baumgartner J; et al. The Regional Impacts of Cooking and Heating Emissions on Ambient Air Quality and Disease Burden in China. Environ. Sci. Technol 2016, 50 (17), 9416–9423. [DOI] [PubMed] [Google Scholar]

- (16).Chafe ZA; Brauer M; Klimont Z; Van Dingenen R; Mehta S; Rao S; Riahi K; Dentener F; Smith KR Household Cooking with Solid Fuels Contributes to Ambient PM2.5 Air Pollution and the Burden of Disease. Environ. Health Perspect 2014, 122 (12), 1314–1320. [DOI] [PMC free article] [PubMed] [Google Scholar]

- (17).Chen J; Li C; Ristovski Z; Milic A; Gu Y; Islam MS; Wang S; Hao J; Zhang H; He C; et al. A Review of Biomass Burning: Emissions and Impacts on Air Quality, Health and Climate in China. Sci. Total Environ 2017, 579 (Supplement C), 1000–1034. [DOI] [PubMed] [Google Scholar]

- (18).Zhang Y-L; Cao F Is It Time to Tackle PM2.5 Air Pollutions in China from Biomass-Burning Emissions? Environ. Pollut 2015, 202 (Supplement C), 217–219. [DOI] [PubMed] [Google Scholar]

- (19).Li Q; Jiang J; Wang S; Rumchev K; Mead-Hunter R; Morawska L; Hao J Impacts of Household Coal and Biomass Combustion on Indoor and Ambient Air Quality in China: Current Status and Implication. Sci. Total Environ 2017, 576, 347–361. [DOI] [PubMed] [Google Scholar]

- (20).Carter E; Archer-Nicholls S; Ni K; Lai AM; Niu H; Secrest MH; Sauer SM; Schauer JJ; Ezzati M; Wiedinmyer C; et al. Seasonal and Diurnal Air Pollution from Residential Cooking and Space Heating in the Eastern Tibetan Plateau. Environ. Sci. Technol 2016, 50 (15), 8353–8361. [DOI] [PubMed] [Google Scholar]

- (21).Shan M; Wang P; Li J; Yue G; Yang X Energy and Environment in Chinese Rural Buildings: Situations, Challenges, and Intervention Strategies. Build. Environ 2015, 91 (Supplement C), 271–282. [Google Scholar]

- (22).Shan M; Li D; Jiang Y; Yang X Re-Thinking China’s Densified Biomass Fuel Policies: Large or Small Scale? Energy Policy 2016, 93 (Supplement C), 119–126. [Google Scholar]

- (23).Roth Christa. Micro Gasification: Cooking with Gas from Biomass, 2nd ed.; GIZ- HERA Poverty-oriented basic energy services.; Federal Ministry for Economic Cooperation and Development, Deutsche Gesellschaft fur Internationale Zusammenarbeit (GIZ) GmbH: Germany, 2014. [Google Scholar]

- (24).Shan M; Carter E; Baumgartner J; Deng M; Clark S; Schauer JJ; Ezzati Majid; Li J; Fu Y; Yang X A User-Centered, Iterative Engineering Approach for Advanced Biomass Cookstove Design and Development. Environ. Res. Lett 2017, 12 (9), 095009. [DOI] [PMC free article] [PubMed] [Google Scholar]

- (25).Carter EM; Shan M; Yang X; Li J; Baumgartner J Pollutant Emissions and Energy Efficiency of Chinese Gasifier Cooking Stoves and Implications for Future Intervention Studies. Environ. Sci. Technol 2014, 48 (11), 6461–6467. [DOI] [PubMed] [Google Scholar]

- (26).World Health Organization. Residential Heating with Wood and Coal: Hea Lth Impacts and Policy Options in Europe and North America. 2015.

- (27).Garland C; Delapena S; Prasad R; L’Orange C; Alexander D; Johnson M Black Carbon Cookstove Emissions: A Field Assessment of 19 Stove/Fuel Combinations. Atmos. Environ 2017, 169, 140–149. [Google Scholar]

- (28).Du W; Shen G; Chen Y; Zhu X; Zhuo S; Zhong Q; Qi M; Xue C; Liu G; Zeng E; et al. Comparison of Air Pollutant Emissions and Household Air Quality in Rural Homes Using Improved Wood and Coal Stoves. Atmos. Environ 2017, 166, 215–223. [Google Scholar]

- (29).Tryner J; Volckens J; Marchese AJ Effects of Operational Mode on Particle Size and Number Emissions from a Biomass Gasifier Cookstove. Aerosol Sci. Technol 2018, 52 (1), 87–97. [Google Scholar]

- (30).Aung TW; Jain G; Sethuraman K; Baumgartner J; Reynolds C; Grieshop AP; Marshall JD; Brauer M Health and Climate-Relevant Pollutant Concentrations from a Carbon-Finance Approved Cookstove Intervention in Rural India. Environ. Sci. Technol 2016, 50 (13), 7228–7238. [DOI] [PubMed] [Google Scholar]

- (31).Cuiping L; Yanyongjie; Chuangzhi W; Haitao H Study on the Distribution and Quantity of Biomass Residues Resource in China. Biomass Bioenergy 2004, 27 (2), 111–117. [Google Scholar]

- (32).Liu H; Jiang GM; Zhuang HY; Wang KJ Distribution, Utilization Structure and Potential of Biomass Resources in Rural China: With Special References of Crop Residues. Renew. Sustain. Energy Rev 2008, 12 (5), 1402–1418. [Google Scholar]

- (33).Yanli Y; Peidong Z; Wenlong Z; Yongsheng T; Yonghong Z; Lisheng W Quantitative Appraisal and Potential Analysis for Primary Biomass Resources for Energy Utilization in China. Renew. Sustain. Energy Rev 2010, 14 (9), 3050–3058. [Google Scholar]

- (34).Zhou X; Wang F; Hu H; Yang L; Guo P; Xiao B Assessment of Sustainable Biomass Resource for Energy Use in China. Biomass Bioenergy 2011, 35 (1), 1–11. [Google Scholar]

- (35).Zeng X; Ma Y; Ma L Utilization of Straw in Biomass Energy in China. Renew. Sustain. Energy Rev 2007, 11 (5), 976–987. [Google Scholar]

- (36).Chen L; Xing L; Han L Renewable Energy from Agro-Residues in China: Solid Biofuels and Biomass Briquetting Technology. Renew. Sustain. Energy Rev 2009, 13 (9), 2689–2695. [Google Scholar]

- (37).Chen Y; Yang G; Sweeney S; Feng Y Household Biogas Use in Rural China: A Study of Opportunities and Constraints. Renew. Sustain. Energy Rev 2010, 14 (1), 545–549. [Google Scholar]

- (38).Peidong Z; Yanli Y; Yongsheng T; Xutong Y; Yongkai Z; Yonghong Z; Lisheng W Bioenergy Industries Development in China: Dilemma and Solution. Renew. Sustain. Energy Rev 2009, 13 (9), 2571–2579. [Google Scholar]

- (39).Gan L; Yu J Bioenergy Transition in Rural China: Policy Options and Co-Benefits. Energy Policy 2008, 36 (2), 531–540. [Google Scholar]

- (40).Han J; Mol APJ; Lu Y; Zhang L Small-Scale Bioenergy Projects in Rural China: Lessons to Be Learnt. Energy Policy 2008, 36 (6), 2154–2162. [Google Scholar]

- (41).Patton MQ Qualitative Research and Evaluation Methods: Integrating Theory and Practice, 4th ed.; Sage: Thousand Oaks, CA, 2015. [Google Scholar]

- (42).Yin RE Case Study Research: Design and Methods, 5th ed.; Sage: Thousand Oaks, CA, 2013. [Google Scholar]

- (43).Corbin Juliet; Strauss Anselm. Basics of Qualitative Research: Techniques and Procedures for Developing Grounded Theory, 3rd ed.; Sage: Los Angeles, CA, 2008. [Google Scholar]

- (44).Anselm Strauss; Barney Glaser. The Discovery of Grounded Theory; Aldine Transaction: New Brunswick, NJ, 1967. [Google Scholar]

- (45).Priest H; Roberts P; Woods L An Overview of Three Different Approaches to the Interpretation of Qualitative Data. Part 1: Theoretical Issues. Nurse Res. 2002, 10 (1), 30. [DOI] [PubMed] [Google Scholar]

- (46).Woods L; Priest H; Roberts P An Overview of Three Different Approaches to the Interpretation of Qualitative Data. Part 2: Practical Illustrations. Nurse Res. 2002, 10 (1), 43. [DOI] [PubMed] [Google Scholar]

- (47).Jones B; O’Neill BC Spatially Explicit Global Population Scenarios Consistent with the Shared Socioeconomic Pathways. Environ. Res. Lett 2016, 11 (8), 084003. [Google Scholar]

- (48).Duan X; Jiang Y; Wang B; Zhao X; Shen G; Cao S; Huang N; Qian Y; Chen Y; Wang L Household Fuel Use for Cooking and Heating in China: Results from the First Chinese Environmental Exposure-Related Human Activity Patterns Survey (CEERHAPS). Appl. Energy 2014, 136, 692–703. [Google Scholar]

- (49).Clark S; Carter E; Shan M; Ni K; Niu H; Tseng JTW; Pattanayak SK; Jeuland M; Schauer JJ; Ezzati M; et al. Adoption and Use of a Semi-Gasifier Cooking and Water Heating Stove and Fuel Intervention in the Tibetan Plateau, China. Environ. Res. Lett 2017, 12 (7), 075004. [Google Scholar]

- (50).Yu S; Eom J; Evans M; Clarke L A Long-Term, Integrated Impact Assessment of Alternative Building Energy Code Scenarios in China. Energy Policy 2014, 67 (Supplement C), 626–639. [Google Scholar]

- (51).MOHURD. 《严寒和寒冷地区居住建筑节能设计标准 JGJ26–2009》 (Design Standard for Energy Efficiency in Residential Buildings in the Severe Cold and Cold Zones JGJ26–2009)”. Beijing: China Architecture and Building Press; 2009. [Google Scholar]

- (52).Wan KKW; Li DHW; Yang L; Lam JC Climate Classifications and Building Energy Use Implications in China. Energy Build. 2010, 42 (9), 1463–1471. [Google Scholar]

- (53).Whiting LS Semi-structured interviews: guidance for novice researchers https://journals.rcni.com/doi/abs/10.7748/ns2008.02.22.23.35.c6420 (accessed Nov 29, 2017). [DOI] [PubMed]

- (54).Wengraf T Qualitative Research Interviewing: Biographic Narrative and Semi-Structured Methods; SAGE, 2001. [Google Scholar]

- (55).Saldana Johnny. The Coding Manual for Qualitative Researchers, 3rd ed.; Sage: Arizona State University, USA, 2016. [Google Scholar]

- (56).Heath H; Cowley S Developing a Grounded Theory Approach: A Comparison of Glaser and Strauss. Int. J. Nurs. Stud 2004, 41 (2), 141–150. [DOI] [PubMed] [Google Scholar]

- (57).Glaser Barney. Basics of Grounded Theory Analysis: Emergence Vs. Forcing, 1st ed.; Sociology Press: Mill Valley, CA, 1992. [Google Scholar]

- (58).Glaser BG; Holton J Remodeling Grounded Theory. Forum Qual. Sozialforschung Forum Qual. Soc. Res 2004, 5 (2). [Google Scholar]

- (59).Holton JA The Coding Process and Its Challenges In The Sage Handbook for Grounded Theory; Sage Publications: Los Angeles, CA, 2010; pp 265–289. [Google Scholar]

- (60).Anito JJ; Prudente M; Aguja S; Rubi S, Tracking P Conceptual Saturation in Classical Grounded Theory Using Lead and Link Technique. Adv. Sci. Lett 2015, 21, 2479–2482. [Google Scholar]

- (61).Armstrong D; Gosling A; Weinman J; Marteau T The Place of Inter-Rater Reliability in Qualitative Research: An Empirical Study. Sociology 1997, 31 (3), 597–606. [Google Scholar]

- (62).Paula Roberts HP Reliability and validity in research https://journals.rcni.com/doi/abs/10.7748/ns2006.07.20.44.41.c6560 (accessed Dec 4, 2017).

- (63).Pope C; Ziebland S; Mays N Analysing Qualitative Data. BMJ 2000, 320 (7227), 114–116. [DOI] [PMC free article] [PubMed] [Google Scholar]

- (64).Moretti F; van Vliet L; Bensing J; Deledda G; Mazzi M; Rimondini M; Zimmermann C; Fletcher I A Standardized Approach to Qualitative Content Analysis of Focus Group Discussions from Different Countries. Patient Educ. Couns 2011, 82 (3), 420–428. [DOI] [PubMed] [Google Scholar]

- (65).Krippendorff K Measuring the Reliability of Qualitative Text Analysis Data. Qual. Quant 2004, 38 (6), 787–800. [Google Scholar]

- (66).Ni K; Carter E; Schauer JJ; Ezzati M; Zhang Y; Niu H; Lai AM; Shan M; Wang Y; Yang X; et al. Seasonal Variation in Outdoor, Indoor, and Personal Air Pollution Exposures of Women Using Wood Stoves in the Tibetan Plateau: Baseline Assessment for an Energy Intervention Study. Environ. Int 2016, 94, 449–457. [DOI] [PubMed] [Google Scholar]

- (67).Baumgartner J; Carter E; Schauer JJ; Ezzati M; Daskalopoulou SS; Valois M-F; Shan M; Yang X Household Air Pollution and Measures of Blood Pressure, Arterial Stiffness and Central Haemodynamics. Heart 2018, heartjnl-2017–312595. [DOI] [PubMed] [Google Scholar]

- (68).Shan M; Yang X; Ezzati M; Chaturvedi N; Coady E; Hughes A; Shi Y; Yang M; Zhang Y; Baumgartner J A Feasibility Study of the Association of Exposure to Biomass Smoke with Vascular Function, Inflammation, and Cellular Aging. Environ. Res 2014, 135, 165–172. [DOI] [PubMed] [Google Scholar]

- (69).Secrest MH; Schauer JJ; Carter EM; Lai AM; Wang Y; Shan M; Yang X; Zhang Y; Baumgartner J The Oxidative Potential of PM2.5 Exposures from Indoor and Outdoor Sources in Rural China. Sci. Total Environ 2016, 571, 1477–1489. [DOI] [PubMed] [Google Scholar]

- (70).Rehfuess EA; Puzzolo E; Stanistreet D; Pope D; Bruce NG Enablers and Barriers to Large-Scale Uptake of Improved Solid Fuel Stoves: A Systematic Review. Environ. Health Perspect. Online Res. Triangle Park 2014, 122 (2), 120. [DOI] [PMC free article] [PubMed] [Google Scholar]

- (71).Snider G; Carter E; Clark S; Tseng J (Tzu W; Yang X; Ezzati M; Schauer JJ; Wiedinmyer C; Baumgartner J Impacts of Stove Use Patterns and Outdoor Air Quality on Household Air Pollution and Cardiovascular Mortality in Southwestern China. Environ. Int 2018, 117, 116–124. [DOI] [PMC free article] [PubMed] [Google Scholar]

- (72).National Development and Reform Commission of People’s Republic of China. Interim Administration Measures for Reduction and Substitution of Coal Consumption in the Key Areas of China. 2014.

- (73).Fang M; Chan CK; Yao X Managing Air Quality in a Rapidly Developing Nation: China. Atmos. Environ 2009, 43 (1), 79–86. [Google Scholar]

- (74).Wang W; Ouyang W; Hao F A Supply-Chain Analysis Framework for Assessing Densified Biomass Solid Fuel Utilization Policies in China. Energies 2015, 8, 7122–7139. [Google Scholar]

- (75).Chen M; Yang X Situations and Challenges of Household Energy Consumption in Chinese Small Towns. Energy Build. 2015, 107 (Supplement C), 155–162. [Google Scholar]

- (76).Li X; Lin C; Wang Y; Zhao L; Duan N; Wu X Analysis of Rural Household Energy Consumption and Renewable Energy Systems in Zhangziying Town of Beijing. Ecol. Model 2015, 318 (Supplement C), 184–193. [Google Scholar]

- (77).Sun C; Ouyang X; Cai H; Luo Z; Li A Household Pathway Selection of Energy Consumption during Urbanization Process in China. Energy Convers. Manag 2014, 84 (Supplement C), 295–304. [Google Scholar]

- (78).Liu W; Spaargaren G; Heerink N; Mol APJ; Wang C Energy Consumption Practices of Rural Households in North China: Basic Characteristics and Potential for Low Carbon Development. Energy Policy 2013, 55 (Supplement C), 128–138. [Google Scholar]

- (79).Chen Y; Shen H; Zhong Q; Chen H; Huang T; Liu J; Cheng H; Zeng EY; Smith KR; Tao S Transition of Household Cookfuels in China from 2010 to 2012. Appl. Energy 2016, 184, 800–809. [Google Scholar]

- (80).Chan KH; Lam KBH; Kurmi OP; Guo Y; Bennett D; Bian Z; Sherliker P; Chen J; Li L; Chen Z Trans-Generational Changes and Rural-Urban Inequality in Household Fuel Use and Cookstove Ventilation in China: A Multi-Region Study of 0.5 Million Adults. Int. J. Hyg. Environ. Health 2017. [DOI] [PMC free article] [PubMed] [Google Scholar]

- (81).Zheng YH; Li ZF; Feng SF; Lucas M; Wu GL; Li Y; Li CH; Jiang GM Biomass Energy Utilization in Rural Areas May Contribute to Alleviating Energy Crisis and Global Warming: A Case Study in a Typical Agro-Village of Shandong, China. Renew. Sustain. Energy Rev 2010, 14 (9), 3132–3139. [Google Scholar]

- (82).Song S; Liu P; Xu J; Ma L; Chong C; He M; Huang X; Li Z; Ni W An Economic and Policy Analysis of a District Heating System Using Corn Straw Densified Fuel: A Case Study in Nong’an County in Jilin Province, China. Energies 2016, 10 (1), 8. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.