Abstract

The sustainability of the ship recycling industry strongly linked with the global shipping market and international commodity flows. More than 80% of the End of Life (EoL) ships are dismantled in South Asian countries, namely Bangladesh, India, and Pakistan. Due to measures taken to minimize the propagation of the Coronavirus disease (COVID-19), an international supply chain is broken to a historic low, except for certain medical-related urgencies. Due to the disruption of global supply chains, the industry may submerge into uncertainty due to, perhaps, lack of adequate labor force to dismantle increased EoL ships and due to disturbances of vessel transportation to the recycling nations amid strong precautionary measures. Our estimate suggests that about 300 million Gross Tonnage (GT) available for demolition in the next five years and the inability to get them recycled would cost about 20 billion dollars. More importantly, South Asian recycling nations would suffer from economic losses and employment opportunities. In this study, we also apply a scenario analysis technique to understand the impact range of COVID-19 in the short term and in the long term. The disruption is viewed through a circular economy framework, identifying a critical lack of ‘global scale’ acknowledgment in the circular economy framework. This article suggests that a formalized global scale, paralleled with favorable policies, may reduce supply chain disruption and improve sustainable development in the receiving nations.

Keywords: COVID-19, circular economy, disruption response, global circular economy, scenario analysis, ship recycling

1. Introduction

On June 19, 2020, 8.5 million people are infected by the Coronavirus disease (COVID-19) in which 4.56 hundred thousand are reported to be dead, affecting 213 countries and territories worldwide. The initial onslaught of this virus was in China and then in EU countries with Italy, Spain, and France hard hit in terms of death counts before it is found a new epicenter to the United States (US) where the death tolls exceed a hundred thousand already. The virus is now spreading at an alarming rate in Brazil and Russia and the South Asian countries (Worldometer, 2020). Top three ship recycling nations – India, Pakistan and Bangladesh- are now experiencing steep curve for new cases with global rank 4, 13 and 17 respectively. Death tolls seem to be lower for countries that responded, earlier rather than later, through complete lockdown, early mass testing and isolating the affected. Examples of such countries are, arguably, New Zealand, Germany, and others. The significant effect of the lockdown as measures for minimizing the propagation of the COVID-19 is the slowdown of economic activities driven by the shutdown of manufacturing industries and consumer-driven demand fall for the goods and services.

About 90 percent of global trade is accomplished by the shipping sector, which is considered to be the ‘artery’ of international supply chains. ILO reported that the volume of merchandise trade is declined by about 13 percent in mid-April and expected to be about 32% decline in the subsequent months. The first half of 2020 is expected to observe a 25 percent decline, which may be a 10 percent decline overall in the year 2020 (ILO 2020). European shipping is undergoing a ‘critical’ moment due to the outbreak of the COVID-19 pandemic. European community of ship-owners’ association surveyed its member companies to assess the impact on EU shipping. They reported that except tankers, all other types of vessel would incur significant immediate losses, with already declined turnover higher than 60% (European Community of Ship-owners’ Associations 2020). The duration of this trend may not last for long and expected to a partial recovery by the end of the year. International maritime organization in tandem with World Health Organization issue a joint statement, urging the cooperation from the member states to avoid unnecessary restrictions while ensuring safety for all involved (International Maritime Organization 2020). Long-term impact on shipping is yet to be provided by the relevant organizations.

1.1. Ship recycling, supply chain, and impact of economic recession

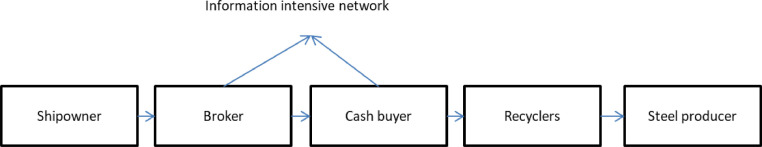

The ship recycling process starts from ship-owners and occurs at several stages (Figure 1 ). Brokers and Cash buyers provide an important service to the selling process informally. These two essential players shape how the ship recycling is occurring at the behest of current ship recycling regimes such as the Hong Kong Convention, European Ship recycling regulation, and the like. They possess very important market information and maintain a high level of communication among the other supply chain actors. Ship-owners contact brokers when decide to terminate a vessel, and then, brokers collect and analyze relevant End of Life (EoL) markets and contact cash buyers for the settlement of the contracts on behalf of ship-owners. Brokers get an agreed percentage, usually 1% of the price of EoL ships. Unlike brokers, Cash buyers buy the ships with a cash payment in about two installments while reselling them to the recyclers with a bank letter of credit. This transaction is thus highly dependent on the financial institutions in transferring and securing risks among the actors. Recyclers take about 180 days to finish dismantling an average sized ship and start selling the scraps to steel producers. Then, they start to pay the bank against the letter of credits. There is not enough understanding of the nature of the transaction in the selling process of EoL ships in the shipbreaking literature. Recyclers pay insurance costs, taxes, and duties related to the vessels, yard rental costs, investment costs, cost of consumables, and labor costs, summed up to 15-20% of the purchase costs (Mikelis 2018).

Fig. 1.

Shipbreaking value chain

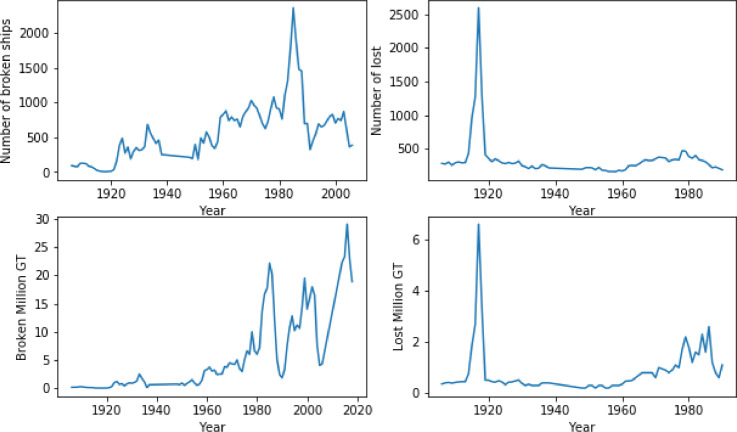

As indicated above, South Asian ship recycling industry is considered to be a volatile industry where the business robustness depends on the several supply and demand factors. Supply factors include world economic trend, type and age of the ships, and regulations, while demand factors include the price of steel in the world market and the role of financial institutions (Knapp et al. 2008). Apart from these factors, uncertain disruption may cause these factors to respond differently. For example, in World War I, II, and the economic recession in the 1980s, an increasing number of vessels were broken for scraps or lost in the international water (Figure 2 ).

Fig. 2.

Number of broken and lost ships from the year 1906 to 2020

(data from Lloyd's register 2020)

Figure 2 shows that the number of broken ships is steadily increasing from the year 1920 with occasional fluctuations, quite importantly noted for the First and Second World War. In this period, the number remains the same before and after the events. The most notable fluctuation is observed during the 1980 global recession. In the next five years, the number of broken ships rose dramatically from about 1,000 ships to 2,000 ships, (9 million Gross Tonnage (GT) to 23 million GT), which sharply drops in the next five years in the 1990s. Besides, there were always some ships lost, not more than 500 ships, equivalent to about 1 million GT. During the 1980s recession, it is found that the number of ships lost also gets doubled from 1 million GT to 2 million GT. It is also noteworthy that during the First World War or a few years before the First World War, the number of ships lost was dramatically increased . The increasing trend of lost ships during a recession may indicate that the shipowners were preferred to give them away rather than to incur the operational cost of the idle vessels. Operating cost constitutes about 65% of the total life cycle cost of a ship. For example, Tthe operating costs of Panamax (4,000 TEU), Post-Panamax (6,000 TEU), and Post-Panamax Plus (10,000 TEU) are 9, 12, and 14.5 million USD respectively, which accounts for about 0.5 million USD per year. 60 % of the total operating costs are attributed to port charges and fuel costs (Drewry Shipping Consultants Ltd. 2020). The most common cause of losses was reported to be foundering (sinking or submerging), often driven by heavy weather (Allianz 2014).

The interrelationship of the global economy, number of vessels addition and the number vessels broken and lost in the past hundred year indicates that the economic recession driven by the supply chain disruption due to the COVID-19 pandemic may leave an impact on the ship recycling for few years to come (Supplementary material). While it is certain that in the few years to come, the number of vessels open for dismantling would vary unpredictably, it is critical to think ahead of how the variation would be appeared and responded. More importantly, is there any possibility that the response would be steered towards more sustainable solutions. To understand the disruption of this global circularity, we first analyze to what extent circular economy considers global scale as a scale of analysis and how the disruption is perceived, managed, and responded in the circular economy literature.

1.2. Circular economy: global scale and social dimension

The circular economy has gained momentum in developed countries, especially in the EU, China, Japan, and other developed countries through the formulation of pollution mitigation policies. The aim is to decouple resource consumption from economic activities through the promotion of higher-order value retention options (Rahman et al. 2019). While the implementation of circular economy in the microscale (i.e., firm-level, product level) and mesoscale (i.e. eco-industrial parks) is discussed, a massive gap exists in how the circular economy is perceived at the global level (Moraga et al. 2019, Rahman and Kim 2020). While there are confusions in how one understands by the terms - meso and macro scale- the flows that connect more than two regions (For example, EU nations to Asian nations) is not mentioned in circular economy literature (Moraga et al. 2019).

The circular economy seems to be driven by five principles – namely climate change, sustainable development, national regulations and policy, consumer awareness and activism, and business continuity (Ul.com 2020). Taking shipbreaking system as an example, the global flows seem to be satisfying at least three factors (Climate change, sustainable development, and business continuity) while the rest seems not at standard. For example, EoL ship recycling in substandard nations avoids 10 million tons of CO2 eq. per year and accounts for over 50% of total scrap reused, accompanied by waste management burdens of about 100 thousand tons per year to the recycling nations (Rahman and Kim 2020). From sustainable development point of view, the flow sustains national economy to a varying degree, ranging from 10% to 60% of the total steel demand of the recycling countries and creates a strong social and institutional embeddedness across the recycling nations, arguably helping to reduce economic hardship and poverty through employment (Gregson et al. 2010, Rahman and Mayer 2015). More importantly, the flow is business-friendly where upstream and downstream actors gain economically (ship-owners earn about 1.2 billion dollars more, for example) compared to more desired alternatives (standard recycling facilities) (Rahman and Kim 2020). Thus, being economically self-sustaining and globally sustainable, a global flow can be brought under circular economy discussion. The formalization of global flow could reduce the unintended and often contextually bound, social, and economic vulnerability (Gregson et al. 2013, Cairns 2014, Rahman and Mayer 2016, Rahman et al., 2018).

The importance of viewing shipbreaking in a global scale is paramount. Shipbreaking has been presented as an example of world system where core connects periphery for the waste disposal (Frey 2013). This industry continues to play an important role in minimizing waste burden of the ship-owner and, instead, return a handsome amount of money by selling at the EoL (Yujuico 2014, Rahman and Kim 2020). The sheer amount of service that this industry provides also contributes to the reduction of greenhouse gas emission (Rahman et al. 2016, Rahman and Kim 2020). Plethora of studies also indicates that the industry causes negative impact on the coastal environment and ecosystem (Hossain and Islam 2006, Abdullah et al. 2013). Despite these positive roles, this industry has never been considered as worthy of financial and technical assistance from the upstream stakeholders and policy makers. Many studies including European Commission outlines the potential strategies and approaches for the provision of financial assistance but never attracted a strong policy agenda (Yujuico 2014, Rahman and Mayer 2016). The lack of responsibility towards the downstream, therefore, remains an example of ‘unequal exchange of ecological distribution’ (Demaria 2010).

Lack of global scale recognition brings another crucial lacking of circular economy, namely social and institutional dimensions. Several articles have highlighted this aspect of circular economy as a potential limit (Gregson et al. 2015, Moreau et al. 2017, Murray et al. 2017, Miller et al. 2019, Rahman and Kim 2020). Murray et al. (2017) argues that

“The Circular Economy, however, is virtually silent on the social dimension, concentrating on the redesign of manufacturing and service systems to benefit the bio-sphere… it is unclear how the concept of the Circular Economy will lead to greater social equality, in terms of inter- and intra-generational equity, gender, racial and religious equality and other diversity, financial equality, or in terms of equality of social opportunity” (p 22).

Murray et al. (2017) argue that many of the circular economy literature explicitly mention social equity as one of the important achievements of circular economy implementation in China. Still, those studies are without any empirical support or quantitative evidence (Geng et al. 2012). More importantly, much-noted CE policy development in China fails to mention any indicator that reliably represents social equity. While others who mentioned about social aspects essentially refer them to job creation (Geissdoerfer et al. 2017). Notwithstanding this point, the CE literature fails to investigate further if this lacking is a systematic denial of the CE practitioners and why?

The partial answer to this question is that intra-generational discrimination never has an issue in the so-far discussed micro and meso scale that deals with national level circularity at maximum. For example, when CE is centered on micro and mesoscale, the social and institutional settings are almost identical among the parties involved in such scales. Thus, the contextual difference in terms of occupational hazards and human degradation between the poor and rich world remains unattended. For example, Gregson et al., 2010 and Rahman and Mayer (2015) demonstrated that the physical flow of waste is socially ingrained in Bangladesh that the recyclers do not mind being ‘dirty’. Instead, they feel pride in their work of small engineering that adds values to the waste – a social and cultural norm that is highly different from the western practices. Social and environmental externalities originated from such global flow in the new social and cultural norm are poorly perceived by western advocates and unattended in the CE literature. Rather, westerners perceive the activities in the developing world as a severe human degradation and a violation of intra-generational rights, which is only partially true and over simplified, thus essentially undermines such flow. Thus, the value creation in other parts of the world remains simplistic, subjective and informal as far as social issue is concerned (Rahman et al. 2018). It is often a logical consequence that if ship recycling in developing countries is officially recognized under global scale circular flow, a corresponding policy response would be offered that would more robustly address the social and environmental externalities, as is explained in the scenario analysis later. Therefore, formalizing such activities as a new scale - global - in the circular economy is crucial.

The lack of discussion of a global scale is attributed to three potential attitudes – technocratic politics, environmental justice, and resource security (Gregson et al. 2015). In technocratic politics, Gregson et al. (2015) indicate that the EU exhibits a wrong attitude to low-quality recycling as tantamount to landfilling the waste in the EU region. They seem to nurture a fiction that the desired circularity would be a “perfect circle achieved via perfect recovery” (p. 25). Secondly, global circuits of materials are misrepresented as a wrong form of resource recovery, utilizing unprotected labor force in an environmentally degraded way. It is also important to consider how profitable, such activities would be if the same flow is persuaded to occur in the EU region. The attitude seems to cover a hidden denial to the fact that the current practice can be upgraded to an acceptable standard such as recycling facilities in China. Thus, lack of global scale recognition implies that the recovery can only be appropriately made in the EU, the notion that is not just incorrect; it represents a Eurocentrism. Finally, the concern for resource insecurity (95% dependence for rare earth elements on China and recent 30% export cuts) lead to a desperate attempt to improve secondary supplies, which accounts for about 50% for iron and steel industry but much lower for rare earth element recovery (Gregson et al. 2015). However, this is also the fact that despite such an attempt, waste as informal trade continues to evade EU region to Asian and African informal resource recovery sites. Most fear that amid the Chinese waste ban, India may be the alternative for such informal waste trade, mostly ICTs.

1.3. Circular economy and disruption response

A short review of disruption response in relations to the circular economy reveals only a few hits, suggesting that the scale limited to micro and meso scale did not potentially bring to the fore the challenges of supply risks. The reason is that the distances between factories, in meso scale, are often negligible and occurred in the similar social and institutional frameworks that somewhat guarantee the steady supplies. Geng et al. (2016) pointed out three levels of CE implementation with meso level having some potentials of supply chain implications, while the risk is higher at the macro level, . Disruption risks are highly discussed in the supply chain literature but little highlighted in CE literature. Particularly, how the disruption is perceived and how the same would be responded so that the disruptive pattern does not encourage alternative route that leads to more environmental and social degradation is not well understood. Under circular economy, disruption is discussed mainly to understand the challenges associated with critical metal supply shortages (Sprecher et al. 2017, Gaustad et al., 2018, Fraccascia et al. 2019, Lapko et al. 2019). Although dealing with entirely different supply chains, they are nonetheless helpful in developing insights for this study.

Sprecher et al. (2017) applied event sequence analysis to quantify the time lag needed to recover the disturbances while mentioning the other similar works that applied scenario analysis to understand the risk factors. They found that as a strategy to disruption response, material substitution, and diversity of supply in terms of replacement of primary production have been put in place. Still, they did not opt for recycling as a response even after two years of disturbances. They argued that based on the case study, the disruption did not turn the stakeholders to action till two years. The four useful qualitative indicators to disruption response are a diversity of supply, stockpiling, improving material properties, and material substitution; all of these four indicators were extracted from the NdFeB Magnets supply chain. Gaustad et al. (2018) identified that recycling - both pre-consumer and post-consumer products - can be the source of about 24% of total indium supply during the disruption. They indicated that the diversity of supply within the umbrella of the same organization through recycling could enhance resilience and reduce dependencies on supply chains. Fraccascia et al. (2019) discuss technical and economic disruptions in the context of industrial symbiosis, representing the meso scale for CE. Changes in the production level of main products, changes in production technologies, and changes in the waste quality are the technological disruption. In contrast, economic disruptions include reduction in waste disposal costs and input purchase costs, an increase in operational costs, and changes in company benefits sharing policy. These indicators do not represent the associated disruptions in international supply chains.

A more detailed response mechanism at the dyadic level of the supply chain actors is analyzed in Bode et al. (2011). They demonstrated that the use of the most common mechanism i.e., buffering (diversifying the supply chains) and bridging (strengthening the chains in times of no alternatives) does not always report a favorable outcome when considered issues with inter-firm (Trust and resources dependences) and intra-firm consideration (disruption orientation and prior experience). They argued that the latter inter and intra-firm relationships might substantially alter the choice of strategies (buffering and bridging). For example, if the prior experience of a firm provides enough confidence on the counterpart, buffering would be less preferred. Adding resource dependence perspective to this decision-making process makes the decision more complicated. For example, even if the prior experience of a firm provides enough confidence, in a high resource dependence environment, buffering (alongside bridging) would be contemplated for better resilience – developing an inverted U shape strategy. The choice also differs by the time scale. In the short term, bridging would be preferred. Still as time passes, other options (buffering) would be chosen as an additional resource point so that the critical dependence environment is avoided. Although from two different contexts and levels, Sprecher et al. (2017) and Bode et al. (2011) share common response mechanisms (buffering, bridging, and reduction of resource dependencies) and offer valuable insights on how we develop response scenario in the face of COVID-19.

As stated earlier, shipbreaking value chain consists of ship-owners, brokers, cash buyers, financial institutions and recyclers. In business as usual situation, the response trajectory would be diverse as expected. It appears that ship-owners can have both bridging and buffering response whereas recyclers may be more interested in bridging the relationship in order to draw resources since they have resource dependency. Recycling nations would show similar attitude. EU policy seems to be more in identifying more proximate recycling through capacity enhancement (Table 1 ).

Table 1.

Response of stakeholders in business as usual situation

| Stakeholders | Motivation | Response | References |

| Shipowner | Only option that secure capital recovery | Bridging | Choi et al. 2016 |

| Bargaining opportunity as the needs for EOL ship exists | Buffering | Rahman and Mayer (2015) | |

| Recycler | Resource dependency | Bridging/stability motive | Gregson et al. (2010) |

| Broker/Cash buyer | Transaction costs/trust | Inter-firm relationships | - |

| Recycling nations | Revenue/tax/economic/Resource dependancy | Bridging | Rahman and Mayer (2016) |

| EU Commission /policy makers | Ignoring flow; capacity enhancement focus | Buffering | Rahman and Kim (2020) |

The following section advances as follows: a method section detailing the Weibull distribution function and the scenario analysis method, followed by the result and discussion section that analyzes the EoL ship flow until 2025 and outlines the consequences of four scenarios, as well as the implications of the different scenarios on the disruption response mechanism are discussed.The conclusion section discusses the theoretical contribution of the paper.

2. Methods And Data

In this study, we have applied Weibull distribution to estimate EoL ship open for dismantling based on the put-on-the-market (POM) data using the following equation (1). The data from the year 1900 to 2000 are sourced from Lloyd's register (2020). Data on total in-service vessel, demolished and lost vessel from the year 1900 -2000 is also collected from Lloyd register's historical data archives (Figure 2). This data help understands the relationship between the global recession and ship recycling and the lost trend. The data of the GT period from 2000-2018 is taken from UNCTADstat (UNCTADstat 2020), which was triangulated by the data of GT for the period 2005-2018 from Equasis annual reports (Equasis 2020). Demolition dataset from the year 2012-2019 is taken from the NGO shipbreaking platform.

| (1) |

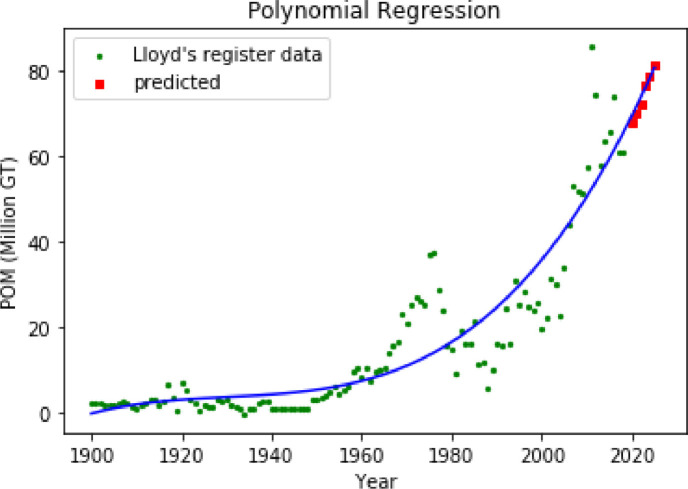

The POM data in figure 3 represents a steady flow of vessel with occasional noise. The linear regression model for this data type performs poorly as the noises were not properly recognized. Initial linear regression model for this POM data only gives about 60% goodness of fit. Then, Polynomial regression model is tried, which yields 82% goodness of fit. Polynomial regression is applied for a data with non-linear trend using linear regression estimation function with default degree 2. The entire process is executed in Python open access programming language using sci-kit learn library. The regression curve is then extrapolated until 2025 using model.predict function (Figure 3).

Fig. 3.

Polynomial regression of the POM data in million GT. The green data points represents real data point and the red data points are prediction for the year 2020 to 2025.

Weibull distribution is a widely applied method in the waste management literature, which is used to model future waste generation. The waste estimation using the Weibull distribution function is as follows:

| (2) |

F (y) is the waste for the year y; y is the lifespan of a product; the average lifespan of a product is described with yav, k is a parameter indicating the deviation of the distribution and Γ is the gamma function.

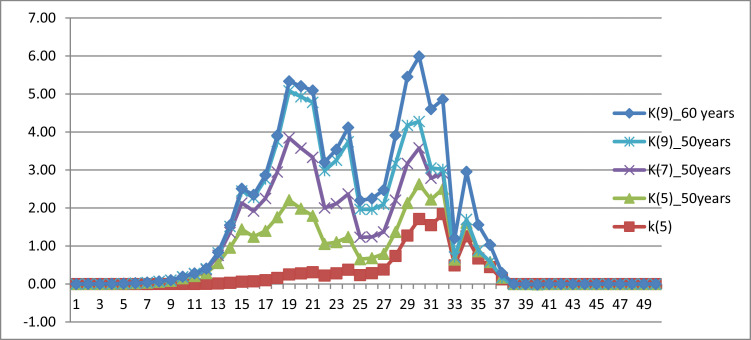

Small values for k indicate that most products leave the usage phase early; high values for k indicate that the products last longer. In this study, we have examined k value in the range from 5 to 9 and chosen 9 as the best k value (Figure 4 ). The waste estimate out of k (9) corresponds to the age distribution of the EoL ships from 2012-2019 given in figure S4 in the supplementary material. From the figure 4, average life span is also estimated to be 30 years that gives better match with NGO shipbreaking platform data.

Fig. 4.

The waste discharge trajectory of different k values. The number in () is the k value chosen, followed by the life span period for which the waste discharge is taken into account.

The Weibull estimation was based on business as usual scenario, and then a factor is applied to estimate the future ship recyclability based on the 1980 global recession status in figure 2. An economic cost analysis is also performed on the increasing stock of EoL ships, based on the operating costs data from Drewry consultants Ltd. and ship selling price data from Mikelis (2018) and Rahman and Kim (2020).

Scenario analysis allows an understanding of possible alternatives to a certain phenomenon and helps develop parameters so that informed decisions can be made for any possible outcome. Scenario analysis is successfully applied in different disciplines, including management, medicine, engineering, finance, and economics (Dutta and Babbel 2014). Scenario analysis usually follows three basic strategies: Identification of the parameters in the context, a new way of perceiving a phenomenon, and understanding nuanced variations within and among scenarios (Rahman et al. 2019, Amer et al. 2013). Scenario analysis is also applied in the measurement of operational risk capital and, thus very relevant to use in the case of ship recycling. Scenario analysis is also applied before in ship recycling study in Bangladesh (Cairns 2014).

In this study, we have developed four scenario: S1 - Short term impact with strict lockdown, S2-Short term impact with low or medium lockdown, S3- Long term impact with strict lockdown and S4 - Long term impact with Low or Medium lockdown (Table 3 ).

Table 3.

Scenario setting based on the impact duration and severity of lockdown

| Scenario symbol | Scenario description |

| S1 | Short term impact + strict lockdown |

| S2 | Short term impact + relaxed or no lockdown |

| S3 | Long term impact + strict lockdown |

| S4 | Long term impact + relaxed or no lockdown |

Short term impact is defined here as the impact observed in the first year of the COVID-19 outbreak, whereas long term impact considers the impact over the next five years. The strict lockdown is meant to the complete shutdown of the economy when long-distance travel is cut off, whereas relaxing or no lock down means that some transportation is allowed. People can travel a shorter distance with appropriate protective equipment such as face mask and social distancing.

3. Results And Discussion

3.1. Potential recyclable volume (Weibull estimates)

Predicting EoL ships is difficult due to wide variations. table 4 shows that total demolition volume in NGO shipbreaking platform data fluctuates quite largely. For example, in the year 2013, the amount drops by 13 million GT, accounts for about 100 percent drops while in 2014, the volume sharply rises at about 90%, which lowered by 2 million GT in the next year. In the year 2016, the volume rose again to 27 million GT. In the subsequent years, the volume was decreased by 7, 2, and 5 million GT, respectively. A somewhat similar pattern is also evident in the historic ship demolition data in figure 2. The demolition data from the UNCTADstat also demonstrates similar fluctuations and also entirely consistent with NGO shipbreaking platform data.

Table 4.

The estimation of EoL ships by Weibull distribution (rounded so may not represent the exact calculation)

| Year of demolition | Demolition data in million GT (UNCTADstat, 2020) | Demolition data in million GT (NGO shipbreaking platform, 2020) | Estimated demolition in million GT (Weibull) | 50% increase | 100% increase (Estimate based 1980 recession) |

| 2012 | - | 26.6 | - | - | - |

| 2013 | - | 13.1 | - | - | - |

| 2014 | 22.4 | 22.7 | - | - | - |

| 2015 | 23.3 | 20.4 | - | - | - |

| 2016 | 29.1 | 27.5 | - | - | - |

| 2017 | 22.9 | 20.7 | - | - | - |

| 2018 | 18.9 | 18.9 | 15.47 | 23.21 | 30.94 |

| 2019 | - | 13.5 | 15.85 | 23.78 | 31.71 |

| 2020 | - | - | 16.50 | 24.74 | 32.99 |

| 2021 | - | - | 17.44 | 26.16 | 34.88 |

| 2022 | - | - | 18.67 | 28.01 | 37.34 |

| 2023 | - | - | 20.10 | 30.14 | 40.19 |

| 2024 | - | - | 21.58 | 32.36 | 43.15 |

| 2025 | - | - | 22.98 | 34.46 | 45.95 |

Using the Weibull distribution function, we estimated that the volume available for dismantling is gradually increasing from 15.5 million GT in 2018 to 23 million GT in 2025, accounting for about a 70% increase in just five years (Table 4). This estimation is business as usual case and reflective of the previous demolition trend. However, if we see a 50% increase and even a 100% increase, we see the total demolition demand increases to 34.6 million GT and 46 million GT, respectively in the year 2025. This estimate exceeds previous record of 27.5 million GT in 2016.

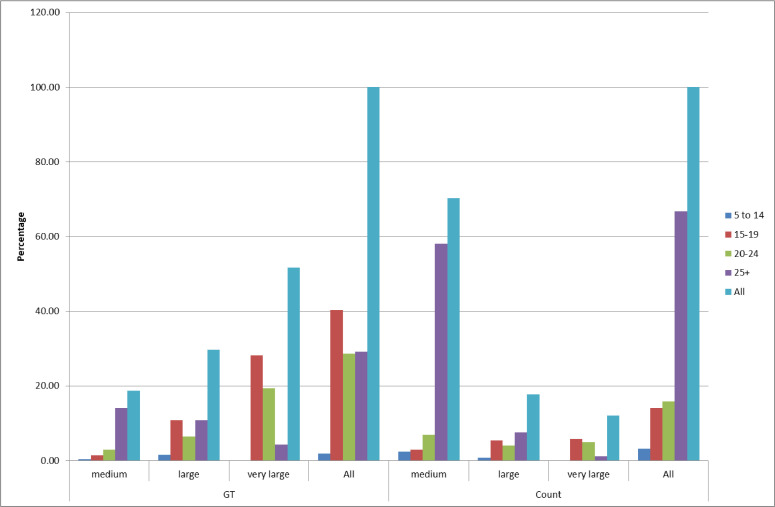

Dismantling age varies significantly by the size of the vessels. From figure 5 , we see that 40%, 28.6%, and 29.2% of the total GT dismantled in 2018 is in the age range 15-19, 20-24, and over 25. Besides, the highest 28% of very large ships are dismantled in the age range 15-19, indicating that ships over 15 years of age are potentially open for the demolition. In contrast, about 70% of the medium-size vessels dismantled in 2018 are over 25+. This result indicates that the inclusion in potential stock for large and very large vessels starts from the age of 15, whereas, for the medium vessels, it is at the age of 25.

Fig. 5.

Demolished ships in percentage of total GT million by age and size for the year 2018

3.2. Chances of demolition in relation to total volume

From figure 2 and figure S3, we see that usually, 2% of the total GT was dismantled. For example, before 1980, there were about 400 million GT in service, but about 10 million GT were dismantled, accounting for about 2.5 % of the total GT. During the recession, the amount was doubled to 20 million GT, accounting for about 5% of the total GT.

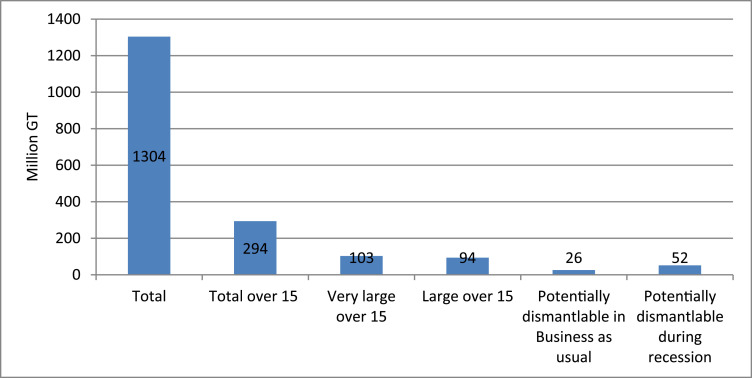

In 2017 total volume was 1302 million GT in which 294 million GT represents vessels over 15 years of age, potentially open for dismantling, especially for very large or large vessels (Figure 6 ).

Fig. 6.

Ship in service in 2017 (Equasis 2020)

During the recession, old vessels operates marginally at the discretion of the ship-owner. It is expected that during COVID-19, 294 million GT would potentially be idle, incurring high operating costs for the shipowners. Out of this stock, 103 million GT represents very large vessels, exclusively available for the South Asian facilities, while 94 million GT open for other big recycling nations. It is quite evident that over five years, the stock would be depleting, meaning that either they will be recycled or potentially get lost- the other option that the shipowners may often utilize. Estimating the operating cost incurred by the ship-owners, this may amount to at least 2 billion USD per year for large and very large vessels of age over 15 and 3.25 billion USD of medium-sized vessels of age over 25 (Table 5 ).

Table 5.

Stock characteristics and economic information

| Number of very large vessels over 15 = 1026 and volume = 103 million GT |

| Number of large vessels over 15 = 2603 and volume = 94 million GT |

| Number of medium vessels over 25 = 13689 and volume = 41 million GT |

| Scrap price = 400 USD /LDT or 100 USD / GT |

| Operating costs per year = 0.5 million USD for large vessels |

| Operating costs per year for medium vessel = 0.25 million USD |

| Total stock open for dismantling = 25% of the overall vessels in GT million. Actual probability of dismantling (Business as usual) = 2% of the overall vessels in GT million. Actual probability of dismantling (economic downturn) = 4-5% of the overall vessels in GT million |

Given the recycling revenue of 100 US dollars per GT (1 GT = 0.25 Light tonnage) (Mikelis 2018), 20 billion dollars revenue can be generated for the very large and large vessels, while another 2 billion can be generated for the medium vessels. If the stock is considered to be lost, the total revenue lost would be about 17 billion dollars, with immense environmental cost in the ocean. Interesting is the net profit (1.25 bullion USD) generated by the medium-sized vessels if they are submerged (Table 6 ). The reason is that during recession, medium vessels are assumed to be dismantled in standard facilities with a low selling price at about 50 USD, while saving about 3.25 billion USD by avoiding operational costs.

Table 6.

Estimation of economic consequences of the three potential consequences due to COVID-19

| Cost if remain idle (billion USD) | Potential value if recycled (billion USD) | Potential loss if submerged (billion USD) | |

| Very large and Large vessels (2000 vessels) | 2 (Operating costs 0.5 million USD per year) | 100 USD*197 million GT = 20 | 18 |

| Medium vessels over 25 | 3.25 | 50*41 million GT =2 | -1.25 |

| Potential recycling volume during epidemic | 0.5 (10% of the stock) | 2.2 | 1.7 |

3.3. Ship sighting and recycling distance

From the ship sighting data, Equasis (2020) reported that 37.5% of total maritime traffic occurs in Asia, whereas only 13.1% occurs in the Mediterranian Sea, summing of about 50% total sighting. By ship size, 24% of small-sized ships were sighted in the Mediterranian Sea, whereas 40.2% very large ships were sighted in Asia. About 80 million GT of small and medium ships are in the Western Europe region. 55% of the small and medium ships are over 25 years of age. This means that about 40 million tons of small and medium ships could be dismantled in the European standard facilities. Similarly, the right amount of very large vessels is expected to be idle in the Asian ports, which is again potentially very close to the South Asian facilities. Although ship sighting data is an indirect representation of the location of the EoL vessels at the time of ship-owner decision to recycle their ships, the segregation provides useful insights that the site of the vessels may be closer to where they can potentially be dismantled.

3.4. Scenario analysis

Four scenarios were chosen to analyze the impact of COVID-19 on ship recycling. Scenario S1 begins the impact from the low ship breaking activities. The scenario assumes that the stakeholders would prioritize the health crisis more than the economic crisis as the COVID-19 impact would be treated as a short term phenomenon. In fact, from the trend observed, two to three months were found to be the significant propagation and that the strict lockdown helps slow down the propagation. In this scenario, government and policymakers would thus close down the economic activities, including the shipbreaking yards, and encourage personnel relevant to avoid social contacts. Therefore, the real demand from the recyclers for EoL ships would be minimal.

On the other hand, ship-owners would instead decide to ‘wait and see’ policy and continue to incur economic costs, even if the extra capacity of the vessels remain inactive for the time. This policy would make sense as the recyclers’ demand for EoL ships would be lower than expected. In April, similar instances have already recorded: a VLCC of 300,000 DWT is sold in USD 13.6 million, which is USD 3.5 million less than sending the same ship to Bangladesh a year earlier(Saftey4sea.com 2020).

The low shipbreaking activities may also be triggered by the low scrap demand (also overall steel demand) in the recycling countries due to low construction activities amid COVID-19. This low demand may initiate the entire down cycle that simultaneously adds to the already low shipbreaking activities. Another trigger for S1 may also be started by the disruption in supply chain communication, which makes it challenging to navigate EoL ships to the recycling destinations due to strict COVID-19 measures in the shipping services. As we have seen that the ship recycling supply chain is largely informal and based on market information. That means that unless an embedded relationship among recyclers, brokers, and buyers had already been established, the high effort required during COVID-19 restriction would not simply begin. IMO and International shipping continues to encourage uplifting unnecessary barriers from the member states so that the complete breakdown of the supply chain network does not occur. Yet, recycling nations are reported to have taken specific measures that put the navigation in international water seemingly difficult. The situation exacerbates when the transportation cost is even higher due to port charges, crew salaries, and others. That makes the vessels economically less feasible to be dismantled in south Asian countries unless the ships already stranded near Asian geographic zones.

Another event may unfold concerning the small or medium level vessel recycling, which may be recycled in the EU or other adjacent standard facilities since these facilities can recycle smaller size ships. Under this scenario, these facilities may experience upturn. They may prove to be an opportunity for increased ship recycling in this region, although larger ships would remain idle in this scenario.

Under S2, a recycling country seems to be more open for economic activities and that the COVID-19 pandemic seems to be in control or adjusted with socio-economic needs and priorities. In S2, recycler's policy is to vitalize shipbreaking activities, and thus, more ships are expected to be dismantled. This aspect may lead to a situation where forced labor may reappear, and plights for migrant workers may worsen. As the frequent movement of the migrant workers may end up more contamination and with explicit and implicit coerce may degrade the shipbreaking activities more socially vulnerable. The resumption of yard activities is a two-edged knife for workers – the fear of unemployment and lack of subsistence and the fear of being virus-infected while at work. The scenario depends largely on the policy of the government of the relevant recycling nations and the status of the COVID-19 propagation. For example, the Indian government seems to be stricter, while Bangladesh seems to be opening up offices and facilities despite the upward curve of COVID-19 contamination (Table 7 ).

Table 7.

Scenario analysis of the impact of COVID-19 on ship recycling

| S1 | Low shipbreaking activities- price drop – ship idle |

| Low steel scrap demand-Low shipbreaking activities- Owner prefer to incur operating cost- ship idle | |

| Supply chain communication drop-Transportation barrier-cost of EOL ship transportation higher- Distant recycling not feasible | |

| More proximate small or medium ship recycling- capacity limitation – large ship idle | |

| S2 | Force labor- health risks – contamination- social or humanitarian cost |

| S3 | Proximate capacity development- ship-owner choice/ adjustment for low return-structural change |

| S4 | South Asian beaching recovery- more EOL ship price offer- ship-owner choice back to beaching |

| South Asian beach development- standardization initiatives- financial assistance- more standard beaching- More sustainable | |

| Locally oriented manufacturing – stable or reduced number of shipping- low extra tonnage – low but steady recycling- less fluctuation |

In S3, the policy may be put in place for proximate capacity development. As the global supply chain vulnerability is exposed, and the development of localized supply chain may replace centralized supply network, EU countries may focus on the ways to develop recycling capacity in the EU facilities. Rather than depending on the South Asian facilities that give ship-owner a significant amount of capital return, ship-owner would opt to EU facilities with moderate capital return as they cannot continue to incur a loss for daily operating costs. The capacity development policy in EU would be a move toward resilience in times of crisis.

In S4, recycling nations would relax the lockdown measures and be willing to get more ships for recycling. More workers under protective measures will be engaged in ship recycling. To get the economy going along with the demand for steel scrap, the recyclers would like to start offering higher prices, and thus, ship-owner may return to South Asian facilities. Given the tricky situation, international policy initiatives may seriously consider the improvement of the South Asian facilities as the capacity-building measures in the EU facilities may sound economically unattractive (Rahman and Kim 2020). A more durable initiative can also be visible in which international commodity flow can be reduced as a response to COVID-19 and more localized production and consumption pattern may appear (Sarkis 2020).

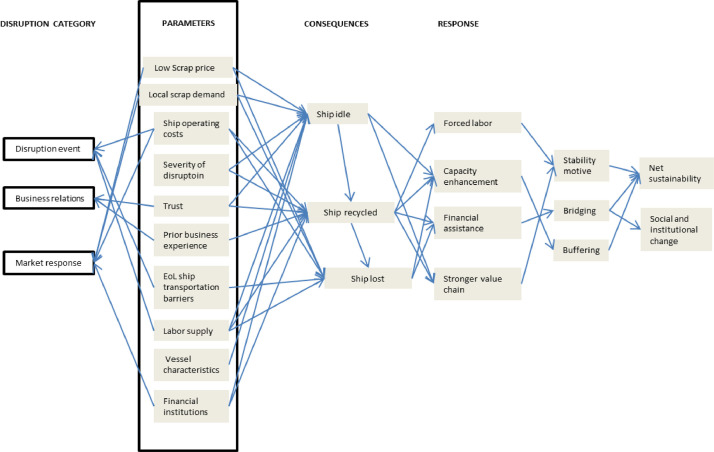

From the scenario analysis and the disruption response mechanism, it is quite evident that the traditional disruption response literature provides important insights on how the response management can be initiated. From the scenario analysis, we have found ten parameters, vital to understand the impact of COVID-19, with some new parameters that emerged as a potential factor for response management. The ten parameters include Low scrap price, Local scrap demand, Ship operating costs, Severity of disruption, Trust, Prior business experience, EoL ship transportation barriers, Labor supply, Vessel characteristics, and Role of financial institutions. These ten parameters can be classified into disruption events, business relations, and market response categories. The disruption event refers to more direct variables to COVID-19. In contrast, business relations represent stakeholder level interaction concerning the epidemic, and the market response is often the impact of the measures taken by the government on the market. The consequences revolve around three possible alternatives – ship idle, recycled, and lost. The responses may be, for the short term, forced labor as part of the stability motive of the stakeholders to keep the business going. In the long term, the policy may focus on a standard capacity building so that the resilience in times of crisis is ensured. Notwithstanding their monetary disincentives, ship-owners would still find the standard facility economically viable than the case when ships cannot but be submerged. Alternatively, financial and technical assistance can be effectively enforced so that impacts of substandard practices are minimized.

The policy direction depends mainly on how the circular economy advocates perceive the ship recycling and if the global scale recognition would entail much stronger policy support for improving social and environmental dimensions. Another response would be a transformation of the quality of the ship recycling value chain. Now, ship recycling value chain, as discussed above, is mostly informal, and very few information exists as to how the ship-owners get their ships recycled through brokers and cash buyers. The transparency of this process would be a positive move towards sustainability (figure 7 ).

Fig. 7.

A response framework of the scenario analysis and the theoretical implications

The theoretical implication of the responses would be threefold. Firstly, it is found that bridging can emerge as one of the strategic response management as ship-owners may not have many options to get their large ships dismantled so they along with the policy stakeholder may decide to approve a financial mechanism so that the yard in the developing nations are stimulated to improve their social and environmental conditions (Bode and Macdonald, 2017). The bridging decision can also be analyzed in light of the fact that most of the large vessels are sighted around the Indian subcontinent, indicating that the transportation savings can be deciding factor as to where the vessels will be demolished. At the individual recycler level, there are always multiple players to contact and negotiate for the desired price, so the bridging effect would not be so desperately wanted. As a result, a lack of real ‘motivation to act’ appear as Bode et al. (2011) pointed out that the need to realize a response does not always translate into a task for action if the resource dependence environment is low. At the same time, a capacity development program for the standard facilities may also be the option as a buffering strategy for EU decision-makers. The interaction of these two parameters may be interesting and a matter of future research direction. Whether the COVID-19 triggers these two policy directions simultaneously or exclusively remains to be seen in the few months to come.

Secondly, stakeholder stability motive seems to appear through force labor syndrome. It is expected that migrant workers for the shipbreaking – representing more than 60% of the total labor in different substandard nations, would not be readily available. Hence, a forced labor syndrome may appear in the face of additional vessels dismantling demand. The stability motive of the recyclers may play a vital role in the case to preserve the inter-firm relationship. Rahman and Kim (2020) signaled that there might have an embedded relationship between cash buyers and recyclers in developing nations. If so, both parties need to adjust actions so that neither is too harmed. However, stability motive from the part of the stakeholders can only function under the rubrics of market-related behavior. If the scrap demand (also world scrap price) falls too low that the recyclers’ stabilizing attitude may not be much useful. Thus, the response mechanism, to an extent, depends on the market characteristics that are, again, a function of the severity of the pandemic.

A total of three variables that appeared to be significant are related to market characteristics; Operating costs of old ships, EoL ship selling price, and Local scrap demand. Operating costs of old ships may be increased due to increasing crew maintenance and port charges and a function of the measure taken due to COVID-19. The increasing costs may be a trigger for the shipowners to get it dismantled. In contrast, a drop of local rerolling demand trigged by the absence of construction works put economic sustainability at risk for recyclers and shipowners –as noted by Fraccascia et al. (2019) that the technical and economic disruption in terms of changes in input and operational cost significantly disrupt the symbiosis linkages and independent of the effect of stakeholders’ interpretive postures and trust relationship.

Unlike the previous recessionary events, COVID-19 is exceptionally disruptive as the local level Welcome-In-My-Backyard phenomenon drops significantly due to the weak market behavior and the strictness of the government lockdown measures. Realizing reduced commodity flows, ship-owners quickly decide to reduce their excess capacity through recycling at a relatively lower price than before. For example, some bulk carriers have already been sold to the Indian subcontinent with the reduced price offered. Demolition activities have increased by 62% in the first quarter of 2020 compared to the first quarter of 2019 (Safety4asia.com. 2020). The increasing demolition activity is not going to persist for long as the COVID-19 begins to affect this part of the world from mid-April. By mid-April, three major shipbreaking nations have closed their yards, meaning that the vessels heading for demolition will be denied entry. This lockdown will put many ship-owners with unwanted tonnage in a problematic situation. Under sheer uncertainty, ship-owners neither can get their ship recycled nor continue to support for day-to-day operating costs, which may lead to more ships lost.

The variation of the lockdown measures as a representation of disruption identification by Bode and Macdonald (2017) is observed among the substandard destination nations. When Bangladesh is relaxing the lockdown measures at the time of increasing propagation, India sanctions additional measures so that the vessels with crews from certain nationalities are returned. Indian authorities banned EoL vessels with crews of affected nationalities with stricter restrictions imposed on vessels entry into the Alang facilities. The entire supply chains, including cash buyers, agents, and financing institutions and others, have been informed with the decision taken (Insurance Marine News 2020).

It is too early to predict how the scenario would have interacted with each other. For example, how long the epidemic warrants strict sanctions on the mobility and transportation of goods and services. The economic necessity and propagation pattern is very specific to the recycling nations, and thus, the duration and severity would vary significantly. Related to disruption identification, diagnostics, and processing, the understanding among the stakeholders would converge in the long run, which in turn pave the way to a more acceptable policy outcome.

Finally, framing this study as a circular economy, we have stressed that the lack of global scale discussion fails to evoke a ‘net global sustainability’ indicator. The missing link may unfold a whole different policy initiative, undermining some of the successful aspects. For example, buffering would be a disruption response from the European community if the south Asian practices are not acknowledged. Rahman and Kim (2020) suggest that the South Asian practice is more environmentally and socially sustainable. Ship recycling in South Asia, for example, avoids 70-90% of the total environmental impacts with only 5-20% domestic processing impacts and 1-5% disposal impacts. Second-hand consumerism, Market demand for steel, National dependency, Employment generation, fixed investment, owner incentive are the parameters that perform better for the south Asian facilities with only two variables occupational hazards and efficient sorting that perform for EU facilities or other standard facilities.

The lack of global scale may prompt EU policy makers to focus on the development of EU facilities so that any future crisis can be avoided. Whereas in global scale, bridging through technical and financial assistance would be a policy direction, in that south Asian facilities would be supported to effectively progress towards more socially and environmentally sustainable.

On a much deeper level, the negligence of such flow may have serious unintended consequences ensued from the small-scale outcome analysis of the implemented or proposed projects or programs adopted under circular economy. Tisserant et al. (2017) found that countries with advanced recycling systems with high share of waste recycled often import products that embody untreated waste and that the trend of embodied waste in trade is increasing rapidly. Korhonen et al. (2018) argued that global net sustainability within the planetary boundary has to be the central vision of CE and then identify what problems and issues arise when it comes to problems shifting related to spatial boundaries. Plethora of scientific evidences demonstrate the presence of problem shifting phenomenon across supply chains, value chains, product life cycles and their networks that are located in geography- contextually different and culturally distinctive. Most importantly, the unaccounted and – systematically missed - spatial effects worst hit the poor – a form of violation of equity of the intra-generations. Likewise, Cairns (2014) conducted a critical scenario analysis among different policy alternatives and suggested that any other options that signal the reduction of ship recycling activities in Bangladesh may exacerbate the poverty dimension both at the worker level and national level – implying social embeddedness of this industry so profoundly ingrained that only bridging (identification of the problematic practices and helping them to improve through technical and financial assistance) can be effective. Rahman and Mayer (2015) show that businesses in Bangladesh that rely on ship scraps emerge in different places of the country, far away from the ship recycling sites, indicating the high level of dependence on the scrap steel socially and culturally. Nationally, about 60%, 15%, 11%, and 2% of national steel demand are met in Bangladesh, Pakistan, Turkey, and India.

Can the spatial effect be minimized with global CE? The answer is currently not known. Contrastingly, academic discussion argues that lack of global scale undermine sustainable development initiatives and hinder emergence of global model for CE governance. For example, Korhonen et al. (2018) stated that CE type projects so focused on the micro and meso level that a departure from sustainable development goals is an inevitable consequence. Because the aim of sustainable development is inherently global- a scale that emphasizes inter as well as intra-generational equity at the center of any projects or programs. Furthermore, the performance of sustainable development goals and targets is constantly monitored by the global governance body. No such institutions currently exist to carry forward the goals of CE at global level. European Commission (2020) adopted a new action plan in March 2020, comprising one of the six sections that explicitly outline how EU can lead to realize a global CE. In the staff working document, they stated that the waste management has been a more global phenomenon. Murray et al. (2017) expresses concerns that how the limitations of CE can be managed is currently unknown and urged researchers and business organizations to think along this line.

4. Conclusion

This study argues that COVID-19 may have an uncertain yet diverse effect on the industry. Ten parameters were developed that may be more rigorously analyzed so that the impact can be quantified. Unlike the previous disruption literature, four market-related parameters have emerged, which significantly determines the level of disruption and how the response would be effectuated. From the historical data, it is quite evident that the epidemic may increase the number of idle vessels, but whether they are recycled or lost depends on the ten parameter frameworks discussed. The COVID-19 pandemic differs from the earlier disruptions, in that the Welcome- In-My-Backyard phenomenon in the south Asian nations is almost non-existent in the short term, dropping the demand of EoL vessels. However, as shown above, the business relations and market characteristics may interact together to stimulate a stronger value chain and stability motive to save the mutual interest of the stakeholders by the epidemic. In the long term, the situation is expected to improve positively. However, a well-planned policy response seems to be elusive as the EoL ship flow often not recognized as a ‘desired’ one.

This study views COVID-19 as an opportunity to reframe our mode of production and consumption pattern towards more sustainable pathways. Sarkis et al. (2020) envisage that the epidemic provides us a rare opportunity to reshuffle our ‘business as usual’ mode of production, supply, and consumption to a more sustainable one through the adoption of a new type of global development and governance model. The social, cultural, and institutional settings that deemed as barriers for such innovative models may have already been experienced enough shock to accept toil that is necessary to adopt a new lifestyle. They indicated a more ‘local’ approach for production and consumption. However, for the EoL vessel recycling, developing recycling facilities in the EU, for example, may not be socially, economically, and environmentally sustainable. Despite this, this study suggests that a scenario may co-exist where the EU facilities can be developed so that it can act as a buffer in crisis.

This study can provoke some future research directions: 1) a more quantified approach of the parameters developed and how such parameters impact on the EoL vessel recycling possibilities 2) an in-depth literature review for the global scale implications of the circular economy – a scale that interconnects two continents with social and cultural differences. And finally, 3) how can a disruption mechanism be developed for a global scale circularity.

CRediT author statement

S.M. Mizanur Rahman: Conceptualization, Data collection and calculation, Writing- Original draft preparation. Junbeum Kim: Writing- Reviewing and Editing, Bertrand Laratte: Supervision, Writing- Reviewing

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Abdullah H.M., Mahboob M.G., Banu M.R., Seker D.Z. Monitoring the drastic growth of ship breaking yards in Sitakunda: a threat to the coastal environment of Bangladesh. Environmental monitoring and assessment. 2013;185(5):3839–3851. doi: 10.1007/s10661-012-2833-4. www.allianz.com/en/press/news/studies/news-2014-03-13.html Allianz. 2014. Shipping losses decline, new risks emerge. Available at. accessed on 06/02/2020. [DOI] [PubMed] [Google Scholar]

- Amer M., Daim T.U., Jetter A. A review of scenario planning. Futures. 2013;46:23–40. [Google Scholar]

- Bode C., Wagner S.M., Petersen K.J., Ellram L.M. Understanding responses to supply chain disruptions: Insights from information processing and resource dependence perspectives. Academy of Management Journal. 2011;54(4):833–856. [Google Scholar]

- Bode C., Macdonald J.R. Stages of supply chain disruption response: Direct, constraining, and mediating factors for impact mitigation. Decision Sciences. 2017;48(5):836–874. [Google Scholar]

- Cairns G. critical perspectives on international business; 2014. A critical scenario analysis of end-of-life ship disposal. [Google Scholar]

- Choi J.K., Kelley D., Murphy S., Thangamani D. Economic and environmental perspectives of end-of-life ship management. Resources, Conservation and Recycling. 2016;107:82–91. [Google Scholar]

- Demaria F. Shipbreaking at Alang–Sosiya (India): an ecological distribution conflict. Ecological economics. 2010;70(2):250–260. [Google Scholar]

- Dutta K.K., Babbel D.F. Scenario analysis in the measurement of operational risk capital: a change of measure approach. Journal of Risk and Insurance. 2014;81(2):303–334. [Google Scholar]

- Equasis. 2020. Available at www.equasis.org/EquasisWeb/public/PublicStatistic?fs=Registration accessed on 06/25/2020.

- European Commission. 2020. Commission staff working document. Leading the way to a global circular economy: state of play and outlook. Brussels. Retrieve from https://ec.europa.eu/environment/circular-economy/pdf/leading_way_global_circular_economy.pdf accessed on 06/23/2020.

- European community on Shipowners’ associations (ECSA). 2020. Survey report shows severe economic impact of the COVID-19 pandemic on European shipping, available at www.ecsa.eu/news/survey-report-shows-severe-economic-impact-covid-19-pandemic-european-shipping.

- Fraccascia L. The impact of technical and economic disruptions in industrial symbiosis relationships: An enterprise input-output approach. International journal of production economics. 2019;213:161–174. [Google Scholar]

- Frey R.S. Alang India and Chittagong; Bangladesh: 2013. Breaking ships in the world-system: An analysis of two ship breaking capitals. [Google Scholar]

- Gaustad G., Krystofik, M M., Bustamante M., Badam K., Gaustad, G., Krystofik, M., , M., & Badami, K. Circular economy strategies for mitigating critical material supply issues. Resources, Conservation and Recycling. 2018;135:24–33. [Google Scholar]

- Geissdoerfer M., Savaget P., Bocken N., Hultink E. The circular economy – a new sustainability paradigm? J. Clean. Prod. 2017;143:757–768. [Google Scholar]

- Geng Y., Sarkis J., Ulgiati S. Sustainability, well-being, and the circular economy in China and worldwide. Science. 2016;6278(Supplement):73–76. [Google Scholar]

- Gregson N., Crang M., Fuller S., Holmes H. Interrogating the circular economy: the moral economy of resource recovery in the EU. Economy and society. 2015;44(2):218–243. [Google Scholar]

- Gregson N., Crang M., Ahamed F., Akhter N., Ferdous R. Following things of rubbish value: End-of-life ships,‘chock-chocky'furniture and the Bangladeshi middle class consumer. Geoforum. 2010;41(6):846–854. [Google Scholar]

- Hossain M.M.M., Islam M.M. Power in Social Action (YPSA); Young: 2006. Ship breaking activities and its impact on the coastal zone of Chittagong, Bangladesh: Towards sustainable management. Chittagong, Bangladesh: Advocacy & Publication Unit. [Google Scholar]

- ILO. 2020. COVID-19 and maritime shipping & fishing. available at www.ilo.org/wcmsp5/groups/public/-ed_dialogue/-sector/documents/briefingnote/wcms_742026.pdf.

- Insurance Marine News, 2020. India moves on COVID-19 affect shipbreaking. Available at insurancemarinenews.com/insurance-marine-news/india-moves-on-covid-19-affect-shipbreaking/.

- International Maritime Organization. 2020. A Joint statement on the response to the outbreak of COVID-19 outbreak. available at www.imo.org/en/MediaCentre/HotTopics/Documents/Joint%20Statement_COVID-19.pdf.

- Knapp S., Kumar S.N., Remijn A.B. Econometric analysis of the ship demolition market. Marine Policy. 2008;32(6):1023–1036. [Google Scholar]

- Korhonen J., Honkasalo A., Seppälä J. Circular economy: the concept and its limitations. Ecological economics. 2018;143:37–46. [Google Scholar]

- Lloyd's register. 2020. hec.lrfoundation.org.uk/archive-library/lloyds-register-of-ships-online, accessed on 26/06/2020.

- Mikelis. N. 2018. The recycling of ships. Available at www.gmsinc.net/gms_new/assets/ads/folder.pdf.

- Millar N., McLaughlin E., Börger T. The circular economy: swings and roundabouts? Ecological economics. 2019;158:11–19. [Google Scholar]

- Moraga G., Huysveld S., Mathieux F., Blengini G.A., Alaerts L., Van Acker K., Dewulf J. Circular economy indicators: What do they measure? Resources, Conservation and Recycling. 2019;146:452–461. doi: 10.1016/j.resconrec.2019.03.045. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Moreau V., Sahakian M., van Griethuysen P., Vuille F. Coming full circle: why social and institutional dimensions matter for the circular economy. J. Ind. Ecol. 2017;21(3):497–506. [Google Scholar]

- Murray A., Skene K., Haynes K. The circular economy: an interdisciplinary exploration of the concept and application in a global context. Journal of business ethics. 2017;140(3):369–380. [Google Scholar]

- NGO shipbreaking platform, 2020. Available at www.shipbreakingplatform.org/resources/annual-lists/.

- Rahman S.M., Kim J., Lerondel G., Bouzidi Y., Clerget L. Value Retention Options in Circular Economy: Issues and Challenges of LED Lamp Preprocessing. Sustainability. 2019;11(17):4723. [Google Scholar]

- Rahman S.M., Mayer A.L. Policy compliance recommendations for international shipbreaking treaties for Bangladesh. Marine Policy. 2016;73:122–129. [Google Scholar]

- Rahman S.M., Kim J. Circular economy, proximity, and shipbreaking: A material flow and environmental impact analysis. Journal of Cleaner Production. 2020 [Google Scholar]

- Rahman S.M., Mayer A.L. How social ties influence metal resource flows in the Bangladesh ship recycling industry. Resources, Conservation and Recycling. 2015;104:254–264. [Google Scholar]

- Rahman S.M., Handler R.M., Mayer A.L. Life cycle assessment of steel in the ship recycling industry in Bangladesh. Journal of Cleaner Production. 2016;135:963–971. [Google Scholar]

- Rahman S.M.M., Schelly C., Mayer A.L., Norman E.S. Uncovering Discursive Framings of the Bangladesh Shipbreaking Industry. Soc. Sci. 2018:7–14. [Google Scholar]

- Sarkis J., Cohen M.J., Dewick P., Schröder P. Resources, Conservation, and Recycling; 2020. A brave new world: lessons from the COVID-19 pandemic for transitioning to sustainable supply and production. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Saftey4sea.com. 2020. COVID -19 affect fleet development and demand. Available at safety4sea.com/covid-19-impacts-fleet-development-and-demand, accessed on 23/06/2020.

- Sprecher B., Daigo I., Spekkink W., Vos M., Kleijn R., Murakami S., Kramer G.J. Novel indicators for the quantification of resilience in critical material supply chains, with a 2010 rare earth crisis case study. Environmental science & technology. 2017;51(7):3860–3870. doi: 10.1021/acs.est.6b05751. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Worldometer. 2020. Available at www.worldometers.info/coronavirus/.

- Tisserant A., Pauliuk S., Merciai S., Schmidt J., Fry J., Wood R., Tukker A. Solid waste and the circular economy: a global analysis of waste treatment and waste footprints. Journal of Industrial Ecology. 2017;21(3):628–640. [Google Scholar]

- Ul.com. 2020. Five factors drive circular economy. Available at www.ul.com/news/five-factors-driving-circularity.

- UNCTADstat. 2020. available at unctadstat.unctad.org/wds/ReportFolders/reportFolders.aspx.

- Yujuico E. Demandeur pays: The EU and funding improvements in South Asian ship recycling practices. Transportation Research Part A: Policy and Practice. 2014;67:340–351. [Google Scholar]