Abstract

Gold-mediated exfoliation of MoS2 has recently attracted considerable interest. The strong interaction between MoS2 and Au facilitates preferential production of centimeter-sized monolayer MoS2 with near-unity yield and provides a heterostructure system noteworthy from a fundamental standpoint. However, little is known about the detailed nature of the MoS2–Au interaction and its evolution with the MoS2 thickness. Here, we identify the specific vibrational and binding energy fingerprints of this interaction using Raman and X-ray photoelectron spectroscopy, which indicate substantial strain and charge doping in monolayer MoS2. Tip-enhanced Raman spectroscopy reveals heterogeneity of the MoS2–Au interaction at the nanoscale, reflecting the spatial nonconformity between the two materials. Micro-Raman spectroscopy shows that this interaction is strongly affected by the roughness and cleanliness of the underlying Au. Our results elucidate the nature of the MoS2–Au interaction and guide strain and charge doping engineering of MoS2.

Several groups have recently introduced a method of exfoliating large-area transition metal dichalcogenide monolayers using gold substrates or sacrificial layers.1−3 For MoS2 in particular, it is possible to prepare centimeter-sized monolayers, thanks to their preferential near-unity exfoliation yield and the high quality of natural molybdenite.3 This is a major advancement for mechanical exfoliation, which produces the highest-quality crystals but has been challenging to scale up, unlike the readily scalable chemical vapor deposition (CVD) or liquid phase-exfoliation that produces lower-quality crystals. Gold-mediated exfoliation has quickly attracted attention and has been utilized in the fabrication of flexible gas sensors,4 lithography patterning for transistor applications,5 and construction of large-area van der Waals (vdW) heterostructures.6,7

When bulk MoS2 is pressed against freshly deposited Au and peeled off, monolayer MoS2 crystals with a near-unity yield remain on the Au surface.2,3 This was rationalized theoretically, showing that the binding energy between the bottom-most MoS2 layer and Au is larger than the interlayer equivalent in bulk MoS2,3 and that the biaxial strain induced in MoS2 facilitates preferential monolayer exfoliation in the naturally AB-stacked molybdenite (2H phase in Ramsdell notation).8 It was suggested that the MoS2–Au interaction is of vdW rather than covalent nature, and that when the Au is removed, the optical and electronic properties of monolayer MoS2 match those of the semiconducting 1H phase, exfoliated directly onto insulating substrates.2,3,5,6 This signifies that the metallicity of MoS2 endowed by the Au3,9 can be reversed after its transfer onto another substrate, significantly increasing the scope of this method to optoelectronics, photovoltaics, and photocatalysis. Despite these efforts, little is known about the nature of the interaction between MoS2 and Au, its dependence on the number of MoS2 layers, and specific effects brought about in MoS2.

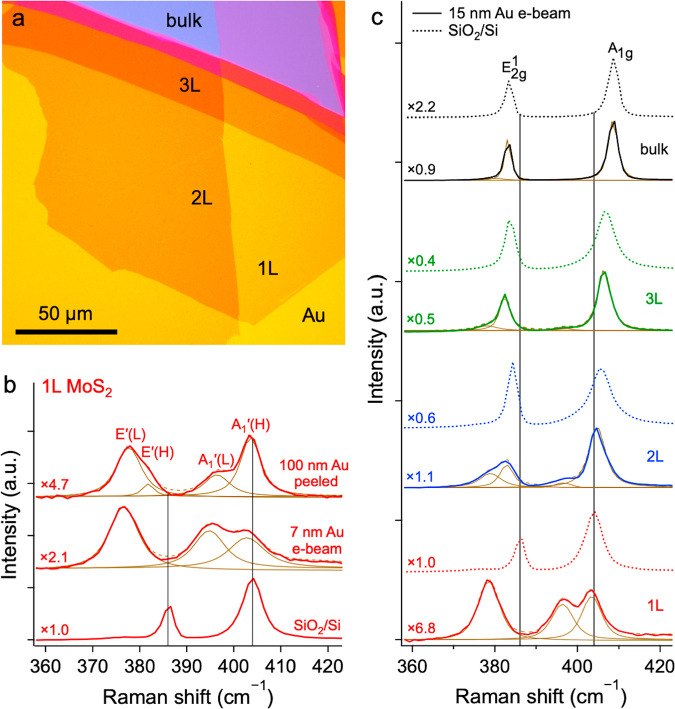

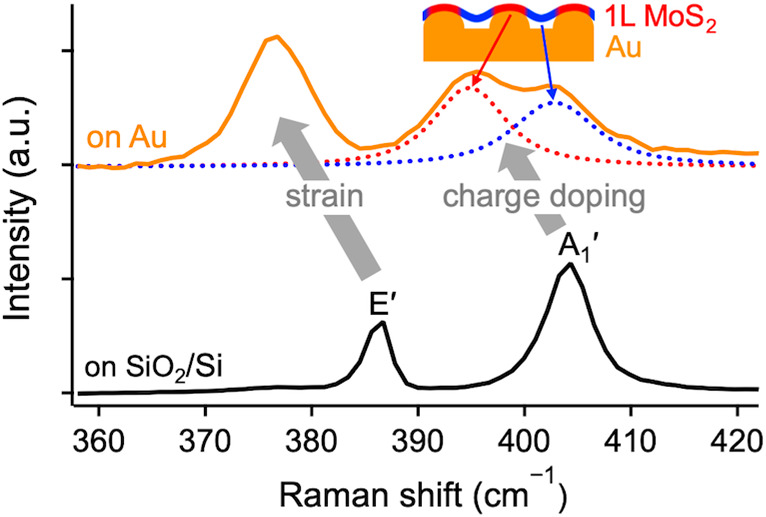

Here, we study the interaction between MoS2 and Au using Raman spectroscopy and X-ray photoelectron spectroscopy (XPS). MoS2 was mechanically exfoliated on a range of polycrystalline Au substrates with thicknesses of 3–100 nm, prepared by magnetron sputtering, electron-beam (e-beam) evaporation, and thermal evaporation (see the Methods section in the Supporting Information for details). Monolayer (1L), bilayer (2L), trilayer (3L), and bulk MoS2 crystals were readily identified due to their high optical contrast,10 as demonstrated in Figure 1a. The far-field micro-Raman spectra of 1L MoS2 on Au exhibit conspicuous broadening and downshift of the E′ mode and splitting of the A1′ mode, in comparison to 1L MoS2 on SiO2/Si (Figure 1b). Lattice deformation (strain) and charge transfer (doping) are the two main factors influencing Raman frequencies in 1L MoS2.11 The effect of lateral strain is more pronounced for the in-plane E′ phonon,12,13 while charge doping has a greater influence on the out-of-plane A1′ phonon.14,15 The E′ mode broadening and downshift can thus be interpreted as heterogeneous biaxial strain, originating in the lattice mismatch between MoS2 and Au.16,17 The induced change in the frequency of a generic Raman mode M can be estimated as δωM = ωM0 – ωM = 2γMωMε, where ωM0 and ωM are the Raman frequencies of the M mode in unstrained and strained lattices, respectively, γM is the Grüneisen parameter of the M mode, and ε is the biaxial strain.11

Figure 1.

Micro-Raman spectra of MoS2 on Au. (a) Optical image of MoS2 exfoliated on Au (15 nm e-beam). (b) Raman spectra of monolayer MoS2 on different substrates: SiO2/Si, 7 nm e-beam Au, and 100 nm thermal Au peeled from Si. (c) Raman spectra of 1L, 2L, 3L, and bulk MoS2 on 15 nm e-beam Au (solid) and SiO2/Si (dotted). Spectra were collected using a 532 nm excitation and normalized to their highest peaks with the corresponding multiplicators shown on the left. Curve fittings using the Voigt function are shown in brown.

Since the precise values of zero-strain Raman frequencies in 1L MoS2 (ωE′0 and ωA1′) are unknown, we use ωE′SiO2/Si = (385.9 ± 0.2) cm–1 measured on SiO2/Si as a reference. The E′ mode peak frequency for all the 1L MoS2/Au samples in this study averages at ωE′ = (378.2 ± 0.6) cm–1, which yields δωE′ = 7.7 cm–1 and implies a tensile strain of ε = (1.2 ± 0.1)% when γE′ = 0.82 is used (average from refs (11 and 12)). If the observed broadening of the E′ mode on Au with a line width of ΓE′ = (6.1 ± 0.5) cm–1 were caused solely by heterogeneous lattice deformation, the biaxial tension would fall between 0.6% and 1.9%, taken as the 5th and 95th percentiles of the distribution of peaks with ΓE′ = 2.4 cm–1 (as measured on SiO2/Si) within the broadened E′ peak.

The average strain-induced downshift of the A1′ mode should be δωA1′ = (1.7 ± 0.2) cm–1, calculated using ε = 1.2%, ωA1′SiO2/Si = (404.0 ± 0.2) cm–1, and γA1′ = 0.18.11,12 However, the A1′ mode is visibly split into two components (Figure 1b), which we define as the lower-frequency A1′(L) mode at (396.4 ± 0.3) cm–1 and the higher-frequency A1′(H) mode at (403.7 ± 0.2) cm–1, corresponding to δωA1′(L) = 7.6 cm–1 and δωA1′(H) = 0.3 cm–1. The most probable origin of the highly downshifted A1′(L) component is the substrate-induced doping, which affects a portion of the 1L MoS2. The net A1′(L) shift δωA1′(L) = 5.9 cm–1, corrected for the strain by subtracting 1.7 cm–1, implies n-type doping and the electron concentration estimate of ne ∼ 2.6 × 1013 cm–2 for A1′(L).14,18 Conversely, the strain-corrected net A1′(H) shift, δωA1′(H)corr = −1.4 cm–1, points to an electron withdrawal. Since the SiO2/Si reference is known to induce n-doping in MoS2,19,20 this suggests that A1′(H) corresponds to regions of undoped MoS2 without direct contact with Au. The dominant n-type doping of MoS2 induced by the Au was confirmed independently by estimating the MoS2–Au work function difference (ΔΦ) from the ultraviolet photoelectron spectroscopy (UPS) as ∼0.3 eV and from Kelvin probe force microscopy (KPFM) as ∼0.2 eV (Figures S1 and S2, respectively). The small difference in ΔΦ determined by these two techniques can be attributed to the environmental effects of the adsorbed moisture and/or oxygen in the case of KPFM, which was performed in the ambient.21

The broadening and splitting of the E′ and A1′ Raman modes suggest that the MoS2–Au interaction is heterogeneous, leading to a multitude of strain and doping states of the MoS2, manifested in the convoluted multicomponent spectral response in Figure 1b,c. In the extreme case of the top spectrum in Figure 1b (100 nm Au peeled), the dominating low-frequency component E′(L) is accompanied by a high-frequency shoulder E′(H), the presence of which is correlated with the A1′(H) intensity, as discussed below.

The evolution of the Raman spectra with the number of MoS2 layers shown in Figure 1c for the Au (15 nm e-beam) and SiO2/Si substrates brings further clarity. It transpires that only the bottom-most MoS2 layer interacts strongly with the adjacent Au substrate, while the top layers in 2L, 3L, and bulk MoS2, without a direct contact with Au, are only partially strained and virtually undoped (see also Figure 4a). We arrive at this conclusion since E′(L) and A1′(L) are replicated in the thicker layers also, with their frequencies and absolute intensities maintained. These components are readily resolved in 2L, less so in 3L, and negligible in bulk, due to the increased intensities of E′(H) and A1′(H) (Figure 1c). Note that the notation of the Raman modes in MoS2 is layer-dependent due to symmetry considerations. Thus, E′ and A1′ versus E2g1 and A1g irreducible representations are used for an odd number of layers versus even number of layers and bulk.22

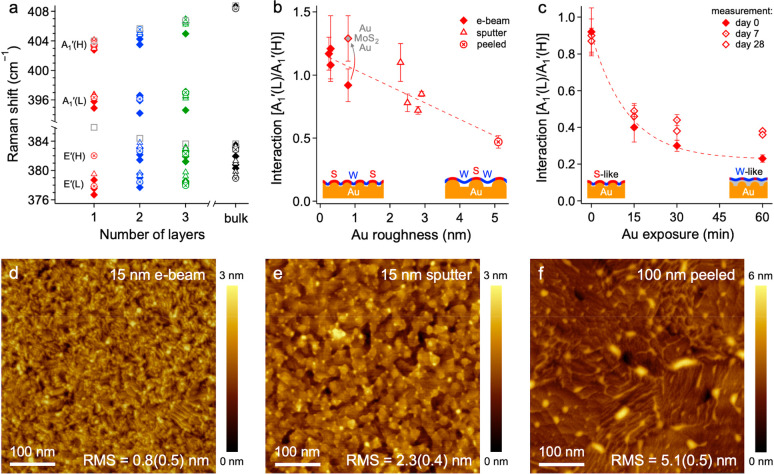

Figure 4.

Correlation between surface structure and Raman vibrations of MoS2. (a) Raman frequencies as a function of the number of MoS2 layers for all samples. (b) A1′(L)/A1′(H) as a function of the Au roughness, determined by AFM. In comparison, the average roughness of 1L MoS2 was (0.4 ± 0.1) nm. The gray-filled marker corresponds to the 5 nm Au/1L MoS2/15 nm Au “sandwich”. (c) A1′(L)/A1′(H) as a function of the Au exposure to air prior to the MoS2 exfoliation (0, 15, 30, 60 min), measured at different times after sample preparation (day 0, 7, 28). Diamond, triangle, circle, and square markers in panels a–c, obtained using the Voigt fitting of the micro-Raman spectra (532 nm excitation), denote the e-beam Au, sputtered Au, peeled Au, and SiO2/Si substrates, respectively. (d–f) AFM images of 1L MoS2 on 15 nm e-beam, 15 nm sputter, and 100 nm peeled Au, respectively, noting the root-mean-square roughness (RMS) of the Au (MoS2) surface.

The observed strain and doping are among the highest observed to date.9,12,14,15,18,23−25 Several previous studies of the MoS2/Au heterostructure report the Raman spectra. Upshifts of both the E′/E2g1 and A1′/A1g modes with the MoS2 thickness were observed using a low-resolution spectrometer,3,10 consistent with Figure 1c if heavily averaged spectra are considered. A broadening and downshift of E′ due to strain and upshift of A1′ explained by out-of-plane vibration stiffening were observed for 1L CVD MoS2 with the Au deposited on top,16 contradicting the appearance of A1′(L) in our study. A downshift of E′ assigned to strain and an undiscussed low-frequency component near A1′ were reported recently.9,13 A similar behavior of both the E′ and A1′ modes to that in our work was observed in 1L CVD MoS2 grown on single-crystal Au(111) but was interpreted as an out-of-plane strain26 arising from the moiré heterostructure buckling due to the MoS2/Au lattice mismatch.17

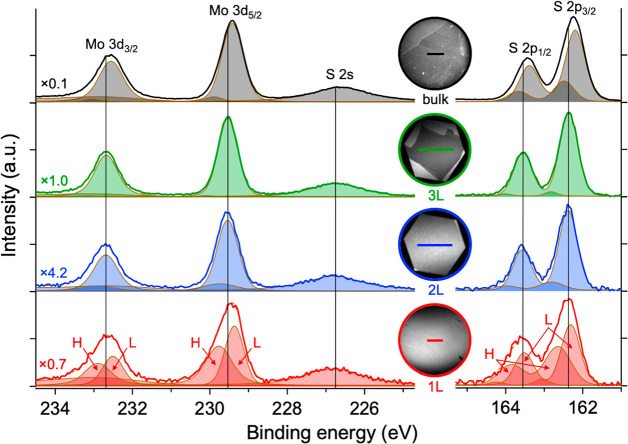

Figure 2 shows the micro-XPS data for the Mo 3d and S 2p core levels, obtained from 1L, 2L, 3L, and bulk MoS2. Care was taken to minimize the effects of edges in 1L, which were shown to induce splitting of Mo 3d core levels.27 Photoemission electron microscopy (PEEM) images of the sampled areas are shown in the insets. The Mo 3d and S 2p peaks in 1L are asymmetric, and their fitting with two Voigt doublets yields a good match with the spectra, revealing a chemical shift of ∼0.4 eV between the higher (H) and lower (L) binding energy components, which appear to have the same origin as A1′(L) and A1′(H) in the 1L Raman spectra (Figure 1b,c), respectively. The upshift (downshift) of H (L) in 1L from the dominant L component in 2L and 3L (vertical lines) reflects the Fermi level upshift (downshift) in 1L MoS2 due to electron injection (withdrawal). This provides further evidence of the suspected heterogeneity of the MoS2–Au interaction, with the MoS2 n-doped when in contact with the Au (H) and undoped when detached from the Au (L). The H components are also partially replicated in the thicker layers, in analogy to A1′(L) in the Raman spectra of Figure 1c.

Figure 2.

Micro-XPS of MoS2 on Au. Mo 3d (left) and S 2p (right) core-level spectra for 1L, 2L, 3L, and bulk MoS2 on Au (15 nm e-beam). Normalization and fitting, qualitatively similar to that in Figure 1, were applied. The insets show the PEEM images of the measured areas with 30 μm scale bars.

The core-level peak energies in bulk MoS2 are less reliable and burdened by larger uncertainties stemming from the weak Au 4f7/2 signal used as an internal calibration reference, effects of finite probing depth and charging, and presence of step-edges.28 Importantly, despite the observed shifts in the XPS binding energies and Raman frequencies, the spectral responses are fully consistent with the thermodynamically stable semiconducting 1H phase of 1L MoS2,3,9 rather than the unstable metallic 1T′ phase observed elsewhere.29,30 This important conclusion demonstrates that the lattice symmetry of 1L MoS2 is preserved and that the Au-induced metallicity can be fully reversed after a transfer onto an insulating substrate.2,5

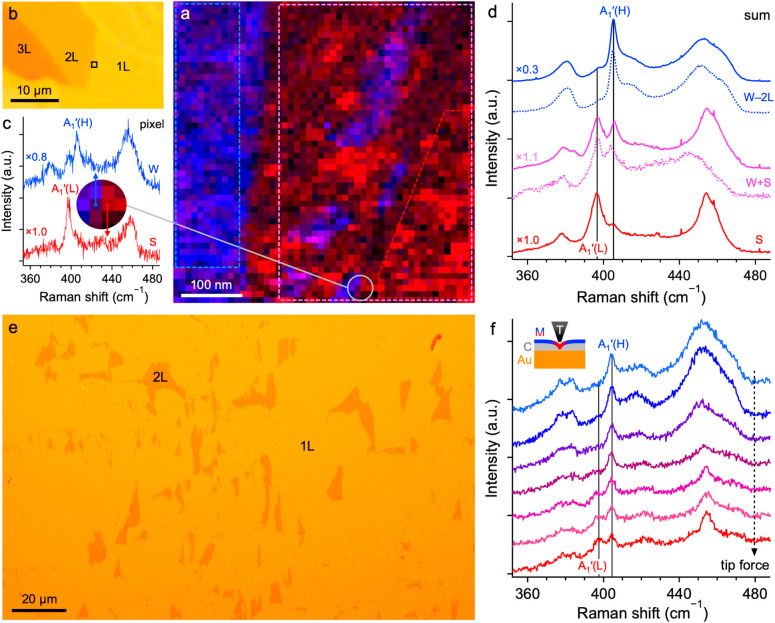

Figure 3a shows the near-field tip-enhanced Raman spectroscopy (TERS) mapping of an area in Figure 3b, which allowed us to isolate the A1′(L) and A1′(H) components of the Raman spectra of 1L MoS2 on Au. The spectra of two individual adjacent (10 × 10) nm2 pixels shown in Figure 3c differ greatly and correspond to 1L MoS2 strongly (S in red) and weakly (W in blue) interacting with the Au. The S spectrum features only A1′(L), while the W spectrum is dominated by A1′(H) with a small A1′(L) shoulder. The blue patches in a larger red region in the right-hand portion of Figure 3a therefore indicate the presence of weakly interacting nanoscale inclusions in a strongly interacting 1L MoS2 sheet. TERS signals summed over the pure weakly interacting bilayer (W–2L), pure strongly interacting monolayer (S), and mixed (S+W) regions of the map, shown as solid curves in Figure 3d, corroborate this conclusion. The mixed response in particular (magenta) is in excellent agreement with the micro-Raman spectrum (dotted curve) recorded in the same area. Unreliability of the absolute intensities in fast TERS mapping makes the differentiation between signals from 2L and weakly interacting 1L challenging. We therefore cannot rule out the disruption of the preferential 1L exfoliation by a locally weakened MoS2–Au interaction, potentially leading to nanoscale traces of 2L. Indication of such a phenomenon, with 2L inclusions in a continuous sheet of 1L, was occasionally observed at the microscale (Figure 3e).

Figure 3.

Tip-enhanced Raman spectroscopy of MoS2 on Au. (a) TERS map (633 nm excitation) of an interface between 1L and 2L. Red, blue, and magenta hues correspond to the intensities of A1′(L), A1′(H), and both components, respectively. (b) Optical image of MoS2 on Au (50 nm e-beam) with the TERS map area defined by a black rectangle. (c) Single-pixel (10 × 10) nm2 TERS of the adjacent strongly (S) and weakly (W) interacting 1L MoS2. (d) TERS summed over the weakly interacting 2L (W–2L), strongly interacting 1L (S), and mixed regions (S+W), from areas highlighted in panel a by dashed polygons of matching colors. Corresponding micro-Raman spectra (633 nm excitation) are shown as dotted curves. (e) Optical image of microscale 2L inclusions in 1L MoS2. (f) TERS acquired with a variable tip force to alter the MoS2–Au interaction. The inset illustrates how the tip (T) pushes the MoS2 (M) closer to the Au through a layer of contamination (C).

However, a direct proof of the 1L origin of A1′(L) is provided by a series of TERS measurements in Figure 3f, acquired using a variable tip force on 1L MoS2 transferred onto 50 nm Au using a polydimethylsiloxane stamp. As no attention was paid to the freshness and cleanliness of the MoS2 and Au surfaces in this case, a layer of contamination was trapped between the two materials, through which we pushed the TERS tip to alter their separation. The top spectrum in Figure 3f corresponds to the weakly interacting 1L MoS2/Au with A1′(H) present but A1′(L) missing. As the tip force increases, and the MoS2 is pressed against the Au (Figure 3f, inset), their interaction is strengthened, and A1′(L) begins to appear at the expense of the A1′(H) intensity. The fact the A1′(L) and A1′(H) modes show no frequency change also proves that no measurable strain is induced by the tip compression.31 On the contrary, the only changing parameter is the relative intensity of the two A1′ components, indicating that an increasingly larger area of MoS2 interacts electronically with the Au.

Figure 4a details the evolution of the E′/E2g1 and A1′/A1g frequencies with the number of MoS2 layers determined by micro-Raman for all the Au (color) and SiO2/Si (gray) substrates. The A1′(H) component on Au upshifts with an increasing number of layers the same way A1′/A1g does on SiO2/Si.32,33 In contrast, the A1′(L) component maintains its frequency for 1L–3L, which makes evident its origin in the strongly interacting regions of the bottom-most MoS2 layer. Figure 4b shows that the ratio between the A1′(L) and A1′(H) intensities of 1L MoS2 [A1′(L)/A1′(H)], which is proportional to the strength of the MoS2–Au interaction, strongly correlates with the Au roughness determined by atomic force microscopy (AFM). This supports the intuitive expectation that the increased conformity of MoS2 to smoother Au increases the strength of their interaction (Figure 4b, insets). In Figure 4c, we show that A1′(L)/A1′(H) decreases exponentially with the time of Au exposure to air prior to the MoS2 exfoliation. This further makes evident the weakening of the MoS2–Au interaction due to airborne contamination (see Figure 4c, insets), in agreement with the observed suppression of the initially near-unity 1L yield after 15–20 min of Au exposure to air.3 For the freshly made Au (0 min), A1′(L)/A1′(H) does not depend on the time delay between the Raman measurement and MoS2 exfoliation (day 0 to day 28). In contrast, A1′(L)/A1′(H) slightly increases with the time delay for the aged Au (15–60 min), indicating that the contact between MoS2 and contaminated Au improves with time.

AFM images of the 1L MoS2/Au heterostructure in Figure 4d–f show signs of MoS2 being suspended between the nanocrystalline features on the Au surface, with a good (poor) contact at the protrusions (depressions). As the Au roughness increases, a larger portion of MoS2 becomes decoupled from the substrate, leading to an increased intensity of the weakly interacting A1′(H) (Figure 4b, insets). A larger portion of weakly interacting, suspended MoS2 also leads to a relative increase in the E′(H) intensity, as seen for the roughest Au substrate (top spectrum in Figure 1b). The enhancement of the MoS2–Au interaction through an increased contact area is further made evident by the Au/MoS2/Au “sandwich” made by covering 1L MoS2 on 15 nm Au with another layer of 5 nm Au, leading to a 40% increase in A1′(L)/A1′(H) indicated by the gray-filled marker in Figure 4b.

The wide range of Au thicknesses (3–100 nm) and roughnesses (0.3–5.1 nm) prepared by three different techniques makes evident the fact that the strong MoS2–Au interaction and the resulting near-unity 1L MoS2 exfoliation yield are universal, as long as the surfaces are kept clean. Polycrystallinity of our Au also disproves the previous suggestion that only single-crystal Au(111) exhibits the strong interaction with MoS2.26 This, along with the fact that both the exfoliation and characterization are performed in the ambient environment, and not limited to ultrahigh vacuum conditions, opens this research up to a broad scientific community.

The novel experimental evidence in this study unequivocally links the appearance of the downshifted A1′(L) Raman mode to that portion of 1L MoS2, which strongly interacts with the Au substrate. The n-doping of 1L MoS2 in contact with Au, proven by XPS, UPS, and KPFM, corroborates that it is the increased electron concentration which is responsible for the A1′(L) downshift, in line with electrochemically gated MoS2 experiments.14,15,18 Nevertheless, one could envisage alternative explanations. The strong binding in MoS2–Au heterostructures with a clean interface could cause softening of the Mo–S bonds,26 instead of the stiffening seen for the contaminated MoS2–Au interface.16 The MoS2–Au interaction could also lead to activation of phonons otherwise silent in 1L MoS2, such as those present in multilayer systems.33,34 However, this can be ruled out for A1′(L), since an activation of another mode would not lead to a disappearance of the original A1′, observed in our TERS data. Furthermore, we observed the same apparent splitting of A1′ into A1′(L) and A1′(H) in the micro-Raman spectra of 1L WS2 on Au, with the A1′(L) downshifted by ∼7 cm–1 (Figure S3). This is a nearly identical shift to that for 1L MoS2, which points to an electron density increase rather than activation of a new mode.

In summary, we identify the specific vibrational and binding energy fingerprints of the strong interaction between MoS2 and Au. Raman spectroscopy reveals significant downshift and broadening of the in-plane E′ mode of 1L MoS2 on Au, compared to MoS2 on SiO2/Si, arising from heterogeneous biaxial tensile strains of up to 1.9%. Splitting of the out-of-plane A1′ Raman mode and XPS Mo 3d and S 2p core levels into two separate components implies that a portion of MoS2 is in close contact with the Au and experiences n-type charge doping with electron concentrations up to 2.6 × 1013 cm–2, while another portion is suspended and undoped. The evolution of the spectra with the MoS2 thickness confirms that the MoS2–Au interaction is confined to the bottom-most MoS2 layer. TERS mapping confirms the nanoscale heterogeneity of this interaction caused by the spatial nonconformity between the two materials. Finally, we show that the MoS2–Au interaction can be effectively tuned by the surface roughness and cleanliness of the underlying Au substrate, which could be exploited for strain and charge doping engineering of MoS2.

Acknowledgments

This project has received funding from the European Union’s Horizon 2020 research and innovation program under the Marie Skłodowska-Curie grant agreement No. 746685, EPSRC grant No. EP/N025938/1, and the Czech Science Foundation project GACR 17-18702S. This work was performed in part at the Cornell NanoScale Science & Technology Facility, a member of the National Nanotechnology Coordinated Infrastructure, which is supported by the NSF (Grant NNCI-1542081), and made use of the Cornell Center for Materials Research Shared Facilities, which are supported through the NSF MRSEC program (DMR-1719875). This work was supported by the Ministry of Education, Youth and Sports of the Czech Republic (MEYS), and The European Union—European Structural and Investments Funds in the frame of Operational Programme Research Development and Education project Pro-NanoEnviCz (Reg. CZ.02.1.01/0.0/0.0/16_013/0001821). Photoemission spectroscopy experiments were supported by the MEYS of the Czech Republic through project CZ.02.1.01/0.0/0.0/16_013/0001406.

Supporting Information Available

The Supporting Information is available free of charge at https://pubs.acs.org/doi/10.1021/acs.jpclett.0c01287.

Methods; work function estimation from UPS; work function estimation from KPFM; and Raman spectra of 1L WS2 on Au (PDF)

The authors declare no competing financial interest.

Supplementary Material

References

- Magda G. Z.; Pető J.; Dobrik G.; Hwang C.; Biró L. P.; Tapasztó L. Exfoliation of Large-Area Transition Metal Chalcogenide Single Layers. Sci. Rep. 2015, 5, 14714. 10.1038/srep14714. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Desai S. B.; Madhvapathy S. R.; Amani M.; Kiriya D.; Hettick M.; Tosun M.; Zhou Y.; Dubey M.; Ager J. W.; Chrzan D.; et al. Gold-Mediated Exfoliation of Ultralarge Optoelectronically-Perfect Monolayers. Adv. Mater. 2016, 28, 4053–4058. 10.1002/adma.201506171. [DOI] [PubMed] [Google Scholar]

- Velický M.; Donnelly G. E.; Hendren W. R.; McFarland S.; Scullion D.; DeBenedetti W. J. I.; Correa G. C.; Han Y.; Wain A. J.; Hines M. A.; et al. Mechanism of Gold-Assisted Exfoliation of Centimeter-Sized Transition-Metal Dichalcogenide Monolayers. ACS Nano 2018, 12, 10463–10472. 10.1021/acsnano.8b06101. [DOI] [PubMed] [Google Scholar]

- Guo S.; Yang D.; Li B.; Dong Q.; Li Z.; Zaghloul M. E.. 2019 IEEE 62nd International Midwest Symposium on Circuits and Systems, 4–7 Aug. 2019; pp 884–887.

- Gramling H. M.; Towle C. M.; Desai S. B.; Sun H.; Lewis E. C.; Nguyen V. D.; Ager J. W.; Chrzan D.; Yeatman E. M.; Javey A.; et al. Spatially Precise Transfer of Patterned Monolayer WS2 and MoS2 with Features Larger than 104 μm2 Directly from Multilayer Sources. ACS Appl. Electron. Mater. 2019, 1, 407–416. 10.1021/acsaelm.8b00128. [DOI] [Google Scholar]

- Nguyen V.; Gramling H.; Towle C.; Li W.; Lien D.-H.; Kim H.; Chrzan D. C.; Javey A.; Xu K.; Ager J.; et al. Deterministic Assembly of Arrays of Lithographically Defined WS2 and MoS2 Monolayer Features Directly From Multilayer Sources Into Van Der Waals Heterostructures. J. Micro Nano-Manuf. 2019, 7, 041006. 10.1115/1.4045259. [DOI] [Google Scholar]

- Liu F.; Wu W.; Bai Y.; Chae S. H.; Li Q.; Wang J.; Hone J.; Zhu X.-Y. Disassembling 2D van der Waals crystals into macroscopic monolayers and reassembling into artificial lattices. Science 2020, 367, 903–906. 10.1126/science.aba1416. [DOI] [PubMed] [Google Scholar]

- Sun H.; Sirott E. W.; Mastandrea J.; Gramling H. M.; Zhou Y.; Poschmann M.; Taylor H. K.; Ager J. W.; Chrzan D. C. Theory of thin-film-mediated exfoliation of van der Waals bonded layered materials. Phys. Rev. Mater. 2018, 2, 094004. 10.1103/PhysRevMaterials.2.094004. [DOI] [Google Scholar]

- Blue B. T.; Jernigan G. G.; Le D.; Fonseca J. J.; Lough S. D.; Thompson J. E.; Smalley D. D.; Rahman T. S.; Robinson J. T.; Ishigami M. Metallicity of 2H-MoS2 induced by Au hybridization. 2D Mater. 2020, 7, 025021. 10.1088/2053-1583/ab6d34. [DOI] [Google Scholar]

- Donnelly G. E.; Velický M.; Hendren W. R.; Bowman R. M.; Huang F. Achieving extremely high optical contrast of atomically-thin MoS2. Nanotechnology 2020, 31, 145706. 10.1088/1361-6528/ab6237. [DOI] [PubMed] [Google Scholar]

- Michail A.; Delikoukos N.; Parthenios J.; Galiotis C.; Papagelis K. Optical detection of strain and doping inhomogeneities in single layer MoS2. Appl. Phys. Lett. 2016, 108, 173102. 10.1063/1.4948357. [DOI] [Google Scholar]

- Lloyd D.; Liu X.; Christopher J. W.; Cantley L.; Wadehra A.; Kim B. L.; Goldberg B. B.; Swan A. K.; Bunch J. S. Band Gap Engineering with Ultralarge Biaxial Strains in Suspended Monolayer MoS2. Nano Lett. 2016, 16, 5836–5841. 10.1021/acs.nanolett.6b02615. [DOI] [PubMed] [Google Scholar]

- Pető J.; Dobrik G.; Kukucska G.; Vancsó P.; Koós A. A.; Koltai J.; Nemes-Incze P.; Hwang C.; Tapasztó L. Moderate strain induced indirect bandgap and conduction electrons in MoS2 single layers. npj 2D Mater. Appl. 2019, 3, 39. 10.1038/s41699-019-0123-5. [DOI] [Google Scholar]

- Chakraborty B.; Bera A.; Muthu D. V. S.; Bhowmick S.; Waghmare U. V.; Sood A. K. Symmetry-dependent phonon renormalization in monolayer MoS2 transistor. Phys. Rev. B: Condens. Matter Mater. Phys. 2012, 85, 161403. 10.1103/PhysRevB.85.161403. [DOI] [Google Scholar]

- Melnikova-Kominkova Z.; Jurkova K.; Vales V.; Drogowska-Horná K.; Frank O.; Kalbac M. Strong and efficient doping of monolayer MoS2 by a graphene electrode. Phys. Chem. Chem. Phys. 2019, 21, 25700–25706. 10.1039/C9CP04993B. [DOI] [PubMed] [Google Scholar]

- Gong C.; Huang C.; Miller J.; Cheng L.; Hao Y.; Cobden D.; Kim J.; Ruoff R. S.; Wallace R. M.; Cho K.; et al. Metal Contacts on Physical Vapor Deposited Monolayer MoS2. ACS Nano 2013, 7, 11350–11357. 10.1021/nn4052138. [DOI] [PubMed] [Google Scholar]

- Sørensen S. G.; Füchtbauer H. G.; Tuxen A. K.; Walton A. S.; Lauritsen J. V. Structure and Electronic Properties of In Situ Synthesized Single-Layer MoS2 on a Gold Surface. ACS Nano 2014, 8, 6788–6796. 10.1021/nn502812n. [DOI] [PubMed] [Google Scholar]

- Sohier T.; Ponomarev E.; Gibertini M.; Berger H.; Marzari N.; Ubrig N.; Morpurgo A. F. Enhanced Electron-Phonon Interaction in Multivalley Materials. Phys. Rev. X 2019, 9, 031019. 10.1103/PhysRevX.9.031019. [DOI] [Google Scholar]

- Scheuschner N.; Ochedowski O.; Kaulitz A.-M.; Gillen R.; Schleberger M.; Maultzsch J. Photoluminescence of freestanding single- and few-layer MoS2. Phys. Rev. B: Condens. Matter Mater. Phys. 2014, 89, 125406. 10.1103/PhysRevB.89.125406. [DOI] [Google Scholar]

- Rodriguez A.; Verhagen T.; Kalbac M.; Vejpravova J.; Frank O. Imaging Nanoscale Inhomogeneities and Edge Delamination in As-Grown MoS2 Using Tip-Enhanced Photoluminescence. Phys. Status Solidi RRL 2019, 13, 1900381. 10.1002/pssr.201900381. [DOI] [Google Scholar]

- Konečný M.; Bartošík M.; Mach J.; Švarc V.; Nezval D.; Piastek J.; Procházka P.; Cahlík A.; Šikola T. Kelvin Probe Force Microscopy and Calculation of Charge Transport in a Graphene/Silicon Dioxide System at Different Relative Humidity. ACS Appl. Mater. Interfaces 2018, 10, 11987–11994. 10.1021/acsami.7b18041. [DOI] [PubMed] [Google Scholar]

- Pimenta M. A.; del Corro E.; Carvalho B. R.; Fantini C.; Malard L. M. Comparative Study of Raman Spectroscopy in Graphene and MoS2-type Transition Metal Dichalcogenides. Acc. Chem. Res. 2015, 48, 41–47. 10.1021/ar500280m. [DOI] [PubMed] [Google Scholar]

- Li H.; Contryman A. W.; Qian X.; Ardakani S. M.; Gong Y.; Wang X.; Weisse J. M.; Lee C. H.; Zhao J.; Ajayan P. M.; et al. Optoelectronic crystal of artificial atoms in strain-textured molybdenum disulphide. Nat. Commun. 2015, 6, 7381. 10.1038/ncomms8381. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Rice C.; Young R. J.; Zan R.; Bangert U.; Wolverson D.; Georgiou T.; Jalil R.; Novoselov K. S. Raman-scattering measurements and first-principles calculations of strain-induced phonon shifts in monolayer MoS2. Phys. Rev. B: Condens. Matter Mater. Phys. 2013, 87, 081307. 10.1103/PhysRevB.87.081307. [DOI] [Google Scholar]

- Trainer D. J.; Zhang Y.; Bobba F.; Xi X.; Hla S.-W.; Iavarone M. The Effects of Atomic-Scale Strain Relaxation on the Electronic Properties of Monolayer MoS2. ACS Nano 2019, 13, 8284–8291. 10.1021/acsnano.9b03652. [DOI] [PubMed] [Google Scholar]

- Yasuda S.; Takahashi R.; Osaka R.; Kumagai R.; Miyata Y.; Okada S.; Hayamizu Y.; Murakoshi K. Out-of-Plane Strain Induced in a Moiré Superstructure of Monolayer MoS2 and MoSe2 on Au(111). Small 2017, 13, 1700748. 10.1002/smll.201700748. [DOI] [PubMed] [Google Scholar]

- Bruix A.; Füchtbauer H. G.; Tuxen A. K.; Walton A. S.; Andersen M.; Porsgaard S.; Besenbacher F.; Hammer B.; Lauritsen J. V. In Situ Detection of Active Edge Sites in Single-Layer MoS2 Catalysts. ACS Nano 2015, 9, 9322–9330. 10.1021/acsnano.5b03199. [DOI] [PubMed] [Google Scholar]

- Mattila S.; Leiro J. A.; Heinonen M.; Laiho T. Core level spectroscopy of MoS2. Surf. Sci. 2006, 600, 5168–5175. 10.1016/j.susc.2006.08.038. [DOI] [Google Scholar]

- Yu Y.; Nam G.-H.; He Q.; Wu X.-J.; Zhang K.; Yang Z.; Chen J.; Ma Q.; Zhao M.; Liu Z.; et al. High phase-purity 1T′-MoS2- and 1T′-MoSe2-layered crystals. Nat. Chem. 2018, 10, 638–643. 10.1038/s41557-018-0035-6. [DOI] [PubMed] [Google Scholar]

- Yin X.; Wang Q.; Cao L.; Tang C. S.; Luo X.; Zheng Y.; Wong L. M.; Wang S. J.; Quek S. Y.; Zhang W.; et al. Tunable inverted gap in monolayer quasi-metallic MoS2 induced by strong charge-lattice coupling. Nat. Commun. 2017, 8, 486. 10.1038/s41467-017-00640-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Peña-Álvarez M.; del Corro E.; Morales-García Á.; Kavan L.; Kalbac M.; Frank O. Single Layer Molybdenum Disulfide under Direct Out-of-Plane Compression: Low-Stress Band-Gap Engineering. Nano Lett. 2015, 15, 3139–3146. 10.1021/acs.nanolett.5b00229. [DOI] [PubMed] [Google Scholar]

- Lee C.; Yan H.; Brus L. E.; Heinz T. F.; Hone J.; Ryu S. Anomalous Lattice Vibrations of Single- and Few-Layer MoS2. ACS Nano 2010, 4, 2695–2700. 10.1021/nn1003937. [DOI] [PubMed] [Google Scholar]

- Zhang X.; Qiao X.-F.; Shi W.; Wu J.-B.; Jiang D.-S.; Tan P.-H. Phonon and Raman scattering of two-dimensional transition metal dichalcogenides from monolayer, multilayer to bulk material. Chem. Soc. Rev. 2015, 44, 2757–2785. 10.1039/C4CS00282B. [DOI] [PubMed] [Google Scholar]

- Scheuschner N.; Gillen R.; Staiger M.; Maultzsch J. Interlayer resonant Raman modes in few-layer MoS2. Phys. Rev. B: Condens. Matter Mater. Phys. 2015, 91, 235409. 10.1103/PhysRevB.91.235409. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.