Abstract

Polypropylene (PP) is a commodity plastic known for high rigidity and crystallinity, which is suitable for a wide range of applications. However, high flammability of PP has always been noticed by users as a constraint; therefore, a variety of additives has been examined to make PP flame-retardant. In this work, research papers on the flame retardancy of PP have been comprehensively reviewed, classified in terms of flame retardancy, and evaluated based on the universal dimensionless criterion of Flame Retardancy Index (FRI). The classification of additives of well-known families, i.e., phosphorus-based, nitrogen-based, mineral, carbon-based, bio-based, and hybrid flame retardants composed of two or more additives, was reflected in FRI mirror calculated from cone calorimetry data, whatever heat flux and sample thickness in a given series of samples. PP composites were categorized in terms of flame retardancy performance as Poor, Good, or Excellent cases. It also attempted to correlate other criteria like UL-94 and limiting oxygen index (LOI) with FRI values, giving a broad view of flame retardancy performance of PP composites. The collected data and the conclusions presented in this survey should help researchers working in the field to select the best additives among possibilities for making the PP sufficiently flame-retardant for advanced applications.

Keywords: flame retardancy, polypropylene, Flame Retardancy Index (FRI), cone calorimetry, flame retardants

1. Introduction

Polymers are building blocks of advanced materials and systems, but their flammability has been a serious constraint in their usage in advanced applications [1,2,3]. Polypropylene (PP) is a commodity plastic widely used in a variety of applications, particularly in the form of composites in load-bearing uses due to its high rigidity and crystallinity [4]. By the end of 2020, the PP market size is expected to reach $112 billion, and it is estimated to reach $155 billion by 2026 [5,6]. Its global production was 56.0 million metric tons in 2018, and it is estimated to reach around 88.0 million metric tons by 2026. This growing demand reflects the importance of PP for applications where low density, hardness, high flexural modulus, and chemical resistance are needed [7,8]. Moreover, PP is a low-cost plastic capable of being processed with various methods, e.g., extrusion, thermoforming, and injection molding [9,10]. Therefore, a huge number of PP products, including fibers, films, sheets, textiles, pipes, and profiles, have been developed and used in the automotive, electrical and electronic, packaging, and construction industries [11,12,13,14]. On the other hand, due to the inherent flammability, the use of flame-retardant additives in PP is necessary to minimize the risk of fire [15]. Different types of flame retardants have been used in PP including minerals, phosphorus-based, nitrogen-based, and intumescent [16,17,18]. It was recognized that additive selection plays a crucial role in achieving acceptable flame retardancy [19], where the type, the size, and the loading percentage of flame retardants control the fire behavior of PP matrix.

A diversity of additives are used in PP to make it flame retardant. There is a need for a comprehensive survey to classify PP composites in terms of flame retardancy. In the present paper, several families of flame retardants examined in PP have been identified and categorized to evaluate their flame retardancy performance in terms of Flame Retardancy Index (FRI) [19,20]. FRI is a universal dimensionless index that takes into account well-known parameters obtained from cone calorimeter test (peak of heat release rate (pHRR), the total heat release (THR), and the time to ignition (TTI)). FRI can be simply calculated using Equation (1):

| (1) |

Basically, the use of FRI makes it possible to semi-qualitatively classify polymer composites by labeling them as Poor, Good, or Excellent flame retardancy performance and thus enables evaluation of the efficiency of the incorporated flame retardant (FR). There has always been a need for fast-tracking and classifying polymers for their flame retardant performance. The use of FRI made possible classifying polymers and polymer composites in terms of flame retardancy in a simple manner. For FRI values below 100 obtained by the use of Equation (1), we have the case (namely Poor) where the addition of FR adversely affects flame retardancy of polymer. When FRI takes values in the range of 100–101, we name it Good flame retardancy performance, such that addition of FR enhances the resistance of polymer against fire. For FRI values above 101, which is rare in practical cases, we have an Excellent case, where FR significantly improves flame retardancy. It is worth mentioning that some important parameters of testing such as irradiance and sample thickness as well as sample weight can be neglected due to the fact that, in the FRI formula, the parameters related to the neat polymer are divided by those of polymer/FR composite. Thus, the dimensionless value obtained can be used as a reliable measure of the efficiency of FR in polymer. In this survey, the data from the literature were extracted first, and five families of flame retardants that served as PP were considered including phosphorus-based, nitrogen-based, mineral, carbon-based, and bio-based flame retardants, and hybrid cases composed of the aforementioned five categories were distinguished. The main aim of the present survey is to give the readers a broad view of FR systems used in PP via FRI classification method. Certainly, this classification is not a precise and unique data set for FR selection for PP, but it can be considered as a database to compare different systems. The focus of this work was particularly placed on the reports in which cone calorimetry test was carried out. However, some other parameters such as smoke quantity or the percentage of FR elements (phosphorus, nitrogen, …) were not systematically given in this research paper due to the lack of data, which could lead to unreliable judgments. For some papers, limiting oxygen index (LOI) and UL-94 data were also available, which were used in finding possible correlations between the FRI variation and other criteria.

2. Phosphorus-Based Flame Retardants

Various types of phosphorus-based flame retardants have been incorporated into PP to make it flame-retardant [21,22,23]. Table 1 reviews the names and the percentages of these flame retardants incorporated into PP. Moreover, the values obtained from cone calorimetry such as the peak of heat release rate (pHRR), the total heat release (THR), and the time to ignition (TTI) are summarized in this Table. The FRI value, calculated from cone calorimetry parameters, as well as the LOI and UL-94 values, are also presented in Table 1. In some cases, if LOI and/or UL-94 values were not available, the sign “―” was used.

Table 1.

Flame-retardant PP materials containing phosphorus-based (P) flame retardants. Data are extracted from the literature: cone calorimetry parameters (TTI, pHRR, THR), LOI, and UL-94 values. The FRI values were calculated by authors of the present review. The name and the percentage of flame retardants are provided in separate columns. “wt.%” was used for loading level of additives, while “―” stands for the systems free of additive or the neat PP. * FR means flame retardant. Since all comparisons were made in terms of FRI, classification of polymers in terms of their flame retardant properties was not surveyed based on the chemistry of additives, heat flux, sample thickness, etc.

| PP Containing Phosphorus-Based (P) FR * | wt.% | TTI (s) | pHRR (kW·m−2) |

THR (MJ·m−2) |

Irradiance (kW·m−2) |

Sample Thickness (mm) | FRI | LOI | UL-94 | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|

| ― | 14 | 1104 | 106 | 35 | 0.4 | ― | ― | ― | [24] | |

| Ammonium polyphosphate (APP) | 10 | 24 | 925 | 92 | 35 | 0.4 | 2.35 | ― | ― | [24] |

| ― | 54 | 1610 | 106 | 35 | 3 | ― | 20.8 | NR | [25] | |

| APP | 12 | 37 | 510 | 97 | 35 | 3 | 2.36 | 22.3 | V-2 | [25] |

| APP | 15 | 27 | 339 | 89 | 35 | 3 | 2.82 | 25.4 | V-0 | [25] |

| ― | 34 | 1294 | 154.2 | 50 | 4 | ― | 19 | NR | [26] | |

| APP | 20 | 21 | 306 | 141.6 | 50 | 4 | 2.84 | 27 | NR | [26] |

| ― | 48 | 1351 | 107 | 35 | 3.2 | ― | 18.5 | NR | [27] | |

| APP | 20 | 40 | 787 | 92 | 35 | 3.2 | 1.66 | 20.5 | NR | [27] |

| ― | 24.3 | 1388.3 | 80.3 | 50 | 2.4 | ― | ― | NR | [28] | |

| APP | 20 | 19.3 | 254.8 | 54.5 | 50 | 2.4 | 6.37 | ― | V-0 | [28] |

| ― | 66 | 633 | 44.2 | 35 | 3 | ― | 17 | NR | [23] | |

| APP | 20 | 31 | 424 | 38.6 | 35 | 3 | 0.80 | 21 | NR | [23] |

| ― | 18 | 1457 | 156 | 50 | 3 | ― | 19 | NR | [29] | |

| APP | 25 | 20 | 1455 | 148 | 50 | 3 | 1.17 | 21.9 | V-2 | [29] |

| ― | 25 | 981 | 147 | 50 | ― | ― | 17.6 | NR | [30] | |

| APP | 25 | 18 | 579 | 109 | 50 | ― | 1.64 | 23.2 | NR | [30] |

| ― | 48 | 988 | 88.3 | 35 | 3.2 | ― | 17 | NR | [31] | |

| APP | 25 | 43 | 652 | 80 | 35 | 3.2 | 1.49 | 21 | NR | [31] |

| ― | 20 | 809 | 96 | 50 | 3 | ― | 17.6 | NR | [32] | |

| APP | 25 | 11 | 397 | 87 | 50 | 3 | 1.23 | 20.6 | NR | [32] |

| ― | 21 | 1242 | 111 | 50 | 3.2 | ― | 18.6 | NR | [33] | |

| APP | 25 | 21 | 979 | 107 | 50 | 3.2 | 1.31 | 21.7 | NR | [33] |

| ― | 35 | 1203 | 197.6 | 50 | 6 | ― | 18.2 | NR | [34] | |

| APP | 25 | 33 | 390.8 | 196 | 50 | 6 | 2.92 | 20.9 | NR | [34] |

| ― | 25 | 841.6 | 89.1 | 50 | 3 | ― | 18 | NR | [35] | |

| APP | 25 | 13 | 473.3 | 90.2 | 50 | 3 | 0.91 | 20 | NR | [35] |

| Piperazine-modified APP (m-APP) | 25 | 17 | 162.6 | 84.5 | 50 | 3 | 3.71 | 32.5 | V-0 | [35] |

| ― | 33 | 1416 | 219 | 50 | 6 | ― | 17 | NR | [36] | |

| APP | 25 | 19 | 526 | 180 | 50 | 6 | 1.88 | 19.6 | NR | [36] |

| Polysiloxane shell-coated APP (mc-APP) | 25 | 19 | 214 | 137 | 50 | 6 | 6.08 | 25 | NR | [36] |

| ― | 45 | 759.2 | 98.8 | 35 | 3 | ― | 17 | NR | [37] | |

| Melamine and phytic acid-modified APP (m-APP) | 25 | 33 | 218.1 | 80.6 | 35 | 3 | 3.12 | 22.5 | V-2 | [37] |

| ― | 37 | 1284 | 121 | 50 | 3 | ― | ― | ― | [38] | |

| APP | 30 | 22 | 767 | 111 | 50 | 3 | 1.08 | 21.7 | NR | [38] |

| ― | 48 | 988 | 88.3 | 35 | 3 | ― | 17 | NR | [39] | |

| APP | 30 | 32 | 459 | 77.6 | 35 | 3 | 1.63 | 22 | NR | [39] |

| ― | 50 | 1350 | 91.2 | 35 | 3 | ― | 17 | NR | [40] | |

| APP | 30 | 58 | 851 | 74.4 | 35 | 3 | 2.25 | 22 | NR | [40] |

| ― | 33 | 1238 | 123.7 | 50 | 3 | ― | 17.8 | NR | [41] | |

| Melamine-formaldehyde-tris(2-hydroxyethyl) isocyanurate resin microencapsulated APP (mc-APP) | 30 | 24 | 375 | 116.4 | 50 | 3 | 2.55 | 32 | V-0 | [41] |

| ― | 44 | 831 | 158 | 35 | 3 | ― | 17.5 | NR | [42] | |

| APP | 30 | 30 | 432 | 114 | 35 | 3 | 1.81 | 22 | NR | [42] |

| Dipentaerythritol and 4,4′ diphenylmethanediisocyanate and melamine microencapsulated APP (mc-APP) | 30 | 27 | 300 | 100 | 35 | 3 | 2.68 | 32.1 | V-0 | [42] |

| ― | 29 | 1186 | 215 | 50 | 6 | ― | 17 | NR | [43] | |

| APP | 30 | 18 | 543 | 180 | 50 | 6 | 1.61 | 20.1 | NR | [43] |

| Epoxy acrylate microencapsulated APP (mc-APP) | 30 | 13 | 332 | 149 | 50 | 6 | 2.31 | 24.8 | NR | [43] |

| ― | 40 | 1174.7 | 102.2 | 35 | 3 | ― | 17 | NR | [44] | |

| APP | 30 | 38 | 526.5 | 80.6 | 35 | 3 | 2.68 | 20 | NR | [44] |

| 4,4′-diphenylmethane diisocyanate and melamine and pentaerythritol microencapsulated APP (mc-APP) | 30 | 30 | 301.8 | 65.1 | 35 | 3 | 4.58 | 25 | V-1 | [44] |

| ― | 68 | 577.5 | 82.7 | 35 | 3 | ― | 18.2 | NR | [45] | |

| APP | 30 | 41 | 201.1 | 44.5 | 35 | 3 | 3.21 | 20.1 | NR | [45] |

| Thermoplastic polyurethane microencapsulated APP (mc-APP) | 5 | 57 | 395.4 | 67.2 | 35 | 3 | 1.50 | 18.7 | NR | [45] |

| Thermoplastic polyurethane microencapsulated APP (mc-APP) | 10 | 42 | 282.5 | 63.7 | 35 | 3 | 1.63 | 19.6 | NR | [45] |

| Thermoplastic polyurethane microencapsulated APP (mc-APP) | 15 | 40 | 214.9 | 59.9 | 35 | 3 | 2.18 | 20 | NR | [45] |

| Thermoplastic polyurethane microencapsulated APP (mc-APP) | 20 | 32 | 193.6 | 57.3 | 35 | 3 | 2.02 | 20.3 | NR | [45] |

| Thermoplastic polyurethane microencapsulated APP (mc-APP) | 25 | 30 | 145.4 | 64.1 | 35 | 3 | 2.26 | 22.2 | NR | [45] |

| Thermoplastic polyurethane microencapsulated APP (mc-APP) | 30 | 31 | 140.6 | 41.8 | 35 | 3 | 3.70 | 22.9 | NR | [45] |

| ― | 25 | 841.6 | 89.1 | 50 | 3 | ― | 18 | NR | [46] | |

| APP | 35 | 11 | 435.9 | 83.9 | 50 | 3 | 0.90 | 20.4 | NR | [46] |

| Ethylenediamine-modified APP (m-APP) | 35 | 11 | 156.1 | 60.5 | 50 | 3 | 3.49 | 30.5 | V-0 | [46] |

| ― | 25 | 841.6 | 89.1 | 50 | 3 | ― | 18 | NR | [47] | |

| APP | 35 | 11 | 435.9 | 83.9 | 50 | 3 | 0.90 | 20.4 | NR | [47] |

| Ethanolamine-modified APP (m-APP) | 35 | 18 | 96.6 | 22.6 | 50 | 3 | 24.73 | 35 | V-0 | [47] |

| ― | 33 | 837 | 212 | 50 | 6 | ― | 17 | NR | [48] | |

| APP | 40 | 30 | 440 | 186 | 50 | 6 | 1.97 | 20.8 | NR | [48] |

| Pentaerythritol triacrylate microencapsulated APP (mc-APP) | 40 | 32 | 214 | 183 | 50 | 6 | 4.39 | 30.5 | V-0 | [48] |

| ― | 38 | 1284 | 214 | 50 | 6 | ― | 18.2 | NR | [49] | |

| APP | 25 | 34 | 537 | 177 | 50 | 6 | 2.58 | 20.9 | NR | [49] |

| Phosphorus-based charring agent: 3,9-Bis-(1-oxo-2,6,7-trioxa-1-phospha-bicyclo[2,2,2]oct-4-ylmethoxy)-2,4,8,10-tetraoxa-3,9 diphospha-spiro[5.5]undecane 3,9-dioxide (P-CA) | 25 | 35 | 480 | 168 | 50 | 6 | 3.13 | 22.6 | NR | [49] |

| ― | 42 | 831 | 112 | 35 | 3 | ― | 18 | NR | [50] | |

| APP | 25 | 36.4 | 578 | 83 | 35 | 3 | 1.68 | 21 | NR | [50] |

| ― | 36 | 1373 | 174.8 | 50 | 3 | ― | 18.5 | NR | [51] | |

| APP-based intumescent flame retardant (APP-IFR) | 20 | 22 | 326 | 149.9 | 50 | 3 | 3.00 | 29.5 | V-0 | [51] |

| ― | 28 | 865 | 30.7 | 35 | 5 | ― | 18.4 | NR | [52] | |

| Phosphorus-based IFR: Six(1-oxo-2,6,7-trioxa-1-phosphabicyclo[2,2,2]octane-4-methyl) cyclotriphosphazene (P-IFR) | 10 | 28 | 595 | 28.2 | 35 | 5 | 1.58 | 19.7 | NR | [52] |

| Phosphorus-based IFR: Six(1-oxo-2,6,7-trioxa-1-phosphabicyclo[2,2,2]octane-4-methyl) cyclotriphosphazene (P-IFR) | 15 | 30 | 515 | 25.8 | 35 | 5 | 2.14 | 22.8 | NR | [52] |

| Phosphorus-based IFR: Six(1-oxo-2,6,7-trioxa-1-phosphabicyclo[2,2,2]octane-4-methyl) cyclotriphosphazene (P-IFR) | 20 | 33 | 433 | 23 | 35 | 5 | 3.14 | 26.1 | V-2 | [52] |

| Phosphorus-based IFR: Six(1-oxo-2,6,7-trioxa-1-phosphabicyclo[2,2,2]octane-4-methyl) cyclotriphosphazene (P-IFR) | 25 | 35 | 407 | 19.5 | 35 | 5 | 4.18 | 29.4 | V-0 | [52] |

| ― | 30 | 390 | 44 | 35 | 1.6 | ― | 17.4 | ― | [53] | |

| Phosphorus-based IFR: Poly (4,4-diamino diphenyl methane Obicyclicpentaerythritol phosphate-phosphate) (P-IFR) | 20 | 24 | 224 | 27 | 35 | 1.6 | 2.26 | 25 | ― | [53] |

| ― | 37 | 363 | 56 | 35 | 3 | ― | ― | ― | [54] | |

| Phosphorus-based IFR: compound containing Phosphorus(22%) and Nitrogene(18%) (P-IFR) | 28 | 33 | 62 | 24 | 35 | 3 | 12.18 | ― | ― | [54] |

| ― | 37 | 363 | 56 | 35 | 3 | ― | ― | ― | [55] | |

| Phosphorus-based IFR: compound containing Phosphorus(22%) and Nitrogene(18%) (P-IFR) | 28 | 33 | 62 | 24 | 35 | 3 | 12.18 | ― | ― | [55] |

| ― | 29 | 980 | 136 | 50 | ― | ― | 18.5 | ― | [56] | |

| Phosphorus and Nitrogene-based IFR | 30 | 22 | 229 | 93 | 50 | ― | 4.74 | 36.3 | ― | [56] |

| ― | 65 | 1416.6 | 128.5 | 35 | 3 | ― | ― | NR | [57] | |

| Phosphorus-based flame retardant: Tri (1-oxo-2,6,7-trioxa-1-phosphabicyclo [2,2,2] octane-methyl) phosphate (P-FR) | 30 | 38 | 640.2 | 104.8 | 35 | 3 | 1.58 | ― | NR | [57] |

| ― | 54 | 1199 | 97.8 | 35 | ― | ― | ― | ― | [58] | |

| Phosphorus-based FR: Poly(4,4-diaminodiphenyl methane spirocyclicpentaerythritol bisphosphonate) (P-FR) | 20 | 69 | 620 | 78.5 | 35 | ― | 3.07 | ― | ― | [58] |

| ― | 61 | 1026 | 166 | 35 | 4 | ― | ― | ― | [15] | |

| 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO) | 10 | 60 | 648 | 141 | 35 | 4 | 1.83 | ― | ― | [15] |

| ― | 84 | 1000 | 96 | 35 | 3 | ― | ― | ― | [59] | |

| Tetraethyl orthosilicate microencapsulated bisphenol-A bis (diphenyl phosphate) (mc-BDP) | 10 | 57 | 808 | 101 | 35 | 3 | 0.79 | ― | ― | [59] |

| Tetraethyl orthosilicate microencapsulated BDP (mc-BDP) | 20 | 60 | 932 | 93 | 35 | 3 | 0.79 | ― | ― | [59] |

| ― | 44 | 1172 | 87.1 | 35 | 2.5 | ― | 18.1 | NR | [60] | |

| Organic phosphinate (OP) | 20 | 46 | 1052 | 84.2 | 35 | 2.5 | 1.20 | 20.1 | V-2 | [60] |

| ― | 34 | 1052.4 | 90.8 | 50 | 3 | ― | 17.5 | NR | [61] | |

| Aluminum hypophosphite (AHP) | 24 | 23 | 267.1 | 77.3 | 50 | 3 | 3.13 | ― | ― | [61] |

| ― | 66 | 480 | 93 | 35 | 3 | ― | 17 | ― | [62] | |

| Aluminium phosphinate (ALPi) | 30 | 73 | 524 | 89.8 | 35 | 3 | 1.04 | 26 | ― | [62] |

| ― | 44 | 1175 | 106 | 35 | 3 | ― | ― | ― | [63] | |

| Pentaerythritol phosphate (PEPA) | 40 | 35 | 776 | 81 | 35 | 3 | 1.57 | ― | ― | [63] |

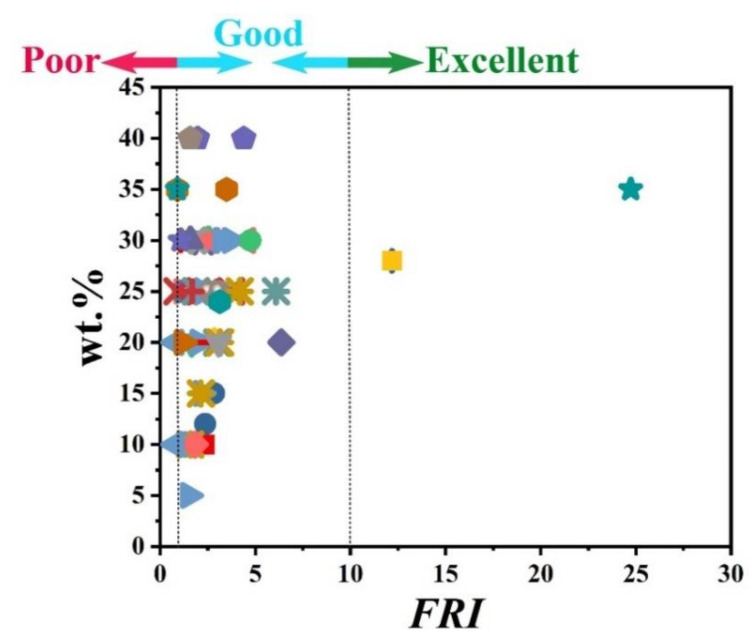

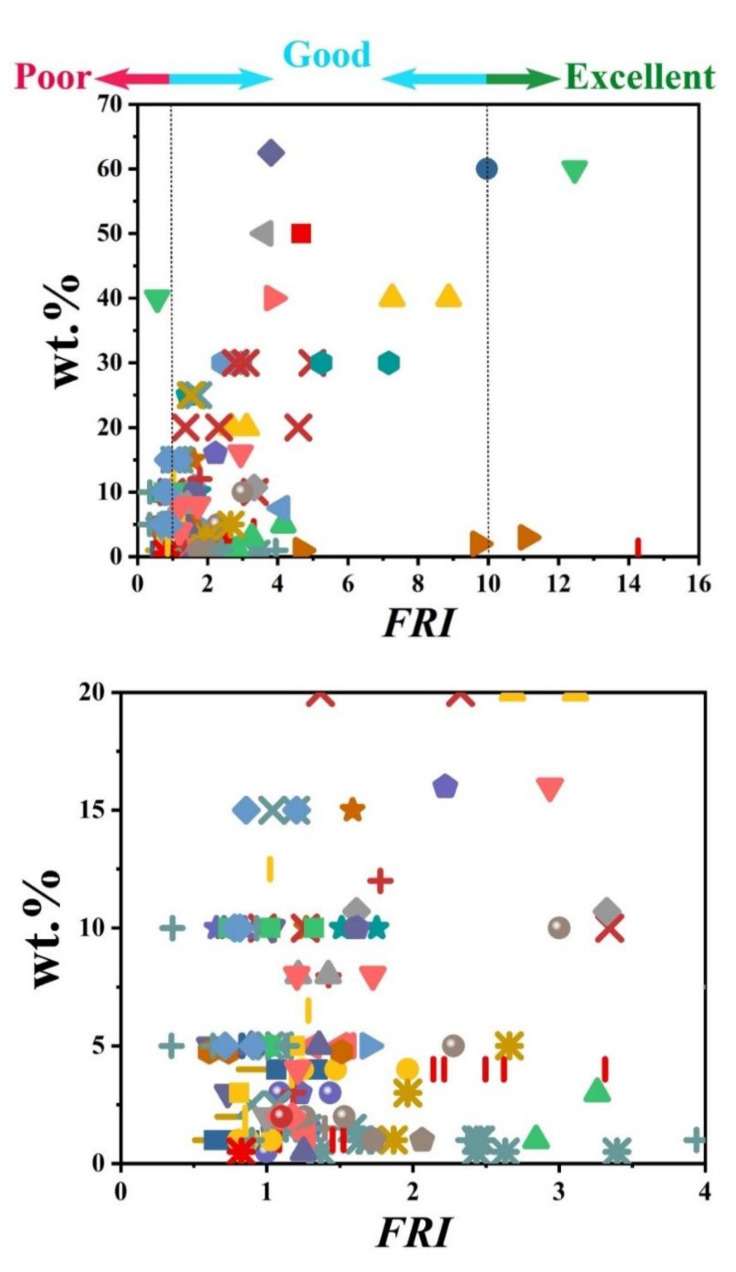

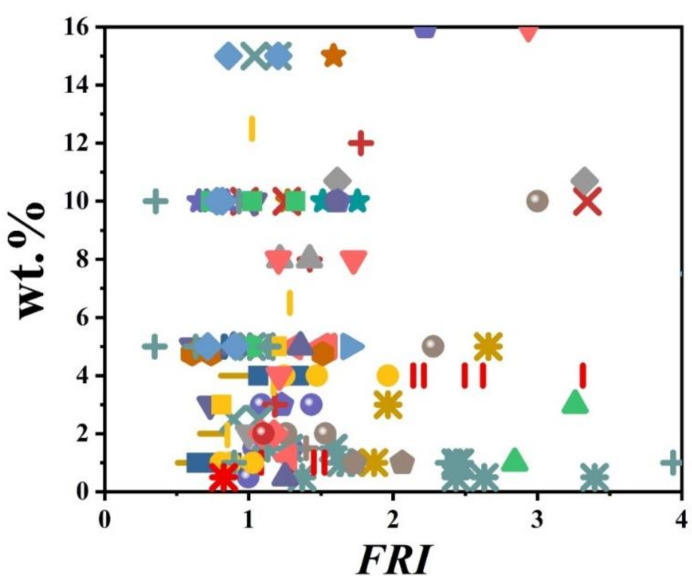

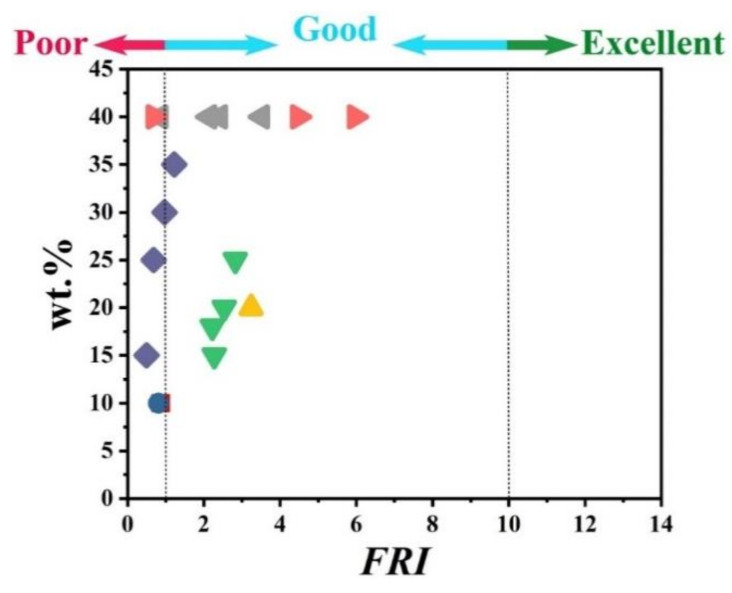

The information provided in Table 1 clearly reveals that APP is quite frequently used as a major phosphorus flame retardant in PP matrix. The percentage of incorporation of phosphorus flame retardants was variable from 10 to 40 wt.%. Figure 1 displays the FRI as a function of wt.% phosphorus-based FR in PP systems. The name/type of each phosphorus flame retardant is provided in the caption of Figure 1. Three formulations reached the Excellent level of flame retardancy, which is quite rare among such data pool. The loading percentage of FR in these formulations varied from 28 to 35 wt.%. Many additives were modified APP and modified phosphorus-nitrogen flame retardants. It can also be speculated that a high loading percentage cannot necessarily guarantee the Excellent level of flame retardancy; besides, the type of phosphorus FR is also an important parameter. Figure 1 also reveals that the majority of points are located in the Good zone of FRI. Therefore, it can be concluded that phosphorus-based flame retardants have quite satisfactorily reinforced PP against flame.

Figure 1.

Flame Retardancy Index (FRI) values as a function of phosphorus flame retardant (FR) type and content. Symbols are indicative of different types of phosphorus flame retardant used. Here: ■ APP-10 [24],  APP-12, APP-15 [25],

APP-12, APP-15 [25],  APP-20 [26],

APP-20 [26],

APP-20 [27],

APP-20 [27],

APP-20 [28],

APP-20 [28],

APP-20 [23],

APP-20 [23],

APP-25 [29],

APP-25 [29],

APP-25 [30],

APP-25 [30],

APP-25 [31],

APP-25 [31],

APP-25 [32],

APP-25 [32],

APP-25 [33],

APP-25 [33],

APP-25 [34],

APP-25 [34],

APP-25, m-APP-25 [35],

APP-25, m-APP-25 [35],  APP-25, mc-APP-25 [36],

APP-25, mc-APP-25 [36],  m-APP-25 [37],

m-APP-25 [37],

APP-30 [38],

APP-30 [38],

APP-30 [39],

APP-30 [39],

APP-30 [40],

APP-30 [40],

mc-APP-30 [41],

mc-APP-30 [41],

APP-30, mc-APP-30 [42],

APP-30, mc-APP-30 [42],

APP-30, mc-APP-30 [43],

APP-30, mc-APP-30 [43],

APP-30, mc-APP-30 [44],

APP-30, mc-APP-30 [44],

APP-30, mc-APP-5, mc-APP-10, mc-APP-15, mc-APP-20, mc-APP-25, mc-APP-30 [45],

APP-30, mc-APP-5, mc-APP-10, mc-APP-15, mc-APP-20, mc-APP-25, mc-APP-30 [45],  APP-35, m-APP-35 [46],

APP-35, m-APP-35 [46],  APP-35, m-APP-35 [47],

APP-35, m-APP-35 [47],  APP-40, mc-APP-40 [48],

APP-40, mc-APP-40 [48],  APP-25, P-CA-25 [49],

APP-25, P-CA-25 [49],  APP-25 [50],

APP-25 [50],

APP-IFR-20 [51],

APP-IFR-20 [51],

P-IFR-10, P-IFR-15, P-IFR-20, P-IFR-25 [52],

P-IFR-10, P-IFR-15, P-IFR-20, P-IFR-25 [52],

P-IFR-20 [53],

P-IFR-20 [53],

P-IFR-28 [54],

P-IFR-28 [54],

P-IFR-28 [55],

P-IFR-28 [55],

PN-IFR-30 [56],

PN-IFR-30 [56],

P-FR-30 [57],

P-FR-30 [57],

P-FR-20 [58],

P-FR-20 [58],

DOPO-10 [15],

DOPO-10 [15],

mc-BDP-10, mc-BDP-20 [59],

mc-BDP-10, mc-BDP-20 [59],

OP-20 [60],

OP-20 [60],

AHP-24 [61],

AHP-24 [61],

ALPi-30 [62],

ALPi-30 [62],

PEPA-40 [63].

PEPA-40 [63].

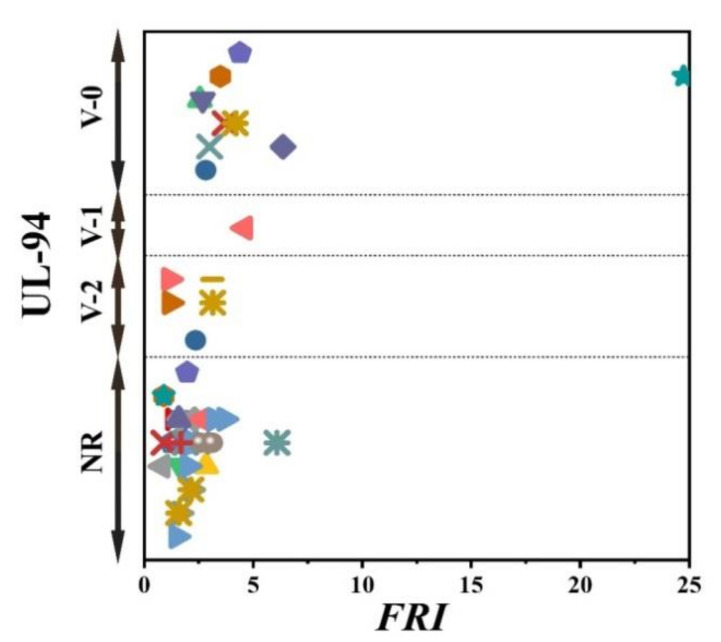

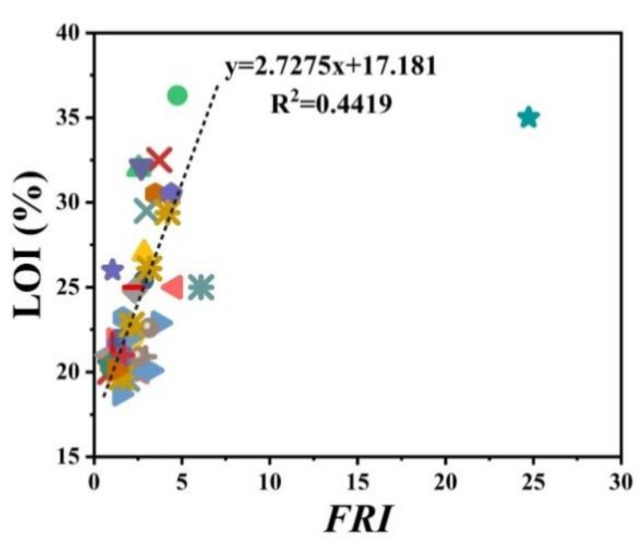

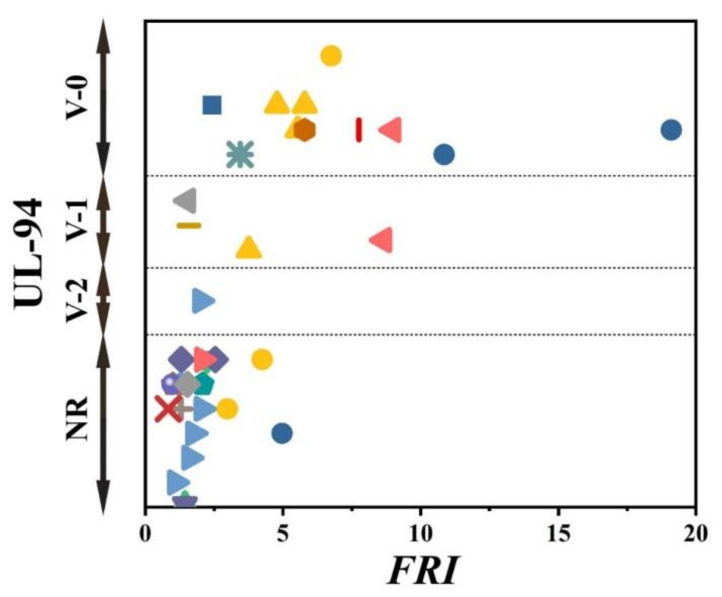

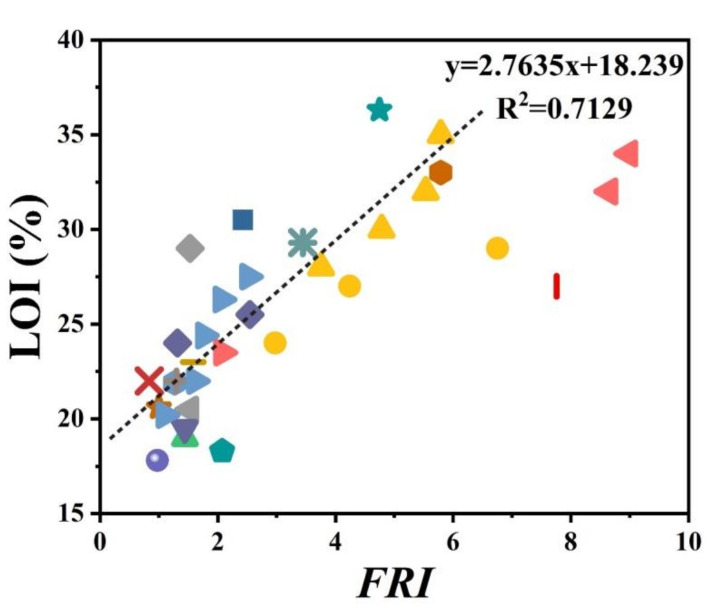

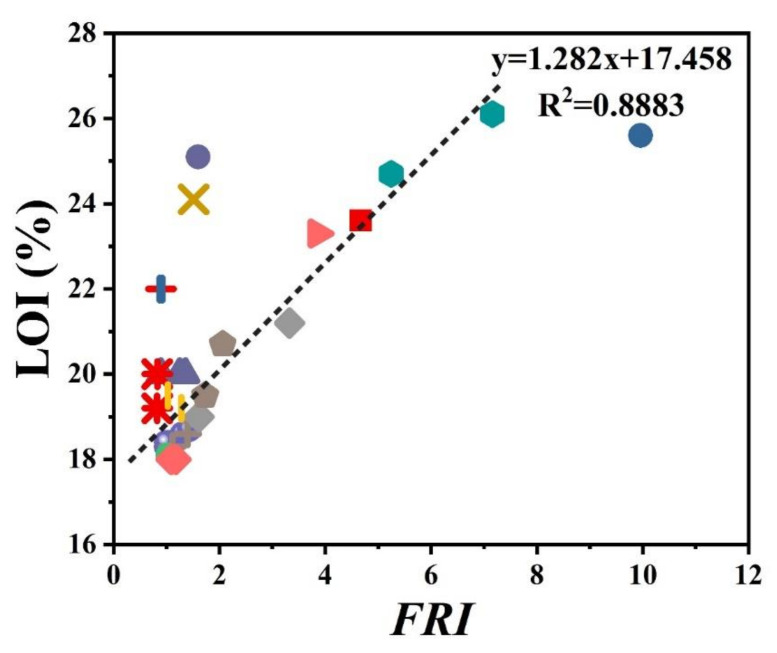

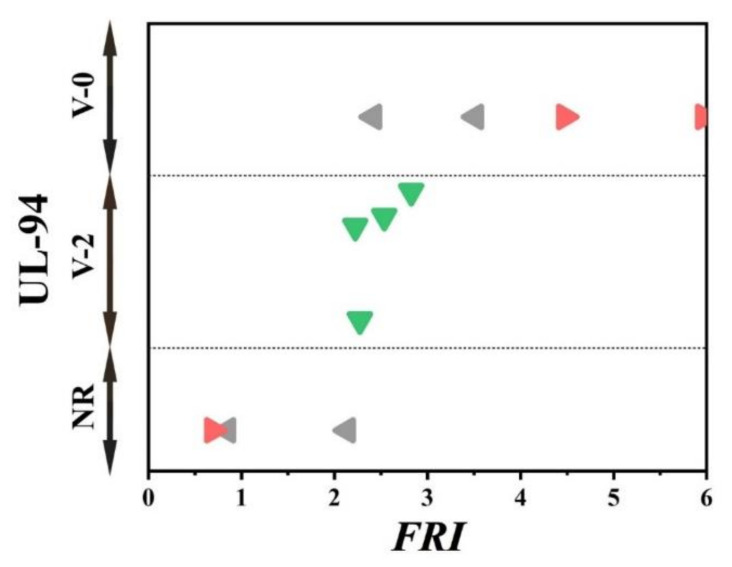

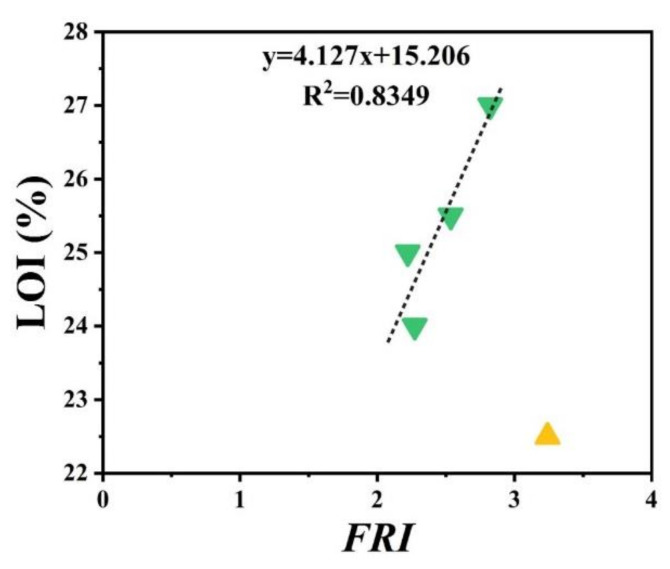

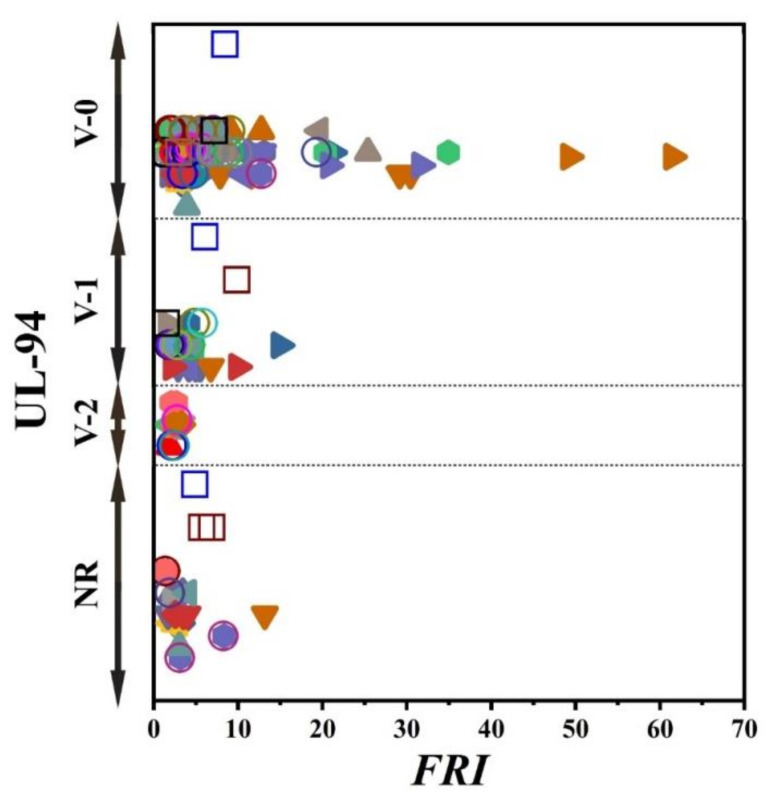

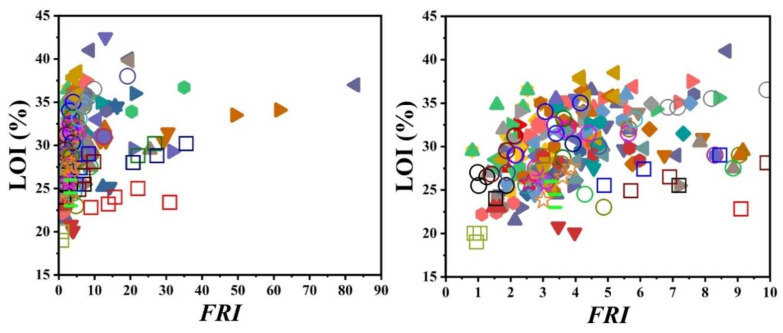

There has always been interest in exploring possible correlations between the data collected from different analyses made on PP materials. Figure 2 shows the flame retardancy performance of phosphorus FR-containing PP in terms of FRI versus the corresponding UL-94 test outcomes. From these data, it is evident that no specified correlation exists between the qualitative results collected from UL-94 and the quantitative ones obtained in cone calorimeter measurements. However, in the case of LOI results, Figure 3 suggests a meaningful relationship can be drawn among data achieved from the calculated FRI and the LOI test results. The LOI value for pure PP is around 17; however, it is increased by addition of flame retardant up to 36, more than a two-fold rise.

Figure 2.

FRI values versus UL-94 test results. Symbols are indicative of different types of phosphorus flame retardant (FR) used. The vertical intervals in each category, i.e., V-0, V-1, V-2, and NR, are schematically representative of the amount of additive used. For example, two data distinguished by different symbols having the same or very close FRI values (horizontal quantity) in a given category (e.g., V-1) may have different vertical quantities, e.g., both reveal V-1 behavior in the UL-94 test, but the upper contains more FR in Polypropylene (PP).

Figure 3.

FRI values of PP as a function of limiting oxygen index (LOI) test results. Symbols are indicative of different types of phosphorus flame retardant used.

3. Nitrogen-Based Flame Retardants

Nitrogen-based flame retardants have also been used in PP to make it resistant against fire. Table 2 gives the names and the percentages of incorporation of these flame retardants, where the data were obtained in cone calorimetry (pHRR, THR, and TTI), FRI calculated from cone calorimetry parameters, as well as LOI and UL-94 values. Some of the nitrogen-based FRs listed in Table 2 also contain a phosphorus element. However, the percentage of nitrogen is more important, and therefore these FRs are listed in this Table.

Table 2.

Flame retardant PP materials containing nitrogen-based (N) flame retardants. Data are extracted from the literature: cone calorimetry parameters (TTI, pHRR, THR), LOI, and UL-94 values. The FRI values were calculated by authors of the present review. The name and the percentage of flame retardants are provided in separate columns. “wt.%” was used for loading level of additives, while “―” stands for the systems free of additive or the neat PP. * FR means flame retardant. Since all comparisons were made in terms of FRI, classification of polymers in terms of their flame-retardant properties was not surveyed based on the chemistry of additives, heat flux, sample thickness, etc.

| PP Containing Nitrogen-Based (N) FR * | wt.% | TTI (s) |

pHRR (kW·m−2) |

THR (MJ·m−2) |

Irradiance (kW·m−2) |

Sample Thickness (mm) | FRI | LOI | UL-94 | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|

| ― | 44 | 1175 | 106 | 35 | 3 | ― | ― | ― | [63] | |

| Melamine phosphate (MP) | 40 | 39 | 296 | 78 | 35 | 3 | 4.78 | ― | ― | [63] |

| ― | 54 | 930 | 140 | 35 | 4 | ― | ― | NR | [64] | |

| Melamine salt of pentaerythritol phosphate kaolinite (MPPK) | 15 | 30 | 208 | 70 | 35 | 4 | 4.96 | ― | NR | [64] |

| MPPK | 20 | 28 | 148 | 42 | 35 | 4 | 10.86 | ― | V-0 | [64] |

| MPPK | 25 | 34 | 130 | 33 | 35 | 4 | 19.10 | ― | V-0 | [64] |

| ― | 30 | 929 | 134 | 50 | 3 | ― | 17 | NR | [65] | |

| Melamine salt of tripentaerythriol phosphate (MTP) | 15 | 22 | 480 | 101 | 50 | 3 | 1.88 | ― | ― | [65] |

| MTP | 20 | 22 | 267 | 91 | 50 | 3 | 3.75 | 28 | V-1 | [65] |

| MTP | 25 | 22 | 226 | 73 | 50 | 3 | 5.53 | 32 | V-0 | [65] |

| MTP | 30 | 22 | 219 | 72 | 50 | 3 | 5.78 | 35 | V-0 | [65] |

| Methyl hydrogen siloxane modified MTP (m-MTP) | 30 | 21 | 253 | 72 | 50 | 3 | 4.78 | 30 | V-0 | [65] |

| ― | 65 | 1417 | 128.5 | 35 | 3 | ― | ― | NR | [57] | |

| Melamine pyrophosphate (MPyP) | 30 | 36 | 437 | 103.1 | 35 | 3 | 2.23 | ― | NR | [57] |

| ― | 34 | 1727 | 112 | 35 | 3 | ― | 17 | NR | [66] | |

| MPyP | 30 | 19 | 511 | 83 | 35 | 3 | 2.54 | 25.5 | NR | [66] |

| Triazine-based charring foaming agent: synthesized by reaction of cyanuric chloride and ethanolamine and ethylenediamine (TA-CFA) | 30 | 13 | 584 | 96 | 35 | 3 | 1.31 | 24 | NR | [66] |

| ― | 48 | 988 | 88.3 | 35 | 3 | ― | 17 | NR | [39] | |

| Triazine-based CFA: synthesized by reaction of cyanuric chloride and piperazine (TA-CFA) | 30 | 34 | 468 | 86.6 | 35 | 3 | 1.52 | 20.5 | V-1 | [39] |

| ― | 50 | 1350 | 91.2 | 35 | 3 | ― | 17 | NR | [40] | |

| Triazine-based CFA: synthesized by polycondensation of 2-chloro-4,6-di-(2-hydroxyethylamino)-s-triazine (TA-CFA) | 30 | 38 | 518 | 86.7 | 35 | 3 | 2.08 | 23.5 | NR | [40] |

| ― | 45 | 759.2 | 98.8 | 35 | 3 | ― | 17 | NR | [37] | |

| Triazine-based CFA: synthesized from a macromolecular triazine derivative containing hydroxyethylamino and triazine rings and ethylenediamino groups (TA-CFA) | 25 | 34 | 487.4 | 91.6 | 35 | 3 | 1.26 | 21.9 | NR | [37] |

| ― | 20 | 809 | 96 | 50 | 3 | ― | 17.6 | NR | [32] | |

| Triazine-based CFA: Poly[N4-bis(ethylenediamino)-phenyl phosphonic-N2, N6-bis(ethylenediamino)-1,3,5-triazine-N-phenyl (TA-CFA) | 25 | 12 | 529 | 88 | 50 | 3 | 1.00 | 20.6 | NR | [32] |

| ― | 18 | 1457 | 156 | 50 | 3 | ― | 19 | NR | [29] | |

| Triazin-based CA—Zinc oxide (TA-CA-ZnO) | 25 | 17 | 694 | 149 | 50 | 3 | 2.07 | 18.3 | NR | [29] |

| ― | 41 | 840.3 | 115.7 | 35 | 3 | ― | 16.4 | NR | [67] | |

| Triazin-based CA: Poly(ethanediamine-1,3,5-triazine-p-4-amino-2,2,6,6-tetramethylpiperidine) (TA-CA) | 25 | 30 | 684 | 106.7 | 35 | 3 | 0.97 | 17.8 | NR | [67] |

| ― | 48 | 1351 | 107 | 35 | 3.2 | ― | 18.5 | NR | [27] | |

| Triazin-based CA: compound containing pentaerythritol and triazine structure (TA-CA) | 20 | 42 | 994 | 98 | 35 | 3.2 | 1.29 | 22 | NR | [27] |

| ― | 66 | 633 | 44.2 | 35 | 3 | ― | 17 | NR | [23] | |

|

Triazin-based CA: synthesized by

reaction of tris (2-hydrooxyethyl) isocyanurate and 2-carboxyethyl (phenyl) phosphinic acid (TA-CA) |

20 | 31 | 417 | 37.6 | 35 | 3 | 0.83 | 22 | NR | [23] |

| ― | 31 | 1239 | 123.6 | 50 | 3 | ― | 18.5 | NR | [68] | |

|

Triazin-based IFR: synthesized by

reaction of tris(2-hydroxyethyl) isocyanurate and polyphosphoric acid and melamine (TA-IFR) |

20 | 18 | 289.9 | 89 | 50 | 3 | 3.44 | 29.3 | V-0 | [68] |

| ― | 48 | 988 | 88.3 | 35 | 3.2 | ― | 17 | NR | [31] | |

|

Triazin-based IFR: synthesized by

reaction of cyanuric chloride and N-amino ethylpiperazine (TA-IFR) |

25 | 38 | 504 | 86.6 | 35 | 3.2 | 1.58 | 23 | V-1 | [31] |

| ― | 20 | 904.4 | 126.2 | 50 | 3 | ― | 18 | NR | [69] | |

|

Piperazine-based FR: synthesized by

reaction of diphenylphosphinyl chloride and piperazine (PI-FR) |

25 | 58 | 487.7 | 87.5 | 50 | 3 | 7.75 | 27 | V-0 | [69] |

| ― | 45 | 1269 | 146.4 | 50 | 3 | ― | 17.5 | NR | [70] | |

| Piperazine-based IFR: Piperazine spirocyclic phosphoramidate (PI-IFR) | 30 | 17 | 240.4 | 120.2 | 50 | 3 | 2.42 | 30.5 | V-0 | [70] |

| ― | 47 | 802 | 104 | 35 | 3 | ― | 18 | NR | [71] | |

|

Piperazine-based IFR: synthesized by

reaction of phosphorus chloride and 2,6,7-trioxa-l-phosphabicyclo[2,2,2]-octane-4-methanol and anhydrous piperazine (PI-IFR) |

20 | 36 | 275 | 78 | 35 | 3 | 2.97 | 24 | NR | [71] |

|

Piperazine-based IFR: synthesized by

reaction of phosphorus chloride and 2,6,7-trioxa-l-phosphabicyclo[2,2,2]-octane-4-methanol and anhydrous piperazine (PI-IFR) |

30 | 37 | 209 | 74 | 35 | 3 | 4.24 | 27 | NR | [71] |

|

Piperazine-based IFR: synthesized by

reaction of phosphorus chloride and 2,6,7-trioxa-l-phosphabicyclo[2,2,2]-octane-4-methanol and anhydrous piperazine (PI-IFR) |

40 | 37 | 162 | 60 | 35 | 3 | 6.75 | 29 | V-0 | [71] |

| ― | 36 | 799.3 | 170.9 | 35 | 4 | ― | 18 | NR | [72] | |

| N-alkoxy hindered amine (NOR116) | 0.5 | 44 | 738.8 | 156.5 | 35 | 4 | 1.44 | 19 | NR | [72] |

| ― | 36 | 799 | 170 | 35 | 4 | ― | 17.5 | NR | [73] | |

| NOR116 | 0.3 | 44 | 738 | 156 | 35 | 4 | 1.44 | 19.5 | NR | [73] |

| ― | 42 | 831 | 112 | 35 | 3 | ― | 18 | NR | [50] | |

| Polyurethane containing Phosphorus-based CA (PPU-CA) | 25 | 27.3 | 475 | 83 | 35 | 3 | 1.53 | 29 | NR | [50] |

| ― | 42 | 1025 | 137.7 | 35 | 4 | ― | ― | ― | [74] | |

| Nitrogen-based FR: compound containing Nitrogen (27.5.wt.%) and Phosphorus (15.6 wt.%) (N-FR) | 22 | 22 | 170 | 50.3 | 35 | 4 | 8.64 | 32 | V-1 | [74] |

| Nitrogen-based FR: compound containing Nitrogen (27.5 wt.%) and Phosphorus (15.6 wt.%) (N-FR) | 25 | 21 | 160 | 49.1 | 35 | 4 | 8.98 | 34 | V-0 | [74] |

| ― | 30 | 1093 | 108.2 | 50 | 3 | ― | 18 | NR | [75] | |

| Nitrogen-based IFR: Poly (diallyldimethylammonium) and polyphosphate polyelectrolyte complexe-based IFR (N-IFR) | 5 | 28 | 968.5 | 103.4 | 50 | 3 | 1.10 | 20.2 | NR | [75] |

| Nitrogen-based IFR: Poly (diallyldimethylammonium) and polyphosphate polyelectrolyte complexe-based IFR (N-IFR) | 10 | 25 | 626.2 | 97.1 | 50 | 3 | 1.62 | 22 | NR | [75] |

| Nitrogen-based IFR: Poly (diallyldimethylammonium) and polyphosphate polyelectrolyte complexe-based IFR (N-IFR) | 15 | 23 | 543.1 | 94.3 | 50 | 3 | 1.76 | 24.4 | NR | [75] |

| Nitrogen-based IFR: Poly (diallyldimethylammonium) and polyphosphate polyelectrolyte complexe-based IFR (N-IFR) | 20 | 21 | 443.9 | 90.1 | 50 | 3 | 2.06 | 26.3 | NR | [75] |

| Nitrogen-based IFR: Poly (diallyldimethylammonium) and polyphosphate polyelectrolyte complexe-based IFR (N-IFR) | 25 | 18 | 335.3 | 83.9 | 50 | 3 | 2.52 | 27.5 | V-2 | [75] |

| ― | 25 | 874.1 | 89.3 | 50 | 3 | ― | 18 | NR | [76] | |

| Nitrogen-based IFR: compound containing Nitrogen (23%) and Phosphorus (21%) (N-IFR) | 25 | 12 | 94.9 | 68.2 | 50 | 3 | 5.78 | 33 | V-0 | [76] |

| ― | 29 | 980 | 136 | 50 | ― | ― | 18.5 | ― | [56] | |

| Phosphorus and Nitrogene based IFR | 30 | 22 | 229 | 93 | 50 | ― | 4.74 | 36.3 | ― | [56] |

To give a bright view of the variation trend, Figure 4 illustrates the FRI values as a function of wt.% of nitrogen-based flame retardants incorporated into the PP. The percentage of incorporation was changed from 15 to 40 wt.%. Of note, all points are located in the Good zone of FRI, except two points remarked as Excellent. These two points correspond to a kaolinite additive modified with nitrogen and phosphorus agents. A very noticeable point to be considered is that increasing the amount of diallyldimethylammonium (nominated with the  symbol in Figure 4) from 5 to 25 has no serious effect on the value of FRI, so that they are aligned vertically around FRI values between 1.0 and 2.5. Overall, like what happened to other polymers [77,78], combinatorial flame retardants may be the solution to flammability reduction of PP materials.

symbol in Figure 4) from 5 to 25 has no serious effect on the value of FRI, so that they are aligned vertically around FRI values between 1.0 and 2.5. Overall, like what happened to other polymers [77,78], combinatorial flame retardants may be the solution to flammability reduction of PP materials.

Figure 4.

FRI values as a function of nitrogen FR type and content. Symbols are indicative of different types of nitrogen flame retardant used. Here: ■ MP-40 [63],  MPPK-15, MPPK-20, MPPK-25 [64],

MPPK-15, MPPK-20, MPPK-25 [64],  MTP-15, MTP-20, MTP-25, MTP-30, m-MTP-30 [65],

MTP-15, MTP-20, MTP-25, MTP-30, m-MTP-30 [65],  MPyP-30 [57],

MPyP-30 [57],  MPyP-30, TA-CFA-30 [66],

MPyP-30, TA-CFA-30 [66],  TA-CFA-30 [39],

TA-CFA-30 [39],

TA-CFA-30 [40],

TA-CFA-30 [40],  TA-CFA-25 [37],

TA-CFA-25 [37],

TA-CFA-25 [32],

TA-CFA-25 [32],  TA-CA-ZnO-25 [29],

TA-CA-ZnO-25 [29],

TA-CA-25 [67],

TA-CA-25 [67],

TA-CA-20 [27],

TA-CA-20 [27],

TA-CA-20 [23],

TA-CA-20 [23],

TA-IFR-20 [68],

TA-IFR-20 [68],  TA-IFR-25 [31],

TA-IFR-25 [31],

PI-FR-25 [69],

PI-FR-25 [69],

PI-IFR-30 [70],

PI-IFR-30 [70],

PI-IFR-20, PI-IFR-30, PI-IFR-40 [71],

PI-IFR-20, PI-IFR-30, PI-IFR-40 [71],

NOR116-0.5 [72],

NOR116-0.5 [72],

NOR116-0.3 [73],

NOR116-0.3 [73],

PPU-CA-25 [50],

PPU-CA-25 [50],

N-FR-22, N-FR-25 [74],

N-FR-22, N-FR-25 [74],

N-IFR-5, N-IFR-10, N-IFR-15, N-IFR-20, N-IFR-25 [75],

N-IFR-5, N-IFR-10, N-IFR-15, N-IFR-20, N-IFR-25 [75],

N-IFR-25 [76],

N-IFR-25 [76],

PN-IFR-30 [56].

PN-IFR-30 [56].

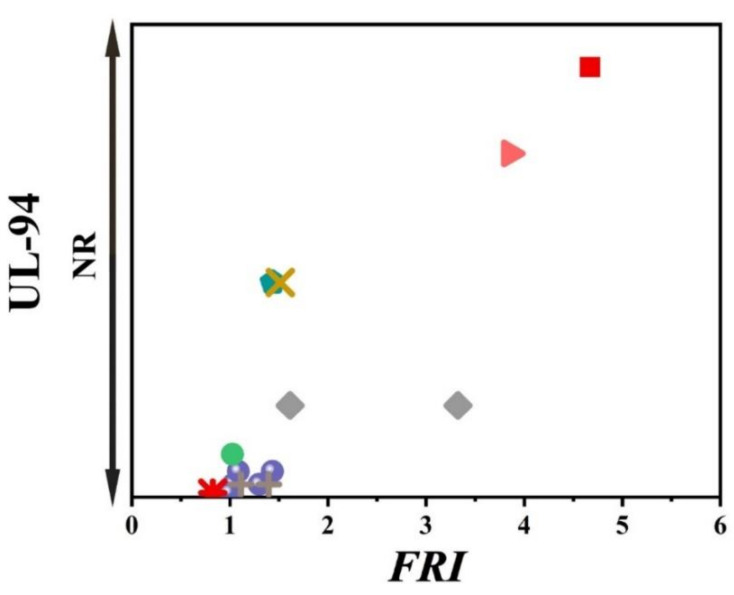

Figure 5 patterns UL-94 results as a function of FRI for nitrogen-based flame retardant in PP. It can be observed that even at small quantities of FRI, V0 in UL-94 was achieved. The diversity of data in Figure 5 can be taken as a signature of sensitivity of UL-94 to FRI. Figure 6 shows LOI values as a function of FRI. There is a quite reasonable correlation between the LOI and FRI values, up to FRI value of 6.

Figure 5.

FRI values versus UL-94 test results. Symbols are indicative of different types of nitrogen flame retardant (FR) used. The vertical intervals in each category, i.e., V-0, V-1, V-2, and NR, are schematically representative of the amount of additive used. For example, two data distinguished by different symbols having the same or very close FRI values (horizontal quantity) in a given category (e.g., V-1), may have different vertical quantities; e.g., both reveal V-1 behavior in UL-94 test, but the upper contains more FR in PP.

Figure 6.

FRI values of PP as a function of LOI test results. Symbols are indicative of different types of nitrogen flame retardant used.

4. Mineral-Based Flame Retardants

Mineral additives have been widely used in polymers for their acceptable cost and properties [79]. Mineral-based flame retardants including clays are widely used in PP due to their low cost and acceptable thermal resistance. In this family, the most used flame retardants in volume were aluminum trihydroxide (ATH) and magnesium dihydroxide (MDH). However, due to their low efficiency, a high percentage of loading was necessary for achieving an acceptable level of flame retardancy of polymers. The name and the percentage of the used mineral-based flame retardants in PP are listed in Table 3. Cone calorimetry data, FRI, LOI, and UL-94 values are also given so as to make possible a detailed view on the status of flame retardant efficiency of PP materials.

Table 3.

Flame-retardant PP materials containing mineral-based (M) flame retardants. Data are extracted from the literature: cone calorimetry parameters (TTI, pHRR, THR), LOI, and UL-94 values. The FRI values were calculated by authors of the present review. The name and the percentage of flame retardants are provided in separate columns. “wt.%” was used for loading level of additives, while “―” stands for the systems free of additive or the neat PP. * FR means flame retardant. Since all comparisons were made in terms of FRI, classification of polymers in terms of their flame-retardant properties was not surveyed based on the chemistry of additives, heat flux, sample thickness, etc.

| PP Containing Mineral-Based (M) FR * | wt.% | TTI (s) |

pHRR (kW·m−2) |

THR (MJ·m−2) | Irradiance (kW·m−2) |

Sample Thickness (mm) | FRI | LOI | UL-94 | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|

| ― | 37 | 1425 | 121.4 | 50 | 3 | ― | 17.3 | NR | [80] | |

| Aluminum trihydroxide (ATH) | 50 | 52 | 539 | 96.6 | 50 | 3 | 4.66 | 23.6 | NR | [80] |

| ― | 32 | 1470 | 175 | 50 | 4 | ― | 18 | ― | [81] | |

| ATH | 60 | 34 | 280 | 98 | 50 | 4 | 9.96 | 25.6 | ― | [81] |

| ― | 26 | 1967 | 112 | 50 | 3 | ― | ― | ― | [82] | |

| ATH | 20 | 27 | 817 | 90 | 50 | 3 | 3.11 | ― | ― | [82] |

| ATH | 40 | 28 | 467 | 70 | 50 | 3 | 7.25 | ― | ― | [82] |

| Magnesium dihydroxide (MDH) | 20 | 31 | 1000 | 98 | 50 | 3 | 2.68 | ― | ― | [82] |

| MDH | 40 | 34 | 433 | 75 | 50 | 3 | 8.87 | ― | ― | [82] |

| ― | 30 | 1684 | 89 | 50 | 3 | ― | ― | ― | [82] | |

| MDH | 40 | 3 | 377 | 71 | 50 | 3 | 0.55 | ― | ― | [82] |

| MDH | 60 | 29 | 228 | 51 | 50 | 3 | 12.46 | ― | ― | [82] |

| ― | 63.2 | 521.35 | 49.8 | 30 | ― | ― | ― | ― | [83] | |

| MDH | 62.5 | 81.1 | 115.5 | 75.7 | 30 | ― | 3.81 | ― | ― | [83] |

| ― | 71 | 2283 | 218 | 35 | 1 | ― | ― | ― | [84] | |

| MDH | 50 | 97 | 789 | 238 | 35 | 1 | 3.62 | ― | ― | [84] |

| ― | 38 | 1425 | 121.4 | 50 | 3 | ― | 17.5 | NR | [85] | |

| MDH | 40 | 46 | 548 | 99.1 | 50 | 3 | 3.85 | 23.3 | NR | [85] |

| ― | 29 | 1660 | 33.4 | 35 | 1 | ― | ― | ― | [86] | |

| MDH | 30 | 39 | 989 | 28.3 | 35 | 1 | 2.66 | ― | ― | [86] |

| Dodecanoic acid-treated MDH (m-MDH) | 30 | 32 | 882 | 28.7 | 35 | 1 | 2.41 | ― | ― | [86] |

| Dodecylphosphate treated MDH (m-MDH) | 30 | 29 | 651 | 28.8 | 35 | 1 | 2.95 | ― | ― | [86] |

| ― | 37 | 584 | 75.6 | 50 | 3 | ― | ― | ― | [87] | |

| MDH | 10 | 33 | 471 | 65.9 | 50 | 3 | 1.26 | ― | ― | [87] |

| MDH | 15 | 31 | 381 | 61.2 | 50 | 3 | 1.58 | ― | ― | [87] |

| ― | 54 | 930 | 140 | 35 | 4 | ― | ― | NR | [64] | |

| Kaolinite (Kaol) | 25 | 32 | 463 | 116 | 35 | 4 | 1.43 | ― | NR | [64] |

| ― | 29 | 1474 | 142 | 50 | 3 | ― | 18 | NR | [88] | |

| Kaol | 0.5 | 28 | 1429 | 142 | 50 | 3 | 0.99 | 18.3 | NR | [88] |

| Kaol | 1.5 | 27 | 1346 | 140 | 50 | 3 | 1.03 | 18.3 | NR | [88] |

| Kaol | 3 | 26 | 1279 | 135 | 50 | 3 | 1.08 | 18.4 | NR | [88] |

|

Ammonium sulfamate intercalated kaol

(m-Kaol) |

0.5 | 27 | 1389 | 141 | 50 | 3 | 0.99 | 18.4 | NR | [88] |

|

Ammonium sulfamate intercalated kaol

(m-Kaol) |

1.5 | 28 | 1169 | 133 | 50 | 3 | 1.29 | 18.6 | NR | [88] |

|

Ammonium sulfamate intercalated kaol

(m-Kaol) |

3 | 27 | 1079 | 126 | 50 | 3 | 1.43 | 18.7 | NR | [88] |

| ― | 27 | 1474 | 142 | 50 | ― | ― | 18 | NR | [89] | |

| Kaol | 1.5 | 27 | 1346 | 140 | 50 | ― | 1.11 | 18.3 | NR | [89] |

|

Ammonium sulfamate intercalated Kaol

(m-Kaol) |

1.5 | 28 | 1169 | 133 | 50 | ― | 1.39 | 18.6 | NR | [89] |

| ― | 44 | 1000 | 145 | 50 | ― | ― | ― | ― | [90] | |

| Kaol | 10 | 35 | 634 | 144 | 50 | ― | 1.26 | ― | ― | [90] |

| Kaol | 20 | 38 | 396 | 136 | 50 | ― | 2.33 | ― | ― | [90] |

| Kaol | 30 | 41 | 348 | 126 | 50 | ― | 3.08 | ― | ― | [90] |

| Trisilanolisooctyl polyhedral oligomeric silsesquioxane modified kaol (m-Kaol) | 10 | 35 | 850 | 140 | 50 | ― | 0.96 | ― | ― | [90] |

| Trisilanolisooctyl polyhedral oligomeric silsesquioxane modified kaol (m-Kaol) | 20 | 38 | 650 | 141 | 50 | ― | 1.36 | ― | ― | [90] |

| Trisilanolisooctyl polyhedral oligomeric silsesquioxane modified kaol (m-Kaol) | 30 | 50 | 430 | 137 | 50 | ― | 2.79 | ― | ― | [90] |

| Talc (TC) | 10 | 49 | 377 | 128 | 50 | ― | 3.34 | ― | ― | [90] |

| TC | 20 | 56 | 341 | 118 | 50 | ― | 4.58 | ― | ― | [90] |

| TC | 30 | 50 | 295 | 112 | 50 | ― | 4.98 | ― | ― | [90] |

| ― | 45 | 1831.96 | 110.8 | 50 | ― | ― | ― | ― | [91] | |

| Ni-Al layered double hydroxide (LDH) | 0.5 | 53 | 1635.53 | 106.8 | 50 | ― | 1.36 | ― | ― | [91] |

| Ni-Al LDH (LDH) | 1 | 92 | 1430.59 | 117.8 | 50 | ― | 2.46 | ― | ― | [91] |

| Ni-Al LDH (LDH) | 1.5 | 41 | 1266.66 | 129.1 | 50 | ― | 1.13 | ― | ― | [91] |

| Organically modified Ni-Al LDH (m-LDH) | 0.5 | 59 | 1116.37 | 70.2 | 50 | ― | 3.39 | ― | ― | [91] |

| Organically modified Ni-Al LDH (m-LDH) | 1 | 45 | 1026.86 | 81.24 | 50 | ― | 2.43 | ― | ― | [91] |

| Organically modified Ni-Al LDH (m-LDH) | 1.5 | 49 | 1254.95 | 111.1 | 50 | ― | 1.58 | ― | ― | [91] |

| Cu-Al LDH (LDH) | 0.5 | 45 | 1026.86 | 81.2 | 50 | ― | 2.43 | ― | ― | [91] |

| Cu-Al LDH (LDH) | 1 | 57 | 1276.46 | 123 | 50 | ― | 1.63 | ― | ― | [91] |

| Cu-Al LDH (LDH) | 1.5 | 50 | 1449.98 | 121.8 | 50 | ― | 1.27 | ― | ― | [91] |

| Organically modified Cu-Al LDH (m-LDH) | 0.5 | 69 | 985.91 | 120 | 50 | ― | 2.63 | ― | ― | [91] |

| Organically modified Cu-Al LDH (m-LDH) | 1 | 54 | 1175.99 | 121.6 | 50 | ― | 1.70 | ― | ― | [91] |

| Organically modified Cu-Al LDH (m-LDH) | 1.5 | 54 | 1345.14 | 114.3 | 50 | ― | 1.58 | ― | ― | [91] |

| ― | 20 | 1849 | 121 | 50 | 3 | ― | ― | ― | [92] | |

| Mg-Al LDH with mole ratio: Zn:Mg:Al/0:2:1 (A-LDH) | 1 | 15 | 1981 | 141 | 50 | 3 | 0.60 | ― | ― | [92] |

| A-LDH | 2 | 16 | 1764 | 139 | 50 | 3 | 0.73 | ― | ― | [92] |

| Zn-Mg-Al LDH with mole ratio: Zn:Mg:Al/0.5:1.5:1 (B-LDH) | 1 | 14 | 1997 | 136 | 50 | 3 | 0.57 | ― | ― | [92] |

| B-LDH | 2 | 14 | 1512 | 133 | 50 | 3 | 0.77 | ― | ― | [92] |

| B-LDH | 4 | 13 | 1153 | 128 | 50 | 3 | 0.98 | ― | ― | [92] |

| Zn-Mg-Al LDH with mole ratio: Zn:Mg:Al/1:1:1 (C-LDH) | 1 | 18 | 2004 | 135 | 50 | 3 | 0.74 | ― | ― | [92] |

| C-LDH | 2 | 14 | 1546 | 132 | 50 | 3 | 0.76 | ― | ― | [92] |

| C-LDH | 4 | 12 | 1225 | 125 | 50 | 3 | 0.87 | ― | ― | [92] |

| Zn-Mg-Al LDH with mole ratio: Zn:Mg:Al/1.5:0.5:1 (D-LDH) | 1 | 18 | 1938 | 135 | 50 | 3 | 0.76 | ― | ― | [92] |

| D-LDH | 2 | 15 | 1656 | 130 | 50 | 3 | 0.77 | ― | ― | [92] |

| D-LDH | 4 | 13 | 1294 | 123 | 50 | 3 | 0.91 | ― | ― | [92] |

| Zn-Al LDH with mole ratio: Zn:Mg:Al/2:0:1 (E-LDH) | 1 | 16 | 1977 | 136 | 50 | 3 | 0.66 | ― | ― | [92] |

| E-LDH | 2 | 17 | 1543 | 113 | 50 | 3 | 1.09 | ― | ― | [92] |

| E-LDH | 4 | 14 | 1382 | 126 | 50 | 3 | 0.89 | ― | ― | [92] |

| ― | 17 | 2380 | 140 | 50 | 3 | ― | ― | ― | [92] | |

| A-LDH | 1 | 20 | 1906 | 135 | 50 | 3 | 1.52 | ― | ― | [92] |

| A-LDH | 4 | 16 | 1137 | 129 | 50 | 3 | 2.13 | ― | ― | [92] |

| B-LDH | 1 | 17 | 1715 | 134 | 50 | 3 | 1.44 | ― | ― | [92] |

| B-LDH | 4 | 17 | 1025 | 124 | 50 | 3 | 2.62 | ― | ― | [92] |

| C-LDH | 1 | 16 | 1875 | 130 | 50 | 3 | 1.28 | ― | ― | [92] |

| C-LDH | 4 | 14 | 992 | 125 | 50 | 3 | 2.21 | ― | ― | [92] |

| D-LDH | 1 | 15 | 2008 | 135 | 50 | 3 | 1.08 | ― | ― | [92] |

| D-LDH | 4 | 16 | 997 | 126 | 50 | 3 | 2.49 | ― | ― | [92] |

| E-LDH | 1 | 17 | 1796 | 13 | 50 | 3 | 14.27 | ― | ― | [92] |

| E-LDH | 4 | 16 | 757 | 125 | 50 | 3 | 3.31 | ― | ― | [92] |

| ― | 26 | 1975 | 125 | 50 | 3 | ― | ― | ― | [92] | |

| A-LDH | 1 | 21 | 1831 | 149 | 50 | 3 | 0.73 | ― | ― | [92] |

| A-LDH | 4 | 23 | 1274 | 127 | 50 | 3 | 1.34 | ― | ― | [92] |

| B-LDH | 1 | 23 | 1838 | 135 | 50 | 3 | 0.88 | ― | ― | [92] |

| B-LDH | 4 | 18 | 1017 | 126 | 50 | 3 | 1.33 | ― | ― | [92] |

| C-LDH | 1 | 20 | 1676 | 137 | 50 | 3 | 0.82 | ― | ― | [92] |

| C-LDH | 4 | 17 | 981 | 124 | 50 | 3 | 1.32 | ― | ― | [92] |

| D-LDH | 1 | 19 | 1833 | 136 | 50 | 3 | 0.72 | ― | ― | [92] |

| D-LDH | 4 | 15 | 1061 | 126 | 50 | 3 | 1.06 | ― | ― | [92] |

| E-LDH | 1 | 18 | 1966 | 136 | 50 | 3 | 0.63 | ― | ― | [92] |

| E-LDH | 4 | 17 | 965 | 126 | 50 | 3 | 1.32 | ― | ― | [92] |

| ― | 23 | 1726 | 133 | 50 | 3 | ― | ― | ― | [92] | |

| A-LDH | 1 | 22 | 1763 | 121 | 50 | 3 | 1.02 | ― | ― | [92] |

| A-LDH | 4 | 20 | 1283 | 125 | 50 | 3 | 1.24 | ― | ― | [92] |

| C-LDH | 1 | 19 | 1795 | 131 | 50 | 3 | 0.80 | ― | ― | [92] |

| C-LDH | 4 | 16 | 897 | 121 | 50 | 3 | 1.47 | ― | ― | [92] |

| E-LDH | 1 | 21 | 1845 | 130 | 50 | 3 | 0.87 | ― | ― | [92] |

| E-LDH | 4 | 18 | 750 | 122 | 50 | 3 | 1.96 | ― | ― | [92] |

| ― | 16 | 1443 | 141 | 50 | 3 | ― | — | — | [93] | |

| Sodium dodecyl sulphate modified Ni-Al LDH (m-LDH) | 1 | 30 | 1100 | 122 | 50 | 3 | 2.84 | ― | ― | [93] |

| Sodium dodecyl sulphate modified Ni-Al LDH (m-LDH) | 3 | 32 | 1040 | 120 | 50 | 3 | 3.26 | ― | ― | [93] |

| Sodium dodecyl sulphate modified Ni-Al LDH (m-LDH) | 5 | 36 | 975 | 113 | 50 | 3 | 4.15 | ― | ― | [93] |

| ― | 44 | 1443 | 158 | 35 | 3 | ― | ― | ― | [94] | |

| Undecenoate modified Mg-Al LDH (m-LDH) | 3 | 40 | 1627 | 174 | 35 | 3 | 0.73 | ― | ― | [94] |

| Undecenoate modified Mg-Al LDH (m-LDH) | 5 | 32 | 1629 | 167 | 35 | 3 | 0.60 | ― | ― | [94] |

| Undecenoate modified Mg-Al LDH (m-LDH) | 10 | 42 | 1339 | 157 | 35 | 3 | 1.03 | ― | ― | [94] |

| ― | 31 | 1302 | 114 | 50 | 4 | ― | 17.8 | NR | [95] | |

| Carbonate intercalated Mg-Al LDH (LDH) | 10.7 | 22 | 837 | 78 | 50 | 4 | 1.61 | 19 | NR | [95] |

| Dihydrogen phosphate intercalated Mg-Al LDH (m-LDH) | 10.7 | 23 | 534 | 62 | 50 | 4 | 3.32 | 21.2 | NR | [95] |

| ― | 52 | 1792 | 219.4 | 35 | ― | ― | ― | ― | [96] | |

| Octadecyltrimethyl ammonium chloride (alkyl-NH4Cl) | 1.2 | 53 | 1463 | 215.6 | 35 | ― | 1.27 | ― | ― | [96] |

| Montmorillonite (MMT) | 5 | 45 | 1196 | 216.7 | 35 | ― | 1.31 | ― | ― | [96] |

| Protoned MMT (H-MMT) | 5 | 42 | 1000 | 211.4 | 35 | ― | 1.50 | ― | ― | [96] |

| Dioctadecyldimethyl ammonium chloride modified MMT (m-MMT) | 5 | 43 | 996 | 210.8 | 35 | ― | 1.54 | ― | ― | [96] |

| ― | 55 | 1740 | 219.8 | 35 | ― | ― | ― | ― | [96] | |

| Dioctadecyldimethyl ammonium chloride modified MMT (m-MMT) | 5 | 50 | 982 | 208.6 | 35 | ― | 1.69 | ― | ― | [96] |

| ― | 37 | 2655 | 131 | 35 | 3 | ― | ― | ― | [97] | |

| Methyl tallow bis(2-hydroxyethyl) ammonium modified MMT (m-MMT) | 4.75 | 27 | 1365 | 123 | 35 | 3 | 1.51 | ― | ― | [97] |

| Silica pillared methyl tallow bis(2-hydroxyethyl) ammonium modified MMT (m-MMT) | 4.75 | 22 | 2585 | 132 | 35 | 3 | 0.60 | ― | ― | [97] |

| Silica pillared methyl tallow bis(2-hydroxyethyl) ammonium modified MMT powder supported with CuO (m-MMT) | 4.75 | 24 | 2315 | 132 | 35 | 3 | 0.73 | ― | ― | [97] |

| ― | 14 | 1104 | 106 | 35 | 0.4 | ― | ― | ― | [24] | |

| MMT | 10 | 18 | 1005 | 99 | 35 | 0.4 | 1.51 | ― | ― | [24] |

| Modified MMT (m-MMT) | 10 | 19 | 925 | 98 | 35 | 0.4 | 1.75 | ― | ― | [24] |

| ― | 53 | 1896 | 102 | 35 | 3 | ― | ― | ― | [98] | |

| Alkylstyrene surfactant modified MMT (m-MMT) | 3 | 50 | 1502 | 99 | 35 | 3 | 1.22 | ― | ― | [98] |

| Alkylstyrene surfactant modified MMT (m-MMT) | 10 | 50 | 1200 | 94 | 35 | 3 | 1.61 | ― | ― | [98] |

| Alkylstyrene surfactant modified MMT (m-MMT) | 16 | 51 | 882 | 95 | 35 | 3 | 2.22 | ― | ― | [98] |

| ― | 60 | 1136 | 296 | 35 | ― | ― | ― | ― | [99] | |

| MMT | 2 | 51 | 633 | 295 | 35 | ― | 1.53 | ― | ― | [99] |

| Alkylammonium modified MMT (m-MMT) | 2 | 58 | 870 | 297 | 35 | ― | 1.25 | ― | ― | [99] |

| Alkylammonium modified MMT (m-MMT) | 5 | 55 | 459 | 295 | 35 | ― | 2.27 | ― | ― | [99] |

| Alkylammonium modified MMT (m-MMT) | 10 | 56 | 357 | 293 | 35 | ― | 3.00 | ― | ― | [99] |

| ― | 52 | 1897 | 101 | 35 | 3 | ― | ― | ― | [100] | |

| Ammonium salt of an oligomer modified MMT (m-MMT) | 3 | 48 | 1577 | 95 | 35 | 3 | 1.18 | ― | ― | [100] |

| Ammonium salt of an oligomer modified MMT (m-MMT) | 8 | 49 | 1309 | 97 | 35 | 3 | 1.42 | ― | ― | [100] |

| Ammonium salt of an oligomer modified MMT (m-MMT) | 12 | 52 | 1160 | 93 | 35 | 3 | 1.77 | ― | ― | [100] |

| ― | 43 | 1845 | 118 | 50 OR 35 | — | ― | — | — | [101] | |

| Styrene-vinylbenzyl chloride copolymer modified MMT (m-MMT) | 2.5 | 47 | 1953 | 114 | 50 OR 35 | — | 1.06 | ― | ― | [101] |

| Styrene-vinylbenzyl chloride copolymer modified MMT (m-MMT) | 5 | 45 | 1889 | 111 | 50 OR 35 | — | 1.08 | ― | ― | [101] |

| Styrene-vinylbenzyl chloride copolymer modified MMT (m-MMT) | 15 | 37 | 1448 | 108 | 50 OR 35 | — | 1.19 | ― | ― | [101] |

| Styrene-vinylbenzyl chloride copolymer modified MMT (m-MMT) | 25 | 38 | 1191 | 102 | 50 OR 35 | — | 1.58 | ― | ― | [101] |

| Methyl methacrylate-vinylbenzyl chloride copolymer modified MMT (m-MMT) | 2.5 | 44 | 2025 | 123 | 50 OR 35 | — | 0.89 | ― | ― | [101] |

| Methyl methacrylate-vinylbenzyl chloride copolymer modified MMT (m-MMT) | 5 | 42 | 1738 | 120 | 50 OR 35 | — | 1.01 | ― | ― | [101] |

| Methyl methacrylate-vinylbenzyl chloride copolymer modified MMT (m-MMT) | 15 | 39 | 1651 | 115 | 50 OR 35 | — | 1.04 | ― | ― | [101] |

| Methyl methacrylate-vinylbenzyl chloride copolymer modified MMT (m-MMT) | 25 | 41 | 1139 | 105 | 50 OR 35 | — | 1.73 | ― | ― | [101] |

| ― | 55 | 1586 | 113 | 35 | — | ― | — | — | [102] | |

|

Methyl methacrylate modified MMT

(m-MMT) |

1 | 66 | 1108 | 104 | 35 | ― | 1.86 | ― | ― | [102] |

|

Methyl methacrylate modified MMT

(m-MMT) |

3 | 44 | 839 | 87 | 35 | ― | 1.96 | ― | ― | [102] |

|

Methyl methacrylate modified MMT

(m-MMT) |

5 | 35 | 557 | 77 | 35 | ― | 2.65 | ― | ― | [102] |

| ― | 50.2 | 789 | 156.6 | 35 | ― | ― | 17.5 | ― | [103] | |

| Nanofil (Nf) | 5 | 48 | 739 | 173.4 | 35 | ― | 0.92 | 22 | ― | [103] |

| Organically modified bentonite (m-BT) | 5 | 45.6 | 774 | 166.6 | 35 | ― | 0.87 | 22 | ― | [103] |

| ― | 33 | 847 | 159.8 | 50 | ― | ― | 17.5 | ― | [103] | |

| Nf | 5 | 37 | 1047 | 174 | 50 | ― | 0.83 | 22 | ― | [103] |

| m-BT | 5 | 36 | 1093 | 164 | 50 | ― | 0.82 | 22 | ― | [103] |

| ― | 35 | 1622 | 103 | 35 | 3 | ― | ― | ― | [104] | |

| Cloisite 20A: Dimethyl, dihydrogenated tallow ammonium modified MMT (C20A) | 1 | 33 | 1751 | 105 | 35 | 3 | 0.85 | ― | ― | [104] |

| C20A | 3 | 34 | 1874 | 107 | 35 | 3 | 0.80 | ― | ― | [104] |

| C20A | 5 | 39 | 1487 | 105 | 35 | 3 | 1.19 | ― | ― | [104] |

| 44 | 1172 | 87.1 | 35 | 2.5 | ― | 18.1 | NR | [60] | ||

| Cloisite 15A: dimethyl dehydrogenated tallow ammonium cation modified sodium MMT (C15A) | 5 | 41 | 1050 | 88.2 | 35 | 2.5 | 1.02 | 18.1 | NR | [60] |

| ― | 88 | 565.9 | 71.9 | 35 | 3 | ― | ― | ― | [105] | |

| C20A | 5 | 76 | 518.2 | 75.9 | 35 | 3 | 0.89 | 20 | ― | [105] |

| C20A | 5 | 89 | 415.6 | 73 | 35 | 3 | 1.35 | 20 | ― | [105] |

| Titanium dioxide (TiO2) | 0.5 | 99 | 488.1 | 75 | 35 | 3 | 1.25 | 20 | ― | [105] |

| ― | 49 | 1247 | 114.2 | 35 | ― | ― | ― | ― | [106] | |

| Activated alumina (Al2O3) | 2 | 35 | 943 | 108.2 | 35 | ― | 0.99 | ― | ― | [106] |

| ― | 28 | 1633 | 132 | 50 | 4 | ― | 18 | ― | [107] | |

| NiFeO | 2 | 27 | 1372 | 129 | 50 | 4 | 1.17 | 18 | ― | [107] |

| CoFeO | 2 | 24 | 1335 | 127 | 50 | 4 | 1.08 | 18 | ― | [107] |

| ― | 38 | 1284 | 241 | 50 | 6 | ― | ― | ― | [108] | |

| Ni2O3 | 7.5 | 53 | 655 | 161 | 50 | 6 | 4.09 | ― | ― | [108] |

| ― | 64 | 1909 | 254 | 50 | 3 | ― | ― | ― | [109] | |

| Mo/Mg/Ni/O catalysts (Nmm-cat) | 1 | 62 | 490 | 205 | 50 | 3 | 4.67 | ― | ― | [109] |

| Nmm-cat | 2 | 63 | 292 | 168 | 50 | 3 | 9.72 | ― | ― | [109] |

| Nmm-cat | 3 | 60 | 275 | 149 | 50 | 3 | 11.09 | ― | ― | [109] |

| ― | 52 | 915.7 | 112.5 | 50 | 3 | ― | 18 | ― | [110] | |

| Magnesium oxysulfate whisker (MOSw) | 30 | 62 | 259.1 | 90.4 | 50 | 3 | 5.24 | 24.7 | ― | [110] |

| Dodecyl dihydrogen phosphate modified MOSw (m-MOSw) | 30 | 64 | 243.3 | 72.8 | 50 | 3 | 7.15 | 26.1 | ― | [110] |

| ― | 48 | 195.5 | 28.6 | 35 | 2 | ― | ― | ― | [111] | |

| Manganese oxide (MnO) | 10 | 54 | 233.7 | 31.8 | 35 | 2 | 0.84 | ― | ― | [111] |

| Manganese oxide (Mn2O3) | 10 | 48 | 271.3 | 31.5 | 35 | 2 | 0.65 | ― | ― | [111] |

| Manganese oxalate (MnC2O4) | 10 | 50 | 281.6 | 29.3 | 35 | 2 | 0.70 | ― | ― | [111] |

| ― | 30 | 390 | 44 | 35 | 1.6 | ― | 17.4 | ― | [53] | |

| Zinc acetyl acetonate (Znacac) | 1 | 31 | 366 | 28 | 35 | 1.6 | 1.73 | 19.5 | ― | [53] |

| Chromium acetyl acetonate (Cracac) | 1 | 31 | 307 | 28 | 35 | 1.6 | 2.06 | 20.7 | ― | [53] |

| ― | 51 | 1053 | 117.6 | 35 | 3 | ― | ― | ― | [112] | |

| Zirconium phenylphosphonate (ZrPP) | 2 | 34 | 754 | 99.4 | 35 | 3 | 1.10 | ― | ― | [112] |

| ― | 40 | 364 | 40 | 35 | 2 | ― | ― | ― | [113] | |

| Siloxane silsesquioxane resin (S4SQH) | 1 | 41 | 354 | 47 | 35 | 2 | 0.89 | ― | ― | [113] |

| S4SQH | 5 | 21 | 500 | 44 | 35 | 2 | 0.34 | ― | ― | [113] |

| S4SQH | 10 | 19 | 445 | 44 | 35 | 2 | 0.35 | ― | ― | [113] |

| n-octyl functionalized S4SQH (m-S4SQH) | 1 | 43 | 227 | 29 | 35 | 2 | 2.37 | ― | ― | [113] |

| n-octyl functionalized S4SQH (m-S4SQH) | 5 | 40 | 481 | 48 | 35 | 2 | 0.63 | ― | ― | [113] |

| n-octadecyl functionalized S4SQH (m-S4SQH) | 1 | 40 | 168 | 22 | 35 | 2 | 3.93 | ― | ― | [113] |

| n-octadecyl functionalized S4SQH (m-S4SQH) | 5 | 43 | 328 | 42 | 35 | 2 | 1.13 | ― | ― | [113] |

| n-octadecyl functionalized S4SQH (m-S4SQH) | 10 | 47 | 391 | 47 | 35 | 2 | 0.93 | ― | ― | [113] |

| ― | 25 | 981 | 147 | 50 | ― | ― | 17.6 | NR | [30] | |

| Polysiloxane based FR (Si-FR) | 25 | 18 | 624 | 110 | 50 | ― | 1.51 | 24.1 | NR | [30] |

| ― | 54 | 1610 | 106 | 35 | 3 | ― | 20.8 | NR | [25] | |

| Sepiolite (SEP) | 0.5 | 48 | 1701 | 108 | 35 | 3 | 0.82 | 20 | NR | [25] |

| Organically modified SEP (m-SEP) | 0.5 | 46 | 1665 | 106 | 35 | 3 | 0.82 | 19.2 | NR | [25] |

| ― | 37 | 584 | 75.6 | 50 | 3 | ― | ― | ― | [87] | |

| SEP | 5 | 24 | 533 | 68.1 | 50 | 3 | 0.78 | ― | ― | [87] |

| Organically treated SEP (m-SEP) | 5 | 23 | 515 | 66.1 | 50 | 3 | 0.80 | ― | ― | [87] |

| ― | 60 | 968 | 100 | 35 | 3 | ― | 19.2 | ― | [114] | |

| Methyl polyhedral oligomeric silsesquioxane (me-POSS) | 1.95 | 54 | 1023 | 100 | 35 | 3 | 0.85 | – | ― | [114] |

| me-POSS | 6.5 | 60 | 786 | 96 | 35 | 3 | 1.28 | 19.2 | ― | [114] |

| Phenyl POSS (ph-POSS) | 3.75 | 61 | 858 | 98 | 35 | 3 | 1.17 | – | ― | [114] |

| ph-POSS | 12.5 | 53 | 872 | 96 | 35 | 3 | 1.02 | 19.5 | ― | [114] |

| ― | 56 | 1103 | 111 | 35 | 3 | ― | ― | ― | [115] | |

| Octaisobutyl POSS (T8-POSS) | 10 | 50 | 1325 | 112 | 35 | 3 | 0.73 | ― | ― | [115] |

| Al-POSS | 10 | 37 | 624 | 98 | 35 | 3 | 1.32 | ― | ― | [115] |

| Zn-POSS | 10 | 54 | 1069 | 108 | 35 | 3 | 1.02 | ― | ― | [115] |

| ― | 54 | 1242 | 221 | 35 | 6 | ― | 17.5 | ― | [5] | |

| Silica aerogel (SA) | 10 | 57 | 892 | 203 | 35 | 6 | 1.60 | 25.1 | ― | [5] |

| ― | 49.5 | 622 | 74.5 | 50 | 3 | ― | ― | ― | [116] | |

| Halloysite nanotube (HNT) | 8 | 44 | 495 | 68.5 | 50 | 3 | 1.21 | ― | ― | [116] |

| HNT-Water injection (HNT-W) | 8 | 45.5 | 451 | 66.5 | 50 | 3 | 1.42 | ― | ― | [116] |

| ― | 52.5 | 620 | 70.5 | 50 | 3 | ― | ― | ― | [116] | |

| HNT | 8 | 48 | 495 | 67 | 50 | 3 | 1.20 | ― | ― | [116] |

| HNT-W | 4 | 49 | 507 | 66.5 | 50 | 3 | 1.21 | ― | ― | [116] |

| HNT-W | 8 | 46 | 367 | 60.5 | 50 | 3 | 1.72 | ― | ― | [116] |

| HNT-W | 16 | 42.5 | 219 | 55 | 50 | 3 | 2.93 | ― | ― | [116] |

| ― | 35 | 749 | 90.1 | 50 | 3 | ― | ― | ― | [117] | |

| HNT | 5 | 34 | 936.7 | 98 | 50 | 3 | 0.71 | ― | ― | [117] |

| HNT | 10 | 31 | 773.6 | 99.3 | 50 | 3 | 0.77 | ― | ― | [117] |

| HNT | 15 | 32 | 557.9 | 91.9 | 50 | 3 | 1.20 | ― | ― | [117] |

|

Melamine and phytic acid modified HNT

(m-HNT) |

5 | 30 | 713.2 | 89.4 | 50 | 3 | 0.90 | ― | ― | [117] |

|

Melamine and phytic acid modified HNT

(m-HNT) |

10 | 28 | 708.4 | 93.4 | 50 | 3 | 0.81 | ― | ― | [117] |

|

Melamine and phytic acid modified HNT

(m-HNT) |

15 | 27 | 678.8 | 89.3 | 50 | 3 | 0.85 | ― | ― | [117] |

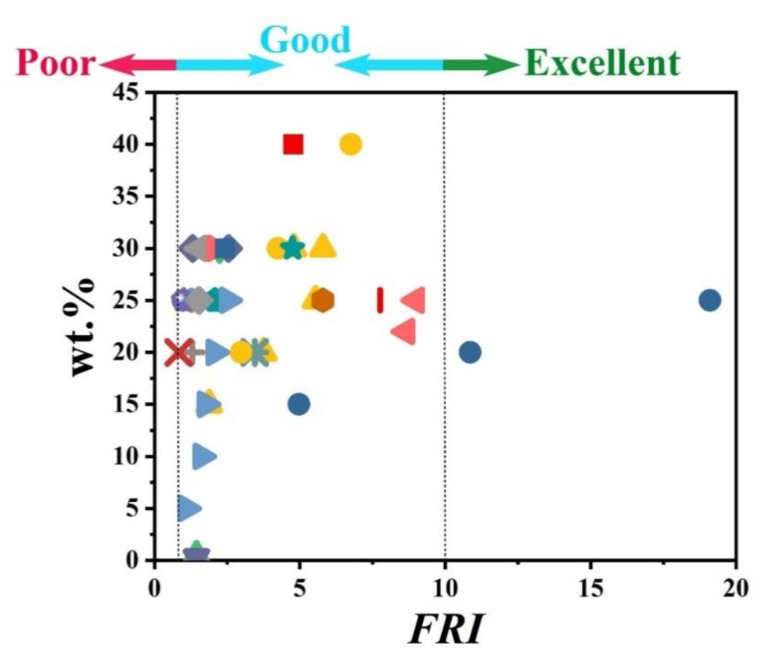

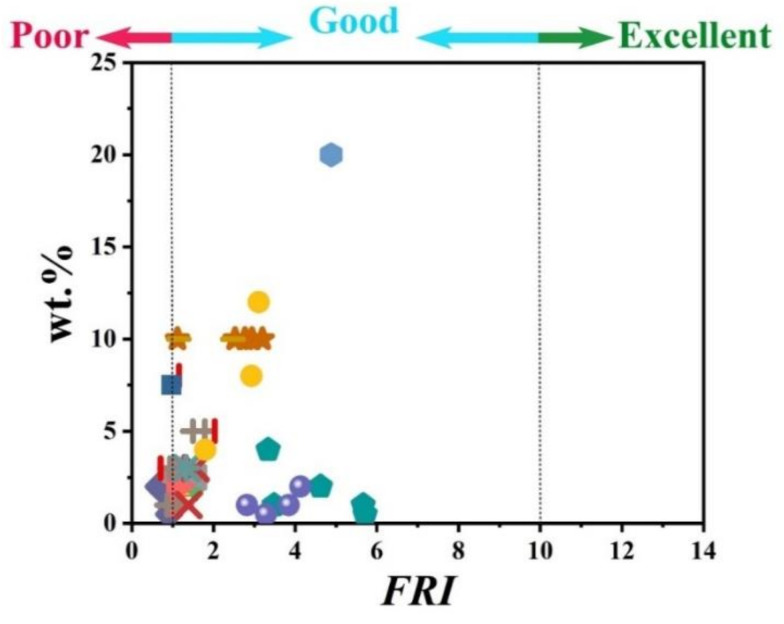

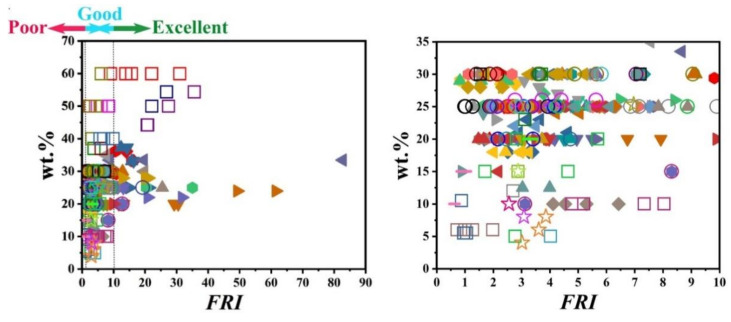

Figure 7 visualizes the variation of FRI value as a function of flame retardant loading in PP systems (for the convenience of readers, two figures are added for giving a better zoom on data points). This figure clearly shows that even at low loading percentages, it is possible to achieve a relatively high FRI value depending on the type of mineral. There is no denying that some parameters such as the state of dispersion and size of particles are important factors affecting the flame retardant properties.

Figure 7.

FRI values as a function of the mineral FR type and content from close-up and long-shot views. Symbols are indicative of different types of mineral flame retardant used. The diversity and abundance of data were reasons why such different scales were provided for detection of behavior of PP against flame. Here: ■ ATH-50 [80],  ATH-60 [81],

ATH-60 [81],

ATH-20, ATH-40, MDH-20, MDH-40 [82],

ATH-20, ATH-40, MDH-20, MDH-40 [82],

MDH-40, MDH-60 [82],

MDH-40, MDH-60 [82],  MDH-62.5 [83],

MDH-62.5 [83],

MDH-50 [84],

MDH-50 [84],

MDH-40 [85],

MDH-40 [85],

MDH-30, m-MDH-30, m-MDH-30 [86],

MDH-30, m-MDH-30, m-MDH-30 [86],

MDH-10, MDH-15 [87],

MDH-10, MDH-15 [87],

Kaol-25 [64],

Kaol-25 [64],

Kaol-0.5, Kaol-1.5, Kaol-3, m-Kaol-0.5, m-Kaol-1.5, m-Kaol-3 [88],

Kaol-0.5, Kaol-1.5, Kaol-3, m-Kaol-0.5, m-Kaol-1.5, m-Kaol-3 [88],

Kaol-1.5, m-Kaol-1.5 [89],

Kaol-1.5, m-Kaol-1.5 [89],

Kaol-10, Kaol-20, Kaol-30, m-Kaol-10, m-Kaol-20, m-Kaol-30, TC-10, TC-20, TC-30 [90],

Kaol-10, Kaol-20, Kaol-30, m-Kaol-10, m-Kaol-20, m-Kaol-30, TC-10, TC-20, TC-30 [90],

LDH-0.5, LDH-1, LDH-1.5, m-LDH-0.5, m-LDH-1, m-LDH-1.5, LDH-0.5, LDH-1, LDH-1.5, m-LDH-0.5, m-LDH-1, m-LDH-1.5 [91],

LDH-0.5, LDH-1, LDH-1.5, m-LDH-0.5, m-LDH-1, m-LDH-1.5, LDH-0.5, LDH-1, LDH-1.5, m-LDH-0.5, m-LDH-1, m-LDH-1.5 [91],

A-LDH-1, A-LDH-2, B-LDH-1, B-LDH-2, B-LDH-4, C-LDH-1, C-LDH-2, C-LDH-4, D-LDH-1, D-LDH-2, D-LDH-4, E-LDH-1, E-LDH-2, E-LDH-4 [92],

A-LDH-1, A-LDH-2, B-LDH-1, B-LDH-2, B-LDH-4, C-LDH-1, C-LDH-2, C-LDH-4, D-LDH-1, D-LDH-2, D-LDH-4, E-LDH-1, E-LDH-2, E-LDH-4 [92],

A-LDH-1, A-LDH-4, B-LDH-1, B-LDH-4, C-LDH-1, C-LDH-4, D-LDH-1, D-LDH-4, E-LDH-1, E-LDH-4 [92],

A-LDH-1, A-LDH-4, B-LDH-1, B-LDH-4, C-LDH-1, C-LDH-4, D-LDH-1, D-LDH-4, E-LDH-1, E-LDH-4 [92],

A-LDH-1, A-LDH-4, B-LDH-1, B-LDH-4, C-LDH-1, C-LDH-4, D-LDH-1, D-LDH-4, E-LDH-1, E-LDH-4 [92],

A-LDH-1, A-LDH-4, B-LDH-1, B-LDH-4, C-LDH-1, C-LDH-4, D-LDH-1, D-LDH-4, E-LDH-1, E-LDH-4 [92],

A-LDH-1, A-LDH-4, C-LDH-1, C-LDH-4, E-LDH-1, E-LDH-4 [92],

A-LDH-1, A-LDH-4, C-LDH-1, C-LDH-4, E-LDH-1, E-LDH-4 [92],

m-LDH-1, m-LDH-3, m-LDH-5 [93],

m-LDH-1, m-LDH-3, m-LDH-5 [93],

m-LDH-3, m-LDH-5, m-LDH-10 [94],

m-LDH-3, m-LDH-5, m-LDH-10 [94],

LDH-10.7, m-LDH-10.7 [95],

LDH-10.7, m-LDH-10.7 [95],

alkyl-NH4Cl-1.2, MMT-5, H-MMT-5, m-MMT-5 [96],

alkyl-NH4Cl-1.2, MMT-5, H-MMT-5, m-MMT-5 [96],

m-MMT-5 [96],

m-MMT-5 [96],

m-MMT-4.75, m-MMT-4.75, m-MMT-4.75 [97],

m-MMT-4.75, m-MMT-4.75, m-MMT-4.75 [97],

MMT-10, m-MMT-10 [24],

MMT-10, m-MMT-10 [24],

m-MMT-3, m-MMT-10, m-MMT-16 [98],

m-MMT-3, m-MMT-10, m-MMT-16 [98],

MMT-2, m-MMT-2, m-MMT-5, m-MMT-10 [99],

MMT-2, m-MMT-2, m-MMT-5, m-MMT-10 [99],

m-MMT-3, m-MMT-8, m-MMT-12 [100],

m-MMT-3, m-MMT-8, m-MMT-12 [100],

m-MMT-2.5, m-MMT-5, m-MMT-15, m-MMT-25, m-MMT-2.5, m-MMT-5, m-MMT-15, m-MMT-25 [101],

m-MMT-2.5, m-MMT-5, m-MMT-15, m-MMT-25, m-MMT-2.5, m-MMT-5, m-MMT-15, m-MMT-25 [101],

m-MMT-1, m-MMT-3, m-MMT-5 [102],

m-MMT-1, m-MMT-3, m-MMT-5 [102],

Nf-5, m-BT-5 [103],

Nf-5, m-BT-5 [103],

Nf-5, m-BT-5 [103],

Nf-5, m-BT-5 [103],

C20A-1, C20A-3, C20A-5 [104],

C20A-1, C20A-3, C20A-5 [104],

C15A-5 [60],

C15A-5 [60],

C20A-5, C20A-5, TiO2-0.5 [105],

C20A-5, C20A-5, TiO2-0.5 [105],

Al2O3-2 [106],

Al2O3-2 [106],

NiFeO-2, CoFeO-2 [107],

NiFeO-2, CoFeO-2 [107],

Ni2O3-7.5 [108],

Ni2O3-7.5 [108],

Nmm-cat-1, Nmm-cat-2, Nmm-cat-3 [109],

Nmm-cat-1, Nmm-cat-2, Nmm-cat-3 [109],

MOSw-30, m-MOSw-30 [110],

MOSw-30, m-MOSw-30 [110],

MnO-10, Mn2O3-10, MnC2O4-10 [111],

MnO-10, Mn2O3-10, MnC2O4-10 [111],

Znacac-1, Cracac-1 [53],

Znacac-1, Cracac-1 [53],

ZrPP-2 [112],

ZrPP-2 [112],

S4SQH-1, S4SQH-5, S4SQH-10, m-S4SQH-1, m-S4SQH-5, m-S4SQH-1, m-S4SQH-5, m-S4SQH-10 [113],

S4SQH-1, S4SQH-5, S4SQH-10, m-S4SQH-1, m-S4SQH-5, m-S4SQH-1, m-S4SQH-5, m-S4SQH-10 [113],

Si-FR-25 [30],

Si-FR-25 [30],

SEP-0.5, m-SEP-0.5 [25],

SEP-0.5, m-SEP-0.5 [25],  SEP-5, m-SEP-5 [87],

SEP-5, m-SEP-5 [87],

me-POSS-1.95, me-POSS-6.5, ph-POSS-3.75, ph-POSS-12.5 [114],

me-POSS-1.95, me-POSS-6.5, ph-POSS-3.75, ph-POSS-12.5 [114],

T8-POSS-10, Al-POSS-10, Zn-POSS-10 [115],

T8-POSS-10, Al-POSS-10, Zn-POSS-10 [115],

SA-10 [5],

SA-10 [5],

HNT-8, HNT-W-8 [116],

HNT-8, HNT-W-8 [116],

HNT-8, HNT-W-4, HNT-W-8, HNT-W-16 [116],

HNT-8, HNT-W-4, HNT-W-8, HNT-W-16 [116],

HNT-5, HNT-10, HNT-15, m-HNT-5, m-HNT-10, m-HNT-15 [117].

HNT-5, HNT-10, HNT-15, m-HNT-5, m-HNT-10, m-HNT-15 [117].

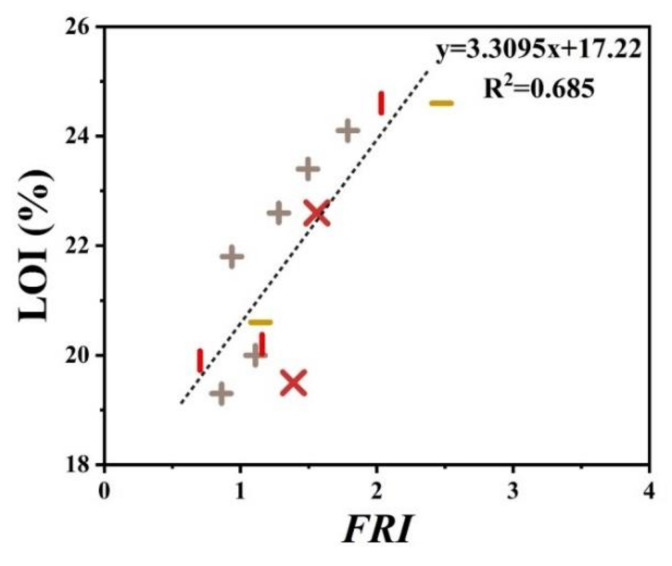

Unfortunately, the number of papers in which cone calorimetry, UL-94, and LOI values were studied was indeed limited, but the ones available are used plotting Figure 8. It should be noted that no formulation among studied ones is rated at V0. In conclusion, it is quite difficult to find a correlation between quantitative and qualitative parameters based on such a tiny set of data. In regard to the relationship between LOI and FRI, a meaningful trend can still be seen in Figure 9.

Figure 8.

FRI values versus UL-94 test results. Symbols are indicative of different types of mineral flame retardant (FR) used. The vertical intervals in each category, i.e., V-0, V-1, V-2, and NR, are schematically representative of the amount of additive used. For example, two data distinguished by different symbols having the same or very close FRI values (horizontal quantity) in a given category (e.g., V-1), may have different vertical quantities, e.g., both reveal V-1 behavior in UL-94 test, but the upper contains more FR in PP.

Figure 9.

FRI values of PP as a function of LOI test results. Symbols are indicative of different types of mineral flame retardant used.

5. Carbon-Based Flame Retardants

Carbon-based additives have been widely used in developing polymer composites and nanocomposites [118,119,120,121]. However, due to expense and limited interaction with PP, a few works based on carbon-based flame retardants have been reported on flame-retardant PP materials. Table 4 summarizes all information available on the flame-retardant PP materials containing carbon-based additives.

Table 4.

Flame-retardant PP materials containing carbon-based (C) flame retardants. Data are extracted from the literature: cone calorimetry parameters (TTI, pHRR, THR), LOI, and UL-94 values. The FRI values were calculated by authors of the present review. The name and the percentage of flame retardants are provided in separate columns. “wt.%” was used for loading level of additives, while “―” stands for the systems free of additive or the neat PP. * FR means flame retardant. Since all comparisons were made in terms of FRI, classification of polymers in terms of their flame-retardant properties was not surveyed based on the chemistry of additives, heat flux, sample thickness, etc.

| PP Containing Carbon-Based (C) FR * | wt.% | TTI (s) |

pHRR (kW·m−2) |

THR (MJ·m−2) |

Irradiance (kW·m−2) |

Sample Thickness (mm) | FRI | LOI | UL-94 | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|

| ― | 49 | 1247 | 114.2 | 35 | ― | ― | ― | ― | [106] | |

| Graphene (GN) | 2 | 35 | 989 | 107.9 | 35 | ― | 0.95 | ― | ― | [106] |

| Activated alumina decorated GN (m-GN) | 2 | 41 | 866 | 110.5 | 35 | ― | 1.24 | ― | ― | [106] |

| ― | 51 | 1053 | 118.4 | 35 | 3 | ― | ― | ― | [122] | |

| P-phenylenediamine modified reduced graphene oxide (m–rGNO) | 2 | 33 | 928 | 104 | 35 | 3 | 0.83 | ― | ― | [122] |

|

Polyaniline nanofiber modified rGNO

(m–rGNO) |

2 | 27 | 763 | 98.4 | 35 | 3 | 0.87 | ― | ― | [122] |

| ― | 45 | 1230 | 113.6 | 35 | 3 | ― | ― | ― | [123] | |

| rGNO | 2 | 30 | 1105 | 97.5 | 35 | 3 | 0.86 | ― | ― | [123] |

| Hexachlorocyclotriphosphazene modified rGNO (m–rGNO) | 2 | 27 | 967 | 112.9 | 35 | 3 | 0.76 | ― | ― | [123] |

|

Hexachlorocyclotriphosphazene modified rGNO decoration with Ni(OH)2 nanosheet

(m–rGNO) |

2 | 35 | 829 | 92 | 35 | 3 | 1.42 | ― | ― | [123] |

| ― | 51 | 1053 | 117.6 | 35 | 3 | ― | ― | ― | [112] | |

| rGNO | 2 | 31 | 835 | 98.3 | 35 | 3 | 0.91 | ― | ― | [112] |

| Zirconium phenylphosphonate decorated rGNO (m-rGNO) | 2 | 39 | 676 | 89.8 | 35 | 3 | 1.55 | ― | ― | [112] |

| ― | 50 | 1044 | 101.4 | 35 | 3 | ― | ― | ― | [124] | |

| Graphene oxide (GNO) | 2 | 33 | 979 | 108.2 | 35 | 3 | 0.65 | ― | ― | [124] |

| Melamine modified GNO (m-GNO) | 0.5 | 40 | 892 | 104.1 | 35 | 3 | 0.91 | ― | ― | [124] |

| Melamine modified GNO (m-GNO) | 1 | 37 | 834 | 100.6 | 35 | 3 | 0.93 | ― | ― | [124] |

| Melamine modified GNO (m-GNO) | 2 | 33 | 739 | 98.7 | 35 | 3 | 0.95 | ― | ― | [124] |

| ― | 38 | 1526 | 47.4 | 35 | ― | ― | ― | ― | [125] | |

| GN | 2.5 | 39 | 1279 | 58.8 | 35 | ― | 0.98 | ― | ― | [125] |

| GN-Nickel oxide (GN-NiO) | 2.5 | 35 | 1110 | 45.4 | 35 | ― | 1.32 | ― | ― | [125] |

| GN and Ni–Ce mixed oxide (GN-NiCexOy) | 2.5 | 32 | 956 | 39.2 | 35 | ― | 1.62 | ― | ― | [125] |

| ― | 32 | 909 | 45.8 | 35 | ― | ― | ― | ― | [126] | |

| rGNO | 2 | 28 | 778 | 40 | 35 | ― | 1.17 | ― | ― | [126] |

|

Phosphomolybdic acid modified rGNO

(m-rGNO) |

1 | 27 | 773 | 39.6 | 35 | ― | 1.14 | ― | ― | [126] |

|

Phosphomolybdic acid modified rGNO

(m-rGNO) |

2 | 23 | 737 | 38.4 | 35 | ― | 1.05 | ― | ― | [126] |

|

Phosphomolybdic acid modified rGNO

(m-rGNO) |

3 | 25 | 700 | 38.4 | 35 | ― | 1.21 | ― | ― | [126] |

| ― | 54 | 1199 | 97.8 | 35 | ― | ― | ― | ― | [58] | |

| Poly(4,4-diaminodiphenyl methane spirocyclicpentaerythritol bisphosphonate)-4,4-diaminodiphenyl methane modified rGNO (m-rGNO) | 20 | 66 | 397 | 73.9 | 35 | ― | 4.88 | ― | ― | [58] |

| ― | 66 | 383 | 76 | 35 | 3 | ― | ― | ― | [127] | |

| Expandable graphite with commercial name ES 350 F5 (EG(ES 350 F5)) | 10 | 32 | 91 | 56 | 35 | 3 | 2.76 | ― | ― | [127] |

| EG with commercial name ES 700 F5 (EG(ES 700 F5)) | 10 | 35 | 92 | 57 | 35 | 3 | 2.94 | ― | ― | [127] |

| EG with commercial name Nyagraph FP (EG(Nyagraph FP)) | 10 | 44 | 92 | 66 | 35 | 3 | 3.19 | ― | ― | [127] |

| EG with commercial name TEG 315 (EG(TEG 315)) | 10 | 53 | 134 | 69 | 35 | 3 | 2.52 | ― | ― | [127] |

| EG with commercial name Nyagraph KP251 (EG(Nyagraph KP251)) | 10 | 54 | 308 | 69 | 35 | 3 | 1.12 | ― | ― | [127] |

| ― | 38 | 1361 | 85 | 35 | 3 | ― | ― | ― | [128] | |

| Carbon nanotube (CNT) | 1 | 37 | 431 | 75 | 35 | 3 | 3.48 | ― | ― | [128] |

| Modofied CNT (m-CNT) | 0.5 | 42 | 361 | 62 | 35 | 3 | 5.71 | ― | ― | [128] |

| Modofied CNT (m-CNT) | 1 | 42 | 342 | 66 | 35 | 3 | 5.66 | ― | ― | [128] |

| Modofied CNT (m-CNT) | 2 | 41 | 386 | 70 | 35 | 3 | 4.61 | ― | ― | [128] |

| Modofied CNT (m-CNT) | 4 | 39 | 450 | 79 | 35 | 3 | 3.33 | ― | ― | [128] |

| ― | 40 | 1360 | 80 | 35 | 3 | ― | ― | ― | [129] | |

| CNT | 1 | 35 | 462 | 73 | 35 | 3 | 2.82 | ― | ― | [129] |

| Fullerene C60 decorated CNT (m-CNT) | 0.5 | 38 | 443 | 71 | 35 | 3 | 3.28 | ― | ― | [129] |

| Fullerene C60 decorated CNT (m-CNT) | 1 | 39 | 400 | 69 | 35 | 3 | 3.84 | ― | ― | [129] |

| Fullerene C60 decorated CNT (m-CNT) | 2 | 38 | 385 | 65 | 35 | 3 | 4.13 | ― | ― | [129] |

| ― | 35 | 1203 | 208 | 50 | 6 | ― | 18.2 | ― | [130] | |

| Multiwall carbon nanotube (MWCNT) | 1 | 24 | 945 | 211 | 50 | 6 | 0.86 | 19.3 | ― | [130] |

| MWCNT | 3 | 23 | 845 | 208 | 50 | 6 | 0.93 | 21.8 | ― | [130] |

| MWCNT | 5 | 23 | 553 | 199 | 50 | 6 | 1.49 | 23.4 | ― | [130] |

| Modified MWCNT (m-MWCNT) | 1 | 25 | 775 | 208 | 50 | 6 | 1.10 | 20 | ― | [130] |

| Modified MWCNT (m-MWCNT) | 3 | 24 | 670 | 200 | 50 | 6 | 1.28 | 22.6 | ― | [130] |

| Modified MWCNT (m-MWCNT) | 5 | 24 | 485 | 198 | 50 | 6 | 1.78 | 24.1 | ― | [130] |

| ― | 30 | 1261 | 208 | 50 | 6 | ― | 18 | ― | [131] | |

| MWCNT | 1 | 21 | 678 | 195 | 50 | 6 | 1.38 | 19.5 | ― | [131] |

| MWCNT | 3 | 20 | 584 | 192 | 50 | 6 | 1.55 | 22.6 | ― | [131] |

| ― | 24 | 1620 | 110 | 50 | 3 | ― | ― | ― | [132] | |

| MWCNT | 3 | 17 | 931 | 102 | 50 | 3 | 1.32 | ― | ― | [132] |

| ― | 38 | 1284 | 214 | 50 | 6 | ― | 18.2 | ― | [133] | |

| MWCNT | 10 | 25 | 367 | 199 | 50 | 6 | 2.47 | 24.6 | ― | [133] |

| Carbon fiber (CF) | 10 | 30 | 915 | 207 | 50 | 6 | 1.14 | 20.6 | ― | [133] |

| ― | 35 | 1212 | 198 | 50 | 6 | ― | 18.2 | ― | [134] | |

| CF | 3 | 25 | 1203 | 203 | 50 | 6 | 0.70 | 19.9 | ― | [134] |

| CF | 8 | 26 | 777 | 198 | 50 | 6 | 1.15 | 20.2 | ― | [134] |

| Carbon black (CB) | 5 | 23 | 417 | 186 | 50 | 6 | 2.03 | 24.6 | ― | [134] |

| ― | 38 | 1284 | 241 | 50 | 6 | ― | ― | ― | [108] | |

| Activated carbon (AC) | 7.5 | 15 | 682 | 185 | 50 | 6 | 0.96 | ― | ― | [108] |

| ― | 48 | 1518 | 112.4 | 35 | 3.1 | ― | ― | ― | [6] | |

| Vapor grown carbon nanofiber (VGCNF) | 4 | 35 | 610 | 113.1 | 35 | 3.1 | 1.80 | ― | ― | [6] |

| VGCNF | 8 | 47 | 525 | 108.6 | 35 | 3.1 | 2.93 | ― | ― | [6] |

| VGCNF | 12 | 49 | 547 | 102.4 | 35 | 2.9 | 3.10 | ― | ― | [6] |

Figure 10 shows that with low loading percentage (1 wt.%) of carbon nanotubes, it is possible to achieve the Good FRI. No data were available for UL-94 tests. Comparison between Figure 7 and Figure 10 also suggests that low-cost minerals were used at higher loadings, while carbon-based additives were used almost at loadings below 10 wt.%. A limited number of data have also been reported on LOI values. These points are plotted as a function of FRI in Figure 11, where a good correlation can be established between FRI and LOI values. Deeper understanding of the mechanism behind such correlation requires a detailed view of the origin of tests as well as the chemical structure of additives and possible interaction between the PP and additives.

Figure 10.

FRI values as a function of carbonaceous FR type and content. Symbols are indicative of different types of carbonaceous flame retardant used. Here: ■ GN-2, m-GN-2 [106],

m–rGNO-2, m–rGNO-2 [122],

m–rGNO-2, m–rGNO-2 [122],

rGNO-2, m-rGNO-2, m-rGNO-2 [123],

rGNO-2, m-rGNO-2, m-rGNO-2 [123],

rGNO-2, m-rGNO-2 [112],

rGNO-2, m-rGNO-2 [112],

GNO-2, m-GNO-0.5, m-GNO-1, m-GNO-2 [124],

GNO-2, m-GNO-0.5, m-GNO-1, m-GNO-2 [124],

GN-2.5, GN-NiO-2.5, GN-NiCexOy-2.5 [125],

GN-2.5, GN-NiO-2.5, GN-NiCexOy-2.5 [125],

rGNO-2, m-rGNO-1, m-rGNO-2, m-rGNO-3 [126],

rGNO-2, m-rGNO-1, m-rGNO-2, m-rGNO-3 [126],

m-rGNO-20 [58],

m-rGNO-20 [58],

EG(ES 350 F5)-10, EG(ES 700 F5)-10, EG(Nyagraph FP)-10, EG(TEG 315)-10, EG(Nyagraph KP251)-10 [127],

EG(ES 350 F5)-10, EG(ES 700 F5)-10, EG(Nyagraph FP)-10, EG(TEG 315)-10, EG(Nyagraph KP251)-10 [127],

CNT-1, m-CNT-0.5, m-CNT-1, m-CNT-2, m-CNT-4 [128],

CNT-1, m-CNT-0.5, m-CNT-1, m-CNT-2, m-CNT-4 [128],

CNT-1, m-CNT-0.5, m-CNT-1, m-CNT-2 [129],

CNT-1, m-CNT-0.5, m-CNT-1, m-CNT-2 [129],

MWCNT-1, MWCNT-3, MWCNT-5, m-MWCNT-1, m-MWCNT-3, m-MWCNT-5 [130],

MWCNT-1, MWCNT-3, MWCNT-5, m-MWCNT-1, m-MWCNT-3, m-MWCNT-5 [130],

MWCNT-1, MWCNT-3 [131],

MWCNT-1, MWCNT-3 [131],

MWCNT-3 [132],

MWCNT-3 [132],

MWCNT-10, CF-10 [133],

MWCNT-10, CF-10 [133],

CF-3, CF-8, CB-5 [134],

CF-3, CF-8, CB-5 [134],

AC-7.5 [108],

AC-7.5 [108],

VGCNF-4, VGCNF-8, VGCNF-12 [6].

VGCNF-4, VGCNF-8, VGCNF-12 [6].

Figure 11.

FRI values of PP as a function of LOI test results. Symbols are indicative of different types of carbon-based flame retardant used.

6. Bio-Based Flame Retardants

In recent years, due to sustainability issues, the use of bio-based additives has also been investigated in PP. However, the number of research papers is limited on this subject. Table 5 gives the name and loading percentage of these bio-based FR. The obtained results from cone calorimetry, LOI, and UL-94 tests are also listed in Table 5. Figure 12 and Figure 13 display UL-94 and LOI results as a function of FRI for bio-based flame retardant in PP, respectively.

Table 5.

Flame-retardant PP materials containing bio-based (Bio) flame retardants. Data are extracted from the literature: cone calorimetry parameters (TTI, pHRR, THR), LOI, and UL-94 values. The FRI values were calculated by authors of the present review. The name and the percentage of flame retardants are provided in separate columns. “wt.%” was used for loading level of additives, while “―” stands for the systems free of additive or the neat PP. * FR means flame retardant. Since all comparisons were made in terms of FRI, classification of polymers in terms of their flame-retardant properties was not surveyed based on the chemistry of additives, heat flux, sample thickness, etc.

| PP Containing Bio-Based (Bio) FR * | wt.% | TTI (s) | pHRR (kW·m−2) | THR (MJ·m−2) | Irradiance (kW·m−2) | Sample Thickness (mm) | FRI | LOI | UL-94 | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|

| ― | 46 | 1541 | 90 | 35 | 3 | ― | ― | ― | [135] | |

| Cyclodextrin nanosponge (CD) | 10 | 34 | 1462 | 80 | 35 | 3 | 0.87 | ― | ― | [135] |

| ― | 61 | 1026 | 166 | 35 | 4 | ― | ― | ― | [15] | |

| Hydroxyapatite and Cyclodextrin-based FR (HAandCD-FR) | 10 | 32 | 708 | 156 | 35 | 4 | 0.80 | ― | ― | [15] |

| Propylene-block-ethylene copolymer | ― | 49 | 1350 | 87.3 | 35 | 3 | ― | 17.5 | ― | [136] |

| Phosphorus and nitrogen elements modified lignin (m-lig) | 20 | 38 | 380 | 74.2 | 35 | 3 | 3.24 | 22.5 | ― | [136] |

| ― | 22.5 | 1004.7 | 122.6 | 50 | 3.2 | ― | 18 | NR | [137] | |

| Phytic acid and Piperazine-based FR (PHPI-FR) | 15 | 17.5 | 388.5 | 108.5 | 50 | 3.2 | 2.27 | 24 | V-2 | [137] |

| PHPI-FR | 18 | 17 | 386.2 | 108.4 | 50 | 3.2 | 2.22 | 25 | V-0 | [137] |

| PHPI-FR | 20 | 17 | 346 | 106.1 | 50 | 3.2 | 2.53 | 25.5 | V-0 | [137] |

| PHPI-FR | 25 | 16.5 | 303.4 | 105.4 | 50 | 3.2 | 2.82 | 27 | V-0 | [137] |

| ― | 29 | 1054 | 97 | 50 | ― | ― | ― | ― | [138] | |

| Biochar (BC) | 15 | 12 | 753.01 | 112.68 | 50 | ― | 0.49 | ― | ― | [138] |

| BC | 25 | 13.3 | 616.31 | 111.26 | 51 | ― | 0.68 | ― | ― | [138] |

| BC | 30 | 15 | 539.34 | 101.2 | 52 | ― | 0.96 | ― | ― | [138] |

| BC | 35 | 16.3 | 477.22 | 98.31 | 53 | ― | 1.22 | ― | ― | [138] |

| ― | 24.3 | 1388.3 | 80.3 | 50 | 2.4 | ― | ― | NR | [28] | |

| Wool | 40 | 12.3 | 858.7 | 77.3 | 50 | 2.4 | 0.85 | ― | NR | [28] |

| Phosphoric acid-treated wool fiber (m-wool) | 40 | 14.3 | 426.7 | 72 | 50 | 2.4 | 2.13 | ― | NR | [28] |

| Phosphoric acid-treated wool fiber (m-wool) | 40 | 15 | 436.3 | 65.3 | 50 | 2.4 | 2.41 | ― | V-0 | [28] |

|

Phosphoric acid-treated chicken feather

(m-CF) |

40 | 14.7 | 336.7 | 57 | 50 | 2.4 | 3.51 | ― | V-0 | [28] |

| ― | 24.7 | 1198.2 | 78.7 | 50 | 2.4 | ― | ― | NR | [139] | |

| Chicken feather (CF) | 40 | 17 | 1234.1 | 76.1 | 50 | 2.4 | 0.69 | ― | NR | [139] |

| Phosphoric acid and ethylenediamine treated chicken feather (m-CF) | 40 | 19.3 | 280.5 | 58.7 | 50 | 2.4 | 4.47 | ― | V-0 | [139] |

| Phosphoric acid and ethylenediamine treated chicken feather (m-CF) | 40 | 17.7 | 216.1 | 52.4 | 50 | 2.4 | 5.96 | ― | V-0 | [139] |

Figure 12.

FRI values versus UL-94 test results. Symbols are indicative of different types of bio-based flame retardant (FR) used. The vertical intervals in each category, i.e., V-0, V-1, V-2, and NR, are schematically representative of the amount of additive used. For example, two data distinguished by different symbols having the same or very close FRI values (horizontal quantity) in a given category (e.g., V-1) may have different vertical quantities, e.g., both reveal V-1 behavior in UL-94 test, but the upper contains more FR in PP.

Figure 13.

FRI values of PP as a function of LOI test results. Symbols are indicative of different types of bio-based flame retardant used. The green triangles are related to a mixture of phytic acid and piperazine-based FR. The increase of LOI is directly related to the percentage of FR loading, 15, 18, 20, and 25 wt.%.

FRI values are plotted as a function of loading percentage of bio-based FR in Figure 14. It can be observed that a high quantity of bio-based FR, 40 wt.% is needed to achieve FRI equal to 6.

Figure 14.

FRI values as a function of bio-based FR type and content. Symbols are indicative of different types of bio-based flame retardant used. Here: ■ CD-10 [135],  HAandCD-FR-10 [15],

HAandCD-FR-10 [15],

m-lig-20 [136],

m-lig-20 [136],

PHPI-FR-15, PHPI-FR-18, PHPI-FR-20, PHPI-FR-25 [137],

PHPI-FR-15, PHPI-FR-18, PHPI-FR-20, PHPI-FR-25 [137],

BC-15, BC-25, BC-30, BC-35 [138],

BC-15, BC-25, BC-30, BC-35 [138],

Wool-40, m-wool-40, m-wool-40, m-CF-40 [28],

Wool-40, m-wool-40, m-wool-40, m-CF-40 [28],

CF-40, m-CF-40, m-CF-40 [139].

CF-40, m-CF-40, m-CF-40 [139].

7. Combination of Flame Retardants

As observed in previous sections, using an additive alone can to a limited extent improve flame-retardant properties of PP. Combination of flame retardants is a strategy to improve further the flame retardancy via synergism between various flame retardants [140,141,142]. Moreover, the quantity of the used flame retardant can be reduced in polymer so as to prevent mechanical properties deterioration. Different combinative additive systems were considered in PP. The corresponded data are collected and summarized in Table 6. The third column gives the ratio between flame retardants.

Table 6.