Abstract

It is demanded to supply foods with good quality for all the humans. With the advent of aging society, palatable and healthy foods are required to improve the quality of life and reduce the burden of finance for medical expenditure. Food hydrocolloids can contribute to this demand by versatile functions such as thickening, gelling, stabilising, and emulsifying, controlling texture and flavour release in food processing. Molar mass effects on viscosity and diffusion in liquid foods, and on mechanical and other physical properties of solid and semi-solid foods and films are overviewed. In these functions, the molar mass is one of the key factors, and therefore, the effects of molar mass on various health problems related to noncommunicable diseases or symptoms such as cancer, hyperlipidemia, hyperglycemia, constipation, high blood pressure, knee pain, osteoporosis, cystic fibrosis and dysphagia are described. Understanding these problems only from the viewpoint of molar mass is limited since other structural characteristics, conformation, branching, blockiness in copolymers such as pectin and alginate, degree of substitution as well as the position of the substituents are sometimes the determining factor rather than the molar mass. Nevertheless, comparison of different behaviours and functions in different polymers from the viewpoint of molar mass is expected to be useful to find a common characteristics, which may be helpful to understand the mechanism in other problems.

Keywords: Structure, Rheology, Function, Processing, Nutrition

Graphical abstract

Highlights

-

•

Examples of rheology control by molar mass are shown.

-

•

High and low molar mass compounds often show opposite effects.

-

•

Effects of lower mass compounds on the properties of food polymers are discussed.

-

•

Molar mass effects in physiological function of foods are discussed.

-

•

Molar mass effects in flavour release are discussed.

1. Introduction

To contribute to the universal demand for secure and sustainable food supply, food colloids science and technology can do many things. It can create palatable foods from underutilized resources, and can reduce the food loss. It is reported that there are many people who die from the insufficient supply of foods and malnutrition while food was wasted by improper distribution in some regions as pointed out by the World Health Organization (WHO). International Union of Food Science and Technology (IUFoST) aims to supply sufficient foods helping secure the world's food supply and eliminate world hunger. While the life expectancy in Japan is the longest in the world, it is demanded to extend the healthy life expectancy, which is defined as the period in which the person can enjoy life without any limitation in day-to-day activities resulting from health problems, because the increase of the life-style related diseases make some people ill, which lowers quality of life and causes a significant financial burden.

Palatable, healthy, and sustainable foods are demanded. From the nutritional standpoint it is possible to have a completely adequate diet in the form of fluid foods that require no mastication. However, few people are content to live on such a diet. Modern food and pharmaceutical companies sell manna-like foods, which proclaim to be palatable and healthy. But, people don't eat them every day. Bourne (2002) raises the great number of dentists in the developed countries which supports his argument. Even if ready-made convenient foods are palatable and good for health, most people like to eat something different every time when the situation allows except in a serious calamity such as the earthquake and typhoon/hurricane. Palatable and healthy foods are even more demanded in such a situation as in the age of covid-19 because disadvantaged persons, such as refugees and patients, are under the harsh stresses.

Recent studies clarified that the palatability is closely related with human health through the postprandial thermogenesis (LeBlanc, 2000; LeBlanc & Labrie, 1997) which was found to be induced by brown adipose tissue (BAT) (Okamatsu-Ogura et al., 2019). Small molecules such as resveratrol, bile acid, genipin, short fatty acids like butyric acid, have been reported to increase thermogenic activities in animal or cellular models (Gao et al., 2009). Nguo et al. (2018) examined the effect of chain length of fatty acids on mean-induced thermogenesis (MIT) since monounsaturated fatty acids induced greater MIT than saturated fatty acids. They found that MIT was independent of the chain length. Therefore, the palatability plays a role not only in mental and spiritual domain, but also it is correlated with physiological function. Texture and flavour are key factors governing the palatability and molar mass effects on these factors are discussed in the present review.

Most foods except beverages are gels, and gels can realize a broad range of textures from fluid-like to solid-like (Djabourov, Nishinari, & Ross-Murphy, 2013). Although traditional techniques such as extrusion cooking (Isobe & Noguchi, 1988) and structuring by transglutaminase (Motoki & Seguro, 1998) have been effective to modify food texture, a new gel technology using e.g. 3D printing will be able to produce palatable and healthy foods from plant proteins. People demand the diversity. A flexible manufacturing system which can manage to produce small quantity but various kinds is required in production of foods. This is a characteristic feature demanded for food industry different from other industries where most products can be exactly the same and produced massively at a lower price as much as possible although artificial intelligence (AI) technology may be able to make custom-made products for each individuals in the future.

Since foods generally consist of multiple components, and are changing comparatively rapidly in comparison with other industrial products made of hard materials such as metals, ceramics, and synthetic plastics, therefore the shelf-life is comparatively shorter. While super strong and unchangeable products are required in the other industry, food should be fragile in a sense that it should be chewable and digested by enzymes to be processed in oral and gastrointestinal organs.

It is well known that not only the molar mass but also the structural characteristics such as linkage mode of glucose in polysaccharides make the performance diversity even for similar molar mass compounds. Functional proteins have their specific molar mass because their role in the life phenomenon is designed naturally. Therefore, it seems to be absurd to dare to write an overview on the effects of molar mass in food quality and health related properties. The authors tried to find some common characteristics or rules governing the mechanism which could be applied to other materials or phenomena within food and health problems.

Molecular weight (MW) is a term most widely used although IUPAC recommends to replace it with molar mass. As an intrinsic characteristic quantity of a matter, it should not depend on the gravity and should be the same on the earth and on the other planet. However, many papers have been using the former term. In some communities, a concept of the molecular weight is used to represent the mass of the particle even if this particle is composed of different molecules. Starch is known to consist of different molecules, a linear molecule amylose and a branched molecule amylopectin, but many starch chemists use a term starch molecule or a term molecular weight of starch. Strictly speaking, a term starch molecule should be “molecules constituting a starch”. Although the detailed discussion of the definition of molar mass or molecular weight is not a main topic of this paper, it is important to clarify the definition of molar mass especially when the structure and properties of complex heterogeneous molecules extracted from natural resources are discussed.

1.1. Developing new palatable and healthy foods

Omission test can identify necessary taste ingredients to make an imitation food such as scallop, crab, sea urchin. However, the combination of these tastants in liquid does not give the pleasure or satisfaction for a man to actually chew a real food. Successful examples are kanikama (crab stick) and ikura (salmon roe) where texture is reproduced. Omission tests were done by Watanabe, Lan, Yamaguchi, and Konosu (1990). They found eight taste-active components, glycine, alanine, glutamic acid, arginine, adenosine monophosphate, sodium, potassium, and chloride ions and stated that glycogen enhanced continuity, complexity, fullness, mildness and thickness. Since glycogen is a highly branched polysaccharide, the molar mass is a determining factor of its thickening function. The necessity of inorganic ions to make imitation foods realistic is understood by the cross modal interaction of different sensations and psychophysical effects, which will be discussed in section 9 Molar mass effect on flavour intensity.

The concept of koku was recently re-visited by Nishimura and Egusa (2014) and koku was defined as a phenomenon perceived when humans feel complexity, mouthfulness, long-lastingness with a good balance between taste, odor and tactile sensation. A simple taste such as pure sweetness or bitterness was excluded from koku. The calcium sensing receptor (CaSR) was found as the receptor for koku by Ajinomoto group (Ohsu et al., 2010) who found that various extracellular CaSR agonists enhance sweet, salty, and umami tastes, although they have no taste themselves. Nishimura et al. (2016) reported that the enhancing effect of retronasal aroma by umami compounds. Although this term koku was originally a Japanese word like umami, it was used now internationally, for example, Dunkel, Koster, and Hofmann (2007) found that a nearly tasteless aqueous extract consisting of γ-glutamyl-cysteinyl-β-alanine and some other compounds extracted from beans (Phaseolus vulgaris L.) enhanced its mouthfulness and complexity and induced a much more long-lasting savory taste sensation on the tongue when added to a model chicken broth. They stated that it was exactly the same koku what was proposed by Japanese research groups. Recently, the addition of a kokumi peptide, γ-Glu-Val-Gly was found to improve the reduced-fat peanut butter (Miyamura, Jo, Kuroda, & Kouda, 2015) and chicken consommé (Miyaki, Kawasaki, Kuroda, Miyamura, & Kouda, 2015). A research group of Kyoto University and Fuji Oil Ltd recently reported that the combined use of γ-glutamyl peptides and oligosaccharides, raffinose and stachyose, present in soybeans can increase the kokumi intensity, which suggests that soybean extracts or soymilk can be used to enhance the kokumi taste sensation in food products (Shibata et al., 2017). These papers described successfully the substances which are useful to design palatable foods, but it is necessary to add the viewpoint of the texture which contribute to especially the important factor of koku, the continuity and fullness. This was already pointed out by a pioneering work of Watanabe et al. (1990) which stated that the glycogen, a polymer not a small molecule, played an important role to make a scallop taste. Molar mass problem is involved in physical and chemical aspects in designing koku or palatability. A systematic understanding of the kind of amino acids, their arrangement order, and their length as well as their effects on the viscosity is required for the design. To make the taste research more practical, the texture should be taken into account, and also the role of salt should be understood from the viewpoint of taste-odor, or taste-taste interaction. This will be discussed later in section 9 Molar mass effect on flavour intensity.

Granular protein can prevent the shrinking and dripping of liquid, during frying, of hamburger steak consisting of minced meat with granular protein. Size and shape of this granular soy protein can be controlled by changing the extruder outlet, composition of raw materials, running condition of extrusion (Isobe & Noguchi, 1988). Not only the fibrous texture but also juiciness is an important texture characteristics to produce an authentic meat mouthfeel (Puolanne, 2017; Warner, 2017).

Low molar mass and high molar mass emulsifiers act differently on the surface of oil droplets. While low molar mass emulsifiers may adsorb faster on the surface of oil droplets because their diffusion coefficient is larger than that of high molar mass ones, high molar mass emulsifiers may show a steric stabilisation effect (Dickinson, 2009). The steric repulsion is dependent not only on molar mass of the polymer forming layers surrounding droplets but also on the conformation and branching (Dickinson, 2018).

1.2. Why molar mass?

All the hydrocolloid scientists know the importance of molar mass, for example, to control the viscosity of fluid foods, high molar mass polysaccharides can increase the viscosity at a very low dose (concentration) if the conformation is not completely random coil. Random coil polysaccharides such as pullulan and dextran are not effective to increase the viscosity. The solution viscosity of low molar mass saccharide is much lower than that of higher molar mass saccharide, i.e. polysaccharide. Though there have been many papers studying food processing or health related problems by changing the dose (concentration) of different polysaccharides without controlling the molar mass, it is evident that it is not possible to compare the concentration dependence or the different effects of these polysaccharides when the molar mass of each polysaccharide is different. In the industrial application of these thickening and gelling polysaccharides, the solubility and the hydration rate and extent are important, which are related to the molar mass and other structural characteristics. In electrolytic copolymers such as pectins and alginates or chitosans, the degree of blockiness, type of cations/anions, the position of cations/anions, degree of substitution (methoxylation/acetylation) are also determining factors of the function. In cellulose derivatives, the degree of substitution and its position and length are determining factor of the function. Although the conformation or the stiffness of polysaccharide chain plays important roles in their performance, it is worthwhile to pay attention to the molar mass effect. In the present paper, the terms molar mass, molecular mass, and molecular weight represented in Da (Dalton) or g/mol are used interchangeably. Since it is generally time/energy consuming to obtain food polymers with narrow molar mass distribution, most published papers used polydisperse polymers. Nevertheless, high molar mass and low molar mass have been shown to affect the function/property differently as will be discussed in the present review. The molar mass of some polysaccharides have not been determined with high precision because their structures are heterogeneous and difficult to purify to be subjected to molar mass determination.

Since fibrils of globular protein appeared, the concept of globular protein that forms a gel only at high concentrations changed drastically. It was reported that fibrils of β-lactoglobulin can form a gel at a very low concentration (Veerman, Sagis, & van der Linden, 2003) and the transglutaminase was shown effective to enhance the gelling ability at low protein concentration (Wu, Nishinari, Gao, Zhao, Zhang, Fang, et al., 2016). It is necessary to check the safety of fibrils of β-lactoglobulin as food materials, and Bateman, Ye, and Singh (2010) showed that BLG fibrils, prepared by heating at pH 2 and 80 °C for 20 h, could be digested in simulated gastric fluid. They found that the fibrils were digested completely by pepsin within 2 min and that the peptides in the fibrils with molar mass of 2000–8000 Da could be digested to smaller peptides (mostly < 2000 Da) by pepsin.

Since the publication on the harmful effect of lower mass carrageenan (Tobacman, 2001), it became an active research area (McKim, Willoughby, Blakemore, & Weiner, 2019). McKim et al. (2019) criticizes the assertion of Tobacman (2001) stating that the induced tumour promoting effect of carrageenan reported by Tobacman and her supporters is based on an unrealistic experiment using a very low molar mass carrageenan prepared in a non-physiological condition at a higher temperature > 80 °C and at a very low pH 0.7–1.3, and such a harsh degradation never occurs in normal digestion process in human gastrointestinal organs. This will be discussed later in 6.5.4. Here, the molar mass seems to be a key word to understand the safety issues.

In pharmaceutical/medical sciences, structure/function of heparin has been studied extensively since its discovery hundred years ago mainly because of its anti-thrombin action. Heparin is a naturally occurring sulphated polysaccharide with MW ranging from 5 to 40 kDa belonging to the family of glycosaminoglycan. Since forty years ago, low molecular weight heparin (LMWH) prepared by chemical or enzymatic hydrolysis or ultrasonic degradation has attracted more attention because of its stronger activity. Since the structure of heparin extracted from different sources is heterogeneous, and difficult to clarify the structure/function relation, chemoenzymatic synthesis has been performed to make a better product (Hemker, 2016; Oduah, Linhardt, & Sharfstein, 2016; Wang, Liu, & Voglmeir, 2020). This research area is vibrant and a plethora of papers have been published, 3895 papers in 2019, 2171 papers in 2020 and 15 papers in 2021 (heparin × molecular weight) according to Science Direct. It was reported recently that LMWH reduced the mortality in severe COVID-19 patients (Tan et al., 2020) although the optimum molar mass was not yet determined.

In the nutrition science, it was believed that proteins are hydrolysed into amino acids to be absorbed at intestinal walls. Ejima, Nakamura, Suzuki, and Sato (2018) and Ejima, Yamada, and Sato (2019) reported, however, that di- or tri-peptides were detected in human plasma after ingestion of maize and wheat gluten hydrolysates, and aspartic dipeptides in rat plasma after administration of liver protein hydrolysates. This detection became possible by adopting a new high-sensitive method liquid chromatography-electrospray ionization-tandem mass spectrometer (LC-MS/MS) via multiple reaction monitoring. The same research group led by Sato (2017) detected di-peptide in human plasma after ingestion of collagen or elastin hydrolysates. They emphasize the importance of detecting bioactive compounds such as dipeptides in the body because it can be related with the biological response upon ingestion of the protein hydrolysate.

A similar situation is developing in the other part of the body. Synovial fluids play a key role for the smooth movement of joints of knee or any other part conferring the lubrication as well as shock absorption. Hyaluronan (also called hyaluronic acid, HA) is a main ingredient, also occurring in connective, epithelial, and neural tissues e.g., in eyes, umbilical cord, skin, blood vessels, heart valves (Laurent & Fraser, 1992). Many elderly persons suffer from knee joint pain from osteoarthritis (OA), and the traditional therapy was an injection of hyaluronic acid (Balazs & Denlinger, 1985). Since hyaluronan is hydrolysed by endogenous hyaluronidase and cannot function for a long time, cross-linked hyaluronan was introduced, which can keep longer (Balazs & Denlinger, 1985). HA a copolymer consisting of glucuronic acid and N-acetyl-glucosamine, and occurring naturally, but is also produced by microbial fermentation. Its molar mass is reported to be increased with increasing UDP-N-acetylglucosamine (UDP = uridine diphosphate) concentration (Chen, Marcellin, Hung, & Nielsen, 2009). Physiological functions of HA have been found strongly influenced by molecular weight (MW) and some examples are discussed in section 6.4.

Since human skin plays a role of barrier to prevent the penetration of harmful molecules, higher molar mass compounds above 500 Da are believed to be not able to penetrate (Bos & Meinardi, 2000). Recently, the topical cream on the knee was proposed, and oral therapy, i.e. hyaluronan as a healthy food was commercialized. In a traditional nutrition science, it is believed that all the nutrients are digested into monomers and absorbed in the intestine. Oe et al. (2016) summarised a recent study on the efficacy of ingested HA in treating knee pain based on data from randomized, double-blind, placebo-controlled trials as well as the mechanism of action and safety of dietary HA.

In all therapies, injection, topical, oral ingestion, the molar mass is recognized as an important factor. The increase in molar mass of the permeant (Fluorescein isothiocyanate-dextran) was found to decrease the transport (Medi, Layek, & Singh, 2017).

Electroporation method as a transdermal drug delivery which allows the penetration of higher molar mass drugs has been attracting attention (Kawai et al., 2008; Kawai, 2012; Lombry, Dujardin, & Preat, 2000) (Fig. 1 ).

Fig. 1.

Molar mass of a hydrocolloid molecule increases when it is reconstructed or synthesized while it decreases when it is degrade or digested.

Since food is a complex material consisting of many ingredients, and the human body also consists of various parts and is a complex system in which each part interact each other. In each specific problem, the degradation and reconstruction of molecules are governed by specific enzymes and thus different problems cannot be compared directly each other, but methods of study are sometimes similar thus a study on one problem can learn from another study, and finally the total aspects should be overviewed to solve each specific problem. It is the authors’ hope that each specialists share their own area with other areas to collaborate to find a better solution.

The viscosity of the liquid foods is in most cases determined by food macromolecules and the molar mass is the determining factor together with the structural characteristics, conformation, molecular shape, stiffness, and degree of branching. Some problems of the mixture of high molar mass and low molar mass polymers, which have an important practical significance in medical problems such as hyaluronate related with knee pain (in 6.4), and alginate related with cystic fibrosis (in 6.5), and also the interaction between polysaccharides and proteins in food industry are also discussed.

There have not been many studies on the effect of molar mass distribution by mixing monodisperse polymers because it is time/energy consuming to get well fractionated polymers with wide molar mass range. The elasticity of solid or semi-solid, gel-like foods is also dependent on molar mass and also the structure of junction zones, the network density and the elastically active network chains, which are also dependent on molar mass. Electric charges, ionic strength and pH are also important factors, and therefore the effect of molar mass is not isolated from these factors. Nevertheless, it is expected that extraction of common features in various phenomena which are strongly influenced by the molar mass of polymers which play an important role is useful. From this overview, unresolved problem may find a clue from the other problems. Although it is difficult to find a general rule to understand the role of molar mass in food characteristics and disease therapy, effects of molar mass on structural formation and breakdown in food and health are overviewed in the present paper.

1.3. How to control the molar mass?

There are many methods to obtain or analyse polysaccharides and proteins with different molar masses (Table 1 ). Each methods have advantages and disadvantages. For example, oligomers of sulphated polysaccharides have been attracted much attention because of their biological activities, and depolymerised by ultrasonication, gamma-irradiation, acid or enzymatic hydrolysis. Sulphate groups tend to be removed by acid hydrolysis, while the structure of the repeating units was retained by gamma-irradiation in fucoidan (Choi & Kim, 2013). In another report, the sulphate content of fucoidan slightly increased by ultrasonic degradation (Guo et al., 2014). In ultrasonic degradation of xanthan, removal of pyruvate groups from native xanthan increased the thermal stability keeping the helical conformation, and lowered the sensitivity of molecular conformation to the salt concentration, and thus led to lower degradation efficiency (Li & Feke, 2015).

Table 1.

Methods of molar mass control.

Some methods of molar mass change, decrease or increase, applied to polysaccharides and proteins in food and health industries are shown in Table 1.

2. Molar mass effect on the viscosity and diffusion

2.1. Molar mass effect on the viscosity

The intrinsic viscosity (also called limiting viscosity number) is often determined by an Ubbelohde type capillary viscometer. The relative viscosity is defined as the ratio of the viscosity of the solution to that of the solvent η rel = η/η s , and the specific viscosity (relative viscosity increment) η sp = (η -η s)/η s = η rel -1 per unit concentration is extrapolated to zero concentration to obtain the intrinsic viscosity [η] = Lim (C→0) η sp/C. The intrinsic viscosity has a unit of the inverse of the concentration, and represents the volume the polymer occupies in the solution. Therefore stiff chains or an expanded chain molecules show a high intrinsic viscosity value while compact or less expanded molecules show a lower value.

The relation between the intrinsic viscosity and molar mass of polymers, called Mark-Houwink-Sakurada (MHS) equation, is written as

| [η] = K Ma |

Where K and a depend on solvent quality, a < 1/2 for poor solvent, a = 1/2 for θ solvent, a > 1/2 for good solvent (Doi, 2013; Tanaka, 2011). The MHS exponent a is reported as 0.5 for amylose (in 0.33 M KCl), dextran (water), and 0.8 for stiff chains such as locust bean gum, 0.8–1.1 for anionic polysaccharides such as carboxymethyl cellulose, alginate, κ-carrageenan, xanthan, pectin (Walstra, 2003). Solution properties of pullulan was extensively studied (Kawahara et al., 1984; Buliga & Brant, 1987; Nishinari et al., 1991) and the reported MHS exponent 0.65 was coincident in all the references. The MHS exponent of guar gum was reported as 0.51 (Funami et al., 2005a,b) while that of fenugreek was 0.67 (Funami et al., 2008a,b). Polymers with larger values of [η] are used for thickening agents because they can increase the viscosity of the solution by the addition of a small quantity. The concentration (C) dependence of the viscosity of polymer solutions is usually represented by double logarithmic plot of the zero shear specific viscosity η sp vs coil overlap parameter, C[η], since this master curve was observed for many polysaccharides. The intrinsic viscosity has units of reciprocal concentration, so the product with concentration is dimensionless. Since the viscosity of polymer solutions is generally dependent on shear rate, the viscosity obtained by the extrapolation to zero shear rate is used to understand the concentration dependence systematically.

The critical coil overlap concentration C* is approximately given by 4/[η], and at this concentration the zero shear viscosity was found η sp ~ 10 (see Fig. 2 ). The slope above the critical concentration was found about 3.3 for most random coil polymers including the data for polystyrene in toluene, but this slope was approximately 4.4 for guar gum and locust bean gum for which the critical concentration was found a little bit lower than for the other random coil polymers. The deviation of the behaviour for galactomannans (guar gum and locust bean gum) may be due to specific attractive interactions between side groups on the polymer chains or the stiffness of polymer chains. It should be reminded that a typical behaviour shown in Fig. 2 is limited to the viscosity at very low shear rates.

Fig. 2.

Zero shear specific viscosity as a function of the coil overlap parameter, C[η], for a range of random coil polysaccharides. At C[η] ~ 4 the transition from dilute to concentrated solution behaviour is found for a number of random coil polysaccharides (Morris, Cutler, Ross-Murphy, Rees, & Price, 1981).

As typical shear rate dependence of the viscosity for the solutions of water soluble polymers, data for cellulose derivatives and cereal β-glucans are shown in Fig. 3 A and B. While all the glucose residues are linked by β-(1 → 4) in cellulose which is insoluble in water, in cereal β-glucans about one third of the linkages between the glucose residues are β-(1 → 3) linkages in addition to β-(1 → 4) linkages, and more soluble in water. Cellulose derivatives are soluble and have been studied extensively. For cellulose derivative compounds with different molar masses but approximately the same degree of substitution, the steady shear viscosity of 2% solutions as a function of shear rate is shown in Fig. 3A. A similar shear rate dependence of the steady shear viscosity for beta glucans from oat, barley, wheat flour and wheat bran is shown in Fig. 3B. Another example is shown for galactomannan solutions in Fig. 3C.

Fig. 3.

A. Shear rate dependence of the viscosity for 2% sulfoethylcarboxy-methylcellulose with different MW in 0.1MNaNO3 solution. MW (g/mol)/106: ■, 1.49; □, 0.86; ▲, 0.76; △, 0.68; ●, 0.44; ○, 0.22 (Clasen & Kulicke, 2001). B. Shear rate dependence of the viscosity for 2% cereal β-D-glucans with different MW in water, at 25 °C. MW (g/mol)/106: Oat □, 1.2; barley ■, 0.8; wheat flour ○, 0.4; wheat bran ●, 0.3 (Cui & Wood, 2000). C. Shear rate dependence of the viscosity for 1% solutions of galactomannans from Delonix regia with different MW 4.86 × 105 Da (♦), 4.15 × 105 Da ( ), 2.85 × 105 Da (●), and 1.95 × 105 Da (

), 2.85 × 105 Da (●), and 1.95 × 105 Da ( ). (Rodriguez-Canto et al., 2019).

). (Rodriguez-Canto et al., 2019).

The following features are noted: 1) the viscosity at lower shear rates increases with increasing molar mass; 2) the viscosity decreases with increasing shear rate, which is called shear thinning; 3) The viscosity of the solution of the lowest molar mass does not depend so much on the shear rate, and shows approximately a constant value at lower shear rates. This is called a Newtonian plateau. Because of the limited sensitivity of the rheometer, the viscosity at very low shear rates cannot often be measured. In this case, the viscosity of the solution of the lowest molar mass was not measured below the shear rate of 3 s−1 (Fig. 3A) or 0.1 s−1 (Fig. 3B) or 2 s−1 (Fig. 3C). It should be noted that some published papers erroneously showed a steep rise of the viscosity at lower shear rate with decreasing shear rate, which were probably caused by neglecting the low sensitivity limit of the sensor.

2.2. Molar mass effect on the diffusion

Diffusion is a ubiquitous phenomenon of motion of molecules or particles in any phase (gas, liquid, or solid) caused by the concentration gradient. This is caused not by an external force but by spontaneous collision in Brownian movement (Doi, 2013; Tanaka, 2011). The diffusion is described by a Fick's equation

| ∂C/∂t = D ∂2C/∂x2, |

where C is the concentration (mol/m3), t the time (s), x the position (m) in one dimension. This can be generalized to three dimension.

Rate of diffusion of aroma compounds in a gas phase, carbon dioxide diffusion into egg white through the pore of shell during storage, that of seasonings such as salts, acid, and of sugars in pickling and salting as well as release of tastants in oral cavity, and release of nutrients and drugs in gastrointestinal tract, plasticizers motion in packaging films, and many others, …all play important roles in food and health.

Diffusion coefficient is given by Stokes-Einstein equation

| D = kT / (6πRHη), |

where k is the Boltzmann constant (1.38 × 10−23 J K−1), T is the temperature (K), R H is the hydrodynamic radius of a spherical particle (m), η the viscosity of the surrounding medium (Pa.s). This equation is valid only for an infinitely dilute solution, and for a particle which is larger than the solvent molecule.

The hydrodynamic radius R H is related with the radius of gyration R g = KM ν (Flory Equation, ν is called Flory exponent) by ρ = R g/R H.. For linear, flexible chains in the theta solvent ρ = 1.505, while in the limit of large excluded-volume effects (ν = 0.587) a value of ρ = 1.78 is obtained. Polydispersity increases this value by 14% (i.e. ρ = 2.05) for a most probable (Schulz-Flory) distribution with a polydispersity index PI, the ratio of weight average molecular weight M w and the number average molecular weight M n, PI = M w/M n = 2 (Burchard, 1994).

The Flory exponent ν is related with the mass fractal dimension d f by ν = 1/d f. Some typical values of ν and d f are known: ν = 0.6 (or 0.588), d f = 1.67 (or 1.70) for linear random coil polymer in good solvent), ν = 0.5, d f = 2.0 for linear random coil polymer behaving like a Gaussian chain in theta solvent, ν = 1.0, d f = 1.0 for rigid rod, ν = 0.5, d f = 2.0 for thin disc, ν = 0.33, d f = 3.0 for homogeneous sphere. The fractal dimension represents to which extent the space is filled, and therefore, completely packed sphere with no empty space shows d f = 3.0. When a rigid rod molecule rotates, it can sweep a large volume with low density and thus its d f is 1 much smaller than d f of a sphere (Burchard, 1994).

Diffusion coefficient of biomolecules has been measured by ultracentrifugation, dynamic light scattering (DLS), nuclear magnetic resonance (NMR), and fluorescence correlation spectroscopy (FCS). Globular protein molecules have been approximated as spheres, and thus the diffusion coefficient is expected to be related with molar mass as follows: D ~ M -ν, where the exponent ν is theoretically estimated as 0.33 for a sphere.

Summarizing many experimental data for globular proteins, ν = 0.39 and d f = 2.56 was found (Evans, 2020; Augé et al., 2009; Enright et al., 2005). Globular proteins are an example of a class of chemical species where values of ν tend towards 0.33 while the ν value measured in strongly denaturing solutions increased tended to approach 0.6, similar to the exponent expected for a random coil polymer in a good solvent as mentioned above. This difference in the ν value can be used to distinguish between folded, disordered and denatured proteins (Evans, 2020). Dudás and Bodor (2019) acquired diffusion coefficients of 12 globular proteins and 10 intrinsically disordered proteins (IDPs). They reported ν = 0.382 for native folded globular proteins, and ν = 0.492 for intrinsically disordered proteins (Fig. 4 ). The value close to 0.5 indicated that the elongated and loose structures similar to a random coil polymer shown below for pullulan (0.51 by Nishinari et al. (1991); 0.49 by Viel, Capitani, Mannina, and Segre (2003) and poly(ethylene oxide) (0.52–0.55 by Hakansson, Nyden, and Soderman (2000)).

Fig. 4.

Logarithmic representation of diffusion coefficients as a function of molecular weight for folded proteins (red circles), IDPs (blue squares), viscosity corrected denatured folded proteins (open green circles), and IDPs (open green squares) (Dudás et al., 2019).

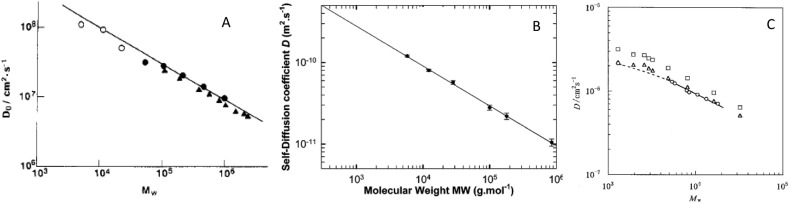

Pullulan has been studied extensively as a water soluble, model random coil polysaccharide. The diffusion coefficient of pullulan as a function of molar mass is shown in Fig. 5 A and B. The exponent ν was found as 0.51 (Nishinari et al., 2016). The exponent 0.38–0.41 was reported for hydroxyethyl starch (Kuz’mina, Moiseev, Krylov, Yashkir, & Merkulov, 2015) indicating the deviation of these molecules from random coil conformation.

Fig. 5.

A. Double-logarithmic plot of DO against MW for pullulan samples at 25 °C: (●) from PCS, (○) from the classical boundary formation, Nishinari et al. (1991), (▲) (Kato et al., 1984). B. Double-logarithmic plot of D against MW for six pullulan fractions as determined by DOSY experiments recorded at 300 K in dilute D2O solution (Viel et al., 2003). C. Double-logarithmic plot of D for cycloamylose in 0.5 N aqueous NaOH at 25 °C (○). □, Monte Carlo data; △, Monte Carlo data recalculated with two glucose units taken as one bead and corrected for the effects of bead diameter and fluctuating hydrodynamic interaction (Nakata et al., 2003).

Cycloamylose, a cyclic (1 → 4)-α-D-glucan is a large ring cyclodextrin (CD) (cyclic (1 → 4)-α-D-glucans with DP = 6, 7 and 8 have been known as α-CD, β-CD, and γ- CD described later in 9.3.2 Effect of molar mass of carriers on the retention of aroma compounds) has been attracting much attention (Fenyvesi & Szente, 2016). Nakata, Amitani, Norisuye, and Kitamura (2003) studied the conformation of seven cycloamylose samples with weight-average molecular weight from 5 × 103 to 1.8 × 104. They determined the MW and diffusion coefficient D for cycloamylose samples from sedimentation equilibrium (in dimethylsulphoxide) and by dynamic light scattering (in 0.5 N aqueous NaOH). Dependence of D on MW is shown in Fig. 5C. The exponent α was found as 0.53. They noticed, taking into account that correction is made for the effect of fluctuating hydrodynamic interaction, that measured translational diffusion coefficients in the aqueous NaOH agreed fairly well with Monte Carlo data and also with the prediction from the Yamakawa–Fujii theory for the associated Kratky-Porod ring combined with relevant theoretical expressions for the expansion factors (Nakata et al., 2003).

The Stokes-Einstein equation is valid only for infinitely dilute solution. For finite concentration, a corresponding relation

| Dc = kT / (6πξHη) |

Where ξ H is hydrodynamic correlation length, should be used (De Gennes, 1979). Diffusion coefficient of pullulan was found to decrease with increasing concentration for lower MW (5.5 kDa −23.8 kDa) observed by ultracentrifuge and for higher Mw (53.9 kDa–478 kDa) observed by PCS (Nishinari et al., 1991). Diffusion coefficient of αS- casein as a function of concentration is shown in Fig. 6 A (Kusova, Sitnitsky, Idiyatullin, Bakirova, & Zuev, 2018). This dependence can be generalized by scaling as shown in Fig. 6B (Nesmelova, Melnikova, Ranjan, & Skirda, 2019).

Fig. 6.

A. Concentration dependences of the protein self-diffusion coefficient (D) as a function of protein volume fraction for αS-casein at 30 °C (squares), 5 °C (circles) (Kusova et al., 2018). B. Concentration dependence of the diffusion coefficient of αS -casein (red squares), the master curve representing the concentration dependence of the diffusion coefficient for globular proteins (black symbols) and for flexible polymers (light blue line), and the theoretical concentration dependence for Brownian rigid spheres (blue line). Concentration is normalized by a critical volume fraction φ0. The asymptote with zero slope is shown by black dashed line. All curves are normalized by the procedure that merely leads to the shift of the concentration dependence along the horizontal and vertical axes (Nesmelova et al., 2019). (For interpretation of the references to colour in this figure legend, the reader is referred to the Web version of this article.)

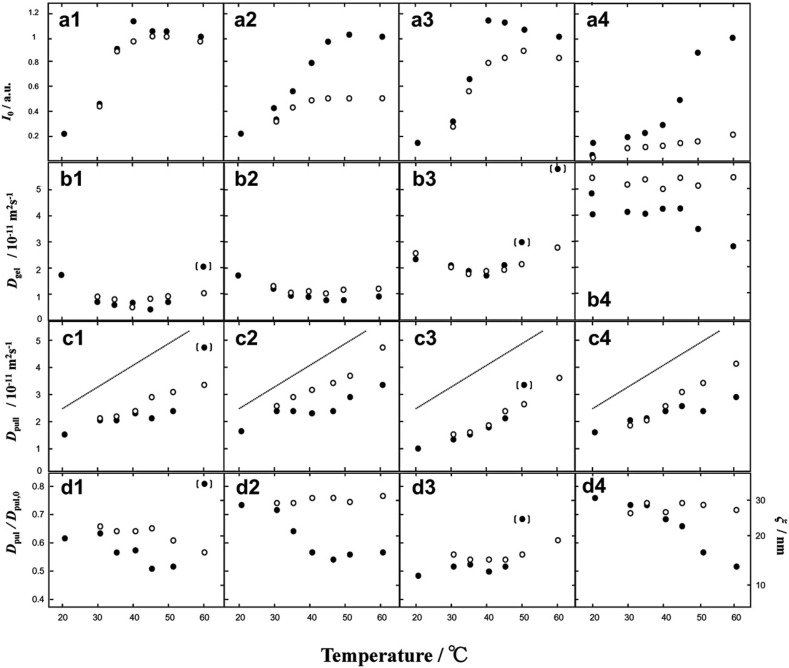

Diffusion coefficient of probe molecules introduced in gelling polymers was used to estimate the mesh size of gel networks. Shimizu, Brenner, Liao, and Matsukawa (2012) using pullulan (MW112 kDa) studied the gelation of potassium type deacylated gellan by a pulse-gradient-stimulated-echo (PGSTE) pulse sequence. The echo signal intensity I 0 = I(0) of a methyl proton in rhamnose residue in gellan in the absence of field gradient decreased at T I(0), 36, 43, 38 and 45–50 °C for 2 mM CaCl2, 5 mM CaCl2, 40 mM KCl and 80 mM KCl, respectively (Fig. 7 ), that reflects the decrease in total random coil content and the helix formation and the aggregation, in agreement with results obtained by circular dichroism (CD) measurements (Ogawa et al., 2006; Morris, Nishinari, & Rinaudo, 2012). The diffusion coefficient of gellan chains, D gel, for solutions with 2 mM CaCl2, 5 mM CaCl2 and 40 mM KCl remained nearly constant during cooling down to T I(0) and increased with further cooling, as shown in Fig. 7b. The decrease of solute gellan concentration at T I(0) might cause a decrease in the local viscosity because solubilized random coil gellan molecules were incorporated into helices and their aggregates. The increase of D gel at T I(0) was more pronounced than expected from the decrease of local viscosity. Therefore, it is considered that the MW distribution of the gellan remaining as a random coil as a solute among the network of aggregates was shifted to lower MW values because higher molar mass gellan chains were preferentially incorporated to junction zones than lower MW chains. This is consistent with the observation that shorter chains preferentially eluded out from gellan gels when gels were immersed in solvents (Hossain & Nishinari, 2009). On the other hand, D gel for the solution with 80 mM KCl showed a different behaviour, that is, D gel became higher with decreasing temperature down to T I(0), remained almost constant with further cooling, increased during holding time at 20 °C (12 h) and remained almost constant during reheating. This behaviour probably reflects the collapse of the solute gellan chain, which is caused by effective shielding (high salt concentration) of repulsion between negative charges on the carboxylate ions (Ogawa et al., 2006).

Fig. 7.

Temperature dependence of the NMR echo signal intensity at 1.3 ppm, I(0), the echo signal intensity without the gradient pulse, for gellan (a), diffusion coefficient of gellan Dgel (b), diffusion coefficient of pullulan Dpull (c) and Dpull/Dpull,0 (d) in 1% gellan solution containing 0.1% pullulan, and the following ionic compositions: 2 mM CaCl2 (1), 5 mM CaCl2 (2), 40 mM KCl (3) and 80 mM KCl (4). Closed circles, cooling; open circles, heating. Data points inside brackets indicate D values that are overestimated by convection. The solid straight lines indicate Dpul in dilute solution. The value ξ at the right vertical axis in (d) is the hydrodynamic mesh size (Shimizu et al., 2012).

The diffusion coefficient of pullulan decreased with decreasing temperature, and it was concluded that pullulan chains were not involved directly in the aggregation of gellan, and remained dissolved during the gelling process, probably due to the high solubility of pullulan in water. The diffusion of pullulan is thought to be restricted by the hydrodynamic interaction with the solute gellan as well as the network of aggregates. The restriction became smaller with decreasing solute gellan concentration and increasing network pore size, both of which result from the thickening of the aggregates.

Since probe molecules (pullulan) in the solution have no intermolecular interaction with the host polymer (gellan) except the hydrodynamic interaction, the diffusion is expressed as follows (Cukier, 1984; De Gennes, 1979; Matsukawa & Ando, 1996):

| DinHost/DinPure = exp (-Rh/ξ) | (4) |

Where D inHost and D inPure are D of the probe molecule in the host polymer solution and that in pure dilute solution, respectively, and ξ is the hydrodynamic mesh size which represents the hydrodynamic mesh size made of the solute gellan and the network of aggregates. Values of ξ are shown in the right vertical axis in Fig. 7d. The change in the microscopic surroundings of pullulan during the cooling process is shown schematically in Fig. 8 .

Fig. 8.

A schematic representation of the microscopic environment of pullulan above (a), at (b) and below (c) TI(0) (Shimizu et al., 2012).

When a physical polymer gel is immersed in a solvent, molecular chains which are not connected to the junction zones were found to release out from the gel to the solvent (Djabourov et al., 2013). It has been observed that the immersion of potassium type deacylated gellan gels in water or electrolyte solution induces chain release, and this release is more noticeable for shorter chains. Ultimately the gel becomes eroded and then disintegrates, and the rate of collapse depends on polymer concentration, original molecular mass and the initial salt content of the gels and the solvent. Salt diffusion from the gels into the solution is faster than chain release; chains which lose condensed or bound ions cannot retain a helical conformation, and so they diffuse out into the solution. The storage Young's modulus E′0 of gellan gels immersed in various solvents was observed as a function of time. For the first 3 h, E′0 increased both in water and in Me4N Cl solution, a solution which inhibits the helix aggregation of gellan. Subsequently, E′0 for a gel immersed in water decreased because of the release of chains contributing to the network (Hossain & Nishinari, 2009). Funami et al., 2008a, Funami et al., 2008b reported that a gellan gel collapsed after 8 h immersion in pure water. They estimated the diffusion coefficient (1.6–2.8) × 10 −11 m2 s−1, which was slightly larger than diffusion coefficient ranging from 0.6 × 10 −11 m2 s−1 to 1.0 × 10 −11 m2 s−1 at 25 °C in 25 mM NaCl for molar mass range from 2.2 × 10 5 to 1.3 × 10 5 reported by Takahashi et al. (2004). This is reasonable since molecular chains released out from the gel network were shorter than un-released chains.

De Silva, Poole-Warren, Martens, & in het Panhuis (2013) studied the chain release of also deacylated but Ca2+ cross-linked gellan gels at 37 °C in a phosphate buffer saline (PBS). These authors also found the chain release as mass loss up to 168 days. Since the CD ellipticity was proportional to the gellan concentration, they estimated the diffusion coefficient of gellan from the CD data D = 1.1 × 10 −13 m2 s−1, which was two orders of magnitude smaller than the reported value of deacylated gellan at 40 °C (Takahashi et al., 2004). They ascribed this difference to the retardation of the mobility of gellan molecules in gel network.

3. Molar mass effect on mechanical properties of gels and solids

Molar mass is a key for the gel formation. When the material changes from sol state to gel state, the molecules are connected each other spanning the whole space in the vessel, and this is called the percolation at which the molar mass is thought to diverge to infinity (De Gennes, 1979; Nishinari, 2009; Tanaka, 2011; Tokita, 1989). Gelling polysaccharides and proteins have been used widely for controlling the food texture. Mechanical strength of gels can be indexed by the elastic modulus and/or fracture stress/strain. Although the oral processing is a dynamic process, that is time dependent, only the fracture stress has been used to characterize the mechanical properties quite often neglecting the intermediate stress/strain of the compression/shearing in the mastication. For example, in fishery industry in Japan a so-called “gel rigidity”, which was defined as the ratio of the force to deformation at break using a spherical probe of 5 mm diameter, has been used widely. Though it may have some merit, it does not distinguish two concave and convex curves connecting the origin and the break point in the force-deformation plot. We hope that these distinction will be taken into account in the near future.

3.1. Minimum chain length for helix formation

Since the average number of residues per helical turn to form α-helix has been established as 3.6, and 13 atoms are involved in the ring formation by hydrogen bond, α-helix is also called 3.613-helix. The average number of residues per helical turn for other protein helices is also determined as 3.0 for 310-helix, and 4.4 for π-helix (https://biomedapps.curtin.edu.au/biochem/tutorials/prottute/index.htm , Interactive Protein Structure Tutorial, Retrieved Feb 2, 2020).

While the helix structure is studied extensively in proteins, that is not so much studied in polysaccharides. The helix formation is the prerequisite for gel formation for agarose, gellan, carrageenan (double helices) , schizophyllan (triple helices), however the minimum molar mass required to form a double helix or triple helix has not been so much studied because of the difficulty to get samples. For gellan, Ogawa et al. (2006) using 6 sodium type samples of different molar masses almost free from cations did not observe the step-wise increase in the intrinsic viscosity for the lowest molar mass sample with decreasing temperature (Fig. 9 A). It was thought that the chain length was too short to form double helices. This assertion is corroborated by DSC thermograms which ceased to show exothermic peaks (Fig. 9B) or endothermic peaks on cooling or heating below a certain molar mass and by circular dichroism experiments. The DSC exothermic peak accompanying the coil to helix transition shifted slightly to lower temperatures with decreasing molar mass which can be fitted with a zipper model (Nishinari, Koide, Williams, & Phillips, 1990).

Fig. 9.

A. Temperature dependence of intrinsic viscosity for Na-gellan aqueous solutions with 25 mmol NaCl. Molar mass G1 > G2 > G3 > G4 > G5> G6 (Ogawa et al., 2006). B. DSC cooling curves for 1% Na-gellan aqueous solutions with 25 mmol NaCl. Molar mass G1 > G2 > G3 > G4 > G5. No peak was observed for G6. (Ogawa et al., 2006). C. Temperature dependence of specific optical rotation [α]300 of κ-carrageenan oligomers with different DPs and polymer at 300 nm in the presence of 2.5 M KCI (Rochas, Rinaudo, & Vincedon, 1983).

A similar tendency was reported for κ-carrageenan. Rochas, Rinaudo, & Vincendon (1983) found that the optical specific rotation [α] at 300 nm did not increase with lowering temperature for oligomers with DP < 4 (Fig. 9C) which was corroborated by 13C NMR observation.

Stokke, Smidsrød, Zanetti, Strand, and Skjåk-Bræk (1993) estimated eight contiguous guluronic residues were necessary to form an egg box junction in the presence of calcium ions, while Powell, Morris, Gidley, and Rees (1982) estimated at least 14 contiguous non-esterified galacturonic acid residues were required to form a stable dimeric junction zone in the gelation of pectin. Bowman et al. (2016) confirmed the previous result of Stokke et al. (1993) by AFM observation.

3.2. Gelation of amylose and oat β-glucan with different molar masses

Amylose gelation is known to be a triggering in the early stage of retrogradation of starch, but only a few studies have been published on the gelation kinetics using amylose samples with different chain lengths (Clark, Gidley, Richardson, & Ross-Murphy, 1989). Fig. 10 A shows the gelation process of 2% solutions of amylose with different chain lengths. Storage shear modulus G′ increased fast and then reached a plateau value earlier in lower molar mass samples. The plateau value increased with increasing molar mass within the DP range from 250 to 1100 however the highest molar mass DP 2550 still continued to increase even after 10,000 min (Clark et al., 1989).

Fig. 10.

A. Storage shear modulus G' (10 rad/s) vs time for 2% aqueous amyloses having chain lengths (DP) as shown beside each curve. Hot solutions were introduced in rheometer which had been kept at 25 °C beforehand (Clark et al., 1989). B. Time dependence of G' (thick line) and G″ (thin line) for oat β-glucan (OGL) solutions (10% w/v) with different molar masses (35, 65, 110, 140 kDa) (frequency 1 Hz, 25 °C) (Lazaridou et al., 2003).

Cereal (Oat, barley, wheat) β-glucans are linear homopolysaccharides composed of d-glucopyranosyl residues (Glcp) linked via a mixture of β- (1 → 3) and β-(1 → 4) linkages (Lazaridou et al., 2003). The chain consists mainly of β-(1 → 4) –linked β-d-glucose in blocks that are separated by single (1 → 3)-linkage. The resultant structure is a polysaccharide built mainly from β-(1 → 3)-linked cellotriosyl (58–72%) and cellotetraosyl (20–34%) units, but a minor amount of sequences with consecutive (1 → 4) linkages longer than the tetraose type and up to 14 glucosyl units (Cui & Wood, 2000). Lazaridou et al. (2003) extracted and purified oat β-glucans (OGL) and obtained five samples with different molar masses 35, 65, 110, 140 and 250 kDa. Gelation process of these OGL solutions is shown in Fig. 10B. Storage modulus G′ of lower molar mass samples showed faster increase and reached a plateau earlier than higher molar mass samples. The highest molar masse sample (MW 250 kDa) did not show any tendency to gel, i.e., G' < G″, under the same experimental conditions even after 200 h of storage (Fig. 10B, inset) (Lazaridou et al., 2003).

The concentration dependence of plateau modulus of amylose gels and β-glucan gels is shown in Fig. 11 . While the plateau storage modulus of amylose gels in the concentration range from 1 to 3%, the modulus is higher for higher molar mass than for lower molar mass (Fig. 11A), the modulus of β-glucan gels in the concentration range from 4 to 12%, the modulus is higher for lower molar mass than for lower molar mass (Fig. 11B).

Fig. 11.

A. Experimental G' (10 rad/s, 25 °C) values vs concentration (% w/v) for gels of amylose with different molar masses: (●) DP = 300, [□] DP = 660, (▲) DP = 1100. Theoretical fits obtained by using the Clark-Ross-Murphy approach (f = 3, 6, and 10) are indicated by broken lines (Clark et al., 1989). B. Concentration dependence of plateau value of G' (1 Hz, 25 °C) for gels of oat β-glucan with MW = 35 kDa (◇) and 110 kDa (△) (Lazaridou et al., 2003).

In amylose gelation, the plateau value increased with increasing molar mass as shown in Fig. 10A, while in β-glucan gelation, the plateau value seemed to decrease with increasing molar mass as shown in Fig. 10B, though for slow gelling samples with higher molar mass did not reach the plateau within 100 h. The apparent inconsistency between Fig. 11A and B, that the apparent plateau modulus increases with increasing MW in the former (amylose) while it is smaller for higher MW in the latter (β-glucan), originates from the non-equilibrium nature of these apparent plateau moduli. As shown in Fig. 11B, the gelation proceeds much slower in β-glucan than in amylose, it is impossible to compare directly with Fig. 11A and B. This reminds us the slow gelation rate of gelatin solutions. The storage modulus of 1.95% (w/w) gelatin/water increased faster at lower temperatures but it has not reached an equilibrium plateau but continued to increase even after 100 h (Nijenhuis, 1981). It is also necessary to take into account the molar mass range and in addition molecular conformation, flexible or stiff, when the modulus of different gelling polymers are compared as a function of molar mass. The effect of minor component of intermediate DP higher than 4 and a small amount of protein in β-glucan seems to be difficult to be quantified accurately, and is a future problem.

It should be noted that there is a critical molar mass and a critical concentration below which no gelation occurs. For amylose this critical molar mass was in between DP = 110 and DP = 250, and below DP = 110 only precipitates were observed. The critical concentration for gelation of amylose was found to depend on the molar mass (Gidley & Bulpin, 1989).

3.3. Elastic modulus and fracture stress of gels as a function of molar mass

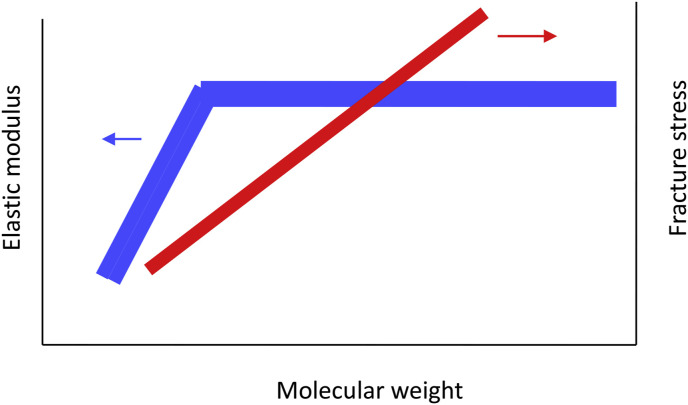

Since it is difficult to prepare samples with different molecular weight and with a narrow molecular weight distribution, there have not been so many studies on the molecular weight dependence of elastic modulus of gels. Saunders and Ward (1955) studied rheological properties of gelatin gels with different molecular weights indexed by intrinsic viscosity, and showed that the elastic modulus increased with increasing molecular weight up to a certain value and then levelled off whilst the breaking stress continued to increase with increasing molecular weight (Saunders & Ward, 1955). More recent study (Eysturskarð, Haug, Elharfaoui, Djabourov, & Draget, 2009) on fish gelatin showed a similar tendency. In addition, Eysturskarð (2010) showed that the addition of lower mass gelatin decreased the elastic modulus of gelatin gels.

Shear modulus of alginate gels as a function of weight average degree of polymerisation was reported to show two regions; the initial steep ascending region and then levelled off and show a long horizontal region. Smidsrød (1974) showed this tendency for both alginate gels and κ-carrageenan gels. He suggested that the difference of the plateau values, independent of the DP, is due to the difference in the number or the strength of the junctions in alginate and κ-carrageenan. Twenty years later, the same group Draget, Skjåk Braæk, and Smidsrød (1994) reported the molar mass dependence of apparent Young's modulus E app and storage shear modulus G′ of gels of alginate. In the range of molar mass from 300 kDa to 700 kDa, they observed that both E app and G′ increased with increasing molar mass and did not show the molar mass independency as shown in Fig. 12 . It should be mentioned that they noticed that elastic modulus increased with increasing guluronic acid residues as reported previously from the same group (Smidsrød & Haug, 1972). This comparison is difficult because it is difficult to obtain the series of samples with the same molar mass and only different in the guluronic acid residue content. Quite a similar behaviour was reported for κ-carrageenan gels with different molecular weights (Rochas et al., 1990). These tendencies can be summarised as shown in Fig. 12. The elastic modulus increases steeply with increasing molar mass, and then it levels off above a certain molar mass.

Fig. 12.

Schematic representation of the relation between the elastic modulus of gels and molecular weight of gelatin, κ-carrageenan, and alginate based on Saunders and Ward (1955), Rochas et al. (1990), Smidsrød (1974), Mitchell (1980).

The temperature dependence of the elastic modulus has been attracting much attention. Whether the elasticity of agarose is entropic or energetic has been debated for a decade just after the 2nd world war in Japan (Nishinari, 2000a). Nishinari, Watase, and Ogino (1984) tried to separate the entropic term and energetic term from the observed temperature dependence of Young's modulus E′ for gels of agarose with different molar masses (indexed by the intrinsic viscosity) and with the same sulphate content and the 3,6 anhydro-l-galactose content, both of which are important factors influencing the helix and gel formation (Nishinari & Fang, 2017). The Young's modulus E′ increased with increasing molar mass and temperature for higher molar mass fractions (Fig. 13 A). The tendency observed for the increase of E′ with increasing molar mass is consistent with the above Fig. 12 for gels of gelatin, κ-carrageenan, and alginate. The elastic modulus was determined as dynamic Young's modulus E′ by observing longitudinal vibrations of a cylindrically moulded gel, which is free from slippage. While E′ decreased monotonically for a gel of agarose with a low molar mass (F1), E′ of other gels with higher molar masses (F2, F3, F4, F5) increased gradually from 5 °C up to a certain temperature T max, and then decreased (Nishinari et al., 1984). This temperature T max shifted to higher temperatures with increasing molar mass and concentration (Fig. 13A). It was found that the entropic part decreased while the energetic part increased with increasing temperature. The increase of E′ with increasing temperature was explained by a reel-chain model (Nishinari, Koide, & Ogino, 1985).

Fig. 13.

A. Storage Young's modulus E′ of gels of agarose with different molar masses MW(F1) < MW(F2) < MW(F3) < MW(F4) < MW(F5) as a function of temperature (Nishinari et al., 2016). B. Strain-Stress curves of 2.4% gels of agarose with different molar masses MW(f1) < MW(f2) < MW(f3) < MW(f4). Stress values were taken after 2 min strain (Watase; Nishinari, 1983)..

Stress relaxation of agarose gels with different molar masses were observed, and the relaxation spectra were obtained using time-temperature superposition (Watase & Nishinari, 1983). It was shown that box type spectra extended to longer relaxation times with increasing molar mass at a constant concentration, and that both breaking stress and breaking strain increased with increasing molar mass (Fig. 13B).

More recently, Moritaka. Yamanaka, Kobayashi, Ishihara, & Nishinari (2019) examined the size distribution of the masticated fragments of agarose gels, and found that the size distribution depended on molar mass as well as a mouthful size. As expected, the size of masticated fragments decreased with decreasing molar mass of agarose, which forms more brittle gels broken at lower fracture strains.

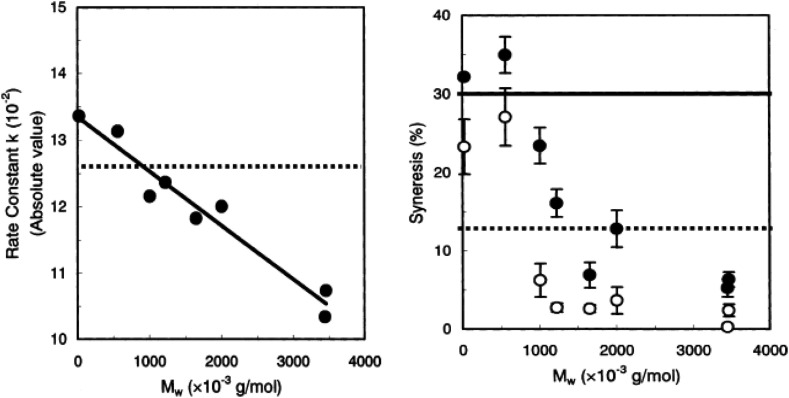

3.4. Molar mass effect of alginate, pectin, methylcellulose and konjac glucomannan in rheology control

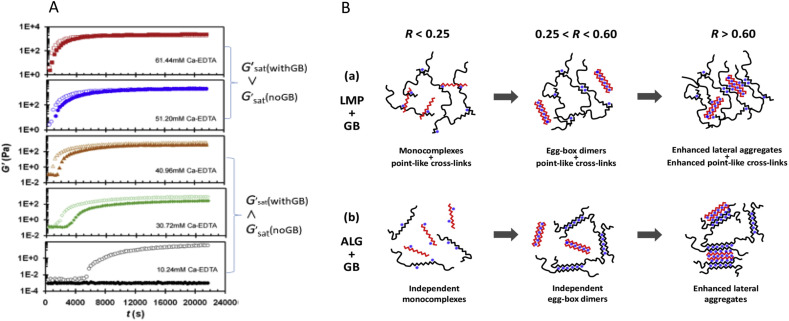

Alginate is unbranched binary copolymer of (1 → 4)-β-linked-d-mannuronic acid (M) and α-l-guluronic acid (G), which occur in a blockwise distribution pattern containing M-, G- and MG-blocks (Draget & Taylor, 2011). Although an egg-box model proposed by a research group of Unilever Research has been widely accepted, the detailed mechanism of the binding of Ca2+ to alginate at a molecular level was not understood. Fang et al. (2007) examined the binding process by stepwise addition of small amounts of CaCl2 into dilute alginate solutions, of different molecular weights and mannuronate/guluronate ratios, and by the investigations using high-sensitivity isothermal titration calorimetry (ITC), Ca2+ -selective potentiometry, and relative viscometry. The results revealed three distinct and successive steps in the binding of calcium to alginate with increased concentration of Ca ions. They were assigned to (i) interaction of Ca2+ with a single guluronate unit forming monocomplexes; (ii) propagation and formation of egg-box dimers via pairing of these monocomplexes; and (iii) lateral association of the egg-box dimers, generating multimers. The boundaries between these steps were found critical, and they were closely correlated with the Ca/guluronate stoichiometry expected for egg-box dimers and multimers with 2/1 helical chains. In this multi-step binding of Ca to alginate, the dimerization process was found to be highly critical, only occurring when the stoichiometry of egg-box dimers is met, that is, Ca/G = 0.25, one calcium ion per four guluronate residues. The formation of egg-box dimers and their subsequent association are thermodynamically equivalent processes and can be fitted by a model of independent binding sites. In addition, the step (iii) showed different association modes depending on the molar mass of alginate. While the relative viscosity η r continues to increase in (iii) indicating that lateral association of egg-box dimers for lower molar mass alginate occurs between different dimers, ηr decreases in (iii) for higher molar mass alginate indicating the association makes the volume of aggregates smaller.

Fig. 14A shows the gelation profiles of 5 mg/mL ALG with and without addition of 5 mg/mL oligoguluronate, guluronate block (GB) at various concentrations of Ca-EDTA. It is well known that alginate forms an inhomogeneous gel by a rapid ionic reaction, and the slow release of calcium from calcium carbonate or Ca-EDTA in the presence of slow acidifier like glucono-delta-lactone is used to make a homogeneous alginate gel (Draget, Ǿstgaard, & Smidsrød, 1991; Thu, Smidsrød, & SkjåkBraæk, 1996). Gelation kinetics and equilibrium gel properties of alginate aqueous solutions induced by in-situ release of Ca ions from Ca-EDTA during D-glucono-delta-lactone (GDL) hydrolysis were observed and the modulatory effects of GB were analysed quantitatively. It is apparent that when Ca-EDTA < 51.20 mM the systems without 5 mg/mL GB gelled faster than those with the addition of 5 mg/mL GB and also attained a higher value of saturated equilibrium storage modulus. It manifests an inhibitory effect exerted by the addition of GB. On the contrary, when Ca-EDTA > 51.20 mM, the systems with 5 mg/mL GB tended to end up with a higher saturated equilibrium storage modulus than those without 5 mg/mL GB. Moreover, the gelation kinetics seems not to be altered significantly by the addition of GB.

Fig. 14.

A. Gelation profiles of storage modulus G′ versus time at fixed ALG and GB concentrations and various Ca-EDTA concentrations. ALG, 5 mg/mL; GB, 0 mg/mL (open symbol) and 5 mg/mL (closed symbol) (Liao et al., 2015). B. Proposed mechanisms of GB modulating the gelation of LMP in different Ca concentration regimes (a), and comparison to the case of ALG (b). The black lines represent macromolecular LMP or ALG. The red zigzag lines represent oligomer GB. The blue dots represent Ca2+ ions. (For interpretation of the references to colour in this figure legend, the reader is referred to the Web version of this article.) (Zhang et al., 2019).

The effect of guluronate block GB depends on the ratio of calcium ions to guluronate unit, R = Ca/G. The addition of GB shows an inhibitory effect in the range of 0.25 < R (Ca/G) < 0.60, and promotive effect in the range of R > 0.60 based on static and dynamic viscoelastic measurements. Mixed egg-box dimers between ALG and GB were ruled out because of cooperativity requirement of dimerisation. The promotive effect in the higher Ca concentration regime was assigned to the role of GB dimers participating in and enhancing the lateral aggregation of ALG dimers. In conclusion, short chain guluronate block is found to inhibit the gelation of alginate at low concentration of Ca2+ ions while it enhances the gelation at higher Ca2+ concentration. Inhibitory effect is attributed to the binding of calcium ions to shorter guluronate chains. Those findings may be useful in food processing and also have some therapeutical significance in the rheology of sputum as discussed in the following section.

More recently, Zhang, Hu, et al. (2019) studied the effect of lower molar mass (10 kDa) alginate, GB, on gelling behaviour of high molar mass (118 kDa) low methoxyl pectin (LMP) and high molar mass (240 kDa) alginate. GB was found to promote the gelation of LMP in the range of R ([Ca]/[guluronate + galacturonate]) < 0.25 and could make non-gelling systems gellable. This is significantly different from the case of alginate where no gelation could be induced at all. In the range of 0.25 < R < 0.60, the addition of GB was found to inhibit the gelation of LMP, whereas it had a negligible effect on the gelation of alginate as long as a fixed R was considered. In the range of R > 0.60, GB was found to promote the gelation of LMP again, which is similar to the case of alginate as described above (Fig. 14 B).

Polysaccharides are frequently used to reduce the fat content, and to improve the texture and water holding capacity (WHC) of protein gels. Yao, Zhou, Chen, Ma, Li, & Chen (2018) recently examined the effect of the addition of sodium alginate (SA) with three different molar masses on the WHC of chicken breast myosin gels. They found that WHC increased simultaneously with turbidity and thermal stability, accompanied with the decrease in surface hydrophobicity with increasing molar mass of added SA. They noticed that the addition of sodium alginate shifted the thermal transition temperature to higher temperatures detected by DSC with the higher contribution by a higher molar mass SA, which is consistent with the same stabilisation by the addition of flaxseed gum to salt-soluble meat protein, but is contradictory with the reported thermal destabilisation of myofibrillar, sarcoplasmic and connective tissue protein by the addition of SA. They observed that inhomogeneity of cavities formed in SA-protein gel network was enhanced by the higher molar mass SA, which resulted in the increase in WHC because they thought that large cavities could store more water.

3.5. Molar mass effect in cryogels and heat set gels

Some polysaccharides such as locust bean gum and cereal β-glucan as well as poly(vinyl alcohol) (PVA) form cryogels after freezing and thawing cycles while most polysaccharides such as agarose, carrageenans donot but only framework structure remains after freezing because water exudes out and not retained (Djabourov et al., 2013). Lazaridou and Biliaderis (2004) examined the effect of molar mass of oat, barley and wheat β-glucan on the small and large deformation rheology of cryogels. They found that the elastic modulus, compression modulus and true stress at 40% deformation all increased with increasing number of freezing cycles, concentration and molar mass as had been found previously for PVA cryogels (Djabourov et al., 2013). Fig. 15 A shows the compression stress σ -Hencky strain εH curves of oat β-glucan cryogels. Compressive stress increased with increasing molar mass which is in good agreement with Fig. 15B which shows the force-extension curves for cryogels of PVA with different DPs 500 (curve (1)), 1000 (curve (2)), 1700 (curve (3)), and 2400 (curve (4)). However, the storage shear modulus G′ of oat β - glucan cryogels showed opposite tendency as illustrated in Fig. 15C. The finding that G′ increased with increasing concentration of β-glucan is a common phenomenon.

Fig. 15.

A. Compression stress (σ)-Hencky strain εH curves of cryogels of oat β-glucans with different molar masses (110 kDa, 140 kDa and 200 kDa). Initial solution concentration 3% w/v, 12 freeze–thaw cycles (Lazaridou & Biliaderis, 2004). B. Force-extension curves for 15 wt % PVA gels (DS = 98.5 ± 0.5 mol %, number of freeze-thaw cycles = 3) of various DP (1): 500; (2), 1000; (3), 1700; (4), 2400. PVA gels of square shape (110 mm × 110 mm) with 3 mm thick was clamped between metal plates having 18 mm diameter hole in the center, and were subjected to compression using 5 mm diameter spherical metal probe at 50 mm/min (Watase & Nishinari, 1985). C. Storage modulus G′ recorded at 5 °C, 1.06 Hz, and 0.1% strain, cryogels of oat β-glucan with different molar masses 65 kDa, 110 kDa, 140 kDa and 200 kDa, and with different concentrations 1, 2, and 3% obtained after 12 freeze–thaw cycles (Lazaridou & Biliaderis, 2004).

Holding periods of samples at − 18 °C for 24 h, and at 5 °C for 24 h is defined as one freezing–thawing cycle in oat glucan (A & C) while one cycle of PVA cryogel formation (B) was as follows: holding PVA solutions at −20 °C for 24 h, then it was raised to 15 °C at a constant rate of 0.194 K/min, and hold there for 7 h. Then, the gel was cooled to −20 °C at the same rate and held at −20 °C for 11 h (one cycle).

However, the G′ values of cryogels decreased with increasing molecular size. Lazaridou and Biliaderis (2004) had found a similar trend in their earlier study for cereal β-glucan gels formed at room temperature and it had been attributed to the higher mobility of shorter chains (Lazaridou et al., 2003, 2004). Their interpretation was as follows: the molecular size has a significant impact on the viscosity of polymer solutions, thus influencing the diffusion rates of the interacting polysaccharide chains. However, it is difficult to understand this explanation because the stress-strain curves shown in Fig. 15A, the Young's modulus estimated from the initial slope of the curve is the largest for the gel from the higher molar mass oat glucan 200 kDa and the smallest for the gel from the lowest molar mass oat glucan 110 kDa. Unfortunately, gels from 65 kDa were so weak to keep the shape to do the compression measurements. The inconsistency between the Young's modulus from the slope of stress-strain curves in Fig. 15A and the storage shear modulus shown in Fig. 15C should be studied further.

Heat set gel formation also depends on molar mass. The gelation process of solutions of methyl cellulose (MC) with different molar masses and with approximately the same methoxy content (29 wt%) was observed by measuring G′ and G″ at a constant temperature 55 °C. The gelation time at which G′ began to increase above the base line was shorter in a higher molar mass MC solution. This rheological tendency is in accordance with DSC observation in which an endothermic peak appeared on heating accompanying the gelation. The longer chains have a greater tendency to form junction zones which are induced mainly by hydrophobic interaction (Nishinari, Hoffmann, Moritaka, Kohyama, & Nishinari, 1997). Whether the gel formation of MC is caused by spinodal decomposition or by the nucleation and growth is still a matter of hot debate (McAllister, Schmidt, Dorfman, Lodge, & Bates, 2015). More detailed studies on the gelation of MC changing molar masses at a constant degree of substitution, preferably using regioselective substitution, are expected in the future.

The gelation of KGM occurs through the alkali-induced removal of acetyl groups which confer the solubility for this polysaccharide (Nishinari, 2000b). KGM forms a thermally stable gel by deacetylation upon addition of alkaline coagulant and the gelation of KGM is promoted by heating, in contrast to many other cold-set thermo-reversible gels. The increase in the concentration or molecular weight of KGM shortened the gelation time and increased the rate constant of gelation, and the resulted gels show higher modulus (Yoshimura & Nishinari, 1999; Zhang et al., 2001). This is consistent with the general tendency observed in gelatin, carrageenan, alginate and agarose gels as described above. The effect of the degree of acetylation (DA) on the gelation of KGM was studied (Huang, Takahashi, Kobayashi, Kawase, & Nishinari, 2002; Gao & Nishinari, 2004). To understand the effect of molar mass on the gelation, it is necessary to obtain KGM sample with a constant degree of acetylation (DA) with different molar masses, but this has not yet been done because of the difficulty of sample preparation. The same difficulty is encountered in the study of the interaction of KGM with other polysaccharides such as κ-carrageenan, agarose, starch or proteins such as gelatin and myofibrillar proteins although these mixtures have been used in food products without understanding the detailed mechanism. The more detailed knowledge will improve further the products.

3.6. Molar mass effects in oleogels

Crystallinity of solid fat is generally much higher than high molar mass polysaccharides and proteins, and the linear elastic range is much narrower than in semi-solid foods mainly composed of polysaccharides and proteins. Spreadability of semi-crystalline solid fat such as butter and margarine is an important functionality during consumption, and this characteristics is different from high molar mass polysaccharide and protein food gels.

Since the intake of trans fatty acid was reported to pose a health risk (Mozaffarian, Katan, Ascherio, Stampfer, & Willett, 2006), an alternative technique to solidify the oil without using partially hydrogenated oils which contain trans fatty acids has been sought by food industry. Oleogels can produce three-dimensional crystalline networks and structuring oils (Marangoni & Garti, 2018). Ethyl cellulose (EC) has been used as oil structuring materials. Gravelle, Barbut, Quinton, and Marangoni (2014) examined the oleogel composed of canola oil or soybean oil in the presence of EC with or without surfactants. Fig. 16 shows the effects of molar mass of EC on the mechanical properties of oleogels.

Fig. 16.

Back Extrusion force for oleogels (soybean oil) as a function of mass fraction of EC (ΦEC) with different molar masses, 28.6 ± 6.2 kDa (●), 51.9 ± 10 kDa (■), and 72.8 ± 15 kDa (▲) (Gravelle et al., 2014).

As is shown in Fig. 16, the gel strength was found to increase with mass fraction of EC in a power law fashion, and also to increase with increasing molar mass of EC. From the cryo-SEM observation of partially de-oiled gels, it was found that the internal structure consisted of oil droplets entrapped within a network of interconnected strands or bundles of EC, which formed a scaffolding to support the gel (Zetzl et al., 2014). Therefore, Gravelle et al. (2014) interpreted that reducing the MW of the gelator EC would produce a less entangled network with shorter strands/bundles, having fewer interconnections per structural unit, hence the gel strength was reduced. The finding that the gel strength increased with increasing molar mass of EC was also found for EC oleogels of other vegetable oils, canola, soybean, and flaxseed oil (Zetzl et al., 2014).

Replacing trans and saturated fatty acids in margarines or shortenings has been pursued by bakery industry to produce pastries, croissants, and danishes. Blake and Marangoni (2015) examined the effect of composition of a fat substitute for pastries on rheological properties. This fat substitute is called rolled-in shortenings which are folded into dough to form thin laminated layers between dough layers. Therefore, this fat substitute should have an appropriate rheological property, plastic enough to be spread easily, yet enough hard and with a certain level of yield stress so that it can fit into dough layers, and with high melting temperature. Chain length of fatty acid is one of most important factor controlling the rheology of this fat substitute. In the optimisation of the variable parameter of Coasun (developed in Marngoni's lab) they found that monoglyceride of chains of 18 carbons (Coasun C18) is better than Coasun16 or Coasun 22. Thus, they found the optimum chain length of monoglyceride in the production of pastries, croissants, and danishes.

3.7. Molar mass effect in protein gelation

Rennet-induced gelation of casein micelles has been studied extensively because it is the basis of cheese production. Niki et al. (1994) prepared the casein micelles with different sizes by differential centrifugation. Since the κ-casein, the substrate of rennet enzyme chymosin, exists mainly on the surface of casein micelles, the smaller micelles are richer in κ-casein content. Therefore, glycomacropeptide is liberated faster in smaller casein micelles as shown in Fig. 17 A.

Fig. 17.

A. Time course of glycomacropeptide (GMP) liberated from different casein micelles after renneting. Casein micelle solution (3%) in artificial milk serum. The enzymatic reaction was performed at 30 °C (Niki et al., 1994). B. The relationship between the micellar diameter and G′sat (open circles), G″sat (closed circles) and loss tan δ (open squares). The experiments were carried out at 30 °C. Casein micelle solution: 3% (Niki et al., 1994).

The saturated value of the storage shear modulus was largest in the gel formed by the smallest casein micelles (Fig. 17B). Then, the smallest casein micelles can form a gel faster and can form a stronger gel. In this case, the gelation is dominated not only the size of the casein micelles but the difference of the distribution of κ-casein in the casein micelles should also be taken into consideration.