Abstract

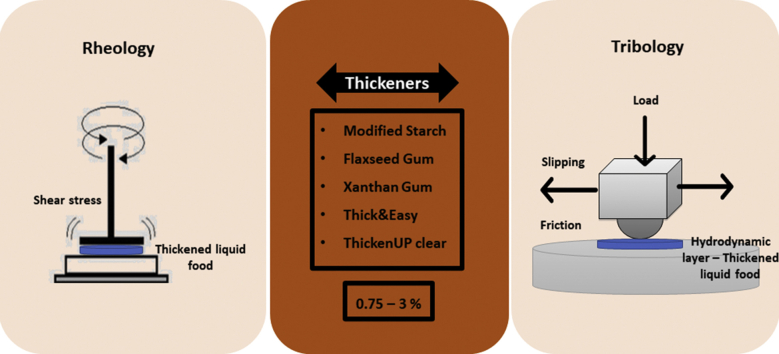

Dysphagia is a swallowing disorder that mainly affects elderly but can be minimized by thickening of liquid foods. Flaxseed gum (FG) was studied as a potential alternative thickener for dysphagia patients in comparison to commercial thickeners based on xanthan gum (XG) and modified starch (MS). Rheological and tribological responses of biopolymer-based thickening solutions (0.75–3% w/w) incorporated in different food matrices (water, orange-flavoured soy juice and skim milk) were recorded and correlated. In general, the increase in gums concentration led to increases in viscosity, viscoelastic properties and lubricating capacity. An opposite behavior was observed for the MS-based products, since an increase in concentration led to a lower increase in viscosity and viscoelastic properties but caused a decrease in the lubricating capacity. These results indicated that associating tribology to rheology is crucial to further define formulations with pleasant swallowing characteristics.

Keywords: Dysphagia, Thickeners, Flaxseed gum, Rheology, Tribology

Graphical abstract

Highlights

-

•

Modified starch-based (MS) has lower thickening and lubricant capacities than gums.

-

•

Higher MS concentrations increased viscosity, while decreased lubrication.

-

•

Flaxseed gum & xanthan-based solutions are better thickeners and lubricants than MS.

1. Introduction

Dysphagia is a swallowing disorder caused by aging or neurological complications. In recent years the number of patients diagnosed with oropharyngeal dysphagia (the most prevalent and severe stage) has increased worldwide (affecting 8% of the population). This disturbance occurs in the food transition from the oral cavity to the esophagus. Food aspiration is the major risk in this process, since the food bolus can accidently enter the respiratory pipe blocking the airways (Chen, 2009, Clavé and Shaker, 2015). As a strategy to circumvent the problems associated with dysphagia patients, thickened liquid foods by biopolymers are usually prescribed in order to increase the bolus passage time from the mouth to the esophagus, allowing time for the longer response of the muscles typical of these patients (Dewar and Joyce, 2006, Mackley et al., 2013, Hori et al., 2015).

Pregelatinized starch has been widely studied and used in commercially available products for dysphagia patients (usually in concentrations between 4 - 7%). However, the action of salivary amylase may cause a thinning effect, which is considered as potentially unsafe (Martínez et al., 2019). Therefore, gum-based thickeners, with emphasis on xanthan gum (usually dosed at concentrations between 0.88 and 11.5%) (Hadde and Chen, 2019), have emerged as an alternative, promoting a greater increase of viscosity and shear-thinning properties in aqueous systems. The rigid xanthan structure makes the systems containing this gum stable to pH, ionic strength and temperature, favoring its use in commercial thickeners (Martínez et al., 2019, Torres et al., 2019). Flaxseed gum (FG), the soluble polysaccharide fraction extracted from the Linum usitatissimum, is a potential and promising alternative thickener, since it exhibits interesting and stable rheological characteristics at neutral and acidic pH values (Vieira et al., 2019). FG is mainly composed by polysaccharide fractions, including fibers that prevent the occurrence of colorectal cancer, promoting an improvement in postprandial glycemia and weight control (Vieira et al., 2019, Qian et al., 2012, Elboutachfaiti et al., 2017, Foster-Powell et al., 2002, Ding et al., 2014, Liu et al., 2016).

Viscosity is a fundamental property obtained from rheological measurements, which is used as the most important criterion in the development of thickeners for dysphagia patients. An agreement published in the National Dysphagia Diet T (2002) by American Dietetic Association was reached to establish a categorization according to the viscosity (at 50 s−1) range values (Nectar-like (51–350 cP); Honey-like (351–1750 cP); Spoon thick (>1750 cP)) in order to ensure safe swallowing and facilitate palliative care procedures for different types of patient needs, although it does not consider very relevant sensory aspects. Although viscosity values are obtained at 50 s−1, there is not a consensus in the scientific community about the shear rate value of the swallowing process (National Dysphagia Diet T, 2002). A broad range of oral shear rates involving the bolus has been considered such as 10 s−1 (Cutler et al., 1983) or 400 s−1 to correlate with oral shear rates (Meng et al., 2005). On the other hand, other rheological properties such as pseudoplasticity and viscoelastic properties as complex viscosity at 50 rad s−1 of thickened fluids may also give a good empirical correlation with sensorial characteristics or a probable mouthfeel, which may help in the choice of biopolymer to be used as a thickener (Richardson et al., 1989). In order to improve understanding of the relationship between mechanical properties and sensory perception, some scientific groups have recently focused on the study of surface properties of thickened liquids (Torres et al., 2019, Chen and Stokes, 2012, Sarkar and Krop, 2019).

Tribology is defined as the study of lubrication, friction and wears of compliant surfaces in relative motion, and has been used as a tool to understand the lubrication ability of polymer solutions, fluid gels and gelled particles and emulsions (Douaire et al., 2014, Upadhyay and Chen, 2019). The selection of a physiologically relevant configuration is essential for the successful application of tribology: the choice of instrument, surfaces and the model food system should be considered (Prakash et al., 2013). The coefficient of friction obtained in tribological analyses can vary significantly with food properties, such as viscosity, but its magnitude also depends on the nature and characteristics of the chosen surface (Upadhyay and Chen, 2019, Stokes et al., 2013). Thus, the coefficient of friction is an effective indication of the lubricating properties between two surfaces at a given moving speed resulting in sensory/textural indicia. However, the correlation between coefficient of friction and texture is still a challenge, given the complexity in establishing a bridge between tribology and sensory perception, since both are affected by multiple physical and chemical properties (Upadhyay and Chen, 2019). Therefore, the interest of this work was the use of tribological analysis associated to rheological properties to evaluate FG as a potential thickener to dysphagia patients establishing a comparison with other biopolymers and commercial products, observing the impact of these thickeners in different food matrices.

2. Materials and methods

2.1. Materials

Golden flaxseeds were kindly provided by CISBRA Ltda (Panambi, RS, Brazil). Xanthan gum was donated by Danisco (Brazil) and pregelatinized starch by Cargill (Brazil). Two commercial thickeners purchased in local market were used: one based on xanthan gum (also containing maltodextrin and potassium chloride) (ThickenUP, Nestlé) and another on modified starch (containing maltodextrin) (Thick & Easy, Hormel). The food matrices orange-flavoured soy juice (composition: water, soybean, sugar, concentrated orange juice, maltodextrin, vitamins C, B3, B6 and B12, zinc, pectin, guar gum, citric acid, flavorings, malic acid, urucum, curcuma and sucralose; pH 4.14) (Ades, Unilever, Brazil) and skim milk (pH 6.77) (Shefa, Brazil) were also purchased in local market. The material used to simulate the tongue surface was polydimethylsiloxane (PDMS) produced from a Sylgard 184 silicone elastomer kit (Dow Corning Corporation, U.S.A.). Base and curing agents were used in a mass ratio of 9:1 to obtain disks with 5 mm thickness sheet and 50 mm diameter. In order to eliminate air bubbles, the PDMS disks were cured for 2 h in an oven at 55 °C.

2.2. FG extraction

FG was extracted according to Vieira et al. (2019). Flaxseeds (500 g) were soaked in distilled water (4 L) and stirred (800 rpm) for 5 h at 25 °C. Then, the water containing the dissolved FG was treated with 99.5% ethanol (1:1) to separate and remove the low molecular weight and insoluble polysaccharides. Ethanol was then evaporated, and the dialyzed precipitates were freeze-dried (LS3000, Terroni, Brazil).

2.3. Thickened beverages preparation

Aqueous, soy juice and milk dispersions were prepared using the following thickeners: pregelatinized starch; flaxseed gum; xanthan gum; MS-based commercial thickener (Thick & Easy); XG-based commercial thickener (ThickenUP) (Table 1) at concentrations of 0.75, 1.5, 2.25 and 3 (% w/w). All samples were prepared by dissolution of thickeners at room temperature in distilled water, skim milk and orange-flavoured soy juice using mechanical stirring for 30 min at 800 rpm.

Table 1.

Thickeners studied at different concentrations in water, milk and orange-flavoured soy juice and their abbreviations.

| Thickener | Prevailing biopolymer | Abbreviation |

|---|---|---|

| Pregelatinized Starch | Starch | MS |

| Flaxseed Gum | Flaxseed Gum | FG |

| Xanthan Gum | Xanthan | XG |

| Thick&Easy | Starch | TE |

| ThickenUP | Xanthan | TU |

2.4. Rheological properties

Rheological properties of the thickened food matrices were obtained using an AR1500ex rheometer (TA Instruments, USA) with a stainless-steel cone-plate geometry (6.0 cm, 2° angle, truncation 67 μm) or double concentric cylinders (rotating bob: external diameter 21.96 mm and internal diameter 20.38 mm, stationary cylinder: internal diameter of 20 mm and external diameter 22.38 mm). The choice of geometry depended on the viscosity of the thickened solution.

Flow curves were obtained by an up–down–up step program using different shear stress ranges to provide shear rates between 0 - 400 s−1 at 25 °C. The shear rate range between 10 and 400 s−1 encompasses the swallowing process and is commonly used by several authors to allow comparison between studies (Meng et al., 2005, Shama and Sherman, 1973, Morris and Vaisey-Genser, 2003). Also within this range, the shear rate of 50 s−1 is suggested by the National Dysphagia Diet guidelines as a standard to evaluate apparent viscosity. Newtonian (Eq. (1)), power-law (Eq. (2)) and Herschel-Bulkley (Eq. (3)) equations were fitted to the data to obtain rheological properties:

| (1) |

| (2) |

| (3) |

where σ is the shear stress (Pa), is the viscosity (Pa.s), is the consistency index (Pa.sn), is the shear rate (s−1) and n is the flow index.

Oscillatory measurements were performed at 25 °C using a frequency sweep between 0.1 and 10 Hz within the linear viscoelastic domain. The contributions of the elastic and viscous properties were analysed from storage (G′) and loss (G″) moduli, respectively. The complex viscosity at 50 rad s−1 () (Eq. (4)) was also evaluated, since this property showed a good correlation with the sensorial consistency of viscoelastic materials (He et al., 2016).

| (4) |

where G∗ is the vector sum of the elastic (G′) and viscous (G″) moduli and ω is the angular frequency (rad.s−1).

2.5. Tribological measurements

Tribological tests were carried out at 25 °C using a reciprocating ball-on-plane configuration in an UMT-2 (CETR) equipment (USA) (Fig. 1). The AISI 52100 steel ball (ø = 10 mm) slid without rolling on the PDMS plane surface (disc with 40 mm diameter and 5 mm thickness) during measurements, forming the friction contact (ball-on-disc). The ball was used to represent the palate and the PDMS disc was meant to mimic the human tongue surface. PDMS is currently a feasible choice for food tribology studies and it is selected due to its well-defined mechanical properties and surface chemistry. PDMS shows a low elastic modulus that could mimic the low-pressure contact typical in bio-lubrication (Upadhyay and Chen, 2019, Zhang et al., 2017).

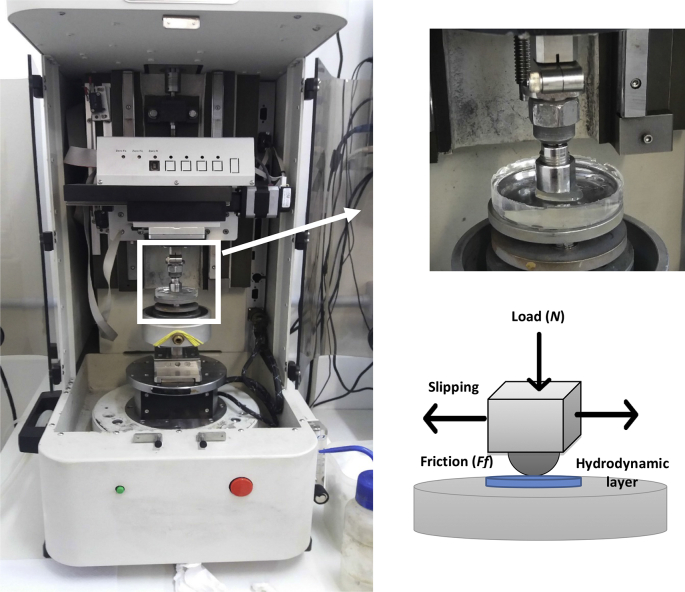

Fig. 1.

Tribometer (UMT-2 (CETR)) configuration and its schematic representation. A normal load (N) is applied and the friction force (Ff) measured while the steel surface slips on the hydrodynamic layer at a given speed.

The wear track was 10 mm long with 2 Hz of reciprocating frequency, speed of 40 mm s−1, with a normal load of 5 N during 20 s (swallowing process occurs between milliseconds up to 20 s). The human tongue speeds have been estimated between 10 and 200 mm s−1 and the in-mouth force has been reported between 0.01 N and 10 N (Laiho et al., 2017). The tribological measurements in our study are within this range (40 mm s−1 and 5 N), as these were considered to be average values for dysphagic patients in the framework of the present study. In addition, this velocity value (40 mm s−1) was chosen based on a previous study evaluating biopolymers dispersions, which demonstrated that the maximum coefficient of friction was measured at 40 mm s−1 for a wide speed range (until 1000 mm s−1) (Torres et al., 2019, Zhang et al., 2017). It was placed 1.5 mL of each thickened sample on the PDMS surface and the tribological behaviour of the thickened matrices was tested. The coefficient of friction (CoF) was measured according to Equation (5) and reported for each sample as a function of time (s). Reported results were taken at steady state conditions.

| (5) |

where is the friction force (calculated as a function of the applied entrainment speed - 40 mm s−1 of the PDMS disc) and N is the applied load (5 N). Results are presented as the average of five replicates with the corresponding standard deviation.

2.6. Statistical analyses

The data were analysed using Statistica 7.0 software and Microsoft Windows Excel 2017 software. Data were subjected to analysis of variance (ANOVA) (p < 0.05) and the means were compared using the Tukey's HSD test to examine if differences between formulations were significant (α = 0.05).

3. Results and discussion

3.1. Rheological behaviour

Thickened liquids are used to reduce the flow velocity from the mouth to the oro-pharynx region in order to avoid aspiration of fluid into the pulmonary airways. In addition, no phase separation or syneresis should occur throughout the swallowing process (Germain et al., 2006), which means that the liquids should be homogeneous and stable. The different thickeners were added to the water, soy orange juice and skim milk, being these matrices representative of liquid foods. The juice and milk matrices were chosen to understand if the presence of other biopolymers could synergistically or antagonistically modify the rheological and tribological properties. The flow curves of shear stress as a function of shear rate of each thickener incorporated in water, milk and orange-flavoured soy juice were analysed (Supplementary material) to obtain rheological properties (n: flow index, : yield stress, k: consistency index) and the apparent viscosity at different shear rates (Table 2 and Fig. 2). The steady shear rheological properties are associated to the flow velocity of the food bolus (or viscosity), being that the flow index (n) values are related to sliminess perceived in the mouth (Funami, 2011).

Table 2.

Rheological properties (n, k and ) of the MS, FG, XG, TU and TE at different concentrations in water, milk and orange-flavoured soy juice.

| (% w/w) |

n |

k [Pa.sn] |

[Pa] |

|||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Water | Milk | Orange-flavored soy juice | Water | Milk | Orange-flavored soy juice | Water | Milk | Orange-flavored soy juice | ||

| MS | 0.75 | 1.00 ± 0.03 | 0.67 ± 0.01 | 0.63 ± 0.01 | 0.002 ± 0.001 | 0.08 ± 0.00 | 0.14 ± 0.03 | – | – | – |

| 1.5 | 0.87 ± 0.03 | 0.65 ± 0.01 | 0.63 ± 0.01 | 0.011 ± 0.002 | 0.22 ± 0.03 | 0.23 ± 0.01 | – | – | – | |

| 2.25 | 0.80 ± 0.05 | 0.65 ± 0.01 | 0.59 ± 0.02 | 0.032 ± 0.006 | 0.22 ± 0.02 | 0.45 ± 0.06 | – | – | – | |

| 3 | 0.41 ± 0.05 | 0.63 ± 0.01 | 0.59 ± 0.01 | 1.824 ± 0.032 | 0.33 ± 0.01 | 0.65 ± 0.03 | – | – | – | |

| FGa | 0.75 | 0.83 ± 0.02 | 0.65 ± 0.03 | 0.73 ± 0.01 | 0.047 ± 0.001 | 0.14 ± 0.02 | 0.11 ± 0.01 | – | – | – |

| 1.5 | 0.72 ± 0.01 | 0.64 ± 0.02 | 0.66 ± 0.01 | 0.287 ± 0.011 | 0.45 ± 0.03 | 0.44 ± 0.02 | – | – | – | |

| 2.25 | 0.60 ± 0.03 | 0.57 ± 0.02 | 0.63 ± 0.02 | 1.561 ± 0.034 | 1.76 ± 0.18 | 1.34 ± 0.18 | – | – | – | |

| 3 | 0.58 ± 0.01 | 0.48 ± 0.02 | 0.60 ± 0.02 | 3.178 ± 0.082 | 4.41 ± 0.31 | 2.32 ± 0.05 | – | – | – | |

| XG | 0.75 | 0.17 ± 0.02 | 0.50 ± 0.03 | 0.55 ± 0.01 | 5.223 ± 0.253 | 0.73 ± 0.14 | 0.65 ± 0.04 | 8.87 ± 0.18 | 3 ± 1 | 7.62 ± 0.15 |

| 1.5 | 0.11 ± 0.02 | 0.43 ± 0.04 | 0.39 ± 0.03 | 17.340 ± 0.352 | 2.07 ± 0.43 | 3.55 ± 0.46 | 21.45 ± 1.90 | 18 ± 4 | 23.20 ± 3.13 | |

| 2.25 | 0.10 ± 0.01 | 0.35 ± 0.02 | 0.38 ± 0.02 | 30.272 ± 0.730 | 5.19 ± 0.97 | 5.43 ± 0.51 | 37.43 ± 0.60 | 31 ± 6 | 39.74 ± 4.21 | |

| 3 | 0.11 ± 0.02 | 0.25 ± 0.03 | 0.32 ± 0.02 | 34.758 ± 1.572 | 18.68 ± 1.91 | 9.51 ± 0.73 | 51.79 ± 2.96 | 64 ± 8 | 49.05 ± 5.22 | |

| TE | 0.75 | 0.91 ± 0.03 | 0.67 ± 0.00 | 0.61 ± 0.02 | 0.009 ± 0.004 | 0.09 ± 0.00 | 0.10 ± 0.01 | – | – | – |

| 1.5 | 0.84 ± 0.03 | 0.68 ± 0.02 | 0.62 ± 0.02 | 0.022 ± 0.003 | 0.09 ± 0.01 | 0.14 ± 0.02 | – | – | – | |

| 2.25 | 0.71 ± 0.02 | 0.66 ± 0.01 | 0.61 ± 0.02 | 0.331 ± 0.061 | 0.22 ± 0.01 | 0.32 ± 0.06 | – | – | – | |

| 3 | 0.61 ± 0.03 | 0.65 ± 0.02 | 0.60 ± 0.01 | 1.511 ± 0.124 | 0.44 ± 0.04 | 0.70 ± 0.01 | – | – | – | |

| TU | 0.75 | 0.38 ± 0.03 | 0.44 ± 0.02 | 0.43 ± 0.01 | 0.718 ± 0.219 | 0.95 ± 0.13 | 1.03 ± 0.01 | – | – | – |

| 1.5 | 0.29 ± 0.02 | 0.42 ± 0.03 | 0.44 ± 0.04 | 2.085 ± 0.131 | 2.56 ± 0.11 | 1.86 ± 0.03 | – | – | 6.34 ± 1.02 | |

| 2.25 | 0.27 ± 0.02 | 0.39 ± 0.02 | 0.38 ± 0.02 | 3.035 ± 0.105 | 2.64 ± 0.18 | 3.02 ± 0.04 | 7.39 ± 0.56 | 6 ± 1 | 15.20 ± 2.12 | |

| 3 | 0.26 ± 0.01 | 0.34 ± 0.02 | 0.34 ± 0.03 | 4.362 ± 0.139 | 3.42 ± 0.12 | 3.29 ± 0.18 | 9.94 ± 0.36 | 12 ± 1 | 20.65 ± 3.55 | |

FG in water was adapted from Vieira et al., 2019

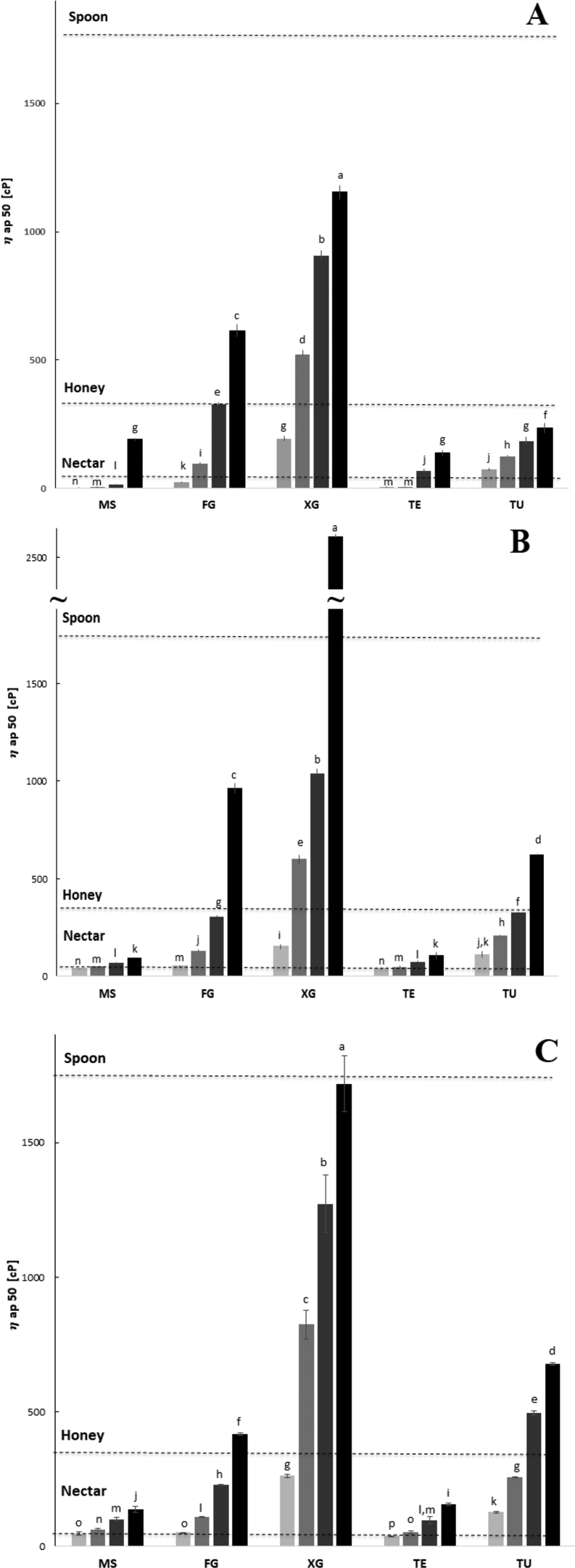

Fig. 2.

Apparent viscosity at 50 s−1 of the MS, FG, XG, TE and TU (0.75% ■, 1.5% ■, 2.25% ■ and 3% ■) incorporated in water (A), milk (B) and orange-flavoured soy juice (C).

All thickened solutions presented a shear time independent behaviour, meaning no thixotropy or rheopexy was noted. In addition a non-Newtonian shear-thinning behaviour was also observed, as n values were lower than 1, except for the solution with 0.75% w/w of MS (Table 2). Shear thinning behaviour implies a decrease in apparent viscosity at increased shear rates, which is commonly observed in polysaccharide solutions (Vieira et al., 2019, Li et al., 2016, Jo et al., 2018). The flow index varied between 0.10 ± 0.01 and 1.00 ± 0.03 and these extreme values were observed in water as food matrix. It should be noticed that the n values of the most complex matrices were closer to the same (concentration) condition compared to water, indicating that the matrix composition plays a relevant role on the rheological properties of thickened solutions. The lowest n values of XG-based thickened solutions (XG and TU) indicate that xanthan is likely to facilitate swallowing and reduce organoleptic viscosity (slimy feel) due to its greater pseudoplasticity, providing a pleasant and light mouthfeel (Szczesniak and Farkas, 1963, Cho and Yoo, 2014). Therefore viscosity of XG-based solutions will be high at low shear rates, but viscosity will be low at high shear rates as a consequence of a fast organization of XG molecules with the flow field. Moreover only xanthan gum-based solutions (XG and TU) showed yield stress, which was not observed for other biopolymers solutions. Consistency index (k), pseudoplasticity and yield stress (for XG solutions) increased with biopolymers concentration (Table 2), indicating the formation of a stronger and complex network (Cho and Yoo, 2014).

The apparent viscosity of gum-based solutions, regardless of shear rate and concentration, were pointedly higher than starch-based (MS and TE). However, the flow curves of modified starch-based solutions showed a significant increase in shear stress at 3% (w/w) MS concentration and 2.25% (w/w) TE concentration and therefore an increase of viscosity (Fig. 2). This result is in line with previous studies that have observed a more pronounced viscosity increase when hydrocolloid concentration allows to reach a viscosity range of 10–20 cP (Ferry et al., 2006). Higher viscosity was also observed in more complex and viscous matrices (milk and orange-flavoured soy juice presented higher viscosity than water but no significant differences were observed between them) compared to water with the addition of the same amount of thickener, indicating that a similar thickening effect (viscosity) could be achieved with a smaller amount of biopolymers. Nevertheless, very high viscosity can result in high cohesiveness, causing difficulty in the swallowing process due to the high resistance to stretching deformation, in particular in patients with weak tongue muscle and low oral pressure (Razavi et al., 2018).

The three types of consistency (nectar, honey and spoon) according to NDD were achieved for the different biopolymer solutions in relation to the viscosity obtained at 50 s−1. The two modified starch-based solutions presented the lowest viscosity values, with 3% w/w MS in water being necessary for adequacy to the dysphagic diet. However, the required amount of MS decreased to 1.5% (w/w) to achieve nectar-like consistency for milk and orange-flavoured soy juice. All thickened solutions based on xanthan gum presented adequate consistency for the consumption of dysphagic patients. XG solutions presented the three categories depending on thickener concentration, even showing spoon-like properties at the highest concentration in more complex matrices. However, solutions thickened with TU (also based in xanthan) presented nectar-like categorization in water and a honey-like category was achieved only at the highest thickener concentrations in milk and soy juice. It is noteworthy that the viscosity of the most complex matrices (milk and orange juice) was similar and higher than that of water with the addition of MS or xanthan-based thickeners. Finally, FG thickened solutions showed nectar-like consistency between the concentrations from the 1.5% w/w in water and the honey-like was reached only for the highest concentration in all matrices. However, FG presented an unlike behaviour in relation to the other thickeners, since solutions with the highest FG concentrations (2.25 and 3% w/w) in soy juice presented a lower viscosity compared to milk and water. This result indicates that FG can present a repulsive or antagonistic interaction with the other biopolymers present in the soy juice at acidic conditions (Razavi et al., 2018).

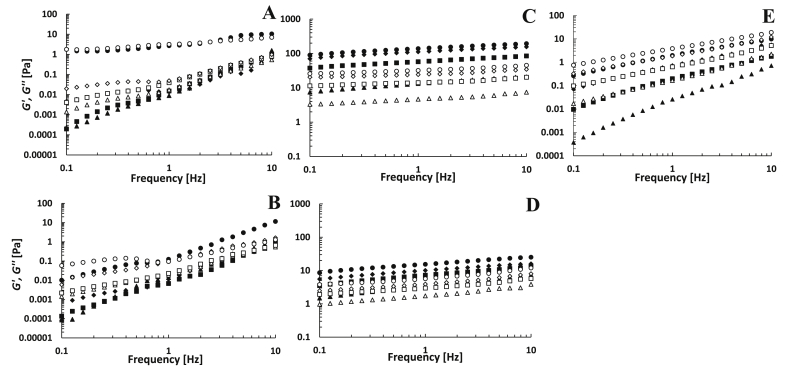

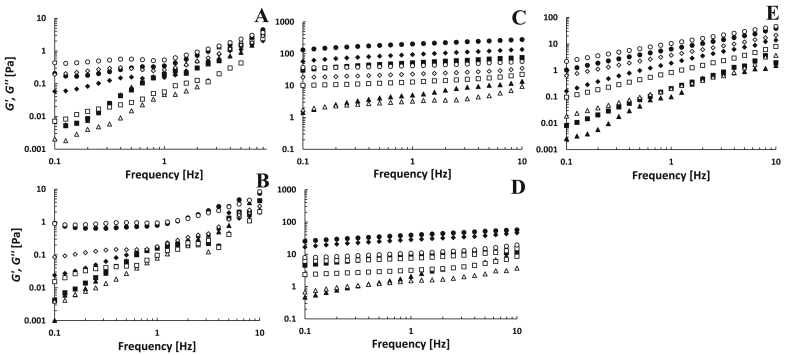

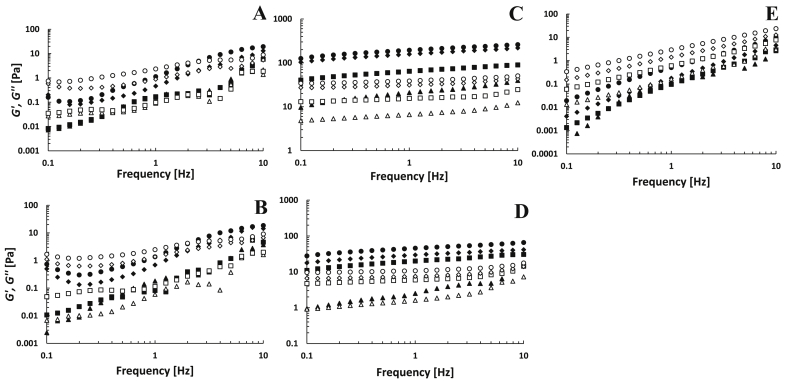

The dynamic rheological behaviour of the biopolymer solutions suggests that liquid food should be carefully prepared according to the thickener to support safe swallowing, since these properties of viscoelastic materials are also related to the food texture and consequent predicted mouthfeel (Funami, 2011). Higher frequency dependence (or lower stability of rheological behaviour) was observed for the viscoelastic moduli of MS and FG-based solutions (Fig. 3, Fig. 4, Fig. 5) when compared to those based on XG, mainly with decreasing biopolymers concentration. The viscoelastic moduli (G′ and G″) of thickened solutions based on MS presented the lowest values of viscoelastic properties, besides the lowest pseudoplasticity and apparent viscosity (Table 2 and Fig. 2). In addition, G′ and G″ showed similar values with prevailing viscous behaviour at low frequencies and predominance of elastic properties at high frequencies, as typical of diluted solutions (Duffy, 2015). Dynamic moduli (G′ and G″) were similar in complex matrices (milk and soy juice) but larger than water with MS-based thickeners (MS and TE). This fact may be associated with the starch capacity of structurally bind to other biopolymers present in these matrices, resulting in better thickening properties (Russ et al., 2016).

Fig. 3.

Elastic modulus (closed symbols) and viscous modulus (open symbols) as a function of frequency under isothermal (25 °C) conditions of the studied biopolymer solutions based on modified starch (MS (A) and TE (B)), xanthan gum (XG (C) and TU (D)) and flaxseed gum (FG (adapted from Vieira et al., 2019) (E)), at different concentrations (0.75% ▲, 1.5% ■, 2.25% ◆ and 3% ●) in water.

Fig. 4.

Elastic modulus (closed symbols) and viscous modulus (open symbols) as a function of frequency under isothermal (25 °C) conditions of the studied biopolymer solutions based on modified starch (MS (A) and TE (B)), xanthan gum (XG (C) and TU (D)) and flaxseed gum (FG (E)), at different concentrations (0.75% ▲, 1.5% ■, 2.25% ◆ and 3% ●) in milk.

Fig. 5.

Elastic modulus (closed symbols) and viscous modulus (open symbols) as a function of frequency under isothermal (25 °C) conditions of the studied biopolymer solutions based on modified starch (MS (A) and TE (B)), xanthan gum (XG (C) and TU (D)) and flaxseed gum (FG (E)), at different concentrations (0.75% ▲, 1.5% ■, 2.25% ◆ and 3% ●) in orange-flavored soy juice.

On the other hand, a predominance of elastic over viscous behaviour was observed for the XG-based systems (XG and TU). A typical gel behaviour was observed, since G′ was always greater than G″ and both exhibited a small frequency-dependence within the studied frequency range (Fig. 3, Fig. 4, Fig. 5). The predominance of elastic properties may be associated with more promising properties for pleasant swallowing since elastic properties have been considered important for palatability and smooth texture (Cho and Yoo, 2014). Viscoelastic properties of XG solutions were similar for all matrices, but they were higher in soy juice for TU systems. However, FG behaved as a predominant viscous material: G″ was always greater than G′, and the frequency dependence of the moduli decreased with increasing FG concentration. The magnitude of both moduli, although smaller than that of XG, was greater than that of MS-based thickeners in water and milk. Thus, in addition to the higher viscosity achieved for solutions with different concentrations of FG in relation to MS, FG solutions presented a significantly higher elastic parameter (G′) in these two matrices. As observed in the viscosity values, FG-based thickeners added to soy juice showed a reduction in elastic properties, confirming the incompatibility or antagonistic interaction between FG and other compounds of this matrix (soy juice).

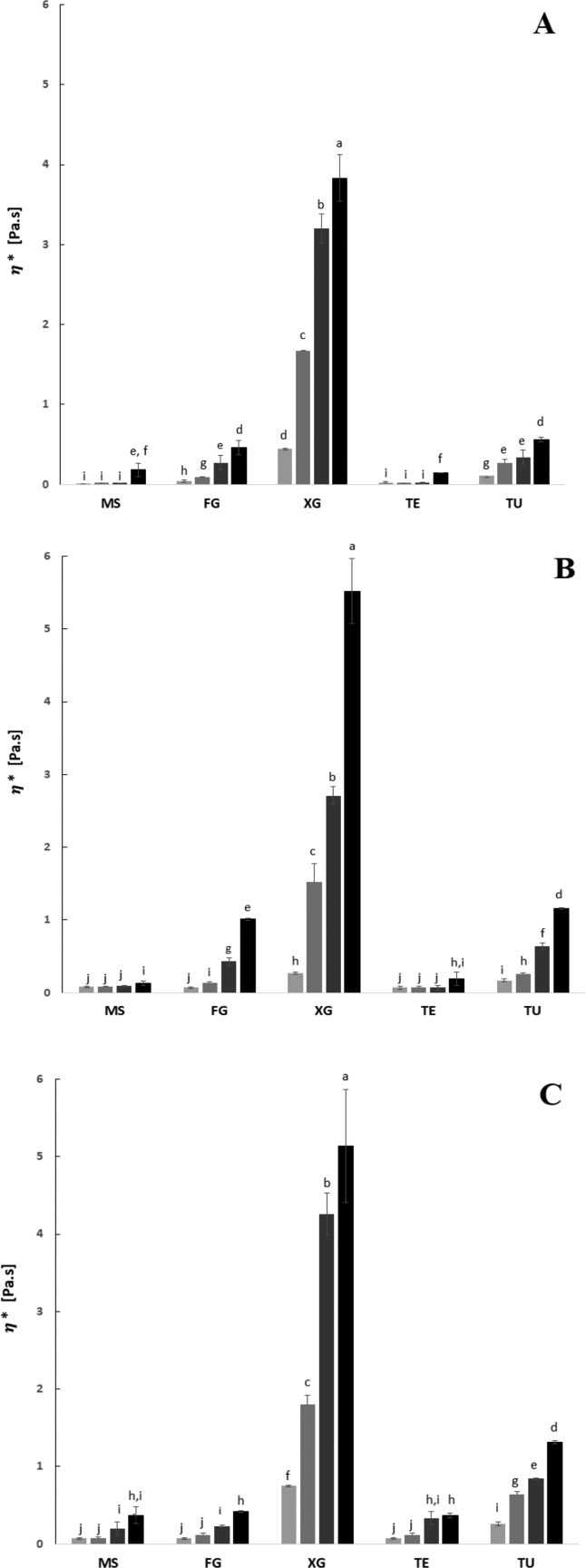

Complex viscosity () at 50 rad s−1 (Fig. 6) can be used to provide information on the stability and sensory consistency of viscoelastic foods (Richardson et al., 1989, Farahmandfar et al., 2017). Higher values of are associated with a stable/structured gel (higher elastic property), which is potentially relevant for the swallowing process (He et al., 2016, Cho and Yoo, 2014, Anvari and Joyner, 2018). The value of increased with increasing concentration of biopolymers. Moreover, at the same biopolymer concentration, XG systems showed higher complex viscosity, followed by TU and FG thickened solutions that presented similar values mainly at high concentrations. The lowest XG concentrations showed similar to the highest FG concentration, displaying the strong thickening capacity of xanthan. At the same concentration of MS and commercial MS-based thickened solutions, no significant differences were observed in complex viscosity. Again, the thickener and its concentration should be considered in detail for the final formulation used in the dysphagic diet, as different properties play different roles during swallowing, e.g., elastic properties may result in better sensory properties, but the amount of components that promote these properties must be regulated to avoid a solid-like behaviour at low swallowing velocity, but allowing for safe swallowing.

Fig. 6.

Complex viscosity at 50 rad/s () of the biopolymers incorporated in water (A), milk (B) and orange-flavoured soy juice (C).

3.2. Tribological properties

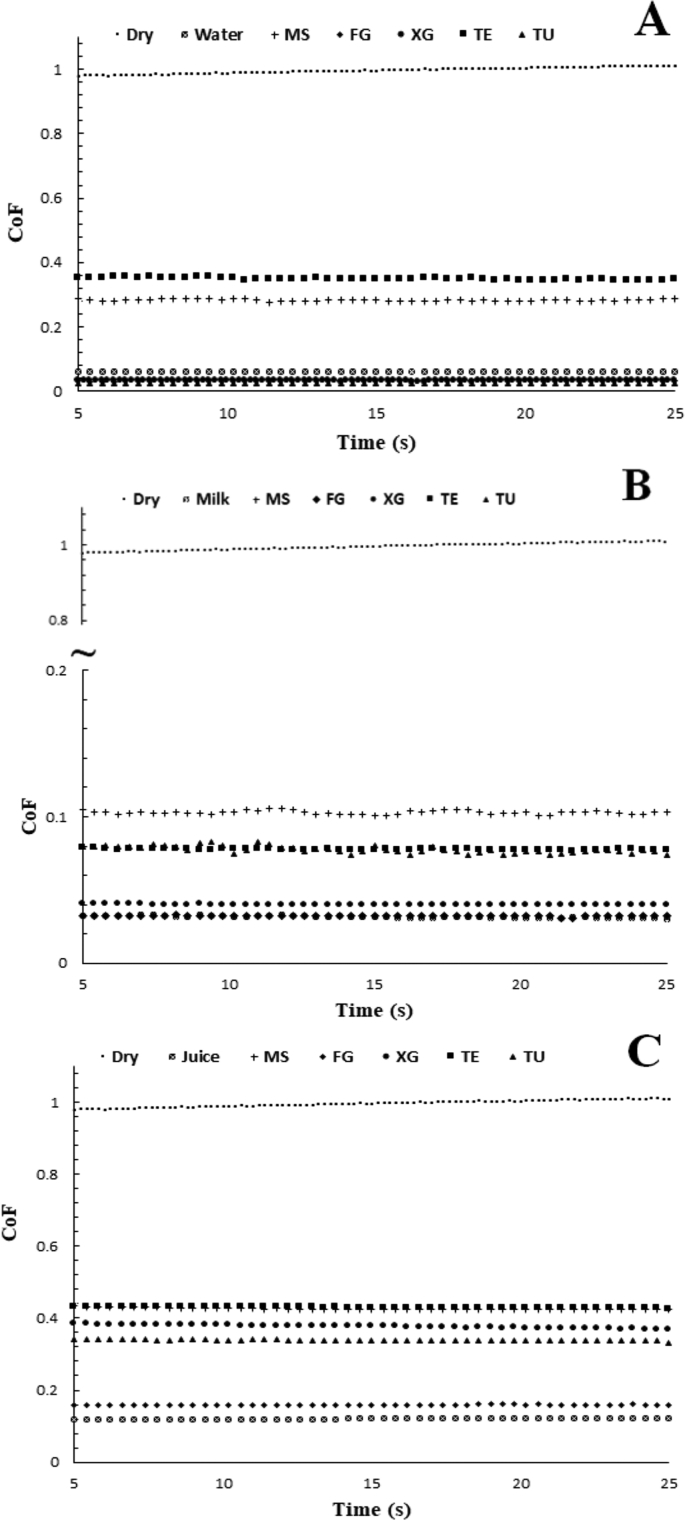

The emerging new methods to understand the swallowing process can be crucial in the development of thickeners for dysphagia patients. In this sense, soft tribology is an emerging tool in food science, correlating the coefficient of friction with some sensory properties, especially at the end of chewing (Torres et al., 2019, Hayashi et al., 2016, Marconati et al., 2019). Factors such as contact angle formed between the thickeners and the contact surface as well as the adhesiveness forces may interfere with the values obtained for the coefficient of friction. However, the focus of the present work was mostly on the relationship between rheological parameters and the coefficient of friction. The coefficient of friction as a function of time was evaluated for all the biopolymers’ dispersions and the responses for the highest concentration of thickeners are shown in Fig. 7, allowing to observe the significant differences between them in different matrices. Entrainment velocity and normal force were kept fixed while the coefficient of friction was measured over time in order to be correlated with the sensorial characteristics in the final stage of swallowing. Some authors consider that this perceived sensation results from the dynamic response of food products retained/held between the surfaces of the oral cavity, such as the tongue and palate (Selway and Stokes, 2013). The friction curves suggest that the friction coefficient of most formulations remains almost constant at the fixed speed used in the experiments (40 mm s−1), which means that the coefficient of friction would be constant during the chewing time if the force and velocity in the oral cavity were in the order of that value. However, these parameters change during the swallowing process and therefore it is relevant to consider that these results are only qualitative allowing to compare the lubricant effect of the different thickeners. Fig. 7, Fig. 8 shows that the lubricating properties were dependent on the matrix properties, type and concentration of thickener. Orange-flavoured soy juice presented a higher coefficient of friction than water, which can be attributed to the presence of components in its formulation that, besides promoting higher viscosity, also reduce lubricating capacity. On the other hand the milk matrix presented the highest lubricating capacity compared to water and soy juice, probably due to the presence of a small amount of fat (skim milk) and proteins, which increase the viscosity and are considered components with reduced coefficient of friction (Laiho et al., 2017, Liu et al., 2015). Increase, decrease or maintenance of the lubricant capacity of the original matrix will depend on the concentration/viscosity and nature of the incorporated material, and this had an impact on the sensory characteristics (Nguyena et al., 2017).

Fig. 7.

Coefficient of friction (CoF) versus time obtained at a fixed entrainment speed (40 mm s−1) for different matrices (water (A), milk (B) and orange-flavoured soy juice (C)) at the highest thickeners' concentration (3% w/w).

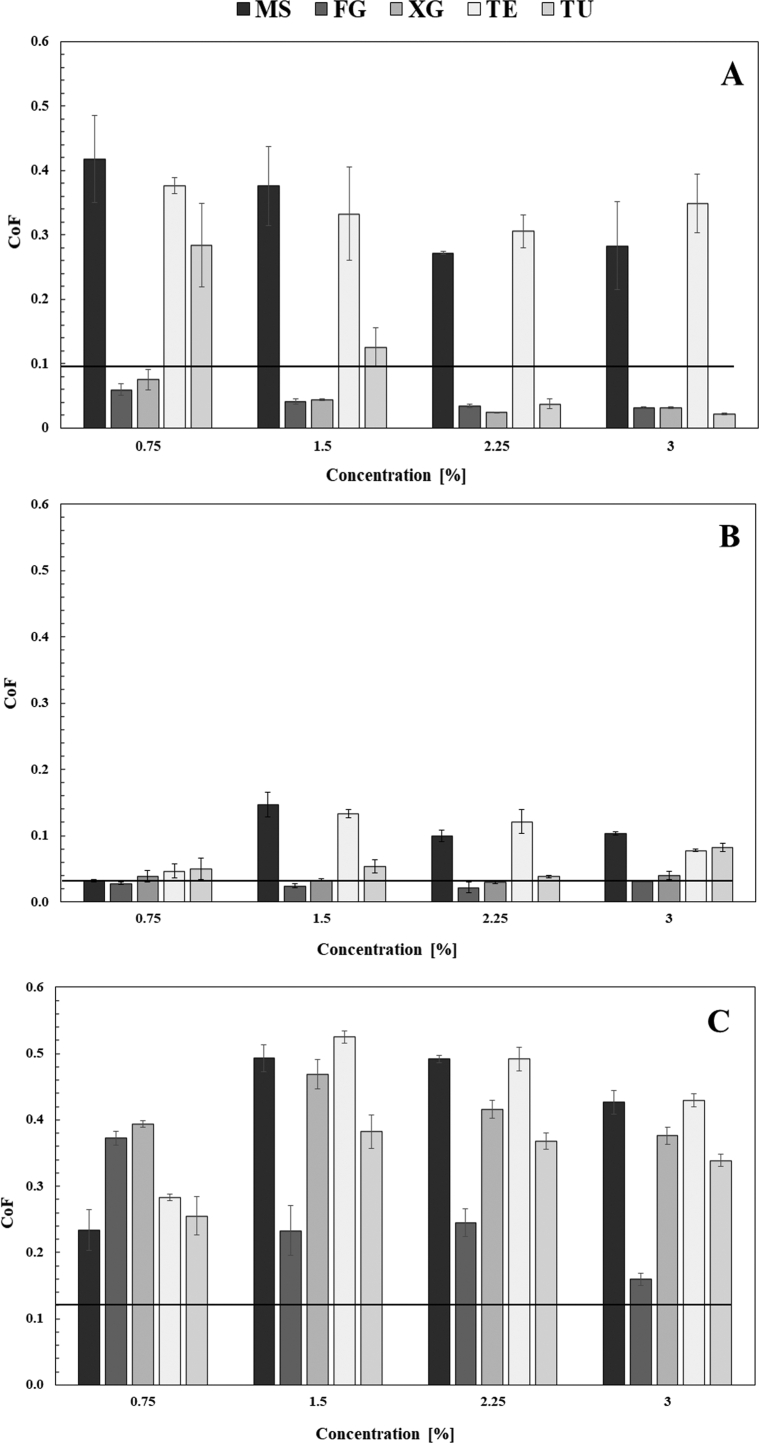

Fig. 8.

Coefficient of friction (CoF) of the thickeners measured from tribological analysis at steady state regime. Crossed line represents the coefficient of friction of the control (water (A), milk (B) and orange-flavoured soy juice (C)). Different letters (a–e) at the same concentration correspond to statistically different samples (p < 0.05).

MS-based thickeners showed greater dependence on biopolymer concentration and lower lubricating capacity, while gum-based thickeners showed minor influence of concentration mainly on more complex matrices. The coefficient of friction of MS in water decreased from 0.42 ± 0.07 (0.75% w/w) to 0.28 ± 0.06 (3% w/w) and that of the MS-based thickener (TE) remained almost constant with increasing concentration, being that all these values were higher than those of the coefficient of friction of water. As shown in Fig. 2, a marked increase in the viscosity of the MS solution from 2.25 to 3% w/w was observed, but the sudden change in viscosity between these two concentrations did not affect the MS lubricating capacity. Previous studies (Zhang et al., 2017) have concluded that starch may have a lubricating effect, which was not clear in our study. This discrepancy may be associated with the need to modify starch granules (pre gelatinization) into a structure suitable for integration in a dysphagic diet. As noticed in water, the formulations that presented higher friction coefficients over time in milk and soy juice were those based on modified starch (MS and TE). This result may be attributed to the structure of the starch-thickened formulations, which can show a release of gel particles with larger size that exhibit a higher friction mainly at low entrainment speed (Liu et al., 2015, Nguyena et al., 2017) and could interact with proteins and other compounds present in milk and soy juice.

On the other hand, the dispersions produced with XG and the XG-based commercial product (TU) showed a low friction coefficient in all studied concentrations, thus presenting a better lubrication capacity than MS-based thickeners. A reduction in the coefficient of friction was observed with increasing concentration of XG-based thickeners in water, but this tendency was not so clear in the other matrices. However the lowest coefficient of friction was observed at the highest biopolymers’ concentration. Once a threshold concentration is achieved to form a particles layer that provides a complete barrier to surface contact, a further increase in particles number does not have a marked influence on the coefficient of friction (Zhang et al., 2017, Yakubov et al., 2015). Unlike starch, XG-containing systems increased their lubricating capacity with increased concentration and viscosity. At the maximum concentration used (3% w/w) and consequently the highest viscosity, the xanthan and flaxseed-based thickeners presented the lowest coefficient of friction (Fig. 7). It should be noted that FG is the biopolymer that presents the lowest coefficient of friction when incorporated into the orange-flavoured soy juice and the one that least alters this matrix lubricating profile at higher concentrations when compared to the other biopolymers.

3.3. Rheology and tribology: relation with sensorial properties

The different rheological and tribological profiles of the studied biopolymers can interfere with the perceived texture and on the underpinning mechanisms applied for texture perception (Chen and Stokes, 2012, Liu et al., 2015). Our results show evidence of sensorial divergences between gums and modified starch. Indeed, a sensory analysis with a trained panel showed that modified starch and commercial thickener based on modified starch were classified as “Denseness”, while xanthan obtained higher values to “Oily mouth coating” (Krop et al., 2019, Sharma et al., 2017).

XG-based and FG dispersions showed similar tribological profiles for most concentrations when dispersed in water (Fig. 8). However, FG exerted a significantly different influence on the lubricating capacity of the soy juice and milk as a decreasing coefficient of friction with increasing FG concentration was observed. Therefore, the lubrication capacity of the thickened solutions cannot be directly related to the viscosity alone, since as observed in the XG-based thickeners, when increasing their concentration and consecutively their viscosity, a decrease in the friction between the studied surfaces occurs, concluding that the characteristics and nature of the food matrix and the interactions established with the polymer are also relevant.

It should be evidenced that the order of magnitude of the coefficient of friction obtained for starch and xanthan agrees with the literature (Torres et al., 2019). It should be also remarked that commercial XG-based products presented more components than MS products. This fact made all the rheological and tribological properties similar between starch-based solutions, unlike xanthan gum-based solutions, since the viscosity of the commercial product TU was different from xanthan, despite having similar elastic character and tribological properties. Therefore, lubrication properties varied depending on the biopolymer composition and concentration in solution, and the gum-based formulations have undergone minor changes for different concentrations (Fig. 7A) when compared to those based in modified starch. Each biopolymer behaved differently when incorporated in the matrices, thus obtaining varied rheological and tribological properties probably associated to the strong interactions between the components of the thickeners and the matrices, resulting in possible different consumption perception. Gums (xanthan and flaxseed) show a strong ability to a fast hydration than other types of hydrocolloids due to their numerous side chains, which could at least partly explain their lubricating properties capable of reducing the friction process (Martínez et al., 2019, Qian et al., 2012, Hamilton and Norton, 2016, Liu et al., 2017, Sun et al., 2018).

4. Conclusions

The present study provided additional evidences of FG as a potential thickener to dysphagic patients. The rheological properties and lubricating characteristics were evaluated to cover forces and velocity during swallowing and the results were promising as compared to the commercially available thickeners according to the food matrices. The increase in the biopolymer concentration significantly affected rheological properties, but XG showed the highest viscosity, pseudoplasticity and viscoelasticity, followed by FG. MS and the MS-based thickener only exerted a relevant impact on the viscosity, pseudoplasticity and viscoelastic properties (G′, G″) at the highest concentration studied (3% w/w). Similar to rheological studies, the biopolymer nature and concentration had a significant impact on the tribological behavior. The matrices’ composition in which the thickeners were incorporated showed a significant impact on the tribological behaviour, not only because they have a significant different lubricating capacity, but also because the coefficient of friction can increase or decrease for a similar thickener content, depending on the matrix. For example, FG and XG reduced the coefficient of friction after addition in water and milk but increased the coefficient of friction in orange-flavoured soy juice at higher concentrations. In general, similar lubricating capacity was observed between the gum-based formulations, mainly in water and milk. On the other hand, MS based solutions tended to maintain the coefficient of friction similar to original matrix (in low concentration) but increased at the highest studied concentration. Thus, the greater lubrication capacity of the gums can occur in the swallowing process and avoid the unpleasant stickiness feeling. Therefore, our results suggest that although FG shows less pseudoplasticity (such as MS) than XG-based products, FG exhibited a low coefficient of friction as XG-based products, which could be correlated with a pleasant sensation in the last step of swallowing. Thus, these rheological and tribological results coupled showed that the choice of the biopolymer base to be incorporated into a potential food thickener has a significant impact on the mechanical properties, thus leading to differences in the sensory texture. These findings, coupled with the high nutritional value of flaxseed gum may contribute to generate a more complete formulation of a product directed to dysphagic patients, and thus helping in the mitigation of the consequences imposed by the current treatments. However, in vivo analyses will be required to confirm the effects and acceptance of FG consumption as a thickener for dysphagic patients.

CRediT author statement

J.M. Vieira: Conceptualization, Methodology, Formal analysis, Investigation, Writing- Original draft preparation; F.D. Oliveira Jr: Validation (rheology part); D.B. Salvaro: Validation, Investigation (tribology part); G.P. Maffezzolli: Validation (tribology part); J.D.B. de Mello: Validation (tribology part); A.A. Vicente: Supervision, Writing- Reviewing and Editing; R.L. Cunha: Conceptualization, Writing- Reviewing and Editing, Project administration, Supervision.

Declaration of Competing Interest

There are no conflicts of interest.

Acknowledgements

This study was financed by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior - Brasil (CAPES) (Finance code 001); Fundação de Apoio à Pesquisa do Estado de São Paulo (FAPESP) (Process numbers 2016/05448-8; 2011/51707-1; EMU 2009/54137-1; 2007/58017-5; 2006/03263-9; 2004/08517-3) and by the Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq).

Footnotes

Supplementary data to this article can be found online at https://doi.org/10.1016/j.crfs.2020.02.001.

Appendix A. Supplementary data

The following is the Supplementary data to this article:

References

- Anvari M., Joyner H.S. Effect of fish gelatin and gum Arabic interactions on concentrated emulsion large amplitude oscillatory shear behavior and tribological properties. Food Hydrocolloids. 2018;79:518–525. doi: 10.1016/j.foodhyd.2017.12.016. [DOI] [Google Scholar]

- Chen J. Food oral processing – a review. Food Hydrocolloids. 2009;23:1–25. doi: 10.1016/j.foodhyd.2007.11.013. [DOI] [Google Scholar]

- Chen J., Stokes J.R. Rheology and tribology: two distinctive regimes of food texture sensation. Trends Food Sci. Technol. 2012;25(1):4–12. doi: 10.1016/j.tifs.2011.11.006. [DOI] [Google Scholar]

- Cho H.M., Yoo B. Rheological characteristics of cold thickened beverages containing Xanthan Gum–based food thickeners used for dysphagia diets. J. Acad. Nutr. Diet. 2014;115(1):106–111. doi: 10.1016/j.jand.2014.08.028. [DOI] [PubMed] [Google Scholar]

- Clavé P., Shaker R. Dysphagia: current reality and scope of the problem. Nat. Rev. Gastroenterol. Hepatol. 2015;12:259–270. doi: 10.1038/nrgastro.2015.49. [DOI] [PubMed] [Google Scholar]

- Cutler A.N., Morris E.R., Taylor L.J. vol. 14. Food and Nutrition Press; 1983. pp. 377–395. (Oral Perception of Viscosity in Fluid Foods and Model Systems). [Google Scholar]

- Dewar R.J., Joyce M.J. The thixotropic and rheopectic behaviour of maize starch and maltodextrin thickeners used in dysphagia therapy. Carbohydr. Polym. 2006;65:296–305. doi: 10.1016/j.carbpol.2006.01.018. [DOI] [Google Scholar]

- Ding H.H., Cui S.W., Goff H.D., Wang Q., Chen J., Han N.F. Soluble polysaccharides from flaxseed kernel as a new source of dietary fibres: extraction and physicochemical characterization. Food Res. Int. 2014;56:166–173. doi: 10.1016/j.foodres.2013.12.005. [DOI] [Google Scholar]

- Douaire D., Stephenson T., Norton T. Soft tribology of oil-continuous emulsions. J. Food Eng. 2014;139:24–30. doi: 10.1016/j.jfoodeng.2014.04.007. [DOI] [Google Scholar]

- Duffy J. Malvern Instruments Worldwide; 2015. Measuring the Rheology of Polymer Solutions. [Google Scholar]

- Elboutachfaiti R., Delattre C., Anthony Quérro A., Roulard R., Julie Duchêne J., Mesnard F., Petit E. Fractionation and structural characterization of six purified rhamnogalacturonans type I from flaxseed mucilage. Food Hydrocolloids. 2017;62:273–279. doi: 10.1016/j.foodhyd.2016.08.005. [DOI] [Google Scholar]

- Farahmandfar R., Asnaashari M., Salahi M.R., Rad T.K. Effects of basil seed gum, Cress seed gum and Quince seed gum on the physical, textural and rheological properties of whipped cream. Int. J. Biol. Macromol. 2017;98:820–828. doi: 10.1016/j.ijbiomac.2017.02.046. [DOI] [PubMed] [Google Scholar]

- Ferry A.-L., Hort J., Mitchell J.R., Cook D.J., Lagarrigue S., Pamies B.V. Viscosity and flavour perception: why is starch different from hydrocolloids? Food Hydrocolloids. 2006;20:855–862. doi: 10.1016/j.foodhyd.2005.08.008. [DOI] [Google Scholar]

- Foster-Powell K., Holt S.H., Brand-Miller J.C. International table of glycemic index and glycemic load values: 2002. Am. J. Clin. Nutr. 2002;76(1):5–56. doi: 10.1093/ajcn/76.1.5. [DOI] [PubMed] [Google Scholar]

- Funami T. Next target for food hydrocolloid studies: texture design of foods using hydrocolloid technology. Food Hydrocolloids. 2011;25(8):1904–1914. doi: 10.1016/j.foodhyd.2011.03.010. [DOI] [Google Scholar]

- Germain I., Dufresne T., Ramaswamy H.S. Rheological characterization of thickened beverages used in the treatment of dysphagia. J. Food Eng. 2006;73:64–74. doi: 10.1016/j.jfoodeng.2005.01.006. [DOI] [Google Scholar]

- Hadde E.K., Chen J. Shear and extensional rheological characterization of thickened fluid for dysphagia management. J. Food Eng. 2019;245:18–23. doi: 10.1016/j.jfoodeng.2018.10.007. [DOI] [Google Scholar]

- Hamilton E., Norton I.T. Modification to the lubrication properties of xanthan gum fluid gels as a result of sunflower oil and triglyceride stabilised water in oil emulsion addition. Food Hydrocolloids. 2016;55:220–227. doi: 10.1016/j.foodhyd.2015.11.020. [DOI] [Google Scholar]

- Hayashi M., Takei R., Umene S., Narita K., Kato K., Kobayashi Y., Honma Y. Tribological analysis of the surface of food gels. Food Hydrocolloids. 2016;58:343–346. doi: 10.1016/j.foodhyd.2016.03.010. [DOI] [Google Scholar]

- He Q., Hort J., Wolf B. Predicting sensory perceptions of thickened solutions based on rheological analysis. Food Hydrocolloids. 2016;61:221–232. doi: 10.1016/j.foodhyd.2016.05.010. [DOI] [Google Scholar]

- Hori K., Hayashi H., Yokoyama S., Ono T., Ishihara S., Magara J., Taniguchi H., Funami T., Maeda Y., Inoue M. Comparison of mechanical analyses and tongue pressure analyses during squeezing and swallowing of gels. Food Hydrocolloids. 2015;44:145–155. doi: 10.1016/j.foodhyd.2014.09.029. [DOI] [Google Scholar]

- Jo W., Bak J.H., Yoo B. Rheological characterizations of concentrated binary gum mixtures with xanthan gum and galactomannans. Int. J. Biol. Macromol. 2018;114:263–269. doi: 10.1016/j.ijbiomac.2018.03.105. [DOI] [PubMed] [Google Scholar]

- Krop E.M., Hetherington M.M., Holmes M., Miquel S., Sarkar A. On relating rheology and oral tribology to sensory properties in hydrogels. Food Hydrocolloids. 2019;88:101–113. doi: 10.1016/j.foodhyd.2018.09.040. [DOI] [Google Scholar]

- Laiho S., Williams R.P.W., Poelman A., Appelqvist I., Logan A. Effect of whey protein phase volume on the tribology, rheology and sensory properties of fat-free stirred yoghurts. Food Hydrocolloids. 2017;67:166–177. doi: 10.1016/j.foodhyd.2017.01.017. [DOI] [Google Scholar]

- Li N., Qi G., Sun X.S., Wang D. Characterization of gum isolated from Camelina seed. Ind. Crop. Prod. 2016;83:268–274. doi: 10.1016/j.indcrop.2016.01.029. [DOI] [Google Scholar]

- Liu K., Stieger M., van der Linden E., van de Velde F. Fat droplet characteristics affect rheological, tribological and sensory properties of food gels. Food Hydrocolloids. 2015;44:244–259. doi: 10.1016/j.foodhyd.2014.09.034. [DOI] [Google Scholar]

- Liu J., Shim Y.Y., Poth A.G., Reaney M.J.T. Conlinin in flaxseed (Linum usitatissimum L.) gum and its contribution to emulsification properties. Food Hydrocolloids. 2016;52:963–971. doi: 10.1016/j.foodhyd.2015.09.001. [DOI] [Google Scholar]

- Liu J., Shim Y.Y., Shen J., Wang Y., Reaney M.J.T. Whey protein isolate and flaxseed (Linum usitatissimum L.) gum electrostatic coacervates: turbidity and rheology. Food Hydrocolloids. 2017;64:18–27. doi: 10.1016/j.foodhyd.2016.10.006. [DOI] [Google Scholar]

- Mackley M.R., Tock C., Anthony R., Butler S.A., Chapman G., Vadillo D.C. The rheology and processing behavior of starch and gum-based dysphagia thickeners. J. Rheol. 2013;57(6):1533–1553. doi: 10.1122/1.4820494. [DOI] [Google Scholar]

- Marconati M., Engmann J., Burbidge A.S., Mathieu V., Souchon I., Ramaioli M. A review of the approaches to predict the ease of swallowing and post-swallow residues. Trends Food Sci. Technol. 2019;86:281–297. doi: 10.1016/j.tifs.2019.02.045. [DOI] [Google Scholar]

- Martínez O., Vicente M.S., De Vega M.C., Salmerón J. Sensory perception and flow properties of dysphagia thickening formulas with different composition. Food Hydrocolloids. 2019;90:508–514. doi: 10.1016/j.foodhyd.2018.12.045. [DOI] [Google Scholar]

- Meng Y., Rao M.A., Datta K. Computer simulation of the pharyngeal bolus transport of Newtonian and Non-Newtonian fluids. Food Bioprod. Process. 2005;83(4):297–305. doi: 10.1205/fbp.04209. [DOI] [Google Scholar]

- Morris D.H., Vaisey-Genser M. second ed. 2003. FLAXSEED, Encyclopedia of Food Sciences and Nutrition; pp. 2525–2531. [Google Scholar]

- National Dysphagia Diet Task Force . American Dietetic Association; Chicago, IL: 2002. National Dysphagia Diet: Standardization for Optimal Care. [Google Scholar]

- Nguyena P.T.M., Kravchuk O., Bhandari B., Prakash S. Effect of different hydrocolloids on texture, rheology, tribology and sensory perception of texture and mouthfeel of low-fat pot-set yoghurt. Food Hydrocolloids. 2017;72:90–104. doi: 10.1016/j.foodhyd.2017.05.035. [DOI] [Google Scholar]

- Prakash S., Tan Y.Y.D., Chen J. Applications of tribology in studying food oral processing and texture perception. Food Res. Int. 2013;54(2):1627–1635. doi: 10.1016/j.foodres.2013.10.010. [DOI] [Google Scholar]

- Qian K.Y., Cui S.W., Nikiforuk J., Goff H.D. Structural elucidation of rhamnogalacturonans from flaxseed hulls. Carbohydr. Res. 2012;362:47–55. doi: 10.1016/j.carres.2012.08.005. [DOI] [PubMed] [Google Scholar]

- Razavi S.M.A., Alghooneh A., Behrouzian F. Thermo-rheology and thermodynamic analysis of binary biopolymer blend: a case study on sage seed gum-xanthan gum blends. Food Hydrocolloids. 2018;77:307–321. doi: 10.1016/j.foodhyd.2017.10.007. [DOI] [Google Scholar]

- Richardson R.K., Morris E.R., Ross-Murphy S.B., Taylor L.J., Dea I.C.M. Characterization of the perceived texture of thickened systems by dynamic viscosity measurements. Food Hydrocolloids. 1989;3(3):175–191. doi: 10.1016/S0268-005X(89)80002-5. [DOI] [Google Scholar]

- Russ N., Zielbauer B.I., Ghebremedhin M., Vilgis T.A. Pre-gelatinized tapioca starch and its mixtures with xanthan gum and ι-carrageenan. Food Hydrocolloids. 2016;56:180–188. doi: 10.1016/j.foodhyd.2015.12.021. [DOI] [Google Scholar]

- Sarkar A., Krop E.M. Marrying oral tribology to sensory perception: a systematic review. Curr Opin Food Sci. 2019;27:64–73. doi: 10.1016/j.cofs.2019.05.007. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Selway N., Stokes J.R. Insights into the dynamics of oral lubrication and mouthfeel using soft tribology: differentiating semi-fluid foods with similar rheology. Food Res. Int. 2013;54:423–431. doi: 10.1016/j.foodres.2013.07.044. [DOI] [Google Scholar]

- Shama F., Sherman P. Identification of stimuli controlling the sensory evaluation of viscosity II. Oral methods. J. Texture Stud. 1973;4(1):111–118. doi: 10.1111/j.1745-4603.1973.tb00657.x. [DOI] [Google Scholar]

- Sharma M., Kristo E., Corredig M., Duizer L. Effect of hydrocolloid type on texture of pureed carrots: rheological and sensory measures. Food Hydrocolloids. 2017;63:478–487. doi: 10.1016/j.foodhyd.2016.09.040. [DOI] [Google Scholar]

- Stokes J.R., Boehm M.W., Baier S.K. Oral processing, texture and mouthfeel: from rheology to tribology and beyond. Curr. Opin. Colloid Interface Sci. 2013;18:349–359. doi: 10.1016/j.cocis.2013.04.010. [DOI] [Google Scholar]

- Sun C., Liang B., Sheng H., Wang R., Zhao J., Zhang Z., Zhang M. Influence of initial protein structures and xanthan gum on the oxidative stability of O/W emulsions stabilized by whey protein. Int. J. Biol. Macromol. 2018;120:34–44. doi: 10.1016/j.ijbiomac.2018.08.070. [DOI] [PubMed] [Google Scholar]

- Szczesniak A.S., Farkas E. Objective characterization of the mouthfeel of gum solutions. J. Food Sci. 1963;27:381–385. doi: 10.1111/j.1365-2621.1962.tb00112.x. [DOI] [Google Scholar]

- Torres O., Yamada A., Rigby N.M., Hanawa T., Kawano Y., Sarkar A. Gellan gum: a new member in the dysphagia thickener family. Biotribology. 2019;17:8–18. doi: 10.1016/j.biotri.2019.02.002. [DOI] [Google Scholar]

- Upadhyay R., Chen J. Smoothness as a tactile percept: correlating ‘oral’ tribology with sensory measurements. Food Hydrocolloids. 2019;87:38–47. doi: 10.1016/j.foodhyd.2018.07.036. [DOI] [Google Scholar]

- Vieira J.M., Mantovani R.A., Raposo M.F.J., Coimbra M.A., Vicente A.A., Cunha R.L. Effect of extraction temperature on rheological behavior and antioxidant capacity of flaxseed gum. Carbohydr. Polym. 2019;213:217–227. doi: 10.1016/j.carbpol.2019.02.078. [DOI] [PubMed] [Google Scholar]

- Yakubov G.E., Branfield T.E., Bongaerts J.H.H., Stokes J.R. Tribology of particle suspensions in rolling-slidding soft contacts. Biotribology. 2015;3:1–10. doi: 10.1016/j.biotri.2015.09.003. [DOI] [Google Scholar]

- Zhang B., Selwayc N., Shelat K.J., Dhital S., Stokes J.R., Gidley M.J. Tribology of swollen starch granule suspensions from maize and potato. Carbohydr. Polym. 2017;155:128–135. doi: 10.1016/j.carbpol.2016.08.064. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.