Abstract

In the era of Industry 4.0 and circular economy, small and medium enterprises (SMEs) are under huge pressure to make their manufacturing operations ethical and sustainable. Business with ethical and sustainable operations has become the need of the day in the present environment of Industry 4.0 and circular economy. It has been observed that the application of Industry 4.0 technologies may help in achieving the goal of ethical and sustainable operations. Although a lot of research has been done in context to larger enterprises, limited research is available on the application of Industry 4.0 technologies in SMEs for ethical and sustainable operations.

The espousal of Industry 4.0 technologies is a challenging task for SMEs due to various operational and financial constraints. The problem is more acute, specifically in context to developing countries like India. Keeping in mind the role of technologies in ethical business and circular economy, we have identified fifteen challenges, impacting the application of Industry 4.0 technologies in SMEs. A questionnaire was designed for collecting the response from industry and academic experts. On the collected data, the DEMATEL approach has been applied to check the degree of influence and interrelationship among challenges. It has also helped in the categorization of factors as cause and effect. Sensitivity analysis is also performed to validate the results obtained from the DEMATEL approach. Authors have observed that lack of motivation from partners and customers on the application of I4.0 technologies is the leading challenge. Fear of failure of I4.0 technologies is the main effect group challenge. The findings of the study will help SMEs in formulating strategies for implementing Industry 4.0 technologies for ethical and sustainable business processes.

Keywords: Industry 4.0, SMEs, Challenges, DEMATEL, Ethical and sustainable business, Circular economy

Highlights

-

•

Fifteen challenges in application of Industry 4.0 technologies for sustainable manufacturing operations are identified.

-

•

Decision Making Trial and Evaluation Laboratory approach is used for analyzing the challenges.

-

•

Lack of motivation from original equipment manufacturers and customers has emerged as the major challenge in cause category.

-

•

Fear of sustainability of Industry 4.0 technologies is the main challenge in the effect category.

-

•

Findings will help SMEs in integrating Industry 4.0 technologies with manufacturing operations.

1. Introduction

Under current global scenario, markets all over the world have observed the disruptions in the value chains due to reduction in trade and lack of supplies (Fernandes, 2020). To sustain in such scenario, organizations should restructure their supply chains by sourcing of raw materials and components from different sources including SMEs (Ramelli and Wagner, 2020). SMEs are major contributor to the industrial growth in developing economies all over the globe (Singh and Kumar, 2020; Rauch et al., 2019). Partnership of SMEs with large organizations can enhance opportunities of developing ethical and sustainable operations for them. To become globally competitive for availing emerging opportunities, SMEs need to meet the global standards on quality, technology, sustainability, and pricing (Singh and Kumar, 2020). Many organizations are in transition stage from linear economy to circular economy. Adopting the concept of circular economy (CE) by SMEs may give emerging business opportunities to them (Mura et al., 2020). According to Lieder and Rashid (2016), organizations should adopt the principles of CE for being sustainable in their operations. Technologies may also help organizations in achieving the goals of the circular economy (Prieto-Sandoval et al., 2019; Rosa et al., 2020).

Application of Industry 4.0 technologies may provide a positive direction towards corporate social responsibility and sustainable operations (Kamble et al., 2020; Luthra and Mangla, 2018). According to Battaglia et al. (2018), the experience of the global market helps in acquiring technologies and innovation in processes. SMEs of the manufacturing sector are less reactive to changing business demands of customers in the modern era. They are under pressure due to increasing customization and complexity of products (Dutta et al., 2020). Reduction in time to market, resource optimization, waste minimization, and resource circularity are other few key challenges. The application of technologically advanced sustainable practices imparts a competitive edge to manufacturing organizations of developed economies (Yadav et al., 2020; Mastos et al., 2020). According to Garcia-Muina et al. (2018), Industry 4.0 technologies will help in the transition from linear to CE. Advanced practices of Industry 4.0 can quash costs, meliorate sustainability, and render customizable products to customers (Turner et al., 2019; Machado et al., 2019). Linder (2019) stated that in SMEs, improved communication and information flow can help in achieving efficient processes and cost reduction.

In the cyber-physical environment, machines are made capable of communicating, collecting information, and taking informed decisions by real time data collection through tools like IIoT, AI, big data and clouds (Dutta et al., 2020; Tiwari and Khan, 2020; Lee et al., 2015). Customers’ demands and product queries can be collected in real-time by smart technologies. The adoption of intelligent technologies is being predicted as the next industrial revolution (Hofmann and Rusch, 2017). Industry 4.0 technologies will help in effective life cycle management of products in the era of CE (Zhou et al., 2020; Bag et al., 2020c). Therefore, to provide a new innovative environment in the Industry, managers need to adopt or implement the latest technologies such as 3D printing, internet of things (IoT) and cyber-physical system (Almada-Lobo, 2015; Song and Wang, 2018). Rauch et al. (2019) have stated that despite a substantial contribution of SMEs in the economic and employment front, they lack in terms of technology adoption even in developed countries like the European Union and the United States. Effective strategies are required for the application of technologies in small enterprises (Rauch et al., 2019). Many countries like Australia, China, and Thailand are also working on the adoption of Industry 4.0 technologies (Orzes et al., 2020).

1.1. Problem description and research objectives

Ninety-five per cent of Indian manufacturing units with forty per cent value addition fall in small scale category (Singh et al., 2012). SMEs are not able to compete in global markets due to their technological deficiencies and lack of sustainability in operations (Singh and Kumar, 2020). To excel in global competition, manufacturing companies have to upgrade their technologies for ethical and sustainable business operations. The Industry 4.0 techniques are important in the transition from linear to the circular economy (Luthra and Mangla, 2018). Their integration with production systems generate opportunities for sustainable business models aligned with ethical principles of corporate social responsibility (de Sousa Jain et al., 2018 a).

According to Singh and Kumar (2020) global market conditions are very ambitious for Indian SMEs. SMEs should leverage the application of technologies to improve the sustainability of manufacturing operations in the era of the circular economy. In the modern business environment, highly competitive organizations are planning business strategies considering ethical and sustainable business criteria (Longoni and Cagliano, 2015). Mani et al. (2020) have observed that social sustainability affects a firm’s performance. Yadav et al. (2020) ascertained that industry 4.0 technologies and circular economy approach could give a competitive edge to supply chains. A focus on the social aspects of sustainability can improve performance and job satisfaction (Sangwan et al., 2019). The efficiency and energy saving of manufacturing processes can be improved by technology adoption (Nascimento et al., 2018). Manufacturing processes can be made efficient and sustainable by effective use of process digitization and quality control tools (Shivajee et al., 2019). Ghobakhloo (2020) has observed that by effectuation of Industry 4.0 technologies, production efficiency, process innovations and sustainability can be improved. To survive and excel in the present business scenario, SMEs need to implement emerging technologies for their sustainable growth (Kumar et al., 2015).

SMEs in developing countries like India are not able to ensure sustainable manufacturing operations due to the high cost of sustainable practices, lack of skills and training, lack of standardized metrics, and lack of adoption of emerging technologies (Kumar, 2020a,b). The incomplete implementation of sustainable and innovative technical processes may impact the performance of SMEs (Shashi et al., 2019). Radziwon et al. (2014) have ascertained that Industry 4.0 technologies can help in improving the sustainability and efficiency of operations. By applying emerging technologies, SMEs can increase productivity, flexibility, responsiveness, and environmental performance (Pedersen et al., 2016). Technologies of Industry 4.0 can be used for resolving sustainability problems (Kumar, 2020a). Kumar et al. (2014) have found that SMEs face challenges in managing their supply chains due to a lack of effective strategies. In recent times, the application of smart technologies has changed the attention of the manufacturing sector drastically (Jain et al., 2017). Effectuation of practices of Industry 4.0 in SMEs faces different issues like security, networking, integration of supply chain, etc. Therefore, to fix such types of problems in SMEs, there is a need to analyze different challenges in the effectuation of emerging technologies (Marques et al., 2017). It is observed that very few studies have holistically examined the challenges coming on the path of new technology adoption by SMEs in developing countries like India (Singh et al., 2019). The majority of the studies are done in context to developed countries and larger enterprises. Therefore, authors are trying to solve the following research questions concerning SMEs of developing countries like India.

RQ1.What are the potential challenges in adopting Industry 4.0 technologies in SMEs for ethical and sustainable operations in context to CE?

RQ2.How these challenges can be prioritized and categorized from a strategy perspective.

RQ3.Which major challenge should be resolved on a priority basis by SMEs for adopting ethical and sustainable business models.

After formulating above research questions and observations from literature, authors feel the need of a study for analyzing challenges in adoption of emerging technologies by SMEs. The remaining part of this study has been organized as follows: Section 2 discourses the literature on the challenges of adopting Industry 4.0 technologies. Section 3 discourses the methodology of the research. Section 4 deals with results and discussion. Section 5 discusses the conclusion with the implications. Section 6 discusses the limitations and future research.

2. Literature review

Review of related literature has been divided into two sections. The first section (2.1) is on the application of Industry 4.0 technologies for ethical and sustainable operations, and the second is on challenges in implementing technologies of Industry 4.0.

2.1. Industry 4.0 technologies applications for ethical and sustainable operations

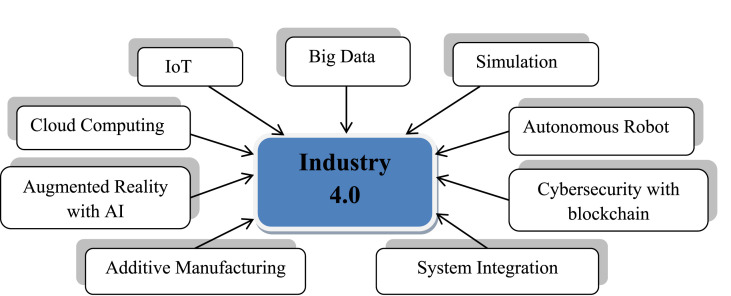

Industry 4.0 comprises of different technologies like internet of things (IoT), cloud computing, additive manufacturing, cyber security with blockchain, augmented reality with artificial intelligence (AI), big data, system integration, simulation and autonomous robot (Kerin and Pham, 2019; Gurtu and Johny, 2019) (Fig. 1 ). Techniques of Industry 4.0 have capacities to improve the energy, equipment, and human resource utilization (Lasi et al., 2014). Industry 4.0 is a futuristic construct that nurtures the evolution of autonomous production systems with the application of IoT, CPS, and AI (Pacaux-Lemoine and Trentesaux, 2019). New sensor-based technologies help SMEs in continuously monitoring machine utilization, energy needs, and staff training. By thorough analysis of different Industry 4.0 technologies, data from various IoTs devices can be processed for improving the sustainability of manufacturing operations (Song and Wang, 2017).

Fig. 1.

Technologies of industry 4.0 (source: Kerin and Pham, 2019).

For sustainable operations, products need to be manufactured by environment-friendly, socially viable, and economically sound processes. Production systems based on ethical and sustainable manufacturing processes are highly efficient in saving energy and natural resources. Shivajee et al. (2019) have ascertained that manufacturing processes can be made efficient and sustainable by effective use of process digitization and quality control tools. According to Beier et al. (2020), Industry 4.0 is a sociotechnical construct in which technological, social and organizational prospects interacts. Connect of sustainability with Industry 4.0 needs to be studied in depth. For saving energy, reduction of scrap and its impact on the environment, the industrial value chain ought to be oriented towards sustainability (Fatimah et al., 2020). Challenges of ethical and sustainable supply chains can be managed by industry 4.0 and CE concepts (Yadav et al., 2020). According to Garcia-Muina et al. (2018), innovations lead to ethical and sustainable operations when environmental measures are employed across the products life cycle.

Piyathanavong et al. (2019) have observed that knowledge, investment, and training of sustainability concepts are critical requirements for implementing sustainable practices in Thai manufacturing organizations. Efficiency and energy saving of manufacturing processes can be improved by technology adoption (Nascimento et al., 2018). Make to specifications, efficient energy usage, tractability, and closed-loop SCM can be managed by application of Industry 4.0 technologies (Cezarino et al., 2019). Fundamentals of the closed supply chain (circular economy) have introduced a new approach to sustainability. It has become essential for easing reuse and recycle epitome. The closed-loop supply chain adds more sustainability benefits in comparison to the open-loop supply chain (Lieder et al., 2017).

Digital practices can contribute significantly to sustainability by reducing carbon footprints, renewable energy usage, and technology solutions suitable for both individuals and society (Kumar, 2020 b). The evolution of Industry 4.0 helps in the optimal usage of resources in a more transparent manner (Dutta et al., 2020). By effectuation of Industry 4.0 practices, production efficiency and innovation can be improved, which influence the social and environmental sustainability (Ghobakhloo, 2020; Bag et al., 2021). Thakur and Mangla (2019) stated that the professionals of developing economies should emphasize on human, operational, and technological aspects of the sustainable supply chains in the home appliances manufacturing organizations. Government rules and support, awareness of environment protection, and information technologies are the decisive constituents for circular economy implementation (Bhatia et al., 2020). Chauhan et al. (2019) and Cezarino et al. (2019) have observed that with the association of Industry 4.0, manufacturing operations may become sustainable and ethical. De Sousa Jabbour et al. (2018b) also ascertained that ethical and sustainable societal development is possible only by using cleaner production principles. According to Guarnieri and Trojan (2019), in modern times, suppliers are selected by considering the sustainability of operations. There are many benefits contributed individually by different technologies of Industry 4.0. The critical applications of these Industry 4.0 technologies have been summarized in Table 1 .

Table 1.

Applications of Industry 4.0 technologies for ethical and sustainable operations of SMEs.

| Industry 4.0 technologies | Applications of technologies | Reference |

|---|---|---|

| IoTs | The convenience of data collection from multiple sources on energy, pollution, efficiency, machine utilization, etc.; cost reduction in manufacturing; technology up-gradation as per ethical and sustainable standards; information on product life cycle can be accessed to promote reuse. | Bhatia et al. (2020); Frank et al. (2019); Kerin and Pham (2019); Thakur and Mangla (2019); Chauhan et al. (2019); Bag and Pretorius (2020) |

| Cloud computing | All-time anywhere access of available data; transparency and responsiveness of the supply chains; easy sharing of important data; support from supply chain partners in improving ethical and sustainable operations, technology up-gradation, data on product life cycle can be stored & retrieved as per CE philosophy. | Frank et al. (2019); Zhou et al. (2020); Ghobakhloo (2020); Yadav et al. (2020); Cezarino et al. (2019); Pacaux-Lemoine and Trentesaux (2019) |

| Flexible manufacturing | Reduction in lead time; increased productivity and quality; improved machine utilization; more efficient energy consumption, ethical and sustainable processes. | Yadav et al. (2020) |

| Additive manufacturing | Negligible scrap generation; environment-friendly process; highly flexible and consistent (intricate designs are easy to produce); testing and prototyping becomes easy, accurate, and affordable for SMEs. | Ford and Despeisse (2016); Bhatia et al. (2020); Thakur and Mangla (2019) |

| Big Data Analytics | Data gathered from multiple IoTs based devices can be analyzed to get information & trends; data can be used for programming AI devices; machine & human resources utilization can be optimized; traceability of products will improve CE integration & ethical sustainability of operations. | Frank et al. (2019); Horváth and Szabó (2019); Thakur and Mangla (2019); Bag et al. (2020a); Dubey et al. (2020); Pacaux-Lemoine and Trentesaux (2019) |

| Augmented Reality (AR) | Enables smooth integration of the workforce and resources available within the digital environment; it compounds the real world without substituting it; increased versatility, speed, efficiency, and ethical sustainability of processes; even semi-skilled workforce can work on high-end technologies. | Masood and Egger (2019); Ghobakhloo (2020); Yadav et al. (2020); Guarnieri and Trojan (2019) |

| Cyber-Physical Systems (CPS) | Machines utilization will improve; data/information on machine tools can be used to improve overall performance; user-friendly human-machine interaction for sustainable operations; autonomous decision-making; perform a task that is difficult for humans | Pater and Gils (2003); Lass and Gronau (2020); Schleinkofer et al. (2019); Alcacer and Cruz-Machlado (2019); Bag et al. (2020d) |

| Autonomous Robots | Suitability for industrial use in risky surroundings; enhanced versatility, ethical and sustainability of manufacturing operations |

Alcacer and Cruz-Machlado (2019); Ghobakhloo (2020); Yadav et al. (2020); Guarnieri and Trojan (2019) |

2.2. Challenges in implementing industry 4.0 technologies for ethical and sustainable operations

In the modern business environment of the circular economy, organizations need to use technology for ethical and sustainable value addition. Organizations should not focus only on profit. They need to make a proper balance among different perspectives of performance. To ensure long term growth, adopted business models need to be ethical, sustainable, and transparent without exploiting human values (Machado et al., 2019). Technologies of Industry 4.0 can maintain the whole product life cycle from design to delivery of the product (Hofmann and Rusch, 2017). By IoTs, devices are interconnected via the internet and can share information in the form of commands or data between two or more points (Wollschlaeger et al., 2017). Alqahtani et al. (2019) stated that the IoTs play a critical role in eradicating equivocality about the present and the persisting lives of any product. 3D printing helps in attaining the cheaper and lighter products (DebRoy et al., 2018). System integration is the combination of different software and hardware to get easy design modification and maximum value creation (Zhou et al., 2020). By using big data analytics, we can take decisions on future growth and business improvement (Jain et al., 2017). Virtually augmenting (augmented reality) has multiple applications nowadays like gaming, business, and education (Muller et al., 2018a). Cyber security makes a safe and secure system (Muller et al., 2018b). Simulation technology helps in making physical products in the virtual world and save a lot of costs and energy (Pinto Taborga et al., 2018). Robotics and artificial intelligence help in designing and manufacturing products with high accuracy and quality without regular human intervention (Pedersen et al., 2016). IT services of ‘Cloud’ gives cost-effective data storage (Alsmadi and Prybutok, 2018). Frank et al. (2019) have observed that Industry 4.0 is associated with the espousal of technologies for the entire system.

Few studies support Industry 4.0 implementation and provide a roadmap for its implementation (Zhou et al., 2020). Manufacturing and cyber-physical systems could be integrated by digital learning. Some examples of blended learning could be virtual classrooms, visualization of real data, and adaptive learning (Muller et al., 2018 b). Kumar (2020b) has observed that Indian manufacturing SMEs are more influenced by the technologies of the second industrial revolution and lagging to the fourth industrial revolution. On the other side, Germany’s manufacturing sector is more advanced on the technology front (Pfohl et al., 2017). In recent times, the attention on the circular economy has increased, and therefore organizations have started looking for innovative and sustainable technologies (Kumar et al., 2019). As per increasing global competition on the international manufacturing network, there is a need for investigating the challenges of this sector in the Industry 4.0 era (Mishra et al., 2019). Organizations should focus on ethical issues also along with social, economic, and environmental measures while managing their operations for sustainable growth (Guarnieri and Trojan, 2019). Despite many contributions of Industry 4.0 for ethical and sustainable business, many organizations struggle in implementing these technologies in their processes. Fast-changing technological disruptions impose many challenges for SMEs in developing countries (Morrar et al., 2017). SMEs of developing countries face problems due to poor financial condition, lack of technical skills in workers, and the high cost of sustainable practices (Kumar et al., 2014; Moktadir et al., 2018; Bag et al., 2020b; Kumar, 2020a). Apart from it, creating solutions, compatible to environment, culture, and society is also challenging. Lack of awareness about emerging technologies among the workers, the risk of social displacement caused due to unemployment, changes in the market structure due to emerging technologies are other major challenge for sustainable development (Muller et al., 2018b; Satapathy, 2017; Zezulka et al., 2016; Shin et al., 2019; Kumar, 2020b; Cezarino et al., 2019). Lack of global standards and guidelines on the implementation of sustainable technologies are also found challenging for SMEs in developing economies (Shin et al., 2019; Dawson, 2014; Moktadir et al., 2018). The 4th industrial revolution renders a gravid chance to curb these challenges and give a competitive edge in the implementation of sustainable practices (Kumar et al., 2018; Kumar, 2020b).

Machado et al. (2019) have observed that organizations should consider social, environmental, ethical, human rights-related measures while formulating their strategies for sustainable growth. Many developed countries outsource their services to SMEs in developing countries such as India, Bangladesh, Vietnam, etc. to lower the production cost and to avoid restrictive legislation. Transparency of operations is the main challenge for sustainable and ethical services. It becomes more challenging in developing countries to ensure transparency of operations due to lack of IT infrastructure, poor organization culture, lack of legislations and lack of advanced technologies applications (BRICS Business Council, 2017; Luthra and Mangla, 2018; Rauch et al., 2019; Chauhan et al., 2019; Ehrgott et al., 2011). Indian SMEs of manufacturing area lack in awareness about Industry 4.0 contributions to ethical and sustainable production (Dutta et al., 2020).

SMEs are not able to implement technologies efficiently for their sustainable development (Almada-Lobo, 2015). Support of top management is vital for technological changes in SMEs. Senior management should create awareness among employees about the contributions of these technologies for ethical and sustainable operations (Feng et al., 2018; Luthra and Mangla, 2018). According to Dawson (2014), there is a need for knowledge up-gradation on these technologies. SMEs of developing economies faces the problem of lack of funds while implementing Industry 4.0 technologies (Mokhtar et al., 2018; Almada, 2016; Schwab et al., 2019; Dutta et al., 2020; Theorin et al., 2017). Organizations are not aware of government policies on emerging technologies and sustainable business models (BRICS Business Council, 2017; Chauhan et al., 2019). Moktadir et al. (2018) suggested the need for systematic investigation on the application of Industry 4.0 technologies. SMEs’ philosophy of short term planning needs to be changed in long term planning for a futuristic approach towards technologies and sustainable operations (Feng et al., 2018; Luthra and Mangla, 2018; Kumar,2020a; Hofmann and Rusch, 2017). SMEs have IT infrastructure related issues (Both software and hardware) in developing economies (Bedekar, 2017; Pfohl et al., 2017; Leitao et al., 2016). SMEs lack in the skilled workforce. There is also need of training about the technologies to upgrade the skills of management and staff (Feng et al., 2018; Sommer, 2015; Luthra and Mangla, 2018; Muller et al., 2018a; Bhatia et al., 2020). From the review of the literature and discussion with Industrial and academic experts, authors have finalized fifteen key challenges affecting the espousal of Industry 4.0 in SMEs for ethical and sustainable value addition (Table 2 ).

Table 2.

Challenges in the espousal of Industry 4.0 technologies.

3. Research methodology

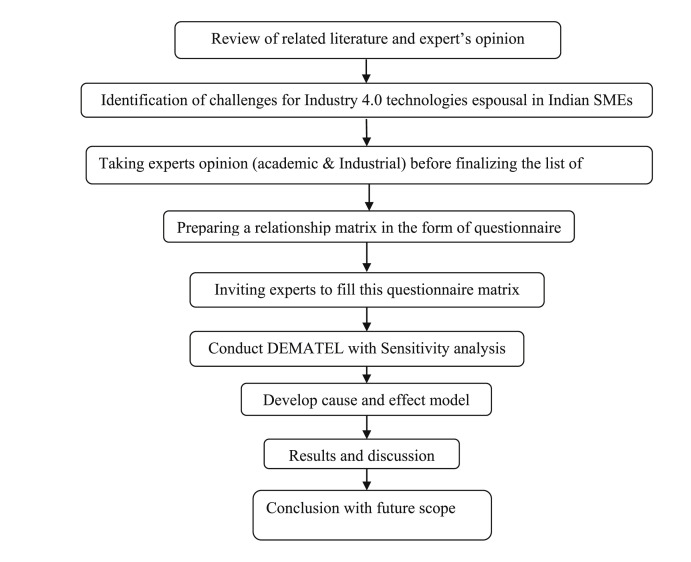

Decision Making Trial and Evaluation Laboratory (DEMATEL) technique has been used to develop interrelationship among the challenges and for identifying the most influential challenges. Sensitivity analysis is also performed to check the hardiness of DEMATEL analysis. To showcase the general steps adopted for this study, the authors have designed a research model, as shown in Fig. 2 . This model discusses all steps followed by the authors during the study of all concerned issues in this research paper. DEMATEL is a preferred technique over AHP, TISM, ISM, or any MCDM techniques as it divides challenges into cause and effect group and indicates the severity of their effects also (Singh et al., 2019). Policymakers can get observations with a quantifiable and ocular kinship among challenges through matrices or diagraphs (Bai and Satir, 2020). It has a wide range to respond as (0, 1, 2, 3, and 4) to explore the cause-effect relationship among the challenges. The categorization of factors further helps managers in formulating effective strategies to handle them. The DEMATEL is the multiple criteria decision making (MCDM) technique, which helps in developing interrelationship among the challenges or barriers. This tool works as a potent tool for decision making. Rajput and Singh (2019b) have categorized the enablers and challenges of CE and Industry 4.0 using DEMATEL. Yadav and Singh (2020) used Fuzzy-DEMATEL for classifying the blockchain factors in cause and effect groups. Rajput and Singh (2019a) have used DEMATEL for analyzing the enablers of IoTs based system. Kumar and Dixit (2018) applied the DEMATEL approach to develop the framework for analyzing challenges to electronic waste management. Singh et al. (2019) applied the DEMATEL for ICTs use in Indian food SMEs. The detailed procedure for this methodology has been shown in Fig. 2. The overall method of DEMATEL has been divided into four steps. The step by step procedure to apply the DEMATEL approach is as follows:

Step 1: Development of Average Direct-relationship Matrix

Fig. 2.

Research methodology model.

Experts have given their opinion about the influence of different challenges on each other by analysing the given matrix.

Experts’ opinions are collected based on the comparison scale of 0–4. The score is assigned like “0 for no impact, 1 for low impact, 2 for medium impact, 3 for high impact, and 4 for very high impact”. This scale is known as the DEMATEL scale. After collecting the expert’s opinion, the average direct-relation matrix is prepared, and it is represented as Aij.

Step 2: Normalizing the average Direct-Relation Matrix (X)

In this stride, the average Direct-Relation Matrix is further normalized(X = ) (Table 4 ).

Step 3: Development of full direct/Indirect influence Matrix

| (1) |

Where z = min {}

| (2) |

Step 4: Obtaining the Total Relation Matrix (T)

| (3) |

Table 4.

Normalize Direct Relation matrix.

| Chn1 | Chn2 | Chn3 | Chn4 | Chn5 | Chn6 | Chn7 | Chn8 | Chn9 | Chn10 | Chn11 | Chn12 | Chn13 | Chn14 | Chn15 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Chn1 | 0 | 0.068409 | 0.076864 | 0.059954 | 0.076864 | 0.09403 | 0.059954 | 0.076864 | 0.076864 | 0.076864 | 0.042788 | 0.068409 | 0.076864 | 0.068409 | 0.076864 |

| Chn2 | 0.068409 | 0 | 0.068409 | 0.068409 | 0.059954 | 0.085575 | 0.102485 | 0.068409 | 0.076864 | 0.076864 | 0.051243 | 0.051243 | 0.059954 | 0.076864 | 0.038432 |

| Chn3 | 0.076864 | 0.059954 | 0 | 0.068409 | 0.051243 | 0.085575 | 0.076864 | 0.051243 | 0.059954 | 0.068409 | 0.085575 | 0.076864 | 0.068409 | 0.076864 | 0.038432 |

| Chn4 | 0.059954 | 0.085575 | 0.051243 | 0 | 0.059954 | 0.068409 | 0.051243 | 0.042788 | 0.09403 | 0.076864 | 0.076864 | 0.042788 | 0.051243 | 0.051243 | 0.076864 |

| Chn5 | 0.059954 | 0.051243 | 0.051243 | 0.051243 | 0 | 0.042788 | 0.042788 | 0.042788 | 0.076864 | 0.059954 | 0.034333 | 0.042788 | 0.059954 | 0.059954 | 0.051243 |

| Chn6 | 0.059954 | 0.09403 | 0.068409 | 0.085575 | 0.042788 | 0 | 0.042788 | 0.051243 | 0.085575 | 0.076864 | 0.051243 | 0.042788 | 0.076864 | 0.076864 | 0.038432 |

| Chn7 | 0.085575 | 0.068409 | 0.09403 | 0.09403 | 0.059954 | 0.076864 | 0 | 0.068409 | 0.068409 | 0.085575 | 0.059954 | 0.068409 | 0.068409 | 0.059954 | 0.038432 |

| Chn8 | 0.076864 | 0.09403 | 0.059954 | 0.059954 | 0.059954 | 0.085575 | 0.085575 | 0 | 0.059954 | 0.076864 | 0.076864 | 0.085575 | 0.042788 | 0.042788 | 0.064053 |

| Chn9 | 0.102485 | 0.059954 | 0.059954 | 0.076864 | 0.051243 | 0.042788 | 0.051243 | 0.034333 | 0 | 0.09403 | 0.051243 | 0.051243 | 0.068409 | 0.076864 | 0.012811 |

| Chn10 | 0.076864 | 0.034333 | 0.076864 | 0.076864 | 0.076864 | 0.051243 | 0.059954 | 0.042788 | 0.059954 | 0 | 0.059954 | 0.076864 | 0.068409 | 0.059954 | 0.025621 |

| Chn11 | 0.051243 | 0.034333 | 0.068409 | 0.034333 | 0.034333 | 0.051243 | 0.059954 | 0.059954 | 0.059954 | 0.059954 | 0 | 0.042788 | 0.076864 | 0.051243 | 0.089675 |

| Chn12 | 0.034333 | 0.068409 | 0.042788 | 0.042788 | 0.034333 | 0.059954 | 0.042788 | 0.025621 | 0.042788 | 0.068409 | 0.034333 | 0 | 0.051243 | 0.025621 | 0.038432 |

| Chn13 | 0.051243 | 0.059954 | 0.059954 | 0.068409 | 0.042788 | 0.059954 | 0.059954 | 0.051243 | 0.051243 | 0.059954 | 0.025621 | 0.042788 | 0 | 0.034333 | 0.025621 |

| Chn14 | 0.042788 | 0.085575 | 0.059954 | 0.042788 | 0.051243 | 0.076864 | 0.068409 | 0.042788 | 0.034333 | 0.059954 | 0.051243 | 0.034333 | 0.076864 | 0 | 0.076864 |

| Chn15 | 0.025621 | 0 | 0.025621 | 0.038432 | 0.025621 | 0.025621 | 0.038432 | 0.089675 | 0 | 0.025621 | 0 | 0.038432 | 0.076864 | 0.076864 | 0 |

Eqn. (3) helps in the formation of the total relation matrix in which I represent the Identity matrix.

Step 5

Producing the causal and effect values from Total Relation Matrix

In the Total Relation Matrix, Sum of the all ‘i’th row elements represented as Di and Sum of the entire ‘j’th row element described as Rj. Now Di + Rj and Di-Rj values are obtained, where Di + Rj indicates the relation of challenges with each other and Di - Rj suggests the kind of relationship in the form of cause and effect. Where positive values are considered as cause group, and negative values are considered as effect group of challenges.

4. Results obtained and discussion of findings

In this section, authors have discussed the categorization of challenges into cause and effect groups by DEMATEL technique. Sensitivity analysis has been done to validate the consistency of results. Subsections like 4.1 will explore the results of DEMATEL, subsection 4.2 will explore the finding of sensitivity analysis and subsection 4.3 will focus on conclusive discussion on the findings of this study.

4.1. Analysis based on DEMATEL approach

An expert team was formed to take the inputs for analyzing the influence of different factors over each other. Each industrial and academic expert has minimum experience ten years in the relevant field of advanced manufacturing systems and research, respectively. All industrial and academic experts were from organizations located in the National capital region (NCR), Delhi-India. A detailed questionnaire was designed for the survey (Appendix-I). Industrial experts were of manager-level position with professional qualification and had worked in the concerned organization for at least five years. Academic experts were of associate professor level and above with Ph.D. as the minimum qualification. Experts were briefed about the purpose of the survey, standard definition, and title of the study. For collecting the response, the questionnaire was circulated among 80 experts (60 from Industry & 20 from academia). The responders were contacted by different sources of correspondence. A total of 36 experts (21 from Industry & 15 from academia) replied by filling the complete questionnaire. It represents a response rate of 45 per cent.

For the calculation of the DEMATEL approach, first, the average Direct-Relation Matrix A is developed, as shown in Table 3. After this, the average matrix is normalized to express the values in the range of 0–1 (Table 4). Then the total relation matrix is obtained (Table 5 ). Further calculations are performed as per steps of methodology, and the results are shown in Table 6 and Table 7 , respectively. The obtained values of ‘Di’, ‘Rj’, ‘Di + Rj’, and ‘Di –Rj’ are shown in Table 6. These values will help in analyzing the challenges. The magnitude of ‘Di – Rj’ values categorizes the challenges into ‘Effect’ and ‘Cause’ groups. The positive values of ‘Di – Rj’ are considered into cause group, and negative values of ‘Di – Rj’ are considered into effect group.

Table 3.

Average direct – relation matrix.

| Chn1 | Chn2 | Chn3 | Chn4 | Chn5 | Chn6 | Chn7 | Chn8 | Chn9 | Chn10 | Chn11 | Chn12 | Chn13 | Chn14 | Chn15 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Chn1 | 0 | 2.67 | 3 | 2.34 | 3 | 3.67 | 2.34 | 3 | 3 | 3 | 1.67 | 2.67 | 3 | 2.67 | 3 |

| Chn2 | 2.67 | 0 | 2.67 | 2.67 | 2.34 | 3.34 | 4 | 2.67 | 3 | 3 | 2 | 2 | 2.34 | 3 | 1.5 |

| Chn3 | 3 | 2.34 | 0 | 2.67 | 2 | 3.34 | 3 | 2 | 2.34 | 2.67 | 3.34 | 3 | 2.67 | 3 | 1.5 |

| Chn4 | 2.34 | 3.34 | 2 | 0 | 2.34 | 2.67 | 2 | 1.67 | 3.67 | 3 | 3 | 1.67 | 2 | 2 | 3 |

| Chn5 | 2.34 | 2 | 2 | 2 | 0 | 1.67 | 1.67 | 1.67 | 3 | 2.34 | 1.34 | 1.67 | 2.34 | 2.34 | 2 |

| Chn6 | 2.34 | 3.67 | 2.67 | 3.34 | 1.67 | 0 | 1.67 | 2 | 3.34 | 3 | 2 | 1.67 | 3 | 3 | 1.5 |

| Chn7 | 3.34 | 2.67 | 3.67 | 3.67 | 2.34 | 3 | 0 | 2.67 | 2.67 | 3.34 | 2.34 | 2.67 | 2.67 | 2.34 | 1.5 |

| Chn8 | 3 | 3.67 | 2.34 | 2.34 | 2.34 | 3.34 | 3.34 | 0 | 2.34 | 3 | 3 | 3.34 | 1.67 | 1.67 | 2.5 |

| Chn9 | 4 | 2.34 | 2.34 | 3 | 2 | 1.67 | 2 | 1.34 | 0 | 3.67 | 2 | 2 | 2.67 | 3 | .5 |

| Chn10 | 3 | 1.34 | 3 | 3 | 3 | 2 | 2.34 | 1.67 | 2.34 | 0 | 2.34 | 3 | 2.67 | 2.34 | 1 |

| Chn11 | 2 | 1.34 | 2.67 | 1.34 | 1.34 | 2 | 2.34 | 2.34 | 2.34 | 2.34 | 0 | 1.67 | 3 | 2 | 3.5 |

| Chn12 | 1.34 | 2.67 | 1.67 | 1.67 | 1.34 | 2.34 | 1.67 | 1 | 1.67 | 2.67 | 1.34 | 0 | 2 | 1 | 1.5 |

| Chn13 | 2 | 2.34 | 2.34 | 2.67 | 1.67 | 2.34 | 2.34 | 2 | 2 | 2.34 | 1 | 1.67 | 0 | 1.34 | 1 |

| Chn14 | 1.67 | 3.34 | 2.34 | 1.67 | 2 | 3 | 2.67 | 1.67 | 1.34 | 2.34 | 2 | 1.34 | 3 | 0 | 3 |

| Chn15 | 1 | 0 | 1 | 1.5 | 1 | 1 | 1.5 | 3.5 | 0 | 1 | 0 | 1.5 | 3 | 3 | 0 |

Table 5.

Total relation matrix.

| Chn1 | Chn2 | Chn3 | Chn4 | Chn5 | Chn6 | Chn7 | Chn8 | Chn9 | Chn10 | Chn11 | Chn12 | Chn13 | Chn14 | Chn15 | D | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Chn1 | 0.353 | 0.415 | 0.421 | 0.41 | 0.369 | 0.452 | 0.396 | 0.371 | 0.416 | 0.459 | 0.328 | 0.374 | 0.44 | 0.402 | 0.346 | 5.952 |

| Chn2 | 0.412 | 0.345 | 0.409 | 0.412 | 0.349 | 0.438 | 0.427 | 0.357 | 0.411 | 0.453 | 0.332 | 0.353 | 0.418 | 0.402 | 0.307 | 5.825 |

| Chn3 | 0.409 | 0.393 | 0.336 | 0.402 | 0.334 | 0.43 | 0.396 | 0.335 | 0.387 | 0.436 | 0.355 | 0.368 | 0.417 | 0.394 | 0.302 | 5.694 |

| Chn4 | 0.373 | 0.39 | 0.362 | 0.316 | 0.323 | 0.389 | 0.352 | 0.31 | 0.395 | 0.418 | 0.328 | 0.318 | 0.379 | 0.352 | 0.318 | 5.323 |

| Chn5 | 0.319 | 0.308 | 0.308 | 0.311 | 0.221 | 0.312 | 0.293 | 0.263 | 0.327 | 0.344 | 0.246 | 0.271 | 0.33 | 0.307 | 0.252 | 4.412 |

| Chn6 | 0.381 | 0.408 | 0.384 | 0.403 | 0.315 | 0.335 | 0.353 | 0.322 | 0.397 | 0.427 | 0.313 | 0.324 | 0.408 | 0.381 | 0.289 | 5.44 |

| Chn7 | 0.439 | 0.421 | 0.443 | 0.447 | 0.361 | 0.444 | 0.345 | 0.368 | 0.416 | 0.475 | 0.351 | 0.38 | 0.438 | 0.399 | 0.318 | 6.045 |

| Chn8 | 0.418 | 0.43 | 0.401 | 0.404 | 0.349 | 0.438 | 0.413 | 0.295 | 0.396 | 0.453 | 0.354 | 0.385 | 0.403 | 0.373 | 0.331 | 5.843 |

| Chn9 | 0.4 | 0.36 | 0.36 | 0.377 | 0.308 | 0.358 | 0.342 | 0.291 | 0.299 | 0.422 | 0.298 | 0.317 | 0.382 | 0.362 | 0.253 | 5.129 |

| Chn10 | 0.375 | 0.336 | 0.373 | 0.375 | 0.328 | 0.363 | 0.347 | 0.298 | 0.354 | 0.334 | 0.305 | 0.338 | 0.381 | 0.345 | 0.263 | 5.115 |

| Chn11 | 0.322 | 0.303 | 0.335 | 0.307 | 0.263 | 0.331 | 0.319 | 0.291 | 0.321 | 0.356 | 0.222 | 0.282 | 0.358 | 0.311 | 0.297 | 4.618 |

| Chn12 | 0.257 | 0.285 | 0.263 | 0.266 | 0.222 | 0.287 | 0.256 | 0.215 | 0.26 | 0.31 | 0.215 | 0.196 | 0.282 | 0.239 | 0.209 | 3.762 |

| Chn13 | 0.307 | 0.313 | 0.312 | 0.323 | 0.259 | 0.323 | 0.304 | 0.266 | 0.301 | 0.34 | 0.236 | 0.267 | 0.267 | 0.279 | 0.225 | 4.322 |

| Chn14 | 0.328 | 0.363 | 0.341 | 0.329 | 0.291 | 0.369 | 0.341 | 0.287 | 0.313 | 0.371 | 0.282 | 0.285 | 0.372 | 0.276 | 0.295 | 4.843 |

| Chn15 | 0.2 | 0.18 | 0.18 | 0.213 | 0.174 | 0.21 | 0.207 | 0.234 | 0.172 | 0.218 | 0.146 | 0.193 | 0.255 | 0.238 | 0.139 | 2.959 |

| R | 5.293 | 5.25 | 5.228 | 5.295 | 4.466 | 5.479 | 5.091 | 4.503 | 5.165 | 5.816 | 4.311 | 4.651 | 5.53 | 5.06 | 4.144 |

Table 6.

The sum of influence given and received on challenges.

| Challenges | Di | Rj | Di-Rj | Di + Rj | Overall Ranking |

|---|---|---|---|---|---|

| Chn1 | 5.952 | 5.293 | 0.659 | 11.245 | 1 |

| Chn2 | 5.825 | 5.25 | 0.575 | 11.075 | 3 |

| Chn3 | 5.694 | 5.228 | 0.466 | 10.922 | 5 |

| Chn4 | 5.323 | 5.295 | 0.028 | 10.618 | 7 |

| Chn5 | 4.412 | 4.466 | −0.054 | 8.878 | 13 |

| Chn6 | 5.44 | 5.479 | −0.039 | 10.919 | 6 |

| Chn7 | 6.045 | 5.091 | 0.954 | 11.136 | 2 |

| Chn8 | 5.843 | 4.503 | 1.34 | 10.346 | 8 |

| Chn9 | 5.129 | 5.165 | −0.036 | 10.294 | 9 |

| Chn10 | 5.115 | 5.816 | −0.701 | 10.931 | 4 |

| Chn11 | 4.618 | 4.311 | 0.307 | 8.929 | 12 |

| Chn12 | 3.762 | 4.651 | −0.889 | 8.413 | 14 |

| Chn13 | 4.322 | 5.53 | −1.208 | 9.852 | 11 |

| Chn14 | 4.843 | 5.06 | −0.217 | 9.903 | 10 |

| Chn15 | 2.959 | 4.144 | −1.185 | 7.103 | 15 |

Table 7.

Ranking of challenges subdivided into cause and effect group.

| Cause Group |

Effect Group |

||

|---|---|---|---|

| Challenges | Ranking | Challenges | Rank |

| Chn8 | 1 | Chn13 | 1 |

| Chn7 | 2 | Chn15 | 2 |

| Chn1 | 3 | Chn12 | 3 |

| Chn2 | 4 | Chn10 | 4 |

| Chn3 | 5 | Chn14 | 5 |

| Chn11 | 6 | Chn5 | 6 |

| Chn4 | 7 | Chn6 | 7 |

| Chn9 | 8 | ||

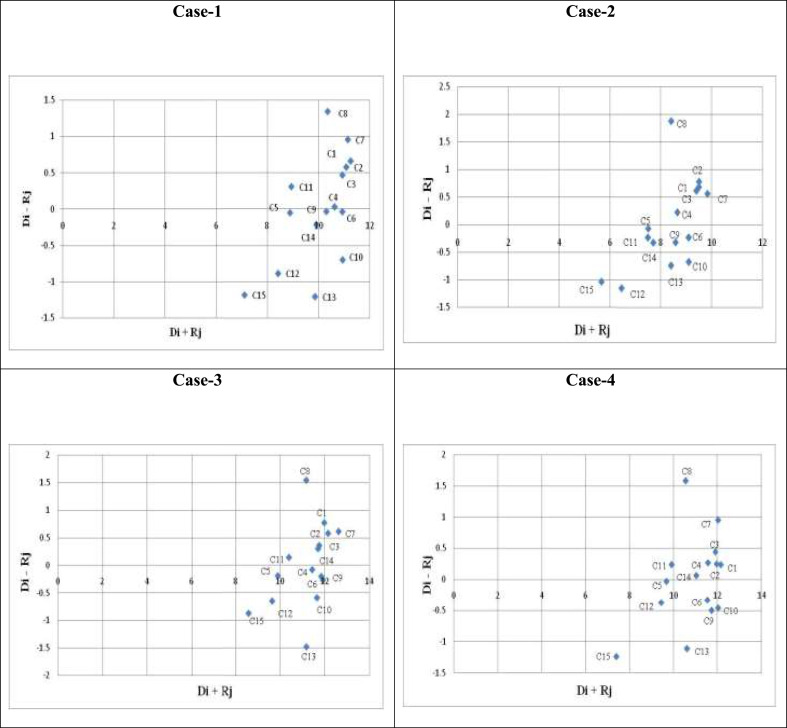

In this study, it has been observed that lack of motivations from customers/OEMs on adopting I4.0 technologies for ethical and sustainable operations (Chn8) has the highest positive value. Therefore, it is considered as the most critical challenge in the cause category. The exact values for cause and effect challenges are shown in Table 7. Further, it is observed that lack of long term planning on the adoption of I4.0 technologies for ethical and sustainable operations (Chn7), lack of awareness about I4.0 contributions to ethical and sustainable production (Chn1), lack of management support for I4.0 technologies (Chn2) and High initial cost of I4.0 technologies for ethical and sustainable operations (Chn3); are the second, third, fourth and fifth-ranked challenges respectively in the cause category. Further findings of the study also indicate that fear of failure of I4.0 technologies (Chn13), fear of demand uncertainty due to market disruptions (Chn15), fear of unemployment/reduction in workforce (Chn12), lack of trained workforce on sustainable operations & I4.0 technologies (Chn10) and lack of alternative solutions to the technological breakdown (Chn14) are top five effect category challenges. The observations from this study will help in developing the framework for analyzing the Industry 4.0 challenges and finding the interrelatedness among these challenges. Authors in current study have also prepared a causal diagram to represent the graphical relationship between the challenges for this study (Fig. 3 ).

Fig. 3.

The Cause-effect diagram (Case 1 to 4).

4.2. Sensitivity analysis

Sensitivity analysis can be used to check the hardiness of the optimal solution of any system or model so that it could be applied for effective decision making (Pannell, 1997). We can use this analysis in two ways, firstly by varying the weight assigned to every challenge and secondly by changing the weight assigned to every expert. Xia et al. (2015) applied sensitivity analysis by changing the weight assigned to every expert to check the robustness of the solution for analyzing the cause and effect relationship. This analysis helps to check biasedness for a specific expert, which may affect the outcome of this study. In this study, the authors used this approach by varying the weight of every expert. In Case-1, every expert was assigned with equal weight, and in Case-2, Case-3, and Case-4, higher weight was assigned to one expert, and the other two expert’s weights remained the same (Table 8 ). Then, for different possible scenarios, calculations are performed for sensitivity analysis. After that, in each case, the cause-effect relationship and causal diagrams are generated (Fig. 3-Cases 1–4). The results found from this sensitivity analysis indicate the consistency of findings (Table 9 ). No considerable change in the results under different conditions confirms the robustness of the model.

Table 8.

Varying the weight of experts in the sensitivity analysis.

| Case-1 | Case-2 | Case-3 | Case-4 | |

|---|---|---|---|---|

| Expert 1 | 0.33 | 0.50 | 0.25 | 0.25 |

| Expert 2 | 0.33 | 0.25 | 0.50 | 0.25 |

| Expert 3 | 0.33 | 0.25 | 0.25 | 0.50 |

Table 9.

Sensitivity analysis of results.

| Challenge Code |

Case-1 |

Case-2 |

Case-3 |

Case-4 |

||||

|---|---|---|---|---|---|---|---|---|

| D + R | Ranking | D + R | Ranking | D + R | Ranking | D + R | Ranking | |

| Chn1 | 11.245 | 1 | 9.494 | 3 | 11.974 | 3 | 12.151 | 1 |

| Chn2 | 11.075 | 3 | 9.501 | 2 | 12.145 | 2 | 11.968 | 3 |

| Chn3 | 10.922 | 5 | 9.395 | 4 | 11.746 | 6 | 11.901 | 4 |

| Chn4 | 10.618 | 7 | 8.65 | 7 | 11.431 | 9 | 11.552 | 6 |

| Chn5 | 8.878 | 13 | 7.506 | 12 | 9.887 | 13 | 9.661 | 12 |

| Chn6 | 10.919 | 6 | 9.092 | 6 | 11.915 | 4 | 11.524 | 7 |

| Chn7 | 11.136 | 2 | 9.834 | 1 | 12.612 | 1 | 12.029 | 2 |

| Chn8 | 10.346 | 8 | 8.406 | 9 | 11.161 | 11 | 10.538 | 10 |

| Chn9 | 10.294 | 9 | 8.576 | 8 | 11.836 | 5 | 11.716 | 5 |

| Chn10 | 10.931 | 4 | 9.096 | 5 | 11.646 | 8 | 12.029 | 2 |

| Chn11 | 8.929 | 12 | 7.492 | 13 | 10.388 | 12 | 9.902 | 11 |

| Chn12 | 8.413 | 14 | 6.456 | 14 | 9.635 | 14 | 9.423 | 13 |

| Chn13 | 9.852 | 11 | 8.401 | 10 | 11.169 | 10 | 10.599 | 9 |

| Chn14 | 9.903 | 10 | 7.704 | 11 | 11.696 | 7 | 11.019 | 8 |

| Chn15 | 7.103 | 15 | 5.649 | 15 | 8.579 | 15 | 7.386 | 14 |

4.3. Discussions of findings

Results of study discussed in section 4.1 and section 4.2 indicate that for SMEs, motivation from customers and original equipment manufacturers (Partners) and top management support are very important for adoption of smart technologies. SMEs in developing countries are mostly dependent on their partners for economical and other business advancements. Therefore, there is a need of effective coordination among different members of supply chains. Luthra and Mangla (2018) in their study have found challenges related to finance, government policies, and management supports while implementing Industry 4.0 technologies. Chakraborty et al. (2020) in their study on logistics sector have observed that lack of awareness about technologies is a significant concern for implementing new technologies. Liao et al. (2018) found that organizations of developed countries have more knowledge of advanced technologies in comparison to developing countries. Findings of the current study have highlighted that in developing economy, SMEs face major challenges of awareness, knowledge and funding while adopting Industry 4.0 technologies for ethical and sustainable operations.

Frank et al. (2019) have mentioned about the non-availability of hardware/software while implementation these technologies. Rajput and Singh (2019a) have found out that artificial intelligence (AI), service, and policy framework can enable the implementation of Industry 4.0 technologies for ethical and sustainable operations. The findings of the current study imply that the challenges such as lack of IT based infrastructure, lack of trained workforce, fear of failure of I4.0 technologies, lack of alternative solutions at the time of breakdowns are highly significant for SMEs, and should be given more priority while formulating strategies. Raj et al. (2019) have found lack of strategy for process digitalization and scarcity of resources as major challenges for implementing new technologies. Kamble (2018); Bogoviz et al. (2019) and Chakraborty et al. (2020), have highlighted the importance of regulations, rules, allegiance and willingness for the digitalization of processes in Indian manufacturing organizations. We have also sensed the inadequacy of legislations and commitment on Industry 4.0 technologies in present study on Indian SMEs.

Study of Piyathanavong et al. (2019), in Thai manufacturing organizations have highlighted the issues of investment, training, and knowledge of technologies for implementing sustainability practices. Chakraborty et al. (2020) have discussed in their study about the issues of poor infrastructure, scarcity of finance, poor information sharing, and the inadequacy of expertness of Indian logistics sector in implementing IT tools. For validation of findings, sensitivity analysis needs to be done (Pannell, 1997; Xia et al., 2015). In this study, after doing sensitivity analysis, we have observed that there is no considerable difference in the results under different conditions. It indicates about the robustness of our model. Observations from causal diagram, indicates that lack of motivations from customers/OEMs on adopting I4.0 technologies for ethical and sustainable operations and fear of failure of I4.0 technologies are the key challenges in the espousal of Industry 4.0 technologies and these are the top-ranked challenges in their respective group. Therefore, there is a need for overcoming the fear of failure in the adoption of Industry 4.0 technologies.

5. Conclusion and implications

Across the globe, specifically in developing countries, SMEs are considered the backbone of the economy. In developing countries like India, out of a total of 16% contribution of the manufacturing sector to India’s GDP, approximately 8% comes from SMEs (Singh and Kumar, 2020). SMEs are also a significant source of employment in India. To compete in global markets, SMEs need to adopt ethical, efficient, and sustainable business models. Many researchers have observed the importance of Industry 4.0 technologies for ethical and sustainable operations in context to larger enterprises. However, studies in context to SMEs are limited. Therefore, authors wanted to analyze the challenges in the implementation of Industry 4.0 technologies in SMEs for ethical and sustainable operations. Fifteen critical challenges after the review of literature have been identified. For further ranking and categorization of these challenges, the DEMATEL approach is used. Lack of motivation in customers/OEMs on adopting I4.0 technologies for ethical and sustainable operations is found as the most crucial challenge in the cause category. Lack of long term planning on adoption of I4.0 technologies for ethical and sustainable operations, lack of awareness about I4.0 contributions to ethical and sustainable production, lack of management support for I4.0 technologies and the high initial cost of I4.0 technologies for ethical and sustainable operations is other significant challenge under cause category. Under the effect category, fear of failure of I4.0 technologies and fear of demand uncertainty due to market disruptions are significant challenges in the implementation of Industry 4.0 technologies for ethical and sustainable operations in SMEs. Challenges falling in the cause category may influence other challenges, so management should prioritize the strategies accordingly.

5.1. Managerial implications

Findings of this study imply that SMEs need to be motivated to adopt ethical and sustainable business models. SMEs should create awareness about these technologies and their contributions within their organizations and for other stakeholders. Management of SMEs should allocate sufficient funds for such initiatives considering it as long term goals. Usually, SMEs take their decisions based on short term gains. It means overall culture within SMEs needs to be changed. SMEs should integrate these Industry 4.0 technologies with different manufacturing processes for ethical and sustainable operations. As SMEs lack in terms of knowledge and expertise (Kumar, 2020 b), so consultants should be engaged for effective strategy formulation. Integrating digital technologies with manufacturing processes for ethical and sustainable value addition should be part of the strategies. It will not only help them in resource optimization but will also make them responsive to changing market requirements. Telukdarie et al. (2018) have considered the applications of Industry 4.0 technologies for sustainable operations in planning of long term strategies.

5.2. Theoretical implications

Findings of the current study have many theoretical implications too. Government and larger supply chain partners should focus on the need of awareness programs for SMEs in adopting Industry 4.0 technologies. Bogoviz et al. (2019) have stressed on the need for policies and regulations on the implementation of Industry 4.0 in developing economies. To excel on the global front, SMEs need a plan for future and adopt technologies for ethical and sustainable operations. Initiatives taken on time in this direction will make them more resilient and competitive. Researchers and academic experts all over the globe should focus more on case studies and empirical researches for future directions in this context. Multiple researches and observations will help in reducing the challenges of technologies adoption in SMEs of both developing and developed economies.

6. Limitations and future research directions

Despite significant contribution in motivating SMEs for ethical and sustainable business by implementing Industry 4.0 technologies, this study has also got few limitations. The authors have selected fifteen challenges for adopting Industry 4.0 technologies for ethical and sustainable operations in SMEs from the Indian perspective. SMEs from other sectors and developed countries may face different kind of challenges. Therefore, findings cannot be generalized. DEMATEL methodology has also got its limitations due to the biasedness of experts’ opinions while taking inputs. Therefore, the findings of the study cannot be generalized. For further validation, the study can be extended in context to the other countries and sectors by applying other MCDM tools and case studies. It will help in doing the comparative analysis and in generalizing the findings of this study. Sensing the importance of automation and Industry4.0 technologies in current scenario, findings of this study could be very helpful for SMEs all over the globe. Influence of pandemic (COVID-19) has affected the functioning of almost all supply chains. Lockdown, isolation, social distancing and migration of labors will lead the companies to rethink about their location and investment strategies. In the future also for resuming production in new normal, findings of this study will be very helpful for SMEs in developing ethical and sustainable operations.

CRediT authorship contribution statement

Ravinder Kumar: It is certified that all the three authors have contributed in this research work, Introduction and LR have been done by Ravinder Kr, Analysis of results by RAJESH Kr Singh and Discussion with conclusion by Yogesh Dwivedi. Rajesh Kr. Singh: It is certified that all the three authors have contributed in this research work, Introduction and LR have been done by Ravinder Kr, Analysis of results by RAJESH Kr Singh and Discussion with conclusion by Yogesh Dwivedi. Yogesh Kr. Dwivedi: It is certified that all the three authors have contributed in this research work, Introduction and LR have been done by Ravinder Kr, Analysis of results by RAJESH Kr Singh and Discussion with conclusion by Yogesh Dwivedi.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgement

Authors would like to thank reviewers and Editor of the journal for valuable inputs and suggestions for improvements in this paper.

Biographies

Dr. Ravinder Kumar is an Associate Professor at Amity University, Noida, India. He holds a bachelor’s degree in Mechanical Engineering with Honors. He did his Master’s and Ph.D. from Delhi College of Engineering, University of Delhi, India. He has published about 45 research papers in reputed international journals and Conferences. His areas of interest include supply chain management and quality management in SMEs. He has published papers in journals such as Competitiveness Review: An International Journal, Global Journal of Flexible Systems and Management, IIMB Management Review, Benchmarking: an International Journal, International Journal of Pharmaceutical and Healthcare Marketing, International Journal of Business Information Systems, International Journal of Manufacturing Research, etc.

Dr. Rajesh Kr. Singh is a Professor at the Management Development Institute, Gurgaon, India. His areas of interest include supply chain management, Industry 4.0, quality management and circular economy. He has about 170 research papers published in reputed international/national journals and conferences. He has published papers in journals such as Resources, Conservation and Recycling, Journal of Cleaner Production, Industrial Management and Data Systems, Production planning and Control, Singapore Management Review, International Journal of Productivity and Performance Management, Benchmarking: An International Journal, Journal of Modelling in Management, Competitiveness Review: An International Business Journal, Global Journal of Flexible Systems and Management, International Journal of Productivity and Quality Management, International Journal of Services and Operations Management, International Journal of Automotive Industry and Management, International Journal of Logistic Systems Management, IIMB Management Review and Productivity Promotion.

Yogesh K. Dwivedi is a Professor of Digital Marketing and Innovation, Founding Director of the Emerging Markets Research Centre (EMaRC) and Co-Director of Research at the School of Management, Swansea University, Wales, UK. Professor Dwivedi is also currently leading the International Journal of Information Management as its Editor-in-Chief. His research interests are at the interface of Information Systems (IS) and Marketing, focusing on issues related to consumer adoption and diffusion of emerging digital innovations, digital government, and digital marketing particularly in the context of emerging markets. Professor Dwivedi has published more than 300 articles in a range of leading academic journals and conferences that are widely cited (more than 15 thousand times as per Google Scholar). Professor Dwivedi is an Associate Editor of the European Journal of Marketing, Government Information Quarterly and International Journal of Electronic Government Research, and Senior Editor of the Journal of Electronic Commerce Research. More information about Professor Dwivedi can be found at: http://www.swansea.ac.uk/staff/som/academic-staff/y.k.dwivedi/.

Handling editor: Cecilia Maria Villas Bôas de Almeida

Footnotes

Supplementary data to this article can be found online at https://doi.org/10.1016/j.jclepro.2020.124063.

Appendix A. Supplementary data

The following is the Supplementary data to this article:

References

- Alcácer V., Cruz-Machado V. Scanning the industry 4.0: a literature review on technologies for manufacturing systems. Eng. Sci. Technol. Int. J. 2019;22:899–919. doi: 10.1016/j.jestch.2019.01.006. [DOI] [Google Scholar]

- Almada-Lobo F. The industry 4.0 revolution and the future of manufacturing execution systems (MES) J. Innovat. Manag. 2016;3:16–21. doi: 10.24840/2183-0606_003.004_0003. [DOI] [Google Scholar]

- Alqahtani A.Y., Gupta S.M., Nakashima K. Warranty and maintenance analysis of sensor embedded products using internet of things in industry 4.0. Int. J. Prod. Econ. 2019;208:483–499. doi: 10.1016/j.ijpe.2018.12.022. [DOI] [Google Scholar]

- Alsmadi D., Prybutok V. Sharing and storage behavior via cloud computing: security and privacy in research and practice. Comput. Hum. Behav. 2018;85:218–226. doi: 10.1016/j.chb.2018.04.003. [DOI] [Google Scholar]

- Bag S., Gupta S., Kumar S. Industry 4.0 adoption and 10R advance manufacturing capabilities for sustainable development. Int. J. Prod. Econ. 2021;231:107844. doi: 10.1016/j.ijpe.2020.107844. [DOI] [Google Scholar]

- Bag S., Gupta S., Luo Z. Examining the role of logistics 4.0 enabled dynamic capabilities on firm performance. Int. J. Logist. Manag. 2020 doi: 10.1108/IJLM-11-2019-0311. ahead-of-p. [DOI] [Google Scholar]

- Bag S., Pretorius J.H.C. Relationships between industry 4.0, sustainable manufacturing and circular economy: proposal of a research framework. Int. J. Organ. Anal. 2020 doi: 10.1108/IJOA-04-2020-2120. ahead-of-p. [DOI] [Google Scholar]

- Bag S., Wood L.C., Mangla S.K., Luthra S. Procurement 4.0 and its implications on business process performance in a circular economy. Resour. Conserv. Recycl. 2020;152:104502. doi: 10.1016/j.resconrec.2019.104502. [DOI] [Google Scholar]

- Bag S., Wood L.C., Xu L., Dhamija P., Kayikci Y. Big data analytics as an operational excellence approach to enhance sustainable supply chain performance. Resour. Conserv. Recycl. 2020;153:104559. doi: 10.1016/j.resconrec.2019.104559. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bag S., Yadav G., Wood L.C., Dhamija P., Joshi S. Industry 4.0 and the circular economy: resource melioration in logistics. Resour. Pol. 2020;68:101776. doi: 10.1016/j.resourpol.2020.101776. [DOI] [Google Scholar]

- Bai C., Satir A. Barriers for green supplier development programs in manufacturing industry. Resour. Conserv. Recycl. 2020;158:104756. doi: 10.1016/j.resconrec.2020.104756. [DOI] [Google Scholar]

- Battaglia D., Neirotti P., Paolucci E. The role of R&D investments and export on SMEs’ growth: a domain ambidexterity perspective. Manag. Decis. 2018;56:1883–1903. doi: 10.1108/MD-02-2017-0136. [DOI] [Google Scholar]

- Bedekar A. Opportunities & challenges for IoT in India. 2017. http://www.startupcity.com/leaders-talk/-opportunities-challenges-for-IoT-in-india-nid-3444.html Online available at:

- Beier G., Ullrich A., Niehoff S., Reißig M., Habich M. Industry 4.0: how it is defined from a sociotechnical perspective and how much sustainability it includes – a literature review. J. Clean. Prod. 2020;259:120856. doi: 10.1016/j.jclepro.2020.120856. [DOI] [Google Scholar]

- Bhatia M.S., Jakhar S.K., Mangla S.K., Gangwani K.K. Critical factors to environment management in a closed loop supply chain. J. Clean. Prod. 2020;255:120239. doi: 10.1016/j.jclepro.2020.120239. [DOI] [Google Scholar]

- Bogoviz A.V., Osipov V.S., Chistyakova M.K., Borisov M.Y. 2019. Comparative Analysis of Formation of Industry 4.0 in Developed and Developing Countries; pp. 155–164. [DOI] [Google Scholar]

- BRIC Business Council Skill development for industry 4.0. A white paper by BRICS skill development working group, BRICS business Council, India group. 2017. http://www.globalskillsummit.com/Whitepaper-Summary.pdf Online available at:

- Cezarino L.O., Liboni L.B., Oliveira Stefanelli N., Oliveira B.G., Stocco L.C. Diving into emerging economies bottleneck: industry 4.0 and implications for circular economy. Manag. Decis. 2019 doi: 10.1108/MD-10-2018-1084. MD-10-2018-1084. [DOI] [Google Scholar]

- Chakraborty S., Sharma A., Vaidya O.S. Achieving sustainable operational excellence through IT implementation in Indian logistics sector: an analysis of barriers. Resour. Conserv. Recycl. 2020;152:104506. doi: 10.1016/j.resconrec.2019.104506. [DOI] [Google Scholar]

- Chauhan C., Sharma A., Singh A. A SAP-LAP linkages framework for integrating Industry 4.0 and circular economy. Benchmark Int. J. 2019 doi: 10.1108/BIJ-10-2018-0310. ahead-of-p. [DOI] [Google Scholar]

- Chien C.F., Tseng M.L., Tan R.R., Tan K., Velek O. Industry 3.5 for sustainable transition and total resource management, 2020. Resour. Conserv. Recycl. 2020;152:104482. doi: 10.1016/j.resconrec.2019.104482. [DOI] [Google Scholar]

- Dawson T. 2014. Industry 4.0 – Opportunities and Challenges for Smart Manufacturing.http://blog.ihs.com/q13-industry-40-opportunities-and-challenges-for-smart-manufacturing [Google Scholar]

- de Sousa Jabbour A.B., Jabbour C.J.C., Godinho Filho M., Roubaud D. Industry 4.0 and the circular economy: a proposed research agenda and original roadmap for sustainable operations. Ann. Oper. Res. 2018;270:273–286. doi: 10.1007/s10479-018-2772-8. [DOI] [Google Scholar]

- de Sousa Jabbour A.B.L., Jabbour C.J.C., Foropon C., Godinho Filho M. When titans meet – can industry 4.0 revolutionise the environmentally-sustainable manufacturing wave? The role of critical success factors. Technol. Forecast. Soc. Change. 2018;132:18–25. doi: 10.1016/j.techfore.2018.01.017. [DOI] [Google Scholar]

- DebRoy T., Wei H.L., Zuback J.S., Mukherjee T., Elmer J.W., Milewski J.O., Beese A.M., Wilson-Heid A., De A., Zhang W. Additive manufacturing of metallic components – Process, structure and properties. Prog. Mater. Sci. 2018;92:112–224. doi: 10.1016/j.pmatsci.2017.10.001. [DOI] [Google Scholar]

- Dubey R., Gunasekaran A., Childe S.J., Papadopoulos T., Luo Z., Wamba S.F., Roubaud D. Can big data and predictive analytics improve social and environmental sustainability? Technol. Forecast. Soc. Change. 2019;144:534–545. doi: 10.1016/j.techfore.2017.06.020. [DOI] [Google Scholar]

- Dutta G., Kumar R., Sindhwani R., Singh R.K. Digital transformation priorities of India’s discrete manufacturing SMEs – a conceptual study in perspective of Industry 4.0. Compet. Rev. An Int. Bus. J. 2020;30:289–314. doi: 10.1108/CR-03-2019-0031. [DOI] [Google Scholar]

- Ehrgott M., Reimann F., Kaufmann L., Carter C.R. Social sustainability in selecting emerging economy suppliers. J. Bus. Ethics. 2011;98(1):99–119. doi: 10.1007/sl0551-010-0537-7. [DOI] [Google Scholar]

- Fatimah Y.A., Govindan K., Murniningsih R., Setiawan A. Industry 4.0 based sustainable circular economy approach for smart waste management system to achieve sustainable development goals: a case study of Indonesia. J. Clean. Prod. 2020;269:122263. doi: 10.1016/j.jclepro.2020.122263. [DOI] [Google Scholar]

- Feng L., Zhang X., Zhou K. Current problems in China’s manufacturing and countermeasures for industry 4.0. EURASIP J. Wirel. Commun. Netw. 2018;90 doi: 10.1186/s13638-018-1113-6. 2018. [DOI] [Google Scholar]

- Fernandes N. Economic effects of coronavirus outbreak (COVID-19) on the world economy. 2020. https://ssrn.com/abstract=3557504 SSRN Working paper, available at:

- Ford S., Despeisse M. Additive manufacturing and sustainability: an exploratory study of the advantages and challenges. J. Clean. Prod. 2016;137:1573–1587. doi: 10.1016/j.jclepro.2016.04.150. [DOI] [Google Scholar]

- Frank A.G., Dalenogare L.S., Ayala N.F. Industry 4.0 technologies: implementation patterns in manufacturing companies. Int. J. Prod. Econ. 2019;210:15–26. doi: 10.1016/j.ijpe.2019.01.004. [DOI] [Google Scholar]

- Garcia-Muiña F., González-Sánchez R., Ferrari A., Settembre-Blundo D. The paradigms of industry 4.0 and circular economy as enabling drivers for the competitiveness of businesses and territories: the case of an Italian ceramic tiles manufacturing company. Soc. Sci. 2018;7:255. doi: 10.3390/socsci7120255. [DOI] [Google Scholar]

- Ghobakhloo M. Industry 4.0, digitization, and opportunities for sustainability. J. Clean. Prod. 2020;252:119869. doi: 10.1016/j.jclepro.2019.119869. [DOI] [Google Scholar]

- Guarnieri P., Trojan F. Decision making on supplier selection based on social, ethical, and environmental criteria: a study in the textile industry. Resour. Conserv. Recycl. 2019;141:347–361. doi: 10.1016/j.resconrec.2018.10.023. [DOI] [Google Scholar]

- Gurtu A., Johny J. Potential of blockchain technology in supply chain management: a literature review. Int. J. Phys. Distrib. Logist. Manag. 2019;49:881–900. doi: 10.1108/IJPDLM-11-2018-0371. [DOI] [Google Scholar]

- Hofmann E., Rüsch M. Industry 4.0 and the current status as well as future prospects on logistics. Comput. Ind. 2017;89:23–34. doi: 10.1016/j.compind.2017.04.002. [DOI] [Google Scholar]

- Horváth D., Szabó R.Z. Driving forces and barriers of Industry 4.0: do multinational and small and medium-sized companies have equal opportunities? Technol. Forecast. Soc. Change. 2019;146:119–132. doi: 10.1016/j.techfore.2019.05.021. [DOI] [Google Scholar]

- Jain S., Shao G., Shin S.-J. Manufacturing data analytics using a virtual factory representation. Int. J. Prod. Res. 2017;55:5450–5464. doi: 10.1080/00207543.2017.1321799. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kamble S., Gunasekaran A., Dhone N.C. Industry 4.0 and lean manufacturing practices for sustainable organisational performance in Indian manufacturing companies. Int. J. Prod. Res. 2020;58:1319–1337. doi: 10.1080/00207543.2019.1630772. [DOI] [Google Scholar]

- Kamble S.S., Gunasekaran A., Sharma R. Analysis of the driving and dependence power of barriers to adopt industry 4.0 in Indian manufacturing industry. Comput. For. Ind. 2018;101:107–119. doi: 10.1016/j.compind.2018.06.004. [DOI] [Google Scholar]

- Kerin M., Pham D.T. A review of emerging industry 4.0 technologies in remanufacturing. J. Clean. Prod. 2019;237:117805. doi: 10.1016/j.jclepro.2019.117805. [DOI] [Google Scholar]

- Kumar A., Dixit G. An analysis of barriers affecting the implementation of e-waste management practices in India: a novel ISM-DEMATEL approach. Sustain. Prod. Consum. 2018;14:36–52. doi: 10.1016/j.spc.2018.01.002. [DOI] [Google Scholar]

- Kumar R. 2020. Sustainable Supply Chain Management in the Era of Digitialization; pp. 446–460. [DOI] [Google Scholar]

- Kumar R. 2020. Espousal of Industry 4.0 in Indian Manufacturing Organizations; pp. 245–252. [DOI] [Google Scholar]

- Kumar R., Singh K., Shankar R. Strategy development by Indian SMEs for improving coordination in supply chain. Compet. Rev. 2014;24:414–432. doi: 10.1108/CR-06-2012-0016. R. [DOI] [Google Scholar]

- Kumar R., Singh R.K., Shankar R. Critical success factors for implementation of supply chain management in Indian small and medium enterprises and their impact on performance. IIMB Manag. Rev. 2015;27:92–104. doi: 10.1016/j.iimb.2015.03.001. [DOI] [Google Scholar]

- Kumar R., Singh S.P., Lamba K. Sustainable robust layout using Big Data approach: a key towards industry 4.0. J. Clean. Prod. 2018;204:643–659. doi: 10.1016/j.jclepro.2018.08.327. [DOI] [Google Scholar]

- Kumar V., Sezersan I., Garza-Reyes J.A., Gonzalez E.D.R.S., AL-Shboul M.A. Circular economy in the manufacturing sector: benefits, opportunities and barriers. Manag. Decis. 2019;57:1067–1086. doi: 10.1108/MD-09-2018-1070. [DOI] [Google Scholar]

- Lasi H., Fettke P., Kemper H.-G., Feld T., Hoffmann M. Industry 4.0. Bus. Inf. Syst. Eng. 2014;6:239–242. doi: 10.1007/s12599-014-0334-4. [DOI] [Google Scholar]

- Lass S., Gronau N. A factory operating system for extending existing factories to Industry 4.0. Comput. Ind. 2020;115:103128. doi: 10.1016/j.compind.2019.103128. [DOI] [Google Scholar]

- Lee J., Bagheri B., Kao H.-A. A Cyber-Physical Systems architecture for Industry 4.0-based manufacturing systems. Manuf. Lett. 2015;3:18–23. doi: 10.1016/j.mfglet.2014.12.001. [DOI] [Google Scholar]

- Liao Y., Loures E.R., Deschamps F., Brezinski G., Venâncio A. The impact of the fourth industrial revolution: a cross-country/region comparison. Production. 2018;28 doi: 10.1590/0103-6513.20180061. [DOI] [Google Scholar]

- Lieder M., Asif F.M.A., Rashid A., Mihelič A., Kotnik S. Towards circular economy implementation in manufacturing systems using a multi-method simulation approach to link design and business strategy. Int. J. Adv. Manuf. Technol. 2017;93:1953–1970. doi: 10.1007/s00170-017-0610-9. [DOI] [Google Scholar]

- Lieder M., Rashid A. Towards circular economy implementation: a comprehensive review in context of manufacturing industry. J. Clean. Prod. 2016;115:36–51. doi: 10.1016/j.jclepro.2015.12.042. [DOI] [Google Scholar]

- Linder C. Customer orientation and operations: the role of manufacturing capabilities in small- and medium-sized enterprises. Int. J. Prod. Econ. 2019;216:105–117. doi: 10.1016/j.ijpe.2019.04.030. [DOI] [Google Scholar]

- Longoni A., Cagliano R. Environmental and social sustainability priorities. Int. J. Oper. Prod. Manag. 2015;35:216–245. doi: 10.1108/IJOPM-04-2013-0182. [DOI] [Google Scholar]

- Luthra S., Mangla S.K. Evaluating challenges to Industry 4.0 initiatives for supply chain sustainability in emerging economies. Process Saf. Environ. Protect. 2018;117:168–179. doi: 10.1016/j.psep.2018.04.018. [DOI] [Google Scholar]

- Machado C.G., Winroth M.P., Ribeiro da Silva E.H.D. Sustainable manufacturing in Industry 4.0: an emerging research agenda. Int. J. Prod. Res. 2020;58:1462–1484. doi: 10.1080/00207543.2019.1652777. [DOI] [Google Scholar]

- Mani V., Jabbour C.J.C., Mani K.T.N. Supply chain social sustainability in small and medium manufacturing enterprises and firms’ performance: empirical evidence from an emerging Asian economy. Int. J. Prod. Econ. 2020;227:107656. doi: 10.1016/j.ijpe.2020.107656. [DOI] [Google Scholar]

- Marques M., Agostinho C., Zacharewicz G., Jardim-Gonçalves R. Decentralized decision support for intelligent manufacturing in Industry 4.0. J. Ambient Intell. Smart Environ. 2017;9:299–313. doi: 10.3233/AIS-170436. [DOI] [Google Scholar]

- Masood T., Egger J. Augmented reality in support of Industry 4.0—implementation challenges and success factors. Robot. Comput. Integrated Manuf. 2019;58:181–195. doi: 10.1016/j.rcim.2019.02.003. [DOI] [Google Scholar]

- Mastos T.D., Nizamis A., Vafeiadis T., Alexopoulos N., Ntinas C., Gkortzis D., Papadopoulos A., Ioannidis D., Tzovaras D. Industry 4.0 sustainable supply chains: an application of an IoT enabled scrap metal management solution. J. Clean. Prod. 2020;269:122377. doi: 10.1016/j.jclepro.2020.122377. [DOI] [Google Scholar]

- Mishra S., Singh S.P., Johansen J., Cheng Y., Farooq S. Evaluating indicators for international manufacturing network under circular economy. Manag. Decis. 2019;57:811–839. doi: 10.1108/MD-05-2018-0565. [DOI] [Google Scholar]

- Moktadir M.A., Ali S.M., Kusi-Sarpong S., Shaikh M.A.A. Assessing challenges for implementing Industry 4.0: implications for process safety and environmental protection. Process Saf. Environ. Protect. 2018;117:730–741. doi: 10.1016/j.psep.2018.04.020. [DOI] [Google Scholar]

- Morrar R., Arman H. The fourth industrial revolution (industry 4.0): a social innovation perspective. Technol. Innov. Manag. Rev. 2017;7:12–20. doi: 10.22215/timreview/1117. [DOI] [Google Scholar]

- Müller J.M., Buliga O., Voigt K.-I. Fortune favors the prepared: how SMEs approach business model innovations in Industry 4.0. Technol. Forecast. Soc. Change. 2018;132:2–17. doi: 10.1016/j.techfore.2017.12.019. [DOI] [Google Scholar]

- Müller J.M., Kiel D., Voigt K.-I. What drives the implementation of industry 4.0? The role of opportunities and challenges in the context of sustainability. Sustainability. 2018;10:247. doi: 10.3390/su10010247. [DOI] [Google Scholar]

- Mura M., Longo M., Zanni S. Circular economy in Italian SMEs: a multi-method study. J. Clean. Prod. 2020;245:118821. doi: 10.1016/j.jclepro.2019.118821. [DOI] [Google Scholar]

- Nascimento D.L.M., Alencastro V., Quelhas O.L.G., Caiado R.G.G., Garza-Reyes J.A., Rocha-Lona L., Tortorella G. Exploring Industry 4.0 technologies to enable circular economy practices in a manufacturing context. J. Manuf. Technol. Manag. 2019;30:607–627. doi: 10.1108/JMTM-03-2018-0071. [DOI] [Google Scholar]

- Orzes G., Poklemba R., Towner W.T. Industry 4.0 for SMEs. Springer International Publishing; Cham: 2020. Implementing industry 4.0 in SMEs: a focus group study on organizational requirements; pp. 251–277. [DOI] [Google Scholar]

- Pacaux-Lemoine M.-P., Trentesaux D. Ethical risks OF human-machine symbiosis IN industry 4.0: insights from the human-machine cooperation approach. IFAC-PapersOnLine. 2019;52:19–24. doi: 10.1016/j.ifacol.2019.12.077. [DOI] [Google Scholar]

- Pannell D.J. Sensitivity analysis: strategies, methods, concepts, examples. Agric. Econ. 1997;16:139–152. [Google Scholar]

- Pater A., Van Gils A. Stimulating ethical decision-making in a business context. Eur. Manag. J. 2003;21:762–772. doi: 10.1016/j.emj.2003.09.016. [DOI] [Google Scholar]

- Pedersen M.R., Nalpantidis L., Andersen R.S., Schou C., Bøgh S., Krüger V., Madsen O. Robot skills for manufacturing: from concept to industrial deployment. Robot. Comput. Integrated Manuf. 2016;37:282–291. doi: 10.1016/j.rcim.2015.04.002. [DOI] [Google Scholar]

- Pfohl H.-C., Yahsi B., Kurnaz T. 2017. Concept and Diffusion-Factors of Industry 4.0 in the Supply Chain; pp. 381–390. [DOI] [Google Scholar]

- Pinto Taborga C., Lusa A., Coves A.M. A proposal for a green supply chain strategy. J. Ind. Eng. Manag. 2018;11:445. doi: 10.3926/jiem.2518. [DOI] [Google Scholar]

- Piyathanavong V., Garza-Reyes J.A., Kumar V., Maldonado-Guzmán G., Mangla S.K. The adoption of operational environmental sustainability approaches in the Thai manufacturing sector. J. Clean. Prod. 2019;220:507–528. doi: 10.1016/j.jclepro.2019.02.093. [DOI] [Google Scholar]

- Prieto-Sandoval V., Jaca C., Santos J., Baumgartner R.J., Ormazabal M. Key strategies, resources, and capabilities for implementing circular economy in industrial small and medium enterprises. Corp. Soc. Responsib. Environ. Manag. csr. 2019;1761 doi: 10.1002/csr.1761. [DOI] [Google Scholar]

- Radziwon A., Bilberg A., Bogers M., Madsen E.S. The smart factory: exploring adaptive and flexible manufacturing solutions. Procedia Eng. 2014;69:1184–1190. doi: 10.1016/j.proeng.2014.03.108. [DOI] [Google Scholar]

- Raj A., Dwivedi G., Sharma A., Lopes de Sousa Jabbour A.B., Rajak S. Barriers to the adoption of industry 4.0 technologies in the manufacturing sector: an inter-country comparative perspective. Int. J. Prod. Econ. 2020;224:107546. doi: 10.1016/j.ijpe.2019.107546. [DOI] [Google Scholar]

- Rajput S., Singh S.P. Identifying Industry 4.0 IoT enablers by integrated PCA-ISM-DEMATEL approach. Manag. Decis. 2019;57:1784–1817. doi: 10.1108/MD-04-2018-0378. [DOI] [Google Scholar]

- Rajput S., Singh S.P. Connecting circular economy and industry 4.0. Int. J. Inf. Manag. 2019;49:98–113. doi: 10.1016/j.ijinfomgt.2019.03.002. [DOI] [Google Scholar]

- Ramelli S., Wagner A. Mitigating the COVID Economic Crisis: Act Fast and Do Whatever. vol. 63. 2020. What the stock market tells us about the consequences of COVID-19. [Google Scholar]

- Rauch E., Dallasega P., Unterhofer M. Requirements and barriers for introducing smart manufacturing in small and medium-sized enterprises. IEEE Eng. Manag. Rev. 2019;47:87–94. doi: 10.1109/EMR.2019.2931564. [DOI] [Google Scholar]