Abstract

While 17O NMR is increasingly being used for elucidating the structure and reactivity of complex molecular and materials systems, much effort is still required for it to become a routine analytical technique. One of the main difficulties for its development comes from the very low natural abundance of 17O (0.04%), which implies that isotopic labeling is generally needed prior to NMR analyses. However, 17O-enrichment protocols are often unattractive in terms of cost, safety, and/or practicality, even for compounds as simple as metal oxides. Here, we demonstrate how mechanochemistry can be used in a highly efficient way for the direct 17O isotopic labeling of a variety of s-, p-, and d-block oxides, which are of major interest for the preparation of functional ceramics and glasses: Li2O, CaO, Al2O3, SiO2, TiO2, and ZrO2. For each oxide, the enrichment step was performed under ambient conditions in less than 1 h and at low cost, which makes these synthetic approaches highly appealing in comparison to the existing literature. Using high-resolution solid-state 17O NMR and dynamic nuclear polarization, atomic-level insight into the enrichment process is achieved, especially for titania and alumina. Indeed, it was possible to demonstrate that enriched oxygen sites are present not only at the surface but also within the oxide particles. Moreover, information on the actual reactions occurring during the milling step could be obtained by 17O NMR, in terms of both their kinetics and the nature of the reactive species. Finally, it was demonstrated how high-resolution 17O NMR can be used for studying the reactivity at the interfaces between different oxide particles during ball-milling, especially in cases when X-ray diffraction techniques are uninformative. More generally, such investigations will be useful not only for producing 17O-enriched precursors efficiently but also for understanding better mechanisms of mechanochemical processes themselves.

Short abstract

The direct 17O enrichment of s-, p-, and d-block metal oxides is achieved with high efficiency using mechanochemistry. Atomic-level insight into the enrichment process is obtained using high-resolution solid-state 17O NMR and dynamic nuclear polarization analyses, which demonstrate that enriched oxygen sites are present both at the surface and within the oxide particles. Moreover, it is demonstrated how these labeling schemes allow the study of unique aspects of mechanochemical reactions between oxides by 17O NMR.

Introduction

Oxygen, as an element, is present in the majority of natural and synthetic materials. It is thus essential to have access to information about the local binding environment around this element to be able to rationalize structure–property relationships in a variety of systems. 17O NMR spectroscopy is one of the most promising spectroscopic techniques for this.1 Indeed, thanks to the very wide range of variation of the 17O NMR parameters, detailed insight into the bulk and surface structures of a variety of materials can be obtained. For example, recent studies have used 17O NMR to elucidate the structures of porous materials like zeolites and metal–organic frameworks,2−5 of mixed-metal oxides used as electrode materials,6,7 or of nanoparticle surfaces.8−11

Natural-abundance 17O NMR unfortunately suffers from a very poor absolute signal sensitivity because of the very low abundance of the NMR-active isotope (only 0.04%). This implies that enriching the compounds of interest in 17O is generally necessary to be able to perform high-resolution 17O NMR studies. Until recently, this has actually hampered the large-scale development of 17O NMR spectroscopy because of the lack of cost-efficient and user-friendly enrichment protocols. Indeed, some of the early labeling schemes employed excessive amounts of expensive 17O-enriched precursors (H217O or 17O2) and/or were experimentally constraining because of the need to operate under an inert atmosphere or at high temperatures, or because of excessive experimental times (lasting hours or days).1,12 In the case of oxides, among the different labeling procedures proposed, those based on sol–gel chemistry have found some success for the preparation of 17O-enriched phases. However, they rely on the availability of metal alkoxide precursors and also require optimization of not only the hydrolysis and condensation steps, but also the drying step in order to remove the alcohol byproduct from the reaction mixture and produce a dry gel that can be then converted into the metal oxide of interest.12−16 More recently, affordable and practical 17O-enrichment protocols have been proposed3,17,18 either for direct labeling of the inorganic or hybrid materials of interest or for labeling of the precursors that can then be used for the preparation of these materials. In both cases, mechanochemistry techniques like ball-milling (BM) have been shown to be particularly attractive.7,18

In BM, mechanical forces are applied to solid particles, in order to mix them efficiently, alter their size and shape, and make them react at their interfaces.19,20 The addition of small amounts of liquid during the milling process (typically on the order of 0.1 μL/mg of sample) can have a significant impact on the course of the reactions, such as accelerating their speed.21 This general approach, which is referred to as “liquid-assisted grinding” (LAG), served as a basis for the development of new 17O-enrichment schemes. Indeed, we showed that using 17O-enriched water as a liquid grinding assistant, it was possible to enrich in 17O a variety of organic and inorganic compounds of synthetic interest, including metal hydroxides like Mg(OH)2, Ca(OH)2, and Al(OH)3.18 These were then converted into the corresponding metal oxides by heat treatment under an inert atmosphere, leading to the formation of 17O-labeled MgO, CaO and Al2O3 (Scheme 1).

Scheme 1. Strategy Previously Proposed for the 17O Labeling of Magnesium, Calcium, and Aluminum Oxides, Starting from Their Hydroxides18.

The possibility of easily producing 17O-enriched oxides is highly attractive because these can then be engaged in a variety of reactions using previously established synthetic protocols to prepare enriched ceramics, glasses, or hybrid organic–inorganic materials. However, in order to further broaden the scope of oxides that can be enriched in 17O using mechanochemistry, it appeared to us necessary to look into synthetic approaches that would not require starting from a hydroxide. Indeed, in contrast to Mg(OH)2, Ca(OH)2, and Al(OH)3, a well-defined and stable form of the starting hydroxide may not be readily available, as is the case for titania and silica. Moreover, the initial labeling step of the hydroxide by LAG proceeds by equilibration in the presence of 17O-enriched water (Scheme 1), which is not optimal in terms of the enrichment yield, because the byproduct formed after full isotopic scrambling will be partially enriched H2*O (with the same 17O-labeling level as the final labeled hydroxide). Using oxides as precursors instead of hydroxides should allow both of these issues to be addressed at the same time. Preliminary evidence that oxides could potentially be directly enriched in 17O using LAG was provided in a recent study in which 17O-labeled alkali transition-metal oxides like Li2MO3 (M = Mn, Ru) were synthesized by performing an initial LAG step on nonenriched oxide precursors in the presence of 17O-enriched water, followed by a heat treatment at high temperature.7 However, no detail regarding the mechanisms by which the isotopic labeling was occurring was proposed, making it difficult to determine at what moment of the reaction the enrichment had taken place and how to adapt this strategy to other materials systems in order to achieve optimal labeling for high-resolution 17O NMR.

In this Article, we study the reactivity of a selection of oxides under LAG using 17O-labeled water, with the overall goal of producing 17O-enriched compounds of synthetic interest for the elaboration of advanced functional materials. First, an improved strategy for preparing Ca*O will be described, with calcium oxide being of interest for the elaboration of bioceramics and bioglasses. Its extension to the synthesis of Li2*O is also presented, with this precursor being important for preparing electrode materials for lithium-based batteries and ion-conducting glasses. Then, the direct labeling of four widely used oxides of different compositions and crystallinities (silica, alumina, titania, and zirconia) will be discussed, providing insight into the isotopic enrichment process using high-resolution 17O NMR and dynamic nuclear polarization (DNP) analyses. Besides interest for direct and efficient 17O labeling, it will be shown how our approach offers new opportunities for understanding mechanochemical processes at the atomic level.

Results and Discussion

Improved LAG Approach for the 17O Labeling of s-Block Metal Oxides

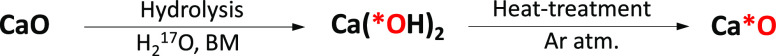

We first focused on improving the labeling strategy that we had previously proposed for enriching calcium oxide.18 More specifically, in order to avoid the initial equilibration step (Scheme 1) and to achieve a better enrichment level of the intermediate hydroxide, we started from the non-labeled oxide CaO and hydrolyzed it by mechanochemistry to produce Ca(*OH)2 (Scheme 2). The idea here is that all of the 17O labels introduced as H2*O during the LAG step react with CaO to form the 17O-enriched hydroxide.

Scheme 2. Alternative Strategy Proposed Here for the 17O Labeling of CaO.

The BM conditions required to perform the hydrolysis step were initially tested using non-labeled water, by analyzing the reaction medium by powder X-ray diffraction (PXRD). It was found that, after 1 h of milling of CaO at 25 Hz in the presence of 1 equiv of water, complete conversion into the hydroxide phase occurred. Using these synthetic conditions with 17O-enriched water, 17O-labeled Ca(*OH)2 was then obtained, as shown by PXRD (Figure 1a) and solid-state 17O magic-angle-spinning (MAS) NMR (Figure 1b, top). This phase could then be transformed into enriched Ca*O by heat treatment under an inert atmosphere (Figure 1b, bottom).

Figure 1.

(a) PXRD analyses before and after LAG: CaO precursor obtained after the heat treatment of commercial Ca(OH)2 (top) and enriched phase recovered after LAG in the presence of H2*O (bottom). The symbols ■ and ○ correspond to the diffraction peaks expected for CaO (ICSD 163628) and Ca(OH)2 (ICSD 15471), respectively. (b) Solid-state 17O NMR spectra of 17O-enriched Ca(*OH)2 (prepared by LAG of CaO using H217O) and Ca*O (obtained after the heat treatment of Ca(*OH)2). These 17O MAS NMR spectra are in agreement with previous measurements at this magnetic field.18

On the basis of the above, it is clear that direct conversion of oxides like CaO into their hydroxides can be achieved by BM in the presence of stoichiometric amounts of 17O-enriched water, which is an improvement for the production of labeled hydroxides like Ca(*OH)2.18 Using a similar approach, the labeling of other s-block oxides like Li2O could be achieved, which provide attractive alternatives in comparison to the existing protocols,22,23 as discussed in Supporting Information S1. As detailed below, extension of this type of approach to oxides of the p and d blocks was then studied, in order to expand the scope of precursors that could be enriched by this technique.

17O Labeling of p and d-Block Oxides Using LAG

Enrichment of SiO2, Al2O3, TiO2, and ZrO2: Structural Analyses after 1 h of LAG

Silica, alumina, titania, and zirconia were selected for 17O-labeling tests on p- and d-block oxides because of their numerous uses for the preparation of functional materials. For each of these phases, the starting materials were commercially available porous samples with relatively high surface areas (all above 80 m2/g) because this was expected to favor surface reactions with the enriched water during BM. On the basis of scanning electron microscopy (SEM) and PXRD analyses, each precursor was initially composed of agglomerated nanoparticles of ∼10–20 nm diameter but with different crystallinities. Indeed, while the silica precursor was fully amorphous, the three others gave diffraction peaks in X-ray diffraction (XRD), which could be assigned to the anatase phase for titania, to the monoclinic polymorph for zirconia, and to a mixture of γ and δ polymorphs for alumina (Figure 2, insets).

Figure 2.

17O MAS NMR spectra recorded at 14.1 T for the SiO2, Al2O3, TiO2, and ZrO2 phases after 1 h of BM in the presence of H217O (followed by drying under vacuum at room temperature). The insets show the PXRD patterns before (gray) and after (blue) 1 h of BM in the presence of H217O. The symbols * correspond to spinning sidebands and the symbols ◇ to the zirconia rotor background signal (Figure S6a). All NMR acquisition conditions are provided in Table S1.

Each compound was milled in the presence of stoichiometric amounts of 17O-enriched water, for durations of up to 1 h. The initial LAG conditions were set such that 1 equiv of “MOy” (y = 2 for M = Si, Ti, and Zr and y = 3/2 for M = Al) was reacted with y/2 equiv of H2*O as a means to minimize losses of H2*O if the BM hydrolysis reaction were to be incomplete. Milled samples were characterized by PXRD, N2 adsorption/desorption isotherms, SEM, energy-dispersive X-ray spectroscopy (EDXS), and 17O MAS NMR (Figure 2 and S2–S5).

After 1 h of LAG, no new phase was observed by PXRD, and the diffractograms of all phases were essentially the same as those recorded before milling (Figure 2, insets). In SEM, the presence of agglomerated nanoparticles could still be observed, without any significant change in the particle size, except in the case of silica, for which nanoparticles appeared to have merged into larger entities. More striking differences were found in the N2 adsorption/desorption isotherms of all oxides before and after milling (Figures S2–S5) because of changes in the surface area and/or pore geometry. In the case of silica, a decrease in the porosity was observed (with the surface area being reduced by a factor of ∼3), while in the case of alumina, the main change concerned the pore geometry (because the surface area remained essentially the same as that before milling). For titania and zirconia, the differences in the isotherms revealed that both a reduction in the surface area and a change in the pore geometry had occurred, pointing to significant surface reconstruction taking place during milling. In order to understand the changes in texture of the different oxides, high-resolution NMR experiments were performed.

All four materials were analyzed by solid-state 17O NMR (Figure 2). The spectra obtained show that in all cases the labeling was successful. Indeed, for each oxide, 17O NMR resonances attesting to the formation of a significant proportion of *OMx environments (M = Si, Al, Ti, Zr) were observed. In the case of silica, the observed quadrupolar line shape is consistent with enriched siloxanes (Si–*O–Si), as shown by the fit of the 17O MAS NMR spectrum (Figure S7).1,24,25 Concerning alumina, two broad resonances are observed, with the high-frequency contribution (centered at ∼60 ppm at 14.1 T) coming from various *OAlx environments (x = 3, 4)12,25,26 and the other originating from *OH groups, as further discussed below. In the case of titania, the main 17O resonance is centered at ∼560 ppm, which corresponds to the *OTi3 environments of anatase.27,28 Regarding zirconia, two sharp resonances are observed, which are centered at 325 and 403 ppm, and correspond to the *OZr4 and *OZr3 environments of the monoclinic form.14,27,29 For the latter two phases, it is particularly noteworthy that the main 17O NMR resonances detected are those of crystalline environments of titania (anatase form) and zirconia (monoclinic form). Hence, although XRD had not revealed any strong changes during the LAG step, 17O NMR shows that a significant restructuring of the four oxides actually occurs, which leads to the breaking/formation of multiple M–O bonds and eventually results in a significant proportion of enriched *OMx core-like environments.

The solid-state 17O NMR data also reveal that the overall 17O-enrichment level is high (see Figure S6b for a comparison with natural-abundance data). More quantitative analyses were carried out on the silica and titania samples using surface-ion mass spectrometry (SIMS) in order to determine the absolute enrichment after the LAG step. Measurements were performed on 18O-enriched samples, which were prepared using a procedure similar to that above but with 97% 18O-labeled water to achieve better quantification by SIMS. Under these conditions, given that 1 equiv of H2*O is reacted with 1 equiv of MO2 (M = Si, Ti), the maximum enrichment was expected to be ∼32% (i.e., ∼97/3) in the case of complete isotopic scrambling of the oxygen sites during the H218O LAG. After 1 h of LAG (followed by drying at room temperature under vacuum), the 18O enrichments determined by SIMS were 27% for silica and 15% for titania. This demonstrates that the isotopic scrambling was indeed nearly complete for silica under the milling conditions used here but that a higher enrichment level is potentially achievable for titania. From a more general perspective, considering that the natural abundance of 17O is only 0.04%, these analyses confirm that high enrichment levels of oxides can be easily reached by LAG in just 1 h, using stoichiometric amounts of enriched H2*O.

Insight into the Labeling Mechanisms: NMR Analyses after Different LAG Times

Given that the source of 17O is enriched water, it is reasonable to propose that part of the labeled *OMx sites have formed by condensation reactions involving intermediate M–*OH species (M = Si, Al, Ti, Zr). Additional multinuclear NMR analyses at different milling times were thus performed on each of the oxides to gain more insight into the enrichment mechanisms. The most complete studies were carried out on alumina and titania, as described below.

Alumina

Quantitative 17O NMR analyses were performed on alumina phases recovered after different LAG times (between 5 min and 1 h). In all cases, two main resonances were observed at 14.1 T, which were centered at ∼9 and 60 ppm. As mentioned above, the higher-frequency signal corresponds to *OAlx environments, and its intensity was found to gradually increase with the milling time (Figure 3a,b). This is all the more interesting that no significant changes could be observed for these samples in the XRD patterns or in the 27Al MAS and 27Al{1H} cross-polarization MAS (CPMAS) NMR spectra (aside from the appearance of a very weak AlV signal after 1 h of BM, as shown in Figure S8). These observations confirm that 17O NMR can provide unique insight into both structural and kinetic aspects of the bonding rearrangements occurring at the atomic level during BM for this system.

Figure 3.

(a) Quantitative single-pulse 17O MAS NMR spectra, recorded at 14.1 T for Al2O3 phases obtained after different milling times in the presence of H217O, followed by drying under vacuum at room temperature (all spectra were acquired over 18 h, using a π/12 excitation pulse and a recycle delay of 16 s). (b) Evolution of the relative proportion of *OAlx sites as a function of the milling time, as determined by quantifying the relative intensity of the *OAlx signal to that of the natural-abundance zirconia rotor peak (spectra shown in part a/ of this figure) and normalizing the mass of the sample introduced in the rotor (Figure S9). (c) 17O MAS NMR spectrum recorded at 35.2 T for an Al2O3 phase enriched in 17O by LAG after 15 min of grinding, followed by drying the sample at room temperature (this spectrum was recorded using a much shorter recycle delay and different excitation scheme than those in Figure 3a). (d) 17O MQMAS NMR spectrum recorded at 35.2 T, in which the *OAlx (dashed green circle) and Alx-*OH (dashed brown circle) sites are resolved. The colored bars above the spectra in parts c and d correspond to the shift ranges expected for different oxygen environments, based on the literature.12,25,26,31,32 Acquisition conditions can be found in Table S1. The symbols * correspond to spinning sidebands.

The broad low-frequency signal (centered at ∼9 ppm) is consistent with labeled *OH groups. Given that both Alx-OH species and water molecules can potentially be found in this chemical shift range at 14.1 T,25,26,30−32 additional characterizations were performed at ultrahigh magnetic field (35.2 T) to reduce the effect of second-order quadrupolar broadening12 and discriminate better the *OH and H2*O species. In a comparison of the 1D MAS spectrum at 35.2 T to the data reported in the literature,4,25,31,32 it appears that few 17O-enriched water molecules are likely to be present, meaning that the majority of enriched *OH groups correspond to Alx-*OH species (Figure 3c). In order to achieve higher resolution, complementary analyses were performed using the 17O multiple quantum MAS (MQMAS) sequence.33 This allowed the Alx-*OH sites to be more clearly separated from the *OAlx ones (Figure 3d, dashed circles). Moreover, it revealed a significant distribution in the 17O chemical shifts for both types of sites, each of which spans more than 30 ppm. This means that there are several different local environments for the enriched oxygen sites, possibly because of variations in the hydrogen-bonding network around them and/or in the number and type of Al3+ cations to which they are bound. To analyze this in more detail, additional high-resolution 1H–17O and 27Al–17O heteronuclear correlation experiments were carried out.

The different types of protons present around the enriched oxygen sites were studied using fast 1H{17O} MAS HMQC (heteronuclear multiple quantum coherence) NMR experiments at high magnetic field (20.0 T), looking at through-bond connectivities (J-HMQC) as well as through-space proximities (D-HMQC). The main crosspeak observed on the 2D J-HMQC spectrum correlates the low-frequency 17O resonance (Alx-*OH) to a 1H resonance centered at ∼3.8 ppm (Figure 4a). This 1H chemical shift is consistent with a surface OH group acting as a hydrogen-bond donor (denoted here as μ-OHHBD).34 The significant line width of the 1H resonance points to a distribution in the μ-OHHBD···O bond distances and angles.34,35 Complementary 2D D-HMQC experiments were carried out to further characterize these hydroxyl environments (Figure 4b). At a short recoupling time (τrec = 100 μs), the D-HMQC spectrum provides conclusions similar to those of the J-HMQC experiment, given that only correlations to the closest hydrogen atoms appear in these conditions, i.e., with hydrogen atoms that are directly bound to 17O. In contrast, at longer recoupling times (τrec = 300 μs), an additional correlation is observed with *OAlx resonances. This points to the close proximity of some of the μ-OHHBD protons to *OAlx sites, possibly due to μ-OHHBD···*OAlx hydrogen bonds. It is worth noting that recent computational studies of γ-alumina surfaces suggest that μ-OHHBD···OAlx hydrogen bonds can indeed be present at the surface.34 The diversity of hydrogen-bonding environments of surface hydroxyls can thus account, at least in part, for the distribution in oxygen environments around the Alx-*OH and *OAlx moieties mentioned above (Figure 3d).

Figure 4.

(a) 1H{17O} J-HMQC NMR spectrum recorded at 20.0 T and 60 kHz MAS on an Al2O3 phase enriched in 17O by LAG after 15 min of grinding, followed by drying the sample at room temperature. The projection corresponds to the double-frequency sweep (DFS)-1 pulse signal for this phase. (b) 1H{17O} D-HMQC NMR spectra recorded at 20.0 T and 60 kHz MAS on the same phase, using two different recoupling times (100 and 300 μs). (c) 27Al{17O} J-HMQC NMR spectrum recorded at 20.0 T for an Al2O3 phase enriched in 17O by LAG (15 min of BM), after drying under vacuum at room temperature (the total acquisition time was ∼50 h for this spectrum). Projections correspond to Hahn echo spectra recorded for the sample at this magnetic field. (d) 1H Hahn echo NMR spectra recorded at 20.0 T and 60 kHz MAS, using echo delays of 2 (black) and 50 (brown) rotor periods (see Figure S10 for a comparison to the background 1H NMR spectrum). 1H resonances are assigned based on recent literature (HBD = hydrogen-bond donor).34

To go one step further, a 27Al{17O} J-HMQC experiment was performed to see which of the hexacoordinate (AlVI) and tetracoordinate (AlIV) sites of alumina were linked to *OAlx and Alx-*OH moieties (Figure 4c). Three crosspeaks are observed on the 2D spectrum, which provide direct evidence of the presence of AlVI-*OH, AlVI-*O, and AlIV-*O bonds. Considering the *OAlx sites, this spectrum clearly shows that part of the chemical shift distribution observed in Figure 3d can come not only from the number but also from the type of aluminum atoms attached to the oxygen sites (AlIV and/or AlVI).

The lack of AlIV-*OH correlations in Figure 4c may seem surprising when considering the 1H MAS NMR data (see Figures 4d and S10). Indeed, the 1D 1H NMR spectrum (which was recorded using two different echo delays to achieve better resolution) shows sharp resonances, notably at ∼− 0.2, 0.7, and 1.1 ppm. On the basis of the literature, these could correspond to terminal (μ1-OH) and bridging (μ2-OH) sites,34,36 located at the surfaces and edges of alumina particles. In particular, the signal at −0.2 ppm has recently been attributed to μ1-OH species present at the edges,34 which are likely to be linked to tetrahedral AlIV sites.36 This would imply that while AlIVOH species appear to be present in the sample, they could not be detected in 17O NMR. Several explanations can be proposed for this. First, this observation could be consistent with the known difference in reactivity of the different surface hydroxyls.34,37 Indeed, it is possible that, upon exposure of the sample to air and hence ambient humidity (when recovering the sample after the LAG step or during the packing/unpacking of NMR rotors), some of the enriched Al-*OH groups back-exchange with non-labeled hydroxyls. The fact that the samples are still porous after LAG would indeed be in favor of surface exchanges of reactive OH groups, which would be more likely to occur for the hydroxyls that are more reactive and/or less tightly bound, as would be the case for μ1-OH and μ2-OH groups with 1H resonances below 3 ppm, which are not involved in strong hydrogen bonds.34 This exchange would also be consistent with the fact that, on the 1H{17O} J-HMQC data, only the 1H resonances of the hydrogen-bonded μ-OH groups at ∼3.8 ppm correlate to the Alx-*OH resonance but not those at ∼−0.2, 0.7, and 1.1 ppm (due to their back-exchange). Second, from a purely NMR perspective, it is also possible that the small proportion of μ1-OH and μ2-OH resonances (shown by 1H NMR), combined with potentially smaller values of J couplings, renders them “invisible” in the 2D 27Al{17O} NMR experiment (Figure 4c). All of the above reasons could explain (at least in part) why no cross-peak correlating AlIV sites to OH groups could be observed on the 27Al{17O} J-HMQC NMR spectrum.

The observation of the progressive formation of *OAlx sites (Figure 3b), and the potential back-exchange of some of the enriched hydroxyls, prompted us to use 17O DNP–surface-enhanced NMR spectroscopy (SENS)38,39 to examine the nature of the oxygen environments present at the surface of the alumina particles. DNP analyses were performed on a sample recovered after 15 min of milling, after impregnation by a biradical solution of TEKPol in deuterated tetrachloroethane. Two types of NMR sequences were used as a means to polarize differently the surface oxygen atoms during microwave irradiation: (i) direct-excitation 17O NMR (preceded by a DFS enhancement) in order to polarize the surface oxygen sites directly from the radical and (ii) 17O{1H} CPMAS NMR, where 17O sites are detected based on their relative proximity to the protons polarized by the biradical (by varying the contact time used). In both situations, the 17O NMR signals of *OAlx and *OH groups were found to be enhanced upon microwave irradiation (Figure 5), suggesting that both of these 17O environments are present at the surface of the alumina particles. In particular, under 17O{1H} DNP CPMAS NMR conditions (Figure 5), both sites were enhanced by a factor of ∼4, meaning that protons located at the surface of the particles after LAG can transfer their polarization to neighboring Al-*OH (at short contact time) and *OAlx (at longer contact time) sites. Although these DNP–SENS experiments did not allow any absolute quantification of the relative labeling of the bulk or surface of the material, they clearly suggest that some enriched oxygen sites are still present at the surface of the particles, despite possible partial 17O/16O back-exchanges upon exposure of the sample to an ambient atmosphere.

Figure 5.

17O DNP experiments carried out at 14.1 T on an Al2O3 phase enriched in 17O by 15 min of LAG (followed by drying the sample at room temperature) and impregnation by TEKPol/D2-TCE: (i) direct-excitation 17O DNP NMR spectra (with a DFS enhancement) and (ii) 1H{17O} CPMAS DNP NMR spectra recorded at 50 μs and 5 ms contact times (CT). Spectra recorded without (brown) and with (blue) microwave irradiation are compared (μw on/μw off). DNP acquisition conditions and enhancements are discussed in Supporting Information S11 and comparisons to 17O NMR data recorded at room temperature are reported in Figure S12.

In summary, although the overall structure of alumina appears to be maintained during the LAG step (according to XRD and 27Al NMR), part of this phase actually undergoes several reactions in the presence of H2*O, leading to a change in the texture of the material and to the formation of Alx-*OH and *OAlx species. The fact that *OAlx environments were detected after only 5 min of milling underscores that the condensation of Alx-*OH groups proceeds very quickly under the reaction conditions used here. For both Alx-*OH and *OAlx species, high-resolution NMR experiments were able to shed light on the diversity of oxygen local environments because of the presence of hydrogen bonds and differences in the nature and number of aluminum sites to which they are bound. Moreover, 17O DNP–SENS experiments were performed, suggesting that some of the enriched Alx-*OH and *OAlx sites are located at the surface of the particles.

Titania

Enriched titania phases were studied by 17O MAS NMR after different LAG times (1 min, 15 min, and 1 h). NMR spectra were recorded both on “fresh” samples, which were analyzed by NMR directly after milling, and on samples that had undergone an additional drying step at room temperature. In all cases, signals belonging to *OTi3 environments were observed around 550 ppm. The resonance characteristic of crystalline anatase was found to increase with the milling time (signal at 560 ppm in Figure 6a). Weaker underlying resonances, which span between 500 and 600 ppm (Figure 6b), were also observed at all milling times and can be ascribed to more distorted/disordered *OTi3 environments and surface defects.9,28,40

Figure 6.

(a) 17O MAS NMR spectra recorded at 14.1 T on “fresh” TiO2 phases enriched in 17O by LAG (for 1 min, 15 min, and 1 h milling times). (b) 17O MAS NMR spectrum recorded at 35.2 T on a TiO2 phase enriched in 17O by LAG (15 min of BM), after drying under vacuum at room temperature. (c) 17O DNP NMR spectrum of a TiO2 phase enriched in 17O by LAG (15 min of BM), after drying under vacuum at room temperature, and impregnation by a 16 mM solution of TEKPol in tetrabromoethane (spectra recorded at ∼100 K with and without microwave irradiation). (d) 17O{1H} DNP CPMAS NMR spectra recorded at 50 μs and 3 ms contact times, in comparison to the DFS-enhanced echo spectrum recorded at ∼100 K. All acquisition parameters can be found in Table S1. The symbols * correspond to spinning sidebands, and the symbol ◇ corresponds to the zirconia rotor background signal.

In the case of the “fresh” phases, residual 17O labeled water was detected at ∼0 ppm. Its relative proportion was found to decrease as the milling time increased (Figure 6a). However, no clear evidence of Ti-*OH groups was observed. On the basis of the literature, Ti-*OH resonances were expected to be centered just above 200 ppm.9,40,41 Complementary 17O DNP–SENS analyses were thus carried out to try to detect more clearly the surface species (Figure 6c,d) and bring direct evidence of Ti*OH groups (if any). First, it is worth noting that at low temperatures, such as those used for DNP analyses (∼100 K), a very weak signal could be detected at ∼200 ppm, suggesting the presence of a small number of Ti-*OH species. Dynamics within the Ti-*OH moieties at room temperature may explain why they could not be detected by conventional NMR. This signal could then be enhanced by direct-excitation 17O DNP (Figure 6c) and even more so using 17O{1H} DNP CPMAS experiments at very short contact times (Figure 6d). Indeed, the main signal observed by 17O{1H} DNP CPMAS for 50 μs contact time was centered at ∼200 ppm.

On the basis of previous experimental and computational studies reported in the literature, the extent of water dissociation on anatase surfaces is known to be highly dependent on several parameters, including the nature of the surface exposed and the extent of surface defects.42,43 Hence, it is possible that the formation of Ti-*OH groups by dissociation of H2*O on anatase requires the creation of reactive surfaces by mechanochemistry. Moreover, given that very few Ti-*OH species could be detected at the surface of the materials (even for “fresh” phases), it is possible that these recondense quickly to form *OTix sites under the reaction conditions used here. Overall, this would explain the evolution of the reaction medium shown in Figure 6a.

DNP–SENS analyses were able to provide additional information regarding the other enriched oxygen sites, which were present close to the surface, aside from the Ti-*OH moieties. First, upon analysis of the results of the DNP experiments performed with direct 17O acquisition (Figure 6c), it is clear that bulklike *OTi3 environments are also present close to the surface of the particles. Second, by increasing the contact time in the 17O{1H} DNP CPMAS experiment, it was possible to observe weak resonances in the *OTi3 region (Figure 6d, CT = 3 ms). These correspond to oxygen species that are spatially close to protons (but not directly bound to them) and appear to contribute to the “underlying” disordered/distorted *OTi3 resonances detected in Figure 6b. Such detailed information on the different oxygen environments is expected to be of high interest for proposing realistic models of the anatase surface recovered after the milling step, by combining computational modeling to ab initio calculations of the 17O NMR parameters, and comparing the results to experimental 17O NMR data, as previously proposed for other studies on titania surfaces.9,44

In summary, although the overall structure of anatase appears to be maintained according to XRD, the texture of the material is affected by the milling process, and 17O NMR further shows that this phase reacts with labeled water to form enriched anatase-like *OTi3 environments after only 1 min of milling. However, in contrast to alumina, only a very small number of labeled *OH species were observed in the 1D 17O MAS NMR spectra (even upon analysis of freshly recovered samples), and these could only be clearly detected using DNP–SENS analyses.

Silica and Zirconia

Preliminary investigations were also performed at different milling times on silica and zirconia. For the former (Figure 7a), characterizations after only 1 min of milling suggested the presence of both silanols (Si-*OH) and siloxanes (Si-*O-Si). The significant proportion of siloxane bridges after 1 min of milling is particularly noteworth because it demonstrates that the condensation reactions of intermediate Si*OH groups proceeds quickly under the reaction conditions used here. In contrast, in the case of zirconia, it was found that the 17O enrichment using LAG is much more challenging to achieve. Indeed, the two resonances characteristic of the monoclinic form were barely visible after 15 min of milling (Figure 7b). Moreover, no direct evidence of Zr-*OH groups could be detected by conventional 17O NMR (with these being expected around ∼100 ppm).10 The underlying resonances observed as a shoulder around 400 ppm after 1 h of milling may be due to more disordered *OZrx environments. Further investigations are currently in progress on these phases, from both the synthesis and NMR/DNP points of view, in order to better characterize and control the nature of enriched *OMx and M-*OH groups at different milling times and to establish the optimal conditions for isotopic labeling.

Figure 7.

(a) 17O MAS NMR analysis performed at 20.0 T and 60 kHz MAS on a SiO2 phase enriched in 17O by LAG (1 min BM), after drying under vacuum at room temperature. The fit (dashed red line) was performed considering siloxanes (green) and silanols (purple). The silanol resonances could be more clearly resolved using 17O{1H} CPMAS NMR analyses at short contact times (Figure S13), and their NMR signature is consistent with previous reports.24,45 (b) 17O MAS NMR analyses performed at 14.1 T and 20 kHz MAS on a ZrO2 phase enriched in 17O by LAG, after 15 min (black) and 1 h (blue) of milling. The “m” symbols indicate the two main resonances of monoclinic zirconia. The symbols * correspond to spinning sidebands, and the symbol ◇ corresponds to the zirconia rotor background signal (Figure S6).

17O Labeling of Mixtures of Oxides: From Liquid to Solid Oxygen-Transfer Reactions

Having demonstrated that it is possible to perform the direct 17O enrichment of simple oxides using LAG, the obvious next step was to see how mechanochemistry can be used to synthesize 17O-labeled mixed oxides. Two mechanochemical approaches were considered to introduce the 17O label (Figure 8a): (i) milling the nonlabeled oxide precursors together with H2*O or (ii) separately preenriching oxide precursors before “dry”-milling them together. While the former strategy was recently used for enriching lithium-ion-battery electrode materials like Li2RuO3,7 no 17O NMR analysis of the milling medium just after the LAG step was reported. Moreover, comparing the two strategies may actually shed light on how oxides react with each other in the solid state during mechanochemical reactions.

Figure 8.

(a) Schematic representation of the two synthetic approaches tested for enriching mixtures of SiO2 and TiO2 in 17O using mechanochemistry (shades of red are used to reflect the average relative 17O labeling of the oxides after milling). (b and c) Characterizations of 17O-enriched SiO2/TiO2 mixtures using PXRD and solid-state 17O MAS NMR at 20 T. Top: Dry-milling of nonlabeled SiO2 with enriched Ti*O2 for 3 min (blue curves). Bottom: LAG of a mixture of TiO2 and SiO2 for 3 min in the presence of H2*O (black curves). The symbols △ correspond to the diffraction peaks of anatase in PXRD (ICSD 7206075), and the symbols * correspond to spinning sidebands in 17O NMR. The shaded regions on the 17O MAS NMR spectra correspond to the chemical shifts expected for OTix (light blue) and siloxane (light gray) environments. An expansion of the 17O NMR spectra in the siloxane region can be found in Figure S14.

These two approaches were tested on a TiO2/SiO2 mixture, using the same oxide sources as those mentioned previously (mesoporous anatase and amorphous silica), with the aim of comparing the media recovered just after the milling step, i.e., before any further heat treatment. On the one hand, equimolar quantities of TiO2 and SiO2 were milled together by LAG using H2*O. On the other hand, a preenriched Ti*O2 phase was dry-milled in the presence of an equimolar quantity of nonlabeled SiO2. Both media were compared after 3 min of BM. Although the XRD patterns were found to be the same (Figure 8b), their solid-state NMR spectra were completely different (Figure 8c).

In the LAG case, the 17O signatures of enriched titania and silica were both visible but with a significant discrepancy in their relative enrichment, with the vast majority of the isotopic label having entered the silica phase (Figure 8c, black curve). Interestingly, in addition to the *OTi3 and siloxane resonances, it is worth noting that a broad signal is also observed between ∼450 and 100 ppm, i.e., in a zone that covers the range expected for *OTi4, Si-*O-Ti, and Ti-*OH groups.46,47 The more distinct contribution around ∼200 ppm could be indicative of the formation of a small number of Ti-*OH groups under these synthetic conditions.

In the Ti*O2/SiO2 “dry-milling” case, although the *OTi3 anatase signal is still predominant, a broad signal is also detected between ∼450 and 100 ppm, along with a new resonance around ∼30 ppm (Figure 8c, red curve). The latter resonance can be assigned to enriched Si-*O-Si bridges (see Figure S14 for an expansion into the siloxane region). Given that the silica precursor was initially nonlabeled, this clearly points to the fact that the reactions occurring at the interface of Ti*O2 and SiO2 during the BM eventually result in bonding rearrangements around the oxygen atoms, which lead to the enrichment of the silica phase. More importantly, such an “oxygen transfer” between the two oxides starts to occur after just 3 min, meaning that very short milling times are sufficient to mix the reagents intimately, so that they can start reacting at their interface.

The comparison of the two 17O-labeling approaches points to the major advantages of 17O NMR for studying the reactivity of inorganic oxides in BM and helps to understand better the differences in reactivity of oxides during BM. On the one hand, it allows identification of the different oxygen environments present, thereby revealing oxygen bonding rearrangements that occur at the interfaces between the oxides. On the other hand, it can also bring clear evidence of discrepancies in the oxygen isotopic distribution within samples. Moreover, the H217O-LAG approach used here could more generally help to shed light on the differences in reactivity of liquid grinding assistants like water with respect to the different components of a mixture, a feature that has not been looked into so far.

Discussion

New 17O-Enrichment Approaches for Oxides

The enrichment strategies described above significantly broaden the scope of approaches available for producing 17O-enriched s-, p-, and d-block oxides and offer synthetic alternatives that are highly efficient, in terms of both cost and practicality. One of the reasons for this comes from the nature of the precursors involved: oxides and 17O-enriched water. Oxides are indeed very interesting starting materials either because they are directly commercially available (as for TiO2, SiO2, Al2O3, and ZrO2) or because they can be easily produced by the heat treatment of hydroxides (as illustrated here for CaO and Li2O) or even carbonates. Moreover, being able to perform 17O labeling on commercially available sources of titania, silica, alumina, and zirconia, which can be stored and handled under ambient conditions for several months, is a key advantage in comparison to other procedures used so far for enriching these phases, in which more sensitive alkoxide or chloride precursors had been used.12−15,46,48−51 Indeed, no safety hazard was involved here in the LAG step that could be easily scaled up to produce gram quantities of labeled material, which contrasts with syntheses involving highly reactive and toxic reagents such as SiCl4 and TiCl4. Although the maximum 17O enrichment is meant to be higher in the latter case (because the only source of oxygen is 17O-enriched water), the 17O content of the phases recovered after LAG was, nevertheless, sufficient for performing a wide range of high-resolution NMR experiments, as shown in the case of the 2D 1H–17O and 27Al–17O MAS NMR experiments performed on alumina (Figure 4a–c). Moreover, it is expected that further optimizations of the LAG step could lead to higher enrichments than those achieved so far, by increasing the amount of H2*O added, varying the texture/porosity of the oxide precursor used, and/or optimizing the BM conditions. Indeed, a preliminary investigation on the 17O labeling of monoclinic zirconia phases of different initial crystallinities was performed, showing the importance of the choice of a precursor on the efficiency of the isotopic enrichment (Figure S15).

Using stoichiometric amounts of 17O-enriched water for the labeling step is also much less hazardous and constraining than having to manipulate 17O-enriched O2 gas at high temperatures, as had been described in previous 17O-enrichment protocols for oxides.9,10,12,52 Indeed, labeling reactions were performed here under ambient temperature and pressure and proceeded extremely quickly (less than 1 h of milling). Moreover, in terms of cost, all syntheses were relatively cheap, amounting to less than ∼40 euros for enriching ∼50 mg of compound (when using 90% 17O-enriched water in the syntheses). Overall, this implies that these protocols are expected to be accessible to both research and teaching laboratories and to contribute to the development of advanced spectroscopic studies on various oxides (or oxide mixtures), which would require 17O (or 18O) labeling.

Another very attractive feature of the protocols developed here is that the 17O-enriched phases recovered after LAG can be used in multiple ways. First, they can be converted into related oxide phases by performing additional heat treatments under inert conditions, as illustrated in Figure S16 for alumina and titania. Alternatively, they can directly serve as precursors for the synthesis of more complex mixed-metal oxides, as illustrated in the previous section for the dry-milling of Ti*O2 with SiO2. Last but not least, given that one of the unique properties of the enriched p- and d-block oxides produced here is that they are still mesoporous after LAG, with some of the surface sites enriched in 17O (as suggested by DNP), they could be used as model systems for studying the surface reactivity of oxides by high-resolution 17O NMR. In particular, considering the wide range of applications of transitional aluminas like γ- and δ-Al2O3 in heterogeneous catalysis, the 17O-labeled alumina phases prepared by LAG could be of high interest to gain new insight into the surface reactivity of catalytic materials using high-resolution 17O NMR and DNP.

Atomic-Level Insight into Reactions Occurring during BM

Beyond the production of 17O-enriched materials, our results also show how high-resolution 17O NMR and DNP can help to gain atomic-level information into LAG processes and more generally reaction mechanisms in BM. Mechanochemical reactions are indeed far from trivial because they involve both physical steps (mixing of reagents, particle size reduction, creation of reactive surfaces, diffusion of atoms/molecules at the interfaces, etc.) and chemical steps (chemical reactions), both of which are important for the system to evolve toward a given product.53,54 Despite numerous investigations, some of which include in situ measurements and/or innovative designs of the milling equipment,54−59 many blind spots remain regarding both the physics and chemistry of mechanochemical reactions. This is even more true when common techniques like XRD are not informative, as observed here for the four p- and d-block oxides, as well as for the mixed SiO2/TiO2 system.

In the case of titania, alumina, and silica, 17O NMR and DNP measurements at different milling times were able to provide clear evidence of the presence of intermediate M-*OH species, which can then condense to form *OMx sites. One important point arising from these analyses was that the quantity of M-*OH sites detected differed significantly from one oxide to the other. In particular, at the shortest milling times, while Al-*OH and Si-*OH groups could be clearly observed, this was not the case for Ti-*OH species, for which DNP analyses were needed to bring evidence of their presence. Given that several parameters can influence the formation of M-*OH groups (the initial degree of covalency or ionicity of the M–O bonds within the oxide, texture, and surface area of the material and reactivity under the BM conditions used), further investigations will be needed to determine the mechanism(s) by which enriched M-*OH groups form for each phase, i.e., whether it is by surface hydrolysis, dissociative adsorption of water, or exchange of labile M-OH groups initially present at the surface. From a more practical perspective, the differences in reactivity shown here demonstrate that milling conditions need to be optimized case by case for each oxide, in order to find how to achieve the highest 17O enrichment possible.

On the basis of the different high-resolution NMR experiments and the changes in porosity observed by N2 volumetric analyses, it is reasonable to say that the initial formation of bulklike *OMx environments by BM under ambient conditions results from the condensation of (transient) M-*OH sites. Because of these surface-reconstruction processes, which lead to changes in some of the oxygen bonds of the initial particles, some enriched oxygen sites that were located at the surface of the oxide particles may become more “core-like”. Under a given set of milling conditions, the extent of formation of these *OMx sites and the depth of enrichment of the initial oxide particles depend on the nature and texture of the initial oxide and the capacity of mechanochemistry to create “fresh” reactive surfaces to trigger these reactions.53 This is illustrated when comparing the 17O MAS NMR data and SIMS analyses of SiO2 and TiO2 and even more so when considering the different 17O NMR analyses of Al2O3, as detailed below.

Concerning alumina, solid-state NMR analyses enabled us to shed light on additional features of BM reactions. First, as shown in Figure 3b, it is interesting to note that no “induction time” in the formation of *OAlx species could be detected within the time scale investigated. Induction periods in BM are generally made evident using XRD techniques,60−62 but such analyses would have led to an erroneous conclusion here, given that essentially no change was observed in PXRD. Moreover, it is interesting to note that while an increase in the relative number of *OAlx environments with time was observed, it progressively slowed down after the first 15 min. Given that Al-*OH and *OAlx environments very easily formed during the milling (because they were detected after only 5 min of reaction), this suggests that other rate-limiting steps take over after 15 min. It is possible that the enrichment of *OAlx sites then proceeds by other mechanisms, involving the gradual rearrangement of oxygen-bonding environments within the intermediate oxyhydroxy phase. Alternatively, changes in the texture and rheological properties of the medium (due to the progressive consumption of enriched water and/or modification of the mesoporosity of the material) may render the milling process less efficient in creating new reactive surfaces, thereby slowing the speed of enrichment. To go one step further, additional high-resolution 17O NMR and DNP analyses will be needed to study the relative binding of oxygen atoms to AlIV and AlVI sites as a function of the milling time, and the reactivity of the different surface *OH groups created by LAG. This should, in return, help rationalize the enrichment process at the atomic level and better control the nature and proportion between the enriched sites.

Finally, studies on the mixed SiO2/TiO2 system show how 17O NMR can be used for looking at reactions occurring at the interfaces between different oxides during BM. Indeed, the 17O NMR characterization performed on the {SiO2 + Ti*O2} system demonstrates that, after only 3 min of reaction, a variety of 17O-enriched oxygen environments are present, which include enriched oxygen atoms within the silica phase. Being able to provide such atomic-level insight at the very early stages of the reaction is important to evaluate the efficiency of a given milling process to mix different solid particles (whether they are crystalline or amorphous, as is the case here) and to create contacts between them that will allow solid/solid reactions to occur. More generally, such analyses will certainly help to understand better what chemical reactions occur during BM when disordered or amorphous phases are involved, with such reactions being intrinsically very complex to study.

Conclusion

In this manuscript, we have shown how the 17O labeling of oxides using mechanochemistry can be used for two main purposes: (i) preparing 17O-enriched oxides and (ii) understanding reaction mechanisms occurring during BM. Concerning the first point, LAG in the presence of 17O-enriched water was shown to be a highly attractive enrichment strategy for the fast and straightforward labeling of simple oxides of the s, p, and d blocks, starting from the nonlabeled oxide precursors. Regarding the second point, it was demonstrated how, thanks to mechanochemistry-mediated isotopic labeling, it becomes possible to address questions regarding the physical and chemical processes occurring at the atomic level during BM, by performing advanced solid-state 17O NMR analyses, including ultrahigh-field NMR, DNP, and fast MAS measurements. In this context, one of the highlights of this work is to shed light on what chemical reactions start to occur at the interfaces between different oxide particles in the first few minutes of milling. Given that milling together inorganic precursors is frequently one of the first steps in the synthesis of functional mixed-metal oxides, performing similar high-resolution 17O NMR analyses on different mixtures of enriched oxide precursors and under different milling conditions could not only help to optimize the milling process but also help to identify intermediate phases, which could, in turn, serve for the preparation of novel materials.

Experimental Section

Synthesis of 17O-Labeled Phases

Reagents and Milling Equipment

Calcium hydroxide [Ca(OH)2, Sigma-Aldrich, ≥96%] and lithium hydroxide monohydrate (LiOH·H2O, Prolabo Normapur, Analytical Reagent, ≥99.0%) were used as received and served as precursors for the synthesis of CaO and Li2O. Silica (SiO2, Aerosil 200, Degussa, 180 m2/g), alumina (Al2O3, “aluminoxid C”, Degussa, mixture of γ and δ forms, 100 m2/g), titania (TiO2, St-Gobain Norpro, anatase phase, 150 m2/g), and zirconia (ZrO2, St-Gobain Norpro, monoclinic form, 85 m2/g) were dried under vacuum for 3 to 4 h at room temperature prior to use. 17O-labeled water (with 40% or 90% 17O enrichment) was purchased from CortecNet. 18O-labeled water (with 97% 18O enrichment) was purchased from Eurisotop. For DNP experiments, TEKPol63 was purchased from Cortecnet.

All milling treatments were carried out at ∼22 °C (±3 °C) in a Retsch Mixer Mill 400 apparatus, using 10 mL stainless steel grinding jars with screwtop or push-fit lids. Unless otherwise noted, the protocols were first tested in triplicate using non-labeled water, before being performed with 17O (or 18O)-enriched water.

Synthesis of Ca(*OH)2 and Ca*O

Nonlabeled Ca(OH)2 was first heat-treated to 950 °C in a tubular furnace under an argon atmosphere (heating rate, 10 °C/min; dwell time at 950 °C, 4 h) to produce CaO. The freshly prepared CaO phase (50 mg, 0.9 mmol, 1 equiv) was introduced into a grinding jar, together with 16 μL of 40%-enriched H217O (0.9 mmol, 1 equiv) with two stainless steel balls (10 mm diameter). The jar was closed and subjected to grinding for 1 h in the mixer mill operated at 25 Hz. The reactor was opened, and the white powder, which progressively dries upon contact with air, was recovered by scraping the edges of the reactor and beads with a spatula and characterized by XRD and solid-state 17O NMR, showing the formation of Ca(*OH)2 [average yield (n = 4): 54 mg, 82%]. 17O-enriched CaO was then synthesized by heat treatment of the labeled hydroxide for 4 h at 950 °C in a tubular furnace under an argon atmosphere, using the same conditions as those above.

LAG of SiO2

SiO2 (50 mg, 0.84 mmol, 1.0 equiv) was introduced into a screwtop grinding jar with 17O-labeled water (15 μL, 0.83 mmol, 1.0 equiv) and two stainless steel balls (10 mm diameter). The jar was closed and subjected to grinding for milling times ranging from 1 min to 1 h in a mixer mill operated at 25 Hz. The reactor was opened, and the sample was recovered by scraping the edges of the reactor and beads with a spatula [average mass of the crude material (n = 4): 60 mg]. The recovered sample was white for short milling times but light gray beyond 15 min of milling (see Figure S2 for EDXS analyses). Samples were then dried under vacuum at room temperature.

LAG of Al2O3

Al2O3 (50 mg, 0.49 mmol, 1.0 equiv) was introduced into a grinding jar with 17O-labeled water (13 μL, 0.72 mmol, 1.5 equiv) and one stainless steel ball (10 mm diameter). The jar was closed and subjected to grinding for milling times ranging from 5 min to 1 h in a mixer mill operated at 25 Hz. The reactor was opened, and the solid powder was recovered by scraping the edges of the reactor and beads with a spatula [average mass of the crude material (n = 4): 45 mg]. The recovered sample was white for short milling times but very light gray beyond 15 min of milling (see Figure S3 for EDXS analyses). Depending on the sample, further treatments were performed either under vacuum at room temperature or at high temperature under an argon atmosphere (heating rate, 10 °C/min; dwell time at 900 °C, 4 h; Figure S16).

LAG of TiO2

TiO2 (50 mg, 0.63 mmol, 1.0 equiv) was introduced into a grinding jar with 17O-labeled water (11 μL, 0.61 mmol, 1.0 equiv) and one stainless steel ball (10 mm diameter). The jar was closed and subjected to grinding for milling times ranging from 1 min to 1 h in a mixer mill operated at 25 Hz. The reactor was opened, and the solid powder was recovered by scraping the edges of the reactor and beads with a spatula [average mass of the crude material (n = 4): 44 mg]. The recovered sample was white for short milling times but light gray/yellowish beyond 15 min of milling (see Figure S4 for EDXS analyses). Depending on the sample, further treatments were performed, either under vacuum at room temperature or at high temperature under an argon atmosphere (heating rate, 10 °C/min; dwell time at 900 °C, 4 h; Figure S16).

LAG of ZrO2

ZrO2 (50 mg, 0.41 mmol, 1 equiv) was introduced into a grinding jar with 17O-labeled water (7 μL, 0.39 mmol, 1 equiv) and one stainless steel ball (10 mm diameter). The jar was closed and subjected to grinding for milling times ranging from 15 min to 1 h in a mixer mill operated at 25 Hz. The reactor was opened, and the solid powder was recovered by scraping the edges of the reactor and beads with a spatula [average mass of the crude material (n = 4): 42 mg]. The recovered sample was white for short milling times but very light gray beyond 15 min of milling (see Figure S5 for EDXS analyses). Samples were then dried under vacuum at room temperature.

LAG of TiO2 and SiO2

TiO2 (28.3 mg, 0.35 mmol, 1 equiv) and SiO2 (21.5 mg, 0.35 mmol, 1 equiv) were introduced into a grinding jar with 17O-labeled water (13 μL, 0.72 mmol, 2 equiv) and one stainless steel ball (10 mm diameter). The jar was closed and subjected to grinding for 3 min in a mixer mill operated at 25 Hz. The reactor was opened, and the white powder was recovered by scraping the edges of the reactor and beads (m ∼ 43 mg).

BM of Ti*O2 with SiO2

Ti*O2 was first synthesized as described above, by milling TiO2 for 15 min and then drying the sample under vacuum for 1 h at room temperature. Then, labeled Ti*O2 (28.6 mg, ∼0.35 mmol, 1 equiv) was introduced into a grinding jar with nonlabeled SiO2 (21.4 mg, 0.35 mmol, 1 equiv) and one stainless steel ball (10 mm diameter). The jar was closed and subjected to grinding for 3 min in a mixer mill operated at 25 Hz. The reactor was opened, and the solid powder was recovered by scraping the edges of the reactor and beads (m = 42 mg).

Characterization Techniques

PXRD

PXRD analyses were carried out on a Philips X’pert Pro MPD diffractometer using Cu Kα1 radiation (λ = 1.5406 Å) in a Bragg–Brentano scanning mode with a 2θ angle between 10 and 70° and a time per step ranging from of 30 to 240 s, depending on the sample.

SEM and EDXS Analyses

SEM measurements were conducted on a Hitachi S4800 instrument under an excitation voltage between 0.5 and 8.0 kV depending on each powder’s surface charging. For SEM, powdered samples were deposited on double-sided conducting carbon tape and then platinum-metallized by sputtering under vacuum. EDXS analyses were carried out on a Zeiss Evo HD15 scanning electron microscope equipped with an Oxford Instruments X-MaxN SDD 50 mm2 EDXS detector. For EDXS, powdered samples were deposited on double-sided conducting carbon tape and then metallized with carbon before analyses.

N2 Adsorption/Desorption Isotherms

N2 volumetric analyses were performed by physisorption of N2 using a Tristar instrument (Micromeritics, Norcross, GA). Prior to measurements, samples were degassed under vacuum overnight at 150 °C.

SIMS

SIMS analyses were performed on (i) SiO2 and TiO2 samples that had been enriched by LAG as described previously (1 h of BM) but using 97% 18O-labeled water and (ii) nonlabeled SiO2 and TiO2 phases, which served as controls. All samples were pelletized, dried under vacuum, and then sputtered by a thin layer of gold prior to analysis. Measurements were performed on the IMS4F apparatus (Cameca) of the Geosciences Platform of the University of Montpellier, equipped with a 10 keV cesium sputter gun. For each sample, average 18O/16O ratios were determined by analyzing three different zones of the surface and performing five blocks of 10 measurements on each zone.

Solid-State 17O NMR 1D Experiments

The majority of solid-state 17O NMR experiments were performed on a Varian VNMRS 600 MHz (14.1 T) NMR spectrometer, using either Varian 3.2 mm HX or HXY probes or a Phoenix 3.2 mm probe, tuned to 1H (599.82 MHz) and 17O (81.31 MHz). Spectra were recorded under MAS conditions, with spinning speeds ranging from 16 to 20 kHz, depending on the sample. Additional 17O MAS NMR experiments were performed on a Bruker 850 MHz (20.0 T) NMR spectrometer, using Bruker 1.3 or 3.2 mm probes, tuned to 1H (850.23 MHz) and 17O (115.26 MHz). Finally, ultrahigh-magnetic-field experiments were also performed on the 1.5 GHz (35.2 T) SCH instrument in Tallahassee, FL,64 using a 3.2 mm single-channel MAS probe, spinning at 18 kHz. The acquisition parameters used for each sample can be found in Table S1. 17O-enriched Ca(*OH)2 was used to set up the DFS enhancement scheme65 and 17O{1H} CPMAS NMR experiments. 17O chemical shifts were referenced externally to tap water at 0.0 ppm (or to D2O at −2.7 ppm).

Solid-State 27Al NMR 1D Experiments

Solid-state 27Al NMR experiments were performed on a Varian VNMRS 600 MHz (14.1 T) NMR spectrometer, using a Varian 3.2 mm HX probe or a Phoenix 3.2 mm probe, tuned to 1H (599.82 MHz) and 27Al (156.29 MHz). Samples were packed into low-aluminum background zirconia rotors for these measurements. Single-pulse experiments were performed by spinning at 18 kHz, using a 27Al excitation pulse of 0.7 μs (π/18 tip angle) and a recycle delay of 6 s, and acquiring a total of 512 transients. 27Al{1H} CPMAS NMR experiments were performed by spinning at 18 kHz, using a 1H excitation pulse of 6 μs (π/2 tip angle) and a contact time of 0.5 ms. The recycle delay was set to 1 s, and the number of scans acquired ranged from 8000 to 61700, depending on the sample. 27Al chemical shifts were referenced externally to a 1 M aqueous solution of Al(NO3)3.

Solid-State 1H NMR 1D Experiments

Solid-state 1H fast MAS NMR spectra were recorded on a Bruker 850 MHz (20.0 T) instrument, using a Bruker 1.3 mm probe spinning at 60 kHz. A Hahn-echo sequence was used, with π/2 and π pulses of 2.05 and 4.1 μs, and a rotor-synchronized echo delay corresponding to 2 or 50 rotor periods (Figure 4d). 1H chemical shifts were referenced to a dipeptide (Asp-Ala), used as a secondary reference, with the low-frequency signal being set to 1.1 ppm with respect to tetramethylsilane. Additional Hahn-echo 1H NMR spectra were also recorded on a Varian VNMRS 600 MHz (14.1 T) NMR spectrometer using a Phoenix 1.2 mm MAS probe, in order to evaluate the potential contributions of background 1H signals from the rotor and caps (Figure S10).

27Al{17O} J-HMQC NMR

A 27Al{17O} J-HMQC MAS NMR experiment was performed on a Bruker 850 MHz (20.0 T) NMR spectrometer, using a 3.2 mm HXY probe, tuned to 1H (850.29 MHz), 27Al (221.56 MHz), and 17O (115.27 MHz), and spinning at 24 kHz. DFS excitation pulses were first applied on 27Al (1 ms pulse of 30 W with a 600 to 150 kHz sweep). The π/2 and π pulses on 27Al were set to 8.3 and 16.6 μs, respectively [∼10 kHz radio frequency (RF)]. The evolution delay following the π/2 pulse on 27Al was set to 2.5 ms. The π/2 pulses on 17O were set to 8.5 μs (∼10 kHz RF). Spinal-64 1H decoupling (100 kHz RF) was applied throughout the sequence (except during the DFS). The recycle delay was set to 1 s, and a total of 10000 scans were acquired for each of the 18 increments of the 2D experiments. The 17O and 27Al chemical shifts were referenced using respectively tap water (at 0 ppm) and a 1 mol/L solution of aluminum nitrate (at 0 ppm).

1H{17O} D- and J-HMQC NMR

1H{17O} HMQC MAS NMR experiments were performed on a Bruker 850 MHz (20.0 T) NMR spectrometer, using a 1.3 mm HX probe, tuned to 1H (850.29 MHz) and 17O (115.27 MHz), and spinning at 60 kHz. The π/2 and π pulses on 1H were set to 2.05 and 4.1 μs, respectively. The π/2 pulses on 17O were set to 6.0 μs. For the J-HMQC experiment, the evolution delay following the π/2 pulse on 1H was set to 600 μs. For the D-HMQC experiment, the recoupling time τrec was set to 100 or 300 μs, during which an SR421 pulse was applied on 1H (120 kHz RF) and a WURST pulse was applied on 17O (at an offset of 120 kHz).66 The recycle delay was set to 0.5 s. The number of scans and duration of each experiment can be found in Table S1. 17O and 1H chemical shifts were referenced using respectively tap water (at 0 ppm) and a dipeptide (Asp-Ala), for which the low-frequency signal was set to 1.1 ppm with respect to tetramethylsilane.

17O MQMAS NMR

A 17O MQMAS NMR experiment was performed on an enriched alumina phase on the SCH instrument in Tallahassee, FL,64 using a 3.2 mm single-channel MAS probe, and spinning at 16 kHz. 17O excitation and conversion pulses were respectively set to 4 and 1.4 μs (600 W power), followed by a 4.4 μs pulse (36 W power). The recycle delay was set to 0.2 s, and a total of 240 scans were acquired for each of the increments of the 2D experiments. 17O chemical shifts were referenced externally to D2O at −2.7 ppm (which was measured to be equivalent to tap water at 0 ppm).

17O DNP

The MAS DNP experiments were carried out on the 600 MHz/395 GHz setup installed at the NHMFL in Tallahassee, FL. The magnetic field was set at 14.094 T, and the gyrotron generates a microwave power of 12 W at the probe base and a frequency of 395.166 GHz. The sample was packed in a 3.2 mm thin-wall ZrO2 rotor and spun at 13 kHz. The temperatures for VT/bearing/drive were 91.6/98/110 K, leading to a sample temperature under microwave irradiation of ∼100 K and ∼94 K in the absence of it.38 The higher drive temperature allowed us to achieve a 13 kHz spinning frequency while reducing the pressure needed. The sample was prespun at room temperature with a benchtop spinner (home-built), and electron paramagnetic resonance measurement was carried out prior to the MAS DNP experiment. Finally, three freeze–thaw cycles were applied to the sample before insertion into the probe. The powder was impregnated with a 16 mM solution of TEKPol (purchased from Cortecnet) in tetrachloroethane-d2 (Cortecnet) for Al2O3 or tetrabromoethane (Sigma-Aldrich) for TiO2. For the experiments, ∼30 mg of powder was impregnated with ∼30 μL of solution, leading to a toothpasty texture. The NMR acquisition parameters used for each spectrum are reported in Table S1 for the 17O{1H} CPMAS NMR and DFS-echo experiments performed with or without microwaves.

Acknowledgments

This project has received funding from the European Research Council (ERC) under the European Union’s Horizon 2020 research and innovation program (Grant 772204; 2017 ERC–COG, MISOTOP project). A portion of this work was performed at the NHMFL, which is supported by the National Science Foundation Cooperative Agreement DMR-1644779, the State of Florida, and the United States Department of Energy. The MAS-DNP system at the NHMFL is funded in part by Grants NIH S10 OD018519 and P41 GM122698. Financial support from the IR-RMN-THC Fr3050 CNRS for conducting part of the high-field NMR experiments is gratefully acknowledged. The UK 850 MHz solid-state NMR facility used in this research was funded by EPSRC and BBSRC, as well as the University of Warwick including via part funding through Birmingham Science City Advanced Materials Projects 1 and 2 supported by Advantage West Midlands and the European Regional Development Fund. Dr. Franck Fayon (CEMHTI, CNRS) and Dr. Dinu Iuga (University of Warwick) are acknowledged for discussions and Anastasia Kuznetsova for the BM enrichment of some of the alumina phases studied here.

Supporting Information Available

The Supporting Information is available free of charge at https://pubs.acs.org/doi/10.1021/acs.inorgchem.0c00208.

Preliminary study on the synthesis of 17O-enriched Li2*O (including Figure S1); SEM, N2 adsorption/desorption isotherms, and EDXS analyses of SiO2 (Figure S2), Al2O3 (Figure S3), TiO2 (Figure S4), and ZrO2 (Figure S5); 17O MAS NMR spectra of enriched Zr*O2 and the empty zirconia rotor (Figure S6a) and a non-labeled Al2O3 phase (Figure S6b); fit of the 17O MAS NMR spectrum of enriched Si*O2 recovered after 1 h of BM (Figure S7); 27Al MAS and 27Al{1H} CPMAS NMR analyses of Al2O3 phases before and after enrichment (Figure S8); fits of 17O MAS NMR spectra of enriched Al2*O3 after different milling times (Figure S9); fast MAS 1H NMR spectra of enriched Al2*O3 and comparison to the rotor 1H background signal (Figure S10); 17O DNP and 17O{1H} DNP CPMAS NMR spectra of enriched Al2*O3 (Figure S11); 17O MAS and 17O{1H} CPMAS NMR spectra of enriched Al2*O3 (Figure S12); fit of the 17O MAS NMR spectrum of enriched Si*O2 recovered after 1 min of BM (Figure S13); analysis of the siloxane region of 17O MAS NMR spectra of SiO2/TiO2 mixtures labeled using different procedures (Figure S14); 17O MAS NMR spectra of zirconia phases of different initial crystallinity recovered after 1 h of BM (Figure S15); 17O MAS NMR spectra of enriched alumina and titania after heat treatment at 900 °C (Figure S16); and 17O NMR parameters used for acquisition of the NMR spectra (Table S1) (PDF)

Author Contributions

C.-H.C., E.G., R.B., B.R., T.-X.M., and D.L. participated in the synthesis and characterization of the enriched materials. C.-H.C., P.G., B.A., and D.L. performed SSNMR analyses at 14.1 T. F.M.-V. carried out all DNP experiments. K.C., Z.G., P.F., C.B., M.E.S., B.A., and D.L. participated in the ultrahigh-field NMR experiments. C.-H.C., T.-X.M., B.A., and D.L. designed the investigations, and D.L. coordinated the project. All coauthors participated in the writing of the manuscript.

The authors declare no competing financial interest.

Supplementary Material

References

- Ashbrook S. E.; Smith M. E. Solid state 17O NMR—an introduction to the background principles and applications to inorganic materials. Chem. Soc. Rev. 2006, 35, 718–735. 10.1039/B514051J. [DOI] [PubMed] [Google Scholar]

- Huo H.; Peng L.; Gan Z.; Grey C. P. Solid-State MAS NMR Studies of Brønsted Acid Sites in Zeolite H-Mordenite. J. Am. Chem. Soc. 2012, 134, 9708–9720. 10.1021/ja301963e. [DOI] [PubMed] [Google Scholar]

- Bignami G. P. M.; Davis Z. H.; Dawson D. M.; Morris S. A.; Russell S. E.; McKay D.; Parke R. E.; Iuga D.; Morris R. E.; Ashbrook S. E. Cost-effective 17O enrichment and NMR spectroscopy of mixed-metal terephthalate metal–organic frameworks. Chem. Sci. 2018, 9, 850–859. 10.1039/C7SC04649A. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bignami G. P. M.; Dawson D. M.; Seymour V. R.; Wheatley P. S.; Morris R. E.; Ashbrook S. E. Synthesis, Isotopic Enrichment, and Solid-State NMR Characterization of Zeolites Derived from the Assembly, Disassembly, Organization, Reassembly Process. J. Am. Chem. Soc. 2017, 139, 5140–5148. 10.1021/jacs.7b00386. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Heard C. J.; Grajciar L.; Rice C. M.; Pugh S. M.; Nachtigall P.; Ashbrook S. E.; Morris R. E. Fast room temperature lability of aluminosilicate zeolites. Nat. Commun. 2019, 10, 4690. 10.1038/s41467-019-12752-y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Reeves P. J.; Seymour I. D.; Griffith K. J.; Grey C. P. Characterizing the Structure and Phase Transition of Li2RuO3 Using Variable-Temperature 17O and 7Li NMR Spectroscopy. Chem. Mater. 2019, 31, 2814–2821. 10.1021/acs.chemmater.8b05178. [DOI] [Google Scholar]

- Geng F.; Shen M.; Hu B.; Liu Y.; Zeng L.; Hu B. Monitoring the evolution of local oxygen environments during LiCoO2 charging via ex situ 17O NMR. Chem. Commun. 2019, 55, 7550–7553. 10.1039/C9CC03304A. [DOI] [PubMed] [Google Scholar]

- Hope M. A.; Halat D. M.; Magusin P. C. M. M.; Paul S.; Peng L.; Grey C. P. Surface-selective direct 17O DNP NMR of CeO2 nanoparticles. Chem. Commun. 2017, 53, 2142–2145. 10.1039/C6CC10145C. [DOI] [PubMed] [Google Scholar]

- Li Y.; Wu X.-P.; Jiang N.; Lin M.; Shen L.; Sun H.; Wang Y.; Wang M.; Ke X.; Yu Z.; Gao F.; Dong L.; Guo X.; Hou W.; Ding W.; Gong X.-Q.; Grey C. P.; Peng L. Distinguishing faceted oxide nanocrystals with 17O solid-state NMR spectroscopy. Nat. Commun. 2017, 8, 581. 10.1038/s41467-017-00603-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Shen L.; Wu X.-P.; Wang Y.; Wang M.; Chen J.; Li Y.; Huo H.; Hou W.; Ding W.; Gong X.-Q.; Peng L. 17O Solid-State NMR Studies of ZrO2 Nanoparticles. J. Phys. Chem. C 2019, 123, 4158–4167. 10.1021/acs.jpcc.8b11091. [DOI] [Google Scholar]

- Chen J.; Wu X.-P.; Hope M. A.; Qian K.; Halat D. M.; Liu T.; Li Y.; Shen L.; Ke X.; Wen Y.; Du J.-H.; Magusin P. C. M. M.; Paul S.; Ding W.; Gong X.-Q.; Grey C. P.; Peng L. Polar surface structure of oxide nanocrystals revealed with solid-state NMR spectroscopy. Nat. Commun. 2019, 10, 5420. 10.1038/s41467-019-13424-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- MacKenzie K. J. D.; Smith M. E.. Multinuclear Solid-State Nuclear Magnetic Resonance of Inorganic Materials; Pergamon, 2002; Chapter 6. [Google Scholar]

- Jaworski A.; Stevensson B.; Edén M. Direct 17O NMR experimental evidence for Al–NBO bonds in Si-rich and highly polymerized aluminosilicate glasses. Phys. Chem. Chem. Phys. 2015, 17, 18269–18272. 10.1039/C5CP02985F. [DOI] [PubMed] [Google Scholar]

- Bastow T. J.; Smith M. E.; Whitfield H. J. Characterisation of zirconia gels by 17O nuclear magnetic resonance. J. Mater. Chem. 1992, 2, 989–990. 10.1039/jm9920200989. [DOI] [Google Scholar]

- Bastow T. J.; Moodie A. F.; Smith M. E.; Whitfield H. J. Characterisation of titania gels by 17O nuclear magnetic resonance and electron diffraction. J. Mater. Chem. 1993, 3, 697–702. 10.1039/jm9930300697. [DOI] [Google Scholar]

- Babonneau F.; Bonhomme C.; Gervais C.; Maquet J. Advances in Characterisation Methods for Sol-Gel Derived Materials: High Resolution Solid State Nuclear Magnetic Resonance. J. Sol-Gel Sci. Technol. 2004, 31, 9–17. 10.1023/B:JSST.0000047953.77510.0b. [DOI] [Google Scholar]

- Griffin J. M.; Clark L.; Seymour V. R.; Aldous D. W.; Dawson D. M.; Iuga D.; Morris R. E.; Ashbrook S. E. Ionothermal 17O enrichment of oxides using microlitre quantities of labelled water. Chem. Sci. 2012, 3, 2293–2300. 10.1039/c2sc20155k. [DOI] [Google Scholar]

- Métro T.-X.; Gervais C.; Martinez A.; Bonhomme C.; Laurencin D. Unleashing the Potential of 17O NMR Spectroscopy Using Mechanochemistry. Angew. Chem. 2017, 129, 6907–6911. 10.1002/ange.201702251. [DOI] [PubMed] [Google Scholar]

- James S. L.; Adams C. J.; Bolm C.; Braga D.; Collier P.; Friščić T.; Grepioni F.; Harris K. D. M.; Hyett G.; Jones W.; Krebs A.; Mack J.; Maini L.; Orpen A. G.; Parkin I. P.; Shearouse W. C.; Steed J. W.; Waddell D. C. Mechanochemistry: opportunities for new and cleaner synthesis. Chem. Soc. Rev. 2012, 41, 413–447. 10.1039/C1CS15171A. [DOI] [PubMed] [Google Scholar]

- Friščić T.; Mottillo C.; Titi H. M. Mechanochemistry for Synthesis. Angew. Chem., Int. Ed. 2020, 59, 1018. 10.1002/anie.201906755. [DOI] [PubMed] [Google Scholar]

- Bowmaker G. A. Solvent-assisted mechanochemistry. Chem. Commun. 2013, 49, 334–348. 10.1039/C2CC35694E. [DOI] [PubMed] [Google Scholar]

- Leskes M.; Moore A. J.; Goward G. R.; Grey C. P. Monitoring the Electrochemical Processes in the Lithium–Air Battery by Solid State NMR Spectroscopy. J. Phys. Chem. C 2013, 117, 26929–26939. 10.1021/jp410429k. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Abys J. A.; Barnes D. M.; Feller S.; Rouse G. B.; Risen W. M. Preparation of O17-labelled glasses and glass precursers. Mater. Res. Bull. 1980, 15, 1581–1587. 10.1016/0025-5408(80)90238-X. [DOI] [Google Scholar]

- Merle N.; Trébosc J.; Baudouin A.; Rosal I. D.; Maron L.; Szeto K.; Genelot M.; Mortreux A.; Taoufik M.; Delevoye L.; Gauvin R. M. 17O NMR Gives Unprecedented Insights into the Structure of Supported Catalysts and Their Interaction with the Silica Carrier. J. Am. Chem. Soc. 2012, 134, 9263–9275. 10.1021/ja301085m. [DOI] [PubMed] [Google Scholar]

- Freude D.; Haase J.. Survey of NMR Parameters for Quadrupolar Nuclei in Powder Materials. Particular for 27Al, 23Na and 17O; 2019; http://www.quad-nmr.de.

- Walter T. H.; Oldfield E. Magic angle spinning oxygen-17 NMR of aluminum oxides and hydroxides. J. Phys. Chem. 1989, 93, 6744–6751. 10.1021/j100355a034. [DOI] [Google Scholar]

- Bastow T. J.; Stuart S. N. 17O NMR in simple oxides. Chem. Phys. 1990, 143, 459–467. 10.1016/0301-0104(90)87025-7. [DOI] [Google Scholar]