Abstract

Effective geothermal power generation depends on two main elements: geothermal reservoir management and maintenance of the power plant. Reservoir management consists of both the fluid production and reinjection of brine to the underground. The management of wells is important to ensure the sustainability of the reservoir. Thus, the flow rate control systems are essential to protect geothermal reservoirs under long-term power production. The second issue is the daily change in electricity prices and the load change process is complex because geothermal well controls are not flexible operations. The well management thus requires control approaches, and fuzzy control can be one effective solution. In this study, a fuzzy control system has been developed to control flow rates of the wells in Kızıldere geothermal field and its performance has been compared with the real data taken from the Kızıldere Power Plant. The results of comparison show that the fuzzy controllers achieved the target energy production in 2 h instead of 5 h, compared to the real data. Based on the real data, the reinjection was only able to stabilize at the end of the fourth hour and the process took only 2 h when using the fuzzy controllers.

Keywords: Geothermal power plant, Geothermal reservoir, Well management, Fuzzy control, Western anatolia

Highlights

-

•

Effective geothermal power generation depends on reservoir management and maintenance.

•The management of wells is important to ensure the sustainability of the reservoir.

•The daily load change is complex because geothermal well control isn’t flexible.

•Fuzzy control expresses the experience of a geothermal energy expert mathematically.

•A fuzzy control system was developed to control flow rates of the geothermal wells.

1. Introduction

Geothermal power plants are power generation systems that use geothermal fluids formed in the depths of the earth and are not directly affected by meteorological conditions in the way that solar, wind and hydropower systems are, thus differing them from other power plants that use renewable sources. Based on the temperatures and characteristics of geothermal reservoirs, geothermal fluids can also be used for different purposes such as space heating and cooling [1,2], combined heat and power (CHP) technology and even cooling through trigeneration along with power generation [3], [4], [5], [6] industrial and agricultural drying, balneology, cosmetics or mineral recovery, which are classified as the direct applications aside from power generation.

It is noted that geothermal power plants (GPP) are base load electricity supplying systems and have higher capacity factors (>80%) like other thermal power plants but less CO2 emissions [7,8]. The total installed geothermal power capacity is around 16 GWe the world, with Turkey estimated to produce around 10% of this by 2020 [9]. If the Covid-19 pandemic does not affect ongoing global geothermal power projects, the total installed capacity will exceed 17 GWe in 2021.

The majority of GPPs currently use the ORC, while the single flash is the second most preferred technology for power production around the world (Fig. 1 a). The ORC is also widely used, while flash cycle technologies are used at only a few geothermal fields, such as Kızıldere (Denizli city), Germencik (Aydın city) and Alaşehir (Manisa city), in Turkey (Fig. 1b; [10].

Fig. 1.

a Numbers of geothermal power plants in the world (modified after [10]. b Numbers of geothermal power plants in Turkey in 2020.

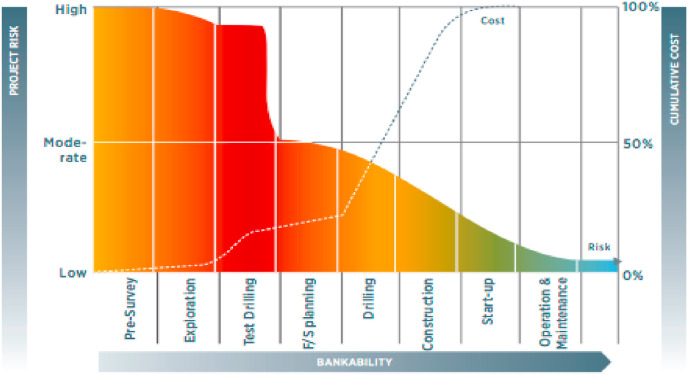

Although GPPs have some advantages compared to other renewables; there are also some challenges and risks during the investment and operation periods. The early stages of the development of each geothermal power project have significant financial risks (Fig. 2 ). During the geothermal resource exploration phase of a project, detailed geological, geophysical and geochemical investigation is required to find the possible geothermal capacities in a license area (Fig. 2). The cost of drilling operations equals 42% of total project costs for a geothermal power development project [11], at around 2.9 million USD for well at 1500–2500-m depth in Western Anatolia (Turkey; [12,13]. Deep geothermal drilling operations are complex and expensive enterprises, requiring strong teamwork based around different areas of expertise. For this reason, protection and sustainable operation of wells and reservoirs in geothermal power plant investments will eliminate these expensive well drilling operations or ensure their delay for a long time.

Fig. 2.

Development stages of a geothermal power project [14].

Besides the investment period, after commissioning the power plant, two main operations can be identified as critical to providing sustainability at a geothermal power plant: geothermal reservoir management and plant management [15]. Power plant management requires continuous attention to all surface equipment, including separator systems, turbine-generator systems, cooling systems, condensers, cooling towers, re-injection pumps and pipelines, to prevent in particular mineral scaling, corrosion and other effects due to fluids. Although plant management is essential to provide uninterrupted electricity production, reservoir management is the most critical application for high-temperature reservoir systems. A sustainable geothermal reservoir model can be provided by optimum geothermal fluid production and reinjection scenarios in a geothermal field.

Geothermal power systems generally need many production wells based on the capacity of the turbine and require reinjection wells to protect the environment from hot geothermal fluids and to provide feeding geothermal reservoirs. It means that geothermal well management is of high importance to long-term energy production and ensures geothermal reservoir sustainability; optimum production and effective reinjection are required. This management is particularly necessary with flash and multi-flash and high capacity ORC systems, all of which have well numbers that are numerous and optimization can expand the geothermal reservoir lifetime.

Nowadays, simultaneous continuous production and re-injection well management can only be carried out by the instant decision of a specialist in the geothermal power plant. Existing control systems such as PID only apply the decision made by the expert at the moment, whereas geothermal systems are quite dynamic, and conditions in the wells can sometimes change rapidly, sometimes necessitating a new well optimization. Noticing this change and trying to re-optimize the system while avoiding an energy drop is a complex and slow process from the current perspective. A fuzzy control application will be used to minimize energy loss by determining new optimization conditions more quickly in reservoir conditions during the management of production and reinjection wells in a geothermal field. Fuzzy logic is one of the important control techniques to express human expertise mathematically, and the expertise and experience of a geothermal energy expert is transferred to fuzzy controllers here.

Fuzzy control systems have been used globally in various studies since 1965 [16] and provides solutions in a variety of areas of daily life [17]. Fuzzy control is an approach that allows the definition of intermediate values between clear evaluations such as “true or false,” and it is widely applied in a variety of engineering sciences [14]. Although the application of artificial intelligence methods for different purposes in geothermal systems has been started in recent years, methods such as artificial neural networks, machine learning can enable optimization in systems by using mostly historical data [9,[18], [19], [20]]. The fuzzy control is a more suitable method for decision mechanisms that will rapidly optimize the instantaneous changes in production and reinjection wells under dynamic geothermal reservoir conditions. In the literature, the number of studies that have used fuzzy applications in geothermal reservoirs is quite limited; the current studies have been performed in low-temperature systems or are studies of the optimization of chemical inhibitor injection and geothermal-based hybrid power plant studies [[21], [22], [23], [24]]. This study contributes to making well-flow optimization in the geothermal field faster by reducing the energy loss by noticing the changes in the geothermal power plants quickly due to reservoirs or wells by fuzzy controllers, and this will be first for a geothermal power system.

The aim of the study is to design a fuzzy control system to provide effective reservoir management and sustainability of the reservoirs in high-temperature geothermal systems. Long-term geothermal power production must well designed geothermal production and reinjection strategies, and it is generally difficult to follow these strategies due to the large well numbers at geothermal fields. Electricity prices also vary hourly in the energy market, and it is more profitable for investors to produce and sell more energy while electricity prices are high. In some countries, such as Turkey with the Renewable Energy Support Mechanism (YEKDEM), the government guarantees a certain period of time for the purchase of electricity produced from renewable energy to promote renewable energy investments. At the end of this promotion period, GPP operators must follow the hourly electricity prices as other power plants in the country. Thus, energy production scenarios must be changed due to new rules, and power generation must be adjusted. This study may help the power plant operators.

In this study, a fuzzy control system is designed to optimize the flow rates of wells required for optimum energy production by using a human operator’s experiments. Fuzzy logic is used to convert heuristic control rules expressed by a human operator into an automatic control strategy [25]. For this reason, a fuzzy control system is applied to control 8 production wells and 3 reinjection wells with two scenarios based on the energy requirement. In the first scenario, while optimization of production and reinjection wells with fuzzy controllers is shown, in the second scenario, real data taken from a geothermal power plant and the results of fuzzy controllers are compared. The simulation results are presented in this study.

2. Importance of sustainable development at geothermal power systems

“Sustainability” can be considered to provide long-term energy production without interruption at power generation. Each power plant type may require specific operation and maintenance conditions, but the common goal is to attain and remain at the targeted energy production level for a long time [26]. Sustainability is an important element of uninterrupted energy production at geothermal power systems, because there are many thermodynamic conditions that require continuous control during the power production period. Ensuring sustainability in geothermal power plants consists of two main stages: sustainability of geothermal reservoirs and sustainability of the power plant. For reservoir protection, well optimization, reinjection, reservoir pressure control and mineral scaling are critical parameters, while controlling surface equipment and surface equipment–fluid interactions are important to uninterrupted energy production and thus the sustainability of the power plant.

2.1. Sustainability of geothermal reservoirs

Geothermal reservoirs can be classified as water-dominated or steam-dominated, and both types of systems are suitable for electricity production in high-temperature geothermal systems. A geothermal reservoir may be likened to a vehicle’s gas tank: As long as there is fuel in the tank, the vehicle keeps running, and when there is no fuel in the tank, it stops in a moment. Long-term geothermal power generation also requires the continuous production of geothermal fluids, and it can only apply an effective production scenario at the beginning of the commissioning of the plant (Fig. 3 [15]).

Fig. 3.

Sustainability of geothermal reservoirs [15].

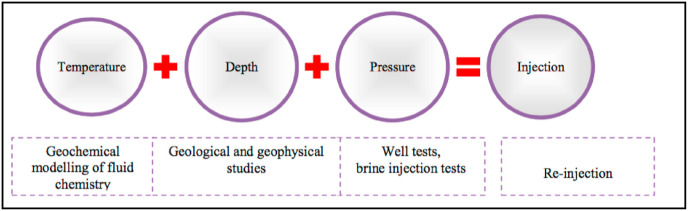

Geothermal reservoir systems are controlled by fractures and cracks, and these fracture systems can be identified by some models, such as the discrete fracture network (DFN), in the field of reservoir engineering [27]. Natural water recharge has generally not been enough by itself to feed the geothermal reservoir, and reservoir performance, heat recovery, well distribution and reinjection are also critical parameters during the long power production period [28]. In addition to the production phase, the waste hot or condensed water must be injected to the reinjection area after steam production to provide sustainability in water- or steam-dominated reservoirs. At the first phase of the feasibility study, during the assessment of geothermal reservoirs, the conditions of production must be evaluated, as must the conditions of reinjection. During the reinjection application, geothermal fluids are exposed to a series of thermodynamic changes, such as temperature and pressure, after the separation systems, so the application must be controlled by hydrogeochemistry to understand the changing of geothermal fluids in its path [29].

Resource and reservoir assessment methods have been examined based on the historical or single-point data for geothermal fields [30,31]. Reservoir risk management may be classified as exploration and management risks at geothermal reservoirs [28].

Akın et al. [32] point out that CO2 emissions have rapidly decreased, by between 7.81% and 19% per year, in both the Büyük Menderes and Gediz Graben geothermal systems between 2019 and 2024 [32]. Although this appears to be good news for environmental protection, it indicates that the reservoir pressures are also tending to decrease in Western Anatolia (Fig. 4 ).

Fig. 4.

Reservoir pressure trend along the geothermal production in Western Anatolia [8].

The reinjection of non-condensable gases into geothermal reservoirs can be a good option to decrease greenhouse gas emissions such as CO2 and H2S, while protecting the reservoir pressure (Fig. 5 ) and potentially increasing the permeability of the reservoir at depth [31]. Some geothermal emission abatement methods that may help to increase reservoir pressure after a long production period in a geothermal field have been discussed by researchers. Some of these researchers have tried to model absorbing H2S and CO2 by a packed absorption column in water under high-pressure conditions [33]. The other approach is to mix non-condensable gases and water at different proportions and send them to the reinjection wells. Kaya and Zarrouk [31] point out that this approach can work and increase reservoir pressure after 10 years of steam production; however, increasing exploitation may affect steam production. New approaches such as artificial neural networks have begun to be used for reinjection well placement and optimization since the beginning of the 2000s [18,34,35].

Fig. 5.

Essential parameters for a proper reinjection in a geothermal system [15].

Geothermal mineral scaling is another problem that directly affects fluid production in water-dominated reservoirs. The fluids consist of highly mineralized hot water, steam and non-condensable elements, and when total pressure is measured as lower than Pgas + Pliquid, the boiling process begins, and some minerals in the fluids after the release of dissolved gases such as calcite and aluminosilicates precipitate in boreholes (Fig. 6 [10]). Geothermal reservoirs have dynamic thermodynamic conditions and require continuous hydrogeochemical monitoring, and to solve mineral precipitation problems, chemical inhibition systems are used in each wellhead in a geothermal field.

Fig. 6.

Mineral precipitation at pipeline and stereoscopic enlargement of a scale sample (Photo: Kızıldere-I geothermal field).

Finally, during the operation of geothermal wells, some casing and pipes may be damaged due to the high-corrosion conditions, which can also affect sustainable production in a geothermal field [36].

2.2. Sustainability of geothermal power plants

A number of power technologies have been developed for geothermal power production, such as the binary organic rankine cycle (ORC), flash cycle, multi-flash and advanced (flash + binary) systems, dry steam and hot dry rock (HDR) system based on geothermal reservoir types for medium-high temperature systems [37].

The sustainability of geothermal power plants generally depends on steam quality and the harmony of geothermal fluid and equipment, in addition to geothermal fluid production. Mineral scaling due to the pressure and temperature of geothermal fluids and corrosion due to high non-condensable gas effects are the main operational problems for equipment at the power plant [10].

Steam quality is quite important to the performance of each steam turbine system, and to increase steam quality, that is, to obtain purer and drier steam, scrubber- or demister-type mechanical equipment has been used between each steam separator and steam turbine-generator system [15]. High amounts of dry and clean steam prevent small particles and bullet effects on the turbine blades at high rpm conditions. Corrosion fatigue and stress corrosion failures are another probable problem at steam turbines and require the monitoring of the turbine [38].

The NCG removal system is one of the important stages to remove wet steam and NCG from the turbine by a compressor. These gases and wet steam are sent to the condenser to increase steam turbine performance. Spray wash applications have been used to cool these gases in the cooling tower. There are two types of cooling towers: air-cooled and water-cooled systems, the latter of which require chemical treatment because of the dark, wet and highly gassy conditions [15].

The material of the equipment used in a geothermal power plant is essential for long-term energy production. The design criteria of a geothermal power plant include the physical and chemical characteristics of the steam, gas and water phases of geothermal fluid. The non-condensable gas composition and the concentration of gases such as H2S makes it extremely important to select the correct material for each component of the power plant to prevent corrosion effects.

Due to the continuous thermodynamic changes, different mineral precipitations can be also observed at each temperature and pressure drop point in a geothermal power plant. Calcite scaling is the dominant precipitation at production wells under gas release depths, while silica scaling is dominant in re-injection lines due to the drop in temperature values. Calcite and silica solubility are inconsistent with the geothermal system and require chemical and physical monitoring during the chemical inhibitor applications at pressure and temperature drop points [10].

New heuristic optimization and control approaches have been studied to increase the efficiency of geothermal power plants. Various algorithms such as gravitational search [39], swarm and generic algorithms [40,41] have started to be used for performance analysis and the optimization of different geothermal power plants aside from the chemical simulator; these include Aspen Plus to model and simulate binary power plants [42].

3. Overview of The Kızıldere geothermal field

In this study, the Kızıldere geothermal field and Kızıldere-I GPP were selected as the setting in which to apply a fuzzy control system for well management in a simulation environment (Fig. 7 ).

Fig. 7.

Kızıldere-I single flash geothermal power plant in Western Anatolia.

The Kızıldere geothermal field, located in Western Anatolia, was the first high-temperature geothermal system discovered, in the 1960s, and it boasts a reservoir temperature of around 200 °C. The geothermal field is located at the east edge of the Büyük Menderes Graben, and the first geothermal power plant, Kızıldere-I, was installed as a single flash cycle with 17.8 MWegross in 1984.

The Kızıldere geothermal system is formed by highly fractured zones due to the Aegean Extensional Zone and consists of a few reservoirs at depth [43].

After the privatization of the field, the investor company began the rehabilitation and the capacity building studies in 2008. Between 2013 and 2018, the Kızıldere-II GPP (80 MWegross; 60 MWe triple flash + 20 MWe ORC binary) and Kızıldere-III GPP’s Unit-1 95 MW egross (72 MWe triple flash type +23 MW e ORC binary) and the Unit-2 73 MW egross (50 MWe triple flash +23 MWe ORC binary) were commissioned [10].

Kızıldere-I produced electricity as the only plant in the field between 1984 and 2013. After the commissioning of Kızıldere-II, it was integrated into the low-pressure separator system of Kızıldere-II and the common re-injection application was started in the field. The effective re-injection started after the completion of the rehabilitation studies for Kızıldere-I in 2010.

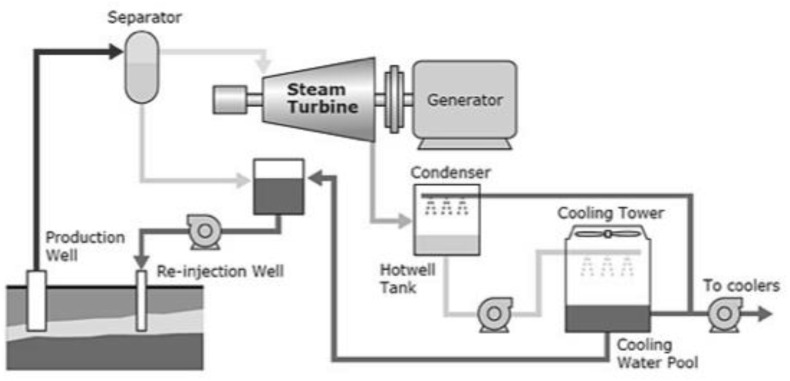

At a single flash system; geothermal fluid is transported to the surface from the water-dominated reservoir by a production well and reaches the separator to separate water and steam phases each other. After the separation process, brine (waste hot water) is sent to the reinjection well by a reinjection pump, while steam is sent to the turbine-generator system. The steam is expanded through the turbine down to the condenser and cooling tower system (Fig. 8 ).

Fig. 8.

Basic process flow diagram of a single flash geothermal power plant.

In this study, data on the KD14, KD15, KD16, KD20, KD21, KD22, R1 and R3 production wells and KD-1A, KD8, R2 reinjection wells from March 2010 to March 2012 was used for the high-fidelity simulation of the field. This data range was selected because it is within the timeframe during which effective re-injection was realized in the Kızıldere geothermal field. The total production flow rate changed between 953 tph and 1743 tph, and maximum reinjection was realized around 900 tph in the field during the selected operation period.

4. Methodology

4.1. Using fuzzy control systems

A fuzzy control system is a multi-valued logic that allows the identification of intermediate values between typical evaluations such as "yes or no" or "true or false." Fuzzy control systems can be viewed in a number of ways: A fuzzy controller may be seen as a non-linear controller represented by linguistic rules rather than differential equations, or it can be seen as the application of a human expert’s control skill [44]. The main advantage of the system is that it eliminates the function of the mathematical model found in conventional controllers and replaces it with another that is based on a number of smaller rules that usually only describe a small portion of the system [14].

After the introduction of this control system by Zadeh in 1965, various researchers have started to apply this approach to solve the control problems experienced in various study areas. The first industrial-scale fuzzy applications were to control cement kilns [45] and to operate automatic container cranes [46]. Use of this control approach became wider in engineering fields at the beginning of the 1990s [47]. Fuzzy controllers have also been using widely at renewable energy industry [[48], [49], [50], [51]] and energy storage systems [52] since the 2010s. Specific studies have also used fuzzy controllers in direct [53,54] and indirect applications, such as scale controllers and hybrid system controllers in geothermal energy [21,24].

4.2. Fuzzy control of the production and injection well flow rates in a geothermal field

Depending on the technology used in a geothermal power plant, the process of generating energy from geothermal fluid to re-injection underground can be complicated. Geothermal reservoir management can be provided to control geothermal wells in a geothermal field. Medium-high temperatures geothermal systems have been widely used for power production, meaning that many production and geothermal wells must be managed to reach long-term energy production and sustainable geothermal reservoirs. Geothermal power plants require requires many wells (sometimes more than 20–30 wells) to provide steam and providing sustainability of the all system is significant to reach constant energy production for a long time.

Each geothermal power project investment requires a comprehensive feasibility study, which includes different energy production scenarios for the long production license periods. These production scenarios include mathematical reservoir predictions; however, geothermal system behaviors may change during the production time, and some undefined reservoir characteristics regarding production and reinjection interaction at depth or external factors such as another geothermal power plant installation close to the existing power plant [43]. Deep geothermal reservoirs are thus generally complex and dynamic systems and sometimes even detailed geology, geochemistry and reservoir studies cannot understand the unknown cases at the underground conditions that directly affect the production scenarios. For uninterrupted geothermal power production, the fluid production and reinjection application can be evaluated together, which is extremely difficult field work given the number of wells in a geothermal field [55]. If there are many production and geothermal wells, the controlling and operating of a system will be hard by manually in a geothermal field.

In addition, in finding the best production strategies for the natural changes in geothermal reservoirs, another issue is to follow hourly electricity prices in the market at the geothermal power plant management side. Although there are special electric tariffs from renewable energy sources such as YEKDEM in Turkey, these are fixed-term regulations in most countries, and at the end of the term, the company must follow hourly energy prices. Thus, each geothermal operator company following both reservoir conditions and electricity prices and geothermal power plants cannot reduce the load suddenly to protect the well conditions in the systems. At critical cases such as a power plant trip, first, excess steam must be removed from the system before the turbine inlet to reduce energy production, after which the flow rates of each well may be adjusted fractionally by an operator to protect the overall system. However, if there are borehole pumps at the production wells, the adjustment of flow rates will be easier, and the system will adapt more rapidly.

It is difficult to obtain a mathematical model that describes the relation of geothermal reservoir characteristics and geothermal flow rates because the system is nonlinear and has a many dependent and independent variables. Fuzzy control replaces the role of the mathematical model in conservative controllers and substitutes it with another that is built from a number of smaller rules that, in general, only describe a small section of the whole system [56].

Fuzzy control systems can be used to adjust the flow rates of both production and reinjection wells. This approach can help control many wells and prevent new thermodynamic changes in geothermal systems and can allow a more rapid response to changing energy production conditions. In this study, two fuzzy logic controller groups for production and reinjection wells are designed to control the flow rates both production and reinjection wells.

4.2.1. Fuzzy control of the geothermal production well flow rate

In this study, a total of eight fuzzy flow rate controllers for each production well—KD14, KD15, KD16, KD20, KD21, KD22, R1 and R3—were designed. The inputs of the controller are the steam flow rate of the production well and required energy production; the output has been the change of flow rate of the production well (Fig. 9 ).

Fig. 9.

Inputs and output of fuzzy production well flow rate controller.

The fuzzy associative matrix, a set of rules to represent all combinations of inputs, is illustrated in Table 2. The steam flow rate of the production well and required energy production is characterized by the following primary fuzzy sets: Very High (VHS), High (HS), Medium (MS), Low (LS), Very Low (VLS), VHE, HE, ME, LE and VLE (Table 1 ). The change of the production well flow rate is characterized by the following primary fuzzy set: Very High (FH2), High (FH1), Medium (M), Low (FL1) and Very Low (FL2).

Table 2.

The fuzzy associative matrix for fuzzy reinjection well flow rate controller.

| Reinjection wellhead pressure change rate |

||||||

|---|---|---|---|---|---|---|

| VLPCR | LPCR | MPCR | HPCR | VHPCR | ||

| Well head pressure difference | VLPD | M | FL1 | FL1 | FL1 | FL1 |

| LPD | FH1 | M | FL1 | FL1 | FL1 | |

| MPD | FH1 | FH1 | M | FL1 | FL1 | |

| HPD | FH2 | FH2 | FH1 | M | FL1 | |

| VHPD | FH2 | FH2 | FH1 | FH1 | M | |

Table 1.

The fuzzy associative matrix for fuzzy production well flow rate controller.

| Production Steam Flow Rate |

||||||

|---|---|---|---|---|---|---|

| VLS | LS | MS | HS | VHS | ||

| Required Energy Production | VLE | FL2 | FL2 | FL1 | FL1 | FL1 |

| LE | FL1 | FL1 | FL1 | FL1 | FL1 | |

| ME | M | M | M | M | M | |

| HE | FH1 | FH1 | FH1 | FH1 | FH1 | |

| VHE | FH1 | FH1 | FH1 | FH2 | FH2 | |

The ranges of inputs and outputs are customized for each production well using the reservoir characteristic features based on the production well data of Kızıldere-I GPP between March 2010 and March 2012. Based on these data, a mathematical model was obtained using the relation between the production well flow rate and wellhead pressure. Output of the controller was ranged to limit the determined wellhead pressures based on the existing fluid production application by the power plant management.

4.2.2. Fuzzy control of the reinjection well flow rate

In this study, a total of three fuzzy flow rate controllers for each reinjection well—KD-1A, KD8 and R2—were designed. The inputs of the controller were the wellhead pressure change rate of the reinjection well and the wellhead pressure difference; the output was the portion of the total reinjection flow rate (Fig. 10). The wellhead pressure difference was calculated using the difference between the maximum and actual wellhead pressure of a re-injection well.

Fig. 10.

Inputs and output of fuzzy reinjection well flow rate controller.

The fuzzy associative matrix is illustrated in Table 2. The wellhead pressure change rate of the reinjection well and the wellhead pressure difference is characterized by the following primary fuzzy sets: Very High (VHPCR), High (HPCR), Medium (MPCR), Low (LPCR), Very Low (VLPCR), VHPD, HPD, MPD, LPD and VLPD (Table 2). The change of the reinjection well flow rate is characterized by the following primary fuzzy set: Very High (FH2), High (FH1), Medium (M), Low (FL1) and Very Low (FL2).

The ranges of inputs and outputs were customized for each reinjection well using their reservoir characteristic features based on the production well data of Kızıldere-I GPP between March 2010 and March 2012. Based on these data, a mathematical model was obtained using the relation between the reinjection well flow rate and wellhead pressure. One of the important criteria was to control the reinjection maximum well pressure, because if the threshold pressure is exceeded, the reinjection well cannot receive more brine. Thus, the wellhead pressure was selected as an input of the control system.

5. Simulations and results

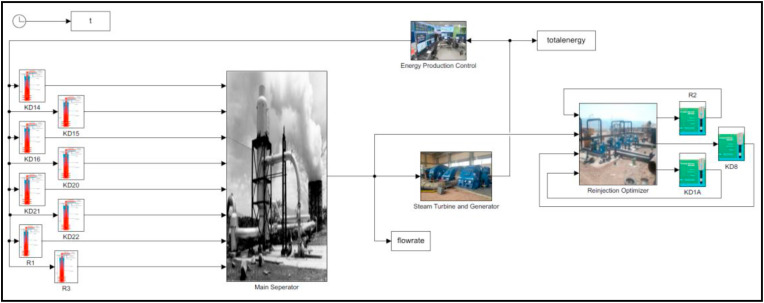

In this study, a simulation model of a geothermal field was revealed using Matlab/Simulink. Simulink is a visual programming environment based on Matlab for the modeling, simulation and study of dynamic systems in a multi-domain. The model contains blocks, signals and notes on a background.

The simulation consists of three main parts: geothermal fluid production, water-steam separation and reinjection of brine and based on controlling of flow rates at production and reinjection wells in a geothermal field (Fig. 11 ). The production and reinjection available data of Kızıldere-I GPP between March 2010 and March 2012 were taken as a basis for the high realism of the simulation. This data range was chosen because it is within the timeframe during which effective re-injection was realized in the Kızıldere geothermal field.

Fig. 11.

The Matlab-Simulink block diagram of Kızıldere-I geothermal power system.

5.1. Simulation Scenario-I for controlling flow rates at production and reinjection wells

5.1.1. Definition

Based on the selected simulation scenario, the total energy production was increased from 10.70 MWe to 15 MWe, the maximum energy production, and then reduced to 13 MWe after 12 h in geothermal power due to reasons such as operational problems in production wells or decreasing energy prices following a few hours in the Turkish energy market. The system had eight production and three re-injection wells to provide 15 MWe net output between 2010 and 2012. The initial flow rates of the production and re-injection wells in the scenario is presented in Table 3 and Table 4 .

Table 3.

Initial flow rates of the production wells in the simulation scenario.

| Production Wells | Initial Flow Rate (tph) |

|---|---|

| KD14 | 141 |

| KD15 | 100 |

| KD16 | 166 |

| KD20 | 101 |

| KD21 | 101 |

| KD22 | 91 |

| R1 | 131 |

| R3 | 131 |

Table 4.

Initial flow rate of the reinjection wells in the simulation scenario.

| Reinjection Wells | Initial Flow Rate (tph) |

|---|---|

| KD1A | 237 |

| KD8 | 237 |

| R2 | 295 |

5.1.2. Results

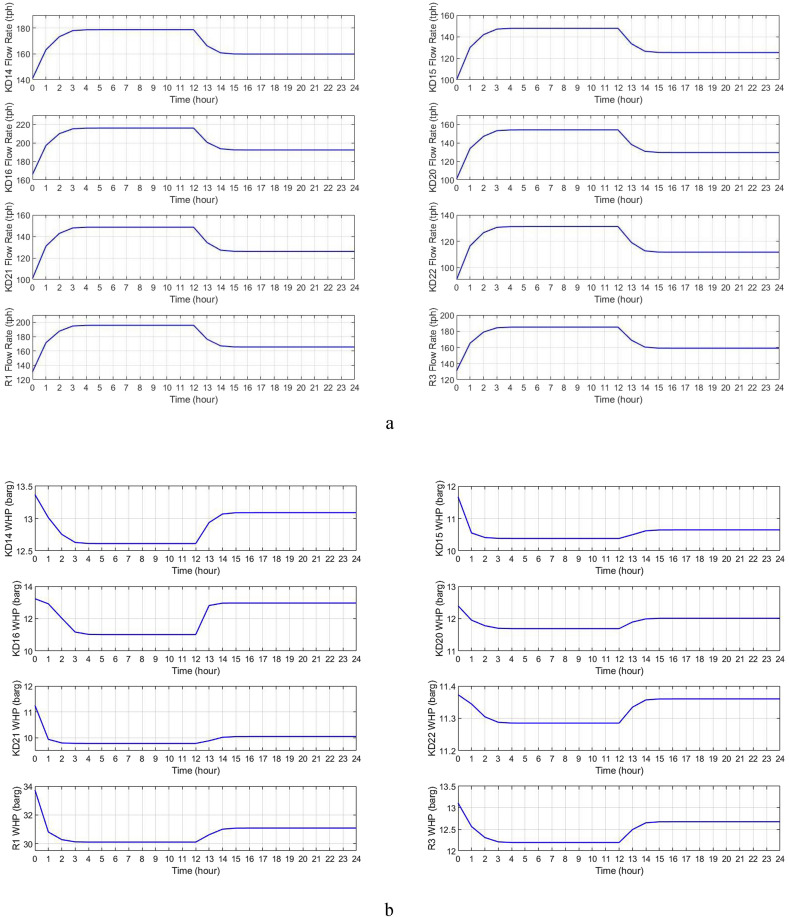

The model of the Kızıldere-I GPP was implemented and a simulation performed with the Matlab Simulink. The results are shown in Fig. 12, Fig. 13, Fig. 14 .

Fig. 12.

a Total energy production results versus time. b. Total flow rates results versus time.

Fig. 13.

a. Based on the energy production scenario, flow rate changes at each production well. b Based on the energy production scenario, well head (WHP) versus time at each production well.

Fig. 14.

a Based on the energy production scenario, flow rate changes at each reinjection wells. b Based on the energy production scenario, wellhead pressure (WHP) changes at each reinjection well.

In the first part of the simulation scenario, while the total flow is 961 tph and the energy produced is 10.70 MWe, the plant operator ordered that the load be increased to 15 MWenet capacity (Fig. 12a). The fuzzy controllers of the production wells indicated that the flow rate amounts should be increased using the steam flow rate and required energy production as an input in an attempt to maintain total energy production at 15 MWe (Fig. 12b). Based on the simulation, at the end of the 3 h, the total production flow rate increased to 1357 tph, and energy production reached the 15 MWe. The flow variation in each production well is observed in Fig. 12a; a decrease in the wellhead pressures with an increase in the flow in the production wells can be observed in Fig. 12b, as expected.

At the same time, together with an increase in the total flow rate at the production wells, the amount of fluid to be sent to the reinjection wells also increased. In accordance with this increase, fuzzy controllers of reinjection wells controlled the wellhead pressures of each well and calculated the instantaneous well reinjection flows, enforcing them to the system, as in Fig. 13a. In Fig. 13b, parallel to the increase in the amount of brine, the change in reinjection wellhead pressures can be observed. The wellhead pressure in each reinjection well increased within the determined limits and became stable after 3 h. Until the second order, the system was in a steady state.

In the second part of the simulation scenario, the load was decreased from 15MWe to 13 MWe after 12 h for specific operational reasons. The fuzzy controllers of the production and reinjection wells indicated that the flow rates should be decreased, as they were supposed to be based on the simulation. After 2 h, total energy production decreased to 13 MWe, and total production flow decreased to 1170 tph (Fig. 12a and b). Based on the simulation results, when the production flow rates increased, the wellhead pressures of the production wells decreased, while the re-injection wellhead pressures increased. The flow variation in each production well can be observed in Fig. 13a. As the flow in the production wells is reduced, wellhead pressures also increased, as expected (Fig. 13b).

In parallel with the reduction of flow in production wells, the amount of fluid to be sent to reinjection wells was reduced. Accordingly, fuzzy controllers of reinjection wells controlled the wellhead pressures of each well, calculating instantaneous well reinjection flows and enforcing them to the system, as in Fig. 14a. In Fig. 14b, changed wellhead pressure of reinjection wells are shown in Fig. 14b. The wellhead pressure in each reinjection well decreased within the determined limits and became stable after a certain period of time.

The performance of the controller was sufficient and satisfied the operational requirements. In particular, it provided more effective flow rate control than conventional techniques, while also helping reduce the response time to flow rate changes in the production wells for energy production rates.

5.2. Simulation Scenario-II

5.2.1. Definition

Scenario II was created to compare the performances of fuzzy controllers developed within the scope of this study with the operating decisions realized at the Kızıldere geothermal power plant.

Based on the existing operational data, the total energy production was increased from 12.26 MWe to 14.30 MWe. The initial flow rates of the production and re-injection wells in the scenario presented are Table 5, Table 6 .

Table 5.

Initial flow rates of the production wells in the simulation scenario.

| Production Wells | Initial Flow Rate (tph) |

|---|---|

| KD14 | 101 |

| KD15 | 99 |

| KD16 | 189 |

| KD20 | 102 |

| KD21 | 102 |

| KD22 | 100 |

| R1 | 206 |

| R3 | 203 |

Table 6.

Initial flow rate of the reinjection wells in the simulation scenario.

| Reinjection Wells | Initial Flow Rate (tph) |

|---|---|

| KD1A | 371 |

| KD8 | 92 |

| R2 | 536 |

5.2.2. Results of Scenario-II

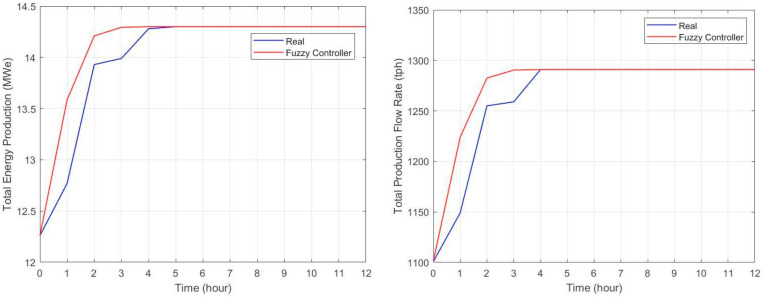

The results are shown in Fig. 15, Fig. 16, Fig. 17 .

Fig. 15.

a Total energy production results versus time. b Total flow rates results versus time.

Fig. 16.

a Based on the energy production scenario, flow rate changes at each production well. b Based on the energy production scenario, wellhead pressure (WHP) versus time at each production well.

Fig. 17.

a Based on the energy production scenario, flow rate changes at each reinjection wells. b Based on the energy production scenario, wellhead pressure (WHP) changes at each reinjection well.

According to the real data taken from the power plant, the energy production increased from 12.26 MWe to 14.30 MWe (Fig. 15a) while the total flow increased from 1101 tph to 1291 tph, as shown by the blue line in Fig. 15a.

Based on the real data, as seen in Fig. 15a, the realization of this increase takes 5 h in the power plant. The total flow value required for the same initial energy production conditions and the flow rate values of each production well calculated by the fuzzy controllers are shown by the red line in Fig. 15, Fig. 16a. Based on the model, the energy production increased to 13.6 MWe at the end of the first hour and to 14.25 MWe at the end of the second hour with fuzzy controllers. After 3 h, the energy production stabilized at 14.30 MWe and is shown by the red line at Fig. 15a. The results of Scenario II show that the fuzzy controllers achieved the targeted energy production in a shorter period of time compared to the real data taken from the power plant, and at the same time, the production wells performed efficiently considering the steam production flow rates.

In the real data taken from the power plant, the flow rate changes of the production wells were analyzed while increasing the energy production in the power plant, and the flow rate change was not preferred in some wells, such as KD-20, 22, 15, R3. In addition, it was detected that changes in the KD14, KD16, and KD21 production wells were made by increasing and decreasing the flow rates by the trial-and-error method (Fig. 16a). This approach is likely to be the result of a desire not to risk low-pressure wells in the field. However, the required energy increase can be achieved by increasing the flow rates in all production wells by the fuzzy controllers that control the flow of each production well and provide flow stability.

The increase in the flow in the production wells through fuzzy controllers can be seen in red in Fig. 16a. The effect of trial and error on the increase of flow rates in the real data is also observed in WHP; rapid pressure drops may endanger in the production wells (Fig. 16b).

In conjunction with the increase in flow in the production wells, the amount of fluid to be sent to reinjection wells has increased in both the real data and the fuzzy controller. Accordingly, the fuzzy controllers of the reinjection wells control the wellhead pressures of each well to adjust the flow rates. After calculating instantaneous the flow rates and applying them to the system, as in Fig. 17a, it was decided how much brine would be sent to which wells using the WHP values of the reinjection wells. In this way, increasing the WHPs of the reinjection wells was prevented, providing uninterrupted reinjection application in the field. In the real data, as with the increase in the flow rates of production wells, the increase of the reinjection flow rate was realized by trial and error. For example, according to the real data, the flow of the R2 reinjection well was increased to 640 tph after 2 h. After the reinjection at this flow for one more hour, the flow rate had to be reduced after the third hour because the WHP value increased above the determined limit value for this well. In order to realize this flow reduction in well R2, the flow rate of the KD-8 well had to be increased. In real data, reinjection was only able to stabilize at the end of the fourth hour (Fig. 17a and b) and the stabilization of the reinjection application took only 2 h using the fuzzy controller.

6. Conclusion

Sustainability is essential for continuous energy production in geothermal power plants. Unlike other renewable power plants, energy production depends on the reservoir management and power plant management at geothermal power plants. The reservoir management has a close relationship with production and reinjection strategies and the long-term full capacity energy production directly related to optimization and management of the wells in a geothermal system. Geothermal reservoirs are so sensitive to different production and reinjection strategies and geothermal well characterization can be changed with these strategies in a geothermal system. At the same time, all geothermal wells need to maintenance and it is no easy to predict the maintenance with the existing technology most of geothermal power plants. In addition to the reservoir and the well management, day-ahead electricity markets may also encourage the energy companies to increase or reduce the energy production hourly or daily period. However, changing the flow rates of production and reinjection wells by considering all environments, thermodynamic conditions can be a complicated and slow process and it may negatively affect to flow production in some geothermal production wells. For these reasons, a new expert system approach such as fuzzy control can help geothermal well management realize effective energy production.

In the study, a fuzzy control system was developed to control flow rates of the production, especially to determine the total energy production and reinjection wells in a geothermal field. A model of the Kızıldere-I GPP was implemented using available data on the production and reinjection wells from March 2010 to March 2012. A total of 8 fuzzy flow rate controllers for each production well and 3 fuzzy flow rate controllers for each re-injection well were designed. The simulation was performed in a scope of a real world scenario with the Matlab Simulink. The performance of the controllers was sufficiently good, satisfying the operational requirements of a geothermal power plant. These controllers provided more effective flow rate control and the reduced response time of changing total energy production in a day. The results of scenario-II show that the fuzzy controllers achieved the target energy production in a shorter period of time, in 2 h instead of 5 h, compared to the real data taken from the power plant.

In the real power plant data, the flow rate changes of the production wells were analyzed while increasing the energy production, and it was observed that the flow rate change was not preferred in some wells because of possible critical production problems in these wells. Flow rate adjustment of some the production wells was also seen to be made by the trial-and-error method to prevent rapid pressure-drop effects in the wells. However, it is understood that the required energy increase can be achieved by increasing the flow rates in all production wells by the fuzzy controllers that control the flow of each production well and provide flow stability.

One other important result from the reinjection part is that based on the real data, the reinjection was only able to stabilize at the end of the fourth hour and the stabilization of reinjection application took only 2 h when using the fuzzy controllers.

Credit author statement

The paper has one author. All contribution has been provided by Fusun Servin Tut Haklıdır.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

The author is grateful thank to Mr. Mehmet Haklıdır for sharing his experiences on fuzzy control approach techniques who works as a Chief Researcher in TÜBİTAK-BİLGEM and to Mr. Ali Kındap who is the General Manager in one of the significant energy investors at Zorlu Energy Company who always supports geothermal energy based scientific studies in Turkish geothermal industry.

Footnotes

Supplementary data to this article can be found online at https://doi.org/10.1016/j.energy.2020.118817.

Appendix A. Supplementary data

The following is the Supplementary data to this article:

References

- 1.Lund J., Chicson A. Proceedings European geothermal congress, unterhaching, Germany, 30 may-1 june. 2007. Examples of combined heat and power plants using geothermal energy. [Google Scholar]

- 2.Wang J., Ren C., Gao Y., Chen H., Dong J. Energy Conversion and Management; 2020. Performance investigation of a new geothermal combined cooling, heating and power system; p. 208. [Google Scholar]

- 3.Akrami E., Chitsaz A., Ghamari P., Mahmodi S.M.S. Energy and exergy evaluation of a tri-generation system driven by the geothermal energy. J Mech Sci Technol. 2017;31(1):401–408. [Google Scholar]

- 4.Gholizadeh T., Vajdi M., Rostamzadeh H. A new trigeneration system for power, cooling, and freshwater production driven by a flash-binary geothermal heat source. Renew Energy. 2020;148:31–43. [Google Scholar]

- 5.Siddiqui O., Dinçer I. Energy and exergy analyses of a geothermal-based integrated system for trigeneration. In: Dincer Ibrahim, Ozgur Colpan C., editors. Onder kizilkan exergetic, energetic and environmental dimensions. Academic Press; 2018. pp. 213–231. [Google Scholar]

- 6.Karlsdottir M.R., Heinonen J., Palsson H., Palsson O.P. Geothermics Life cycle assessment of a geothermal combined heat and power plant based on high temperature utilization. Geothermics. 2020;84 [Google Scholar]

- 7.IRENA . 2017. Geothermal power technology brief. September 2017 report. [Google Scholar]

- 8.Tut Haklıdır F.S., Baytar K., Kekevi M. Global CO2 capture and storage methods and new approach to reduce the emissions of geothermal power plants with high CO2 emissions: a case study from Turkey. In: Qudrat-Ullah Hasan, Kayal Aymen A., editors. Climate change and energy dynamics in the Middle East. Springer; 2019. pp. 323–360. [Google Scholar]

- 9.Tut Haklıdır F.S., Haklidir M. Prediction of geothermal originated boron contamination by deep learning approach: at Western Anatolia Geothermal Systems in Turkey. Environmental Earth Sciences. 2020;79:180. [Google Scholar]

- 10.Tut Haklıdır F.S., Balaban Özen T. A review of mineral precipitation and effective scale inhibition methods at geothermal power plants in West Anatolia (Turkey) Geothermics. 2019;80:103–118. [Google Scholar]

- 11.Jehnejohn D. Geothermal Energy Association; Washington, USA: 2009. Research and development in geothermal exploration and drilling, report. [Google Scholar]

- 12.Tut Haklıdır F.S., Haklıdır M. Proceedings, 43rd workshop on geothermal reservoir engineering stanford university. 2019. The fluid temperature prediction with hydro-geochemical indicators using a deep learning model: a case study Western Anatolia (Turkey) CA, February 11–13. [Google Scholar]

- 13.Tut Haklıdır F.S., Haklıdır M. Natural Resources Research; 2019. Prediction of reservoir temperatures using hydrogeochemical data, Western Anatolia Geothermal Systems (Turkey): a machine learning approach. [Google Scholar]

- 14.Nedungadi A. A fuzzy robot controller-hardware implementation. [1992 Proceedings] IEEE International Conference on Fuzzy Systems. 1992. pp. 1325–1331. San Diego, CA, USA. [DOI] [Google Scholar]

- 15.Tut Haklıdır F.S., Şengün R., Uzun A., Kılınçrslan S. Proceedings of world geothermal congress, melbourne-Australia, 19-24 april 2015. 2015. The importance of processing geothermal fluids for sustainability of geothermal power plants: with Kızıldere (Turkey) geothermal field case. [Google Scholar]

- 16.Zadeh L.A. Fuzzy sets. Inf Control. 1965;8(3):338–353. [Google Scholar]

- 17.Dombi J., Hussain A. A new approach to fuzzy control using the distending function. J Process Contr. 2020;86:16–29. [Google Scholar]

- 18.Akın S., Kok M.V., Uraz I. Optimization of well placement geothermal reservoirs using artificial intelligence. Comput Geosci. 2010;36:776–785. [Google Scholar]

- 19.Li Y., Júlíusson E., Pálsson H., Stefánsson H., Valfells Machine learning for creation of generalized lumped parameter tank models of low temperature geothermal reservoir systems. Geothermics. 2017;70:62–84. [Google Scholar]

- 20.Porkhial S., Salehpour M., Ashraf H., Jamali A. Modeling and prediction of geothermal reservoir temperature behavior using evolutionary design of neural networks. Geothermics. 2015;53:320–327. [Google Scholar]

- 21.Khosravi A., Syri S., Zhao X., Assad M.E.H. An artifical intelligence approach for thermodynamic modeling of geothermal based-organic Rankine cycle equipped with solar system. Geothermics. 2019;80:138–154. [Google Scholar]

- 22.Sadeghi B., Khalajmasocmi M. A futuristic review for evaluation of geothermal potentials using fuzzy logic and binary index overlay in GIS environment. Renew Sustain Energy Rev. 2015;43:818–831. [Google Scholar]

- 23.Şahin Şencan A., Yazıcı H. Thermodynamic evaluation of the Afyon geothermal district heating system by using neural network and neuro-fuzzy. J Volcanol Geoth Res. 2012;233–234:65–71. [Google Scholar]

- 24.Tut Haklıdır F.S., Haklıdır M. Fuzzy control of calcium carbonate and silica scales in geothermal systems. Geothermics. 2017;70:230–238. [Google Scholar]

- 25.Mamdani E.H., Assilian S. An experiment in linguistic synthesis with a fuzzy logic controller. Int J Man Mach Stud. 1975;7(1):1–13. [Google Scholar]

- 26.Rybach L. Geothermal energy: sustainability and the environment. Geothermics. 2003;32:463–470. [Google Scholar]

- 27.Aydın H., Akın S. Proceedings, 44th workshop on geothermal reservoir engineering, stanford university, CA, february 11-13. 2019. Discrete fracture network modeling of Alaşehir geothermal field. [Google Scholar]

- 28.Ungemach P., Antics M., Papachristou M. Proceedings world geothermal congress, antalya-Turkey, 24-29 april. 2005. Sustainable reservoir management. [Google Scholar]

- 29.Tut Haklıdır F.S., Şengün R. Proceedings, 41th workshop on geothermal reservoir engineering stanford university, CA, february 24-26. 2016. Thermodynamic effects on scale inhibitor performance at multi-flash and advanced geothermal power systems. [Google Scholar]

- 30.Ciriaco A.E., Zarrouk S.J., Zakeri G. Geothermal resource and reserve assessment methodology: overview, analysis and future directions. Renew Sustain Energy Rev. 2020;119 [Google Scholar]

- 31.Kaya E., Zarrouk S.J. Reinjection of greenhouse gases into geo-thermal reservoirs. Int J. Greenhouse Gas Control. 2017;67:111–129. [Google Scholar]

- 32.Akın S., Orucu Y., Fridriksson T. 45th workshop on geothermal reservoir engineering stanford university, CA, february 10-12. 2020. Characterizing the declining CO2 emissions from Turkish geothermal power plants. [Google Scholar]

- 33.Manente G., Lazzaretto A., Bardi A., Paci M. Geothermal power plant layouts with water absorption and reinjection of H2S and CO2 in fields with a high content of non-condensable gases. Geothermics. 2019;78:70–84. [Google Scholar]

- 34.Akın S., Uraz I. Proceedings, 28th workshop on geothermal reservoir engineering stanford university, CA, january. 2003. Optimization of reinjection in geothermal reservoirs; pp. 27–29. [Google Scholar]

- 35.Islam J., Vasant P.M., Negash B.M., Laruccia M.B., Myint M., Watada J. A holistic review on artificial intelligence techniques for well placement optimization problem. Adv Eng Software. 2020:141. [Google Scholar]

- 36.Zarrouk S., Mclein K. Academic Press; 2019. Operation and management of geothermal wells. Geothermal well test analysis; pp. 217–255. [Google Scholar]

- 37.DiPippo R. fourth ed. Butterworth-Heinemann; Waltham, MA: 2016. Geothermal power plants: principles, applications, case studies and environmental impact. [Google Scholar]

- 38.Sinkar Y., Ojha A., Shah M., Shah R. A review on corrosion of steam turbine. International Journal of Advance Engineering and Research Development. 2017;4(3):455–461. [Google Scholar]

- 39.Özkaraca Ö., Keçebaş A. Performance analysis and optimization for maximum exergy efficiency of a geothermal power plant using gravitational search algorithm. Energy Convers Manag. 2019;185:155–168. [Google Scholar]

- 40.Clarke J., Mcleskay James T. Multi-objective particle swarm optimization of binary geothermal power plants. Appl Energy. 2015;138:302–314. [Google Scholar]

- 41.Promata F., Reyseliani N., Syauqi A., Daud Y., Purwanto W.W., Wulan P.P.D.K., Hidayatno A. Thermoeconomic assessment and optimization of wells to flash–binary cycle T using pure R601 and zeotropic mixtures in the Sibayak geothermal field. Geothermics. 2020;85 [Google Scholar]

- 42.Ghasemi H., Paci M., Tizzanini A., Mitsos A. Modeling and optimization of a binary geothermal power plant. Energy. 2013;50:412–428. [Google Scholar]

- 43.Tut Haklıdır F.S. Proceedings, Turkey geothermal conference; GT’2020. JESDER, 05-06.02.2020. 2020. Intelligent Geothermal Power Plants: an introduction to the new generation power plants. [Ankara-Turkey (Turkish)] [Google Scholar]

- 44.Jakel J., Mikut R., Bretthauer G. In: Fuzzy control systems. Control systems, robotics and automation. Heinz Unbehauen v., editor. Encyclopedia of Life Support System(UNESCO); Singapore: 2019. pp. 1–36. 17. [Google Scholar]

- 45.Holmblad L.P., Ostergaard J. Control of a cement kiln by fuzzy logic. In: Gupta M.M., Sanchez E., editors. Fuzzy information and decision processes. 1982. pp. 389–399. [North-Holland] [Google Scholar]

- 46.Yasunobu S., Hasegava T. Evaluation of an automatic container crane operation system based on predictive fuzzy control. Contr Theor Adv Technol. 1986;2:419–432. [Google Scholar]

- 47.Babuska R., Mamdani E. Fuzzy control. Scholarpedia. 2008;3(2):2103. [Google Scholar]

- 48.Carvalho W.C., Bataglioli R.P., Fernandes R.A.S., Coury D.V. Fuzzy-based approach for power smooting of a full-converter wind turbine generator using supercapacitor energy storage. Elec Power Syst Res. 2020:184. [Google Scholar]

- 49.Jahangiri M., Shamsabadi A.A., Mostafaeipour A., Rezaei M., Yousefi Y., Pomares L.M. Using fuzzy MCDM technique to find the best location in Qatar for exploiting wind and solar energy to generate hydrogen and electricity. Int J Hydrogen Energy. 2020 (in press) [Google Scholar]

- 50.Mahela O.P., Shaik A.G. Power quality recognition in distribution system with solar energy penetration using S-transform and Fuzzy C-means clustering. Renew Energy. 2017;106:37–51. [Google Scholar]

- 51.Rani P., Mishra A.R., Mardani A., Cavallaro F., Alfrasheedi M., Alrashidi A. J Clean Prod. 2020;257 [Google Scholar]

- 52.Çolak M., Kaya I. Multi-criteria evaluation of energy storage technologies based on hesitant fuzzy information: a case study for Turkey. Journal of Energy Storage. 2020;28 [Google Scholar]

- 53.Farghally H.M., Atia D.M., El-madany H.T., Fahmy F.H. Fuzzy logic controller based on geothermal recirculating aquaculture system. The Egyptian Journal of Aquatic Research. 2014;40(2):103–109. [Google Scholar]

- 54.Sencan Sahin A., Yazıcı H. Thermodynamic evaluation of the Afyon geothermal district heating system by using neural networks and neuro-fuzzy. J Volcanol Geoth Res. 2012;233–234:65–71. [Google Scholar]

- 55.Akın S., Güney A., Şentürk E., Şengün R., Kılınçaslan S. Proceeding, 41st workshop on geothermal reservoir engineering stanford university, CA, february 22-24. 2016. Tracer testing at kizildere geothermal field, Turkey, using naphtalene sulfonates. [Google Scholar]

- 56.Haklidir M., Tasdelen I. Modeling, simulation and fuzzy control of an anthropomorphic robot arm by using Dymola. J Intell Manuf. 2009;20(2):177–186. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.