Abstract

The COVID-19 pandemic unveils unforeseen and unprecedented fragilities in supply chains (SC). A primary stressor of SCs and their subsequent shocks derives from disruption propagation (i.e., the ripple effect) through related networks. In this paper, we conceptualize current state and future research directions on the ripple effect for pandemic context. We scrutinize the existing OR (Operational Research) studies published in international journals dealing with disruption propagation and structural dynamics in SCs. Our study pursues two major contributions in relation to two research questions. First, we collate state-of-the-art research on disruption propagation in SCs and identify a methodical taxonomy along with theories displaying their value and applications for coping with the impacts of pandemics on SCs. Second, we reveal and systemize managerial insights from theory used for operating (adapting) amid a pandemic and during times of recovery, along with becoming more resistant to future pandemics. Streamlining the literature allowed us to reveal several new research tensions and novel categorizations and classifications. The outcomes of our study show that methodical contributions and the resulting managerial insights can be categorized into three levels, i.e., network, process, and control. Our analysis reveals that adaptation capabilities play the most crucial role in managing the SCs under pandemic disruptions. Our findings depict how the existing OR methods can help coping with the ripple effect at five pandemic stages (i.e., Anticipation; Early Detection; Containment; Control and Mitigation; and Elimination) following the WHO classification. The outcomes and findings of our study can be used by industry and researchers alike to progress the decision-support systems guiding SCs amid the COVID-19 pandemic and toward recovery. Suggestions for future research directions are offered and discussed.

Keywords: supply chain, ripple effect, COVID-19, Pandemic, Disruption propagation, Structural dynamics

1. Introduction

COVID-19 was first reported in late 2019 in Wuhan, China. By September 15, 2020, over 29 million people were infected and approximately 927,000 people had died. The COVID-19 pandemic has created significant uncertainty in all areas of life, supply chains (SC) in particular. SCs experience unprecedented vulnerabilities in lead times and order quantities, disruptions in network structures, and severe demand fluctuations. Furthermore, many of these vulnerabilities are encountered simultaneously. Of the Fortune 1000 companies, 94% have reported coronavirus-driven SC disruptions (Fortune, 2020). A recent survey by ISM of about 600 US companies revealed that in mid-April 2020, average lead times were at least twice as long as compared to "normal" operations, for Asian (222% for China, 217% for Korea, and 209% for Japan), European (201%) and domestically sourced inputs (200%) (ISM 2020). The same report says that Chinese and European manufacturing is at about one-half normal capacity, 53% and 50% respectively.

While management of SC disruptions (i.e., unexpected events with severe negative impacts such as tsunamis, fires, or strikes) has grown to a mature research topic for the last two decades (Sawik, 2020), the COVID-19 pandemic is viewed as a new type of disruption quite unlike any seen before (Ivanov and Das, 2020). The outbreak of COVID-19 and the associated global pandemic has clearly shown the key role of SCs in securely providing goods and services to society. The pandemic became a test for SCs regarding their robustness (i.e., the ability to withstand), flexibility (i.e., the ability to adapt), and recovery (i.e., the ability to restore operations and performance after a disruption) pointing to the central role of resilience in managing the SCs in this volatile world (Peck, 2005; Ponomarov and Holcomb, 2009; Pettit et al., 2010, Brandon-Jones et al. 2014, Ivanov, 2018, Wood et al., 2019). A number of resilience-related questions have arose throughout the COVID-19 pandemic; e.g., are local SCs more resilient than global ones? Are SCs with lean principles (i.e., Just-in-Time and single sourcing) less resilient as firms with high cycle and safety inventory? Can traditional resilience assets (e.g., risk inventory, capacity buffers, backup suppliers) help during times of pandemic? Are SCs with advanced digital twins and visibility and analytics technologies more resilient? Will resilience be prized over efficiency in the post-pandemic world (i.e., should we expect a paradigm shift away from "design-for-efficiency" toward "design-for- resilience"?

The COVID-19 pandemic has shed light on one specific aspect of network resilience, i.e., the scope and scale of the observed ripple effect of disruption propagation within global SCs (Ivanov et al., 2014a; Dolgui et al., 2018). In several contexts, disruptions can be localized without a subsequent cascading throughout a network. However, in other situations upstream disruptions propagating downstream from SCs adversely impact the performance of individual firms and networks. According to Dolgui et al. (2020), the ripple effect “refers to structural dynamics and describes a downstream propagation of the downscaling in demand fulfilment in the supply chain as a result of a severe disruption.” Ivanov et al. (2014b) state that the “Ripple effect describes the impact of a disruption on supply chain performance and disruption-based scope of changes in the supply chain structures and parameters.” These definitions imply that the ripple effect refers to multi-stage networks and triggering failures in the network elements as a domino effect. Between 2010 and 2014, studies first appeared in the area of the ripple effect, along with an increased interest in disruption propagation and correlated disruptions (Liberatore et al., 2012; Mizgier et al., 2013; Chatfield et al., 2013; Ghadge et al., 2013; Ivanov et al., 2014a). The first explicit definition of the ripple effect has been undertaken by Ivanov et al. (2014b) as indicated above. Thus far, much progress has been made in the area deploying different methodologies and obtaining relevant managerial outcomes and recommendations (Swierczek, 2014; Chaudhuri et al., 2016; Scheibe and Blackhurst, 2018).

The COVID-19 pandemic has caused numerous ripple effects. Haren and Simchi-Levi (2020) observed two examples of a ripple effect triggered by COVID-19 immediately after the epidemic outbreak. Fiat Chrysler Automobiles NV halted production at a car factory in Serbia in response to being unable to receive parts from China. As Hyundai stated, it had “decided to suspend its production lines from operating at its plants in Korea … due to disruptions in the supply of parts resulting from the coronavirus outbreak in China.” While these observations were made in the second half of February 2020, the scaling of the ripple effects between March and May 2020 has been exponential, driven by the closures of manufacturing facilities, stores, and logistics activities, and adversely affecting almost all industries and services worldwide (Choi et al., 2020; Choi, 2020; Ivanov 2020a,b; Ni et al., 2020). The World Economic Forum - WEF (2020) emphasized the need for firms and organizations to adapt their SCs amid the COVID-19 pandemic and in light of future trade challenges. In its totality, the COVID-19 pandemic wreaks havoc on SCs and thus poses a number of novel decision-making context for SC professionals and questions for researchers that are relevant amid the pandemic, as well as the course of future economic recoveries.

The motivation for our study stems from the current unprecedented situation, along with the significant impacts of the pandemic on SCs, which necessitates a rapid response to questions around the ripple effect and what methods and insights can be used to assist SC managers within this new environment. Over the last decades, an enormous array of methods and tools has been developed, which can be applied to decision-making support under uncertainty (Silbermayr and Minner, 2014; Demirel et al., 2019; Li and Zobel, 2020). We refer to comprehensive surveys on these operational and disruption risks (Klibi et al., 2010; Snyder et al., 2016; Shen and Li, 2017; Hosseini et al., 2019a,b; Ghadge et al., 2019; Yu et al., 2019; Essuman et al., 2020). Similar literature on epidemics and humanitarian disasters in the context of SCs and logistics presents a body of promising methods and outcomes (Altay and Green, 2006; Dasaklis et al., 2012; Gupta et al., 2016; Dubey et al., 2019b; Fosso Wamba, 2020).

Our study is devoted to one dominant stressor of SCs during a pandemic in particular: disruption propagation throughout networks (i.e., the ripple effect) and the subsequent changes within SC structures (i.e., structural dynamics). Adversely, SC disruptions are stimulated by simultaneous disruptions and uncertainties in supply and demand. The existing knowledge on structural dynamics and SC ripple effect modeling is multi-faceted and deserves to be analyzed due to the unique set of factors shaping SC adaptations during a global pandemic. Dolgui et al. (2018) and Mishra et al. (2019) reviewed progress in ripple effect research over previous years, primarily focusing on classifications of the aspects of resilience and risk type categorization. However, there is no published survey comprehensively encompassing disruption propagation in SCs and the resulting structural dynamics from the point-of-view of OR (Operational Research) methodology.

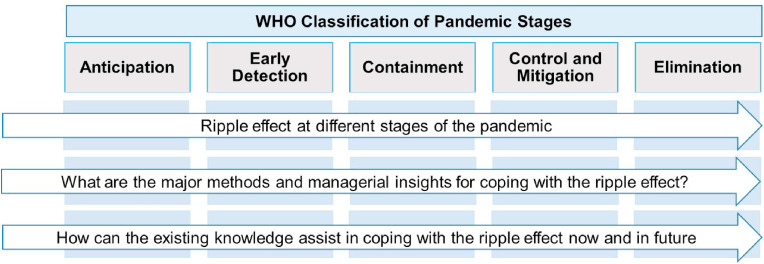

Our study thus pursues two contributions (Fig. 1 ). First, we collate state-of-the-art research on the SC ripple effect and structural dynamics, and identify a methodical taxonomy and theories representing the value and application of quantitative methods for coping with the pandemic impact on SCs. Second, we reveal and systemize managerial insights from this theory that can be applied to recovering from COVID-19, as well as withstanding future pandemics.

Fig. 1.

Organization of our study.

We scrutinize 40 quantitative studies published in 15 international journals (cf. Appendix 1) dealing with disruption propagation and structural dynamics in SCs. Streamlining the literature allowed us to uncover several new research tensions and novel categorizations and classifications. To this end, our study aims to address two central research questions (RQ):

RQ1

How does the literature address issues related to the ripple effect and structural dynamics in SCs in terms of methodologies, problem settings, outcomes and managerial insights?

RQ2

How can the existing knowledge be used to support SC managers in adapting supply networks amid the COVID-19 pandemic, and what are the potential future research opportunities?

In particular, we find that outcomes of quantitative modeling contributions and the resulting managerial insights can be categorized into three levels: network, process, and control. Our outcomes in both managerial and theoretical domains are structured into five stages (i.e., Anticipation, Early Detection, Containment, Control and Mitigation, and Elimination) following the WHO classification. Our study can be used by industry and researchers alike to progress the decision-support systems guiding SCs amid the COVID-19 pandemic and thus recovering them thereafter. Suggestions for future research directions are offered and discussed.

The remainder of this study is organized as follows: in section 2, we present the methodology of our study. Section 3 is devoted to analysis of OR theories in terms of applications and managerial insights. In Section 4, we organize the discussion around an extrapolation of existing knowledge on pandemic situations. We discuss both managerial implications and future research angles for each pandemic stage and extend by cross-stage perspectives in Section 5. We conclude the paper in Section 6 by summarizing this study.

2. Methodology of our study

The literature for analysis of recent methodical contributions to managing the ripple effect has been selected based on a long-term authors’ work in the area of ripple effect over the last decade and observing the relevant publications along with editing several related special issues in prestigious international journals. This selection was supplemented by a search in the most common academic databases such as Scopus, ScienceDirect (Elsevier), Emeraldinsight (Emerald), Wiley Online Library (Wiley), Taylor & Francis Online (Taylor & Francis), Springer Link (Springer), and Informs PubsOnline, to ensure that a majority of representative studies were included in our analysis according to the following protocol:

(supply AND chain AND disruption) AND (ripple OR cascade OR cascading OR propagation OR (correlated AND disruption) OR (structural AND dynamics) OR transmission).

The keywords have been selected based on our expert analysis of the definitions associated with the disruption propagation effects in SCs used in the extant literature.

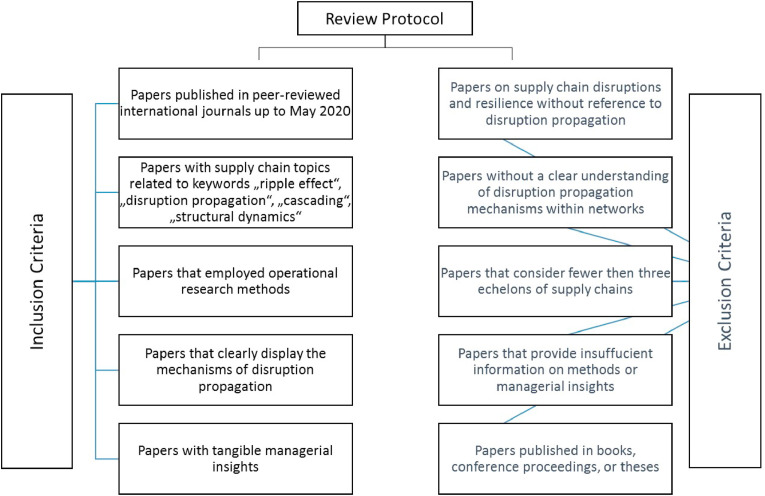

As an outcome of our expert and supplementary automatic search, we obtained a list of 121 journal papers in the areas of operational and supply chain research that has been manually processed and narrowed to meet the scope and scale of our analysis. We do not claim that the literature analyzed in this paper represents a complete collection of all influential contributions; however, we believe it comes close. We emphasize that we do not follow a classical structured literature review scheme, but rather analyze the most representative studies in terms of theoretical tensions and managerial applications. The details of our literature review protocol are given in Fig. 2 .

Fig. 2.

Literature selection criteria.

We followed five major inclusion criteria. The search was performed on April 30, 2020 and the papers published by this date in international peer-reviewed journals have been included. We considered only papers with SC topics related to the keywords "ripple effect," "disruption propagation," "cascading," and "structural dynamics." Moreover, we restricted ourselves to the papers utilizing quantitative modeling methods. For example, empirical studies have not been analyzed to avoid too broad of an analysis scope; in spite of this, we acknowledge the rich contributions to SC risk analysis from the system-wide perspectives obtained with the help of empirical methods (i.e., Pournader et al., 2016; Dubey et al., 2019a, 2020). Further, we considered only papers that clearly display the mechanisms of disruption propagation. In particular, we excluded papers on two-echelon problems since meaningful disruption propagation must be treated in this context using three echelons as a minimal complexity level to study the ripple effect. Obviously, in a two-echelon setting, we can observe a disruption at one echelon and its impact on another echelon. However, a disruption propagation (i.e., if any other entity in a network would be affected) cannot be observed to full extent. For example, if a second tier supplier is disrupted, the tier-1 firm would be affected as well, and the disruption can propagate down to an OEM. In other words, a network for modeling the ripple effect should be large enough to observe where a propagation ends. It might be difficult in a two-stage setting since the ripple effect rarely ends at the next downstream stage. With that said, we acknowledge numerous useful OR results, methods and insights for studying the SC resilience and disruptions on two-echelon (i.e., buyer-supplier) settings which can be of value for ripple effect research (Yildiz et al., 2016; Yoon et al., 2018; Hosseini et al., 2019b; Pournader et al., 2020). Finally, papers without or with insufficient information on managerial insights have not been included.

3. Theories, major outcomes and managerial insights

3.1. Methodical perspectives

Our analysis revealed numerous theories that have been successfully applied to SC issues related to disruption propagation (Table 1 ).

Table 1.

Theories used in the studies on disruption propagation.

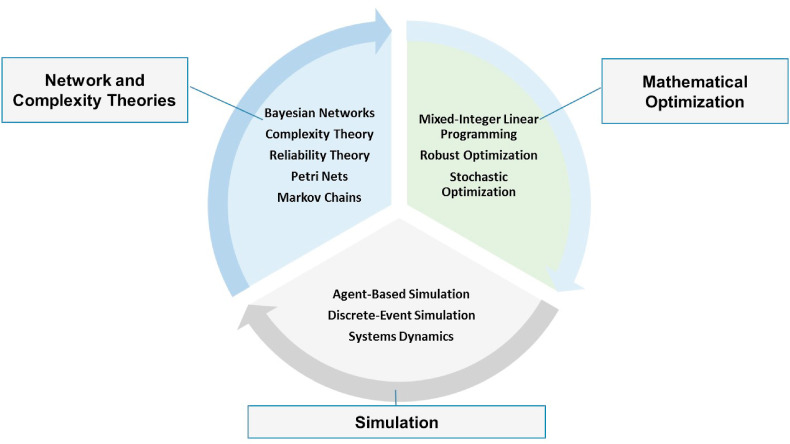

We found applications for the following theories and methods (in alphabetical order): agent-based simulation; Bayesian networks; complexity theory; discrete-event simulation; entropy analysis; graph theory; linear/mixed-integer programming; Markov chains; Monte-Carlo simulation; optimal control; Petri nets; reliability theory; robust optimization; statistical analysis; stochastic optimization; and systems dynamics. The highest number of publications can be seen in mixed-integer and linear programming and Bayesian networks (six papers respectively); optimal control, complexity and graph theories (five papers respectively); and reliability theory and discrete-event simulation (four papers respectively).

When aggregating different methods at a larger scale, the largest number of studies was found in the area of network and complexity theory (24 papers); with regards to mathematical optimization, we observed 11 papers in total; simulation studies count for eight papers, while five papers are related to control theory (Fig. 3 ).

Fig. 3.

Ripple-effect research methodologies.

An analysis of these aggregated categories lead us to a proposition of classifying the existing studies into three levels, i.e., network level, process level, and control level in line with (Ivanov and Dolgui 2019) and echoed by Golan et al. (2020). A similar classification has been used by Peck (2005) who specified an infrastructure level, a process level, and an organizational network level viewing the SC as an interactive adaptive system. Such a classification appeared the most logical and convenient for developing further categorizations of main outcomes, managerial insights, and future research directions.

We now specify the differences between the network, process, and control levels. The major criterion used for differentiation is the scope of the models. The network level models are characterized by a macro view of SC structures and disruption propagation focusing on structural properties and relations. This level operates in terms of networks and graphs from a more generalized perspective of structures and does not consider operational parameters. These parameters are within the scope of the models at the process level, which organize the debate around the parametrized structures required to balance demands, processing capacities, and supply. Typical problems at the process level are related to network design, location-allocation problems, and production-distribution planning in terms of flow optimization. A common feature of these models is their flow-orientation (e.g., aggregate planning). However, these models do not elaborate on details regarding inventory control, production-ordering policies, and routing which are accommodated at the control level. As a difference to the process level, the control models operate in terms of customer orders and at a more granular timing rather than aggregate material flows distributed over some periods.

3.2. Major outcomes and managerial insights

We now draw the reader's attention toward the analysis of major outcomes and managerial insights. A detailed paper-by-paper analysis is offered in Table 2 .

Table 2.

Operational Research studies on the disruption propagations in the SCs.

| Authors and publication year | Title | Journal | Central Focus | Method(s) | Outcomes & Managerial Insight(s) | Analysis level |

|---|---|---|---|---|---|---|

| Basole, R.C. and Bellamy, M.A. (2014) | Supply Network Structure, Visibility, and Risk Diffusion: A Computational Approach | Decision Sciences | Network tendency toward disruption propagation | Graph theory; Complexity theory | Significant association between network structure and risk propagation; small-world supply network topologies consistently outperform supply networks with scale-free characteristics | N |

| Blackhurst, J., Rungtusanatham, M.J., Scheibe, K., Ambulkar, S. (2018) | Supply chain vulnerability assessment: A network based visualization and clustering analysis approach | Journal of Purchasing and Supply Management | Visualization and mapping of disruption propagation | Petri net and Triangularization Clustering Algorithm | Understand potential weaknesses in SC design while taking into account structure, connectivity, and dependence within the SC | N |

| Bueno-Solano, A., Cedillo-Campos, M.G. (2014). | Dynamic impact on global supply chains performance of disruptions propagation produced by terrorist acts | Transportation Research Part E: Logistics and Transportation Review | Understanding disruption propagation through the SC to ensure security and efficient movement of goods | System Dynamics simulation | Measures for disruption propagation can drastically increase inventory levels in the SC | P |

| Cao, S., Bryceson, K., Hine, D. (2019). | An Ontology-based Bayesian network modeling for supply chain risk propagation | Industrial Management and Data Systems | To quantitatively assess the impact of dynamic risk propagation in fresh product SCs | Ontology-based Bayesian network | Supply discontinuity, product inconsistency, and/or delivery delay originating from the ripple effect | N |

| Deng, X., Yang, X., Zhang, Y., Li, Y., Lu, Z. (2019). | Risk propagation mechanisms and risk management strategies for a sustainable perishable products supply chain. | Computers and Industrial Engineering | Identify dimensions of risk propagation SCs with perishable products | Tropos Goal-Risk framework | Three-dimension model to control the ripple effect (paths of risk propagation, dependencies between nodes, modes of risk propagation); sustainability issues connected to ripple effect | N |

| Dolgui A., Ivanov D., Rozhkov M. (2020). | Does the ripple effect influence the bullwhip effect? An integrated analysis of structural and operational dynamics in the supply chain | International Journal of Production Research | To identify relations between the bullwhip effect and ripple effect | Discrete-event simulation | The ripple effect can be a bullwhip-effect driver, while the latter can be launched by a severe disruption even in downstream direction; backlog accumulation over disruption time is the major influencer of the ripple effect on SC performance; SC visibility and information coordination is the key capability to cope with the ripple effect. | C |

| Garvey, M.D., Carnovale, S. (2020) | The Rippled Newsvendor: A New Inventory Framework for Modeling Supply Chain Risk Severity In The Presence of Risk Propagation | International Journal of Production Economics | Inventory control policies with ripple effect considerations | Bayesian Network simulation | Reliability control of inventory policies; managers should focus more attention on control or mitigation of exogenous events that directly impact their own firm, while spending less effort and resources on mitigating the propagation of exogenous risk from a supplier to the exogenous risk of the firm itself. | P |

| Garvey, M.D., Carnovale, S., Yeniyurt, S. | An analytical framework for supply network risk propagation: A Bayesian network approach | European Journal of Operational Research | Inter-dependencies among different risks, as well as the idiosyncrasies of SC structures | Bayesian Network simulation | Measuring disruption propagation in the SC to analyze network vulnerability to ripple effect | N |

| Ghadge, A., Dani, S., Chester, M., & Kalawsky, R. (2013). | A systems thinking approach for modeling supply chain risk propagation | Supply Chain Management: An International Journal | Prediction of potential failure points in an SC and overall impact of failure risks on performance | System Dynamics simulation | Prediction of potential failure points in the SC along with overall impact of ripple effect on performance | P |

| Goldbeck, N., Angeloudis, P., Ochieng, W. (2020) | Optimal supply chain resilience with consideration of failure propagation and repair logistics | Transportation Research Part E: Logistics and Transportation Review | Resilient SC designs with considerations of trade-offs between redundancy costs and disruption-resistance | Scenario tree generation method for risk propagation modeling; Multi-stage stochastic programming model |

Joint optimization of SC capacities and recovery capabilities for new and existing SCs; trade-off between investments in increased recovery capability and redundant capacity provision; decision-making support on safety stock management, reconfiguration of production and inventory plans after disruption, and recovery scheduling | P |

| Han, J., Shin, K.S. (2016) | Evaluation mechanism for structural robustness of supply chain considering disruption propagation | International Journal of Production Research | Structural robustness evaluation | Reliability theory/Probabilistic analysis | To verify whether the SC design is robust to disruption propagation | N |

| Hosseini S., Ivanov D. (2019). | Resilience Assessment of Supply Networks with Disruption Propagation Considerations: A Bayesian Network Approach | Annals of Operations Research | Measuring of the ripple effect with consideration of both disruption and recovery stages | Bayesian Network simulation | To identify the resilience level of their most important suppliers; to identify disruption profiles in the supply base and associated SC performance degradation due to the ripple effect | N |

| Hosseini S., Ivanov D., Dolgui A. (2019). | Ripple effect modeling of supplier disruption: Integrated Markov Chain and Dynamic Bayesian Network Approach | International Journal of Production Research | Measuring of the ripple effect with consideration of state changes within individual SC nodes | Discrete-Time Markov Chain (DTMC) and a Dynamic Bayesian Network (DBN) | A metric that quantifies the ripple effect of supplier disruption on manufacturers in terms of total expected utility and service level; uncovering latent high-risk paths in the SC and prioritizing contingency and recovery policies | N |

| Ivanov D. (2019) | Disruption tails and revival policies: A simulation analysis of supply chain design and production-ordering systems in the recovery and post-disruption periods | Computers and Industrial Engineering | Production-ordering behavior in an FMCG SC with disruption risks during recovery and post-disruption periods | Discrete-event simulation | Non-coordinated ordering and production policies during the disruption period may result in backlog and delayed orders, the accumulation of which causes post-disruption SC instability, resulting in further delivery delays and non-recovery of SC performance; Specific policies must be developed for the transition from recovery to disruption-free operation mode to avoid “disruption tails” |

C |

| Ivanov D. (2020) | Predicting the impact of epidemic outbreaks on the global supply chains: A simulation-based analysis on the example of coronavirus (COVID-19/SARS-CoV-2) case | Transportation Research Part E: Logistics and Transportation Review | Predicting the impact of epidemic outbreaks on global SCs | Discrete-event simulation | Timing of the closing and opening of facilities at different echelons might become a major factor that determines the epidemic outbreak impact on SC performance. Lead-time, speed of epidemic propagation, and the upstream and downstream disruption duration in the SC are other important factors; results can be used to predict the operative and long-term impacts of epidemic outbreaks on SCs, to develop pandemic SC plans, and to identify the successful and problematic elements of risk mitigation/preparedness and recovery policies in case of epidemic outbreaks | C |

| Ivanov D., Sokolov B., Pavlov, A. (2013) | Dual problem formulation and its application to optimal re-design of an integrated production-distribution network with structure dynamics and ripple effect considerations | International Journal of Production Research | Identify an SC design structure that would satisfy some performance criteria under different disruptions | Optimization: linear Programming | Building robust distribution plans and interconnecting decisions on distribution network design, planning, and sourcing. | P |

| Ivanov, D. (2017) | Simulation-based the ripple effect modeling in the supply chain | International Journal of Production Research | Performance impact of disruption propagation in the SC | Discrete-event simulation | Advantages and costs of backup SC designs for mitigating ripple effect | C |

| Ivanov, D., Sokolov B., Kaeschel J. (2010) | A multi-structural framework for adaptive supply chain planning and operations control with structure dynamics considerations | European Journal of Operational Research | SC multi-structural design and dynamic control of macro states | Control theory | SC designs are not restricted to the network of firms; rather, they are multi-structural systems spanning organizational, informational, financial, technological, process-functional, and productive structures | N |

| Ivanov, D., Sokolov, B., & Dolgui, A. (2014b) | The ripple effect in supply chains: Trade-off ‘efficiency-flexibility-resilience’ in disruption management | International Journal of Production Research | Conceptualization of the ripple effect concept in SCs; Dynamic view on SC ripple effect |

Control theory | Disruption propagation represents a specific type of SC risks, i.e., the ripple effect | N |

| Ivanov, D., Sokolov, B., & Pavlov, A. (2014a) | Optimal distribution (re)planning in a centralized multi-stage network under conditions of the ripple effect and structure dynamics | European Journal of Operational Research | Reconfiguration of material flows in an SC subject to changes in network structures over many periods | Optimization: linear programming and optimal control | Considering different execution scenarios and developing suggestions on re-planning in the case of disruption propagation; scenario-based risk identification strategy and operational distribution planning | P |

| Ivanov, D., Sokolov, B., Hartl, R., Dolgui, A., Pavlov, A., Solovyeva, I. (2015) | Integration of aggregate distribution and dynamic transportation planning in a supply chain with capacity disruptions and ripple effect considerations | International Journal of Production Research | Distribution and transportation capacity disruptions and the ripple effect | Optimization: linear programming and optimal control | Dynamic, time-dependent issues of the ripple effect | P |

| Ivanov, D., Sokolov, B., Pavlov, A., Dolgui, A., & Pavlov, D. (2016) | Disruption-driven supply chain (re)-planning and performance impact assessment with consideration of pro-active and recovery policies | Transportation Research Part E: Logistics and Transportation Review | Impact of disruption durations on the ripple effect and SC performance with consideration of recovery costs | Optimization: linear programming and optimal control | A model to analyze proactive SC structures, compute recovery policies, and to re-direct material flows to mitigate the ripple effect; a method to compare SC design resistance to the ripple effect; suggesting rules to recover and reallocate resources and flows after a disruption | P |

| Lei, Z., Lim, MK., Cui L. & Y. Wang (2020) | Modeling of risk transmission and control strategy in the transnational supply chain. | International Journal of Production Research. | Mechanisms of risk transmission in global SCs | Susceptible-infectious-susceptible (SIS) model; complexity theory | Global supplier diversification and risk control are crucial management activities to mitigate the ripple effect | N |

| Levner E., Ptuskin A. (2018) | Entropy-based model for the ripple effect: managing environmental risks in supply chains | International Journal of Production Research | Impact of environmental risks on the ripple effect | Complexity theory; entropy analysis | Assessing the economic loss caused by the ripple effect due to environmental risks | N |

| Li, Y., Zobel, C. W. (2020). | Exploring Supply Chain Network Resilience in the Presence of the Ripple Effect | International Journal of Production Economics | Impact of the ripple effect on SC resilience | Graph theory; simulation | Network type has more influence on resistance to the ripple effect from a short-term perspective; from a long-term perspective, it is more advantageous to enhance node risk capacity as adjusted to the structure; increasing robustness may lead to prolonged recovery time | N |

| Li, Y., Zobel, C. W., Seref, O., and Chatfield, D. C. (2019) | Network Characteristics and Supply Chain Resilience under Conditions of Risk Propagation | International Journal of Production Economics | Impact of network characteristics on SC resilience with disruption propagation considerations | Graph theory | Metrics to analyze impact of the ripple effect on SC resilience; recovery time is primarily determined by the disruption process, and significantly less so by the network structure | N |

| Liberatore F, Scaparra M.P., Daskin M.S. (2012). | Hedging against disruptions with ripple effects in location analysis | Omega | How to fortify SC facilities to hedge against the ripple effect | Optimization: mixed-integer programming | Identification of facilities to be fortified to mitigate the ripple effect | P |

| Lu, M., Ran, L., Shen, Z.-J.M. (2015) | Reliable facility location design under uncertain correlated disruptions | Manufacturing & Service Operations Management | Worst-case analysis of reliable facility location problems with consideration of correlated disruptions | Robust optimization | Reliable SC design with cost minimization for some given disruption probabilities of correlated events | P |

| Mizgier, KJ, SM Wagner, JA Holyst (2013) | Modeling defaults of companies in multi-stage supply chain networks | International Journal of Production Economics | Modeling defaults of companies caused by structural dynamics | Agent-based simulation | Should a company be unable to quickly adapt to the changing environment, it might be exposed to the risk of the collective defaults of suppliers, which can give rise to disruptions and delays in production. | N |

| Ojha, R., Ghadge, A., Tiwari M.K. & U. S. Bititci (2018) | Bayesian network modeling for supply chain risk propagation | International Journal of Production Research | Analysis of SC exposure to the ripple effect risk | Bayesian Network simulation | Ripple effect quantification by fragility, service level, inventory cost, and lost sales | N |

| Osadchiy, N., Gaur, V., Seshadri, S. (2016) | Systematic risk in supply chain networks | Management Science | Mapping supply networks of industries and firms to investigate how the SC structure mediates the effect of economy on industry or firm sales. | Statistical analysis | To identify mechanisms that can affect the correlation between sales levels and SC states; effects of risk propagation on production decisions, aggregation of orders from multiple customers in an SC, and aggregation of orders over time. | N |

| Özçelik, G., Ö. F. Yılmaz & F. B. Yeni (2020) | Robust optimization for ripple effect on reverse supply chain: an industrial case study | International Journal of Production Research | Ripple effect in reverse SC | Robust optimization | Method to proactively increase SC design robustness against the ripple effect with consideration of reverse network | P |

| Pariazar, M., Root, S., Sir, M.Y. (2017). | Supply chain design considering correlated failures and inspection in pharmaceutical and food supply chains | Computers and Industrial Engineering | Impact of correlated disruptions on SC design | Stochastic programming; Monte-Carlo simulation | Correlated supplier failures increase total cost and influence SC design | P |

| Pavlov A., Ivanov D., Pavlov D., Slinko A. (2019) | Optimization of network redundancy and contingency planning in sustainable and resilient supply chain resource management under conditions of structural dynamics | Annals of Operations Research | Search for an optimal SC design with intensities of processing policies at nodes and arcs subject to multi-period changes in network structures and budget restrictions | Optimization: linear programming | To identify balanced levels of capacity utilization and production rates at different firms in the SC to achieve maximum performance. | P |

| Pavlov A., Ivanov D., Werner F., Dolgui A., Sokolov B. (2020). | Integrated detection of disruption scenarios, the ripple effect dispersal and recovery paths in supply chains | Annals of Operations Research | Identification of disruption scenarios of different severity and the resulting ripple effects | Reliability theory | A methodology to identify the most severe disruption scenarios, respective ripple effects, and optimal recovery paths | N |

| Sinha, P., Kumar, S., Prakash S. (2019) | Measuring and Mitigating the Effects of Cost Disturbance Propagation in Multi-Echelon Apparel Supply Chains | European Journal of Operational Research | Impact of demand variation propagation on SC performance | Graph theory | SC reconfiguration strategies to reduce the negative impact of disturbance propagation | P |

| Sokolov, B., Ivanov, D., Dolgui A., Pavlov A. (2016). | Structural quantification of the ripple effect in the supply chain | International Journal of Production Research | Analysis of different performance indicators in light of uncertainty for SCs with ripple effects | Graph theory, MCDM | Interrelations between network robustness, centralization, and flexibility | N |

| Tang, L., K. Jing, J. He, H.E. Stanley (2016) | Complex interdependent supply chain networks: Cascading failure and robustness | Physica A | Robustness of cyber-physical SC with disruption propagation considerations in material and information flows | Reliability theory | Helps to identify critical nodes, the removal of which would lead to network discontinuity, or even collapse | N |

| Zeng, Y., & Xiao, R. (2014). | Modeling of cluster supply network with cascading failure spread and its vulnerability analysis | International Journal of Production Research | Analysis and mitigation of SC vulnerability in the presence of disruption propagation | Complexity theory; entropy analysis | To analyze and predict dynamic SC behaviors caused by vulnerabilities during the process of failure spreading | N |

| Zhao M., Freeman, N.K. (2019) | Robust Sourcing from Suppliers under Ambiguously Correlated Major Disruption Risks | Production and Operations Management | Sourcing policies under conditions of ambiguously correlated disruptions | Distributionally robust model | Profit maximization for scenarios with worst-case disruption distribution. | P |

Table 2 summarizes the titles, authors, journals, central research questions, methods and outcomes, and managerial insights of each paper analyzed. We focus now on major outcomes and managerial insights, and generalize the insights from individual paper analyses at an aggregated scale according to the previously introduced classifications at the network (N), process (P), and control (C) levels. The major outcomes and managerial insights that can be deduced from the existing studies are categorized and presented in Table 3 .

Table 3.

Outcomes and managerial insights from OR contributions to the ripple effect and structural dynamics.

| Level of Analysis | OR Methods | Outcomes | Managerial Insights |

|---|---|---|---|

| Network Level | Graph Theory |

|

|

| Complexity Theory | |||

| Entropy | |||

| Petri Nets | |||

| Bayesian Networks | |||

| Markov Chains | |||

| Reliability Theory/Statistical Analysis | |||

| Process Level | Stochastic Optimization |

|

|

| Robust Optimization | |||

| Linear/Mixed-Integer Programming | |||

| Control Level | Optimal Control |

|

|

| Systems Dynamics | |||

| Agent-Based Simulation | |||

| Discrete-Event Simulation |

The detailed analysis follows.

3.2.1. Network level

The studies at the network level primarily look at unlocking associations between network structures and risk propagations (Li et al., 2019). For example, Basole and Bellamy (2014) show that small-world supply network topologies (i.e., networks where each node is connected to several of its neighbors and a few distant nodes) consistently outperform supply networks with scale-free characteristics (networks where nodes are connected to a few other nodes, while a small number are connected to many other nodes). The network- and graph-theoretical studies allow us to understand potential weaknesses in SC designs, taking into account the structure, connectivity, and dependence within the SC (Blackhurst et al., 2018). An important contribution can be seen in detecting disruption scenarios and identifying critical nodes (or combinations of nodes), the failure of which would lead to SC discontinuities and operational collapse (Zeng and Xiao, 2014; Tang et al., 2016; Deng et al., 2019; Pavlov et al., 2020). Another important application area consists of measuring SC robustness and resilience under disruption propagation and structural dynamics (Han and Shin, 2016; Sokolov et al., 2016; Hosseini & Ivanov, 2019; Li and Zobel, 2020). Along with the stress-testing of existing SC designs, the network level analyses suggest directions to enhance the resilience, e.g., through supplier diversification (Lei et al., 2020). Occasionally, the issues beyond mere economic performance such as sustainability have been examined (Levner and Ptuskin, 2018). Moreover, the macro problems of SC economies, such as supplier bankruptcies (Mizgier et al., 2013) and retail dynamics (Osadchiy et al., 2016) have been studied. With the use of Bayesian networks, the studies allow us to model dependencies and inter-dependencies in supply networks; moreover, the robustness and resilience analyses, with consideration of both vulnerabilities and recovery, thus become possible (Garvey et al., 2015; Ojha et al., 2018; Cao et al., 2019). An integration of Markov chains and Bayesian networks enables an additional and valuable contribution, i.e., to model the node's behaviors along with the overall network dynamics (Hosseini et al., 2019a,b).

3.2.2. Process level

Compared to the network level, the studies at the process level are positioned from a more specific perspective. These studies build upon parametrized structures to balance demands, processing capacities, and supply. Production-distribution planning in terms of flow optimization under disruption propagation and structural dynamics is the focus of the process level analysis. The analysis at the process level is mostly grounded in mathematical optimization and system dynamics simulation.

The process level studies help to analyze measures for disruption propagation mitigation. The mathematical optimization studies are usually organized around an SC design, which may vary structurally and parametrically over time, and optimize flow reconfigurations under disruption propagation. For example, Bueno-Solano and Cedillo-Campos (2014) show that protective measures against the ripple effect can drastically increase the inventory levels in an SC. Garvey and Carnovale (2020) argue that “managers should focus more of their attention on control or mitigation of exogenous events […] and spend less of an effort and resources on mitigating the propagation of exogenous risk …” Ghadge et al. (2013) show how systems dynamics simulation can help in the prediction of potential failure points in the SC, along with the overall impact of the ripple effect on performance. Although details differ across studies, most of them share a common set of outcomes and managerial insights, such as joint optimization of SC capacities and recovery capabilities for new and existing SCs; trade-offs between investments in increased recovery capability and redundant capacity provision; decision-making support on safety stock management, reconfiguration of production and inventory plans after disruptions, and recovery scheduling (Ivanov et al., 2015; Sinha et al., 2020; Goldbeck et al., 2020). As the most desirable outcome, process level analysis seeks to identify and test resilient SC designs to sustain disruptions, which range from optimistic and pessimistic scenarios (Ivanov et al., 2014a), probability-based disruptions (Pariazar et al., 2017) to worst-case scenarios in robust optimization (Zhao and Freeman, 2019; Özçelik et al., 2020). In some settings, the authors solve inverse problems and search for the elements in SC structures that should be strengthened to withstand disruption propagation (Liberatore et al., 2012; Pavlov et al., 2013). Some extensions and adjustments of these models can be seen to include recovery costs (Ivanov et al., 2016) and sustainability issues (Pavlov et al., 2019).

3.2.3. Control level

The control level studies are distinctively characterized by the inclusion of details about inventory control and production-ordering policies in the analysis. At this level, simulation methods are the most dominant. They facilitate the analysis of dynamic SC behaviors and time dependencies in disruption propagation and responses. One interesting observation from these studies provides insight into “disruption tails.” Several works (Ivanov, 2019; Dolgui et al., 2020) have observed that non-coordinated ordering and production policies during a disruption period may result in backlog and delayed orders, the accumulation of which causes post-disruption SC instability, resulting in further delivery delays and non-recovery of SC performance. These residues have been named “disruption tails.” The extant literature suggests that specific “revival” policies must be developed for the transition from the recovery to disruption-free operation mode to avoid these “disruption tails.” Interestingly, the first research conducted on the impacts of the COVID-19 pandemic on SCs has utilized the simulation methodology, revealing several unique features which make the pandemic a specific and very severe risk type for SCs (Ivanov, 2020a).

4. Directions for managerial applications and future research in pandemic settings

COVID-19 pandemic has been the strongest test to resilience of SCs. It has also been the test for SC resilience theory. Have the established SC resilience measures, e.g., (i) redundancies such as risk mitigation inventories, subcontracting capacities, backup sup-ply and transportation infrastructures, (ii) data-driven, real-time monitoring and visibility systems, and (iii) contingent recovery plans helped the companies? Does the SC resilience theory provide a sufficient conceptual foundation, principles and methods to help firms to survive and recover through the pandemic times?

SC resilience theory has been developed in response to more and more frequent natural and man-made disasters early in the first decade of 2000s (Blackhurst et al., 2005; Peck, 2005; Sheffi and Rice, 2005). These events have been considered as severe disruption risks in contrast to more “light” operational risks (examples). Indeed, disruption risks such as tsunamis, fires, and strikes may have high impact on SC operations and performance. These disruptions share a common set of attributes, i.e., discrete-event orientation (i.e., disruptions as singular or combined events), single feedback control (i.e., normal → disruption → return-to-normal cycle), and finite-dimensional view on economic performance within a fixed time horizon as the major resilience assessment criterion.

The pandemic setting is different. First, it is characterized by a very long-term existence of disruption and its unpredictable scaling. Thus far, SC resilience theory has not studied such settings. Second, we have simultaneous disruption and epidemic outbreak propagations which is a novel timing setting with simultaneous and/or sequential openings and closures of suppliers, facilities and markets. Third, one specifics of the pandemic setting are simultaneous severe disruptions in supply, demand, and logistics infrastructure leading to a novel complex setting with both forward and backward disruption propagations (i.e., forward and reverse ripple effects).

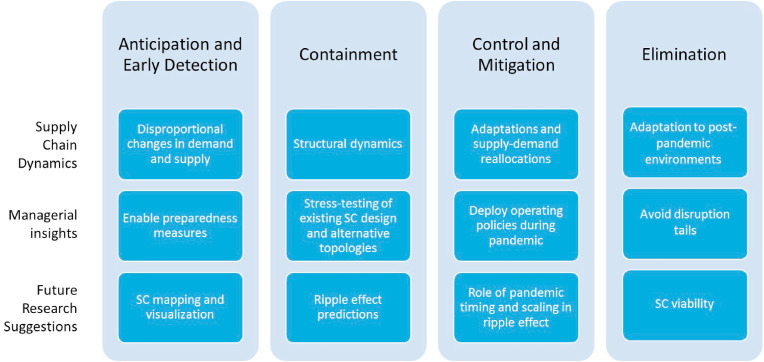

In this section, we focus on the articulation of state-of-the-art knowledge in OR about disruption propagation and structural dynamics for a pandemic context. In particular, we extrapolate the outcomes and managerial insights revealed in Section 3 on the COVID-19 pandemic and elaborate on future research directions (Fig. 4 and Table 4 ).

Fig. 4.

Summary of theoretical and managerial insights.

Table 4.

Suggestions for future research and applications in pandemic settings.

| Pandemic stages | Suggestions for future research and applications of OR methods in pandemic settings | |

|---|---|---|

| Managerial applications | Future research directions | |

| Anticipation and early detection |

|

|

| Containment |

|

|

| Control and mitigation |

|

|

| Elimination |

|

|

Our analyses of outcomes in both managerial and theoretical domains in Fig. 4 and Table 4 are structured into five stages (i.e., Anticipation; Early Detection; Containment; Control and Mitigation; and Elimination) following the WHO classification (WHO, 2018).

4.1. Anticipation and early detection

The pandemic cycle usually begins with the anticipation and early detection stage. At this stage, SCs should be aware of and thus enable preparedness measures. OR methods can help in a number of areas, such as how to identify critical scenarios of disruption propagation according to epidemic outbreak dynamics and forecast the impact of possible propagating disruption on SC performance (Mizgier et al., 2013; Basole and Bellamy, 2014; Li et al., 2019; Garvey et al., 2015; Ojha et al., 2018; Cao et al., 2019). Moreover, quantitative theories can be efficiently used to predict the time periods during which SCs can sustain disruption propagation and survive despite discontinuities, identify critical suppliers and facilities for maintaining SC operations, and select and fortify SC designs to sustain epidemic outbreaks (Blackhurst et al., 2018; Zeng and Xiao, 2014; Tang et al., 2016; Deng et al., 2019; Pavlov et al., 2020). Overall, the decision on the anticipation and early detection stage aim toward the implementation of “Design-for-Resilience” network structures (Yildiz et al., 2016).

Nonetheless, further research directions arise for communities in the midst of pandemic settings. There are crucial opportunities to develop theories and models for disruption propagation analysis in supply networks with specific consideration of pandemics to visualize the ripple effect and their structural dynamics, and to extend toward a multi-categorical analysis spanning dimensions of resilience and sustainability. Moreover, researchers can examine new analysis categories, such as network viability (Ivanov and Dolgui, 2020; Ivanov, 2020a,b). It is also important to investigate data analytics and digital technology capabilities for early detection of disruption propagation following epidemic outbreaks.

4.2. Containment

At the containment stage, the environment becomes increasingly vulnerable following periods of quarantine, interruption of logistics due to variations in containment timing, and scaling in different geographical areas, as well as certain lockdowns. At this stage, SCs are experiencing initial misbalances in supply and demand due to longer lead-times, demand drops, and supply unavailability due to facility closures. OR methods can support SC managers at this stage by stress-testing the existing and alternative SC configurations and production-distribution plans for some scenarios of structural dynamics in anticipation of, or as a reaction to, facility and market closure due to quarantines and lockdowns (Hosseini & Ivanov, 2019; Tan et al., 2019; Li and Zobel, 2020; Sawik, 2020). OR methods can also help optimize contingency-preparedness plans for their efficient and timely deployment under different scenarios of epidemic propagation (Liberatore et al., 2012, Ghadge et al., 2013, Ivanov et al., 2015; Sinha et al., 2020; Pavlov et al., 2019; Goldbeck et al., 2020).

The new research opportunities for communities during the containment pandemic stage are promising. For example, there is an urgent need to examine new understandings, theories, and novel approaches concerning SC preparedness and disruption mitigation during the beginning of epidemic outbreaks. This can help articulate the antecedents, drivers, and economic and social performance implications of simultaneous disruption and epidemic propagation. One specific and underexplored area is the re-designing of SCs to facilitate production switches to unusual products (e.g., mask production at car manufacturing plants).

4.3. Control and mitigation

Amid the control and mitigation stage, SCs must adapt to a “new normal” and start preparing for recovery. For example, OR models can help to identify balanced levels of capacity utilization and production rates at different firms in the SC to achieve maximum possible performance (Ivanov et al., 2016; Pariazar et al., 2017; Goldbeck et al. 2020). It is now highly relevant to the COVID-19 pandemic since SCs are misbalanced, which makes it difficult to decide at which level of capacity firms should start and then scale during a subsequent recovery. The OR models can help identify the optimal material flows in a multi-period mode during which SC structures change throughout these periods (Ivanov et al., 2014a; Lücker et al. 2017, 2019; Pavlov et al., 2019). This is highly relevant to the modeling of SC flows amid a pandemic and throughout recovery. Another relevant issue is the consideration of backlog accumulations over the disruption time, which can become a major driver of disruption propagation during production and logistics ramp-up activities (Ivanov and Rozhkov, 2020). At the control and mitigation stage, the role of digital twins is increasing since SC visibility and information coordination are the key capabilities for coping with the ripple effect (Sokolov et al. 2020). OR methods can help analyze the impacts of disruption propagation on dynamics with adaptations for ordering, production, and inventory control policies, and to simulate operations policies amid a pandemic (Zeng et al. 2014, Spiegler and Naim, 2017, Schmitt et al., 2017; Ivanov and Rozhkov, 2020). Moreover, OR theories can be used to explore reallocations of supply and demand during a pandemic, given simultaneous upstream and market disruptions (Gupta et al., 2020). In addition, OR methods can be applied to propose recovery plans along with an analysis of timing and scaling of facility/market closures and openings in different geographical regions (Tang and Musa 2011, Snyder et al., 2016;.

As for future research, we point to opportunities for substantial contributions to develop and examine digital SC twins to map the network elements and adapt SCs according to disruption propagation and structural dynamics. There is also promising research through exploring the role of timing and scaling of production and logistics ramp-ups after quarantine and lockdown eliminations.

4.4. Elimination or eradication

Exiting a pandemic can be even more challenging than being inside one. During the elimination stage, SCs must be recovered and adapted to new post-pandemic realities. OR methods can help incorporate post-pandemic environments in the re-designing of the SCs and supplier base (Yoon et al., 2018; Snoeck et al., 2019). They can also be of value to examine the existing and potential SC configurations under post-pandemic conditions within markets and the supply base. Furthermore, modeling techniques can be used to analyze the “disruption tails” and long-term stabilization of production-inventory systems (Ivanov 2019; Paul et al. 2018, 2019; Ivanov and Rozhkov, 2020; Macdonald et al., 2018).

The elimination stage contains a variety of novel research problem settings. For example, there is a research gap in how to establish the optimal scaling and timing of production and logistics ramp-ups during the “exit” after lockdown. It is also timely and crucial to examine SC re-design methods for several structural changes in supply and demand in the wake of a pandemic (e.g., supplier bankruptcies, shifts and drops in demand). Finally, we point to the need to explore the concept of SC viability as a means for the long-term maintenance of survivability under different and ever-changing environmental conditions.

5. Some interesting cross-stage future research directions

Along with the research directions at each of the pandemic stages outlined above, there are some cross-stage areas which can become promising research avenues. These directions have been discussed during our INFORMS webinar “Ripple Effects in Supply Chains at different Pandemic Stages” on May 14, 2020. We thank the audience for interesting and relevant questions some of which are addressed in this section.

5.1. Efficiency vs. resilience: toward adaptable redundancy

Resilience theory in OR is predominantly organized around three major assets (Hosseini et al., 2019b), i.e.,

-

(i)

redundancies such as risk mitigation inventories, subcontracting capacities, backup supply and transportation infrastructures,

-

(ii)

data-driven, real-time monitoring and visibility systems, and

-

(iii)

contingent recovery plans.

Obviously, these resilience assets are costly. One of the fundamental questions in the context of ripple effects under pandemic conditions stems from the trade-offs between efficiency and resilience. A manager could ask if it is really needed to invest in resilience when such a global pandemic is a one-in-a-century event. Perhaps it is better to lose some revenues during a pandemic than to invest every year in resilience? Undoubtedly, the SC strategies such as lean, agile, and leagile have a great impact on the ripple effects. Which strategy could decrease the negative impact of the ripple effect, particularly in case of the COVID-19?

It is frequently claimed that lean SC principles (e.g., Just-in-Time (JIT), low inventory levels or single sourcing) might be the triggers of ripple effect during a pandemic. Other trigger is seen in globalization of SCs and utilizing the efficiency of global sourcing and production. This might be true in certain settings; however this should not be considered as an automatic rule. JIT inventory systems are not necessarily less resilient as high-level inventory systems. Important is the locations of inventory which needs to be accessible by in- and outbound logistics. The same general rule – ability to network the SC redundancy assets holds true for other resilience capabilities such capacity flexibility or back-up suppliers. Redundancy assets make sense only if they can be used to adapt the SC quickly. Equally, globalization is frequently seen as a strong driver of the ripple effects. It is argued that localization might be a panacea to increase resilience of future SCs. However, lockdowns in Europe and USA in spring 2020 clearly showed examples that even the local SCs can be broken due to quarantine-driven capacity shutdowns. At the same time, global SC footprints played a positive role for some SCs. For example, automotive companies with factories in Asia, Europe and USA were able to maintain at least a part of their operations and sales due to sequential timing of the pandemic propagation (e.g., while the European factories and market were shutdown end of March 2020, the Chinese facilities and market were gradually re-opening around this time).

In this context, we see a need for research in adaptable redundancy using leagility and resilience principles. For example, Ivanov and Dolgui (2019) proposed an LCN (low-certainty-need) SC framework which conceptually defines the notion of resileanness (i.e., resilient and lean). The traditional way of designing resilient SCs and operations is to predict disruptions and include the perceived uncertainties in network design and planning (i.e., high need for certainty in SC operations) at the costs of efficiency. The LCN framework assumes that SCs are inherently operating at very high level of uncertainty which is very difficult to predict. Thus far, it rather looks at efficient adaptable SC designs and operations which allow for situational reconfigurations in response to external changes regardless of their nature (i.e., low need for certainty). With that, the LCN framework constitutes a novel approach to managing SC resilience in an efficient manner. The main idea is to actively maintain efficient and agile “ready-to-change” SC states in dynamics rather than pre-designing some static and costly “ready-to-absorb”, passive redundancies.

Analysis of SC operations and performances in January–August 2020 shows that redundant resilience assets (i.e., risk mitigation inventories, subcontracting capacities, backup supply and transportation infrastructures) have not really helped firms since the disruption period was very long. In automotive industry, many processes are organized just-in-time and inventory was available for a period of about 30 days at maximum. Moreover, suppliers and factories have been located in different regions subject to different timing of shutdowns and lockdowns (regardless of whether globally or locally organized). As such, even the available inventory or backup capacities were not accessible for longer periods of time.

More positive experiences have been done with agile capacities and data-driven, real-time monitoring and visibility systems. Agile capacities have enabled firms to re-purpose their SCs. Luxury goods manufacturers have completely transformed their operations to manufacture urgently needed items during the COVID-19 virus outbreak in March 2020. LVMH, L'Oreal and Coty repurposed their perfume and hair gel factories to producing hand sanitizers. Giorgio Armani, Burberry, Gucci and Prada altered their designer clothing factories in Italy to produce masks, gloves and nonsurgical gowns. Similarly, many automotive giants like Ford, Tesla, Suzuki, etc. shifted their production from cars to ventilators and hospital beds by collaborating with local manufacturers. Thus, adaptability and reconfigurability played a critical role in SCs, including rapid raw material sourcing, product design, development and testing, and distribution. In addition, some companies resolved shortages of parts for life saving ventilators and masks by using additive manufacturing. Moreover, data-driven, real-time monitoring and visibility technologies were of help for companies to map their SCs and utilize the data for decision-making support when preparing their responses to the COVID-19 pandemic settings.

5.2. Correlations of bullwhip and ripple effects

Ripple effect and bullwhip effect have commonalities and differences. Both bullwhip and ripple effect belong to systemic risks dealing with correlated and mutually triggered fluctuations; however, they originate differently. Bullwhip effect is triggered by a small demand fluctuation while ripple effect is triggered by a severe disruption. COVID-19 pandemic has shed light on unforeseen interrelations of both effects. First, the panic purchasing has been observed in many regions as a consequence of a pandemic announcement. Simultaneously, supply has been disrupted. Second, in many regions it came to simultaneous or subsequent demand disruption. This novel context raises a number of research questions on interrelations of ripple and bullwhip, and on interrelation of operations and disruption risks in general.

5.3. SC viability, intertwined networks and structural dynamics

Under pandemic settings, many companies have experienced critical disruptions in their operations leading to the tasks of maintaining the existence of SCs as such. In such unique context, the issues of viability were brought in the forefront of consideration. The views about pandemic impacts on SCs are diverse. On one hand, the pandemic is seen as one-in-a-century event, and a return to normal design-for-efficiency with some elements of resilience will happen when the pandemic is over. This optimistic scenario might be true. In another, pessimistic scenario the sentiment is that deep demand and supply uncertainty can exist for a longer time, and even become a “new normal”. SC managers should take this into account and re-build the SCs, e.g., following the Viable Supply Chain (VSC) model (Ivanov 2020b). The principal ideas of the VSC model are adaptable structural SC designs for situational supply-demand allocations and, most importantly, establishment and control of adaptive mechanisms for transitions between the structural designs. The VSC model can help firms in guiding their decisions on recovery and re-building of their SCs after global, long-term crises such as the COVID-19 pandemic.

Ripple effect analysis in the viability settings is an underexplored area. Moreover, it has been observed that SCs are actually intersecting with other SCs, i.e., intertwined supply networks exist (Ivanov and Dolgui et al., 2020b). For example, a supplier in an automotive SC can be a producer of valves for a healthcare SC simultaneously playing the role of buyers and suppliers at the same time in different SCs. Ripple effect analysis for intertwined supply networks is a promising research direction. In addition, ripple effect refers not only to organizational structures of SCs (i.e., structure of firms). We can also observe intersections of process, product, informational, technological, and financial structures (Queiroz et al., 2020). For example, automotive and perfume companies changed their product and related technological structures by producing ventilators and hand sanitizers instead of cars and luxury perfumes. Such a transformation leads to dynamics in supplier base, informational and financial structures. Ripple effect analysis in the context of multi-structural dynamics represents a novel research array.

5.4. Note on the usage of SC resilience models for pandemic settings

Undoubtedly, the existing knowledge on SC disruption risk and resilience will be the dominant perspective guiding researchers and industry leaders throughout the pandemic and subsequent recovery. That being said, there exists the danger of an incorrect usage of SC resilience models for pandemic settings. The optimization and simulation research community has developed a mature body of literature on coping with different types of disruption risks. A pandemic is one specific type of disruption risk with unique implications for SCs, which are not encountered with other types of disruptions. In contrast to geographically-centered natural and industrial disasters with a singular occurrence, a pandemic is not limited to a particular region or confined to a particular time period (Ivanov and Das, 2020). Different SC components are thus affected sequentially or concurrently—manufacturing, DCs, logistics, and markets can all become paralyzed within subsequent or overlapping time frames. Pandemics cause long-term disruption with unpredictable scaling. Other specific issues include simultaneous disruption propagation (i.e., the ripple effect) and epidemic outbreak propagation, and simultaneous severe disruptions in supply, demand, and logistics infrastructure (Ivanov, 2020a). Under pandemic conditions, it may be difficult to apply directly the most well-known SC resilience mechanisms, such as risk mitigation inventories, subcontracting capacities, or backup supply and transportation infrastructures. As such, studies on SC resilience should explicitly present pandemic-specific settings to be classified as a contribution in a pandemic context Otherwise, each study on supply disruptions may be adapted to the pandemic background, which would be fundamentally problematic.

6. Conclusions

The COVID-19 pandemic unveils the fragility of SCs at an unforeseen scale. Specifically, one dominant stressor to SCs amid a pandemic and during post-pandemic recoveries arises from disruption propagations through networks (i.e., the ripple effect) and the subsequent changes in SC structures (i.e., structural dynamics).

This paper deduced managerial implications from the existing literature on disruption propagation in SCs and revealed future research directions. We collated for the first time the existing knowledge on modeling the SC ripple effect and its structural dynamics. We believe that such an overview would be useful for industry leaders and researchers in shaping SC adaptations during and after a global pandemic. On one hand, we collated the state-of-the-art in research on SC disruption propagation and identified a methodical taxonomy. On the other hand, we revealed and systemized managerial insights from a theory, which can be used for COVID-19 recovery and for withstanding future pandemics. These results can be used by both industry and researchers to progress the decision-support systems guiding SCs amid the COVID-19 pandemic and their subsequent recovery.

The outcomes of our study show that methodical contributions and the resulting managerial insights can be categorized into three levels, i.e., network, process, and control. Our analysis shows that adaptation capabilities play the most crucial role in managing the SCs under pandemic disruptions. Our findings depict how the existing OR methods can help coping with the ripple effect at five pandemic stages (i.e., Anticipation; Early Detection; Containment; Control and Mitigation; and Elimination) following the WHO classification. The outcomes and findings of our study can be used by industry and researchers alike to progress the decision-support systems guiding SCs amid the COVID-19 pandemic and toward recovery.

As with any study, there exists limitations. We have narrowed our analysis of the disruption propagation literature to that which relates to commercial SCs. Obviously a wide variety of knowledge in the area of humanitarian logistics and SCs can enrich the findings of our study. We also do not present ourselves to be encyclopedic, for we assume that some relevant studies might have not been uncovered and thus remain outside of our review. In addition, we restricted ourselves to OR studies. The analysis of the ripple effect would greatly benefit from empirical studies as well. Finally, we reviewed the literature published by May 15, 2020. In the meantime, several new studies on the ripple effect in SCs have appeared (Hsieh and Chang, 2020, Hosseini and Ivanov, 2020, Lee et al., 2020, Lohmer et al., 2020, Singh et al., 2020) which confirms the strong and growing interest in this research area.

As for future research, we point toward numerous opportunities for substantial contributions to develop and test new theories, models, and resilience mechanisms for the control and mitigation of disruption propagation in SCs, with special consideration of pandemic features, such as:

-

•

long-term existence of disruption and its unpredictable scaling: this setting is an understudied area in ripple effect research;

-

•

simultaneous disruption and epidemic outbreak propagation: this is a novel timing setting with simultaneous and/or sequential openings and closures of suppliers, facilities, and markets;

-

•

simultaneous severe disruptions in supply, demand, and logistics infrastructure: this is a novel complex setting with both forward and backward disruption propagation.

Future research can be advanced by investigating the role of digital twins in mitigating the ripple effect, research on the ripple effect in the setting of SC viability, and intertwined supply networks. Moreover, the ripple effect refers not only to organizational structures, but also the intersection of process, product, informational, technological, and financial structures. As such, the research on the multi-structural ripple effect is a promising and novel direction.

We hope that the novel systematizations and categorizations proposed in this study will be of value for researchers and practitioners alike in guiding SCs through the pandemic and preparing them for future recovery. Along with the constructed generalized perspectives, our study can be of value for researchers and industry professionals to cope with the existing COVID-19 pandemic, aid them in recovery, and, most importantly, to create a valuable resource for future pandemics or pandemic-like disruptions.

Acknowledgments

The authors thank two anonymous reviewers for their invaluable comments which helped to improve this paper immensely.

Appendix 1. Journals

Annals of Operations Research.

Computers and Industrial Engineering.

Decision Sciences.

European Journal of Operational Research.

Industrial Management and Data Systems.

International Journal of Production Economics.

International Journal of Production Research.

Journal of Purchasing and Supply Management.

Management Science.

Manufacturing & Service Operations Management.

Omega.

Physica A.

Production and Operations Management.

Supply Chain Management: An International Journal.

Transportation Research Part E: Logistics and Transportation Review

References

- Altay N., Green W.G. OR/MS research in disaster operations management. Eur. J. Oper. Res. 2006;175(1):475–493. [Google Scholar]

- Basole R.C., Bellamy M.A. Supply network structure, visibility, and risk diffusion: a computational approach. Decis. Sci. J. 2014;45(4):1–49. [Google Scholar]

- Blackhurst J., Craighead C.W., Elkins D., Handfield R. An empirically derived agenda of critical research issues for managing supply-chain disruptions. Int. J. Prod. Res. 2005;43(19):4067–4081. [Google Scholar]

- Blackhurst J., Rungtusanatham M.J., Scheibe K., Ambulkar S. Supply chain vulnerability assessment: a network based visualization and clustering analysis approach. J. Purch. Supply Manag. 2018;24(1):21–30. [Google Scholar]

- Brandon‐Jones E., Squire B., Autry C.W., Petersen K.J. A contingent resource‐based perspective of supply chain resilience and robustness. J. Supply Chain Manag. 2014;50(3):55–73. [Google Scholar]

- Bueno-Solano A., Cedillo-Campos M.G. Dynamic impact on global supply chains performance of disruptions propagation produced by terrorist acts. Transport. Res. E Logist. Transport. Rev. 2014;61:1–12. [Google Scholar]

- Cao S., Bryceson K., Hine D. An Ontology-based Bayesian network modelling for supply chain risk propagation. Ind. Manag. Data Syst. 2019;119(8):1691–1711. [Google Scholar]

- Chatfield D.C., Hayya J.C., Cook D.P. Stockout propagation and amplification in supply chain inventory systems. Int. J. Prod. Res. 2013;51(5):1491–1507. [Google Scholar]

- Chaudhuri A., Srivastava S.K., Srivastava R.K., Parveen Z. Risk propagation and its impact on performance in food processing supply chain: a fuzzy interpretive structural modeling based approach. J. Model. Manag. 2016;11(2):660–693. [Google Scholar]

- Choi T.Y., Rogers D., Vakil B. Harvard Business Review. 2020. Coronavirus is a wake-up call for supply chain management. March 27th. [Google Scholar]

- Choi T.-M. Innovative “bring-service-near-your-home” operations under corona-virus (COVID-19/SARS-CoV-2) outbreak: can logistics become the messiah? Transport. Res. Part E: Logistics and Transportation. 2020;140:101961. doi: 10.1016/j.tre.2020.101961. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Dasaklis T.K., Pappis C.P., Rachaniotis N.P. Epidemics control and logistics operations: a review. Int. J. Prod. Econ. 2012;139(2):393–410. [Google Scholar]

- Demirel G., MacCarthy B.L., Ritterskamp D., Champneys A., Gross T. Identifying dynamical instabilities in supply networks using generalized modeling. J. Oper. Manag. 2019;65(2):133–159. [Google Scholar]

- Deng X., Yang X., Zhang Y., Li Y., Lu Z. Risk propagation mechanisms and risk management strategies for a sustainable perishable products supply chain. Comput. Ind. Eng. 2019;135:1175–1187. [Google Scholar]

- Dolgui A., Ivanov D., Rozhkov M. Does the ripple effect influence the bullwhip effect? An integrated analysis of structural and operational dynamics in the supply chain. Int. J. Prod. Res. 2020;58(5):1285–1301. [Google Scholar]

- Dolgui A., Ivanov D., Sokolov B. Ripple effect in the supply chain: an analysis and recent literature. Int. J. Prod. Res. 2018;56(1–2):414–430. [Google Scholar]

- Dubey R., Altay N., Blome C. Swift trust and commitment: the missing links for humanitarian supply chain coordination? Ann. Oper. Res. 2019;283(1–2):159–177. doi: 10.1007/s10479-017-2676-z. [DOI] [Google Scholar]

- Dubey R., Gunasekaran A., Childe S.J., Fosso Wamba S., Roubaud D., Foropon C. Empirical investigation of data analytics capability and organizational flexibility as complements to supply chain resilience. Int. J. Prod. Res. 2020 doi: 10.1080/00207543.2019.1582820. [DOI] [Google Scholar]

- Dubey R., Gunasekaran A., Childe S.J., Papadopoulos T., Blome C., Luo Z. Antecedents of resilient supply chains: an empirical study. IEEE Trans. Eng. Manag. 2019;66(1):8–19. doi: 10.1109/TEM.2017.2723042. [DOI] [Google Scholar]

- Essuman D., Boso N., Annan J. Operational resilience, disruption, and efficiency: conceptual and empirical analyses. Int. J. Prod. Econ. 2020 doi: 10.1016/j.ijpe.2020.107762. Available online. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Fortune. 2020. https://fortune.com/2020/02/21/fortune-1000-coronavirus-china-supply-chain-impact/

- Fosso Wamba S. Humanitarian supply chain: a bibliometric analysis and future research directions. Ann. Oper. Res. 2020 doi: 10.1007/s10479-020-03594-9. (Forthcoming) [DOI] [Google Scholar]

- Garvey M.D., Carnovale S. The rippled newsvendor: a new inventory framework for modelling supply chain risk severity in the presence of risk propagation. Int. J. Prod. Econ. 2020 doi: 10.1016/j.ijpe.2020.107752. (forthcoming) [DOI] [PMC free article] [PubMed] [Google Scholar]

- Garvey M.D., Carnovale S., Yeniyurt S. An analytical framework for supply network risk propagation: a Bayesian network approach. Eur. J. Oper. Res. 2015;243(2):618–627. [Google Scholar]

- Ghadge A., Dani S., Chester M., Kalawsky R. A systems thinking approach for modelling supply chain risk propagation. Supply Chain Manag.: Int. J. 2013;18(5):523–538. [Google Scholar]

- Ghadge A., Weiß M., Caldwell N.D., Wilding R. Managing cyber risk in supply chains: a review and research agenda. Supply Chain Manag.: Int. J. 2019;25(2):223–240. [Google Scholar]