Graphical abstract

Keywords: Metal–organic framework, Commercialization, Mass production, Future applications, Shaping, Dispersion

Abbreviations: MOF, metal–organic framework; ZIF, zeolitic imidazolate framework; DMF, N,N-Dimethyl formamide; DEF, N,N-Diethyl formamide; DMA, Dimethylacetamide; TEA, Triethylamine; STY, space–time yield, grams of MOF per cubic meter of reaction mixture per day of synthesis; NMP, N-methyl-2-pyrrolidone; CNG, compressed natural gas; PEI, Polyetherimide; PS, Polystyrene; PVA, Polyvinyl alcohol; MRA, mesoporous ρ-alumina; ABS, acrylonitril-butadiene-styrene; CA, Cellulose-acetate; PXRD, Powder x-ray diffraction; PVC, Polyvinylchloride; PVF, Polyvinylformal; PVB, Polyvinyl Butyral; DLS, Dynamic light scattering; BET, Brunauer–Emmett–Teller; PEG-CCM, polyethylene-glycol-modified mono-functional curcumin; MB, methylene blue; DDM, n-dodecyl β-D-maltoside; ECS, Extrusion-crushing-sieving; TIPS-HoP, Thermally induced phase separation-hot pressing; PM, Particulate matter; VOC, Volatile organic compound; CWA, Chemical warfare agent; PPC, Polypropylene/polycarbonate; PAN, Polyacrylonitrile; SEM, Scanning electron microscope; SBU, Secondary building unit; DFT, Density functional theory; SALI, Solvent assisted ligand incorporation; FT-IR, Fourier-transform infrared spectroscopy; NMR, Nuclear magnetic resonance; DRIFTS, Diffuse reflectance infrared fourier transform spectroscopy; XPS, X-ray photoelectron spectroscopy; SCXRD, Single-crystal X-ray diffraction; CWC, Chemical weapons convention; POM, Polyoxometalate; DMMP, Dimethyl methylphosphonate; GC–MS, Gas chromatography–mass spectrometry; EXAFS, Extended X-ray absorption fine structure; MMP, Methyl methylphosphonate; DIFP, Diisopropylfluorophosphate; MVTR, Moisture vapor transport rate; CEES, 2-Chloroethyl ethyl sulfide; DCP, Diethylchlorophosphonate; DFP, Diisopropyl fluorophosphate; ROS, Reactive oxygen species; E. Coli, Escherichia coli; MRSA, Methicillin-resistant staphylococcus aureus; MIC, Minimum inhibitory concentration; MBC, Minimum bactericidal concentration; PSM, Post-synthetic modification; CNF, Cellulose nanofiber; GRGDS, Gly-Arg-Gly-Asp-Ser; Fn, Fusobacterium nucleatum; Pg, Porphyromonas gingivalis; PEMFCs, Proton-exchange membrane fuel cells; SSEs, Solid-state electrolytes; MOGs, Metal-organic gels; LIBs, Lithium-ion batteries; SIBs, Sodium-ion batteries; hXAS, Hard X-ray absorption spectroscopy; sXAS, Soft X-ray absorption spectroscopy; EDLCs, Electrochemical double-layer capacitors; PANI, Polyaniline; ILDs, Interlayer dielectrics; ITRS, International technology roadmap for semiconductors; CVD, Chemical vapor deposition; MIM, Metal-insulator–metal; LMOF, Luminescent metal–organic framework; UPS, Ultraviolet photoelectron spectroscopy; EPA, Environmental protection agency; WHO, World health organization; LOD, Limit of detection; TNT, 2,4,6-trinitrotoluene; TNP, 2,4,6-trinitrophenol; 2,4-DNT, 2,4-dinitrotoluene; 4-NP, 4-nitrophenol; RDX, 1,3,5-trinitro-1,3,5-triazinane; LED, Light-emitting diode; WLED, White light emitting diode; CIE, Commission international ed’Eclairage

Abstract

Progress in metal–organic frameworks (MOFs) has advanced from fundamental chemistry to engineering processes and applications, resulting in new industrial opportunities. The unique features of MOFs, such as their permanent porosity, high surface area, and structural flexibility, continue to draw industrial interest outside the traditional MOF field, both to solve existing challenges and to create new businesses. In this context, diverse research has been directed toward commercializing MOFs, but such studies have been performed according to a variety of individual goals. Therefore, there have been limited opportunities to share the challenges, goals, and findings with most of the MOF field. In this review, we examine the issues and demands for MOF commercialization and investigate recent advances in MOF process engineering and applications. Specifically, we discuss the criteria for MOF commercialization from the views of stability, producibility, regulations, and production cost. This review covers progress in the mass production and formation of MOFs along with future applications that are not currently well known but have high potential for new areas of MOF commercialization.

1. Introduction

Metal–organic frameworks (MOFs) have attracted interest from various industrial and engineering fields such as petrochemicals, vehicles, gas, and even cosmetic and biomedical areas because of their high surface area, different porous environments, designable pore sizes, and synergistic effects of the metal ions and ligand functional groups [1], [2], [3], [4], [5], [6], [7], [8]. Excellent progress has been made in MOF synthesis, structure, chemistry, properties, and applications on the fundamental level [9], [10], [11], [12], [13], but challenges remain both in the development of engineering processes and exploring game-changing applications on the industrial level. Recently, many research groups have focused on the development of MOF manufacturing, activation, shaping, and dispersion processes, and various startup and global companies have increased their efforts toward the development of MOFs for new business areas. However, these developments in engineering and industrial processes typically arise from studies performed according to the specific demands and goals of the individual projects. Therefore, the challenges and findings are difficult to share with researchers across various MOF-related fields.

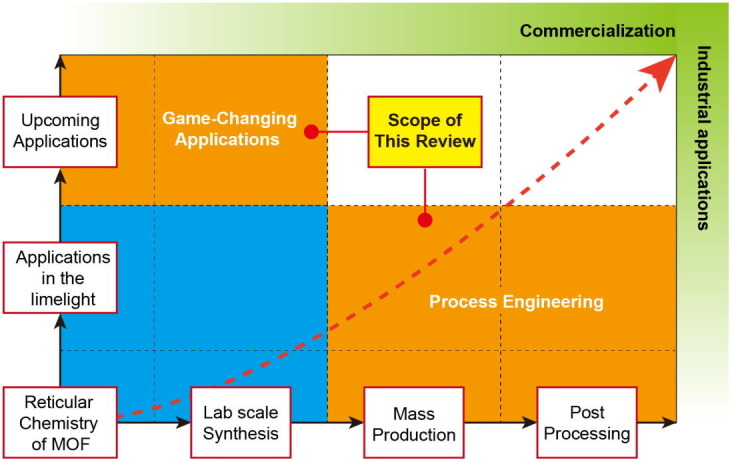

In this review, we examine MOF issues and demands from process engineering and industrial points of view (Scheme 1 ). The criteria for MOF commercialization are discussed in terms of stability, producibility, regulations, and production cost. We also explore recent advances in processes for the scaled-up synthesis, product recovery, activation, drying, shaping, and dispersion of MOFs. Furthermore, we investigate possible future applications that are not currently well known but have significant potential to serve as new business areas for MOF commercialization. In this regard, we focus on purification, biological toxicant removal, antibacterial implementation, ion transport for solid-state electrolytes (SSEs), electrode materials, low-kappa dielectric materials, and sensors. We believe that this review will enhance the understanding of recent progress and future demands for MOF commercialization.

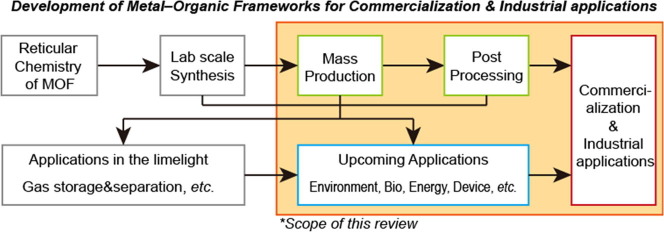

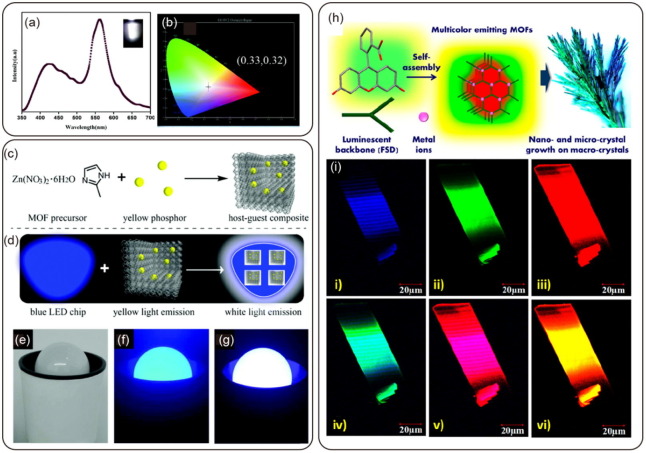

Scheme 1.

Scope of this review paper: From process engineering to upcoming applications.

2. MOF commercialization criteria

MOFs have experienced rapid development in the last two decades, and there have been many reports on their synthesis, structure, processes, and applications. However, there are still several challenges in adapting MOFs to different industries. First, only a few MOFs maintain their properties in aqueous acidic/basic conditions [14], [15], [16], [17], [18]. Second, syntheses for the mass production of many MOFs have not yet been established [19], [20], [21], [22]. Third, MOF production costs are still higher than those of competing materials (activated carbon, silica, and zeolites). In this section, we focus on criteria for MOF commercialization in terms of stability, producibility, regulations, and production costs.

2.1. Stability

Since MOF-5 was first published as a model compound in 1997 [23], most related research interest has focused on increasing the surface area, which has resulted in values as high as ~7,000 m2 g−1 [24]. However, many MOFs, especially those based on Zn, decompose easily from humidity and chemicals. Other MOFs synthesized through hydrothermal reactions have been reported to have better stabilities but are still below the necessary specifications [25], [26]. Many studies have suggested potential MOF applications in various devices and appliances. Adapting MOFs to such industrial applications places key emphasis on the lifetime of the components. The acceleration test is the standard method to judge the lifetime of a module or set and is usually performed under 85 °C/85% humidity or 120 °C steam conditions to shorten the test period. Unfortunately, most MOFs lose their properties under these conditions because of their lack of aqueous acid/base stability. There is a pioneer reference mentioning the steam stabilities of MOFs [27]. Steam stability was investigated through experimental and calculated observations on 10 types of MOF consisting of Zn, Cu, Cr and Al metal source. It demonstrates that the bonding strength of metal oxide and linker is the most important factor of steam stability. Zr/Hf/Al-based MOFs and zeolitic imidazolate frameworks (ZIFs) have been demonstrated as capable of passing the standard acceleration test, and an interesting method has also been reported for fortifying the hydrothermal stability of MOFs [15]. For example, the HKUST-1 consists of three different sized cages and these cages form a ship-in-a-bottle complex that is preventing access to reactants and improving stability.

2.2. Producibility

The second challenge in MOF commercialization is scaling up their production. Approximately 70,000 MOFs have been reported [28], but their typical synthetic schemes are designed to yield <1 g per batch to achieve high-quality crystallinity. Crystallization is highly sensitive to many factors such as reaction temperature, heating rate, ligand/metal ion concentration, the empty space of the reaction vessel, and even the roughness of the reactor surface. Therefore, the crystallization process is one of the factors hindering the producibility of MOFs. Sometimes, a synthetic scheme must be completely modified to increase the reaction volume. There are also several reaction types that are not conducive to a large-volume scale such as vapor/base diffusion, solvent layering, and solvent evaporation because of their limited reaction volumes. Thus far, solvothermal/hydrothermal/mechanochemical reactions have been regarded as appropriate for the mass production of MOFs.

Another factor in producibility is reaction temperature. The usual MOF synthesis involves heating of the reaction medium, and in many cases, the temperature must exceed the boiling points of the solvents [29], [30], [31]. Usually, water-based reactions are heated to above 100 °C and require a high-pressure reactor, called a “digestion bomb.” This approach is inadequate for large-scale production because it requires costly, large-scale, pressure-proof reactors, which decreases the producibility. Room-temperature (RT) or mild heating (below the solvent boiling points) is highly recommended to enhance the producibility of manufacturing processes. Finally, the reactant concentration is also important for improving the production efficiency. Usually, the product crystallinity improves in dilute conditions, but the yield per batch reaction decreases, which could result in higher labor and facility costs. High concentrations also typically worsen the crystallinity and surface area. There are good references that considered concentration in their cost assumptions [32]. This patent from BASF SE introduced a strong base for large-scale synthesis of zinc methylimidazole (ZIF). The synthesized ZIF has a high Langmuir surface area of 2000 m2/g while showing a high synthesis yield of 760 kg m−3 day−1.

2.3. Regulations

Regulations are perhaps the least-considered factor but the most serious issue for commercialization. Based on previous reports, many studies used Hg, Cd, Mn, Cr, or Ni as the metal for the prepared MOFs. In the EU and many countries including the US, Japan, and Korea, these metals are highly controlled and restricted by the government because of their potential negative environmental effects and toxicity. Ligands and solvents are under the same regulations. For example, N,N-dimethylformamide (DMF), dimethylacetamide (DMA), and N-methyl-2-pyrrolidone (NMP) are highly controlled materials in the EU, where their concentrations in products must be <3000 mg kg−1 [33]. Furthermore, many MOFs are synthesized in amide solvents and can contain them after activation. For the performance and regulation of MOF mass product, an efficient activation process is mandatory.

Another issue is a chemical registration with the government. For example, the Korean government has enforced a chemical registration law since 2015 dictating that all chemicals and their safety information must be reported to the government if over 1000 kg year−1 is produced and sold to customers. Since MOFs can have multiple topologies even with the same starting components, it could become mandatory to file safety information (oral/inhale/dermal toxicity data) for all the different variations.

2.4. Production cost

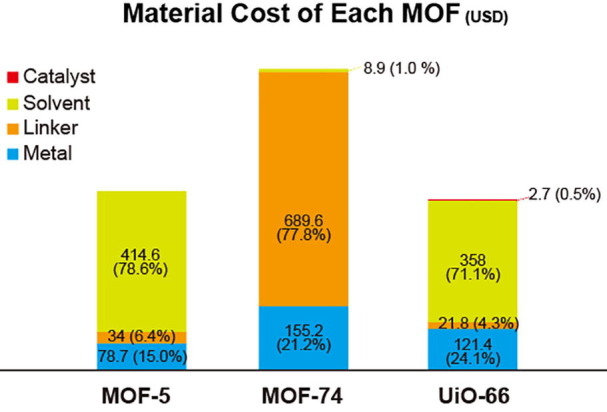

Production cost, another key factor in MOF commercialization, usually comprises the costs of materials, labor, and facilities. Facility costs are directly connected to the reaction conditions (pressure, concentration, yield) and procedures (number of washing and drying cycles), which have been aptly discussed in the literature [34], [35], [36], [37], [38], [39], [40]. This review focuses only on material costs in terms of yield.

There are four components in MOF syntheses: solvent(s), metal source(s), organic ligand(s), and acid/base catalyst. The material cost can be categorized into three groups based on the types of components: 1) Standard ligand and standard metal (e.g., terephthalic acid and Zn/Cu/Zr); 2) specialized ligand and standard metal (e.g., 2,5-dihydroxyterephthalic acid and Zn/Cu/Mg); and 3) standard ligand and specialized metal (e.g., terephthalic acid and Hf/Pd). The prices of the materials in the examples below were obtained from SciFinder without further inquiry.

A typical example of the first cost case is MOF-5, where the parameters and yield for synthesis were adapted from a previous paper [41]. Obtaining 1 kg of activated MOF-5 requires 81.30 L of DMF, 1.03 kg of terephthalic acid, and 3.45 kg of zinc acetate dihydrate for 63% yield; these component amounts cost 414.6, 34.0, and 78.7 USD, respectively. The total material cost for MOF-5 is 527.3 USD kg−1, of which 78.6% comes from the solvent. In this case, solvent recycling, cheaper solvent, and concentrated formulas are strongly recommended to achieve competitive prices compared with other candidates (activated carbon, zeolites, silicas).

Ni-MOF-74 is an example of the second cost case, with a specialized ligand and standard metal; the synthesis parameters and yield were adapted from a previous paper [42]. Obtaining 1 kg of activated Ni-MOF-74 requires 4.75 L of water, 959.9 g of 2,5-dihydroxy-1,4-benzenedicarboxylic acid, and 941.14 g of nickel acetate, which cost 8.9, 689.6, and 188.2 USD, respectively. The total material cost of Ni-MOF-74 is 886.7 USD kg−1, of which approximately 78% is for the ligand. The biggest challenge in this case is to find an adequate material supplier or alternative ligand. One example of an alternative ligand is 4,6-dihydroxy-1,3-benzenedicarboxylic acid, the MOF of which has similar properties and topology to those of MOF-74 [43]. Unlike 2,5-dihydroxy-1,4-benzenedicarboxylic acid, 4,6-dihydroxy-1,3-benzenedicarboxylic acid can be synthesized by a one-step reaction and thus costs less.

UiO-66 is an example of the third cost case, with a standard ligand and specialized metal. The parameters and yield of UiO-66 were adapted from a previous paper [44]. Obtaining 1 kg of activated UiO-66 requires 23.81 L of DMF, 924.7 g of zirconium chloride, 659.2 g of terephthalic acid, and 401.9 g of concentrated HCl; these amounts cost 121.4, 358.0, 21.8, and 2.7 USD, respectively. The total material cost of UiO-66 is 503.9 USD kg−1 (Fig. 1 ).

Fig. 1.

Material Cost of MOF-5, Ni-MOF-74, UiO-66(USD).

The material costs of MOFs are much higher than those for other adsorbents such as activated carbon, zeolites, and silica gel (40, 47.5, and 33.5 USD kg−1, respectively). A target cost for MOFs of 15 USD kg−1 has been reported [40], toward which several approaches have been suggested. First, the solvent must be collected and reused several times. DMF is used in the synthesis of MOF-5 and UiO-66 and accounts for 78.6% and 71.7%, respectively, of the material costs. Solvent recycling is the most important factor for cost-saving with MOF synthesis. Solvent recovery systems are usually installed in petrochemical factories. Another approach is to use water as a solvent, as is the case for Ni-MOF-74, where the water solvent accounts for only 1% of the material cost. However, water-based syntheses require high-pressure reaction vessels, which are difficult to adapt to large-scale production. The third method is mechanochemical synthesis, which requires only a small amount of solvent compared with solvo/hydrothermal reactions. The mechanochemical synthesis of a MOF was first reported in 2006 [45] and has since been used to synthesis several MOFs such as COF [46], [47], [48], MOF-5 [49], ZIF-8 [50], [51], [52], MIL-53 [53], MIL-101 [54]. However, no mechanochemical syntheses for Zr-based MOFs have been established. UiO-66 MOFs with functional groups (amine, fluoride) have been reported, but pristine UiO-66 still requires a solvothermal method. The pioneer of mechanochemical synthesis is MOF Technologies [54] in Belfast, UK.

Another cost factor is the choice of an appropriate metal source. Metal sources for MOF syntheses are usually selected from nitrates, sulfates, acetates, halides, or oxides. One factor determining the metal selection is its solubility in the reaction solvent. MOF synthesis is highly similar to crystallization, and thus solubility is critical for obtaining high-quality products. Metal nitrates, acetates, and sulfonates are popular choices in many studies because they are highly soluble in the typical solvents employed in MOF syntheses, such as DMF, alcohol, and water. Halides are another common choice, especially for UiO MOFs, whereas oxides are perhaps the least common because of their poor solubility in many solvents. Nitrates, acetates, and sulfates remain as anions in the solution after the reaction, leading to higher costs for waste chemical deposition and limiting the recycling of used solvents. Halide metal sources have the additional disadvantage of producing HCl gas from some metal ions (for example, ZrCl4) when dissolved in DMF. This necessitates an acid-resistant coating on the walls of the reactor or changing to a higher quality reactor material such as stainless steel.

Finally, the organic ligands are generally selected from polymer monomers or the intermediates of drugs or pesticides. One example is terephthalic acid, which is a monomer of polyethylene terephthalate and is thus already established for mass production. Other examples are imidazole and its derivatives. Imidazole is a component of many drugs, such as antifungal and antibacterial medicines. Since various derivatives are on the market for the drug industry, they are easy to adapt to MOF chemistry.

2.5. Road to commercialization: from hydrogen/methane storage by BASF and startups

The most established application in MOF is a gas storage of hydrogen, methane, acetylene and SF6. The advantage of MOF is to reduce tank pressure for storage or increase the capacity in same volume. A typical example is a hydrogen storage. Since MOF-5 was firstly reported as hydrogen adsorbent in 2003 [55], series of papers have been reported for hydrogen storages [56], [57], [58], [59]. The hydrogen storage material is the core component of fuel cell vehicle and the requirement is given by the department of energy (DOE). The DOE targets are 4.5 wt% (gravimetric working capacity) and 30 g L−1 (volumetric working capacity) by 2020. Some MOFs satisfy the DOE gravimetric target so far [60].

The front runner in MOFs commercialization is BASF. BASF started MOF research in 1999 and they launched the first Product in 2013 for compressed natural gas (CNG) storage in heavy duty trucks [61]. However, the CNG vehicle is not still popular yet and the commercialization is still on the way. The application in next generation vehicle is not ripen and would take more times to sell in market. Another application on market is specific gas storage. NuMat tech announced its ION-X technology in 2017 for AsH3, PH3, BF3 storage with Linde (current Versum Materials). Those gases are used in semiconductor manufacturing. The company reported their materials improved the tank gas capacity and delivered to the customers [62].

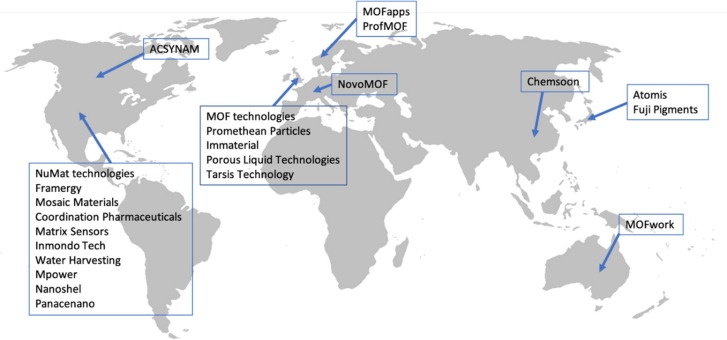

Now there are some startups trying to launch MOFs in market or selling MOFs. The list is following, MOF technologies, Promethean Particles, Immaterial, Porous Liquid Technologies, Tarsis Technology (UK), NuMat technologies, Framergy, Mosaic Materials, Coordination Pharmaceuticals, Matrix Sensors, Inmondo Tech, Water Harvesting, MPower, Nanoshel, Panacenano (US), MOFapps, ProfMOF (Norway), MOFwork (Australia), ACSYNAM (Canada), NovoMOF (Switzerland), Atomis, Fuji Pigments (JP), Chemsoon(China) (Fig. 2 ).

Fig. 2.

Global map for MOF companies.

3. MOF mass production processes

For more than two decades, numerous MOFs have been discovered and synthesized in academia. Their characteristics and applications have been widely studied, and now it is time to move forward with their practical mass production and application. MOF synthesis requires chemical components such as organic ligands, metal ions, solvents, and modulators, as well as thermal energy and pressure conditions. Research on the academic level has yielded diverse MOFs and synthetic techniques on the gram scale. However, the units required for commercial usage are tons and kilograms, which necessitate entirely new synthetic procedures for mass production. In this context, the areas of concern are the chemical costs, reaction vessel efficiency, reaction yields, reproducible quality, environmental regulations, and mild conditions for safety. In general and lab-scale MOF synthetic procedures, the organic ligands and metal precursors are chemically combined in organic solvents to afford powder products, which are then recovered from the reaction solution. Finally, the product is activated to afford empty pores in the resulting MOFs. This section will discuss how to produce MOFs on a large scale and what kinds of procedures have been chosen for industrial-scale production. The scaling methods are divided into static and continuous processes, and we will introduce various synthetic strategies and methods for each.

3.1. Synthesis scaling

3.1.1. Static processes

Static processes are based on fixed reaction vessels, and for scaling, most approaches expand the size of the container based on the lab-scale method. A majority of static processes employ solvents to mediate the reaction between the organic ligands and metal ions. Considering environmental regulations and cost concerns, it is desirable to develop more solvent-free synthetic systems, but the common synthetic procedures still rely on solvent-based systems. Depending on the equipment and energy source, solvent syntheses can be divided into ambient temperature (RT) and ambient pressure (1 atm), high-temperature (>RT) and ambient pressure (1 atm), high-temperature (>RT) and high pressure (>1 atm), microwave heating, sonochemical, and electrochemical syntheses. Solvent-free processes are mainly mechanochemical, typically via grinding or ball-milling. In the next section, these methods will be introduced and discussed in terms of their pros and cons with representative cases.

3.1.1.1. Solvent-based static processes

In solvent-based static syntheses, MOFs are synthesized by adding energy to the solvent in which the organic ligands and metal precursors are dissolved in a fixed vessel. Because solvent-based static syntheses are the most common in the traditional academic community, a database of MOF syntheses for various conditions has accumulated, allowing for easy access to scaled-up syntheses by expanding the reactor size. This type of method also facilitates diverse reaction conditions for general MOF syntheses as well as more specific conditions. However, the larger the reaction becomes, the more solvent is required. In particular, polar aprotic solvents, which are widely used in MOF synthesis due to their ability to solubilize the reactants, generally have a high boiling point and thus require a high temperature for hydrothermal synthesis. Most of these solvents are organic, such as DMF, DEF (N,N-diethylformamide), and DMA, which are environmentally regulated and expensive, accounting for 60% of the total MOF synthesis cost. In addition, the use of fixed vessels makes it difficult to automate static solvent syntheses into continuous processes.

-

•

Ambient temperature (RT) and ambient pressure (1 atm) processes

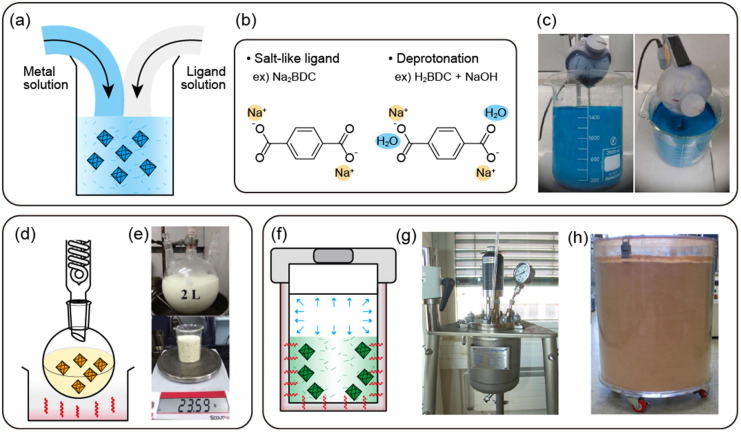

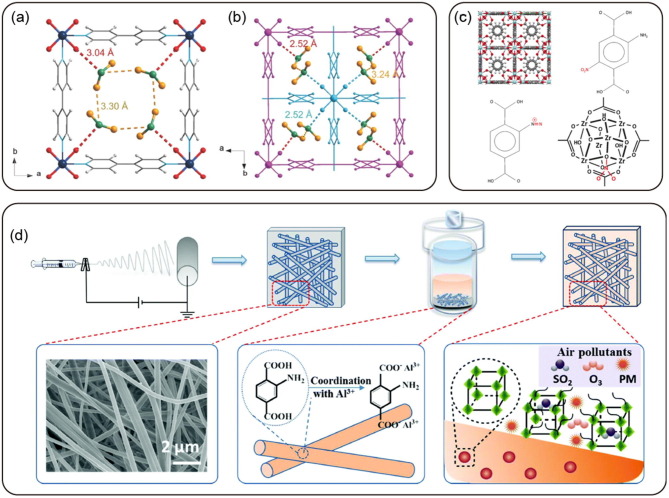

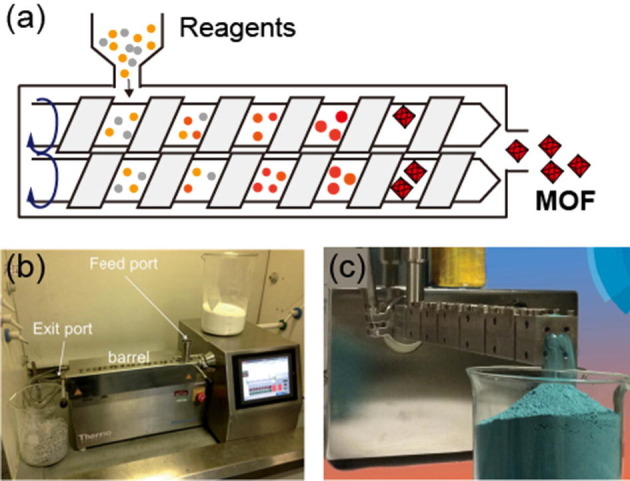

The types of MOFs that can be easily synthesized at RT are primarily based on Cu and Zn, such as MOF-5 [41], HKUST-1 [63], [41], and ZIF-8 [64] as well-known examples. The organic ligands and metal salts are usually pre-activated in separate solutions, ready for vigorous nucleation upon mixing (Fig. 3 a). Ligands can be pre-activated ligand by either using a salt-like ligand [65] or deprotonating the ligand by adding a base [41], [64], [65] (Fig. 3b). This increases the solubility of the ligand in polar solvents to improve the reactivity, and the deprotonated moiety has a pre-activated form that can immediately participate in the synthesis. As examples, MIL-53(Al) and MOF-5 were synthesized at RT using a sodium carboxylate-type pre-activated ligand (sodium terephthalate) and a general carboxylic acid-type ligand (terephthalic acid) with added NaOH, respectively [65]. In addition, with other bases, MOF-5 and ZIF-8 were synthesized by inducing ligand deprotonation with trimethylamine (TEA) [41], [64]. For the metal reagent, the reactivity depends on the type of counter anion in the metal salt. It is advantageous to use metal salts with acetate (CO2CH3 −) as the counter anions since they exhibit faster nucleation than nitrate (NO3 −), sulfate (SO4 2−), and chloride (Cl−) salts [41], [66], [63], [65]. Huo et al. synthesized HKUST-1 with Cu(NO3)2 and Cu(CO2CH3)2 and compared the synthetic properties. The use of the acetate yielded a higher amount of particles in a shorter time due to rapid nucleation, where the precursors achieved efficiencies of 41 and 2035 g m−3 d−1 STY (space–time yield; grams of MOF per cubic meter of reaction mixture per day of synthesis), respectively (Fig. 3c) [63].

Fig. 3.

Ambient temperature (RT) and ambient pressure (1 atm) process (a) Schematic illustration (b) Strategies to synthesize MOF (c) Photographs of synthesizing HKUST-1 in 1.2 L aqueous solvent. Reproduced with permission from [63]. Copyright 2013 Royal Society of Chemistry. High-temperature (>RT) and ambient pressure (1 atm) process (d) Schematic illustration (e) Photographs of UiO-66-NH2 (upper) reaction equipment (lower) synthesized to 23.59 g. Adopted with permission from [69]. Copyright 2017 Royal Society of Chemistry. High-temperature (>RT) and pressure (>1 atm) process (f) Schematic illustration (g) Photograph of 3 L autoclave for large-scale MIL-101(Cr) production. Reproduced with permission from [75]. Copyright 2015 by Royal Society of Chemistry. (c) Digital image of 70 L box containing large-scale produced MIL-100(Fe). Reproduced with permission from [76]. Copyright 2012 Elsevier.

Ambient-temperature solvent synthesis is the most facile way to produce MOF particles and can be scaled up without additional costs or energy for nucleation and growth. It is advantageous to use heat-labile ligands such as acetylenedicarboxylic acid and functionalized ligands [41], [65]. In addition, ligands in the form of a salt (e.g., Na2BDC) generate harmless salts (NaNO3, NaCl) rather than corrosive acids (HNO3, HCl) as byproducts, which is eco-friendly and safe [65], and the issue of surface area reduction due to ligand insertion into the pores during synthesis is alleviated. Nitrates have strong oxidizing properties and may explode with organic ligands, and thus other metal salts should be selected for mass production. Solvent costs and environmental issues must also be considered as the amount of solvent increases relative to the reaction capacity for mass production. In addition, there are limitations on the types of MOFs that can be synthesized at RT, and a deprotonated ligand can only be used if the ligand or metal is stable under basic conditions (Table 1 ).

-

•

High-temperature (>RT) and ambient pressure (1 atm) processes

Table 1.

Summary of MOF that synthesized with ambient temperature (RT) and ambient pressure (1 atm) process.

| MOF | Metal source | Ligand | Modulator | Solvent | Time | STY (kg m−3 day−1) | Yield (g) | Yield (%) | Surface area (m2 g−1) | Ref |

|---|---|---|---|---|---|---|---|---|---|---|

| MOF-5 | Zinc acetate dihydrate | Terephthalic acid | TEA | DMF | 2.5 h | – | 4.92 | 63 | 3909 | [41] |

| MOF-5 | Zinc acetate dihydrate | Terephthalic acid | – | DMF | 45 min | – | – | – | – | [41] |

| MOF-74 | Zinc acetate dihydrate | 2,5-Dihydroxyterephtalic acid | – | DMF | 18 h | – | 0.27 | 69 | 1187 | [41] |

| MOF-177 | Zinc acetate dihydrate | Benzenetribenzoic acid | – | DEF | 3 h | – | 0.49 | 60 | 4944 | [41] |

| HKUST-1* | Copper acetate monohydrate | 1,3,5-Benzenetricarboxylic acid | TEA | DMF/EtOH/water | 23 h | – | 0.32 | 44 | – | [41] |

| IRMOF-0 | Zinc acetate dihydrate | Acetylenedicarboxylic acid | TEA | DMF | overnight | – | – | – | – | [41] |

| HKUST-1 | Copper(II) acetate monohydrate | 1,3,5-Benzenetricarboxylic acid | – | water | 1 h | 2035 | – | 84.8 | 1763 | [63] |

| HKUST-1 | Copper(II) nitrate hemi(pentahydrate) | 1,3,5-Benzenetricarboxylic acid | – | water | 1 h | 41 | – | 34.2 | 1403 | [63] |

| ZIF-8 | Zinc nitrate hexahydrate | 2-Methylimidazole | TEA | water | 30 min | – | – | 90 | 491.54 | [64] |

| MIL-53(Al) | Aluminum nitrate nanohydrate | Disodium terephthalate | – | water | 4 h-7d | – | – | – | 1048 | [65] |

| MIL-53(Al) | Aluminum nitrate nanohydrate | Terephthalic acid | NaOH | water | 24 h | – | – | – | 1072 | [65] |

| NH2-MIL-53(Al) | Aluminum chloride hexahydrate | 2-Aminoterephthalic acid | NaOH | water | 24 h | – | – | – | – | [65] |

| NO2-MIL-53(Al) | Aluminum nitrate nanohydrate | 2-Nitroterephthalic acid | NaOH | water | 24 h | – | – | – | – | [65] |

| MOF-74(Zn) | Zinc acetate dihydrate | 2,5-Dihydroxyterephtalic acid | NaOH | water | 24 h | – | – | – | – | [65] |

| MOF-5 | Zinc nitrate hexahydrate | Disodium terephthalate | – | DMF | 24 h | – | – | – | – | [65] |

| MOF-74(Zn) | Zinc acetate dihydrate | 2,5-Dihydroxyterephtalic acid | – | DMF | 20 h | – | – | – | 867 | [67] |

| MOF-74(Ni) | Nickel acetate tetrahydrate | 2,5-Dihydroxyterephtalic acid | – | DMF | 20 h | – | – | – | 402 | [67] |

| MOF-74(Co) | Cobalt acetate tetrahydrate | 2,5-Dihydroxyterephtalic acid | – | DMF | 20 h | – | – | – | 521 | [67] |

| MOF-74(Mn) | Manganese acetate tetrahydrate | 2,5-Dihydroxyterephtalic acid | – | DMF | 20 h | – | – | – | 491 | [67] |

| MOF-74(Mg) | Magnesium acetate tetrahydrate | 2,5-Dihydroxyterephtalic acid | – | DMF | 20 h | – | – | – | 1007 | [67] |

*MOF-199.

Most RT MOF syntheses studied in academic laboratories have yield limitations below the gram scale with exceptions such as HKUST-1, and thus it is a challenge to produce MOFs on an industrial scale at RT. On the other hand, in a high-temperature reaction, the injected thermal energy increases the solubility and reactivity of the precursors with the solvent and promotes nucleation, allowing for the production of MOFs with high yields in short reaction times (Fig. 3d). Additionally, high-temperature synthesis enables the production of tetravalent metal-based MOFs, which are difficult to nucleate without added energy. Because tetravalent metal-based MOFs have a stronger Mn +-O interaction than di- and trivalent metals, ligand exchange for crystallization is slower.

High-temperature processes are favorable in terms of high yields and time efficiency compared with RT processes. In a previous study on Al-MOF, the synthetic conditions were kept the same, and the temperature was adjusted to RT or 60 °C [68], [72]. The higher reaction temperature not only increased the STY from 4742 to 5339 g m−3 d−1 but also nearly doubled the surface area from 723 to 1140 m2 g−1 .

In particular, heating processes allow for the synthesis of Zr-, Hf-, and Ti-based MOFs, which are difficult to react at RT because thermal energy is needed to accelerate the binding of the metal salts and ligands for nucleation [69], [70]. However, even with heating, the Mn +-O bond is strong, and thus ligand exchange is still slow, requiring several hours to several days. The table below summarizes the conditions under which MOFs have been synthesized in short periods. First, when ZrOCl2 was used as a metal source, nucleation occurred faster than with other metal sources like ZrCl4 due to the influence of the counter ions [71]. Second, to promote the nucleation of Zr-MOFs, He at al. introduced water to accelerate the hydrolysis of the metal salt and deprotonation of the ligands. Additionally, acetic acid was used as a modulator to control the reactivity because a fast reaction results in poor crystallinity of the grown MOF. Finally, 23.59 g of UiO-66-NH2 was synthesized in a 2-L flask under reflux at 120 °C for 15 min by controlling the reaction rate (Fig. 3e) [69].

This type of high-temperature and ambient-pressure process is one of the more moderate syntheses conducted under reflux. However, it is still more reactive than ambient-temperature processes, making it advantageous for mass production. In addition, since the solubility of the precursor is increased by the high temperature, the reaction can be optimized using less solvent, and solvent loss can be reduced by recovering the evaporated solvent through a reflux system. However, most such reactions take longer than one day without adjusting the metal source or adding a modulator, and there are still many MOFs that are synthesized at reflux conditions harsher than 100 °C. In addition, it is disadvantageous in terms of cost and the environment to mass-produce MOFs using mainly organic solvents such as DMF, DEF and dimethylsulfoxide (DMSO) for their increased solubility and high-temperature heating (Table 2).

Table 2.

Summary of MOF that synthesized with high-temperature (>RT) and ambient pressure (1 atm) process.

| MOF | Metal source | Ligand | Modulator | Solvent | Time | Temperature (℃) | STY (kg m−3 day−1) | Yield (g) | Yield (%) | Surface area (m2 g−1) | Ref |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Al-fum*, a | Aluminum sulfate octadecahydrate | Fumaric acid | NaOH | water | 10 min | RT | 4742 | 26.2 | 76% | 723 | [68] |

| Al-fum* | Aluminum sulfate octadecahydrate | Fumaric acid | NaOH | water | 10 min | 60 | 5339 | 29.5 | 86% | 1140 | [68] |

| MOF-74(Ni) | Nickel acetate tetrahydrate | 2,5-Dihydroxyterephtalic acid | – | water | 1 h | 160 (reflux) | 680 | 17.9 | 91.60% | 1233 | [42] |

| MOF-74(Mg) | Magnesium nitrate hexahydrate | 2,5-Dihydroxyterephtalic acid | – | DMF/EtOH/water | 24 h | 120 (reflux) | – | 7.6 | – | 984 | [73] |

| MOF-174(Mg) | Magnesium nitrate hexahydrate | 4-(4-carboxy-3-hydroxy-phenyl)-2-hydroxy-benzoic acid | – | DMF/EtOH/water | 12 h | 120 (reflux) | – | 3.82 | – | 2465 | [73] |

| MOF-184(Mg) | Magnesium nitrate hexahydrate | 4-[2-(4-carboxy-3-hydroxy-phenyl)ethynyl]-2-hydroxy-benzoic acid | – | DMF/EtOH/water | 24 h | 120 (reflux) | – | 0.78 | – | 3154 | [73] |

| MOF-74(Ni) | Zinc nitrate hexahydrate | 2,5-Dihydroxyterephtalic acid | – | DMF/EtOH/water | 24 h | 120 (reflux) | – | 46.4 | – | 1176 | [73] |

| MOF-174(Ni) | Zinc nitrate hexahydrate | 4-(4-carboxy-3-hydroxy-phenyl)-2-hydroxy-benzoic acid | – | DMF/EtOH/water | 12 h | 120 (reflux) | – | 2.82 | – | 1444 | [73] |

| MOF-184(Ni) | Zinc nitrate hexahydrate | 4-[2-(4-carboxy-3-hydroxy-phenyl)ethynyl]-2-hydroxy-benzoic acid | – | DMF/EtOH/water | 12 h | 120 (reflux) | – | 1.95 | – | 2449 | [73] |

| UiO-66 | Zirconyl chloride octahydrate | Terephthalic acid | Formic acid | DMF | 2 h | 140 (reflux) | – | 100 | – | 604 | [71] |

| MOF-801 | Zirconyl chloride octahydrate | Fumaric acid | Formic acid | DMF | 2 h | 140 (reflux) | – | 100 | – | 838 | [71] |

| UiO-66-NH2 | Zirconium chloride | 2-Aminoterephthalic acid | Acetic acid/water | DMF | 15 min | 120 (reflux) | – | 23.59 | 90.70% | 1075 | [69] |

| UiO-66 | Zirconium chloride | Terephthalic acid | Acetic acid/water | DMF | 15 min | 120 (reflux) | – | – | – | 995 | [69] |

| UiO-66-(OH)2 | Zirconium chloride | 2,5-Dihydroxyterephtalic acid | Acetic acid/water | DMF | 15 min | 120 (reflux) | – | – | – | 575 | [69] |

| UiO-66–2,6-NDC | Zirconium chloride | 2,6-naphthalenedicarboxylic acid | Acetic acid/water | DMF | 15 min | 120 (reflux) | – | – | – | 781 | [69] |

| UiO-67 | Zirconium chloride | Biphenyl-4,4′-dicarboxylic acid | Acetic acid/water | DMF | 15 min | 120 (reflux) | – | – | – | 2087 | [69] |

| BUT-12 | Zirconium chloride | H3CTTA** | Acetic acid/water | DMF | 15 min | 120 (reflux) | – | – | – | 1254 | [69] |

| PCN-222-Ni | Zirconium chloride | Tetrakis(4-carboxyphenyl)porphyrin-Ni | Acetic acid/water | DMF | 15 min | 120 (reflux) | – | – | – | 1724 | [69] |

| PCN-222-Co | Zirconium chloride | Tetrakis(4-carboxyphenyl)porphyrin-Co | Acetic acid/water | DMF | 15 min | 120 (reflux) | – | – | – | – | [69] |

| Hf-UiO-66 | Hafnium tetrachloride | Terephthalic acid | Acetic acid/water | DMF | 15 min | 120 (reflux) | – | – | – | – | [69] |

| Hf-UiO-66-NH2 | Hafnium tetrachloride | 2-Aminoterephthalic acid | Acetic acid/water | DMF | 15 min | 120 (reflux) | – | – | – | – | [69] |

| Hf-UiO-66-(OH)2 | Hafnium tetrachloride | 2,5-Dihydroxyterephtalic acid | Acetic acid/water | DMF | 15 min | 120 (reflux) | – | – | – | – | [69] |

| Hf-UiO-66–2,6-NDC | Hafnium tetrachloride | 2,6-naphthalenedicarboxylic acid | Acetic acid/water | DMF | 15 min | 120 (reflux) | – | – | – | – | [69] |

| Hf-BUT-12 | Hafnium tetrachloride | H3CTTA | Acetic acid/water | DMF | 15 min | 120 (reflux) | – | – | – | – | [69] |

| CAU-10-H | Aluminum sulfate | Sodium isophthalate | NaOH | water | 3 h | reflux | – | – | – | – | [74] |

| CAU-10-H | Aluminum sulfate | Sodium isophthalate | Sodium aluminate | EtOH | 10 h | reflux | – | 500 | 93% | – | [74] |

*Basolite A520, **5′-(4-carboxyphenyl)-2′,4′,6′-trimethyl-[1,1′:3′,1″-terphenyl]-4,4″-dicarboxylic acid), a Control condition of Al-fum.

-

•

High-temperature (>RT) and pressure (>1 atm) processes

Traditional heating synthesis, which has been studied the most, is conducted by dissolving the precursors in a solvent at a high temperature and pressure. Synthetic conditions for this traditional process have been well established for most types of MOFs, making their customization straightforward through modification of the underlying conditions.

When the reaction temperature is above the boiling point of the solvent, the autogenous pressure generated by the solvent vapor also affects the synthesis. Therefore, it is necessary to use heat- and pressure-resistant vessels. A high temperature and autogenous pressure enhance the solubility to the point where even reactants that are insoluble in a specific medium (e.g., organic ligands in water) can be used, which can expand the options for combinations of solvents and reactants. In general, Teflon-sealed glass vials can be used for low vapor pressures near the boiling point, but digestion bombs (Teflon-lined autoclave reactor, high-pressure digestion tank) are necessary for harsh conditions such as high temperatures and pressures for long-term reactions(Fig. 3f). To apply such a container to mass synthesis, a large-capacity pressure vessel can be manufactured and employed like that reported previously [75] (Fig. 3g). These traditional heating methods can be largely divided into hydrothermal and solvothermal approaches, which use water and organic solvents, respectively. Hydrothermal methods are advantageous in terms of environmental regulations and solvents when scaled to industrial production, which require a large amount of solvent due to the usage of water. While ionic precursors are highly soluble in water, typical organic ligands are poorly water soluble, and hydrogen bonding between the solvent and precursor can interfere with nucleation. Typical examples of large-scale solvothermal synthesis include MIL-100(Fe) in a 200-L reactor [76] and MIL-101(Cr) in a 3-L reactor [75]. Seo at al. synthesized MIL-100(Fe), also known as Basolite F300 (trade name of BASF SE), with 70 L of reaction solvent in a 200-L metal alloy reactor vessel (Hastalloy C-276) at 160 °C for 12 h. The amount of product was 15.6 kg per batch, and the STY of approximately 450 kg m−3 d−1 was improved to 1700 kg m−3 d−1 by controlling the synthesis time [76] (Fig. 3h). Furthermore, Zhao at al. produced MIL-101(Cr) in a 3-L autoclave at 200 °C for 15 h at a yield of 82.3% based on Cr [75].

Solvothermal synthesis mainly employs polar solvents (DMF, DEF, DMSO, alcohols, etc.) that dissolve the inorganic precursors, where the solvent selection affects the precursor reactivity and crystal growth. In this case, the temperature in the reactor is usually 100–240 °C. With a solvent that does not dissolve the ligand or metal source well, the reaction should be carried out at higher pressures and temperatures to improve the solubility. Therefore, proper solvent selection is important for large-scale syntheses. Another option for solvent selection is ionic thermal synthesis using an ionic liquid, which gives a temperature above the melting point of the salt and rarely generates pressure from the solvent or reactant.

Although these thermal syntheses are well known and widely applied, they do have limitations. Nucleation occurs on the surface of the vessel; thus, since increasing the vessel volume decreases the ratio of the vessel surface area to the solvent volume, the reaction efficiency decreases. In addition, issues can occur with uneven MOF synthesis due to non-uniform heat and pressure distributions. The reactions are also long, from several hours to several days, and require a large amount of solvent (Table 3).

-

•

Microwave heating synthesis

Table 3.

Summary of MOF that synthesized with high-temperature (>RT) and pressure (>1 atm) process.

| MOF | Metal source | Ligand | Modulator | Solvent | Reactor | Time (h) | Temperature (°C) | STY(kg m−3 day−1) | Yield (g) | Yield (%) | Surface area (m2 g−1) | Ref |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MIL-100(Fe) | Iron(III) nitrate nonahydrate | Trimesic acid | – | water | 200L Metal alloy reactor | 12 | 160 | 1700 | – | – | 2280 | [76] |

| MIL-101(Cr) | Chromium(III) nitrate nonahydrate | Terephthalic acid | Nitric acid | water | 3L Autoclave | 15 | 200 | – | 127.1 | 82.3 | 3450 | [75] |

| HKUST-1(Cu-BTC) | Copper(II) nitrate hemi(pentahydrate) | Trimesic acid | – | EtOH/water | Autoclave | 18 | 150 | – | 80 | – | 964.5 | [77] |

| UiO-66 | Zirconium chloride | Terephthalic acid | HCl | DMF | 100L Glass reactor | 24 | 120 | – | – | 93 | 1387 | [44] |

| MIL-101(Cr) | Chromium(III) nitrate nonahydrate | Terephthalic acid | – | water | Teflon rector | 11 | 210 | – | 0.1 | – | 3800 | [78] |

| MIL-100(Fe) | Iron chloride | Trimesic acid | – | water | Teflon rector | 8 | 160 | – | – | 1500 | [78] | |

| UiO-67 | Zirconium chloride | Biphenyl-4,4′-dicarboxylic acid | – | DMF | – | 24 | 120 | – | – | – | 1800 | [79] |

| Zr-TPDC (UiO-68) | Zirconium chloride | Terphenyl dicarboxylic acid | – | DMF | – | 24 | 120 | – | – | – | 4000 | [79] |

| NH2-UiO-66 | Zirconium chloride | 2-Aminoterephthalic acid | – | DMF | – | 24 | 120 | – | – | – | – | [79] |

| MOF-867 | Zirconium chloride | 2,2′-bipyridine-5,5-dicarboxylic acid | – | DMF | – | 48 | 100 | – | – | – | – | [79] |

Microwaves are electromagnetic radiation with wavelengths between 1 m and 1 mm. Microwave heating synthesis applies dipole rotation and ion conduction to heat the solution, unlike traditional heating systems [80]. Many molecules have a dielectric moment, which causes them to rotate and align with the alternating direction of the microwave electric field [81]. Therefore, solvents with high dipole moments are considered optimal for microwave heating synthesis. Loss of tangent (tan δ) determines the ability of a solvent to convert electromagnetic energy into heat at a certain frequency and temperature, where a higher tan δ leads to faster heating (Table 4 ) [82].

Table 4.

Loss tangents (tan δ) of various solvents (2.45 GHz, 20 °C).

| High microwave-absorbing (tan δ > 0.5) |

Medium microwave-absorbing (0.1 < tan δ < 0.5) |

Low microwave-absorbing (tan δ < 0.1) |

|||

|---|---|---|---|---|---|

| Solvent | tan δ | Solvent | tan δ | Solvent | tan δ |

| Ethylene glycol | 1.35 | 2-butanol | 0.447 | Chloroform | 0.091 |

| Ethanol | 0.941 | 1,2-dichlorobenzene | 0.28 | Acetonitrile | 0.062 |

| Dimethyl sulfoxide | 0.825 | 1-methyl-2-pyrrolidone | 0.275 | Ethyl acetate | 0.059 |

| 2-propanol | 0.799 | Acetic acid | 0.174 | Acetone | 0.054 |

| Formic acid | 0.722 | N,N'-dimethylformamide | 0.161 | Tetrahydrofuran | 0.047 |

| Methanol | 0.659 | 1,2-dichloroethane | 0.127 | Dichloromethane | 0.042 |

| Nitrobenzene | 0.589 | Water | 0.123 | Toluene | 0.04 |

| 1-butanol | 0.571 | Chlorobenzene | 0.101 | Hexane | 0.02 |

Reproduced with permission from [82].

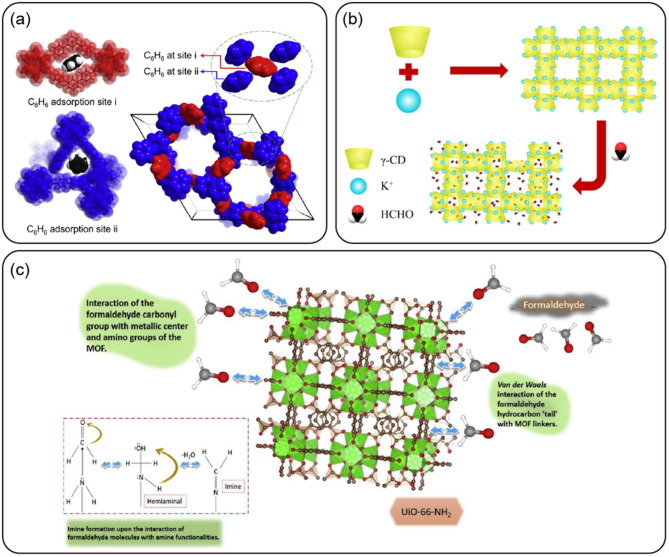

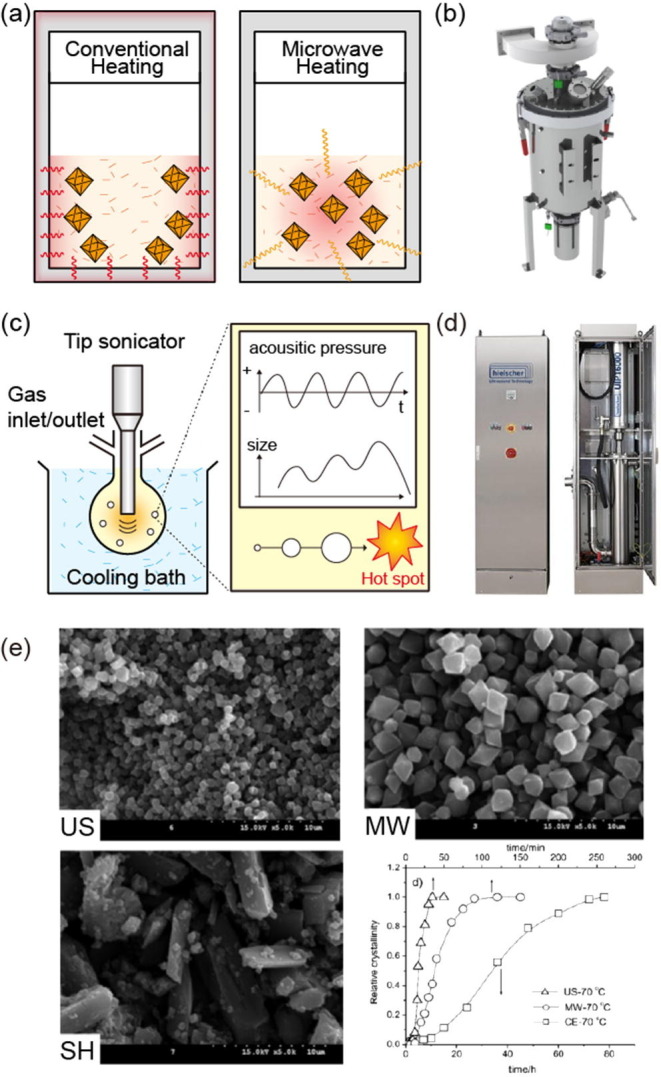

However, this does not mean that a solvent with a low tan δ cannot react in a microwave system if the mixed solution of MOF precursors is polar. The molecular movement of the solvent produces heat, which disperses as the molecules collide. Microwave heating synthesis is energy efficient because it only transfers energy inside the reaction solution. Conventional heating methods first heat the surface of the vessel to add heat energy, but microwave synthesis produces heat directly throughout the material (Fig. 4 a). Therefore, uniform heat transfer occurs inside the vessel within a short time (a few seconds to hours), resulting in rapid nucleation and enabling the easy synthesis of small, uniformly sized MOF particles. The power level, temperature, and reaction time of the microwave irradiation can be adjusted to control the MOF size and characteristics. Although the synthesis time is short, solvent evaporation makes pressure control difficult and requires the use of a pressure vessel.

Fig. 4.

Microwave heating synthesis (a) Schematic illustration for principle (b) Digital images of large-scale microwave instrument of SAIREM. Copyright SAIREM. Sonochemical synthesis (c) Schematic illustration for principle. (d) Digital images of large-scale sonochemical instrument of Hielscher Ultrasonics GmbH. Copyright by © Hielscher Ultrasonics GmbH. (e) SEM images and crystallization curves for the synthesis of MIL-53(Fe) by sonochemistry synthesis (US), microwave heating synthesis (MW) and heating synthesis (SH). Adopted with permission from [87]. Copyright 2010 John Wiley and Sons.

Taddei et al. optimized the large-scale synthesis of UiO-66 with a microwave system [84]. A DMF mixture of zirconium chloride, terephthalic acid, acetic acid, and water was placed in a PTFE vessel and subjected to microwave heating using a CEM MARS 5 multimode instrument in 2 stages (1st stage: 200 W for 3 min; 2nd stage: 80 W for 15 min). UiO-66 was obtained in only 18 min at a high STY of 2241 kg m−3 d−1 compared with that of conventional heating (23 kg m−3 d−1).

On the industrial scale, it is expected that large-scale MOF synthesis using microwaves can be carried out using a SAIREM reactor (Fig. 4b) [83]. However, microwave synthesis conditions have yet to be confirmed for many MOFs, which limits suitable synthesis conditions. In addition, using different equipment from the reference method makes it difficult to reproduce the same conditions, and thus ultimately the reproducibility is limited (Table 5 ).

-

•

Sonochemical synthesis

Table 5.

Summary of microwave heating synthesized MOF.

| MOF | Metal source | Ligand | Modulator | Solvent | Instrument | Reactor | Time | Power (W) | Temperature (°C) | STY (kg m−3 day−1) | Yield (g) | Yield (%) | Surface area (m2 g−1) | Ref |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| UiO-66 | Zirconium chloride | Terephthalic acid | Acetic acid | DMF | Multi-mode microwave synthesizer | PTFE vial | 18 min | 100 | 120 | 2241 | 2.72 | 78 | 1206 | [84] |

| Cu-BDC | Copper(II) nitrate trihydrate | Terephthalic acid | – | DMF | Domestic microwave | – | 30–90 min | 300/100 | – | – | – | – | 624 | [85] |

| HKUST-1 | Copper(II) nitrate trihydrate | Trimesic acid | – | Water/DMF/EtOH | 900 W magnetron | Teflon pot | 10 min | 360 | 70 | – | 0.27 | 50 | 1185 | [86] |

| MIL-53(Fe) | Iron(III) chloride hexahydrate | Terephthalic acid | – | DMF | Mars-5, CEM | – | 2 h | – | 60–70 | – | – | – | – | [87] |

| MIL-101(Cr) | Chromium(III) nitrate nonahydrate | Terephthalic acid | HF | Water | Mars-5, CEM | Teflon autoclave | 1–60 min | 600 | 210 | – | – | – | 3891 | [88] |

| MIL-53(Al) | Aluminum chloride hexahydrate | Terephthalic acid | – | Water | Mars-5, CEM | Teflon autoclave | 5.5 h | 1200 | 150 | – | – | – | 1282 | [89] |

| MIL-53(Cr) | Chromium(III) chloride hexahydrate | Terephthalic acid | – | Water | Mars-5, CEM | Teflon autoclave | 7 h | 1200 | 175 | – | – | – | 1419 | [89] |

| MIL-47(V) | Vanadium(III) chloride | Terephthalic acid | – | Water | Mars-5, CEM | Teflon autoclave | 3 h | 1200 | 135 | – | – | – | 1049 | [89] |

| MIL-88A | Iron(III) chloride hexahydrate | Fumaric acid | – | Water | Mars-5, CEM | Stirring | 2–10 min | 600 | 80 | – | – | – | – | [90] |

| MOF-5 | Zinc nitrate tetrahydrate | Terephthalic acid | – | NMP | MDS-2100. CEM | Teflon autoclave | 15–30 min | 600 | 105 | – | – | – | 2798 | [91] |

| MOF-5 | Zinc nitrate hexahydrate | Terephthalic acid | Water | DMF | – | Teflon pot | 210 s | – | 80 | – | 0.123 | 47 | 2489 | [92] |

| IRMOF-1 | Zinc nitrate hexahydrate | Terephthalic acid | – | DEF | 520A, Resonance Instrument Inc. | Pyrex vial | 25 s | 150 | – | – | – | – | – | [93] |

| IRMOF-2 | Zinc nitrate hexahydrate | 2-Bromoterephthalic acid | – | DEF | 520A, Resonance Instrument Inc. | Pyrex vial | 40 s | 150 | – | – | – | – | – | [93] |

| IRMOF-3 | Zinc nitrate hexahydrate | 2-Aminoterephthalic acid | – | DEF/EtOH | 520A, Resonance Instrument Inc. | Pyrex vial | 35 s | 150 | – | – | [93] | |||

| MOF-74(Ni) | Nickel nitrate hydrate | 2,5-dihydroxyterephthalic acid | – | DMF/EtOH/Water | Multiwave 3000/Synthos 3000, Anton Paar | Teflon autoclave | 90 min | – | 100 | – | – | – | 1252 | [94] |

| MOF-74(Mg) | Magnesium nitrate hydrate | 2,5-dihydroxyterephthalic acid | – | DMF/EtOH/Water | – | Teflon autoclave | 90 min | – | 125 | – | – | – | 1416 | [94] |

| MIL-101(Cr) | Chromium(III) chloride hexahydrate | Terephthalic acid | NaOH | Water | MDS-2002A | Teflon autoclave | 3 min | – | 210 | – | – | – | 3208 | [95] |

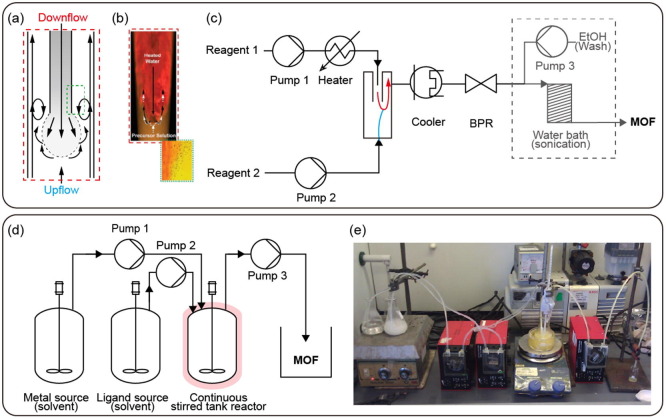

Sonochemical synthesis applies ultrasonic irradiation as energy for reactions at RT. Similar to microwave heating, sonochemical methods can afford MOF particles of a uniform size in a short time using concentrated vibrational energy. Sonochemical synthesis employs extreme transients using powerful ultrasonic waves (20 kHz–1 MHz) that create localized hotspots, which can reach temperatures above 5000 K, heating and cooling rates above 1010 K s−1, and pressures above 1000 atm [80], [96]. This phenomenon arises from “acoustic cavitation,” which involves the formation, growth, and implosive collapse of bubbles (Fig. 4c).

Sonochemical syntheses can employ two types of equipment. The reaction vessel can be immersed in an ultrasonic bath, where energy is transferred from outside the vessel to the inside. Alternatively, as commonly used in laboratories, tips for generating ultrasound are immersed in the reaction solution to transfer energy directly. This method is 100 times more powerful than the use of an ultrasonic bath. In addition, industrial ultrasonic devices can be applied for mass production (Fig. 4d).

The sonochemical syntheses of only a few types of MOFs have been studied, including ZIF-8, HKUST-1, MOF-5, and MIL-53. Cho et al. synthesized ZIF-8 with TEA and NaOH as a pH modulator in as little as 1 h with a probe-type sonicator (60% power of 500 W, 20 kHz) and achieved a high synthetic yield of 85% and STY of 2140 kg m−3 d−1 [97]. The dependence of MOF characteristics on the heating method was explored by a study comparing MIL-53(Fe) prepared by solvothermal heating (SH), microwave heating (MW), and sonochemical syntheses (US) [80], [87]. The nucleation and crystal growth times decreased in the order of US > MW≫SH. The morphologies of the MOFs formed at the same temperature were compared by scanning electron microscope (SEM) imaging, which showed that MW and US syntheses produced uniformly sized MOF particles, and the particle sizes increased in the order of US < MW < SH (Fig. 4e).

MOF synthesis with ultrasound can generate uniformly nanosized MOF particles. Additionally, the intense ultrasonic waves accelerate chemical reactions such as homogeneous nucleation and crystal growth, and it is easy to combine ultrasound with additional cooling and heating systems or stirring processes. However, unlike conventional heating syntheses, it will be difficult to control the predetermined synthetic conditions from existing methods due to the lack of autogenous pressure. The sonochemical synthesis of MOFs has not yet been actively studied in the laboratory, but it is expected to be applicable to industrial production under mild conditions instead of high temperatures and pressures (Table 6 ).

-

•

Electrochemical synthesis for MOF film production

Table 6.

Summary of sonochemical synthesized MOF.

| MOF | Metal source | Ligand | Modulator | Solvent | Instrument | Max power | Power | Time | Temperature (°C) | STY (kg m−3 day−1) | Yield (%) | Surface area (m2 g−1) | Ref |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ZIF-8 | Zinc nitrate hexahydrate | 2-methylimidazole | TEA, NaOH | DMF | Probe (VCX 500) | 500 W, 20 kHz | 60% | 1 h | – | 2140 | 85 | 1174 | [97] |

| MIL-53(Fe) | Ferric chloride hexahydrate | Terephthalic acid | – | DMF | Probe (VCX 750) | – | 25–40% | 0.58–1.5 h | 50–80 | – | – | – | [87] |

| MIL-53(Fe) | Ferric chloride hexahydrate | Terephthalic acid | – | DMF | Probe (VCX 500) | 500 W, 20 kHz | 60% | 15 min | – | – | 30.2 | – | [98] |

| Zn-HKUST-1 | Zinc acetate dihydrate | Trimesic acid | – | DMF | – | – | 305 W, 40 kHz | 30 min | – | – | – | – | [99] |

| TMU-4 | Zinc nitrate hexahydrate | 4,4′-Oxybis(benzoic acid) 4-BPDB* | TEA | DMF | Bath (SONICA-2200 EP) | 40 kHz | 40 kHz | 30–90 min | – | – | 88 | – | [100] |

| CPO-27(Zn) | Zinc nitrate hexahydrate | 2,5-dihydroxyterephthalic acid | Water | DMF | Probe (VCX 500) | 500 W, 20 kHz | 35% | 70 | – | – | 979 | [101] | |

| CPO-27(Co) | Cobalt nitrate hexahydrate | 2,5-dihydroxyterephthalic acid | Water | DMF | Probe (VCX 500) | 500 W, 20 kHz | 35% | 70 | – | – | 1083 | [101] | |

| CPO-27(Ni) | Nickel nitrate hexahydrate | 2,5-dihydroxyterephthalic acid | Water | DMF | Probe (VCX 500) | 500 W, 20 kHz | 35% | 70 | – | – | 1113 | [101] |

*1,4- bis(4-pyridyl)-2,3-diaza-1,3-butadiene.

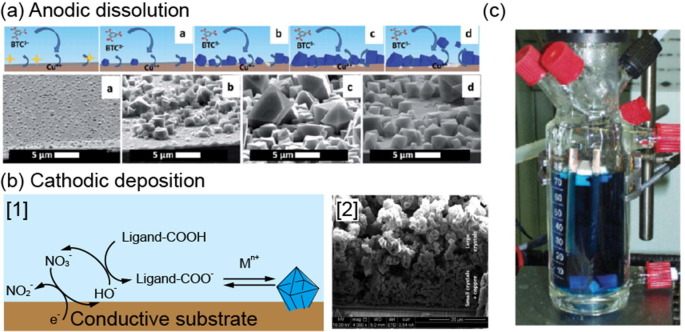

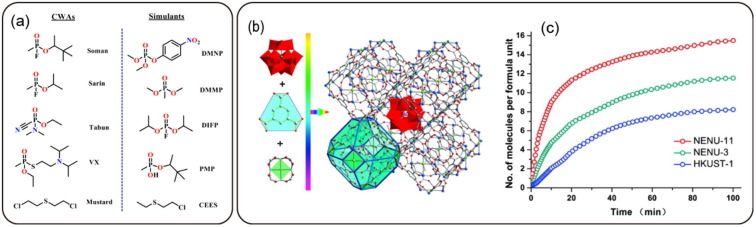

Electrochemical synthesis uses electrical reactions between metal electrodes and ligand solutions. This method was first introduced by a BASF patent in 2005, which detailed the synthesis of HKUST-1 (Cu-BTC) in thin layers via Cu plate electrodes (Fig. 5c) [102]. Despite being a static synthesis, this method allows for continuous production as long as reactants are present. In addition, electrochemical syntheses have the significant advantages of mild conditions and short reaction times compared with hydrothermal synthesis. The MOF is synthesized by a reaction between the electrode and precursor, which is controlled by adjusting the current and voltage. Electrochemical syntheses can be classified into anodic dissolution and cathodic deposition, which produce a MOF film on the electrode (Fig. 5) [103]. The mechanism of anodic dissolution consists of four phases: initial nucleation, growth of islands, intergrowth, and detachment. As the metal ions are released from the electrode into the ligand solution, nucleation initiates at defects on the metal substrate. Nuclei continue to grow next to the initial nuclei, forming intergrown MOF islands. This has been confirmed not only for Cu-based HKUST-1 but also for Zn and Fe-based MOFs [103], [104], [105]. After the MOF film is formed, the metal ions dissolved from the metal substrate pass through the MOF layer to continuously synthesize the MOF at the MOF–solution interface. As a result, a void forms between the first MOF layer and the metal substrate, which separates the two. This method requires time for MOF electrodeposition, which depends on the current, and the size of the crystal depends on the reaction time and solvent. In addition, the use of metal anodes limits the MOFs that can be synthesized depending on the type of metal selected. Additionally, in terms of the reaction solvent, it should be noted that an aqueous solvent can generate hydrogen in the cathode.

Fig. 5.

(a) Schematic illustration and SEM images for synthesized HKUST-1 with anodic dissolution. (b) (left) Schematic illustration and (right) SEM images for synthesized HKUST-1 with cathodic deposition (c) Digital image of HKUST-1 synthesis cell for electrochemical preparation of MOFs with Cu-plates as electrode material. Both (a) and (b) (left) have been reprinted with permission from [103]. Copyright 2016 American Chemical Society. Part (c) has been reproduced with permission from [102]. Copyright 2006 Royal Society of Chemistry.

The second electrochemical method is cathodic deposition, where the electrode is immersed in a mixed solution of metal ions, ligand, and probase, and the MOF is synthesized from the electrode through electrical energy. Unlike anodic dissolution, cathodic deposition does not require a metal electrode but instead uses a conductive substrate to grow the MOF film. The cathodic deposition mechanism consists of three steps: nucleation of dispersed nuclei, formation of crystal islands, and intergrowth [103], [106]. The difference from the anodic method is that after the first layer, another layer forms between the electrode and MOF, and thus no MOF detachment occurs. The reaction rate can be adjusted by controlling the protonation of the ligand via the pH.

Electrochemical synthesis can produce MOFs by either anodic dissolution or cathodic deposition depending on the characteristics of the metal source and the conditions of the reaction solution. Using electrochemistry, MOFs can be synthesized continuously in a short time at RT and atmospheric pressure. In particular, anodic dissolution is advantageous in that no counter ion waste is generated from the metal precursor. Comparing metal materials in terms of cost efficiency, anodic dissolution uses a metal substrate, whereas cathodic deposition uses metal ions, making the latter reaction easier and cheaper. However, in terms of reaction solvents and electrolytic baths, the cathodic method requires expensive solvents such as DMF, and the bath has a short lifetime of several days. The anodic method, on the other hand, is more suitable for long-term and large-scale syntheses due to the inexpensive solvents like alcohol and long lifetime of the bath [103]. In electrochemical synthesis, MOFs are synthesized by coating on the electrode, and thus it is difficult to produce uniformly sized particles since they are aggregated rather than separated. Thus far, electrochemical methods have yet to be applied to many MOFs, and most research has been aimed at MOF film coating. Electrochemical syntheses are more suitable for producing large-area MOF films (Table 7 ).

Table 7.

Summary of MOF with electrochemical synthesis.

|

a. Anodic deposition | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| MOF | Metal source | Ligand | Solvent | Electolyte | Voltage (V) | Current (mA) | Time (min) | Temperature (℃) | Productivity (g h−1) | Surface area (m2 g−1) | Ref |

| HKUST-1 | Cu plate (5 mm) | Trimesic acid | MeOH | – | 19–12 | 1.3 A | 150 | – | – | 1820 | [102] |

| HKUST-1 | Cu plate | Trimesic acid | EtOH/Water | MTBS* | 2–30 | 50 | – | 40 | 0.215 | 1404 | [107] |

| ZIF-8 | Zinc plate | 2-methylimidazole | DMF | MTBS | – | 50 | – | 25 | 0.25 | 1656 | [107] |

| MIL-100(Al) | Aluminium plate | Trimesic acid | EtOH/Water | – | – | – | – | 60 | – | 969 | [107] |

| MIL-53(Al) | Aluminium plate | Terephthalic acid | Water/DMF | KCl | – | 10–100 | – | 90 | 0.775 | 910 | [107] |

| NH2-MIL-53(Al) | Aluminium plate | 2-Aminoterephthalic acid | Water/DMF | KCl | – | 10–100 | – | 20–90 | – | 875 | [107] |

| Zn3(BTC)2 | Zinc plate | Trimesic acid | Water | NH4F | 2 | – | 40 s | 65 | – | – | [108] |

| ZIF-4 | Zinc foil | Imidazole | DMF/Water | MTBAMS** | 2.5 | – | 15–60 | 85 | – | 75 | [109] |

| ZIF-7 | Zinc foil | Benzimidazole | DMF | MTBAMS | 2.5 | – | 120 | 55 | – | 358 | [109] |

| ZIF-8 | Zinc foil | 2-methylimidazole | Water | MTBAMS | 2.5 | – | 60 | 55 | – | 1730 | [109] |

| ZIF-14 | Zinc foil | 2-ethylimidazole | DMF/Water | MTBAMS | 2.5 | – | 60 | 85 | – | 598 | [109] |

| ZIF-67 | Cobalt foil | 2-methylimidazole | DMF/Water | MTBAMS | 2.5 | – | 60–300 | 55–100 | – | 1521 | [109] |

| *methyltributylammonium methyl sulfate, **methyltributylammonium methyl sulphate | |||||||||||

| b. Cathodic deposition | ||||||

| MOF | Metal source | Ligand | Solvent | Electolyte | Substrate | Ref |

| MOF-5 | Zinc nitrate hexahydrate | Terephthalic acid | DMF | (NBu4)PF4 | FTO | [106] |

| MOF-5 | Zinc nitrate hydrate | Terephthalic acid | DMF/water | TBAPF6 | FTO | [110] |

| MOF-5 | Zinc Chloride | Terephthalic acid | DMF/water | TBAPF6 | FTO | [110] |

| MOF-5 | Zinc nitrate hexahydrate | Terephthalic acid | DMF | TBAPF6 | FTO | [111] |

| IRMOF-3 | Zinc nitrate hydrate | 2-Aminoterephthalic acid | DMF/water | TBAPF6 | FTO | [111] |

3.1.1.2. Solvent-free static processes (mechanochemical synthesis)

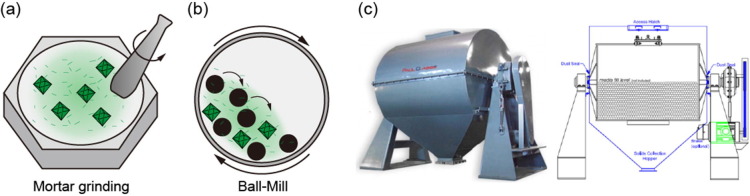

Mechanochemical syntheses are well known as solvent-free (or solvent-less) methods involving grinding or milling a solid mixture of metal and organic ligands. Typically, in academic research, the reactants are ground by a mortar and pestle (Fig. 6 a) or ball-milled (Fig. 6b, c). The mechanical force breaks the intramolecular bonds, and new bonds form between the metal and ligands to drive MOF formation. Since this is a quantitative reaction, the proportion of metal to ligand is an important element affecting the reaction yield and efficiency. Additionally, a catalytic amount of liquid or ionic material (salts) can be employed to accelerate the reaction, also called liquid-assisted grinding or ion-assisted grinding, respectively. The small amount of solvent increases the mobility of the reagent [112], and anionic salts induce templating effects [113].

Fig. 6.

(a) Schematic illustration of mortar grinding synthesis (b) Schematic illustration of ball-mill synthesis (c) Pictures of industrial ball-mill instrument of Paul O. Abbe®. Copyright by Paul O. Abbe®.

Kimakow et al. synthesized the Cu-based MOFs HKUST-1 and MOF-14 by ball-milling with copper acetate. The surface area of HKUST-1 was low at 758 m2 g−1 without activation but increased to 1713 m2 g−1 after EtOH washing. This was caused by the byproduct, acetic acid, blocking the product pores [112]. Thus, a washing process is required to remove any byproducts other than water.

Mechanochemical syntheses are advantageous for their simplicity, rapidity, high yields, RT conditions, low cost, and solvent-free reactions yielding small-sized MOF products. It is also possible to use various types of metal sources, such as pure metals, metal oxides, metal hydroxides, metal carbonates, and even insoluble metals [114]. Furthermore, mechanochemical synthesis can be applied to a stoichiometric ratio of mixed distinct metal components to synthesize mixed-metal MOFs by milling [115]. However, if the byproducts also react under the employed conditions, a solvent may be necessary, as is the case for pore activation by solvent exchange. For mass production, the grinding operation is simple and cost-effective. In particular, solvent-free methods reduce the cost of solvents and environmental regulations. However, the worn metallic impurities from ball milling equipment are the main drawback of this method for certain applications [116] (Table 8).

Table 8.

Summary of MOF synthesized by Ball-mill (mechanochemical synthesis).

| MOF | Metal source | Ligand | M:L ratio | Reactor size (mL) | Solvent | Ion | By-product | Time | Temperature (℃) | Rotational speed | Yield (g) | Yield (%) | Surface area (m2 g−1) | Ref |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cu(INA)2 | Copper acetate monohydrate | Isonicotinic acid(INA) | 1:2 | 20 | – | – | Water, Acetic acid | 10 min | – | 25 Hz | – | – | – | [117] |

| MOF-5 | Zinc acetate dihydrate | Terephthalic acid | 3:1 | 80 | – | – | – | 60 min | – | 1100 rpm | – | – | 3465.9 | [49] |

| HKUST-1 | Copper acetate monohydrate | Trimesic acid | 3:2 | 10 | EtOH | – | Water, Acetic acid | 25 min | – | 25/40 Hz | – | – | 1713 | [112] |

| MOF-14 | Copper acetate monohydrate | H3BTB | 3:2 | 10 | EtOH | – | Water, Acetic acid | 25 min | – | 25/40 Hz | – | – | 628 | [112] |

| Ni-MOF | Nickel(II) acetate tetrahydrate | Trimesic acid | 3:2 | 80 | Water | – | – | 1–180 min | – | 10–50 Hz | – | 79.76 | 10.08 | [118] |

| UiO-66 | Zirconium(IV) propoxide/Methacrylic acid | Terephthalic acid | 1:6 | 10 | MeOH | – | – | 75 min | – | 30 Hz | 2.85 | – | 1020 | [119] |

| NH2-UiO-66 | Zirconium(IV) propoxide/Methacrylic acid | 2-aminoterephthalic acid | 1:6 | 10 | MeOH | – | – | 42 min | – | 30 Hz | 1.34 | – | 945 | [119] |

| Zn2(ta)2(dabco) | Zinc oxide | Terephthalic acid (ta) Triethylenediamine (dabco) |

1:1:0.5 | – | DMF | NaNO3 | – | 60 min | 20–25 | 30 Hz | – | – | – | [113] |

3.1.2. Continuous processes

In Section 3.1.1, we examined static processes for industrial MOF production. Static syntheses use one large reactor, which is not suitable for mass production by repeated synthesis and recovery processes. This section introduces continuous flow systems capable of continuous synthesis, recovery, and wash steps, where the ligands and metal precursors are synthesized into MOFs as they enter the reactor. With a constant pump pressure, the reagents are continuously supplied to the reactor, and the product is sent out. Finally, flow systems can be managed with a computer program, and it is possible to maintain uniform synthesis conditions by checking and adjusting the temperature and flow rate at different points. In addition, continuous processes can result in improved MOF reproducibility because the continuous reaction maintains the same synthetic conditions. Continuous processes can be classified as solvent-based or mechanical depending on the use or lack of a solvent, respectively, as a reaction medium. We take a closer look in the following subsections.

3.1.2.1. Solvent-based continuous processes

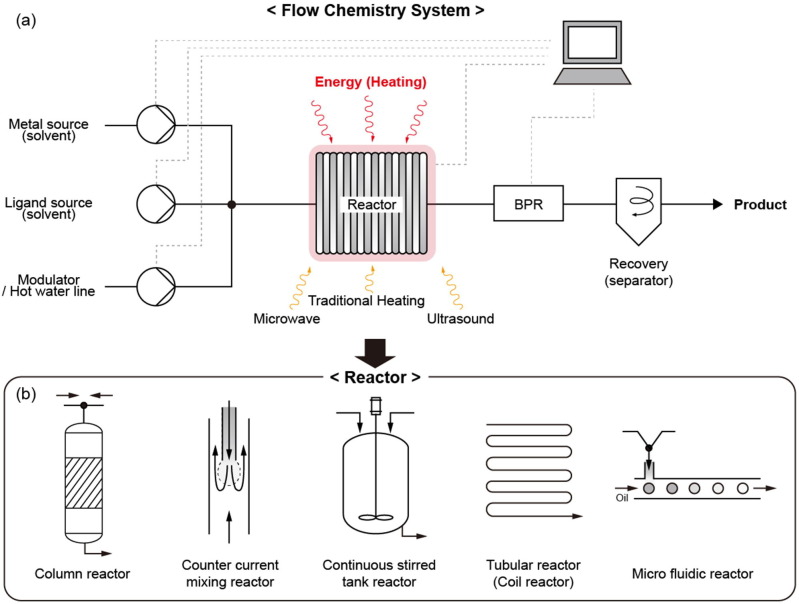

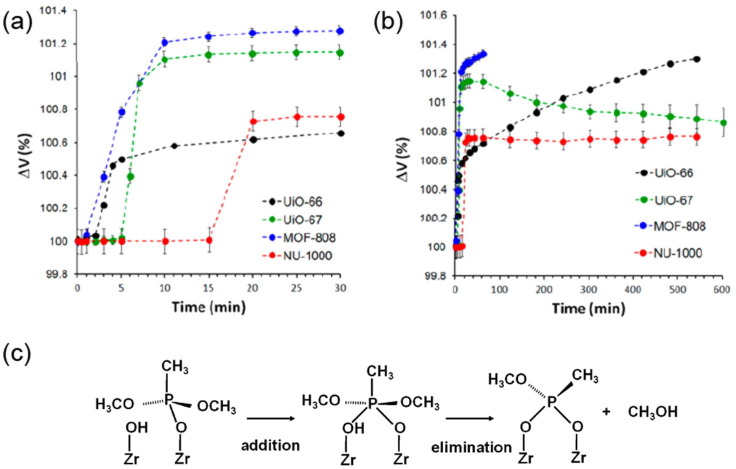

The static heating syntheses described in Section 3.1.1 involve expanding the laboratory-scale synthetic methods to a large-scale reactor. At this time, the use of a large amount of solvent causes environmental and cost problems, and larger containers have lower surface-to-volume ratios and thus poor reactivity. On the other hand, flow heating systems are optimal for industrial production with their high surface-to-volume ratios, which improve the mass and heat transfer, reaction efficiency, and reaction rate. Such flow systems are commercially available and have been studied for the synthesis of various materials, such as quantum dots, metal nanoparticles, and metal oxides [120] (Fig. 7 ). Therefore, flow systems are an effective approach that can be easily applied to industrial production.

Fig. 7.

Commercially available flow chemistry systems. Reproduced with permission from [120]. Copyright 2014 John Wiley and Sons.

As shown in Fig. 8 a, in flow heating synthesis, the metal and ligand precursors are transported by a pump to be mixed in a reactor and receive energy to synthesize MOFs. Immediately afterward, the reaction is stopped by the cooling system to obtain MOFs with a uniform and controlled shape. Then, the as-synthesized MOFs are moved to a constant pressure by a back pressure regulator (BPR), which solves the tube clogging problem caused by MOF powders. This type of system is eco-friendly and cost-efficient because it expends a small amount of solvent and reuses the separated solvent through recovery. In addition, the activated final product can be manufactured by simultaneously performing the synthesis, recovery, and washing steps. The reactors can be divided into 5 types depending on their shape and the manner of mixing of the ligand and metal source (Fig. 8b): column, counter-current mixing, continuous stirred tank, tubular flow, and microfluidic reactors. Additionally, various types of energy sources can be applied to the reaction by irradiating with microwaves and ultrasound in addition to heat.

-

•

Column reactor

Fig. 8.

(a) Schematic illustration of flow chemistry systems. (b) Schematic illustration of reactor for solvent-based continuous process.

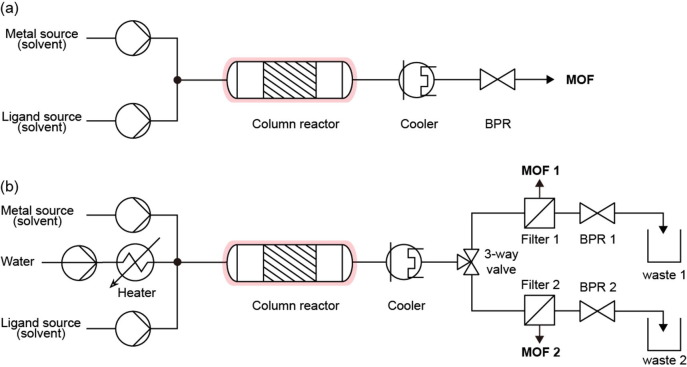

In a column reactor, the reaction occurs as the reactants are mixed in a fixed column. This is the simplest reactor with no mixing device, where the reactants are instead blended by the flow rate (Fig. 9). Kim et al. obtained HKUST-1 at 2.04 g h−1 with a column reactor, where the size and crystal phase of the MOF were controlled by adjusting the EtOH/water ratio of the metal source and the reaction temperature (Fig. 9a) [121]. Bayliss et al. prepared a metal, ligand, and hydrothermal line to synthesize MIL-53(Al) [122], where the reagent line with an aqueous solution at RT met the hydrothermal line in a column reactor (Fig. 9b). However, since terephthalic acid (H2BDC) as an organic ligand is not soluble in cold water, disodium terephthalate (Na2BDC) was used instead as a soluble salt. Importantly, this study established a system capable of simultaneous synthesis and recovery, which is the goal of industrial production. After the reaction, it was possible to perform continuous recovery in the flow system by a filter replacement method through two divided filter lines. The filtered MOF product was transferred to a critical EtOH extraction reactor for pore activation, which demonstrates the possibility of extending flow heating synthesis to the washing process. This system achieved 500 g of MIL-53(Al) in 4 h with an STY of 1300 kg m−3 d−1. The surface areas of HKUST-1 and MIL-32(Al) synthesized through this column reactor were 1673 and 1010 m2 g−1, respectively, which are higher than those of the same MOFs synthesized by static solvent methods. This illustrates that the porous properties of MOFs are properly maintained when mass-produced.

Fig. 9.

(a) General flow synthesis system with column reactor (process of [121]) (b) Continuous flow synthesis system with filtration system (process of [122]).

Column reactors are the simplest flow systems and are capable of connecting to a recovery system for one-step flow. However, since there is no specific mixing element, it is difficult to obtain instant and powerful mixing. Other systems are subsequently introduced to address this need (Table 9).

-

•

Counter-current mixing reactor (CCR)

Table 9.

Summary of MOF synthesized by column reactor, counter current mixing reactor, and continuous stirred tank reactor.

| Reactor type | MOF | Time | Pressure | Reactor size | Temperature (℃) | Solvent | STY (kg m−3 day−1) | Productivity (g h−1) | Yield (%) | Surface area (m2 g−1) | Ref |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Column Reactor | HKUST-1 | 5 min (reaction) | – | 1.59 mm ID, 30 cm | 60 (60–160) | EtOH/Water | – | 2 | 97 | 1673 | [121] |

| Column Reactor | MIL-53(Al) | 5–6 min(reaction) | 230 bar | 0.370 in ID, 20.3 mL | 250 (200–300) | Water | 1,300 | – | 86 | 1010 | [122] |

| Column Reactor | HKUST-1 | – | 75 bar | 0.370 in ID, 20.3 mL | 300 (200–300) | EtOH | 730 | – | 63 | 1554 | [122] |

| Counter current mixing reactor | HKUST-1 | – | 250 bar | – | 300 (100–400) | DMF/EtOH/Water | – | 132 | – | 1950 | [123] |

| Counter current mixing reactor | CPO-27 | – | – | – | 200 | DMF/Water | – | – | – | 1030 | [123] |

| Counter current mixing reactor | ZIF-8 | 1 min (reaction) | 240 bar | 55 mL | 100 | Water | 3,875 | 810 | – | 1800 | [124] |

| Continuous stirred tank reactor | MOF-5 | 4 h (residence) | atmospheric pressure | Conical flask | 100 (reflux) | DMF/DEF | 984 | 4 | – | 2302 | [126] |

A CCR consists of a pipe-in-pipe concentric arrangement as shown in Fig. 10 a, b. This reactor rapidly mixes a preheated solution down through the inner pipe with a RT solution flowing upward. The advantage of this method is that the reagents are mixed quickly and uniformly in a few seconds by the stream, resulting in a short residence time [125]. Thereafter, the reaction is terminated through rapid cooling, and a sample is collected by a BPR (Fig. 10c).

Fig. 10.

Counter current mixing reactor (a) Schematic mixing process with a pipe-in-pipe concentric arrangement and (b) heat transfer processes. Reproduced with permission from [123]. Copyright 2012 Royal Society of Chemistry. (c) Flow synthesis system of CCR. Continuous stirred tank reactor (d) Flow synthesis system CSTR. (b) Photograph of MOF-5 synthesis system with CSTR. Reproduced with permission from [126]. Copyright 2016 Elsevier.

The synthesis of the MOFs, HKUST-1 and CPO-27, using a CCR was first introduced in 2012 [123]. Preheated water was used for the downward flow in the inner tube, and a mixed solution of ligand and metal (RT) was used for the upward flow. The size and surface area of the MOF were controlled by optimizing the temperature of the reactor and the concentration of the metal source. In a subsequent work, ZIF-8 was synthesized using an organic ligand and base solution as the pre-heated downward stream and metal solution (RT) as the upward stream [124]. The synthesized MOF was then transferred to a coil in a water bath by BPR, and pore activation was performed by heating and sonication to manage the surface area. This demonstrated the advantages of a continuous process with simultaneous synthesis and activation in one flow system. The system produced ZIF-8 with a high STY of 3875 kg m−3 d−1. The surface areas of HKUST-1, CPO-27, and ZIF-8 produced by CCR were 1950, 1030, and 1800 m2 g−1, which were similar to or higher than the reference values of 1694 (Basolite C300), 1200, and 1654 m2 g−1, respectively. Additionally, HKUST-1 produced in a CCR had a 300–400 m2 g−1 higher surface area than those of the MOFs prepared in the other two kinds of column reactors.

The advantage of the CCR is that it can achieve highly uniform reactant mixing in a short time, which also improves the reaction extension and transport properties. It has also been shown that the synthesis and washing steps can be performed sequentially in one flow system [124]. Although CCRs produce MOFs with a well-controlled size, surface area, and yield, the required high temperature and pressure are limiting factors for practical applications (Table 9).

-

•

Continuous stirred tank reactor (CSTR)

In a CSTR, the ligand and metal solution flow into the reactor and mix through direct stirring to perform the reaction. Choline et al. synthesized MOF-5 using a CSTR and analyzed the product according to synthesis time to confirm that impurity-free MOF-5 could be obtained after 5 h, then adjusted the reaction time to increase the yield (Fig. 10d, e). The resulting MOF-5 had a surface area of 2302 m2 g−1, which was higher than the reference value of 2200 m2 g−1 [126].

The CSTR system is a semi-flow reactor that combines batch and flow reactor features. In particular, the MOF-5 synthesis system described above can be considered as introducing flow characteristics into reflux synthesis. Therefore, the advantage is that the reaction can proceed at ambient pressure, but the reaction time is 4–5 h longer than that for other flow methods (Table 9).

-

•

Tubular flow reactor

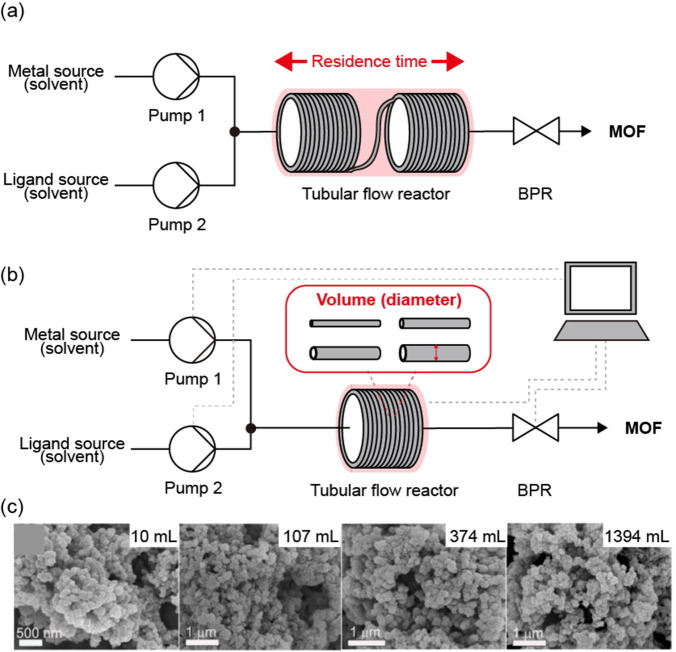

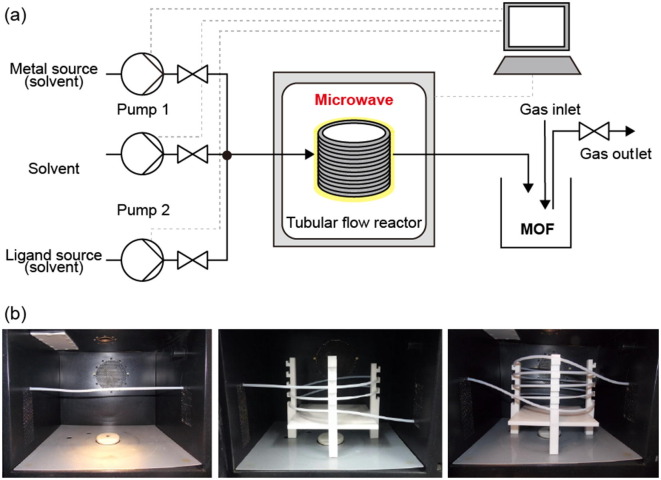

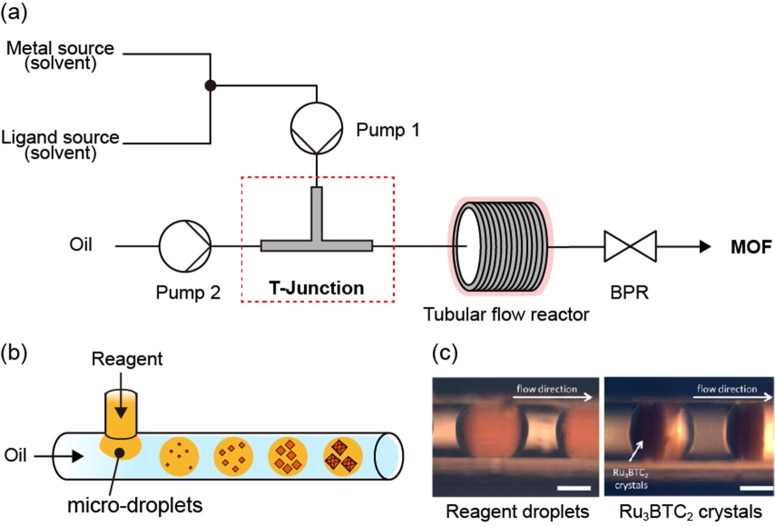

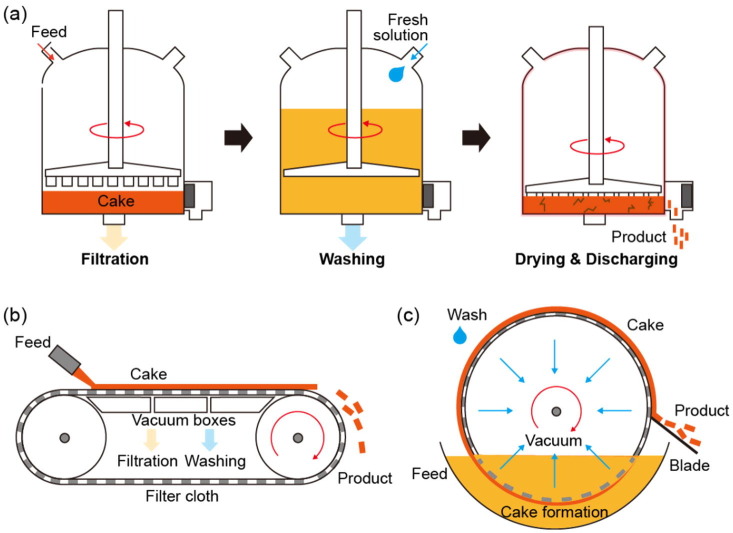

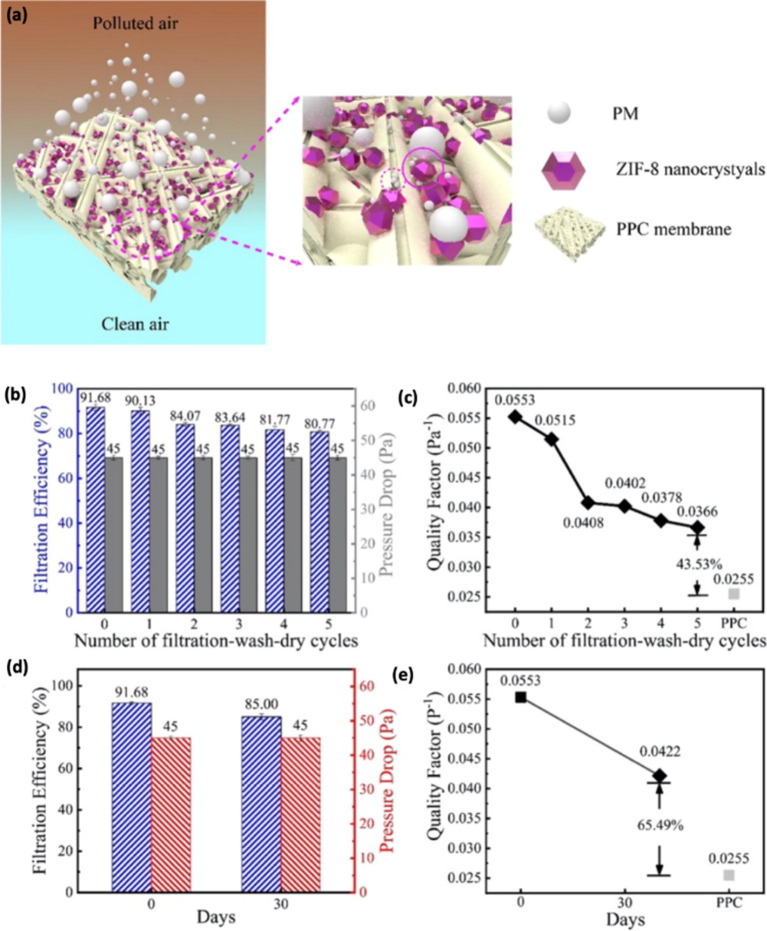

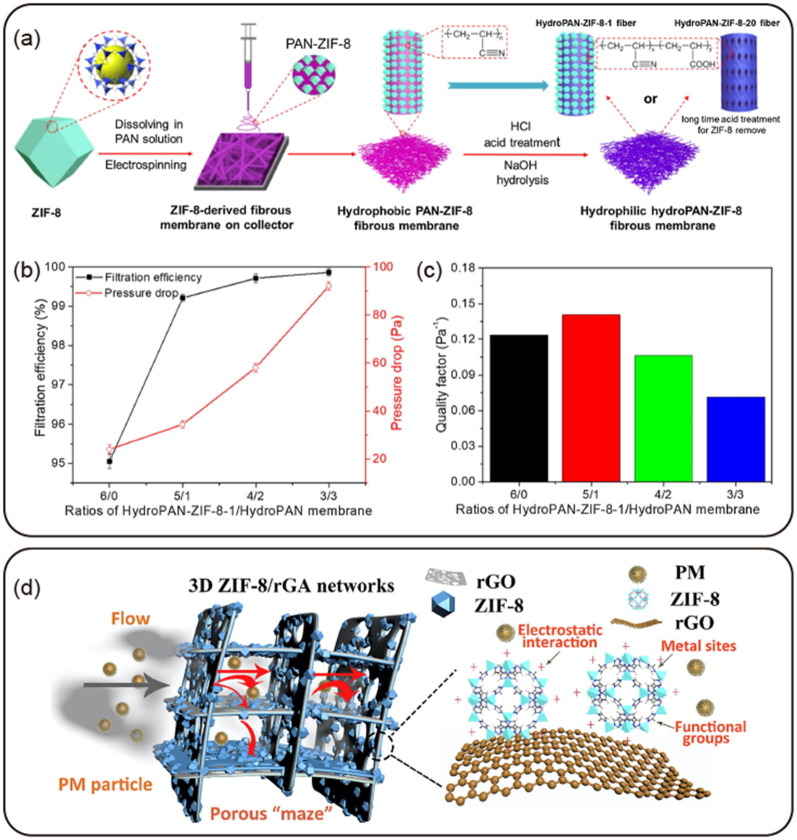

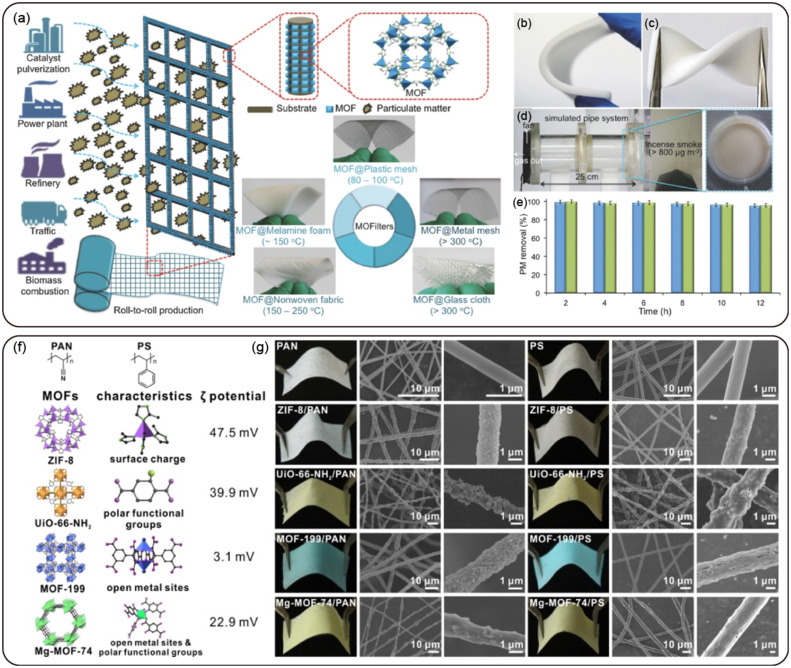

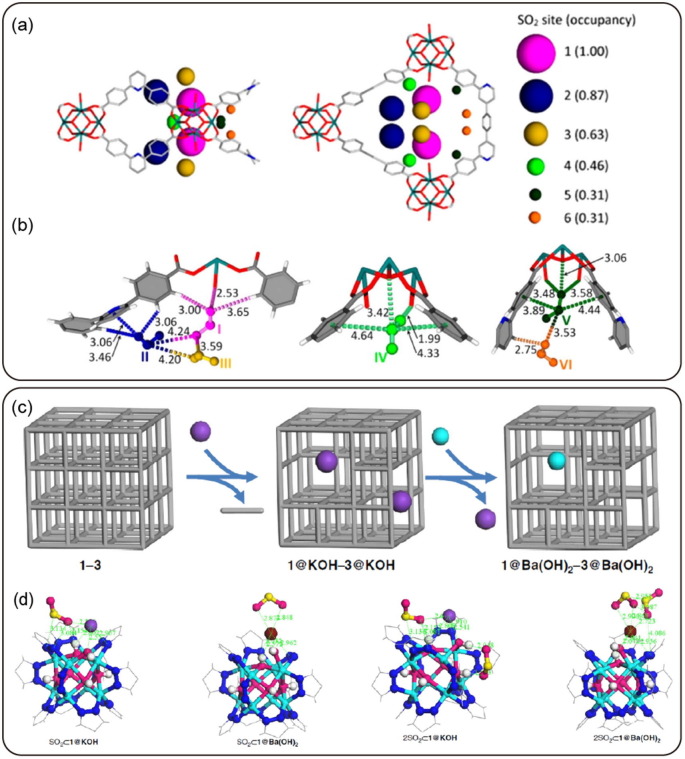

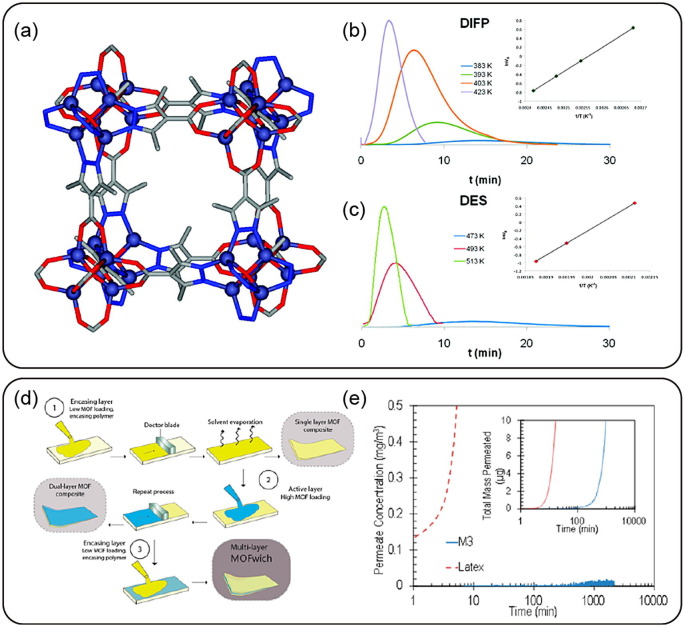

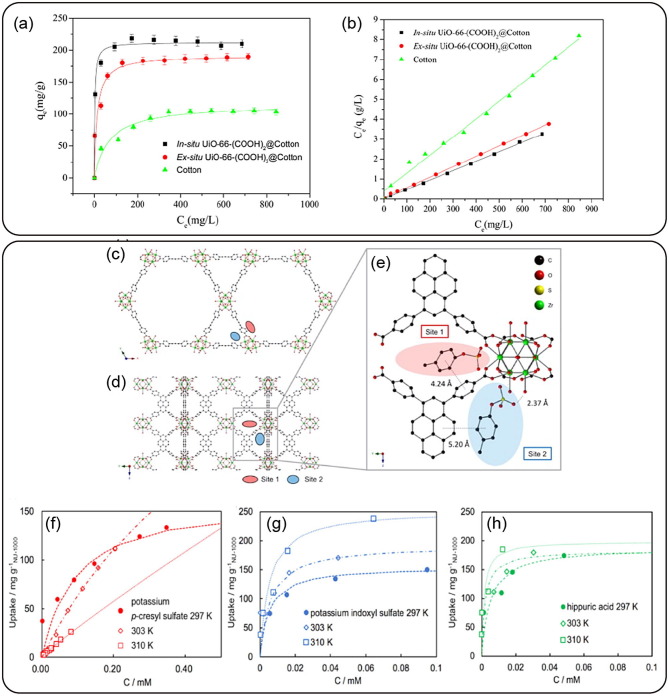

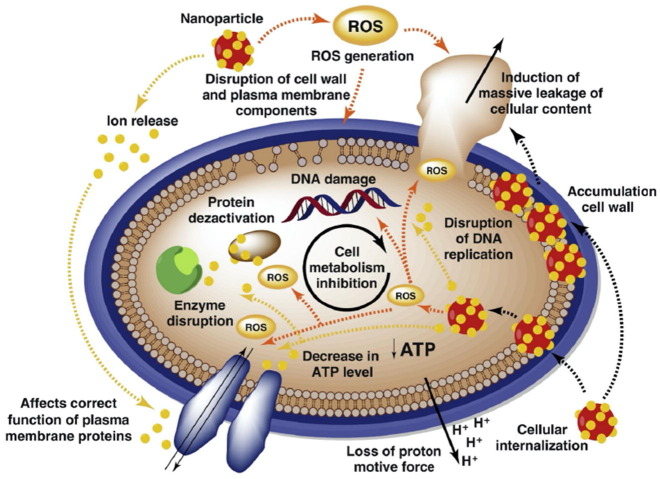

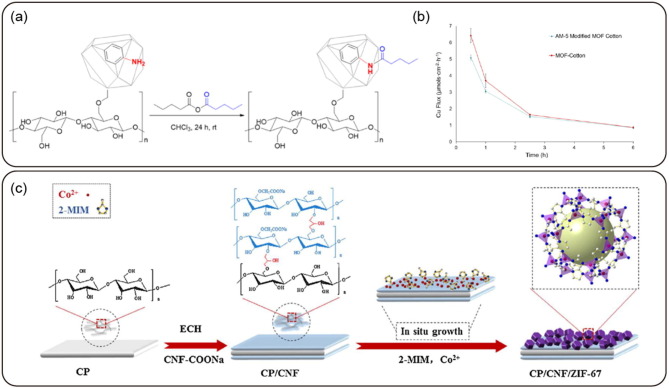

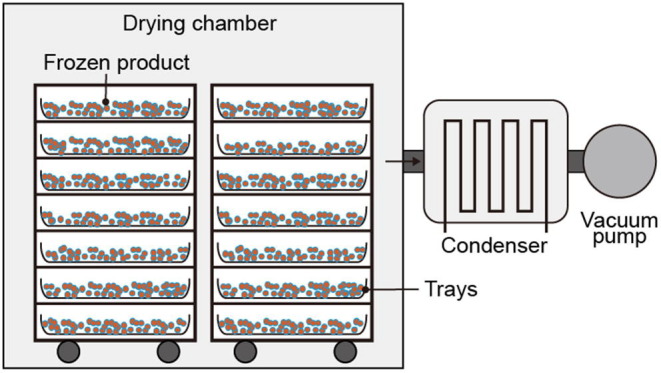

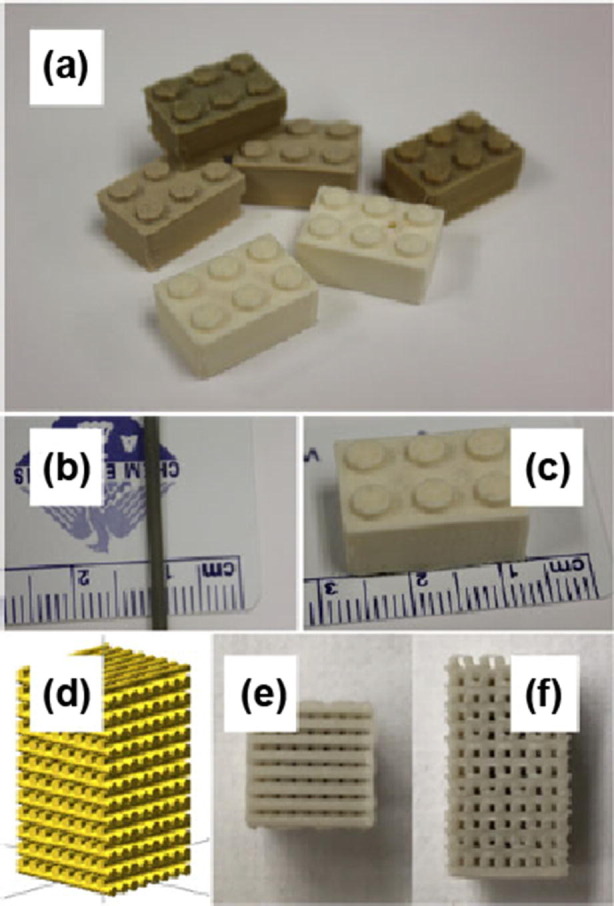

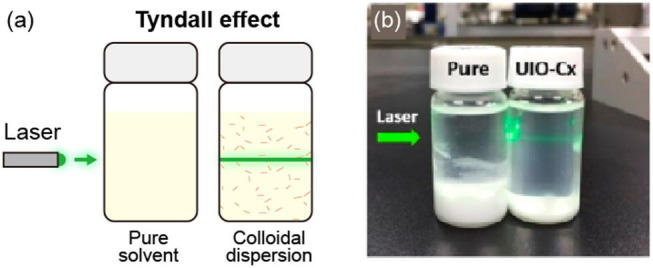

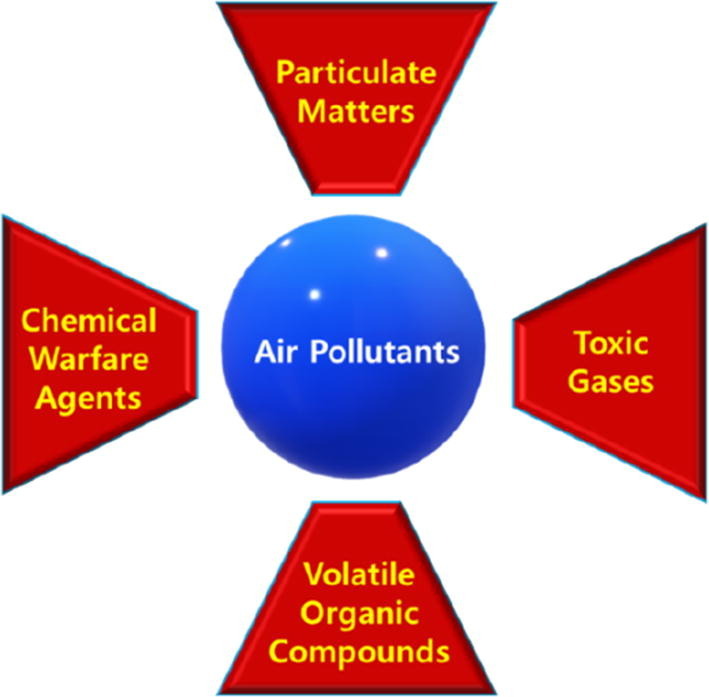

In a tubular flow reactor, reactants mix and flow in a post-mixing line, and the MOF is synthesized by irradiation of the line with energy. This type of reactor not only allows for control of the concentration, temperature, pressure, and reaction time but also enables optimization of the reaction rate by adjusting the residence time and reactor volume through the length and diameter of the line itself. In addition, in the previously described mixing reactors, synthesis is performed using heated reactants or heat transferred instantaneously to the reactor, whereas flow line reactors can not only heat the reaction zone but also progress the reaction by irradiation with microwave energy.