Abstract

Supply Chain Management (SCM) is one of the key aspects of making agriculture sector more competitive in India. India and other developing countries arefacing issues for coordination of their Agriculture Food Supply Chain Management (AFSCM) as not having technical and resources support; especially in natural disaster condition like recent COVID-19 outbreak. The purpose of this research is to develop anInternet of Things (IoT) based efficient and supportive coordinating system for enhancing the coordinating mechanism in AFSC under natural outbreaks. With the help of a literature review and experts’ inputs, seven enablers have been identified by grouping thirty sub enablers. Further, ISM methodology has been employed for developing a framework for enablers’ relationships to improve the coordination in the AFSC for taking strategic and operational decisions. After that, DEMATELtechnique is utilised to develop the causal and effectrelationships between all the identified enablers of a coordination system in IoT based AFSC. It has been noticed that‘Top Management Support (TMS)’ is the main driver by MICMAC analysis and categorised in a cause group based on (R-C) value. Further, the coordination index of the entire model is calculated based on the Cleveland theory. This paper also discussed a case study of the sugar mill industry. This paper also discussed stakeholder theory in developing IoT based coordination system of AFSC. Further, theoretical contribution may also guide the managers of the organisation in developing their strategies by using Strengths-Weaknesses-Opportunities-Threats (SWOT) analysis based on Cleveland index.

Keywords: COVID-19, Internet of things (IoT), Agriculture food supply chain (AFSC), DEMATEL, Coordination index

Introduction

The Agriculture Food Supply Chain (AFSC) consists of complete activities from the farm to the consumer’s hand. The AFSC is an interrelated system based on the “production adjustment and consumption-driven”. An efficient AFSC consists of primary food processing, delivering and distributing of agri-food to develop an integrating and interactive system of transportation, data and entities flow (Dong et al. 2015; Bravi et al. 2019). AFSC can be grouped into perishable AFSC and processing AFSC. AFSC for fresh products consists of practices related to primary grain growing, wholesale, import-export and retailing and raw products and other services providers (Tan 2001; Phaal et al. 2004; Yan et al. 2014; Ghanbari et al. 2017). In the processing AFSC, the agri-products are available obtained by the processing of raw food grains, results in better quality, the quality of the raw food grains is enhanced by improved process/growing conditions (Mensah and Julien 2011; Cao et al. 2013; Nobre and Tavares 2017; Gill et al. 2017). Based on the process type for food grains AFSC can be grouped into primarily processed food grains (rice, wheat), secondary processed of agri-food (supermarket products), and tertiary processed agri-food (directly consumed packed products having highest quality) (Yuan et al. 2015; Hossain et al. 2016; Shi and Yan 2016; Botta et al. 2016; Galvez et al. 2018).

The current age of AFSC is very much prone to disruptions likewise recent COVID-19 outbreaks in most of the countries (Araz et al. 2020). This outbreak has been broken the physical linkage by effecting different stakeholders at an internal or external level due to lockdown or physical distancing. Further, in accordance of Resource-Based Theory (RBT), Supply Chain Disruption (SCD) cause by COVID 19 has a negative impact to both physical capital resources e.g. technologies andorganisational capital resources (human capital resources) e.g. 3PLs (Faisal et al. 2006; Dubey et al. 2017; Huo et al. 2019). Thus, SCD has reduced the SC integration capabilities, which may reduce traceability and flexibility during logistics activities within AFSC. Therefore, Institutional theory has forced the different external stakeholders of AFSC like government, food regulatory bodies, customers, technologies providers (3PLs) to adopt technology-based information sharing and sustainable practises related to logistics competitiveness and other activities of AFSC (Cohen 2020). Conventional AFSC system has not been meeting the customer’s demands as far as concerning their daily demands of fresh vegetables and other Agri products. Therefore, IoT based AFSC is prerequisite mainly due to poor coordinating system which promotes poor traceability of AFSC entities and information,a big data problem, increased logistics and monitoring costs of agricultural products for maintaining its quality and safety due to increased lead time of Agri products supply (Tretyak and Sloev 2013; Kohtamäki and Rajala 2016).

An effective coordinating system organised the different practices to effectively manage the entire system by knowing every related practice. Further, each stakeholder’s practices have to achieve their task, independent of other practices for achieving a common goal of food safety and hygiene (Cao et al. 2008; Jie et al. 2015). Lack of a coordinating system will result in improper information sharing or bullwhip effect (Dwaikat et al. 2018). This leads to increase agriculture products processing expenditure inventory’s maintaining expenditure, stock out time, distribution, product’s promotion expenditure and customer’s dissatisfaction etc. (Paik and Bagchi 2007). Therefore in the current scenario, there is an immense requirement of an IoT based supply chain system to resolve the traditional coordination issues of ASC. In this context, IoT technologies have been proposed, which is a new paradigm of emerging Industry 4.0 (Cai 2012). Theeventual goals of this IoT technology are to build an improved environment for things (human, objects, machines, software) in which entities surrounding each other have recognised the common protocols and thus communicates with other in the absence of commands (Zhong et al. 2015; Alon et al. 2019). IoT is on emerging stage to influence/controlling the entire objects surrounded by us. It may have an efficient computational method with the help of cloud-based computation. It has recognised as one of the smart methods which can sense, identify and interact. It may be used for sense, collect and process the data for its transmission. Managing of all of these activities has been done by remotely based sensors, which can communicate via the internet (Devi and MeenaKumari 2013; Ben-Daya et al. 2019).

Nowadays, the consumer’s concern for their agri-based food stuffs either primary food grains or packed food items which are consumed. Customers are more concerned aboutagri-food origination, raw food grains, processing means, organisation’s standards and the sustainable effect of agriculture practices (Trienekens et al. 2012). This behaviour of consumers has surely promoted the adoption of effective coordination system in the AFSC. A perfect coordinating system may provide a group of continuous information to every stakeholder regarding the origination of agri-food grains, agriculture practices, and proper tracking and tracing of agri-products throughout the AFSC for gathering the information during transportation, warehouse storage. The prime objective of an effective coordinating mechanism is to gather records about the food products, e.g. to provide processing method of any food stuff to ensure its safety (Meuwissen et al. 2003). This type of arrangement may useful in maintaining quality’s standards set by different organisations, returning the food stuffs from consumers and other data. Implementing these practices have increased customer’sand market’s fulfilment in the AFSC (Liu et al. 2013; Manning and Soon 2014; Duan et al. 2017).

With the growing customer’s awareness regarding the quality of the products due to the current COVID-19 outbreak,there is an urgent need of developing an effective IoT based coordinating system for managing AFSC. There is limited literature available for an effective IoT based coordination system for AFSCM. Different researchers has been conducted research in the past for the need and the outcomes of developing coordinating mechanisms (Tieman 2011; Shafii and Khadija 2012; Soon et al. 2016). However,there are a lot of gaps in the research based on implementing IoT oriented coordinating mechanism in the agriculture sector. For maintaining the integration of the agriculture sector, the effective coordinating mechanism is required for AFSC. But, in the present scenario of shutting down the logistics industry, the task of implementing an efficient coordination arrangement is difficult to achieve. Key enablers for implementing coordination structure may prove supportive for reducing the above obstacles. These following research objectives have been set:

To identify key enablers in developing an effective coordinating system for AFSC;

To develop a framework for identified enablers’ relationships in the AFSC for taking strategic and operational decisions to improve coordination;

To develop the causal and effect relationships between the identified enablers of IoT based coordination system in AFSC to develop responsive supply chain; and

To calculate the coordination index of the developed system.

Current AFSCs are not being able of handling the coordination and integration efficiently as there is negligible knowledge of real-time information due to breaking down of all logistic activities and its impacts on a long term basis. Therefore, this research is an attempt to identify various key enablers for developing an effective coordinating AFSC and provide a hierarchical based structure of key enablers by ISM; and to analyse this structure with the help of fuzzy DEMATEL. Finally, the coordination index of the proposed IoT based coordination model of AFSC is calculated.

This structure may also be used by the organisations, which provides strategies to AFSC for improving the competitiveness of the AFSC at the globalised level. This research has several implications at managerial and policy making stage. The planning of managers at the different period of business is important in achieving the goals by following market behaviour e.g. a retailer would not be able to supply the product to customers without proper sharing of day to day production schedule between purchase and operations’ managers.

Further, the organisation of this paper is as: Section 2 elaborates the literature review. Section 3 explains the research methodology. Section 4 develops an IoT based framework for information sharing in AFSCM. Section 5 provides a practical application of the proposed framework with the numerical illustration. The results of the numerical illustration are provided in Section 6. Section 7 discusses findings along with the implications of the research. Finally, Section 7 provides conclusions with limitations and future scope of the research.

Literature review

A literature review consists of three subsections. The first subsection briefly explainsthe stakeholder theory. The second subsection explains the IoT technology role in developing a coordinating system and third subsection identifies key enablers, which will help in developing an IoT based coordinating system for AFSC.

Stakeholder theory

Freeman and McVea (2001) defined a stakeholder as “discrete collections of individual who may influence or is influenced by the accomplishment of an organisation’s goals”. This theory emphasised on the standards that an organisation’s judgments and goals are extremely inclined on the awareness of different stakeholders (Kannan 2018). Stakeholder theory is mainly integrated form of Resource Based Theory (RBT) and Institutional theory while considering sustainable practices (Yuen et al. 2017). Shnayder et al. (2016) examined the influencing power of various stakeholder and institutional pressures as motivational theories for corporative and social responsibilities in the perishable AFSC. Further, Saint Ville et al. (2017) studied the type of interrelationships between different involved stakeholders and their implications for the advancement of AFSC associated policies. This theory is suitable for this research as there are involvement various stakeholders having different knowledge and influencing power at the organisational level, yet there have been indications of overlapping while considering the functions, shared objectives and jointly decisions taking for innovative practices.

Role of IoT Technology in Developing Coordination System

IoT technology mainly consists of three key technologies: cloud computing for data management, data transmission layer and data networking layer (Chandrakanth et al. 2014). Botta et al. (2016) termed IoT as quick response networks having sense based entities, which are interconnected in a vibrant and worldwidenetworking configuration. It is a highly disordered technology having evolved computational properties. This technology can also be termed as an internetwork of tangible, intangible entities, WSN and other devices, all of these communicates to each other for serving social life (Wu et al. 2016). Radio Frequency Identification (RFID) is one of the key elements in the IoT technology, it has tags and readers for communicating information with the help of networking technology likeWSN (Da Xu et al. 2014). The IoT allows physical objects to communicate in real-world to exchange data for achieving coordinated SC. These entities became smarter by implementing related technologies like cloud computational technology, networking technology, data acquisition technology, IoT protocol and other applicability (Al-Fuqaha et al. 2015).

The adoption of IoT technology can yield efficient and resilience coordinating system throughthe transparent and visible mode of data and resources transfer between the SC practices. Further, IoT adoption avails the accurate and tracked dynamic data throughout the upstream as well as the downstream flow of products in a service type of organisations which is prerequisite for attaining SC resilience (Reaidy et al. 2015; Kumar et al. 2016). Next advantage of IoT adoption is the development of an effective tracked and traced system for SC entities (Uddin and Al Sharif 2016). Further, IoT adoption can be achieved in managing and controlling the inventory‘s level (Fan et al. 2015; Reaidy et al. 2015; Thiesse and Buckel 2015), improving different business‘s practices and integrating their strategies (Mann 2015), to increase performance at operations levelby improving resilient capabilities in any SC disruption (Ferretti and Schiavone 2016; Li and Li 2017).

Identification of enablers for IoTBased coordination system of agriculture food supply chain

As per Xue et al. (2005) and Cao et al. (2008), SC coordinating mechanism encompassed all attempts for data exchanging by integrating it during production, logistics process and consumer’s servicing. The prime aim of AFSCM is the coordination of different entities worked independently to achieve the shared objective of SC for obtaining competitive advantages at the globalised level. An effective coordinating system needs to be measured at different levels of the product’s quality,the process of products and consumer’s fulfilment (Grittell and Weiss 2004). The IoT based coordination system for AFSC is defined as the factors that “enable proper implementation” of IoT technology in AFSC coordination system and has its interchangeable terms as moderators, antecedents and principles (Kilubi and Haasis 2015; Sharma and Bhatia 2016).

In this research, a literature review was made using search keywords e.g. The IoT based coordination system for AFSC; IoT based coordination index and such like on Google and Google Scholar. In this way, a total of 30 coordination enablers have been identified. To simplify, these enablers are grouped into seven categories with the discussion with experts (more detail about experts is provided in subsection 5.2). These identified seven categories are discussed below.

Top management support (TMS)

Once any SC risk or disruption has been noticed, it is the TMS responsibilities to develop a flexible SC system for dealing with future risks. The top-level supportive system is prerequisite for inter-organisational functioning, integrating the business’s activities and effective vendor management for improving the responsiveness of the SC and making it more competitive (Ganesan and Saumen 2005; Sandberg and Abrahamsson 2010). Further, TMS is essential for building SC’s decisions at strategically level (Sun et al. 2009). TMS provides different facilities of IoT, efficient labour, finance and raw products etc., which are utilised by SC for information transfer within SC (Shin et al. 2000; Stanley et al. 2009).

SC responsiveness (SCR)

The SC responsive is the capability of SC to quick response to any change in the SC. SCR is very important for developing fragility in SC. SC resilience improves the speed, accuracy, and flexibility of SC-risk management (Alicke et al. 2020). Li et al. (2008) noticed agility as a critical aspect, which needs to be focused on developing responsiveness within SC. The different shared interest of SC stakeholders due to the delay of information exchange (Unresponsiveness) leads to benefits limited to the personal level in place of entire SC (Arshinder and Deshmukh 2007). Further, SCs having a quick response to any change prompt on-time delivery of products, economical service and exact prediction of future trends (Mehrjerdi 2009).

Supply chain integration (SCI)

SCI is important in improving the coordination of SC. SCI needs proper data exchange and establish agile properties within SC by improving responsiveness (Yan et al. 2014). SCI means effective sharing of information between food regulatory bodies, supplier, food processing organisations and primary producer farmers. Further, SCI leads to the collaboration of the organisation’s practices at strategic, tactical andoperations stage; and exchange of information, finance and other entities. SCI starts with raw products purchasing and processing and ends to customer’s satisfaction at an economical level with the fast rate (Flynn et al. 2010).

IoT based infrastructure (IBI)

Bidua and Patel (2015) analysed about IoT and cloud-based technology for AFSCM in the Indian context. Digitised SCM improves the quick and accurate delivery of agri products with a shorter lead time for insuring SC risk management. IoT based infrastructure may provide automated farming practices along with smart irrigation system, proper security system, cloud-based system for network availability, technical manpower and other innovative capabilities. But, currently, these facilities are not yet implemented in the agriculture field (Bo and Wang 2011; Channe et al. 2015). In the Indian context, network availability due to poor IoT based facilities is key barriers for IoT adoption in AFSC.

Information sharing (IS)

IS among the SC entities is necessary for maintaining coordination in AFSC (Stanley et al. 2009; Dwaikat et al. 2018). IS in an SC is a key process in any type of collaborating processes. Type of information and sharing approach may depend on types of relationships among the stakeholders of SC practice (Zhang and Chen 2013). IS mainly deal with information of inventories, customer’s order and end product details. Nowadays, organisations are adopting technology-based traceable mechanism to track the information of agriculture products processing, purchasing, warehouse and market trends, thus provide a background for AFSCM. This mechanism helps in developing an effective system for resource managing by proper coordination within the AFSC (Prince et al. 2014; Patel and Cassou 2015). In the past few years, IoT has been evolved as awell-organised technology for IS in ASFC.

Mutual understanding (MU)

MU is prerequisite for data exchanging within the SC. MU is prerequisite for developing trust and confidence of consumers regarding food safety and security. MU distributes the organisational risks and rewards within different SC member. Confliction of agreed plan and suggestions between SC stakeholders is mainly taking place due to the restriction of shared benefits and other facilities to the individual rather than entire SC entities (Cachon and Lariviere 2005). Further, MU is essential for improving coordination along with the improved quality of information by using agreed common protocols of IoT in a country like India (Bianchi and Saleh 2010).

Third-party logistics service providers (3PLs)

A 3PLs is an external agency working independently for providing products/services distribution and storage facilities temporarily mainly for suppliers, processing organisations and end-users (Aguezzoul 2008). Göl and Çatay (2007) describes 3PLs as external service providers for providing the highly flexible system with improved organisational practices, end consumer’s demands, and focused business ‘s strategies. In case of any disturbance in ASC associated with any operational (demand fluctuations) and disruption (Tsunami, COVID-19) risk (Xu et al. 2020), 3PLs mainly provides external services like IoT based infrastructure, logistic activities, warehouse management, smart packing of Agri products and customer services with product returning facilities (Delfmann et al. 2002). In today market, there is a lot of 3PLs organisation, which has created market competitions by providing different services. So, there should be a complete awareness about selecting those (Diabat et al. 2013). Enablers for IoT based coordinating systemwith brief description have been provided in Table 1.

Table 1.

Identification of enablers for IoT based coordinating system

| S. No. | Categories | Enablers | References |

|---|---|---|---|

| 1. | Top Management Support (TMS) | Investment of time and money for resource development like IoT based infrastructure and other training programs within the organisation (C1) | Bauk et al. 2017 |

| 2. | Ready to adopt new technology e.g. IoT, cloud computing, big data computational for improving the information sharing within the SC (C2) | Neirotti et al. 2018 | |

| 3. | Employees training and empowerment to enhance the skill and knowledge needed in IoT based technical environment of work culture within SC (C3) | Haddud et al. 2017; León-Bravo et al. 2019 | |

| 4. | Focused on the communication system of the SC during logistics, warehousing and even farming practices based on WSN, RFID tags and readers etc. (C4) | Mathieu and Pal 2011;Yan et al. 2017 | |

| 5. | Encourage the external service providers for providing IoT based infrastructure support, managing logistics, warehousing and other service providing activities e.g. 3PLs (C5) | Zeng et al. 2013; Tu et al. 2018 | |

| 6. | Third-Party Logistics Service Providers (3PLs) | 3PLs for IoT based infrastructure support by providing different equipment and hardware like EPC, RFID tags and readers (C6) | Fernandez and Kekale 2007; Söderberg and Bengtsson 2010 |

| 7. | 3PLs for logistics activities like proper tracking and tracing of the perishable products during the transportation stage (C7) | Yang and Zhao 2016 | |

| 8. | 3PLs for warehouse management for managing the tracking of shipment planning and distributing the required demands (C8) | Shi et al. 2016a | |

| 9. | 3PLs for customers service like the accuracy of order fulfilment, quick response to customers etc. (C9) | Shi et al. 2016b | |

| 10. | IoT based Infrastructure (IBI) | A proper cloud computing system for better IoT network availability to access the services regarding information exchange between every stack holders of the SC (C10) | Ahmed et al. 2017 |

| 11. | A proper security support system to avoid the unauthentic data sharing for misusing the information by the stake holders of the SC (C11) | Kumar and Patel 2014 | |

| 12. | Proper automation system for farming processes like sensors based irrigation system and pest detection during the plantations of the crops (C12) | Balamurugan et al. 2016 | |

| 13. | Proper technical manpower for managing the IoT based irrigation, plantation and pest controlling mechanisms etc. (C13) | Balamurugan et al. 2016 | |

| 14. | Information Sharing (IS) | Use of IoT technology for sharing the local and outer information of the organisation by different members of the SC based on local Object Naming Service (ONS), global ONS and Electronic Data Exchange (EDI) (C14) | Min et al. 2005; Wu et al. 2016 |

| 15. | Tracking of logistics information by the managers during the transportation of the perishables products regarding the condition of the products and avoid the accidents (C15) | Bhattacharya et al. 2010; Marucci et al. 2017 | |

| 16. | Tracking and tracing of food processing and warehousing and logistics information for the monitoring of the related activities in a Flexible Production System (FPS) (C16) | Marucci et al. 2017; Wu et al. 2014 | |

| 17. | Knowledge sharing between the SC members with the help of research and development programs in the organisations (C17) | Parry et al. 2016 | |

| 18. | Mutual Understanding (MU) | Trust development in SC members so that all of the activities executed for achieving a common goal without any conflicts of interest among the members (C18) | Karkouch et al. 2016 |

| 19. | Supply chain risk/reward sharing for motivating the SC members to achieve their target of maintaining the quality of primary and processed food products (C19) | Falkenreck and Wagner 2017 | |

| 20. | Agreed vision and goals of members of the SC so that a shared effort of every stakeholder leads to overall performance improvement for the organisation (C20) | Shin and Park 2017; Mor et al. 2019 | |

| 21. | Share common protocols in IoT based system for easily interpreting the information generated from new technologies of IoT like EPC code, RFID tags and readers and other WSN (C21) | Ghanbari et al. 2017 | |

| 22. | Supply Chain Integration (SCI) | Integration along with multiples SC with heterogeneous technologies for sharing the technical facilities across the inter and intra organisation boundaries (C22) | Hardgrave et al. 2011; Kumar et al. 2016 |

| 23. | Information integration among the members for monitoring or controlling the activities (C23) | Jing et al. 2014; Mor et al. 2018a | |

| 24. | Process integration means complete collaboration among the SC system members in strategically, tactically and operational decision-making (C24) | Flynn et al. 2010 | |

| 25. | Supplier and customer integration starts with raw agriculture products suppliers, added quality to the product by processing within the organisation to fulfil the requirements of consumers at lesser cost and within quick time (C25) | Flynn et al. 2010; Mor et al. 2018b | |

| 26. | Material/Product flow integration means resources planning of inter and intra organisation mainly controlled by Enterprises Resources Planning (ERP) initiated by TMS (C26) | Pagell 2004 | |

| 27. | SC Responsiveness (SCR) | Quick transactional inter and intra enterprises reactions to meet the continuing changing demand of the customer, market and other SC stakeholders for achieving resilience capabilities (C27) | Yan et al. 2017 |

| 28. | Just-In-Time (JIT) is prerequisite for achieving coordinative based resilientagri products processing and delivery in dynamic AFSCM as agri products are mainly perishable (C28) | Adnan et al. 2018 | |

| 29. | Fast exchange of real-time information in AFSCM to provide flexibility/resilience and awareness among the stakeholders in the SC (C29) | Barenji et al. 2017 | |

| 30. | The resilience of AFSC to adapt new technology during the agriculture basic practices automation and during the interpretation of data generated from sensors, RFID readers etc. (C30) | Ahmed et al. 2017; Irfan et al. 2019 |

Research gaps

The following research gaps have been reported based upon the review of the literature (Ochoa et al. 2017; Trappey et al. 2017; Tiwari et al. 2018; Fortune 2020).

It has been noticed that the majority of research has discussed managing issues in isolation like quality, technologies and organisation practices without integrating the role of each other. Only a few studies have discusseda theoretical based approach for coordinating system as a holistic approachfor developing a complete coordinating system (Information sharing, trust and IoT) to improve its resilience in any natural disruptionof AFSC for risk management regarding food safety, security and availability.

A large number of researchers have only discussed the conceptual view of a coordinating system for AFSC. Only a few researchers have focused on the effectiveness of the developed system, particularly inthe Indian context.

Most of the researchers have only discussed IoT implementation and AFSCM as separate issues. Only a few studies focused on a combined approach of IoT and AFSCM or impact of IoT technology on developing coordination in AFSC.

In previous studies, there is a lack of measurement system for quantifying the effectiveness of IoT based coordinating system. None of the study has calculated coordination index for entire AFSC based on IoT.

Research methodology

In this research, a structure-based systematic model of coordination system in AFSC has been developed based on Interpretive Structural Model (ISM). Fuzzy DEMATEL has been applied to calculate the level of relationship and then Cleveland approach to calculate the coordinating index of the complete model.

Based on the previous research, it has been noticed that key advantage of ISM approach is the transforming of vague information in the organised hierarchical system having complete visibility in both upstream and downstream direction (Azar et al. 2011). However, the ISM approach has some limitations e.g. this approach may have a biasing problem from decision-makers as interaction among variables given by decision-makers is mainly depend on individual judgment. The biasing may change the outcomes given by ISM approach (Diabat and Govindan 2011; Raut et al. 2017; Wang et al. 2018). Further, the ISM approach does not provide any weightage to the interrelated enablers, thus in ISM, the only conceptual model can be developed.

Therefore, to avoid the limitation of ISM another approach DEMATEL is used. In DEMATEL extend of relationship between variables is calculated based on the decision-makers opinions thus provide a quantitative model of interrelated variables by calculating the influencing and dependent power of each variable (Kumar and Dixit 2018). DEMATEL approach is an accurate method for finding out extend of relationships in a model, however sometimes exact crisp value does not fit in practical situations, this may lead to biasing as well as inaccurate interpretation of interrelationships. Therefore Fuzzy sets theory (Zadeh 1965) is introduced in the DEMATEL approach to overcome the inaccuracy and biasing of expert-based decision taking.

By combining ISM and DEMATEL technique only context-based structure of the identified enablers (Sage 1977) and extend of individual contextual relationships between enables by constructing a causal/effect model but it does not provide coordination extend of the entire model. So, Cleveland theory has been utilised for calculating the coordinating index of the complete IoT dependent coordinatingmodel for the AFSC.

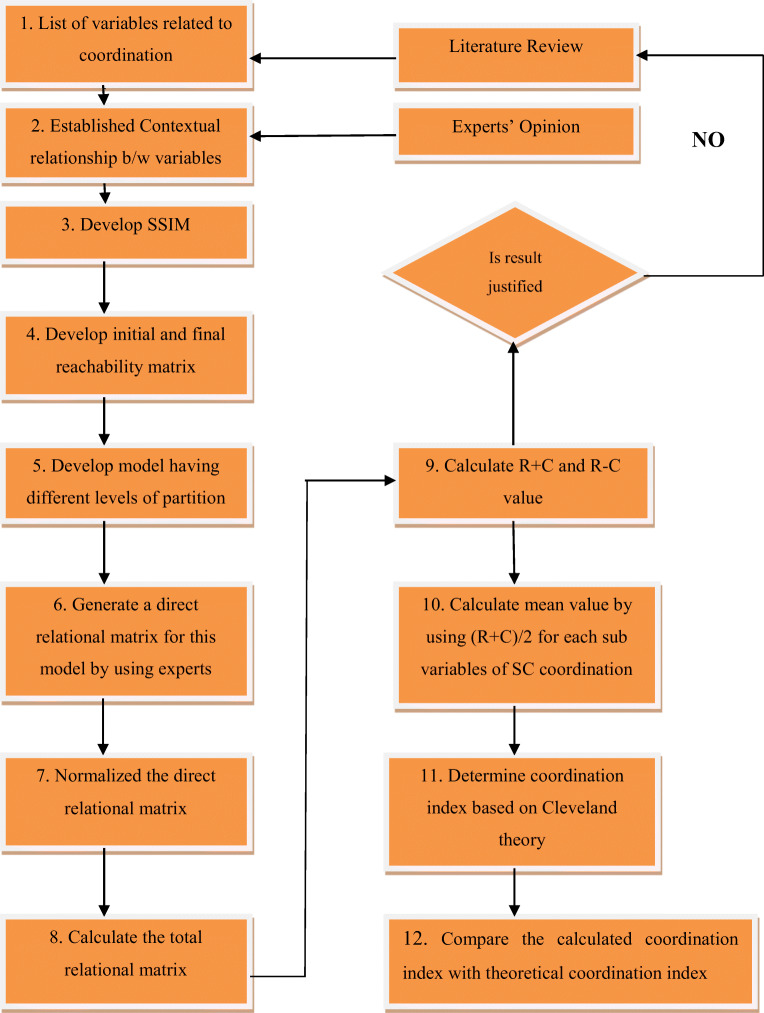

Thus, in this paper combined methodologies of ISM-DEMATEL and Cleveland is used for validating the developed model by calculating the coordinating index. Further to deal with practical situations and vagueness/not clearin judgments, fuzzy sets theory-based DEMATEL is required to deal with this situation (Wu 2008; Tseng 2010). The complete model has explained with the means of a case study. The combined framework of the research is shown in Fig. 1.

Fig. 1.

Framework of the proposed research

The used methods in this research are explained as under.

ISM methodology

ISM technique is used to construct ordered and directional based interrelationships between identified factors for a particular model (Sage 1977). In this method overall model based upon interrelationships have been developed from the complicated identified set of factors. Thus, ISM may help in the overall interpretation of the individual’s relationships based on the digraphs obtained depending on contextual relationships. Jharkharia and Shankar (2005) have implemented the ISM technique for interpreting the barriers in ICT based SC. Singh et al. (2007) has applied ISM in advance manufacturing for enhancing SMEs’ competitive capabilities.

This technique has been applied in various fields like construction organisations and services based SCs etc. (Govindan et al. 2012; Kannan 2018). The implementing of ISM has improved the manager’s understanding of linking the organisational based critical factors. There are following steps followed in the ISM technique:

Identifying different factors significant for developing any model or system based on extensive literature done.

Developing contextual interrelationships among identified factors.

Constructing a Structural based Self-Interaction Matrix (SSIM) of factors, for indicating pairwise comparisons of the factors.

Constructing a reachability metrices based on the SSIM and finding out transitivity links for finding out more than one relation among factors.

Segregate the reachability metrics into several levels.

Removing of transitivity relations in the reachability metrics by drawing digraph.

Converting the digraph intothe structure-based model (ISM) by changing nodes with some description.

Checking any inconsistency and modify the developed ISM.

Fuzzy DEMATEL method

DEMATEL technique proceeds through causal and effect diagram of the identified factors based on their influential/interdependent power. In this,all factors are classified into cause and effects groups. This may give a better understanding of structure-based factors for defining a relationship (Quezada et al. 2018). The relationships among causal and effect are changedin the DEMATEL form. There are the following key steps in this technique.

- Constructing a direct relational matrix. For measuring the extent of relation established between two factors a Triangular Fuzzy Number (TFN) scale has followed i.e. (0,0.1,0.3) for (no relation) for, (0.1,0.3,0.5) (very low relation), (0.3,0.5,0.7) (low relation), (0.5,0.7,0.9) (high relation) and (0.7,0.9,1) (very high relation)respectively. Thus an initial direct relational matrix is constructed as T. In this factor i affect the factor j as:

-

2.

Normalised the direct relational table into normalising direct relational matrix S by following five steps as given by Opricovic and Tzeng (2003) as shown in Appendix 2

Step 5. Integrate crisp values:

Where

-

3.

Obtained a total relation matrix T as T = S[I − S]−1, where I matrix is the identity matrix

-

4.Producing a cause and effect diagram. In this x axis (R+ C) denotes the cause axis and y axis (R- C) denotes causal based effects axis as shown below.

Cleveland theory for coordination index

For calculating the coordinating index, all factors of coordinating systems are considered. The framework proposed for producing competitiveness hascontinued to calculate coordinating index. Singh et al. (2012) has also implemented this theory for evaluating the competitiveness index for any SC. By adopting this theory, coordinating index calculated as:

- Where, Cj

Coordinating index

- I

Coordinating factors

- R

Ranking of coordinating factors

- Ki

Inverse Ranking (If R = 1, K = 7, if R = 2, K=6)

- Wi

Weightage given to coordinating factors

Forgiving weightage to factors for the coordinating system, a seven-point Likert scale has been used, i.e. 7 and 1 corresponds to 100 and 0%, respectively. (Wi) is as under:

Wi = +1 (strength), where % score > 80% (mean value, 5.6)

Wi = 0 (neutral), where % score is between 40 and 80% (mean value ranging 2.8 to 5.6)

Wi = −1 (weakness), where % score < 40% (mean value, 2.8)

The proposed framework for IoT based coordination system of AFSC

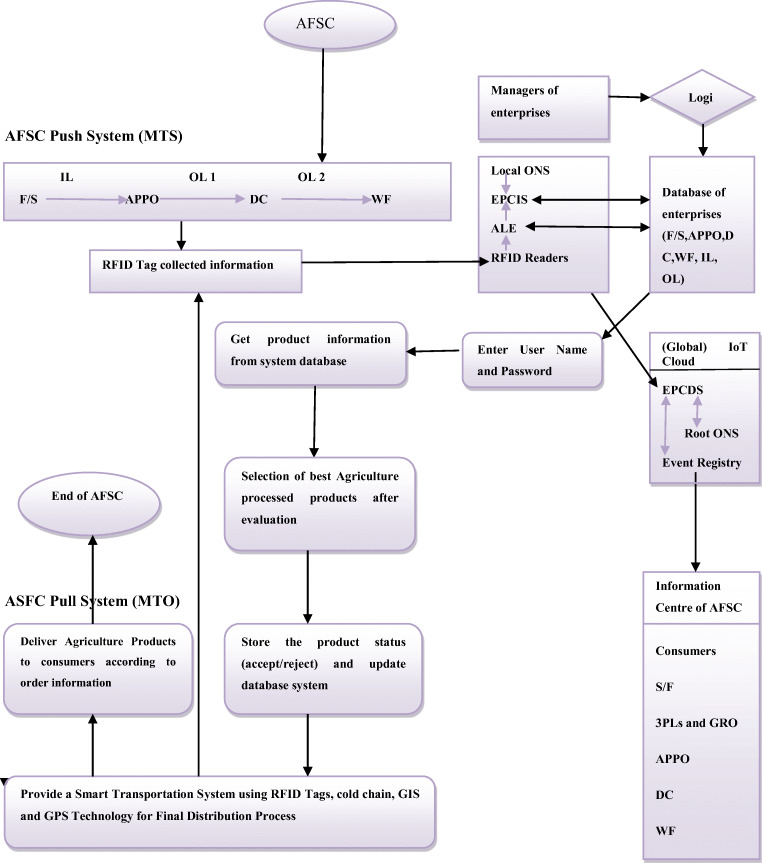

AFSC is a specific sector in which real time-based information is required as there is a requirement of controlling the various activities with high resilience capabilities. For improving the resilience capacity, the AFSC must be managed by considering different decoupling points for interconnecting the stakeholders within SC. ASFC “push/pull” system is a Customer Ordered Decuple Point (CODP). The CODP has separated the ASC in two sections, the first section is the “pull” system or Make -To- Stock (MTS) activities, in this SC’, is mainly decided based onconsumer’s demands. The other part is the “push” system or Make-To- Order (MTO) activities, in this customer’s demands within AFSC are forecasted. These demands are mainly dependent on processing plans, distribution centres, supplier’s capacity and warehouse facilities. Further, as ASC involves large numbers of members and associated practices so it is consisting ofmany Decupling Points (DP). Figure 2 describes an entire model of AFSC coordination.

Fig. 2.

Framework for IoT based coordination system of AFSC

At initially three decoupling points (DP 1, DP2 and DP3), all agri- products are supplied to the specific organisations through Inbound or Outbound logistics (IL, OL) mode having negligible knowledge about consumers. At DP4, value-added agriculture products delivered to customers. At this consumer’s oriented practices have done to meet their specific requirements. Finally, DP5 is the connection the growers/farmers and consumers have been made for delivering the end products.

Poor qualities of Agri products may affect the consumer’s lives. Therefore, a quick responsiveness system is required for AFSC. For achieving this, some advanced technologies have been implemented for tracking and tracing real time-based monitoring of AFSC data. Presently, organisation are implementing some advance traceable system for tracking farming practices, purchasing department, warehouse thus improves the coordination within the ASC (Bosona and Gebresenbet 2013; Kang and Lee 2013; Lotfi et al. 2013; Kwon et al. 2014; Prince et al. 2014). IoT technology has emerged as new tools for achieving effective data exchange in a flexible or resilient AFSC.

The inbuilt concepts of IoT are the interconnection of different things and IoT based technologies like Radio-Frequency Identification (RFID) tags and readers, sensing technologies, transmitting technologies like, GPS, mobile phones etc. All entities or stakeholders within AFSC are interconnected by IoT networking layer. The IoT technology mainly includes six pillars like Electronic Product Code (EPC), RFID tags and reader, EPC middleware, Application Level Events (ALE), EPCIS, and Object Naming Service (ONS). By combining EPC and IoT different entities within AFSC has a unique identity for their identification. This provides resilience capabilities within ASC for giving inquiry-based data to the end customers and other members. Based on the obtained EPC data of required entities by using IoT, data is transferred by the RFID networking system to the EPCIS this will be obtained the address of EPCIS by ONS enquiry. If the data is required at the organisational level then local ONS is used otherwise root ONS is used. Figure 2 represents the entire flow of processes.

A practical application of the proposed framework: numerical illustration

Practical application of the proposed research is discussed below. This section includes a case study, questionnaire development and data collection for the numerical illustration.

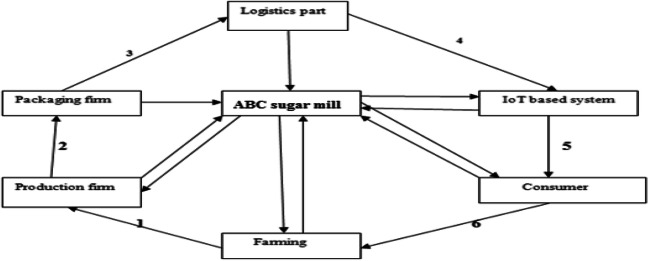

A case information of sugar mill industry

ABC (fictitious name) has more than 40 years of experience in sugar production and its supply. This group start from a small single unit to multi located large industry. This industry supplies sugar to both the Indian and global market. Over the last few years, this industry has a tremendous track record of large project execution and their coordination. This group of industry handled a range of projects ranging from small project of 500 Tons of Sugar per Day (TSD) to 3000 TSD. Further, this mill not only produces primary level sugar but also it also produces a wide range of sugar-related products like low-fat yoghurt, health drinks, sugar cubes and jiggery etc. This type of mills mainly located in the Western part of Uttar Pradesh.

Each sugar mill requires tons of sugarcane, which need to be collected from the authorised nearby located village. This mill requires sugarcane availability throughout the production of the sugar but local farmers transport grown sugarcane to the mill as per their convenience for this they may use traditional transport system likewise bull cart, tractors etc. This process of sugarcane may slow dawn sugar production.

Another challenge in sugar production mills in crushing sugarcane as soon as possible as delay in the crushing process may result in low contents of sugar. Next challenge comes in the night when there is low availability of sugarcane but its requirement is continued during the sugar production. To avoid the above challenges, ABC Sugar Mills has tried to adopt the following steps.

To increase the yield of sugarcane, an efficient IoT based farming technologies and farming practices have been adopted by farmers along with other experts to guide them. Also, farmers can gather information regarding whether condition, fertilisers used, market-rate etc. in advance.

The mill management can also track the growth rate and quality of sugarcane yield besides quantity available from each farmer with the help of the GPS system.

Each Collecting Warehouse (CW) for sugarcane is located in a suitable area for the convenience of farmers. Further mill database of information is updated by proper monitoring of CW with the help of RFID tags and readers by using local ONS so that sugarcane availability can be traced out at any time of production.

The sugarcane collected at the warehouse is inspected for quality and sugar contents. This information transferred to the mill database. Collected sugarcane then loaded to the truck for their expedite movement to the mills for sugar production. Also, sugarcane condition and truck movement during the transportation is traced with the help of GPS/GIS for maintaining the sugarcane quality and to avoid any accidents or delay respectively. This information also transferred tothe mill database system with the help of root ONS.

Finally, the sugar produced at the mills again loaded to the truck with IoT technology for their distribution to the retailers.

Following advantages may be obtained byimplementing IOT technology in ABC sugar mill.

Farmers have to cover the shorter distance as warehouse collecting centres are located nearby local farms. Earlier they have to spend 5–7 h during transportation. Further, they have a shorter waiting time at warehousing centres as each facility at centres well organised.

ABC sugar mill gets fresh sugarcane as improved IoT based farming techniques and practices. Due to this production of the mill has increased from 9 to 15%.

Reduced the uncertainty and variability of sugarcane availability to ABC sugar mill.

Each product of ABC sugar mill available to consumers in the right quality and at the right time. Thus improves customer satisfaction and maintain trust.

Thus, by adopting IoT based technology ABC sugar mills maybe increase its productivity and quality which makes it a profitable business for each stakeholder of the supply chain. The complete framework illustrated in given Fig. 3.

Fig. 3.

Complete framework of the proposed case study of sugar

Questionnaire development and data collection

The framing of questions takes place based on the experts from different fields of academics and industries as shown in Appendix 1. A total of 20 experts were approached from case company, related suppliers and academics between January 2020 and April 2020 as per convenience sampling. Out of 20, 05 experts agreed to participate in this research. These participated 05 experts were categorised as their demographic characteristics. As per professional qualification level of experts, 02 experts were graduates, 02 were post graduate and 01 was doctorate. According to work experience, 01 expert was in the range of 05–10 years, 02 experts were in the range of 10-15 years and remaining experts were having work experience greater than 15 years. Based on the filled questionnaire, 02 experts from the third-party logistics sector, 02 experts from customer-based services and 01 expertfrom regulatory bodies working in this domain for managing quality and safety of agri products by using ISO standards. The experts were the managers from third-party logistics companies for providing different services, administrative officers from consumer based industries and Research and Development (R&D) team member from regulatory bodies.

Numerical illustration for results interpretation

This section explains the numerical illustration of the study. It consists of three subsections namely ISM application, DEAMATEL application and Cleveland application as explained below.

ISM application

This section explains various steps of ISM with the help of a numerical illustration. There are following steps, which need to be followed:

Structural self-interaction matrix

For defining the dependencies between the variables for coordinating ASC four symbols have been applied for denoting therelations among between the parameters i and j as given below.

- V

Variable i drive the Variable j.

- A

Variable j drive the Variable i.

- X

Variable i and j drive each other.

- O

Variables i and j are unrelated.

Experts mentioned in sub-section 5.2 were asked to make consensus to frame an initial comparison matrix by using above said four symbols. Initial comparison matrix for enablers is shown in Table 2.

Table 2.

Initial comparison matrix for enablers

| S. No. | Factors | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

|---|---|---|---|---|---|---|---|---|

| 1. | TMS | – | V | V | V | V | V | V |

| 2. | SCR | – | X | A | A | A | O | |

| 3. | SCI | – | A | A | A | O | ||

| 4. | IBI | – | V | O | A | |||

| 5. | IS | – | X | O | ||||

| 6. | MU | – | O | |||||

| 7. | 3PLs | – |

Initial reachability matrix

The SSIM matrix has been changed to an initial reachability matrix by putting the binary values (0, 1) at the place of V, A, X and O for (i, j) by following the rules as given below.

V at the place of (i,j) in the SSIM changed to 1 for (i,j) and 0 for (j,i) in the reachability matrix.

A at the place of (i,j) in the SSIM changed to 0 for (i,j) and 1 for (j,i) in the reachability matrix.

X at the place of (i,j) in the SSIM changed to 1 for (i,j) and 1 for (j,i) in the reachability matrix.

O at the place of (i,j) in the SSIM changed to 0 for (i,j) and 0 for (j,i) in the reachability matrix (Table 3).

Table 3.

Initial reachability matrix for enablers

| S. No. | Factors | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

|---|---|---|---|---|---|---|---|---|

| 1. | TMS | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| 2. | SCR | 0 | 1 | 1 | 0 | 0 | 0 | 0 |

| 3. | SCI | 0 | 1 | 1 | 0 | 0 | 0 | 0 |

| 4. | IBI | 0 | 1 | 1 | 1 | 1 | 0 | 0 |

| 5. | IS | 0 | 1 | 1 | 0 | 1 | 1 | 0 |

| 6. | MU | 0 | 1 | 1 | 1 | 1 | 1 | 0 |

| 7. | 3PLs | 0 | 0 | 0 | 1 | 0 | 0 | 1 |

Final reachability matrix

The final reachability matrix is developed by using the transitivity links as shown in Table 4.

Table 4.

Final reachability matrix for enablers

| S. No. | Factors | 1 | 2 | 3 | 4 | 5 | 6 | 7 | DR.P |

|---|---|---|---|---|---|---|---|---|---|

| 1. | TMS | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 7 |

| 2. | SCR | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 2 |

| 3. | SCI | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 2 |

| 4. | IBI | 0 | 1 | 1 | 1 | 1 | 1* | 0 | 5 |

| 5. | IS | 0 | 1 | 1 | 1* | 1 | 1 | 0 | 5 |

| 6. | MU | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 5 |

| 7. | 3PLs | 0 | 1* | 1* | 1 | 1* | 1* | 1 | 6 |

| DP. P | 1 | 7 | 7 | 5 | 5 | 5 | 2 |

In this Driving (DR) and Dependency (DP) Power are calculated by summing up driving (help in achieving) and dependence (achieved by other) variables respectively. These powers help in the formulation of 4 clusters for the variables like autonomous, depending, linkingand not depending.

Levelling based partitions

Based on the final reachability matrix the intersection of the antecedent set (dependence power) and reachability set (driving power) has been obtained. Based on common points obtained from the intersection and reachability set, different levels have been identified. Table 5 illustrates the first level iteration.

Table 5.

Initial iteration matrix for enablers

| Factors | Reachability set | Antecedent set | Intersection set |

|---|---|---|---|

| 1. | 1,2,3,4,5,6,7 | 1 | 1 |

| 2. | 2,3 | 1,2,3,4,5,6,7 | 2,3 |

| 3. | 2,3 | 1,2,3,4,5,6,7 | 2,3 |

| 4. | 2,3,4,5,6 | 1,4,5,6,7 | 4,5,6 |

| 5. | 2,3,4,5,6 | 1,4,5,6,7 | 4,5,6 |

| 6. | 2,3,4,5,6 | 1,4,5,6,7 | 4,5,6 |

| 7. | 2,3,4,5,6,7 | 1,7 | 7 |

Iteration will continue to the identification of each level as shown in Tables 6, 7 and 8.

Table 6.

Second iteration matrix for enablers

| Factors | Reachability set | Antecedent set | Intersection set |

|---|---|---|---|

| 1. | 1,4,5,6,7 | 1 | 1 |

| 4. | 4,5,6 | 1,4,5,6,7 | 4,5,6 |

| 5. | 4,5,6 | 1,4,5,6,7 | 4,5,6 |

| 6. | 4,5,6 | 1,4,5,6,7 | 4,5,6 |

| 7. | 4,5,6,7 | 1,7 | 7 |

Table 7.

Third iteration matrix for enablers

| Factors | Reachability set | Antecedent set | Intersection set |

|---|---|---|---|

| 1. | 1,7 | 1 | 1 |

| 7. | 7 | 1,7 | 7 |

Table 8.

Fourth iteration matrix for enablers

| Factors | Reachability set | Antecedent set | Intersection set |

|---|---|---|---|

| 1. | 1 | 1 | 1 |

Classification of factors

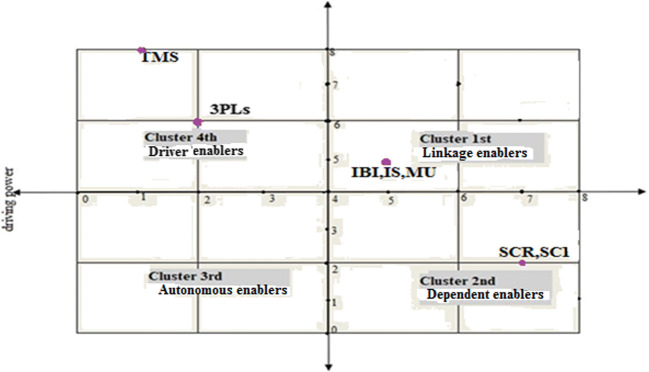

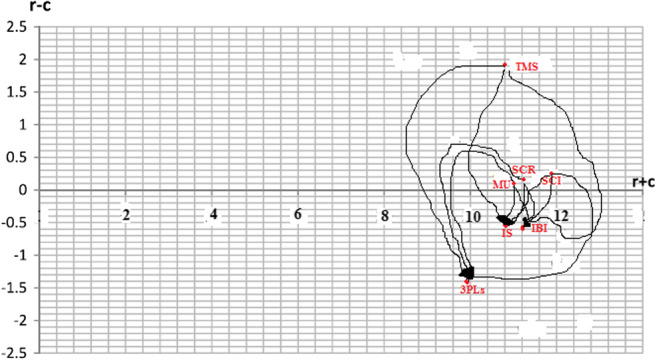

Clustering of variables takes placed on the basis of driving and dependence power as shown in Fig. 4. This clustering is same as that of Kannan (2018).

Fig. 4.

ISM based MICMAC analysis

The first quadrant is for the “autonomous factors” having low driving and depending values. Autonomous variables are not well connected to the other variables or very few linking within the system given by ISM. The second quadrant is for depending variables having high depending values and low driving values. The third quadrant is for the linking variables having high driving and depending values. These variables are unstable as they are not affected by other variables. The fourth quadrant is for independent variables having high driving power and low dependence values.

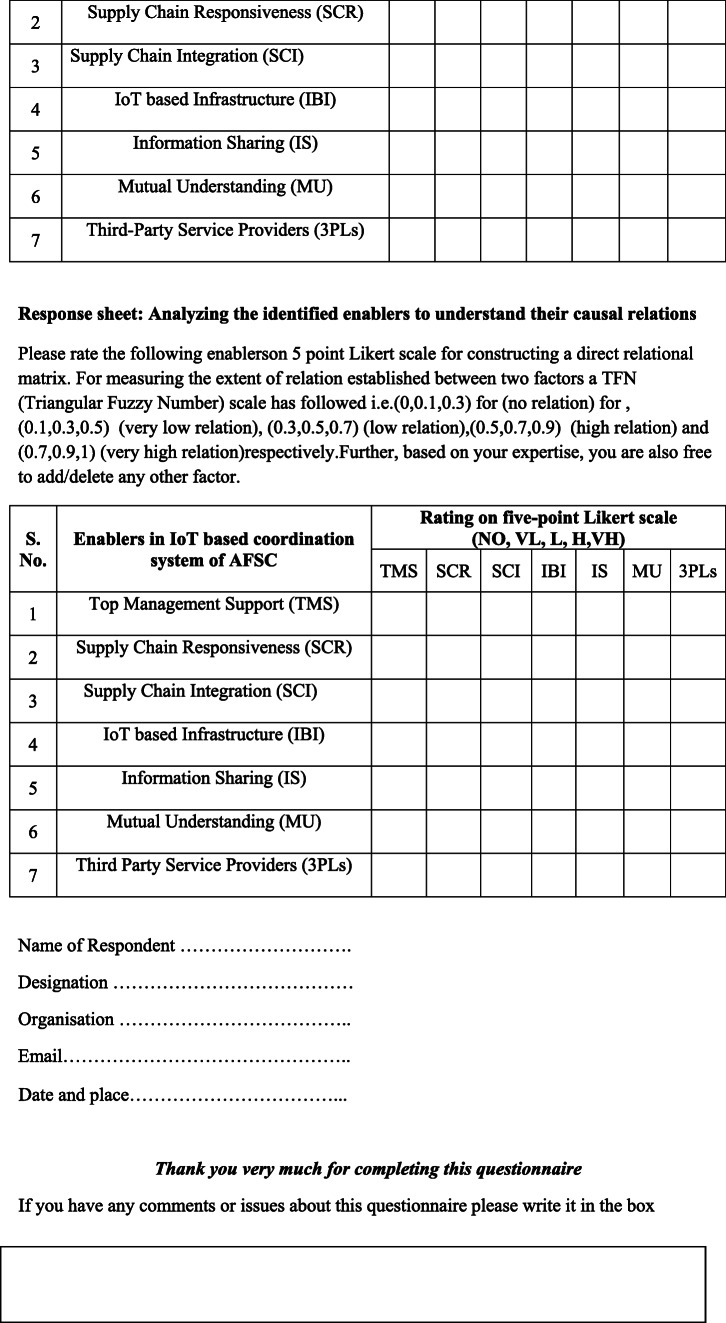

ISM based hierarchical structure

From the final reachability matrix (Table 4) and level partitioning (Table 5-8), an ISM based hierarchical structure of enablers for developing IoT Based coordination system of ASC and depicted in Fig. 5.

Fig. 5.

ISM based hierarchical structure for showing dependencies

Fuzzy DEMATEL application

After formulating the model by ISM analysis, we applied fuzzy DEMATEL method, a fuzzy aggregation method by using linguistic variables to deal with vague and imprecise judgments.

Construct adirect relational matrix

The experts mentioned in a subsection in 5.2 were used to evaluate the variables in the pairwise matrix or direct relational matrix by using thefuzzy linguistic variables, which are shown in Appendix 2.

Construct a normalised direct relational matrix

Normalise the direct relation matrix of TFN values given by the experts, by using sub-steps 1 to 5 of main step 2 described in F- DEAMATEL approach as shown in Table 9.

Table 9.

Normalised direct relational matrix

| TMS | SCR | SCI | IBI | IS | MU | 3PLs | |

|---|---|---|---|---|---|---|---|

| TMS | 0.028423 | 0.147798 | 0.181825 | 0.190192 | 0.130785 | 0.147798 | 0.173178 |

| SCR | 0.121857 | 0.028423 | 0.138871 | 0.139151 | 0.164531 | 0.147518 | 0.147518 |

| SCI | 0.122138 | 0.173178 | 0.028423 | 0.155885 | 0.164531 | 0.138871 | 0.173178 |

| IBI | 0.130224 | 0.122138 | 0.156165 | 0.028423 | 0.147518 | 0.131065 | 0.096758 |

| IS | 0.06245 | 0.139151 | 0.156165 | 0.147518 | 0.028423 | 0.156445 | 0.096477 |

| MU | 0.096477 | 0.156165 | 0.164531 | 0.096477 | 0.156445 | 0.028423 | 0.164531 |

| 3PLs | 0.105405 | 0.08755 | 0.08755 | 0.164812 | 0.082281 | 0.08755 | 0.028423 |

Construct a total relational matrix

Attain a total relational matrix from the normalised matrix by using step 3. Calculate (R + C), (R-C) and (R + C)/2 from Table 10 as shown below.

Table 10.

Total relational matrix

| TMS | SCR | SCI | IBI | IS | MU | 3PLs | R | |

|---|---|---|---|---|---|---|---|---|

| TMS | 0.658556 | 0.921143 | 0.993252 | 1.009423 | 0.9278 | 0.906082 | 0.958628 | 6.374884 |

| SCR | 0.675037 | 0.732006 | 0.871708 | 0.878827 | 0.870391 | 0.825783 | 0.852468 | 5.706221 |

| SCI | 0.713109 | 0.9045 | 0.820096 | 0.942309 | 0.91746 | 0.863723 | 0.920077 | 6.081275 |

| IBI | 0.646317 | 0.774473 | 0.839612 | 0.730938 | 0.811847 | 0.769145 | 0.765698 | 5.33803 |

| IS | 0.570477 | 0.763596 | 0.812271 | 0.808081 | 0.681443 | 0.765213 | 0.739434 | 5.140516 |

| MU | 0.638135 | 0.825851 | 0.869494 | 0.823279 | 0.843398 | 0.699246 | 0.847615 | 5.547018 |

| 3PLs | 0.520474 | 0.607975 | 0.639885 | 0.709862 | 0.617875 | 0.598941 | 0.56187 | 4.256883 |

| C | 4.422106 | 5.529543 | 5.84632 | 5.902718 | 5.670215 | 5.428134 | 5.645791 | |

| R + C | R-C | (R + C)/2 | ||||||

| 10.79699 | 1.952779 | 5.3985 | ||||||

| 11.23576 | 0.176678 | 5.61788 | ||||||

| 11.92759 | 0.234956 | 5.9638 | ||||||

| 11.24075 | −0.56469 | 5.62037 | ||||||

| 10.81073 | −0.5297 | 5.40537 | ||||||

| 10.97515 | 0.118884 | 5.48758 | ||||||

| 9.902674 | −1.38891 | 4.95134 | ||||||

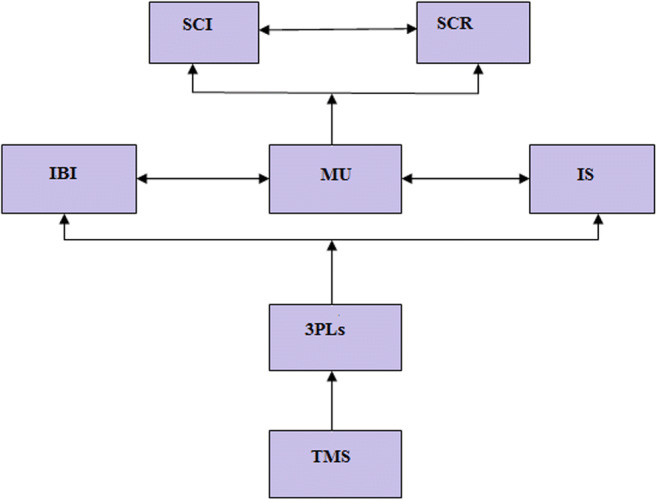

Cause and effect diagram

Draw a cause and effect diagram of the enablers (Fig. 6) based on (R + C) and (R-C).

Fig. 6.

The cause and effect diagram of enablers

From Fig. 6, it can be observed that IBI, IS and 3PLs are categorised into effect group which is cause by other 4 enablers.

Calculation of coordination index given by Cleveland based on DEMATEL and ISM

For calculating the coordinating extent in SCM, an index has been defined. The model of Cleveland et al. (1989) determine the SCM coordinating index based on the mean value of enablers i.e.(R + C)/2 obtained from DEAMATEL. Coordination Index (CI) of the entire is calculated based on DEAMATEL result by using Cleveland theory as shown in Table 11.

Table 11.

Calculation of coordination index (CI) based on Cleveland theory

| Enablers | Mean[(R + C)/2] | Rank | I.R (Ki) | log (Ki) | Wi | Wi*log (Ki) |

|---|---|---|---|---|---|---|

| TMS | 5.39850 | 6 | 2 | 0.30 | 0 | 0 |

| SCR | 5.61788 | 3 | 5 | 0.70 | +1 | 0.70 |

| SCI | 5.96380 | 1 | 7 | 0.84 | +1 | 0.84 |

| IBI | 5.62037 | 2 | 6 | 0.78 | +1 | 0.78 |

| IS | 5.40537 | 5 | 3 | 0.48 | 0 | 0 |

| MU | 5.48758 | 4 | 4 | 0.60 | 0 | 0 |

| 3PLs | 4.95134 | 7 | 1 | 0 | 0 | 0 |

For quantification of the coordination role by particular enablers in an IoT based coordinating system of AFSC, a Cleveland index (2.32) has been employed in this research. Based on the individual index, it may be concluded that some enablers like SCR, SCI and IBI are most significant in IoT based coordination system based on (R + C) value. Some enablers like TMS, MU, IS and 3PLs which are classified as linkage and independent enablers based on ISM have less scored as these enablers are highly unstable. Therefore,organisational strategies should be more focused on TMS, MU, IS and 3PLs. Further, enablers having positive Cleveland index may be utilised by the managers as benchmark setting for improving the strategies in a coordinating system, which may improve the competitiveness of an SC at the globalised level.

Discussion of findings

The conventional AFSC system has been designed for the cost optimisationbut has not been designed for dealing efficiently with anyunexpected natural disruptions (Dolgui et al. 2018) and pandemic such as COVID-19 etc. For maintaining competitiveness, AFSC must consist of either operational flexibility or have safety stocks of agri-food even if there is shutting down of entire logistics and processing activities. Therefore a flexible AFSC network needs to be designed for aligning its strategies and practises to adjust natural disruption risks in term of both technological and other practises (Li and Zobel 2020; Wang and Franke 2020). Therefore, a digitised coordination system is required fordeveloping AFSC resilience. Based on ISM, (R + C) and (R-C) analysis in developing IoT based coordination system for ASC, the following discussion may be noted.

Top management support is most important cause enabler based on (R-C) value as investment by TMS for innovating new technology like IoT constantly associated with some expenditure losses in the organisations (Ericsson 2015; Lee and Lee 2015). Thus, only a few implications of IoT showed net profitable condition on the expenditure for any organisation. This validates the finding of this research as top management support is the main driver based on ISM based MICMAC analysis and it has highest R-C value, which indicates TMS effects most to the other enablers. Investment in food safety programs (Hazard Analysis and Critical Control Point (HACCP)) by top management and employee training in maintaining food hygiene (Good Hygiene Practices (GHP)) during packing, storing and delivering is the main critical factor, encouraging the 3PLs is the next important factor, adopting new technology and focused on communication are the other important factors.

Integrating SC is classified into second important cause enabler based on (R-C) value for affecting the entire coordination system when considering upstream information sharing with food regulatory body (WHO, ISO etc.) and food processing organisations. But, it comes under dependent variables by MICMAC analysis when considering downstream information sharing with retailers and consumers. It depends mainly on integration along with multiple SC with heterogeneous technology, integrating the information and practices related to suppliers and customers. Integrating the agriculturesupply is a not a unidirectional idea but it involves insight of various strategically, operational and tactical practices at organisational levels, so it also affects most of the criterion (Vallet-Bellmunt and Rivera-Torres 2013).

Supply chain responsiveness is classified into third important cause enablers based on (R-C) value for affecting the entire coordinating system and based on MICMAC it is also highly dependent enablers. Fast exchange of real-time information in AFSC has the highest significance in SC responsiveness as it improves the flexibility or resilience, which enhances AFSC adaptability to any risk management during natural disruption (COVID-19). Other sub enablers in this list are JIT agri product processing and delivery in dynamic ASC, the ability of SC to adopt process technology change and quick transactional inter enterprises reaction. Responsiveness of SCs would affect in gaining reliability, agility and quick data transfer etc., which facilitate in improving different practices (Bi et al. 2014; Reaidy et al. 2015; Dweekat and Park 2016; Cohen 2020).

Mutual understanding isthe fourth important cause enabler affecting other criterion and comes under linkage variable based on MICMAC analysis. It further accompanied by other sub enablers. Trust development among SC members has been given priority as it improves the confidence of consumers regarding food safety and security. Mutual understanding helps in setting common visions and aims of the stakeholders (Food regulation organisations, logistics supplier, warehouse distributions and farmers) of AFSC; and sharing common protocols in IoT based system i.e. SC risk and reward sharing. Therefore, mutual understanding is a must for successfully implementing new technologies to develop better coordinating system for AFSC (Park and Han 2001; Ahuja and Khamba 2008).

Third-party service is considered as most affected enablers by other variables based on (R-C) value in developing an IoT based coordinating system for AFSC and based on MICMAC, it is alsoan important driver after TMS. 3PLs is an external service providing agencies which provide mainly logistics, processing and storage activities during shutting down logistics and other organisations activities during any natural AFSC disruption. 3PLs are meeting consumers’ requirement, which is time-dependent at a lower cost thus providing facilities with profit to organisations (Domingues et al. 2015). Thus, five key services provided by 3PL are related to logistics, raw product processing, managing inventories, data exchanging and product packing (Delfmann et al. 2002). 3PLs mainly hired for logistic activities of SC followed by warehouse management, customer service and IoT based infrastructure.

Based on R-C value, IoT based infrastructure is the second effect enabler by other variables for developing an efficient coordinating system. Based on MICMAC value, it is alsoa linkage-type of enablers. Proper security support system plays a major role for IoT based infrastructure system followed by proper technical manpower for AFSC activities i.e. irrigation, plantation, smart packing of agri products using Artificial Indigence (AI) packing, safe storing of food grains and secure logistics activities using IoT based traceability etc., a proper cloud computing system for network availability support during, proper automation system for traditional agri processes. Integrating IoT technologies or developing IoT based infrastructure includes IoT based SC operations, big data analytics and others protocols within AFSC (Bi et al. 2014; Bughin et al. 2015; Riggins and Wamba 2015).

Information sharing is the third effect enabler and it also categorised into linkage enablers. Use of IoT technology is most important in information sharing as it ensures collaboration among upstream and downstream stakeholders of ASFC by offering a considerable level of volume and delivery flexibility to demand fluctuations (Jin et al. 2014). Further, it provides tracking of logistic information, tracking of processing and warehousing information required for maintaining the quality of agri products knowledge sharing to provide the food regulations and standards during processing and storage of agri products (Holmberg 2000). It has been noticed that information’s sharing and quality has a positive effect by the trust-building in SC but the negative impact of fluctuating raw products demands (Wang et al. 2013).

Next discussion is on analysing coordination index of ASC. Coordination index is calculated based on Cleveland theory. Depending on all of the seven enablers in developing efficient coordination system for AFSC, coordination index has been calculated based on mean dependence value calculated from DEMATEL approach. Then calculated CI value compared with theoretical CI value for SC. Theoretical CI value ranges from −2.86 to +2.86. Calculated CI value which is 2.32 is some close to 2.86. So, coordination for SC has been achieved very close to the theoretical value. However, there is a scope for further improvement. Finally, based on Cleveland index, some information may be reduced from complex strategies or scenario and thus facilitate the SWOT analysis in decisions making by the experts (Marchet et al. 2017).

- Next part of discussion compares the Figs. 4 and 6 for comparing the ISM and DEMATEL results. Unlike DEMATEL, ISM does not provide any considerable indication of the enablers’ degree of importance on IoT based coordination in AFSCM. Further, the ISM approach does not provide the interpretations of established links between enablers and transparency (Singh and Sushil 2013; Dubey and Ali 2014). Thus, there is some contradiction between final results based on ISM and (R-C) values of DEMATEL e.g.

- 3PLs based on ISM comes in the driver category but it comes in effect category based on (R-C) value in DEMATEL.

- SCR and SCI are coming under the dependent category based on ISM but classified into a cause group based on DEMATEL.

Nevertheless, (R + C) values which mean the degree of significance of a particular variable within the entire system (Raut et al. 2019) have justified the result to some extent. SCI has obtained the highest (R + C) value of 11.927 due to its impact on strategies, tactical and operational practices for effective coordination at inter and intra organisation level (Pivoto et al. 2018). Thus, it is the most significant enablers in the entire IoT based coordinating system. Similarly, SCR is the second important significance enabler with (R + C) value of 11.24 as it improves the traceability by the collecting, recording, maintaining the data regarding the condition of the product and process of AFSCM (Antonucci et al. 2019). Further, 3PL is the least significant and highly dependent enablers with (R + C) value of 9.902 as it mainly depends on SCI, SCR and TMS for orchestrating the SC (Marchet et al. 2017).

Some of the ISM and DEMATEL results as discussed above are consistent to some extent for providing a robust and control framework. TMS classified into independent factor based on ISM with a cause group based on DEMATEL results. Similarly, other enablers like IS and IBI are highly unstable as classified into linkage enablers (any change may affect the entire system) and classified into effect group by DEMATEL. Finally, MU also classified into linkage variables and comes under cause group.

Managerial and practitioners implications

As the IoT implementation is still at a nascent stage. The findings of this paper may guide the practitioners and managerial implications. Based on the study following managerial as well as practitioners implications have emerged:

This paper will guide the new business processes, which are looking for embracing new technologies like IoT and big data analysis etc. This paper also helps in providing TMS by improved understanding of the business practices by considering the IoT implementation in achieving coordinating system. Managers may also get aware of the technical barriers of business that are most likely to be faced in IoT implementation.

This research guides the managers of the food processing organisations to organise programs related to GHP during product packing, processing, storing, transportation and distribution of the agri products by getting information regarding the food safety standards from Food Safety Management Systems (FSMS) based on the HACCP for managing food safety risks and prevent food contamination. Thus, this research may be utilised for providing good quality food during a natural AFSC disruption.

The organisations of AFSC may be changed toa new IoT based industrial model of coordination. Based on business to the business orientation of consumer’s different practices like servicing, processing, supplying have been influenced bythe fulfilment of demands.

This research encourages some new projects for providing a common platform for information sharing among farming based population thus creating business profit. Further, this research developed more trust within the AFSC by sharing information in an effective manner (Fast Company 2017).

This study may motivate the managers of the organisations for investing more in new emerging tracking and tracking technologies like RFID tags and readers, and GPS etc. This will surely guide the managers for recruiting trained workers for effective use of the adopted IoT based technologies. Further, this research may motivate the managers to organise more training and development programs within the organisation.

Further, this study may help in IoT technology-based enhancement of agri products quality, consumer requirement and services etc. Thus, if this study is appropriately harnessed by managers of the organisations then it has the capability of a complete transformation of conventional business-to-consumers’ connections into a real-time exchanging of data by using RFID tags, readers and other embedded electronic devices.

Unique theoretical contribution

This research considered the interaction among different stakeholders associated with AFSC for ensuring IoT based sustainable food security system. Some stakeholders identified based on this study are TMS, 3PLs, technology providers and some government organisations. These stakeholders helped in the identification ofa total of 7 enablers based on 30 more sub enablers (Table 1) for ensuring agri-food by adopting sustainable practices. Thus, this research provides some applications to practitioners in different areas. This study observed that different stakeholders have to respond in different ways in AFSC. TMS is the most important influencing stakeholders; it implies that TMS must follow a proactive and policies dependent approach. Similarly, 3PLs is the most important influenced stakeholder and act as a supportive stakeholder for TMS. These two stakeholders initiate the other enablers like IBI, IS, MU, SCR and SCI.

Further, all enablers may guide other sets of stakeholders involved in technologies implementation, logistics practices, farming sustainable practices, agri-products processing, qualities’ inspection with safe packing of products. In the nutshell of theoretical contribution, this research identified three types of drivers based on stakeholder theory for achieving sustainable based food secure system. The first driver identified the interested stakeholders and their needs or demands, the second driver identified the role of each stakeholder or its influence on others and the third driver identified practices (3PLs support) or technologies (IoT) used by stakeholders.

Conclusion

In the last few years, it has been noticed that AFSC is still following its traditional pattern for information sharing between different SC members. This sector is at a growing stage as it mainly depends on the conventional mode of communication used in different practices related to farming, logistics, processing and agri products packing etc. For this, an IoT based model developed, which handle all the activities of AFSC relate to primary and secondary processing of food grains and products, logistic, warehousing and storage, customer’s information, managing third-party service providers and other activities at decoupling points of AFSC. The handling of all the information made effective by incorporating IoT devices likewise, ALE, root ONS, local ONS, EPC, EPCDS and RFID. An IoT based system will certainly fulfil all the 7R’ principle. Thus, each stack holders of AFSC are capable of monitoring the position of each AFSC entities for preparing a chart of activities inunexpected risks and disruptions. Such arrangements intend to recover the effectiveness and responsiveness of the AFSC in any natural disruptions.

This research develops an IoT based coordinating system for AFSC. This paper further identified 7 enablers based on 30 sub enablers. These enablers enhance the implementation of IoT in ASC. The interrelationships between enablers have been set by using ISM based MICMAC analysis and DEMATEL will decide the cause and effect of each enabler on others. From DEMATEL, TMS is the best enabler and came to the main driver. Similarly, IBI facilities, the role of 3PLs and SC responsiveness are the dependent variable based on the R-C value. Another variable like MU, SCI and IS can be seen as linkage variable. Finally based on Cleveland theory, Coordinating index of the entire IoT based coordination system is 2.32. This is not bad for such an IoT based complex AFSC system which has to manage big data problem when comparing to theoretical CI of the SC i.e. -2.86 to +2.86 (Singh et al. 2012).

The research has a limitation of taking an only limited number of factors related to inter and intra organisation. Though this research has some quantitative approach for calculating coordination index of the entire IoT based coordination model of AFSC this research did not show any calculation of CI for different stakeholder’s perspectives. Further, this research does not incorporate social and environmental aspects in IoT implementation. Future researchers can extend this research to reach the sustainable outcomes of this research at the level of social, environmental and economical. Further, in future other technologies like blockchain may be adopted for developing a coordinating system of AFSC (Lin et al. 2017). Based on this research different start-up plans can be used to aware the farmers of the different demographical area about different practices of AFSC.

Appendix 1

Sample Questionnaire

Appendix 2

Normalization steps:

A five-step algorithm as follows for a particular fuzzy number (l, m, r):

-

Step 1.Normalization

-

Step 2.Compute right (rs) and left (ls) normalisation values:

-

Step 3.Compute total normalised crisp values:

-

Step 4.Compute crisp values:

Table 12.

An initial direct relational matrix by decision maker 1

| TMS | SCR | SCI | IBI | IS | MU | 3PLs | |

|---|---|---|---|---|---|---|---|

| 0 | 0.1 | 0.5 | 0.1 | 0 | 0.5 | 0.5 | |

| TMS | 0.1 | 0.3 | 0.7 | 0.3 | 0.1 | 0.7 | 0.7 |

| 0.3 | 0.5 | 0.9 | 0.5 | 0.3 | 0.9 | 0.9 | |

| 0 | 0 | 0.7 | 0.7 | 0.1 | 0.7 | 0.1 | |

| SCR | 0.1 | 0.1 | 0.9 | 0.9 | 0.3 | 0.9 | 0.3 |

| 0.3 | 0.3 | 1 | 1 | 0.5 | 1 | 0.5 | |

| 0.7 | 0.1 | 0 | 0.7 | 0 | 0.7 | 0.1 | |

| SCI | 0.9 | 0.3 | 0.1 | 0.9 | 0.1 | 0.9 | 0.3 |

| 1 | 0.5 | 0.3 | 1 | 0.3 | 1 | 0.5 | |

| 0.7 | 0.7 | 0.7 | 0 | 0 | 0.3 | 0.5 | |

| IBI | 0.9 | 0.9 | 0.9 | 0.1 | 0.1 | 0.5 | 0.7 |

| 1 | 1 | 1 | 0.3 | 0.3 | 0.7 | 0.9 | |

| 0.7 | 0.1 | 0.1 | 0.7 | 0 | 0.7 | 0.1 | |

| IS | 0.9 | 0.3 | 0.3 | 0.9 | 0.1 | 0.9 | 0.3 |

| 1 | 0.5 | 0.5 | 1 | 0.3 | 1 | 0.5 | |

| 0.7 | 0.7 | 0.7 | 0.5 | 0.5 | 0 | 0.1 | |

| MU | 0.9 | 0.9 | 0.9 | 0.7 | 0.7 | 0.1 | 0.3 |

| 1 | 1 | 1 | 0.9 | 0.9 | 0.3 | 0.5 | |

| 0.7 | 0.7 | 0.7 | 0.5 | 0.7 | 0.7 | 0 | |

| 3PLs | 0.9 | 0.9 | 0.9 | 0.7 | 0.9 | 0.9 | 0.1 |

| 1 | 1 | 1 | 0.9 | 1 | 1 | 0.3 |

Table 13.

An initial direct relational matrix by decision maker 2

| TMS | SCR | SCI | IBI | IS | MU | 3PLs | |

|---|---|---|---|---|---|---|---|

| 0 | 0.7 | 0.3 | 0.3 | 0 | 0.7 | 0.5 | |

| TMS | 0.1 | 0.9 | 0.5 | 0.5 | 0.1 | 0.9 | 0.7 |

| 0.3 | 1 | 0.7 | 0.7 | 0.3 | 1 | 0.9 | |

| 0.7 | 0 | 0.5 | 0.5 | 0.5 | 0.5 | 0.1 | |

| SCR | 0.9 | 0.1 | 0.7 | 0.7 | 0.7 | 0.7 | 0.3 |

| 1 | 0.3 | 0.9 | 0.9 | 0.9 | 0.9 | 0.5 | |

| 0.7 | 0.5 | 0 | 0.5 | 0.7 | 0.7 | 0.1 | |

| SCI | 0.9 | 0.7 | 0.1 | 0.7 | 0.9 | 0.9 | 0.3 |

| 1 | 0.9 | 0.3 | 0.9 | 1 | 1 | 0.5 | |

| 0.7 | 0.1 | 0.7 | 0 | 0.7 | 0.3 | 0.7 | |

| IBI | 0.9 | 0.3 | 0.9 | 0.1 | 0.9 | 0.5 | 0.9 |

| 1 | 0.5 | 1 | 0.3 | 1 | 0.7 | 1 | |

| 0.5 | 0.7 | 0.7 | 0.7 | 0 | 0.5 | 0.1 | |

| IS | 0.7 | 0.9 | 0.9 | 0.9 | 0.1 | 0.7 | 0.3 |

| 0.9 | 1 | 1 | 1 | 0.3 | 0.9 | 0.5 | |

| 0.5 | 0.7 | 0.7 | 0.5 | 0.5 | 0 | 0.1 | |

| MU | 0.7 | 0.9 | 0.9 | 0.7 | 0.7 | 0.1 | 0.3 |

| 0.9 | 1 | 1 | 0.9 | 0.9 | 0.3 | 0.5 | |

| 0.7 | 0.7 | 0.7 | 0.5 | 0.7 | 0.7 | 0 | |

| 3PLs | 0.9 | 0.9 | 0.9 | 0.7 | 0.9 | 0.9 | 0.1 |

| 1 | 1 | 1 | 0.9 | 1 | 1 | 0.3 |

Table 14.

An initial direct relational matrix by decision maker 3

| TMS | SCR | SCI | IBI | IS | MU | 3PLs | |

|---|---|---|---|---|---|---|---|

| 0 | 0.3 | 0.3 | 0.7 | 0.3 | 0 | 0 | |

| TMS | 0.1 | 0.5 | 0.5 | 0.9 | 0.5 | 0.1 | 0.1 |

| 0.3 | 0.7 | 0.7 | 1 | 0.7 | 0.3 | 0.3 | |

| 0.5 | 0 | 0.7 | 0.7 | 0.3 | 0.7 | 0.1 | |

| SCR | 0.7 | 0.1 | 0.9 | 0.9 | 0.5 | 0.9 | 0.3 |

| 0.9 | 0.3 | 1 | 1 | 0.7 | 1 | 0.5 | |

| 0.5 | 0.7 | 0 | 0.7 | 0.7 | 0.7 | 0.1 | |

| SCI | 0.7 | 0.9 | 0.1 | 0.9 | 0.9 | 0.9 | 0.3 |

| 0.9 | 1 | 0.3 | 1 | 1 | 1 | 0.5 | |

| 0.7 | 0.5 | 0.7 | 0 | 0.7 | 0.3 | 0.5 | |

| IBI | 0.9 | 0.7 | 0.9 | 0.1 | 0.9 | 0.5 | 0.7 |

| 1 | 0.9 | 1 | 0.3 | 1 | 0.7 | 0.9 | |

| 0.5 | 0.7 | 0.7 | 0.3 | 0 | 0.5 | 0.1 | |

| IS | 0.7 | 0.9 | 0.9 | 0.5 | 0.1 | 0.7 | 0.3 |

| 0.9 | 1 | 1 | 0.7 | 0.3 | 0.9 | 0.5 | |

| 0.5 | 0.5 | 0.7 | 0.5 | 0.5 | 0 | 0.1 | |

| MU | 0.7 | 0.7 | 0.9 | 0.7 | 0.7 | 0.1 | 0.3 |

| 0.9 | 0.9 | 1 | 0.9 | 0.9 | 0.3 | 0.5 | |

| 0.7 | 0.7 | 0.5 | 0 | 0 | 0.7 | 0 | |

| 3PLs | 0.9 | 0.9 | 0.7 | 0.1 | 0.1 | 0.9 | 0.1 |

| 1 | 1 | 0.9 | 0.3 | 0.3 | 1 | 0.3 |

Table 15.

An initial direct relational matrix by decision maker 4

| TMS | SCR | SCI | IBI | IS | MU | 3PLs | |

|---|---|---|---|---|---|---|---|

| 0 | 0.3 | 0.7 | 0.1 | 0 | 0.1 | 0.5 | |

| TMS | 0.1 | 0.5 | 0.9 | 0.3 | 0.1 | 0.3 | 0.7 |

| 0.3 | 0.7 | 1 | 0.5 | 0.3 | 0.5 | 0.9 | |

| 0.7 | 0 | 0.7 | 0 | 0.7 | 0.7 | 0.1 | |

| SCR | 0.9 | 0.1 | 0.9 | 0.1 | 0.9 | 0.9 | 0.3 |

| 1 | 0.3 | 1 | 0.3 | 1 | 1 | 0.5 | |

| 0.7 | 0.7 | 0 | 0 | 0.7 | 0.3 | 0.1 | |

| SCI | 0.9 | 0.9 | 0.1 | 0.1 | 0.9 | 0.5 | 0.3 |

| 1 | 1 | 0.3 | 0.3 | 1 | 0.7 | 0.5 | |

| 0.7 | 0.3 | 0.1 | 0 | 0.7 | 0.3 | 0.7 | |

| IBI | 0.9 | 0.5 | 0.3 | 0.1 | 0.9 | 0.5 | 0.9 |

| 1 | 0.7 | 0.5 | 0.3 | 1 | 0.7 | 1 | |

| 0.3 | 0.7 | 0.5 | 0.3 | 0 | 0.5 | 0.3 | |

| IS | 0.5 | 0.9 | 0.7 | 0.5 | 0.1 | 0.7 | 0.5 |

| 0.7 | 1 | 0.9 | 0.7 | 0.3 | 0.9 | 0.7 | |

| 0.3 | 0.3 | 0.1 | 0.5 | 0.7 | 0 | 0.3 | |

| MU | 0.5 | 0.5 | 0.3 | 0.7 | 0.9 | 0.1 | 0.5 |

| 0.7 | 0.7 | 0.5 | 0.9 | 1 | 0.3 | 0.7 | |

| 0.5 | 0.3 | 0.7 | 0 | 0 | 0.3 | 0 | |

| 3PLs | 0.7 | 0.5 | 0.9 | 0.1 | 0.1 | 0.5 | 0.1 |

| 0.9 | 0.7 | 1 | 0.3 | 0.3 | 0.7 | 0.3 |

Table 16.

An initial direct relational matrix by decision maker 5

| TMS | SCR | SCI | IBI | IS | MU | 3PLs | |

|---|---|---|---|---|---|---|---|