Abstract

Background

Occupational accidents occur for a variety of reasons, such as unsafe behaviors of workers and insufficient safety equipment at the workplace, but there are also various economic and social factors that can impact working conditions and working environment. This study analyzed the relationship between changes in economic factors and the occurrence of occupational accidents in Korea.

Methods

Multilinear regression analysis was used as the analysis model. The general to specific method was also used, which consecutively removes statistically insignificant variables from a general model that includes dependent variables and lagged variables of dependent variables.

Results

The frequency of occupational accidents was found to have a statistically significant relationship to economic indicators. The monthly number of cases of occupational injury and disease and fatal occupational injuries were found to be closely related to manufacturing capacity utilization, differences in the production index in the services sector, and commencements of building construction. The increase in equipment investment indicators was found to reduce fatal occupational injuries.

Conclusion

The results of this study may be used to develop occupational accident trends or leading indicators, which in turn can be used by organizations that manage and monitor occupational accidents toward taking administrative action designed to reduce occupational accidents. The results also imply that short-term and mid- to long-term economic and social changes that can impact workers, workplaces and working conditions, and workplace organizations must be taken into account if more effective government policies are to be established and implemented toward further prevention of occupational accidents.

Keywords: Business cycle, Occupational injuries and diseases, Regression analysis

1. Introduction

Occupational accidents result in enormous human and economic damage such as decease or disability of workers, workforce loss, and productivity decline. As part of efforts to reduce occupational accidents, many studies try to identify the causes of occupational accidents. Most studies found causes for occupational accidents in individual unsafe behaviors and insufficient safety equipment in the workplace (Park [1]; Kim et al [2]; Mun [3], and so on) [[1], [2], [3]]. A few studies, however, focus on various economic and social factors that influence the working conditions and working environment. According to the pioneering study, Kossoris [4], economic development inevitably causes an increase in occupational accidents. In other words, growth of the economy, accompanied by a rise in demand for products, requires workers to shoulder greater workloads at faster speeds. This increases the input of unskilled workers, thereby increasing the possibility of occupational accidents. A variety of studies exist to support this. First, Asfaw et al [5] reported that increases in gross domestic product, unemployment rate, and industry production index are accompanied by an increased occupational accident rate. Neumayer [6] also stated the rise of fatal occupational injuries was related to economic expansion. Rhys et al. [7] found changes in employment status, structural conditions of the labor force, and the structure of economic incentives result in cyclical fluctuation of occupational accidents. Chang and Tsai [8] examined the relation between changes in unemployment rate and occupational accidents in Taiwan's manufacturing industry. The study found that the rapid recovery of the economy in 2005, after the recessionary period of 2001 to 2004, led to a dramatic decline in unemployment. This finding signified that a large number of new and unskilled workers entered the labor market, which was why there was a corresponding increase in the number of occupational accidents. The study also concluded that changes in industrial structure were triggering changes in types of occupational accidents. Similarly, Fabiano et al. [9] found a relation between Italy's economic cycles and occupational accident rates. According to the study, the fatal occupational injury rate increased excessively during the postwar period when industries and buildings were being reconstructed. The study also claimed that the occupational accident rate began to fluctuate with the emergence of an industrial production cycle after economic expansion and recession. Based on these findings, the authors stated that considering the long-term trend, economic factors were underlying factors for occupational accidents. Dong et al. [10] also showed that changes in the economy were closely related with falling accidents in their analysis of the mortality rate in occupational accidents in the U.S. construction industry. As such, the relationship between economic factors (such as unemployment rate and economic cycle) and occupational accident rates has been confirmed in numerous studies in other countries. In contrast, however, there have been very few similar studies in Korea.

Choi et al. [11] used major social, economic, and labor indicators in estimating occupational accident rates. The study found that the economic participation rate of workers in the 45–49 age group was a key variable to estimate the rate of occupational accidents for every 10,000 workers. The authors also showed that the funds budgeted for support of small workplaces had to be considered as a priority to estimate the occupational injury rate for every 100,000 workers [11]. Bang et al. [12] asserted that a high daily worker index pushes up the rate of occupational accidents for every 10,000 workers. Shin and Oh [13] analyzed factors that influenced the differences in occupational accident rates between countries. The study used the occupational accident rate between 1990 and 2007 for 30 countries worldwide, as provided by the International Labour Organization and economic indicator data from the Organization for Economic Cooperation and Development and other institutions [13]. The analysis found that a country's occupational accident rate declined as gross national product (GNP) per capita increased, while countries with a larger proportion of their gross domestic product made up by manufacturing and construction had a higher occupational accident rate. In addition, the higher the percentage of male workers, the more increase in nonfatal occupational injuries. The rising employment rate is identified to relate to the increasing number of fatal occupational injuries.

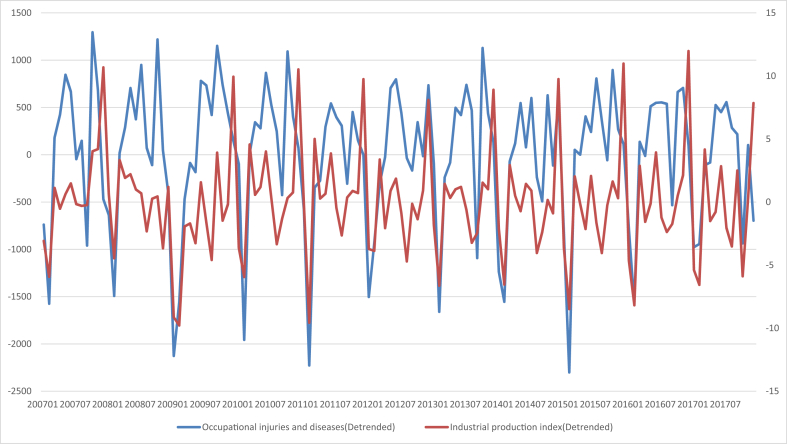

The close relation between economic and social factors and the occurrence of occupational accidents has also been identified in a few studies on South Korean case, but few such studies exist that use econometric analysis techniques. Fig. 1 shows a comovement of cyclical components of the monthly number of occupational injuries and the industrial production index over the past eleven years in South Korea. The original data of the two indicators have apparent long-term trends with moderately declining number of occupational injuries and significantly rising index of industrial production. Therefore, to focus on the cyclical components of the indicators, this study removed their trends using the Hodrick–Prescott filter (Hodrick et al [14]). The correlation coefficient between the two detrended indicators is 0.52, confirming a considerable positive correlation. This study aims to use an econometrical technique to examine objectively and quantitatively how major economic indicators that represent economic fluctuations are connected to occupational accidents. The economic indicators identified to be closely related to the occurrence of industrial accidents will serve as good indicators for effective implementation of occupational accident prevention.

Fig. 1.

Occupational Injuries and Disease and Industrial Production Index (Detrended). Sources: OSHRI internal data (2018a), Statistics Korea (2018). OSHRI, Occupational Safety and Health Research Institute.

2. Data and methods

The goal of this study is to use an econometric technique to carry out time series analysis to identify the impact of economic fluctuation factors, such as capacity utilization rate in the manufacturing sector and commencement of building construction, on occupational accidents, including the number of occupational injuries and number of fatal occupational injuries. The following data and analysis methods were applied for this purpose.

2.1. Data

Monthly occupational accident data and the number of businesses and workers from 2007 to 2017 are based on occupational accident statistics produced by the Occupational Safety and Health Research Institute. In addition, the study used available monthly data on a variety of indicators related to economic fluctuations published by institutions such as Statistics Korea [[15], [16], [17]] (Table 1).

Table 1.

Data and sources

| Data name | Source |

|---|---|

| Number of occupational injuries and diseases, Number of occupational injuries, Number of fatal occupational injuries, Number of workplaces, Number of workers | OSHRI |

| Index of industrial production, Manufacturing average capacity utilization rate, Index of manufacturing production, Index of service industry, Index of equipment investment, Production index of machinery for equipment investment, Value of machine orders received, Value of domestic construction orders received, Value of domestic building orders received, Value of construction completed, Economically active population, Number of unemployed persons, Male ratio of employed persons, Unemployment rate, Employment rate | Statistics Korea |

| Housing construction permits, Commencement of housing construction, Housing completion, Construction permits, Commencement of building construction | Ministry of Land, Infrastructure and Transport |

OSHRI, Occupational Safety and Health Research Institute.

The occupational accident data used in this study is not based on the commonly used occupational accident rate but on the number of occupational injury and disease, occupational injuries, and fatal occupational injuries victims. When the typical occupational accident rates are used, the mere increase of workers can lower the accident rate even if no change in occupational accidents occurs. Similarly, when using occupational accident rate data, the incidence of occupational accidents may be mistakenly seen as having decreased. To avoid such errors, the number of cases of occupational injuries and disease was adopted as a dependent variable and the core subject of analysis. The change in number of workers may also be considered as a major economic factor and was therefore included in the regression analysis model as a control variable. Meanwhile, it should be noted that the typical occupational accident statistics currently published are based on the dates the Korea Workers' Compensation and Welfare Service approved the claim from a work-related accident. The approval procedure is a time-consuming process so that it can make us mistake the exact time when the occupational accident occurred. This implies, for instance, if an occupational accident occurred in January 2018 but the occupational injury claim was approved in April 2018, the relevant occupational injury is included in the occupational accident statistics in April 2018. This study collected the number of cases of occupational injury and disease based on the occurrence date rather than the typical claim approval date. Therefore, this study can more accurately analyze the impact of economic fluctuations than other similar studies. Table 2 shows the descriptive statistics of collected data.

Table 2.

Descriptive statistics of data

| Variable | Mean | Standard deviation | Minimum | Maximum |

|---|---|---|---|---|

| Number of occupational injuries and diseases (case) | 7,656 | 804.5 | 5,148 | 9,196 |

| Number of occupational injuries (case) | 7,008 | 771.5 | 4,631 | 8,528 |

| Number of fatal occupational injuries (case) | 88 | 16.9 | 44 | 134 |

| Number of workplaces | 1,843,571 | 366,002 | 1,293,124 | 2,507,364 |

| Number of workers (person) | 1.53e+07 | 1,911,403 | 1.18e+07 | 1.86e+07 |

| Index of industrial production | 94.18 | 8.63 | 74.4 | 116.4 |

| Manufacturing average capacity utilization rate (%) | 76.72 | 3.78 | 62.5 | 82.7 |

| Index of manufacturing production | 93.80 | 11.18 | 61 | 110.9 |

| Index of service industry | 90.24 | 11.70 | 64.9 | 118 |

| Value of domestic construction orders received (million KRW) | 9,009,485 | 3,596,322 | 3,557,119 | 2.20e+07 |

| Value of domestic building orders received (million KRW) | 6,289,340 | 2,790,790 | 1,832,891 | 1.57e+07 |

| Value of construction completed (million KRW) | 8,258,800 | 1,789,412 | 5,306,577 | 1.46e+07 |

| Commencement of housing construction (apartment building) | 16,382 | 3,415 | 7,225 | 22,840 |

| Housing construction permits (apartment unit) | 239,518 | 180,359 | 9,282 | 765,328 |

| Index of equipment investment | 101.3 | 15.1 | 61.3 | 143.7 |

| Production index of machinery for equipment investment | 99.95 | 11.03 | 72.65 | 122.17 |

| Value of machine orders received (million KRW) | 4,501,450 | 1,028,586 | 2,806,788 | 9,320,662 |

| Economically active population (thousand persons) | 25,897 | 1,248 | 23,660 | 28,081 |

| Male ratio of employed persons (%) | 58.1 | 0.41 | 57.2 | 59.1 |

| Number of unemployed persons (thousand persons) | 893 | 129 | 702 | 1,342 |

| Unemployment rate (%) | 3.45 | 0.46 | 2.6 | 5 |

| Employment rate (%) | 59.8 | 1.18 | 56.7 | 61.6 |

KRW, Korean won.

2.2. Methods

The gathered data were examined to determine the model to be used for analysis. First of all, a close review was conducted on the stationarity of key dependent variables, which are the number of occupational injuries and diseases, occupational injuries, and fatal occupational injuries. If a variable is a stationary time series, it will satisfy the following conditions (Min and Choi [18]).

Condition 1. : The average is not a function of time but a consistent value.

Condition 2. : The variance is also not a function of time but a consistent value.

Condition 3. cov: The covariance of the two points in time does not depend on time but only on the gap(s) between the two points.

If all the three conditions previously mentioned are met, it is called “stationary time series” or “covariance stationary time series”. A linear regression model using time series data that does not satisfy the earlier mentioned conditions can lead to problems of spurious regression, rendering the analysis nonobjective. If a part of the time series is nonstationary, linear regression must be conducted after differencing is used to make it a stationary time series. If all of the time series are nonstationary, a suitable methodology must be sought and applied. First, as shown in Table 3, a unit root test was conducted on all data to be used as dependent variables and were all found to be stationary time series.

Table 3.

Unit root test results of dependent variables (ADF test)

| Variables | Occupational injuries and diseases | Occupational injuries | Fatal occupational injuries |

|---|---|---|---|

| t- value (p-value) | -7.289∗∗∗ (0.0000) | -7.156∗∗∗ (0.0000) | -8.567∗∗∗ (0.0000) |

Statistical significance: ∗∗∗ 1%, ∗∗ 5%, ∗ 10%.

ADF, augmented Dickey-Fuller.

Stationarity of the time series was also tested on independent variables. To acquire enough usable independent variables, the critical value, which determines the existence of unit root, was set at 10%. Variables evaluated as stationary time series were used as is,whereas nonstationary variables were made stationary time series using differencing and a variety of other methods, before the regression analysis. To determine the analysis model, the general to specific method was applied. The method consecutively removes variables that are statistically insignificant from a general model that includes both dependent variables judged to be stationary time series and lagged dependent variables up to a certain number of past months (t-12m etc.). In determining the inclusion of a certain variable in the analysis model, it was first included to see if the adjusted R-squared increased in the regression analysis result. If the adjusted R-squared increased, the variable was included. In trying to explain the amount of change caused in dependent variables by selecting p of a total k number of independent variables, variables that increase the determination coefficient were generally selected and analyzed. Multilinear regression analysis is an increasing function, meaning that if p increases – in other words, if the number of independent variables used in an analysis increases – the coefficient of determination (R-squared) also increases. Therefore, a disadvantage exists in that if the number of independent variables increases, the R-squared also increases, regardless of whether there is a meaningful relationship with independent variables. To complement this weakness, this study used the adjusted R-squared, which can identify the number of independent variables that are able to minimize the residual sum of squares by minimizing changes not explained by the regression analysis. This makes it more suitable when changing from a general to a specific model analysis.

This study used dummy variables to analyze the impact of the period of great change in Korea's government policies to prevent occupational accidents during the period of analysis. Notable changes in these accident prevention policies within the analysis period (after 2007) were the policy to prevent occupational injuries and diseases in the services industry, which became full fledged in January 2010 and the risk assessment system implemented in March 2014. The periods before and after implementation of the two policies were handled and analyzed as dummy variables.

3. Result

The following model analyzes the relationship between the monthly number of cases of occupational injury and disease, occupational injuries, and fatal occupational injuries and the factors of economic fluctuation.

In the aforementioned formula, t refers to time, Y to occupational accidents, X to economic factors, D to dummy variables of the period in which there were changes in policy to prevent occupational injuries, and to error terms. The X variable refers to economic factor variables selected according to the method of selection as explained earlier. D was included in the analysis as Dummy Variable 1 and Dummy Variable 2 for January 2010 and March 2014, respectively.

3.1. Occupational injuries and disease [Model 1]

The Table 4 shows the results of regression analysis of the overall number of occupational injury and disease victims and economic fluctuation factors. First, the number of occupational injury and disease victims was found to have a positive regression coefficient with capacity utilization rate in manufacturing, commencement of building construction, employment rate, and the male ratio of employed persons. More specifically, an increase of 1% in capacity utilization in a manufacturing workplace resulted in an increase of around 45 occupational injury or disease victims, while for every additional 100 buildings for which construction commenced, there was an increase of around 11 occupational injury or disease victims. In addition, an increase of 1% in employment rates leads to a rise of around 284 occupational injury or disease victims, while a 1% increase in the male ratio of employed persons leads to an additional 488 occupational injury or disease victims. Monthly economic fluctuation indicators were found to be linked with the relevant number of occupational injuries and diseases for that month, meaning that such economic fluctuations are a type of occupational accident trend indicator.

Table 4.

Economic indicators and occupational injuries and diseases [Model 1]

| Variable | Description | Regression Coefficient |

p-value |

|---|---|---|---|

| m_or | Manufacturing average capacity utilization rate (%) | 45.39 | 0.005 |

| L12.ln_csm | Logarithm of domestic construction orders received (12 months ago, million KRW) | 365.82 | 0.009 |

| cod_n | Commencement of building construction (100 buildings) | 11.11 | 0.000 |

| L.d_sid | Difference of index of services (1 month ago) | 18.30 | 0.088 |

| em_rate | Employment rate (%) | 283.77 | 0.005 |

| L2.d_wmn | Difference of number of workers (2 months ago, hundred thousand persons) | 44.35 | 0.009 |

| m_r | Male ratio of employed persons (%) | 487.74 | 0.106 |

| dum1 | Value = 1 since January 2010, value = 0 otherwise | -417.32 | 0.002 |

| dum2 | Value = 1 since March 2014, value = 0 otherwise | -665.65 | 0.000 |

| constant | Constant term | -48243 | 0.037 |

| Adjusted R-squared | 0.62 | ||

KRW, Korean won.

In contrast, domestic construction orders received were found to have an impact on occupational injuries and diseases, with a time lag of 12 months. A domestic construction order is a contract between a construction company and an orderer to build a structure within a country in a certain given term. The domestic construction orders received can be interpreted as a 12-month leading indicator on occupational injuries and diseases due to its broad use as a general leading indicator of investment in construction. Monthly difference (not level value) in the production index in services shows a positive regression coefficient with the number of cases of occupational injury and disease, with a lag of one month. This implies that an increase of monthly production (that is, value added) in the services industry can cause the increase in cases of occupational injuries and diseases. Meanwhile, analysis using dummy variables for the period after January 2010, when the policy to prevent occupational accidents began in the services industry, and March 2014, when the risk assessment system was adopted (two major changes in policy on preventing occupational accidents), found that these policies have meaningful statistical influence on reducing the number of occupational injury and disease victims.

3.2. Occupational injuries [Model 2]

This section presents the results of analysis related solely to occupational injuries, excluding occupational diseases. The reason for the separate analysis of occupational injuries is that occupational diseases occur not only while working but often much later after having engaged in work that caused the disease in the first place, such as in the case for people suffering from pneumoconiosis. When applying for compensation for an occupational accident, the applicant is required to enter the date on which the accident occurred. As explained earlier, this study constructed data based on the date of occurrence, but a large number of cases of occupational disease are recorded as occupational after a significant amount of time has passed, and therefore, the recorded date of occurrence is often inaccurate. Furthermore, the rate of recognition of disease as occupational changes with time for a variety of reasons, including an expansion of coverage with compensation policy changes. This differs somewhat from the purpose of this study's analysis, which is why this section conducts analysis on the occurrence of occupational injuries separate from its analysis of both occupational injuries and diseases. This is related to the current Korean administration's policy direction. In January 2018, the Ministry of Employment and Labor announced a plan to reduce occupational accidents (Ministry of Employment and Labor, 2018) and halve the number of fatal occupational injuries. The plan is focusing its efforts overall to use policy to prevent occupational accidents [19]. This analysis was conducted to identify implications from occupational injuries and fatalities in accordance with this policy direction.

Indicators related to economic fluctuations explaining the occurrence of occupational injuries show that an increase in manufacturing capacity utilization rate, buildings construction commencement, and the male ratio of employed persons are factors that increase the number of occupational injuries. Analysis showed that an increase of 1% in manufacturing capacity utilization rate leads to an occurrence of around 29 additional occupational injuries, whereas an increase of 100 buildings for which construction commenced leads to a rise of around 14 occupational injuries. In Model 1, where both occupational injuries and diseases were analyzed, these independent variables were found to influence dependent variables, albeit with a time lag. However, in this analysis model for occupational injuries, it was found that an increase of 1% in employment rate and male ratio of employed persons resulted in an increase of 123 occupational injuries with a two-month lag and 577 occupational injuries with a six-month time lag, respectively. The reason why there is a time lag between changes in these two factors and their influence on the number of occupational injuries is probably because after a worker is employed, he or she is generally assigned to the field after a few months of training, which is when accidents usually occur. In the analysis of Model 1, the data for the occurrence of occupational diseases may possibly have offset this impact. Therefore, in the analysis of occupational injuries alone, employment rate and male ratio of employed persons are of greater statistical significance than in analysis of both occupational injuries and diseases. It was found that domestic construction orders received impacted occupational injuries with a 12-month time lag – similar to our analysis of both occupational injuries and diseases. The production index in services also showed an increase of occupational injuries with a one-month time lag when the difference in the production index increases, similar to that in the analysis of both occupational injuries and diseases. The regression coefficient of dummy variables that represent the period of time after implementation of the occupational accident prevention policy in services and the risk assessment system shows that the decrease in the number of occupational injuries was statistically significant after these projects began, similar to Model 1 (Table 5).

Table 5.

Economic indicators and occupational injuries [Model 2]

| Variable | Description | Regression Coefficient |

p-value |

|---|---|---|---|

| m_or | Manufacturing average capacity utilization rate (%) | 28.99 | 0.037 |

| L12.ln_csm | Logarithm of domestic construction orders received (12 months ago, million KRW) | 487.14 | 0.000 |

| cod_n | Commencement of building construction (100 buildings) | 14.44 | 0.000 |

| L.d_sid | Difference of index of services (1 month ago) | 17.71 | 0.063 |

| L2.em_rate | Employment rate (2 months ago, %) | 123.00 | 0.012 |

| L2.d_wmn | Difference of number of workers (2 months ago, hundred thousand persons) | 40.10 | 0.007 |

| L6.m_r | Male ratio of employed persons (6 months ago, %) | 577.21 | 0.000 |

| dum1 | Value = 1 since January 2010, value = 0 otherwise | -258.32 | 0.027 |

| dum2 | Value = 1 since March 2014, value = 0 otherwise | -650.70 | 0.000 |

| constant | Constant term | -45826 | 0.000 |

| Adjusted R-squared | 0.68 | ||

KRW, Korean won.

3.3. Fatal occupational injuries [Model 3]

Lastly, this section presents the results of analysis on the impact of economic fluctuation indicators on fatal occupational injuries which are most closely related to the current Korean government's policy goals designed to prevent occupational accidents. According to the results, indicators with a statistically significant impact (10% significance level) are commencements of building construction, equipment investment index, difference in the number of workers, and employment rate. In addition, the rate of manufacturing capacity utilization and differences in the services production index were also included in our analysis but were found to have weaker statistical significance (Table 6).

Table 6.

Economic indicators and fatal occupational injuries [Model 3]

| Variable | Description | Regression Coefficient |

p-value |

|---|---|---|---|

| L3.m_or | Manufacturing average capacity utilization rate (3 months ago, %) | 0.45 | 0.214 |

| L5.d_sid | Difference of index of services (5 months ago) | 0.33 | 0.255 |

| cod_n | Commencement of building construction (100 buildings) | 0.24 | 0.000 |

| L6.inv_id | Index of equipment investment (6 months ago) | -0.33 | 0.003 |

| L3.d_wn | Difference of number of workplaces (3 months ago, ten thousand) | 0.57 | 0.082 |

| L2.em_rate | Employment rate (2 months ago, %) | 5.69 | 0.000 |

| dum2 | Value = 1 since March 2014, value = 0 otherwise | -23.69 | 0.000 |

| constant | Constant term | -286.57 | 0.000 |

| Adjusted R-squared | 0.46 | ||

According to our analysis of fatal occupational injuries, although the statistical significance was somewhat weak, as the manufacturing capacity utilization rate and differences in the services production index increase, this resulted in an increase in fatal occupational injuries, with a time lag of three months and five months, respectively. Commencement of building construction was statistically significant similar to the analyses in Model 1 and 2. An increase of 100 building construction commencements was found to result in around 0.24 fatal occupational injuries. It is worth noting that the equipment investment index was found to have a negative (-) relation to the number of fatal occupational injuries, with a time lag of around six months. Given that equipment investment is widely accepted as a leading economic indicator, this negative relation suggests that, in contrast to other economic indicators, an increase in equipment investment leads to the provision of new equipment in the workplace, for production and safety equipment and vehicles, which presumably leads to a reduction of fatal occupational injuries. More detailed data are needed to thoroughly analyze whether safety equipment is a deciding factor in this relationship, as the Korean equipment investment index does not record such details. Meanwhile, contrary to the analysis of occupational injuries and diseases and of occupational injuries alone, it was found that changes in the number of workplaces and increases in the employment rate increased the number of fatal occupational injuries, with a time lag of around two or three months. This result may imply that a rapid increase in workplaces increases the input of unskilled workers, which in turn increases the risk of fatal occupational injuries.

In our analysis of the relationship between fatal occupational injuries and economic fluctuations, only the dummy variable representing the risk assessment system of March 2014 was found to have statistical significance. In contrast to the Model 1 and 2, dummy variables related to projects to prevent occupational accidents in services were found to have somewhat weak statistical significance in the analysis of fatal occupational injuries. This result may be assumed to be due to the transition of the central structure of industry and employment toward services, as the major goal of accident prevention policies in services is to prevent new cases of occupational disease and occupational stress, among others, and protect mental health. These policies were implemented to reduce occupational injuries and disease rather than to prevent fatal occupational injuries.

4. Discussion

This study is the first attempt to analyze the relationship between monthly indicators on economic fluctuations and occupational accidents using Korean data in an econometric model. It confirms that economic fluctuations, such as changes in manufacturing capacity utilization and demand for services, are factors that can increase or decrease the incidence of occupational accidents by affecting working pace, number of workers and size of workplace, and the level of skills in the workforce, among others.

The Table 7 summarizes the results of our analyses, including indicators and statistically significant levels in the analysis models on the relation between economic fluctuation indicators and occupational injuries and diseases, occupational injuries alone, and fatal occupational injuries.

Table 7.

Comparison of key variables by occupational injuries analysis models

| Models | Model 1 | Model 2 | Model 3 |

|---|---|---|---|

| Dependent variable | Occupational injuries and diseases | Occupational injuries | Fatal occupational injuries |

| Independent variables | Manufacturing average capacity utilization rate∗∗∗ | Manufacturing average capacity utilization rate∗∗∗ | Manufacturing average capacity utilization rate (3 months ago) |

| Logarithm of domestic construction orders received (12 months ago)∗∗∗ | Logarithm of domestic construction orders received (12 months ago)∗∗∗ | ||

| Commencement of building construction∗∗∗ | Commencement of building construction∗∗∗ | Commencement of building construction∗∗∗ | |

| Difference of index of services (1 month ago)∗ | Difference of index of services (1 month ago)∗ | Difference of index of services (5 months ago) | |

| (-) Index of equipment investment (6 months ago) ∗∗∗ | |||

| Employment rate∗∗∗ | Employment rate (2 months ago)∗∗∗ | Employment rate (2 months ago)∗∗∗ | |

| Difference of number of workers (2 months ago)∗∗∗ | Difference of number of workers (2 months ago)∗∗∗ | Difference of number of workers (3 months ago)∗∗∗ | |

| Male ratio of employed persons | Male ratio of employed persons (6 months ago)∗∗∗ |

Statistical significance: ∗∗∗ 1%, ∗∗ 5%, ∗ 10%.

The analysis shows that the rate of manufacturing capacity utilization, differences in production index in services, and building construction commencements, among other economic fluctuation indicators, were statistically significant in terms of their relation to monthly occupational accidents.

Economic fluctuation indicators were found to be statistically meaningful in their relationship to occupational accidents in terms of both overall changes in trend and the increase or decrease in differences. As was pointed out in previous studies, rapid increases in demand lead to a rapid increase in the number of workers in related labor markets. This increases the number of unskilled workers entering the market, which in turn heightens the probability of occupational accidents.

An examination of the number and proportion of fatal occupational injuries by length of service shows that those involving workers with a service length of less than a month account for 42.4% of all fatal occupational injuries (Occupational Safety and Health Research Institute, 2018b), which reconfirms the significance of this study's findings [20,21]. Meanwhile, analysis also showed that increases in the equipment investment index were accompanied by a reduction in the number of fatal occupational injuries, with a lag of several months. However, identifying the kind of equipment investment that contributed to this reduction requires more detailed investment data, such as the amount invested in safety and health-related equipment. Such specific safety-related data are essential if more sophisticated policies to prevent occupational accidents in the future are to be designed.

There is a need for further research because the analysis period is a little limited, and the analysis of the mechanism of association between the indices analyzed to be relevant and occupational accidents is somewhat insufficient. In addition, there are few existing studies that analyze the relationship between these short-term economic fluctuations and occupational accidents and thus have limitations in comparative analysis, but it also implies that this research is quite pathbreaking.

This study is significant in that it is the first of its kind to identify the statistical significance between occupational accidents and economic fluctuations in Korea. The results of this study may be used to develop occupational accident trends or leading indicators, which in turn can be used by organizations that manage and monitor occupational accidents toward taking administrative action designed to reduce occupational accidents. The results also imply that short-term and mid- to long-term economic and social changes that can impact workers, workplaces and working conditions, and workplace organizations must be taken into account if more effective government policies are to be established and implemented toward further prevention of occupational accidents.

Conflicts of interest

Dong Koo Kim is employed at the Korea Energy Economics Institute and Sunyoung Park is employed at the Occupational Safety and Health Research Institute.

Footnotes

Supplementary data to this article can be found online at https://doi.org/10.1016/j.shaw.2020.05.002.

Appendix A. Supplementary data

The following is/are the Supplementary data to this article:

References

- 1.Park S. The effects of organizational psychosocial factors on occupational accidents. Soc Welf Pol. 2003;16:61–78. [Google Scholar]

- 2.Kim C.Y., Jeon M.J., Byun D.H. Five-year industrial accidents of ship-building workers at a ship- yard. Korean. J Occup Environ Med. 2003;15(4):436–445. [in Korean] [Google Scholar]

- 3.Mun S.H. An analysis on factors affecting industrial accidents. Soc Welf Pol. 2004;20:155–169. [Google Scholar]

- 4.Kossoris M.D. Industrial injuries and the business cycle. Month Labor Rev. 1938;46:579. [Google Scholar]

- 5.Asfaw A., Pana-Cryan R., Rosa R. The business cycle and the incidence of workplace injuries: Evidence from the U.S.A. J Saf Res. 2011;42(1):1–8. doi: 10.1016/j.jsr.2010.10.008. [DOI] [PubMed] [Google Scholar]

- 6.Neumayer E. Recessions lower (some) mortality rates: Evidence from Germany. Soc Sci Med. 2003;58(6):1037–1047. doi: 10.1016/s0277-9536(03)00276-4. [DOI] [PubMed] [Google Scholar]

- 7.Rhys D., Paul J., Imanol N. The impact of the business cycle on occupational injuries in the UK. Soc Sci Med. 2009;69(2):178–182. doi: 10.1016/j.socscimed.2009.04.033. [DOI] [PubMed] [Google Scholar]

- 8.Chang D.S., Tsai Y.C. Investigating the long-term change of injury pattern on severity, accident types and sources of injury in Taiwan’s manufacturing sector between 1996 and 2012. Saf Sci. 2014;68:231–242. [Google Scholar]

- 9.Fabiano B., Parentini I., Ferraiolo A., Pastorino R. A century of accidents in the Italian industry: Relationship with the production cycle. Saf Sci. 1995;21:65–74. [Google Scholar]

- 10.Dong X.S., Choi S.D., Borchardt J.G., Wang X., Largay J.A. Fatal falls from roofs among US construction workers. J Saf Res. 2013;44:17–24. doi: 10.1016/j.jsr.2012.08.024. [DOI] [PubMed] [Google Scholar]

- 11.Choi E.S., Jeon G.S., Lee W.K., Kim Y.S. The Prediction of Industrial Accident Rate in Korea: A Time Series Analysis. Kor J Occup Health Nurs. 2016;25(1):65–74. [in Korean] [Google Scholar]

- 12.Bang Y.W., Im H.J., Kwon Y.J., Cho S.S., Lee T.K., Yoon I.K. The effect of socio-economic factors on occupational injuries in Korea: A time series analysis. Kor J Occup Environ Med. 2011;23(4):397–406. [in Korean] [Google Scholar]

- 13.Shin I.S., Oh J.B. 2009. Empirical analysis on the factors of international differences in occupational injuries. OSHRI research paper. [in Korean] [Google Scholar]

- 14.Hodrick R., Prescott E., Postwar U.S. Business Cycles: An Empirical Investigation. J Money Credit Bank. 1997;29(1):1–16. [Google Scholar]

- 15.Occupational Safety and Health Research Institute . 2018. Internal data. [Google Scholar]

- 16.Bank of Korea . 2020. Economic statistics system.http://ecos.bok.or.kr/ [Google Scholar]

- 17.Ministry of Land . 2020. Infrastructure and transport statistics system.https://stat.molit.go.kr/portal/main/portalMain.do [Google Scholar]

- 18.Min I.S., Choi B.H. Korea STATA institute; 2014. Time series analysis. [KR] [Google Scholar]

- 19.Ministry of Employment and Labor press release . 2018. “Plan to reduce fatal occupational accidents to halve the number of fatal occupational injuries by 2022”. 1.23. [Google Scholar]

- 20.Occupational Safety and Health Research Institute . 2018. Industrial accidents statistics news release. [Google Scholar]

- 21.Ministry of Employment and Labor . 2018. Industrial accidents occurrence status in 2017. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.