Abstract

Background

From only frequency rate of industrial accidents, it is difficult to define the industry composition of accident statistics in a nation. This study aims to propose and develop a new index for measuring the degree of concentration of industrial accidents using the concept of the Herfindahl-Hirschman Index in the case of European countries.

Methods

Using the concept of the Herfindahl-Hirschman Index, the concentration index of accidents in the country is developed, and the conditions of European countries are compared using indexes of frequency rate and concentration ratio.

Results

The frequency rate and concentration ratio of fatal and nonfatal accidents in European countries are compared. According to the economic condition and geographical position, different patterns of accidents concentration are presented in terms of frequency rate and concentration ratio.

Conclusion

We develop the concentration index of industrial and occupational accidents that identifies the industrial ratio of accident occurrence, and the differentiated strategy can be formulated such as approaches to reducing frequency and prioritizing target industries.

Keywords: Accident concentration, Accident statistics, Concentration Index, European countries, Herfindahl-Hirschman index

1. Introduction

Measuring the occupational injuries for analyzing safety and health at work has been recognized as a precondition for managing occupational accidents [1]. The World Health Organization has focused on increasing the importance of occupational health and safety to ensure that workers can safely adapt to their work [2]. Above all, countries should annually survey the descriptive statistics of accidents for monitoring the health and safety level at work in the industry [3]. The descriptive statistics include time lost, frequency of injury, and the number of deaths caused by accidents and disasters [4]. The International Labour Organization (ILO) provides the key indicators of safety and health at work through statistics such as time lost, fatal and nonfatal injuries, and labor inspection through a web site, collected from major countries [5]. Most countries also individually survey the statistics for occupational safety and health management.

These data have usually been used to measure the degree of seriousness of industrial accidents by measuring the frequency of occupational injuries and their severity, which is measured using time lost due to the accidents [3,6]. Because construction sites, chemical plants, and service areas are prone to accidents, there is an increasing concern for occupational safety and health management in the construction, chemical, and service industries [7]. Many global and national institutes publish disaster statistics for frequency of accidents and time lost as a measure for mitigating and preventing occupational accidents and disasters [8,9]. After monitoring the patterns and trends of health and safety statistics in industries, responsible agencies and institutes such as ILO, Occupational Safety and Health Administration (OSHA), and Health and Safety Executive have taken the decision to manage industrial conditions to reduce hazards and accidents.

However, almost all countries have focused only on the number of accidents in industry. Although frequencies of occupational injuries are similar with the countries, the component ratio of the occupational injuries of countries at the individual industry level can be different. For example, assume that each of the three industries in Country A has 20 accidents while the three industries in Country B have 5, 5, and 50 accidents, respectively. In this case, the total frequency for Country A and B is 60 accidents, but Country B has an industry that is more dangerous compared to Country A. The overall index indicates that the nations are managing the safety issues well, but the risk of specific industries, which exhibit chronically unsafe behavior and conditions, has deteriorated. According to similar concept of Pareto and root-cause analysis for safety management, it is more important to identify and prioritize the hazardous industries or firms to be controlled [[10], [11], [12]]. Thus, examining the concentration of accidents with respect to a specific industry could have a more significant meaning for accident management, rather than doing the overall frequency and severity of accidents of industries. When accidents are concentrated in a particular industry, that industry should be managed with increased focus.

Thus, this study aims to propose and develop a new index for measuring the degree of concentration of industrial accidents. For this, we apply the Herfindahl-Hirschman Index (HHI), one of the indexes for measuring concentration and industrial share in the market, industry, or national level [13]. The HHI is defined as the sum of squares of the component ratio according to the level of a target [13]. Among the concentration index such as Gini index and Entropy index, the HHI is useful in that it is easy to calculate the index and understand the result [14]. In the European and other developed countries, HHI is considered an economic measure and an indicator for monitoring competition and concentration [15]. Owing to this concept, this index has been usually applied to measure the degree of concentration into other fields such as transportation, computer algorithm, and telecommunications [16,17].

In this study, the concentration index for industrial accidents at the national level is defined as HHI of accidents (called as the HHIA) which presents the two concentration ratios of fatal accidents (deaths or mortalities) and nonfatal accidents (injuries) for the countries with respect to each industry. It is calculated as the sum of squares of occupational injuries in each industry within a country. The HHIA notes how many fatal or nonfatal accidents are concentrated in specific industries within a country. From HHIA, we find the country that includes specific industries with a large share of fatal or nonfatal accidents. Furthermore, based on HHIA for fatal and nonfatal accidents, a case study on several European countries has been presented. Because the industrial characteristics of European countries differ in terms of region, economy, and culture, the concentration of industrial accidents can be different. The results of HHIA among countries are compared using the positioning map in terms of frequency rate and concentration ratio. The differences among the indexes developed in this study provide policy makers and industrial managers with the outlook to focus considerably on risky industries that have a higher concentration ratio of industrial accidents.

2. Materials and methods

2.1. Conventional statistics for occupational accidents

Several statistical measures have been developed for measuring the degree of severity of accidents and disasters. Among them, three indexes have usually been used for the above purposes. First, “injury rate” is defined as the number of workers injured in an accident per workers as a fraction of 100 or 1000. Also, “fatal injury rate” represents the number of workers died in an accident per workers. Second is the “frequency of rate of injury,” defined as the rate of the number of injuries in 200,000 work hours by OSHA 1996 standard, which has also been adopted by ILO [3]. Third is the “severity of the rate of injury,” defined by the OSHA 1996 standard as the rate of the number of losses a day caused by accident in 200,000 work hours. However, in addition to these standards, some countries have modified these indexes to adapt to their own national conditions. For example, frequency rate of injury is calculated as the rate of number of accidents in 1,000,000 work hours in a method for injury frequency rate of Health and Safety Executive of United Kingdom and Korea Occupational Safety and Health Agency of South Korea.

In this study, we simply define frequency rate (FR) of accidents in a nation as the number of accidents divided by total number of employees in a nation. Because the frequency rate of accidents is dependent on the size of the economy or the number of employees, FR can be used as the representative index for measuring the absolute number of industrial accidents per employee. Based on FR, this study proposes two indexes in the form of the equations (1), (2): frequency ratio of fatal accidents (FR-F) and frequency ratio of nonfatal accidents (FR-NF). Fatal accidents mean accidents that cause the death (or mortality), while nonfatal accidents mean accidents that lead to the injury, not the death.

| (1) |

| (2) |

2.2. Development of concentration index of injuries

2.2.1. Index for concentration ratio in economics

Conventionally, two indexes are deemed to be of importance in measuring the economic concentration ratio: the concentration ratio of N-Firm (CR#N) and HHI. These two indexes are published in some countries and international economic institutes for monitoring market conditions [14,18].

First, CR#N is defined as the sum of the market shares of top N firms with the highest market shares. For example, assume that the automobile market consists of 10 firms. Of the 10 firms, if the top three firms enjoy market shares of 18%, 12%, and 10%, respectively, then, the CR#3 (or presented as CR3) of the automobile market is measured as 40%. It is a very simple index for diagnosing competition conditions of current market.

However, CR#N has a limitation in measuring all of the components in the system. Thus, a different index was developed for calculating the concentration ratio using the ratios of all the components. In economics, the HHI is widely used for economic concentration of a specific industry. The HHI is defined as the sum of squares of the economic size of an individual market divided by total economic size of all markets, as shown in Equation (3). If the market shares are even, i.e., 1/N, the HHI is found to be the same as the market shares of 1/N. The range of HHI can indicate the market conditions in different situations as shown in Table 1. Thus, HHI can be used as a measure of the degree of economic concentration of industries or markets.

| (3) |

Table 1.

Degree of accident concentration with respect to HHI

| Previous approach for market [18] |

Current approach for accident |

||

|---|---|---|---|

| Range | Market concentration | Range | Accident concentration |

| 0.00 < HHI < 0.10 | Perfect competition | Below the average value of HHIA | Low concentration |

| 0.10 < HHI < 0.18 | Monopolistic competition | ||

| 0.18 < HHI < 0.40 | Oligopoly | Above the average value of HHIA | High concentration |

| 0.40 < HHI | Monopoly | ||

HHIA, HHI of accidents; HHI, Herfindahl-Hirschman Index.

2.2.2. Development of concentration index

The concentration ratio of industry accidents is developed in this study by borrowing this concept of HHI. With respect to fatal and nonfatal accidents, two indexes for HHIA have been developed in the forms of Eqs. (4), (5). According to the original equation of HHI, the concentration of industrial accident can be measured as the sum of the squared ratios of the number of accidents (death or injury) in an industry to the total number of accidents in all industries. In the equation, the n denotes the number of industries included in a nation. Here, unlike the measure where frequency is considered because this index is obtained by measuring the proportion of accidents in individual industries to total industrial accidents in the country, the number of employees in each country is not considered for this index. The HHIA-F and the HHIA-NF are defined as the HHI of fatal accidents and the HHI of nonfatal accidents, respectively.

| (4) |

| (5) |

2.2.3. Evaluation of concentration condition

The HHI provides a numerical base for categorizing the economic conditions of markets into four types: perfect competition, monopolistic competition, oligopoly, and monopoly. Although several criteria have been suggested to classify markets according to their conditions, these four categories are widely used for identifying market competition [18]. Accordingly, HHIA–F and HHIA–NF can be used for diagnosing industrial concentration of accidents like original HHI in economy. However, in both theory and practice, our study is limited in deciding the range of decoupling because this study is the first empirical study on suggesting a new measure of identifying the concentration ratio of accidents in industry or country. Thus, the criteria of dividing the level of concentration are simply proposed with the average value as shown in Table 1.

3. Results

3.1. Data collection

The data for the illustration were collected from the ILO website, which provides the key indicators of the labor market. The ILOs web page (www.ilo.org/ilostat/) provides data for various parameters such as population, employment, working time, earnings, and labor cost, labor productivity, and safety and health at work. We gathered the statistics for accident data of fatal and nonfatal injuries and the number employees for 6 years from 2010 to 2015 (downloaded from the menu of safety and health at work through the ILOs web page) as shown in Table 2. The 21 target European countries with the standard industry composition of International Standard Industrial Classification (ISIC) were selected based on data availability. Statistics for some years were missing for some countries. Accident statistics are available for only 21 countries for all 27 industries as per ISIC-rev.4 from 2010 to 2015. Also, for reflecting the different industry composition among countries, the number of employees is also collected. However, it should be noted that among the 21 countries, only Finland has no data for fatal and nonfatal accidents in ILO table of 2015, and thus, the results for Finland show the average value from 2010 to 2014.

Table 2.

Data collection

| Data | Contents | Year | Accident index used |

|---|---|---|---|

| Fatal injury | The number of accidents generating the deaths of employees | 2010–2015 | FR-F, HHIA-F |

| Nonfatal injury | The number of accidents generating the injuries of employees | 2010–2015 | FR-NF, HHIA-NF |

| Employee | The number of employees in the industries of country | 2010–2015 | FR-F, FR-NF |

HHIA, HHI of accidents; HHI, Herfindahl-Hirschman Index; FR-F, frequency ratio of fatal accidents; FR-NF, frequency ratio of nonfatal accidents.

3.2. Concentration of industrial and occupational accidents

3.2.1. Overall statistics

Based on the proposed accident indexes, the FR and the concentration of fatal and nonfatal accidents are calculated as shown in Table 3. Each value indicates the average FR and HHIA from 2010 to 2015. The European nations rank differently according to the different indexes. First, for fatal accidents, Portugal has the highest FR-F (0.0000375, i.e., 3.75 per 100,000), followed by Romania and Austria, but the HHIA-F indicates that the accidents of Austria are mostly dependent on a few dangerous industries (25.4%), followed by Cyprus and Greece. A gap between the two indexes represents the different implications by each of indexes. It is revealed that the nation which has the largest gap in the ranks according to FR-F and HHIA-F is Greece (a difference of 16 ranks) followed by Italy and France. To be specific, Greece shows a higher ranking for HHIA than FR-F, but Italy and France represent a lower rank for HHIA than for FR-F. This indicates that Greece has managed the total number of fatal accidents, but some dangerous industries are more dangerous than the others are and lead to a greater number of fatal accidents. However, Italy and France have a higher FR-F with a low HHIA-F. Thus, in these countries, occurrences of fatal accidents are distributed more or less evenly among most of the industries.

Table 3.

Frequency rate and concentration ratio (average value from 2010 to 2015)

| Nation | Fatal accident |

Nonfatal accident |

||||||

|---|---|---|---|---|---|---|---|---|

| FR-F∗1000 | Rank | HHIA-F | Rank | FR-NF∗1000 | Rank | HHIA-NF | Rank | |

| Austria | 0.0338 | 3 | 25.4% | 1 | 0.0160 | 9 | 12.7% | 12 |

| Belgium | 0.0140 | 15 | 17.4% | 5 | 0.0137 | 11 | 13.5% | 8 |

| Croatia | 0.0221 | 6 | 18.9% | 4 | 0.0076 | 15 | 13.5% | 9 |

| Cyprus | 0.0163 | 12 | 25.0% | 2 | 0.0034 | 19 | 14.6% | 7 |

| Czech Republic | 0.0256 | 5 | 13.9% | 17 | 0.0093 | 13 | 23.7% | 1 |

| Denmark | 0.0145 | 14 | 12.6% | 21 | 0.0200 | 5 | 11.2% | 17 |

| Finland | 0.0132 | 16 | 16.1% | 8 | 0.0194 | 6 | 10.0% | 21 |

| France | 0.0210 | 7 | 12.7% | 20 | 0.0229 | 2 | 11.8% | 16 |

| Germany | 0.0124 | 17 | 14.5% | 13 | 0.0213 | 4 | 13.2% | 10 |

| Greece | 0.0072 | 19 | 22.7% | 3 | 0.0024 | 20 | 15.7% | 6 |

| Hungary | 0.0095 | 9 | 16.1% | 9 | 0.0049 | 17 | 17.6% | 4 |

| Italy | 0.0265 | 4 | 12.8% | 19 | 0.0152 | 10 | 12.0% | 14 |

| The Netherlands | 0.0056 | 21 | 14.1% | 16 | 0.0165 | 8 | 10.9% | 18 |

| Norway | 0.0184 | 10 | 16.1% | 7 | 0.0097 | 12 | 12.7% | 13 |

| Portugal | 0.0375 | 1 | 17.0% | 6 | 0.0271 | 1 | 15.8% | 5 |

| Romania | 0.0343 | 2 | 14.1% | 15 | 0.0004 | 21 | 18.4% | 3 |

| Slovakia | 0.0205 | 8 | 15.9% | 10 | 0.0038 | 18 | 20.6% | 2 |

| Spain | 0.0175 | 11 | 15.7% | 11 | 0.0228 | 3 | 10.5% | 20 |

| Sweden | 0.0095 | 18 | 14.4% | 14 | 0.0075 | 16 | 12.0% | 15 |

| Switzerland | 0.0156 | 13 | 13.7% | 18 | 0.0190 | 7 | 12.8% | 11 |

| United Kingdom | 0.0071 | 20 | 15.7% | 12 | 0.0079 | 14 | 10.6% | 19 |

HHIA, HHI of accidents; HHI, Herfindahl-Hirschman Index; FR-F, frequency ratio of fatal accidents; FR-NF, frequency ratio of nonfatal accidents.

∗Bold letters mean top five European countries.

On the other hand, for nonfatal accidents, there are distinct differences among several countries. Compared with the rankings for fatal accidents, some developed countries such as France, Spain, Germany, and Denmark are positioned higher in terms of FR-NF. However, HHIA-NF shows that the Eastern European countries, namely Czech, Slovakia, and Romania rank among the first three countries. The nations that have a higher FR-NF show a comparatively low value for HHIA-NF such as France (rank of 16), Spain (rank of 20), Germany (rank of 10), and Denmark (rank of 17). Thus, some developed countries have managed that the accidents of industries are not driven into the serious accidents.

Numeric statistics are only not sufficient to explain the significant differences between fatal and nonfatal accidents. Thus, in the next section, we use the positioning map, that is, we position the countries in terms of FR and HHIA indexes to monitor the distribution of European countries.

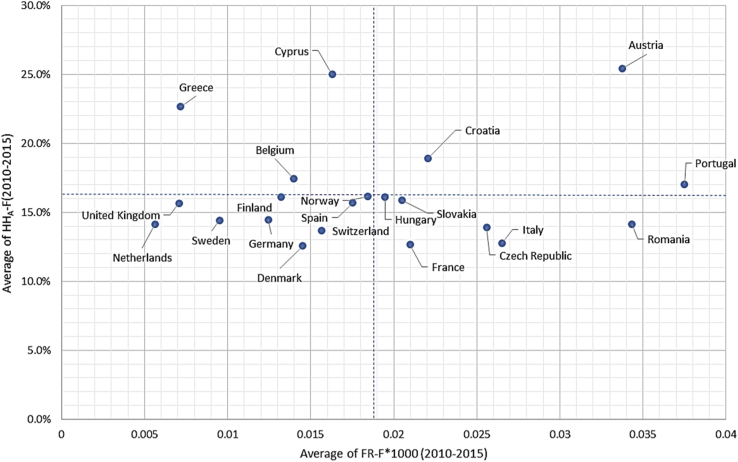

3.2.2. Frequency and concentration of “fatal accidents”

In Fig. 1, we find that the differences between FR-F and HHIA-F values are highlighted with respect to 21 European countries. Here, we use a large scale of FR-F multiplied by 1,000 because values for the original FR-F are too small to present the results.

Fig. 1.

FR and HHIA for fatal accidents (Note: The dotted line means the average value). HHIA, HHI of accidents; HHI, Herfindahl-Hirschman Index; FR-F, frequency ratio of fatal accidents.

Based on the average value of FR-F and HHIA-F as pointed out before in Table 1, the three countries, Austria, Croatia, and Portugal, are categorized in the group that has a comparatively higher value of both FR-F and HHIA-F. The countries included in this group demonstrate a strong bias for industrial accidents. In other words, a few industries have generated most of the industrial accidents in the nation. These countries should try to reduce the general accidents generated from all industries. Moreover, specific policies should be formulated for reducing the number of accidents in specific industries where several accidents occur.

Second, the three countries, Belgium, Cyprus, and Greece, show comparatively low FR-F. This result indicates that these countries have a low count of industrial accidents, but the accidents have occurred in several industries. Countries in this category should foremost manage the top industries where most of the accidents occur for efficiently increasing the degree of safety.

Third, the countries Czech, France, Hungary, Italy, Romania, and Slovakia have presented a high FR-F and low HHIA-F. Thus, though industrial accidents have occurred, they are not limited to specific industries. Thus, they should formulate an overall industrial policy to control the risk factors in all industries in general.

Finally, the last group of countries shows a low frequency as well as concentration of fatal accidents. Several countries of Northern Europe such as Norway, Finland, and Sweden, which focus on health and welfare, have ranked low on both the criteria, and some developed countries, such as UK, Germany, and the Netherlands, have maintained a low degree of frequency and concentration. This implies that these countries have tried to reduce the accidents in general and for specific industries as well.

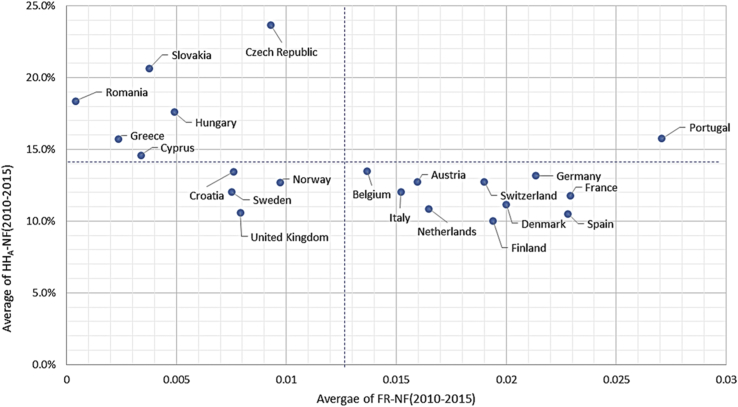

3.2.3. Frequency and concentration of “nonfatal accidents”

The second part analyses the frequency rate and HHI for nonfatal accidents that are defined as FR-NF and HHIA-NF, respectively. Just like FR-F, FR-NF is multiplied by 1,000 to present the original small value of FR-NF on a larger interpretable scale. Fig. 2 presents a positioning map in terms of FR-NF and HHIA-NF of European countries with average value presented by dotted lines.

Fig. 2.

FR and HHIA for nonfatal accidents (Note: The dotted line means the average value). HHIA, HHI of accidents; HHI, Herfindahl-Hirschman Index; FR-NF, frequency ratio of nonfatal accidents.

Portugal is the only country that has both a high FR-NF and HHIA-NF. This country occupies a similar position in the case of fatal accidents. This result indicates that Portugal has recorded a higher frequency and concentration of both fatal and nonfatal accidents. Thus, Portugal should consider innovative ways to reduce accidents of all the industries, specifically hazardous industries. In particular, compared with average values of European countries, addressing the frequency of accidents is a more pressing need than addressing the concentration of them.

Countries with a higher concentration of accidents are Cyprus, Czech, Greece, Hungary, Romania, and Slovakia. Although the frequency of nonfatal accidents is lower, these countries should focus on a few industries that are responsible for the higher share of industrial accidents. Thus, a strategy to reduce the concentration of accidents is required to maintain sustainable safety.

Third, most of the European countries show a higher frequency and lower concentration of nonfatal accidents. These countries attempt to foster a safety culture although nonfatal accidents are unavoidable in the process of increasing the productivity of the economy. The safety culture is a movement that manages minor and casual hazards in the industrial sites through collaboration and participation of all employees and employers. Thus, campaign and the safety movement can be considered sustainable solutions for reducing the number of inevitable nonfatal accidents.

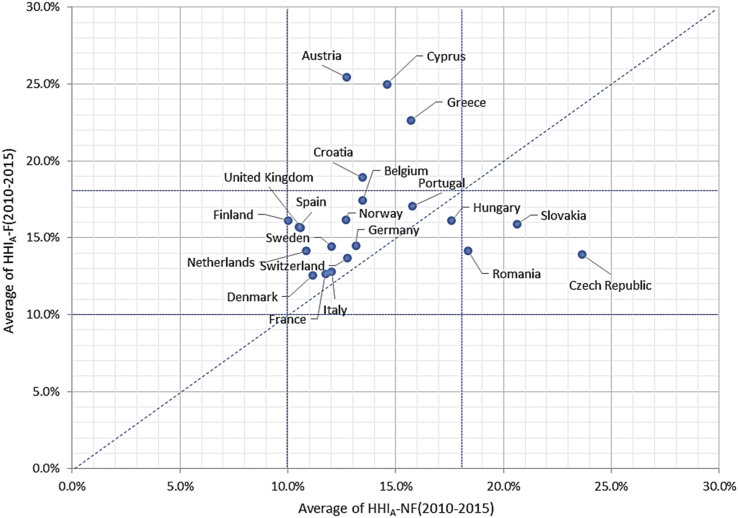

3.3. Comparison of HHIA values for fatal and nonfatal accidents

For identifying the differences between concentration of fatal and nonfatal accidents, we compare HHIA-F and HHIA-NF as shown in Fig. 3. The diagonal line stands for identical concentrations of fatal and nonfatal accidents and the dotted lines mean the level of concentration as described in Table 1. Because most of the nations are located above or under this diagonal line, this reveals that there is a difference of concentration between fatal and nonfatal accidents. Most of the countries are grouped above the diagonal line, which means they have higher levels of HHIA-F than HHIA-NF. Several countries in this group are revealed to have high concentration of fatal accidents with moderate concentration of nonfatal accidents: Austria, Croatia, Cyprus, and Greece. The countries falling below these countries have a moderate concentration of both fatal and nonfatal accidents. This indicates that except four countries, namely, Czech, Hungary, Romania, and Slovakia in Eastern Europe, most of the countries among the 21 European countries have included some focus industry that generate more fatal accidents than nonfatal accidents. Thus, most countries should formulate an emergency plan to focus on the industries that generate a greater number of fatal accidents.

Fig. 3.

Correlation of HHIA between fatal and nonfatal accidents. HHIA, HHI of accidents; HHI, Herfindahl-Hirschman Index.

4. Discussion

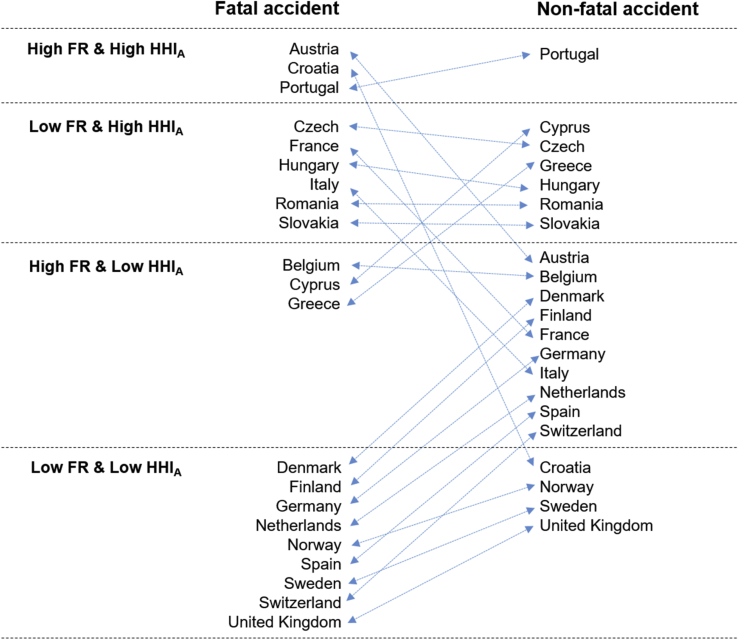

4.1. Comparative analysis between fatal and nonfatal accidents

Through the results of this study, we identify the different patterns of fatal and nonfatal accidents in the European nations. Four groups are made with every possible combination of FR and HHIA, and the nations' conditions are monitored by matching fatal accidents with nonfatal accidents as shown in Fig. 4.

Fig. 4.

Comparison between fatal and nonfatal accidents for European countries. HHIA, HHI of accidents; HHI, Herfindahl-Hirschman Index; FR, frequency ratio.

Most of the countries occupy the same positions for frequency and concentration ratio with respect to both fatal and nonfatal accidents such as Portugal, France, Italy, Cyprus, Greece, Norway, Sweden, and United Kingdom. These countries could make an integrated policy for dealing with both types of accidents, simultaneously.

Issues of managerial concern are extracted in the countries which have incompatible conditions with respect to patterns between fatal and nonfatal accidents. First, while some of the developed countries show patterns of a higher frequency rate of nonfatal accidents, the frequency rate and concentration ratio of fatal accidents have been well managed: particularly Denmark, Finland, Germany, the Netherlands, Spain, and Switzerland. These developed countries have grown through early industrialization, and this industrialization leads to mature economic and social growth. Minor accidents are inevitable during the development of various industries because the countries should sustain the economy level and economic growth. Although the nonfatal accidents do not directly result in the death or disability of workers, however, such indirect effect on the health and safety of workers could cause substantial accidents because of the accumulation of unsafe actions and conditions. Thus, the safety culture movement could resolve this situation by removing minor problems in the industrial sites.

Second, it is also interesting that the frequency rate of accidents in several countries of Eastern Europe such as Czech, Hungary, Romania, and Slovakia is lower, but the concentration ratio of both fatal and nonfatal accidents is higher. These results indicate that these countries are barely able to manage the accidents that lead to deaths in specific industries. Minor accidents are also concentrated in few industries. As the Eastern European countries have relatively immature industries and society compared with developed countries because of the late industrialization, managing risks in all industries may be problem and burdensome. Thus, a strategy could be implemented in any one direction: either direct reduction of fatal accidents or management of concentrated industries could be addressed first or first. Between the two, we prefer the strategy where the industries that face nonfatal accidents are inspected first because the fatal accidents could be driven by high concentrations of nonfatal accidents. An attempt by policy makers and safety managers to reduce the concentration ratio will affect the frequency level of fatal accidents. Consequently, these countries require a strategy that targets the specific risk-prone industries.

4.2. Practical applications for safety strategy formulation

We can formulate different safety strategies according to the level of fatal and nonfatal accidents as described in Table 4. The fatal accidents, which are caused by several critical problems such as leakage of hazardous materials, use of heavy equipment, and human errors, should be managed by the government. In this case, the facility, workers, and environment of the industrial sites should be strictly supervised based on the tight regulations. The managerial, technological, systemic, and legal solutions to these problems should be prepared to form the fundamentals of safety management. On the other hand, nonfatal accidents are generated by the minor and casual problems in and around the industrial sites. It is highly possible that these accidents are inevitable, and the risk of those accidents are acceptable. In this case, voluntary regulations need to collaborate for maintaining records of injuries with the stakeholders, such as owners, employers, employees, and safety managers.

Table 4.

Managerial and practical implications for safety strategy formulation

| Fatal | Nonfatal |

|||

|---|---|---|---|---|

| High FR & High HHIA | Low FR & High HHIA | High FR & Low HHIA | Low FR & Low HHIA | |

| High FR & High HHIA |

Country: Portugal Holistic management

|

Country: Croatia Government-driven management of critical industries based on strict regulation and inspection system

|

||

| Low FR & High HHIA |

Country: Czech, Hungary, Romania, Slovakia Management of accident-concentrated industries

|

(combined strategy is required) | ||

| High FR & Low HHIA | (combined strategy is required) |

Country: Belgium Management of overall industries

|

||

| Low FR & Low HHIA |

Country: None Corporation-driven management of critical industries based on voluntary regulation and safety culture

|

Country: Norway, Sweden, UK Sustainable management

|

||

Interestingly, we also consider the different strategies in terms of discrepancy between the frequency and the concentration ratio. If the frequency is high and the concentration ratio is low, then safety of overall industries should be managed. It is important to prepare and publish the integrated manual for reducing general accidents to all industries. In contrast, the policy makers of the country should endeavor to find major industries with a higher concentration of accidents. By prioritizing the accident-concentrated industries, the strict regulations and rules of those industries are specifically introduced. In this respect, using both frequency and concentration ratio, various approaches to safety management can be developed to arrive at different solutions.

4.3. Limitations and future directions

Although this study proposes a useful concentration index for fatal and nonfatal injuries in country level, further future study is required to corroborate our result. Primarily, the economic level and structure of countries should be considered while analyzing the results. The concentration ratio should be different according to the respective national policies and economic strategies of the countries. In this study, Eastern and the Northern Europe show interesting results; these two regions have different economic regimes and industrial organization. Thus, the background of the countries should be analyzed. Second, for advanced analysis, the accident data at further decentralized industry specific levels should be considered because the industry composition differs among the countries. This study considers only two levels: nation and industry because of the lack of data availability; the ILO data are only used, not considering the nature of each country's policy. However, if the hierarchical subindustry data are collected, the concentration ratio can be sequentially and systematically measured from the top to the bottom level. In this case, the concentration ratio can prove to be of great use in interpreting the origin of accident occurrence from subindustries. For this, we started the domestic analysis, collecting subindustries’ accident data of South Korea. Finally, we should develop concentration ratios using other concepts of concentration measures. Besides the economic measure, scientific, and statistical measures are helpful in suggesting various indexes to identify the status of industrial and occupational accidents.

5. Conclusion

This study aims at developing new statistical tools to identify the concentration of industrial accidents. So far, there has not been any suggestion on finding the composition ratio of the accidents. Not doing so makes it difficult to find industries in a nation that are particularly hazardous; we can only find the frequency of accidents in a nation. Various types of the concentration index are widely applied in economics to identify dispersion and inequality. Borrowing the concept of economic concentration, we develop the accident concentration index to measure the accident bias among industries. We chose the HHI in this study above other indexes because of its simplicity and applicability. Using data on fatal and nonfatal accidents published by ILO, we present a case study of European countries and justify the usefulness of the concentration ratio as a measure along with the frequency. From the results, we classify the European countries in terms of frequency and concentration ratio and suggest different safety strategies such as strict supervision and building a safety culture. As for the frequency level and HHIA, this study reveals that most of the developed countries show both low frequencies and concentrations of accidents, but some Eastern European countries have a higher concentration of nonfatal accidents. Frequency rates and concentration ratios will vary according to the economic structure and the degree of industrialization.

Conflicts of interest

The authors declare that there is no potential conflict of interests.

Acknowledgment

This work was supported by the Ministry of Education of the Republic of Korea and the National Research Foundation of Korea (NRF-2018S1A5A8027985).

Footnotes

Supplementary data to this article can be found online at https://doi.org/10.1016/j.shaw.2020.05.003.

Appendix A. Supplementary data

The following is the Supplementary data to this article:

References

- 1.Podgórski D. Measuring operational performance of OSH management system–A demonstration of AHP-based selection of leading key performance indicators. Saf Sci. 2015;73:146–166. [Google Scholar]

- 2.Kokangül A., Polat U., Dağsuyu C. A new approximation for risk assessment using the AHP and Fine Kinney methodologies. Saf Sci. 2017;91:24–32. [Google Scholar]

- 3.Hamidi N., Omidvari M., Meftahi M. The effect of integrated management system on safety and productivity indices: case study; Iranian cement industries. Saf Sci. 2012;50(5):1180–1189. [Google Scholar]

- 4.Venkataraman N. Safety performance factor. Int J Occup Saf Ergo. 2008;14(3):327–331. doi: 10.1080/10803548.2008.11076772. [DOI] [PubMed] [Google Scholar]

- 5.Cornelissen P.A., Van Hoof J.J., De Jong M.D. Determinants of safety outcomes and performance: a systematic literature review of research in four high-risk industries. J Safey Res. 2017;62:127–141. doi: 10.1016/j.jsr.2017.06.009. [DOI] [PubMed] [Google Scholar]

- 6.Vikhireva O., Pikhart H., Pajak A., Kubinova R., Malyutina S., Peasey A., Topor-Madry R., Nikitin Y., Marmot M., Bobak M. Non-fatal injuries in three Central and Eastern European urban population samples: the HAPIEE study. Eur J Public Health. 2010;20(6):695–701. doi: 10.1093/eurpub/ckp193. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Ryen L., Bonander C., Svensson M. From loss of life to loss of years: a different view on the burden of injury fatalities in Sweden 1972–2014. Eur J Public Health. 2018 doi: 10.1093/eurpub/cky083. [DOI] [PubMed] [Google Scholar]

- 8.Hajakbari M.S., Minaei-Bidgoli B. A new scoring system for assessing the risk of occupational accidents: a case study using data mining techniques with Iran's Ministry of Labor data. J Loss Prevent Proc. 2014;32:443–453. [Google Scholar]

- 9.Wagenaar W.A., Reason J.T. Types and tokens in road accidents causation. Ergonomics. 1990;33(10–11):1365–1375. [Google Scholar]

- 10.Brkić V.S., Klarin M.M., Brkić A.D. Ergonomic design of crane cabin interior: the path to improved safety. Saf Sci. 2015;73:43–51. [Google Scholar]

- 11.Piccinini G.B., Engström J., Bärgman J., Wang X. Factors contributing to commercial vehicle rear-end conflicts in China: a study using on-board event data recorders. J Safey Res. 2017;62:143–153. doi: 10.1016/j.jsr.2017.06.004. [DOI] [PubMed] [Google Scholar]

- 12.Obolewicz J., Dabrowsk A. An application of the Pareto method in surveys to diagnose managers’ and workers’ perception of occupational safety and health on selected Polish construction sites. Int J Occup Saf Ergo. 2018;24(3):406–421. doi: 10.1080/10803548.2017.1375781. [DOI] [PubMed] [Google Scholar]

- 13.Rhoades S.A. The herfindahl-hirschman index. Fed Reserve Bull. 1993;79:188. [Google Scholar]

- 14.Giroud X., Mueller H.M. Corporate governance, product market competition, and equity prices. J Financ. 2011;66:563–600. [Google Scholar]

- 15.Mariniello M, Antonielli M. Antitrust risk in EU manufacturing: a sector-level ranking (No. 2014/07) Bruegel Working Paper.

- 16.Susilo Y.O., Axhausen K.W. Repetitions in individual daily activity–travel–location patterns: a study using the Herfindahl–Hirschman Index. Transportation. 2014;41(5):995–1011. [Google Scholar]

- 17.Lu C., Qiao J., Chang J. Herfindahl–Hirschman Index based performance analysis on the convergence development. Cluster Comput. 2017;20(1):121–129. [Google Scholar]

- 18.Pavic I., Galetic F., Piplica D. Similarities and differences between the CR and HHI as an indicator of market concentration and market power. Br J Econ Manage Trade. 2016;13(1):1–8. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.